Page 1

Grid Tie Solar Inverter

Xantrex Grid Tie

Solar Inverter

GT2.5-NA

GT3.0-NA

GT3.3-NA

Owner’s Manual

Page 2

Page 3

Xantrex Grid Tie Solar Inverter

Owner’s Manual

Page 4

About Xantrex

Xantrex Technology Inc. is a world-leading supplier of advanced power electronics and controls with products from

50 watt mobile units to one MW utility-scale systems for wind, solar, batteries, fuel cells, microturbines, and backup

power applications in both grid-connected and stand-alone systems. Xantrex products inclu de inverters, batt ery

chargers, programmable power supplies, and variable speed drives that convert, supply, control, clean, and distribute

electrical power.

Trademarks

Xantrex Grid Tie Solar Inverter is a trademark of Xantrex International. Xantrex and Xanbus are registered

trademarks of Xantrex International.

Other trademarks, registered trademarks, and product names are the property of their respective owners and are used

herein for identification purposes only.

Notice of Copyright

Xantrex Grid Tie Solar Inverter Owner’s Manual © October 2005 Xantrex International. All rights reserved.

Disclaimer

UNLESS SPECIFICALLY AGREED TO IN WRITING, XANTREX TECHNOLOGY INC. (“XANTREX”)

(a) MAKES NO WARRANTY AS TO THE ACCURACY, SUFFICIENCY OR SUITABILITY OF ANY

TECHNICAL OR OTHER INFORMATION PROVIDED IN ITS MANUALS OR OTHER DOCUMENTATION.

(b) ASSUMES NO RESPONSIBILITY OR LIABILITY FOR LOSS OR DAMAGE, WHETHER DIRECT,

INDIRECT, CONSEQUENTIAL OR INCIDENTAL, WHICH MIGHT ARISE OUT OF THE USE OF SUCH

INFORMATION. THE USE OF ANY SUCH INFORMATION WILL BE ENTIRELY AT THE USER’S RISK.

Date and Revision

October 2005 Revision C

Part Number

975-0245-01-01

Contact Information

Telephone: 1 800 670 0707 (toll free North America)

1 360 925 5097 (direct)

Fax: 1 360 925 5143 (direct)

Email: customerservice@xantrex.com

Web: www.xantrex.com

Page 5

About This Manual

The purpose of this Owner’s Manual is to provide expl anations and procedures for

installing, operating, maintaining, and troubleshooting the Xantrex Grid T ie Solar

Inverter™.

Scope

The manual provides safety guidelin es, detailed planning and setup informatio n. It

provides procedures for installing the inverter and information about operating

and troubleshooting the unit. It does not provide details about particular brands of

photovoltaic (PV) panels. You need to consult individual PV manufacturers for

this information.

Audience

The manual is intended for anyone who needs to install and operate the GT

Inverter. Installers should be fully educated on the hazards of installing electrical

equipment. Certified electricians or technicians are recommended.

Organization

This manual is organized into 6 chapters and an appendix.

Chapter 1, “Introduction”, contains information about the features and functions

of the Xantrex Grid Tie Solar Inverter.

Chapter 2, “Installation”, provides information about planning for and installing

the GT Inverter. It contains information to help you plan wire routes, AC and DC

connections, and find a suitable location for installation. It also discusses

requirements for grounding the GT Inverter and your PVarray.

Chapter 3, “Wiring the Inverter”, provides procedures for making DC and AC

wiring connections, and grounding the GT Inverter and the PV array. Instructions

for wiring multiple inverters are also provided.

Chapter 4, “Starting the Inverter”, contains information on starting up the Xantrex

Grid Tie Solar Inverter and performing a Functional Test.

Chapter 5, “Monitoring the Inverter”, contains information for understanding the

LCD screens and the LED indicators.

Chapter 6, “Maintenance and Troubleshooting”, contains information about how to

provide general maintenance for the Xantrex Grid Tie Solar Inverter. It also

provides information about troubleshooting the unit.

Appendix A, “Specifications”, contains information about the electrical and

environmental specifications of the Xantrex Grid Tie Solar Inverter.

975-0245-01-01 iii

Page 6

About This Manual

Conventions Used

The following conventions are used in this guide.

WARNING

Warnings identify conditions that could result in personal injury or loss of life.

CAUTION

Cautions identify conditions or practices that could result in damage to the unit or other

equipment.

Important:

serious as a caution or warning.

These notes describe things which are important for you to know, but not as

Abbreviations and Acronyms

AC Alternating Current

CEC California Energy Commission

CSA Canadian Standards Association

DC Direct Current

GT Grid Tie

GUI Graphical User Interface

LCD Liquid Crystal Display

LED Light Emitting Diode

MPPT Maximum Power Point Tracking

NEC US National Electrical Code NFPA-70

PC Personal Computer

PV Photovoltaic

PVGFP PV Ground Fault Protection

PWM Pulse Width Modu lation

STC Standard Test Condition

UL Underwriters Laboratories

Vac Volts AC

Vdc Volts DC

V

MP

V

OC

iv 975-0245-01-01

Voltage at Maximum Power

Open Circuit Voltage

Page 7

Related Information

You can find more information about Xantrex Technology Inc. as well as its

products and services at www.xantrex.com.

About This Manual

975-0245-01-01 v

Page 8

vi

Page 9

Important Safety Instructions

SAVE THESE INSTRUCTIONS—This manual contains important instructions that shall be followed

during the installation and maintenance of the Xantrex Grid Tie Solar Inverter.

1. Before installing and using the GT Inverter, read all instructions and cautionary markings on the

inverter, wiring box, and all appropriate sections of this guide.

2. To reduce risk of fire hazard, do not cover or obstruct the heat sink.

3. Observe the clearance recommendations as described on page 2–18. Do not install the G T In verter in a

zero-clearance or non-ventilated compartment. Overheating may result.

4. Use only accessories recommended or sold by the manufacturer. Doing otherwise may result in a risk

of fire, electric shock, or injury to persons.

5. To avoid a risk of fire and electric shock, make sure that existing wiring is in good condition and that

wire is not undersized. Do not operate the GT Inverter with damaged or substandard wiring.

6. Do not operate the G T Inverter if it has received a sharp blow, been dropped, or otherwise damaged in

any way. If the GT Inverter is damaged, see the Warranty section.

7. Do not disassemble the G T Inverter. It contains no user -serviceable parts. See Warranty for instructions

on obtaining service. Attempting to service the GT Inverter yourself may result in a risk of electrical

shock or fire and will void the factory warranty.

8. To reduce the risk of electrical shock, disconnect both AC and DC power from the GT Inverter before

attempting any maintenance or cleaning or working on any circuits connected to the inverter. Turning

off controls will not reduce this risk. Internal capacitors remain charged for 5 minutes after

disconnecting all sources of power.

9. The GT Inverter must be connected to an equipment-groun din g conductor directly or via the AC

ground.

975-0245-01-01 vii

Page 10

Safety

Regulatory Compliance

The GT Inverter has complete on-board over-current, over-temperature and anti-islanding protection, and

meets U.S., Canadian and international safety operating standards and code requirements:

• UL 1741 1st Edition – Standard for Inverters, Converters, and Controllers for Use in Independent

Power Systems

• CSA C22.2 No. 107.1-01 General Use Power Supplies

• IEEE C62.41 Recommended Practice on Surge Voltages in Low-Voltage AC Power Circuits (Location

Category B3).

To locate the firmware version number

The firmware version number for the protection processor is visible on a screen that appears when the unit

starts up or is powered up after switching the DC/AC Disconnect switch to “on.” The screen reads:

Flash = 01.01

ROM = 01.01

The number appearing after “ROM” is the firmware version number for the protection processor.

FCC Information to the User

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant

to part 15 of the FCC Rules. These limits are designed to provide reasonable protection against harmful

interference in a residential installation. This equipment generates, uses and can radiate radio frequency

energy and, if not installed and used in accordance with the instructions, may cause harmful interference to

radio communications. However, there is no guarantee that interference will not occur in a particular

installation. If this equipment does cause harmful interference to radio or television reception, which can

be determined by turning the equipment off and on, the user is encouraged to try to correct the interference

by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and the receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

viii 975-0245-01-01

Page 11

Safety

Verification and Commissioning Test

Purpose

This procedure is designed to verify correct operation of the Xantrex Grid Tie Solar Inverter both on initial

operation and periodically through its life as required by the utilities.

Commissioning Test

Follow the startup and monitoring procedures as documented in Chapters 4 and 5.

When operation of the inverter has been verified and the unit is producing power, run the disconnect test as

described in this section.

Verification Test

Periodically run the disconnect test. The inverter must respond within the 2-second limit for compliance

and then hold off on producing power for the required delay (default value of 5 minutes).

Disconnect Test

This test requires that the AC circuit for the inverter be switched off. This can be accomplished by

switching the breaker on the main panel that feeds the inverter(s). As an alternate, the disconnect for the

home or business may be used as well. Have someone watch the front panel of the inverter. Within 2

seconds of switching the breaker, the green light on the front of the inverter must go out. The display will

respond with an AC Fault display, indicating that the AC is out of the operating range.

Re-energize the breaker to the inverter. The unit will respond by beginning its countdown. The green light

will be off during this time. Five minutes after applying AC (default value), the green light will turn on and

the inverter will begin to push power to the grid. The display will then return to its on-line display showing

the power being produced along with the total kWh p r oduced to date.

Note: The default voltage, frequency and reconnect delay values as defined by UL1741 and CSA 107.1 -01

are programmed into the unit at time of shipment from the factory. No changes to these settings can be

made in the field by the user. Only authorized personnel with the utility’s permission may change these

settings. Contact Xantrex Technology to gain permission and the procedure/equipment to make these

changes.

975-0245-01-01 ix

Page 12

x

Page 13

Contents

Important Safety Instructions

Regulatory Compliance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

FCC Information to the User - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - viii

Verification and Commissioning Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - ix

1

Introduction

About the Xantrex Grid Tie Solar Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

Standard Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–3

Front Panel Features - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Wiring/Disconnect Box - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Safety and Standards - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

2

Installation

Installation Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Single Inverter Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Multiple Inverter Installations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Planning the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–2

Inverter Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–4

PV Array Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–5

Grounding Requirements - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–8

Routing the Wires - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–11

Preparing for the Installation - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Circuit Breakers and Disconnect Switch - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–13

Other Materials Needed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Equipment Needed - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–14

Mounting the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Preparing to Mount the Unit - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–16

Installing the Mounting Bracket - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–17

Mounting the Inverter on the Bracket - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–22

3

Wiring the Inverter

Accessing the Wiring Terminals - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Connecting the DC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Connecting the AC Wiring - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–7

975-0245-01-01 xi

Page 14

Contents

Connecting Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

DC and AC Wiring for Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–10

Communications Wiring for Multiple Inverters- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Xanbus Network Technology - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–12

Guidelines for Routing the Network Cables - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -3–15

Connecting Network Cable Between Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - -3–16

Communications Wiring for Monitoring a Single Inverter - - - - - - - - - - - - - - - - - - - - - - - -3–18

4

Starting the Inverter

Startup Procedure- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Checking the PV Array DC Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Checking the AC Utility Voltage - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–2

Replacing the Wiring/Disconnect Box Cover - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–3

Starting up the GT Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Commissioning Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

Disconnect Test - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–6

5

Monitoring the Inverter

Monitoring the Front Panel Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Front Panel Display Screens and What They Mean - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Startup Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Normal Operation Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Offline Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Fault Mode - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–7

Special Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Custom Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Status Indicator Lights- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

6

Maintenance and Troubleshooting

Factors Affecting GT Inverter Performance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

PV Array Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–2

Other Factors - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–3

Performing General Maintenance - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–3

Replacing Parts - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–3

Replacing the Ground Fault Protection Fuse - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–4

Replacing the Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–6

Identifying Error/Fault Conditions and Solutions- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–9

xii 975-0245-01-01

Page 15

Contents

A

Specifications

Electrical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–2

Input - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Output - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–2

Adjustable Disconnect Settings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–3

Efficiency - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–5

Environmental Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

User Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–6

Mechanical Specifications - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - A–6

Warranty and Return Information - - - - - - - - - - - - - - - - - - - - - - - - - - - - -WA–1

Index- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -IX–1

975-0245-01-01 xiii

Page 16

xiv

Page 17

Figures

Figure 1-1 Basic System Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–2

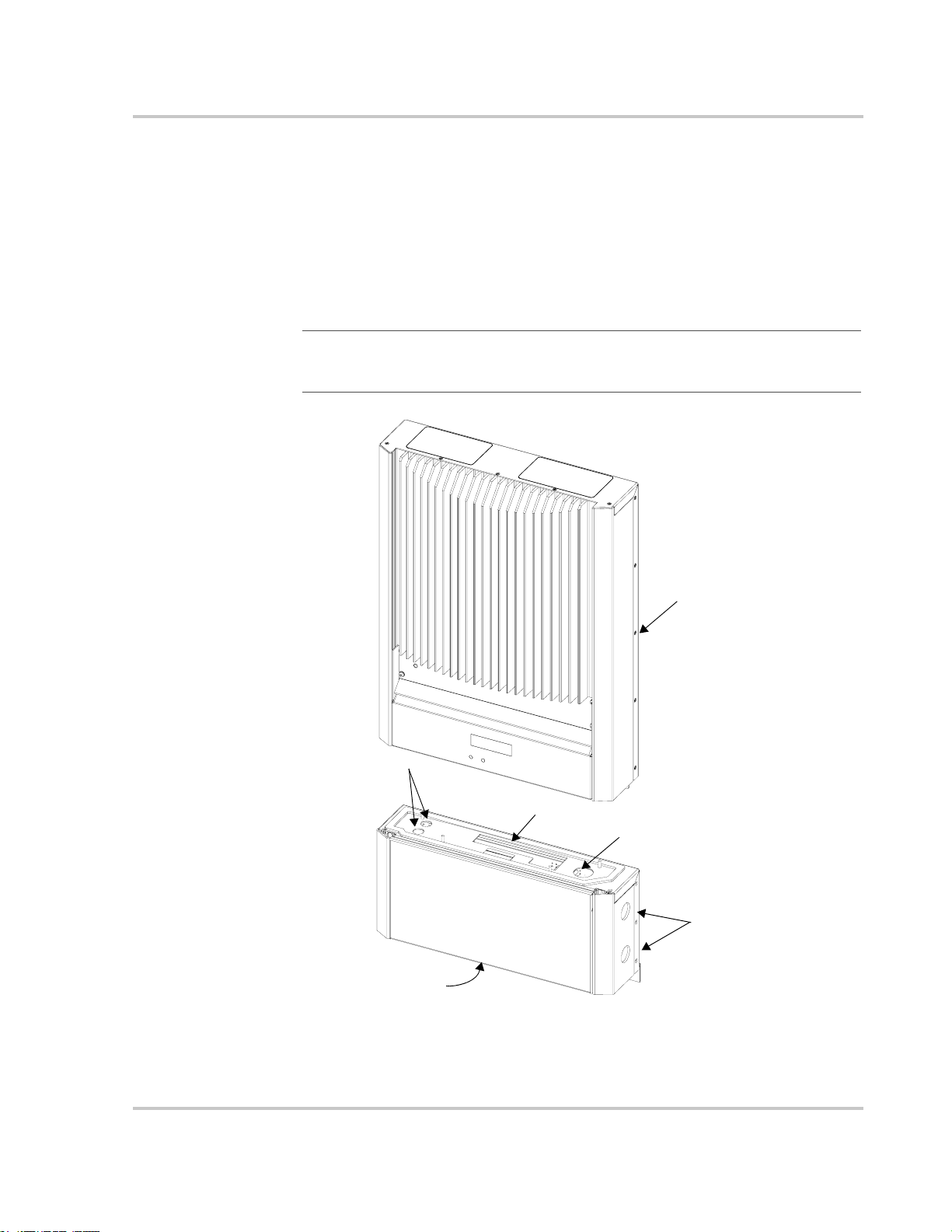

Figure 1-2 Main Features of the GT Inverter- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–4

Figure 1-3 Wiring Box and Removable Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–5

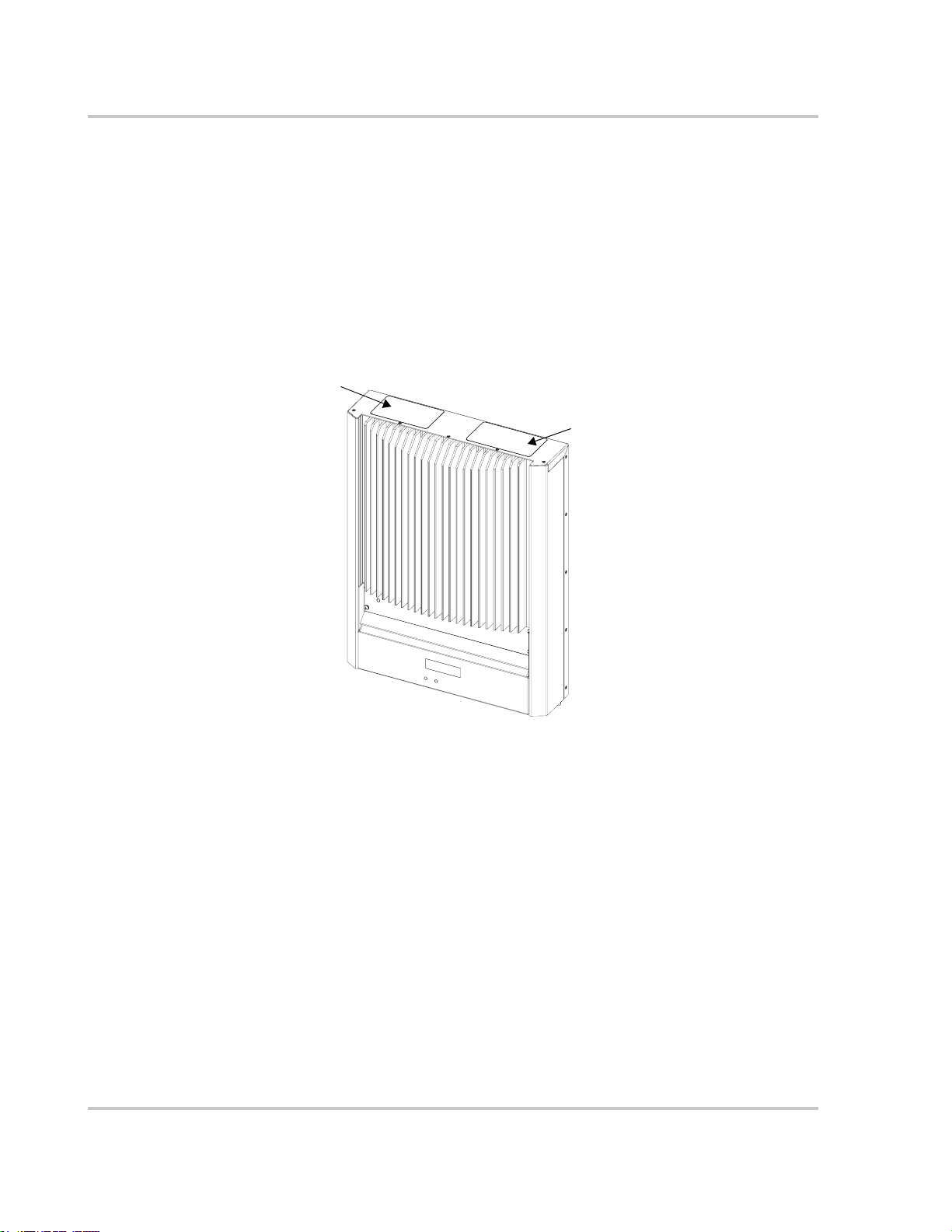

Figure 1-4 Safety and Data Label Locations - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 1–6

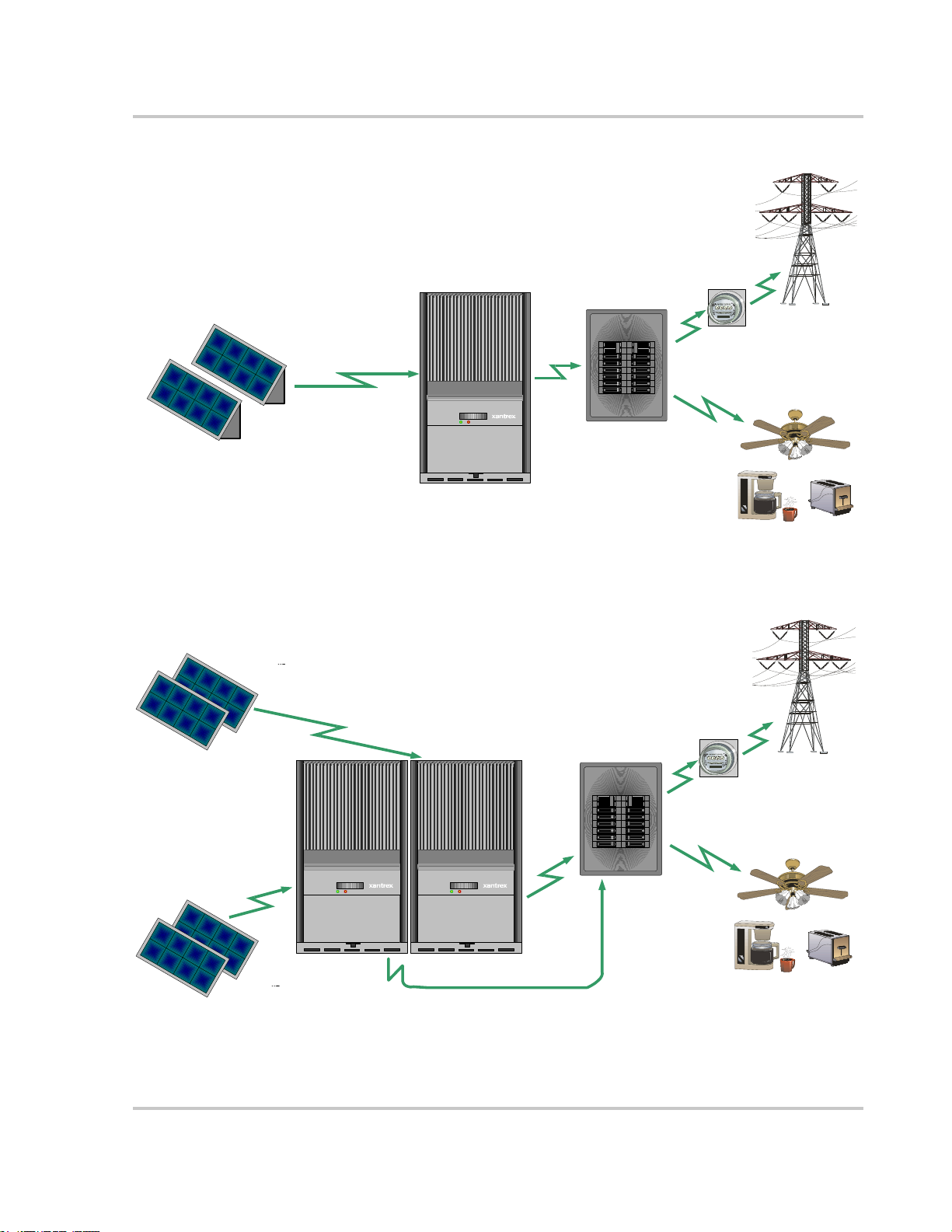

Figure 2-1 Installation Options Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–3

Figure 2-2 Basic Grounding Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–9

Figure 2-3 Long Distance Grounding Overview - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–10

Figure 2-4 Grounding With Extra Lightning Protection Overview - - - - - - - - - - - - - - - - - - - - - - 2–11

Figure 2-5 Conduit Hole and Knockout Locations- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–12

Figure 2-6 Installation Overview- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–15

Figure 2-7 Dimensions of GT Inverter and Knockout Locations- - - - - - - - - - - - - - - - - - - - - - - - 2–17

Figure 2-8 Mounting Bracket and GT Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

Figure 2-9 Examples of Mounting on a Pole or Rails - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–20

Figure 2-10 Installing the Mounting Bracket using Plywood Support - - - - - - - - - - - - - - - - - - - - - 2–21

Figure 2-11 Proper Placement of the Inverter on the Mounting Bracket - - - - - - - - - - - - - - - - - - - 2–22

Figure 3-1 Removing the Wiring Box Cover- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–2

Figure 3-2 AC and DC Terminal Block Location in the Wiring Box- - - - - - - - - - - - - - - - - - - - - - 3–3

Figure 3-3 DC/AC Disconnect Switch Positions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–4

Figure 3-4 DC Connections for Multiple PV Strings - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–6

Figure 3-5 AC Connections from GT Inverter to Utility Service Panel - - - - - - - - - - - - - - - - - - - - 3–8

Figure 3-6 Improper Multiple Inverter Connections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–9

Figure 3-7 DC and AC Wiring With Multiple GT Inverters- - - - - - - - - - - - - - - - - - - - - - - - - - - 3–11

Figure 3-8 Daisy Chain Layout- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–12

Figure 3-9 Male Network Terminator - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–13

Figure 3-10 Xanbus RJ45 Ports in the GT Inverter Wiring Box - - - - - - - - - - - - - - - - - - - - - - - - - 3–13

Figure 3-11 RJ45 Connector - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Figure 3-12 Communications Wiring for Multiple GT Inverters - - - - - - - - - - - - - - - - - - - - - - - - 3–17

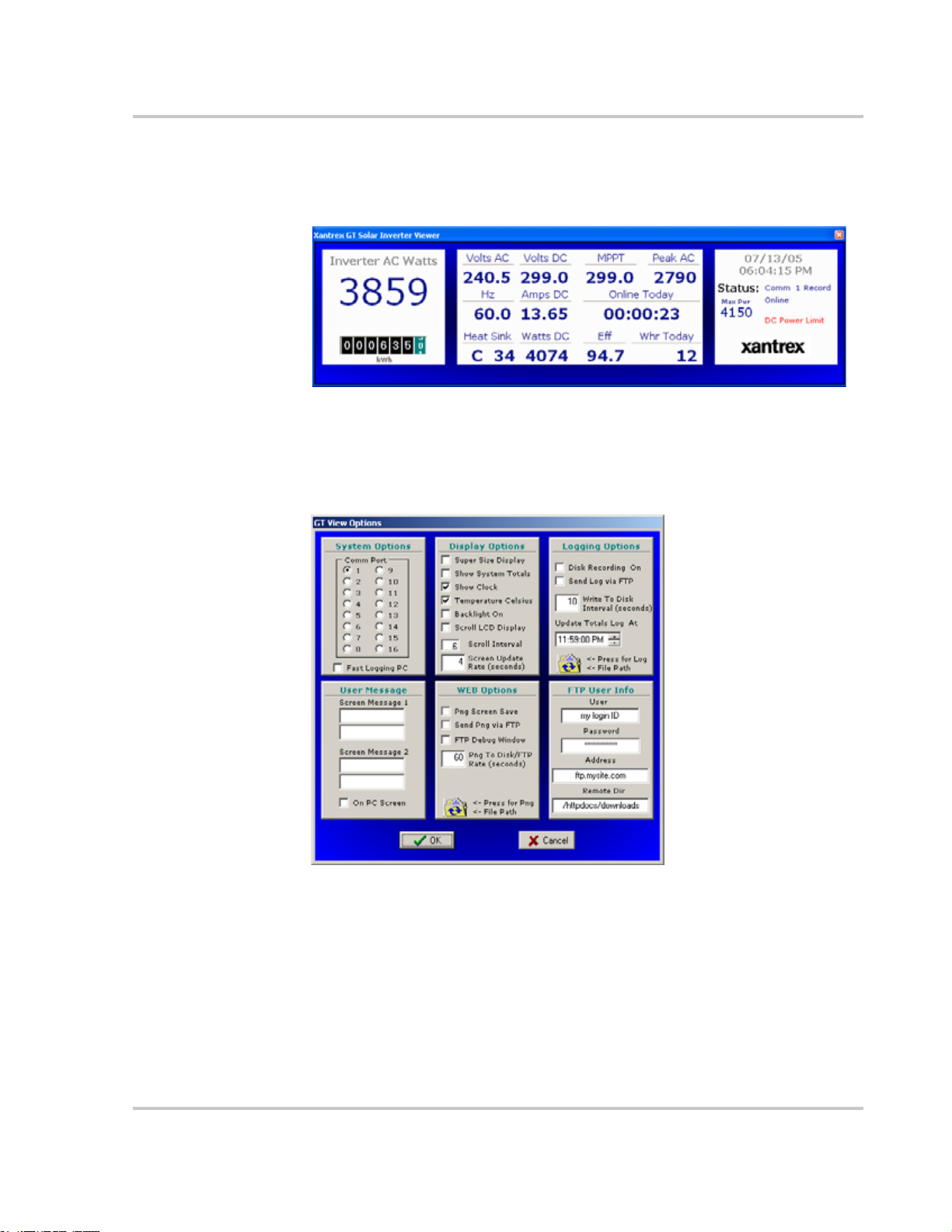

Figure 3-13 GT-View Display - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–19

Figure 3-14 GT-View Options - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–19

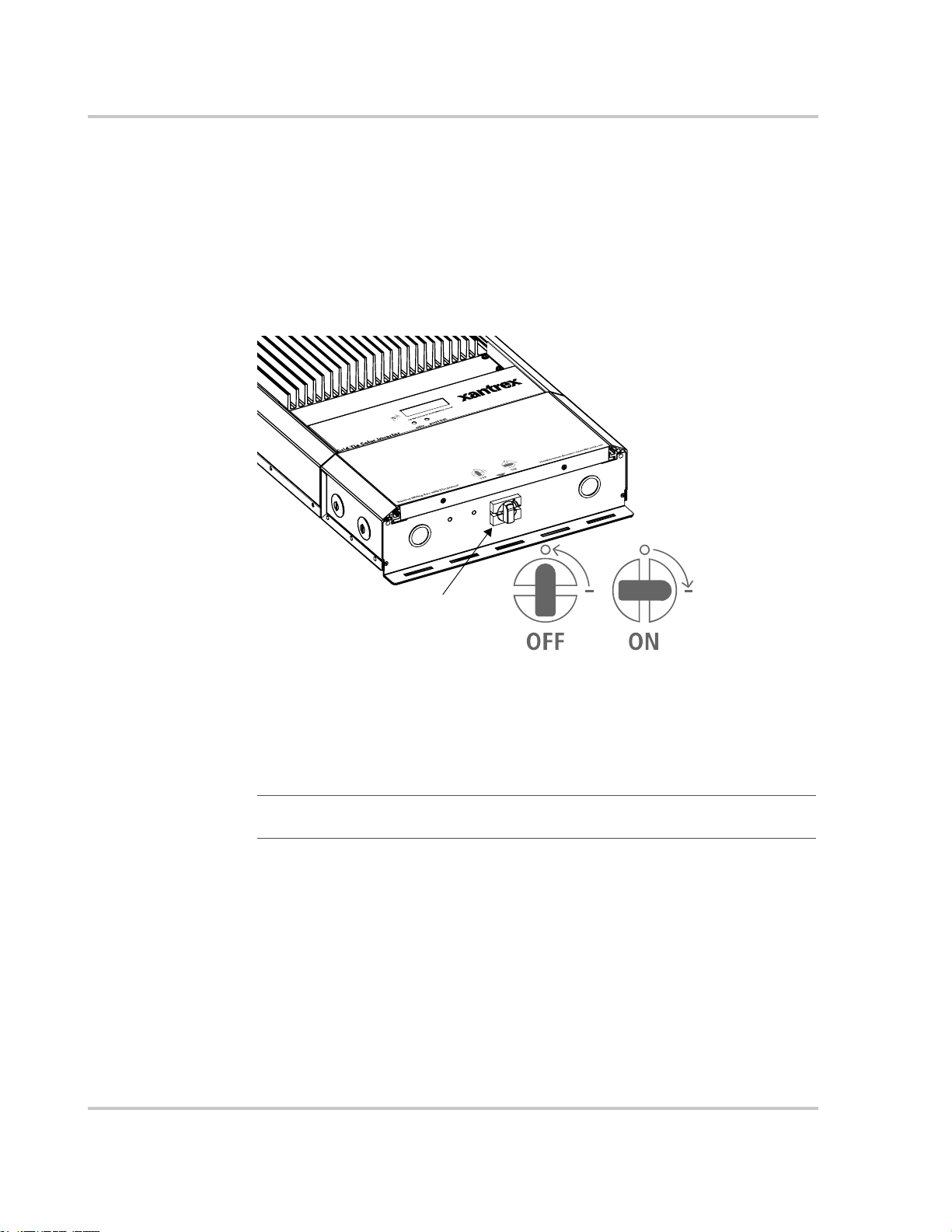

Figure 4-1 DC/AC Disconnect Switch Positions - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–4

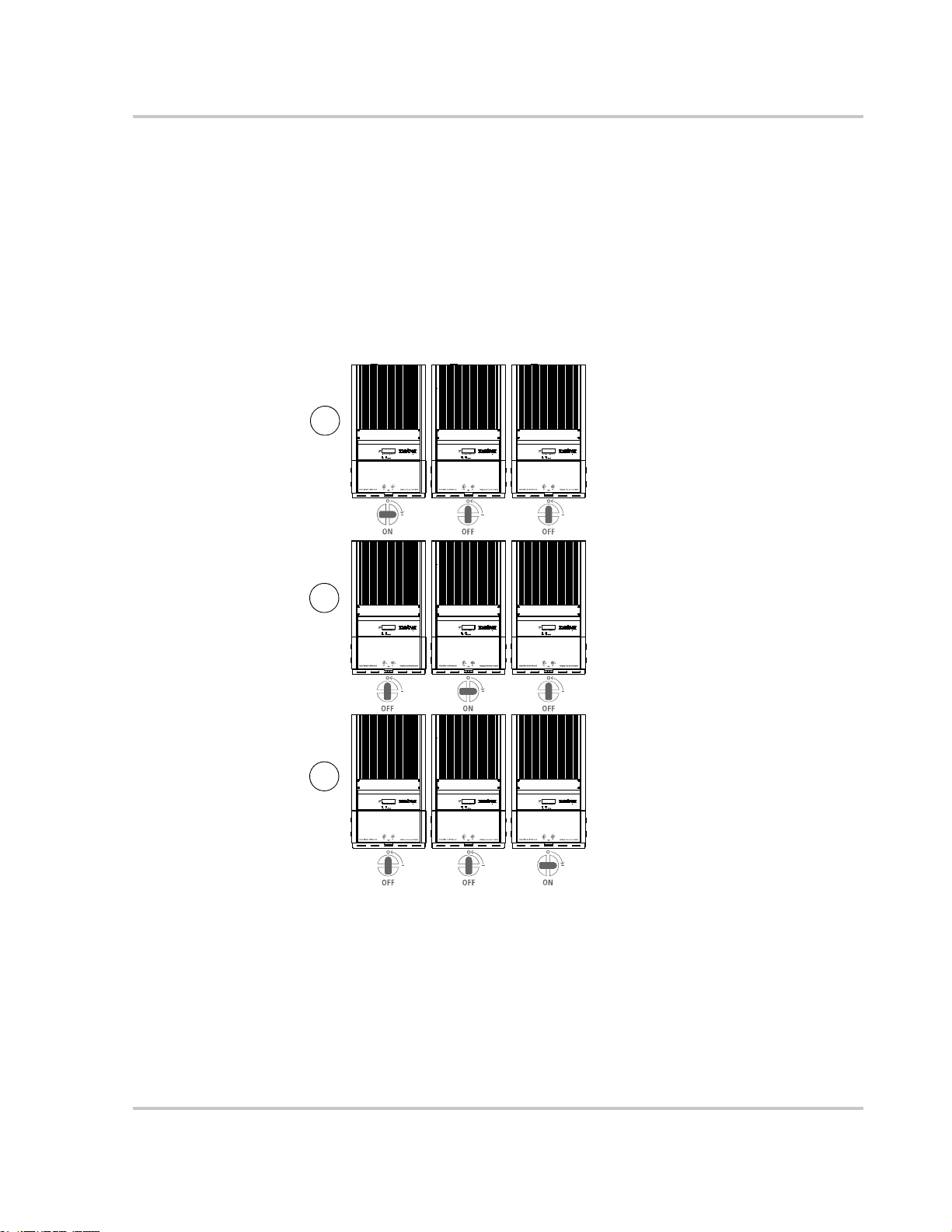

Figure 4-2 Commissioning Sequence for Multiple Inverters - - - - - - - - - - - - - - - - - - - - - - - - - - - 4–5

Figure 5-1 Front Panel LCD Location - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–2

Figure 5-2 Location of Status Indicator Lights - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

Figure 6-1 Location of Fuse, Front Panel Cover Removed - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–5

Figure 6-2 Display Front Panel Assembly - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–5

Figure 6-3 Wiring/Disconnect Box and Removable Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–7

Figure 6-4 Inverter and Wiring/Disconnect Box Sections - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–8

Figure A-1 Output Power vs. Ambient Temperature at Various DC Voltages - - - - - - - - - - - - - - - -A–4

Figure A-2 Typical Efficiency- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -A–5

975-0245-01-01 xv

Page 18

xvi

Page 19

Tables

Table 2-1 MPPT Operational Window - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–6

Table 2-2 Inverter Clearance Requirements- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 2–18

Table 3-1 Torque Values for Wires* - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–5

Table 3-2 T568A Standard Wiring- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–14

Table 3-3 Network Components and Part Numbers- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 3–15

Table 5-1 Startup Screens on GT Inverter Front Panel Display - - - - - - - - - - - - - - - - - - - - - - - - - 5–3

Table 5-2 Normal Operation Default Screen - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Table 5-3 Normal Operation Screens for All GT Inverter Units - - - - - - - - - - - - - - - - - - - - - - - - 5–4

Table 5-4 Additional Normal Operation Screens for Each GT Inverter Unit in a Multiple Unit System

5–5

Table 5-5 Offline Mode Default Display- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–5

Table 5-6 Offline Mode Screens for All GT Inverter Units- - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–6

Table 5-7 Additional Offline Mode Screens for Each GT Inverter Unit in a Multiple Unit System - 5–6

Table 5-8 Fault Message Screens- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–7

Table 5-9 Additional Fault Mode Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–8

Table 5-10 Special Message Screens - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–9

Table 5-11 Status Indicator LEDs - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5–10

Table 6-1 Troubleshooting the GT Inverter - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 6–9

975-0245-01-01 xvii

Page 20

xviii

Page 21

1

Introduction

Chapter 1, “Introduction”, contains information about the features

and functions of the Xantrex Grid Tie Solar Inverter.

The topics in this chapter are organized as follows:

• “Standard Features” on page 1–3

• “Safety and Standards” on page 1–6

Page 22

Introduction

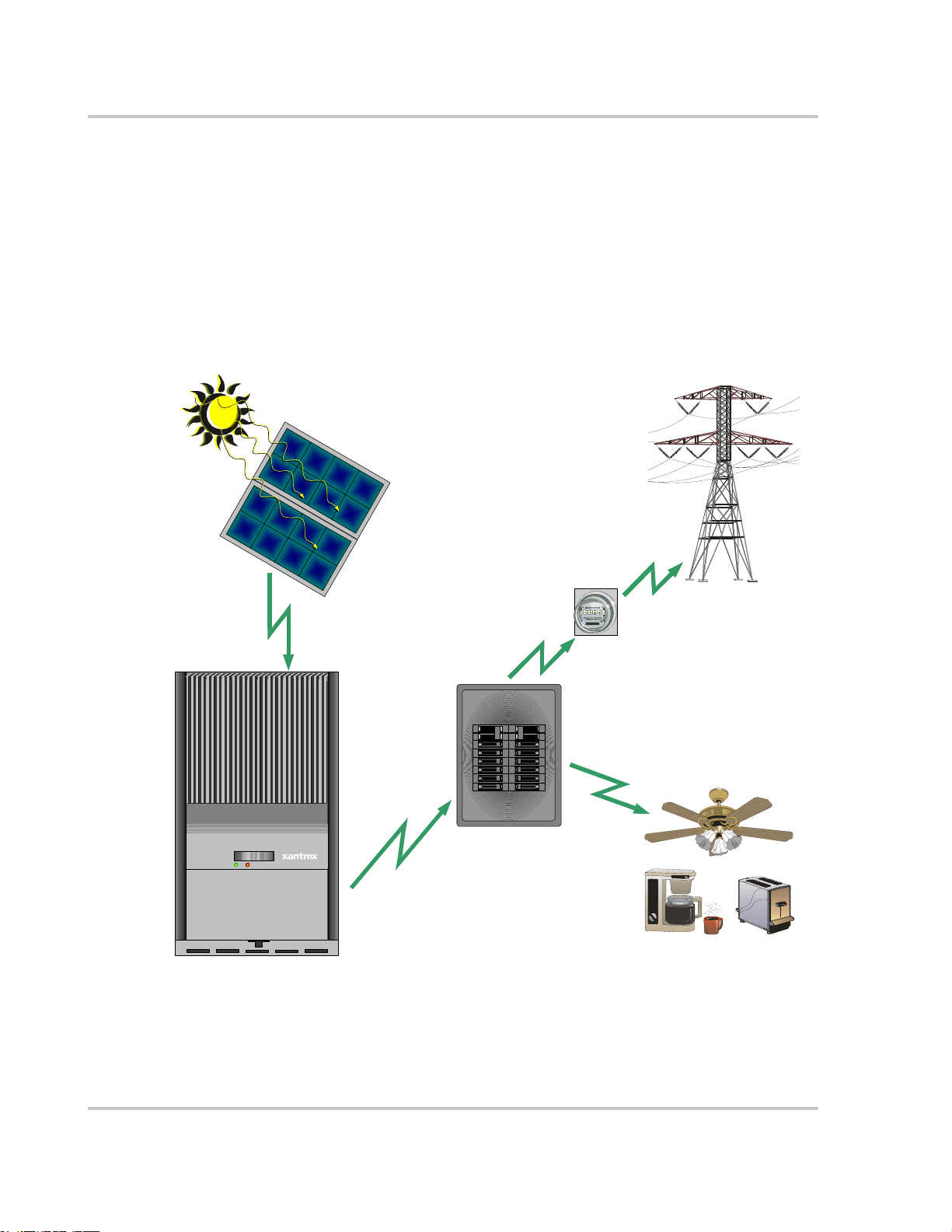

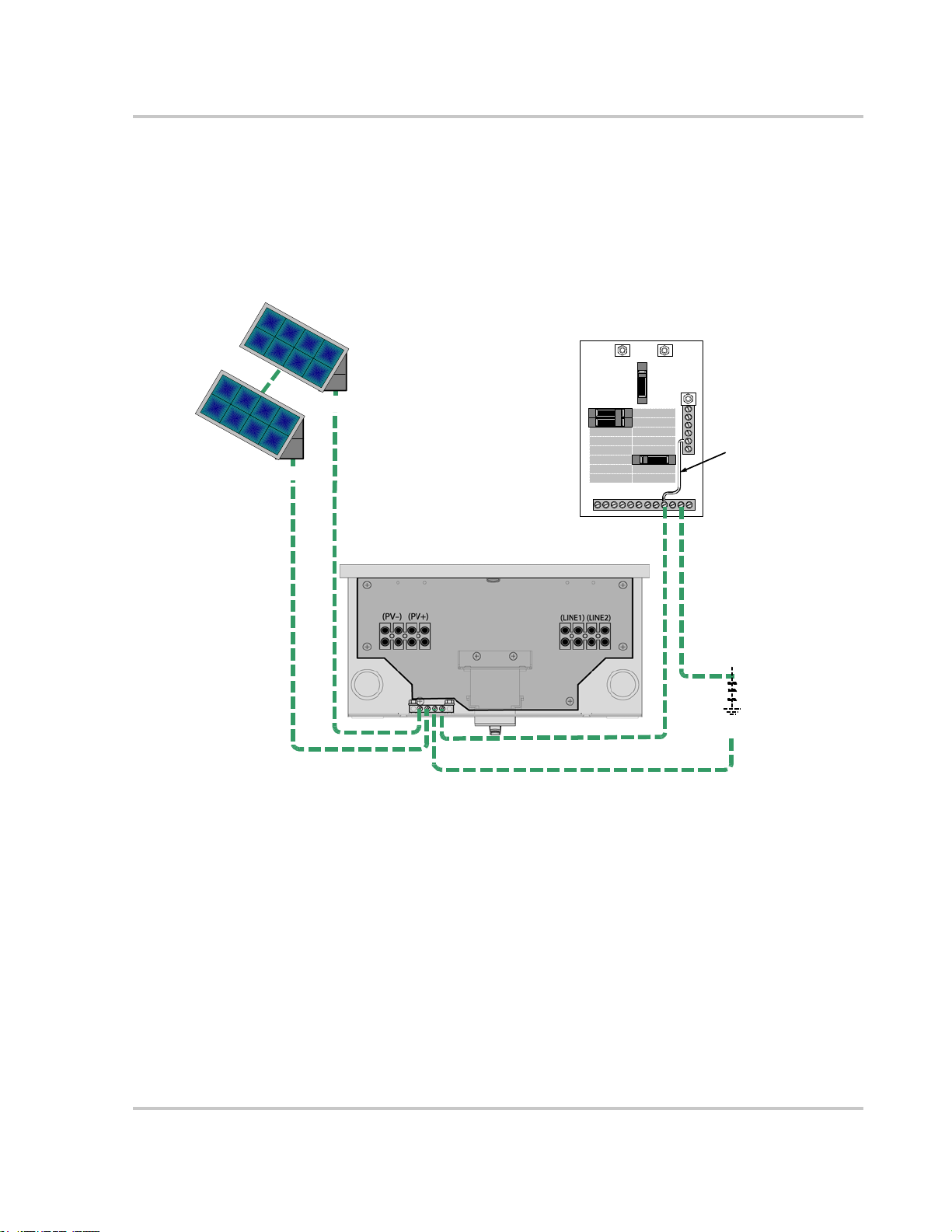

About the Xantrex Grid Tie Solar Inverter

The Xantrex Grid Tie Solar Inverter (GT Inverter) is designed to convert solar

electric (photovoltaic or PV) power into utility-grade electricity that can be used

by the home or sold to the local power company.

Installing the GT Inverter consists of mounting it to the wall and connecting the

DC input to a PV array and the AC output to the utility. See Figure 1-1 for a

simple diagram of a typical installation.

In order to operate, the GT Inverter must have grid power available and connected.

It will not provide backup power if the AC grid fails.

Photovoltaic (PV)

Panels - PV Array

Harvested

solar energy

Grid Tie Inverter

Figure 1-1 Basic System Overview

DC converted

to AC

Xantrex

GT Inverter

Utility

Meter

Utility Grid

Surplus power

route d to Utility Grid

Powe r ro ute d

to loads

Main Utility

Service Panel

Loads

1–2 975-0245-01-01

Page 23

About the Xantrex Grid Tie Solar Inverter

PV compatibility The G T Invert er is designed to take advantage of solar modules configured as high

voltage PV string arrays—single crystalline, poly crystalline, or thin film—with a

195 to 550 Vdc input voltage Maximum Power Point range.

Maximum Power

Point Tracking

(MPPT)

The GT Inverter uses Xantrex proprietary Maximum Power Point Tracking

(MPPT) technology to harvest the maximum amount of energy from the solar

array. Xantrex MPPT learns your array’s specific characteristics, maximizing its

output at all times.

High efficiency The high-frequency, solid-state design of the GT Inverter is extremely efficient—

up to 95%.

Expandable Multiple GT Inverters may be networked together for increased net metering

capacity or future system growth.

Communications

protocol

The GT Inverter uses the Xanbus

communicate with multiple units connected within the system. For more

®

Communications protocol, enabling it to

information, see “Xanbus Network Technology” on page 3–12.

Standard Features

The GT Inverter has the following standard features:

• Sealed inverter section protecting power electronic components;

• Liquid Crystal Display (LCD) providing easy-to-read system status and daily

cumulative energy production information;

• Two LED indicator lights providing status and ground fault indication;

• Wiring/disconnect box providing protection for all AC and DC connections

and eliminating exposed “live” wiring if the inverter is removed.

WARNING: Shock hazard

The 600 volt DC/AC disconnect in the wiring/disconnect box meets NEC Article 690. It is

a non-serviceable component and shall remain in place. Removal can expose energized

conductors.

975-0245-01-01 1–3

Page 24

Introduction

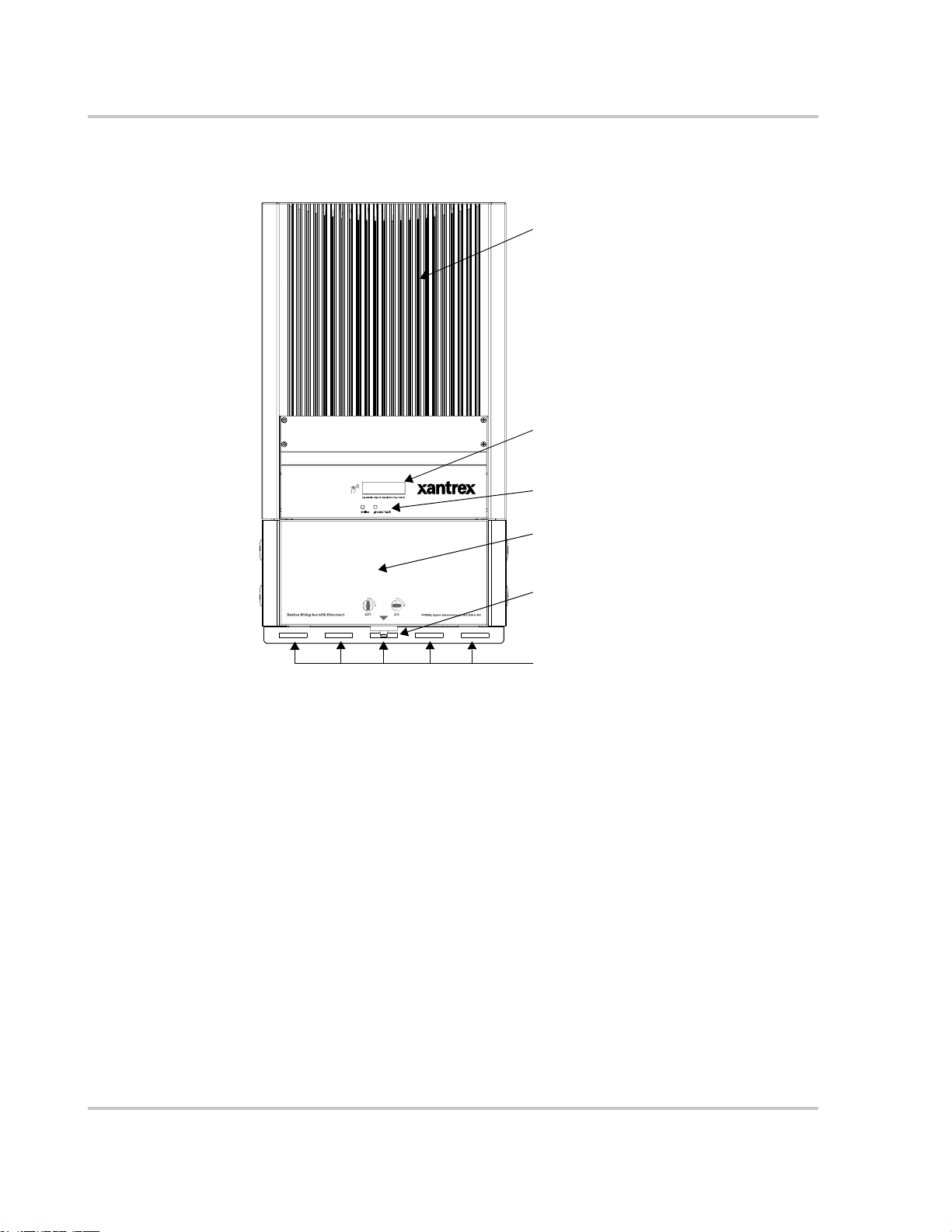

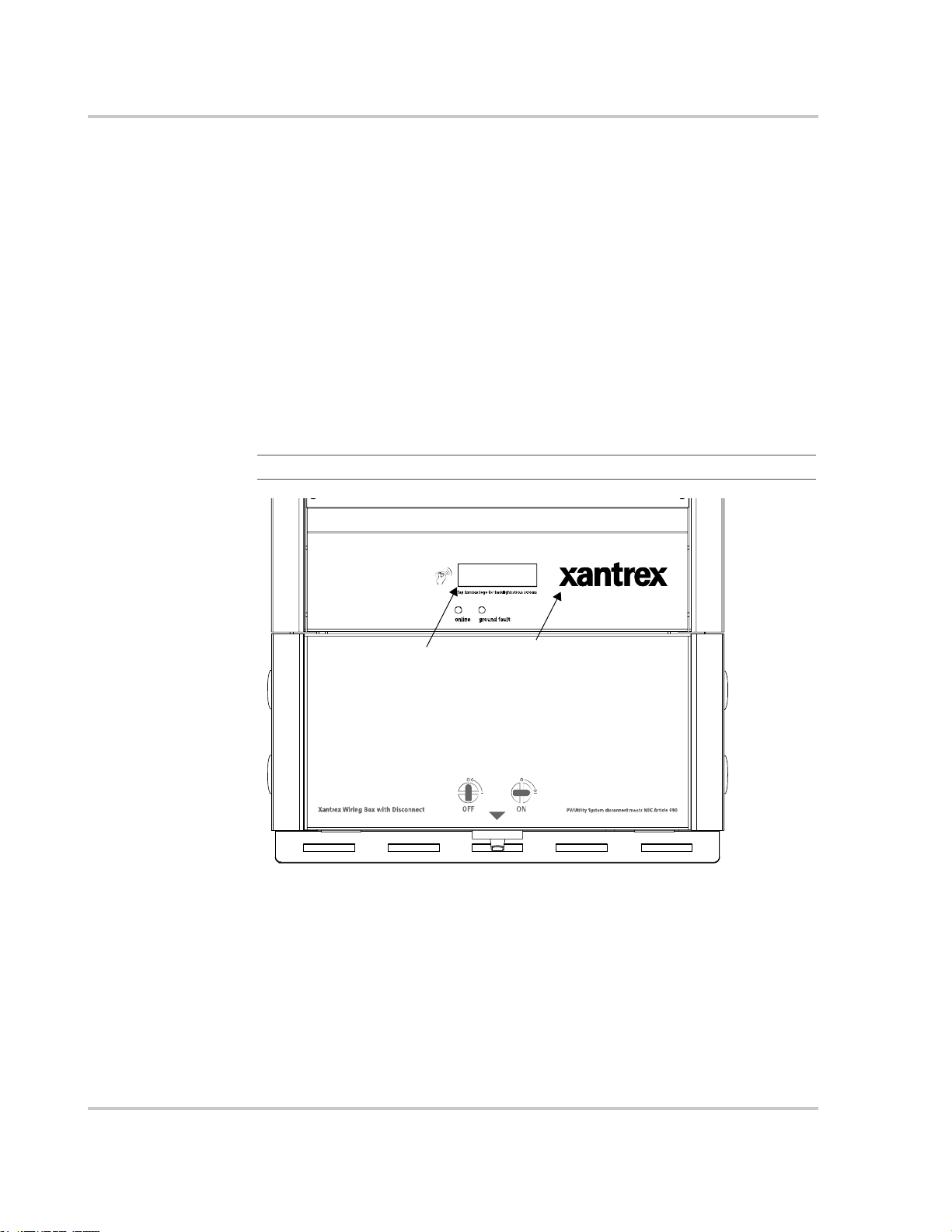

Front Panel Features

Heat Sink

LCD

LED Indicator Lights

Grid Tie Solar Inverter

Wiring/Disconnect Box

Figure 1-2

Wiring/Disconnect Box

The wiring/disconnect box is standard for all North American models of the GT

Inverter.

The wiring/disconnect box provides a location for making AC, DC and ground

connections. It also contains the DC/AC (PV array/Utility) disconnect switch.

Although the GT Inverter is shipped as a complete system, it is essentially two

separable products: a PV inverter and a wiring/disconnect box. The manual

disconnect switch in the wiring box allows easy access and a quick one-turn

disconnect for both AC and DC inputs. It has been designed to be physically

mated to the electronics section of the GT Inverter at the factory, but remains in

place as a non-serviceable item in the event that the inverter electronics section is

ever required to be removed. When used with the GT Inverter, the DC/AC

disconnect switch is 600V AC and DC rated and also is identified on the outside

by an illustration showing the open and closed switch positions. The DC/AC

DC/AC Disconnect Switch

Mounting Slots

Main Features of the GT Inverter

1–4 975-0245-01-01

Page 25

AC Disconnect

About the Xantrex Grid Tie Solar Inverter

wiring/disconnect box is an NEMA 3R enclosure to allow outdoor installation and

is clearly marked as a PV system disconnect. The lockable switch meets NEC

section 690 requirements as a means of disconnect.

In some jurisdictions, where the local utility requires that the AC disconnect be

capable of being locked in the open position by its service personnel, this

disconnect switch can also serve as a lockable and visible break isolating device.

Important:

electrical code requirement. It must be attached during operation. Check with your local

authorities before removing the GT Inverter wiring/disconnect box.

DC Connect

holes

In North America and other locations the wiring/disconnect box is an

Removable inverter (for

servicing, if required)

Control Board Connect hole

AC Connect hole

Wiring/Disconnect Box

Front Cover

DC/AC Disconnect

Switch

Figure 1-3

975-0245-01-01 1–5

Wiring Box and Removable Inverter

27 mm (1”) threaded

conduit holes

Page 26

Introduction

Safety and Standards

The GT Inverter has complete on-board over-current, over-temperature and antiislanding protection, and meets U.S. and Canadian safety operating standards and

code requirements:

• UL 1741 – Standard for Inverters, Converters, and Controllers for Use in

• CSA C22.2 No. 107.1-01 General Use Power Supplies.

Figure 1-4 shows the location of the safety label and the data label with model,

serial and part number information.

Safety Label

Location

Independent Power Systems

Data Label

Location

Figure 1-4

1–6 975-0245-01-01

Safety and Data Label Locations

Page 27

2

Installation

Chapter 2, “Installation”, provides information about planning for and

installing the GT Inverter. It contains information to help you plan

wire routes, AC and DC connections, and find a suitable location for

installation. It also discusses requirements for grounding the GT

Inverter and your PVarray.

Procedures are provided for installing the Xantrex Grid Tie Solar

Inverter.

The topics in this chapter are organized as follows:

• “Installation Options” on page 2–2

• “Planning the Installation” on page 2–2

• “Preparing for the Installation” on page 2–12

• “Mounting the Inverter” on page 2–15

Page 28

Installation

Installation Options

The GT Inverter may be installed as a single inverter for a single PV array of one

or two PV strings, or in a multiple inverter configuration for multiple PV arrays

(see Figure 2-1 for diagrams of both options).

Single Inverter Installation

In this configuration, a single inverter collects the harvested solar energy and

routes the power to the main utility service panel to be used by the loads. Any

surplus power not used by the loads will be directed to the utility grid.

Multiple Inverter Installations

If multiple inverters are used, each inverter must be wired to an independent PV

array . In this configuration, each inverter collects the harvested solar energy from

a separate PV array and routes the power to the main utility service panel to be

used by the loads. Any surplus power not used by the loads will be directed to the

utility grid.

Communications between inverters can be enabled by installing network cabling

to the inverter RJ45 ports. See “Connecting Network Cable Between Multiple

Inverters” on page 3–16.

Planning the Installation

The following issues need to be considered when planning for an installation

using the GT Inverter. See the specified sections for more information.

• “Inverter Location” on page 2–4

• “PV Array Requirements” on page 2–5

• “Grounding Requirements” on page 2–8

• “Routing the Wires” on page 2–11.

Ensure that you have obtained all permits required by local authorities or utilities

before commencing installation.

2–2 975-0245-01-01

Page 29

Single Inverter Installation

Planning the Installation

Utility Grid

Photovoltaic Panels - PV Array

PV String #1

PV String #2

PV Array #1

#2

Harvested solar energy

Multiple Inverter Installation

Xantrex

GT Inverter

Grid Tie Inverter

DC

converted

to AC

Main Utility

Service Panel

Power route d

to loads

Utility

Meter

Surplus power

routed to Utility Grid

Loads

Utility Grid

Utility

Meter

Surplus power

routed to Utility Grid

Loads

Powe r route d

to loads

Photovoltaic Panels:

Multiple PV Array s

Figure 2-1

solar energy

Harvested

solar energy

PV Array #2

Harvested

#1

Xantrex GT I nv ert ers

GT Inverter #1

Installation Options Overview

Main Utility

Service Panel

DC

converted

to AC

Grid Tie InverterGrid Tie Inverter

GT Inverter #2

DC converted to AC

975-0245-01-01 2–3

Page 30

Installation

Inverter Location

WARNING: Burn hazard

Do not install in a location where people can accidentally come into contact with the front

of the inverter. High temperatures can be present on the face of the inverter, causing a

potential burn hazard.

In extreme conditions, the GT Inverter chassis can reach temperatures over 70° C

(158° F), which can cause skin burns if accidentally touched. Ensure that the GT Inverter

is located away from normal traffic areas.

Inverter failure due to improper installation will void the inverter warranty.

Consider the following when determining where to install the inverter.

Fire Safety

Indoor/Outdoor

Orientation

Temperature

Ground

Clearance

• Do not install anywhere near combustible or flammable materials.

• The GT Inverter uses a Type 3R-rated enclosure (vertical mount

only) that can be mounted indoors or outdoors. (Type 3R

enclosures are intended for outdoor use primarily to provide a

degree of protection against falling rain; and to be undamaged by

the formation of ice on the enclosure.)

• While the 3R-rated enclosure protects the GT Inverter from

moisture, outdoor installations should be located away from lawn

sprinklers and other sources of spray.

• The GT Inverter must be mounted vertically on a wall or pole.

• Do not mount the GT Inverter horizontally.

• Ensure that the GT Inverter is mounted in a location where the

ambient temperature range is

• At extreme hot or cold temperatures, the front panel LCD may not

function normally.

• At higher temperatures, the GT Inverter may derate power.

See“Output Power vs. Ambient Temperature at Various DC

Voltages” on page A–4 and “Environmental Specifications” on

page A–6.

• Outdoors, the GT Inverter requires at least 100 cm (39 inches) of

clearance between the bottom of the unit and the ground.

• Indoors, it is recommended that the same clearance between the

bottom of the unit and the floor be used.

-25° to +65° C (-13° to +149° F).

Distance

2–4 975-0245-01-01

• To minimize copper losses, ensure that wire lengths between the

PV array and the GT Inverter and between the inverter and the

Main Utility Service Panel are kept to a minimum.

• Maximum distances will depend on wire gauges used and PV

array output voltages.

Page 31

Planning the Installation

Debris free

• Excessive debris (such as dust, leaves, and cobwebs) can

accumulate on the unit, interfering with wiring connections and

ventilation. Do not install in a location where debris can

accumulate (under a tree, for example).

PV Array Requirements

WARNING: Shock hazard

Whenever a PV array is exposed to sunlight, a shock hazard exists at the output wires or

exposed terminals. To reduce the risk of shock during installation, cover the array with an

opaque (dark) material before making any connections.

General Recommendations

It is important that the PV array is installed correctly to the manufacturer’s

specifications and to local code requirements.

Equipment and Installation Recommendations

Important:

small obstructions such as vent pipes, chimneys and power lines. A small amount of shade

can have a disproportionately high impact on system performance.

The PV array should be free of shade. This requirement includes even

Equipment

recommendations

Installation

recommendations

• All electrical equipment should be listed for the voltage and current ratings

necessary for the application.

• All wiring should be sized correctly to minimize voltage drop.

• All exposed wires or conduits should be sunlight resistant.

• All required overcurrent protections should be included in the system and

accessible for maintenance.

• Depending on the installation, an external disconnect may be required if the

inverter is installed in a location not easily accessible to utility or fire

personnel. Consult local authorities for additional information.

• Integral roofing products should be properly rated.

• All electrical terminations should be fully tightened, secured, and strain

relieved as appropriate.

• All mounting equipment should be installed according to the manufacturer’s

specifications.

• All roof penetrations should be sealed with an acceptable sealing method that

does not adversely impact the roof warranty.

• All wires, conduit, exposed conductors and electrical boxes should be secured

and supported according to code requirements.

975-0245-01-01 2–5

Page 32

Installation

Voltage and MPPT Requirements

MPPT operational

window

Voltage

requirements

Maximum PV

Power

The MPPT software maximizes the output energy of solar arrays as long as the

operating voltage is within the MPPT operational window. Ensure that the PV

array used in the system operates within the MPPT operational window.

Effects of array voltages outside of the MPPT operational window are shown in

Table 2-1.

Table 2-1

Voltage Effect of Array Voltage Inverter Mode

< 195 Vdc Operating voltage will be shifted to 195 Vdc;

195 to 550 Vdc Maximum harvest of solar energy MPPT window

550 to 600 Vdc Will not allow maximum harvest of solar

> 600 Will shut down and may cause damage to the

MPPT Operational Window

Low power

the array will not be at its maximum power

point

Power derating

energy

Shutdown

inverter; stops selling surplus energy

The maximum power point voltage of a string connected to the GT Inverter should

be a minimum of 195 Vdc. If it is less than 195 Vdc, the inverter will continue to

operate, but it will regulate the PV voltage to 195 V. Because the array will not be

operating at its maximum power point, this may result in lower than expected

energy harvest.

The solar array should be sized such that its maximum power output does not

exceed the limits of the MPPT operational window (195 to 550 Vdc). See

“Guidelines for Matching PV Array Size to Xantrex Grid Tie Solar Inverter

Input”.

The array voltage should never exceed 600 V

(open circuit voltage) under any

OC

thermal condition.

Likewise, ensure that the Isc (short circuit current) rating of the array at any

temperature does not exceed the short circuit current rating of the inverter.

2–6 975-0245-01-01

Page 33

Planning the Installation

Guidelines for Matching PV Array Size to Xantrex Grid Tie Solar Inverter Input

For determining the number of panels required in the PV string (panels connected

in series), you must ensure that the following requirements are met:

1. To avoid damage to the inverter, ensure that the PV array output will never

exceed 600 Vdc under any conditions.

2. Do not exceed the maximum array short circuit-current rating marked on the

inverter.

3. To achieve maximum energy harvest from your array, ensure that the V

(voltage at maximum power) does not drop below 195 Vdc or increase above

550 Vdc under most conditions.

Guidelines to help you meet these requirements:

• Consider the expected V

panel manufacturer provides a V

°C (77°F). Ensure that the V

25

does not exceed 600 Vdc. Panel voltage increases in cold temperatures—the

panel manufacturer should be able to provide a coefficient of voltage increase

per degree.

• The NEC also has required temperature/voltage deratings that must be used;

these can be found in Table 690.7 of the 2002 NEC handbook. You need to

determine the coldest temperatures expected on the site, and size the array

strings accordingly. The array’s maximum DC voltage in coldest expected

temperature, with both manufacturer coefficient and NEC derating, must not

exceed 600 Vdc to prevent inverter damage.

• Panel voltage decreases in high temperatures. This will affect the panels’

V

. Again, the manufacturer’s coefficient must be used with the highest

MP

expected temperature to determine the minimum V

Once you know the specifications of your panels, all these factors will help

determine the maximum and minimum number of panels that can be used.

of the string under all possible conditions. The

OC

rating per panel, but it is usually rated at

OC

rating at the coldest ambient temperature

OC

.

MP

MP

Note:

975-0245-01-01 2–7

The GT PV array sizing tool is available at www.xantrex.com.

Page 34

Installation

Grounding Requirements

WARNING: Shock hazard

The GT Inverter must be grounded by connection to a grounded permanent wiring system.

AC Grounding

North America The GT Inverter must be connected to a grounded, permanent wiring system via

the GT Inverter ground bar. See Figure 2-2 for the location of the GT Inverter

ground bar.

The ground bar must also be connected to the main utility breaker panel ground

bar and to the house grounding rod according to NEC requirements.

Elsewhere In other locations, AC grounding is governed by local codes. Consult with the

local utility for specific grounding requirements.

PV Grounding

The GT Inverter is designed to have all PV positive, negative, and ground

conductors connected inside its wiring box. The PV equipment ground should be

connected to the GT Inverter ground bar.

The size for the conductor is usually based on the size of the largest conductor in

the DC system.

A DC grounding electrode conductor may be required by the Authority Having

Jurisdiction (AHJ). Use the GT Inverter ground bar for this connection.

Important:

ground system within the inverter’s ground fault detection circuit. Inverter models marked

with the “-POS” suffix are positive grounded and have the positive PV conductor

internally bonded to the ground system through the inverter’s ground fault protection

circuit. It is important that the negative (or positive) PV conductor is not bonded to the

ground at any other point in the system.

Long Distance Grounding

If the PV array is more than 30 meters (100 feet) from the inverter, then there

must also be a direct connection from the array frame to an earth ground next to

the array. A connection between this ground and the primary earth ground

connection via a buried wire between the two points is also necessary (see

Figure 2-3).

In most models, the negative PV conductor is internally bonded to the

2–8 975-0245-01-01

Page 35

Lightning Protection

Planning the Installation

Reduce the risk of lightning damage by using a single-point grounding system. In

this system, all ground lines terminate at the same point—the primary earth

ground. This point normally is the main utility ground installed by the utility

company to provide a ground for the house wiring (see Figure 2-4). This ground

usually consists of a copper rod driven 1.5 to 2.5 meters (6 to 8 feet) into the earth.

G

PV String #1

PV String #2

G

PV Array

G

GND bar

Xantrex GT Inve rter

Wirin g Box

DC/AC Disconnect Switch

Main Utility

Service Pan el

L1

NEUTRAL

GROUND

G

L2

Neutral

-to-

Ground

Bond

AC Ground

Primary Eart h

Ground

DC Ground if required by AHJ

Figure 2-2

Basic Grounding Overview

975-0245-01-01 2–9

Page 36

Installation

Array

Earth

Ground

PV Array

G

PV String #2

G

Distance >30 m (100 ft)

PV String #1

When the distance between the PV Array and the GT

Inverter is greater than 30 m (100 ft), the array should have

its own earth ground, which should be connected to the

Primary Earth Ground by a buried wire.

Check your local codes for grounding requirements.

Main Utility

Service Pan el

L1

GROUND

L2

NEUTRAL

G

Neutral

-to-

Ground

Bond

G

Xantrex GT Invert er

Wiri ng Bo x

AC Gr ound

GND bar

Figure 2-3

Buried wire

DC G round

Long Distance Grounding Overview

G

DC/AC Disconnect Switch

Primary

Earth

Ground

2–10 975-0245-01-01

Page 37

Planning the Installation

PV Array

PV String #1

G

PV String #2

G

Main Utilit y

Service Pan el

L1

GROUND

G

L2

NEUTRAL

G

Neutral

-to-

Ground

Bond

Xantrex GT Inverter

Wiri ng Bo x

AC Gro u n d

GND bar

G

DC/AC Disconnect Switch

DC Ground

Primary

Earth

Ground

Figure 2-4

Grounding With Extra Lightning Protection Overview

Routing the Wires

Typical

configurations

975-0245-01-01 2–11

Determine all wire routes to and from the GT Inverter. Typical routing

configurations include:

• AC wiring from the GT Inverter to the main utility service panel

• DC input wiring from the PV array to the GT Inverter

• DC ground from the PV array to the Primary Earth Ground.

All wiring and installation methods should conform to applicable electrical and

building codes.

For installations in the United States, the National Electrical Code (NEC) and

local codes apply. For installations in Canada, the Canadian Electrical Code

(CEC) and local codes apply.

For all installations, local utilities may have additional requirements.

Page 38

Installation

WARNING: Shock hazard

Check for existing electrical or plumbing prior to drilling holes in the walls.

Conduit

holes/knockouts

Pre-plan the wire and conduit runs. Dual knockouts for 35 mm (1 3/8 inch) or

27 mm (1 inch) conduit holes are located on the bottom and back of the wiring

box—four dual knockouts in total. T wo threaded 2 7 mm (1 inch) conduit holes are

located on each side of the wiring box (Figure 2-5).

For maximum safety , run AC, DC, and communication wires in separate conduits.

35 mm (1 3/8”) and 27 mm (1”)

dual knockouts

Figure 2-5

Bottom

Conduit Hole and Knockout Locations

27 mm (1”) threaded

conduit holes

DC/AC

Disconnect Switch

Side

Preparing for the Installation

Ensure your local utility is consulted for any requirements for connecting to or

returning power to the grid. Obtain all permits necessary to complete the

installation. Consult your local and national electrical codes for more information.

This section includes the following topics:

• “Wiring” on page 2–13

• “Circuit Breakers and Disconnect Switch” on page 2–13

• “Other Materials Needed” on page 2–14

• “Equipment Needed” on page 2–14.

Important:

DC wiring/cabling and wires/cables.

2–12 975-0245-01-01

In this manual “wiring” and “wires” are used in reference to both AC and

Page 39

Wiring

Preparing for the Installation

Wire size and length will be determined by the location of each component and

their relative distance to each other. W ire sizes may also be affected by whether or

not conduit is used.

Recommended wire

stripping length

Acceptable wire

sizes

Strip all wires 9 mm (3/8 inch).

The AC and DC terminal blocks in the GT Inverter accept wire sizes from

#14 AWG to #6 AWG.

Important:

significant power losses and reduction in system efficiency.

Wiring should not be undersized. Undersized wiring can result in

Circuit Breakers and Disconnect Switch

The following circuit breakers, disconnect switch and fuse are required for

installing this equipment.

AC Circuit Breaker Requirements

In North America, the main utility service panel must dedicate a double pole

breaker to operate each G T Inverter installed. This breaker must be sized to handle

the rated maximum output voltage and current of the GT Inverter (see “Electrical

Specifications”, “Output” on page A–2).

DC/AC Disconnect Switch

The wiring box includes a PV/Utility disconnect switch that switches both AC and

DC at the same time.

WARNING: Shock hazard

Do not remove the wiring/disconnect box. The 600 volt DC/AC disconnect in the wiring

box meets NEC Article 690. It is a non-serviceable component and shall remain in place.

Removal can expose energized conductors.

Use caution when working around sources of DC power. Although the DC/AC disconnect

switch disconnects the inverter from DC power, hazardous voltages from paralleled PV

strings may still be present upstream of the switch.

Ground Fault Fuse

The GT Inverter is equipped with a 600 volt 1-Amp ground fault protection fuse

(replace with Littelfuse KLKD 1 or equivalent).

975-0245-01-01 2–13

Page 40

Installation

WARNING: Shock hazard

Do not attempt to service the ground fault protection fuse yourself. This should only be

done by qualified service personnel, such as certified electricians or technicians.

Other Materials Needed

• Mounting support material, such as plywood or poles

• Conduit for wire runs and appropriate fittings/bushings

• Wood screws and anchors for screws, depending on mounting surface.

Equipment Needed

• Wire cutters/wire crimpers/wire strippers

• Assorted screwdrivers, drill, etc.

• Level

• Digital Voltmeter

• Frequency counter (optional, for troubleshooting).

2–14 975-0245-01-01

Page 41

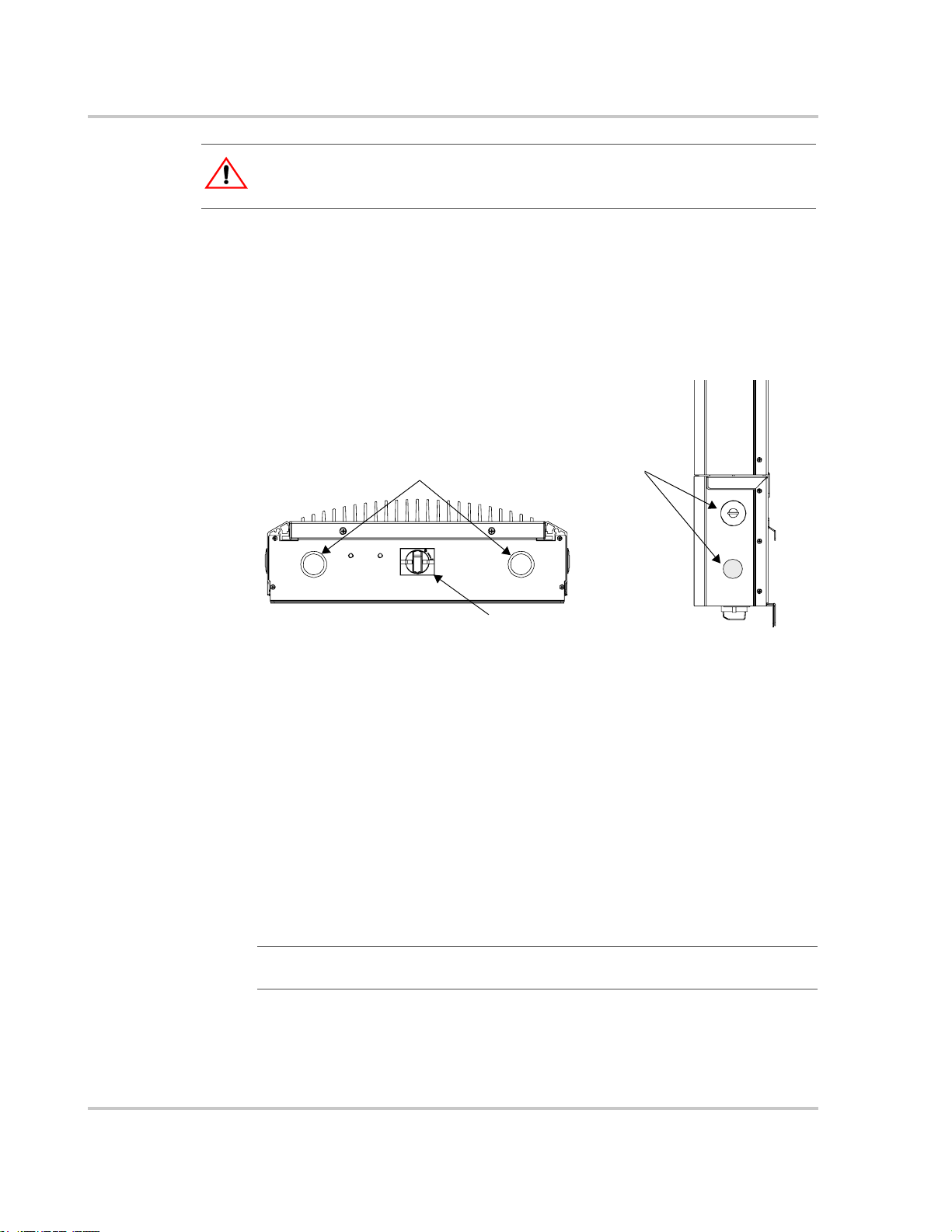

Mounting the Inverter

Overview

WARNING: Fire, Shock and Energy Hazards

Before installing the GT Inverter, read all instructions and cautionary markings located in

this manual, on the PV array, and on the main service panel.

Mounting the Inverter

General installation

steps

There are four main steps in the installation of the GT Inverter:

1. Mounting the GT Inverter (this chapter)

2. Grounding the PV array (see your PV equipment documentation).

3. Making the DC connections from the PV array to the GT Inverter

(“Connecting the DC Wiring” on page 3–4)

4. Making the AC connections from the GT Inverter to the main utility service

panel (“Connecting the AC Wiring” on page 3–7)

Figure 2-6 summarizes these four steps.

PV Panels

Primary Earth/

Ground

2

Utility

Meter

600 Vdc

3

Open

Circuit

Maximum

Utility Grid

4

Grid Tie Inverter

Main Utility

1

Xantrex GT Inverter

Figure 2-6

Installation Overview

Service Panel

975-0245-01-01 2–15

Page 42

Installation

In this chapter only the first step, mounting the inverter and installing accessories,

is described.

Mounting steps Instructions for mounting the GT Inverter are described in the following sections:

• “Preparing to Mount the Unit” on page 2–16

• “Installing the Mounting Bracket” on page 2–17

• “Mounting the Inverter on the Bracket” on page 2–22.

Multiple inverter

instructions

Mounting instructions for multiple inverters are described in “Mounting Multiple

Inverters” on page 2–23.

Special wiring instructions for multiple inverter installations are described in

“Connecting Multiple Inverters” on page 3–9.

Preparing to Mount the Unit

Dimensions and Knockout Locations

The dimensions of the inverter and the mounting bracket and some of the

knockout locations on the wiring/disconnect box are shown in Figure 2-7.

Four 27 or 35 mm (1 or 1 3/8 inch) dual knockouts are provided on the back and

bottom of the unit to accommodate wiring:

• two on the bottom, on either side of the DC/AC Disconnect Switch

• two on the back of the wiring/disconnect box.

Four 27 mm (1 inch) conduit holes on the sides of the wiring/disconnect box (two

on each side) are filled with plastic plugs, which can be removed to insert conduit

nipples as required for multiple inverter installations. One or two of these side

conduit holes may be used to accommodate Xanbus network cables connected

between multiple inverters.

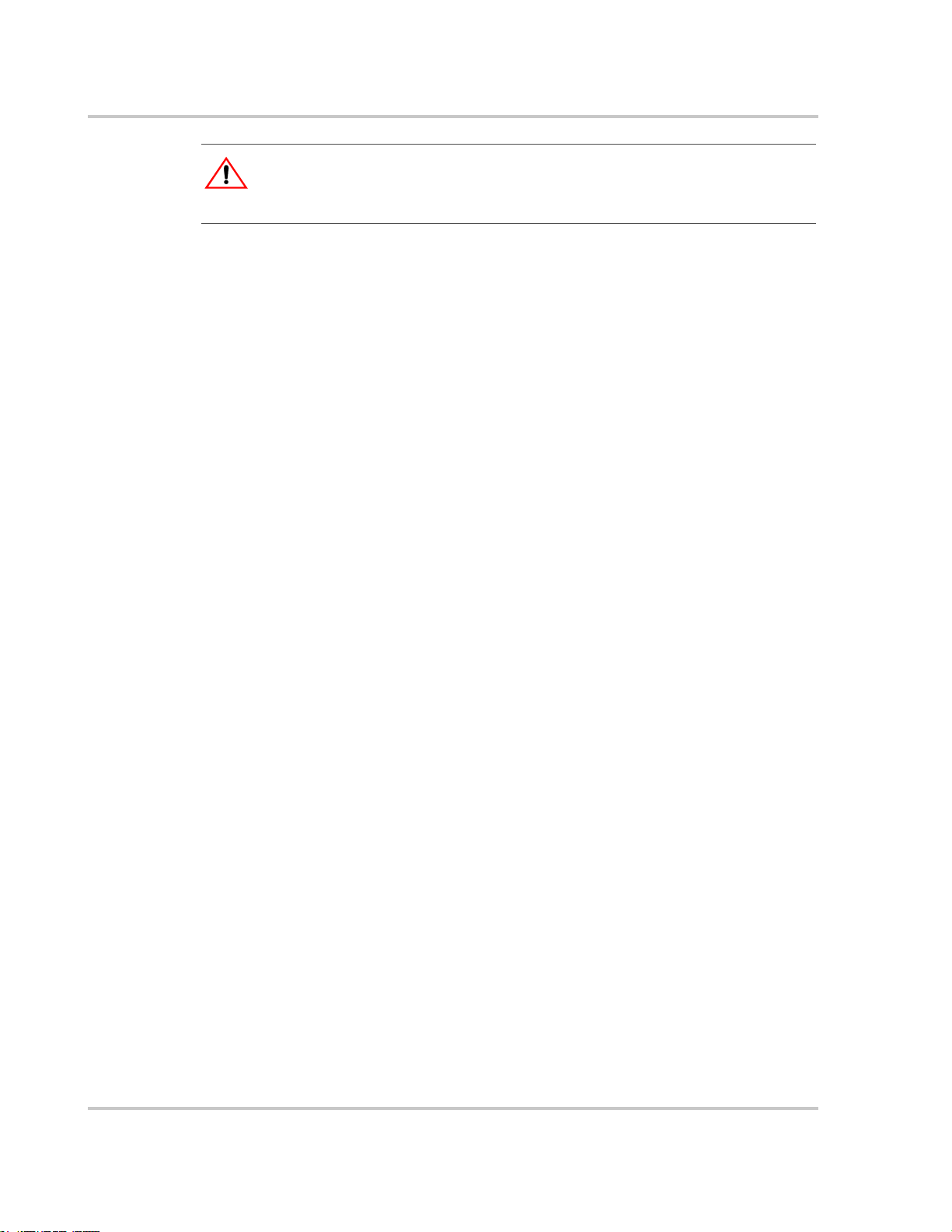

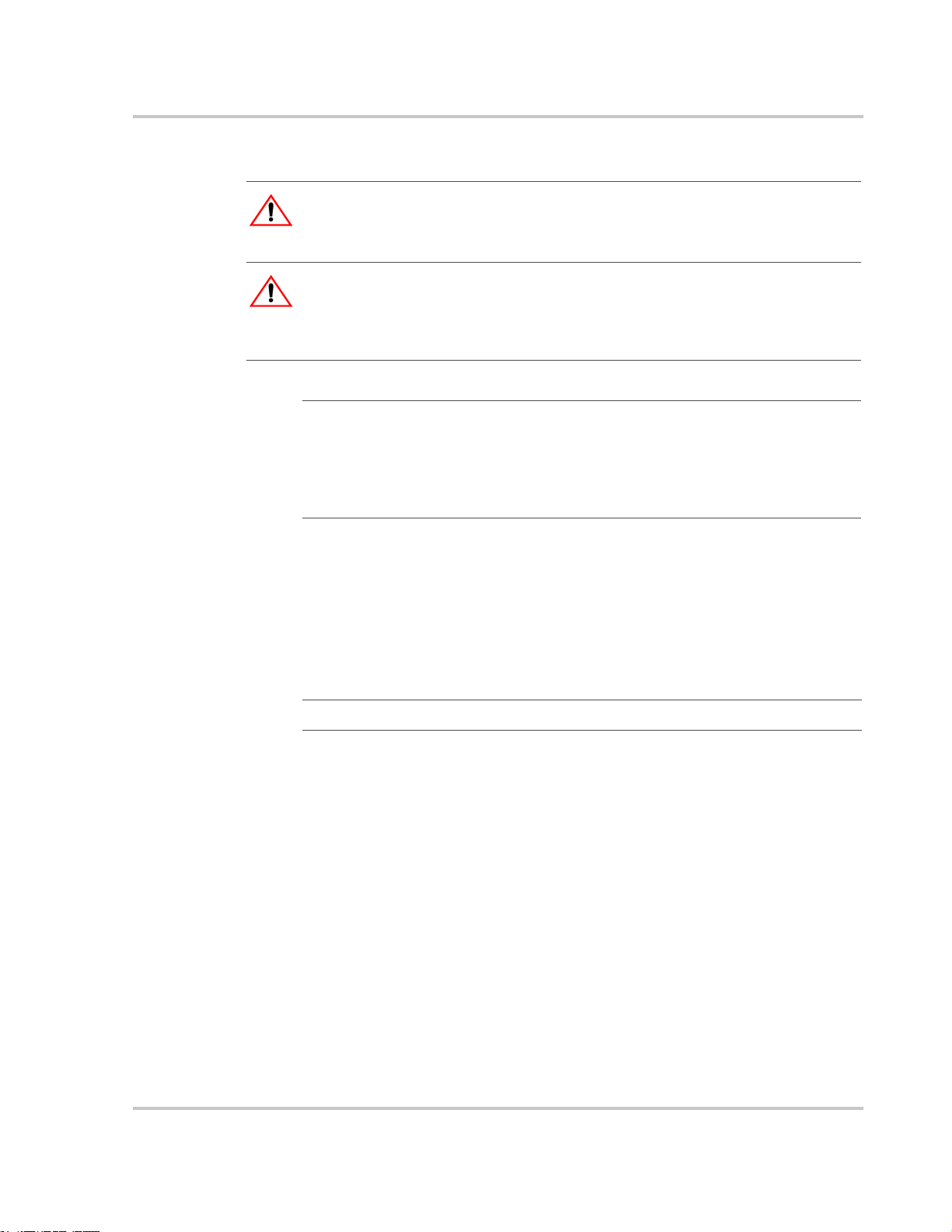

CAUTION: Equipment damage

If your installation location requires that you drill additional conduit holes into the

wiring/disconnect box, ensure that there are no metal shavings left inside the unit. These

could cause a short circuit when the unit is operating.

Knockout Preparation

Remove your choice of knockouts from the wiring box to facilitate conduit

installation for wire runs. This is much easier to do prior to mounting the inverter.

Important:

knockouts. These could cause a short circuit when the unit is operating. Be sure to install

bushings or conduits in the knockout holes to protect the wires from damage.

Important:

2–16 975-0245-01-01

Ensure there are no metal shavings left inside the unit after removing the

If installed outdoors, conduit must be sealed where it enters the wiring box.

Page 43

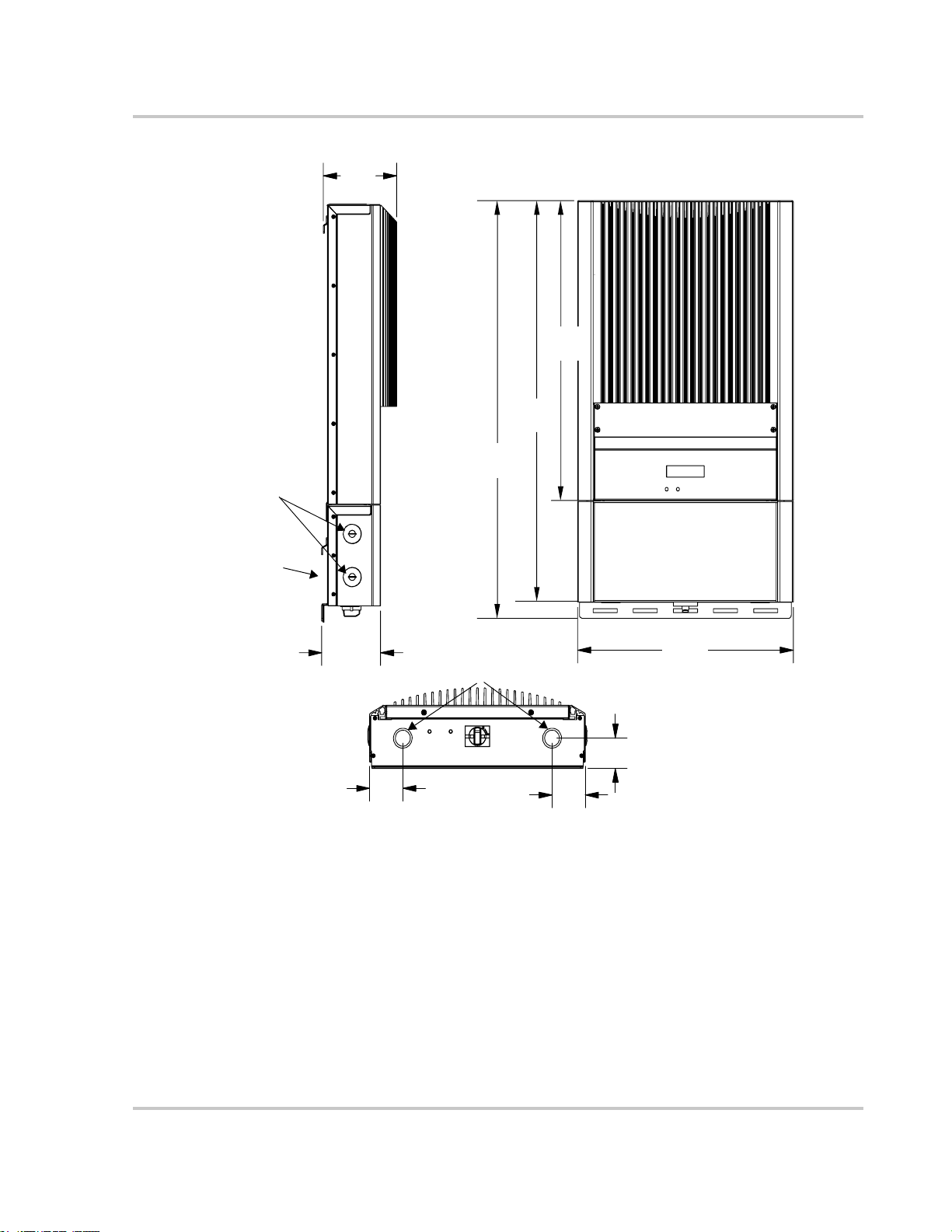

Side view

13.7

(5 3/8)

Mounting the Inverter

Front view

55

(21 5/8)

69.9

(27 1/2)

2.7 cm (1") conduit

holes with threaded

caps, on both sides

Dual 3.5 cm or 2.7 cm

(1 3/8" or 1") knockouts

(on back panel).

Figure 2-7

11

(4 5/16)

7/16)

6.2 (2

Dimensions of GT Inverter and Knockout Locations

Dual 3.5 cm or 2.7 cm

(1 3/8" or 1") knockouts

Installing the Mounting Bracket

72.6

(21 5/8)

27.9 (11)

40.3

(15

All measurements

in cm (inches).

5.2 (2)

7/8)

The mounting bracket for the G T Inverter allows t he unit to be easily mounted and

dismounted for servicing. It has two hooks that match corresponding hooks on the

back side of the inverter and wiring box. The inverter can be separated from the

wiring/disconnect box and removed from the bracket, leaving the

wiring/disconnect box in place.

975-0245-01-01 2–17

Page 44

Installation

Rectangular slots × 25:

0.8 × 3 (5/16 × 1

Mounting bracket Back side of the inverter

25.3 (10)

3/16)

Mounting flanges

Figure 2-8

Mounting Bracket and GT Inverter

Clearance Requirements

For optimal and safe operation, ensure there is adequate clearance around the

inverter. The minimum clearance recommendations in Table 2-2 assume a vertical

mounting. If clearances are reduced below these minimums, rated power may not

be achieved.

Table 2-2

Location Minimum Clearance

Above 30 cm (12 inches)

Below:

•Inverter

• Bracket

In front Sufficient room to allow for easy access to read the display and to prevent

On sides

58.7 (23 1/8)

Mounting slots for securing the inverter

Inverter Clearance Requirements

Outdoors:

• 100 cm (39 inches)

• 110 cm (43 inches)

Indoors: the same clearances are

recommended but not required.

accidental contact with hot surface.

Units can be mounted side by side with no clearance between them, but 15

cm (6 inches) of clearance around the outermost two units is recommended.

In hot climates, some clearance between units may be needed to prevent

thermal derating.

Mounting flanges

All measurements

in cm (inches).

The inverter extends below the

bracket by approximately 10 cm

(4 inches)

2–18 975-0245-01-01

Page 45

Surfaces for Mounting

Mounting on poles

or rails

Mounting to

wallboard with

support

Mounting to siding

using wall studs

Mounting to

concrete surface

Mounting the Inverter

WARNING: Shock hazard

Before drilling holes to mount the GT Inverter, ensure there are no electrical wires or

plumbing in this area.

WARNING: Personal injury

The GT Inverter weighs approximately 20 kg (45 lbs.). Always use proper lifting

techniques during installation to prevent personal injury.

WARNING: Explosion hazard

Do not store combustible or flammable materials anywhere near the inverter.

The GT Inverter weighs approximately 20 kg (45 lbs.). The supporting surface

must be strong enough to handle 75 kg (160 lb.). If the supporting surface is not

strong enough to handle that weight, then supporting material such as a sheet of

plywood can be used to enhance the strength of the mounting surface.

The GT Inverter can be mounted to a vertical surface such as wallboard, wood

siding, concrete wall or pole assembly.

• See “Mounting on Poles or Rails” on page 2–20. Ensure the botto m of the unit

is a minimum of 100 cm (39 inches) from the ground if mounted outdoors.

• Installation onto wallboard requires either the use of a supporting material

such as plywood or securing the mounting screws to supporting wall studs.

Use at least two screws and anchors to secure the unit to the supporting

material.

• If mounting to exterior siding using a wall stud for support, the plywood

backing will not be needed. Use at least two lag screws to secure the unit to

the supporting material. Ensure the screws enter the stud at least 4 cm

(1.5 inches) to adequately support the weight of the unit. See “Mounting on

Wallboard, Siding or Concrete” on page 2–21 .

• If mounting the unit on a concrete surface using anchors with no supporting

material, use four screws and anchors, instead of two, to adequately secure the

unit and distribute the weight.

Important:

or other high-risk areas.

Important:

the GT Inverter. It is recommended to use 6 mm (¼ inch) diameter fasteners. However,

because mounting surfaces can vary, installers must select appropriate hardware for each

installation.

975-0245-01-01 2–19

Local codes may impose additional mounting requirements in earthquake

Other than the mounting bracket, no mounting hardware is supplied with

Page 46

Installation

Mounting on Poles or Rails

To mount the unit using poles:

1. Ensure that poles or rails are securely assembled in place. If using horizontal

rails, three rails are required: two for the mounting bracket and a third for

securing the bottom edge of the inverter wiring box (see Figure 2-9).

2. Connect the mounting bracket vertically to the poles or rails (Figure 2-9):

• Be sure to use at least two bolts to secure the mounting bracket to the

• Position the lower edge of the bracket a minimum of 110 cm (43 inches)

3. If using a single vertical pole, ensure that the inverter is secure and unable to

rotate around the pole.

support.

above the floor or ground.

110 (43)

Ground /

Floor

Mounting Bracket

At least 2 bolts to

secure bracket to

poles/rails.

For securing

the bottom of

the wiring box

All measurements

in cm (inches).

34

(13.5)

48

(18.9)

15

(5.9)

100 (39)

Ground /

Floor

Figure 2-9

2–20 975-0245-01-01

Examples of Mounting on a Pole or Rails

Page 47

Mounting on Wallboard, Siding or Concrete

To mount the GT Inverter to wallboard, siding, or concrete:

1. Locate the area where the GT Inverter is to be installed.

2. Install backing support material if required. See Figure 2-10.

Mounting the Inverter

34 (13.5)

At least 2 screws

with washers to

secure bracket

to plywood

110 (43)

Ground / Floor Ground / Floor

Single GT Inverter Multiple GT Inverters

40.6 (16)

O.C.

15

(6)

110 (43)

All measurements

in cm (inches).

Figure 2-10

Installing the Mounting Bracket using Plywood Support

3. Using a level, place the mounting bracket against the wall surface at least

110 cm (43 inches) from the ground. See Table 2-2 on page 2–18 to ensure

minimum clearance requirements are met.

4. Mark the location for mounting screws if using a wall stud for support. At

least four mounting screws and anchors are needed for concrete installations

or wallboard installations where no wall studs are available for support.

For multiple inverter installations, the brackets should be mounted at least

15 cm (6 inches) apart, or at least 40.6 cm (16 inches) on-center.

5. Remove the bracket and drill the holes using an appropriately sized drill bit.

Drill appropriately sized holes for screws or anchors.

6. Secure the bracket to the supporting surface using at least two screws and

washers.

975-0245-01-01 2–21

Page 48

Installation

Mounting the Inverter on the Bracket

Mounting a Single Inverter

To mount the inverter on the mounting bracket:

1. Place the GT Inverter’s mounting hooks, located on the back of the enclosure,

over the bracket and ensure the inverter is seated properly, as shown in

Figure 2-11.

2. After the unit is correctly seated on the bracket hooks, locate the mounting

slots in the flange below the wiring box and mark the location on the wall for

securing screws.

3. Remove the inverter and drill pilot holes in the wallboard or siding for the

securing screws.

4. Reinstall the G T Inverter on the bracket and secure the bottom of the unit with

appropriate screws or anchors, and tighten.

Slide the mounting hooks on the inverter

over the hooks on the mounting bracket.

Bracket hooks

flange with

mounting slots

Figure 2-11

2–22 975-0245-01-01

Proper Placement of the Inverter on the Mounting Bracket

110 cm (43") 100 cm (39")

Ground/floor

Ensure the inverter is seated

properly on the mounting bracket.

Page 49

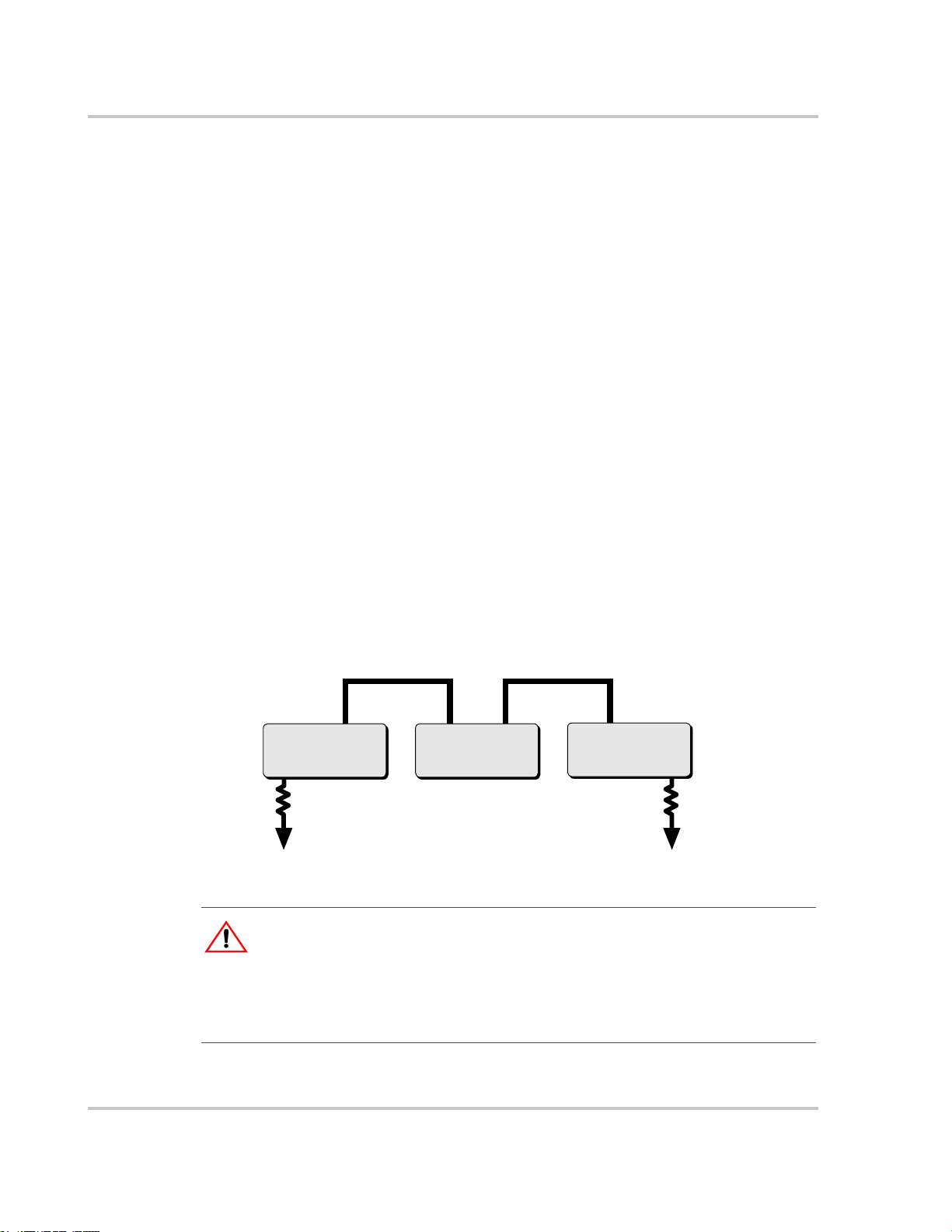

Mounting Multiple Inverters

As shown in Figure 2-10, inverters can be mounted side by side on wallboard or a

plywood support.

Conduit nipples should be installed on one side of the first inverter before

mounting on the bracket. Ensure that the sealing ring is located on the conduit

nipple between inverters, i.e., on the outside of the wiring box. The lock nut is

attached after the nipple is inserted into the conduit hole of the second inverter.

Mounting the Inverter

975-0245-01-01 2–23

Page 50

2–24

Page 51

3

Wiring the Inverter

Chapter 3, “Wiring the Inverter”, provides procedures for making DC

and AC wiring connections, and grounding the GT Inverter and the

PV array. Instructions for wiring multiple inverters are also provided.

The topics in this chapter are organized as follows:

• “Accessing the Wiring Terminals” on page 3–2

• “Connecting the DC Wiring” on page 3–4

• “Connecting the AC Wiring” on page 3–7

• “Connecting Multiple Inverters” on page 3–9.

Page 52

Wiring the Inverter

Accessing the Wiring Terminals

You must remove the GT Inverter wiring box cover to access the terminal blocks,

ground bar and communications ports (for connecting multiple inverters).

To remove the wiring box cover:

1. Using a Phillips screwdriver, remove the two screws on the bottom side of the

wiring box and set in a safe place (see Figure 3-1 for location of screws).

2. Lift the cover off the wiring box.

When replacing the wiring box cover, be careful not to pinch any wires in the

wiring box.

Wiring box

cover screws

Figure 3-1

AC and DC connections are made at the wiring terminals shown in Figure 3-2.

Insulating barrier The clear plastic insulating barrier inside the wiring box is a permanent

component. It is intended to separate the high-voltage AC and DC wiring from

any communications cabling and to prevent wiring from coming into contact with

the wiring box cover.

When wiring the unit, it is necessary to pull the cover back to access the wiring

terminals. After completing the wiring, replace the insulating barrier to its original

position.

Removing the Wiring Box Cover

3–2 975-0245-01-01

Page 53

Accessing the Wiring Terminals

Figure 3-2

DC Terminals

for connecting

PV strings

DC/AC

Disconnect

Switch

AC and DC Terminal Block Location in the Wiring Box

AC Terminals for

connecting to main

utility service panel

975-0245-01-01 3–3

Page 54

Wiring the Inverter

Connecting the DC Wiring

WARNING: Shock hazard

Whenever a PV array is exposed to sunlight, a shock hazard exists at the output wires or

exposed terminals. To reduce the risk of shock during installation, cover the array with an

opaque (dark) material and ensure that the DC/AC Disconnect Switch is set to OFF before

commencing any wiring. See Figure 3-3.

WARNING: Shock hazard

The 600 volt DC/AC disconnect in the wiring box meets NEC Article 690. It is a

non-serviceable component and shall remain in place. Removal can expose energized

conductors.

WARNING: Shock hazard

Use caution when working around sources of DC power. Although the DC/AC disconnect

switch disconnects the inverter from DC power, hazardous voltages from paralleled PV

strings may still be present upstream of the switch. Before servicing a PV string, isolate

each string by completely removing PV wiring from the inverter terminal block.

Figure 3-3

3–4 975-0245-01-01

DC/AC Disconnect Switch Positions

Page 55

Connecting the DC Wiring

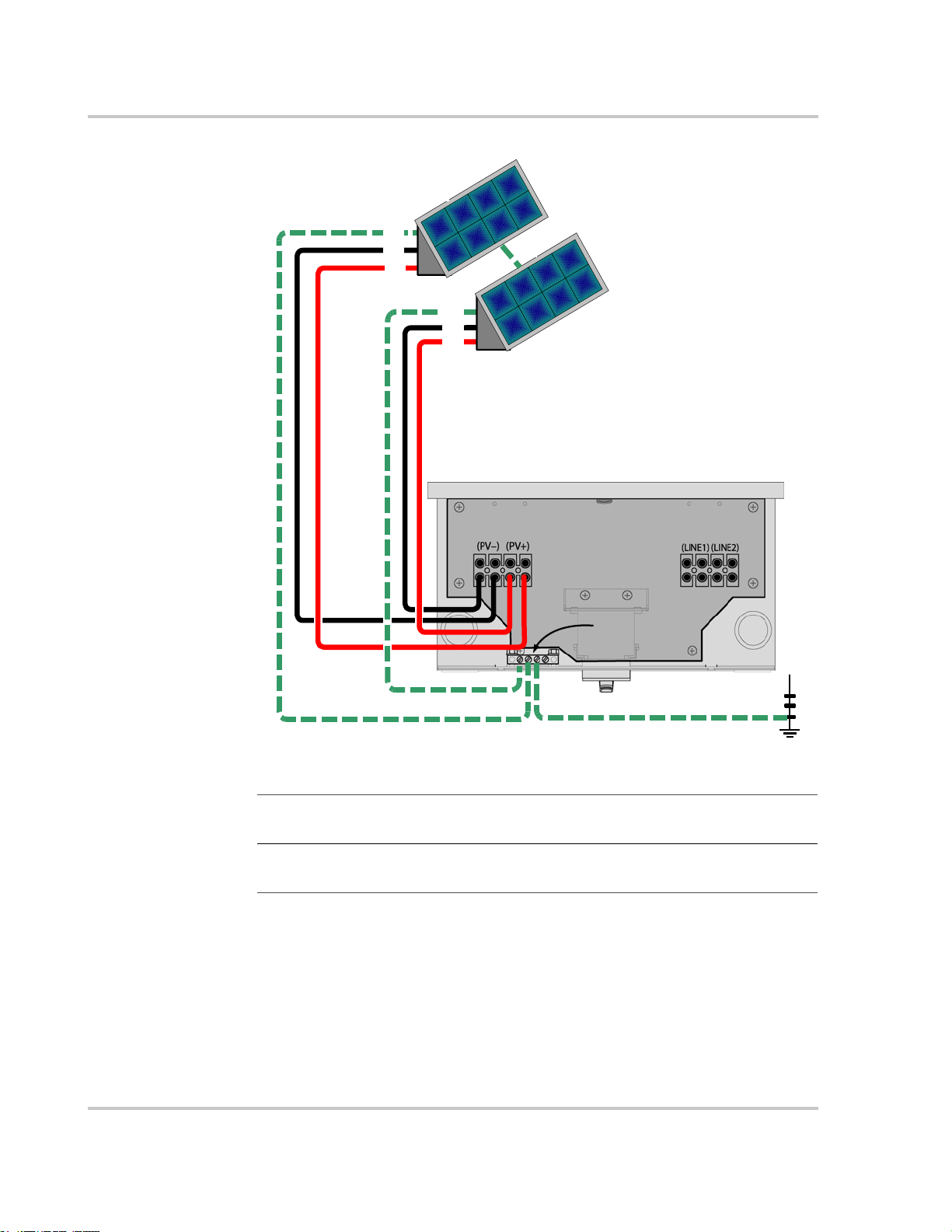

The following procedure is illustrated in Figure 3-4. If there is more than one PV

string, label the positive and negative wire pairs appropriately (for example:

PV1-String #1 POS, PV1-String #1 NEG, PV1-String #1 GND,

PV1-String #2 POS, etc.).

To wire the PV array to GT Inverter:

1. Remove the wiring/disconnect box cover (see page 3–2).

2. Install DC conduit from the PV string(s) to the GT Inverter wiring box,

through one of the knockout holes.

3. Route the wires from the PV string(s) through the conduit an d into the wiring

box.

4. Connect the DC Ground from each PV string to the GROUND bar in the

wiring box.

5. Connect the POSITIVE (+) wire from the PV1 string #1 to one of the PV+

terminals in the wiring box. Double check that the wire is in the proper

location and tighten the screw.

6. Connect the NEGATIVE (–) wire from the PV1 string #1 to one of the

PV– terminals. Double check that the wire is in the proper location and

tighten the screw.

7. Repeat for the PV1 string #2, if there is one.

a) Connect the POSITIVE (+) wire from the PV1 string #2 to the unused

PV+ terminal.

b) Connect the NEGATIVE (–) wire from the PV1 string #2 to the unused

PV– terminal.

Double check that the wires are in the proper locations and tighten the screws.

8. If required, connect the DC ground electrode conductor tot he DC or AC

ground electrode as per NEC 690.47.

9. Ensure all connections are correctly wired and properly torqued according to

values shown in Table 3-1.

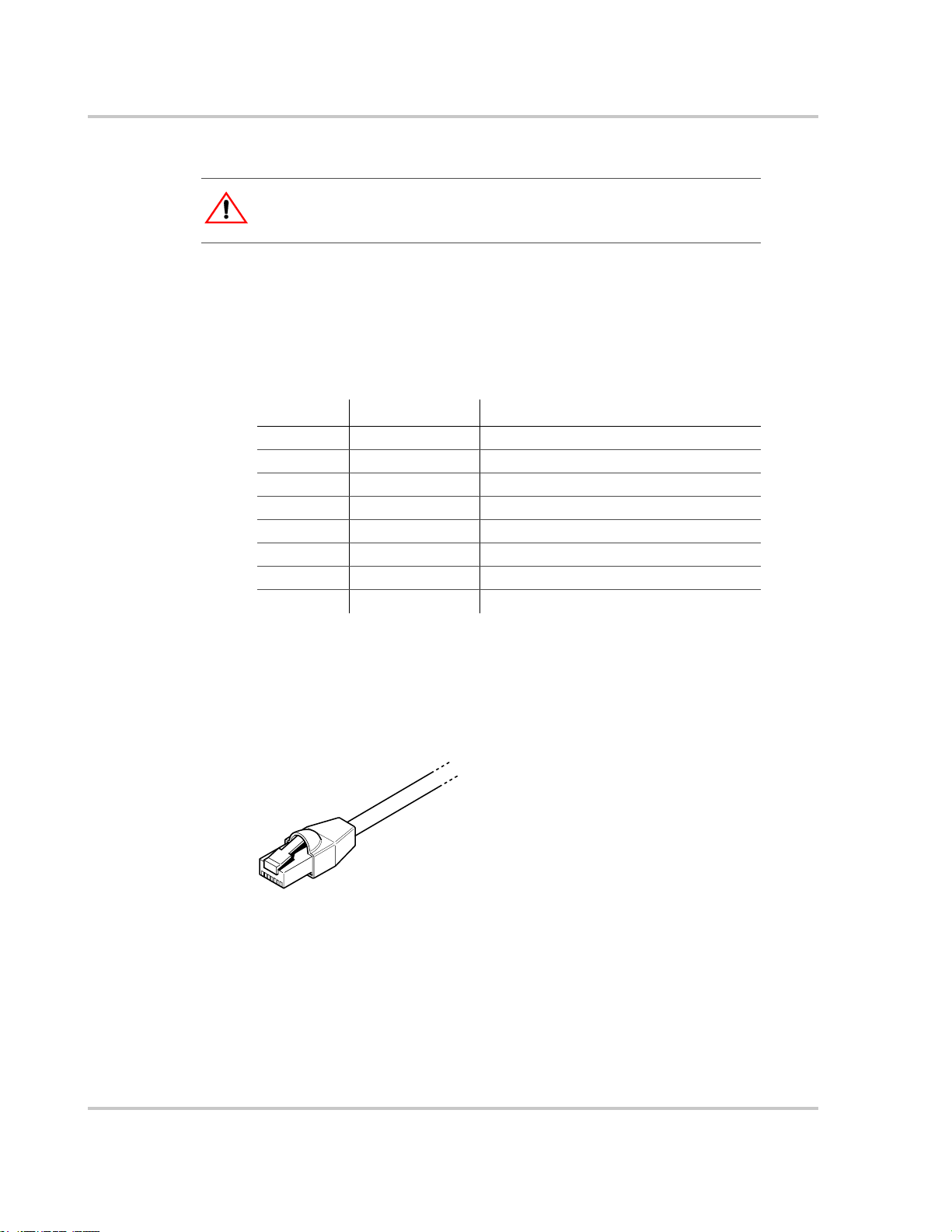

Table 3-1

14 to 10 2.5 to 6.0 35 4.0

Torque Values for Wires*

Wire Size Torque

AWG mm

8 10.0 40 4.5

6 16.0 45 5.1

2

in-lb. Nm

*Use copper conductors only.

975-0245-01-01 3–5

Page 56

Wiring the Inverter

PV1 String #2

PV String #2

G

–

+

G

–

+

PV Array 1

G

PV1 String #1

PV String #1

Xantrex GT Inve rter

Wiring Box

GND bar

DC/AC Disconnect Switch

DC Gro und if r equir ed by AHJ

Figure 3-4

Important:

box may be required. This fusing and combiner box are to be provided by the installer.

Important:

local codes before installation.

DC Connections for Multiple PV Strings

Depending upon installation and local codes, fusing and/or a combiner

A DC grounding electrode conductor may be required by the AHJ. Check

3–6 975-0245-01-01

Page 57

Connecting the AC Wiring

WARNING: Shock hazard

AC utility wiring to the GT Inverter unit is performed directly at the main breaker panel.

This should be done only by a qualified installer or electrician.

WARNING: Shock hazard

Before wiring the G T Inverter , ensure the main br eaker in the primary utility breaker box

is switched OFF . Switch this breaker ON only after all wiring is completed as instructed in

the procedures.

Connecting the AC Wiring

Important:

inverter to be connected to a dedicated circuit and no other outlets or devices may be

connected to this circuit. The NEC also imposes limitations on the size of the inverter and

the manner in which it is connected to the utility grid. The circuit breakers that are used in

the main panel that feed the inverter circuit must be for back-fed operation and labeled as

such.

In the United States, the National Electrical Code (NEC) requires the

The GT Inverter can be connected to a single bi-directional meter, or to dual

meters, where one meter indicates power used and the second meter indicates

power sold (power supplied back to the utility). Consult with the local utility to

determine the proper components to install, and obtain any permits required prior

to installation.

The following procedure is illustrated in Figure 3-5.

Important:

Neutral conductor wiring is not required in this installation.

975-0245-01-01 3–7

Page 58

Wiring the Inverter

To wire the main utility service panel to the GT Inverter:

1. Install conduit from the main utility service panel to the wiring/disconnect

box of the GT Inverter. Run the two HOT wires (L1 and L2) and ground wire

from the service panel through the conduit and into the inverter wiring box.

2. Install or use an existing double-pole 20-Amp circuit breaker (or two

single-pole breakers, ganged) in the main utility service panel, and ensure that

the breakers are set to OFF.

3. Connect the ground wire (green or bare copper) from the ground bar in the

main utility service panel to the GND bar in the wiring box.

4. Connect the L1 HOT wire (black) from the double-pole breaker installed in

the main utility service panel, to the L1 GRID terminal in the wiring box.

5. Connect the L2 HOT wire (red) from the double-pole breaker installed in the

main utility service panel, to the L2 GRID terminal in the wiring box.

6. Ensure all connections are correctly wired and properly torqued according to

values shown in Table 3-1 on page 3–5.

Utility Grid

GND bar

Xantrex GT Inverter

Wiri ng Bo x