Page 1

Xerox Document Services Platform

DocuTech 65/DocuPrint 65

Operator Guide

701P36056

DocuSP version 2.0.x

January 2001

Page 2

Xerox Corporation

Global Knowledge and Document Services

800 Phillips Road

Building 845-17S

Webster, New York 14580

USA

© 2001 by Xerox Corporation. All rights reserved

Copyright protection claimed includes all forms and matters of copyrighted material

and information now allowed by statutory or judicial law or hereinafter granted

including without limitation, material generated from the software programs that are

displayed on the screen such as styles, templates, icons, screen displays, looks, and

so on.

Printed in the U.S.A., U.K., and France.

XEROX®, XEROX Europe®, and XER OX Canada Lim ited® , The Document

Company®, the stylized X, and all names and identifying numbers used in connection

with Xerox products mentioned in this publication are trademarks of XEROX

CORPORATION. All non-Xerox brands and product names are trademarks or

registered trademarks of their respective companies. Other company trademarks are

also acknowledged.

While the information in this Guide is correct at the time of this publication, Xerox

reserves the right at any time to change the information without notice. Changes are

made periodically to this docum ent . Changes and t echinc al updat es will be added in

subsequent editions.

Page 3

Table of contents

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . i

About this guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

Powering down the system . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .i

Contents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ii

Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Telephone requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Service requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .iii

Canadian industry requirements . . . . . . . . . . . . . . . . . . . . . . . . . . .iv

Electromagnetic comparability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

United States . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

European Union . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . v

Safety notes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

Symbology . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . vii

European Union declaration of conformity . . . . . . . . . . . . . . . . . . . . . . .viii

Electricity at Work Regulation - UK . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

The Regulation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . x

Check your understanding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xi

Your responsibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Additional queries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xii

Electrical safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xiii

Printer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiii

Controller . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xiv

Printer power on/off indicator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xv

Printer or controller - emergency power off . . . . . . . . . . . . . . . . . . . . . . .xvi

Printer - ozone information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .xvi

Printer - laser safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xvii

Printer - operational safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . xviii

1. Product overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-1

Hardware components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1

Controller components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2

Printer components . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3

Paper trays (trays 1-4) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4

Bypass tray (tray 5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-5

High Capacity feeder (tray 6) . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-6

Tray guides and loading paper . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7

Changing the Tray 6 settings . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9

DocuTech 65/DocuPrint 65 1

Page 4

Table of contents Operator Guide

Finisher . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11

Unloading the Stacker during printing . . . . . . . . . . . . . . . . . . . 1-13

Peripheral hardware components . . . . . . . . . . . . . . . . . . . . . . . 1-14

Controller software . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

Modems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15

2. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Power-on procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-1

Controller power-on procedure . . . . . . . . . . . . . . . . . . . . . . . . . . 2-2

Printer power-on procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-3

Power-off procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Printer power-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-4

Controller power-off . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-7

Emergency power-off procedures . . . . . . . . . . . . . . . . . . . . . . . 2-8

Printer faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Clearing printer faults . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Paper jams . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-9

Replaceable units and supplies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-13

Replaceable items . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2-14

Ordering CRUs and other supplies . . . . . . . . . . . . . . . . . . . . . . 2-14

Dry Ink (Toner) usage and “Dry Ink Low” message . . . . . . . . . 2-16

3. Paper and other stock . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3-1

Performance information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-1

Paper handling guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-2

General stapling guidelines . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-4

Performance tables . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-5

Recommendations for loading special stock . . . . . . . . . . . . . . . . . . . . . 3-9

Recommendations for handling, loading, and storing paper . . . . . . . . 3-12

Loading and handling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

Storing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3-12

4. Problem solving . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4-1

Avoiding the problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-1

Solving the problems . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-2

Calling the Welcome Center . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4-5

2 DocuTech 65/DocuPrint 65

Page 5

About this guide

Introduction

The DocuTech 65/DocuPrint 65 Operator Guide is one of a number of

publications which make up the Xerox Document Services Platform Series.

This guide is intended for Xerox DocuTech65/DocuPrint 65 operators whose

job consist s of th e routine operation of th is printing syst em: o pera ting each of

the system components, running print jobs, solving simple system problems,

and performing basic maintenance tasks, such as replenishing printer

supplies.

If you are a lead operator , or your job involves some programming or systems

administration tasks, as well as operating the DocuTech 65/DocuPrint 65

system, use the on-line help system and the other documents in the Xerox

Document Services Platform Series to supplement the information in the

DocuTech 65/DocuPrint 65 Operator Guide.

Users should have an understanding of the operations of the DocuSP

controller and be familiar with Solaris and basic UNIX commands.

Before using this Guide, become familiar with its contents and conventions.

Powering down the system

If it is necessary to power down the system, refer to the section entitled

Power-off procedures located in the Maintenance chapter of this Operator

Guide. Never switch off the printer power swit ch or the circuit breakers except

in the case of an emergency or unless you are instructed to do so by this

Operator Guide.

DocuTech 65/DocuPrint 65 i

Page 6

Introduction Operator Guide

Contents

This section lists the contents of this guide.

•“Introduction” gives a basic overview of the Operator Guide and its

contents. It also contains information on requirements and certifications

required by USA and Canadian regulations.

•“Safety Notes” explains the various symbols, Cautions, and Warnings

pertaining to the safe use and operation of the DocuT ech 65/DocuPrint 65

systems. It also contains information on requirements and certifications

required by the European Union Declaration of Conformity and The UK

Electricity at Work Regulation.

• Chapter 1 “System Components and Product Overview” provides printer

and controller component location, system hardware features, and basic

paper loading instructions.

• Chapter 2 “Maintenance” discusses some basic maintenance procedures

and has information on how to clear paper jams. It also includes part

numbers for consumable supplies with instructions on how and where to

place an order.

• Chapter 3 “Paper and Other Stock ” contains information about the stock

you can use in the printer, how you can expect it to perform, stapling

guidelines, the correct loading of special stocks, and stock storage

requirements.

• Chapter 4 “Problem So lving” will assist you in avoiding problems and

solving those that may occur. It also provides information on how to

contact the Welcome Center.

ii DocuTech 65/DocuPrint 65

Page 7

Operator Guide Introduction

Requirements

Telephone requirements

USA FCC requirements:

• The FCC has established rules that permit the device to be directly

connected to the telephone network. Standardized jacks are used for

these connections. This equipment should not be used on party lines or

coin line s.

• If this device is malfunctioning, it may also be causing harm to the

telephone network; this device should be disconnected until repair has

been made. If this is not done, the telephone company may temporarily

disconnect service.

• The telephone company may make changes in its technical operations

and procedures; if such changes affect the compatibility or use of this

device, the telephone company is required to give adequate notice of the

changes. Yo u will be advised of your right to file a complaint with the FCC.

• If the telephone company requests information on what equipment is

connected to their lines, inform them of:

1. The telephone number this unit is connected to

2. The ringer equivalence number

3. The USCO jack required

4. The FCC Registration number

Items “b” and “d” are indicated on the label.

The Ringer Equivalence Number (REN) is used to determine how may

devices can be connected to your telephone line. In most areas, the sum

of the RENs of all devices on any one line should not exceed five (5.0). If

too many devices are attached, they may not ring correctly.

Service requirement s

In the event of equipment malfunction, all repairs should be performed by

Xerox or authorized agent. It is the responsibility of users requiring service to

report the need for service to Xerox or to an authorized agent. Service can be

obtained at:

Xerox Customer Support

1301 Ridgeview Drive, Bldg. 301

Lewisville, TX 75067

Telephone: (800) 821-2797

DocuTech 65/DocuPrint 65 iii

Page 8

Introduction Operator Guide

Canadian industry requirements

Notice: The Canadian Industry Canada label identifies certified equipment.

This certification means that the equipment meets certain

telecommunications network protective, operational and safety requirements.

The Department does not guarantee the equipment will operate to the user’s

satisfaction.

• Before installing this equipment, users should ensure that it is permissible

to be connected to the facilities of the local telecommunications company.

The equipment must also be installed using an acceptable method of

connection. In some cases, the company’s inside wiring associated with a

single line individual service may be extended by means of a certified

connector assembly (telephone extension cord). The customer should be

aware that compliance with the above conditions may not prevent

degradation of service in some situations.

• Repairs to certified equipment should be made by an authorized

Canadian maintenance facility designated by the supplier. Any repairs or

alterations made by the user to this equipment, or equipment

malfunctions, may give the telecommunication s company cause to

request the user to disconnect the equipment.

• Users should ensure for their own protection that the electrical ground

connections of the power utility, telephone lines and internal met allic

water pipe system, if present, are connected together. This precaution

may be particularly important in rural areas.

CAUTION

Users should not attempt to make such connections themselves, but should

contact the electric inspection authority, or electrician, as appropriate.

• The Load Number (LN) assigned to each terminal device denotes the

percentage of the total load to be connected to a telephone loop that is

used by the device, to prevent overloading. The termination on a loop

may consist of any combination of devices subject only to the requirement

that the total of the Load Numbers of all the devices does not exceed 100.

For service in Canada call (800) 939-3769

iv DocuTech 65/DocuPrint 65

Page 9

Operator Guide Introduction

Electrom a gn et ic co mp ara bility

United States

This equipment has been tested and found to comply with the limits for a

Class A digital device, pursuant to part 15 of the FCC Rules. These limits are

designed to provide reasonable protection against harmful interference when

the equipment is operated in a commercial environment. This equipment

generates, uses, and can radiate radio frequency energy and, if not installed

and used in accordance with the instruction manual, may cause harmful

interference to radio communications. Operation of this equipment in a

residential area is likely to cause harmful interference, in which case the user

will be required to correct the interference at his own expense.

Changes or modifications to this equipment not specifically approved by the

Xerox Corporation may void the user’s authority to operate this equipment.

Shielded cables must be used with this equipment to maintain compliance

with FCC regulations.

This Class “A” digital apparatus complies with Canadian ICES-003.

Cet appareil numérique de la classe “A” est conforme à la norme NMB-003 du

Canada.

European Union

This is a Class A product. In a domestic environment, this product may

cause radio interference, in which case the user may be required to take

adequate measures.

Changes or modifications to this equipment not specifically approved by

Xerox Europe may void the user’s authority to operate this equipment.

Shielded cables must be used with this equipment to maintain compliance

with the EMC Directive (89/336/EEC).

In order to allow this equipment to operate in proximity to Industrial,

Scientific, and Medical (ISM) equipment, the external radiation from ISM

equipment may have to be limited or special mitigation measures taken.

WARNING

WARNING

DocuTech 65/DocuPrint 65 v

Page 10

Introduction Operator Guide

-vi DocuTech 65/DocuPrint 65

Page 11

Symbology

Safety notes

Please read the following instructions carefully before planning your install

and/or operating the DocuTec h 65/Doc uPr int 65. Refer to them as needed to

ensure the safe installation and operation of your equipment.

The safety testing and performance of this product have been verified

using Xerox materials only

Your Xerox DocuTech 65/D ocuPri nt 65 and its supplies have been designed

and tested to meet strict safety requirements. These include safety agency

examination and approval, and compliance to established environm ent al

standards.

Follow all warnings and instructions marked on or supplied with the product.

Various symbols are used on the printer and in the documentation.

The symbol on the printer that indicates a hot surface is shown in Figure 1.

Figure 1. Hot surface symbol

Another symbol that indicates a heated surface is shown in Figure 2.

Figure 2. Heated surface symbol

DocuTech 65/DocuPrint 65 vii

Page 12

Safety notes Operator Guide

WARNING

Warnings indicate possible serious personal injury if you do not strictly

follow the practice, procedure, condition, or statement that follows the

WARNING.

CAUTION

Cautions indicate that possible system damage or data loss will occur if yo u

do not carefully follow the practice, procedure, condition or statement that

follows the CAUTION.

European Union declaration of conformity

Approvals and

certification

The CE marking applied to this product symbolizes Xerox Europe Declaration

of Conformity with the following applicable Directives of the European Union

as of the dates indicated below.

January 1, 1995: Council Directive 73/23/EEC amended by Council Directive

93/68/EEC, approximation of the laws of the member states related to low

voltage equipment.

January 1, 1996: Council Directive 89/336/EEC, approximation of the laws of

the member states related to electromagnetic compatibility.

A full declaration, defining the relevant directives and referenced standards

can be obtained from your Xerox Europe representative or by contacting:

Xerox Europe Product Safety,

Xerox Europe Technical Centre,

PO Box 17,

Bessemer Road,

Welwyn Garden City,

Herts AL7 1HE, England

viii DocuTech 65/DocuPrint 65

Page 13

Operator Guide Safety notes

WARNING

This is a Class A product. In a domestic environment this product may

cause radio interference in which case the user may be required to take

adequate measures.

WARNING

This system is certified manufactured and tested in compliance with

strict safety and radio frequency interference regulations. Any

unauthorized alteration which includes the addition of new functions or

the connection of external devices may impact this certification. Please

contact your local Xerox Europe representative for a list of approved

accessories.

Shielded cables must be used with this equipment to maintain

complacence with the EMC Directive (89/336/EEC).

This equipment is not primarily intended for use in a domestic

environment.

WARNING

In order to allow this equipment to operate in proximity to industrial,

scientific and medical (ISM) equipment, the external radiation from the

ISM equipment may have to be limited or special mitigation measures

taken.

DocuTech 65/DocuPrint 65 ix

Page 14

Safety notes Operator Guide

Electricity at Work Regula ti on - UK

The Electricity at Work Regulation applies only to England and Wales.

The Regulation

The Electricity at Work Regulation 1989 came into force in England and

Wales on the 1 April 1990. This 1989 Regulation places a duty on all

employers and self-employed persons to ensure the electrical systems in their

premises are constructed, maintained and operated in such a manner as to

prevent, so far as reasonably practical, danger. This includes ensuring all

electrical equipment connected to such electrical systems are safely

constructed, maintained and operated.

All Xerox equipment have been designed to exacting safety standards. They

have all undergone a variety of stringent safety tests including earth bond,

insulation resistance and electrical strength tests. Xerox Europe

manufacturing plants have been awarded ISO 9000 quality certification and

are subject to regular audits by the British Standards Institution or equivalent

national standards body.

Xerox equipment which has been properly and regularly serviced and

maintained should not have to undergo additional specific safety tests

pursuant to the 1989 Regulation. Customers wishing to complete safety

testing should contact Xerox Europe T echnical Centre for advice prior to any

test implementation. The address of the Xerox T echnical Centre is provided in

the previous section, European Union declaration of conformity.

Xerox equipment should, however, be properly and regularly serviced and

maintained at all times.

x DocuTech 65/DocuPrint 65

Page 15

Operator Guide Safety notes

Check your understanding

Please review the questions and answers that follow to ensure that you

understand the Electricity at Work Regulation in England and Wales.

Question What is the Electricity at Work Regulation?

Answer The Electricity at Work Regulation 1989 came into force in England and

Wales on the 1 April 1990. This 1989 Regulation places a duty on all

employers and self-employed person s to ensure the electrical systems in

their premises are constructed, maintained and operated in such a manner as

to prevent, so far as reasonably practicable, danger. This i ncludes ensuring all

electrical products connected to such electrical systems are safely

constructed, maintained and operated.

Question Does Xerox Europe comply with the Electricity at Work Regulation?

Answer The regulation places a duty on all employers and self-employed persons

to ensure the electrical systems in their premises are, effectively safe.

This regulation does not impose on, amongst others, manufa cturers or

suppliers of such electrical systems. However, rest assured that all Xerox

equipment which Xerox Europe and its authorized distributors supply to

customers, conform with all the relevant safety legislation and standards.

Question Is Xerox equipment safe?

Answer All Xerox equipm ent supplied by Xerox Eu rope and their authorized

distributors conform to all relevant safety legislation and standards.

Question Is the Xerox equipment in my premises safe?

Answer All Xerox equipm ent supplied by Xerox Eu rope and their authorized

distributors conform to all relevant safety legislation and standards. However,

like all electrical equipment, they have to be regularly serviced and

maintained by competent persons.

Xerox Europe Customer Service Engineers ensure Xerox equipment is

serviced and maintained to exacting Xerox safety standards. If you would like

your Xerox equipment to be serviced and maintained to such high standards,

please contact your local Xerox Europe Customer Service Organization. They

will be pleased to assist you.

DocuTech 65/DocuPrint 65 xi

Page 16

Safety notes Operator Guide

Question Does the Xerox equipment in my premises comply with the Electricity at

Work Regula tion s ?

Answer All employers and self-employed persons must ensure that the electrical

systems in their premises are safe. This will include ensuring Xerox

equipment in such premises is safe.

Xerox Europe ’s Product Safety function has prepared a guide which contains

a list of tests which may be completed by your Xerox Europe Customer

Service Organization. T HES E TESTS MUST BE CARRIED OUT ONLY BY

PERSONS WHO POSSESS THE RELEVANT SKILL, KNOWLEDGE AND

EXPERIENCE TO CARRY OUT SUCH TESTS.

Please contact the Xerox Europe Customer Service Organization for further

information.

THE USE OF INAPPROPRIATE TEST PROCEDURES AND TEST

EQUIPMENT MAY PROVIDE MISLEADING RESULTS AND MAY CAUSE

DEA T H, PERSONAL INJURY AND/OR DAMAGE TO PROPERTY.

Question I would like to carry out my own safety tests on the Xerox temperament

in my premises.

Answer You may, of course, request such tests as you deem nece ssary to satisfy

yourself that your Xerox equipment is safe. Your Xerox Europe Customer

Support will be pleased to advise you on such testing.

Question I require records of all tests.

Answer After safety testing, your Xerox Europe Customer Service Engineer will

provide you with a certificate which details the results of all tests completed.

In the event of any defect being noted, the Xerox equipmen t will be swit ch ed

off and disconnected from the supply until the defect has been corrected. You

will be advised of such action to enable such defects to be corrected.

Your responsibility

YOU MUST ENSURE THAT YOUR XEROX EQUIPMENT IS SAFE AT ALL

TIMES.

Additional queries

Please contact the Xerox Europe Tec hni cal Centre if you have any queries

regarding the information provided in this document. The address of the

Xerox Europe T echnical Centre is provided in the previous section, European

Union declaration of conformity.

xii DocuTech 65/DocuPrint 65

Page 17

Operator Guide Safety notes

Electrical safety

Attention to the following requirements ensures the safe operation of your

equipment.

Printer

USA/Canada The printer requires a 115V AC outlet, dedicated 20 Amp, 3-wire circuit.

Europe The printer requires a 220-240V outlet, dedicated 13 Amp or 10 Amp circuit.

The equipment must be connected to a grounded mains outlet.

CAUTION

Ensure that the power connection for your printer satisfies these

requirements.

• The power receptacle for the printer must meet the requirements stated

on the data plate on the rear of the printer.

• The socket outlet shall be installed near the equipment within reach of the

10 ft. (3 m) cable and shall be easily accessible.

• Use the power cable that is supplied with your printer and controller. Do

not use an extension cord, or remove or modify the power cord plug.

• Plug the power cable directly into a correctly grounded electrical outlet. If

you are not sure whether or not an outlet is correctly grounded, consult a

qualified electrician.

• Do not use an adapter to connect the printer to an electrical outlet that

lacks a ground connection terminal.

• The power cord is the disconnect device for this printer.

• Do not override or disable electrical or mechanical interlocks.

• Do not push objects into slots or openings on the printer. Electrical shock

or fire may result.

• Do not obstruct ventilation openings. These openings prevent

overheating of the printer.

DocuTech 65/DocuPrint 65 xiii

Page 18

Safety notes Operator Guide

Controller

USA/Canada The controller requires a dedicated 115V AC 20 Amp grounded receptacle.

Europe The controller requires a 220-240V, 13 or 10 Amp grounded receptacle.

CAUTION

Follow all safety cautions, warnings, and instructions marked on the

controller.

• Ensure that the voltages and frequency rating of the power receptacle

match the electrical rating label on the equipment.

• Do not make electrical or mechanical modifications to the equipment.

• Use the power cable that is supplied with your controller. Do not use an

extension cord, or remove or modify the power cord plug. If the plug must

be changed, a qualified electrician must install the plug correctly on the

power cord.

• Plug the power cable directly into a correctly grounded electrical outlet or

into the power strip that is connected to this outlet. If you are not sure

whether or not the outlet is correctly grounded, consult a qualified

electrician.

• Do not use an adapter to connect the controller to an electrical outlet that

lacks a ground connection terminal.

• The power switch functions as a standby type of device only. The power

cord serves as the primary disconnect device for the system.

• Do not push objects into slots or openings on the equipment. Electrical

shock or fire may result.

• Do not obstruct ventilation openings. These openings prevent

overheating of the controller.

xiv DocuTech 65/DocuPrint 65

Page 19

Operator Guide Safety notes

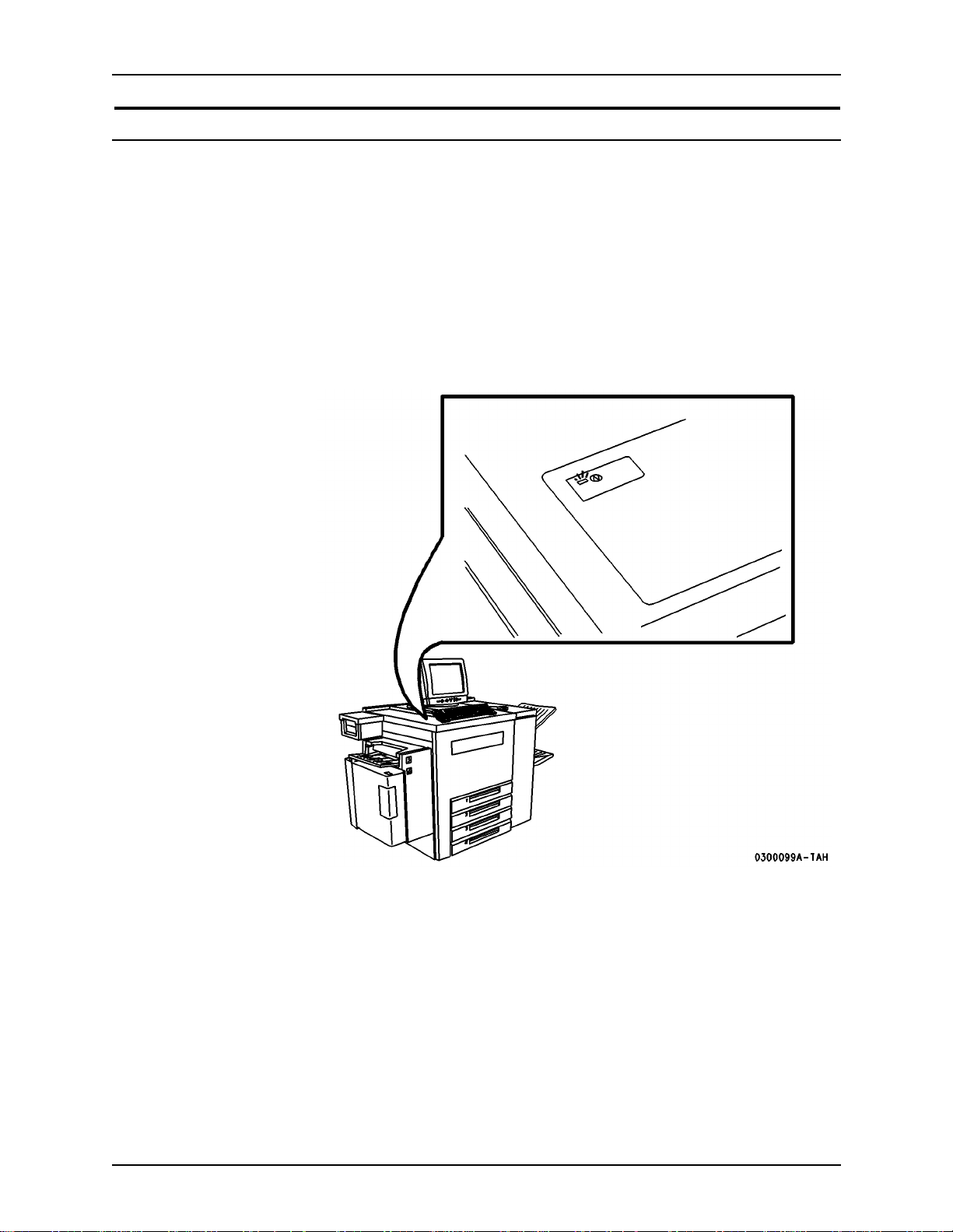

Printer power on/off indicator

A power-on/power-off indicator shows the state of the power for the printer.

This indicator is located on the top front of the printer and has a rectangular

shape. This indicator glows green when printer power is on and emits no light,

is colorless, when the printer power is off.

When you need to determine whether the printer power is on or off, view the

power-on/power-off indicator rather than the message pane on the DocuSP

Print Services main window. Under some conditions, the main window may

not accurately indicate the state of the printer.

The printer power on/off indicator is shown in Figure 3.

Figure 3. Power on/off indi cat or

DocuTech 65/DocuPrint 65 xv

Page 20

Safety notes Operator Guide

Printer or controller - emergency power off

If any of the following conditions occur, turn off the equipment immediately

and disconnect the power cable from the electrical outlet. Contact an

authorized Xerox Service Representative to correct the problem:

• The equipment emits unusual odors, or makes unusual noises.

• The power cable is damaged or frayed.

• A wall panel circuit breaker , fuse, or other safety device has been tripped.

• Liquid is spilled into the equipment.

• The equipment is exposed to water damage or flood.

• Any part of the equipment is physically damaged.

NOTE: The only method to remove all power from the printer is to disconnect

the power cable from the electrical outlet.

Printer - ozone information

This product produces ozone during normal operation. The ozone produced is

dependent on print volume and is heavier than air. Install the system in a well

ventilated room with the minimum cubic requirements size listed below.

Providing the correct environmental parameter will ensure that the

concentration levels meet safe limits.

The minimum cubic volume requirement is: 1,765 cubic feet (50 cubic

meters).

To determine if the room has the required volume to meet the ozone

requirement, the length of the room multiplied by its width and height should

be equal to or greater than the cubic volume listed above.

If you need additional information about ozone, please request the Xerox

publication Ozone (part number 600E74140) by calling 1-800-828-6571 in the

United States and Canada. In Xerox Europe countries, call the local welcome

center.

xvi DocuTech 65/DocuPrint 65

Page 21

Operator Guide Safety notes

Printer - laser safety

CAUTION

The use of controls, adjustments or performance of procedures other than

those specified in this guide may result in hazardous light exposure.

With specific regard to lasers, the equipment complies with laser product

performance standards set by governmental, national, and international

agencies as a Class 1 Laser Product. It does not emit hazardous light, as the

beam is totally enclosed during all phases of customer operation and

maintenance.

DocuTech 65/DocuPrint 65 xvii

Page 22

Safety notes Operator Guide

Printer - operational safety

Safety Quality

Standards

Other National

Standards

Do these To ensure the continued safe operation of your printer, follow these safety

The equipment is manufactured under a BS5750 Quality system accepted by

the British Standards Institution.

The Xerox DocuTech 65/DocuPrint 65 is also certified in compliance with

applicable standards by various national bodies.

guidelines at all times:

• Always connect equipment to a correctly grounded power outlet. If in

doubt, have the outlet checked by a qualified electrician.

• Always follow all warnings and instructions that are marked on or are

supplied with the equipment.

• Always exercise care when moving or relocating the equipment. Please

contact your local Xerox Service Department to arrange relocation of the

printer to a location outside of your building.

• Always locate the printer on a solid support surface (not on plush carpet)

that has adequate strength to support the weight of the printer.

• Always locate the printer in an area that has adequate ventilation and

room for servicing. Refer to the space requirements in the DocuTech 65/

DocuPrint 65 Installation Planning Guide.

• Always use materials and supplies that are specifically designed for your

Xerox equipment. Use of unsuitable materials may result in poor

performance and possibly a hazardous situation.

Do not do these To ensure the continued safe operation of your printer:

• Never use an adapter plug to connect equipment to a power source that

lacks a ground connection terminal.

• Never obstruct ventilation openings. They are provided to prevent

overheating.

• Never push objects of any kind into the ventilation openings.

• Never attempt any maintenance function that is not specifically described

in the DocuT ech 65/DocuPrint 65 documentation.

• Never remove any covers or guards that are fastened with screws. There

are no operator serviceable areas within these covers.

• Never locate the printer near a radiator or any other heat source.

• Never ov erride or “cheat” any of the electrical or mechanical interlock

devices.

• Never operate the equipment if you notice unusual noises or odors.

Disconnect the power cord from the power outlet and call the Xerox

Welcom e Cent er .

-xviii DocuTech 65/DocuPrint 65

Page 23

Operator Guide Safety notes

Your Xerox DocuTech 65/D ocuPrint 65 printer is certified, manufactured, and

tested in compliance with strict safety and radio frequency interference

regulations. Any unauthorized alteration that includes the addition of new

functions or the connection of external devices may invalidate this

certification. Please contact your local Xerox representative or the Xerox

Welcome Center for a list of approved accessories.

Welcome Center phone numbers:

• USA - (800) 821-2797

• Canada - (800) 939-3769

• Europe - local Welcome Center

Additional

information - USA

Additional

information -

Europe

If you need any additional safety information concerning the equipment or the

Xerox supplied materials, please contact the Xerox Welcome Centre.

If you need any additional safety information concerning the equipment or the

Xerox supplied materials, you may call the following number: 01707 353434

DocuTech 65/DocuPrint 65 -xix

Page 24

Safety notes Operator Guide

-xx DocuTech 65/DocuPrint 65

Page 25

1. Product overview

This chapter will introduce the controller and overview the capabilities of the

printer.

Hardware components

The main DocuTech 65/DocuPrint 65 components are:

• Controller (CPU with external modem, CD-ROM drive, diskette drive,

• Printer (with internal modem)

Peripheral components may include:

• External SCSI Hard Drive

• External Tape Drive

monitor, keyboard, and mouse)

Peripheral components may be contained within a special accessory shelf

that is attached to the printer.

DocuTech 65/DocuPrint 65 1-1

Page 26

Product overview Operator Guide

Control ler com ponen ts

The main controller components are shown in Figure 1-1.

Figure 1-1. Controller com p onents

CDROM Drive

Diskette Drive

Modem

Power

Off On

Power On/Off

1-2 DocuTech 65/DocuPrint 65

Page 27

Operator Guide Product overview

Printer components

The main components of the printer are shown in Figure 1-2.

Figure 1-2. Printer components

T ra y 5, Bypa ss

Tray for odd

size or special

stock

Top Tray

Stacker

Finisher for

stapled sets

Tray 6, High Capacity

Feeder with 3100 sheet

capacity for main stock

The following information sources are provided to assist you:

• Power-on/power-off indicator is on the top front of the printer. It glows

green when on and emits no light when off.

• Labels are affixed at the points of need throughout the system. They

depict information about loading the paper stock.

• Green or Gold colored areas act as markers.

– Gold colored areas typically indicate the handle or levers to push or

pull when removing Replaceable Modules or Cartridges.

– Green colored areas are where you clear jams.

Paper Trays 1-4 hold many types of

stock

DocuTech 65/DocuPrint 65 1-3

Page 28

Product overview Operator Guide

Paper trays (trays 1-4)

Paper Trays 1-4 are shown below in Figure 1-3.

Figure 1-3. Trays 1-4

Trays 1 through 4

The Paper Trays hold up to 500 sheets of 20 lb (75 gsm) stock each. You can

adjust the trays to hold many sizes of paper, from 5.5 x 8.5 inches (140 x 216

mm) up to 11 x 17 inches (279 x 432 mm or A3). To handle 12 x 18 inch paper,

a tray must be specially set up. If you wish to dedicate a tray permanently to

handle this size paper please contact the Xerox Welcome Center. Refer to the

chapter on Paper and Stock for a listing of acceptable stock and paper sizes,

orientations, and weights.

NOTE: To achieve the maximum c opying speed, paper should be loaded

Long Edge Feed in the paper trays whenever possible.

1-4 DocuTech 65/DocuPrint 65

Page 29

Operator Guide Product overview

Bypass tray (tray 5)

The Bypass Tray (Tray 5) is an additional paper tray designed for quick and

easy loading of both standard and non-standard paper. It can physically

extend to accommodate different stock sizes and orientations. You can load a

maximum of 50 sheets of standard weight 20 pound (75 gsm) stock. If using a

heavier stock, fill the tray only to the maximum-fill line.

The Bypass Tray has a capability of 4 to 12 inches (102 to 305 mm); 5.83 to

18 inches (148 x 457 mm).

The Bypass Tray can also hold non-standard size and weight paper such as

transparencies, labels, covers, index, and bond paper. The Bypass Tray is

shown below in Figure 1-4.

Figure 1-4. Bypass Tray

Tray 5

DocuTech 65/DocuPrint 65 1-5

Page 30

Product overview Operator Guide

High Capacity feeder (tray 6)

The High Capacity Feeder (Tray 6) is located under the Bypass Tray and

saves you from having to load the other individual paper trays with 8.5 x 11

inch (216 x 279 mm) paper often. You can load 3100 sheets of 20 pound (75

gsm) 8.5 x 11 inch (216 x 279 mm) Long Edge Feed (LEF) paper. The High

Capacity Feeder can feed only 8.5 x 1 1 inch (216 x 279 mm) or A4 LEF paper

and cannot be adjusted to hold any other sizes or orientations.

Figure 1-5. High Capacity Feeder

Tray 6

High

Capacity

Feeder

Reloading Paper Open the cover and wait for the tray to lower in order to reload paper. Fill the

tray only to the maximum-fill line on the left side of the tray. After reloading

paper, close the cover to raise the tray.

The High Capacity Feeder can also accommodate 8.5 x 11 inch (216 x 279

mm) drilled or long-edge paper between 16 to 32 lb (60 to 120 gsm). Detailed

information on using the tray guides to change the stock size capability of

Tray 6 is provided later in this chapter under the heading, Changing the Tray 6

settings.

The High Capacity Feeder is shown in Figure 1-5.

1-6 DocuTech 65/DocuPrint 65

Page 31

Operator Guide Product overview

T ray guides and loading pape r

Do not open a tray that is in use, a paper jam may result. Instead, before

opening a tray, disable the tray in the Printer Manager. After loading the

paper, enable the tray in the Printer Manager.

Performance capabilities

Performance capabilities for various paper types loaded in specific trays are

given in the chapter, Paper and other stock.

Loading paper in Trays 1-4

1. Pull out the paper tray.

Refer to the tray labels as you load the paper neatly in the tray. Make sure

that the left edge of the paper stack is against the bar that is located on

the left-hand edge of the tray, as shown in the top portion of Figure 1-6.

Do not load paper above the maximum fill line.

Figure 1-6. Loading Trays 1-4

2. Ensure that the paper tray edge guides are against the top, bottom, and

side edges of the paper. If the paper size is being changed, adjust the

guides as necessary, as shown in the bottom portion of Figure 1-6.

3. Push in the paper tray.

4. If the Printer Manager programming for the tray does not match the guide

settings, correct the programming. Refer to the DocuSP on-line help for

information on changing the programming.

DocuTech 65/DocuPrint 65 1-7

Page 32

Product overview Operator Guide

NOTE: For information about how to load specific types of paper or other

stock, refer to the chapter, Paper and other stock.

Loading paper in the Bypass Tray (Tray 5)

Insert paper as shown. The Bypass Tray extends to accommodate paper that

is physically longer than the tray. Simply pull out the extension bar. Do not

load paper above the maximum fill line.

Loading paper in the High Capacity Feeder (Tray 6)

To load paper, open the cover and wait for the tray to lower. When the paper

has been loaded, close the cover to raise the tray. The High Capacity Feeder

is shown in Figure 1-7.

Figure 1-7. Loading Trays 5 and 6

Insert paper for the

Bypass Tray here.

Pull the Extension

Bar to extend the

Bypass Tray

Insert paper for the

High Capacity Feed

Tray here

1-8 DocuTech 65/DocuPrint 65

Page 33

Operator Guide Product overview

Changing the Tray 6 settings

You can set Tray 6 to hold either A4 or 8.5 x 11 inch paper.

An example of changing the tray setting from 8.5 x 1 1 inches to A4 is shown in

Figure 1-8.

Figure 1-8. Changing the guides from 8.5 x 11 inches to A4

Rear Guide Starting with the Rear Guide, you will adjust the guide to the A4 position.

Perform the following:

1. Slide the black latch down to release the guide.

2. Move the guide out, over, and in, into the A4 position.

3. Slide the latch up to lock the guide.

Front G uide Repeat the procedure for the front guide

NOTE: Be sure to reprogram the tray in the Printer Manager to reflect the

changed size.

DocuTech 65/DocuPrint 65 1-9

Page 34

Product overview Operator Guide

Rear Guide Starting with the Rear Guide, you will adjust the guide to the 8.5 x 11 inch

position.

Perform the following:

1. Slide the black latch down to release the guide.

2. Move the guide out, over, and into the 8.5 x 11 inch position.

3. Slide the latch up to lock the guide.

Front G uide Repeat the procedure for the front guide

NOTE: Be sure to reprogram the tray in the Printer Manager to reflect the

changed size.

1-10 DocuTech 65/DocuPrint 65

Page 35

Operator Guide Product overview

Finisher

The Finisher consists of the Top Tray and the Stacker Tray, as shown below

in Figure 1-9.

Figure 1-9. Fi ni sher components

Top Tray

Finisher

button

Stapler is within

the finisher

Press the Finisher Button to

unload the Stacker Tray during a

print run

Top Tray

The Top Tray holds sheets that are purged from the system or up to 250

prints.

Stacker Tray

The Stacker Tray is the output tray for all other jobs. The Stacker Tray has two

staplers, each with a 5000-staple cartridge, that can staple sheets ranging in

size from 6.7 x 8 inch (170 x 203 mm) to 12 x 18 inch (305 x 457 mm) of 16 to

1 10 lb (60 to 200 gsm) stock. Up to a maximum of 50 sheets of 20 lb (80 gsm)

can be stapled.

DocuTech 65/DocuPrint 65 1-11

Page 36

Product overview Operator Guide

Stapling

Removing any of the output while the printer is running may produce finished

sets that are incorrectly stapled.

To ensure that the stapling of thin sets is satisfactory , t he printer performs the

fol lowing actio ns.

Finishers before

the end of 1998

Finishers after the

end of 1998

After 30 finished sets of 15 sheets, the printer:

1. cycles down

2. may raise a message to empty the Finisher (Stacker Tray)

3. waits briefly , whether the sets are removed or not

4. cycles up and resumes printing.

After 30 finished sets of 15 sheets, the printer:

1. cycles down

2. raises a message to empty the Stacker

3. waits until the sets are removed

4. raises the Stacker Tray

5. cycles up and resumes printing.

If these parameters are not satisfactory for your printing, contact Xerox.

1-12 DocuTech 65/DocuPrint 65

Page 37

Operator Guide Product overview

Staple placement

For information about the limitations of portrait and landscape staple

placement, refer to the Staple Placement table below.

Table 1-1. Staple placement

Edge Feed

Orientation

Long FAULT FAULT

Long N/A N/A N/A N/A

Short FAULT FAULT

Short FAULT FAULT

Short FAULT FAULT

Portrait

Staple

Unloading the Stacker during printing

Landscape

Staple

Dual

Portrait

Staple

Dual

Landscape

Staple

If it is necessary to unload the Stacker during printing, use the following

procedure:

1. Press the Finisher button.

2. Wait for the printer to finish producing the set being printed.

3. Wait while the Stacker Tray is automatically lowered.

4. Unload the Stacker Tray.

5. Press the Finisher button again to continue operations.

DocuTech 65/DocuPrint 65 1-13

Page 38

Product overview Operator Guide

Peripheral hardware components

You may have peripheral components such as an External SCSI Hard Drive

and an External Tape Drive on a special accessory shelf as shown in Figure

1-10.

Figure 1-10. Special accessory shelf

1-14 DocuTech 65/DocuPrint 65

Page 39

Operator Guide Product overview

Cont ro ller softw ar e

The controller runs the DocuSP Print Services software. This software gives

the printer operator the ability to manage the jobs and the printer . For detailed

information on how to use the DocuSP Print Services software, refer to the

DocuSP on-line Help.

Modems

The controller has an external modem that is on or off according to the site

requirements for this modem or as needed by Xerox service.

The printer has an internal modem that is normally on to enable the Sixth

Sense diagnostics feature or as needed by Xerox service.

DocuTech 65/DocuPrint 65 1-15

Page 40

Product overview Operator Guide

1-16 DocuTech 65/DocuPrint 65

Page 41

2. Maintenance

Your Xerox DocuTech 65/D ocuPri nt 65 system is designed to maximize

printer performance. This includes using a short paper path in order to reduce

jams, and Customer Replaceable Units (CRUs) in order to avoid extended

periods of downtime.

This chapter discusses some basic maintenance procedure s including the

following:

• Powering-on the printer and the controller

• Powering-off the printer and the controller

• Clearing paper jams

• Changing the Customer Replaceable Units

• Estimating dry ink (toner) usage

Power-on procedures

You will first power on the controller and then power on the printe r.

DocuTech 65/DocuPrint 65 2-1

Page 42

Maintenance Operator Guide

Control l er pow er- on proce du re

The controller power-on button and the Light Emitting Diode (LED) are shown

in Figure 2-1. The LED glows green when the controller power is on.

Figure 2-1. Controller pow e r-on button and LED

LED

Power On

Button

To power on the controller:

1. Switch on the power for each of the connected peripherals.

2. Switch on the monitor.

3. Press the controller “On” button.

4. Confirm that the controller LED light is on.

2-2 DocuTech 65/DocuPrint 65

Page 43

Operator Guide Maintenance

Printer power-on procedure

When the printer is on, the power-on/power-off indicator glows green.

The printer must be switched on by pressing a switch on the printer. The

printer cannot be powered on from the DocuSP Print Services interface that

runs on the controller. The printer power switch is shown in Figure 2-2.

Because thi s switch rocks b ac k to its center po sition each t im e it is pressed i n

either direction, you cannot determine whether the printer is on by looking at

the switch position.

To power on the printer:

1. Locate the white on/off switch on the right side of the printer.

2. Press the switch toward the back of the printer.

3. Confirm that the power-on/power-off indicator glows green.

Figure 2-2. Pri nt er power-on

After powering-on, jobs will not print until t he Fuse r is ready and the network

connections are established. The system is usually ready for network printing

within 7 minutes.

DocuTech 65/DocuPrint 65 2-3

Page 44

Maintenance Operator Guide

Power-off procedures

You can power off only the printer and allow the controller to keep on

processing jobs, or you can power off both the printer and the controller.

Printer power-off

When the printer power is off, the power-on/power-off indicator does not emit

light, it is colorless.

Under normal operating conditions the printer should be powered off using the

DocuSP Print Services on the controller, rather than by pressing the printer

on/off switch.

Printer power-off from the controller

Y ou can power-off t he printer from two different DocuSP Print Services menus

and still allow the controller to continue processing jobs.

Preferred Method To power off the printer:

1. Display the System or the Printer menu.

2. Select the Printer Off option.

3. Confirm that the power-on/power-off indicator is colorless.

Printer Power-Off Using The Printer Switch

It is not obvious from the position of the switch whether the printer is on or off.

View the power-on/power-off indicator to determine the printer state: green for

on, colorless for off.

If you need to shut the printer down immediately, and this is an emergency,

use the red button described in the next section. If this is not an emergency,

use the procedure given below.

Alternate Method To power-off the printer:

1. Locate the white on/off switch.

2. Press the switch to the left or front of the printer as shown in Figure 2-3.

3. Confirm that the power-on/power-off indicator is colorless.

2-4 DocuTech 65/DocuPrint 65

Page 45

Operator Guide Maintenance

Figure 2-3. Pri nt er power-off

Printer Power-Off Using The Red Button

A red button, located inside the printer, provides a less gentle method for

powering off the printer. This power-off procedure immediately cuts power to

the printer in an uncontrolled manner without confirmation or delay. Any jobs

in the queue will be imme diat ely lost wit hout confirmation.

Use the red button for the following conditions:

• If you need to switch the power off during the first 15 seconds after initially

switching the power on.

• Upon direction from your authorized Xerox Representative.

Abrupt Method To power-off the printer using the red button:

1. Locate the red button shown in Figure 2-4.

2. Press the button.

3. Confirm that the power-on/power-off indicator is colorless.

DocuTech 65/DocuPrint 65 2-5

Page 46

Maintenance Operator Guide

Figure 2-4. Pr int er power-off, red bu t ton

RED BUTTON

After the Red Button is used, the printer will take longer to reboot.

2-6 DocuTech 65/DocuPrint 65

Page 47

Operator Guide Maintenance

Control l er pow er- of f

The controller power-off button is shown in Figure 2-5. The LED light is out

when the controller power is off.

To power off the controller:

1. Notify the job submitters that the controller is about to be powered off.

2. Back up system files and data.

CAUTION

Before switching off the controller, exit any applications that are running and

shut down the DocuSP Print Services using the Shutdown option so that you

do not lose any data.

3. On the Print Services System menus, select the Shutdown option.

(Shutdown also powers off the printer.)

4. Answer the confirmation prompt. If there are jobs still being processed,

the system will request confirmation before starting the shutdown.

5. Wait for the OK prompt, then press the controller power-off button.

Figure 2-5. Controller pow e r-of f bu t ton a nd LE D

LED

POWER OFF

BUTTON

6. Verify that the controller front panel LED is off and that the controller fans

are not spinning.

7. Switch off external devices or any peripherals.

8. Switch off the monitor.

9. Disconnect the cables to any peripheral equipment.

DocuTech 65/DocuPrint 65 2-7

Page 48

Maintenance Operator Guide

CAUTION

When the power on/standby switch is in stand-by and the AC power cord

remains connected to a power receptacle, AC voltage is present in the power

supply.

10. If the equipment will be serviced or moved, disconnect the AC power cord

from the AC receptacle.

Emergency power-off procedures

An emergency power-off procedure may be used when the power must be

swi tched of f i mmed i ately.

CAUTION

The controller emergency power off procedure may corrupt the DocuSP

software. This method should only be used in an emergency.

Controller Power-

Off

To power off the system in an emergency use any of the following methods:

• Switch off the controller power switch on the front of the controller.

• On the DocuSP Print Services, the System menu, select the option for

Immediate Shutdown.

• Pull the controller power cord from its receptacle.

Printer power-off To power off the printer in an emergency use any of the following methods:

• Press the red button on the printer.

• Pull the printer power cord from the power receptacle.

An emergency power off of the printer will not corrupt the DocuSP system

software. However, you will need to enter Reset at the OK prompt if the

controller displays the OK prompt.

Controller or

Printer Emergency

Conditions

For the printer or the controller, if any of the following conditions occur,

disconnect the power cable from the power socket immediately and contact

an authorized Xerox Service Representative to correct the problem

• The equipment emits unusual odors, or makes unusual noises.

• The power cable is damaged or frayed.

• A wall panel circuit breaker , fuse, or other safety device has been tripped.

• Liquid is spilled into the equipment.

• The equipment is exposed to water damage or flood.

• Any part of the equipment is physically damaged.

2-8 DocuTech 65/DocuPrint 65

Page 49

Operator Guide Maintenance

Printer faults

Occasionally, a fault will occur at the printer that may prevent you from using

the printer, such as:

• Out of Paper

• Low Dry Ink

• Module/Cartridge end of life

• Paper Jam

NOTE: For detailed information on the Customer Replaceable Units, refer to

the DocuTech 65/DocuPrint 65 Operator Guide and the DocuSP Help.

Clearing printer faults

Instructions for clearing faults will be displayed on the controller. Simply follow

the instructions.

NOTE: For detailed information on clearing the printer faults, refer to the

Xerox Document Services Platform Series Problem Solving Guide and the

DocuSP Help.

Paper jams

When a paper jam occurs, the controller automatically displays a fault window

that lists individual faults. If you choose to display additional information about

a given fault, the system will then display instructions or graphics that show

the required actions. After the jam is cleared, follow any additional displayed

instructions.

If the jam oc cu rre d in the middle of your job, the p rin t e r w ill a ut o matically

recover and reprint the sheets that were jammed.

NOTE: When removing jammed sheets from the printer, use the green

handles and knobs.

The jam clearance areas are shown in Figure 2-6.

DocuTech 65/DocuPrint 65 2-9

Page 50

Maintenance Operator Guide

Figure 2-6. Jam clearance areas

Area 1 Sheets may be left in this area when jams occur.

Area 2 The Lift Handle: The printer is programmed to circulate paper to this area in

the event of a jam. Raise the handle to clear this area. Do not move the

handle to the left. Ensure that the handle is fully locked by lowering it before

closing the Front Door or the handle may be blocked or damaged.

Area 3 The Fuser area: This area includes areas 3b, 3c, and 3d. Access these areas

by pulling the green handle.

Area 3a Look beneath the label to find the sheet. Do not push down or lift up on the

label.

Area 3e Open the top 2 trays to access this area. Look for dropped sheets in the areas

to the right of and below Trays 3 and 4.

Area 4 The Duplex area: Look for sheets on top of the open space.

2-10 DocuTech 65/DocuPrint 65

Page 51

Operator Guide Maintenance

Area 5 To access Areas 5, 5a, and 5b you need to open the Finisher area. The

Finisher area is shown in Figure 2-7. Lift and pull Handle 5 to get access to

paper in areas 5a and 5b.

Figure 2-7. Finisher area

DocuTech 65/DocuPrint 65 2-11

Page 52

Maintenance Operator Guide

Area 7 To access Area 7, you need to open the High Capacity Feeder (Tray 6) and

Bypass Tray (Tray 5) areas. The High Capacity Feeder and the Bypass Tray

are shown in Figure 2-8. Lift and pull the top cover of the Bypass Tray to

access area 7a.

Figure 2-8. Access to area 7

2-12 DocuTech 65/DocuPrint 65

Page 53

Operator Guide Maintenance

Replaceable units and supplies

The printer is designed to allow the customer to change major components

such as the Xerographic Module, the Fuser Module, the Dry Ink Cartridge

(Toner), or the Feed Roll Cartridges without having to initiate a service call.

These and other replaceable supplies are shown in Figure 2-9.

Figure 2-9. Location of CRUs and supplies

1. Ink Cartridge (Toner Cartridge) - a consumable supply

2. Fuser Module - a Customer Replaceable Unit (CRU)

3. Xerographic Module - a Customer Replaceable Unit (CRU)

4. Paper Feed Roll Cartridge (1 per paper tray including trays 5 and 6) - a

Customer Replaceable Unit (CRU)

5. Developer Collector Bottle (included as part of the Xerographic Module) a consumable supply

6. Staple Cartridges (behind the Finisher door) - a consumable supply

DocuTech 65/DocuPrint 65 2-13

Page 54

Maintenance Operator Guide

Replaceable items

The following components are replaceable:

• The Xerographic Module

• The Fuser Module

• The Paper Feed Roll Cartridges

• Dry Ink (Toner) Cartridge

• Staple Cartridge

• Developer Collector Bottle

If a replacable item must be changed, a message will appear on the controller.

To replace these units, simply follow the instructions provided with each

replacement box. Also, use the box and prepaid return label to return the old

unit to Xerox.

Instructions for replacing the Dry Ink Cartridge are also found inside the front

door of the machine.

Ordering CRUs and other supplies

The telephone numbers for placing orders are shown in Table 2-1.

Table 2-1. Telephone numb ers for ord ers

Type of Order Number to Call

Supplies USA: (800) 822-2200 (T&M)

Canada - English: (800) 668-0199

Canada - French: (800) 733-9400 (T&M)

Xerox Europe: Contact your local representative.

CRUs USA: (800) 821-2797 (FSMA only)

Canada: (800) 668-0199

Canada - Toronto: (800) 733-9400 (T&M)

Xerox Europe: Contact your local representative.

2-14 DocuTech 65/DocuPrint 65

Page 55

Operator Guide Maintenance

Life expectancies and part numbers for CRUs and supplies are listed in Table

2-2.

Table 2-2. Life expectancy for CRUs and consumable supplies

Item Description and Life Expectancy Part Number

Fuser C RU 400K imps.hard stop, 310K average

Note: DocuT ech 65/DocuPrint 65 ignores the

hard stop but displays a CRU message.

Xerographic CRU (Includes one Developer Collector)

200K imps. hard stop

Note: DocuTech 65/DocuPrint 65 ignores the

hard stop but displays a CRU message.

USA and Canada:

FSMA 109R330 N/A

T&M 109R329

XE:

65PPM FSMA109R334

65PPM Sold 109R333

DMO Latin:

65PPM/115V FMSA 109R345

65PPM/115V Sold 109R344

65PPM/230V FMSA 109R341

65PPM/230V Sold 109R340

USA and Canada:

FSMA 113R132 N/A

T&M 113R131

XE:

FSMA 113R134

Sold 113R133

Paper Feed Roll

All paper tray feeders are 100-125K feeds. USA and Canada:

Cartridge CRU

Dry Ink (Toner) 2 Pack (contains 2 cartridges)

6 Pack (contains 6 cartridges)

XL 6 Pack (contains 6 cartridges)

Each cartridge yields 21.7K at 6% coverage.

Staple Cartridge Each cartridge contains 5K staples.

3 Pack contains 3 cartridges

DMO Latin:

FMSA 113R175

Sold 113R174

FSMA 108R148 N/A

T&M N/A

XE and DMO Latin:

108R150

USA, Canada, and DMO Latin:

6R849 for 2 Pack

6R821 for 6 Pack

XE:

6R90252 for 6 Pack

World wide:

108R53 for 3 Pack

DocuTech 65/DocuPrint 65 2-15

Page 56

Maintenance Operator Guide

When placing orders, give the representative the following information:

• Your Xerox customer number

• Your system model name and number

• A description of the item

• The quantity of the item

Dry Ink (Toner) usage and “Dry Ink Low” message

Dry ink (toner) usage is related to the amount of area that needs to be printed

(covered). The greater the area of coverage, the more dry ink used; for

example, a typical office memo would have these approximate values:

• text only - 6% area coverage

• a solid area of 1 x 2 inches (25 x 51 mm) - 8% area coverage

• a solid area of 1.25 x 7.5 inches (32 x 191mm) that is 8.75% of the memo

area - 15% area coverage.

Table 2-3 shows the dry ink usage and area coverage. For example, at 6%

area coverage, the system will produce approximately 21,700 prints. This

information will help you estimate how long it will be before the system

displays a “dry ink low” message.

“Dry ink is low”

message

Table 2-3. Dry ink (toner) usage and area coverage

PRINTS PER

CARTON -

AREA

COVERAGE

4% 30,400 60,800 182,400

5% 25,000 50,000 150,000

6% 21,700 43,400 130,200

7% 19,100 38,200 114,600

8% 17,100 34,200 102,600

9% 15,400 30,800 92,400

10% 14,000 28,200 84,600

15% 9,700 19,400 58,200

After the system displays a “dry ink is lo w ” mess age , it can print

approximately 2000 additional prints at 6% area coverage. This means that a

system printing at 6% area coverage, with approximately 21,700 prints per

cartridge, will display a “dry ink is low” message at about 19,700 prints.

PRINTS PER

CARTRIDGE

2 PACK

6R849

PRINTS PER

CARTON -

6 PACK

6R821

2-16 DocuTech 65/DocuPrint 65

Page 57

3. Paper and other stock

Your printer can process a variety of paper and other stock to accommodate

your needs.

This chapter contains information about the stock you can use in the printer

and how you can expect it to perform. Stapling guidelines and the correct

loading of special stocks is also discussed as well as stock storage

requirements.

Performance informa tion

The following tables list the printer performance expectations for both onesided and two-sided printing, on paper and on other stock.

Table 3-1 Staple capability for Various Paper Weights

Table 3-2 Printer Performance for Standard Paper 20 lb or 75 gsm (USA paper size)

Table 3-3 Printer Performance for Standard Paper 80 gsm (Xerox Europe paper size)

Table 3-4 Printer performance for Non-standard Paper and Other Stock

Table 3-5 Printer Performance for New and Recycled Plain Paper

DocuTech 65/DocuPrint 65 3-1

Page 58

Paper and other stock Operator Guide

Paper handling guidelines

Paper handling and/or image quality performance degradation might occur in

the following situations:

• Lower quality paper

• Extreme hot and humid or cold and dry environments

The size limitation for duplex printing is shown in Figure 3-1.

Figure 3-1. Size requirement for duplex printing

This edge must be between 6.7 to 18 inches (170 to 457

mm) to be printed on both sides (duplexed).

Feed Direct io n

The di m ension of t his

edge is controlled by the

tray.

3-2 DocuTech 65/DocuPrint 65

Page 59

Operator Guide Paper and other stock

Tray capabilities: The trays are shown in Figure 3-2.

Figure 3-2. Tray capabilities

Tray 5

Tray 6

Trays 1 - 4

Tray 5 The Bypass Tray has a capability of 4 to 12 inches (102 to 305 mm); 5.83 to

18 inches (148 to 457 mm).

Tray 6 The High Capacity Tray has a capability of only 8.5 x 11 inch (216 to 279 mm)

or A4 long-edge feed (LEF), between 16-32 lb (75-120 gsm).

Trays 1-4 Have a capability of 8 to 17 inches (203 to 432 mm); 5.25 to 11 inches (133 to

279 mm). Call the Welcome Center if you want to permanently set any of the

Trays 1-4 to process 12 x 18 inch (305 x 457 mm) stock.

DocuTech 65/DocuPrint 65 3-3

Page 60

Paper and other stock Operator Guide

General stapling guidelines

To ensure that stapling of thin sets is satisfactory, finishers made before the

end of 1998 will cycle down and wait briefly after producing 30 sets of 15

sheets to give you an opportunity to proof the job. Yo u are not required to

empty the Stacker in order to resume printing.

For Finishers made after the end of 1998, a similar process takes place

except that you are required to empty the Stacker in order to resume printing.

If these parameters are not satisfactory for your printing, please contact

Xerox.

Dimensions that can be stapled: The minimum size for stapling is 6.7 by 8

inches (170 x 203 mm). The fed edge must be between 8 to 12 inches (203 x

305 mm) to be stapled.

Figure 3-3. Size requirements for stapling

This edge

must be

between 8 to

12 inches (203

to 305 mm) to

be stapled.

Feed

Direction

Weights that can be stapled: The Finisher can staple a maximum of 50

sheets of 20 lb paper. The maximum staple capability for other stock weights

is shown in Table 3-1.

Table 3-1. Staple capability for various paper wei ghts

Weight Maximum Number of Stapled Sheets

20 lb 75 gsm 50

24 lb or 90 gsm 44

32 lb or 120 gsm 33

65 lb or 244 gsm Cover to

110 or 203 gsm Index

When the Top Tray of the Finisher is used: Short-edge feed (SEF) sheets

less than 6.7 inches (170 mm) long in the feed direction or 8 inches (203 mm)

long in the cross-feed direction will go to the Top Tray rather than to the

Stacker.

During certain jam or error conditions, purged sheets (to be discarded) are

also sent to the Top Tray.

22

3-4 DocuTech 65/DocuPrint 65

Page 61

Operator Guide Paper and other stock

Performance tables

In the printer performance tables, various symbols and characters are used to

convey information.

Symbols The following symbols in the “Rating” column of a table represent the

expected paper handling and image quality performance in typical operating

environments.

l = Best performance

o = Good performance

o = Fair - Good performance

x = Not recommended. Exceeds design specifications. Unaccept able

performance is likely.

** = Indicates the same performance as shown in Ta bles 3-2 and 3-3 for the

corresponding paper sizes.

Characters The following characters in the “Note” column of a table provide additional

information.

a = Cannot be duplexed.

b = The output will go to the Top Tray and cannot be stapled.

c = Requires a Xerox technical specialist to permanently set up any of the

trays 1-4 to handle 12 x 18-inch (305 x 457 mm) paper. After any one of these

trays is set up to handle this size, it cannot run other sizes. Tray 5, however,

can be used without any special set-up intervention from Xerox.

d = For the correct paper loading orientation refer to the paper tray label or to

Table 3-6.

e = Embossed letterhead may caus e degraded pape r hand ling, and possibly

minor image deletion defects near the embossed area on either side of the

paper.

f = Although the carbonless paper might feed through the printer, the fusing

process is likely to cause dry ink contamination on subsequent pages or jobs.

g = Performance is highly dependent on the quality of the coated paper.

Frequent use of coated papers, especially lower quality papers, might cause

increased contamination in the printer which could degrade the paper

handling capability and the image quality performance for all papers.

h = Image deletion defects might occur near the perforation, especially if the

perforation is parallel to the feed direction.

i = Two-sided printing (duplex) should not be selected when this stock is used.

j = It is recommend that only Bypass Tray (Tray 5) is used for this stock.

k = Blank or preprinted covers are acceptable. Cannot print on textured cover

stock.

l = The 1 10 lb index stock (203 gsm) and the 65 lb cover stock (244 gsm) are

both used for covers on documents. The paper handling performance for both

stocks will be similar.

DocuTech 65/DocuPrint 65 3-5

Page 62

Paper and other stock Operator Guide

NOTE: For all trays, the fusing quality and “fix level” for images on 65 lb.

cover stock, Vellum Bristol papers, and other textured-surface stock will be

degraded; therefore, this stock is not recommended for imaging use.

NOTE: Long Edge Feed (LEF) and Short Edge Feed (SEF) indicate the

orientation of the sheet in a Paper Tray and which edge of the paper will be

fed into the printer first.

The printer performance for trays using standard 20 lb (75 gsm) paper in

common USA sizes is shown in Table 3-2.

Table 3-2. Printer performance for standard paper 20 lb (USA)

Rating

Tray

5Tray 6Note

Size Feed

Tray

1-4

Letter

8.5 x 11 in. (216 x 279 mm) LEF

SEF

l

o

l

o

Legal

8.5 x 14 in. (216 x 356 mm) SEF o o x

Ledger

11 x 17 in. (297 x 420 mm) SEF l l x

Statement

5.5 x 8.5 in. (140 x 216 mm)

5 x 7 in. (127 x 177.8 mm)

SEF

SEF

o

x

o

o

Executive

7.25 x 10.5 in. (184 x 267 mm)

LEF

SEF

x

o

o

o

l

x

x

x

b

b

x

x

b

8 x 10 in. (203 x 254 mm)

LEF

SEF

o

o

o

o

x

x

Letter Cover

9 x 11 in. (229 x 279 mm)

LEF

SEF

o

o

o

o

x

x

12 x 18 in. (305 x 457 mm)

SEF

o

o

xc

3-6 DocuTech 65/DocuPrint 65

Page 63

Operator Guide Paper and other stock

The printer performance using standard 80 gsm paper in common Xerox

Europe sizes is shown in Table 3-3.

Table 3-3. Printer performance for standard paper 80 gsm (Xerox Europe)

Rating

Tray

5Tray 6Note

Size Feed

Tray

1-4

A3

297 x 420 mm (11.7 x 16.54 in.) SEF l l x

A4

210 x 279 mm (8.27 x 11.69 in.) LEF

SEF

l

o

l

o

l

x

A4 Cover

223 x 279 mm (8.78 x 11.69 in.) LEF

SEF

o

o

o

o

x

x

A5

148 x 210 mm (5.83 x 8.27 in.) LEF

SEF

x

o

o

o

x

x

a

b

A6

105 x 148 mm (4.13 x 5.83 in.) SEF x o x a, b

B4

257 x 364 mm (10.12 x 14.3 in.) SEF l l x

B5

182 x 257 mm (7.17 x 10.12 in.) LEF

SEF

x

l

o

l

x

xb

B6

128.5 x 182 mm (5.06 x 7.17 in.) SEF x o x b

Foolscap

215 x 330 mm (8.5 x 13 in.)

220 x 330 mm (8.66 x 13 in.)

SEF

SEF

o

o

o

o

x

x

Spanis h (S p. Folio)

216 x 315 mm (8.46 x 12.4 in.) SEF o o x

DocuTech 65/DocuPrint 65 3-7

Page 64

Paper and other stock Operator Guide

The printer performance for non-standard paper and other types of stock is

shown in Table 3-4. You may run the stock if you follow the guidelines in the

table and if the dimensions of the stock are within the size limits previously

discussed for standard paper.

Table 3-4. Printer performance for non-standard pap er and other stocks

Throughput material Rating Note

Letterhead ** d, e

Pre-printed forms ** d

Pre-dri ll ed/ pre-punch e d ho les (standard

** d

locations)

Coated paper o - o g

Mylar reinforced

LEF (Mylar on long edge)

SEF

o

x

Transparencies

Clear/plain

Non-removal white stripe

Removable stripe: LEF

SEF