Page 1

User Guide

English

Xerox CX Print Server, Powered by

Creo Color Server Technology, for

the Xerox Color 550/560 Printer

Version 1.0

731-01952A-EN Rev A

Page 2

Page 3

Copyright

Eastman Kodak Company, 2010. All rights reserved.

This document is also distributed in Portable Document Format (PDF). You may reproduce the

document from the PDF file for internal use. Copies produced from the PDF file must be reproduced in

whole.

Trademarks

Kodak, Creo, InSite, and Prinergy are trademarks of Kodak.

Acrobat, Adobe, Distiller, Illustrator, Photoshop, and PostScript are trademarks of Adobe Systems

Incorporated.

Apple, AppleShare, AppleTalk, iMac, ImageWriter, LaserWriter, Mac OS, Power Macintosh, and

TrueType are registered trademarks of Apple Inc. Macintosh is a trademark of Apple Inc., registered in

the U.S.A. and other countries.

Hexachrome, PANTONE, PANTONE Goe, PANTONE Hexachrome, and PANTONE MATCHING

SYSTEM are the property of Pantone, Inc.

PEARL, PEARLdry, PEARLgold, PEARLhdp, and PEARLsetter are registered trademarks of Presstek,

Inc.

Xerox and the sphere of connectivity design are trademarks of Xerox Corporation in the United States

and/or other countries.

FCC Compliance

Any Creo branded equipment referred to in this document complies with the requirements in part 15 of

the FCC Rules for a Class A digital device. Operation of the Creo branded equipment in a residential

area may cause unacceptable interference to radio and TV reception, requiring the operator to take

whatever steps are necessary to correct the interference.

Product Recycling and Disposal

If you are managing the disposal of your Xerox product, please note that the

product contains perchlorate, lead, mercury, and other materials whose disposal

may be regulated due to environmental considerations in certain countries or states.

The presence of perchlorate, lead and mercury is fully consistent with global

regulations applicable at the time that the product was placed on the market.

Application of this symbol on your equipment is confirmation that you must dispose

of this equipment with agreed national procedures.

In accordance with European legislation, end of life electrical and electronic equipment subject to

disposal must be managed within agreed procedures.

For the proper treatment, recovery, and recycling of old products and used batteries, please take them

to applicable collection points in accordance with your national legislation and directives 2002/96/EC

and 2006/66/EC. By disposing of these products and batteries correctly, you will help save valuable

resources and prevent any potential negative effects on human health and the environment that could

otherwise arise from inappropriate waste handling. In accordance with national legislation, penalties

may be applicable for incorrect disposal of this waste.

Xerox operates a worldwide equipment take back and reuse/recycle program. Contact your Xerox

sales representative (1-800-ASK-XEROX) to determine whether this Xerox product is part of the

program. For more information about Xerox environmental programs visit http://www.xerox.com/

environment .

For perchlorate disposal information, contact your local authorities. In the United States, you may also

refer to the California Department of Toxic Substances Control (DTSC) or see http://www.dtsc.ca.gov/

hazardouswaste/perchlorate .

This electronic information product complies with Standard SJ/T 11363 - 2006 of the

Electronics Industry of the People's Republic of China.

In compliance with Article 7 (d), we hereby certify that this product is in compliance with the EEE

Regulation. "EEE yönetmeliğine uygundur."

REACH

Please consult for information about the presence of substances included on the candidate list

according to article 59(1) of Regulation (EC) No. 1907/2006 (REACH).

Limitation of Liability

The product, software or services are being provided on an "as is" and "as available" basis. Except as

may be stated specifically in your contract, Kodak and its subsidiaries, and affiliates expressly disclaim

all warranties of any kind, whether express or implied, including, but not limited to, any implied

warranties of merchantability, fitness for a particular purpose and non-infringement.

You understand and agree that, except as may be stated specifically in your contract, Kodak and its

subsidiaries, and affiliates shall not be liable for any direct, indirect, incidental, special, consequential

Page 4

or exemplary damages, including but not limited to, damages for loss of profits, goodwill, use, data

or other intangible losses (even if Kodak has been advised of the possibility of such damages),

resulting from: (i) the use or the inability to use the product or software; (ii) the cost of

procurement of substitute goods and services resulting from any products, goods, data, software,

information or services purchased; (iii) unauthorized access to or alteration of your products,

software or data; (iv) statements or conduct of any third party; (v) any other matter relating to the

product, software, or services.

The text and drawings herein are for illustration and reference only. The specifications on which

they are based are subject to change. Kodak may, at any time and without notice, make changes

to this document. Kodak, for itself and on behalf of its parents, subsidiaries, and affiliates,

assumes no liability for technical or editorial errors or omissions made herein, and shall not be

liable for incidental, consequential, indirect, or special damages, including, without limitation, loss

of use, loss or alteration of data, delays, or lost profits or savings arising from the use of this

document.

http://www.creoservers.com

Internal 731-01952A-EN Rev A

Revised 2010-08-23

Page 5

Contents

1 Getting started.......................................................................................................1

Printing this guide....................................................................................................................................1

What's new?............................................................................................................................................1

System overview.....................................................................................................................................2

Hardware and software components................................................................................................2

Supported formats............................................................................................................................3

Optional kits......................................................................................................................................3

Overview of the workspace.....................................................................................................................4

Turning on the CX print server................................................................................................................5

Turning off the CX print server................................................................................................................6

2 Setting up your computer for printing....................................................................7

Setting up your computer overview.........................................................................................................7

Setting up printing on a Windows computer............................................................................................9

Adding a network printer to your Windows computer.......................................................................9

Loading the Print Driver software for the first time......................................................................... 10

Shortcut for adding a printer...........................................................................................................10

Deactivating the Print Driver software............................................................................................11

Removing the Print Driver software................................................................................................11

Downloading fonts..........................................................................................................................12

Setting up a TCP/IP Printer ...........................................................................................................12

Setting up LPR printing...................................................................................................................13

Setting up printing in Mac OS X............................................................................................................14

Installing the Print Driver software in Mac OS X (10.4 and later)...................................................14

Defining a printer with the Print Driver software in Mac OS X (10.4 and later)...............................15

Removing the Print Driver software in Mac OS X (10.4 and later).................................................16

3 Calibration...........................................................................................................17

Calibration overview..............................................................................................................................17

Performing off-the-glass calibration from the Creo Color Server.......................................................... 18

Creating a calibration table using the X-Rite i1 spectrophotometer......................................................20

Troubleshooting calibration...................................................................................................................22

4 Printing a file in Windows and Mac OS...............................................................23

Printing a file to the CX print server.......................................................................................................23

Using a hot folder to print......................................................................................................................23

Password protect jobs...........................................................................................................................24

5 Printing from the color server..............................................................................27

File processing......................................................................................................................................27

Importing and printing a job...................................................................................................................28

Paper stock window.............................................................................................................................. 28

Resubmitting a job.................................................................................................................................29

Printing copies of a job...................................................................................................................29

Editing a job...........................................................................................................................................29

Previewing an RTP file...................................................................................................................30

Moving a page in a job................................................................................................................... 30

Deleting a page from a job............................................................................................................. 30

Merging pages into a job................................................................................................................30

Page 6

Rotating pages 180°.......................................................................................................................31

Replacing pages.............................................................................................................................31

Finding the CMYK values of a specific area...................................................................................32

Verifying the content of the job..............................................................................................................32

Analyzing a PDF job.......................................................................................................................34

Performing a preflight check...........................................................................................................34

Viewing and printing a preflight report............................................................................................35

Preflight report window...................................................................................................................35

Proofing the job using color sets...........................................................................................................37

Printing and reviewing color sets....................................................................................................38

Assigning a color set to your job.....................................................................................................38

Printing a file that contains more than one paper size..........................................................................39

Printing using the manual duplex wizard...............................................................................................39

Running a rush job................................................................................................................................40

Submitting a rush job......................................................................................................................40

6 Managing jobs.....................................................................................................41

Archival and retrieval of jobs.................................................................................................................41

Archiving a job................................................................................................................................41

Retrieving a job...............................................................................................................................41

Forwarding a job to another CX print server ........................................................................................42

Duplicating jobs.....................................................................................................................................43

Accounting Viewer.................................................................................................................................43

Customization in the Accounting Viewer........................................................................................44

Show, hide, and move columns in the Accounting Viewer table....................................................44

Creating a customized view in the Accounting Viewer...................................................................44

Job report..............................................................................................................................................45

Exporting files........................................................................................................................................45

Exporting a PostScript file..............................................................................................................45

PDF2Go jobs..................................................................................................................................45

7 Managing color....................................................................................................47

Color management on the CX print server............................................................................................47

Managing profiles .................................................................................................................................47

Importing a destination profile........................................................................................................48

Importing a source profile...............................................................................................................48

Importing a device link profile.........................................................................................................49

Mapping media using the Media and Color Manager tool.....................................................................49

Managing calibration tables...................................................................................................................50

Calibrations window........................................................................................................................50

Calibration table list........................................................................................................................50

Calibration table Info Data tab........................................................................................................50

Calibration table Info Graph tab......................................................................................................51

Adding an entry to a calibration table.............................................................................................51

Spot Color Editor overview ...................................................................................................................52

Adding a spot color.........................................................................................................................52

Editing a spot color.........................................................................................................................53

Deleting a spot color.......................................................................................................................53

Test–printing spot colors................................................................................................................53

Measuring a spot color with the X-Rite i1 spectrophotometer........................................................54

Spot color variations overview........................................................................................................54

Protecting specific spot colors........................................................................................................56

Color adjustment with the Gradation Tool ............................................................................................57

vi Xerox CX Print Server, Powered by Creo Color Server Technology, for the Xerox Color 550/560

Printer User Guide

Page 7

Creating and editing a gradation table............................................................................................58

Printing color jobs as black and white...................................................................................................60

Printing a job in grayscale mode....................................................................................................60

Printing a job that contains grayscale RGB elements using black toner .......................................60

Preserving black color in a job containing grayscale CMYK elements...........................................60

8 Production workflows..........................................................................................61

Printing using imposition.......................................................................................................................61

Imposition overview........................................................................................................................61

Previewing an imposition layout.....................................................................................................62

Printing a business card job...........................................................................................................63

Printing a saddle-stitch job.............................................................................................................64

Imposition Template Builder tool....................................................................................................65

Printing with exceptions.........................................................................................................................68

Adding exceptions to your job........................................................................................................68

Deleting exceptions from your job..................................................................................................69

Dynamic page exceptions and setpagedevice commands.............................................................69

Printing dynamic page exceptions..................................................................................................69

Printing tabs using the Creo Color Server Tabs plug-in for Acrobat.....................................................70

Tabs plug-in overview.....................................................................................................................70

Tabs plug-in window.......................................................................................................................71

Creating and printing tabs..............................................................................................................75

Managing tabs................................................................................................................................77

Working with near-line finishers............................................................................................................79

Near-line finisher overview.............................................................................................................79

Generating a corner mark and barcode..........................................................................................80

9 Scanning documents...........................................................................................81

Remote Scan Application......................................................................................................................81

Installing the Remote Scan Application in Windows.............................................................................81

Installing the Remote Scan Application in the Mac OS.........................................................................81

Creating a scan box..............................................................................................................................82

Scanning a document on the Xerox Color 550/560 Printer...................................................................84

Saving scanned files to your computer.................................................................................................85

10 Variable data printing jobs...................................................................................87

Variable data printing jobs.....................................................................................................................87

VDP document formats.........................................................................................................................87

Variable Print Specification.............................................................................................................88

PPML..............................................................................................................................................88

Managing VDP elements.......................................................................................................................89

Caching global VDP elements........................................................................................................89

Archiving VDP elements.................................................................................................................89

Retrieving VDP elements...............................................................................................................90

Deleting VDP elements..................................................................................................................90

11 Job parameters...................................................................................................91

Print tab in the job parameters window.................................................................................................91

Imposition tab in the job parameters window........................................................................................94

Quality tab in the job parameters window.............................................................................................98

Color tab in the job parameters window..............................................................................................101

Contents vii

Page 8

Finishing tab in the job parameters window........................................................................................106

Exceptions tab in the job parameters window.....................................................................................109

Services tab in the job parameters window.........................................................................................110

12 Setting up your color server..............................................................................115

Preferences window............................................................................................................................115

Setting up e-mail and text message accounts.....................................................................................119

Setting up a virtual printer...................................................................................................................120

Virtual printers..............................................................................................................................120

Adding and editing a virtual printer...............................................................................................121

Restoring the settings for a default virtual printer.........................................................................122

Removing a virtual printer.............................................................................................................122

Maintaining your settings.....................................................................................................................122

Backing up the configuration........................................................................................................122

Restoring the configuration...........................................................................................................123

Tools for maintaining your system................................................................................................124

13 Working with color server tools on your computer............................................125

Remote Site Manager overview..........................................................................................................125

Activating the remote tools...........................................................................................................125

Installing the Remote Site Manager.............................................................................................126

Adding to the Remote Site Manager ...........................................................................................126

Using the EZ Connect tool to view the printer status....................................................................127

Remote Workspace overview.......................................................................................................127

Connecting to the workspace from your computer.......................................................................127

Using the Web Center.........................................................................................................................128

Overview of the Web Center........................................................................................................128

Connecting to the Web Center.....................................................................................................128

Office Hot Folder tool..........................................................................................................................128

Installing the Office Hot Folder tool..............................................................................................128

Creating an Office hot folder.........................................................................................................129

Using the Office Hot Folder tool to print.......................................................................................129

Creo Color Server Job Ticket software...............................................................................................130

Creo Color Server Job Ticket overview........................................................................................130

Language settings........................................................................................................................130

Installing the Creo Color Server Job Ticket software in Windows................................................131

Installing the Creo Color Server Job Ticket software in Mac OS..................................................131

Creating and managing job tickets...............................................................................................131

Easy VDP File Creator tool.................................................................................................................133

Selecting an Easy VDP File Creator template..............................................................................133

Adding records manually to your variable data job.......................................................................134

Adding records from a database to your variable data job...........................................................135

Creating and printing the variable data job...................................................................................135

14 Troubleshooting.................................................................................................137

Job History window.............................................................................................................................137

Handling alerts and failed jobs............................................................................................................138

Aborting a job......................................................................................................................................138

Resume printing...........................................................................................................................138

Alerts window......................................................................................................................................139

Printing system messages..................................................................................................................139

viii Xerox CX Print Server, Powered by Creo Color Server Technology, for the Xerox Color 550/560

Printer User Guide

Page 9

15 Glossary............................................................................................................141

Contents ix

Page 10

x Xerox CX Print Server, Powered by Creo Color Server Technology, for the Xerox Color 550/560

Printer User Guide

Page 11

1

Getting started

Printing this guide

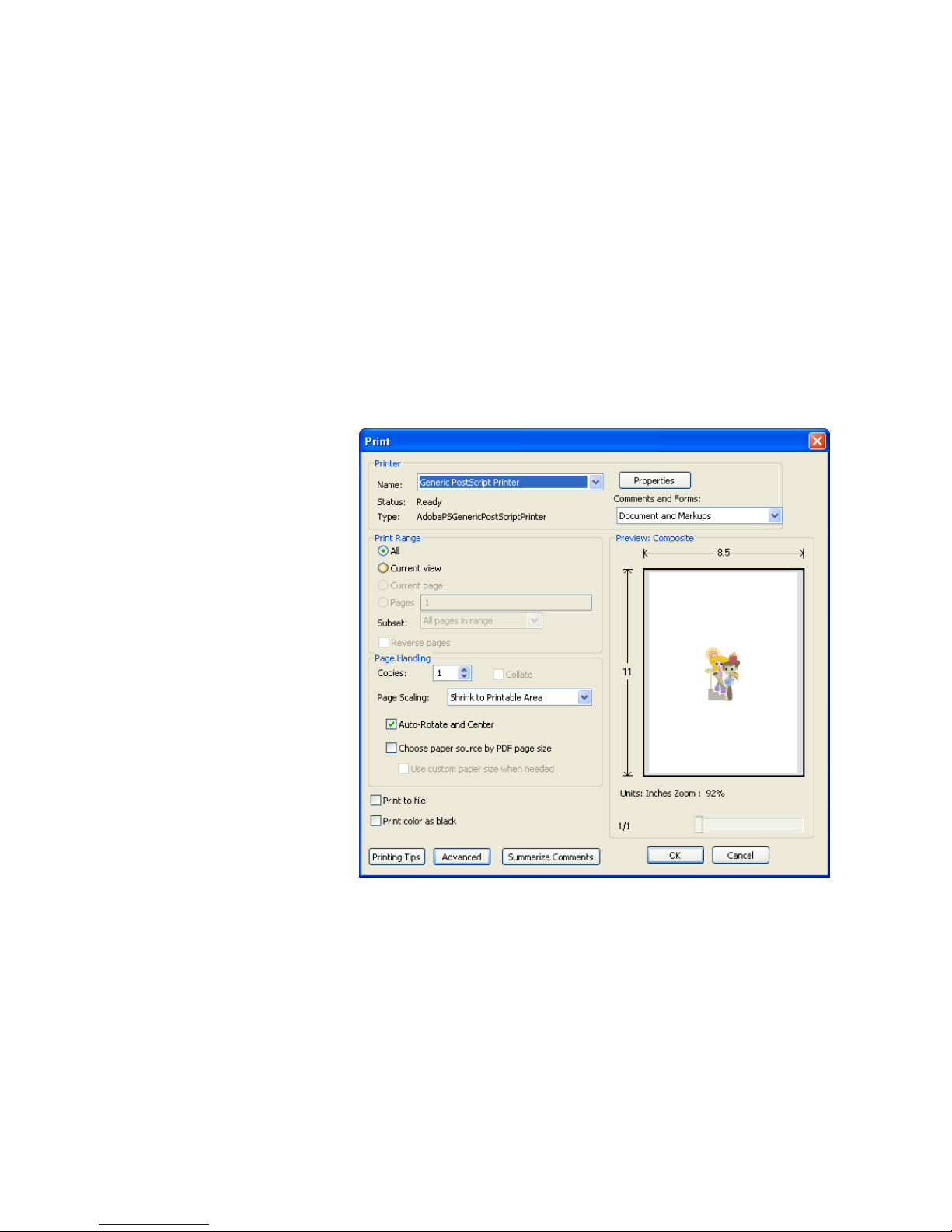

Change the paper size to print this document on any printer.

1. Open the PDF file in Adobe Acrobat.

2. From the File menu, select Print.

The Print dialog box appears.

3. Select the desired paper size, for example, A4 or letter.

4. In the Page Scaling list, select Fit To Printable Area or

Shrink To Printable Area.

Note:

The names in the Page Scaling list vary according to the version

of the Adobe Acrobat software.

5. Click OK.

This document is printed to the selected paper size on your

printer.

What's new?

The CX print server supports these new features:

Page 12

●

APPE 2.0 support

●

Remote Site Manager

●

Text message and e-mail notifications

●

Measure a spot color using the X-rite i1 spectrophotometer

●

Predefined color sets

●

CX print server help

●

Easy VDP File Creator

●

Near-line finisher support

System overview

The Xerox CX print server, powered by Creo Color Server

Technology, is an on-demand prepress system that uses

advanced prepress technologies to drive the Xerox Color 550/560

Printer.

The CX print server enables you to print from computers running

the Microsoft Windows operating system and Apple Mac OS

operating system software. Using raster image processor (RIP)

technology, the CX print server converts image files in pagedescription language (PDL) formats—for example, Adobe

PostScript, PDF, and variable data printing formats—to a suitable

ready-to-print (RTP) format for direct high-quality digital printing.

The CX print server also streamlines the printing process by

allowing you to print with preset workflows.

In combination with the printer, the CX print server enables you to

efficiently print business cards, print flyers, brochures, pamphlets,

catalogs, short-run trials, and print-on-demand publications.

The CX print server combines RIP functionalities, automation,

control tools, and special hardware development capabilities with

Windows-based architecture.

The CX print server supports the Xerox Extensible Interface

Platform (EIP), acting as an intermediary between custom EIP

applications and the press.

See also:

Setting up your computer overview on page 7

Hardware and software components

The CX print server includes:

●

Creo hardware, including the dedicated interface board

●

DVD-RW drive with DVD burning software

●

The following software:

2 Chapter 1—Getting started

Page 13

●

CX print server software

●

Microsoft Internet Explorer 6

●

Microsoft XP for Embedded Systems

Supported formats

The CX print server supports the following file formats:

●

PostScript (composite or pre-separated files) (levels 1, 2, and

3)

●

Adobe PDF (versions 1.2 through 1.7)

●

EPS

●

Creo VPS (Variable Print Specification)

●

Xerox VIPP (Variable Data Intelligent PostScript PrintWare)

●

VIPP.VPC (VIPP Project Container)

●

PPML (Personalized Print Markup Language)

●

PPML.zip

●

File formats from various prepress systems—for example,

TIFF/IT software

●

CT, LW

●

JPEG

●

TIFF

●

Pre-separated formats

Optional kits

The CX print server includes optional kits:

●

Imposition Power Kit, which enables you to build custom

signatures, and define where marks or groups of marks are

placed on a sheet. In addition, there is an interactive job

ganging option.

Note:

A dongle is required for this package.

●

Creative Power Kit, which increases your color and image

quality capabilities and includes:

●

X-Rite i-1 Spectrophotometer

●

Import Device Link profile

●

Advanced calibration information

●

Spot color based on destination profiles

●

Color Picker

●

Predefined color sets

●

Print color set samples

Note:

A dongle is required for this package.

Supported formats 3

Page 14

●

Peripheral Equipment Kit, which includes the stand, keyboard,

mouse, and monitor.

●

Professional Power Kit, extends the feature set of the Creo

Color Server with an emphasis on the capabilities requested by

graphic arts and commercial print providers. This kit includes:

●

Dynamic page exceptions

●

Imposition Template Builder

●

Enfocus PitStop

●

Archive and retrieve VDP files

●

Spot color variation

●

Print mode—progressive, separations and custom

●

Print spot test book

●

VDP Management Tool

●

Slug line

Note: A dongle is required for this package.

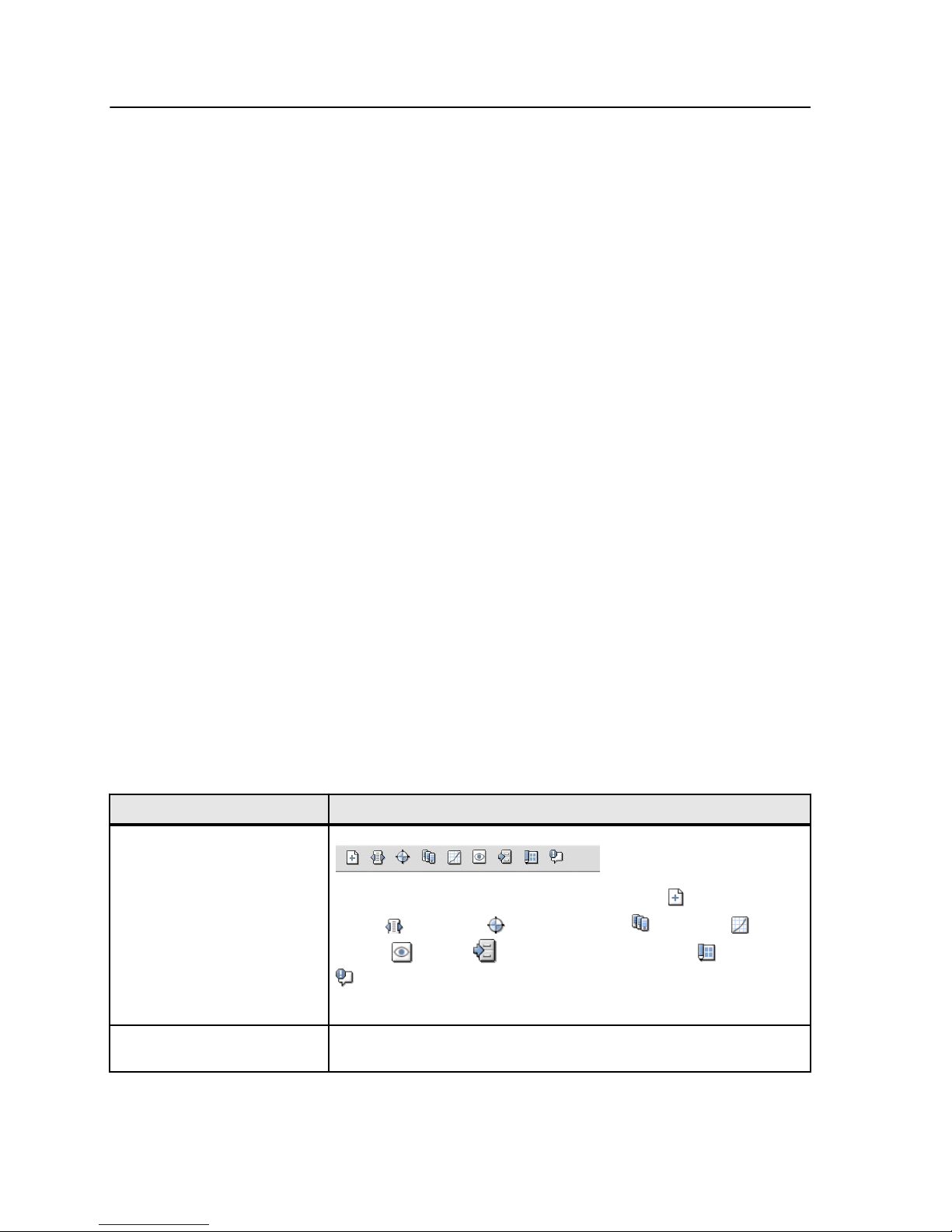

Overview of the workspace

When you start the CX print server software the workspace

automatically appears.

Note:

For the CX print server, jobs are not frozen, but printed irrespective of

any conflicts. In the event of a conflict, check the notifications on the printer

itself.

The workspace contains different areas that enable you to monitor

your job during the process and print stages. In addition, the

workspace includes tools and options that enable you to fully

customize and manage your server and jobs.

Workspace area Description

Toolbar

Consists of shortcut buttons for the Import window , Resource

Center , Calibration , Spot Color Editor , Gradation ,

Preview , Archive , Imposition Template Builder , and Alerts

.

Note: The icons that appear vary according to the optional kits in use.

Printer Status pane The Printer Status pane displays information about the current printer

status—for example, Printing, Ready, Warming up.

4 Chapter 1—Getting started

Page 15

Workspace area Description

Resource details Click Trays, Finishers, Toners, Consumables or Server to display

information about the size and type of paper in each tray, the

connected finishing devices, the available toner, status of

consumables, and disk space and network details.

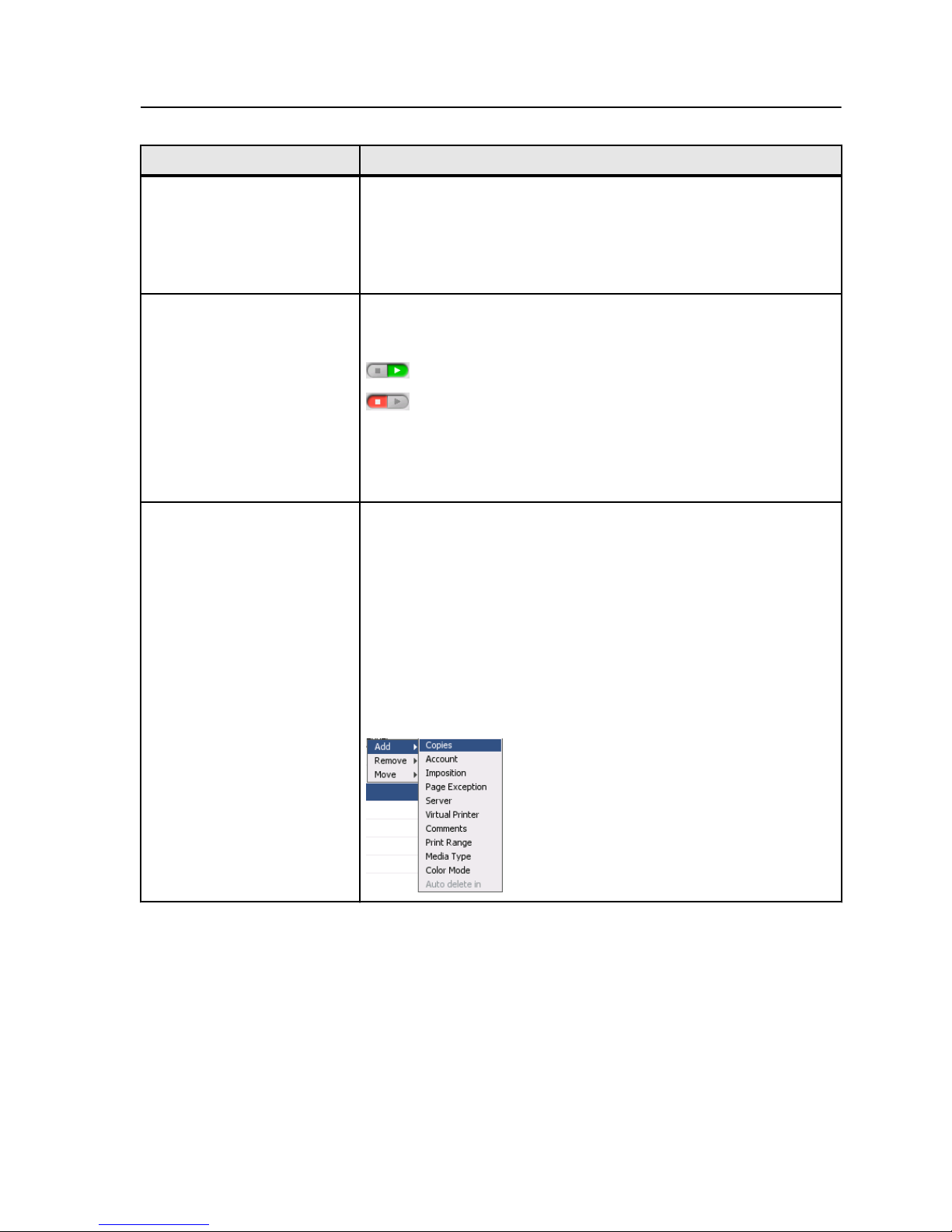

Process Queue and Print

Queue

The Process Queue area lists the files to be processed. After a file has

been processed successfully, it moves either to the Print Queue area

or to the Storage area.

Indicates that the queue is ready for processing or printing.

Indicates that the queue is suspended. You will need to release

the queue in order to process and print the jobs in this queue.

Note: When a queue is suspended you can open and edit the job

parameters of a job, unless the job is active or printing in the print

queue.

Storage area The Storage area contains jobs that:

●

were successfully printed

●

were held, were aborted, or failed during processing or printing

●

were sent directly from the client workstation, or were imported to

the Storage area

There are three different views available in the Storage area: List,

Preview, and Gallery.

You can modify the columns and information that is displayed in the

Storage area. Right-click on a column in the Storage area and select

the column that you want to add or remove.

Turning on the CX print server

1. Turn on the monitor.

2. Push the power control button.

The power indicator on the front panel lights up, and the

Windows operating system logon screen appears.

The CX print server splash screen appears, followed by the

workspace.

Turning on the CX print server 5

Page 16

Notes:

●

If the workspace does not automatically appear, open the application from

the Windows Start menu.

●

If the screen saver is activated with a password, then the user name is

set to operator and password is spire.

See also:

Preferences window on page 115

Turning off the CX print server

1. From the File menu in the workspace, select Exit.

Note: Alternatively, if you want to exit the Workspace only (and not shut

down the color server), select Exit Workspace. This is useful when you

make a change to the settings that requires you to close and open the

Workspace, for example, when changing the units from inches to mm.

To restart the Workspace, right-click on the color server icon in the

system tray and click Start.

A confirmation message appears.

2. Click Yes.

The CX print server software closes. This may take a few

minutes.

Note:

If you move the cursor over the server icon on the taskbar, the

following tooltip appears: Color Server is Stopping. Please Wait.

3. Verify that the CX print server icon does not appear on the

taskbar.

4. From the Windows Start menu, select Shut Down, and click

OK.

5. After the CX print server has shut down, you can turn off the

printer.

6 Chapter 1—Getting started

Page 17

2

Setting up your

computer for printing

Setting up your computer overview

Printing Methods

Some methods for printing with the CX print server:

●

Submit the job to one of the CX print server virtual printers. The

job is spooled and then processed or printed (according to the

selected job flow of the virtual printer). If you use this method,

you can print from any software—for example, Adobe Acrobat—

and use any file format from any Windows and Mac computer.

●

Drag the job to a hot folder. The job is spooled and processed

or printed (according to the selected job flow of the

corresponding virtual printer). If you use the hot folder method,

you can print most PDL files—for example, PostScript, PDF,

EPS, Variable Print Specification, and PPML.

●

Drag Microsoft Office files to a special hot folder and then

submit the files for printing.

Network printers

To print your file using a CX print server virtual printer, you first

need to install the virtual printer as a network printer on your

computer.

After you install a network printer on your computer, you will be

able to submit files for printing. The network printers are installed

by default with the Print Driver software. You can change the

default settings of the network printer to use the PPD parameters

instead of the Print Driver software.

The CX print server supports printing from the following operating

systems:

●

Mac OS X 10.4 and later

●

Microsoft Windows Server 2008, Microsoft Windows Server

2003, Microsoft Windows 7, Microsoft Windows Vista, and

Microsoft Windows XP

The CX print server provides default network printers, referred to

here as virtual printers.

A virtual printer contains preset workflows that are automatically

applied to all print jobs processed with that virtual printer. The

Page 18

default virtual printers are published on the network with specific

parameters set for processing and printing.

The default virtual printers are:

●

ProcessPrint—Files sent to this printer are automatically

processed and immediately sent to the printer for printing.

●

ProcessStore—Files sent to this printer are automatically

processed and stored in ready-to-print (RTP) format in the

Storage area. Later, you can submit an RTP job for printing, or

change the parameters of the job and resubmit it for processing

or printing.

●

SpoolStore—Files sent to this printer are spooled to the

Storage area and wait until you submit them for processing

and printing. The files remain in PDL format (such as PS, PDF,

VPS, and PPML).

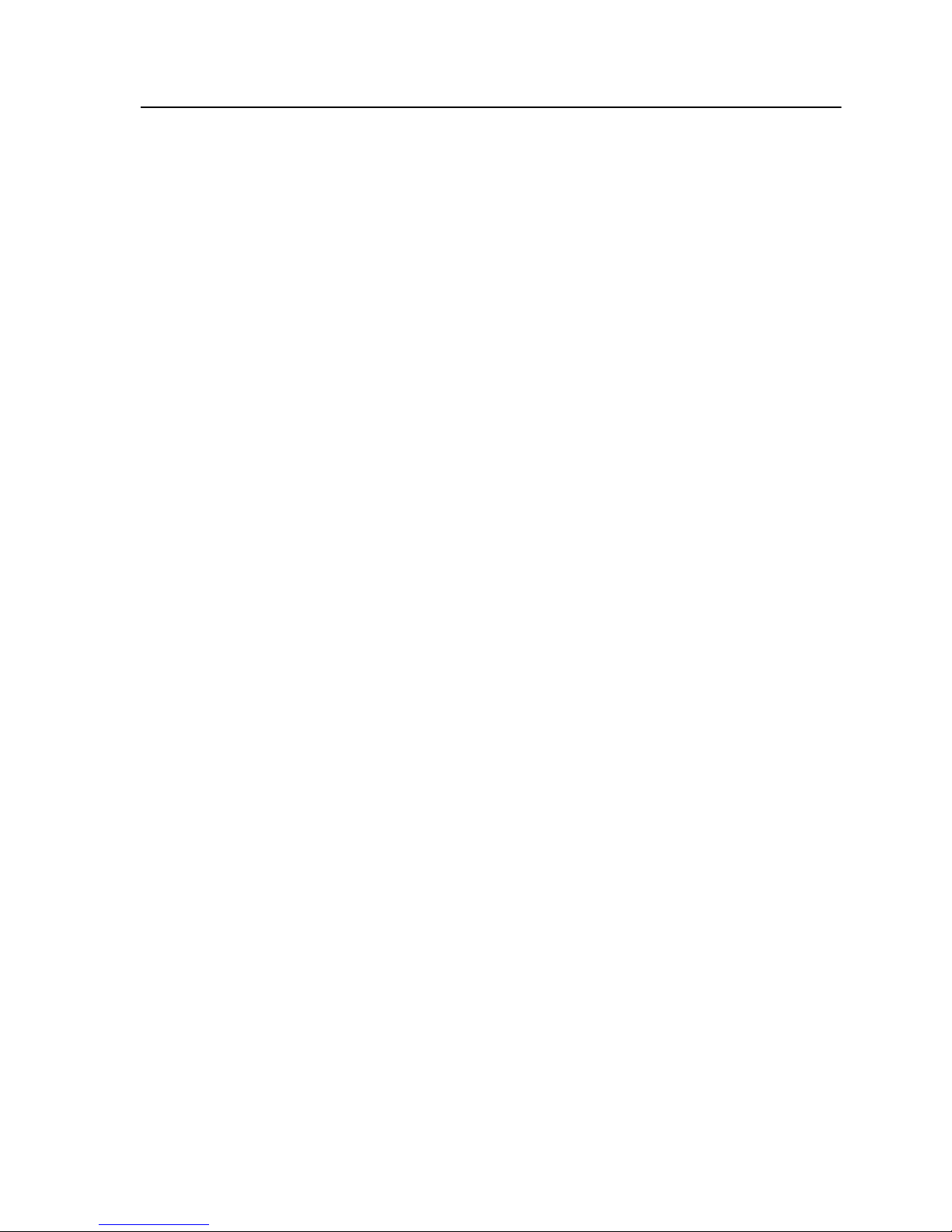

Print Driver software

Use the Print Driver software to set job parameters when you are

submitting a job to the CX print server from any application in your

computer. The Print Driver software provides a graphical user

interface that is similar to the CX print server job parameters

window. The software is automatically installed on a Windows

computer when you set up a network printer.

Note:

On a Mac computer, you must install the Print Driver software

manually.

In the Print Driver window, you can perform the following actions:

●

Define or change job parameters regardless of whether your

computer is connected to the server

●

Lock a job for secure printing

●

Save a set of parameters. Sets are useful when you want to

print different jobs with the same parameters, or if you want to

reprint a job.

●

Retrieve a saved set of parameters

●

Check the status of the printer

●

Define PostScript parameters for the job

●

Preview imposition layout

8 Chapter 2—Setting up your computer for printing

Page 19

Setting up printing on a Windows computer

Adding a network printer to your Windows computer

To print from a Windows computer, you first need to add a CX

print server virtual printer to your client workstation.

Tip: Following are some shortcut tips for setting up a printer. The full

procedure is detailed below.

●

Locate the CX print server in My Network Places, and then double-click

on the network printer you want to install. The network printer is

automatically installed on your computer and appears in the list of

printers.

1. From the Start menu, select Settings > Printers and Faxes.

The Printers and Faxes window appears.

2. In the Printer Tasks area, select Add a printer.

Note: Your computer might have slightly different wording from what

appears in this task.

The Add Printer Wizard appears.

3. Select Next.

4. Select A network printer, or a printer attached to another

computer, and then click Next.

5. Select Browse for a printer, and click Next.

6. Find the CX print server, and double-click it to display the list

of network printers.

7. Select the desired printer, and click Next.

8. When a message appears, click Yes.

9. Select one of the following:

●

Yes if you want to set this printer as the default printer on

your computer.

●

No if you don't want to set the printer as the default printer

on your computer.

10. Click Next.

11. Click Finish to close the wizard.

The CX print server network printer is added to your printer list. In

addition, the Print Driver software and PPD file are automatically

copied.

Setting up printing on a Windows computer 9

Page 20

Loading the Print Driver software for the first time

Requirements:

A network printer must be defined on your Windows-based

computer.

Load the Print Driver software after installing a network printer so

that the CX print server will be ready for printing.

1. Open a file with its corresponding application—for example,

open a PDF file in Adobe Acrobat.

2. From the File menu, select Print.

The Print dialog box appears.

3. Select one of the network printers—for example, Print and

click Properties.

A message tells you that the software is loading.

Note: This process may take a few minutes.

After the software loads successfully, click Finish. The job

parameters window appears.

4. Close the job parameters window and printer Print Dialog box

to complete the installation of the Print Driver.

The network printer is set up for printing using the Print Driver

software.

Shortcut for adding a printer

1. From the Start menu, select Run.

10 Chapter 2—Setting up your computer for printing

Page 21

2. In the Open box, type \\, followed by the host name or IP

address of the color server, and click OK.

The server window opens.

3. Double-click the icon for the desired network printer.

The CX print server network printer is added to your printer list.

Deactivating the Print Driver software

Deactivate the Print Driver software if you want to access the PPD

file parameters. The Print Driver software is active by default.

1. From the Windows Start menu, select Settings > Printers

and Faxes.

2. Right-click the printer icon of the network printer you want to

deactivate the Print Driver, and select Properties.

3. Click the Print Driver tab.

4. In the Enable enhanced user interface, list select off.

5. Click Apply.

6. Click OK.

Removing the Print Driver software

Perform this procedure if you need to upgrade to a later version of

the Print Driver software.

Requirements:

All applications must be closed before removing the Print Driver

software.

1. From the Windows Start menu, select Run.

2. In the Open box, type \\, followed by the host name or IP

address of the server, and click OK.

The server window opens.

3. Navigate to \Utilities\PC Utilities\Driver Extension.

4. Perform one of the following:

●

If you are using Windows XP, double-click

DEX_Uninstaller.exe

●

If you are using Windows Vista or Windows 7, right-click

DEX_Uninstaller.exe, and select Run as Administrator.

The Print Driver software is removed.

Deactivating the Print Driver software 11

Page 22

Downloading fonts

Use the HF_FontDownLoader hot folder, located in D:

\HotFolders, to install new or missing fonts to the CX print server

fonts directory.

The HF_FontDownLoader hot folder can be used with the following

operating systems:

●

Windows Server 2008

●

Windows Server 2003

●

Windows 7

●

Windows Vista

●

Windows XP

●

Mac OS X 10.4 and later

You can drag the required fonts from the computer to the

HF_FontDownLoader hot folder. In the Resource Center, you can

set a default font and delete fonts.

Note: You can only copy fonts if the font license permits.

Setting up a TCP/IP Printer

Set up a TCP/IP printer on a Windows computer.

Requirements:

The following items must be installed and configured on the

Windows-based computer:

●

TCP/IP

●

The latest PostScript printer driver, AdobePSDriver.exe. You

can find the driver in the shared D:\Utilities\PC Utilities

folder on the CX print server, or you can download the driver

from the Adobe Web site, at

http://www.adobe.com.

●

The PPD file, CX560_V1.PPD. The file is located in the shared

D:\Utilities\PPD folder on the CX print server.

1. Open the Printers window.

2. Select File > Server Properties.

3. Click the Port tab, and then click Add Port.

4. In the Printer Ports window, in the Available Port Types list,

select Standard TCP/IP Port, and then click New Port.

The Add Standard TCP/IP Printer Port wizard appears.

5. Click Next.

12 Chapter 2—Setting up your computer for printing

Page 23

6. In the Printer Name or IP Address box, type the exact name

of the CX print server(the name is case-sensitive).

Note: The Port Name box is automatically filled in while you type in the

Printer Name or IP Address box.

7. Type a name for the printer so that you will be able to identify

it on your computer in the Port Name box.

8. Click Next.

9. In the Device Type option, select Custom, and then click

Settings.

10. For Protocol, select LPR.

11. Under LPR Settings, set the values as follows:

a. For Queue Name, type the exact name of the network

printer to which you want to send jobs for printing—for

example, CX560_ProcessPrint.

b. Select the LPR Byte Counting Enabled check box.

12. Click OK, Next, and then Finish.

13. In the Printer Ports window, click Close.

14. Verify that the new port is shown in the Print Server Properties

window on the Ports tab.

15. In the Printer Server Properties window, click Close.

You have successfully installed a network printer for the CX print

server and are ready to start printing.

Setting up LPR printing

Installing an LPR printer in Windows XP

Requirements: Windows installation CD

1. Select Start > Settings > Control Panel.

2. Select Add or Remove Programs.

3. Select Add/Remove Windows Components.

4. Select the Other Network File and Print Services check box.

5. Click Next.

6. Click Browse, and locate the Windows installation files on

your hard disk in the i386 folder, or on your Windows

installation CD.

7. Click Finish.

Installing an LPR printer in Windows Vista

1. Select Start > Settings > Control Panel.

2. Select Select Programs and Features.

3. Select Turn Windows Features On or Off.

Setting up LPR printing 13

Page 24

4. In the User Account Control window, click Continue.

5. In the Windows Features window, click OK.

6. Select the Print Services check box and the LPR Port

Monitor check box.

7. Click OK.

Setting up printing in Mac OS X

Installing the Print Driver software in Mac OS X (10.4 and later)

During the installation of the Print Driver software, the PPD file is

automatically copied to your computer.

1. From the Go menu, select Connect to Server.

2. In the Server Address box, type your server address, and

click Connect.

3. In the Connect as area, select Guest.

4. Click Connect.

5. Select Utilities and click OK.

6. Select the Mac Utilities folder.

7. Double-click the

CX560_V1_ColorServerPrintDriverInstaller.dmg file.

8. Double-click the

CX560_V1_ColorServerPrintDriverInstaller icon.

The Welcome screen appears.

9. Click Continue.

10. In the message window, click Continue.

11. In the Software License Agreement window, click Continue.

12. Click Agree to agree to the terms and continue with the

installation procedure.

13. In the Select Destination area, select the destination volume

in which you want to install the Print Driver software, and click

Continue.

14. Click Install.

15. Type your login name (if necessary) and password, and click

OK.

16. Click Close.

The Print Driver software and PPD are installed.

Note:

If you deactivate the Print Driver software, you can still use the PPD

because it has been installed already.

14 Chapter 2—Setting up your computer for printing

Page 25

Defining a printer with the Print Driver software in Mac OS X

(10.4 and later)

Requirements:

The following information must be available:

●

IP address or computer name of your CX print server

●

Name of the network printer that you want to use with the Print

Driver software

1. On your Mac computer, using the Apple icon, open the

System Preferences window and double-click Print & Fax.

2. In the Print & Fax window, click +.

Note: You can also define your printer using the Default option.

3. In the Printer Browser window, click the IP Printer tab, and

enter the following information:

●

In the Address box, type the address of your server.

●

In the Queue box, type the name of the network printer that

you want to use with the Print Driver software—for

example, CreoCS_Process.

●

In the Name box, type a name for the printer.

●

In the Print Using list, select Other.

4. Navigate to Library / Printers / PPDs / Contents /

Resources / en.lproj, select either Europe-A4 or USLetter, and then select the CX560_V1.PPD file.

5. Click Open.

6. Click Add.

The network printer is defined with the PPD file.

7. In the Print & Fax window, double-click the network printer.

8. Click Utility.

9. If you are working in Mac OS X 10.6. click Open Printer

Utility.

10. In the Enable Enhanced User Interface list, make sure that

On is selected.

11. In the Server Hostname box, type the IP address of the

server.

12. Click Apply, and then click Close.

Defining a printer with the Print Driver software in Mac OS X (10.4 and later) 15

Page 26

Removing the Print Driver software in Mac OS X (10.4 and

later)

Perform this procedure if you need to upgrade to a later software

version of the Print Driver software.

1. From the Go menu, select Connect to Server.

2. In the Server Address box, type your Creo color server host

name or address, and click Connect.

3. In the Connect as area, select Guest.

4. Click Connect.

5. Select Utilities, and then click OK.

6. Select the Mac Utilities folder.

7. Double-click the CCSUninstall.dmg file.

8. Double-click the CCSUninstall.app file.

9. Close all the running applications on your Mac computer, and

then click OK.

10. Select the suitable Creoprinter driver, and then click OK.

11. If necessary, type your name and password, and then click

OK.

12. Click OK.

The Print Driver software is removed. You can now upgrade the

Print Driver software.

Note:

You will need to reinstall the network printers that you removed after

you have upgraded the software.

16 Chapter 2—Setting up your computer for printing

Page 27

3

Calibration

Calibration overview

Obtaining the most satisfactory print quality on your printer

depends on a number of issues. One of the most important issues

is steady toner density. Toner density is affected by many factors

such as heat, humidity, and service settings. Toner density also

tends to vary over time. Such variations cannot be totally

eliminated, but you can perform the calibration process to

compensate for them.

The calibration process consists of creating calibration tables that

are mapped to a specific media type, and screening method.

You can create calibration curves using either of the following

options:

●

Off-the-glass calibration: Enables you use the scanner platen to

create calibration tables.

●

X-Rite i1 spectrophotometer: Enables you to print a color chart,

scan the streams of color patches in the color chart, and create

a calibration table based on the scanned measurements.

The CX print server uses the data in this table to compensate for

the differences between the actual, measured density level and the

target density level.

You should create calibration tables in the following instances:

●

Every 24 hours, to compensate for potential variations in toner

density

●

When you use a new paper stock

●

When prints show “color casts”

●

After machine maintenance or hardware changes

●

If there are drastic ambient changes (temperature and humidity)

In the job parameters window, under Color > Calibration, the

Linked option is selected by default. Any job that meets the media

attributes and screening that you selected during the calibration

process will automatically be mapped or linked to that calibration

table. When you send your job to print, the calibration table that is

linked to the selected media type and screening is automatically

used for printing the job.

Page 28

Performing off-the-glass calibration from the Creo

Color Server

Requirements:

●

Make sure that the Calibration is done off-the-glass option is

selected in the Preferences window.

Calibrate both the printer and scanner at the same time. If you

place only the print chart on the platen, the printer is calibrated. If

you place only the scanner chart on the platen, the scanner is

calibrated.

1. From the Tools menu, select Calibration.

2. Complete the preliminary steps required before you start the

off-the-glass calibration, and then click Next.

3. In the Tray list, select the desired tray. The default tray is Tray

1.

4. In the Screening list, select the screening method.

5. In the Number of copies box, enter the number of copies you

want to print.

Note:

It is recommended that you print at least 25 copies of the

calibration chart, and then use one of the last copies printed.

6. (Optional) Select the Print calibration instructions check

box to print the calibration instructions.

18 Chapter 3—Calibration

Page 29

7. Click Print.

The calibration chart prints.

8. Click Next.

9. On the platen glass of the printer, place the scanner chart and

the off-the-glass calibration chart next to each other, facing

down.

10. On the printer’s touch screen, touch Services Home.

11. Touch Network Scanning.

12. On the Network Scanning tab, touch the calibration scan

box.

13. Touch the Advanced Settings tab.

14. Touch the Color Space button to select the specific color

space of the Xerox Color 550/560 Printer.

15. Touch the Device Color Space button.

16. Touch Save.

17. On the control panel, press Start to start scanning the charts.

The charts are scanned and measured and a calibration table

is created. In the CX print server Calibration Wizard, if the

calibration is successful, step 3 of the Calibration wizard

appears.

If an error occurs during the scanning process, an error

message appears.

18. Click Next.

19. To save the calibration table, do one of the following:

●

Select As default name to automatically name the

calibration table using the screening method, media type,

and date.

●

Select Save as to type your own name.

Note:

For best results, include the media type, and screening method in

the calibration table file name.

20. Select the media type to which to apply the calibration table.

21. Click Finish.

Performing off-the-glass calibration from the Creo Color Server 19

Page 30

Creating a calibration table using the X-Rite i1

spectrophotometer

Requirements:

●

Your spectrophotometer must be connected to the USB port on

the CX print server.

●

Install the driver when prompted for the first time connecting the

device. Refer to the spectrophotometer product documentation

for more details.

●

Make sure that your spectrophotometer is calibrated by placing

the spectrophotometer on its plate.

●

Print a reference job and use the same media and screen type

on which you will print the final job.

●

The Print queue must be ready for printing (not suspended).

●

Make sure that the Calibration is done using device tool

option is selected in the Preferences window.

1. From the Tools menu, select Calibration.

2. In the Tray list, select the desired tray.

The paper attributes for the paper that is loaded in the tray are

displayed.

3. In the Screening list, select the screening method.

Note:

Make sure that you set the screening method to the one you are

going to use to print the job.

4. In the Number of copies box, type the number of copies you

want to print.

Note:

It is recommended that you print at least 25 copies of the

calibration chart, and then use one of the last copies printed.

5. Click Print.

The calibration chart is printed, and step 2 of the Color

Calibration wizard appears.

6. Follow the instructions in the wizard.

7. After each color sweep, wait for the check mark to appear next

to the appropriate icon, and follow the on-screen instructions.

Note:

Make sure that you scan each separation on the chart in the order

in which the icons appear: cyan, magenta, yellow, and then black.

When all of the separation columns have been successfully

scanned, a check mark appears next to all the icons.

20 Chapter 3—Calibration

Page 31

Notes:

●

If at any stage the scanning is not completed properly, click Reset

and scan again.

●

If an error occurs while you are scanning the chart, an alert message

appears. Click OK and rescan the chart.

8. Click Next.

9. To save the calibration table, perform one of the actions:

●

Select As default name to automatically name the

calibration table using the screening method, media type,

and date.

●

Select Save as to type your own name.

Note: It is strongly recommended that you include the media type, and

screening method in the calibration table file name.

10. Select the media type to which to apply the calibration table.

11. Click Finish.

Creating a calibration table using the X-Rite i1 spectrophotometer 21

Page 32

Troubleshooting calibration

Resolve common troubleshooting problems that can occur during

the calibration process.

Message Recovery action

Values

collected

during the

measurement

are not

monotonous.

This message may appear after calibration

measurements are successfully measured. Clicking OK

enables the calibration process to continue without any

problem.

The Eye-One

is not

calibrated.

Place it on

the base

and click

OK to

proceed.

Place the X-rite i1 back on its base in order to recalibrate it.

The

software

cannot

identify

any

calibration

device.

Check that

a device is

connected

and that

you have

defined it.

Make sure the i1 is connected correctly to the USB port

of the CX print server. When prompted, install the

driver.

22 Chapter 3—Calibration

Page 33

4

Printing a file in

Windows and Mac OS

Printing a file to the CX print server

Requirements:

A network printer must be defined on your Windows and Mac

computer.

1. Open a file with its corresponding application—for example,

open a PDF file in Adobe Acrobat.

2. From the File menu, select Print.

3. In the Name list, select the desired network printer—for

example, <servername>_Print.

4. (Optional) To modify job parameters, perform the following

steps:

●

On a Windows computer, click Properties.

●

On a Mac, select Special Features, and then click Job

Parameters.

a. Modify the parameters.

b. Click OK.

5. Click OK.

6. In the Print dialog box, click OK.

The file is sent to the CX print server where it is processed and

printed.

Using a hot folder to print

Use hot folders to automate your workflow and to save time by

simultaneously submitting multiple files for printing.

You can use hot folders to process and print files from any

computer. The following procedure can also be followed on a Mac

computer.

1. On your Windows desktop, double-click the My Network

Places icon.

In Mac OS, from the Go menu, select Connect to Server.

2. Locate the CX print server, and double-click it.

A list of all the shared folders, hot folders, and printers

appears.

Page 34

3. Double-click the desired hot folder—for example,

HF_ProcessPrint.

Tip: You can drag the hot folder icon to your desktop to create a

shortcut to the hot folder for future use.

4. Drag the desired files to the hot folder.

All the files are processed and printed automatically, according to

the hot folder workflow.

Password protect jobs

Control the printing of sensitive data by locking and passwordprotecting a job on your computer.

Requirements:

●

A CX print server network printer must exist on your client

workstation.

●

The Print Driver software must be installed and activated in

Windows and Mac OS.

●

The printer status on the CX print server must be in Ready

mode.

Using the Print Driver software, you can apply a password to a job

that was created in any application. Whoever prints or reprints the

job must use the password to unlock it and release it for printing.

1. On your computer, open a file—for example, a PDF file.

2. From the File menu, select Print.

3. In the Print dialog box, in the Name list, select the name of the

network printer that you want to submit your file to.

4. Click the Properties button.

The Print Driver window appears.

5. In the Print Driver window, click the Lock button .

The Secure Printing dialog box appears.

6. In the Password box, type a password consisting of four digits

—for example, 9999.

Note:

The password must consist of exactly four numeric characters.

7. Click OK.

The job is password-protected, and nobody can print it without

using the password.

8. In the Print Driver window, click OK.

The password-protected job is submitted to the network

printer, which sends it to the CX print server for processing

and printing.

24 Chapter 4—Printing a file in Windows and Mac OS

Page 35

9. In the Print Queue area, right-click the password-protected

job that you want to print, and select Release to print.

The Secure Printing dialog box appears.

10. In the Password box, type the password that was defined for

this job.

11. Click OK.

The job is unlocked and printed. When the printing is finished,

the job is automatically deleted.

Password protect jobs 25

Page 36

26 Chapter 4—Printing a file in Windows and Mac OS

Page 37

5

Printing from the color

server

File processing

The CX print server features the Adobe PDF Print Engine (APPE)

RIP as a complementary workflow to the CPSI RIP, enabling you

to use the RIP that is appropriate for each job. The APPE RIP is

particularly useful for files that need transparencies and overprint

handling. APPE RIP information is added to the job history and

workspace.

The main benefit of the APPE RIP is that complex designs and

effects, including transparencies, can be reproduced reliably.

Designers and printers can make late-stage edits in PDF files more

easily and configure PDF jobs for printing on different types of

output devices and presses.

The APPE RIP applies to PDF files only. If you use Smart mode or

Force mode with a non-PDF file, the system ignores your selection

and renders with the CPSI RIP. Similarly, when the PostScript

driver translates a PDF file to PostScript, the system uses the

CPSI RIP.

The Smart mode option lets the system determine when to apply

the APPE RIP. In Smart mode, the CX print server analyzes your

file and applies an automatic workflow that optimizes the RIP

method. For example, if a file has text only, the system recognizes

that the file does not require the APPE RIP and processes the file

with the CPSI RIP. In Smart mode, the system also checks for

transparencies that use various color spaces and for spot colors

that use overprints.

One of the advantages of using a PDF workflow is that you can

work with embedded ICC profiles. The CX print server includes

APPE RIP support for both CMYK and RGB embedded ICC

profiles.

The CX print server is fully compatible with PDF/X-1a, PDF/X-3,

and PDF/X-4. PDF/X files are a subset of PDF files whose

standard provides for the exchange of final print-ready pages.

Using PDF/X-compliant files eliminates the most common errors in

file preparation (for example, fonts that are not embedded,

incorrect color spaces, missing images, and overprinting or

trapping problems).

Page 38

Importing and printing a job

You can import a job in any of the following circumstances:

●

When a page-description language (PDL) file—for example,

PDF or PostScript—is created on a computer that is not

connected to the CX print server

●

When a PDL file is located on a folder on the network, or on

external media, such as a USB key

●

When the desired file resides locally on the CX print server

1. From the File menu, select Import.

2. In the upper list in the Import window, select the desired file(s)

and click the Add button.

Notes:

●

Use Shift or Ctrl to select several files or Ctrl+A to select all the files.

If desired, add the same file more than once.

●

To remove a file, select the desired file in the lower list in the Import

Job window, and click the remove button.

The file(s) appears in the lower list.

3. From the Virtual printer list, select a printer.

4. Click Import.

All files currently listed on the lower list are sent to the CX print

server to be processed, printed, or stored as defined in the

selected virtual printer.

5. If your job is moved to the Storage area, you can edit the job

parameters before you send the job to print. For example, you

might want to verify that the paper stock that was defined in

your job is loaded on the printer and available for printing.

Paper stock window

The Paper stock window enables you to view the list of paper

stocks that are defined on the press and that are available for

printing. You access the Paper stock window from the Resource

Center.

There is an icon that indicates which paper stock is loaded in the

printer.

28 Chapter 5—Printing from the color server

Page 39

Resubmitting a job

Resubmit a printed job after editing the job parameters or to print

more copies of your job.

In the Storage area, right-click the job that you want to

resubmit for printing, and select Submit.

If you selected an RTP job, it is submitted to the Print Queue;

if you selected any other kind of job, it is submitted to the

Process Queue.

Note: Some RTP jobs may require reprocessing after you edit certain

parameters.

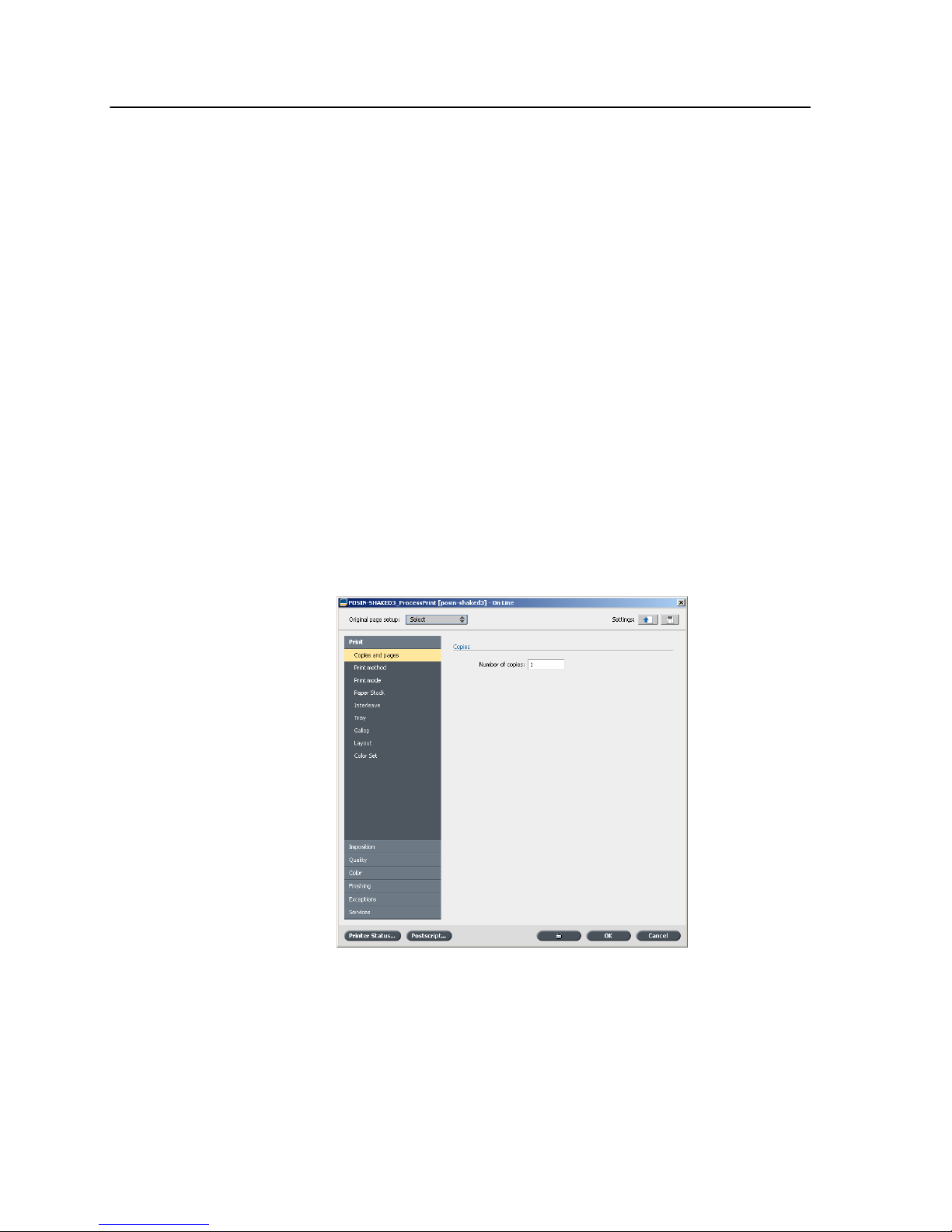

Printing copies of a job

Reprint more copies of a job directly from the Storage area

without opening the job parameters.

1. Right-click on a column heading in the Storage area.

2. Select Add > Copies to add copies to the Copies column in

the Storage area.

3. Select the job, and in the Copies field type the amount of

copies that you want to print.

4. Press Enter.

5. Drag the job to either the Process Queue area or Print

Queue area.

Editing a job

You can preview and edit any PDL and RTP job that is in the

Storage area. PDL files are opened in Adobe Acrobat software,

and RTP files are opened in the Job Preview & Editor tool.

In Adobe Acrobat, you can view and edit the PDL job as you would

normally. In addition, this version of Adobe Acrobat includes the

Enfocus Pitstop plugin that includes more editing tools.

Note:

For more information about the Pitstop plugin, refer to the

documentation included in the Pitstop and Acrobat software.

In the Job Preview & Editor window you can view thumbnails of

the job while you navigate to the various pages of a job. For an

imposed job, you can view the imposed sheets, including the

layout of the pages on each sheet. You can also view the pages'

orientation, crop marks, and fold marks.

Jobs that you edit in the Job Preview & Editor window cannot be

re-RIPed. After a job is saved in the Job Preview & Editor window,

Resubmitting a job 29

Page 40

it is a new RTP file without an associated PDL file. You cannot

apply parameters that require re-RIPing to such jobs.

Previewing an RTP file

In the Storage area, right-click the RTP file that you want to