Page 1

Xerox 4050/4090/4450/4650

Laser Printing Systems

Operator Guide

XEROX

April 1995

720P94000

Page 2

Xerox Corporation

701 S. Aviation Boulevard

El Segundo, CA 90245

© 1993, 1994, 1995 by Xerox Corporation. All rights reserved.

Copyright protection claimed includes all forms and matters of

copyrightable material and information now allowed by statutory

or judicial law or hereinafter granted, including without limitation,

material generated from the software programs which are

displayed on the screen, such as icons, screen displays, looks,

etc.

Printed in the United States of America

Publication number: 720P94000

Xerox® and all Xerox products mentioned in this publication are

trademarks of Xerox Corporation. Products and trademarks of

other companies are also acknowledged.

Changes are periodically made to this document. Changes,

technical inaccuracies, and typographic errors will be corrected in

subsequent editions.

This document was created on the Xerox 6085 Professional

Computer System using VP software. The typeface is Optima.

Page 3

Laser safety

Notices

The Xerox 4050/4090/4450/4650 Laser Printing Systems (LPS) are

certified to comply with laser performance standards set by the

U.S. Department of Health, Education, and Welfare and by IEC

825 for non-U.S. markets as a Class 1 laser product. This is a

class of laser products that does not emit hazardous radiation.

This is possible only because the laser beam is inaccessible

during all modes of customer operation.

WARNING: Use of controls or adjustments, or performances

other than specified herein, may result in hazardous radiation

exposure.

Operational safety

Your Xerox equipment and supplies are designed and tested to

meet strict safety requirements. These requirements include

safety agency examination, approval, and compliance with

established environmental standards. Attention to the following

notes ensures the continued safe operation of your equipment.

U.S. only: If you need any additional safety information

concerning the equipment or if you need Xerox-supplied

materials, call the following toll-free number: 1-800-828-6571.

Always:

• Connect equipment to a properly grounded power source

receptacle. If in doubt, have the receptacle checked by a

qualified electrician.

WARNING: Improper connection of the equipment

grounding conductor can result in electrical shock.

• Place equipment on a solid support surface with adequate

strength for the weight of the machine.

• Use materials and supplies designed specifically for your

Xerox equipment.

WARNING: Use of unsuitable materials may result in poor

performance and can possibly create a hazardous condition.

Never:

• Move or relocate the printer or the system controller without

first contacting Xerox for approval.

• Use a ground adaptor plug to connect equipment to a power

resource receptacle that lacks a ground connection terminal.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE iii

Page 4

NOTICES

Ozone information

• Attempt any maintenance function that is not specifically

described in this guide.

• Remove any covers or guards that are fastened with screws.

There are no operator-serviceable areas within these covers.

• Override or “cheat” electrical or mechanical interlock devices.

• Use supplies or cleaning materials for other than their

intended purposes.

• Operate the equipment if unusual noises or odors are

noticed. Disconnect the power cord from the power source

receptacle and call your Xerox service representative to

correct the problem.

This product produces ozone during normal operation. The

ozone produced is dependent on copy volume and is heavier

than air. Providing the proper environmental parameters as

specified in the Xerox installation intructions ensures that

concentration levels meet safe levels.

Radio communication

U.S. only: If you need additional ozone information, request the

Xerox publication, Ozone, by calling Xerox Product Safety at the

following toll-free number: 1-800-828-6571.

This equipment has been tested and found to comply with the

limits for a Class A digital device, pursuant to Part 15 of the FCC

Rules, for U.S. markets, and with the EEC 82/449 standard for

VDE 08791 Class A device, for non-U.S. markets. These limits are

designed to provide reasonable protection against harmful

interference when the equipment is operated in a commercial

environment.

CAUTION: This equipment generates, uses, and can radiate

radio frequency energy and, if not installed and used in

accordance with this guide, may cause harmful interference to

radio communications. Operation of this equipment in a

residental area is likely to cause harmful interference that users

are required to correct at their own expense.

iv XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 5

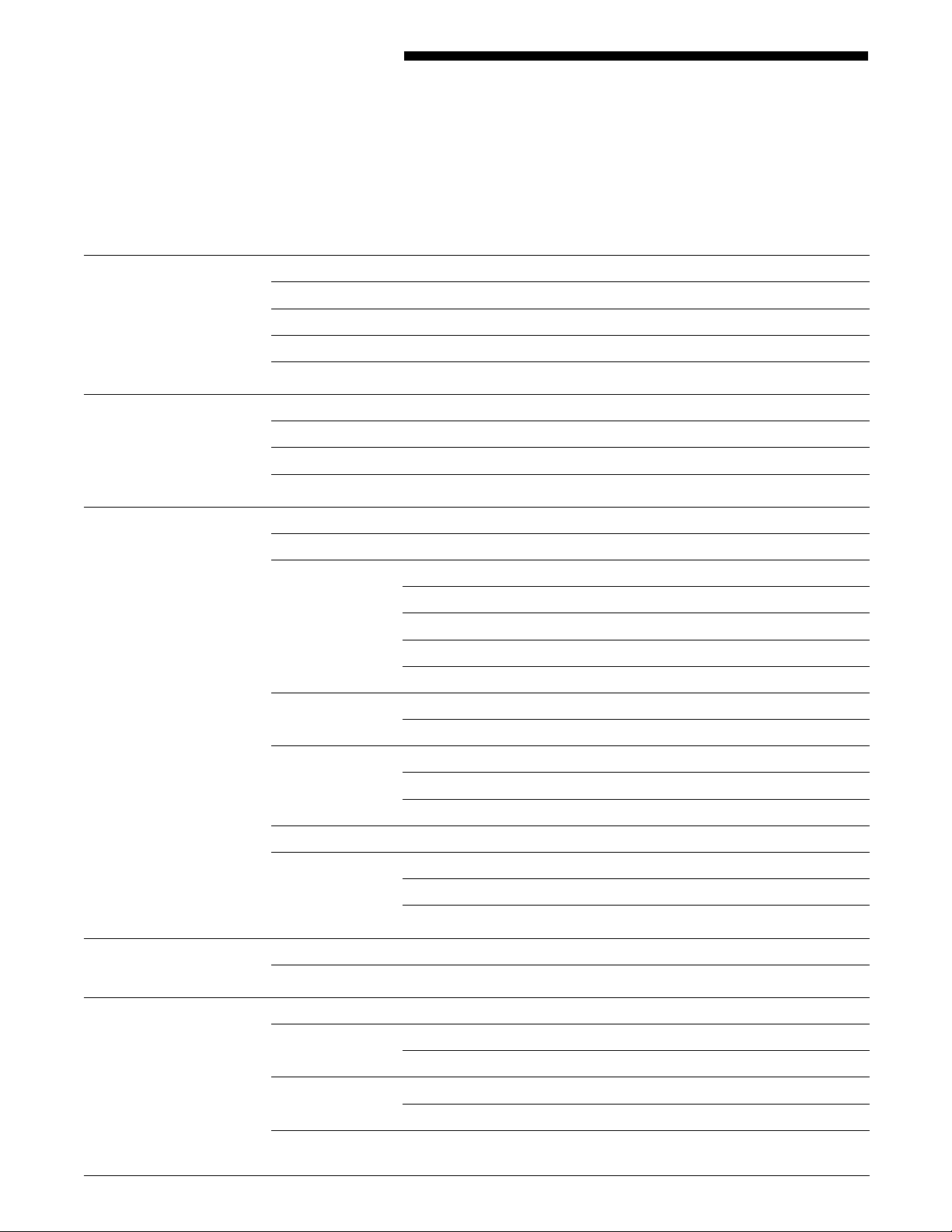

Table of contents

Notices iii

Laser safety iii

Operational safety iii

Ozone information iv

Radio communication iv

Introduction xi

Document conventions xi

Related publications xii

Printing color jobs xiii

1. Overview 1-1

Primary operator tasks 1-1

LPS features 1-2

4050 LPS 1-3

4090 LPS 1-3

4650 LPS 1-3

4450 LPS 1-3

System components 1-4

System controller 1-4

Optional components 1-5

Printer 1-5

System controller options 1-7

Print job sources 1-9

Basic system functions 1-10

Function keys 1-10

Commands 1-11

2. Setting up the LPS 2-1

Powering up the LPS 2-1

3. Setting up print job sources 3-1

9-track magnetic tapes 3-1

Write protection of 9-track magnetic tapes 3-2

18-track cartridge tapes 3-2

Loading an 18-track cartridge tape 3-3

Loading and unloading a floppy diskette from the system controller 3-4

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE v

Page 6

TABLE OF CONTENTS

Using the 9-track magnetic tape drive 3-5

Control panel switches 3-6

Powering on the tape drive 3-9

Loading a 9-track tape 3-9

Placing a tape online to the LPS 3-11

Taking a tape offline from the LPS 3-12

Unloading a tape 3-12

Powering off the tape drive 3-12

Using the 18-track 180 Cartridge Tape System 3-13

Locating CTS components 3-14

Powering on the 180 CTS 3-17

Loading a tape 3-17

Loading a 1/4-inch cartridge tape 3-18

Placing a tape online to the LPS 3-18

Unloading a tape 3-19

Taking a tape offline from the LPS 3-20

Powering off the CTS 3-20

Receiving offline jobs 3-20

Communicating with the channel-attached host 3-21

Placing the LPS online 3-21

Taking the LPS offline 3-21

Communicating through the Shared Disk Interface processor 3-22

Communicating through the host interface processor 3-22

Starting HIP 3-22

Selecting a communication mode 3-22

Changing hosts 3-23

Placing HIP online 3-23

Taking HIP offline 3-24

4. Printing jobs 4-1

Printing task flow overview 4-1

Setting up feeder trays 4-2

Setting up output trays 4-2

Printing samples 4-3

Starting a print job 4-4

Starting an offline or online print job 4-4

Starting a print job through HIP 4-5

Selecting reports within a job 4-6

Printing multiple copies of large jobs 4-6

Checking job and printer status 4-7

Checking printer status 4-7

vi XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 7

TABLE OF CONTENTS

Checking the HIP job queue status 4-8

Checking job status 4-10

Managing print jobs 4-11

Aborting a print job 4-11

Ending a print job 4-12

Interrupting a print job 4-12

What to do when the system stops printing 4-12

Resuming an interrupted print job 4-13

Stopping a HIP print job 4-13

5. Print job maintenance 5-1

Adding dry ink 5-1

Adding stitcher wire 5-3

Adjusting form alignment 5-3

Changing paper size 5-6

Loading feeder trays 5-6

Selecting feeder trays 5-10

Understanding clusters 5-10

Displaying cluster status 5-12

Setting current trays 5-13

Modifying current trays 5-14

Redefining the preferred trays 5-14

Assigning all system trays to a cluster 5-14

Changing the stock in a tray assigned to an active cluster 5-15

Error conditions 5-15

Using the FEED command 5-16

Selecting output trays 5-17

Changing the output tray specification while the job is

printing 5-18

Unloading output trays 5-19

Unloading dual stacker trays 5-19

Unloading the stitcher/stacker tray 5-20

Unloading the sample tray 5-20

6. Printer maintenance 6-1

Adding fuser lubricant 6-1

Cleaning the 9-track magnetic tape drive 6-4

Changing the 1/4-inch cartridge tape drive 6-9

Cleaning the diskette drive 6-10

Cleaning exterior surfaces 6-11

Copying and backing up files 6-11

Copying files 6-11

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE vii

Page 8

TABLE OF CONTENTS

Handling diskettes 6-15

Formatting a diskette 6-16

Replacing the pressure roll wiper 6-17

Setting the time and date 6-24

Time and status display 6-25

7. Shutting down the LPS 7-1

Powering off the system 7-1

Online 7-1

Offline 7-2

8. Solving problems 8-1

Aid to problem solving 8-1

9-track magnetic tape drive on the controller cabinet problems 8-1

Responding to 9-track magnetic tape drive error messages 8-1

Additional diagnostic tests 8-3

Paper jams 8-4

Clearing area 1A 8-6

Clearing area 2A 8-7

Clearing areas 3 through 5 8-7

Clearing areas 6 and 6A 8-10

Clearing area 7 8-11

Clearing areas 8 and 9 8-12

Clearing areas A and B 8-13

Paper misfeeds 8-15

Frequent paper misfeeds 8-16

Stitcher/stacker problems 8-18

Blank display 8-20

Rasterization messages 8-20

Printer fails to respond to the system controller 8-20

System rollover 8-21

System rollover recovery 8-21

Power loss 8-22

Basic recovery procedure 8-22

Recovery in an online system 8-23

Calling for service 8-23

Using the PROBLEM command before placing a service call 8-23

Information to have at hand when calling 8-24

Appendices

A. Paper A-1

B. Meter reading and reporting B-1

viii XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 9

TABLE OF CONTENTS

Glossary GLOSSARY-1

Index INDEX-1

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE ix

Page 10

Page 11

Document conventions

Introduction

The Xerox 4050/4090/4450/4650 Laser Printing Systems Operator

Guide provides step-by-step instructions on operating and caring

for your Xerox 4050/4090/4450/4650 Laser Printing System (LPS).

It is designed as a reference tool to help you with printer setup,

all facets of printing, maintenance, and other general tasks that

are part of an operator's job; therefore, it should be kept near

the printer and readily available.

Refer to the Xerox 4450 Mid-Range Printer Product Reference for

information specific to the 4450 mid-range printer.

This reference is intended for users who have some experience

using Xerox laser printing systems.

This reference uses the following conventions:

BOLD BLUE Uppercase bold blue text indicates required characters, values, or

keywords.

... Ellipses indicate that you can repeat a parameter or option, or list

a series of parameters or options.

bold Bold is used for emphasis. Bolded characters also indicate user

input.

black italics Lowercase black italics are used for variable information.

TERMINAL FONT Terminal or monospace font is used to represent text that

displays on the system screen.

The carat character represents a required space.

UPPERCASE Uppercase letters are used for command names.

Enter The word “enter” indicates that you type the requested user

input, then press the Return key.

CAUTION: Cautions alert you to an action that could damage

hardware or software.

WARNING: Warning alert you to conditions that may affect the

safety of people.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE xi

Page 12

INTRODUCTION

Related publications

You can find additional information related to the Xerox

4050/4090/4450/4650 LPS in the following publications.

Publication Number

Xerox 4050/4090/4450/4650 LPS Master Index 720P94030

Xerox 4050/4090/4450/4650 LPS Product

Reference

Xerox 4050/4090/4450/4650 LPS Bypass

Transport Instructions, V3.5/3.8

Xerox 4050/4090/4450/4650 LPS Bypass

Transport Operator Training Guide Flipcharts

Supplement

Xerox 4050/4090/4450/4650 LPS Bypass

Transport Operator Training Guide

Supplement

Xerox 4050/4090/4450/4650 LPS System

Administration Guide

Xerox 4050/4090/4450/4650 LPS Installation

Planning

Xerox 4050/4090/4450/4650 LPS Operator

Command Summary

Xerox 4050/4090/4450/4650 LPS Command

Reference

Xerox 4050/4090/4450/4650 LPS Operator

Training Guide

Xerox 4050/4090/4450/4650 LPS Operator

Training Guide Flipcharts

720P94060

720P22320

720P22340

720P22330

720P94010

720P92990

720P93050

720P94020

720P22070

720P22080

Xerox 4050/4090/4450/4650 LPS Print

Description Language (PDL) Reference

Xerox 4050/4090/4450/4650 LPS System

Administration Quick Reference Card

Xerox 4050/4090/4450/4650 LPS Forms

Creation Guide

Xerox 4050/4090/4450/4650 LPS Forms

Creation Quick Reference Card

Xerox 4050/4090/4450/4650 LPS Message

Guide

Xerox 4050/4090/4450/4650 LPS Print

Description Language (PDL) Quick Reference

Card

Xerox Dynamic Document Interface

Command Summary

Xerox Dynamic Document Interface

Operator Guide

720P94090

720P93090

720P93990

720P93100

720P93020

720P93090

720P13680

720P13670

xii XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 13

Printing color jobs

INTRODUCTION

If your 4050/4090/4450/4650 LPS runs software version V3.8 or

XDDI, print jobs you create with color commands print in black

and shades of gray. Remember the following when printing

color jobs on your LPS:

• You must recompile forms that use color commands.

• You must print the job you created with color commands to

verify that the colors meet your requirements. Applications

build color sets differently, resulting in color variation on the

LPS. If the print job does not meet your color specifications,

adjust your color command selection, and retry the print job.

• If your color print job calls for a solid color to print on a

black background, the LPS prints the entire job as solid black.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE xiii

Page 14

Page 15

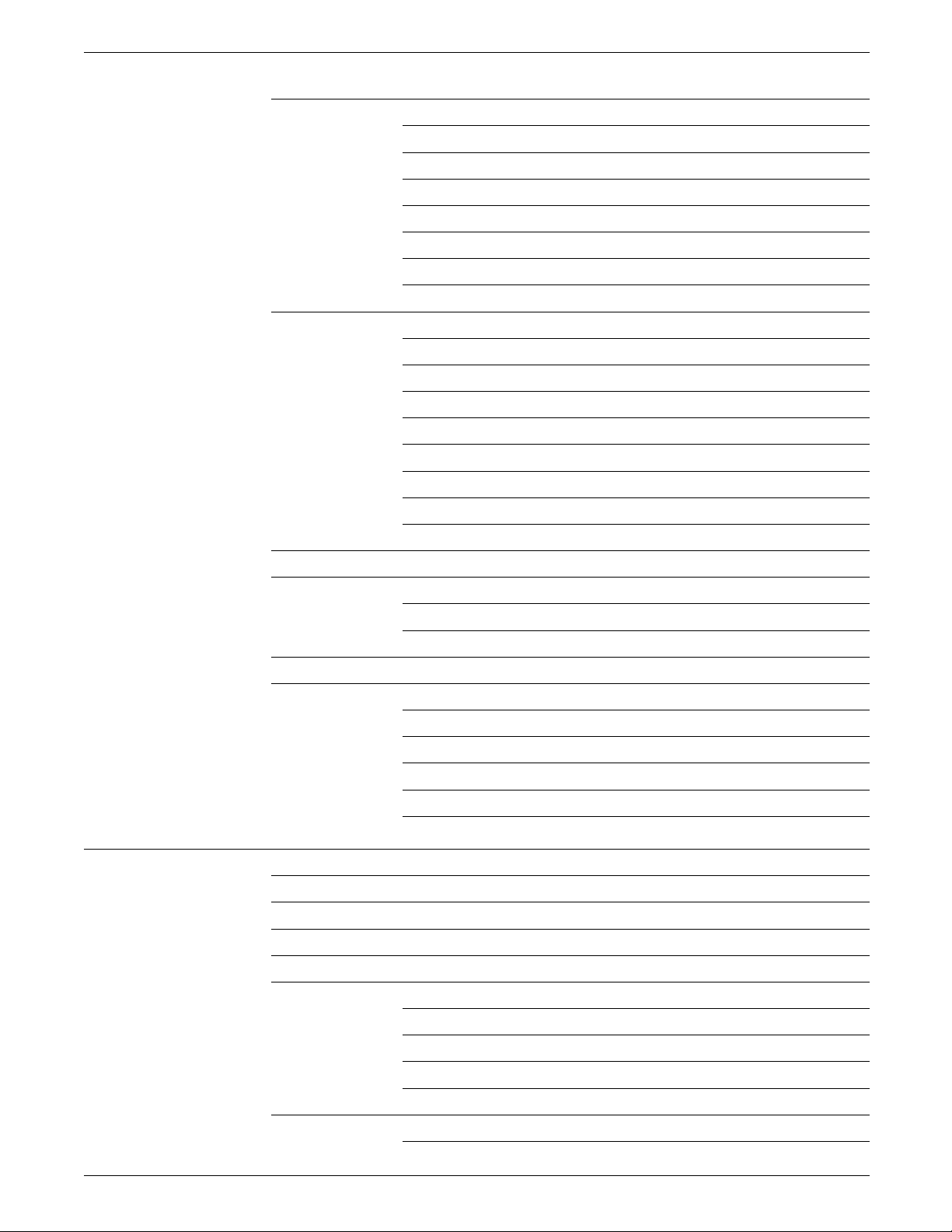

Primary operator tasks

1. Overview

This chapter describes the standard and optional components of

the Xerox 4050/4090/4650 Laser Printing Systems (LPS), as well as

the tasks you will perform in your function as operator.

Table 1-1 provides an overview of the major tasks you perform as

printer operator and describes how these tasks fit into the

process of printing a job on the 4050/4090/4450/4650 LPS.

Table 1-1. Operator task flow overview

Tasks

Set up the system

Set up print job

source

Offline jobs 1. Load the job tape. 3 “Loading a 9-track tape”

Online jobs 1. Establish communication with

Run the print job 1. Set up feeder tray. 4 “Setting up feeder trays”

Procedure

1. Power on the system.

2. Place the appropriate tape

drive online.

the host:

Channel-attached host:

Place the LPS online.

Network environment:

Start HIP.

2. Set up output trays. 4 “Setting up output bins”

3. — Allow the job to be

queued.

Chapter and section

2 “Powering up the LPS”

3 “Loading an 18-track cartridge tape”

3 “Placing a tape online”

3 “Communicating with the channel-

attached host”

3 “Communicating through the host

interface processor”

4 “Managing print jobs”

— Cancel the job.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 1-1

4 “Managing print jobs”

Page 16

OVERVIEW

Table 1-1. Operator task flow overview (continued)

Tasks Procedure

4. Print a sample, if desired:

—Change paper size if

Chapter and section

4

. “Printing samples”

5. “Changing paper size”

necessary.

—Change form alignment if

5. “Adjusting form alignment”

necessary.

5. Start the job. 4. “Starting a print job”

6. Check job and queue status. 4. “Checking job and printer status”

7. Manage print jobs and

4. “Managing print jobs”

queues.

Maintain print jobs • Add paper. 5. “Loading feeder trays”

(perform if requested

• Add dry ink. 5. “Adding dry ink”

by the controller)

• Remove output from the

5. “Unloading output trays”

output bin.

• Add stitcher wire. 5. “Adding stitcher wire”

Maintain the printer

• Various tasks:

6. “Printer maintenance”

—Clean tape and disk drives.

(perform at periodic

intervals)

—Copy and back up files.

—Reset the date and time.

LPS features

The Xerox 4050, 4090, 4450, and 4650 Laser Printing Systems are

versatile, high-performance printing systems. They enable host

mainframe computers and network-connected devices (such as

workstations and graphic scanners) to produce documents

incorporating graphics, forms, logos, signatures, and fonts.

Available fonts range in size from 4 points to 24 points, in all four

orientations (portrait, inverse portrait, landscape, inverse

landscape) and many publishing typefaces to meet your printing

requirements. In addition to the standard set of fonts that is

delivered with the LPS, Xerox Font Services can develop custom

fonts.

With the 4050, 4090, 4450, and 4650, management information

systems and data processing environments have a highperformance printer in which built-in intelligence eliminates the

need for the host computer to store and manage document

resources.

1-2 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 17

4050 LPS

4090 LPS

OVERVIEW

The 4050 prints at a rate of up to 50 pages per minute with a

resolution of 300 dots per inch (dpi). Two 50 MB system disks

come standard on your 4050, with expansion available of up to

200 MB. It has 8 MB of standard font memory, which is

expandable to 16 MB.

Systems with an HPSCSI board and running XDDI software can

support a shared disk, which can send jobs through a front end

host. This feature allows the host to send PostScript, PCL5,

LCDS, and text files at high speed to the printer through an

HPSCSI adapter.

The 4090 prints at a rate of up to 92 pages per minute with a

resolution of 300 dpi. Systems running software version 3.5 have

two standard 170 MB system disks. Two additional 170 MB disks

or 380 MB disks are available, for expansion of up to 1,100 MB.

Systems running software version 3.8 come standard with either

two 170 MB or two 182 MB system disks, with optional

expansion of up to 1,124 MB. Your 4090 has 64 megabits of

font memory, which is expandable to 128 megabits.

4650 LPS

4450 LPS

Systems with an HPSCSI board and running XDDI software can

support a shared disk, which can send jobs through a front end

host. This feature allows the host to send PostScript, PCL5,

LCDS, and text files at high speed to the printer through an

HPSCSI adapter.

The 4650 prints at a rate up to 50 pages per minute with a

resolution of 600 dpi. The 4650 accepts both 300 dpi and 600

dpi jobs. Systems running version 3.5 software come with two

standard 170 MB system disks. Two additional 170 MB disks or

380 MB disks are available, for expansion of up to 1,100 MB.

Systems running software version 3.8 come with either two 170

MB or two 182 MB standard system disks, with optional

expansion of up to 1,124 MB. Your 4090 has 64 megabits of

font memory, which is expandable to 128 megabits.

Refer to the Xerox 4450 Mid-Range Printer Product Reference for

information specific to the 4450 mid-range printer.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 1-3

Page 18

OVERVIEW

System components

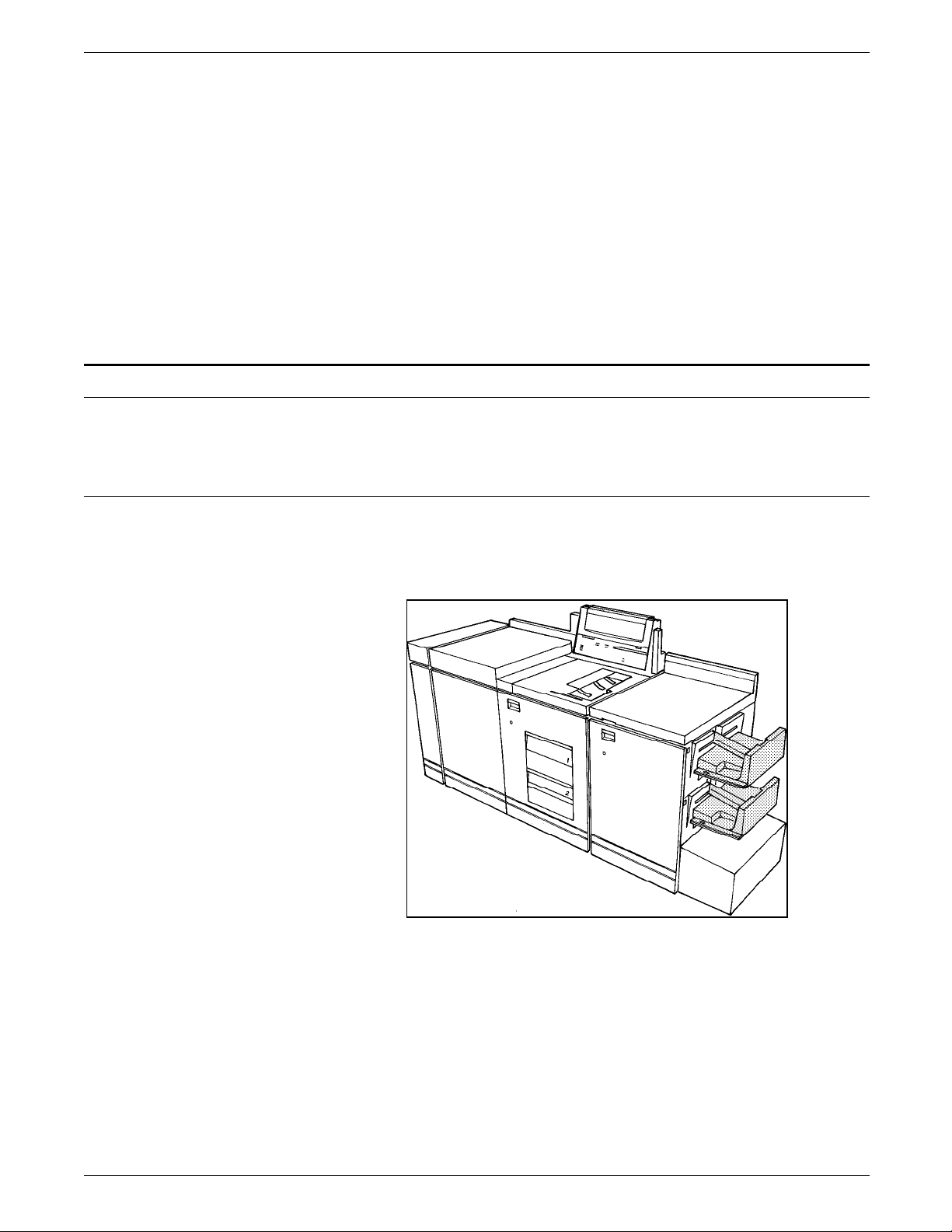

The 4050/4090/4450/4650 LPS consist of two base components

shown in figure 1-1. Your system may also have optional

components. This section helps you identify both the standard

and optional components in your system.

Figure 1-1. LPS base components

System controller

1 System controller

2 Printer

You interact with the system through the components of the

system controller shown in figure 1-2. The system controller also

contains the central processing unit and the system disks.

The configuration of the 4050 LPS system controller is slightly

different than the 4090/4650 system controller. When viewed

from the front, the terminal sits on top of the left side of the

4050 system controller, and on top of the right side of the

4090/4650 system controller. Figure 1-2 shows the 4090/4650

system controller.

Figure 1-2. System controller

1 Terminal

2 System controller panel

3 Diskette drive

1-4 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 19

Optional components

Printer

OVERVIEW

The system controller panel shown in figure 1-3 contains

important controls for operating the printer.

Figure 1-3. System controller panel

There are several hardware options available for your LPS to

increase productivity. This section presents each option.

The printer has two stacker options: the dual stacker shown in

figure 1-4 and the stitcher/stacker shown in figure 1-5.

Figure 1-4. Printer with the dual stacker option

The dual stacker offers a choice of two separate output trays.

The stitcher/stacker offers the ability to staple sets.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 1-5

Page 20

OVERVIEW

Figure 1-5. Printer with the stitcher/stacker option

Both stacker options also provide a sample tray for additional

limited output. The sample tray receives sample prints, rejected

pages, and transparencies.

The printer has two feed trays, shown in figure 1-5. Your LPS

may also have an optional high-capacity feeder, which adds two

feed trays to your system for a total of four feeder trays.

The printer control console shown in figure 1-6 displays

important messages, attention signals, and information about the

setup of your system. The printer control console also contains a

graphic mimic of the system for finding the location of paper

jams.

Figure 1-6. Printer control console

1. Message display

2. Graphic display

3. Information button

4. Print quantity display

5. Stop button

6. Continue button

7. Wire percentage indicator

8. Feeder tray indicators

9. Sample button

10. Power on/off switch

Message display: Shows printer status and simple operating and

maintenance instructions.

1-6 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 21

OVERVIEW

Graphic display: Shows the area of the printer that requires

attention.

Information button: Press this button for information when i is

displayed on the message display. While i continues to display,

you can receive further information by pressing the button.

Print quantity display: Displays the number of prints

completed. Printer fault messages (such as L152) display here as

well.

Stop button: Pressing this button halts printing.

Continue button: Pressing this button resumes printing.

Wire Percentage indicator: Displays the amount of stitcher wire

remaining on the spool (stitcher/stacker output module

configurations only).

Feeder Tray indicators: Indicates the feeder trays selected and

the paper size loaded.

Sample button: Pressing this button causes the printer to

deliver a print sample to the sample tray of the next image

waiting in the queue.

Power on/off switch: This switch is for Service personnel only

for switching the printer module power off and on.

System controller options

This section provides an overview of the optional tape drives

your system may have.

9-track reel-to-reel magnetic tape drive

The 9-track magnetic tape drive can be added to the system

controller as an alternative to online operation. The drive uses 9track 1,600 bits per inch (bpi) phase encoded (PE) and 6,250 bpi

group code recording (GCR) encoded magnetic tapes.

Figure 1-7. 9-track reel-to-reel magnetic tape unit

9-track magnetic tape drive

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 1-7

Page 22

OVERVIEW

18-track cartridge tape system (180 CTS)

The 18-track cartridge tape system (180 CTS) offers alternative or

additional offline capability for inputting print and nonprint data

to the LPS. It reads and writes IBM- and ANSI-compatible 1/2inch/13 mm tape in the 18-track IBM 3480 data format.

Figure 1-8. 18-track cartridge tape system

1 Single transport configuration

2 Dual transport configuration

1/4-inch cartridge tape drive

The 1/4-inch cartridge (QIC) tape drive is also mounted within

the system controller cabinet. This unit provides an alternative

source for loading and backing up user files and loading or

unloading fonts to the system disks.

The capacity of the 1/4-inch cartridge tape drive is either 320 MB

or 525 MB, depending on the choice of DC6320 or DC6525 tape

cartridges. Both tapes are 1/4-inch cartridge ANSI compatible,

and they can be used interchangeably without hardware or

software recognition.

High-capacity feeder

The high-capacity feeder (HCF) is an option that can be added to

your printer. This option increases efficiency and allows you to

use specialized applications. The LPS base configuration includes

two feeder trays (feeder trays 1 and 2). The HCF option provides

two additional feeder trays (feeder trays 3 and 4), increasing the

feeder capacity by approximately 2,000 sheets.

1-8 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 23

Figure 1-9. LPS with high-capacity feeder

1 HCF

2 Feeder tray 3

3 Feeder tray 4

Bypass transport

OVERVIEW

The bypass transport option enables third-party finishing

equipment to connect to your LPS. For more information about

the bypass transport, refer to the Xerox 4050/4090/4450/4650 LPS

Bypass Transport Instructions.

Figure 1-10. Printer with bypass transport

Print job sources

Your LPS can process print jobs from a variety of sources. Print

job sources can be divided into two main categories: online and

offline. Your LPS may have either one or both connection types.

The shared disk option on the 4090/4050 is realized through an

HPSCSI adapter which can be installed inside the system

controller. This adapter allows the printer to receive PostScript,

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 1-9

Page 24

OVERVIEW

Basic system functions

Function keys

PCL5, LCDS, and text format files from the front end adapter at

high speed.

To process online jobs through a network connection or through

a direct channel connection, your system is equipped with an

interface appropriate for the connection. The interface is

mounted inside the system controller cabinet. If you are unsure

of the interfaces installed in your system, consult your system

administrator.

Offline jobs are run from data stored on magnetic tape. You use

one or both of the tape drives discussed previously in this

chapter to process offline jobs with your LPS.

You use special function keys and command syntax to operate

the LPS.

<ALT> Activates the extended (alternate) characters in the green

keyboard. You must hold down the key.

<BACKSPACE> Deletes the character to the left of the cursor.

<CAP LOCK> Makes all characters you enter uppercase (all caps). This key

toggles on and off.

<CLEAR SCREEN> Clears all data from the screen and the display memory. The

cursor returns to column 1, line 1, in the upper-left corner of the

screen.

<CON> Resumes (continues) processing.

<CTRL><E> Deletes the character highlighted by the cursor.

<CTRL><X> Deletes the current line.

<CTRL><Z> Clears all data from the screen and the display memory. The

cursor returns to column 1, line 1, in the upper-left corner of the

screen.

<DELETE> Deletes the character to the left of the cursor.

<ENTER> Executes commands entered at the command line.

<HOME> Moves the cursor to the beginning of the current line.

<JOB STATUS> Displays status information about the print job. There can be a

delay of a few seconds before the status displays.

1-10 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 25

OVERVIEW

<LEFT ARROW> Moves the cursor left one space.

<LINE DELETE> Deletes the current line.

<PRINTER STATUS> Displays printer status information. There can be a delay of a few

seconds before the status displays.

<RIGHT ARROW> Moves the cursor right one space.

<SAMPLE> Sends a sample of the next page to be printed to the sample

tray. Does not interrupt printing.

<SHIFT> Activates the symbols on the upper portion of the numeric keys,

such as punctuation and special characters.

<SPACE BAR> Inserts a space at the cursor position.

<STOP> Halts processing temporarily.

Commands

<TAB> Moves the cursor eight spaces to the right.

You enter commands at the command line of the system

controller. The LPS accepts your commands whenever the

following prompt displays:

READY FOR COMMANDS

For a command to be recognized by the system, you must do

the following:

1. Enter the command in the format specified by the system.

2. Press <ENTER> to execute.

If you make an error entering a command, the system displays

the following message:

OS2710 Invalid command. Re-enter.

1. Verify the command syntax:

— Keyword is correct

— All required parameters are included

— Parameters are correct

— Parameter values are valid

— Commas are in place for all parameters skipped.

2. Enter the command again.

Commands are not case-sensitive. You can enter them using

lowercase, uppercase, or a combination of the two.

The command syntax is made up of the following two elements:

• Keywords

• Parameters.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 1-11

Page 26

OVERVIEW

Keywords

All commands begin with a keyword. This word sends a specific

instruction to the system (for example, SAMPLE).

You can enter keywords in any of the following ways:

• Full spelling (for example, SAMPLE)

• Abbreviation (for example, SAM)

• Three or more characters, up to the full command (for

example, REALLOC for REALLOCATE).

A few commands begin with more than one keyword (for

example, PQA STA). Exceptions to this are I, O, A (for INPUT,

OUTPUT, and ALL) and Q for QUEUE.

Other exceptions to keywords are words for CARTRIDGE and

TAPE. CAR and TAP are reserved and cannot be used as file

names.

Parameters

Most parameters are optional. You use them to refine

commands. For example, the “I” in STOP I specifies input

processing. Likewise, the “O” in STOP O specifies output

processing.

If you use more than one parameter, follow these guidelines:

• Separate each parameter with a comma (for example, PQA

CONTINUE,2,S).

• Do not include spaces around the commas.

• Enter parameters in the order specified for that command.

If you want to omit a parameter, you must enter a comma in its

place (for example, PQA CONTINUE,,S). The default value set

for the omitted parameter is then used.

For more information about commands, refer to the Xerox

4050/4090/4450/4650 LPS Command Reference.

1-12 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 27

Powering up the LPS

2. Setting up the LPS

This chapter describes the procedures for powering up and

logging onto the system.

Follow this procedure to power up the system.

1. Select local or remote control of the system.

Press the Local button on the system controller panel to use

the internal power supply, or press the Remote button to use

a remote power supply. Contact your system administrator if

you are not sure what power supply to use.

2. Press the System Power On button.

Either the Local status indicator or the Remote status

indicator lights show the power supply you selected (refer to

step 1).

The Power On indicator lights.

A cursor appears on the system controller display for about

15 seconds while the system completes its initial diagnostic

tests, then READY $ appears on the display. There may be a

delay of up to 80 seconds before the $ appears.

3. Boot the operating system software.

Your system may be set up to boot automatically after

powering on. This control is set by the system administrator.

In this case, you do not need to boot the operating system

software.

If your system does not boot automatically, enter <B> at

the system controller keyboard.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 2-1

Page 28

SETTING UP THE LPS

When the booting process is complete, the system controller

displays the following messages:

XEROX 4090

LASER PRINTING SYSTEM

Version V4 Revision X.X

Copyright 1991, 1992, 1993,1994 Xerox Corporation. All rights reserved.

Disk ID = system name JAN 3, 1994 15:06:16

When initialization is complete, the system displays the ready

message:

OS1000 READY FOR COMMANDS

4. Log on to the system.

Logging on to security level 1 is automatic. This security

level is usually appropriate for an operator. However, if you

want to enter the SETTIME command, you must log on to

security level 2.

To log on to level 2, enter the LOGON command:

LOGON 2 [,password]

Your system administrator must provide you with the

password for security level 2. For more information about

logging on, refer to the Xerox 4050/4090/4450/4650 LPS

Command Reference.

After powering on, allow four to seven minutes for the

printer to warm up. When the printer is ready, you hear a

tone, and the system displays the following message on the

printer control console:

READY--JOB START WILL BE DELAYED 20-40 SECONDS FOR PRINT

QUALITY ADJUSTMENT

2-2 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 29

3. Setting up print job sources

You can transmit print jobs to the system from one of four

sources:

• From a magnetic tape. This is known as an offline job

source. The system supports 18-track cartridge tape, 9-track

(1600/6250 bpi) 1/2-inch and 1/4-inch cartridge tape, and 9track magnetic tape formats to print offline jobs:

— Mount the tape on the appropriate tape drive. Refer to

the “9-track magnetic tapes” or “18-track cartridge tapes”

section in this chapter.

— Establish communication between that tape drive and the

controller. Refer to the “Receiving offline jobs” section

in this chapter.

• From a channel-attached host computer. This is known as an

online job source. Refer to the “Communicating with the

channel-attached host” section in this chapter.

• From a network connection through the host interface

processor. This is also an online job source. Refer to the

“Communicating through the host interface processor”

section in this chapter.

9-track magnetic tapes

• From a front end host (such as a Sun SPARCstation 10) and

Entire® APPLICATION software using the shared disk option

to print files.

Improper handling of 9-track tapes can cause damage to tapes

and to tape drives, which can result in unreadable data. Observe

the following guidelines when handling 9-track tapes:

• Do not allow dust, dirt, or smoke to come in contact with

the tapes, tape storage area, or tape drives.

• Do not touch the tape beyond the first few feet on the reel.

• Do not place tapes near electric motors or other devices that

generate electromagnetic energy.

• Do not pull on the tape at the end of a reel. Wind tape off

the supply reel by turning the reel at the hub.

• Make sure that the components of a tape drive are clean and

dry before mounting the tape.

• Store tapes vertically in racks in a clean, climate-controlled

environment. If the temperature or humidity of the tape

storage environment differs from the printer environment,

condition tapes for 24 hours in the printer environment

before using them.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-1

Page 30

SETTING UP PRINT JOB SOURCES

Write protection of 9-track magnetic tapes

Write protected 9-track magnetic tapes have a removable writeenable ring that fits into the inside of the reel, as shown in figure

3-1. Removing the write-enable ring prevents the system from

writing data onto the tape. This protects the data on the tape

from accidental erasure.

Figure 3-1. 9-track magnetic tape write protection

In most cases, you do not need to write data to a tape when

running print jobs, so it is not necessary to have the write-enable

ring installed.

18-track cartridge tapes

Improper handling of cartridge tapes can cause damage to tapes

and to tape drives, which can result in unreadable data. Observe

the following guidelines when handling cartridge tapes:

• Inspect each cartridge for obvious damage before inserting it

into the cartridge tape drive.

• Always remove cartridges from the tape drive before

powering off the drive.

• Store cartridges vertically in racks in a clean, climatecontrolled environment. If the temperature or humidity of

the tape storage environment differs from the printer

environment, condition the cartridges for 24 hours in the

printer environment before using them.

• Never attempt to open the cartridge, remove the tape from

the cartridge, or force open the feed slot door.

• Do not expose the cartridges to extreme heat, humidity, or

direct sunlight.

• Do not place tapes near electric motors or other devices that

generate electromagnetic energy.

• Do not attempt to clean a cartridge with anything other than

a dry, lint-free cloth.

• If the leader block comes off a cartridge tape, repair the

cartridge using a leader block repair kit before loading it.

• Do not attempt to insert a cartridge if its label is peeling off.

Peel the old label completely off and replace it with another

label.

3-2 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 31

SETTING UP PRINT JOB SOURCES

• Do not write on a tape cartridge label while it is on the

cartridge. If you want to change a label, write a new label,

remove the old label, and replace it with the new label.

Write protection of cartridge tapes

An 18-track cartridge tape has a thumbwheel on the side of the

cartridge for write protection, as shown in figure 3-2. Write

protection prevents the system from writing data onto the tape.

This protects the data on the tape from accidental erasure.

Figure 3-2. 18-track cartridge tape write protection

To enable write protection (prevent data from being erased), turn

the thumbwheel so that the white dot is showing in the window.

Loading an 18-track cartridge tape

To disable write protection (allow data to be written to the tape),

turn the thumbwheel so that the white dot is not showing in the

window.

In most cases, you do not need to write data to a tape when

running print jobs, so it is safer to enable write protection before

loading tapes.

Follow these steps to load a 18-track cartridge tape:

1. Inspect the cartridge for visible damage.

For more specific information on checking for signs of

damage, refer to the guideline for handling tapes at the

beginning of this section.

CAUTION: Loading a damaged tape can damage the tape

drive and result in data loss.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-3

Page 32

SETTING UP PRINT JOB SOURCES

2. Hold the cartridge with the smooth side on top and the

leader block toward the drive.

3. Insert the cartridge into the entry slot and slide it all the way

into the drive opening until it stops.

CAUTION: When you insert a cartridge, never force it.

Loading and unloading a floppy diskette from the system controller

Follow these steps to load and unload a floppy diskette:

1. Before inserting a floppy diskette into the floppy diskette

drive, make sure the lever is in the open (horizontal)

position. Insert the floppy diskette, label side up, until the

jacket is solidly against the stops. Move the lever clockwise

to the closed (vertical) position.

1 Lever

2 Floppy diskette drive

3 Floppy diskette

3-4 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 33

2. To remove the floppy diskette from the diskette drive, move

the lever counterclockwise to the open position. The floppy

diskette should pop out slightly. Place the diskette in its

protective envelope.

Using the 9-track magnetic tape drive

Another optional 9-track magnetic tape drive resides in a cabinet

on top of the controller. Figure 3-3 shows the basic parts of this

component.

Figure 3-3. 9-track magnetic tape drive components

SETTING UP PRINT JOB SOURCES

1 Control panel

At the upper-left corner are the touch-sensitive switches that

direct the magnetic tape drive. Some tape drive commands

may also be keyed in at the keyboard. Each of these

switches is described in the “Control panel switches” section.

2 Power switch

The main power switch (circuit breaker) is at the upper-right

corner of the tape deck. In the OFF position (the 0 side

pressed), the input AC voltage is removed from the tape

drive power supply. In the ON position (the 1 side pressed),

the transport is powered on by reapplying the input AC

voltage.

3 File reel

The file reel (supply reel) is mounted onto the upper hub.

The tape may be either a job tape or a scratch tape for

diagnostics.

3a Hub latch

3b Hub latch release button

4 Fixed reel

The fixed reel is the one permanently attached to the tape

transport. Sometimes known as the machine reel, it

functions as a take-up reel for the tape supply.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-5

Page 34

SETTING UP PRINT JOB SOURCES

5a and 5b Air bearings

Two air bearing sensor assemblies (upper [b] and lower [a] air

bearings) are used to guide the tape across the magnetic

head on an air cushion and to measure air pressure

reflection. The pressure signal is processed by the control

system, which maintains constant tape velocity and air

pressure by changing the reel motor speed whenever

appropriate.

6 Magnetic head assembly

This assembly consists of a read/write head and an erase

head. The dual-gap read/write head unit is designed to

perform the read/write functions in a 9-track format. It allows

a write-to-tape operation, a read-only operation, or a readafter-write operation. During a write operation, a full-width

erase head erases the tape while it moves forward before the

tape passes over the write head.

7 Erase head

8 BOT/EOT assembly

Located next to the magnetic head assembly, this assembly

optically detects the beginning-of-tape (BOT) and the end-oftape (EOT) markets. Photosensors detect light reflected from

the BOT and EOT markers on the tape so that the tape drive

can recognize starting and stopping areas.

Control panel switches

9 Tape cleaner

The cleaner consists of two blades and a vacuum port to strip

unwanted particles off the tape surface. It is designed so

that the first blade cleans the tape in the forward direction

and the second cleans it in the reverse direction. The

vacuum port removes the unwanted particles from that area.

10 File protect sensor (not shown)

This sensor consists of a reflective ring around the file

(supply) hub and a photosensor next to it that are used to

detect the presence or absence of the write-enable ring on

the file reel.

11 Cover interlock (not shown)

There is an interlock associated with the door latch as a

safety device. The tape unit can be operated only when the

door is closed.

Two types of functions are controlled by the switches on the

control panel: operator and maintenance. Switches to the left

of the two-digit LED display are the operator functions, and

switches to the right of the display are for maintenance

functions. When the magnetic tape drive is online to the printer,

maintenance functions do not work. Figure 3-4 shows the

control panel switches.

3-6 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 35

SETTING UP PRINT JOB SOURCES

Figure 3-4 Control panel switches

• Logic Off switch and indicator

If pressed while the magnetic tape drive is powered on,

logical power (the DC power to the circuit boards) is

removed. The indicator light comes on to signal a standby

power condition.

• Logic On switch and indicator

If pressed while the circuit breaker is on and the magnetic

tape drive is in a standby power condition, the logical power

(the DC power to the circuit boards) is returned to the

magnetic tape drive.

• File protect indicator

The file protect indicator is lit when the write-enable ring in

the magnetic tape reel is absent. When this indicator is on,

data cannot be written to or erased from the tape.

• BOT indicator

The BOT indicator is lit when the tape is positioned at the

BOT marker (a reflective band on the tape indicating the

beginning of data).

• Load/Rewind switch

If the magnetic tape drive is powered on and a tape

threaded, press the Load/Rewind switch to initiate tape

loading. If the tape has already been loaded and threaded,

press the Reset switch and then the Load/Rewind switch to

rewind the tape to the BOT marker.

Note: Following the load or rewind operation, the unit

automatically sets to 25 inches per second (ips) start/stop

mode and positions the tape accordingly. The rewind rate is

75 ips.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-7

Page 36

SETTING UP PRINT JOB SOURCES

• Unload switch

If a tape is loaded, press the Reset switch and then the

Unload switch to unload the tape completely from the fixed

reel and the tape path. If a tape is threaded but not loaded,

pressing the Unload switch causes the tape to slowly unload

to the supply reel.

• On Line switch and indicator

If a tape is loaded, press the On Line switch to place the

magnetic tape drive online to the system controller. The

indicator lights whenever the magnetic tape drive is online.

The magnetic tape drive must be online to the printer to

receive data from magnetic tape or to respond to entered

tape commands.

• Reset switch and indicator

The Reset indicator is lit whenever a magnetic tape drive

error condition occurs or at the completion of a diagnostic

test. Press the Reset switch to take the magnetic tape drive

offline from the printer. Tape motion stops, and error status

is cleared.

You must also press the Reset switch, taking the unit offline

to use other touch-sensitive switches (such as the Unload

and Rewind). Only entered tape control commands are

accepted when the magnetic tape unit is online to the

printer.

Note: Some control faults require a power-off/power-on

sequence to clear. Refer to the Xerox 4850/4890 HighLight

Color LPS Message Guide for additional information.

• High-density indicator

The high-density indicator is lit whenever the magnetic tape

drive is operating in the group code recording (GCR) mode.

GCR refers to the specific density of data as it is recorded on

the tape, which is measured in bits per inch (bpi). The tape

drive operates in 1600 bpi Phase Encoded (PE) or 6250 bpi

(GCR) modes. The default for writing is 1600 bpi. There is

no default for reading because the system checks the speed

and reads it accordingly.

• Two-digit LED display

When in offline diagnostic test mode, the diagnostic test

numbers and results of the microdiagnostic or exerciser

routines display. When the reset indicator lights, a diagnostic

fault code or an online operational failure code displays.

• Diagnostics indicator

The diagnostics indicator is lit when the magnetic tape drive

is in diagnostic test mode.

• Test switch

When the magnetic tape drive is not online, press the test

switch to enter diagnostic test mode. If the magnetic tape

drive is online, there is no response because the

maintenance/diagnostic functions do not operate in the

online mode.

3-8 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 37

SETTING UP PRINT JOB SOURCES

• Step switch

When the magnetic tape drive is in diagnostic test mode,

press the Step switch to advance diagnostic test numbers. If

the magnetic tape drive is online, there is no response

because the maintenance and diagnostic functions do not

operate in the online mode.

• Execute switch

When the magnetic tape drive is in diagnostic test mode,

press the Execute switch to start the diagnostic test indicated

by the numbers in the two-digit display window. If the

magnetic tape drive is online.

• CE switch

This switch aids the service representative with special

diagnostics. If the magnetic tape drive is online, there is no

response because the maintenance/diagnostic functions do

not operate in the online mode.

CAUTION: This switch is used for higher-level diagnostics,

which only a service representative can interpret. Improper

use could cause incorrect status codes and responses, or

information on the magnetic tape could be destroyed.

Powering on the tape drive

Loading a 9-track tape

Follow these steps to power on the tape drive:

1. Open the tape transport door. The power switch is located

in the upper-right corner of the tape deck.

2. Press down the side of the Power switch marked 1.

Follow these steps to load a 9-track tape:

1. Press the large button in the center of the supply hub (the

latch release) to unlock the hub. Place the job tape reel

firmly on the hub, with the read/write ring side (if applicable)

facing away from you.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-9

Page 38

SETTING UP PRINT JOB SOURCES

2. Press the file reel latch until it clicks, to relatch the hub and

lock the reel in place.

3. Carefully unwind about 3 to 4 feet (1 meter) of tape from the

reel. Loosely drape it over the top of the upper air bearing.

Leave some slack between the reel and the air bearing.

CAUTION: When handling the tape, try to touch only the

edges and never handle the tape beyond the BOT reflective

strip. You could damage or destroy data beyond that point.

4. Insert the tape sideways into the slot between the head

covers. Gently guide it beneath the lower air bearing and

drape it over the top of the fixed reel.

CAUTION: Make sure that the tape is correctly positioned

over all tape path components or tape damage may occur.

3-10 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 39

SETTING UP PRINT JOB SOURCES

5. Insert your index finger through one of the holes in the fixed

reel to hold the leading edge of the tape firmly against the

center of the reel. Wind the reel clockwise until the tape

laps over enough of itself to be secured to the reel.

Placing a tape online to the LPS

6. Once the tape is secured, continue to wind the reel in the

clockwise direction to gently take up the remaining slack in

the tape path. The tape is now threaded but not loaded.

7. Close the door to load the tape.

Note: Until you close the door, the cover interlock in its

electrical sensing system continues to disable the command

switches on the operator control panel.

8. Press the Load Rewind switch on the operator control panel.

The BOT indicator lights as soon as the beginning of the tape

is found.

Note: If the tape drive cannot find the BOT within 25 feet

(7.62 meters) in the forward direction, it reverses to search

for it. If the tape drive cannot find the BOT in either

direction, it stops, and an error status code appears in the

two-digit LED display on the operator control panel.

You must now place the tape drive online to the LPS.

Follow these steps to place a tape online:

1. Press the On Line switch to place the unit online to the

system controller. The switch may be pressed while the

loading operation is in progress. When the online indicator

lights, loading is complete. The tape is now threaded and

loaded. You are ready to start jobs.

Note: If the online indicator does not light when you press

the switch, refer to the “9-track magnetic tape drive on the

controller cabinet problems” section of the “Solving

problems” chapter.

2. If your LPS is connected to both a 9-track magnetic tape

drive and an 18-track cartridge tape system, you must tell the

printing system which tape drive you intend to use. You do

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-11

Page 40

SETTING UP PRINT JOB SOURCES

Taking a tape offline from the LPS

Unloading a tape

this by entering MTU 0 or MTU 1. The unit number is

assigned to the tape drive at installation by a service

representative. Check with your service representative or

your system administrator if you are unsure of the number

assigned to your 9-track magnetic tape drive.

CAUTION: To avoid writing on an unprotected tape by mistake,

always enter your tape drive choice before beginning a job.

Press the Reset switch on the control panel to place the unit

offline to the system controller.

A tape may be unloaded either manually or automatically (by a

keyboard command).

Unloading a tape manually

1. Press the Reset switch on the control panel to take the

transport offline from the system controller.

2. Press the Unload switch. The tape rewinds onto the file reel

until the end clears the fixed reel and the tape path.

Tape unloading is performed at low speed. If there is a

considerable amount of tape on the fixed reel and you want

to unload it more quickly, first press the Load Rewind switch

and then the Unload switch.

Note: Pressing only the Load Rewind switch causes the tape

to rewind at the faster rate, but it stops at the BOT marker

instead of completely clearing the tape path.

3. Open the door and press the large button in the center of

the supply hub to unlatch it and release the tape reel.

Remove the reel.

4. Close the door to prevent dust accumulation.

Unloading a tape by using the keyboard commands

When the tape drive is online to the system controller, you can

perform the unload operation through the keyboard. As a safety

precaution, the system ignores the TAPE UNLOAD command

while a job is printing.

1. Enter TAPE UNLOAD. The tape rewinds completely back

onto the supply reel.

2. Remove the file reel by following steps 3 and 4 of the

“Unloading a tape manually” procedure, above.

Powering off the tape drive

Once you have unloaded and removed the tape from the

transport, press down the side of the Power switch marked 0.

(The Power switch is in the upper-right corner of the tape deck.)

3-12 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 41

Using the 18-track 180 Cartridge Tape System

The 18-track 180 Cartridge Tape System (CTS) is an alternative to

the 9-track magnetic tape drive. It also provides additional

offline capability. It reads and writes to IBM- and ANSIcompatible 1/2-inch tape in the 18-track IBM 3480 data format.

Like the 9-track magnetic tape drive, the CTS can be used as a

source for the loading and backing up of non-printing files (such

as forms and fonts) to and from the system disks, as well as

providing an input source for print jobs.

The 18-track CTS uses standard 1/2-inch chromium dioxide

cartridge tapes. Tape loading is fully automatic as soon as the

tape is inserted into the feed slot and the door is closed. The

18-track CTS may be ordered with one or two tape transports. If

only one is ordered initially, a second may be added at a later

date. Figure 3-5 shows both the single and dual transport CTS.

Figure 3-5. 18-track CTS

SETTING UP PRINT JOB SOURCES

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-13

Page 42

SETTING UP PRINT JOB SOURCES

Locating CTS components

Figure 3-6 shows the components of the CTS.

Figure 3-6. Components of the CTS

1 Tape transport

The tape transport is where the tape is processed (read/write

functions) and includes the status and control panel. You

can have one or two tape transports in your cartridge.

2 Power control panel

A description of the switches on the control panel, shown in

figure 3-7, is provided below.

Figure 3-7. Control panel switches

1 Emergency Power Off (EPO) switch

Pressing the EPO switch starts an uncontrolled power down

that can result in lost data and system problems. Once you

press the EPO switch, you must place a service call, because

only a service representative can restore power to the

system.

3-14 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 43

SETTING UP PRINT JOB SOURCES

2 Power on/off switch

Under normal circumstances, the power switch is used to

power the tape system on and off. When you put the power

switch in the off position, you start an orderly power-down

process. When a situation exists that threatens the safety of

an individual or the equipment, you can press the EPO

switch. The green indicator on the upper half of the power

switch lights when the tape drive is powered on.

3 Feed slot

The feed slot is where cartridges are inserted for loading. An

elevator behind it lowers cartridges to their operating

position and raises them again to the feed slot for you to

remove when completed. The door must be closed before

the elevator can work. The Unload button is used to open

this door whenever the transport is neither processing a tape

nor in a ready mode (ready indicator light is not lit). The

tape drive stays cleaner when the feed slot door is kept

closed, whether or not there is a tape loaded.

4 Status and control panel

There is a status and control panel for each tape transport.

Located above the transport, it contains the message

window, three LED message lights, a ready indicator light,

and three tape drive control buttons.

Status and control panel components

Figure 3-8 shows the status and control panel.

Figure 3-8. Status and control panel components

1 Ready indicator light

This indicator lights when you press the Ready button, and

the transport is ready to read and write tapes. While this

light is on, the tape drive ignores the Rewind and Unload

buttons if they are pressed.

2 Ready button

Pressing the Ready button enables the read/write functions of

the tape drive. Pressing it again disables the read/write

functions. If the cartridge tape system is the only magnetic

tape device connected to your LPS, pressing the Ready

button on puts the tape drive online. Pressing the Ready

button again takes it offline. The CTS does not allow you to

use the Unload or Rewind buttons while it is in the ready

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-15

Page 44

SETTING UP PRINT JOB SOURCES

mode. While the tape drive is ready and online to the LPS,

you must enter the TAPE UNLOAD and REWIND commands.

3 Unload button

If a tape is loaded, pressing the Unload button causes the

tape drive to completely rewind the tape into the cartridge

and deliver the cartridge back to the feed slot for removal.

The tape drive ignores the Unload button as long as the drive

is in the ready mode (when the ready light is on).

Alternatively, you can enter the TAPE UNLOAD command

when the tape drive is online to the LPS.

Note: If the feed slot door is closed but no tape is in the

drive, the door opens when you press the Unload button,

regardless of whether or not the ready light is on.

4 Rewind button

If the tape system is powered on and a cartridge is loaded,

pressing the Rewind button rewinds the tape to the BOT

marker. The tape drive ignores this button while it is in the

ready condition (when the ready light is on). Alternatively,

you can enter the TAPE REWIND command when the tape

drive is online to the system.

5 Message window

The 10-character message window is where the transport

displays status messages. Some messages contain 4-digit

status codes that refer to common problems. Others explain

what the tape drive is currently doing; for example,

unloading, rewinding, or cleaning. Figure 3-9 shows what

you see while a cleaning tape is being run.

Figure 3-9. Message window

6 Offline light

When this yellow rectangle is lit and you can see the word

OFFLINE, the transport is offline from the LPS.

7 Operator light

When this red rectangle is lit and you can see the word

OPERATOR, the transport needs operator assistance. A

problem exists that must be handled before the transport can

continue. A message appears in the message window

indicating what to do or providing you with a status message

for your service representative.

3-16 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 45

Powering on the 180 CTS

SETTING UP PRINT JOB SOURCES

8 Select light

When this green rectangle is lit and you can see the word

SELECT, this transport is selected for operation. Once it is

operating, the light blinks on and off as it is receiving

instructions from the controller.

Follow these steps to power on the 180 CTS:

1. Locate the power control panel on the lower-left side of the

font door.

2. Press the Power switch to the ON position by pressing down

on the side marked 1.

The CTS goes through a series of self-tests and initialization.

While it is going through this process, the following message

displays:

*SELFTEST*

Then the following messages display:

DOWNLOAD O, TESTING O, TEST DONE, FUNCTIONAL.

Loading a tape

Note: In the “download” and “testing” messages, the

number may be 0, 1, 2, or 3, depending on how many tape

transports you have. These are the numbers assigned to

each transport by the service representative when your

system is installed. The numbers are used only by the service

representative.

3. When the tape system has completed its initialization or boot

process, a single asterisk (*) appears in the message window.

The transport is now ready for you to load a tape and place

the CTS online to your LPS.

Follow these steps to load a tape:

1. As soon as the asterisk appears in the message window, you

can load a tape. Carefully insert the cartridge into the feed

slot, with the label side up and the latch in the right corner

(away from you).

When you insert the cartridge, the red operator light comes

on, and the following message displays:

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-17

Page 46

SETTING UP PRINT JOB SOURCES

CLOSE DOOR

2. Close the feed slot door by gently pulling down the handle

until the door latches shut.

The operator light goes off, and the following message

displays if the file is unprotected:

READY U

The following message displays if the file is protected:

READY F

Loading a 1/4-inch cartridge tape

Placing a tape online to the LPS

Follow these steps to load a 1/4-inch cartridge tape:

1. Locate the 1/4-inch cartridge tape drive, mounted in the

system controller cabinet next to the floppy disk drive.

2. Press the cover release button.

The tape drive door partially opens.

3. Manually open the door completely.

4. Insert the cartridge (label facing to the left) into the feed slot.

5. Close the tape drive door.

The tape loads automatically.

If the tape has loaded properly, the LED indicator light is

green.

If the LED indicator light is flashing red, the tape has not

loaded properly. Refer to the “Solving problems” chapter, or

see your system administrator.

Follow these steps to place a tape online:

1. If the following message displays, press the Ready button to

enable the read/write mode:

NT READY U or NT READY F

The ready indicator light comes on, and the nt ready

message changes to ready.

If you have only the cartridge tape system for your system,

you are now ready to print jobs. Your system is automatically

online to the LPS as long as the ready indicator light is on.

3-18 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 47

Unloading a tape

SETTING UP PRINT JOB SOURCES

2. If your LPS is connected to both a 9-track magnetic tape

drive and an 18-track cartridge tape system, you must specify

the tape drive. You do this by entering MTU 0 or MTU 1.

The 0 and 1 are assigned to each tape drive at installation by

a service representative. Check with your service

representative or your system administrator if you are not

sure if 0 or 1 was assigned to your 18-track CTS.

Note: This is not necessarily the same number you see in

the message display window of each cartridge tape transport

when the cartridge tape system is powered on and goes

through its testing and downloading routines.

CAUTION: To avoid writing on an unprotected tape by mistake,

always enter your tape drive choice before beginning a job.

Now that your tape drive is loaded and online to the LPS, you

are ready to print jobs.

Follow these steps to unload a tape:

1. When the EOT is reached or a job is completed, the

transport rewinds and unloads the cartridge. The feed slot

door opens automatically. When it does, carefully remove

the cartridge.

To remove a tape at any other time, first press the Ready

button to take the transport out of the read/write mode. The

ready indicator light must be off.

2. Press the Unload button on the transport status and control

panel.

If the tape needs to be rewound before unloading, the

following message displays during that process:

REWINDING

The following message displays for the few seconds required

to return the cartridge to the feed slot and open the door:

UNLOADING

Note: To use the TAPE UNLOAD command from the

keyboard, the tape drive must be online to the LPS.

3. When the feed slot door opens and the cartridge is

unloaded, remove the tape cartridge carefully.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-19

Page 48

SETTING UP PRINT JOB SOURCES

Taking a tape offline from the LPS

Powering off the CTS

Receiving offline jobs

Any time the ready indicator light is off, the CTS is offline from

the LPS.

Press the Ready button once so that the ready indicator light

goes off. The following message displays if a cartridge tape is

still in the drive:

NT READY U or NT READY F

If there is no tape in the drive, a single asterisk (*) appears.

Once you have unloaded and removed the tape cartridge from

the transport, press down the side of the power switch marked

0.

Before printing offline jobs, you must identify the tape drive

where you mounted the tape containing the print job.

If your system is equipped to process offline jobs, you may have

a 9-track magnetic tape drive, a 180 CTS, or your system may

have both. These are your print job sources for offline jobs.

Your system may also be equipped with a 1/4-inch cartridge tape

drive. This is not a source for print jobs.

The system recognizes two keywords for specifying the tape

drive where the job tape is mounted: TAPE and CARTRIDGE.

You must identify the physical tape drive assigned to each of

these keywords. You identify the device using the SUB DEVICE

command. For example, if you are using a cartridge you would

enter a substitute device command, such as SUB DEV SFCTS FOR

TAPE.

The TAPE keyword applies to 9-track magnetic tape drives. Your

system has only one option for a 9-track magnetic tape drive, so

you do not need to identify the physical device for this keyword.

If an open reel tape drive is installed in your system, the TAPE

keyword identifies this device by default.

The CARTRIDGE keyword applies to cartridge tape drives. Your

system has two options for a cartridge tape drive: the 18-track

180 CTS (1/2-inch cartridge tape drive), and the 1/4-inch cartridge

tape drive. The 1/4-inch cartridge tape drive is not a source for

print jobs, but it may be identified for copying and backing up

files.

• If only one of these tape drive options is installed in your

system, you do not need to identify the physical device for

the CARTRIDGE keyword.

• If both cartridge tape drives are installed in your system, you

must identify the drive using the SUB DEVICE command.

3-20 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 49

To identify the 18-track 1/2-inch cartridge tape drive with the

CARTRIDGE keyword, enter the following command:

SUB DEV SFCTS FOR CAR

To identify the 9-track cartridge tape drive and the 1/4-inch

cartridge tape drive with the CARTRIDGE keyword, enter the

following command:

SUB DEV SCTS FOR CAR

The device specification remains in effect until you enter a new

SUB DEVICE command. For more information about the SUB

DEVICE command, refer to the Xerox 4850/4890 HighLight Color

LPS Command Reference.

Communicating with the channel-attached host

A system that is channel attached to a host can receive data from

the host in online mode. Before data can be sent to the printer,

both the printer operator and the host operator must issue

commands to place the LPS online to the host.

All system operations and maintenance tasks can be performed

while the printing system is online. However, you may be asked

to take the system offline for service or other purposes, and to

bring it back online when ready to resume operation.

SETTING UP PRINT JOB SOURCES

Placing the LPS online

Taking the LPS offline

Follow these steps to place the LPS online:

1. Enter ONLINE.

The system responds by displaying:

OS0030 System is “ON-LINE”

OS1000 READY FOR COMMANDS

2. Enter START and begin normal job processing.

Until a START command is entered, the LPS is in an online

but not ready state, and the host does not transmit any data.

3. Request the host operator to vary the system online.

For more information on starting print jobs, refer to the

“Printing jobs” chapter.

Follow these steps to take the system offline:

1. Request the host operator to drain or purge the output from

the host to the LPS, then vary the system offline at the host.

2. Press <JOBS STATUS> to determine if the system is idle.

3. If the job queue is empty, enter OFFLINE, or ENDJOB

followed by OFFLINE.

Entering the ENDJOB command prints any pages remaining

in the print file. Then press <JOBS STATUS> again to verify

that the queue is empty. Enter the OFFLINE command.

XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE 3-21

Page 50

SETTING UP PRINT JOB SOURCES

4. Enter CONTINUE I or press <CON>. The following

message displays:

OS0040 System is “OFF-LINE”

Communicating through the Shared Disk Interface processor

Follow these steps to place the Shared Disk Interface (SDI) online

to the system:

1. Enter SDI to put SDI online and start it.

2. Send the jobs from the front end.

For more information, refer to the Xerox Shared Disk Option

Operator Guide.

Communicating through the host interface processor

The system can communicate with hosts that are not channelattached, in a range of communication environments, or with

other networked devices through the host interface processor

(HIP) software. All you have to know is the interface or mode

you use to communicate with the host or network. A brief

description of each mode is provided in the “Selecting a

communication mode” section later in this chapter. For more

information, refer to the Xerox 4050/4090/4450/4650 LPS

Command Reference.

Starting HIP

Selecting a communication mode

To start HIP, enter HIP.

This is an abbreviated way of entering the commands HIP

ONLINE and HIP START, and is the routine method of starting

the HIP task. After you enter the HIP command, the following

messages display:

HP0010 HOST INTERFACE PROCESSOR loaded

OS1000 READY FOR COMMANDS 15:52:21

HP1210 HOST ONLINE, ACCEPTING ALL JOBS

OS1000 READY FOR COMMANDS 15:52:23.

If the host is not online and not responding, the following

message displays every 15 seconds until the host comes online

or HIP is terminated.

HP1240 HOST NOT RESPONDING

For a complete explanation of all the HIP options available, refer

to the Xerox 4050/4090/4450/4650 LPS Command Reference.

Enter HIP HOST, specifying the communication mode.

HIP HOST {871|DMR|XNS|XPF|XPS}

3-22 XEROX 4050/4090/4450/4650 LPS OPERATOR GUIDE

Page 51

Changing hosts

SETTING UP PRINT JOB SOURCES

When you enter this command, you can specify one of the

following:

• 871—Identifies a host in an SNA/SDLC or BSC environment.

• DMR—Identifies a VAX/VMS host in a DDCMP environment.

• XNS—Identifies a network environment.

• XPF—Identifies an IBM host in an MVS/XA or an MVS/ESA

environment.

• XPS—Identifies Xerox Print Services (XPS) Manager as the

printer front end to other hosts. (This option is available in

XDDI only.)