Page 1

705P01382

October 2017

Xerox® Phaser® 6510 Color Printer/

WorkCentre® 6515 Color MFP

Service Manual - Revised BUS Update: July 2020

Page 2

Prepared by:

Xerox Corporation

800 Phillips Rd

Webster, NY 14580

© 2020 Xerox Corporation. All Rights Reserved. Xerox®, Xerox, Design®, PhaserSMART®,

DocuCard®, DocuSP®, FreeFlow® CentreWare®, infoSMART®, Made For Each Other®,

PagePack™, ProfitAccelertor™, WorkCentre™, and Walk-Up™ are trademarks of Xerox Corporation in the United States and/or other countries.

Other company trademarks are also acknowledged.

NOTICE

While every care has been taken in the preparation of this manual, no liability will be accepted

by Xerox Europe arising out of any inaccuracies or omissions.

All service documentation is supplied to Xerox external customers for informational purposes

only. Xerox service documentation is intended for use by certified, product trained service personnel only. Xerox does not warrant or represent that it will notify or provide to such customer

any future change to this documentation. Customer performed service of equipment, or modules, components or parts of such equipment may affect whether Xerox is responsible to fix

machine defects under the warranty offered by Xerox with respect to such equipment. You

should consult the applicable warranty for its terms regarding customer or third-party provided

service.

Page 3

About This Manual .............................................................................. ......... .... .... .... ....... iii

How To Use This Manual................................................................................................ iii

Change History ............................................................................................................... iv

Service Safety Summary...... .......................... ......................... ......................... ............... v

Symbols Used on the Product......................................................................................... vii

Voltage Measurement and Specifications....................................................................... viii

Health and Safety Incident Reporting ............................................................................. viii

Regulatory Specifications................................................................................. .... .. .... ..... ix

Translation of Warnings.................................................................................................. x

Technical Support Information ................................................................... .... .... .. .... .. ..... xiii

Introduction

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

10/2017

i

Introduction

Page 4

Introduction

10/2017

ii

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 5

About This Manual

The Phaser 6510 Printer (SFP) and WorkCentre 6515 Multifunction Printer (MFP) Service

Manual is part of a multinational service documentation system delivered in the standard Xerox

EDOC service manual format. This manual is the primary document used for diagnosing,

repairing, maintaining, and troubleshooting these systems. The Service Manual is the control

ling publication for a service call. To ensure product understanding, complete the Xerox Service Training Program for this printer.

How To Use This Manual

Always start with the Service Call Procedures, Section 1. Perform Initial Actions and verify the

problem, then follow the directions given.

-

How to Differentiate Between Machine Variants

The machines will be identified in this manual by the model identifier 6510N/DN/DNI or 6515N/

DN/DNI.

Organization

Section titles and the information contained in each is presented in the following paragraphs:

Section 1 Service Call Procedures

This section is used to start and complete a service call. The procedures in this section will

either direct you to a Repair Analysis Procedure (RAP), or identify a faulty component or sub

assembly.

Section 2 Status Indicator Repair Analysis Procedures

This section contains the Repair Analysis Procedures (RAPs) and checkouts necessary to

diagnose, isolate and repair faults other than image quality faults.

Section 3 Image Quality

This section contains the Image Quality Repair Analysis Procedures (IQ RAPs), checkouts and

setup procedures necessary to diagnose, isolate and repair image quality faults.

Section 4 Repairs/Adjustments

This section contains the instructions for removal, replacement, and adjustment of parts.

Section 5 Parts List

This section contains the illustrated spare parts list. Any part that is spared or that must be

removed to access a spared part is illustrated.

Section 6 General Procedures / Information

This section contains all other procedures, product specifications and general information.

Section 7 Wiring Data

This section contains the wiring diagrams.

When a procedure, parts list description or other reference is unique amongst different models

of machine, the appropriate model designator is indicated. Any artwork is also specific. The

Phaser 6510 and WorkCentre 6515 models may also be referred to as SFP and MFP respec

tively.

NOTE: This manual services all configurations of the machine. Ignore references to options

-

not installed on the machine.

Warnings, Cautions and Notes

WARNING

A warning is used whenever an operating or main tenance procedure, practice, condition or statement, if not strictly observed, could result in personal injury.

A translated version of all warnings is in Tr anslation of Warnings.

CAUTION

A caution is used whenever an operation or maintenance procedure, practice, condition or

statement, if not strictly observed, could result in damage to the equipment.

NOTE: A note appears to highlight a procedure, practice, condition or statement.

Service Acronyms

While using this service documentation, you may encounter acronyms that are unfamiliar.

To find definitions for Xerox acronyms, go to the following page in your web browser, then enter

the acronym and click Search:

https://open.xerox.com/Services/acronym

-

Section 8 Principles of Operation

This section contains details of printer operation and component locations.

Component Names

Names of parts that appear in the disassembly procedures may not be exactly the same as the

names that appear on the part or listed in the Parts List. For example; a part called the Regis

tration Chute Assembly may appear on the Parts List as Assembly, Chute REGI.

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

-

10/2017

iii

Introduction

About This Manual, How To Use This Manual

Page 6

Change History

This page gives information on major changes to the service manual. Go to the relevant

update.

• BUS Update June 2018

• BUS Update July 2019

• BUS Update July 2020

BUS Update June 2018

The following procedures are updated:

• SCP 7 Configurations and Options

• 024-933, 940, 941 Drum Cartridge Y Life End RAP

• 077-323 PH Motor Fail RAP

• 091-312 HVPS CC Fail RAP

• 116-314 Ethernet Address Fail RAP

• 116-325 ESS Fan Fail RAP

• 124-310-314, 316, 318, 322, 324, 325, 340, 356, 357, 360 ID/Billing/Data Mismatch RAP

• OF 1 Unusual Noises RAP

• OF 2 Blank UI RAP

• OF 3 POST Fault Codes (LED) Complete RAP

• IQ21 Skew Check

• IQ22 Registration Check

• REP 2.1 LPH Color Head Assembly

• REP 2.3 LPH Xerographic CRUM FFC Kit

• REP 18.1 MCU PWB (MFP)

• REP 18.19 MCU PWB (SFP)

• 5 Parts Lists

• GP 15 Special Boot Modes

• GP 28 Supplies Plan Conversion

• dC132 Device ID / Billing Data

• Change Tags

BUS Update July 2019

• Change History

• SCP 1 Initial Actions

• 016-426 Remote Services Error RAP

• 041-340 to 041-363 MCU NVM (EEPROM) Fail RAP

• 059-314, 315, 326 Fusing Assembly HR STS RAP

• 092-318 to 092-321 ADC Patch System Fail RAP

• 102-356 EWS Soft Fail RAP

• 124-310-314, 316, 318, 322, 324, 325, 340, 356, 357, 360 ID/Billing/Data Mismatch RAP

• REP 2.1 LPH Color Head Assembly

• PL 5.1 Dispenser

• PL 7.1 Fuser

• PL 9.1 Tray

• PL 10.3 Option Feeder (3/3)

• PL 15.2 Registration (2/2)

• PL 50.1 Scanner

• PL 18.5 Electrical SFP (1/4)

• GP 7 Machine Specifications and Configuration

• GP 12 How to Check a Solenoid or Clutch

• GP 15 Special Boot Modes

• GP 18 Printing Reports

• GP 28 Supplies Plan Conversion

• GP 37 Reset Administrator Pas sw ord

• dC 131 NVM Tables

• dC 132 Device ID/Billing data

• dC 945 IIT Calibration

• dC 991 Toner Density Adjustment

• dC 1010 Signals Sending Test

• dC 1011 Relay On/Off Test

BUS Update July 2020

• 010-105, 010-106 Fusing Assembly Exit Sensor RAP

• 124-315, 317, 355 DC132 Error 02, 04 and 14 RAP

• REP 18.3 ESS PWB (MFP)

• REP 18.21 ESS PWB (SFP )

• GP 15 Special Boot Modes

• 061-362 to 061-393 LPH Fault RAP

• PL 18.1 Electrical WC6515 (1/4)

• PL 1.1 UI (WC6515)

• PL 1.2 UI (P6510)

• PL 2.1 LPH

• PL 3.1 Drive

• PL 6.1 Transfer

• PL 7.1 Fuser

• PL 10.1 Option Feeder (1/3)

• PL 10.2 Option Feeder (2/3)

• PL 15.2 Registration (2/2)

• PL 18.5 Electrical P6510 (1/4)

• PL 19.2 Cover WC6515 (2/2)

• PL 19.4 Cover P6510 (2/2)

• PL 50.1 Scanner

Introduction

Change History

10/2017

iv

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 7

Service Safety Summary

General Guidelines

For qualified service personnel only: Refer also to the section Electrical Safety.

Avoid servicing alone: Do not perform internal service or adjustment of this product unless

another person capable of rendering first aid or resuscitation is present.

WARNING

Take care, a hazardous voltage is present at the C inlet, LVPS PWB (PL 18.1 Item 16/PL

18.5 Item 16), and ESS MFP/ES S SFP PWBs (P L 18.1 Item 5/PL 18.5 Item 5). Electricity

can cause death or injury.

Use care when servicing with power applied: Dangerous voltages may exist at several points in

this product. To avoid personal injury, do not touch exposed connections and components

while power is on. Disconnect power before removing the power supply shield or replacing

components.

Do not wear jewelry: Remove jewelry prior to servicing. Rings, necklaces and other metallic

objects could come into contact with dangerous voltages and currents.

Electrical Safety

• Use the Power Cord supplied with the printer.

• Plug the Power Cord directly into a properly grounded electrical outlet.

• Do not use a ground adapter plug to connect the printer to an electrical outlet that does

not have a ground connection terminal.

• Do not use an extension cord or power strip.

• Do not place the system in an area where people might step on the power cord.

• Do not place objects on the power cord.

• Do not block ventilation openings. These openings prevent printer overheating.

• Do not drop paper clips or staples into the printer.

Operational Safety

The printer and supplies were designed and tested to meet strict safety requirements. These

include safety agency examination, approval, and compliance with established environmental

standards.

• Do not use aerosol cleaners. The use of supplies that are not approved may cause poor

performance and could create a hazardous condition.

• Do not burn any consumables or routine maintenanc e items. For information on Xerox

supplies recycling programs, go to www.xerox.com/gwa.

Safety Labels

Read and obey all posted caution, warning, and danger labels. Throughout the printer, these

safety labels are displayed on potentially dangerous components. As you service the printer,

check to make certain that all safety labels remain in place.

• Caution: An unapparent hazard exists that may cause personal injury or damage to the

equipment. For example, a panel may cover the hazardous area.

• Warning: An unapparent hazard exists that may cause serious personal injury.

• Danger: An unapparent hazard exists that may cause serious personal injury or death.

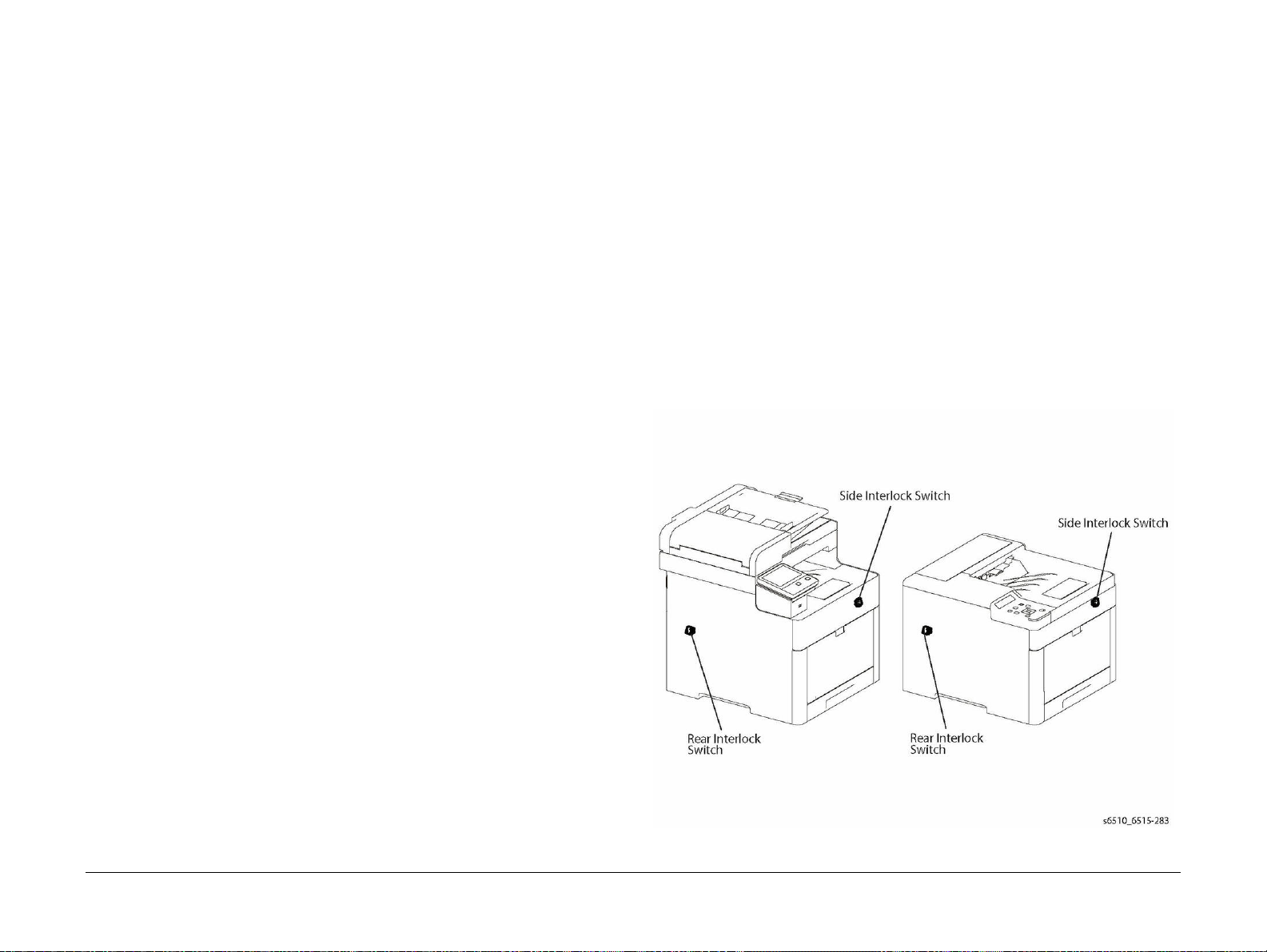

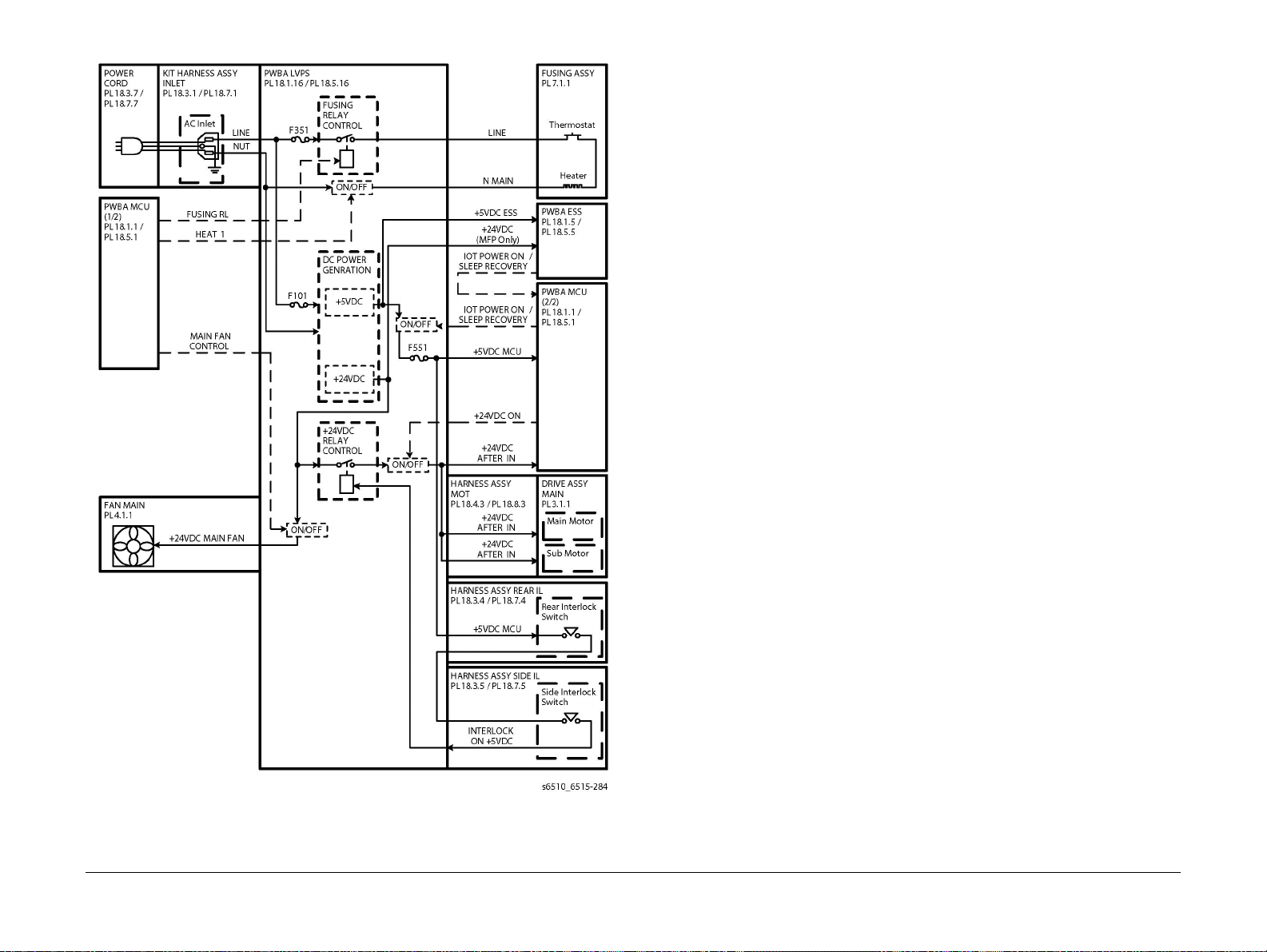

Safety Interlocks

Use caution so that the safety devices for preventing accidents (interlocks switches, fuses,

thermostats, etc.) and the protective parts for users (covers, control panel, etc.) can function as

intended. Make sure all covers are in place and all interlock switches are functioning correctly

after you have completed a service call. If you bypass an interlock switch, use extreme caution

when working on or around the printer. Figure 1 and Figure 2 show the interl ock switch loca

tions and circuitry.

-

Pay attention to these safety guidelines to ensure the continued, safe operation of the printer.

• Use the supplies specifically designed for your system. The use of unsuitable materials

may cause poor performance and a possible safety hazard.

• Follow all warnings and instructions marked on, or supplied with, the system, options and

supplies.

NOTE: The Total Satisfaction Guarantee is available in the United States and Canada. Coverage may vary outside these areas; please contact your local representative for details.

Maintenance Safety

• Do not attempt maintenance not specifically described in the printer documentation.

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

10/2017

Figure 1 Safety Interlock Switch Locations

Introduction

v

Service Safety Summary

Page 8

Drive Units

When servicing gears or other driving units, be sure to Switch off the machine, switch and

unplug the power cord. Drive them manually when required.

High-Temperature Units

When servicing high-temperature units (securing unit, etc.), be sure to turn them off to prevent

burns, injuries and other troubles. Remove the power plug and wait 40 minutes before starting

service processes so they have cooled down sufficiently.

Routing Wire Harnesses

Before starting the service operation, carefully check how the harness wires are routed. When

routing them, check that they are routed in the same way as they were before the servicing,

and that they are not pinched or do not interfere with the corners or edges of any operating

components.

Battery

A lithium battery is used on the ESS PWB.

WARNING

To avoid the possibility of fire or explosion, always replace the battery with the same

type, and dispose of old batteries as required by local regulations.

Figure 2 Safety System Schematic

Introduction

Service Safety Summary

10/2017

vi

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 9

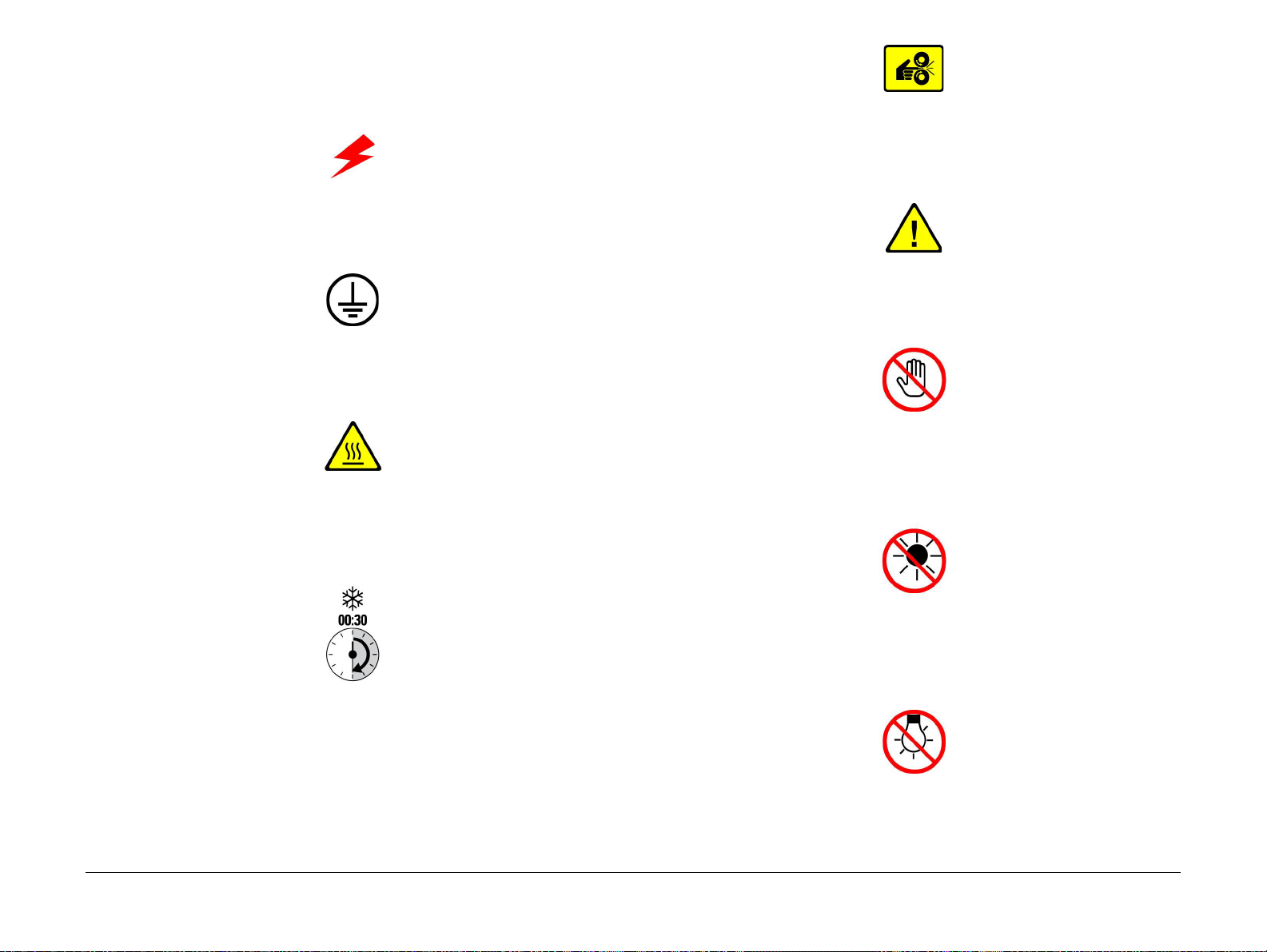

Symbols Used on the Product

The following precautionary symbols may appear on the machine.

Figure 1 indicates Danger High Voltage.

Figure 1 High Voltage symbol

Figure 2 is the Protective Ground (Earth) symbol.

Figure 2 Protective Ground (Earth) symbol

Figure 3 is the symbol indicating a hot surface. Use caution to avoid personal injury.

Figure 3 Hot Surface symbol

Figure 5 Pinch Injury symbol

Figure 6 is the symbol to use caution (or draws attention to a particular component). Refer to

the manual(s) for information.

Figure 6 Use Caution symbol

Figure 7 is the symbol indicating that the item is sensitive and should not be touched.

Figure 7 Do Not Touch symbol

Figure 8 is the symbol indicating the item is sensitive to sunlight, and exposure to it will reduce

its life span.

Figure 4 is the symbol indicating that the surface is hot while the printer is running. After turning

off the power, wait 30 minutes.

Figure 4 Wait 30 Minutes symbol

Figure 5 is the symbol indicating where to avoid pinching fingers in the printer. Use caution to

avoid personal injury.

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Figure 8 No Sunlight symbol

Figure 9 is the symbol indicating the item is sensitive to any light, and exposure to it will reduce

its life span.

Figure 9 No Light symbol

10/2017

vii

Symbols Used on the Product

Introduction

Page 10

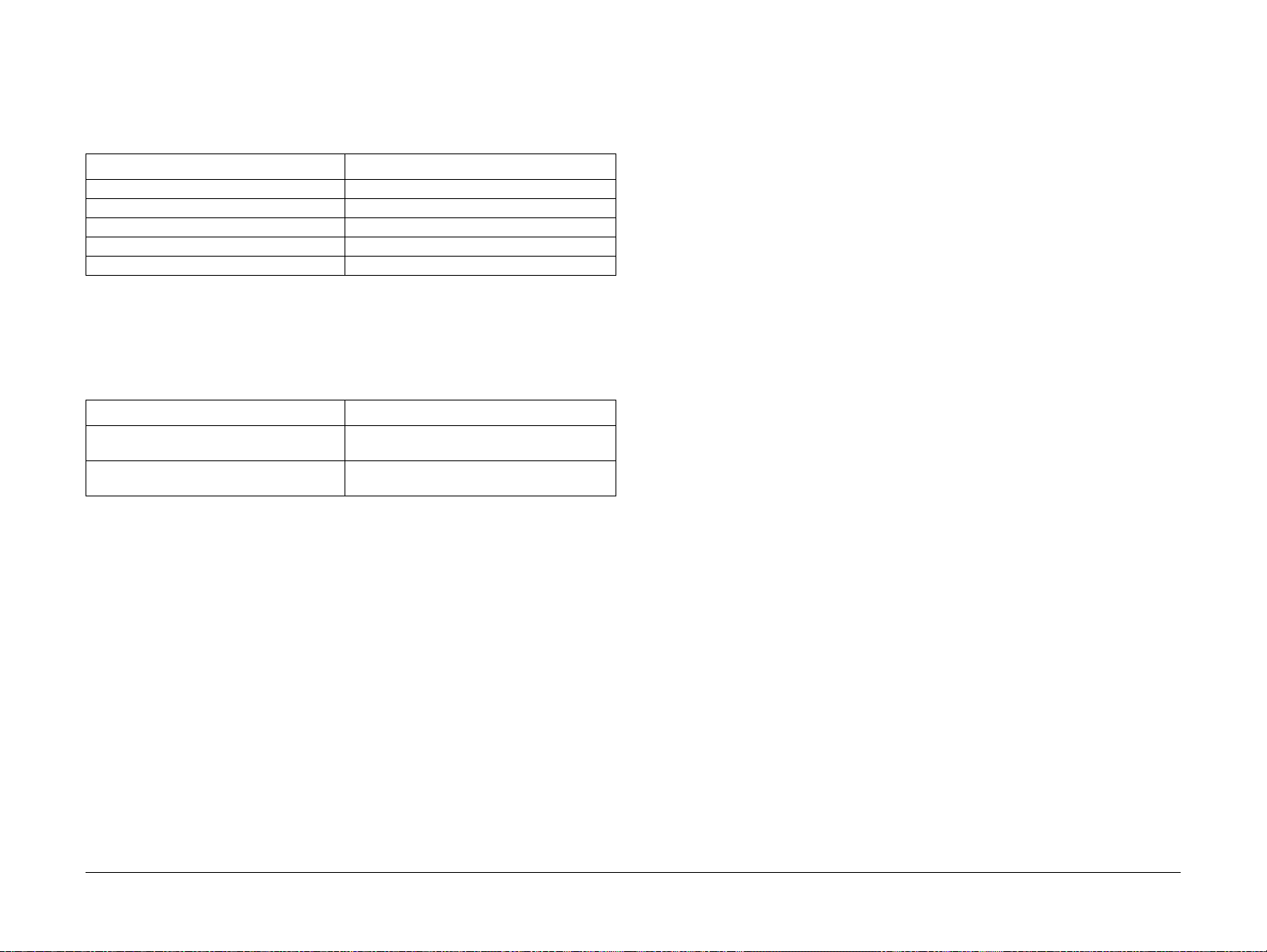

Volt age Me as ureme n t and S pec if ica t ions

Table 1 shows the voltages present in the WorkCentre 6515. Measurements of DC voltage

must be made with reference to the specified DC Com mon, unless some other point is refer

enced in a diagnostic procedure. All measurements of AC voltage should be made with respect

to the adjacent return or ACN wire.

Table 1 Voltage Measurement and Specifications

Voltage Specification

Input Power 220V 198VAC to 254VAC

Input Power 100V 90VAC to 135VAC

Input Power 120V 90VAC to 135VAC

+5VDC +4.75VDC to +5.25VDC

+24VDC +23.37VDC to +27.06VDC

Logic Voltage Levels

Table 2 show the logic levels present in the WorkCentre 6515. Measurements of logic levels

must be made with reference to the specified DC Com mon, unless some other point is refer

enced in a diagnostic procedure.

Health and Safety Incident Reporting

I. Summary

-

This section defines requirements for notification of health and safety incidents involving Xerox

products (equipment and materials) at customer locations.

II. Scope

Xerox Corporation and subsidiaries worldwide.

III. Objective

To enable prompt resolution of health and safety incidents involving Xerox products and to

ensure Xerox regulatory compliance.

IV. Definitions

Incident:

An event or condition occurring in a customer acco unt that has resulted in injury, illness or

property damage. Examples of incidents include machine fires, smoke generation, physical

-

injury to an operator or service representative. Alleged events and product conditions are

included in this definition.

Table 2 Logic Levels

Voltage H/L Specification

+5VDC H = +3.00VDC or greater

L = below 0 .8VDC

+3.3VDC H = +2VDC or greater

L =below 0.8VDC

DC Voltage Measurement in RAPs

The RAPs have been designed so that when it is required to use the DMM to measure a DC

voltage, the first test point listed is the location for the red (+) meter lead and the second test

point is the location for the black meter lead. For example, the following statement may be

found in a RAP.

There is +5VDC from P/J7 to P/J68.

In this example, the red meter lead would be placed on P/J7 and the black lead on P/J68.

If a second test point is not given, it is assumed that the black meter lead may be attached to

chassis ground.

V. Requirements

Initial Report:

1. Xerox organizations shall establish a process for individuals to report product incidents to

Xerox Environment Health & Safety within 24 hours of becoming aware of the event.

2. The information to be provided at the time of reporting is contained in Appendix A (Health

and Safety Incident Report involving a Xerox product).

3. The initial notification may be made by any of the following methods:

• Email Xerox EH&S at: usa.product.incident@xerox.com.

• Fax Xerox EH&S at: 585-422-2249.

NOTE: If sending a FAX, please also send the original via internal mail.

Responsibilities for resolution:

1. Business Groups/Product Design Teams responsible for the product involved in the incident shall:

a. Manage field bulletins, customer correspondence, product recalls, safety retrofits.

b. Fund all field retrofits.

2. Field Service Operations shall:

a. Preserve the Xerox product involved and the scene of the incident inclusive of any

associated equipment located in the vicinity of the incident.

b. Return any affected equipment/part(s) to the location designated by Xerox EH&S

and/or the Business Division.

c. Implement all safety retrofits.

3. Xerox EH&S shall:

a. Manage and report all incident investigation activities.

b. Review and approve proposed product corrective actions and retrofits, if necessary.

c. Manage all communications and correspondence with government agencies.

Introduction

Voltage Measurement and Spec ifications, Health and

10/2017

viii

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 11

d. Define actions to correct confirmed incidents.

VI. Appendices

The Health and Safety Incident Report involving a Xerox Product (Form # E H &S -700) is available in the location that follows:

• GSN Library 1789

Regulatory Specifications

Xerox has tested this product to elec tromagnetic emission and immunity standards. These

standards are designed to mitigate interference caused or receiv ed by this product in a typical

office environment.

United States (FCC Regulations)

The WorkCentre 6515 has been tested and found to comply with the limits for a Class A digital

device pursuant to Part 15 of the FCC Rules. These limits are designed to provide reasonable

protection against harmful interference in a commercial installation. This equipment generates,

uses, and can radiate radio frequency energy. If it is not installed and used in accordance with

these instructions, it may cause harmful interference to radio communications. Operation of

Class A equipment in a residential area is likely to cause harmful interference in which case the

user will be required to correct the interference at his/her own expense. There is no guarantee

that interference will not occur in a particular installation.

If this equipment does cause harmful interference to radio or television reception, which can be

determined by turning the equipment Off and O n, the user is encou raged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiver.

• Increase the separation between the equipment and receiver.

• Connect the equipment to a different electrical circuit.

• Consult the dealer or an experienced radio/ television technician for help.

Any modifications not expressly approved by Xerox could void the user's authority to operate

the equipment. To ensure compliance with Part 15 of the FCC rules, use shielded interf ace

cables.

Canada (Regulations)

This Class A digital apparatus complies with Canadian ICES-003.

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Cet appareil numérique de la classe A est conforme à la norme NMB-003 du Canada.

European Union

CE Mark

The CE mark (Figure 1) applied to this product symbolizes

Xerox’s declaration of conformity with the following applica

Figure 1 CE Symbol

February 26, 2014, Low Voltage Directive 2014/35/EU

April 20, 2014, Electromagnetic Compatibility Directive 2014/30/EU

This product, if used properly in accordance with the user's instructions, is neither dangerous

for the consumer nor for the environment.

10/2017

ix

Health and Safety Incident Reporting, Regulatory

ble Directives of the European Union as of the dates indicated:

-

Introduction

Page 12

To ensure compliance with European Union regulations, use shielded interface cables.

A signed copy of the Declaration of Conformity for this product can be obtained from Xerox.

Translation of Warnings

WARNING

Take care, a hazardous voltage is present at the C inlet, LVPS PWB (PL 18.1 Item 16/PL

18.5 Item 16), and ESS MF P/ESS SFP P WBs (PL 18.1 Item 5/PL 18.5 Item 5 ). Electricity

can cause death or injury.

DANGER: Faire attention, une tension électrique dangereuse est présente au niveau de

la sortie de l'inverseur de la lampe d'exposition.

AVVERTENZA: fare attenzione alla carica elettrica di uscita dell'invertitore della lampada

di esposizione. L'el e ttricità può causare infor tuni o morte.

VORSICHT: Achtung: Spannung am Ausgang des Belichtungslampeninverters.

AVISO: Tenga cuidado; hay tensión peligrosa en la salida del inversor de la lámpara de

exposición. La electricidad puede causar lesiones e incluso la muerte.

WARNING

Isolate the machine from the electrical supply whi le performing tasks that do not need

electricity. Refer to GP 4. Electricity can cause death or injury. Moving parts can cause

injury.

DANGER: Isolez la machine de l’alimentation électrique lorsque vous effectuez des

tâches ne nécessitant pas l’électricité. Reportez-vous à GP 4. L’électricité peut être à

l’origine de blessures, voire d’un accident mortel. Les pièces amovibles peuvent être à

l’origine de blessures.

AVVERTENZA: Isolare la macchina dall’alimentazione elettrica quando si eseguono

attività che non richiedono elettricità. Vedere GP 4. L’elettricità può causare morte o

lesioni personali. Le parti in movimento possono causare lesioni personali.

VORSICHT: Gerät bei Arbeiten, die keinen Strom erfordern, von der Stromversorgung

trennen. Andernfalls besteht Stromschlaggefahr und Verletzungsgefahr durch bew egli

che Teile. Siehe auch GP 4.

AVISO: Mantenga la máquina aislada de la energía eléctrica mientras realiza tareas que

no necesitan electricidad. Consulte GP 4. La electricidad puede causar lesiones e

incluso la muerte. Las partes móviles pueden causar daños.

-

Introduction

Regulatory Specifications, Translation of Warnings

10/2017

x

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 13

WARNING

Switch off the electricity to the machine. Refer to GP 4. Disconnect the power cord from

the customer supply while performing tasks that do not need electricity. Electricity can

cause death or injury. Moving parts can cause injury.

DANGER: Mettez la machine hors tension. Reportez-vous à GP 4. Déconnectez le cordon d'alimentation de l'alimentation du client lorsque vous réalisez des tâches qui ne

nécessitent pas d'électricité. L'électricité peut être à l'origine de blessures, voire d'un

accident mortel. Les pièces amovibles peuvent être à l'origine de blessures.

AVVERTENZA: Spegnere la macchina. Vedere GP 4. Scollegare il cavo di alimentazione

dall'alimentatore quando si eseguono attività che non richiedono elettricità. L'elettricità

può causare morte o lesioni personali. Le parti in movimento possono causare lesioni

personali.

VORSICHT: Schalten Sie die Stromversorgung der Maschine ab. Siehe auch GP 4. Zie hen Sie das Stromkabel ab, wenn Sie Aufg aben ausführen, für die keine Stromversorgung benötigt wird. Stromschläge können Todesfällen oder Verletzungen verursachen.

Bewegliche Teile können zu Verletzungen führen.

AVISO: Apague la electricidad de la máquina. Consulte el GP 4. Desconecte el cable de

alimentación eléctrica de la toma de pared mientras esté realizando tareas que no

necesiten corriente. La electricidad puede causar daños o la muerte. Las partes móviles

pueden causar daños.

WARNING

Do not work in a confined space. 1 m (39 inches) space is needed for safe working.

DANGER: Ne pas travailler dans un espace restreint. 1 mètre d'espace est nécessaire

pour un dépannage en tout e s é cu r ité.

AVVERTENZA: Non lavorare in uno spazio limitato; è necessario uno spazio di almeno

un metro attorno alla macchina per la sicurezza dell'operatore.

VORSICHT: Nur mit ausreichendem Bewegungsspielraum (1 m) arbeiten.

AVISO: No trabaje en un espacio reducido. Se necesita 1 metro de espacio para trabajar

con seguridad.

WARNING

Perform the steps in the following procedure carefully. Failure to follow this procedure

carefully could result in electrical shock and personal injury.

DANGER: Faire très attention en effectuant les étapes de la procédure suivante. Si cette

procédure n'est pas strictement respectée, il y a des risques d'électrocution et d'autres

blessures.

AVVERTENZA: Si prega eseguire attentamente la seguente procedura. Omettere di

eseguire attentamente la procedura indicata può provocare forti scosse e gravi ferite.

VORSICHT: Befolgen Sie die Schritte der folgenden Anleitung genau. Die Nichtbefolgung dieser Anweisungen kann elektrischen Schlag oder andere Körperverletzungen

zur Folge haben.

AVISO: Lleve a cabo los pasos del procedimiento siguiente con mucho cuidado. No

seguir este procedimiento cuidadosamente puede ocasionar una descarga el éctrica y

lesiones personales

WARNING

Use extreme care when working in the following area. Some of the components are electrically energized and could cause electrical shock and personal injury if touched.

DANGER: Faire très attention en travaillant dans la zone suivante. Certains éléments

portent une charge électrique et présentent un risque d 'électrocution et de graves b les

sures s'ils sont touchés.

AVVERTENZA: Maneggiare la seguente area con la massima precauzione. Alcuni componenti sono carici di corrente elettrica e se toccati possono provocare scosse

elettriche e lesioni.

VORSICHT: Bei Arbeiten in folgenden Bereichen besondere Vorsicht walten lassen.

Einige der Komponenten sind elektrisch aufgeladen und können bei Berührung einen

Stromschlag und körperliche Verletzung verursachen

AVISO: Tenga mucho cuidado al trabajar en el área siguiente. Algunos de los componentes están cargados eléctricamente y podrían producir descarga s y lesiones, si se

tocan

-

WARNING

Use high voltage probes when testing high voltage. Electricity can cause death or injury.

DANGER: Utilisez des sondes haute tension lorsque vous testez les hautes tensions.

L'électricité peut être à l'origine de blessures, voire d'un accident mortel.

AVVERTENZA: Quando si esegue il test della tensione ad alto voltaggio, utilizzare pun-

tali appropriati. L'elettricità può causare morte o lesioni personali.

VORSICHT: Verwenden Sie ein Hochspannungsmessgerät zur Prüfung von Hochspan-

nung. Stromschläge können Todesfällen oder Verletzungen verursachen.

AVISO: Utilice sondas preparadas para alto voltaje cuando esté comprobando puntos

de alto voltaje. La electricidad puede causar daños o la muerte.

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

10/2017

WARNING

Do not work in a confined space. 1 m (39 inches) space is needed for safe working.

DANGER: Ne pas travailler dans un espace restreint. 1 mètre d'espace est nécessaire

pour un dépannage en toute sécurité.

AVVERTENZA: Non lavorare in uno spazio limitato; è necessario uno spazio di almeno

un metro attorno alla macch ina per la sicurezza dell'operatore.

VORSICHT: Nur mit ausreichendem Bewegungsspielraum (1 m) arbeiten.

AVISO: No trabaje en un espacio reducido. Se necesita 1 metro de espacio para trabajar

con seguridad.

Introduction

xi

Translation of Warnings

Page 14

WARNING

Use safe handling procedures when removing the module. Refer to GP 16. The module

is heavy.

DANGER: Conformez-vous aux procédures de manipulation de sécurité pour le retrait

du module. Reportez-vous à GP 16. Le module est lourd.

AVVERTENZA: Utilizzare procedure di gestione sicure durante la rimozione del modulo.

Vedere GP 16. Il modulo è pesante.

VORSICHT: Verwenden Sie sichere Vorgehensweisen zum Entfernen des Moduls. Siehe

auch GP 16. Das Modul ist sehr schwer.

AVISO: Utilice los procedimientos de seguridad cuando elimine el módulo. Consulte el

GP 16. El módulo es pesado.

WARNING

Follow the service procedure exactly as written. Use of controls or adjustments other

than those specified in this manual, may result in an exposure to invisible laser radia

tion. During servicing, the invisible laser radiation can cause eye damage if looked at

directly.

DANGER: Les procédures de dépannage doivent être suivies à la lettre. Si les réglages

ou vérifications ne sont pas effectués suivant les instructions de ce manuel, il peut y

avoir un risque d'exposition dangereuse au faisceau laser. Celui-ci peut provoquer des

lésions oculaires s'il est observé directement.

AVVERTENZA: Eseguire le procedure di servizio esattamente come descritto. L'utilizzo

di dispositivi di controllo o di registrazione diversi da quelli riportati in questo manuale

potrebbe comportare un'esposizione a radiazioni laser invisibili. Tali radiazioni possono

danneggiare gli occhi se si guarda direttamente il fascio laser durante gli interventi di

servizio.

VORSICHT: Die Wartungsarbeiten genau den Anweisungen entsprechend durchführen.

Der Umgang mit Steuer- oder Bedienelementen, deren Verwendung nicht ausdrücklich

in diesem Handbuch angewiesen wurde, kann dazu führen, dass unsichtbare Laser

strahlung frei gesetzt wird. Direkter Blickkontakt mit dem Laserstrahl kann bleibende

Augenschäden verursachen.

AVISO: Siga los procedimientos de mantenimiento tal como están descritos. El uso de

controles o ajustes no especificados en este manual puede tener como resultado la

exposición a radiación láser invisible. Durante las operaciones de mantenimiento, la

radiación de láser invisible puede causar daños en los ojos si se mira directamente a

ella.

WARNING

USA and Canada. Do not install this machine in a hallway or exit route that does not

have 1.12 m (44 inches) of space additional to the normal space requirements in front of

the machine. To conform with fire regulations this additional 1.12 m (44 inches) of space

is needed in front of the machine in hallway and exit routes.

DANGER: États-Unis et Canada. Si cette machine est installée dans un couloir ou une

voie de sortie, 1,12 m (44 pouces) d'espace supplémentaire à l'espace normal doit être

disponible devant la machine conformément aux normes de sécurité d'incendie.

AVVERTENZA: N/A

VORSICHT: N/A

AVISO: Estado s Unidos y Canadá. No instale esta máquina en un corredor o ruta de sal-

ida que no tenga 1.12 m (44 pulgadas) de ancho delante de la máquina, sin incluir el

espacio que ocupe la máquina. Este espacio adicional de 1.12 m (44 pulgadas) delante

de la máquina en corredores y rutas de salida es necesario para cumplir los requisitos

de las normas sobre incendios.

-

WARNING

Use only Xerox materials and components. This product is safety certified using Xerox

materials and components. The use of non Xerox materials and components may invali

date the safety certificate.

DANGER: N'utilisez que des matières premières et des composants Xerox. La sécurité

du produit est assurée dans le cadre de son utilisation avec des matières premières et

des composants Xerox. L'utilisation de matières premières et de composants autres

que ceux de Xerox risque d'invalider le certificat de sécurité.

AVVERTENZA: Utilizzare solo materiali e componenti Xerox per avvalersi della certificazione di protezione. L'utilizzo di materiali e componenti non Xerox può rendere nulla la

certificazione di protezione.

VORSICHT: Verwenden Sie nur Materialien und Komponenten von Xerox. Dieses

-

Produkt besitzt die Sicherheitszertifizierung bei Verwendung von Xerox-Materialien und

-Komponenten. Die Verwendung von Materialien und Komponenten anderer Hersteller

setzt möglicherweise das Sicherheitszertifikat außer Kraft.

AVISO: Utilice solo los materiales y componentes Xerox. Este producto dispone de un

certificado de seguridad si se utilizan los materiales y componentes Xerox. Este certifi

cado de seguridad no será válido si se utilizan materiales y componentes que no sean

de Xerox.

-

-

Introduction

Translation of Warnings

WARNING

Do not touch the Fuser while it is hot.

DANGER: Ne pas toucher au four pendant qu'il est encore chaud.

AVVERTENZA: Non toccare il fonditore quando è caldo.

VORSICHT: Fixierbereich erst berühren, wenn dieser abgekühlt ist.

AVISO: No toque el fusor mientras está caliente.

10/2017

xii

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Revised BUS Update: July 2020

Page 15

WARNING

Do not handle the Fuser components until they have cooled. Some Fuser components

operate at hot temperatures and can produce serious personal injury if touched.

DANGER: Ne pas manipuler les éléments du four avant de les laisser refroidir. Certains

éléments du four fonctionnent à des températures très élevées et peuvent causer de

graves blessures s'ils sont touchés.

AVVERTENZA: Non maneggiare i componenti del fusore finché non sono raffreddati.

Alcuni di questi componenti funzionano ad alte temperature e possono provocare gravi

ferite se vengono toccati.

VORSICHT: Die Fixieranlage sollte erst gehandhabt werden, wenn diese genügend

abgekühlt ist. Einige Teile der Fixieranlage erzeugen übermäßige Hitze und führen bei

der Berührung zu schweren Verbrennungen.

AVISO: No manipule los componentes del fusor antes de que se enfrí e n. Algunos de los

componentes del fusor funcionan a altas temperaturas y pueden ocasionar daños per

sonales graves si se los toca.

WARNING

Do not attempt to remove or lift the following component with less than 2 people. The

component is very heavy and requires at least 2 people to lift or remove it. Any attempt

to remove or lift the component with less than 2 people could result in serious personal

injury.

DANGER: Ne pas tenter d'enlever ou soulever l'élément suivant tout seul. Cet élément

est très lourd; au moins 2 personnes doivent être prése ntes pour le soulèvement ou la

dépose. Toute tentative d'enlever ou soulever cet élément sans la collaboration d'au

moins 2 personnes peut causer de graves blessures.

AVVERTENZA: Non tentare di togliere o sollevare il componente seguente con meno di

2 persone. Il componente è molto pesante e richiede almeno 2 persone per sollevarlo o

rimuoverlo. Tentare di rimuovere o sollevare questo componente con meno di 2 persone

può provocare gravi fer ite.

VORSICHT: Versuchen Sie keinesfalls, die folgende Komponente mit weniger als 2 Personen zu entfernen oder zu heben. Die Komponente ist sehr schwer, daher werden

mindestens 2 Personen benötigt, um sie zu heben oder zu entfernen. Der Versuch, die

Komponente mit weniger als 2 Personen zu entfernen oder zu heben, kann schwere Kör

perverletzung zur Folge habe n.

AV IS O: No intente levantar o retirar el componente siguiente usando menos de 2 personas. El componente es muy pesado, y se necesitan por lo menos 2 personas para levantarlo o retirarlo. Intentar retirar o levantar el componente usando menos de 2 personas

puede resultar en lesionales personales serias.

Technical Support Information

The Xerox Service Manual is the primary document used for repairing, maintaining, and troubleshooting the Phaser 6510 and WorkCentre 6515. To ensure complete understanding of

these products, participation in Xerox Service Training is strongly recommended. To service

these products, certification for these products is required.

For updates to the Service Manual, Service Bulletins, knowledge base, etc., go to:

• Xerox Global Service Net - https://www.xrxgsn.com/secure/main.

For further technical support, contact your assigned Xerox Technical Support representative.

-

-

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

10/2017

xiii

Introduction

Translation of Warnings,

Page 16

Introduction

Translation of Warnings,

10/2017

xiv

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 17

SCP 1 Initial Actions........................................................................................................ 1-3

SCP 2 First Call Actions.................................................................................................. 1-4

SCP 3 Normal Call Actions............................ ..................................... .......................... .. 1-4

SCP 4 Fault Analysis ...................................................................................................... 1-5

SCP 5 Subsystem Maintenance ..................................................................................... 1-6

SCP 6 Final Actions........................................................................................................ 1-9

1 Service Call Proced ur es

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

10/2017

1-1

Service Call Procedures

Page 18

Service Call Procedures

10/2017

1-2

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 19

SCP 1 Initial Actions

Initial Actions are used to gather information on printer performance

Start a service call with SCP 1 and end with SCP 6 Final Actions.

Also refer to Machine Specifications, GP 7.

Procedure

WARNING

solate the machine from the electrical supply while performing tasks that do not need

electricity. Refer to GP 4. Electricity can cause death or injury. Moving parts can cause

injury.

WARNING

Do not work in a confined space. 1 m (39 inches) space is needed for safe working.

NOTE: Ignore references to options not installed on the printer.

1. Identify the problem.

• Verify the reported problem does exist.

• Ask the operator to describe or demonstrate the problem.

• Print normal customer prints and service test prints.

• Make note of any print-quality problems in the test prints.

• Print a Usage Profile, if the printer is able to print.

2. Make note of any mechanical or electrical abnormalities present.

3. Make note of any unusual noise or smell coming from the printer.

4. To view engine error and jam histories, perform Diagnostic s dC118, dC120, dC122, and

dC125.

5. Take note of symptoms or error messages.

6. Make su re:

a. The power cord is connected to the wall outlet and to the machine.

b. The AC input from the wall outlet is within specifications.

c. Paper is loaded correctly and all paper trays and covers are closed

d. If installed, the USB cable or network connection is installed correctly.

7. If available, check the service log book for any previous actions that may be relevant to

the call.

8. If this is the f irst service call to th is printer, perform SCP 2 First Call Actions, otherwise go

to SCP 3 Normal Call Actions.

Accessing Engine Fault History

Listed below are three ways in which you can access fault history. Additional fault history information appears in GP 2.

3. If the printer is connected to a network and has a TCP/IP address, view the printer’s web

page using a web browser.

a. Open a web browser.

b. Enter the printer’s IP address as the URL.

c. Select > > and the fault history displays.

NOTE: Error and fault code definitions appear in Section 2.

1. Read (if possible) fault history from Device -> Support -> Support Pages -> Err or Histor y

Report on the control panel. The error history is listed on screen.

2. Accessing fault history in Service Diagnostics

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

10/2017

1-3

Service Call Procedures

SCP 1

Page 20

SCP 2 First Call Actions

First Call Actions are used for the first service call.

SCP 3 Normal Call Actions

Normal Call Actions are used to determine the reason for the service call.

Procedure

1. Check the machine configuration with the customer, refer to Machine Specifications, GP

7. Check that all required hardware and software is installed and/or enabled.

2. Check that all the relevant machine settings are correctly entered, refer to GP 4 System

Administration T ools.

3. If a fault is present, go to SCP 3 Normal Call Actions. If there is no fault present, go to

SCP 6 Final Actions.

4. Enter the printer and customer details in the service log.

Procedure

NOTE: If a fault message appears at any time. Refer directly to the RAP for the fault mes sage

and perform the procedure.

If possible, perform the following:

1. Review any defective print samples.

2. Determine that the user accessible settings are correct. If necessary refer to the user documentation.

3. Check all job queues and verify with the customer any requirement to print the documents

in memory, before switching off the power or clearing memory.

4. Print the Customer Assistance Report (Call for Assistance), then record the total print

count.

5. Go to SCP 4 Fault Analysis.

Service Call Procedures

SCP 2, SCP 3

10/2017

1-4

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 21

SCP 4 Fault Analysis

Fault Analysis is used to identify a fault.

Procedure

When diagnosing or repairing a fault in a particular subsystem, exercise the machine in all

modes until the fault is determined. In the instance of finding more than one fault or failure, cor

rect one fault before going to the next fault. If no fault is found, go to SCP 5 Subsystem Maintenance.

Fault Codes

If a fault code is displayed, go to the relevant RAP. Also refer to Unresolved Faults.

Control Panel Faults

If the power is on but the Control Panel is blank, test the Control Panel with dc305.

Image Quality Defects

If the image quality is defective, go to the IQ1 Image Quality Entry RAP.

Unresolved Faults

If a fault cannot be resolved using the appropriate RAP, and only if instructed by 2nd level support, obtain a device log. Refer to GP 38 Obtaining Audit and Device Logs. Escalate the problem to 2nd level support.

Additional Information

If necessary, refer to the following general procedures and information:

• GP 1 Using the Service Diagnostics

• GP 2 Fault Codes and History Logs

• GP 3 Device In formation

• GP 4 How to Switch Off or Sw i t c h On the Printer

• GP 6 Electrostatic Discharge Prevention

• GP 7 Machine Specifications

• GP 8 General Disassembly Precautions

• GP 9 Firmware Version Upgrade

• GP 10 How to Check a Motor

• GP 11 How to Check a Sensor

• GP 12 How to Check a Solenoid or Clutch

• GP 13 How to Check a Switch

• GP 14 How to Clone Device Settings

• GP 15 Special Boot Modes

• GP 16 Separate System Modules

• GP 17 External FAX Line Test

• GP 18 Printing Reports

• GP 19 Intermittent or Noise Problem

• GP 20 How to Safely Lift or Move the Printer

• GP 21 Machine Lubrication

• GP 22 Installation Space Requirements

• GP 23 First Print Output Time

• GP 24 Restriction of Hazardous Substances (RoHS)

• GP 26 Media Specifications

• GP 27 Environmental Data

-

• GP 28 Supplies Plan Conversion

• GP 29 How to Check a Dispenser Motor

• GP 30 IP (ESS) Specifications

• GP 31 IIT Specifications

• GP 32 FAX Specifications

• GP 33 Interior and Exterior Cleaning

• GP 34 Cleaning the Scanner and DADF

• GP 35 Setting Up an Ethernet Connection

• GP 36 How to Manually Configure an IP Address

• GP 37 Reset Administrato r Password

• GP 38 Obtaining Audit and Device Logs

• GP 39 FFC Cables

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

10/2017

1-5

Service Call Procedures

SCP 4

Page 22

SCP 5 Subsystem Maintenance

Subsystem Maintenance contains information regarding the component life of the machine.

Procedure

WARNING

Isolate the machine from the electrical supply w hile performing tasks that do not need

electricity. Refer to GP 4. Electricity can cause death or injury. Moving parts can cause

injury.

1. Clean the Pick Rollers on every call.

2. Use the Control Panel to check maintenance item counters.

3. Compare the counter values to those listed in Table 1.

4. Advise the customer of any routine maintenance items that are approaching or over the

service limit.

Inspection

Lubrication

CAUTION

Plastic parts deteriorate when unspecified lubricants or chemicals are used. To avoid damage,

use only approved lubricant.

The printer is lubricated during assembly at the factory and does not require periodic lubrication. Some parts require lubrication following replacement. These parts are identified in the

replacement procedures. When lubricating during replacement, use approved grease.

Component Life

The design life of the major components are shown in Table 1. Environmental conditions and

actual use will vary these factors. The component life shown in Table 1 is for reference only.

Dimensions and Mass of Consumables

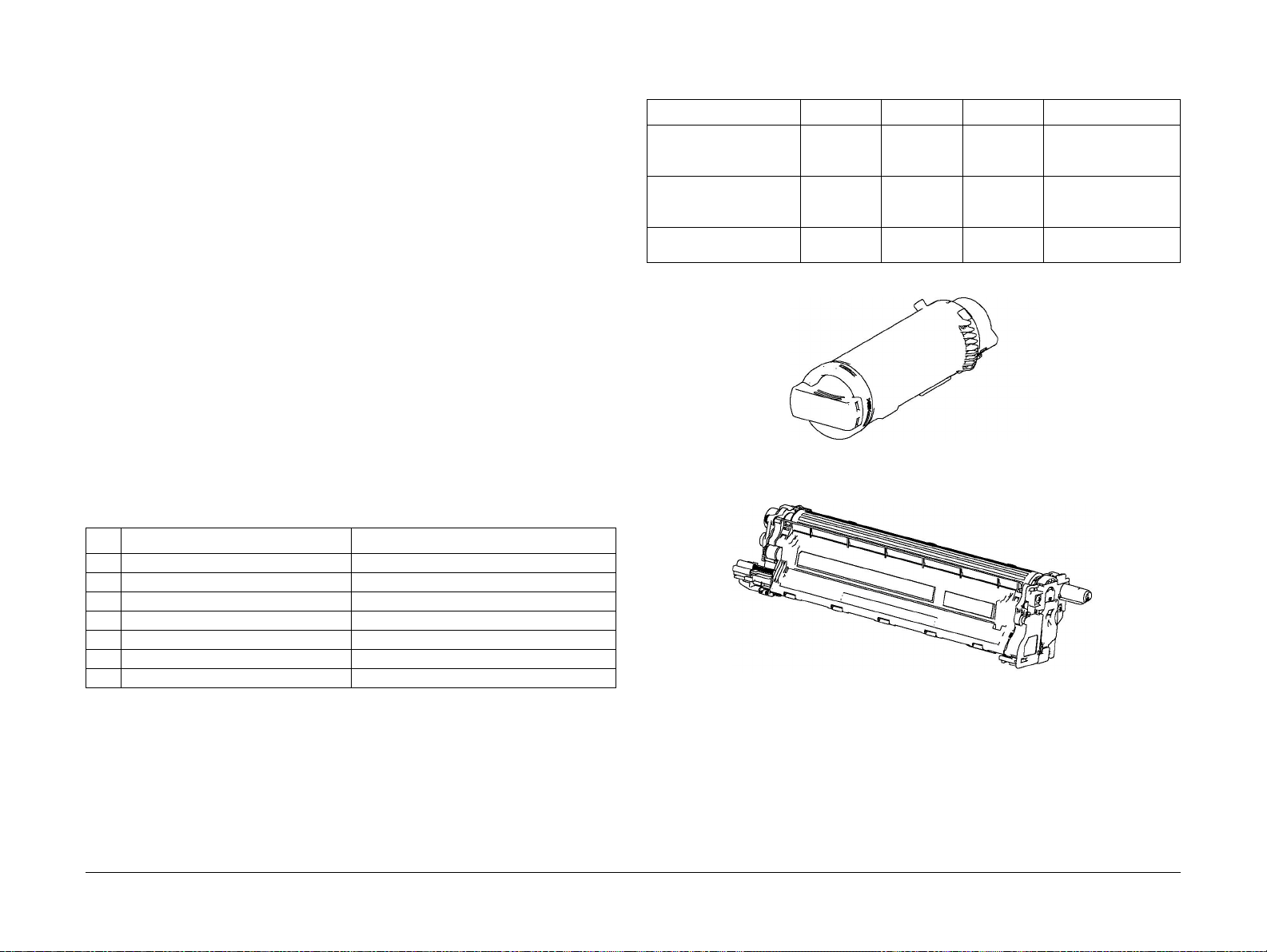

The WC6515 and P6510 contain the consumables shown in Table 1:

Table 2 Dimensions and Mass of Consumables

Consumable Width (mm) Depth (mm) Height (mm) Mass (g)

Toner Cartridges C, M, Y,

K

(Figure 1)

Drum Cartridges C, M, Y,

K

(Figure 2)

Waste Cartridge

(Figure 3)

61.3 180 57.3 K: 100/120/140

C,M,Y: 90/110/120

(STD / HI / EX-HI)

77.3 335.4 78.5 720

357 176.3 33 250

Figure 1 Toner Cartridge

Table 1 Design Life of Major Components

1. Pick and Nudger Rollers 100,000 pages

2. Separator Roller 100,000 pages

3. Transfer Unit / Transfer Roller 100,000 images

4. Fuser 100,000 images

5. Feed Rollers 100,000 pages

6. Waste Cartridge 3 0,000 pages

7. Drum Cartridge 48,000 pages

Consumables and Maintenance

Consumables consist of C, M, Y, and K Toner Cartridges, C, M, Y , and K Drum Cartridges, and

the Waste Cartridge.

Service Call Procedures

SCP 5

10/2017

1-6

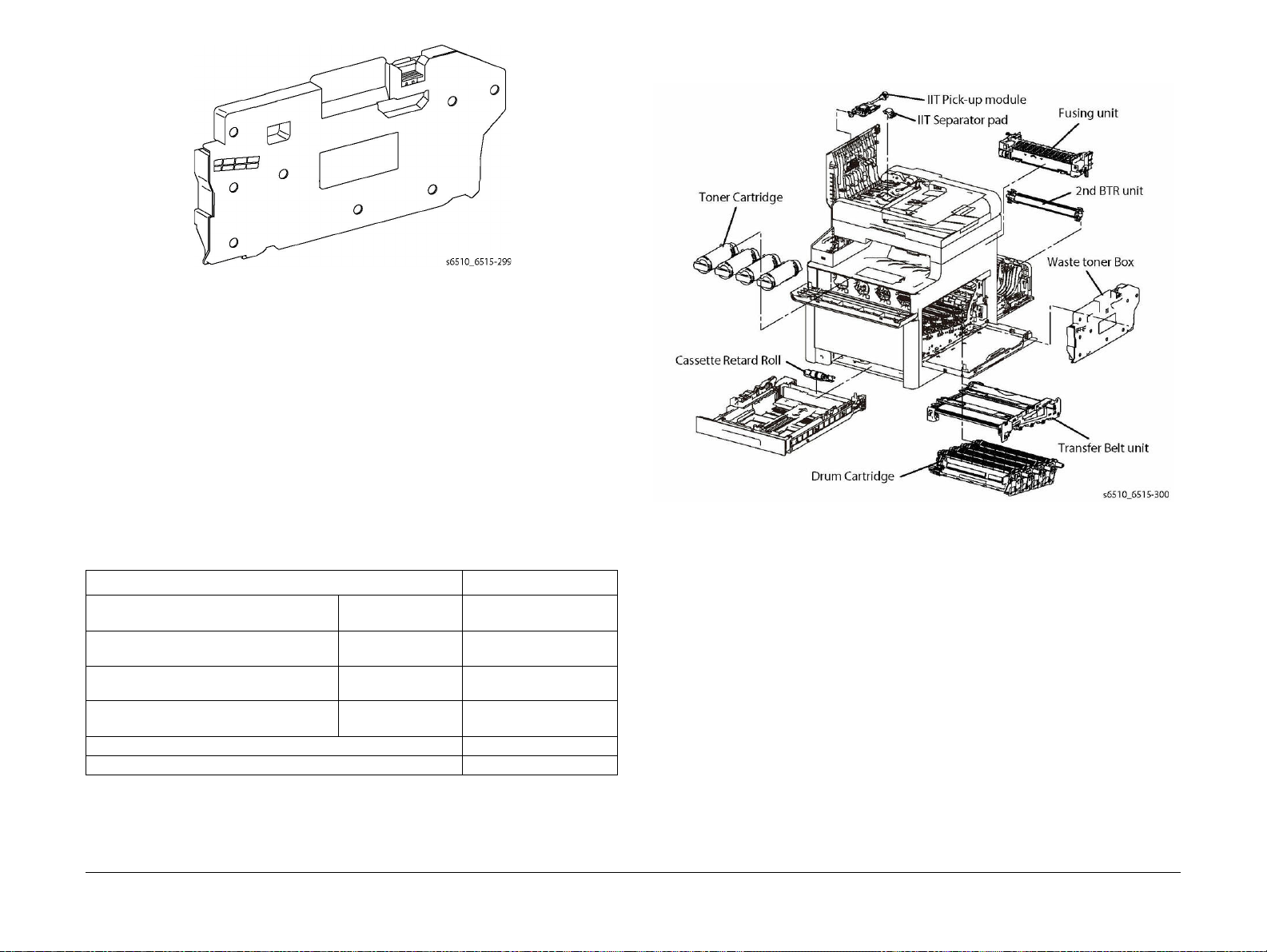

Figure 2 Drum Cartridge

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 23

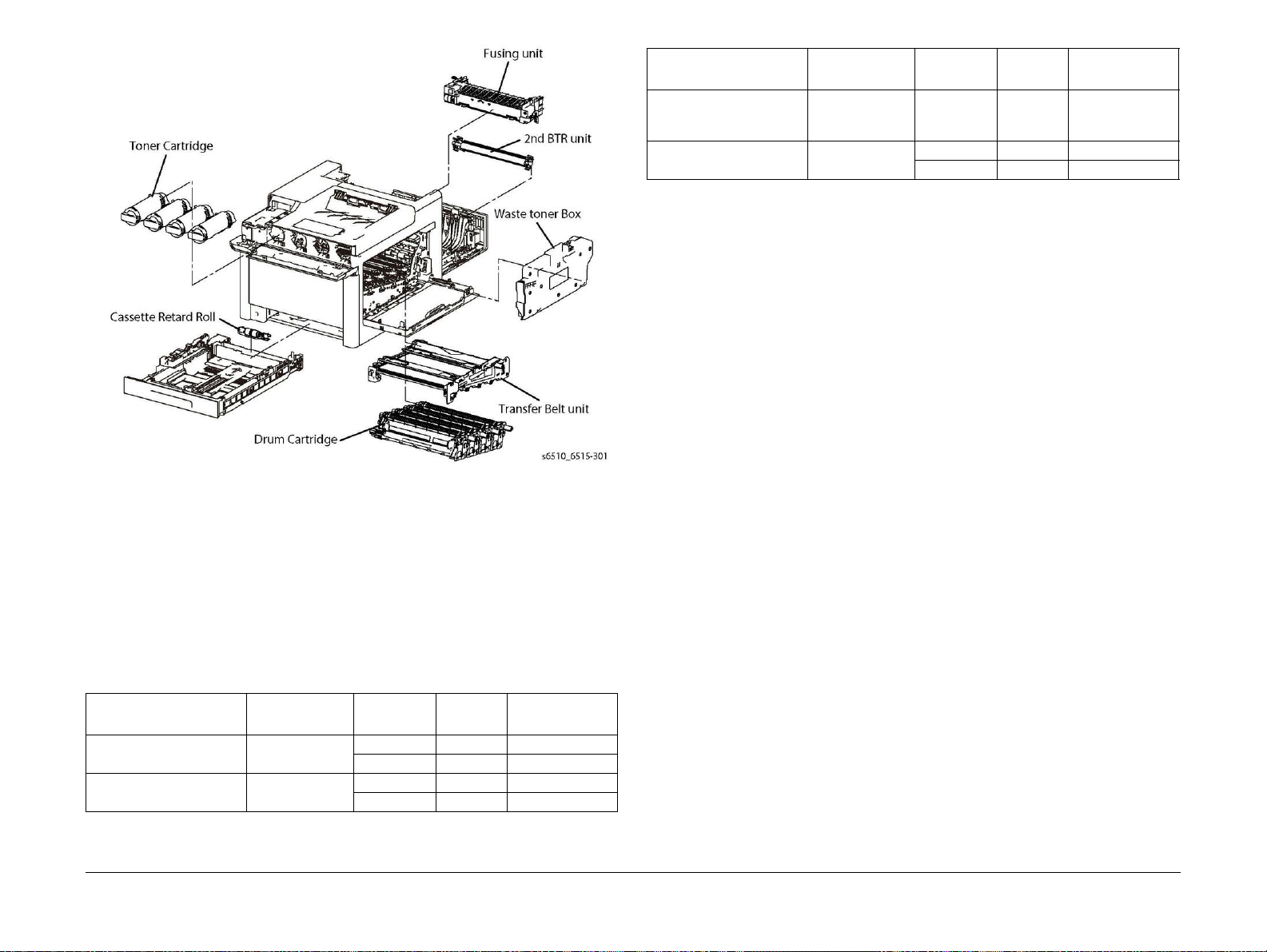

Figure 3 Waste Cartridge

Consumables Life Expectancies

Each Toner Cartridge (except s tarter cartridges) has a CRUM (Customer Replaceable Unit

Monitor) to record regional and toner usage information. The CRUM maintains a count of the

amount of toner consumed. When the count reaches set values, warning and error messages

appear to notify the user when near and end of life status is reached.

Like the Toner Cartridges, each Drum Cartridge has a CR UM to maintain a page count. When

the count reaches a set value, warning and error m essages a ppear to notify the user that the

Drum Cartridge has reached near or end of life status.

NOTE: The specifications showing life ratings are correct at the time of product release. For

the most current values, go to www.xerox.com.

Life ratings are shown in Table 3.

• Transfer Belt unit + Transfer Roller unit: 100 kPV (life of machine)

• DADF Feed Rollers: 100 kPV (WorkCentre WC6515 only) (life of machine)

Figure 4 WC6515 Routine Maintenance Items

Table 3 Life Expectancies for Consumables

Consumable Capacity

CMYK Standard Capacity Toner Cartridges starter cartridges color: 1,000

black: 1,500

sold cartridges color: 1,000

CMYK High Capacity/Extra High Capacity

Toner Cartridges

Drum Cartridge (C, M, Y, K) 48,000

Waste Cartridge 30,000

Routine Maintenance Items

Figure 4 and Figure 5 show the routine maintenance items which are service parts:

• Fuser (110V / 220V): 100 kPV (life of machine)

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

sold cartridges color: 2,500 / 4,500

metered cartridges color: 2,500

black: 2,500

black: 6,000 / N/A

black: 6,000

10/2017

1-7

Service Call Procedures

SCP 5

Page 24

Figure 5 P6510 Routine Maintenance Items

Table 4 Hardware Kit P6510 and WC6515

Type Shape PL Number Size

Screw for sheet metal

Silver, with washer and

plane washer

E-ring E2 D4 354W027278 (2)

SM20 M3x8mm 112W27898 (2)

E6 D6 354W024278 (2)

Part Number

(Quantity)

Hardware Kit

The spare parts available for repairs and maintenance includes a hardware kit. The kit contains

miscellaneous screws and e-clips that can be used to replace hardware that is lost or dam

aged, Table 4.

Since the P6510 and WC6515 use various types of hardware (screws, E-clips), ensure that the

correct hardware is used when installing parts. Use special caution not to confuse the screws

used for plastic with those used for sheet metal. Using the wrong type of screw ma y result in

damage to the screw threads or other problems.

Table 4 Hardware Kit P6510 and WC6515

Part Number

Type Shape PL Number Size

Screw for plastic

Silver, tapping

Screw for sheet metal

Silver

Service Call Procedures

ST20 M3x8mm 115W27878 (10)

ST21 M3x6mm 826E49690 (2)

SM3 M4x6mm 1 13W35688 (5)

SM18 M3x6mm 116W27678 (10)

(Quantity)

10/2017

SCP 5

-

Revised BUS Update: July 2020

1-8

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 25

SCP 6 Final Actions

Final Actions are used to evaluate the total operation of the system and to identif y the actions

required to complete the service call.

Procedure

Complete the following, if a fault is identified, return to SCP 4 Fault Analysis:

1. Perform the end of call subsystem maintenance actions, SCP 5 Subsystem Maintenance.

2. Exercise the machine in all modes, printing from all trays. If a fault message is disp layed

or some other problem is evident, go to SCP 4 Fault Analysis.

3. Make a print of a customer document.

4. If any of the customers selections were changed, return t hem to the cus tomers preferred

settings. Refer to GP 4 System Administration Tools.

5. At the first service and at any subsequent service where changes are made or options are

added, print the configuration report and store it with machine log book. Discard any pre

vious versions of the configuration report.

6. Remove and destroy any copies of test patterns.

7. Ensure the machine and service area are clean before leaving the customer premises.

8. Provide customer training if required.

-

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

10/2017

1-9

Service Call Procedures

SCP 6

Page 26

Service Call Procedures

SCP 6

10/2017

1-10

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

Page 27

2 Status Indicator RAPs

Troubleshooting Overview

Troubleshooting Overview .............................................................................................. 2-9

Chain 001 - 005

1DC +5VDC Power Fault RAP........................................................................................ 2-13

1AC +24VDC Power Fault RAP................................................ ......................... ............. 2-13

002-500 UI Error RAP..................................................................................................... 2-14

003-311 IIT CDI I/F Mismatch....................................................... .... .. ........... .. .... .... ....... 2-14

003-318, 003-319 IIT Software Fail.............................. .. ......... .... .. .... .... ....... .... .. .... .... ..... 2-15

003-320 to 003-343 IISS-ESS Communication Fail........................................................ 2-15

003-344 IISS-ESS X Hotline Fail .................................................................................... 2-16

003-345, 003-346 X PIO Mismatch RAP ................................................................... ..... 2-17

003-700 Returned Documents Error RAP..... .................................................................. 2-17

003-701 Duplication Prevention Code RAP.................................................................... 2-18

003-702 Different Magnification RAP................................................................. .. .. .... ..... 2-18

003-703, 003-704 Color Correction RAP ........................................................................ 2-19

003-705 Energy Saving Paper Size Mismatch RAP ....................................................... 2-19

003-750 Insufficient Documents Duplex Book RAP........................................................ 2-20

003-751 Capacity RAP.................................................................................................... 2-20

003-752, 932, 935 600dpi Cannot be Scanned RAP....................................... .. .... .. .. ..... 2-21

003-753, 913, 930, 933 300dpi Cannot be Scanned RAP.............................................. 2-21

003-754, 003-756 S2X Error RAP................................................................................... 2-22

003-757, 931, 934 400dpi Cannot be Scanned RAP....................................... .. .... .. .. ..... 2-22

003-760, 003-761 Scan Settings Error RAP ................................................................... 2-23

003-763 Adjustment Chart Not Found RAP.................................................................... 2-23

003-764 Document Insufficient (image overlay) RAP ..................................................... 2-24

003-780 Scan Image Compression Error RAP ............................................................... 2-24

003-795 AMS Limit Error RAP ........................................................................................ 2-25

003-940 Insufficient Memory RAP .................................................................................. 2-25

003-941 Insufficient Page Memory RAP......................................................................... 2-26

003-942, 003-956 Document Size Auto Detect RAP...................................................... 2-26

003-944 Repeat Image Count Fail RAP.......................................................................... 2-27

003-946 Image Rotation (Copy APS) RAP ..................................................................... 2-27

003-947, 948 Document Error RAP ................................................................................ 2-28

003-952 Document Color Mismatch RAP ....................................................................... 2-28

003-955 Documents Size Exchange Error RAP ............................................................. 2-29

003-956 Documents Size Unknown Error RAP ......................................................... ..... 2-29

003-963, 965, 966 ATS/APS RAP ......................... .. .. .... .. ....... .. .. .... .. .. ....... .. .... .. .. .... .. ..... 2-30

003-970, 003-976 FAX Line Memory RAP............................................................... ....... 2-30

003-971 Prevention Code Detect With The Right To Cancel RAP................................. 2-31

003-972 Maximum Stored Page RAP............................................................................. 2-31

003-973 Image Rotation RAP ......................................................... .. .... ....... .. .. .. .... .. .. ..... 2-32

003-974 Next Original Specification RAP ....................................................................... 2-32

003-977 Document Mismatch (Multi Scan) RAP. ............................................................ 2-33

003-978 Color Document Mismatch (Multi Scan) RAP................................................... 2-33

005-121, 123, 124, 125, 305, 900, 906, 908, 911, 940 DADF Jam RAP........................ 2-34

005-210, 005-275 DADF Fail RAP........................................................ ....... .. .. .... .. .. .. ..... 2-34

005-500 Write to DADF-ROM Error RAP........................................................................ 2-35

005-941 Not Enough Documents RAP................................................ .... .... .... ......... .... ... 2-35

Chain 010

010-105, 010-106 Fusing Assembly Exit Sensor RAP.................................................... 2-37

010-331, 338, 344 Fusing Assembly HR RAP................................................................ 2-38

Chain 016

016-211, 016-212 SW Option Fail Memory Low RAP..................................................... 2-41

016-214 SW Option Fail (FAX Card) RAP ...................................................................... 2-41

016-234, 016-235 XCP Error RAP .................................................................................. 2-42

016-242 System GMT Clock Fail RAP............................................................................ 2-42

016-244 Self-Signed Certificate Auto Update Fail RAP.................................................. 2-43

016-310 SSMM Job Log Full RAP .................................................................................. 2-43

016-311, 315, 319, 354 Scanner/IIT Errors RAP ............................................................ 2-44

016-320 Document Formatter Fatal Error RAP............................................................... 2-44

016-321 FAX Module Error RAP..................................................................................... 2-45

016-323 B-Formatter Fatal Error RAP............................................................................. 2-45

016-324 Scheduled Image Overwrite RAP ..................................................................... 2-46

016-325 Using Personal Certificate RAP........................................................................ 2-46

016-326, 362, 607 UI Cable Connection Fail RAP....................................................... .. . 2-47

016-328 Connection Fail RAP...................................... .. .... .. .. .. ....... .. .. .... .. .. .... ..... .. .... .. .. . 2-47

016-330 to 016-332 Cont System Memory Fail RAP...................................................... 2-48

016-342 to 016-345 Controller Fail RAP......................................................................... 2-48

016-346 Cont A4FAX Modem Diagnosis Fail RAP......................................................... 2-49

016-349 to 016-351 eMMC Card Errors RAP ................................................................. 2-49

016-352, 609, 610 Internal Network Init/PCI/PCIEX Fail RAP........................................ 2-50

016-353, 356, 606, 608 IOT-Controller Communication Fail RAP .................................. 2-50

016-355, 016-356 Controller ASIC Fail RAP................................................................... 2-51

016-359, 360, 361 Controller USB Fail RAP................................................................... 2-51

016-370 Controller Diagnostic Fail RAP.......................................................................... 2-52

016-371 Controller USB 1.1 Host Fail RAP..................................................................... 2-52

016-383 Controller OS Communication Fail RAP .......................................................... . 2-53

016-400, 401, 402, 403, 406 802.1x Authentication Failure - Network1 RAP................. 2-53

016-404 802.1x Inside Failure RAP ................................................................................ 2-54

016-405 Certificate DB File Error RAP............................................................................ 2-54

016-407 to 016-412 XCP Error RAP.. ............................................................................. 2-55

016-422, 016-423 Offline RAP ....................................... .... .. .... ....... .... .. .... .... .. ....... .... .... . 2-55

016-424, 016-425 Power Mode RAP .............................................................................. 2-56

016-426 Remote Services Error RAP ............................................................................. 2-56

016-427, 428, 429, 430, 431, 432 802.1x Failures (Network 2) RAP.............................. 2-57

016-450 SMB Host Name Duplicated RAP..................................................................... 2-57

016-453, 016-454 IPv6/Dynamic DNS Failure RAP........................................................ 2-58

016-455, 016-456 SNTP Time Out RAP .................................................................... .. ... 2-58

016-461 Under Non-transmitted Image Log Stagnation RAP......................................... 2-59

016-500 ROM Write Error (During DLD Method) RAP.................................................... 2-59

016-503 to 016-505 SMTP Server Fail for Redirector RAP ............................................ 2-60

016-507, 016-508 Image Log Send Fail RAP ................................................................. 2-60

Revised BUS Update: July 2020

Xerox P6510 Color Printer/WC6515 Color MFP Service Manual

10/2017

2-1

Status Indic a tor RAPs

Page 28

016-509, 016-510 Image Log No Send Rule RAP................................ ....... .. .. .. .... .. .. ..... 2-61

016-511, 016-512 Image Log Invalid Send Rule RAP.................................................... 2-61

016-513 SMTP Server Reception Error RAP.................................................................. 2-62

016-514 XPS Error RAP ................................................................................................. 2-62

016-515 XPS Short of Memory ....................................................................................... 2-63

016-516 XPS Print Ticket Description Error RAP ........................................................... 2-63

016-519 Device DV Limit Reached RAP......................................................................... 2-64

016-522 LDAP SSL Error 112 RAP ................................................................................ 2-64

016-523 LDAP SSL Error 113 RAP ................................................................................ 2-65

016-524, 016-525 LDAP SSL Error 114 and 115 RAP...................................... .... .... ..... 2-65

016-526 LDAP SSL Error 116 RAP ................................................................................ 2-66

016-527 LDAP SSL Error 117 RAP ................................................................................ 2-66

016-529 Remote Download Server Timeout RAP .......................................................... 2-67

016-533 Kerberos Attestation Protocol Error 37 RAP..................................................... 2-67

016-534 Kerberos Attestation Protocol Error 41 and 42 RAP......................................... 2-68

016-535 Remote Download File Access Error RAP........................................................ 2-68

016-536 Host Name Solution Error in Remote Download RAP ...................................... 2-69

016-537 Remote Download Server Connection Error RAP ............................................ 2-69

016-539 Kerberos Attestation Other Protocol Error RAP................................................ 2-70

016-543, 545, 546, 548, 553, 554, 555, 556, 557, 558 Attestation Agent Error RAP ..... 2-70

016-559 Remote Download Parameter Error RAP ......................................................... 2-71

016-560 Attestation Agent Error 560 RAP...................................................................... 2-71

016-562 Detected User Duplication RAP . ....................................................................... 2-72

016-563 ImageLog Memory Full (Exp. Kit) RAP............................................................. 2-72

016-564 Remote Download Server Authentication Failed RAP...................................... 2-73

016-570 Job Ticket Out of Memory RAP ........................................................................ 2-73

016-571 Job Ticket Wrong Parameters RAP.................................................................. 2-74

016-572 Job Ticket Media Error RAP ............................................................................. 2-74

016-573 Job Ticket Parse Error RAP.............................................................................. 2-75

016-574 FTP Host Name Solution Error RAP................................................................. 2-75

016-575 FTP DNS Server Error RAP.............................................................................. 2-76

016-576 FTP Server Connection Error RAP................................................................... 2-76

016-577 FTP Service RAP.............................................................................................. 2-77

016-578 FTP Login Name or Password Error RAP ........................................................ 2-77

016-579 FTP Scanning Picture Preservation Place Error RAP ...................................... 2-78

016-580 FTP File Name Acquisition Failure RAP ............................................ .... .. .. ....... 2-78

016-581 FTP File Name Suffix Limit RAP....................................................................... 2-79

016-582, 016-588 FTP File Creation Failure RAP.......................................................... 2-79

016-583, 016-584 FTP Folder Creation Failure RAP...................................................... 2-80

016-585, 587, 589 FTP File Delete/Read Failure RAP .............................................. ..... 2-80

016-586 FTP Lock Folder Delete Failure RAP................................................................ 2-81

016-590 FTP Data Reading Failure RAP................................................................... ..... 2-81

016-591 FTP Scan Filing Policy RAP ............................................................................. 2-82

016-592 FTP DAT File Access Error RAP ...................................................................... 2-82

016-593 to 016-596 FTP Error RAP................................................................................ 2-83

016-597 Same File on FTP Server RAP.................................................................. ....... 2-83

016-598, 016-599 Email Message Size RAP.................................................................. 2-84

016-600, 016-601 KO Authentication Locked RAP......................................................... 2-84

016-604 Debug Log Created RAP. ................................................................................. 2-85

016-700 Password Below Minimum RAP ....................................................................... 2-85

016-702 Out of Page Buffer RAP.................................................................................... 2-86

016-706 Maximum User Number Exceeded RAP . .......................................................... 2-86

016-711 Email Transmission Size Limit RAP . ................................................................. 2-87

016-712 Panther Capacity RAP...................................................................................... 2-87

016-713, 016-714 Security Box Error RAP ..................................................................... 2-88

016-715 ESCP Form Invalid Password RAP .................................................................. 2-88

016-718 Out of PCL6 Memory RAP................................................................................ 2-89

016-719 Out of PCL Memory RAP.................................................................................. 2-89

016-720 PCL Command Error RAP ................................................................................ 2-90

016-721 Settings Error RAP............................................................................................ 2-90

016-725 B-Formatter Library Image Conversion Error RAP ........................................... 2-91

016-726 PDL Auto Switch Fail RAP................................................................................ 2-91

016-728 Unsupported TIFF Data RAP............................................................................ 2-92

016-729 TIFF Data Size RAP.......................................................................................... 2-92

016-731, 016-732 Invalid Data RAP................................................................................ 2-93

016-733 Destination Address Resolution Error RAP....................................................... 2-93

016-735 Updating Job Template RAP............................................................................. 2-94

016-741 Download Mode Fail RAP................................................................................. 2-94

016-742 Download Data Product ID Mismatch RAP....................................................... 2-95

016-743 Device Model/Panel Type Error RAP ................................................................ 2-95

016-744 Download Data CheckSum Error RAP.............................................................. 2-96

016-745 Download Data XPJL Fatal Error RAP.............................................................. 2-96

016-746, 016-751 Unsupported PDF File RAP............................................................... 2-97

016-747 Drawing Annotation Memory RAP .................................................................... 2-97

016-749 JCL Syntax Error RAP ...................................................................................... 2-98

016-750 Print Job Ticket Description Error RAP............................................................. 2-98

016-752 PDF Short of Memory RAP............................................................................... 2 -99

016-753 PDF Password Mismatched RAP ..................................................................... 2-99

016-755 PDF Print Prohibited RAP................................................................................. 2-100

016-756 to 016-759 Auditron-Prohibit Service RAP........................................................ 2-100

016-760 PS Decompose Failure RAP............................................................................. 2-101

016-761 FIFO Empty RAP .............................................................................................. 2-101

016-762 Print Language Not Installed RAP .................................................................... 2-102

016-763 POP Server Connect RAP ................................................................................ 2-102

016-764 SMTP Server Connect RAP.............................................................................. 2-103

016-765, 016-766 SMTP Server Error RAP.................................................................... 2-103

016-767 Invalid Email Address RAP............................................................................... 2-104

016-768 Invalid Sender Address RAP............................................................................. 2-104

016-769 SMTP Server Unsupported DSN RAP.............................................................. 2-105

016-770 Direct FAX Function Canceled RAP ................................................................. 2-105

016-772 Scan Data Repository Error RAP...................................................................... 2-106

016-776 Image Conversion Error RAP............................................................................ 2-106