Page 1

REPAIR THE FUSERS !

Xerox Workcentre Pro645 style & Pro665 style…

Pro635, 645, 657 & Pro665, 685, 765, 785

So, the heat lamp blew… or the gear broke, or the

thing overheated… It used to be that a technician would

replace the fuser part which actually failed and get paid for the

labor as well as little bit for the part. Nowadays though, its all

about “just replace the fuser module”… The tech makes a 15

minute service call, replaces the fuser, makes a few bucks on the fuser and throws the broken

fuser out… or sends it to the manufacturer for a small credit perhaps. Not much labor there,

so you’d better replace a lot of fusers! Lots of independent technicians are hurting partly

because of this trend… especially now that more and more of the fusers are considered to be

customer replaceable.

Stay in the game… Repair the fusers and save your customer money while working in

the comfort of your own workbench. The whole idea of replacing entire fusers was hatched

by the OEM manufacturers. Xerox and other makers like it this way… they get to have

things done in a warehouse assembly line. A very efficient way to handle equipment repairs,

indeed. To push things in this direction, they’ve chosen not to spare many of the important

parts in the fusers. Fortunately, many of these “not spared” parts are beginning to surface in

the aftermarket… and if you are in the business of repairing the fusers, you will gather used

cores which have many of the parts in perfectly useable condition. All you really need to

repair a majority of cases, is to find a source for the fuser lamps and heat rolls.

In a recent article, we got the ball rolling on the issue of repairing fuser modules. We

covered the C35 style (C35, C45, C55, Pro35, Pro45, Pro55, M35, M45, M55, DC535,

DC545, DC555). That one is going to be good and popular it appears… in the next year or so

they should start hitting your work bench. Another group of machines which could use all of

our attention are the Xerox WorkCentre Pro645 style (Pro635, Pro645, Pro657) and the

Pro665 style (Pro665, Pro685, Pro765, & Pro785). These machines had a predecessor in the

7042 style (4010, 4011, 7041, 7042). The 7042 had a very similar fuser (126K3210) although

there were some substantial differences as well. The parts which are common to all three

“styles” include the Fuser Heat Roller, Fuser Pressure Roller, Bearings (both heat and press),

the Fuser Drive Gear, and the 3 fuser idler gears. The items which

fuser include the Fuser Lamp, Thermistor, Thermostat, Exit Switch, Exit Roller and Picker

Fingers.

The only apparent difference between the Pro645 style fuser (126K9420 for the

110volt version) and the Pro665 style (126E1920 for 110 volt) is the Thermistor… the wiring

for the two versions have a different Connector on them.

FUSER REMOVAL PROCEDURE:

Removal procedures for getting the fusers out of the machines vary only in the way

you access the connectors to unplug them. For the Pro645 style:

• Open the clamshell

• Remove the Drum Cartridge / DV Unit Assemblies

• Disconnect a connector at the rear of the fuser and a second one at the front end…

• Remove two screws (one near the front end and one near the rear end), both are down

near the base on the feed-in side of the fuser.

Pro645 style - Fuser Assembly

do not cross to the 7042

Page 2

• Lift the fuser up and out.

The Pro665 style comes out the same way except that you first need to remove the

front and rear covers so that you can access the front and rear plugs (for the rear plug; you

will actually go to the rear of the machine to disconnect it).

The 7042 works the same way as the Pro665 style (remove the front and rear covers

first) except that it has two rear connectors (CN11 & CN12). You will need to disconnect

both of them where they plug into the Driver Board. The front connector is CN101 which

plugs into the Low Voltage Power Supply (LVPS).

DISASSEMBLY:

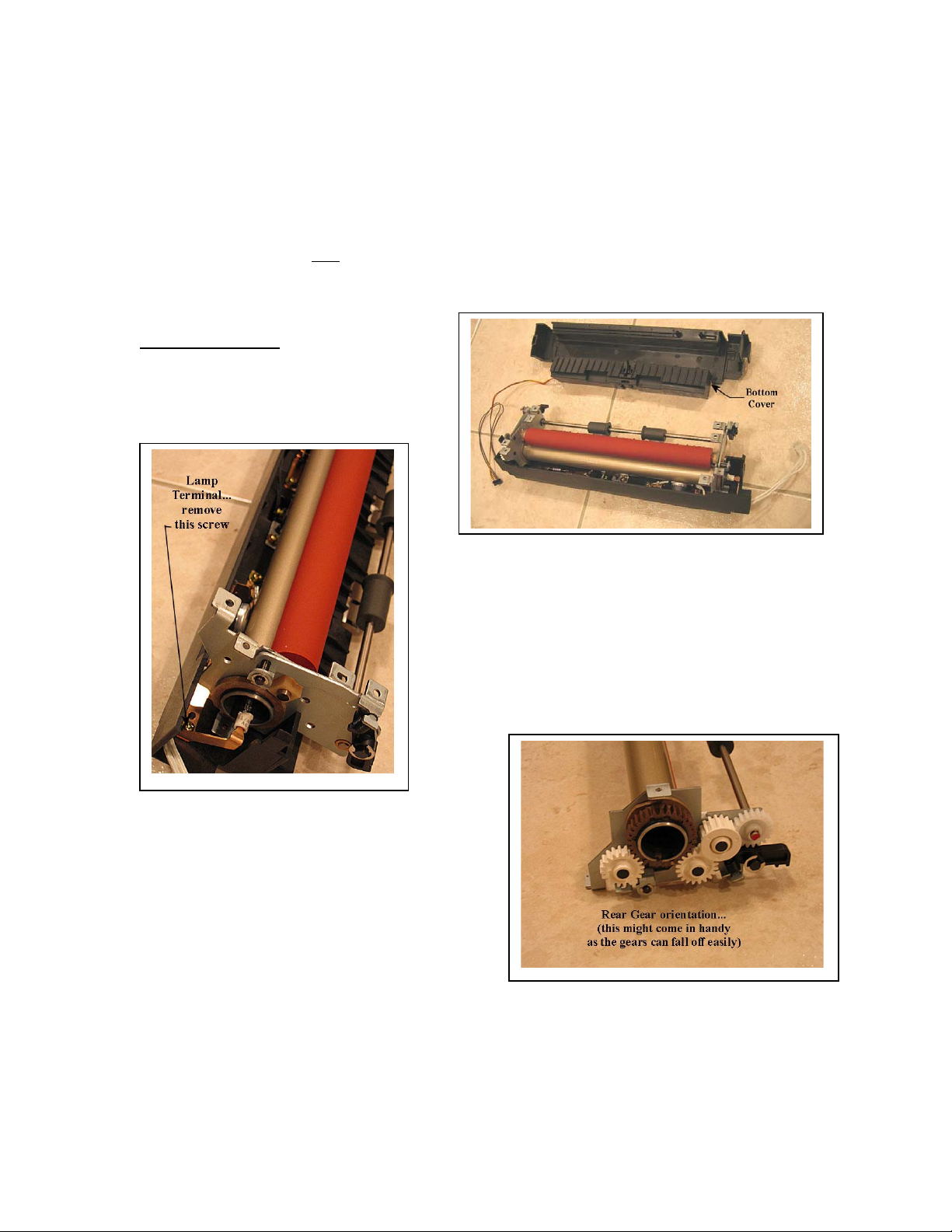

1) Flip the fuser over and remove

the bottom cover, which is as simple as

releasing a pair of clips (one at the front

end and one at the rear end).

2.) Release the Fuser Lamp Rear Terminal’s screw

to disengage the rear terminal. You can slide the Fuser

Heat Lamp out through the front end (the end opposite

the gears).

3.) Now with the lamp out and in a safe place,

turn the assembly right side up again and

remove the top cover (2 screws and lift it off).

Take notice of the layout of the gears as the 3

idler gears are not captive and will fall off

easily.

Page 3

4.) To remove the Heat Roller, remove

the front snap ring (opposite the gear

end). Then hold the heat roll bearings

in place in the metal front and rear

frames, slide the roller out of the rear

(geared) end. Keeping the bearing /

sleeve in place will protect the heat roll

from scratching against the metal

frame.

5.) The other pieces… such as the

Pressure Roll and the Exit Roll can

now be removed easily if you need to

do so.

Reassembly is pretty much the same thing in reverse.

FUSER TEMPERATURE ADJUSTMENT:

The fuser’s temperature could need adjusting in some cases on this series. Each fuser

has a sticker on the top of it which is a grid of numbers 0 - 6. The number which is marked

rates the fuser’s “Rank” or heating level. A higher number means a hotter setting is required

to get proper fusing according to the OEM factory test process. The Service Manual

recommends that you set the machine’s Fuser Setting in memory (from the diagnostics) to the

same number as the one marked on the fuser module. Basically though, if the fuser is running

too hot, the paper will tend to curl up or the thermostat may cut off throwing an overheat

message… if the fuser is too cool, then you’ll get partial fusing.

Here is how to adjust the Fuser Temperature if you ever need to: Turn off the machine

and then Enter Diagnostics by holding down the ‘1’ & the ‘3’ buttons while powering on the

machine. Then press the following sequence of buttons: ‘Up’, ‘9’, ‘2’, ‘0’, ‘8’. The current

setting will show up on screen. Then use the ‘Up’ or ‘Down’ buttons to change the value

shown to the value you’d like to try (0-6 is the range). Then press ‘Enter’ and the display will

show “Accepted”. The ‘Up’ button, by the way, looks more like a triangle pointing up… Just

in case that’s not obvious.

The 7042 style does not use this method of entering diagnostics. If you ever want to

adjust the 7042, you’d need to find someone you can borrow or rent two special tools from:

the “7042 Setup Tool” and the“Tech Drum Card”. It is a strange method… the Setup Tool

plugs into the machine and becomes the interface for diagnostic adjustments. That is the only

way to make this adjustment on the 7041, 7042, 4010, or 4011 models.

That should just about do it… pretty easy one really… Oh and as far as parts

availability goes… I have seen the fuser rollers and fuser drive gears out there already…

other parts are likely to surface as time goes on as well. Don’t let these things slip through the

cracks. Happy Repairs to you all !

We’ll have a closer look at a few other good candidates for fuser repairs next month.

I’m thinking maybe the DC332/340/432/440 etc. Sound good?

Page 4

Britt Horvat works for The Parts Drop, a company who provides parts & supplies for this

series as well as many other Xerox brand copiers, faxes and printers. For more info visit

their website; www.partsdrop.com

Loading...

Loading...