Page 1

XEROX 5915 SERVICE MANUAL

Issued by : Overseas Technical Group,

Xerox of Shanghai Limited.

th

. July 200

7

Page 2

XEROX

THE DOCUMENT COMPANY

Issued: JUNE 2000

XEROX 5915

Service Manual 1st Edition

•••• This service manual covers the follow ing models:

Electrostatic Copier XEROX 5915 manufactured by SHANGHAI XEROX.

•••• Related Materials

No related materials are issued other than this service manual.

•••• Confidentiality

• This service manual is issued intending use by maintenance service

personal authorized by XEROX. Coping, transferring or leasing this

manual without prior consent by XEROX is prohibited.

• Whenever a paper is eliminated because of issuance of a replacement

•••• Revision and Modification Information

When design changes or revisions relating to this service manual occur,

overseas technical information or overseas service bulletins may be

issued as supplementary information until such change will be

accommodated in the updated version of this service manual.

CAUTION: Important changes including revisions of spare part numbers

and adjustment specifications must immediately be reflected

on the respective pages of this service manual upon reception

of such information.

page containing changes modifications, burn it or take the necessary

action including cutting by a shredder.

• Be careful of handing the manual to avoid missing or damaging it.

Page 3

Introduction

1. Scope and Comment Sheet

This service manual is prepared to specify

service standards for the XERO X 5915.

•••• Service Manual Comment Sheet

When you have comments or corrections, or

discover wrong descriptions in the XEROX

5915 service manual, enter these items on the

comment sheet and send it to:

Overseas Support Group,

Technical Services Department,

Xerox of Shanghai Ltd.

Via your company’s Technical Department.

2. How to Use the Service Manual

This service manual covers standard

maintenance servicing procedures for the

XEROX 5915. Observe Section 1 Service

Procedure for efficient work during maintenance

calls.

2.1 Service Manual Composition

This manual is divided into the following 9

sections:

Section 1 Service Procedure

This section describes general an d servici n g

procedures required to carry out maintenance

of the XEROX 5915.

Section 2 Troubleshooting

This section specifies troubleshooting

procedures, except thos e on the imag e or cop y

quality. How to use the diagnostic mode and

programs are also contained in this section.

Section 3 Image Troubleshooting (Under

preparation)

This section describes troubl esh ooti ng

procedures relating to image quality problems.

Section 4 Disassembly, Assembly and

Adjustment

This section instructs the disassembly,

assembly, adjustment and replacement

procedures for compone nts of the XERO X

5915.

Section 5 Parts List

This section lists the component parts of the

XEROX 5915.

Section 6 General

The following pieces of information relating to

the XEROX 5915 are contained in this section:

• Specifications

• Tools and servicing supplies

• Consumables

• Information relating to rnodifications

• Installation and removal procedures

Section 7 Wiring Information

This section contains information relating to

electrical wiring of the XERO X 5915 .

• Wiring connectors list

• Wiring connectors positions

• PWBS reference materials

Section 8 Information of Related Products

(Not to be issued as the 5915 is unique)

Section 9 Block Schematic Diagrams (BSD)

This section contains the following Block

Schematic Diagrams (BSD) of Chains 1

to 9 and other wiring information on the

XEROX 5915.

• Chain 1. STANDBY POWER

• Chain 2. MODE SELECTION, MACHINE

RUN CONTROL START PRINT POWER

• Chain 3. DOCUMENT TRANSPORTATION

OPTICS NO.I

• Chain 4. DOCUMENT TRANSPORTATION

OPTICS NO.2

• Chain 5. PAPER SUPPLYING AND

TRANSPORTATION NO.1

• Chain 6. PAPER SUPPLYING AND

TRANSPORTATION NO.2

• Chain 7. XEROGRAPHIC, COPY

TRANSPORTATION AND FUSING

2.2 Revision Information

This manual will be revised as specified below

and the necessary information sent to all

customer engineers. Revisions must be

incorporated correctly in or der to keep the

manual up-to-date.

Revision Procedure:

• When the entire manual is revised, the

Revision 1 on the front cover will be renewed

to Revision 2, Revision 3 and so on.

• When the manual is partially revised,

Revision A, B, C and after will be issued. Each

revised page will carry Revision A, B, C and

up in order to clarify the revision history.

• Change bar:

When a paragraph, table or figure is revised, a

change bar will be inserted into respective

revisions in order to clearly indicate that a

change or addition is made.

Example:

When the same page is changed a second

time, the previous change bar will be deleted.

3. Warning, Cautions and Notes

WARNING

A Warning is used whenever an operating or

maintenance procedure, practice, condition

or statement, if not strictly observed, could

result in personal injury.

CAUTION

A Caution is u sed whenever an o perating or

maintenance procedure, practice, condition

or statement, if not strictly observed, could

result in damage to the equipment.

NOTE

NOTE: A Note is used where it is essential to

highlight a procedure, practice, condition or

statement.

4. Symbols

The following symbols are used throughout this

manual:

• PL: This indicates you should refer to the

parts list.

Introduction

XEROX 5915 Service Manual

Page 4

Section 1 Service Procedure

Page 5

Section 1 Service Procedure

1.1 Precautions

1.1.1 Safety………………………………………………… 1-2

1.1.2 Other precautions……………………………………1-2

1.2 Work Process When Making Calls ………… 1-2

1.3 Detailed Explanation of Work

When Making Calls………………………………..

1.3.1 What to do first………………………………………1-3

1.3.2 Check for repeatability of the problem……………1-3

1.3.3 Check the image quality……………………………1-3

1.3.4 Feed Counter Check ………………………..……. 1-3

1.3.5 Paper Jam Status Check ………………………. 1-4

1.3.6 TRIM …………………………………………………1-4

1-3

1-1 Contents

Section 1 Service Procedure

Page 6

1-2

Section 1 Service Procedure

1.1 Precautions

Intentional bank page

Page 7

1. Service Call Procedure

FIRST CALL ACTIONS

Perform the following:

1. Discuss with the customer the requir ed an d

agreed configuration for the copier. Check

that all required hardware and software is

installed and/or enabled to meet this

specification.

2. If the copier is configurated with either a

sorter or ADF, check the alignment of the

output device.

NORMAL CALL ACTIONS

1. Ask the operator about the reason for

the call. Obtain the operators description

of the reason for the call and any other

problems that may be occurring. Review

any defective copies to determine what

actions need to be taken.

2. First Call? If this is the first call, carry out

the first call actions.

3. Switch on the copier … Observe the user

interface panel <Note to author add

initialising sequence of events>

4. System initialisation… Confirm that the <

Note to author add initialising sequence of

events eg drives moving etc>

5. Check the service lo g. Review the copier

service log book for any previous actions

that may be relevant to the call.

6. Check and record copy counters. Check

and record copy counters in the XXX book .

Enter the diagnostic Mode and check the

number of sheets of copy paper fed from

Trays and that of originals fed from

Document Feeders.

7. Enter Diagnostic Mode. Perform the

following

- Make a note of any faults

recorded.

- Make a note of the High

Frequency Service Items

8. Verify and classi f y the fa ult . Use the

information obtained in the previous steps

to determine the cause of the fault. If the

previous steps do not determine the faul t,

fully exercise the copier utilising all options

until the fault is determined.

9. Plan the call. Using the information noted

in previous steps, structure the call:

(H.F.S.I) requiring attention.

- Check all H.F.S.I required are

available. Any items

unavailable shall be ordered at

this point.

- When troubleshooting or

repairing a fault in a particular

subsystem, resolve an y

workarou nd and overthreshold

faults and replace any noted

H.F.S.I applicable to that

subsystem.

- Perform any subsystem

maintenance actions applica bl e

to that system.

FINAL ACTION S

1. Perform any remaining maintenance

actions. Check that all maintenance

actions noted during the call have been

completed.

2. Carry out TRIM procedure.

3. Make a copy of the customer do cum e n t.

Clean the document glass and make a

copy. Ensure that the customer is

satisfied with the copy quality.

4. Reset any H.F.S.I counters where items

have been replace d.

5. Clean the copier and clean the service

area.

- Remove any toner spillage’s.

- Use “Formula A” cleaner to

clean the covers.

-

Take care when cleaning the control

6. Provide customer with training (if

required)

7. Make a note of the copy credits and

record copy counters in the XXX book.

8. Complete the copier log book. Record all

service actions performed in the copier log

book and record any other rel eva nt

information.

WARNING

Do not use solvents.

CAUTION

panel to not use an excessive

amount of the cleaner.

1-3

Section 1 Service Procedure

Page 8

1-4

Section 1 Service Procedure

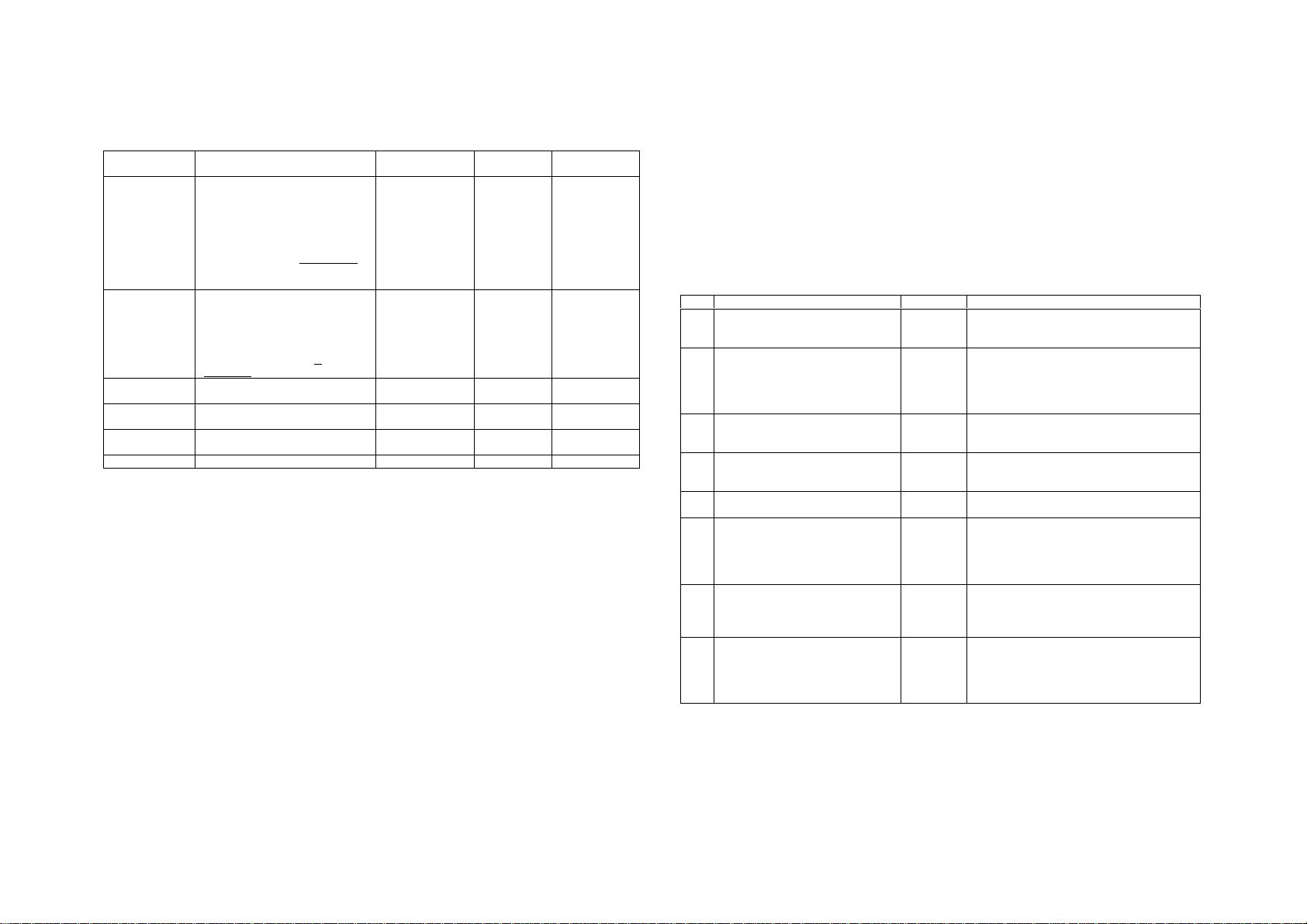

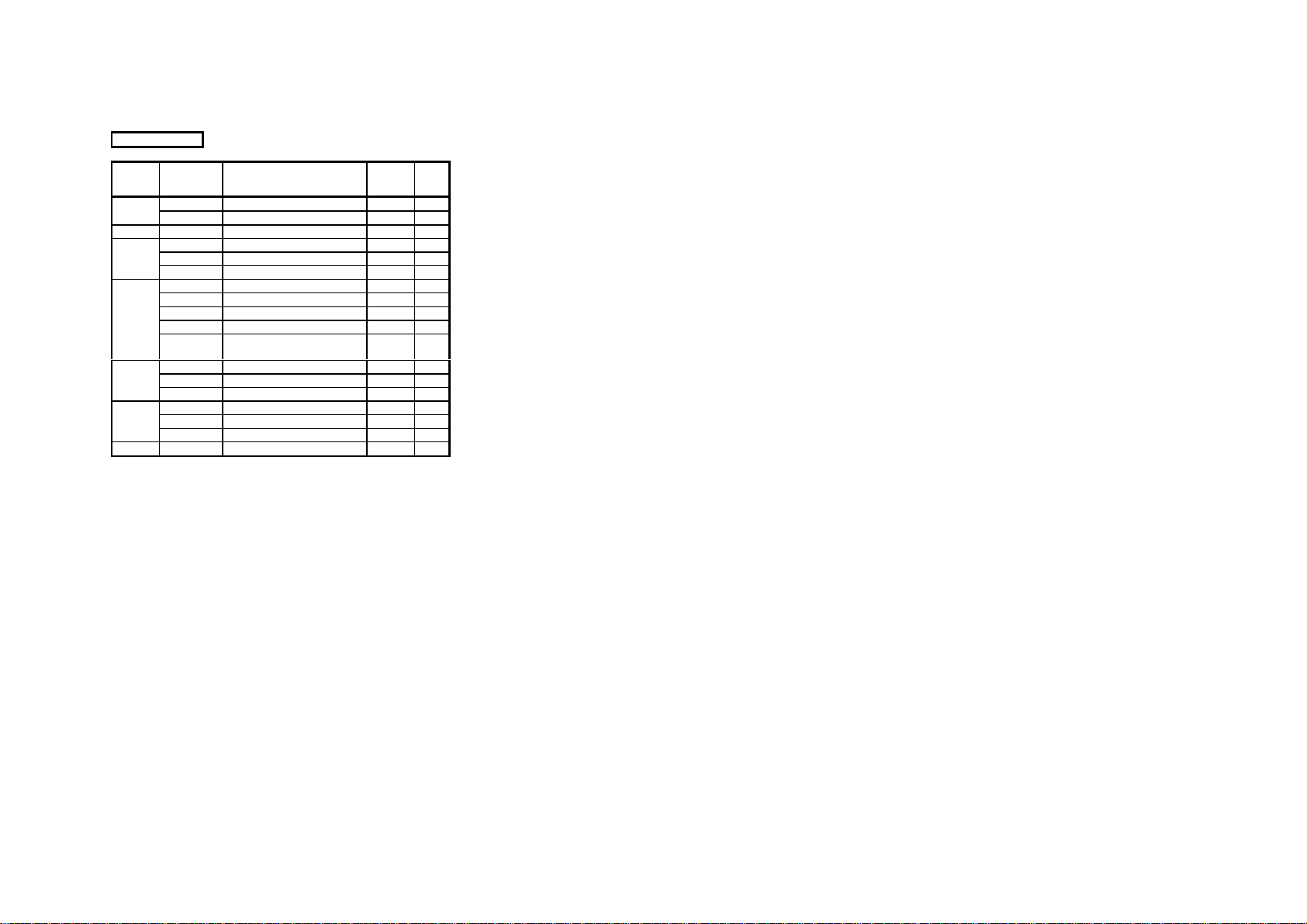

HIGH FREQUENCY

SERVICE ITEMS

Component Indication Replacement

Photoreceptor

drum

Toner

Cartridge

Half-Moon

Feed Roll

MSI Feed

Roller

MSI Retard

Pad

Ozone Filter 50K

4

With the Drum Unit replacement

due, the Control Panel display

turns on at 50K copies indicating

its replacement is required. After

“Replace Drum Cartridge” is

displayed, J7 is displayed at 5K

copies and copying is prohibite d

from this point.

When the Toner Cartridge runs

short of toner, “Supply Toner” is

flashing. When approx. 100

copies have been made since the

display began flashing, J1 is

displayed and copying is

prohibited from this point.

threshold

50K 673S50211 REP 5.1.1

6K

The above copy

quantities apply

to A4 originals

with an area

coverage of 6% .

67K

60K

60K

Parts list Replacement

Procedure

6R01020

59K03261 REP 2.5.1

6S50220 REP 2.3.2

19S50212 REP 2.2.2

53E91510 REP 8.5.2

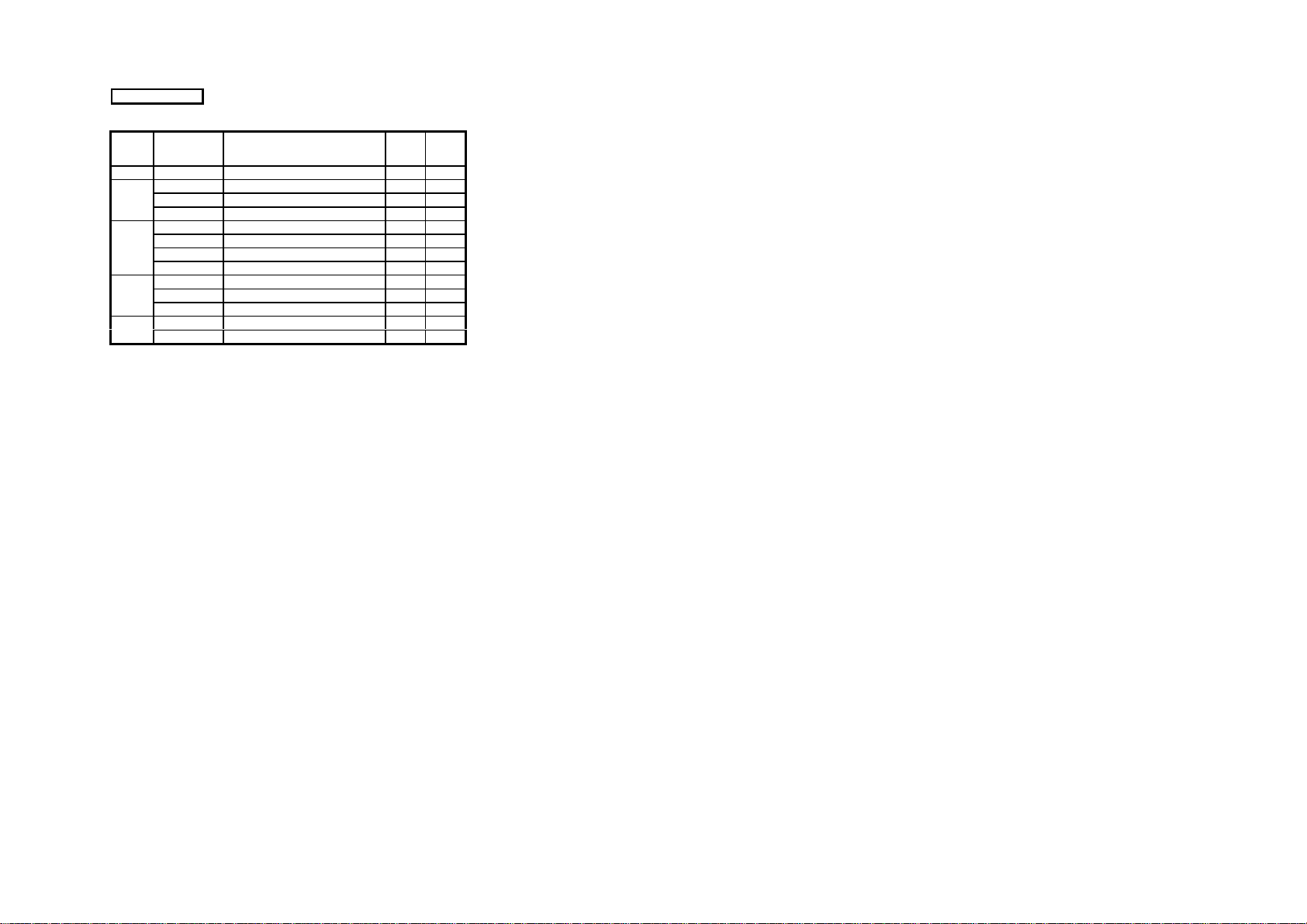

TRIM

• The XEROX 5915 TRIM procedur e shal l be per fo rm ed at

all maintenance calls., unless the procedure has been carried out within the last 10 days.

TRIM work items are listed in the TRIM table.

The work is categorized into the following:

▼▼▼▼:Check at calls. ∇∇∇∇: Make sure to clean

TRIM Check List

<

▼▼▼▼:Check at calls.

∇∇∇∇: Make sure to clean

: Make sure to replace at given intervals.

Work Item Category Main Points

Check the overall M/C operation

1

before work.

Clean Platen Glass(top/bottom

2

surfaces), Platen Cushion and

Mirrors.

Clean Transfer/Detach/Pre-transfer

3

Corotrons.

4 Clean Paper Transport Assy.

Charge Corotron, Seal Glass, and

5

I.S.I.L.

6 Check clean parts subject to wear.

7 Check on safety.

Check the overall M/C operation

8

after work.

▼▼▼▼

• Check on paper feeding, copy quality,

▼▼▼▼

∇∇∇∇

∇∇∇∇

∇∇∇∇

∇∇∇∇

▼▼▼▼

▼▼▼▼

abnormal noise, etc.

• Clean Platen Glass top/bottom surfaces

with silicon cloth and lens cleaning liquid.

• Clean Platen Cushion with wet cloth.

• Clean Mirrors 1-4 and Lamp Reflector with

optics cleaning cloth.

• Clean Wire Shield and Guide with a clean

brush, and wipe them with dry cloth if

necessary.

• Clean Transport Belt and its surrounding

area with a brush, and wipe them with a

dry cloth if necessary.

• Wipe Charge Corotron, Seal Glass, and

I.S.I.L. with dry cloth.

• Check lives of the parts and replace/clean

if necessary.

• Ozone Filter (50k)

• MSI Feed/Retard Roller/P a d (60k )

• Half-Moon Feed Roller (67k)

• Carry out earth continuity check on mains

cable.

• Check Power Plug for damage(cracks/

exposed core)

• Enable all the operations and check paper

feeding, copy quality, abnormal noise, etc.

• Check counters.

• Update the History Card and service

report.

NOTE: a. The Drum doesn’t normally need cleaning.

b. When you can’t help cleaning the Drum because of fingerprints, etc., clean its surface with

the XEROX 5915 toner slightly and then wipe it with dry cloth. (Clean it while rotating it in

the Drum rotating direction.)

c. Never u se Drum Cleaner or Refiner.

Page 9

Section 2 Troubleshooting

Page 10

Section 2 Troubleshooting

2.1 Preface

2.1.1 How to Troubleshoot………………………………. 2-2

2.1.2 Terminology……………………………………….. ..2-2

2.2 Diagnostic(C/E) Mode

2.2.1 How to Enter Diagnostic (C/E) Mode……………. 2-4

2.2.2 Entries of Chain Codes, Function Codes & Set

Values………… …………………………………….2-4

2.2.3 How to Exit Diagnostic (C/E) Mode……………….2-4

2.2.4 Diagnostic Functions and Operating Procedures

………………………………………………………………2-4

2.3 Level 1 Troubleshooting

2.3.1 Level 1 FIP…………………………………………2-12

2.3.2 Chart of Jam Status Codes …………………. ...2-13

2.3.3 A List of Status Codes ……………………….. ...2-15

2.4 Level 2 Troubleshooting

2.4.1 General FIPs………………………………… ….2-16

2.4.2 U Code F.I.P.’s ………………………………… .2-19

2.4.3 Misfeed Jams ………………………………….. .2-25

2-1 Contents

Section 2 Troubleshooting

Page 11

2-2

Section 2 Troubleshooting

2.1 Preface

2.1 Preface

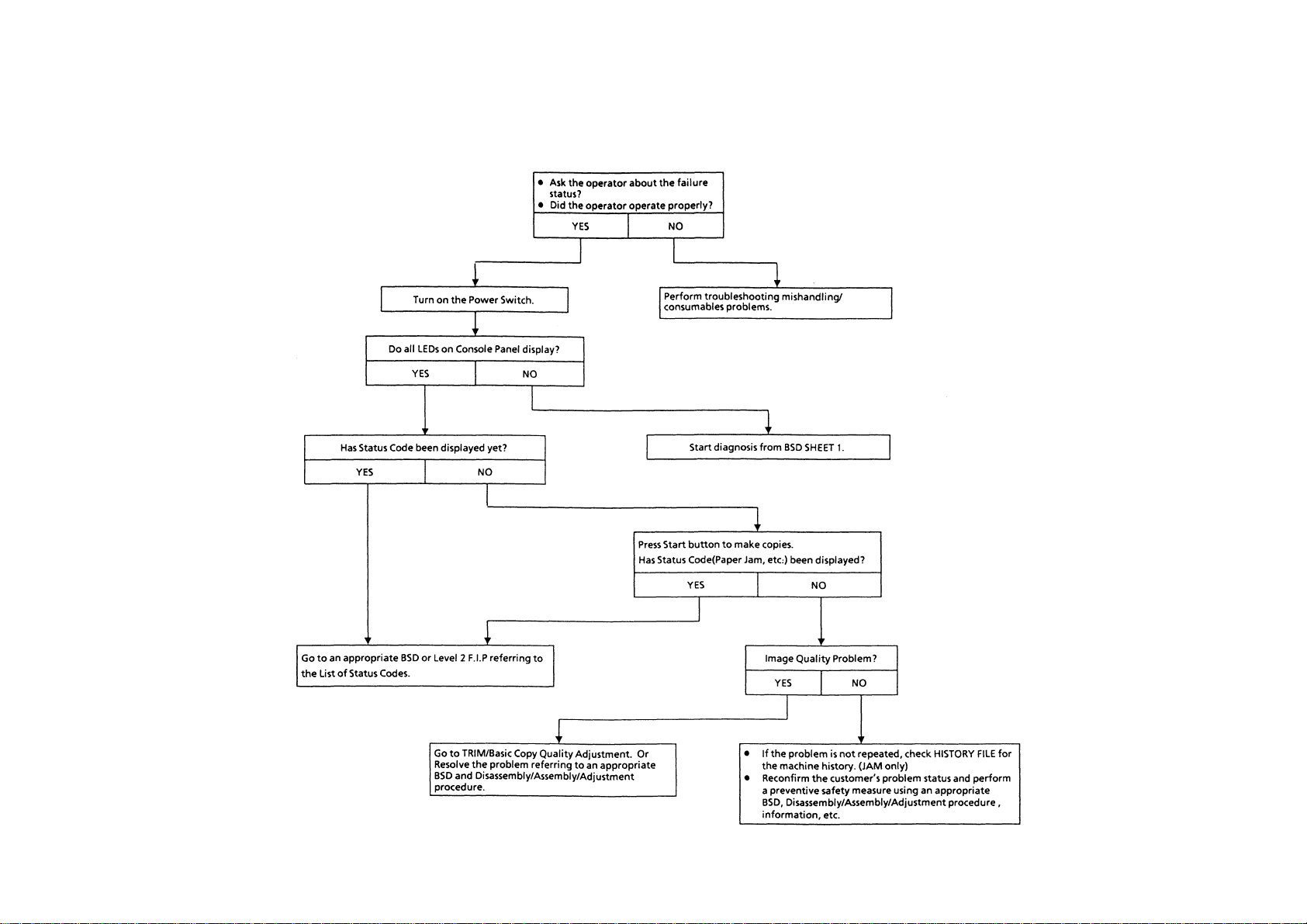

2.1.1 How to Troubleshoot

Level 1 Troubleshooting

• Level 1 Troubleshooting (Level 1 F.I.P.) is the first step

toward the diagnosis of a problem.

Level 1 F.I.P. asks you whether or not any Status Code

and other problems exist, guiding you to Level 2

Troubleshooting.

Level 2 Troubleshooting

• Level 2 Troubleshooting is a diagnostic procedure of

isolating one problem by classified Status Codes,

Misfeed Jams and various problematic symptoms.

Performing a F.I.P. or an appropriate procedure in the

check list enables you to discover causes of a problem

in a short period of time.

• Status Code

When a Status Code alerts you to a machine failure,

perform appropriate troubleshooting items, referring to

the list of Status Codes listing problem contents and

corrective actions or troublesh ooting items.

How to Troubleshoot and Notes

• First perform Level 1 F.I.P. to isolate one problem.

Then go to an appropriate Level 2 Tro ubleshooting,

BSD, or Disassembly/Assem bly/Adjustment proce du re

to resolve the problem. W hen you try to find a cause of a

problem using a F.I.P. or Check Chart, you should read

its procedure carefully and perform it properly. When

there are a number of possible causes , yo u may pe rfo rm

a F.I.P. of the same title again, because it is impossible

to find all causes at once. In this case, pay attention to

different judgments made in the process of the same

F.I.P.

• When taking voltage measurements or performing

operation tests of electric appli a nce s, you shou l d ch eat

their Interlock Switches.

• When replacing PWBs, you should check connectors on

them for proper connections before replacements.

2.1.2 Terminolog y

Troubleshooting uses the following terms. You need to understand these terms in analyzing failures.

Common Terminology

Status Code The message “Report XX.” appears when the machine discovers a problem. This XX

is called Status Code.

Actuate Mechanically press or release the Switch Actuator or the linking Mechanical Linkage.

Block Place a document or a sheet of paper against the Photo Sensor to make the Sensor

detect one.

Check Visually Check parts such as the Relay or Mechanical Linkage for its proper operation

or check to see if parts are defective.

Enter Diagnostic Mode. Enter Diagnostic Mode following the procedure indicated in Diagnostic(C/E) Mode.

Check for a short circuit. Power off. Measure the resistances between the wire and the frame with the tester

Ohm range.

Check for an open circuit Power off. Measure the resistance on the both ends of the wire with the tester Ohm

range.

Set [*.*] to ON Enter Diagnostic Mode following the procedure indicated in Diagnostic(C/E) Mode.

Then enter [Chain Code & Function Code]. Once you have entered Diagnostic Mode,

you must not exit it until you are instructed by the message to “Exit Diagnostic Mode”

or you don’t need to check any more because an area where a failure has occurred is

found.

Stop [*.*] Press the Stop button to set the drive signal for the output component being tested to

OFF.

Exit Diagnostic Mode Exit Diagnostic Mode follo wing the proce d ure described in Diagnostic Mode/Pro g ram .

Check Voltage Levels

+ 5VDC • + 5.2VDC ± 0.25VDC NOTE: The voltage values may exceed their ranges

a little due to varying AC powers or loads.

+ 24VDC • + 24VDC ± 2.4VDC

Breakaway from Failure Analysis Procedure

Mechanical Problem This is used when you should move to mechanical adjustments and parts

replacements. Read all items (describing main causes) and find causes of a problem

in comparison with symptoms the machine shows.

PL 4.2 Refer to Parts List PL 4.2, Section 5.

BSD 6 Refer to BSD 6, Section 9.

4.1.3 Refer to 4.1.3, Section 4 Disassembly/Assembly/Adjustment.

Replace parts in order When it is impossible to further analyze causes of a problem, replace parts in order.

Replacement parts are described in order of highest possible replacement items.

Page 12

Intentional blank page

2-3

Section 2 Troubleshooting

Page 13

2-4

Section 2 Troubleshooting

2.2 Diagnostic(C/E) Mode

2.2 Diagnostic(C/E) Mode

2.2.1 How to Enter Diagnostic(C/E) Mode

Power on while pressing “0” on the keyboard.

• All the LEDs on Console Panel turn on.

When you press the key pad or the Stop Clear

button, the three LEDs: “El JAM”, “E3 JAM” and

“TONER EMPTY” starts flashing while the other

LEDs turn off.

2.2.2 Entries of Chain Codes, Function

Codes and Set Values

If you enter a wrong Chain Code or Fun ction

Code, press the Stop Clear button and re-enter

a correct one.

• If you enter an unspecified Chain Code,

Function Code or Set Value, “Er” appears.

2.2.3 How to Exit Diagnostic(C/E) Mode

Set the Power to OFF/ON.

2.2.4 Diagnostic Functions & Operating

Procedures

Input Check

Function:

This displays the input voltage level from the

Sensor or the Switch with “H” or “L”

Procedure:

1. Enter Diagnostic (C/E) Mode.

2. Enter the Chain Code for a part to be

checked and press the Start but to n.

3. Enter the Function Code for a part to be

checked and press the Start but to n.

4. Operate the part to be checked.

• When the voltage level is high, “H” is

displayed. When it is low, “L” is displayed.

5. When you press the Stop Clear button once

during the check, the Function Code Entry

awaiting status is initiated, while you press it

twice, the Chain Code Entry awaiting status

is initiated.

A/D Input Check

Function:

This displays the input voltage level from the

Sensor with a digital value.

Procedure:

1. Enter Diagnostic (C/E) Mode.

2. Enter the Chain Code for a part to be

checked and press the Start but to n.

3. Enter the Function Code for a part to be

checked and press the Start but to n.

• The voltage levels are displayed with the

digital values of 0~FF.

The varying voltage level will change the

display.

4. When you press the Stop Clear button once

during the check, the Function Code Entry

awaiting status is initiated, while you press it

twice, the Chain Code Entry awaiting status

is initiated.

Console Button Check (2-1)

Function:

This checks any other button than the Stop

Clear one on the Console Panel.

Procedure:

1. Enter Diagnostic (C/E) Mode.

2. Enter Chain Code “2” and press the Start

button.

3. Enter Function Code “1” and press the Start

button.

4. Set any other button than the Stop Clear

one to ON/OFF, then + 2 is added to the

displayed value.

5. When you press the Stop Clear button once

during the check, the Function Code Entry

awaiting status is initiated, while you press it

twice, the Chain Code Entry awaiting status

is initiated.

Page 14

2.2 Diagnostic(C/E) Mode

2.2.4 Diagnostic Functions & Operating procedures

Input Check

CHAIN

FUNCTION

CODE

CODE

1 1 Front Interlock Switch H/L 1

2 RH Upper Interlock Switch H/L 5

2 1 Console Button +1 2

3 10 Option Set H/L 2

11 Option Start H/L 2

12 Option Stop H/L 2

6 1 Lens Sensor H/L 3

2 Optical Regi Sensor H/L 3

8 Exposure Monitor Sign al A/D 3

17 Fuser Thermistor A/D 7

18

7 1 Tray 1 Size Sensor H/L 5

6 Tray 1 No Paper Sensor H/L 5

10 MSI No Paper Sensor H/L 5

8 8 Regi Gate Sensor H/L 5

9 Fuser Exit Switch H/L 7

10 MSI Size Sensor H/L 5

9 9 Toner Empty Sensor H/L 7

PART/SIGNAL

Fuser Thermistor Open

Circuit

DIS-

PLAY

A/D 7

REF.

BSD

2-5 2.2 Diagnostic(C/E) Mode

Section 2 Troubleshooting

Page 15

2-6

Output Check

Function:

This operates parts such as the Solenoid, the

Clutch and the Motor. You can set parts within

the same Chain to the ON positions

simultaneously.

Procedure:

1. Enter Diagnostic(C/E) Mode.

2. Enter the Chain Code for a part to be

operated. Press the Start button.

3. Enter the Function Code and press the Start

button.

• The designated part starts operating.

4. When you operate parts simultaneously,

enter the Function Codes for the parts you

will operate successively. Press the Start

button.

5. When you stop operating a part

simultaneously, press the Stop Clear

button.

• When parts are operating, stop them

simultaneously.

• The following parts stop automatically after

respective specified periods of time:

• All Solenoids/Clutches ..... 1 sec.

• Lamp Carriage Motor ....... 1 sec.

• Exposure Lamp ................ 30 sec.

REF.: When you press the Start button

again after the above parts stop

automatically, they start operating

again.

Section 2 Troubleshooting

2.2 Diagnostic(C/E) Mode

Page 16

Output Check

CHAIN FUNCTION PART/SIGNAL

4 1 Main Motor(& Erase Lamp) 2,7

6 3 Lamp Carriage Motor(Scan) 1sec 3

4 Lamp Carri age Motor(Return) 1sec 3

7 Exposure Lamp(& Erase Lamp) 30sec 2,3,7

8 1 Main Motor (& Erase Lamp) 2,7

2 Tray 1 Feed Solenoid 5

6 Regi Gate Solenoid 5

7 MSI Feed Clutch 5

9 1 Main Motor (& Erase Lamp) 2,7

2 DEVE Bias 7

3ISIL 7

10 1 Optical Cooling Fan Motor 3

4 Fuser fan Motor 7

ON

TIME

REF.

BSD

2-7 2.2 Diagnostic(C/E) Mode

Section 2 Troubleshooting

Page 17

2-8

Section 2 Troubleshooting

2.2 Diagnostic(C/E) Mode

Parameter (NVM Value) Adjustment

Function:

This performs the Parameter (NVM Value)

Adjustment.

Procedure:

1. Enter Diagnostic(C/E) Mode.

2. Enter Chain Code “20” and press the Start

button.

3. Enter the Function Code for the parameter

to be adjusted. Press the Start button.

• The current value is displayed flashing on

the Quantity Display.

4. Enter a new set value with the key pad and

press the Start button.

• The flashing display comes to remain on.

Then the old set value has been changed

to the new one.

5. When you press the Stop Clear button

once,

the Function Code Entry awaiting status is

initiated, while you press it twice, the Chain

Code Entry awaiting status is initiated.

NVM Initialization (20-96)

Function:

This initializes all NVM contents.

Procedure:

1. Enter Diagnostic(C/E) Mode.

2. Enter Chain Code “20” and Function Code

“96.” Press the Start button.

• The Quantity is displayed as follows:

“55” →→ “Ed”

• Initialize the following NVM items:

1) Set initial values in all Functions in

Chain 20.

2) Reset alI Counters in Chains 30/40.

3) Set set-values in all Functions in Chain

50.

4) Set initial values in all programs in

Specification Setup.

3. To exit this mode, press the Stop Clear

button twice.

Page 18

Chain Code 20 Table

CHAIN

CODE

FUNCTION

CODE

20 1 Registration Adjustment 16(-4.13mm) 32 64(+4.13mm) 0.2564mm

2 Light Quantity Adj. 100% 0 30 80 0.8%

Enlargement/Reduction 0 50 99 0.8%

3 Paper Loop Amount Adjustment 0(-8.27mm) 32 64(+8.27mm) 0.2584mm

4 ISIL Lead Edge Erase Amount Adjustment 0(-8.27mm) 32 64(+8.27mm) 0.2584mm

5 ISIL Trail Edge Erase Amount Adjustment 0(-8.27mm) 32 64(+8.27mm) 0.2584mm

6 Fine Tuning of 100% Horizontal Magnification 0(-2.272%) 32 64(+2.272%) 0.071%

7 Fine Tuning of 100% Vertical Magnification 0(-3.16%) 32 64(+3.16%) 0.099%

10 MSI Paper Loop Amount Adjustment 0(-8.27mm) 32 64(+8.27mm) 0.2584mm 11 Registration Adjustment (MSI) 16(-4.13mm) 32 64(+4.13mm) 0.2564mm

14 Selection of Exposure Photoreceptor Sensitivity Correction 0(OFF) 1(ON) 1(ON) 16 Bias Curve Selection 1 0 4 8 17 Bias Curve Selection 2 0(slot) 1(Flat) 1(Flat) 20 Exposure Lamp Adj. 0 50 99

23 Drum Photoreceptor Sensitivity Correction Constant 0(0) 11(1.1) 40(4.0) 0.1 30 Fuser Temperature Adjustment (Stand-by)

31 Fuser Temp. Adjustment (Copy cycle)

41 Density Correction Light 6 0(0V) 52(-413V) 64(-500V) -7.8125V 42 Density Correction Dark 6 0(0V) 16(-125V) 64(-500V) -7.8125V 45 Density Correction Photo Light 6 0(0V) 50(-388V) 64(-500V) -7.8125V 46 Density Correction Photo Dark 6 0(0V) 24(-184V) 64(-500V) -7.8125V 96 NVM Initialization This initializes all NVM values.

50 9 Black band Function Time 1 0(-5.168mm) 20(+9.56mm) 64(+5.168mm) 0.2584mm

10 Black band Function Time 2 0(-6.732mm) 64(+10.3mm) 64(+6.732mm) 0.2584mm

SETUP ITEM MIN. VALUE INITIAL VALUE MAX.VALUE 1 STEP CHANGE ADJ

0(-23°C)

0(-23°C)

32

32

39(+5°C) 0.72°C

39(+5°C) 0.72°C

2.7.6

5.1.4-

5.1.4-

5.1.6

5.1.6

4.3.4

4.3.4

5.1.4-

-

-

2-9 2.2 Diagnostic(C/E) Mode

Section 2 Troubleshooting

Page 19

2-10

Section 2 Troubleshooting

2.2 Diagnostic(C/E) Mode

Feed Counter Check/Clearance.

Function:

This displays or clears Feed Cou nt ers for all

trays .

Procedure:

1. Enter Diagnostic(C/E) Mode.

2. Enter Chain Code “30” and press the Start

button.

3. Enter the Function Code for the Feed

Counter to be checked. Press the Start

button.

• The counter value is displayed by the unit

of k on the Quantity Display.

• When not clearing the counter value, go to

Step 5.

4. Enter “0” with the keyboard and press the

Start button.

• The counter value is cleared.

• If you enter any other value than “0, ” “Er”

appears.

5. Pressing the Stop Clear button once will

initiate the Function Code Entry awaiting

status, while pressing it twice will initiate the

Chain Code Entry awaiting status.

REF.: Counter Value is countable within the

range of 0~99k feeds, but uncount abl e

when it exceeds 99k.

CHAIN

CODE

30 1 Tray 1 Feed Counter

FUNCTION

CODE

4 MSI Feed Counter

COMPONENT

COUNTER

JAM Counter Check.

Function:

This counts Original/Paper Jams and display

their counts for every component where they

occur.

Procedure:

1. Enter Diagnostic(C/E) Mode.

2. Enter Chain Code “40” and press the Start

button.

3. Enter the Function Code for the counter to

be checked. Press the Start button.

• The counter value is displayed on the

Quantity Display.

5. To exit this mode, press the Stop Clear

button twice.

NOTE: Counter Value is countable within

the range of 0~99 feeds, but

uncountable when it exceeds 99K .

CHAIN

CODE

40 1 E1 JAM Counter

FUNCTION

Jam Counter Reset.

Function:

This clears Original/Pap er Jam Count ers.

Procedure:

1. Enter Diagnostic(C/E) Mode.

2. Enter Chain Code “40” and press the Start

button.

3. Enter the Function Code for the counter to

be checked. Press the Start button.

4. To exit this mode, press the Stop Clear

button twice.

CODE

2 E3 JAM Counter

5 C1 JAM Counter

10 C9 JAM Counter

21 E1 JAM Counter Reset

22 E3 JAM Counter Reset

25 C1 JAM Counter Reset

30 C9 JAM Counter Reset

COMPONENT COUNTER

Page 20

Individual Mode Setup

Function:

This sets up the execution/ inhibition of certain

functions for individual users.

Procedure:

1. Enter Diagnostic(C/E) Mode.

2. Enter Chain Code “50” and press the Start

button.

3. Enter the Function Code for the mode

(function) to be set up. Press the Start

button.

• The present value appears on the

Quantity Display.

• When not changing the set value, go to

Step 5.

4. Enter a new set value with the key pad and

press the Start button.

• The old set value is rewritten into the new

one.

5. Pressing the Stop Clear button once will

initiate the Function Code Entry awaiting

status, while pressing it twice will initiate the

Chain Code Entry awaiting status.

U4-6 Failure Clearance

Function:

When U4-6(Fuser Over Heat Fail) occurs,

clear U4-6 by executing [50-20] in Diagnostic

(C/E) Mode.

Procedure:

1. Open the Front Interlock and enter

Diagnostic(C/E) Mod e.

NOTE: During the occurrence of U4-6, you

cannot enter Diagnostic (C/E ) Mo de

2. Enter Chain Code “50” and press the Start

3. Enter Function Code “20” and press the

4. Close the Front Interlock.

5. Set the power to OFF/ON.

without opening the Front Interlock.

button.

Start button.

• The Quantity Display displays “Ed”

indicating the clearance is complete.

U8-7 Failure Clearance

Function:

When U8-7(Exposure Lamp mistakenly turns

on) occurs, clear U8-7 by executing [50-21] in.

Diagnostic(C/E) Mod e.

Procedure:

1. Open the Front Interlock and enter

Diagnostic(C/E) Mod e.

2. Enter Chain Code “50” and press the Start

button.

3. Enter Function Code “21” and press the

Start button.

• The Quantity Display displays “Ed”

indicating the clearance is complete.

4. Close the Front Interlock.

5. Set the power to OFF/ON.

CHAIN

CODE

50 1

FUNCTION

CODE

2 Nation Configuration Setup

4

6

7 Fuser Warm Up Function

8 Copy density selection

9

10

20

21

86

SETUP ITEM

Toner Touch Up Function

Black Band Creation

Function

Related Products’ L6

Detection

Black Band Function

Time1

Black Band Function

Time2

Fuser Over Heat Failure

Clearance

Exposure Lamp Failure

Clearance

Machine Administrator

Reset

SET

VALUE

CONTENT EXPLANATION

0 inhibit

*1 execute

0XE

1KX

*2 AP

Execute

0

*1 Execute

2execute

3 inhibit

*0 No

1Yes

*0 Inhibit

1execute

0 13Phase

*1 7Phase

0~40 20

0~40 20

Cancellation

0

Cancellation

1

Cancellation

0

Cancellation

1

- - Set to “1111”.

Only when the new Drum

unit is installed, this sets

up Toner Touch Up

Function at the start of

copying to prevent Talc

Deletion.

This supplements a lack of

exposure light quantity by

the Deve. Bias when it

doesn’t reach its target

value.

Create a black band of

Toner on the Drum to

prevent Talc Deletion.

This temporarily inhibits

the detection of L6 when

changes are made to

specification setups of the

machine with related

products.

At the start of an initial

copy with the power on,

this warms up the Fuser

by rotating the Main Motor

for 20 sec .

In case of KX

In case of AP

U4-6(Fuser Over Heat

Fail) will be cleared.

U8-7(Exposure Lamp

mistakenly turns on) will

be cleared.

NOTE: Set Value with * indicates that the value is its initial one at the execution of [20-96] .

2-11 2.2 Diagnostic(C/E) Mode

Section 2 Troubleshooting

Page 21

2-12

2.3 Level 1 Troubleshooting

2.3.1 Level 1 F.I.P

Section 2 Troubleshooting

2.3 Level1 Troubleshooting

Page 22

2.3.2 Chart of JAM Status Codes

Machine

OFF CHECK

E3-3

E3-6

FUSER EXIT SW

TRA Y 1

E1-1

ON CHECK

JAM

JAM

STA TIC

JAM

E1-2

E1-6

C9-3

REGI GATE SNR

OFF CHECK

JAM

STA TIC

JAM

MSI MISS

FEED JAM

C1-3

C1-2

2-13 2.3 Level 1 Troubleshooting

Section 2 Troubleshooting

Page 23

2-14

2.3.3 Status Code List

Section 2 Troubleshooting

2.3 level 1 Troubleshooting

STATUS

CODE

U1-1 M/C CLOCK FAIL M/C clock fails to input the signal to Main PWB even once for 0.47 sec., while copying

U2-1 LAMP CARRIAGE FAIL-STAND-BY Lamp carriage doesn’t actuate Optical Registration Sensor for 6.5 sec., during stand-by.

U2-2 LAMP CARRIAGE FAIL-POSITION

U2-3 LAMP CARRIAGE FAIL-SCAN Optical Registration sensor isn’t turned on within 0.46 sec., after Lamp Carriage starts scanning.

U2-4 LAMP CARRIAGE FAIL-RETURN Optical Registration sensor isn’t turned on within 2.5 sec., after Lamp Carriage starts scanning.

U3-1 LENS POSITION FAIL

U4-1 FUSER THERMISTOR OPEN FAIL Open or defective circuit of Fuser Thermistor

U4-2 FUSER WARM UP FAIL Fuser Ready is not initiated within 1 min. After the power is on or Front interlock Switch is turned OFF/ON.

U4-3 FUSER OVER HEAT FAIL 1 Heater Rod has been on for 10 sec. or more after Fuser Ready

U4-4 FUSER OVER HEAT FAIL 2 Heater Rod has been on for 20sec. or more after Cycle Down

U4-6 FUSER OVER HEAT SAFETY FAIL

U6-4 NVM FAIL NVM READ/WRITE VERIFY ERROR

U8-1 EXPOSURE CONTROL FAIL Control Mode is not initiated within 0.5 sec., after Exposure Lamp turns on.

U8-2 NO ZERO CROSS FAIL During Fuse Control, no Zero Cross is input for straight 3 sec.

U8-4

U8-5

EXPOSURE VOLTAGE OVER

FAIL

EXPOSURE VOLTAGE UNDER

FAIL

NAME PROBLEM CORRECTIVE ACTION

1: Optical Registration Sensor isn’t turned on within 0.05 sec., after the initial operation

of Lamp Carriage after copying is finished.

2: Optical Registration sensor isn’t turned on within 0.05 sec., after the start of copying.

Lens Sensor isn’t turned on within 3.1 sec., after the initial operation of Lens.

(i.e. Lens starts moving)

Fuser Thermistor has detected 240°C or a higher temperature for straight 0.5sec. or more • Enter Diagnostic(C/E) Mode and execute [5-20]

Exposure Sensor signal voltage level is over 2.9V when Exposure Lamp is on.

Exposure Sensor signal voltage level is under 0.5V at Standard Reflection Plate.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

• Refer to the U-Code F.I.P.

REF.

BSD

2

3

3

3

3

3

5

5

5

5

5

2

3

5

3

3

Page 24

STATUS

CODE

C1-2 TRAY 1 MIS FEED JAM Regi-gate Sensor isn’t turned on within 2.7sec. after paper starts to be fed.

C9-3 MSI MISFEED JAM Regi-gate Sensor isn’t turned on within 2.3 sec. after paper starts to be fed.

E1-1 FUSER EXIT SWITCH ON CHECK JAM Fuser Exit Switch isn’t turned on within 3.7 sec. After Regi-Gate is open.

E1-2 REGI-GATE SENSOR OFF CHECK JAM

E1-6 REGI-GATE SENSOR STATIC JAM Regi-Sensor is on during Power On or Stand-by. (Paper remains)

E3-3 FUSER EXIT SWITCH OFF CHECK JAM

E3-6 FUSER EXIT SWITCH STATIC JAM Fuser Exit Switch is on during Power On or Stand-by. (Paper remains)

E5-1 FRONT INTLK OPEN FAIL Front Cover is open, or Front Interlock Switch is defective.

E6-1 R/H UPPER INTLK OPEN FAIL R/H Upper Cover is open, or R/H Upper Interlock Switch is defective.

J1-1 TONER EMPTY FAIL Number of copies reaches 100 after toner empty sensor sensed toner end condition.

J1-2 TONER LIFE END The counter value of toner unit reaches the default value 7700.

J3-1 DRUM UNIT SET FAIL Drum unit is not set, or is set incorrectly to the machine.

J3-2 Toner Cartridge SET FAIL Toner unit is not set, or is set incorrectly to the machine.

J3-3 Counter SET FAIL Total counter is corrected improperly.

J6-1 DRUM UNIT ID FAIL Drum unit Read/Write is in error.

J6-2 Toner Cartridge ID FAIL Toner unit Read/Write is in error.

J6-3 Counter ID FAIL Total Counter Read/Write is in error.

J7-1 DRUM UNIT LIFE END Copy Value has become 50K (sheets of paper)

J8-1 DRUM UNIT TYPE NO. FAIL Type No. stored in ID of Drum Unit is not the same as that stored in NVM of the Main PWB.

J8-2 Toner Cartridge TYPE NO. FAIL Type No. stored in ID of Toner Unit does not match with that saved in NVM on main PWB.

J8-3 Counter TYPE NO. FAIL Type No. stored in ID of Total Counter does not match with that saved in NVM on main PWB.

J9-1

J9-2

J9-3

DRUM UNIT ID No. FAIL

TONER UNIT ID No. FAIL

TOTAL COUNTER ID No. FAIL

NAME PROBLEM CORRECTIVE ACTION

Regi-Gate Sensor isn’t turned off (remains ON) a preset period of time (which varies with paper

sizes) after Regi-Gate is open.

Fuser Exit isn’t turned off (remains ON) a preset period of time (which varies with paper sizes) after

Fuser Exit Switch is turned on.

Identification No. of Drum Unit is not of Xerox origin.

Identification No. of Toner Unit is not of Xerox origin.

Identification No. of Total Copy Count is not of Xerox origin.

• Refer to the MISFEED JAM.

• Refer to the MISFEED JAM

• Refer to BSD Sheet 5

• Refer to BSD Sheet 5

• Remove the paper

• Check the Regi-Gate sensor circuit.

• Refer to BSD Sheet 5

• Remove the paper

• Check the Fuser Exit Switch circuit.

• Close Front Cover.

• Check the Front Interlock Switch circuit.

• Check R/H Upper Cover.

• Check the R/H Upper Interlock switch circuit.

• Supply toner.

• Check the Toner Empty Sensor circuit.

• Replace the Toner Cartridge.

• Ensure to install the Drum Unit to the machine

• Ensure to install the Toner Unit to the machine

• Ensure to install the Total Copy Count Unit to

• Replace the Drum Unit.

• Replace th e Toner Unit.

• Replace the Total Copy Count Unit.

• Replace the Drum Unit.

• Replace with correct type Drum Unit

• Replace with correct type Toner Unit

• Replace with correct type Total Copy Count

Unit

• Replace with Xerox Drum Unit

• Replace with Xerox Toner Unit

• Replace with Xerox Total Copy Coun t Unit

REF.

BSD

4

4

5

5

4

5

5

4

4

5

5

5

5

5

5

5

5

5

5

5

5

5

5

5

2-15 2.3 Level 1 Troubleshooting

Section 2 Troubleshooting

Page 25

2-16

2.4 Level 2 Troubleshooting

2.4.1 General F.I.P (General F.I.P for Defective Parts)

Section 2 Troubleshooting

2.4 level 2 Troubleshooting

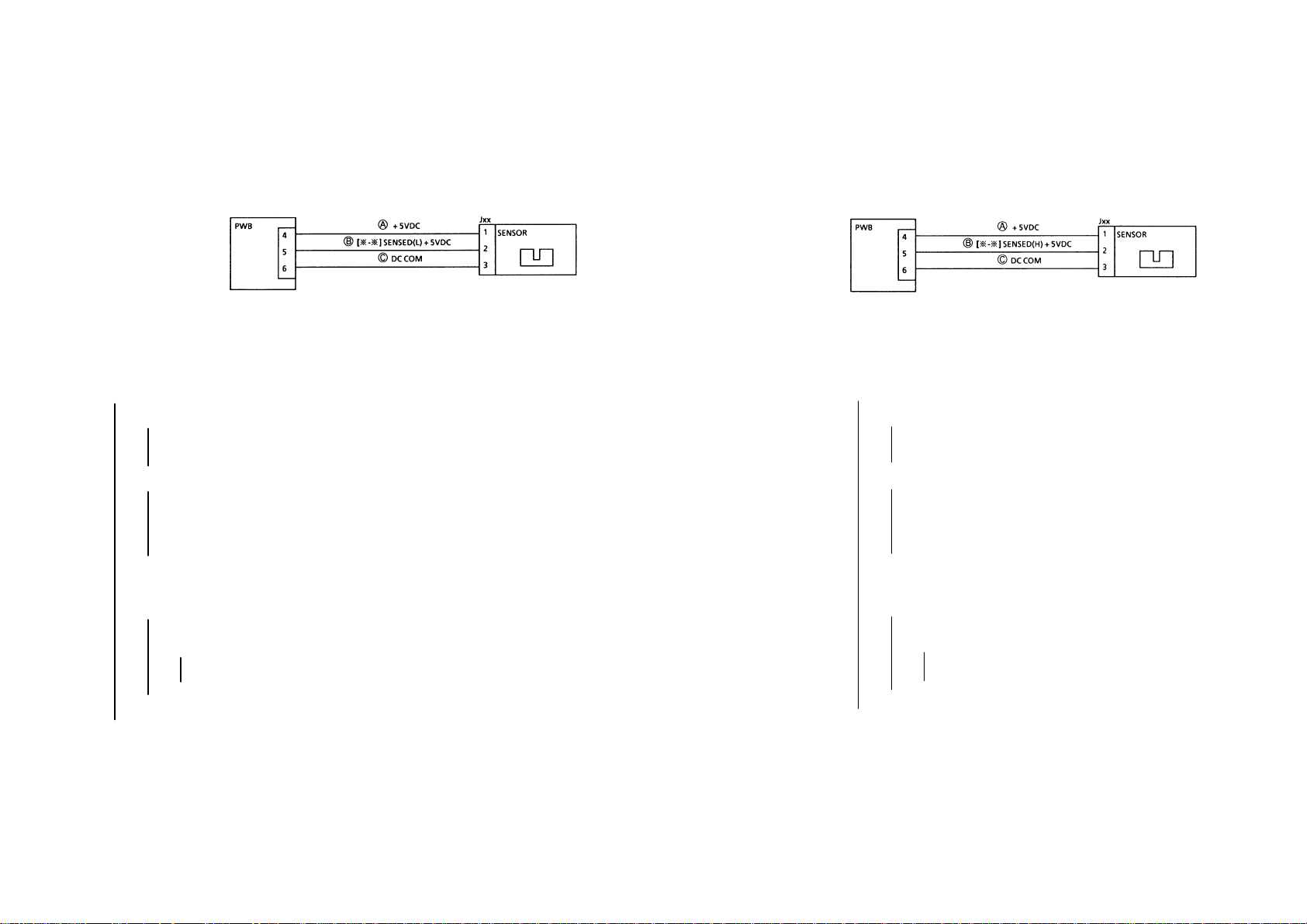

•••• Reflective Sensor F.I.P [SENSED(L)]

ORIGINAL SIZE Sensors 1~4

Preparation: • Remove any remaining paper (if there is any).

Procedure

Enter Diag. [

Make the Sensor turn ON/OFF with a blank sheet of paper.

Does the display repeat (L) and (H) alternately ?

YN

٭ - ٭ ].

Does the display remain (H)?

YN It remains (L).

Check with the tester the harness from Pin 2 of the

Sensor to Pin 5 of PW B for a short circuit. If it is good,

replace the Sensor.

Can the tester lead wire be inserted in Jxx of the Sensor ?

YN

Check Pins 4/5/6 for improper connections or

Harnesses ○

replace the Sensor.

A ○B ○C

for open circuits. If they are good,

٭ You can also check by exchanging the Sensor with

another Sensor of the same type if one is available.

Place the tester wire between Pin 2(+) of the Sensor and

COM(–) .

Make the Sensor turn ON/OFF with blank paper.

Does the voltage repeat (L) and (H) alternately?

YN

Is the voltage from Pin 1(+) to Pin 3 of the Sensor

+5VDC?

YN

Check Pins 4/6 for improper connections or

Harnesses ○

Replace the Sensor.

Check to see if the document detecting position on Platen

Glass is contaminated. If not, replace the PW B.

Check outer light/check the sensor for its installation and (signal)

chattering. If no problem exists, replace the PWB.

A ○C

for open circuits.

••••

•••• Permeable Sensor F.I.P [SENSOR(H)]

OTHER SENSORs with 3

Wiring

Preparation: • Remove any remaining paper (if there is any).

Procedure

Enter Diag. [

Make Actuator turn ON/OFF manually or with paper. (If necessary,

use Output Check.)

YN

٭ – ٭ ].

Does the display remain (H)?

YN It remains (L).

Check with the tester the harness ○

Sensor to Pin 5 of PW B for a short circuit. If it is good,

replace the Sensor.

Can the tester lead wire be inserted in Jxx of the Sensor?

YN

Check Pins 4/5/6 for improper connections or

Harnesses ○

replace the Sensor.

A ○B ○C

for open circuits. If they are good,

B

from Pin 2 of the

٭ You can also check by exchanging the Sensor with

another Sensor of the same type if one is available.

Place the tester wire between Pin 2(+) of the Sensor and

COM(–) .

Make Actuator turn ON/OFF manually or with paper.

Does the voltage repeat (L) and (H) alternately?

YN

Is the voltage from Pin 1(+) to Pin 3 of the Sensor

+ 5VDC?

YN

Check Pins 4/6 for improper connections or

Harnesses ○

Replace the Sensor.

Replace the PWB.

Check the Sensor for its installation and (signal) chattering. If no

problem exists, replace the PWB.

A ○C

for open circuits.

Page 26

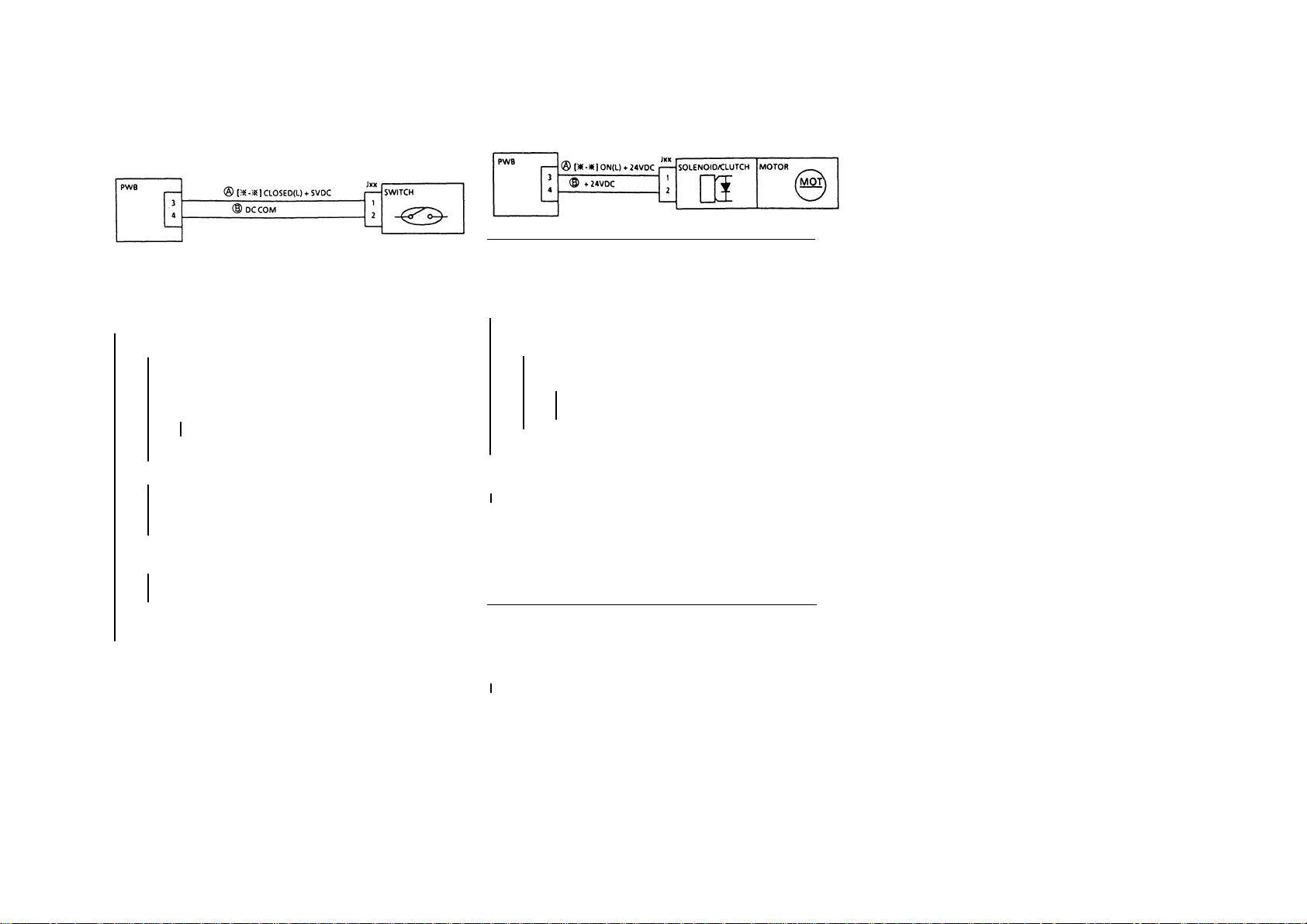

• Switch F.I.P

PLATEN INTLK SWITCH

R/H UPPER INTLK SWITCH

Procedure

Enter Diag. [

Make the Switch turn ON/OFF(Cover open/close). If necessary, use

Output Check.

Does the display repeat (L) and (H) alternately?

YN

٭ - ٭ ].

Does the display remain (H)?

YN It remains (L).

Turn the power off.

Disconnect Connector Jxx of the Switch.

Enter Diag. [

Does the display remain (L)?

YN The display has been changed to(H)

Check shorted areas(i.e. a wire caught in the frame) of

Harness ○

Can the tester lead wire be inserted in Jxx of the Switch?

YN

Check Harnesses A, B for open circuits. If they are

good, replace the S witch.

٭ - ٭ ].

Replace the Switch.

A

and repair them.

٭ You can also check by exchanging the Switch with

another Switch of the same type if one is available.

Is the voltage from Pin 1(+) to COM +5VDC with the Switch

off?

YN(0V)

Check Pin 1 of the Switch or Pin 3 of PWB for an

improper connection or Harness ○

Check Pin 2 of the S witch for an improper connection or

B

Harness ○

Switch.

Check the Panel, etc. for end play or recheck Switch Leads 1/2. If no

problem exists, replace PWB.

for an open wire. If no problem exists, replace the

A

for an open circuit.

• Solenoid/Clutch/Motor F.I.P

1. Solenoid or Clutch doesn’t energize. Motor doesn’t rotate.

Procedure

Enter Diag. [

Don’t start.)

Is the voltage from Pin 3(+) of PWB to COM(–) +24VDC?

YN

Start (or Actuate).

Has Power level dropped to (L)?

YN It remains (H).

Repair the binding Plunger or clear the inside of the Solenoid of

contamination. Don’t clean the Clutch.

If necessary, replace the Solenoid/Clutch/Motor.

2. Solenoid/Clutch keeps energized. Motor keeps rotating.

Procedure

Power off.

Is the resistance value from Connector Pin 3 of PWB to the frame

0~some hundred

YN (~)

Repair shorted areas of the circuit from Connector Pin 3 to Pin 1 of

Solenoid/Clutch/Motor. If no problem(such as a wire caught in the

frame) exists, replace the Solenoid/Clutch/Motor.

٭ - ٭]. (NOTE: All you have to do here is enter Diag.

Is the voltage from Pin 1(+) of Solenoid/Clutch/Motor to GND

(–) +24VDC?

YN

Is the voltage from Pin 2(+) of Solenoid/Clutch/Motor to

GND(–) +24VDC?

YN

Go to 1. STANDBY POWER, BSD to check DC

power(+24VDC).

Replace the Solenoid/Clutch/Motor.

Check the circuit from Pin 3 of PWB to Pin l Solenoid/Clutch/

Motor for an improper connection/open circuit.

Replace the PWB.

Ω?

Replace the PWB.

2-17 2.4 Level 2 Troubleshooting

Section 2 Troubleshooting

Page 27

2-18

Section 2 Troubleshooting

2.4 Level 2 Troubleshooting

• Switch F.I.P

R/H UPPER INTLK SWITCH

Procedure

Enter Diag. [

Make the Switch turn ON/OFF(Cover open/close). If necessary, use

Output Check.

Does the display repeat (L) and (H) alternately?

YN

٭ - ٭ ].

Does the display remain (H)?

YN It remains (L).

Power off.

Disconnect Connector Jxx of the Switch.

Enter Diag. [

Does the display remain (L)?

YN The display has been changed to(H)

Check shorted areas(i.e. a wire caught in the frame) of

Harness ○

Can the tester lead wire be inserted in Jxx of the Switch?

YN

Check Harnesses A B for open circuits. If they are

good, replace the S witch.

٭ - ٭ ].

Replace the Switch.

A

and repair them.

٭ You can also check by exchanging the Switch with

another Switch of the same type if one is available.

Is the voltage from Pin 1(+) to COM +5VDC with the Switch

off?

YN(0V)

Check Pin 1 of the Switch or Pin 3 of PWB for an

improper connection or Harness ○

Check Pin 2 of the S witch for an improper connection or

B

Harness ○

Switch.

Check the Panel, etc. for end play or recheck Switch Leads 1/2. If no

problem exists, replace PWB.

for an open wire. If no problem exists, replace the

A

for an open circuit.

• Solenoid/Clutch/Motor F.I.P

1. Solenoid or Clutch doesn’t energize. Motor doesn’t rotate.

Procedure

Enter Diag. [

Don’t start.)

Is the voltage from Pin 3(+) of PWB to COM(–) +24VDC?

YN

Start (or Actuate).

Has Power level dropped to (L)?

YN It remains (H).

Repair the binding Plunger or clear the inside of the Solenoid of

contamination. Don’t clean the Clutch.

If necessary, replace the Solenoid/Clutch/Motor.

2. Solenoid/Clutch keeps energized. Motor keeps rotating.

Procedure

Power off.

Is the resistance value from Connector Pin 3 of PWB to the frame

0~some hundred

YN (~)

Repair shorted areas of the circuit from Connector Pin 3 to Pin 1 of

Solenoid/Clutch/Motor. If no problem(such as a wire caught in the

frame) exists, replace the Solenoid/Clutch/Motor.

٭ - ٭]. (NOTE: All you have to do here is enter Diag.

Is the voltage from Pin 1(+) of Solenoid/Clutch/Motor to GND

(–) +24VDC?

YN

Is the voltage from Pin 2(+) of Solenoid/Clutch/Motor to

GND(–) +24VDC?

YN

Go to 1. STANDBY POWER, BSD to check DC

power(+24VDC).

Replace the Solenoid/Clutch/Motor.

Check the circuit from Pin 3 of PWB to Pin l Solenoid/Clutch/

Motor for an improper connection/open circuit.

Replace the PWB.

Ω?

Replace the PWB.

Page 28

2.4 Level 2 Troubleshooting

2.4.2 U-Code F.I.P’s

U1-1 M/C CLOCK FAIL

Ref. BSD: 2

Preparation: Ensure that the following connector is securely

Open the Front Cover and cheat the Front Interlock. Enter Diag.

(C/E) Mode. Enter Code[4 -1] and rot ate the Main Motor.

Does the Main Motor keep stoppi ng?

YN

Y N

disconnect the power cord.

power cord

connected.

• P/J404 of Main PWB

Procedure

Does the Main Motor stop after rotatin g for 1-2 seconds?

YN

Open the ClamShell and rest art the Main Mo tor .

Do abnormal noises occur or does the Main Motor

rotate irregularly?

WARNING: Pow er off the machi ne an d

Check the mechanics (Gear, Bearing, etc.) of

the following and replace parts if necessary.

Fuser Assy(PL8.4)

Regi. Roller Gear(PL2.7)

Slide out the Drum Unit and restart the Main Motor.

Do abnormal noises occur or does the Main Motor

rotate irregularly?

YN

Check the Drum Unit for its drive mechanics. If

any load or abnormal noise exists, replace the

Drum Unit.

WARNING: Power off the machine an d disco nn ect the

Check the mechanics(Gear, Bearing, etc.) of the

following and replace parts if necessary.

Deve Assy(PL6.2)

Main Drives(PL1.1/1.2/1.3)

AB

A B

Is the voltage from J404-5 of Main PWB to COM +5VDC?

YN

order.

Is the voltage from J404-1of Main PWB to COM +24VDC?

YN

Is the voltage from J404-3 of Main PWB to COM +5VDC?

YN

Is the voltage from J404-6 of Main PWB to COM +5VDC?

YN

Replace the Main Motor .

Replace the Main Motor(PL1.1/1.2)/Main PWB(PL9.1) in

Replace the Main PWB.

Check +24VDC circuit in the DC Wiring Diagram.

Check +5VDC circuit in the DC Wiring Diagram.

Replace the Main PWB.

2-19 2.4 Level 2 Troubleshooting

Section 2 Troubleshooting

Page 29

2-20

Section 2 Troubleshooting

2.4 level 2 Troubleshooting

U2-1 LAMP CARRIAGE FAIL-STAND-BY

U2-2 LAMP CARRIAGE FAIL-POSITION

U2-3 LAMP CARRIAGE FAIL-SCAN

U2-4 LAMP CARRIAGE FAIL-RETURN

REF. BSD: 3

Preparation: Ensure that the following connectors are securely

• Gently move the Lamp Carriage fro and back by

hand, Check it for the mechanical jam.

• Ensure that the following Connectors are securely

connected.

Procedure

Power on, enter Diag. Mode and enter (6-3). Press the start button.

Does the Lamp Carriage scan?

YN

Are voltages from P/J 405-7,P/J 405-8 to COM +24VDC?

Replace the Main PWB.

Enter [6-4] and press the start button.

Does the Lamp Carriage return?

Y N

Replace the Main PW B.

Using the Permeable Sensor F.I.P., General F.I.P. and the wiring

diagram, perform the diagnosis of Optical Regi Sensor. If no problem

exists, replace the Main PWB.

connected.

• P/J404 of Main PWB.

• P/J405 of Lamp Carriage Motor.

• Check the Scan Cable for disengagement, binding,

load, etc.

YN

Check +24VDC INTLK circuit.

Power off and disconnect P/J 605.

Are J605-1 to -3,J605-1 to-4, J605-2 to -5,J605-2 to -6

resistance values approx. 6.3Ω each?

YN

Replace the Lamp Carriage Motor.

U3-1 LENS POSITION FAIL

Ref. BSD: 3

Preparation: Ensure that the following connectors are securely

Procedure

Power on.

Does the Lens Assy move?(Does it perform its initial operation?)

YN

Check +24VDC circuit

Power off and disconnect P/J604.A re J604-1 to - 3,J604-1 to

-5,J604-2 to -4,J604-2 to -6 resistance values approx. 100Ω

each?

Check P405-3,4,5,6 of Main PWB and P604-3,4,5,6 of

Lens Motor for an open circuit or a short circuit to

ground.

If the harness is good, replace the lens Motor.

Replace the main PWB.

Using the Permeable Sensor F.I.P., General F.I.P. and the wiring

diagram, perform the diagnosis of Lens Sensor. If no problem exists,

replace the Main PW B.

connected.

• P/J405 of Main PWB

• Relay Connector P/J604 of Lens Motor

•

Remedy the mechanical jam

Check the Lens Cable for disengagement, binding,

•

load, etc.

Are voltages from P/J 405-1,P/J 405-2 to COM +24VDC?

Y N

YN

Page 30

U4-1 FUSER THERMISTOR OPEN FAIL

Ref. BSD: 7

Preparation: Ensure that the following connectors are securely

Procedure

WARNING: Power off the machine an d disco nn ect the

power cord.

WARNING: Fuser surfaces are hot, allow the fuser to cool down

before attempting service procedure. Fuser lubricant can cause

discomfort to eyes. Do not allow fuser lubricant to touch eyes

Disconnect P/J118.

Measure the resistance from J118-1 to J118-2.

• Fuser is hot: approx. 13k

• Fuser is cool: approx. 236kΩ

Does the resistance value satisf y the above sp ec. ?

YN(∞)

P/J118-2 to P/J410-4. If no problem exists, replace the Fuser

Replace the Main PWB.

connected.

• P/J410 of Main PWB

• P/J118 of Fuser Thermistor

Ω

Check the wire from P/J118-1 to P/J410-3, and the wire from

Thermistor.

U4-2 FUSER WARM UP FAIL

Ref. BSD: 7

Preparation: Ensure that the following connectors are securely

NOTE: This is sometimes displayed when C/E visits the customer

Procedure

WARNING: Power off the machine an d disco nn ect the

power cord.

connected.

• P/J410 of Main PWB

• P/J430/T111/T110 of AC Drive PWB

• P/J 12/13 of Main Heater Rod

• Relay Connector P/J14

and switches the m/c on after the power has been off after the

occurrences of U4-3, U4-4 & U4-6.

Therefore, the diagnosis of Thermostat is first performed.

WARNING: Fuser surfaces are hot, allow the fuser to cool

down before attempting service procedure. Fuser lubricant

can cause discomfort to eyes. Do not allow fuser lubricant to

touch eyes

Remove the Fuser Cover.

Is there continuity between the Fuser Thermostat leads?

Y N(∞)

Press the Manual Reset button of the Fuser Thermostat.

Is there continuity between the Fuser Thermostat leads?

Y N

Disconnect J12/J13 of Heater Rod?

Is there continuity between J12 and J13?

Y N

Remove the Fuser Cover.

Cheat the Front Interlock Swit ch.

Power on.

Does the Main Heater Rod turn on?

Y N

Y N

Replace the Fuser Thermostat. Proceed with the

diagnosis using U4-3/U4-4/U4-6 Over Heat FIPs.

Proceed with the diagnosis using U4-3/U4-4/U4-6 Over Heat

FIPs.

Replace the Heater Rod.

Is the voltage form T110 to T111 of AC Drive PWB 220VAC?

ABC

Is the voltage from P410-11 of Main PWB to COM

+ 24VDC?

YN

Is the voltage from P410-12 of Main PWB to COM

+ 24VDC?

Check 220VAC circuit.

Is the voltage between Relay Connectors P/J14-1 and -2

220VAC?

Y N

Check the wire from P/J14-1 to P/J12.

Check the wire from P/J14-2 to P/J13.

Power off.

Check for the scraped Heat Roll surface, the raised-off Fuser

Thermistor, the deteriorated Heater Rod. If no problem exists, replace

the Fuser Thermistor.

Replace the AC Drive PWB.

YN

Replace the AC Drive PWB.

Check the wire from P/J14-1 to T111 of AC DRIVER.

Check the wire from P/J14-2 to T110 of AC DRIVER.

A B C

2-21 2.4 Level 2 Troubleshooting

Section 2 Troubleshooting

Page 31

2-22

U4-3 FUSER OVER HEAT FAIL 1

U4-4 FUSER OVER HEAT FAIL 2

U4-6 FUSER OVER HEAT SAFETY FAIL

Ref. BSD: 7

NOTE: At the occurrence of U4-6, open the Front Cover, enter

Diagnostic(C/E) Mod e and clea r U4-6 by exe cuting [50-20].

Procedure

Power on. Check the starting signal of Fuser. Does the level between

P/J410-12 to COM remain low(L)?

YN

WARNING: Power off the machine and disconnect the

power cord.

WARNING: Fuser surfaces are hot, allow the fuser to cool

down before attempting service procedure. Fuser lubricant can

cause discomfort to eyes. Do not allow fuser lubricant to touch

eyes

Disconnect P/J14.

Check the circuit continuity from T111 to T110. (AC DRIVER)

Y N

Replace the AC Drive PWB.

Replace the Main PWB.

Check the following harnesses for short circuits.

• from P/J12 to COM.

• from P/J13 to COM.

Section 2 Troubleshooting

2.4 level 2 Troubleshooting

Page 32

U6-4 NVM FAIL

Ref. BSD: 2

Preparation: • Install th e gro und wire.

Procedure

Power OFF/ON.

Has the display of Status Code disappeared?

YN

Enter Diag.(C/E) Mode.

• Ensure that the power voltage hasn’t dropped 10%

or more (with Power ON or Power OFF).

• Ensure that there is neither operating power

sources nor devices generating high frequencies

around the installation site.

• Ensure that no high voltage wires such as the Corotron

have burnt out or have leakage.

Enter [20-96] and press the Start button.

Power OFF/ON.

Has the display of Status Code disappeared?

YN

Replace the Main PWB.

Make copies. Confirm that the machine operates properly and

monitor the machine operation for several days.

If the problem reoccurs, replace the Main PWB.

2-23 2.3 Level 1 Troubleshooting

Section 2 Troubleshooting

Page 33

2-24

Section 2 Troubleshooting

2.4 level 2 Troubleshooting

U8-1 EXPOSURE CONTROL FAIL

Ref. BSD: 3

Problem Area: Initial Light Quantity Control(Optics)

Cause/Corrective Action

• Defective Main PWB

• Defective AC Drive PWB

• Open harnesses or improper P/J connections of the circuits

controlling the above PWB’s.

U8-2 NO ZERO CROSS FAIL

Ref. BSD: 7

Preparation: Ensure that P/J410 of Main PWB is securely

WARNING: Hazardous voltage. Use extreme care.

Procedure

Power on. Detect the zero cross signal.

Is the level from P/J410-9 to COM +0.5VDC?

connected to P/J430 of AC Drive PWB.

Y N

Is the voltage from P/J437-1 to P/J437-2 220VAC?

Y N

Check 220VAC input circuit.

Is the Front INTLK switch close?

Is the voltage from J431 to COM +24VDC?

Y N

Check the trouble chain E5.

Check the start signal of the INTLK Power Relay.

Is the level from P/J410-11 to com 0v?

Y N

Replace the Main PWB.

Check the wire from P/J430-4 of AC DRIVER to P/J410-11 of

Main PWB for an open circuit, short circuit or improper

connection. If no problem exists, replace the Main PWB

Replace the Main PWB.

U8-4 EXPOSURE VOLTAGE OVER FAIL

Ref. BSD: 3

Problem Area: Light Quantity/Voltage Control(Optics)

Procedure

check the wire from P/J430-1 of AC DRIVER to P/J410-10 of Main

PWB.

Power on. Detect the Exposure Sensor Signal level.

Is the level from P/J410-10 to COM over 2.9VDC?

Y N

Replace Main PWB.

Replace AC DRIVER.

U8-5 EXPOSURE LIGHT QTY/VOLTAGE UNDER FAIL

Ref. BSD: 3

Problem Area: Light Quantity/Voltage Control(Optics)

Preparation: Ensure that P/J410-10 of Main PWB is securely

connected to P/J430-1 of AC Drive PWB.

Procedure

Enter Diag. Mode. Enter [6-7],[6-8].

Check the A/D value, A5-A7.

Is the voltage from P/J430-1 to COM ≤ 0.5V?

Y N

Replace the Main PWB.

Replace the AC DRIVER.

Page 34

2.4.3 MISFEED JAM

C1-3 TRAY 1 MISFEED JAM

Preparation:

• Ensure that no paper jam occurred.

• Ensure that the Feed Roller has not worn out and the friction is

proper.

Procedure

Clear paper jam, start copying.

Does the Feed Roller rotate?

Y N

Enter Diag. (C/E) Mode. Enter [8-2], and check the operation

of Feed Solenoid.

Y N

Check the start signal of Feed Solenoid. Does the

voltage from P/J406-10 to com go high correctly?

Y N

Replace the Main PWB

Remedy the mechanical jam, then check the

operation of Solenoid. If it cannot turn on, replace it.

Check the tension of the pick up gear spring. If the tension is

weak, replace the spring.

Clean the Feed Roller and the Pinch Roller, Check them for the

deterioration.

Y N

Did the lead edge of paper reach the Regi-Gate.

Y N

Replace the Feed Roller, Clean the paper path.

Check the Regi-Gate sensor. Enter [8-8], check the level from

P/J407-8 to com, does it go high(H) and go low(L)? If no

change is the voltage from P/J600-1 to P/J600-3 +5VDC?

Y N

Check the +5VDC circuit.

Replace the Regi-Gate Sensor.

• Replace the Feed Roller.

• Clean the paper path.

C9-3 MSI MISFEED JAM

Procedure:

Start the copying in by in by pass Mode.

Does the MSI feed Roller operate?

Y N

Does the MSI Solenoid operate?

Y N

Enter Diag. Mode, Enter [8-7], does MIS Solenoid

turn on?

Y N

Replace the Main PWB.

Check the wire from P406-2 to P/J210-2.

Remedy mechanical trouble. Check the operation of

Solenoid again. If it does not turn on , replace it.

Replace the pick up Gear Spring.

• Clean MSI Feed Roller and paper path.

• If necessary, replace MSI Feed Roll er, or adjust / replace the Retard

Pad.

2-25 2.4 Level 2 Troubleshooting

Section 2 Troubleshooting

Page 35

Section 4 Disassembly/Assembly / Adjustment

Page 36

Section 4 Disassembly/ Assembly/

Adjustment

1. Main Drive

1.1.1 Main Motor Replacement ………..…………… 4-3

2. Paper Handling

2.1.1 Side Registration Adjustment ……………..…… 4-3

2.2.1 MSI Feeder Assy Removal/Installation ……….. 4-4

2.2.2 MSI Retard Pad Replacement ...............…....... 4-4

2.3.2 MSI Feed Roller Replacement …………………. 4-5

2.3.3 MSI Size Sensor Replacement ………..………. 4-5

2.3.4 MSI No Paper Sensor Replacement ................. 4-5

2.5.1 Feed Roller Replacement ………………………. 4-6

2.5.3 No Paper Sensor Replacement ................……. 4-6

2.5.4 Right Cover Intlk switch Replacement .....…….. 4-8

2.5.5 Tray1 Intlk Switch Replacement…………………4-9

2.5.6 Tray1 Intlk Switch Adjustment...…………………4-9

2.7.1 Registration Assy Removal/Installation ……… 4-10

2.7.2 Registration Gate Solenoid Replacement …... 4-10

Regi-Gate Sensor Replacement .…………. 4-10

2.7.3

2.7.4 Registration Roller Replacement ……………. 4-10

2.7.6 Lead Edge Registration Adjustment …………. 4-11

3. Paper Transport

3.1.1 Vacuum Transport Belt Replacement ……..... 4-12

4. Optics

4.1.1 Plate Glass Replacement ... .....................….... 4-1 3

4.1.2 Optical Cooling Fan Replacement …...………. 4-13

4.2.1 Optical Regi-Sensor Replacement .................. 4-14

4.2.2 Lamp Carriage Motor Replacement ……….. 4-14

4.2.3 Carriage Cable Replacement ………………... 4-15

4.3.1 Full-Rate & Half-Rate Carriages Parallel

Adjustment …………...…………………………. 4-16

4.3.2 Exposure Lamp Replacement ...........….......... 4-18

4.3.3 Optical Skew Adjustment .....................…….... 4 - 1 8

4.3.4 Size-for-Size Fine Tuning ………………...…… 4-19

4.5.3 Lens Cable Replacement ........... ............……. 4-20

4.5.4 Lens Motor Replacement ………………..…… 4-22

5.1.4 Basic Copy Quality Adjustment ………………. 4-24

5.1.5 IS IL Assembly Replacement ………………….. 4-26

5.1.6 ISIL Copy Edge Erase Amount Adjustment ... 4-26

6. Development

6.2.1 Deve. Unit Removal/Installation …………..….. 4-27

6.2.2 Mag. Roll Blade Replacement ……………..… 4-27

6.2.3 Toner Empty Sensor Replacement …..……… 4-27

8. Fuser

8.1.1 Fuser Th e rmostat Replacement ..............….... 4-28

8.1.2 Fuser Thermistor Replacement ………………. 4-28

8.2.1 Heater Rod Replacement ……………...……… 4-29

8.2.2 Heat Roller Replacement ……………………… 4-30

8.2.3 Pressure Roller Replacement …………..……. 4-31

8.2.4 Contact Arc Adjustment ………………………. 4-32

8.3.1 Heat Roller Fingers Replacement …………… 4-33

8.3.2 Pressure Roller Fingers Replacement ………. 4-33

8.5.1 Fuser Fan Motor Assy Replacement ………… 4-34

8.5.2 Ozone Filter (Fuser Fan) Replacement .......... 4-34

9. Electrical

9.1.2 Main PWB Replacement …………………….... 4-35

9.1.3 LVPS Replacement ……………………………. 4-38

9.1.4 AC Drive PWB Replacement ……..………… 4-38

10. Covers L Frame

10.1.1 Front Gas Spring Replacement ……………... 4-39

10.1.2 Rear Gas Spring Replacement ……………… 4-39

10.2.1 Console Assembly Replacement ……………. 4-40

10.2.2 Top Cover Removal/Installation ………………4-40

How to Use the Disassembly/Assembly/Adjustment

Manual

1. Specific removal/installation procedures are not

described for parts for which those procedures are at

first sight understood.

2. Installation procedures refer only to items requiring your

attention.

2. Install parts with their protrusions, if any, fitted into half-

punched dents.

3. Circled numbers such as ➀/➁/➂in each Figure

indicate the order of a procedure and parts applicable.

5. Xerographic

5.1.1 Drum Unit Replacement ……………….……… 4-23

5.1.2 Drum Finger Replacement ……………………. 4-23

5.1.3 Charge Corotron Wire Replacement ………… 4-24

4-1 Contents

Section 4 Disassembly/Assembl y/Adjustment

Page 37

4-2

Section 4 Disassembly/Assembly/Adjustment

Intentional blank page

Page 38

1.1.1 Main Motor Replacement

Removal

1. WARNING: Power off the machine and

disconnect the power cord.

2. Open the Front Cover and the machine.

3. Remove the Drum Unit ……………....... (5.1.1)

4. Remove the Rear Upper Cover.

5. (Fig. 1): Remove the Main Motor.

➀. Disconnect P/J404.

➁. Remove screws (3).

➂. Remove Main Motor

(Fig. 1)

Installation

1. Perform the installation in the reverse order of

the removal.

2.1.1 Side Registration Adjustment

Purpose To adjust the position of the Cassette

Tray to align the document image

transferred onto the Drum with

paper(in the Drum axis direction).

Reference The Tray positions in front/rear

directions are each adjus ta ble b y

2mm (4mm in total) .

Adjustment

1. Slide out the Cassette Tray from the machine.

2. (Fig. 1): Perform the Side Registration

Adjustment as follows.

NOTE: • The Right/Left Stoppers should be

moved by the same distance.

➀. Remove Screws.

➁. Install Screws to slots of both

Stoppers respectively.

➂. Change the positions of Stoppers.

A direction (Front): X will widen.

B direction (Rear): X will narrow.

➃. Tighten Screws.

3. (Fig. 1): After adjustment make a copy-if it is

NOT OK, repeat Steps 1~3.

(Fig. 1)

4-3 1. Main Drive/2. Paper Handling

Section 4 Disassembly/Assembly/Adjustment

Page 39

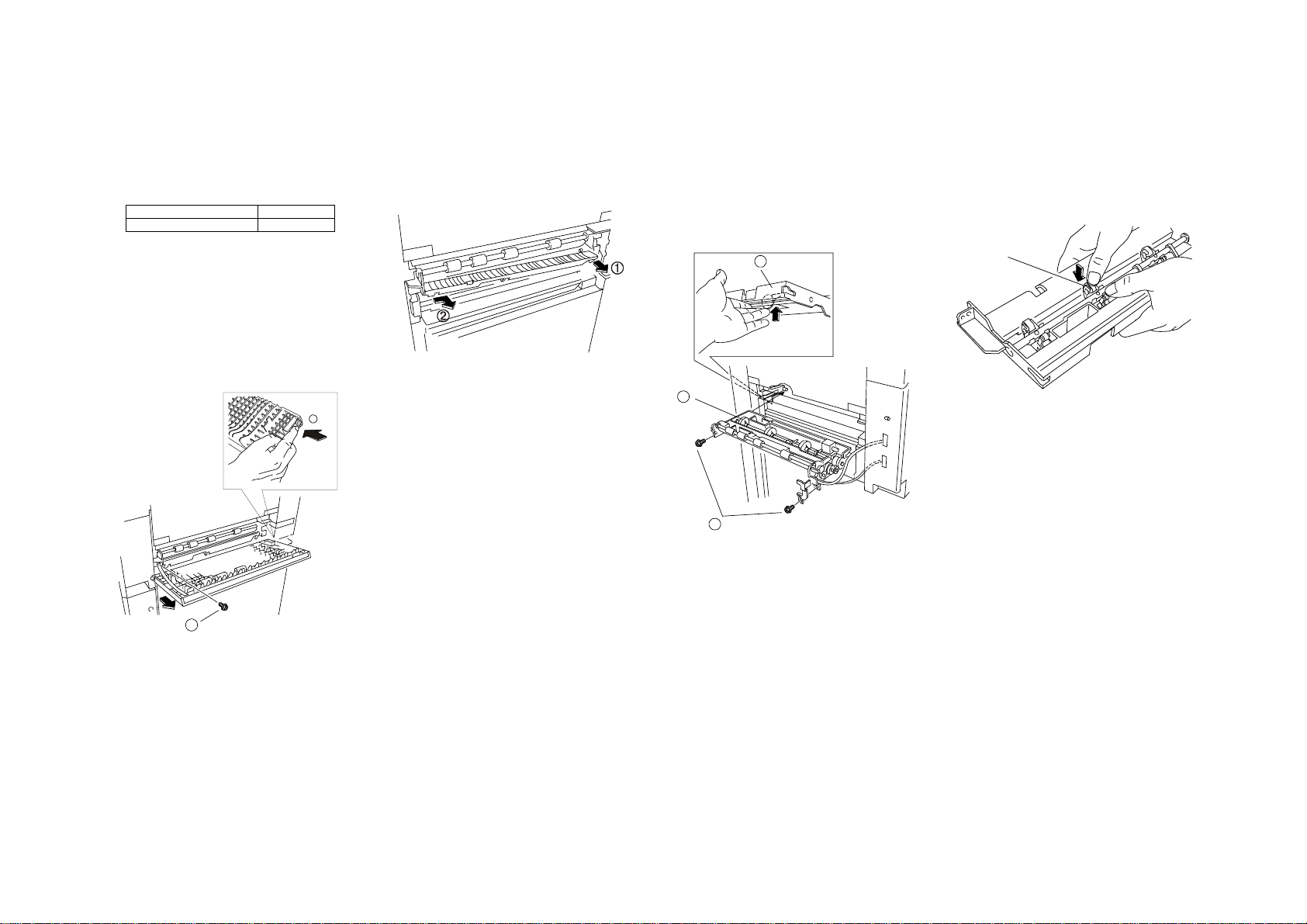

4-4

Section 4 Disassembly/Assembly/Adjustment

2. Paper Handling

2.2.1 MSI Feeder Assy

Removal/Installation

Removal

1. WARNING: Power off the machine and

disconnect the power cord.

2. Open the Rear Upper Cover.

3. Open the Right Upper Cover.

4. (Figs. 1 & 2): Remove the MSI Tray.

➀. Open MSI Tray.

➁. Remove Screw and then open MSI Tray

slide it toward rear and remove it.

12

(Fig. 1)

5. Open the Right Transport Cover.

6. (Fig. 2): Remove the MSI Feeder Assembly.

➀. Disconnect P/J616 and P/J210 .

➁. Remove Screw.

➂. Remove MSI Feeder Assembly.

1

2

(Fig. 2)

Installation

1. Perform the installation in the reverse order of

removal.

3

2.2.2 MSI Retard Pad Replacement

NOTE: • You should replace the Retard Pad, the

Feed Roller(2.3.2).

• You should clear the Feed Counter in

Diag. Mode [30-4].

Removal

1. WARNING: Power off the machine and

disconnect the power cord.

2. Remove the MSI Feeder Assembly ….. (2.2.1)

3. (Fig.1): Remove the Tie Plate Assembly.

➀. Remove Screws (2).

➁. Remove Tie Plate Assembly.

1

(Fig. 1)

4. (Fig. 2): Remove the Retard Pad.

➀. Turn over Tie Plate Assy.

➁. Release locking of the Retard Pad.

==➀

=➁

(Fig. 2)

➂. Remove Retard Pad.

3

(Fig. 3)

Installation

1. Perform the installation in the reverse order of

removal.

Page 40

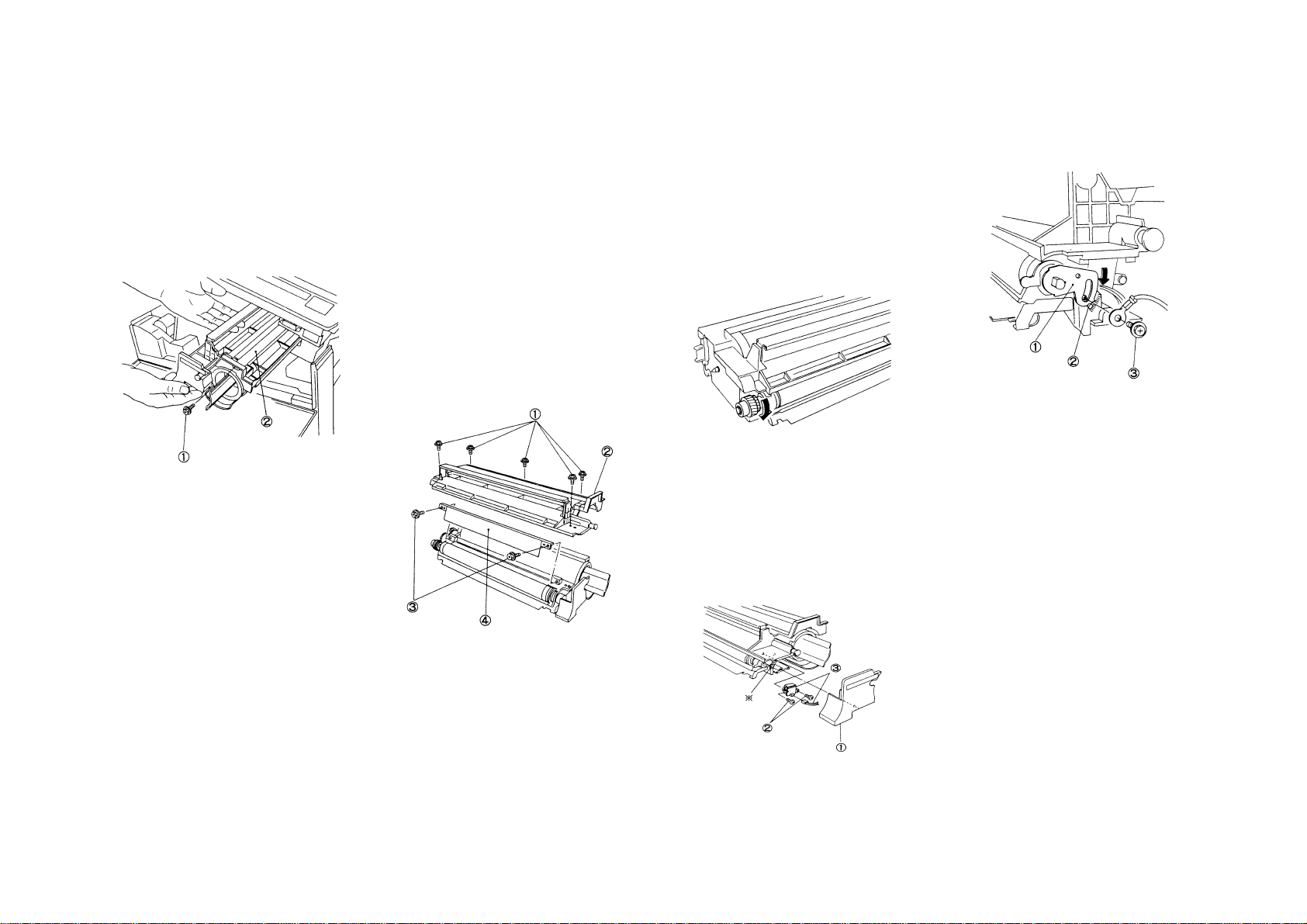

2.3.2 MSI Feed Roller Replacement

NOTE: • You should clear the Feed Counter in

Diag. Mode [30-4] at the time of

replacement.

Removal

1. WARNING: Power off the machine and

disconnect the power cord.

2. Remove the MSI Feeder Assy……….. (2.2.1)

3. (Fig. 1): Remove the MSI Feed Roller.

➀. Remove E Clip.

➁. Remove bearing.

➂. Slide MSI Roll Assy.

➃. Push up hook and then slide Core Roll.

➄. Remove MSI Feed Roller.

2.3.3 MSI Size Sensor Replacement

Removal

1. WARNING: Power off the machi ne an d

disconnect the power cord.

2. Remove the MSI Feeder Assembly ….. (2.2.1)

3. (Fig.1): Remove the MSI Size Sensor.

➀. Disconnect P/J110.

➁. Remove Size Sensor.

➂. Remove Size Sensor Actuator .

1

2.3.4 MSI No Paper Sensor

Replacement

Removal

1. WARNING: Power off the machi ne an d

disconnect the power cord.

2. Remove the MSI Feeder Assembly ….. (2.2.1)

3. (Fig.1): Remove the MSI No Paper Sensor.

➀. Remove Cover.

➁. Disconnect P/J111.

➂. Remove MSI No Paper Sensor.

(Fig. 1)

Installation

1. Perform the installation in the reverse order of

removal.

2

3

(Fig. 1)

Installation

1. Perform the installation in the reverse order of

removal.

2. Perform an Input Check of the MSI Size

Sensor in Diag. Mode[8-10].

=➀

=➁

(Fig. 1)

Installation

1. Perform the installation in the reverse order of

removal.

2. Perform an Input Check of the MSI No Paper

Sensor in Diag. Mode[7-10].

4-5 2. Paper Handling

Section 4 Disassembly/Assembly/Adjustment

Page 41

4-6

Section 4 Disassembly/Assembly/Adjustment

2. Paper Handling

2.5.1 Feed Roller Replacement

2.5.3 No Paper Sensor Replacement

NOTE: • When replacing the Feed Roller, clear

the Feed Counter of the appr opri at e

Tray, using the Diag. Mode applicable:

Content Diag Mode

Tray 1 Feed Counter 30-1

Replacement Procedure Common

to the Above

Removal

1. WARNING: Power off the machine and

disconnect the power cord.

2. Slide out the appropriate Tray.

3. Remove the Transport Cover.

➀. Remove Screw.

➁. Push Transport Cover to rear side.

➂. Remove Transport Cover by sliding away

Pin on its front side.

2

4. (Fig. 2): Remove the Chute.

➀. Remove Chute from Pins by pulling its rear

side.

➁. Slide Chute to rear and remove it.

(Fig. 2)

5. (Fig. 3): Remove the Feeder Assy.

➀. Disconnect P/J610 (Tray 1) and the

Ground wire.

➁. Remove Screws (2). (Wire Guard

disengages together.)

➂. Lift No Paper Sensor Actuator manually.

➃. Remove Feeder Assy.

3

4

2

(Fig.4)

Replacement Procedure

for Feed Roller only

6. (Fig. 5): Remove the Feed Roller.

NOTE: • Do not contaminate the Roller surface

with grease, etc. Clean the

contaminated Roller surface with the

Drum Cleaner.

Feed Roller

(Fig. 5)

1

(Fig. 1)

Page 42

Replacement Procedure

For Pick Up Gear only

6. (Fig. 5): Remove the Pick Up Gear.

➀. Remove the Spring.

➁. Keep pushing the hook of the pick up gear

using the small screw gear.

➂. Remove the pick up gear.

Replacement Procedure

for No Paper Sensor only

6. (Fig. 6): Remove the No Paper Sensor.

➀. Remove No Paper Sensor tab.

➁. Lift Actuator.

➂. Remove No Paper Sensor.

➃. Remove Connector.

Common Procedure

Installation

1. Perform the installation in the reverse order of

removal.

NOTE: • (Fig.7): Install the Feeder Assy to the

machine with the Feed Roller halfmoon shaped facing upwards.

Face up

• (Fig. 8): Install the Feeder Assy to the

machine with the Assy cutouts hooked on

the machine pins.

Cut outs

➂

➀

(Fig. 5)

➁

(Fig. 8)

(Fig.6)

(Fig. 7)

• When installing the Feeder Assembly to

the machine, take great care not to

damage the No Paper Sensor Actuator.

• Reconfirm that the Feed Roller half-moon

shape faces upwards before installing the

appropriate Tray.

NOTE: • After the replacement of the No

Paper Sensor, check the Sensors

using the following Diag Codes.

Sensor Diag. C od e

Tray 1 No Paper Sensor 7-6

Pin

4-7 2. Paper Handling

Section 4 Disassembly/Assembly/Adjustment

Page 43

4-8

2.5.4 Transport Cover INTLK Switch

Replacement

Section 4 Disassembly/Assembly/Adjustment

4. Paper Handling

Removel

1. WARNING: Power off the machine and

disconnect the power cord.

2. Open the Transport Cover.

3. Remove the Transport Cover.

➀. Remove Screw.

➁. Push Transport Cover to rear side.

➂. Remove Transport Cover by sliding away

Pin on its front side.

1

(Fig. 1)

4. (Fig.2)Remove Transport Cover INTLK Switch.