World Dryer LN Installation Manual

Model LN

New Economical and Stylish Hand Dryer

Nuevo secamanos moderno, elegante y económico

Nouveau sèche-mains élégant, économique et moderne

All LN Series

Todos los de la Serie LN

Toutes les séries LN

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or service

the product described. Protect yourself and others by observing all safety information. Failure to comply with

instructions could result in personal injury and/or property damage. Retain instructions for future reference.

Por favor lea y guarde estas instrucciones. Léalas cuidadosamente antes de tratar de montar, instalar, operar o dar mantenimiento al producto aquí

descrito. Protéjase usted mismo y a los demás observando toda la información de seguridad. No seguir las instrucciones puede ocasionar daños, tanto

personales como materiales. Guarde estas instrucciones para referencia en el futuro.

Lire et conserver ces instructions. Les lire attentivement avant de commencer à assembler, installer, faire fonctionner, réparer ou entretenir l’appareil

décrit. Pour se protéger et protéger autrui, observer toutes les consignes de sécurité. Le fait de négliger d’appliquer ces instructions peut entraîner des

blessures et/ou des dommages matériels. Conserver ces instructions pour consultation ultérieure.

World Dryer Corporation

5700 McDermott Drive

Berkeley, IL 60163 U.S.A.

800-323-0701

www.worlddryer.com

1

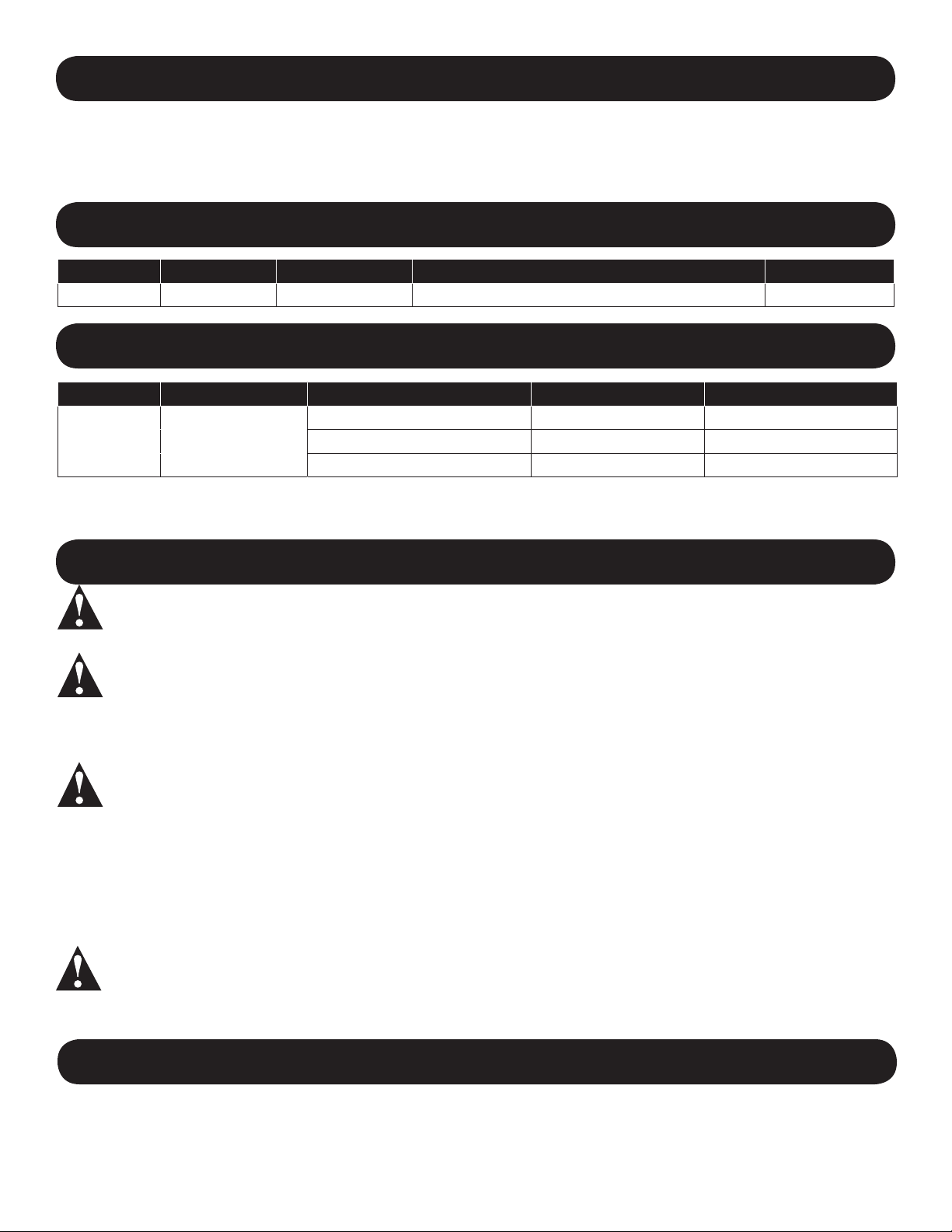

Description

Electric-Aire hand dryer, powered by a universal brush motor, delivering 1150 Watts of drying power. This hand dryer is

multi-voltage running on 115-208-230 Volt AC electrical supply. Operation is automatically controlled on/off, by an infrared

sensor. This appliance is intended for use in hand drying, contributing to hygienic and cost effective hand sanitation in

small business, ofce and light duty environments.

General Specications

Models Nozzle Drying Cycle Dimensions (WxDxH) Weight

LN Integral Automatic 11.59” x 10.75” x 4.90”

294 mm x 273 mm x 124 mm 8 lbs / 3.6 kg

Electrical Specications

Models Type Electrical Input* Amperage Watts

LN Automatic 115 VAC, 50/ 60 Hz 10 1150

LN Automatic 208 VAC, 50/ 60 Hz 6 1150

LN Automatic 230 VAC, 50/ 60 Hz 5 1150

cULus Listed E19860

(*) This hand dryer is a multi-voltage appliance that will self adjust to the available supply from 115 up to 230 VAC.

General Safety Information

Failure to disconnect the power source before installation or servicing can

DANGER

• Always disconnect the power source before servicing or installing the hand dryer.

DANGER

• This hand dryer must be properly grounded (Earthed) for safe operation. An identied ground connection point is

supplied on the hand dryer’s wall base.

• We recommend GFCI protection in wet or damp locations or as required by local code.

WARNING

• Use only the electrical power (voltage and frequency) specied for the model hand dryer being installed.

• Connect the hand dryer to the nearest suitable distribution panel.

• To limit a voltage drop, and insure efcient operation, use wire gauge as required by local or National Electrical Code.

• Do not connect to a branch circuit with CB or fuse protection over 15 Amps. This is in compliance with The National

Electrical Code #210-20.

• All automatic model hand dryers must have a dedicated 15 Amp circuit as required by Underwriters Laboratories, Inc. (UL).

• Route all eld wiring away from any moving parts within the hand dryer.

result in serious injury or death from electric shock.

Failure to properly ground this unit could result in severe electrical shock

and/or death.

Risk of re, personal injury or property damage are possible if local codes,

NEC codes or safety recommendations are not followed.

CAUTION Improper mounting could result in personal injury or property damage.

• Follow the mounting height recommendations in Table 1.

Unpacking

1. Remove all packing material. Recycling is recommended.

2. Carefully remove the hand dryer from the shipping carton, using care not to drop the appliance.

3. Inspect carefully for any damage that may have occurred during transit. Check for any loose, missing or damaged

parts. If the hand dryer is damaged, promptly inform the dealer where you purchased it.

2

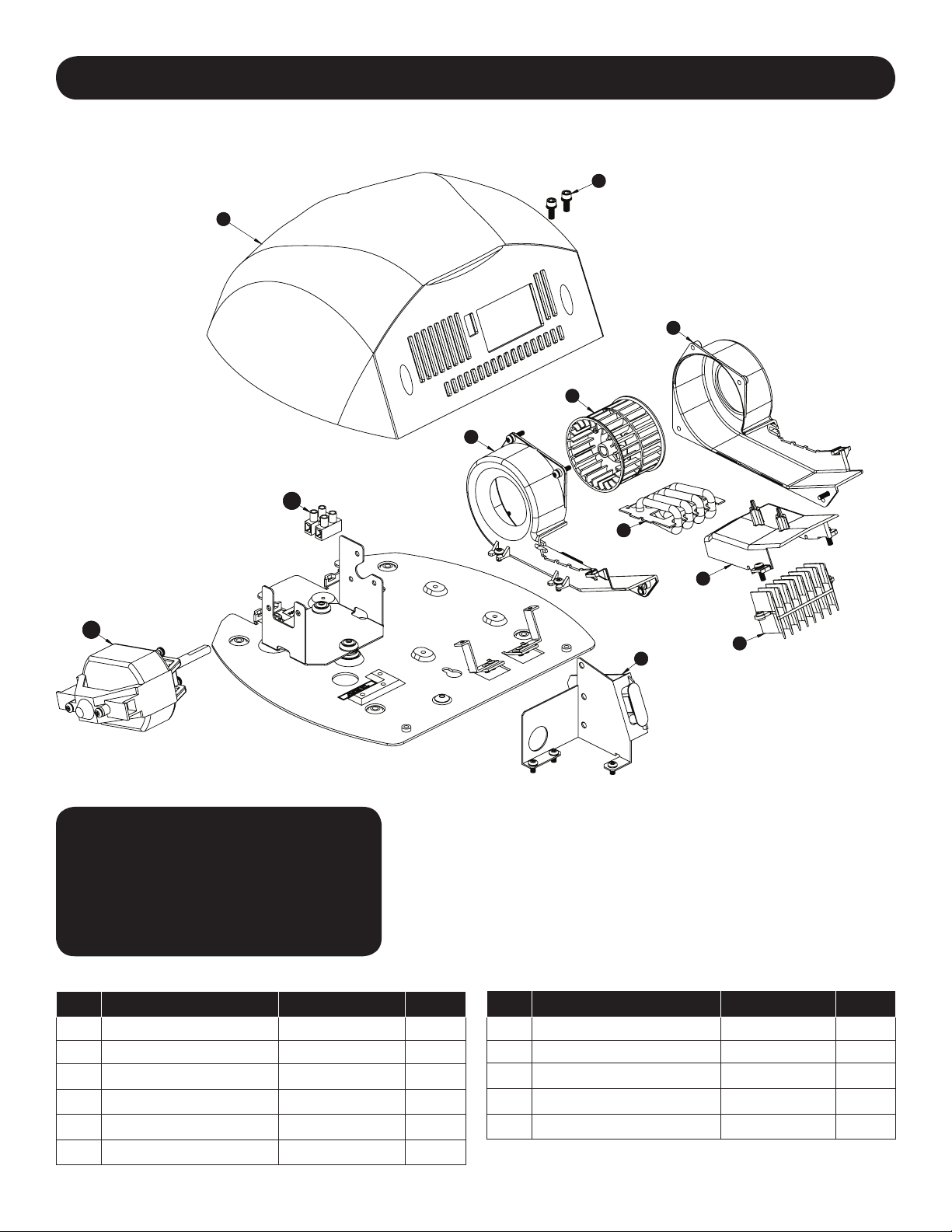

Parts List

Figure 1 - Repair Parts List For Model LN Hand Dryer

2

1

4

3

10

8

5

11

For Repair Parts, visit www.WorldDryer.com

Please provide following information:

- Model number

- Serial number

- Part description and number shown in

parts list

Description Part Number Qty.

#

1 Cover Kit 20-834K 1

2 Screw, Cover 46-006490 2

3 Blower Housing-Left 47-006372 1

4 Blow Wheel 22-006377 1

5 Blow Housing-Right 47-006371 1

6 Blower Housing Lid 47-006373 1

6

9

Description Part Number Qty.

#

7

7 Air Outlet Bafe 12-055881 1

8 Heating Element Assembly 21-055638K 1

9 Circuit Board Assembly 16-055560K 1

10 Terminal Block 15-006531 1

11 Motor Kit 32-056450K 1

3

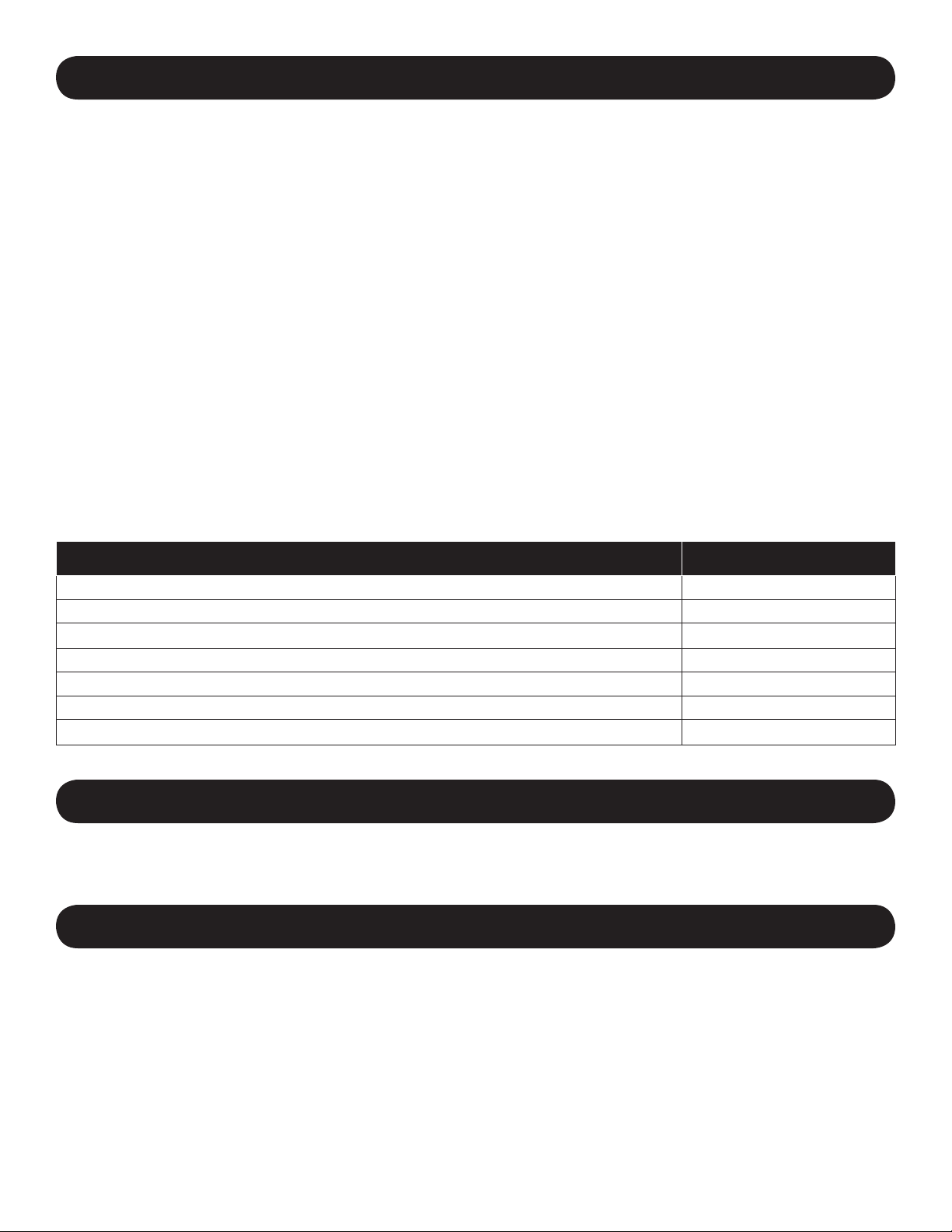

Installation

1. Disconnect the power source.

2. Remove the two cover-mounting screws. Remove the cover from the dryer.

3. Place the hand dryer base on the wall at desired location. Using Table 1 to determine the recommended mounting

height. When two or more dryers are installed, they should be placed no closer than 24” (60 cm) from center to

center. Mark the location of the four mounting bolt holes and the wire entry hole.

4. For recessed wiring, carry the supply wire to the dryer base plate knockout and attach with an acceptable cable

clamp. The dryer requires two conductors for power plus a separate ground wire.

5. For surface wiring, remove the knockout located at the bottom left corner of the cover. Pass the supply wire

according to local code, through the knockout and attach it securely to the bracket. The dryer requires two

conductors for power plus a separate ground wire.

6. Attach the mechanism rmly to the wall. For wood walls or wood studs, use No. 16 screws of proper length to ensure

1” (25 mm) minimum stud penetration. For masonry walls use expansion bolts or anchors for 1/4” (6 mm) screws of

proper length to ensure penetration 1/4” (6 mm) deeper than anchor. Shim if necessary to ensure that the base plate

is level and at against the wall.

7. Connect the supply wires to the terminal block where indicated. Connect the ground wire to the base plate with the

ground screw.

8. Replace the cover. Do not overtighten the screws.

INSTALLATION MUST BE PERFORMED BY QUALIFIED ELECTRICAL PERSONNEL.

Table 1

Recommended Mounting Heights from Floor to Dryer Bottom Edge in. (cm.)

Men’s washrooms 49 (125)

Women’s washrooms 47 (119)

Children’s washrooms, ages 4-7 35 (89)

Children’s washrooms, ages 7-10 39 (99)

Children’s washrooms, ages 10-13 43 (109)

Children’s washrooms, ages 13-17 47 (119)

Handicap Mounting Height 41 (104)

Maintenance

Proper maintenance should be preformed on the units at least every 6 months under normal use. More frequent cleaning is

required in dirty environments or heavy trafc conditions.

Cleaning

Cleaning and maintenance must be performed by qualied electrical personnel.

1. Disconnect the electrical supply

2. Use the security hex driver to remove the two cover-mounting screws

3. Remove the cover

4. Clean all dust and lint from the interior of the dryer using a soft brush and vacuum.

5. Replace the cover. Do not over tighten the screws

6. Wipe the cover with a damp cloth. Never use abrasives to clean the cover

4

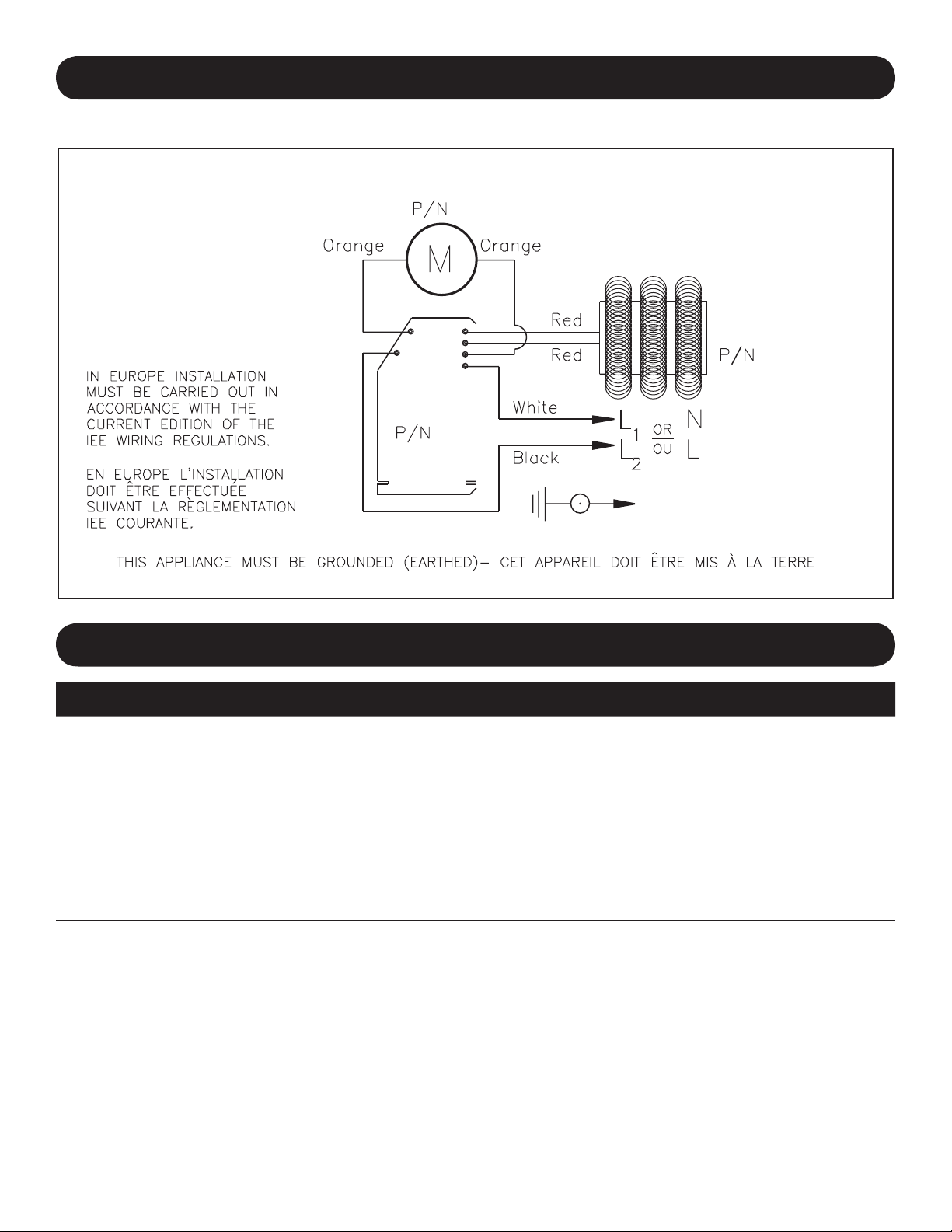

Wiring Diagram

Figure 2

32-056450K

21-055638K

16-055560K

Troubleshooting Chart

Symptom Possible Cause(s) Corrective Action

Dryer will not run Defective circuit board 1. First ensure that the breaker supplying the dryer is operational

2. If it is, disconnect the power and remove the dryer cover. Taking

suitable precautions to avoid shock hazard, reconnect the power

and check for voltage at the wire leads

3. If there is power and the dryer will not run, replace the circuit board

Dryer cycles by itself,

runs all the time, or is

not sensitive enough

Elements get hot but

the fan motor does

not turn

Fan motor runs but

the element does not

get hot

Defective circuit board 1. Ensure that there is no obstruction on or in front of the infra-red lens

2. Disconnect the power. Remove the dryer cover and the screws

holding the circuit board. Ensure that there are no obstructions

between the infra-red “eyes” on the circuit board and the lens

3. If the problem persists, replace the circuit board

Defective fan Defective

motor

Loose or damaged

wires or defective

element

1. Disconnect the power. Remove the dryer cover and check for

obstructions in the fan housings

2. Damaged fans must be replaced

3. If there are no obstructions, replace the motor

1. Disconnect the power and remove the dryer cover. Check for loose

or damaged wires. Remove the access cover on the blower housing.

Check the element for signs of burning or breakage. Damaged

element must be replaced

2. If the element does not appear damaged, disconnect it at the circuit

board and check for continuity across the two element wires. An

open circuit indicates damage to the integral temperature limit

control. If this is the case, replace the element

5

Loading...

Loading...