Page 1

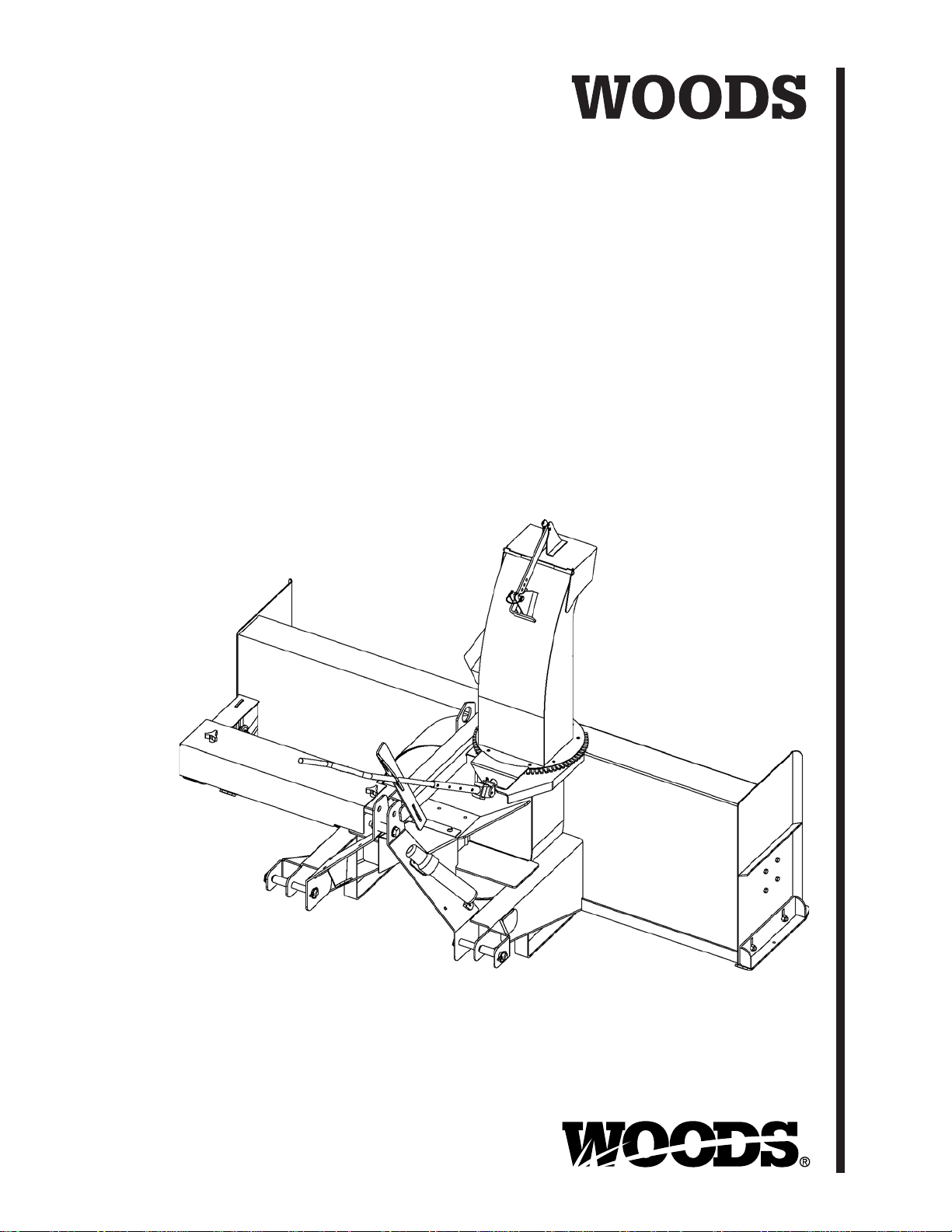

SNOWBLOWER

SB54S

SB64S

SB74C

SB84C

MAN0869

(Rev. 12/6/2011)

Page 2

TO THE DEALER:

®

Assembly and proper installation of this product is the responsibility of the Woods

and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Operator’s Manual

are completed before releasing equipment to the owner.

The dealer must complete the online Product Registration form at the Woods Dealer Website which certifies that

all Dealer Check List items have been completed. Please contact your dealer to complete this form. Dealers can

register all Woods product at dealer.WoodsEquipment.com under Product Registration.

Failure to register the product does not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your Woods equipment. The information presented will prepare you to do a better and

safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and become

acquainted with all adjustment and operating procedures before attempting to operate. Replacement manuals can be

obtained from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in

the United States and Canada call 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your authorized Woods dealer has trained mechanics, genuine Woods service parts, and the necessary

tools and equipment to handle all your needs.

Use only genuine Woods service parts. Substitute parts will void the warranty and may not meet standards required for

safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

dealer. Read manual instructions

Model: _______________________________ Date of Purchase: _____________________

Serial Number: (see Safety Decal section for location) ____________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term NOTICE is used to indicate that failure to observe can cause damage to equipment.

The terms CAUTION, WARNING, and DANGER are used in conjunction with the Safety-Alert Symbol (a triangle with

an exclamation mark) to indicate the degree of hazard for items of personal safety.

2 Introduction

Gen’l (Rev. 12/5/2011)

Page 3

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

OWNER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

TROUBLE SHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

ASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

DEALER CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

INDEX TO PARTS LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

BOLT TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

BOLT SIZE CHART & ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 39

PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

REPLACEMENT PARTS WARRANTY . . . . . . . . . . . . . . . . Inside Back Cover

MAN0869 (04/13/2011)

Introduction 3

Page 4

SPECIFICATIONS

WARNING

Width Of Cut: . . . . . . . . . . . . . . . . . . SB54S . . . . . . . . . . . . . . . . . . . . . . .54"

SB64S . . . . . . . . . . . . . . . . . . . . . . .64"

SB74C. . . . . . . . . . . . . . . . . . . . . . .74"

SB84C. . . . . . . . . . . . . . . . . . . . . . .84"

Cutting Height . . . . . . . . . . . . . . . . . . . . . . . . . 24"(S Models) , 26"(C Models)

Number of Augers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Auger Diameter. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15"

Fan Diameter . . . . . . . . . . . . . . . . . . SB54S/SB64S. . . . . . . . . . . . . . . . .22"

SB74C/SB84C . . . . . . . . . . . . . . . .24"

Auger Flighting Thickness . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5/16" x 2"

Roller Chain . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . #50

Chute Rotation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 270 Deg.

Chute Length . . . . . . . . . . . . . . . . . . SB54S/SB64S. . . . . . . . . . . . . 24-1/4"

SB74C/SB84C . . . . . . . . . . . . . . . .29"

Operating Weight . . . . . . . . . . . . . . . SB54S . . . . . . . . . . . . . . . . . . . . 415lbs

SB64S . . . . . . . . . . . . . . . . . . . . 436lbs

SB74C. . . . . . . . . . . . . . . . . . . . 592lbs

PTO Horsepower Requirement: . . . . SB54S . . . . . . . . . . . . . . . . < = 25 H.P.

Tractor Hitch . . . . . . . . . . . . . . . . . . . SB54S/SB64S. . Limited CAT1 & CAT1

PTO Input . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 540 RPM

Auger Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 180 RPM

Gearbox Oil Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . 0.52 Qt SAE 80W-90

GENERAL INFORMATION

Some illustrations in this manual show the

equipment with safety shields removed to provide

a better view. This equipment should never be

operated with any necessary safety shielding

removed.

The purpose of this manual is to assist you in operating

and maintaining your snowblower. Read it carefully. It

furnishes information and instructions that will help you

achieve years of dependable performance. These

instructions have been compiled from extensive field

experience and engineering data. Some information

SB84C. . . . . . . . . . . . . . . . . . . . 632lbs

SB64S . . . . . . . . . . . . . . . . 15 - 35 H.P.

SB74C. . . . . . . . . . . . . . . . 30 - 50 H.P.

SB84C. . . . . . . . . . . . . . . . 35 - 60 H.P.

SB74C/SB84C . . . . . . . CAT1 & CAT2

may be general in nature due to unknown and varying

operating conditions. However, through experience

and these instructions, you should be able to develop

procedures suitable to your particular situation.

The illustrations and data used in this manual were current at the time of printing, but due to possible inline

production changes, your machine may vary slightly in

detail. We reserve the right to redesign and change the

machines as may be necessary without notification.

Throughout this manual, references are made to right,

left, forward and rearward directions. These are determined by sitting in the tractor operator's seat facing the

direction of forward travel.

4 Introduction

MAN0869 (04/13/2011)

Page 5

TRAINING

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern,

judgement, and proper training of personnel

involved in the operation, transport, maintenance

and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.” We ask you to be that

kind of operator.

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

If you do not understand any part of this manual

and need assistance, see your dealer.

Know your controls and how to stop engine and

attachment quickly in an emergency.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

Make sure that all operating and service personnel know that if hydraulic fluid penetrates skin, it

must be surgically removed as soon as possible by

a doctor familiar with this form of injury or gangrene, serious injury, or death will result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

Never allow children or untrained persons to

operate equipment.

Snowblower_SRs (04/13/2011)

PREPARATION

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Air in hydraulic systems can cause erratic operation and allows loads or equipment components

to drop unexpectedly. When connecting equipment

or hoses or performing any hydraulic maintenance,

purge any air in hydraulic system by operating all

hydraulic functions several times. Do this before

putting into service or allowing anyone to

approach the equipment.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Make sure spring-activated locking pin or collar

slides freely and is seated firmly in tractor PTO

spline groove.

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, front tractor wheels could raise up resulting in loss of steering. The weight may be attained

with front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

OPERATION

Never place hands or body into discharge chute

or auger to unclog. Stored energy can cause auger

to quickly rotate when unclogging occurs and

cause severe injury or amputation. Stop engine,

remove key, disconnect driveline, and carefully

unclog, using a sturdy piece of wood.

Keep bystanders away from equipment.

Never direct discharge toward people, animals,

or property.

Safety 5

Page 6

Do not operate or transport equipment while

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

under the influence of alcohol or drugs.

Operate only in daylight or good artificial light.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Always comply with all state and local lighting

and marking requirements.

Never allow riders on power unit or attachment.

Always sit in power unit seat when operating

controls or starting engine. Securely fasten seat

belt, place transmission in neutral, engage brake,

and ensure all other controls are disengaged

before starting power unit engine.

Operate tractor PTO at RPM listed on safety

decal located on fan housing above gearbox. Do

not exceed.

Do not operate PTO during transport.

Look down and to the rear and make sure area

is clear before operating in reverse.

Do not operate or transport on steep slopes.

Do not stop, start, or change directions sud-

denly on slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Use extreme care when working close to fences,

ditches, other obstructions, or on hillsides.

Watch for hidden hazards on the terrain during

operation.

Watch for traffic when operating near or crossing roadways.

Stop power unit and equipment immediately

upon striking an obstruction. Turn off engine,

remove key, inspect, and repair any damage before

resuming operation.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Before performing any service or maintenance,

disconnect driveline from tractor PTO.

MAINTENANCE

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Before performing any service or maintenance,

disconnect driveline from tractor PTO.

NEVER GO UNDERNEATH EQUIPMENT. Never

place any part of the body underneath equipment

or between moveable parts even when the engine

has been turned off. Hydraulic system leak-down,

hydraulic system failures, mechanical failures, or

movement of control levers can cause equipment

to drop or rotate unexpectedly and cause severe

injury or death.

• Service work does not require going underneath implement.

• Read Operator's Manual for service instructions or have service performed by a qualified

dealer.

Service and maintenance work not covered in

OWNER SERVICE must be done by a qualified

dealership. Special skills, tools, and safety procedures may be required. Failure to follow these

instructions can result in serious injury or death.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its components in any way.

Your dealer can supply original equipment

hydraulic accessories and repair parts. Substitute

parts may not meet original equipment specifications and may be dangerous.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter pins are

installed securely to ensure equipment is in a safe

condition before putting unit into service.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

6 Safety

Snowblower_SRs (04/13/2011)

Page 7

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Do not disconnect hydraulic lines until engine is

stopped, power unit is properly secured, equipment and all components are lowered to the

ground, and system pressure is released by operating all valve control levers.

Use a suitable lifting device of sufficient capacity. Use adequate personnel to handle heavy components.

STORAGE

Block equipment securely for storage.

Keep children and bystanders away from stor-

age area.

Snowblower_SRs (04/13/2011)

Safety 7

Page 8

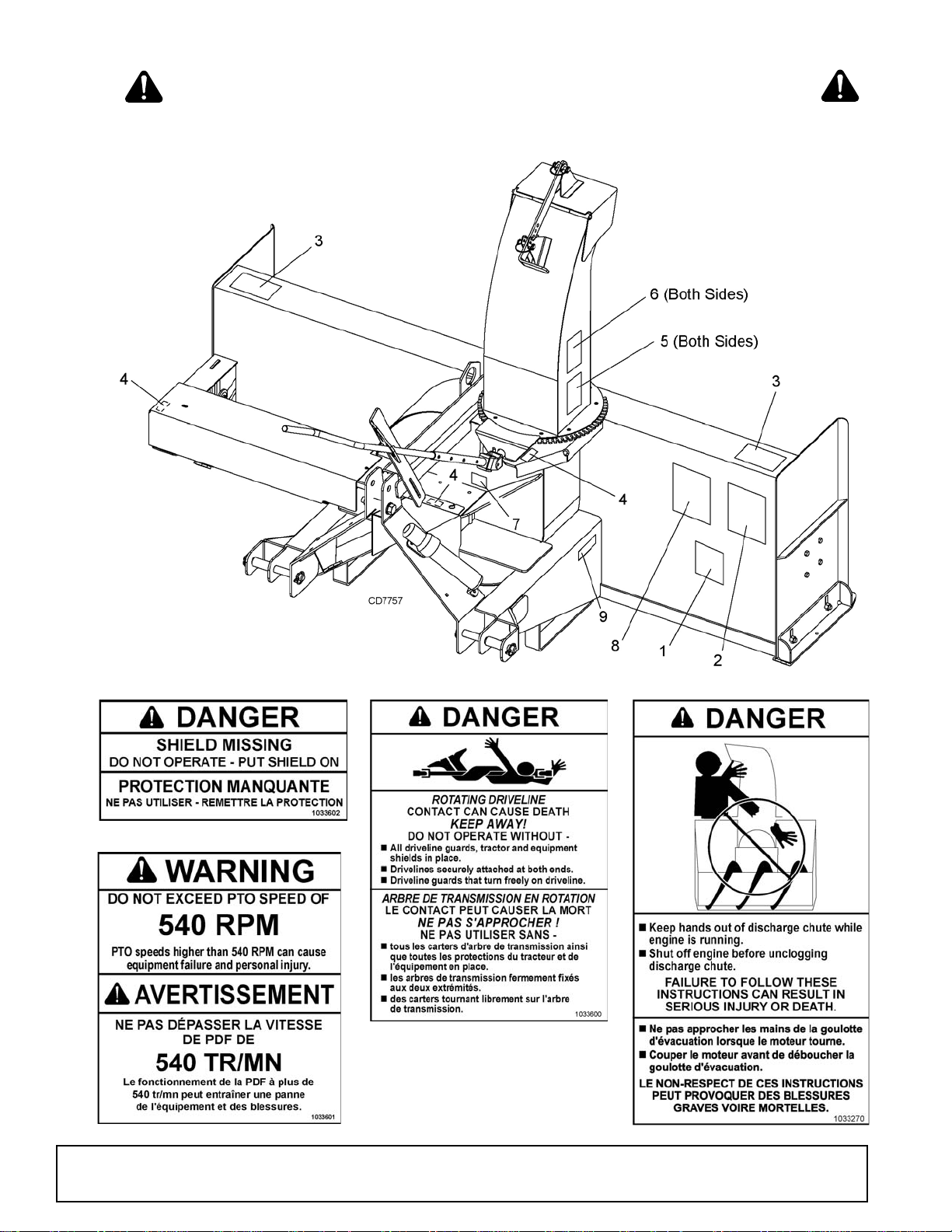

4 - 1033602 1 - 1033600 5 - 1033270

7 - 1033601

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

8 Safety

MAN0869 (04/13/2011)

Page 9

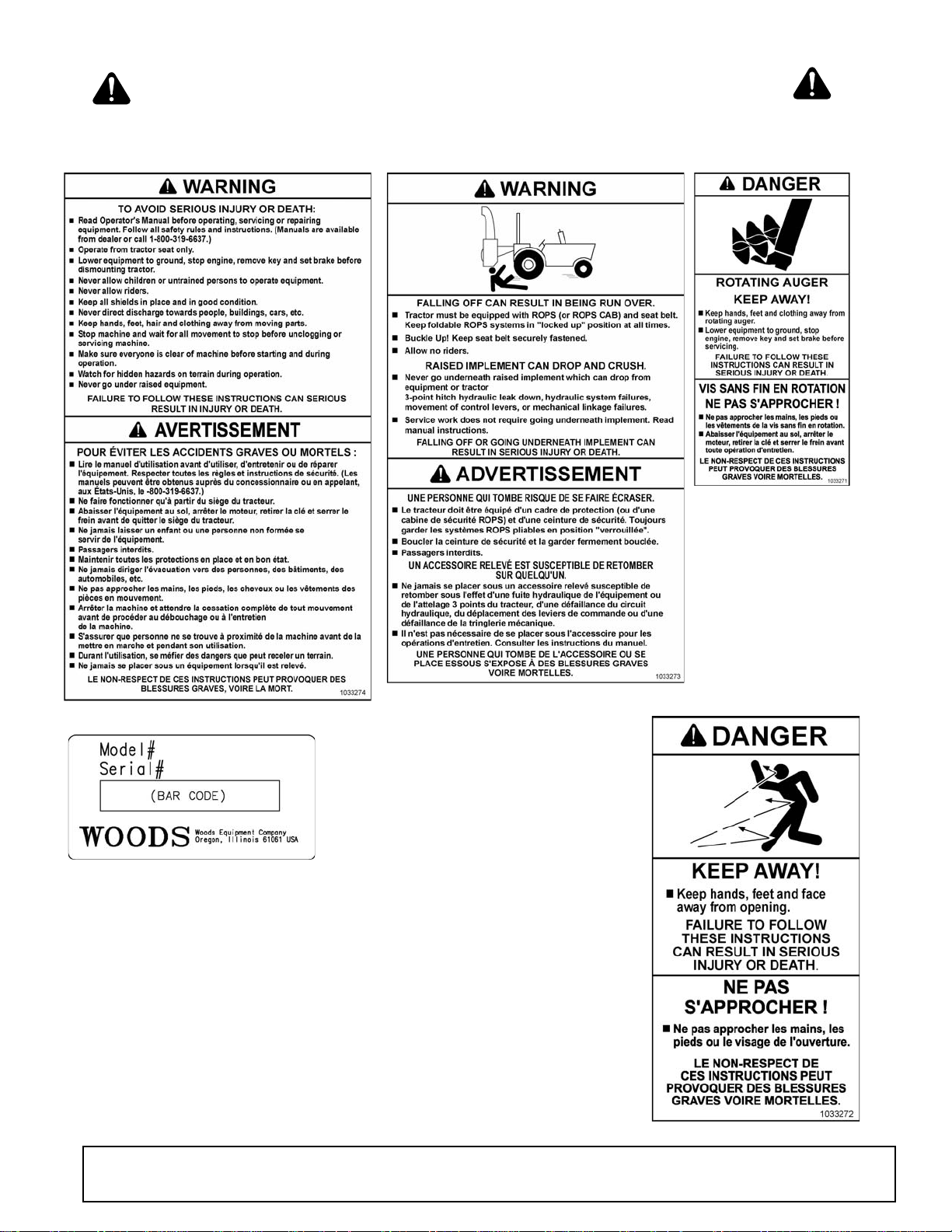

BE CAREFUL!

Use a clean, damp cloth to clean safety decals.

Avoid spraying too close to decals when using a pressure washer;

high-pressure water can enter through very small scratches or under

edges of decals causing them to peel or come off.

Replacement safety decals can be ordered free from your Woods

dealer. To locate your nearest dealer, check the Dealer Locator at

www.WoodsEquipment.com, or in the United States and Canada call

1-800-319-6637.

2 - 1033274 8 - 1033273 3 - 1033271

6 - 1033272

9 - 1033176

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

MAN0869 (04/13/2011)

Safety 9

Page 10

OPERATION

The operator is responsible for the safe operation of

the snowblower. The operator must be properly

trained. Operators should be familiar with the tractor,

snowblower, and all safety practices before starting

operation. Read through safety rules and decals on

page 5 through page 9.

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt securely

fastened. Falling off power unit can result in death

from being run over or crushed. Keep foldable

ROPS system in “locked up” position at all times.

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

Never allow children or untrained persons to

operate equipment.

Never go underneath equipment (lowered to the

ground or raised) unless it is properly blocked and

secured. Never place any part of the body underneath equipment or between moveable parts even

when the engine has been turned off. Hydraulic

system leak down, hydraulic system failures,

mechanical failures, or movement of control levers

can cause equipment to drop or rotate unexpectedly and cause severe injury or death. Follow Operator's Manual instructions for working underneath

and blocking requirements or have work done by a

qualified dealer.

Keep bystanders away from equipment.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Never place hands or body into discharge chute

or auger to unclog. Stored energy can cause auger

to quickly rotate when unclogging occurs and

cause severe injury or amputation. Stop engine,

remove key, disconnect driveline, and carefully

unclog, using a sturdy piece of wood.

Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

Make sure that all operating and service personnel know that if hydraulic fluid penetrates skin, it

must be surgically removed as soon as possible by

a doctor familiar with this form of injury or gangrene, serious injury, or death will result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Make sure spring-activated locking pin or collar

slides freely and is seated firmly in tractor PTO

spline groove.

Operate tractor PTO at 540 RPM. Do not exceed.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

If you do not understand any part of this manual

and need assistance, see your dealer.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

NOTICE

■ Be sure to complete the Pre-Operation Check

List on page 15 prior to operating this Snowblower.

PRINCIPAL COMPONENTS

The snowblower has three main operating components. A 15" diameter auger dislodges the snow and

carries it to a central fan. The snow is then discharged

by the fan and directed away from the blower through a

controllable spout.

10 Operation

MAN0869 (04/13/2011)

Page 11

The snowblower is mounted on a tractor 3-point hitch

and driven by the tractor PTO. A centrally located gearbox directs power to the fan and auger.

4. Attach tractor center link to upper hitch point of

snowblower. Adjust length of center link until the

top edge of the frame ends are parallel to ground.

TRACTOR REQUIREMENTS

3-Point Hitch

The compact snowblower (C series) requires the tractor to be equipped with a Category 1 or 2 three-point

hitch. The sub-compact (S series) snowblower requires

the tractor to be equipped with a limited Category 1 or

Category 1 three-point hitch.

Hydraulic Circuit

Either closed-center or open-center systems can be

used for the optional hydraulic spout control.

Tire Configuration

For best results, the tractor wheels should be set narrower than the cutting width of the snowblower. Wider

wheel settings will cause snow to be pulled under the

tractor and may require additional passes.

PTO Shaft

The tractor must be configured to accept a 1-3/8" 6spline 540 RPM system and must meet horsepower

specifications. See specifications, page 4.

Tractor Stability

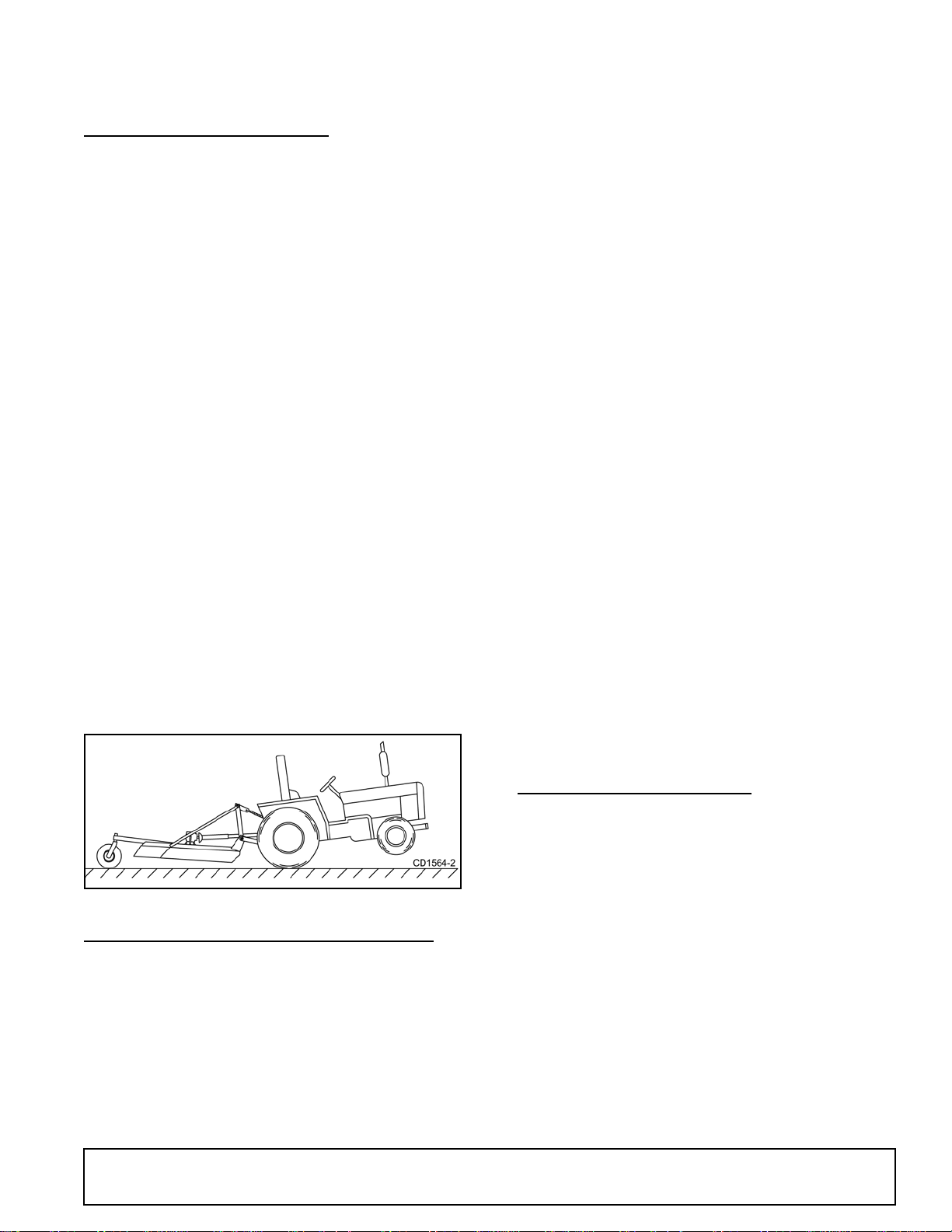

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, front tractor wheels could raise up resulting in loss of steering. The weight may be attained

with front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

5. Adjust tractor lower 3-point arm anti-sway devices

to prevent snowblower from swinging side to side

during transport.

6. Attach front PTO driveline from snowblower to

tractor. Slide front section of PTO driveline into

back section. Slide PTO shaft onto rear of tractor.

NOTICE

■ If the PTO driveline is too long, severe driveline

and gearbox damage is possible when hooking up

the PTO driveline from the rotary snowblower to

the tractor. The front PTO driveline is long enough

to fit a variety of tractors. It is possible that the

front PTO driveline will need to be cut. There will be

NO benefit by cutting only one telescoping section.

Both sections of the driveline must be cut. DO NOT

FORCE THE PTO TO FIT.

■ If attaching with quick hitch, the distance

between the tractor PTO and gearbox input shaft

will increase. Please follow the steps as you would

for a 3-point hitch to insure proper engagement.

■ When attaching snow blower to multiple trac-

tors consider the drive length needed for each tractor and whether the drive line will work in all

combinations.

■ WARRANTY IS VOID IF THE PTO DRIVELINE IS

TOO LONG, resulting in gearbox, PTO, yoke or

cross bearing damage.

NOTE: The PTO driveline, when attached to the

tractor and gearbox, must not extend so there is

less than 10-3/4” (bilobe) or 4-1/2" (trilobe) of overlap within the PTO driveline.

Figure 1. Tractor Stability (Typical)

ATTACHING SNOWBLOWER TO TRACTOR

1. Move the tractor into position in front of the snow-

blower. Move back slowly and carefully, not allowing anyone to be between the tractor and the

snowblower.

2. Turn off tractor engine.

3. Attach two lower arms of 3-point hitch with the two

hitch-pin assemblies.

(Rev. 9/8/2011)

MAN0869 (04/13/2011)

DRIVELINE ATTACHMENT

Attach snowblower to tractor 3-point hitch (or quick

hitch if available). Do not attach driveline the first time

you attach the snow blower to the tractor. Raise and

lower snowblower to determine maximum and minimum distance between tractor PTO shaft and gearbox

input shaft. If distance is too large, driveline will be too

short for proper engagement. If distance is too small,

driveline may bottom out in operation and damage

snowblower or tractor.

If driveline is too short, please call your Woods dealer

for a longer driveline.

If driveline is too long, please follow instructions for

shortening driveline.

Operation 11

Page 12

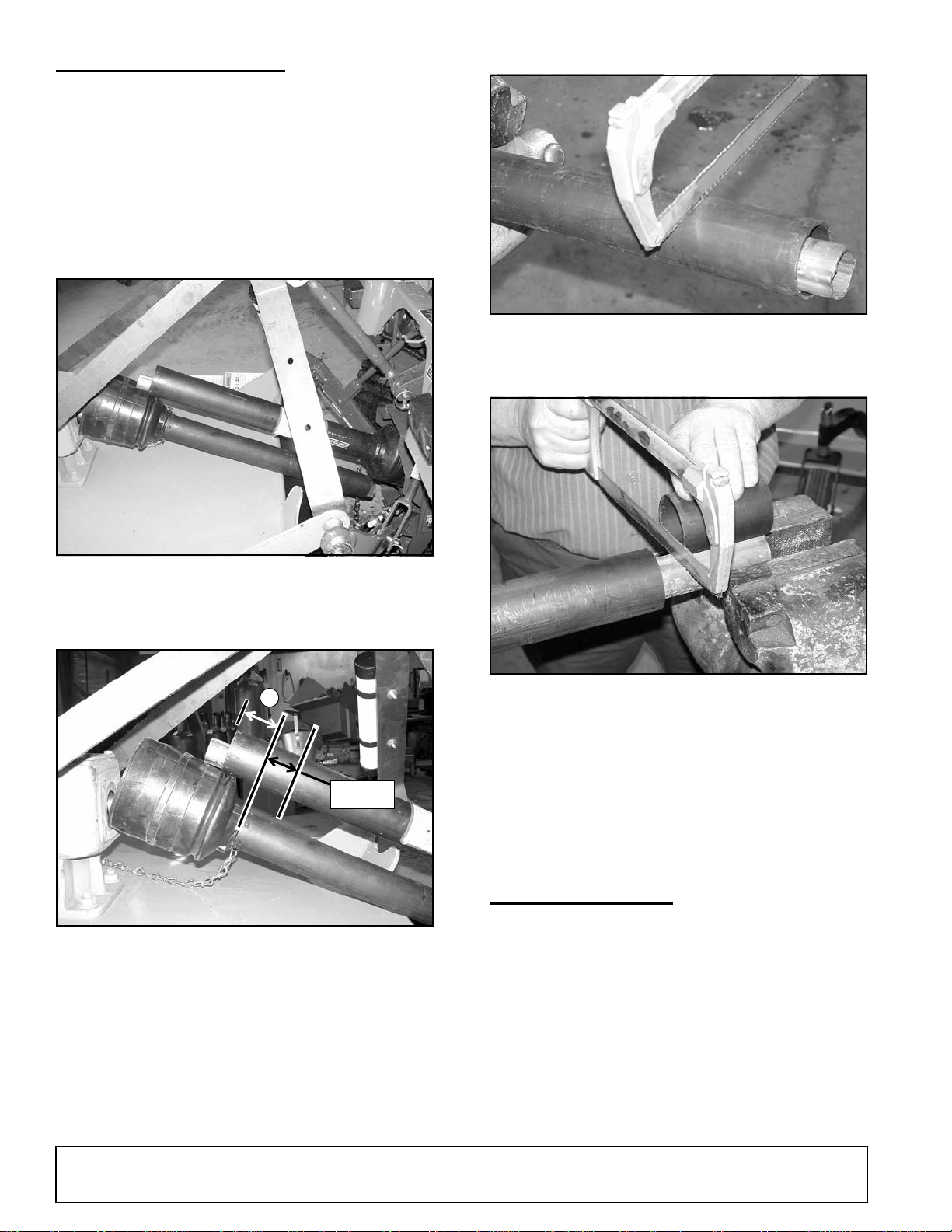

SHORTENING DRIVELINE

1-1/4"

A

1. Move snowblower up and down to get shortest

possible distance between tractor PTO shaft and

gearbox input shaft. Leave snowblower in minimum distance position. Install jack stands under

snowblower for support.

2. Separate driveline into two halves and connect

them to tractor and gearbox.

3. Place driveline halves parallel to one another to

determine how much to shorten the driveline.

5. Cut upper shield to this overall dimension

Figure 4. Cut Shield

6. Place cut portion of shield against end of shaft and

use as a guide. Mark and cut shaft.

Figure 2. Drive Halves Placed Parallel

4. Measure from end of upper shield to base of bell

on the lower shield (A). Add 1-1/4" to dimension

(A).

Figure 3. Determine Shield Length

Figure 5. Cut Shaft to Length

7. Repeat step 4 through 6 for other half of drive.

8. File and clean the cut ends of both drive halves.

Ensure the drive halves slide smoothly together.

Do not run tractor if proper driveline engagement cannot be obtained through these methods.

Connect driveline to tractor PTO shaft, making sure

spring-activated locking collar slides freely and locks

driveline to PTO shaft.

MACHINE BREAK-IN

Although there are no operational restrictions on the

snowblower when used for the first time, the following

items are to be checked.

A. After operating for 1/2 hour:

1. Check all nuts, bolts and other fasteners. Tighten

to their specified torque level.

12 Operation

2. Check drive chain tension. Adjust as required.

3. Check that auger, fan and spout are in good condi-

tion.

MAN0869 (04/13/2011)

Page 13

4. Check oil level in the gearbox. Add as required.

WARNING

WARNING

5. Lubricate all grease points.

B. After operating for 5 to 10 hours:

1. Repeat items 1 through 4 of Section A.

2. Then go to normal Owner Service Section,

page 16.

OPERATION

Each operator should review this section of the manual

at the start of the season and as often as required to be

familiar with the machine. When using, follow this procedure:

1. Review and follow the "Pre-Operation Check List,"

page 15.

2. Review "Attaching Snowblower to Tractor" section,

page 11.

3. Before going to the field, review "Transporting"

section, page 14.

4. Position snowblower in a level area and lower into

working position.

5. Starting Snowblower:

8. Ground Speed: Travel speed can vary between 1.5

and 8 mph depending on material and terrain conditions. It is the responsibility of the operator to

note the condition of the job being done and set the

speed to obtain proper feeding rate and maintain

safe control of machine.

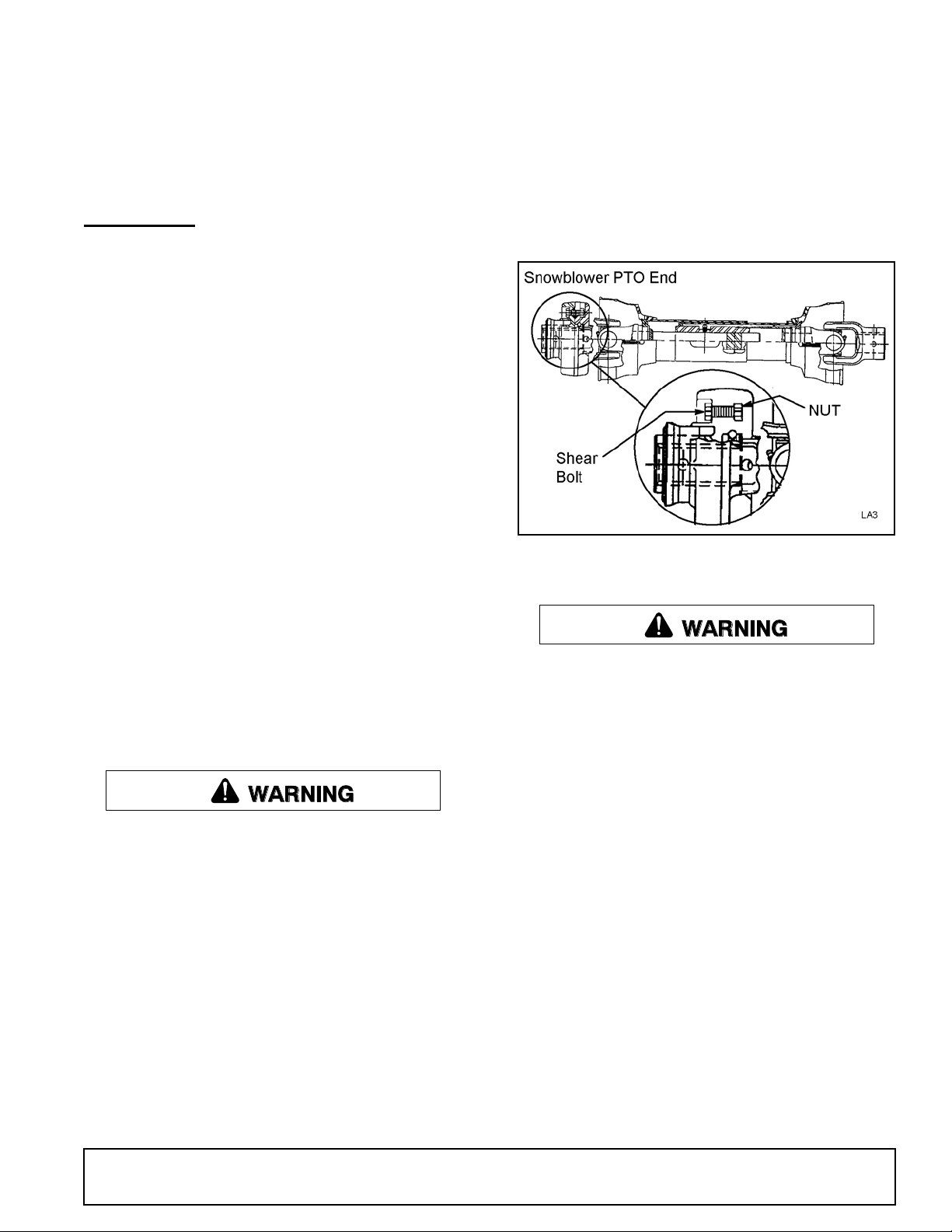

9. The PTO driveline is equipped with a shear bolt,

Figure 6, that protects drive system components

from shock loads if machine strikes an obstruction.

See parts section for bolt size and grade.

■ Be sure area is clear of all bystanders.

■ Run engine at low idle.

■ Slowly engage PTO control to start machine.

■ Slowly bring engine to rated PTO speed. Never

exceed rated speed

6. Stopping Machine:

■ Slowly decrease engine speed to low idle.

■ Wait until PTO drive and snowblower have

slowed to low engine idle speed before disengaging PTO drive.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Before performing any service or maintenance,

disconnect driveline from tractor PTO.

7. Do not operate with bystanders in area. The

machine can pick up stones, sticks, wire and other

debris and throw it out with enough force to cause

severe injury or death to bystanders. Shut down

machine and wait for moving parts to stop before

approaching machine.

Figure 6. Shear Bolts

10. Operating Requirements:

Never direct discharge toward people, animals,

or property.

■ Know where you are operating. Remove all

unwanted trash and debris before starting. It can

wrap around auger or be thrown out of machine

during operation.

■ Keep auger and fan in good condition. Do not

operate with a damaged fan or auger.

■ Do not allow the auger to hit and scalp ground

during operation. Hitting ground will pick up soil or

rocks that can be thrown out of machine.

■ To change direction of snow discharge, rotate

the discharge chute. It will rotate 270°.

To move a discharge chute equipped with an

optional hydraulic control, use tractor hydraulic

control to direct discharge left or right within its

270° range. It will not rotate a full 360°.

NOTE: For hydraulic rotator option, if chute turns

too quickly, adjust flow control on tractor hydraulics.

NOTE: Operating hydraulic deflector cylinder

requires low tractor flow rates. When initially operating cylinder reduce tractor hydraulic flow rate to

MAN0869 (04/13/2011)

Operation 13

Page 14

prevent deflector damage and improve resolution

5. Clevis Pin

8. Discharge Chute

9. Adjustment Strap

WARNING

CAUTION

WARNING

of deflector adjustment.

Adjusting Discharge Chute Position

■ The height of snow discharge is controlled by

position of chute deflector on discharge chute (8),

Figure 7. Remove clevis pin (5), and slide adjustment strap (9) to selected discharge height. Reinstall clevis pin (5).

NOTE: If possible, blow snow with the wind.

Beware of people or buildings in the area.

attachments are in transport position. Without this

weight, front tractor wheels could raise up resulting in loss of steering. The weight may be attained

with front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

Never allow riders on power unit or attachment.

Do not operate PTO during transport.

Always comply with all state and local lighting

and marking requirements.

NOTICE

■ Do not exceed 20 mph (32km/h). Reduce speed

on rough roads and surfaces.

When transporting snowblower, review and follow this

procedure:

■ Be sure all bystanders are clear of machine.

■ Be sure that machine is securely attached to

tractor and all retainer pins are installed.

■ Raise machine.

■ Do not allow riders.

Figure 7. Discharge Chute Position

■ Keep bystanders away from equipment.

■ Wear appropriate hearing protection.

11. Depth of cut can be controlled with the skid shoes

or by tilting the blower forward or backward. Excessive forward or backward tilt may cause U-joint to

flutter resulting in PTO shear bolt failure. Do not

run the PTO shaft at more than a 15° angle.

12. Allow the snowblower to work its way through the

snow rather than forcing it.

13. In deep snow it may be necessary to raise the

snowblower for the first pass through and clean up

the remainder with a second pass.

14. Do not feed snow through snowblower when raising or lowering.

TRANSPORTING

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

STORAGE

Block equipment securely for storage.

Keep children and bystanders away from stor-

age area.

After season's use, machine should be thoroughly

inspected and prepared for storage. Repair or replace

any worn or damaged components to prevent any

unnecessary down time at start of next season.

To insure a long, trouble free life, this procedure should

be followed when preparing unit for storage.

1. Clear area of bystanders.

2. Thoroughly wash machine to remove all dirt, mud,

debris or residue.

3. Check auger, fan and drivelines for damage or

entangled material. Repair or replace damaged

parts. Remove the entangled material.

4. Inspect all hydraulic hoses, fittings, lines and couplers. Tighten any loose fittings. Replace any hose

that is cut, nicked or abraded or is separating from

crimped end of fitting.

5. Change oil in gearbox.

14 Operation

MAN0869 (04/13/2011)

Page 15

6. Lubricate all grease fittings. Make sure that all

grease cavities have been filled with grease to

remove any water residue from washings.

■ Replace any safety decals that are missing or not

readable (supplied free by your Woods dealer). See

Safety Decals section for location drawing.

7. Touch up all paint nicks and scratches to prevent

rusting.

8. Move to storage area.

9. Select an area that is dry, level and free of debris.

10. Unhook from tractor (see page 11).

11. Store machine in an area away from human activ-

ity.

12. Do not allow children to play on or around stored

machine.

CLEANING

After Each Use

■ Remove large debris such as clumps of dirt, grass,

crop residue, etc. from machine.

■ Inspect machine and replace worn or damaged

parts.

■ Replace any safety decals that are missing or not

readable.

Periodically or Before Extended Storage

■ Clean large debris such as clumps of dirt, grass,

crop residue, etc. from machine.

■ Remove remaining debris using a low-pressure

water spray.

1. Be careful when spraying near scratched or torn

safety decals or near edges of decals as water

spray can peel decal off surface.

2. Be careful when spraying near chipped or

scratched paint as water spray can lift paint.

3. If a pressure washer is used, follow the advice

of the pressure washer manufacturer.

■ Inspect machine and replace worn or damaged

parts.

■ Sand down scratches and the edges of areas of

missing paint and coat with Woods spray paint of

matching color (purchase from your Woods dealer).

PRE-OPERATION CHECK LIST

(OWNER'S RESPONSIBILITY)

___ Review and follow all safety rules and safety

decal instructions on pages page 5 through

page 9.

___ Check that all safety decals are installed and in

good condition. Replace if damaged.

___ Check that all shields and guards are properly

installed and in good condition. Replace if damaged.

___ Check that all hardware and cotter pins are prop-

erly installed and secured.

___ Check that equipment is properly and securely

attached to tractor.

___ Make sure driveline spring-activated locking pin

or collar slides freely and is seated firmly in tractor PTO spline groove.

___ Inspect area and remove stones, branches or

other hard objects that might be thrown, causing

injury or damage.

___ Do not allow riders.

___ Check the drive chain for tension. If too loose,

adjust the idler sprocket. A 1/4" sag in the bottom

span is satisfactory.

___ Check all lubrication points and grease as

instructed in "Service, lubrication information".

Make sure the PTO slip joint is lubricated and

that the gearbox fluid levels are correct.

___ Set tractor PTO at correct rpm for your equip-

ment.

___ Check that all hydraulic hoses and fittings are in

good condition and not leaking before starting

tractor. Check that hoses are not twisted, bent

sharply, kinked, frayed or pulled tight. Replace

any damaged hoses immediately.

___ Make sure tractor ROPS or ROPS CAB and seat

belt are in good condition. Keep seat belt

securely fastened during operation.

MAN0869 (04/13/2011)

Operation 15

Page 16

OWNER SERVICE

WARNING

CAUTION

The information in this section is written for operators

who possess basic mechanical skills. Should you need

help, your dealer has trained service technicians available. For your protection, read and follow all safety

information in this manual.

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

NEVER GO UNDERNEATH EQUIPMENT. Never

place any part of the body underneath equipment

or between moveable parts even when the engine

has been turned off. Hydraulic system leak-down,

hydraulic system failures, mechanical failures, or

movement of control levers can cause equipment

to drop or rotate unexpectedly and cause severe

injury or death.

• Service work does not require going underneath implement.

• Read Operator's Manual for service instructions or have service performed by a qualified

dealer.

Before performing any service or maintenance,

disconnect driveline from tractor PTO.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its components in any way.

If you do not understand any part of this manual

and need assistance, see your dealer.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter pins are

installed securely to ensure equipment is in a safe

condition before putting unit into service.

SERVICE AND MAINTENANCE

INTERVALS

By following a careful service and maintenance program, you will prolong the life of your machine.

The service intervals recommended are based on normal operating conditions. Severe or unusual conditions

may require more frequent service.

Lubrication Information

1. Do not let excess grease collect on or around

parts, particularly when operating in sandy areas.

2. Use a hand-held grease gun for all greasing.

3. Use a lithium grease of #2 consistency with a

MOLY (molybdenum disulfide) additive for all locations unless otherwise noted. Be sure to clean fittings thoroughly before attaching grease gun.

4. If grease fitting will not take grease, remove and

clean thoroughly. Also clean lubricant passage

way. Replace fitting if necessary.

5. Two good pumps of most grease guns is sufficient

when the lubrication schedule is followed.

Driveline Lubrication

1. Lubricate the driveline slip joint every 8 hours of

operation. Failure to maintain proper lubrication

could result in damage to u-joints, gearbox, and

driveline.

2. Lower snow blower to ground, disconnect driveline

from tractor PTO shaft, and slide halves apart. Do

not disconnect the halves from each other.

3. Apply a bead of grease completely around male

half where it meets female half. Slide drive halves

over each other several times to distribute grease.

16 Owner Service

MAN0869 (04/13/2011)

Page 17

4. Apply one pump of grease to each driveline u-joint

WARNING

17. Jackshaft Shield

19. Grease Zerk

32. Thumb Screw

33. Idler Sprocket

grease fitting.

5. Apply one pump of grease to each of the plastic

driveline shield bearings.

6. On the shear pin driveline, lubricate the shear yoke

with grease to prevent galling.

7. Periodically check the yokes on the front PTO.

Make sure the bolt and nut are tight and the yoke

is not moving on the gearbox shaft.

Driveline Shear Bolt Replacement

PTO drivelines are equipped with shear bolts to protect

against overloads.

■ Always use approved shear bolt as replace-

ment part. Using a hardened bolt or shear pin may

result in damage to driveline or gearbox.

■ Before proceeding, read and follow all safety

rules.

1. Disconnect driveline from tractor PTO shaft.

2. Remove gearbox shield by removing thumb

screws.

3. Remove damaged bolt from yoke on input shaft of

snow blower gearbox.

4. Rotate driveline to align holes in yoke and shaft.

Install new shear bolt and secure with lock nut.

Tighten to torque specification given on Torque

Chart.

5. Reinstall gearbox shield and reconnect driveline to

tractor PTO shaft.

Figure 8. Drive Chain Lubrication

1. Apply grease to drive sprocket grease zerk (See

Figure 8).

2. Apply grease or oil to the drive chain regularly,

especially after using (See Figure 8).

NOTICE

■ Replacement chain should be only high quality

original equipment chain for longer life.

1. Remove jackshaft shield (17) by removing thumb

screws (32).

2. Loosen cap screw and nut on idler sprocket.

3. Move idler sprocket (33) to obtain 1/4 inch sag

along bottom span of chain (46).

4. Re-tighten idler sprocket and reinstall jackshaft

shield.

Chain Maintenance

The auger chain should be inspected every 25 hours.

New chain has a tendency to stretch, so it is necessary

to check the chain tension to prevent flopping around,

thus causing potential problems. Chain tension is preset at the factory. If chain becomes excessively loose,

it may be necessary to readjust the idler sprocket, Figure 9.

MAN0869 (04/13/2011)

Figure 9. Auger Drive Chain Adjustment

Owner Service 17

Page 18

Auger Drive Shear Bolt Replacement

18. Auger Drive Shaft

21. 1/4 NC x 1” HHCS GR5

22. 1/4 NC Lock Nut

PIC3

WARNING

Oil Plug

DP8

WARNING

■ Always use approved shear bolt as replace-

ment part. Using a hardened bolt or shear pin may

result in damage to driveline or gearbox.

Remove any obstructions from the auger, chain, or

drive sprocket.

Remove jackshaft shield by removing thumb screws.

Remove damaged bolt from shear plates on drive

sprocket and/or jackshaft (18).

Rotate drive sprocket to align holes in sprocket and

shaft. Install new shear bolt (21) and secure with lock

nut (22). Tighten to torque specification given on

Torque Chart.

Gearbox

The gearbox is almost maintenance-free, but should be

checked quarterly to be sure that the oil level is maintained at half full. A high quality gear oil with a viscosity

index of 80W or 90W and an API service rating of GL-4

or -5 is recommended for use in the gearbox. Oil

should be changed after the first 30 hours or 30 days of

operating. Then, normal change should be adequate.

In the case of seasonal usage, it is best to change the

oil at the end of the season to remove moisture and

corrosive contaminants.

■ Before proceeding, read and follow all safety

rules.

To change the oil, follow this procedure, Figure 12:

1. Suction out oil in gearbox through side plug using a

hand pump.

NOTE: It is best to drain the oil when the gearbox

is warm to remove the most contaminants.

Figure 10. Auger Drive Shear Bolt Replacement

Discharge Chute Lubrication

1. Apply grease between the discharge chute base

and ring on the frame tube, Figure 11, annually.

2. Add 0.52 quart SAE 85W90 gear oil through side

plug. Use level hole (halfway up the backside of

gearbox) to check oil level. Add oil accordingly.

3. Install and tighten plug.

Figure 12. Gearbox Oil

Skid Shoes

The machine is equipped with skid shoes on bottom

side of each side plate to prevent wearing frame and to

provide depth control. They should be checked occasionally for wear and replaced if required.

Figure 11. Chute Base and Rotator Ring

18 Owner Service

■ Before proceeding, read and follow all safety

rules.

MAN0869 (04/13/2011)

Page 19

1. Place a 4" x 4" block under each end of snow-

3. 1/2 NC x 1” Carriage Bolt

4. Skid Shoe

31. 1/2 NC Lock Nut

DP7

DP6

blower frame.

2. Rotate bell shield until three reliefs align with white

plastic collar.

NOTE: Block only high enough for the skid shoes

to clear ground.

2. Lower snowblower to sit securely on blocks.

3. Properly secure tractor and release all hydraulic

pressure.

4. Loosen and remove skid shoe mounting bolts (3)

and nuts (31).

5. Remove skid shoe and inspect (4).

6. Adjust skid shoe (4) to provide correct depth of cut.

7. Tighten mounting bolts (3) and nuts (31). Tighten to

specifications given on torque chart.

3. Remove bell housing and shaft.

4. Replace components as needed. Follow steps 1

through 3 in reverse.

Figure 14. Walterscheid Driveline

Comer Driveline

1. Rotate three rectangular plastic pins with a screw

driver 90°.

2. Lift pins out with screw driver.

3. Remove bell housing and shaft.

Figure 13. Skid Shoe Adjustment

PTO Driveline Guard

The shield must turn freely on PTO shaft. Daily lubrication of both shield bearings and periodic cleaning will

ensure safe operation of the shield.

If shield is damaged or worn, replace components with

genuine Woods service parts.

Walterscheid Driveline

1. Remove Phillips screw on driveline bell shield.

NOTE: In order to slide new bell over shaft guard,

place bell in water at 180° F or in sun to expand

bell temporarily.

4. Replace components as needed. Follow steps 1

through 3 in reverse.

Figure 15. Comer Driveline

(Rev. 5/19/2011)

MAN0869 (04/13/2011)

Owner Service 19

Page 20

TROUBLE SHOOTING

PROBLEM PROBLEM CAUSES SUGGESTED SOLUTION

PTO Shaft shear bolt continues

to shear

Snowblower augers continue to

plug

Snow does not discharge

properly

PTO shaft at too great an angle. Do not exceed a 15 degree

angle at PTO shaft.

PTO shear bolt is too soft. Use a grade 5 shear bolt. (GKN)

Use a grade 10.9 bolt. (Comer

20 series)

Use a grade 8.8 bolt. (Comer

40 series)

Tilt on the snowblower is too

great causing an excessive

knuckle angle.

Tractor ground speed is too fast. Reduce ground speed to allow

Insufficient fan speed. Increase tractor PTO speed to

Insufficient fan speed. Maintain a PTO speed of 540

Augers are overloaded with

snow.

Reduce tilt on snowblower by

adjusting upper 3-point link.

augers to clear better.

540 RPM.

RPM.

Reduce ground speed.

Snow is wet and sticky. Reduce ground speed to allow

Snowblower tends to dig or float

on snow

Chute will not turn Insufficient lubrication.

Auger fails to turn Auger drive shear bolt has

Tilt on snowblower not adjusted

properly.

Skid Shoes not adjusted properly.

Incorrect number of spacers.

sheared.

for better aeration of snow.

Adjust upper link on 3-point to

level the blower.

Adjust skid shoes to be even

with cutting edge.

Lubricate chute base and rotator

ring.

Check that 3 spacers are being

used.

Replace auger drive shear bolt.

20 Owner Service

MAN0869 (04/13/2011)

Page 21

ASSEMBLY INSTRUCTIONS

16. Drive Holder

37. 5/16 NC x 1" Carriage Bolt

38. 5/16 NC Lock Nut

34. SMV Bracket

37. 5/16 NC x 1" Carriage Bolt

38. 5/16 NC Hex Locknut

DEALER SET-UP INSTRUCTIONS

Assembly of this snowblower is the responsibility of the

Woods dealer. It should be delivered to the owner completely assembled, lubricated and adjusted for normal

conditions.

The snowblower is shipped partially assembled.

Assembly will be easier if components are aligned and

loosely assembled before tightening hardware. Recommended torque values for hardware are located on

page 38.

Select a suitable working area. A smooth hard surface,

such as concrete, will make assembly much quicker.

Open parts boxes and lay out parts and hardware to

make location easy. Refer to illustrations, accompanying text, parts lists and exploded view drawings.

All Models

1. Remove parts from crate in a suitable work area.

Check packing list to ensure all parts are present.

NOTE: Leave all hardware loose until all components are completely assembled.

5. Remove plug from gearbox and add .52 quart of

SAE85W-90 gear oil, Figure 12.

6. Remove hardware (37) and (38) from SMV bracket

(34) and rotate bracket facing up. Reinstall hardware (37) and (38), Figure 17.

2. Remove driveshaft from snowblower. Slide implement PTO shaft on gearbox shaft. Pull back spring

actuated collar as driveline is installed on gearbox

shaft, releasing collar when driveline is installed.

NOTE: Check that drive shaft is fully engaged in

gearbox shaft groove.

3. Remove hardware (37) and (38) from front right

mast plate hole and rotate drive holder (16) until

holes are aligned, Figure 16.

4. Reinstall hardware (37) and (38).

Figure 17. SMV Installation

7. Remove plastic cable tie holding auger chain in

place.

Install Hand Crank (Figure 18)

8. Fasten mount bracket (5) to upper three-point

channel using two carriage bolts (8) and lock nuts

(9).

NOTE: Bracket is adjustable and can be rotated or

slide up or down for best fit with tractor.

9. Connect clevis rotator (1) to block (2) and clevis

tube (3) with roll pins (6).

10. Remove rotator sprocket from lower hitch pin.

Install in square opening on chute adapter with

block and pin assembly using roll pins (6) and (13).

Hole in sprocket rotator should face towards tractor

hitch.

11. Install trim strip (6.5" long) in slot on mount bracket

(5) which hand crank (4) will protrude through.

Figure 16. Install Drive Holder

MAN0869 (04/13/2011)

(Rev. 10/4/2011)

12. Slide hand crank (4) through mount bracket (5)

and into clevis tube (3). Align hand crank and clevis tube holes for correct length and install cap

screws (7) and hex nut (9).

Assembly 21

Page 22

NOTE: Make sure handle will not protrude into rear

1. Clevis Rotator

2. Block

3. Clevis Tube

4. Hand Crank

5. Mount Bracket

6. 5/16 x 2 Roll Pin

7. 5/16 NC x 1-1/2 HHCS

8. 5/16 NC x 1 Carriage Bolt

9. 5/16 NC Lock Nut

10. Rotator Shield

11. 3/8 Lock Washer

12. 3/8 NC x 1 HHCS

13. 5/16 x 1-3/4 Roll Pin

14. Trim Strip 6.5"

5. 3/8 NC x 1-1/2 HHCS GR5

8. Discharge Chute

27. 3/8 x 1-1/4 HHCS GR5

28. 3/8 NC Hex Locknut

35. Discharge Chute Spacer

40. Discharge Chute Clamp

window of a tractor equipped with cab by checking

the highest 3-point hitch position.

NOTE: Refer to Figure 20 for proper orientation

and installation of hardware.

16. Install two cap screws (5) through front two holes

of discharge chute (8) and discharge chute spacers (35). Secure with nuts (28). Leave hardware

loose.

17. Install six cap screws (27) through discharge chute

clamp (40), discharge chute spacers (35) and discharge chute (8). Secure with nuts (28).

18. Tighten hardware.

19. Operate hand crank to check ease of block and pin

and chute rotation. If hand crank turns too hard,

adjust mounting bracket for a reduced angle. If

chute does not rotate freely check spacers and

chute hardware for binding.

Figure 18. Hand Crank Installation

13. Apply grease to discharge tube ring and frame.

Figure 19. Apply Grease to Discharge Chute Ring

14. Loosen discharge chute hardware and remove

washers. Washers will not be reused.

Install Discharge Chute (Figure 20)

15. Attach discharge chute (8) to chute base using

spacers (35), (6 total, 3 each side), discharge

chute clamp (40), and hardware.

22 Assembly

Figure 20. Install Discharge Chute

(Rev. 10/4/2011)

MAN0869 (04/13/2011)

Page 23

MOUNTING HYDRAULIC CHUTE ROTA-

17. 3/8 NC x 4 HHCS

18. 3/8 NC Locknut

1. Hydraulic Motor

2. Restrictor

3. Hydraulic Hose

4. Coupler

5. Decal

6. Mounting Bracket

7. Coupler

8. Set Screw

9. Roll Pin

10. Shaft Rotator

11. Mounting Link

13. 3/8 x 3/4 crew

15. 3/8 NC x 1" HHCS

16. 3/8 Lock Washer

17. 3/8 NC x 4 HHCS

18. 3/8 NC Locknut

36. Rotator Sprocket

TOR OPTION (FIGURE 22)

1. Fasten coupler (7) to hydraulic motor (1) using

woodruff key and set screw (8).

2. Fasten hydraulic motor assembly to hydraulic

motor mount bracket (6) using cap screws (15) and

lock washers (16).

3. Fasten hydraulic motor coupler (7) to shaft rotator

(10) using roll pin (9).

4. Fasten hydraulic motor mount to upper three-point

channel with cap screws (17), link (11), and hex

nuts (18).

5. Remove rotator sprocket from lower hitch pin.

Position rotator sprocket in square opening on

chute adapter with hole facing towards hitch. Slide

hydraulic motor and channel assembly into rotator

sprocket and fasten using roll pin.

6. Fasten flow restrictors (2) to hydraulic motor.

7. Fasten hydraulic hose (3) to restrictors (2).

8. Fasten couplers (4) to ends of hoses (3).

Figure 21. Motor Mount Position 8" from Front

MAN0869 (04/13/2011)

Figure 22. Hydraulic Chute Rotator Installation

Assembly 23

Page 24

MOUINTING HYDRAULIC CHUTE DEFLEC-

1. Hydraulic Cylinder

2. Male Coupler

3. Swivel Restrictor

4. Elbow

5. 1/2 NPTF x 1/2 NPTM Adapter

6. 3/8 NC Lock Nut

7. 3/8 NC x 1-3/4 HHCS

8. 1/4 Hydraulic Hose

12. 3/8 NC x 4 HHCS

13. 3/8 NC Locknut

1. Hydraulic Motor

2. Wire Harness

3. Mounting Bracket

4. Coupler

5. Cable Tie

6. Roll Pin

7. Shaft Rotator

8. Mounting Link

9. Spring Nut

10. Thumb Screw

11. Rotator Shield

12. 3/8 NC x 4 HHCS

13. 3/8 NC Lock Nut

36. Rotator Sprocket

TOR (FIGURE 25)

1. Fasten cylinder (1) to discharge chute (8) using

hardware (6) and (7). Do not over tighten.

2. Fasten elbows (4) to cylinder (1).

3. Fasten hoses (8) to elbows (4).

4. Fasten adapters (5) to hoses (8).

5. Fasten restrictor (3) to adapter (5).

6. Fasten couplers (2) to adapter (5) and restrictor

(3).

Figure 24. Motor Mount Position 6.62" from Front

4. Fasten coupler (4) to shaft (7) with roll pin (6).

5. Slide rotary actuator and channel assembly into

coupler (4) and attach with roll pin (6). Tighten

loose hardware.

Install Wiring Harness

6. Attach connector "A" to the rotary actuator (1), (12"

long from splice).

Figure 23. Hydraulic Chute Deflector Installation

MOUNTING ELECTRIC CHUTE ROTATOR

OPTION (FIGURE 25)

1. Remove rotator sprocket from lower hitch pin.

Position rotator sprocket in square opening on

chute adapter with hole facing towards hitch. Install

shaft (7) into rotator sprocket (36) using roll pin (6).

Make sure second hole on shaft is facing towards

hitch.

NOTE: Attach connector "B" to linear actuator on

deflector, if equipped, (36" long from splice).

7. Tie the wire harness away from movable parts and

pinching points using cable ties (5).

2. Fasten rotary actuator (1) to mounting bracket (3)

using hardware from actuator.

3. Fasten mounting bracket (3) and actuator (1) to

24 Assembly

upper three point channel using cap screws (12),

link (8), and nuts (13). Leave hardware loose (See

Figure 24).

Figure 25. Electric Chute Rotator Installation

MAN0869 (04/13/2011)

Page 25

MOUNTING ELECTRIC CHUTE DEFLEC-

5. Cable Tie

14. Actuator

15. 1/4 NC x 1-1/2 HHCS

16. 1/4 NC Lock Nut

TOR (FIGURE 26)

1. Install remote deflection option by fastening actua-

tor (14) using cap screws (15) and nuts (16). Do

not over tighten hardware.

Figure 26. Electric Chute Deflector Installation

2. Attach control box in tractor operator area. Attach

end to a power source and ground on the tractor,

(see tractors operator’s manual).

MAN0869 (04/13/2011)

Assembly 25

Page 26

DEALER CHECK LISTS

PRE-DELIVERY CHECK LIST

(Dealer Responsibility)

Inspect the equipment thoroughly after assembly to

ensure it is set up properly before delivering it to the

customer.

The following check lists are a reminder of points to

inspect. Check off each item as it is found satisfactory

or after proper adjustment is made.

___ Check that all safety decals are installed and in

good condition. Replace if damaged.

___ Check that shields and guards are properly

installed and in good condition. Replace if damaged.

___ Check all bolts to be sure they are tight.

___ Check that all cotter pins and safety pins are

properly installed. Replace if damaged.

___ Check and grease all lubrication points as identi-

fied in "Service, lubrication information".

___ Check the level of gearbox fluids before delivery.

Service, if required, as specified in the "Service,

lubrication information."

DELIVERY CHECK LIST

(Dealer Responsibility)

___ Show customer how to make adjustments and

select proper PTO speed.

___ Instruct customer how to lubricate and explain

importance of lubrication.

___ Point out the safety decals. Explain their meaning

and the need to keep them in place and in good

condition. Emphasize the increased safety hazards when instructions are not followed.

___ Present Operator's Manual and request that cus-

tomer and all operators read it before operating

equipment. Point out the manual safety rules,

explain their meanings and emphasize the

increased safety hazards that exist when safety

rules are not followed.

___ Show customer how to make sure driveline is

properly installed and that spring-activated locking pin or collar slides freely and is seated in

groove on tractor PTO shaft.

___ Explain to customer the potential crushing haz-

ards of going underneath raised equipment.

Instruct customer that service work does not

require going underneath unit and never to do so.

___ Point out the correct mounting and routing of

hydraulic hoses. Explain that during operation,

mounting, dismounting and storage, care must be

taken to prevent hose damage from pulling, twisting and kinking.

___ Show customer the safe, proper procedures to be

used when mounting, dismounting, and storing

equipment.

___ For mounted units, add wheel weights, ballast in

front tires, and/or front tractor weight to enhance

front end stability. A minimum 20% of tractor and

equipment gross weight must be on front tractor

wheels. When adding weight to attain 20% of

tractor and equipment weight on front tractor

wheels, you must not exceed the ROPS weight

certification. Weigh the tractor and equipment. Do

not estimate!

___ Make customer aware of optional equipment

available so that customer can make proper

choices as required.

___ Point out all guards and shields. Explain their

importance and the safety hazards that exist

when not kept in place and in good condition.

26 Dealer Check Lists

MAN0869 (04/13/2011)

Page 27

PARTS INDEX

SB54S, SB64S, SB74C & SB84C

SNOWBLOWER

SB54S & SB64S ASSEMBLY. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28 - 29

SB74C & SB84C ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 - 31

HAND CRANK ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

GEARBOX ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

DRIVE ASSEMBLIES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .33 - 35

HYDRAULIC CHUTE ROTATOR & DEFLECTOR (OPTIONAL) . . . . . . . . . 36

ELECTRIC REMOTE CHUTE ROTATOR & DEFLECTOR (OPTIONAL). . . 37

MAN0869 (04/13/2011)

Parts 27

Page 28

SB54S, SB64S SUBCOMPACT SNOWBLOWER ASSEMBLY

28 Parts

(Rev. 10/4/2011)

MAN0869 (04/13/2011)

Page 29

SB54S, SB64S SUBCOMPACT SNOWBLOWER PARTS LIST

REF PART QTY DESCRIPTION

1 1033318 1 Fan

2 1033190 3 Bearing

3 29893 * 4 1/2 NC x 1-1/2 Carriage Bolt

4 1033313 2 Skid Shoe

5 976 * 3 3/8 NC x 1-1/2 HHCS GR5

6 SU105 2 CAT 1 Drawbar Pin

7 90025028 1 3/8 x 1-3/4 Pin

8 1033346 1 Discharge Chute

9 1033339 1 Deflector Handle

10 1002018 1 Sleeve, .81 x 1-1/4 x 2-1/8

11 1026530 1 Manual Tube

13 1033298 1 Gearbox Shield

14 1033291 * 4 3/8 NC x 5-1/2 HHCS GR5

15 1033222 1 Gearbox

16 1033312 1 Drive Holder

17 103329754 1 Jackshaft Shield - SB54S

17 103329764 1 Jackshaft Shield - SB64S

18 103321454 1 Auger Drive Shaft - SB54S

18 103321464 1 Auger Drive Shaft - SB64S

19 12296 * 1 1/4-28 Straight Grease Fitting

20 1033211 1 Drive Sprocket

21 10378 * 3 1/4 NC x 1 HHCS GR5

22 6128 * 3 1/4 NC Lock Nut

23 1033293 4 3/8 Spring Nut

24 31207 * 1 3/4 NC x 4 HHCS GR5

25 2864 * 2 3/4 Flat Washer

26 2371 * 1 3/4 NC Lock Nut

27 12169 * 19 3/8 NC x 1-1/4 HHCS GR5

28 6698 * 29 3/8 NC Lock Nut

29 24576 * 1 1/2 NC x 1-3/4 HHCS GR5

REF PART QTY DESCRIPTION

30 3598 * 3 1/2 Flat Washer

31 765 * 5 1/2 NC Lock Nut

32 1033294 3 3/8 x 3/4 Thumb Screw

33 90311033 1 Idler Bearing

34 1033263 1 SMV Bracket

35 1033286 6 Discharge Chute Spacer

36 12020256 1 Sprocket Rotator

37 51243 * 6 5/16 NC x 1" Carriage Bolt GR5

38 6778 * 6 5/16 NC Lock Nut

39 24549 1 5/16 x 5/16 x 1-3/4 Key

40 1033317 1 Discharge Chute Clamp

41 838 * 1 3/8 Lock Washer

42 103329554 1 Auger - SB54S

42 103329564 1 Auger - SB64S

43 24611 1 SMV Sign

44 839 * 4 3/8 NC x 1" HHCS GR5

45 1033213 1 Sprocket

46 1033277 1 Chain

47 1033977 1 Safety Decal Set

48 33677 1 Washer, 1/2 x 1-9/16 x 10 GA

49 1033956 1 Model Decal Set - SB54S & SB64S

50 565 * A/R Washer, 3/8 Flat (SN 1188497 &

Below)

51 73163 * 2 Nut, Whiz 5/16 NC Flange

HHCS Hex Head Cap Screw

* Standard Hardware - Obtain Locally

A/R As Required

(Rev. 9/8/2011)

MAN0869 (04/13/2011)

Parts 29

Page 30

SB74C, SB84C COMPACT SNOWBLOWER ASSEMBLY

30 Parts

(Rev. 10/4/2011)

MAN0869 (04/13/2011)

Page 31

SB74C, SB84C COMPACT SNOWBLOWER PARTS LIST

REF PART QTY DESCRIPTION

1 1033218 1 Fan

2 1033190 3 Bearing

3 29893 * 4 1/2 NC x 1-1/2 Carriage Bolt

4 1033226 2 Skid Shoe

5 976 * 3 3/8 NC x 1-1/2 HHCS GR5

6 HBL233 2 Pin

6A 27542 4 Klik Pin

6B 56598 2 Sleeve

7 90025028 1 3/8 x 1-3/4 Pin

8 1033246 1 Discharge Chute

9 1033239 1 Deflector Handle

10 1002018 1 Sleeve, .81 x 1-1/4 x 2-1/8

11 1026530 1 Manual Tube

13 1033298 1 Gearbox Shield

14 1033291 * 4 3/8 NC x 5-1/2 HHCS GR5

15 1033222 1 Gearbox

16 1033227 1 Drive Holder

17 103329774 1 Jackshaft Shield - SB74C

17 103329784 1 Jackshaft Shield - SB84C

18 103321474 1 Auger Drive Shaft - SB74C

18 103321484 1 Auger Drive Shaft - SB84C

19 12296 1 1/4-28 Straight Grease Fitting

20 1033211 1 Drive Sprocket

21 10378 * 3 1/4 NC x 1 HHCS GR5

22 6128 * 3 1/4 NC Lock Nut

23 1033293 4 3/8 Spring Nut

24 31207 * 1 3/4 NC x 4 HHCS GR5

25 2864 * 2 3/4 Flat Washer

26 2371 * 1 3/4 NC Lock Nut

27 12169 * 19 3/8 NC x 1-1/4 HHCS GR5

REF PART QTY DESCRIPTION

28 6698 * 29 3/8 NC Lock Nut

29 24576 * 1 1/2 NC x 1-3/4 HHCS GR5

30 3598 * 3 1/2 Flat Washer

31 765 * 5 1/2 NC Lock Nut

32 1033294 3 3/8 x 3/4 Thumb Screw

33 90311033 1 Idler Bearing

34 1033263 1 SMV Bracket

35 1033253 6 Discharge Chute Spacer

36 12020256 1 Sprocket Rotator

37 51243 * 6 5/16 NC x 1" Carriage Bolt GR5

38 6778 * 6 5/16 NC Lock Nut

39 24549 1 5/16 x 5/16 x 1-3/4 Key

40 1033278 1 Discharge Chute Clamp

41 838 * 1 3/8 Lock Washer

42 103319574 1 Auger - SB74C

42 103319584 1 Auger - SB84C

43 24611 1 SMV Sign

44 839 * 4 3/8 NC x 1" HHCS GR5

45 1033213 1 Sprocket

46 1033244 1 Chain

47 1033977 1 Safety Decal Set

48 33677 1 Washer, 1/2 x 1-9/16 x 10 GA

49 1033957 1 Model Decal Set - SB74C & SB84C

50 565 * A/R Washer, 3/8 Flat (SN 1188497 &

Below)

51 73163 * 2 Nut, Whiz 5/16 NC Flange

HHCS Hex Head Cap Screw

* Standard Hardware - Obtain Locally

A/R As Required

HAND CRANK ASSEMBLY

REF PART QTY DESCRIPTION

1 1033342 1 Rotator Shaft

2 1033345 1 Block

3 1033340 1 Clevis and Tube Assembly

4 12030315 1 Hand Crank

5 1033284 1 Handle Mount

6 481757 2 5/16 x 2 Roll Pin

7 24408 * 1 5/16 NC x 1-1/2 HHCS GR5

8 51243 * 2 5/16 NC X 1 HHCS GR5

9 6778 * 3 5/16 NC Hex Nut

10 1033299 1 Shield Rotator

11 838 * 1 3/8 Lock Washer

12 839 * 1 3/8 NC x 1 HHCS GR5

13 41 1 5/16 x 1-3/4 Roll Pin

14 1033774 1 Trim Strip, 6.5" Long

HHCS Hex Head Cap Screw

* Standard Hardware, Obtain Locally

(Rev. 10/4/2011)

MAN0869 (04/13/2011)

Parts 31

Page 32

GEARBOX ASSEMBLY

32 Parts

REF PART QTY DESCRIPTION

1 438 4 Ball Bearing

2 20901 3 Seal

3 1007866 4 Shim Pack

4 307126 8 M8 x 55 Socket Head Cap Screw

5 30515 8 M8 Hex Nut

6 1007859 1 External Circlip, 35 x 1.5

7 1033764 1 Spacer

8 1033765 1 Key

9 1033766 1 Gasket and Plug

MAN0869 (04/13/2011)

Page 33

1031908 - COMER SHEAR BOLT DRIVE ASSEMBLY (OPTIONAL)

SB54S, SB64S

REF PART QTY DESCRIPTION

A 1031908 1 Complete 540 driveline and shear bolt assembly

1 1032411 1 Complete collar yoke C12 1-3/8

2 41534 2 Cross & bearing kit

3 37167 1 Collar, outer tube

4 30922 6 Shield retainer

5 37172 1 Collar, inner tube

6 30917 2 Shield tether chains

7 1032414 1 Yoke, inner tube

8 1032415 1 Flexible pin

9 1032416 1 Inner profile tube

10 1032428 1 Shear yoke assembly

11 1032429 1 Bolt and Nut M6 x 40 cl 10.9

12 1032430 1 Grease fitting

13 30913 1 1-3/8 Push pin set

14 1032423 1 Yoke, outer tube

15 1001305 1 Flexible pin

16 1032425 1 Outer profile tube

17 1025873 1 Complete shield kit

18 1001340 1 Lock collar repair kit

MAN0869 (04/13/2011)

Parts 33

Page 34

1031826 - COMER SHEAR BOLT DRIVE ASSEMBLY (OPTIONAL)

SB74C, SB84C

REF PART QTY DESCRIPTION

A 1031826 1 Complete 540 driveline and shear bolt assembly

1 1001300 1 Complete collar yoke C12 1-3/8

2 38478 2 Cross & bearing kit

3 1019442 1 Collar, outer tube

4 30922 6 Shield retainer

5 1019444 1 Collar, inner tube

6 30917 2 Shield tether chains

7 1001306 1 Yoke, inner tube

8 1001305 1 Flexible pin

9 30928 1 Inner profile tube & yoke

10 1032435 1 Shear yoke assembly

11 1032436 1 Bolt and Nut M8 x 50 cl 8.8

12 1032430 1 Grease fitting

13 30913 1 1-3/8 Push pin set

14 1001301 1 Yoke, outer tube

15 1001302 1 Flexible pin

16 30926 1 Outer profile tube & yoke

17 1021552 1 Complete shield kit

18 1001340 1 Lock collar repair kit

34 Parts

(Rev. 10/4/2011)

MAN0869 (04/13/2011)

Page 35

1033266- WALTERSCHEID DRIVE ASSEMBLY (OPTIONAL)

SB54S, SB64S, SB74C, SB84C

REF PART QTY DESCRIPTION

A 1033266 1 Complete 540 Driveline Assembly

1 38498 1 Yoke Assembly

2 38478 2 Cross Bearing Kit

3 415147 1 Inboard Yoke

4 415146 2 Spring Pin

5 40587 1 Inner Profile

6 40588 1 Outer Profile

7 1029940 1 Inboard Yoke

8 1029941 1 Shearbolt Clutch

10 40766 2 Bearing Ring

13 40778 2 Screw, M3.5 x 10 mm

16 40777 1 Chain

17 1029932 2 Collar

18 1029943 1 Kit - Outer Guard Complete (includes items 9, 10, 11, 13, 14 & 17)

19 1029942 1 Kit - Inner Guard Complete (includes items 9, 10, 12, 13, 16 & 17)

20 40589 1 Collar Repair Kit

21 1005784 1 Quick Disconnect Pin Kit

22 1032436 1 M8 x 50 CL 8.8, Shear Bolt & Nut

MAN0869 (04/13/2011)

(Rev. 12/6/2011)

Parts 35

Page 36

HYDRAULIC CHUTE ROTATOR

(OPTIONAL)

HYDRAULIC CHUTE DEFLECTOR

(OPTIONAL)

REF PART QTY DESCRIPTION

1 90405236 1 Hydraulic Motor

2 90519159 2 .031 x 6MJIC 10MORG Restrictor

3 90519160 2 3/8 x 6JICF x 8 MORB Hose, 54"L

4 64332 2 Male Quick Coupler

5 1033603 1 Decal, WRNG - Hydraulic Pressure

6 1033611 1 Motor Mount Channel

7 10430071 1 Motor Coupler

8 301605 * 1 5/16 NC x 3/8 SHSS

9 41 2 5/16 x 1-3/4 Roll Pin

10 1033613 1 Shaft Rotator

11 1033614 1 Mounting Link

12 1033293 2 3/8 -16 U-Tapped Spring Nut

13 1033294 2 3/8 x 3/4 Thumb Screw

14 1033737 1 Safety Shield

15 839 * 4 3/8 NC x 1 HHCS GR5

16 838 * 4 3/8 Lock Washer

17 14478 * 2 3/8 NC x 4 HHCS GR5

18 6698 * 2 3/8 NC Lock Nut

HHCS Hex Head Cap Screw

SSHS Socket Head Set Screw

* Standard Hardware, Obtain Locally

REF PART QTY DESCRIPTION

1 1033300 1 Hydraulic Cylinder 1 x 3 x 7.75

2 66511 2 1/2 NPT Male Coupler

3 90501531 1 1/2" Swivel Restrictor

4 8572 2 1/4 Elbow

5 11893 2 1/4 NPTF x 1/2 NPTM Adapter

6 6698 * 2 3/8 NC Lock Nut

7 920 * 2 3/8 NC x 1-3/4 HHCS GR5

8 21020219 2 1/4 Hose, 1/4MP x 1/4MP, 101"L

HHCS Hex Head Cap Screw

* Standard Hardware, Obtain Locally

36 Parts

MAN0869 (04/13/2011)

Page 37

ELECTRIC CHUTE ROTATOR (OPTIONAL)

REF PART QTY DESCRIPTION

1 12030819 1 Rotary Actuator

2 12030802 1 Wiring Harness

3 1033611 1 Motor Mount

4 10430071 1 Motor Coupling

5 88 2 Plastic Tie (Ty-Rap) 3/16 x 14-1/4

6 41 3 5/16 x 1-3/4 Roll Pin

7 1033613 1 Shaft, Hydraulic Rotator

8 1033614 1 Mounting Link

9 1033293 2 3/8-16 U-Tapped Spring Nut

ELECTRIC CHUTE DEFLECTOR (OPTIONAL)

REF PART QTY DESCRIPTION

10 1033294 2 3/8 x 3/4 Thumb Screw

11 1033736 1 Rotator Shield

12 14478 * 2 3/8 NC x 4 HHCS GR5

13 6698 * 2 3/8 NC Lock Nut

36 12020256 1 Sprocket Rotator

HHCS Hex Head Cap Screw

* Standard Hardware - Obtain Locally

REF PART QTY DESCRIPTION

5 88 1 Plastic Tie (Ty-Rap) 3/16 x 14-1/4

14 1033727 1 Linear Actuator

15 62788 * 1 1/4 NC x 1-1/2 HHCS GR5

16 6128 * 2 1/4 NC Lock Nut

MAN0869 (04/13/2011)

REF PART QTY DESCRIPTION

HHCS Hex Head Cap Screw

* Standard Hardware, Obtain Locally

Parts 37

Page 38

BOLT TORQUE CHART

A

SAE SERIES

TORQUE

CHART

SAE Bolt Head

Identification

SAE Grade 2

(No Dashes)

SAE Grade 5

(3 Radial Dashes)

SAE Grade 8

(6 Radial Dashes)

METRIC SERIES

TORQUE

CHART

Metric Bolt Head

Identification

8.8

Metric

Grade 10.9

10.9

Metric

Grade 8.8

A

A

Typical Washer

Installations

Lock Washer

Flat Washer

8/9/00

Bolt

Always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific

application.

Fasteners must always be replaced with the same grade as specified in the manual parts list.

Always use the proper tool for tightening hardware: SAE for SAE hardware and Metric for metric hardware.

Make sure fastener threads are clean and you start thread engagement properly.

All torque values are given to specifications used on hardware defined by SAE J1701 MAR 99 & J1701M JUL 96.

A

Diameter

(Inches)

1/4" 7/16" 6 8 10 13 14 18