Page 1

Smart choice for power

SW 2524

SW 2548

Sine Wave Plus

Inverter/Charger

Owner’s Manual

www.xantrex.com

Page 2

Page 3

Sine Wave Plus Inverter/Charger

Owner’s Manual

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells, micro turbines, and backup

power applications in both grid-connected and stand-alone systems. Xantrex products include inverters, battery

chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute

electrical power.

Trademarks

Sine Wave Plus Inverter/Charger is a trademark of Xantrex International. Xantrex is a registered trademark of

Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used

herein for identification purposes only.

Notice of Copyright

Sine Wave Plus Inverter/Charger Owner’s Manual © June 2003 Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Due to continuous quality improvement and product updates, the photographs shown in this manual may not exactly

match the unit purchased.

Date and Revision

June 2003, Revision A

Part Number

976-0043-01-01

Contact Information

Telephone: 1-800-446-6180 (toll free)

Telephone: 1-360-435-8826 (direct)

Fax: 1-360-925-5143

Email: CustomerService@xantrex.com

Web: www.xantrex.com

Page 5

About This Manual

Purpose

The purpose of this Owner’s Manual is to provide explanations and

procedures for installing, operating, maintaining, and troubleshooting the

Sine Wave Plus Inverter/Charger.

Scope

The Manual provides safety guidelines, detailed planning and setup

information, procedures for installing the inverter, as well as information

about operating and troubleshooting the unit. It does not provide details

about particular brands of batteries. You need to consult individual battery

manufacturers for this information.

Audience

The Manual is intended for anyone who needs to install and operate the

Sine Wave Plus Inverter/Charger. Installers should be certified

technicians or electricians.

976-0043-01-01 iii

Page 6

About this Guide

Organization

This guide is organized into nine chapters and nine appendices.

Chapter 1, “Introduction” explains the basic features of the Sine Wave

Plus Inverter/Charger and describes the optional accessories that may or

may not be required for the desired installation configuration.

Chapter 2, “System Configuration” contains information to help you

configure the Sine Wave Plus Inverter/Charger for off-grid, on-grid, and

backup power applications.

Chapter 3, “Installation” describes how to mount and install the Sine

Wave Plus Inverter/Charger and perform cabling procedures for various

configurations.

Chapter 4, “Functional Test” explains how to conduct a functional test of

the inverter.

Chapter 5, “Navigation” explains how to navigate through the Sine Wave

Plus Inverter/Charger menus using the Control Module and the menu

maps.

Chapter 6, “Basic Setup Programming” explains how to program the Sine

Wave Plus Inverter/Charger to operate under basic conditions.

Chapter 7, “Advanced Setup” explains how to program the Sine Wave

Plus Inverter/Charger to operate under special, advanced conditions, such

as automatic generator starting, energy management and auxiliary load

applications.

Chapter 8, “Operation” explains how to operate the Sine Wave Plus

Inverter/Charger. It also explains how to read the LED indicators and

User Menus to determine system status.

Appendix 9, “Chapter 9 contains information and procedures for

troubleshooting the Sine Wave Plus.”

Appendix A, “Inverter Specifications” provides the electrical and

environmental specifications of this inverter. This section also provides

information about how an inverter works, as well as efficiency statistics.

Appendix B, “Configuration Settings” provides worksheets for

programming your inverter/charger for user-specific parameters. Use this

chapter to record the settings specific to your installation. This will make

programming or reprogramming easier.

Appendix C, “Battery Information” supplies general information about

batteries such as battery types, battery bank sizing, battery configurations,

and battery care. For detailed information, see your battery manufacturer

or your system designer. Reading this chapter will help you determine the

battery bank specifications required by your specific system (e.g., types

of batteries, size of battery bank, configuration of the battery bank etc.).

976-0043-01-01 iv

Page 7

About this Guide

Appendix D, “Generators” supplies information about generator starting.

Reading this chapter will help you determine what kind of generator to

use, if any.

Appendix E, “Over-Charge Protection” supplies information about

options for over-charge protection.

Appendix F, “Multiwire Branch Circuit Wiring” supplies information

about Multiwire Branch Circuit Wiring Precautions when using standalone 120 Vac inverters or generators. Reading this chapter will provide

information regarding identifying and correcting the potential fire hazard

that exists when using inverters in this situation.

Appendix G, “Emergency Power Off Switches” supplies information

about the requirements for installing an Emergency Power Off Switch.

“Glossary” contains a glossary of technical terms used in this manual.

The glossary also defines some common electrical terms. It also provides

a list of acronyms used in this manual.

“Warranty and Product Information” Reading this chapter will provide

clarification of the Limited Warranty and instructions for obtaining a

Return Material Authorization, if the product needs to be returned to

Xantrex or one of its authorized service centers.

Conventions Used

The following conventions are used in this guide.

Note:

understanding of how to use the inverter. If the information in the note is

crucial to the chapter, it likely should be in the main flow.

WARNING

Warnings identify conditions that could result in personal injury

or loss of life.

CAUTION

Cautions identify conditions or practices that could result in

damage to the Sine Wave Plus Inverter/Charger or other

equipment.

Notes describe additional information which may add to your

v 976-0043-01-01

Page 8

About this Guide

Important:

reader know, but not as serious as a caution or warning.

Related Information

You can find more information about Xantrex Technology, Inc. as well as

its products and services at www.xantrex.com

You may also need to reference the following installation guides to assist

with this installation. These guides (with the exception of the NEC

Reference Guide) are all provided with the specific components when

purchased.

• Generator Start Module (GSM) Installation Guide

• Auxiliary Load Module (ALM) Installation Guide

• Inverter Stacking Control – Series (ISC-S) Cable Owner’s Guide

• Inverter Communications Adapter (ICA) Owner’s Guide

• Inverter Control Module (ICM) Installation Guide

• AC Conduit Box (ACCB) Owner’s Guide

• DC Conduit Box (DCCB) Installation Guide

• AC and/or DC Conduit Installation Instructions

• T240 Autotransformer Installation Guide

• Manufacturer’s instructions for Electrical Panels (Main, Sub, and

generator disconnect panels)

• Manufacturer’s instructions for battery installation and use

• Manufacturer’s instructions for generator installation and use

• NEC Guide for related electrical, grounding, and bonding

information.

Use Important for content which is important that the

976-0043-01-01 vi

Page 9

Important Safety Instructions

WARNING

This chapter contains important safety and operating

instructions as prescribed by UL and CSA standards for

inverters used in residential applications. Read and keep

this Installation Guide for future reference.

1. Before using the inverter, read all instructions and cautionary

markings on the unit, the batteries, and all appropriate sections of this

manual.

2. Use only attachments recommended or sold by the manufacturer.

Doing otherwise may result in a risk of fire, electric shock, or injury

to persons.

3. The inverter is designed to be permanently connected to your AC and

DC electrical systems. Xantrex recommends that all wiring be done

by a certified technician or electrician to ensure adherence to the local

and national electrical codes applicable in your jurisdiction.

4. To avoid a risk of fire and electric shock, make sure that existing

wiring is in good condition and that wire is not undersized. Do not

operate the inverter with damaged or substandard wiring. See

Appendix, F “Multiwire Branch Circuit Wiring” for information

about multiwire branch circuits.

5. Do not operate the inverter if it has been damaged in any way. If the

unit is damaged, see the Warranty and Product Information section at

the end of this manual.

6. This unit does not have any user-serviceable parts. Do not

disassemble the inverter. See “How do you get service?” on page I–1

for instructions on obtaining service. Attempting to service the unit

yourself may result in a risk of electrical shock or fire. Internal

capacitors remain charged after all power is disconnected.

7. To reduce the risk of electrical shock, disconnect both AC and DC

power from the inverter before attempting any maintenance or

cleaning or working on any components connected to the inverter.

Turning off controls will not reduce this risk.

8. The inverter must be provided with an equipment-grounding

conductor connected to the AC input ground.

976-0043-01-01 vii

Page 10

Important Safety Instructions

9. Do not expose this unit to rain, snow, or liquids of any type. This

product is designed only for use indoors. Damp environments will

significantly shorten the life of this product and corrosion caused by

dampness will not be covered by the product warranty.

10. To reduce the chance of short-circuits, always use insulated tools

when installing or working with the inverter, the batteries, or the PV

arrays.

11. Remove all jewelry while installing this system. This will greatly

reduce the chance of accidental exposure to live circuits.

Explosive gas precautions

1. Working in the vicinity of lead acid batteries is dangerous. Batteries

generate explosive gases during normal operation. Therefore you

must read this guide and follow the instructions exactly before

installing or using your inverter/charger.

2. To reduce the risk of battery explosion, follow these instructions and

those published by the battery manufacturer and the manufacturer of

the equipment in which the battery is installed.

FCC Information to the User

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses

and can radiate radio frequency energy and, if not installed and used in

accordance with the instructions, may cause harmful interference to radio

communications. However, there is no guarantee that interference will not

occur in a particular installation. If this equipment does cause harmful

interference to radio or television reception, which can be determined by

turning the equipment off and on, the user is encouraged to try to correct

the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment receiver.

• Connect the equipment into an outlet on a circuit different from that

to which the receiver is connected.

• Consult the dealer or an experienced ratio/TV technician for help.

viii 976-0043-01-01

Page 11

Contents

Important Safety Instructions

Explosive gas precautions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

FCC Information to the User - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

1

Introduction

Basic Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–2

Front Panel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–3

AC Side - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–4

Emergency Power Off (EPO) Option - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–5

Certification Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–5

DC Side - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–6

Battery Temperature Sensor (BTS) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–7

Top - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -1–8

2

System Configuration

Types of Applications- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

Pre-Configuration Planning - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–2

System Output Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

System Input Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Location Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–4

Mounting Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–5

Ventilation Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

Grounding Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

DC System Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–6

Inverter Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–7

Equipment or Chassis Grounding - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–8

Grounding Electrodes/Ground Rods - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–8

Bonding the Grounding System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–9

Battery Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–10

Battery Bank Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Battery Cable Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–12

Battery Requirements for Dual Inverter Systems - - - - - - - - - - - - - - - - - - - - - - 2–15

Battery Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Wiring Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Code Compliance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–18

Wire Routing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–19

Generator Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -2–19

976-0043-01-01 ix

Page 12

Contents

Additional/Optional Equipment Considerations - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

AC Conduit Box (ACCB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

DC Conduit Box (DCCB) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Fuse Block - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

DC Disconnect Boxes (DC 175/DC250) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

Battery Status Meter (TM500A) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–25

Remote Monitors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

Inverter Control Module (ICM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Inverter Communications Adapter (ICA) - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Generator Start Module (GSM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

Auxiliary Load Module (ALM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

Autotransformer for 240 VAC Applications (T240) - - - - - - - - - - - - - - - - - - - - - - 2–29

Inverter Stacking Control – Series (ISC-S) Cable - - - - - - - - - - - - - - - - - - - - - - - - 2–29

Renewable Energy DC Input Sources - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–30

Off-Grid Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–32

Renewable Energy Systems with/without Generator Backup - - - - - - - - - - - - - - - - 2–32

Single Inverter Configurations (120 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - 2–32

Single Inverter Configurations (120/240 Vac) - - - - - - - - - - - - - - - - - - - - - - - 2–32

Dual Inverter Configurations (240 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–34

Generator-Only Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–36

Single-Inverter Configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–36

Dual Inverter Configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–38

240 Vac-only Input Source - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–38

On-Grid Applications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–40

Backup Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–40

Single Inverter Configurations (120 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - 2–40

Single Inverter Configurations (240 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - 2–40

Dual Inverter Configurations (240 Vac) - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–42

Energy Management - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–44

RE Backup with Utility (SB Mode) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–44

Peak Load Management - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–44

Time-of-Use (TOU) Metering - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–45

AC Load Support - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–46

Renewable Energy with Grid Backup (BX Mode) - - - - - - - - - - - - - - - - - - - - 2–47

3

Installation

Pre-Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Tools Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Hardware / Materials Required - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

Optional System Accessories - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–3

x 976-0043-01-01

Page 13

Contents

Battery Bank Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–4

Unpacking and Inspecting the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–5

Knockout Preparation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–7

Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–8

Shelf-Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–8

Wall-Mounting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–10

DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Preparing the Battery Bank - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Grounding the DC System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

Connecting DC Input Sources – Renewable Energy Configurations - - - - - - - - - - - - 3–18

Installing the Battery Temperature Sensor (BTS) - - - - - - - - - - - - - - - - - - - - - - - - 3–18

Connecting the Batteries to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–20

Procedure for Single Inverter Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–22

Procedure for Dual Inverter Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–24

AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–26

Accessing the AC Terminal Block and Ground Bar - - - - - - - - - - - - - - - - - - - - - - 3–28

AC Wiring for Single Inverter Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–30

Manual and Auto Start Generators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–30

Install AC Output Wiring to the Inverter AC Distribution Panel - - - - - - - - - - - 3–33

Install Generator Wiring to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–35

Install Utility Wiring to the Inverter Input (On-Grid Applications only) - - - - - - 3–38

Optional Equipment - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–39

Stacking Dual Inverter Systems - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–39

Installing the ISC-S Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–40

Remote Monitoring Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–41

Auxiliary Load Module (ALM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–42

Emergency Power Off (EPO) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–43

EPO Port - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–43

4

Functional Test

Basic Functional Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Confirm all Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Applying Battery Power to the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–2

Turning ON the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–3

AC Voltage Check - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–4

Confirming Battery Charger Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–4

Confirming Inverter Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -4–5

976-0043-01-01 xi

Page 14

Contents

5

Navigation

Navigating the Sine Wave Plus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

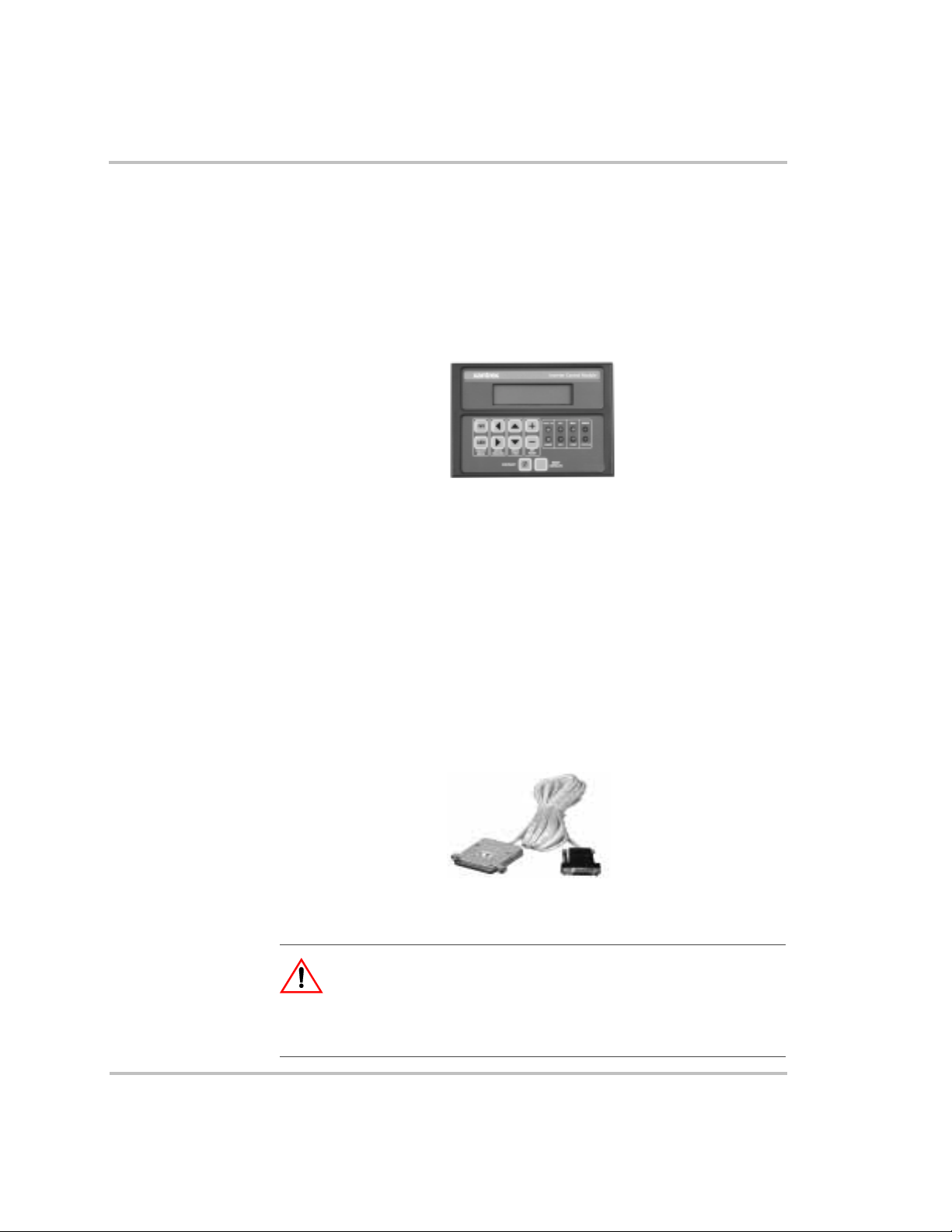

The Inverter Control Module (ICM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Inverter Control Module Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

The display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

The cursor - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Display contrast - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Push-buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

ON/OFF Menu Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Menu Heading Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Menu Item Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Set Point Buttons - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Reset Factory Defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Menu Map - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

6

Basic Setup Programming

Basic Setup Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

Before You Begin Programming - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–4

DC Amps verses AC Amps - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–4

Recording Changes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–5

Basic Setup Process - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–5

Accessing the Basic Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–6

Menu Item Descriptions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–7

10 Time of Day Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–7

10A Set Hour - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–7

10B Set Minute - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–7

10C Set Seconds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–8

11 Inverter Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–8

11A High Battery Cut Out VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–8

11B Low Battery Cut In VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–9

11C Low Battery Cut Out VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–9

11D LBCO Delay Minutes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–9

11E Search Watts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–10

Battery Charger Functions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–11

Multi-Stage Charging Process - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–12

Equalize Charging the Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–14

12 Battery Charging Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–15

12A Finish Stage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–16

12B Bulk Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–16

12C Float Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–16

xii 976-0043-01-01

Page 15

12D Equalize Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–16

12E Max Charge Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–18

12F Bulk Done Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–19

12G EQ VDC Done Timer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–20

12H Max Bulk/EQ Timer h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–21

12I Temp Comp - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–21

13 AC Inputs Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–22

13A Grid (AC1) Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–23

13B Gen (AC2) Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–23

13C Input Upper Limit VAC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–24

13D Input Lower Limit VAC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–24

14 Save/Restore Settings Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–25

14A Push INV now to Save Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–25

14B Push GEN to Restore Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–25

14C Push GEN for factory defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–26

End Basic Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–26

7

Advanced Setup

Advanced Setup Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–2

Before You Begin Advanced Programming - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–5

Accessing the Advanced Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–6

Menu Item Descriptions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–8

20 Silent Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -7–8

20A Refloat High Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–10

20B Refloat Low Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–10

20C Float Done Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–10

20D Must Float Time Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–11

21 Grid (AC1) Usage Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–11

21A Grid Usage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–12

21B Grid Usage Begin h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–12

21C Grid Usage End H:M - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–13

22 Battery Xfer (BX) Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–13

22A High Xfer (HBX) VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–14

22B Low Xfer (LBX) VDC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–14

23 ALM Relays Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–14

23A RY9 VDC Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–15

23B RY9 VDC DeEnergized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–15

23C RY9 Delay At DeEngz. Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–15

23D RY10 VDC Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–15

23E RY10 Vdc DeEnergized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–16

Contents

976-0043-01-01 xiii

Page 16

Contents

23F RY10 Delay at Engz. Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–16

23G RY11 Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–16

Generator Starting Scenarios - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–18

Manual Generator Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–19

Automatic Generator Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–19

24 Generator Timers Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–22

24A Gen Run Time Start h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–22

24B Gen Run Time Stop H:M - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–22

24C Quiet Time Begin h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–22

24D Quiet Time End h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–23

24E Gen Exercise Period Days - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–23

24F Gen Exercise Timer Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–23

24G Gen Cooldown Timer Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–23

24H RN2/Max Gen Run h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–24

25 Gen Starting Details Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–24

Generator Start Module (GSM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–24

25A RY7 Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–25

25B Gen Warm-up Seconds/minutes - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–32

25C Pre Crank Seconds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–32

25D Max Cranking Seconds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–32

25E Post Crank Seconds - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–32

26 Gen Auto Run Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–33

26A Load Start Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–33

26B Load Start Delay Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–33

26C Load Stop Delay Min - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–33

26D 24 Hr Start Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–33

26E 2 Hr Start Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–33

26F 15 Min Start Volts DC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–34

26G Read LBCO 30 Sec Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–34

27 Save/Restore Settings Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–34

27A Push INV now to Save Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–34

27B Push GEN to Restore Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–35

27C Push GEN for Factory Defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–35

End Advanced Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–35

8

Operation

Operating the Sine Wave Plus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–2

Operational Status Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–3

LED Indicators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–3

Inverter Operation Status (Yellow) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–4

xiv 976-0043-01-01

Page 17

Contents

AC Input Status (Green) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–5

Charge Status (Yellow and Green) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–6

Operational Status Indication (Red and Yellow) - - - - - - - - - - - - - - - - - - - - - - -8–7

Error LED Reset - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–8

LED Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -8–9

The User Menu Summary - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–11

Accessing the User Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–14

User Menu Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–15

01 Inverter ON/OFF Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–15

01A Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–15

01B EQ Charge OFF ON - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–16

01C Search Watts (SRCH) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–16

01D Bypass Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–17

02 Generator ON/OFF Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–17

02A Generator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–18

02B Gen Start Load Amps - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–19

02C Gen Start Volts/Manual - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–19

02D Gen Start Exercise Run - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–19

02E Gen Start Run Time - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–19

02F Days Left To Gen Exercise - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–19

03 Time Of Day Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–20

03A SW Plus Software Level - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–20

03B System Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–20

03C Company Name and Address - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–20

03D City, State, and Zip Code - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–20

03E Xantrex Phone Numbers - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–20

Press Reset for Factory Defaults - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–21

04 Meters Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–22

04A Battery Actual Vdc - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–22

04B Battery Comp Vdc - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–23

04C Inverter/Charger Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–23

04D Input Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–23

04E Load Amps AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–23

04F Inverter Volts AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–23

04G Grid (AC1) Volts AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–24

04H Gen (AC2) Volts AC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–24

04I Frequency Hertz - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–24

04J Max Bulk/EQ Time h:m - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–24

04K Battery Temp Degrees C - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–24

04L Fan Speed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–24

05 Error Causes Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–25

976-0043-01-01 xv

Page 18

Contents

05A Over Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–25

05B Transformer Overtemp - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–25

05C Heatsink Overtemp - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–26

05D Low Battery Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–26

05E High Battery Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–27

05F External Err (Stacked) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–27

05G Input Relay Failure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–27

05H Gen Failed to Start - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–28

05I Gen Stopped Due to V/F - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–28

06 Status Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–28

06A Bypass Mode Selected - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–29

06B Chr Selected (No Backup) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–29

06C Gen Signaled to Run - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–29

06D Gen In Cooldown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–29

06E EQ Charge Selected - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

6F Battery VDC < LBCO - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

6G Battery VDC > HBCO - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

06H EPO Shutdown - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

07 GSM/ALM Options Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

07A RY7 (GSM) Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–30

07B RY8 (GSM) Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07C RY9 (ALM) Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07D RY9 DeEngz. Time Minute - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07E RY10 (ALM) Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07F RY10 Engz. Time Minute - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

07G RY11 Energized - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–31

9

Troubleshooting

Inverter Troubleshooting - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9–2

Battery Charger Troubleshooting- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9–4

Error Causes- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 9–7

A

Inverter Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

Theory of Operation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–4

Power Versus Efficiency - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–6

Inverter Capacity versus Temperature - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–8

Time versus Current - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–9

xvi 976-0043-01-01

Page 19

B

Configuration Settings

User Menu Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Basic Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Advanced Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - B–7

C

Battery Information

Introduction - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Battery Types - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Deep-cycle Flooded Lead Acid (FLA) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–2

Sealed Batteries (Gel and AGM) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–3

NiCad and NiFe Batteries - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–3

Understanding Battery Capacity Ratings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–4

Battery Bank Sizing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–4

Understanding Amp-hour Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–5

Calculating Amp Hours - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–6

Amp Hour Example Worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–7

Battery bank size worksheet - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–8

Battery Configurations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–9

Wiring Batteries in Series - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–9

Wiring Batteries in Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–10

Wiring Batteries in Series-Parallel - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–11

Battery Connections for Stacked Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–12

Battery Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–13

Battery charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–13

Equalization Charging - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–15

General Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -C–15

Contents

D

Generators

Two-Wire Start Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

Three-Wire Start Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

Honda™ 3-Wire Type Generators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

Onan™ 3-Wire Type Generators - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–2

3-2 Wire Converters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - D–3

976-0043-01-01 xvii

Page 20

Contents

E

Over-Charge Protection

Over-voltage Protection using a Charge Controller- - - - - - - - - - - - - - - - - - - - - - - - - - - E–2

Diversion Load Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–3

F

Multiwire Branch Circuit Wiring

Multiwire Branch Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–2

Identifying Multiwire Branch Circuits - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–4

Correcting Multiwire Branch Circuit Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–5

G

Emergency Power Off Switches

The Purpose of an EPO switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -G–2

How to use the EPO Port for an EPO Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - -G–4

Warranty - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I–1

Return Material Authorization Policy - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I–3

Out of Warranty Service- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I–4

Information About Your System - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - I–5

xviii 976-0043-01-01

Page 21

Figures

Figure 1-1 The Sine Wave Plus - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-2 The Front Side of the Sine Wave Plus - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Figure 1-3 The AC side of the Sine Wave Plus - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Figure 1-4 Certification Label - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

Figure 1-5 The DC side of the Sine Wave Plus - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

Figure 1-6 Battery Temperature Sensor (BTS) - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–7

Figure 1-7 External Output Circuit Breaker - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–8

Figure 2-1 AWG Wire Size Reference Chart - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Figure 2-2 Sample Warning Sticker for Backfeed Conditions - - - - - - - - - - - - - - - - 2–16

Figure 2-3 AC Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

Figure 2-4 DC Conduit Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–23

Figure 2-5 Sine Wave Plus with AC and DC Conduit Boxes Installed- - - - - - - - - - - 2–23

Figure 2-6 Fuse Blocks - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–24

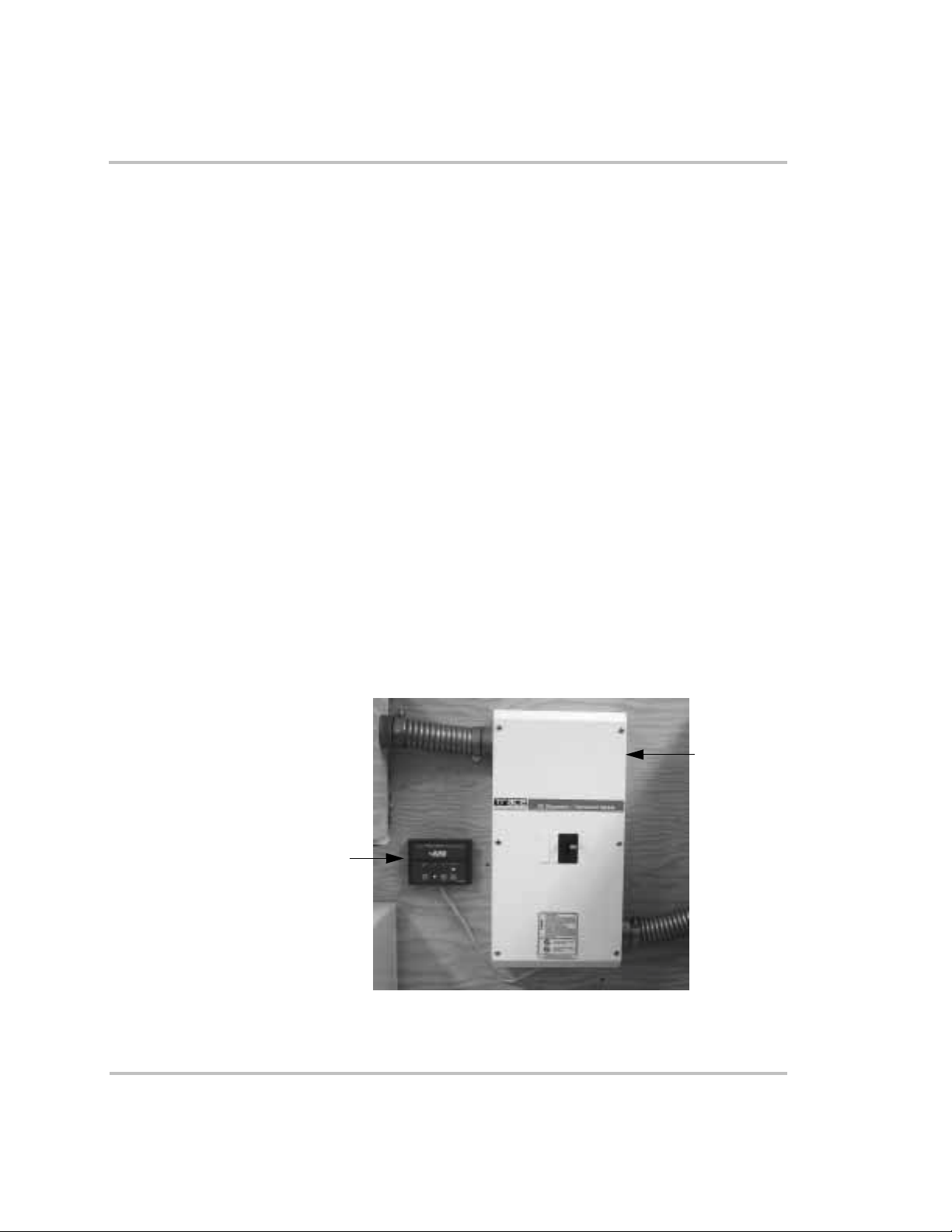

Figure 2-7 DC250 Disconnect Box and TM500A Battery Status Meter- - - - - - - - - - 2–25

Figure 2-8 Accessories for Remote Monitoring - - - - - - - - - - - - - - - - - - - - - - - - - - 2–26

Figure 2-9 Inverter Control Module- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–27

Figure 2-10 Inverter Communications Adapter Cable - - - - - - - - - - - - - - - - - - - - - - 2–27

Figure 2-11 Generator Start Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

Figure 2-12 Auxiliary Load Module - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–28

Figure 2-13 T240 Auto-transformer - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–29

Figure 2-14 ISC-S Cable - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–29

Figure 2-15 Xantrex C-Series Charge Controllers - - - - - - - - - - - - - - - - - - - - - - - - - 2–31

Figure 2-16 PV Ground Fault Protection (PVGFP) - - - - - - - - - - - - - - - - - - - - - - - - 2–31

Figure 2-17 Off-Grid Application – Renewable Energy System using a Single Inverter 2–33

Figure 2-18 Off-Grid Application – Renewable Energy System using Dual Inverters - 2–35

Figure 2-19 Off Grid Generator-Only System using a Single Inverter- - - - - - - - - - - - 2–37

Figure 2-20 Off Grid Application – Generator-Only System using Dual Inverters

Series-stacked - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–39

Figure 2-21 On-Grid Application – Backup System using a Single Inverter- - - - - - - - 2–41

Figure 2-22 On-Grid Application – Backup System using Dual Inverters,

Series-stacked - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–43

Figure 2-23 Time-of-Use Metering - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–45

Figure 2-24 AC Support Mode- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–47

Figure 3-1 Certification Label Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

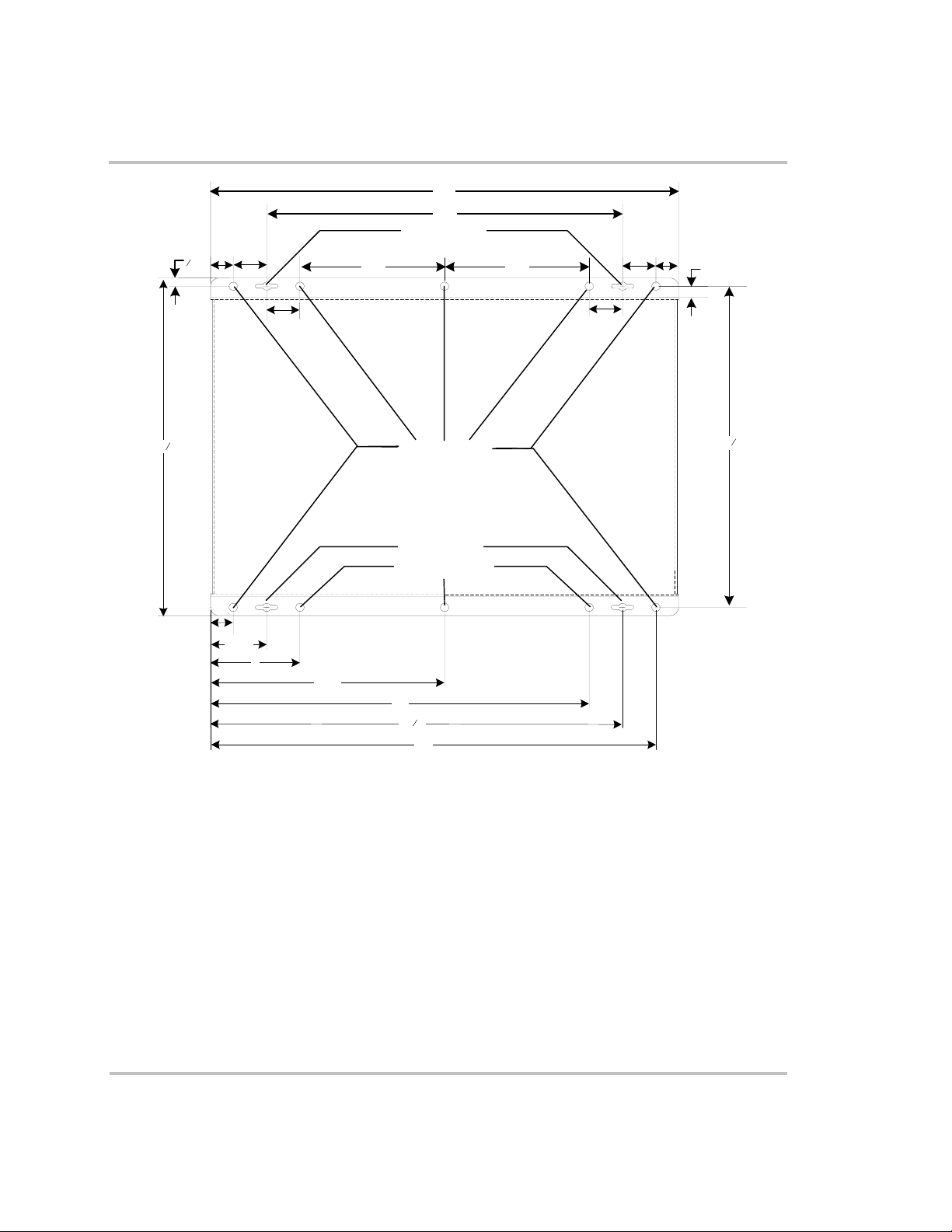

Figure 3-2 Serial Number Sticker and Knockout Locations and Sizes - - - - - - - - - - - - 3–7

Figure 3-3 Dimensional Drawing - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

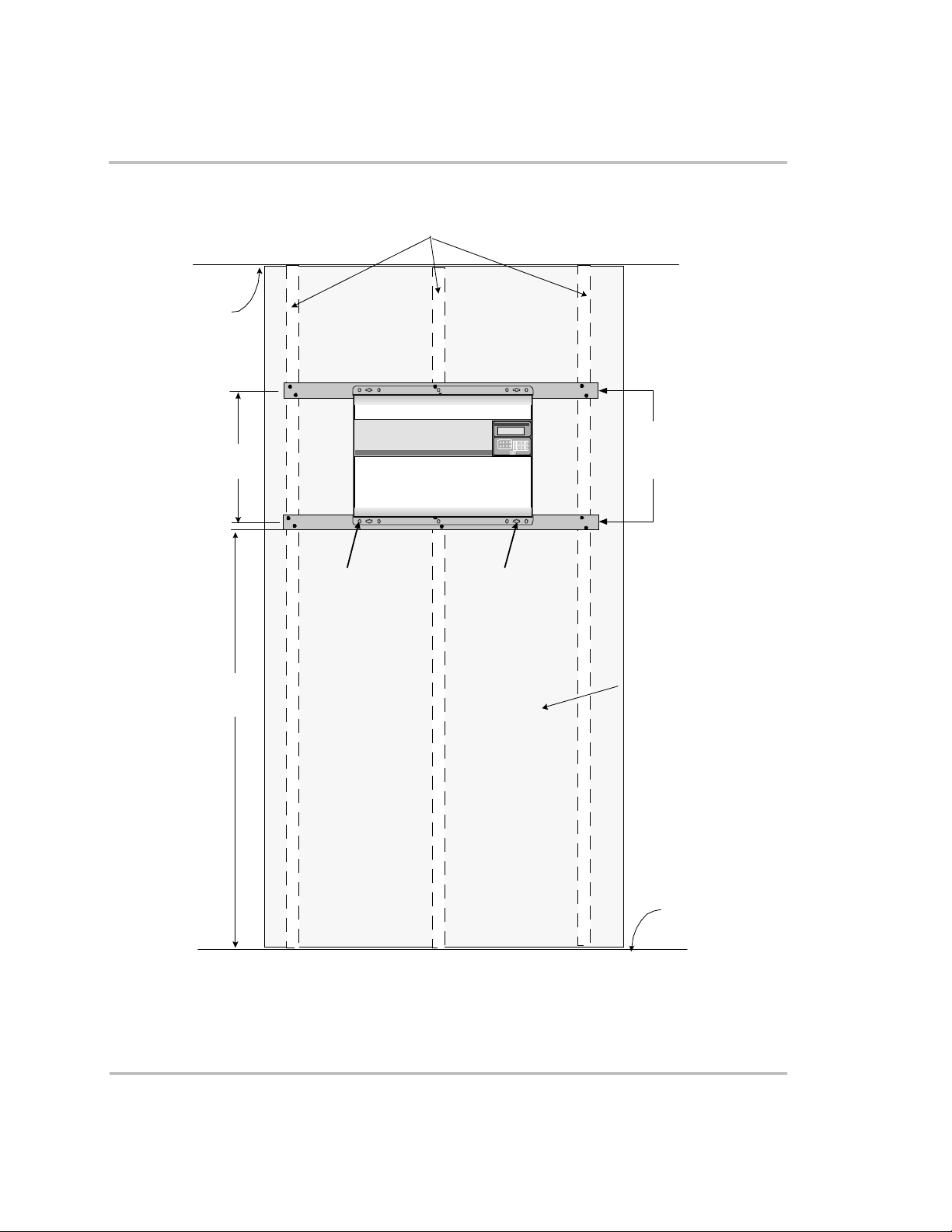

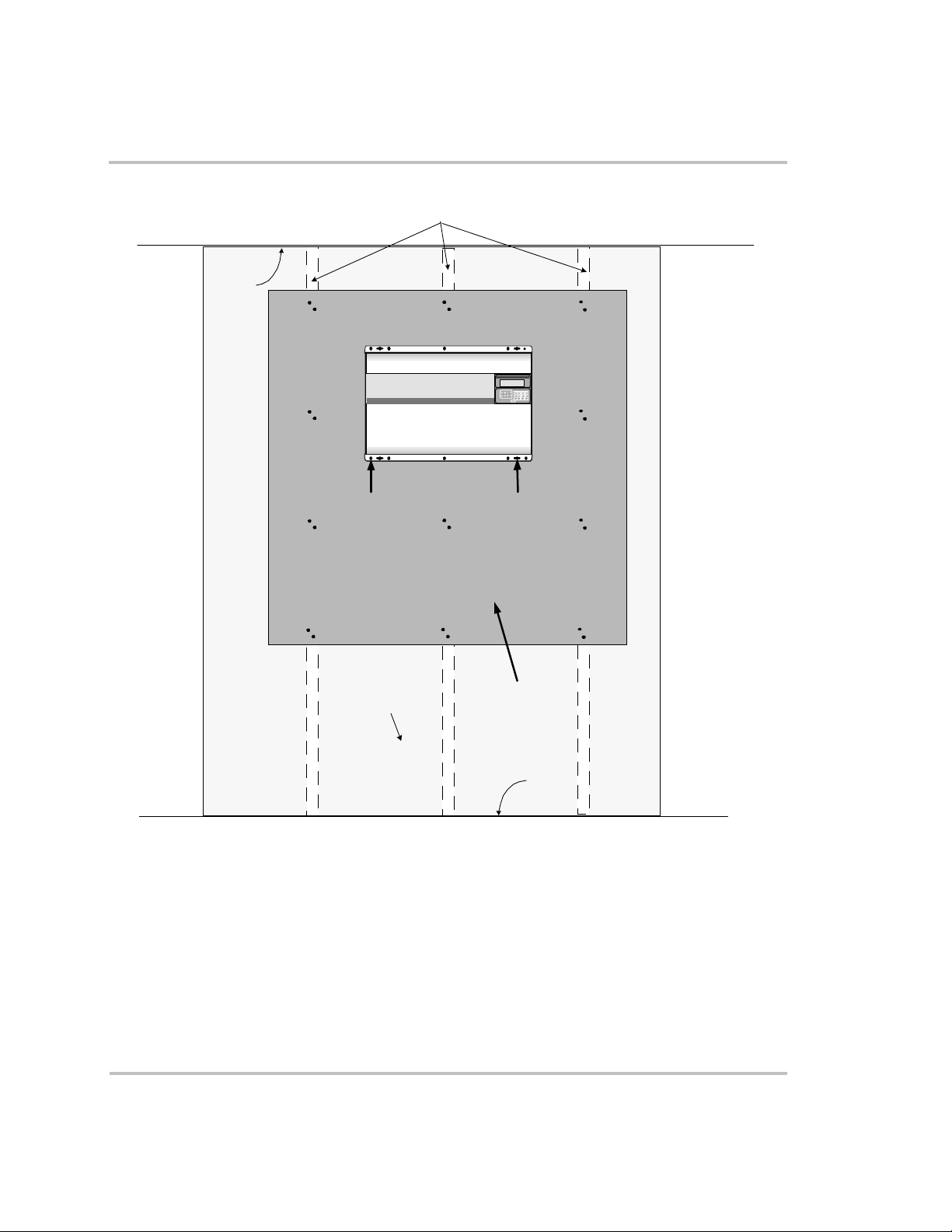

Figure 3-4 Wall-Mounting Method using 2 x 4’s - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

976-0043-01-01 xix

Page 22

Figures

Figure 3-5 Wall Mounting using Plywood - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–13

Figure 3-6 Chassis Ground Lug Location on Inverter DC End - - - - - - - - - - - - - - - - 3–15

Figure 3-7 DC Grounding of a Single Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–16

Figure 3-8 DC Grounding of Dual Inverters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–17

Figure 3-9 BTS (RJ11) Port Location and Installation - - - - - - - - - - - - - - - - - - - - - - 3–19

Figure 3-10 DC Terminal Connections on the Inverter - - - - - - - - - - - - - - - - - - - - - - 3–20

Figure 3-11 Battery Cable Connection - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–21

Figure 3-12 Battery Terminal Covers and Associated Hardware - - - - - - - - - - - - - - - - 3–21

Figure 3-13 DC Connections to a Single Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - 3–23

Figure 3-14 DC Connections to Dual Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–25

Figure 3-15 AC Wiring Access Cover Plate - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–28

Figure 3-16 AC Input/Output Wiring Terminals- - - - - - - - - - - - - - - - - - - - - - - - - - - 3–29

Figure 3-17 Connecting the GSM Communications Cable to the Sine Wave Plus - - - - 3–31

Figure 3-18 AC Input and Output Wiring to a Single Inverter with an Auto-Start

AC Generator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–32

Figure 3-19 AC Output Wiring to the Inverter AC Panel - - - - - - - - - - - - - - - - - - - - - 3–34

Figure 3-20 Generator Input Wiring to a Single Inverter - - - - - - - - - - - - - - - - - - - - - 3–37

Figure 3-21 Utility Wiring to the Inverter Input - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–39

Figure 3-22 Series-stacked Inverters with ISC-S Cable - - - - - - - - - - - - - - - - - - - - - - 3–40

Figure 3-23 Remote Monitor Port Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–41

Figure 3-24 Connecting the ALM Communications Cable to the Sine Wave Plus - - - - 3–42

Figure 3-25 Connecting the EPO - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–43

Figure 4-1 Power Up Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Figure 5-1 ICM Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Figure 5-2 Menu Structure - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Figure 5-3 User Menu Map - Part 1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Figure 5-4 User Menu Map - Part 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–7

Figure 5-5 Basic Setup Menu Map Part 1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Figure 5-6 Basic Setup Menu Map Part 2 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Figure 5-7 Advanced Setup Menu Part 1 - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

Figure 6-1 Accessing the Basic Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–6

Figure 6-2 Multi-Stage Battery Charging Process - - - - - - - - - - - - - - - - - - - - - - - - - 6–12

Figure 7-1 Accessing the Basic Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–6

Figure 7-2 Accessing the Advanced Setup Menu - - - - - - - - - - - - - - - - - - - - - - - - - - 7–7

Figure 7-3 Relay 11 Wiring Example to Dual Inverters with Cooldown selected - - - - 7–17

Figure 7-4 Generator Control Mode (GS and RN1)- - - - - - - - - - - - - - - - - - - - - - - - 7–24

Figure 7-5 Generator Control Mode (RN2) - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–25

Figure 7-6 RY7’s COM and N.O. Contacts Close (energize) to Run Generator - - - - - 7–26

Figure 7-7 Wiring examples of Honda™ and Onan™ Generators - - - - - - - - - - - - - - 7–28

xx 976-0043-01-01

Page 23

Figures

Figure 7-8 RY7 and RY8 Timing Diagram- - - - - - - - - - - - - - - - - - - - - - - - - - - - - 7–29

Figure 7-9 RY7/RY8 Sequence of Events for RN1 or RN2 Selection - - - - - - - - - - - 7–30

Figure 7-10 RY7/RY8 Sequence of Events for GS Selection - - - - - - - - - - - - - - - - - 7–31

Figure 8-1 LED Indicators- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–3

Figure 8-2 Inverter Operation Status LEDs- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–4

Figure 8-3 AC Status LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–5

Figure 8-4 Charge Status LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–6

Figure 8-5 Error and Status LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–7

Figure 8-6 Inverter ON/OFF Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–14

Figure 8-7 Generator ON/OFF Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–14

Figure 8-8 Resetting Factory Default Settings- - - - - - - - - - - - - - - - - - - - - - - - - - - 8–21

Figure A-1 Sine Wave Plus Simple Block Diagram - - - - - - - - - - - - - - - - - - - - - - - - A–4

Figure A-2 Sine Wave Plus Inverter Output Waveform- - - - - - - - - - - - - - - - - - - - - - A–5

Figure A-3 Sine Wave Plus Efficiency Curves- - - - - - - - - - - - - - - - - - - - - - - - - - - - A–7

Figure A-4 Inverter Capacity versus Temperature - - - - - - - - - - - - - - - - - - - - - - - - - A–8

Figure A-5 Time versus Current for the Sine Wave Plus 2524 - - - - - - - - - - - - - - - - - A–9

Figure A-6 Time versus Current for the Sine Wave Plus 2548 - - - - - - - - - - - - - - - - A–10

Figure C-1 6-volt Battery Wiring - Series” Configuration- - - - - - - - - - - - - - - - - - - - C–9

Figure C-2 12-Volt Battery Wiring - “Series” Configuration - - - - - - - - - - - - - - - - - C–10

Figure C-3 Battery Wiring in Parallel (Example Only) - - - - - - - - - - - - - - - - - - - - - C–10

Figure C-4 Step 1 - Wiring Batteries in “Series” - - - - - - - - - - - - - - - - - - - - - - - - - C–11

Figure C-5 Step 2 - Two series strings wiring in “Parallel” - - - - - - - - - - - - - - - - - - C–11

Figure C-6 “Series-Parallel” Configuration Wired to the Inverter - - - - - - - - - - - - - - C–12

Figure C-7 Example of Battery Connections for Stacked Inverters (24 Vdc shown)- - C–12

Figure E-1 Over-voltage using a C-Series Charge Controller - - - - - - - - - - - - - - - - - - E–2

Figure E-2 Diversion Load Control - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - E–3

Figure F-1 Conventional Home-Type Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–2

Figure F-2 Multiwire Branch Circuit Wiring and Current Flow - - - - - - - - - - - - - - - - F–3

Figure F-3 120 Vac Inverter Incorrectly Wired in a Multiwire Branch Circuit - - - - - - F–3

Figure F-4 Multiwire Branch Circuit Wiring- - - - - - - - - - - - - - - - - - - - - - - - - - - - - F–4

Figure F-5 Using a T240 Autotransformer in Multiwire Branch Circuit Wiring - - - - - F–6

Figure G-1 Emergency Power OFF Disconnect Switch - - - - - - - - - - - - - - - - - - - - - - G–2

Figure G-2 Modifying a 6-conductor Cable to connect to the EPO Port - - - - - - - - - - - G–4

976-0043-01-01 xxi

Page 24

xxii

Page 25

Tables

Table 2-1 Recommended Minimum Safety Ground Wire and DC Disconnect

Sizes per NEC - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Table 2-2 Minimum Required Battery Cable Size Versus Length - - - - - - - - - - - - - 2–14

Table 2-3 Battery Cable to Maximum Breaker/Fuse Size- - - - - - - - - - - - - - - - - - - 2–15

Table 3-1 Maximum AC Disconnect and Wire Sizing- - - - - - - - - - - - - - - - - - - - - 3–27

Table 6-1 Basic Setup Menu Default Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

Table 6-2 Battery Voltages For Setting Charging Parameters - - - - - - - - - - - - - - - - 6–17

Table 6-3 Battery Charging Current and Timer Default Settings - - - - - - - - - - - - - - 6–17

Table 6-4 Calculating the Maximum Charge Amps for a 24-volt,

700 amp-hour Battery - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–18

Table 6-5 Calculating the Maximum Charge Amps for a 48-volt,

350 amp-hour Battery - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–19

Table 6-6 Calculating the Bulk Done Amps for a 24-volt, 700 amp-hour Battery- - - 6–20

Table 6-7 Calculating the Bulk Done Amps for a 48-volt, 350 amp-hour Battery- - - 6–20

Table 6-8 Inverter Temperature Compensation Calculation using the BTS - - - - - - - 6–22

Table 7-1 Advanced Setup Menu Headings and Default Settings - - - - - - - - - - - - - - 7–2

Table 7-2 Calculating the Float Done Amps for a 24-volt, 700 amp-hour Battery - - 7–11

Table 7-3 Calculating the Float Done Amps for a 48-volt, 350 amp-hour Battery - - 7–11

Table 8-1 LED Summary Table- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–9

Table 8-2 User Menu - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 8–11

Table B-1 User Menu Default and User Settings- - - - - - - - - - - - - - - - - - - - - - - - - - B–2

Table B-2 Basic Setup Default and User Settings - - - - - - - - - - - - - - - - - - - - - - - - - B–5

Table B-3 Advanced Setup Default and User Settings - - - - - - - - - - - - - - - - - - - - - - B–7

Table C-1 Determining Average Daily Load in Amp-hours - - - - - - - - - - - - - - - - - - C–7

Table C-2 Determining Battery Bank Size - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–8

Table C-3 Typical Appliance Wattage- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–8

Table C-4 Variances in Charging Voltage based on Battery Temperature - - - - - - - - C–14

Table C-5 Temperature Compensation Calculation - - - - - - - - - - - - - - - - - - - - - - - C–14

Table C-6 Battery State-of-Charge - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - C–17

976-0043-01-01 xxiii

Page 26

xxiv

Page 27

1

Introduction

Chapter 1, “Introduction” explains the basic features of the

Sine Wave Plus Inverter/Charger and describes the optional

accessories that may or may not be required for the desired

installation configuration.

Page 28

Introduction

Basic Features

Congratulations on your purchase of a Sine Wave Plus Inverter/Charger

from Xantrex Technology, Inc. The Sine Wave Plus is one of the finest

inverter/chargers on the market today, incorporating state-of-the-art

technology, high reliability, and convenient control features.

Specific features include:

• FCC Part B compliant

• 2.5 kW continuous output of sine wave power (to 40 °C) for 120 Vac/

60 Hz applications

• expandable to 5 kW for 120/240 Vac/60 Hz applications by

combining dual inverters using the Inverter Stacking Control – Series

(ISC-S) cable

• 24-volt or 48-volt models

• multi-stage battery charging

• automatic temperature compensation for battery charging (requires

the use of the Battery Temperature Sensor (BTS) provided with the

unit)

• push-button control module with a liquid crystal display (LCD) for

easy programming and troubleshooting

• light emitting diode (LED) display of system operational status

• automatic on/off control of electric-start generators

(requires additional equipment)

• remote monitoring (requires additional equipment)

• auxiliary load control (requires additional equipment)

• high surge/current capacity (4 times the continuous current rating)

• energy management features control utility and/or generator usage

• energy efficient with greater than 90% peak efficiency (95% peak)

and less than 16 watts of idle current; less than 2 watts in search mode

The default settings of the Sine Wave Plus Inverter/Charger allow the

system to perform in many installations without the need for additional

setup. However, if additional setup parameters are required, the pushbutton features on the Inverter Control Module (ICM) on the front panel

of the unit enables the system to be easily reprogrammed to meet specific

customer configurations.

1–2 976-0043-01-01

Page 29

Basic Features

Front Panel

Figure 1-1

The Sine Wave Plus

The front of the Sine Wave Plus has the following features:

• the Inverter Control Module (ICM)

• the AC Access Cover

Inverter Control Module

AC Access Cover

Figure 1-2

976-0043-01-01 1–3

The Front Side of the Sine Wave Plus

Page 30

Introduction

AC Side

The AC side of the Sine Wave Plus has the following features:

• The Remote Monitor Port for connecting the Inverter Control Module

(ICM) or the Inverter Communications Adapter (ICA)

• The Stacking Port for connecting two Sine Wave Plus inverters

• The AUX Port for connecting the Auxiliary Load Module (ALM)

• The GEN Port for connecting the Generator Start Module (GSM)

• The EPO Port for connecting an Emergency Power Off (EPO) switch

• Certification Label

• The Grid Tie Interface Port. The Grid Tie feature is currently not

available with the Sine Wave Plus models. However, the port has

been included in the event that the feature can be enabled with an

upgrade at a future date. Continue to check our website

www.xantrex.com for more information and future enhancements on

the Sine Wave Plus Inverter/Charger.

• The Serial Number Sticker is on the rail as shows in Figure 1-3.

Grid Tie

Interface

Port

(not used)

Figure 1-3

Remote Monitor Port

AUX Port

GEN Port

The AC side of the Sine Wave Plus

Stacking Port

EPO Port

Certification Label

Serial

Number

Sticker

1–4 976-0043-01-01

Page 31

Emergency Power Off (EPO) Option

The Sine Wave Plus offers an EPO option through the use of the EPO

Port. The EPO feature is designed to shut down the inverter from a remote

location (or switch).

Since the type of the switch will be dependent on the installation, EPO

switches are not provided with the Sine Wave Plus. However, many

commonly available emergency shut off switches will work with the Sine

Wave P lu s EPO. Consult your local system designer or qualified

technician for assistance.

The EPO is connected to the Sine Wave Plus with a telephone cord

(RJ11type connector) to the dedicated EPO port on the AC (left) side of

the inverter.

See Appendix G, “Emergency Power Off Switches” for additional

information about this feature and how to prepare a cable for it.

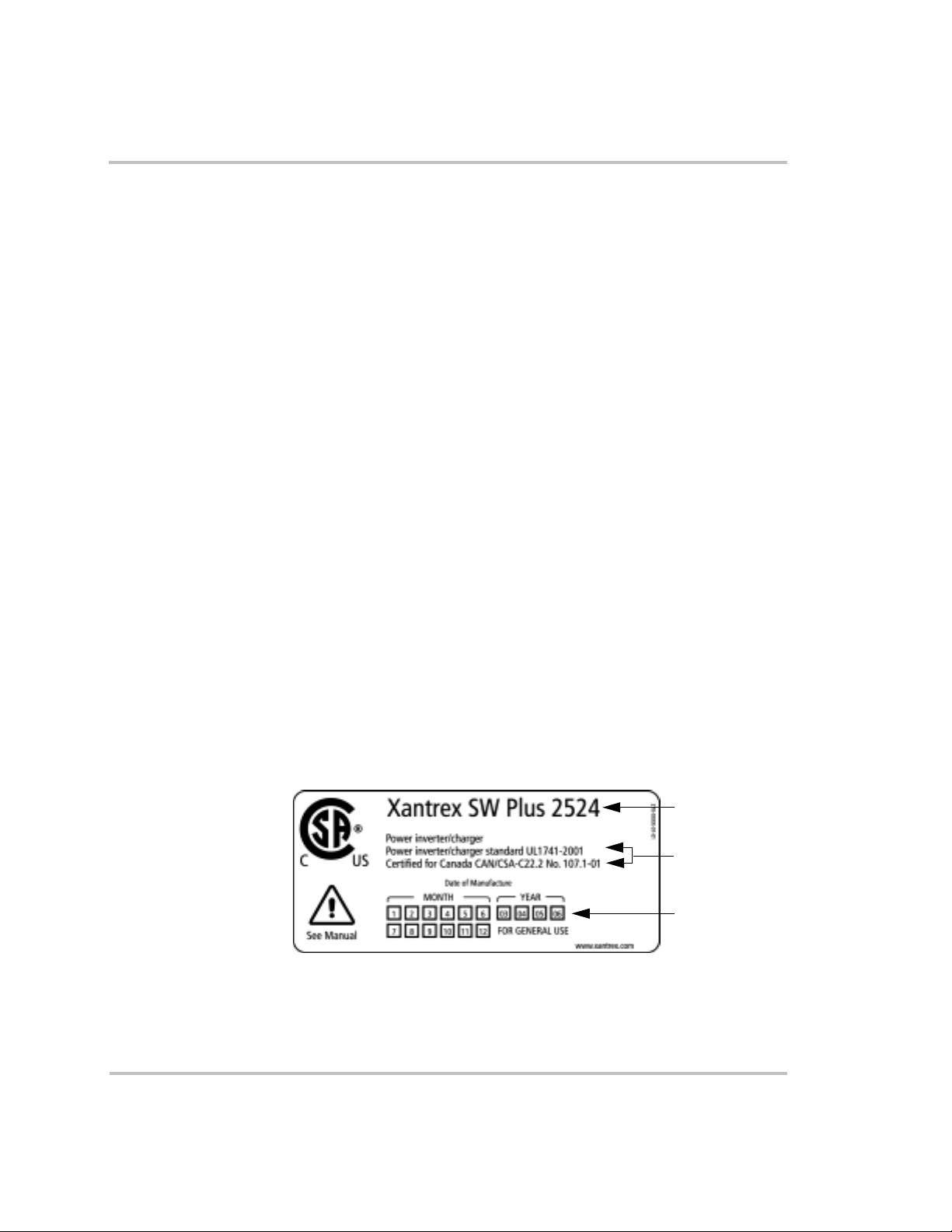

Certification Label

The Sine Wave Plus has been tested to nationally recognized safety

standards and has been found to be free from reasonably foreseeable risk

of fire, electric shock, and related hazards when installed and operated in

accordance with all the instructions provided in this manual and in

accordance with all applicable local and national codes.

Please refer to the Certification Label affixed to the AC side of the

inverter for specific agency information.

See Figure 1-3, “The AC side of the Sine Wave Plus” on page 1–4 for the

location of this information.

Basic Features

Model Number

Certification

Statement

Date of

Manufacture

Figure 1-4

976-0043-01-01 1–5

Certification Label

Page 32

Introduction

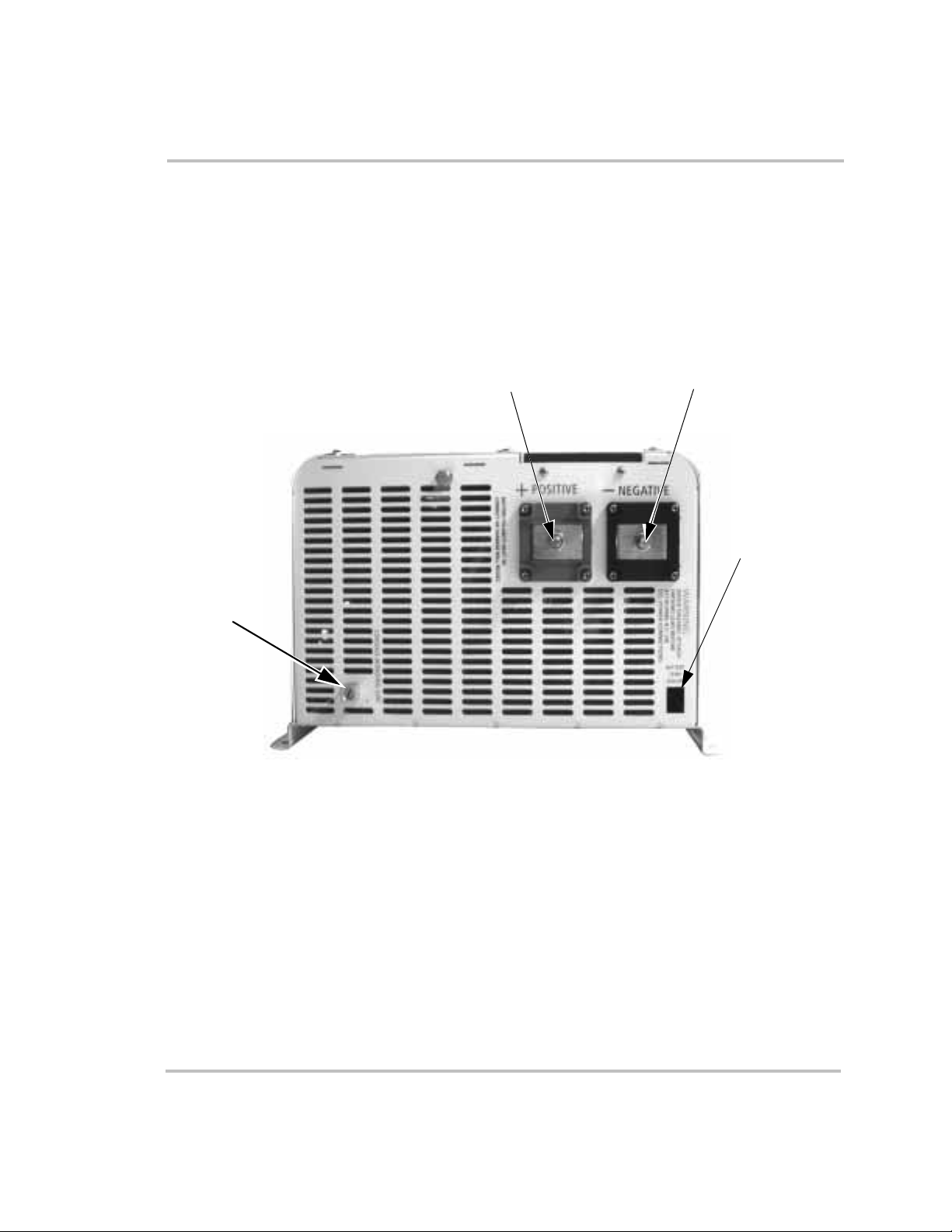

DC Side

The DC side of the Sine Wave Plus has the following features:

• the positive (+) battery terminal

• the negative (–) battery terminal

• the battery temperature sensor port

• the chassis ground lug

Chassis

Ground

Lug

Figure 1-5

Positive (+)

Battery Terminal

The DC side of the Sine Wave Plus

Negative (–)

Battery Terminal

Battery

Temperature

Sensor

1–6 976-0043-01-01

Page 33

Battery Temperature Sensor (BTS)

A BTS is provided with each Sine Wave Plus Inverter/Charger. This

sensor can easily be installed in the system to ensure proper charging of

the batteries based on temperature. Installing a BTS extends battery life

by preventing overcharging in warm temperatures and undercharging in

cold temperatures.

If more than one BTS is being used, install them adjacent to each other so

that they all detect a common temperature.

Basic Features

Figure 1-6

Battery Temperature Sensor (BTS)

See Table C-4, “Variances in Charging Voltage based on Battery

Temperature” on page C–14 and Table C-5, “Temperature Compensation

Calculation” on page C–14 for additional information.

976-0043-01-01 1–7

Page 34

Introduction

Top

The top of the unit has the following features:

• Circuit Breaker - This circuit breaker protects the unit’s internal

wiring while the unit is inverter or charging. It is not used for the

pass-through current. This is not a branch-circuit rated breaker.

Separate output breakers are still required. If the button is protruding

from the chassis as shown in Figure 1-7, it means the circuit breaker

has tripped open. Press the breaker back in to reset it.

• Warnings Label

• Ratings Label

Top View of Sine Wave Plus Inverter/charger

Circuit Breaker

AC End

Warnings Label

Circuit Breaker Open Circuit Breaker Reset

Ratings Label

DC End

Figure 1-7

1–8 976-0043-01-01

External Output Circuit Breaker

Page 35

2

System Configuration

Chapter 2, “System Configuration” contains information to

help you configure the Sine Wave Plus Inverter/Charger for

off-grid, on-grid, and backup power applications.

Page 36

System Configuration

Types of Applications

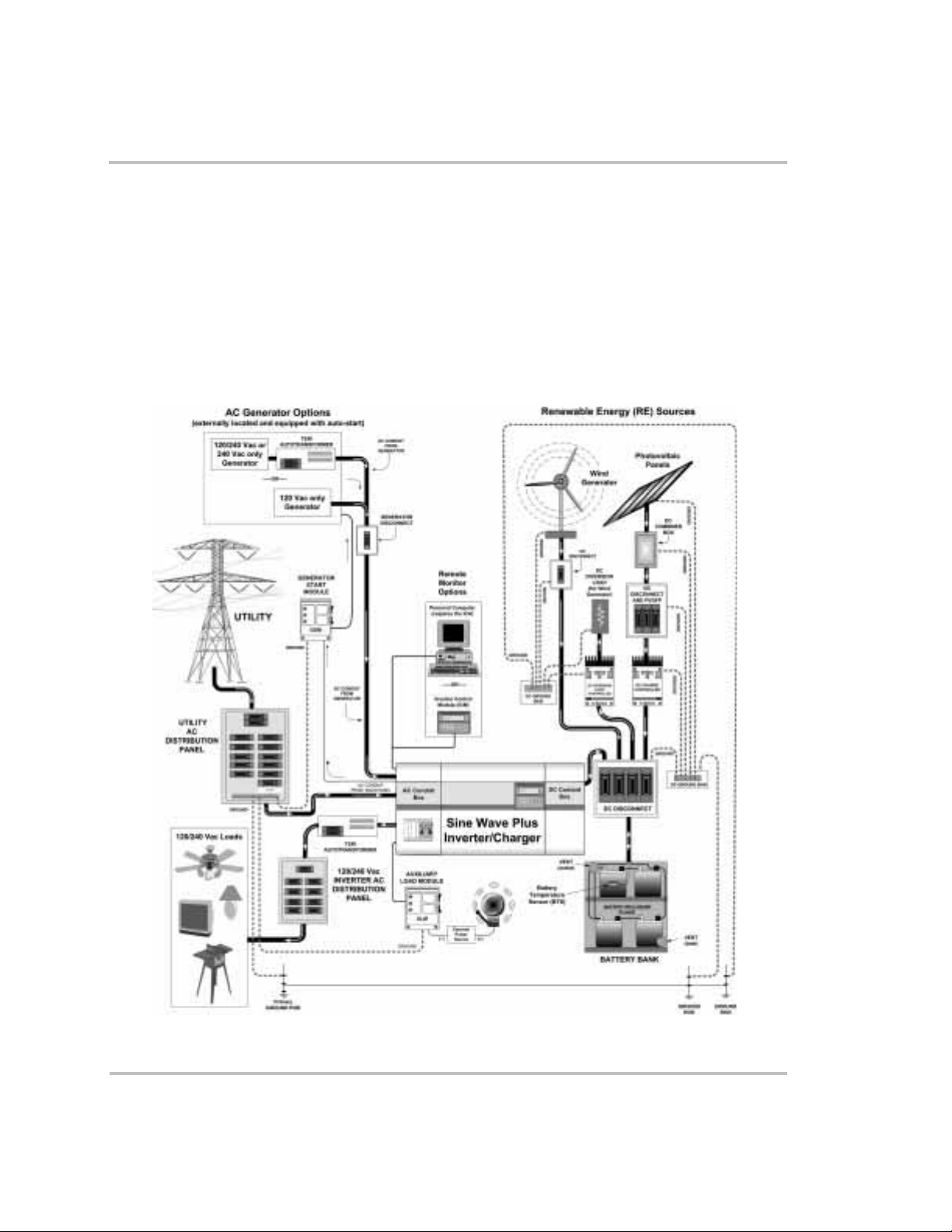

The Sine Wave Plus Inverter/Charger can be configured for the following

applications:

• OFF-GRID (stand-alone) applications where no utility power is

available. See Figure 2-17 through Figure 2-20 for illustrations of offgrid applications.

• ON-GRID applications where it can operate the AC loads when the

Utility System (grid) fails, keep the batteries charged, and/or function

as an energy management controller. See Figure 2-21 and Figure 2-22

for illustrations of on-grid applications.

Pre-Configuration Planning

System Output

Requirements

System Input

Requirements

Important:

permit office to ensure that the desired configuration will be codecompliant. Be sure to obtain the proper licenses and permits as required

by law.

Installations of this equipment should only be performed by skilled

personnel such as qualified electricians and Certified Renewable Energy

(RE) System Installers. For a list of Xantrex Certified RE dealers, please

visit our website at www.XantrexREdealers.com.

Pre-configuration planning is essential to ensure optimal performance for

your system. Pre-configuration planning includes, but is not limited to,

the following considerations.

❐ Single or dual inverters (based on output voltage and output watts

required)

❐ Output watts required (i.e., continuous capacity and surge capacity)

❐ Output voltage (120 Vac or 240 Vac)

❐ Utility power

❐ AC generator (See “Generator Considerations” on page 2–19)

Be sure to consult with your local utility company and/or

❐ Renewable energy systems (i.e., PV arrays, wind turbines etc.)

Code Compliance

and Permits

2–2 976-0043-01-01

❐ Local or national electrical codes

❐ Special permits or licenses (if required)

Page 37

Location

Considerations

Pre-Configuration Planning

❐ Mounting location for optimal performance and easy access of all

components

❐ Ventilation and clearance requirements for all components

❐ Mounting method (wall or shelf)

❐ Additional items/materials required for mounting

Grounding

Considerations

Battery

Considerations

Wiring

Considerations

❐ Grounding type (i.e., ground bar, ground bus, or ground rod)

❐ Neutral-to-ground bonding requirements

❐ Lightning and surge protection

❐ Battery type

❐ Battery cables and sizes

❐ Size of the battery bank and it’s configuration

❐ Location of battery bank to rest of system

❐ Types and sizes of wires needed

❐ Types and sizes of conduits needed

❐ Types and sizes of fuses and/or disconnects

❐ Additional equipment for code compliance (e.g., service panels,

conduit boxes, emergency shutoff switches etc.)

❐ Wire Routing

Additional

Equipment

❐ Additional components or accessories to complete the system design

(e.g., remote monitors, interface cables, stacking cables, DC charge

controllers, auxiliary load controllers, T240 autotransformers etc.)

Generator

Considerations

❐ Voltage Output Requirements

(120 Vac only, 120/240 Vac, or 240 Vac only)

❐ Auto-Start or Manual-Start

Important:

Auto-start generators require the addition of the GSM to

enable the inverter to control the operation of the generator. See

“Generator Considerations” on page 2–19 for additional information.

976-0043-01-01 2–3

Page 38

System Configuration

System Output Requirements

Determine the inverter output size requirements by calculating the

maximum, continuous capacity and surge (inrush current) capacity the

system will demand.

• Add all potential loads which would be on at once to determine

continuous power requirements.

• Add the surge current of all loads which might start at once to

determine surge requirements (e.g., washer spinner, waterpump and

refrigerator compressor could all start at once).

See Appendix C, “Understanding Amp-hour Requirements” for

assistance in determining the System Output Requirements.

System Input Requirements

Determine the input requirements based on the output requirements. In

other words, is grid power available or will renewable energy equipment

be used? Will a generator be used to supplement or backup the other input

sources?

See “Generator Considerations” on page 2–19 and Appendix D,

“Generators” for additional information regarding using generators for

system input.

Location Considerations

Dry Environment/

Stable Temperatures

Avoid Exposure to

Saltwater

Close to Battery

Bank

2–4 976-0043-01-01

Inverters contain sophisticated electronic components and should be