Page 1

FLAIL

SHREDDER

Center Drive

S30CD

(11/8/2011)

MAN0943

Page 2

TO THE DEALER:

®

Assembly and proper installation of this product is the responsibility of the Woods

and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Operator’s Manual

are completed before releasing equipment to the owner.

The dealer must complete the online Product Registration form at the Woods Dealer Website which certifies that

all Dealer Check List items have been completed. Please contact your dealer to complete this form. Dealers can

register all Woods product at dealer.WoodsEquipment.com under Product Registration.

Failure to register the product does not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your Woods equipment. The information presented will prepare you to do a better and

safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and become

acquainted with all adjustment and operating procedures before attempting to operate. Replacement manuals can be

obtained from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in

the United States and Canada call 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your authorized Woods dealer has trained mechanics, genuine Woods service parts, and the necessary

tools and equipment to handle all your needs.

Use only genuine Woods service parts. Substitute parts will void the warranty and may not meet standards required for

safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

dealer. Read manual instructions

Model: _______________________________ Date of Purchase: _____________________

Serial Number: (see Safety Decal section for location) ____________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term NOTICE is used to indicate that failure to observe can cause damage to equipment.

The terms CAUTION, WARNING, and DANGER are used in conjunction with the Safety-Alert Symbol (a triangle with

an exclamation mark) to indicate the degree of hazard for items of personal safety.

2 Introduction

Gen’l (Rev. 3/5/2010)

Page 3

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

BALANCE STATEMENT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .5

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .6

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

OPERATOR SIGN-OFF RECORD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

FIELD OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

SHREDDER STORAGE & CLEANING. . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

SERVICE & MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .35

CONTOUR FLAIL PATTERN WORKSHEETS . . . . . . . . . . . . . . . . . . . . . . .36

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .38

DEALER CHECK LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .46

INDEX TO PARTS LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

BOLT TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .59

BOLT SIZE CHART & ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . .60

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .61

PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .62

REPLACEMENT PARTS WARRANTY . . . . . . . . . . . . INSIDE BACK COVER

!

LEA EL INSTRUCTIVO!

Si no lee Ingles, pida ayuda a

alguien que si lo lea para que le

traduzca las medidas de seguridad.

MAN0943 (07/12/2011)

Introduction 3

Page 4

SPECIFICATIONS

Maximum Outside Body Width: . . . . . . . 31ft. - 3in.

Cutting Height: . . . . . . . . . . . . . . . . . . . . 3in. - 18in. (7.62 cm to 45.7 cm)

Width of Cut:. . . . . . . . . . . . . . . . . . . . . . 30ft

Number of Knives: Cups

176 348 4

Recommended Tire Size: . . . . . . . . . . . . 9.5L - 15,6 ply rated

Tire Inflation Pressure: . . . . . . . . . . . . . . 25 psi

Rotor: Speed . . . . . . . . . . . . . . . . . . . . . 1350 RPM dynamically balanced

Drive: PTO . . . . . . . . . . . . . . . . . . . . . . . 1000 RPM

Weight of Shredder (approximate): . . . . 7400 lbs

“L” “L” Cut-Off

4 Introduction

MAN0943 (07/12/2011)

Page 5

IMPORTANT!

WARNING

BALANCE STATEMENT

Both of the Woods Center Drive Shredder flail tubes

are balanced as rotor assemblies to meet or exceed

factory standards before installation. After installation,

the shredders are statistically inspected to check balance. These factory efforts allow the shredder to operate smoothly and be free of excessive vibration when

delivered to the customer.

■ The operator must be familiar with all safety

rules and safety decals before installing and running the shredder. All personnel must be familiar

with and stay out of the hazard area whenever the

shredder is running. (See Figure 14, page 21).

Smooth, acceptable vibration levels can be easily estimated in the field. After machine shutdown and coast

down has been completed, place a quarter on a clean

top panel of the shredder. At full rotor rpm (while maintaining all safety rules regarding safe distances from

rotating equipment) observe the quarter. If the quarter

stays still and does not bounce around, the operator

can estimate that the shredder is free from excessive

vibration. If the quarter jumps around during full rotor

rpm, the shredder may be operating with excessive

vibration where troubleshooting and maintenance are

required (refer to the Troubleshooting section).

The Woods Center Drive Flail Shredder has been

designed for maximum durability when shredding any

type of crop. While operating in the field, many factors

can affect and degrade shredder rotor balance and

cause increased vibration levels.

● Operating too low to the ground or in frequent con-

tact with the ground can cause the flail knives to

wear unevenly. This can reduce their chopping

effect and also increase vibration levels.

● Hitting large rocks or other foreign objects can

damage knives and other rotor parts, causing

excessive vibration.

● Over time, certain types of soil and crops can also

lead to uneven knife wear and increased vibration

levels.

● Once field operation has been started, it is the

operator’s responsibility to check and maintain

shredder rotor balance.

● If knife replacement is required due to wear or

damage, refer to REPLACING FLAILS, page 30.

● Throughout the life of the flail shredder, removing

the flail tubes for replacement or re-balance may

be necessary.

● If flail tube replacement is required due to wear or

damage, refer to SERVICING ROTORS (FLAIL

TUBES), page 31.

● Any re-balance should be done with all knives

installed.

● Factory balanced repair rotors are available

through your local Woods dealer.

● Consult with your local balance shop experts or

contact Woods Technical Service for re-balance or

replacement options.

Continued operation with excessive vibration can

cause damage to and shorten component life, void

product warranty, and affect personal safety. Checking

and maintaining shredder rotor balance is the owner/

operator’s responsibility.

GENERAL INFORMATION

The purpose of this manual is to assist you in operating

and maintaining your flail shredder. Read it carefully. It

furnishes information and instructions that will help you

achieve years of dependable performance. These

instructions have been compiled from extensive field

experience and engineering data. Some information

may be general in nature due to unknown and varying

operating conditions. However, through experience

and these instructions, you should be able to develop

procedures suitable to your particular situation.

MAN0943 (07/12/2011)

The illustrations and data used in this manual were current at the time of printing but, due to possible inline

production changes, your machine may vary slightly in

detail. We reserve the right to redesign and change the

machines as may be necessary without notification.

Throughout this manual, references are made to right

and left directions. These are determined by standing

behind the equipment facing the direction of forward

travel.

Introduction 5

Page 6

TRAINING

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern,

judgement, and proper training of personnel

involved in the operation, transport, maintenance

and storage of equipment.

It has been said “The best safety device is an

informed, careful operator.” We ask you to be that

kind of operator.

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

If you do not understand any part of this manual

and need assistance, see your dealer.

Know your controls and how to stop engine and

attachment quickly in an emergency.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

Make sure that all operating and service personnel know that if hydraulic fluid penetrates skin, it

must be surgically removed as soon as possible by

a doctor familiar with this form of injury or gangrene, serious injury, or death will result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

Never allow children or untrained persons to

operate equipment.

6 Safety

PREPARATION

Use a suitable lifting device of sufficient capacity. Use adequate personnel to handle heavy components.

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Air in hydraulic systems can cause erratic operation and allows loads or equipment components

to drop unexpectedly. When connecting equipment

or hoses or performing any hydraulic maintenance,

purge any air in hydraulic system by operating all

hydraulic functions several times. Do this before

putting into service or allowing anyone to

approach the equipment.

Make sure all hydraulic hoses, fittings, and

valves are in good condition and not leaking before

starting power unit or using equipment. Check and

route hoses carefully to prevent damage. Hoses

must not be twisted, bent sharply, kinked, frayed,

pinched, or come into contact with any moving

parts. Operate moveable components through full

operational range to check clearances. Replace

any damaged hoses immediately.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Make sure spring-activated locking pin or collar

slides freely and is seated firmly in tractor PTO

spline groove.

Before starting power unit, check all equipment

driveline guards for damage. Replace any damaged

guards. Make sure all guards rotate freely on all

drivelines. If guards do not rotate freely on drivelines, repair and replace bearings before putting

equipment into service.

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt securely

fastened. Falling off power unit can result in death

from being run over or crushed. Keep foldable

ROPS system in “locked up” position at all times.

Connect PTO driveline directly to power unit

PTO shaft. Never use adapter sleeves or adapter

shafts. Adapters can cause driveline failures due to

incorrect spline or incorrect operating length and

can result in personal injury or death.

Shredder_S30CD (07/12/2011)

Page 7

Inspect rubber flaps and swing rod before each

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

use. Replace if damaged or missing. Flaps must

pivot and hang freely so there are no gaps. Do not

put equipment into service until repaired.

Remove accumulated debris from this equipment, power unit, and engine to avoid fire hazard.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, tractor could tip over, causing personal

injury or death. The weight may be attained with a

loader, front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

TRANSPORTATION

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt securely

fastened. Falling off power unit can result in death

from being run over or crushed. Keep foldable

ROPS system in “locked up” position at all times.

Always sit in power unit seat when operating

controls or starting engine. Securely fasten seat

belt, place transmission in neutral, engage brake,

and ensure all other controls are disengaged

before starting power unit engine.

A minimum 20% of tractor and equipment

weight must be on the tractor front wheels when

attachments are in transport position. Without this

weight, front tractor wheels could raise up resulting in loss of steering. The weight may be attained

with front wheel weights, ballast in tires or front

tractor weights. Weigh the tractor and equipment.

Do not estimate.

Always raise unit and install transport locks

before transporting. Leak down or failure of

mechanical or hydraulic system can cause equipment to drop.

Always attach safety chain to tractor drawbar

when transporting unit.

OPERATION

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

Keep bystanders away from equipment.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Operate only in daylight or good artificial light.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Always comply with all state and local lighting

and marking requirements.

Never allow riders on power unit or attachment.

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt securely

fastened. Falling off power unit can result in death

from being run over or crushed. Keep foldable

ROPS system in “locked up” position at all times.

Always sit in power unit seat when operating

controls or starting engine. Securely fasten seat

belt, place transmission in neutral, engage brake,

and ensure all other controls are disengaged

before starting power unit engine.

Operate tractor PTO at the rpm speed stated in

“Specifications” section.

(Safety Rules continued on next page)

Shredder_S30CD (07/12/2011)

Safety 7

Page 8

(Safety Rules continued from previous page)

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Look down and to the rear and make sure area

is clear before operating in reverse.

Do not operate or transport on steep slopes.

Do not stop, start, or change directions sud-

denly on slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Watch for hidden hazards on the terrain during

operation.

Stop power unit and equipment immediately

upon striking an obstruction. Turn off engine,

remove key, inspect, and repair any damage before

resuming operation.

Leak down or failure of mechanical or hydraulic

system can cause equipment to drop.

MAINTENANCE

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Before performing any service or maintenance,

lower equipment to ground or block securely, turn

off engine, remove key, and disconnect driveline

from tractor PTO.

Use a suitable lifting device of sufficient capacity. Use adequate personnel to handle heavy components.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

Never go underneath equipment (lowered to the

ground or raised) unless it is properly blocked and

secured. Never place any part of the body underneath equipment or between moveable parts even

when the engine has been turned off. Hydraulic

system leak down, hydraulic system failures,

mechanical failures, or movement of control levers

can cause equipment to drop or rotate unexpectedly and cause severe injury or death. Follow Operator's Manual instructions for working underneath

and blocking requirements or have work done by a

qualified dealer.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Make certain all movement of equipment components has stopped before approaching for service.

Before working underneath, read manual

instructions, securely block up, and check stability.

Secure blocking prevents equipment from dropping due to hydraulic leak down, hydraulic system

failure, or mechanical component failure.

Work not covered in SERVICE & MAINTENANCE

must be done by a qualified dealership. Special

skills, tools, and safety procedures may be

required. Failure to follow these instructions can

result in serious injury or death.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its components in any way.

Your dealer can supply original equipment

hydraulic accessories and repair parts. Substitute

parts may not meet original equipment specifications and may be dangerous.

8 Safety

Air in hydraulic systems can cause erratic operation and allows loads or equipment components

to drop unexpectedly. When connecting equipment

or hoses or performing any hydraulic maintenance,

purge any air in hydraulic system by operating all

hydraulic functions several times. Do this before

putting into service or allowing anyone to

approach the equipment.

Do not handle knives with bare hands. Careless

or improper handling may result in serious injury.

Your dealer can supply genuine replacement

knives. Substitute knives may not meet original

equipment specifications and may be dangerous.

Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter pins are

installed securely to ensure equipment is in a safe

condition before putting unit into service.

Shredder_S30CD (07/12/2011)

Page 9

Make sure all safety decals are installed.

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace if damaged. (See Safety Decals section for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Do not disconnect hydraulic lines until engine is

stopped, power unit is properly secured, equipment and all components are lowered to the

ground, and system pressure is released by operating all valve control levers.

Leak down or failure of mechanical or hydraulic

system can cause equipment to drop.

STORAGE

Block equipment securely for storage.

Keep children and bystanders away from stor-

age area.

Follow manual instructions for storage.

Shredder_S30CD (07/12/2011)

Safety 9

Page 10

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

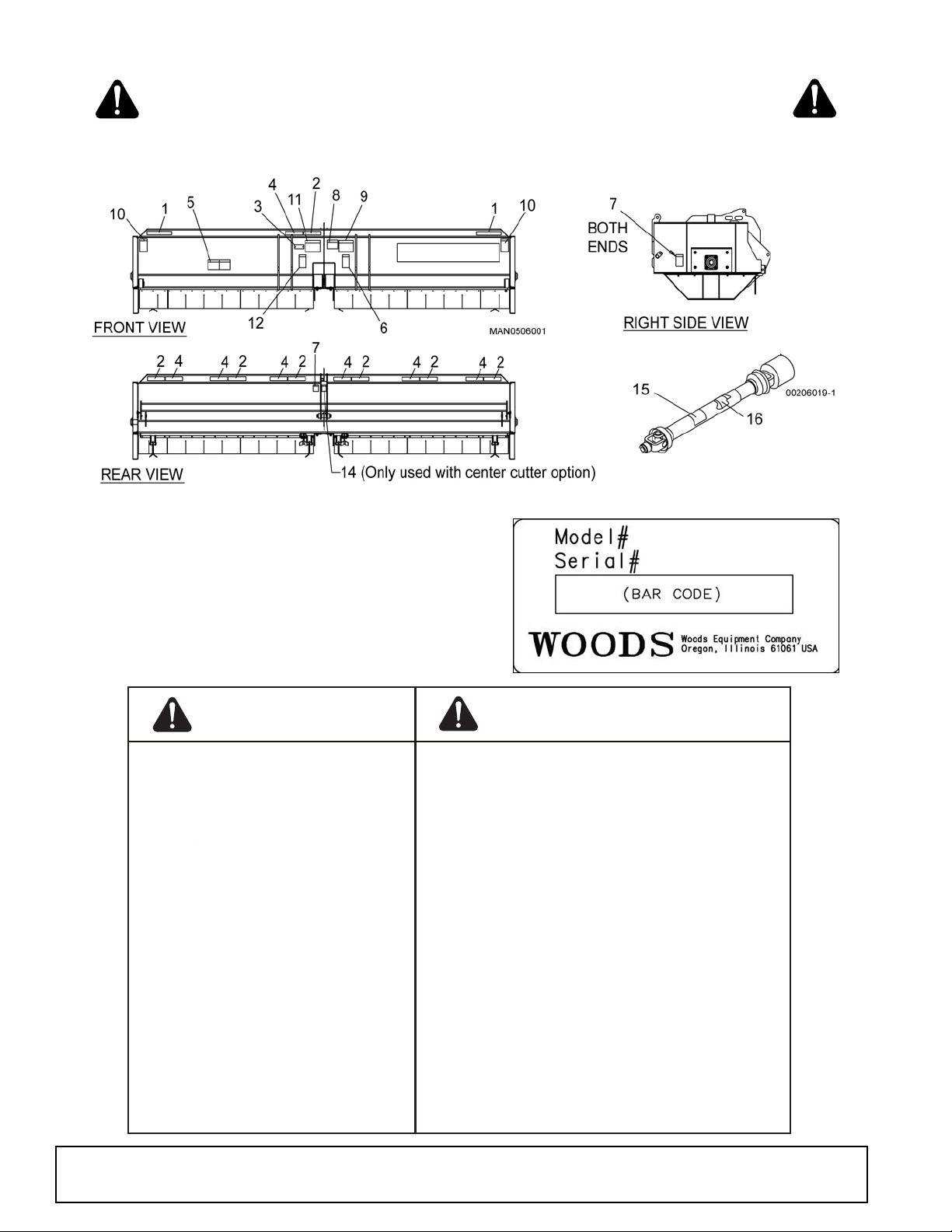

1 - YELLOW REFLECTOR PN 20034004

2 - RED REFLECTOR PN 57123

4 - RED-ORANGE FLUORESCENT MATERIAL

PN 20034034

5 - PN 50030977

3 - SERIAL NUMBER DECAL

CAUTION

1. Read Operator's Manual before starting.

2. Stop tractor engine, place all controls in

neutral, lower machine to the ground, set

park brake, remove ignition key, and wait

for all moving parts to stop before

servicing, adjusting, repairing, or

unplugging.

3. Keep all guards and access doors closed

and secured before operating.

4. Keep hands, feet, hair, and clothing away

from moving parts.

5. Do not allow riders.

6. Do not enter rotor area when engine is

running.

7. Never exceed 20 MPH when transporting.

8. Use hazard flashers when transporting.

9. Use drawbar pin with retainer and attach

safety chain.

10. Wear appropriate hearing protection for

prolonged exposure to excessive noise.

11. Review safety information periodically

prior to use.

1. Lea el Manual del Operario antes de empezar.

2. Pare el motor del tractor, ponga todos los controles en

3. Mantenga cerrados y asegurados todos los protectores y

4. Mantenga retirados de las piezas móviles, las manos, los

5. No permita que nadie vaya con usted en la máquina.

6. No entre en el área del rotor mientras el motor está en

7.

8. Use luces intermitentes de aviso cuando viaja con la

9. Use el pasador de la barra de tiro con fiador y enganche la

10. Use un protector apropiado para los oidos cuando esté

11. R

PRECAUCION

neutro, baje la máquina hasta el suelo, ponga el freno de

estacionamiento, quite la llave del encendido, y espere a

que todas las pizas móviles hayan parado antes de dar

servicio, hacer ajustes, reparaciones, o de desatascar.

las compuertas antes de poner a funcionar la máquina.

pies, el pelo, y la ropa.

marcha.

Nunca exceda 32 km/h (20 MPH) al transportar.

máquina.

cadena de seguridad.

expuesto a ruido excesivo por un tiempo prolongado.

epase la información de seguridad periódicamente

antes del uso.

50030977-B

10 Safety

MAN0943 (07/12/2011)

Page 11

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

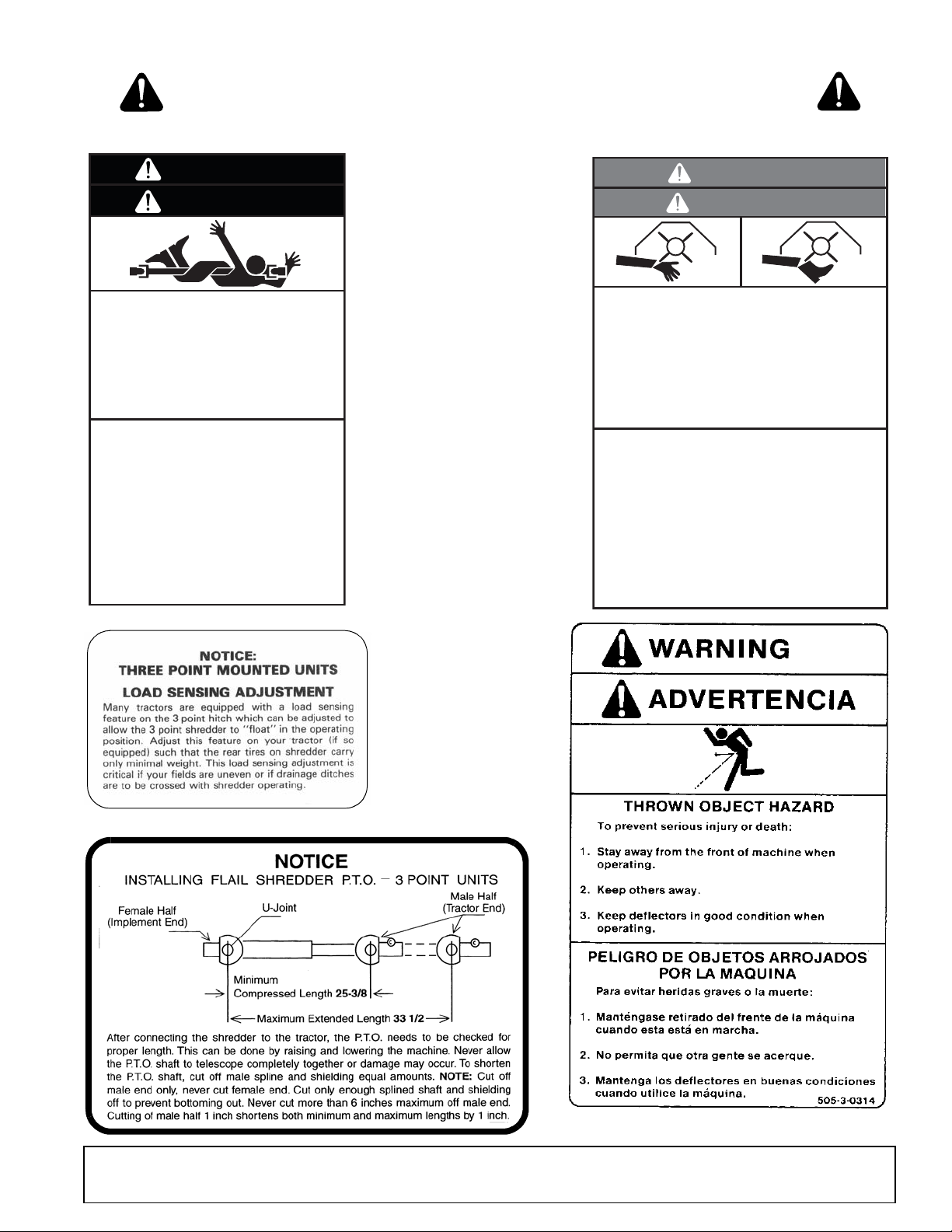

DANGER

PELIGRO

ROTATING DRIVELINE HAZARD

To prevent serious injury or death from

rotating driveline:

1. Keep all guards in place when operating.

2. Operate only at 1000 RPM.

3. Keep hands, feet, clothing, and hair away

from moving parts.

PELIGRO CON EL MOVIMIENTO

ROTATIVO DEL EJE MOTRIZ

Para evitar heridas graves o la muerte a causa

de la rotación del eje motriz:

1. Mantenga todos los protectores en su

puesto mientras esté funcionando la

máquina.

2. Hágala funcionar únicamente a 1000 RPM.

3. Mantenga retirados de las piezas móviles,

las manos, los pies, la ropa y el pelo.

50030978-A

6 - PN 50030978

7 - PN 50030982

DANGER

PELIGRO

ROTATING FLAIL HAZARD

To prevent serious injury or death from

rotating flails:

1. Stop engine, remove ignition key, and wait

for moving parts to stop before servicing.

2. Keep hands and feet away from flails when

engine is running.

3. Keep other people away.

PELIGRO CON LAS CUCHILLAS

CORTADORAS ROTATIVAS

Para evitar heridas graves o la muerte

causadas por las cuchillas rotativas:

1. Pare el motor, quite la llave del encendido

y espere hasta que las piezas móviles

hayan parado antes de dar servicio.

2. Mantenga las manos y los pies retirados de

las cuchillas estando el motor en marcha.

3. No permita que otra gente se acerque.

50030982-A

8 - PN 50530138

10 - PN 50530314

9 - PN 50530225

MAN0943 (07/12/2011)

(Safety Decals continued on next page)

Safety 11

Page 12

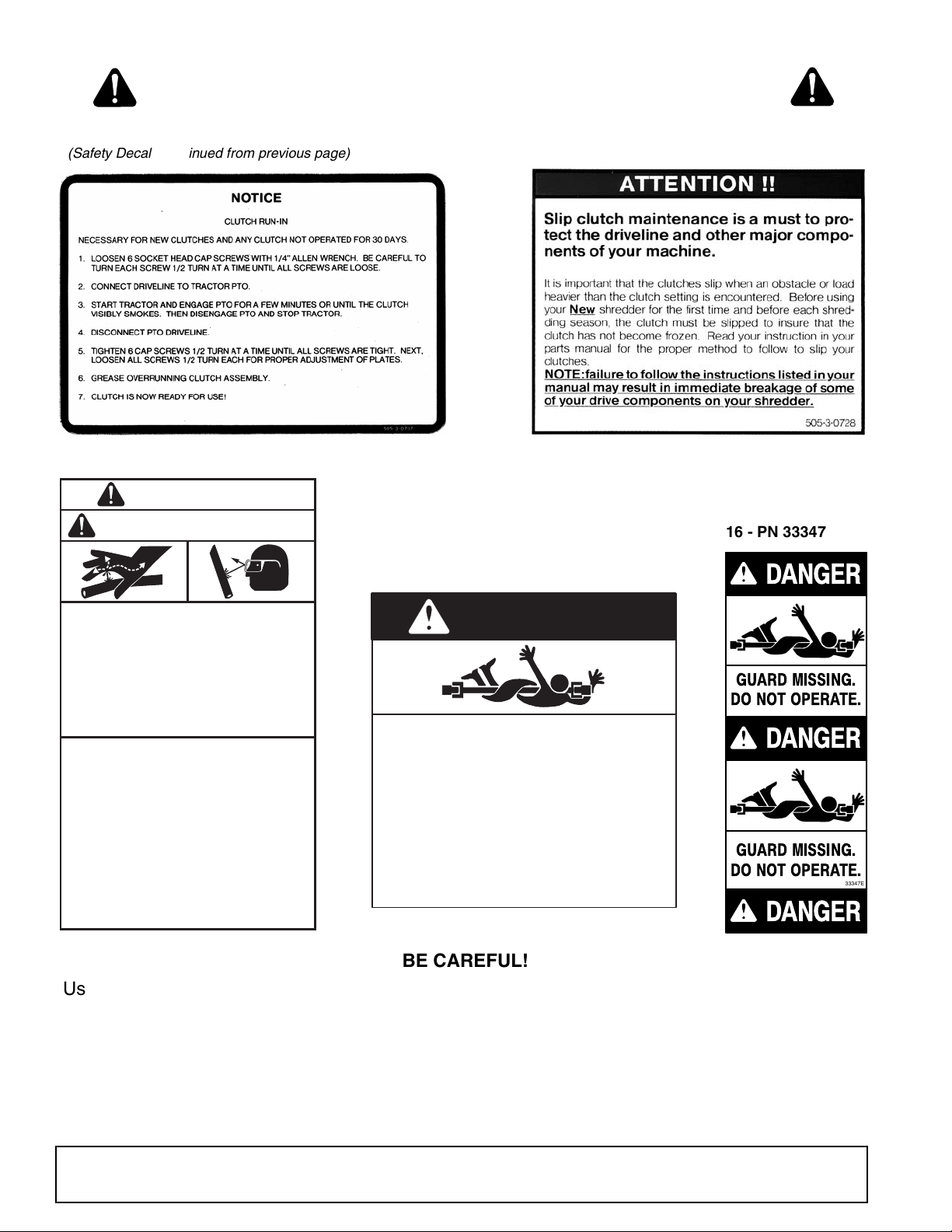

SAFETY & INSTRUCTIONAL DECALS

GUARD MISSING.

DO NOT OPERATE.

DANGER

33347E

DANGER

DANGER

GUARD MISSING.

DO NOT OPERATE.

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

(Safety Decals continued from previous page)

WARNING

ADVERTENCIA

HIGH-PRESSURE FLUID HAZARD

To prevent serious injury or death:

1. Relieve pressure on system before

repairing, adjusting, or disconnecting.

2. Wear proper hand and eye protection

when searching for leaks. Use wood or

cardboard instead of hands.

3. Keep all components in good repair.

PELIGRO DE FLUIDO BAJO

Para evitar heridas graves o la muerte:

1. Alivie la presión del sistema antes de

hacer repara ciones, ajustes o

desconecciones.

2. Use protección apropiada en las

manos y en los ojos, cuando revise

para ver si hay fugas. Utilice una tabla

o un cartón en vez de las manos.

3. Mantenga todos los componentes en

buen estado.

ALTA PRESION

50530315-A

11 - PN 50530707

14 - PN 50530315

ROTATING DRIVELINE

CONTACT CAN CAUSE DEATH

DO NOT OPERATE WITHOUT -

All driveline guards, tractor and

equipment shields in place

Drivelines securely attached at both ends

Driveline guards that turn freely on

driveline

12 - PN 50530728

15 - PN 18864

DANGER

KEEP AWAY!

16 - PN 33347

18864-C

Use a clean, damp cloth to clean safety decals.

Avoid spraying too close to decals when using a pressure washer; high-pressure water can enter

through very small scratches or under edges of decals causing them to peel or come off.

Replacement safety decals can be ordered free from your Woods dealer. To locate your nearest

dealer, check the Dealer Locator at www.WoodsEquipment.com, or in the United States and

Canada call 1-800-319-6637.

12 Safety

BE CAREFUL!

MAN0943 (07/12/2011)

Page 13

OPERATOR SIGN-OFF RECORD

Woods Equipment Company follows the general safety

standards specified by the American Society of Agricultural and Biological Engineers (ASABE) and the

Occupational Safety and Health Administration

(OSHA) for agricultural equipment.

Anyone who will be operating and/or maintaining the

flail shredder must read and clearly understand all

Safety, Operating, and Service & Maintenance information presented in this manual.

Do not operate or allow anyone else to operate this

equipment until this information has been reviewed.

Review this information annually, before the season

start-up. Make periodic reviews of the Safety and

Operation sections standard practice for those using

any of your equipment.

Use the following Operator Sign-off Record to verify

that each operator has read and understood the information in this manual and has been instructed in the

safe operation of the flail shredder.

.

DATE OPERATOR’S NAME (PRINT) OPERATOR’S SIGNATURE

MAN0943 (07/12/2011)

Operator Record 13

Page 14

OPERATION

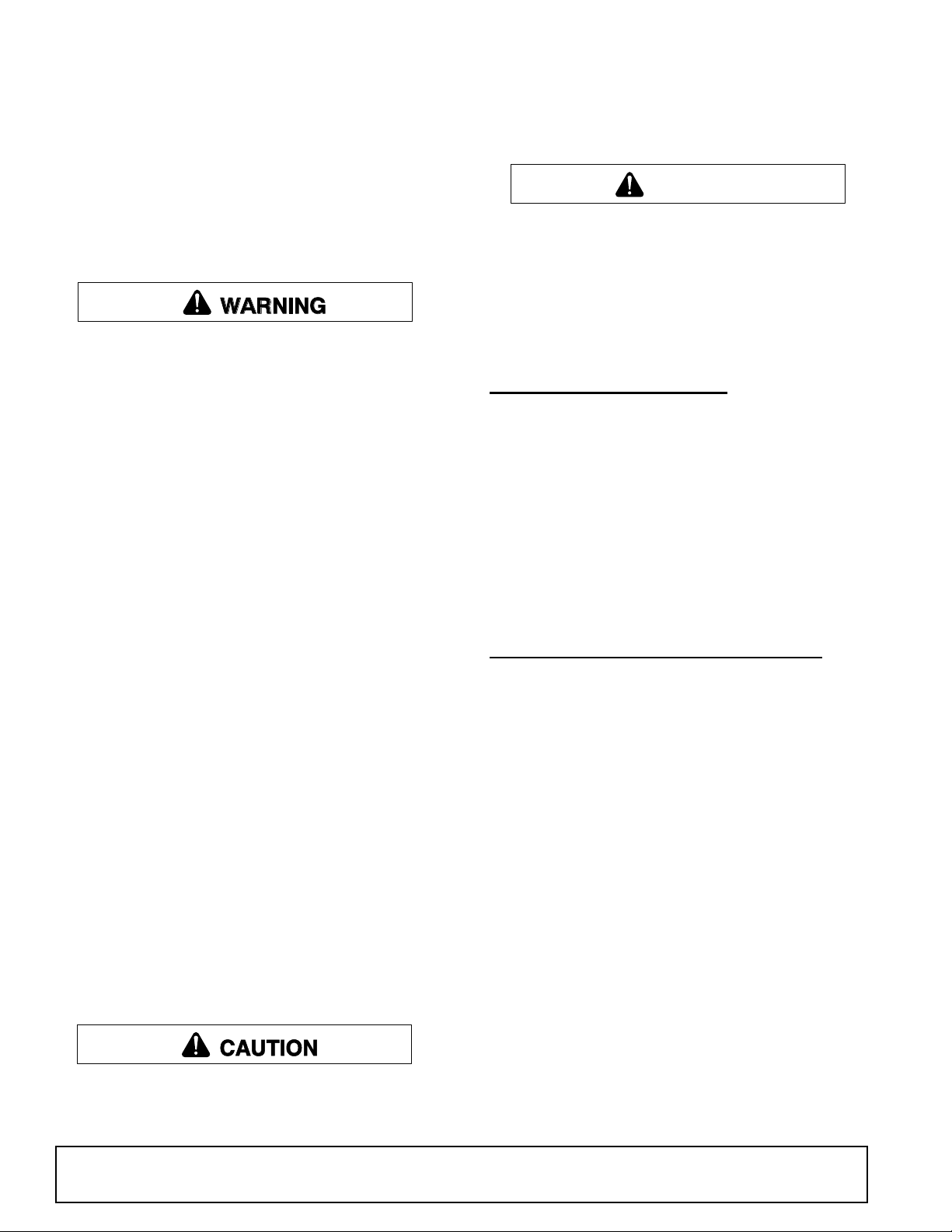

WARNING

CAUTION

CAUTION

The Woods Flail Shredder is designed to pick up and

shred crop and plant residue left in the field. Rotational

power to the flails is provided by the tractor PTO.

Be familiar with the flail shredder before starting.

The owner is responsible for training operators in the

safe operation of the flail shredder.

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

Never allow children or untrained persons to

operate equipment.

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Never allow riders on power unit or attachment.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

and ensure all other controls are disengaged

before starting power unit engine.

Always comply with all state and local lighting

and marking requirements.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

PRINCIPAL COMPONENTS

The Woods Flail Shredder consists of a large rotating

tube with swinging steel flails attached. The flails pick

up or strike crop residue or trash and shred it. Rotational power to the drum is provided by the tractor PTO

through a gearbox in the center of the machine.

For removing the center strip of crop residue, an

optional hydraulically driven blade can be installed

under the cover in the center of the machine.

The flail shredder is designed to be used as a semimounted, or 3-point mounted machine.

BREAK-IN OF THE FLAIL SHREDDER

The following should be observed when operating the

unit for the first time:

After operating for 1/2 hour

1. Check all nuts, bolts, and other fasteners. Tighten

to specifications given in the Bolt Torque Chart,

page 59.

2. Tighten wheel bolts to specifications given in the

Bolt Torque Chart, page 59.

3. Check that the flails are in good condition and

swing freely.

Keep bystanders away from equipment.

Operate tractor PTO at the rpm speed stated in

“Specifications” section.

Always sit in power unit seat when operating

controls or starting engine. Securely fasten seat

belt, place transmission in neutral, engage brake,

14 Operation

4. Check oil level in the gearbox. Add oil if needed.

5. Check that the PTO driveline shield turns freely.

6. Lubricate all grease points.

After operating for 5 to 10 hours

1. Repeat Steps 1 through 5 above.

2. Follow regular service schedule as outlined in

Lubrication Schedule, page 24.

MAN0943 (07/12/2011)

Page 15

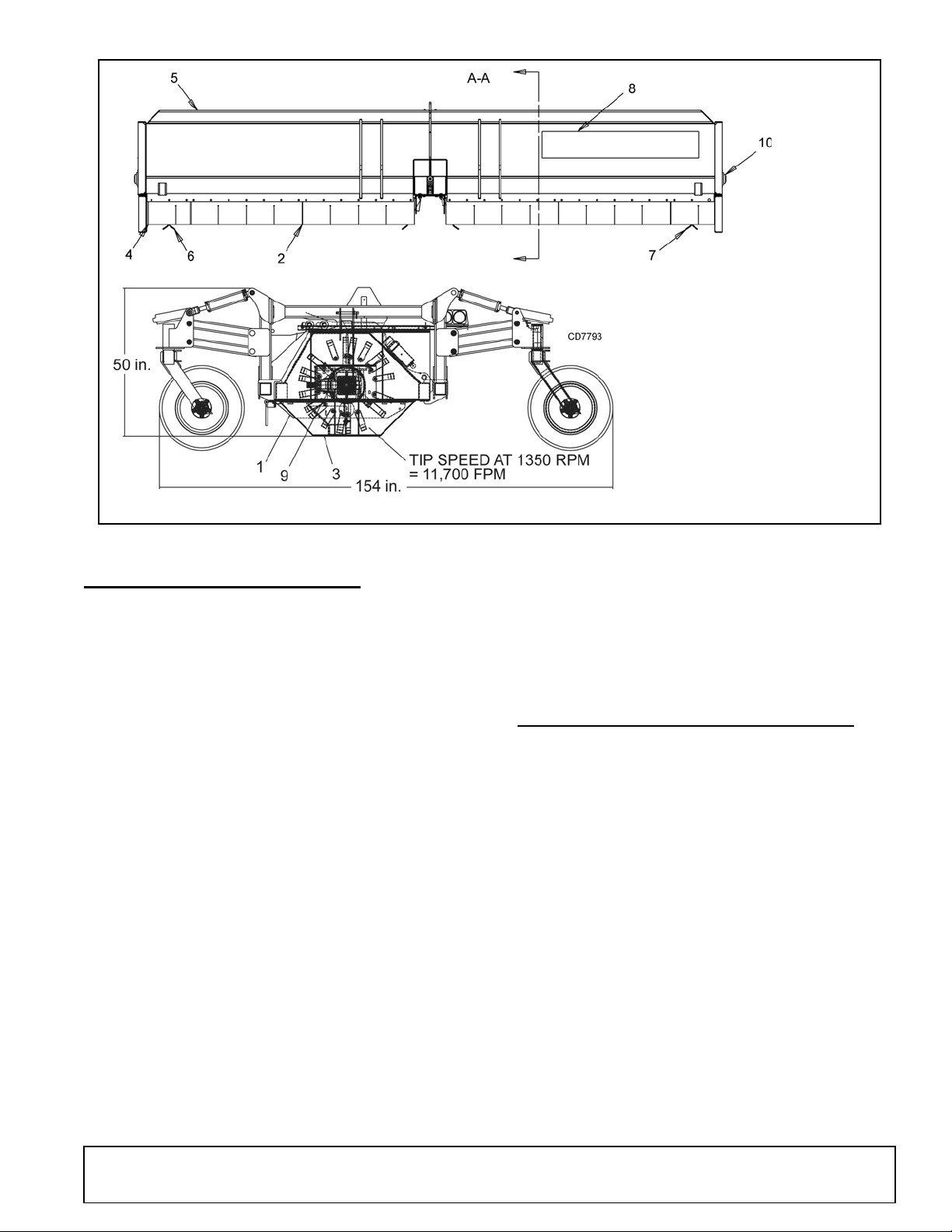

Figure 1. Flail Shredder Principal Components

1. Crossmember

2. Rubber belt shield

3. Skid assembly

4. Rubber belt shield

5. Body weldment

6. Flail tube assembly RH

7. Flail tube assembly LH

8. Woods model decal

9. Gearbox

10. Bearing assembly

PRE-OPERATION CHECK LIST

(OWNER'S RESPONSIBILITY)

NOTICE

■ This Pre-Operation Check List is provided for

the operator. It is important to follow for both personal safety and maintenance of the flail shredder.

___ Check all lubrication points and grease as

instructed in Lubrication Service Record, page

27.

___ Use only a tractor of adequate power and weight

to pull the unit. (See chart on page 16.)

___ Check that the unit is properly attached to the

tractor. On pull-type unit, be sure there is a

mechanical retainer through the drawbar pin and

the safety chain is installed. On 3-point hitch

units, be sure retainers are used on the mounting

pins.

___ Check oil level in gearbox. Add oil as required.

___ Check that the PTO driveline turns freely and that

the driveline can telescope easily.

___ Check tire pressure. Inflate to specified level.

___ Check flails. Inspect for damage or breakage.

Make sure they swing freely on their mount.

Repair or replace as required.

___ Check condition of cutter blade (if so equipped).

MAN0943 (07/12/2011)

___ Inspect all hydraulic lines, hoses, couplers, and

fittings. Tighten, repair, or replace any leaking or

damaged components.

___ Install and secure all guards, doors, and covers.

___ Check PTO clutch operation (see . Weasler Auto-

matic Clutch (30K), page 33).

CHOOSING THE CORRECT TRACTOR

To ensure safe and reliable operation of the flail shredder, use a tractor with the correct specifications. Use

the following guidelines to select the correct tractor.

1. Horsepower

Use Table 1 on page 16 for selecting the tractor horsepower class appropriate for your unit’s width.

Increase the horsepower level by 25 percent when

operating in hilly, soft, or wet conditions.

2. Tractor Weight

By following recommendations for tractor horsepower,

the tractor will have sufficient weight to provide stability

for unit during field operation or when transporting.

When using a 3-point mounted shredder, we recommend that each tractor be equipped with a full complement of suitcase weights on the tractor front (see

Figure 2 for example). This will provide the required

front weight for turning and extra traction if equipped

with front wheel assist.

Operation 15

Page 16

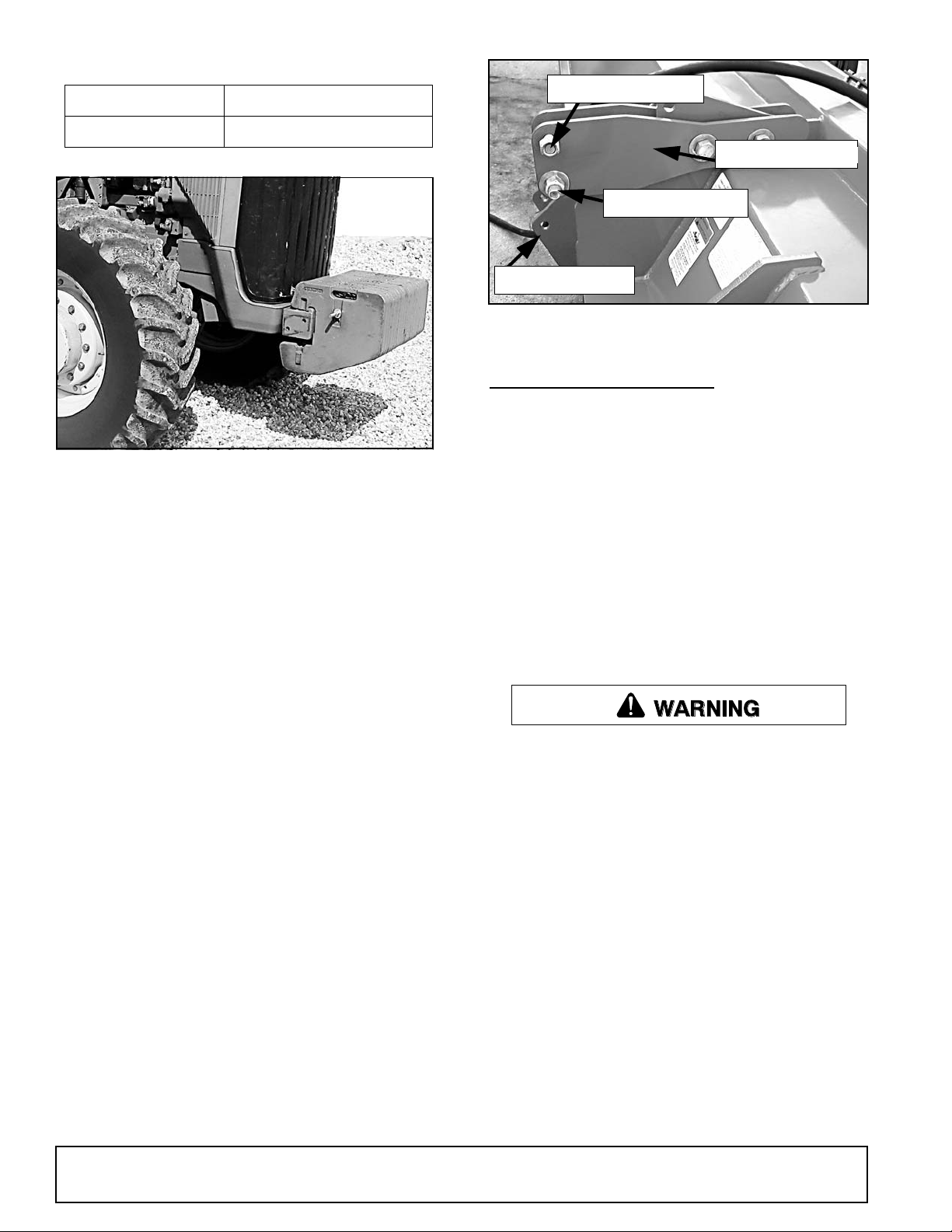

Figure 2. Tractor Front Weight

Table 1: Tractor Horsepower (6-8) vs. Unit Width

Width Minimum Horsepower

30’ 180

DP10

Top Link Assembly

Upper Top Link Hole

Lower Top Link Pin

Lower 3-Point Pin

DP11

WARNING

3. 3-Point Hitch

The 3-point hitch models require that the tractor be

equipped with a Category II or Category III 3-point

hitch. If the hitch can be converted from one to the

other, use a Category III to provide a wider stance and

more stability.

Use the upper top link hole for Category III and the

lower hole for Category II as shown in Figure 3.

For easier attachment, use a quick hitch. If not using a

quick hitch, use optional hitch extension.

4. Hydraulic Requirements when Using Center

Cutter Options

Figure 3. 3-Point Hitch Attachment

NOTICE

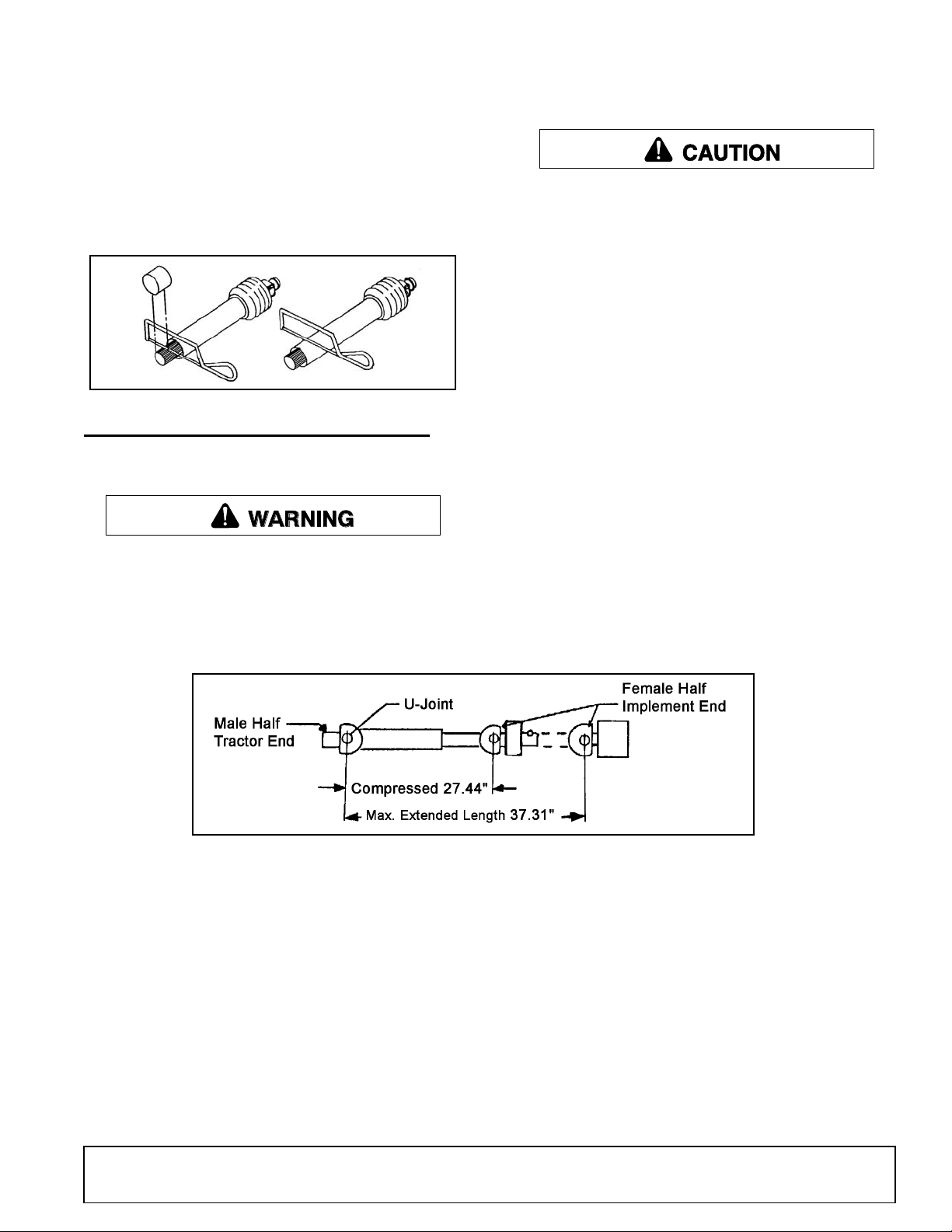

PTO DRIVELINE LENGTH

■ The unit is equipped with a PTO driveline long

enough to fit any tractor and 3-point linkage system.

■ The operator is responsible for measuring the

dimensions of the driveline through its working

range. These dimensions will indicate if the driveline requires shorting to operate on the particular

tractor/unit attachment system. The operator must

check dimensions before using the unit for the first

time and each time a different tractor is used with

the unit.

■ Use the following procedure when determining

driveline dimension:

Keep bystanders away from equipment.

The tractor hydraulic system must be capable of 8 gpm

(30 lpm) at 1500 psi (10,335 kPa). The system cannot

exceed 28 gpm or 3000 psi. Either closed-centered or

open-centered systems can be used.

5. Load Sensing Hydraulics (3-Point Models Only)

Many newer tractors are equipped with “load sensing”

hydraulics. The operator is responsible for setting the

tractor hydraulic system to provide “float” on the 3-point

hitch. Refer to the tractor manual for specific instructions.

The “float” feature will allow the unit to follow the

ground contours during operation. This applies to 3point mounted machines only.

NOTICE

■ Do not use PTO shaft adapters. They will

change the drawbar dimension and can cause driveline failures.

16 Operation

1. Clear the area of all bystanders.

2. Attach the 3-point hitch to the unit but not the PTO

driveline.

3. Raise the unit until the tractor PTO and gearbox

shafts are the same height.

4. Measure the dimension between the shaft grooves

on the tractor and implement ends. If this

dimension is less than 34.81 inches, the shaft will

require shortening.

5. Move the unit to its highest and lowest working

position and measure this dimension again. [The

unit’s shaft can telescope (see Figure 5) before it

has been shortened.]

6. If required, shorten the shaft to prevent bottoming

out during use. NOTE: An extra inch of

compression space in the shaft can eliminate

bottoming out during use. Measure to make sure.

MAN0943 (07/12/2011)

Page 17

7. Use an abrasive wheel power saw to cut the male

WARNING

CAUTION

end of the shaft. Cut the same amount from both

the splined shaft and the safety shield. See Figure

4. Use a file to remove any burrs from the cut end.

NOTICE

■ Cut only the male end. Never cut the female end.

8. Never cut more than 9 inches from the male end.

Cutting 1 inch from the male end shortens both the

minimum and maximum lengths by 1 inch.

Figure 4. Cutting the Driveline Shaft

ATTACHING SHREDDER TO TRACTOR

1. Place unit on a level, dry area free of debris and

other foreign object.

2. Clear the area of bystanders, especially children.

3. Provide enough clearance to back the tractor

safely into the unit.

■ Do not allow anyone to stand between tractor

and unit when backing up to the unit.

With Quick Hitch Attachment:

4. Set the height of the 3-point hitch so that quick

hitch claws are lower than the mounting pins.

5. Make sure 3-point hitch is set in the non-sway

position. See tractor manual for details.

6. Align the claws under the lower and upper mast

mounting pins while backing up.

NOTE: For a Category II hitch, use the bottom

upper mast hole. For a Category III hitch, use the

top upper mast hole.

7. When the claws are under the pins, slowly raise

the 3-point hitch. Make sure each mounting pin

seats in its respective claw.

Keep bystanders away from equipment.

Connect PTO driveline directly to power unit

PTO shaft. Never use adapter sleeves or adapter

shafts. Adapters can cause driveline failures due to

incorrect spline or incorrect operating length and

can result in personal injury or death.

Figure 5. Driveline Dimension

8. Release the claw retainer locks to secure the

mounting pins in the claws.

9. Check the top link frame. It should be free to slide

in its mounting slots. This movement allows the

unit to follow the ground contour when cresting a

hill or going through a depression.

MAN0943 (07/12/2011)

Operation 17

Page 18

Without Quick Hitch Attachment:

DP101

WARNING

FIELD OPERATION

10. Back tractor lower 3-point arms between lower

mast plates and align with lower 3-point hole.

11. Place 1-3/4 OD spacer through 3-point arm pivot

(both sides).

12. Push tractor’s 3-point arm to the inside and slide a

1-7/16 OD spacer between to take up the empty

space. Secure with lower 3-point hitch pin

assembly, 1-3/4 OD spacer, and 7/16 x 2 klik pin.

13. Repeat steps 5 and 6 for other side.

14. Lower the tractor’s top link arm and secure in top

hole of upper mast assembly using spacer, hex

bolt, and lock nut. Attach PTO Driveline

1. Make sure the driveline telescopes easily and

shields rotate freely.

2. Attach the driveline to the tractor by retracting the

locking collar. Slide the yoke over the shaft and

push on the yoke until the lock collar clicks into

position. Make sure the yoke is locked into

position.

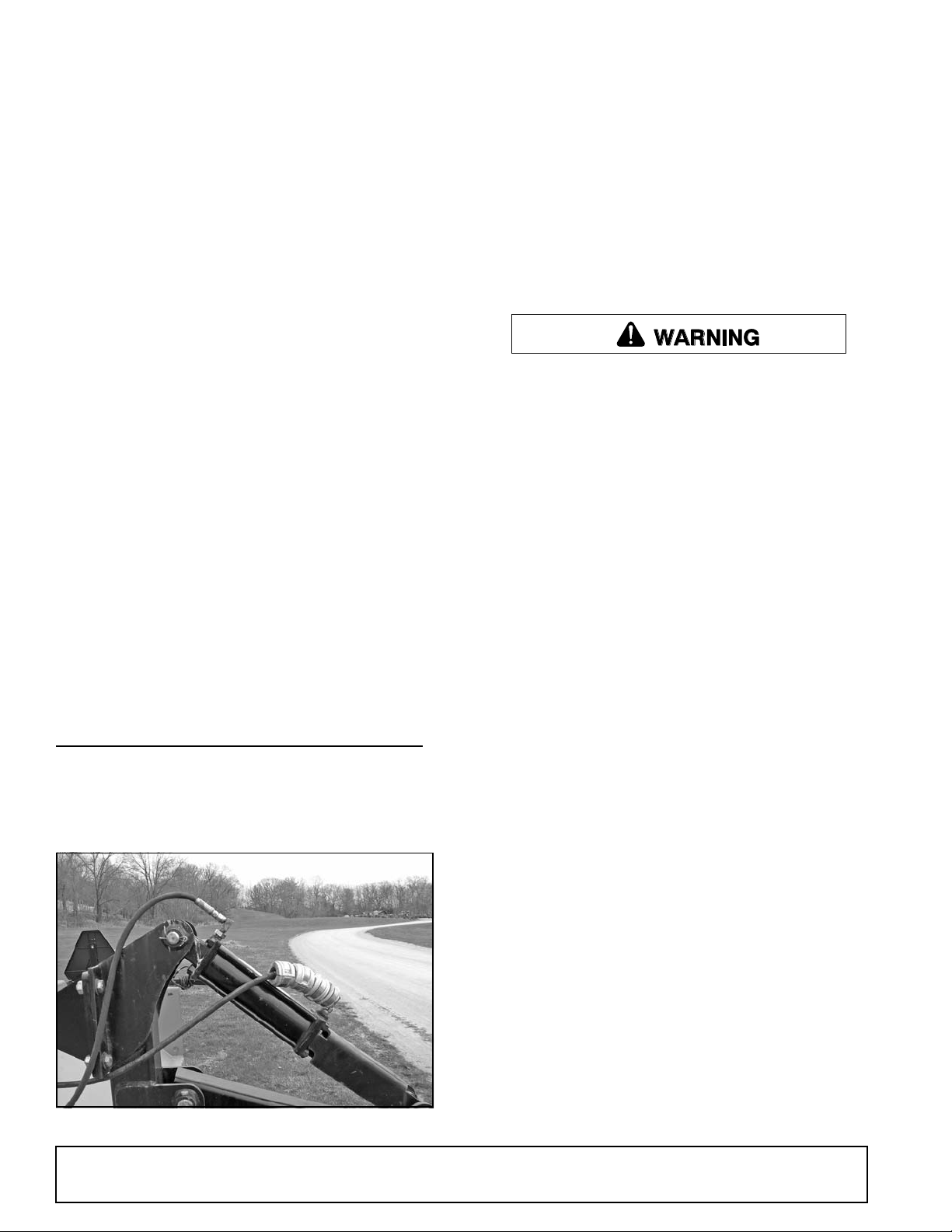

Attach Hydraulics and Lift Cylinder Hose

(Center Cutter Option)

1. Use a clean cloth to clean hose ends and area

around the couplers on the tractor.

2. Insert the hose male ends into the tractor couplers.

Make sure hoses lock in place.

3. Route hoses along or over the hitch and secure in

position with clips, tape, or plastic ties. Provide

enough slack for turning and lifting.

REMOVING SHREDDER FROM TRACTOR

Reverse the above procedure when removing unit from

the tractor. Engage transport lock channel at the four

struts prior to lowering shredder. Release pressure

before removing hoses.

The Woods Flail Shredder is designed with the flexibility to operate well in almost any kind of crop and terrain

conditions. However, the operator is responsible for

being familiar with all operating and safety procedures

and following them. Each operator should review this

Field Operation section at the start of the season and

as often as required to be familiar with the unit.

Operators should also review the PRE-OPERATION

CHECK LIST, page 15, and Attaching Shredder to

Tractor, page 17.

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

Never allow children or untrained persons to

operate equipment.

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Never allow riders on power unit or attachment.

Do not allow bystanders in the area when oper-

ating, attaching, removing, assembling, or servicing equipment.

Figure 6. Transport Lock

18 Operation

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Keep bystanders away from equipment.

Operate tractor PTO at the rpm speed stated in

“Specifications” section.

MAN0943 (07/12/2011)

Page 19

Always sit in power unit seat when operating

CAUTION

Stroke Control

Spacers

DP124

DP12

Floating Top Mast

controls or starting engine. Securely fasten seat

belt, place transmission in neutral, engage brake,

and ensure all other controls are disengaged

before starting power unit engine.

Always comply with all state and local lighting

and marking requirements.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

RUBBER FLAPS OR BELTING

All units are equipped with front shield flaps or belting

along the front of the frame. The shield flaps stop or

deflect trash, stones, or other debris picked up by the

flails.

Be sure the shield flaps or belting are in good condition

for operation. Replace if damaged, torn, or missing.

Figure 7. Setting Operating Height

Be sure the floating mast is free to slide in its mounting

frame to allow the machine to follow ground contours.

Refer to Figure 8.

PREPARING FOR OPERATION

1. Pull into the field and position the unit in a level

area.

2. Lower into operating position.

3. Set the 3-point so the quick hitch is vertical and the

floating upper mast is forward.

4. Use stroke control spacer on four cylinders to set

cutting height.

Flail Height

Set the unit to give a flail height of at least 3 to 6

inches (75 to 150 mm) above the ground. This will

minimize the amount of stones and dirt picked up by

the flails under all operating conditions. (See Balance

Statement, page 5.)

NOTE: To avoid unnecessary wear on knives and

related parts, never set the unit lower than the recommended setting. (See Balance Statement, page 5.)

SET OPERATING HEIGHT

Figure 8. Free-Float Position

FLAIL KNIVES

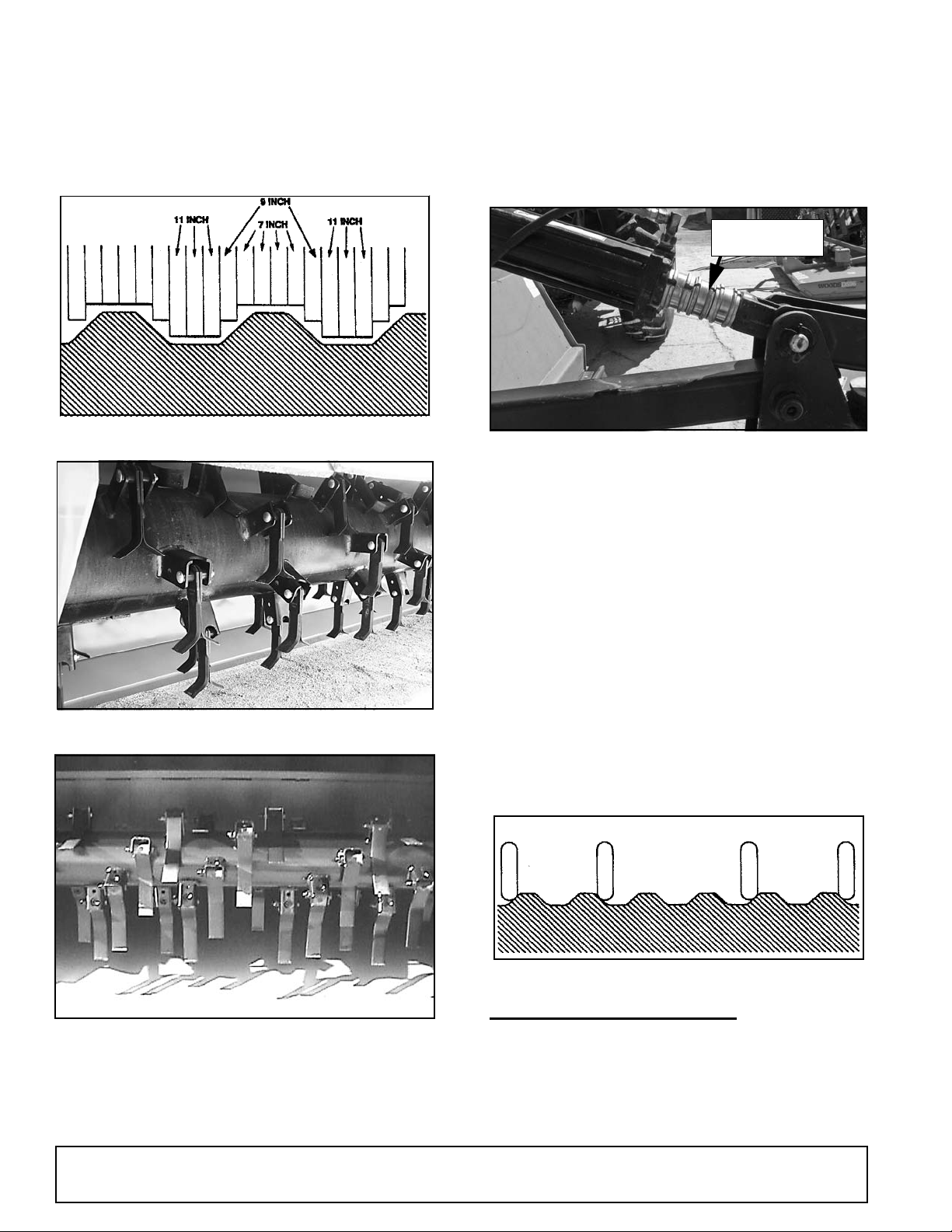

The shredder is factory equipped with “L” or cup type

flails. The two types are interchangeable.

“L” Flails

“L” flails (Figure 10) work best when trash or crop residue is standing.

Cup Flails

Cup flails (Figure 11) can pick up material from the

ground and work best in matted trash conditions.

The standard cup flail is 11 inches (279 mm) long and

is used for most applications. Optional 7 and 9 inch

(177 and 228 mm) flails are available to match the tip

position to ground contour.

Use stroke control spacers. The number and thickness

should be equal on each cylinder to keep shredder

level.

MAN0943 (07/12/2011)

Attach optional cup flails as follows, making sure that

knives at 180° match (see Figure 9) (see Balance

Statement, page 5):

Operation 19

Page 20

1. Leave standard flails located between the rows.

DP13

DP14

Stroke Control

Spacers

DP124

2. Remove others and install shorter flails to follow

ground contour. Be sure to mount the same size

flails on opposite sides of the tube. Measure the

row spacing and flail position carefully to minimize

ground contact. See page 36 and page 37.

.

mm) above the ground. (See Balance Statement,

page 5.)

2. Align the unit with the working area on or between

rows on flat farming.

3. Use stroke control spacers on four cylinders to set

cutting height.

Figure 9. Optional Flail Contour

Figure 10. “L” Flails

Figure 12. Setting Flail Height

Setting Caster Wheels

Normally, wheels are set to track in the row centers,

between the raised seed beds. Tire position will determine flail height, but depth of furrow is also a factor in

setting flail height. In some conditions the furrow

between the seed beds is deeper on the ends, where

irrigation waters enter the field. As furrows change

depth, flail height will change.

To compensate for the depth change, move the caster

wheels against the side of the outer seed bed (see Figure 13). The wheels will then tend to climb up the side

of the seed bed and prevent the flails from hitting the

top of the bed.

Set the flail height after the wheels have been moved

against the seed bed.

Figure 11. Cup Flails

Setting Flail Height

1. Be sure wheels are set to follow in the center of

furrow row. Set flails 3 to 6 inches (75 to 150

20 Operation

Figure 13. Wheel Position

STARTING THE SHREDDER

1. Run tractor engine at low idle.

2. Slowly engage PTO control to start the shredder.

3. Slowly bring tractor engine to rated PTO speed.

Never exceed rated speed.

MAN0943 (07/12/2011)

Page 21

STOPPING THE SHREDDER

WARNING

WARNING

KEEP OUT

OF

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

GROUND SPEED

Travel speed can vary between 3 and 8 mph (5 and 13

kmph) depending on the bulk of residue and terrain

conditions. The operator is responsible for noting the

condition of the work, setting the speed to obtain a

quality shredding job, and maintaining control of the

unit.

Speed may be increased if shredding quality is good.

Decrease speed if trash is left standing or if some is not

picked up.

1. Slowly decrease engine speed to low idle.

2. Disengage center cutter’s hydraulic system (if so

equipped). Never approach unit until the blade has

stopped turning.

3. Slowly disengage PTO clutch. The overrunning

clutch will allow the shredder to freewheel down.

4. Restart the unit only after the drums quit turning.

The PTO will not need to be disengaged to lift the

unit on the ends or while turning.

HAZARD AREA

Make certain all movement of equipment components has stopped before approaching for service.

Stay away from front, side, and rear of unit while it is

running. Flails can pick up stones, sticks, wire, and

other debris and throw it out with enough force to

severely injure bystanders.

Keep out of shaded area shown in Figure 14.

Shut down unit and wait for moving parts to stop before

approaching.

CLEANING

After Each Use

● Remove large debris such as clumps of dirt, grass,

crop residue, etc. from machine.

● Inspect machine and replace worn or damaged

parts.

● Replace any safety decals that are missing or not

readable.

Periodically or Before Extended Storage

● Clean large debris such as clumps of dirt, grass,

crop residue, etc. from machine.

● Remove the remainder using a low-pressure water

spray.

1. Be careful when spraying near scratched or torn

safety decals or near edges of decals as water

spray can peel decal off surface.

2. Be careful when spraying near chipped or

scratched paint as water spray can lift paint.

3. If a pressure washer is used, follow the advice

of the pressure washer manufacturer.

● Inspect machine and replace worn or damaged

parts.

● Sand down scratches and the edges of areas of

missing paint and coat with Woods spray paint of

matching color (purchase from your Woods

dealer).

Figure 14. Hazard Area

MAN0943 (07/12/2011)

● Replace any safety decals that are missing or not

readable (supplied free by your Woods dealer).

See Safety Decals section for location drawing.

END TOW OPERATION

1. While shredder is attached to 3-point hitch on

tractor user 3-point to lift all four wheels off ground.

Rotate and lock two wheels on right end of

shredder in end transport position as shown in

Figure 15.

Operation 21

Page 22

5. An end tow hitch is also available as optional

DP102

DP101

DP104

DP118

Light Bar

DP125

WARNING

equipment for hooking shredder to quick hitch.

Figure 15. Transport Position

2. Set shredder back on all four wheels using 3-point.

Raise all shredder lift cylinders to maximum lift

height. Flip transport locks into transport position

(see Figure 16). Lower cylinders into transport

lock. Make sure all four cylinders have bottomed

out.

Figure 16. Transport Lock

3. Unhook hydraulic hoses, PTO shaft, and 3-point

hitch. Secure hoses and PTO shaft for end

transport.

Figure 18. End Tow - Quick Hitch

6. Slide light bar out to match the widest width of

shredder and pin into position. Attach light harness

to tractor outlet.

Figure 19. Light Bar

■ Do not exceed 20 MPH while transporting

shredder.

STORAGE

4. Move tractor from operating position to end tow

position. Hook hitch to drawbar.

Figure 17. End Tow - Drawbar

22 Operation

Block equipment securely for storage.

Keep children and bystanders away from stor-

age area.

At the end of the season, the shredder should be thoroughly inspected and prepared for storage. Repair or

replace any worn or damage components to prevent

unnecessary down time at the beginning of the next

season.

To ensure a long, trouble-free life, prepare the unit for

storage by carrying out the following procedure:

1. Clear the area of bystanders, especially children.

2. Thoroughly wash the unit, using a pressure washer

to remove all dirt, mud, debris, and residue. See

Cleaning instructions on page 21.

MAN0943 (07/12/2011)

Page 23

3. Inspect the flails and rotors for damage or

entangled material. Remove entangled material.

Repair or replace damaged parts.

4. Inspect all hydraulic hoses, lines, couplers, and

fittings. Tighten all loose fittings. Replace any hose

that is cut, nicked, abraded, or separating from the

crimped end of a fitting.

5. Change gearbox oil.

6. Lubricate all grease fittings. Make sure all grease

cavities have been filled with grease to remove any

water residue from pressure washing.

8. Move to storage area. Select a dry area free of

debris. Store in an area away from human activity.

9. Unhook from tractor (see Removing Shredder from

Tractor, page 18).

10. Place safety stands or large blocks under the

frame to take the load off the tires. NOTE: Do not

deflate tires.

11. If the unit cannot be placed indoors, cover with a

waterproof tarpaulin and tie securely. Store away

from human activity.

7. Touch up all paint nicks and scratches to prevent

rust.

12. Do not allow children to play on or around the

stored unit.

MAN0943 (07/12/2011)

Operation 23

Page 24

SERVICE & MAINTENANCE

WARNING

CAUTION

grease with extreme pressure (EP) performance.

An SAE multi-purpose lithium-based grease is also

acceptable.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Before working underneath, read manual

instructions, securely block up, and check stability.

Secure blocking prevents equipment from dropping due to hydraulic leak down, hydraulic system

failure, or mechanical component failure.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Do not handle knives with bare hands. Careless

or improper handling may result in serious injury.

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make certain all movement of equipment components has stopped before approaching for service.

LUBRICANTS

2. Gearbox Oil

Use an SAE 85W90 gear oil for all operating

conditions. Capacity: 2-1/2 U.S. quarts (110 oz.).

Storing Lubricants

Your unit can operate at top efficiency only if clean

lubricants are used. Use clean containers to handle all

lubricants. Store them in an area protected from dust,

moisture, and other contaminants.

GREASING

NOTE: Use the Lubrication Service Record, page 27 to

keep a record of all scheduled maintenance.

1. Use a hand-held grease gun for all greasing.

2. Wipe grease fitting with a clean cloth before

greasing to avoid injecting dirt and grit.

3. Replace and repair broken fittings immediately.

4. If fittings will not take grease, remove and clean

thoroughly. Also clean lubricant passageway.

Replace fitting if necessary.

LUBRICATION SCHEDULE

NOTE: Recommendations are based on normal oper-

ating conditions. Severe or unusual conditions may

require more frequent lubrication or oil changes. Refer

to Figure 21.

Daily or every 8 hours of operation

1. Grease

Use an SAE multi-purpose high temperature

PTO Driveline Lubricate daily or every 8 hours of operation. See Figure 20 for lubrication points.

24 Service & Maintenance

MAN0943 (07/12/2011)

Page 25

Figure 20. PTO Driveline Lubrication Points

A. Daily or 8 hours

B. 25 hours

C. 40 hours

D. Check Daily/Change Annually

DP106

DP107

Figure 21. Lubrication Points

Daily or every 8 hours of operation

1. Lubricate PTO U-joints and over-running clutch.

2. Check gearbox daily or every 8 hours of operation.

See Figure 22 for gearbox oil fill location.

MAN0943 (07/12/2011)

Figure 22. Gearbox Oil Fill Location

Every 25 hours of operation

1. Lubricate PTO driveline telescoping section (one

location, Position B, Figure 21).

2. Lubricate rotor end bearings. See Figure 23.

Figure 23. Rotor End Bearing

Lubrication Point

Service & Maintenance 25

Page 26

Every 40 hours of operation - Figure 24

DP109

GEARBOX

OIL DRAIN

DP15

DP110

DP113

DP108

1. Lubricate rotor drive couplers next to the couplers

on underside of unit and inside of flail tube (access

through windows on back panel of shredder).

2. Grease the drive hubs with 10 to 20 pumps. You

may use extra grease only on drive hubs.

2. Repack wheel bearings. See Figure 26.

Figure 26. Wheel Bearings

3. Lubricate pivot tube (2 locations each pivot tube).

See Figure 27.

Figure 24. Drive Couplers and Hubs

Annually

1. Change gearbox oil. Refill with SAE 85W90 gear

oil. Capacity: 2-1/2 U.S. quarts (110 oz.). See

Figure 25.

Figure 25. Gearbox Oil Drain Location

Figure 27. Pivot Tube Lubrication Points

4. Lubricate caster pivot bearings as shown in Figure

28.

Figure 28. Wheel Caster Bearing

Lubrication Points

26 Service & Maintenance

MAN0943 (07/12/2011)

Page 27

LUBRICATION SERVICE RECORD

HOURS OF

SERVICE

SERVICED BY

8 Hours or daily

L PTO Driveline (8)

L PTO Driveline telescope

section

L U-Joint (1)

L Overrunning clutch (1)

Gearbox oil level

25 Hours

L Rotor end bearings

L Lift Linkage

40 Hours

L Rotor Drive Couplers

Annually

C Gearbox oil

R Wheel bearings

✔

NOTE: See page 24 through page 27 for details. Copy

this page to continue service record.

MAN0943 (07/12/2011)

Service & Maintenance 27

Page 28

GEARBOX OIL LEAKAGE

NOTICE

■ Major oil leakage from the gearbox shaft seal

area is not acceptable and could cause the gearbox

to fail due to lack of lubrication and cooling. It is

the operator’s responsibility to check the gearbox

oil level per the Lubrication Service Table.

Before checking gearbox oil level, shut down the

shredder for a couple of hours to allow the oil to drain

back into the reservoir for the most accurate reading.

Proper oil level should be between the full and add

lines on dipstick. When oil is needed, add through the

dipstick tube.

NOTICE

■ DO NOT OVERFILL. Lab tests have proven that

overfilling the gearbox can dramatically increase

the gearbox operating temperature. In extreme

cases this can overheat the oil, reducing its lubricating and cooling properties, and eventually

cause shaft seals to deteriorate and fail. Overheated oil has an obvious burnt smell; drain it and

refill with new oil. Overfilling gearbox oil can void

the warranty.

The gearbox should not require frequent servicing of

oil. It is not designed to consume or lose large amounts

of oil. If oil needs to be added frequently, troubleshooting the cause is required (see section below).

3. Closely monitor gearbox for 10 hours of operation.

Check and service oil every 30 minutes or as

needed to ensure operation does not occur with oil

below the add mark.

4. If after 10 hours of operation, oil covers less than

the area described in 1 & 2 above, seepage is

considered to be acceptable.

5. If after 10 hours of operation, oil covers more than

the area described in 1 & 2 above, this seepage is

considered to be unacceptable leakage.

6. Gearboxes with unacceptable leakage should be

rebuilt, replacing old seals and worn parts with new

seals and parts. Gearbox rebuild and seal

replacement parts are available through your local

Woods dealer. Consult with Woods Technical

Service for further details, rebuild

recommendations, or warranty questions.

CHANGING GEARBOX OIL

Although gearbox oil never wears out, dust, dirt, and

moisture can enter through the breather during operation. These contaminants must be removed once a

year to ensure a long life for working components. In

very dusty or dirty conditions, change the oil twice a

year.

1. Clear area of bystanders, especially children.

Gearbox leakage & Troubleshooting

Some gearbox oil leakage may be acceptable if:

1. Oil covers less than a 3-inch diameter circle around

the shaft seal area (see Figure 29).

2. Oil covers less than a 4-inch diameter circle around

the dipstick tube (see Figure 29).

If oil leakage covers an area larger than that described

in 1 and 2, do the following:

1. Properly check oil level. If low, properly service.

2. Clean oily area of gearbox. Use a degreaser to

remove all oil from outside surface of gearbox.

2. Shut off tractor, place all controls in neutral, set

parking brake, remove key, and wait for all moving

parts to stop.

3. Raise the unit to provide access to underside.

Place safety stands or large blocks under frame.

4. Disconnect PTO driveline and hydraulic lines.

5. Place a pan under drain plug. Remove drain plug

and dipstick plug (see Figure 30).

6. Allow gearbox to drain for 10 minutes.

NOTE: To remove the most contaminants, drain oil

when gearbox is hot.

28 Service & Maintenance

MAN0943 (07/12/2011)

Page 29

Figure 29. Acceptable Oil Leakage

GEARBOX

DRAIN PLUG

DP16

DP114

Figure 30. Drain Plug (Underside of Unit)

7. Re-install and tighten drain plug.

8. Dispose of used oil in an approved container.

9. Add SAE 85W90 gear oil through the dipstick

cover. Use the dipstick to check the oil level (Figure

31) and add oil accordingly.

10. Re-install and tighten fill plug.

11. Reconnect PTO driveline and hydraulic lines.

12. Remove blocks or safety stands.

Figure 31. Dipstick Location

WHEEL SPACING

The wheels can be adjusted for alignment with crop

rows.

1. Clear the area of bystanders, especially children.

2. Shut off tractor, place all controls in neutral, set

parking brake, remove key, and wait for all moving

parts to stop.

3. Use a jack with sufficient capacity to lift the frame.

4. To determine wheel spacing, measure from the

center line of the unit. Mark positions on the frame.

MAN0943 (07/12/2011)

5. Lift frame until wheels have cleared the ground.

6. Place safety stands or large blocks under the

frame.

Service & Maintenance 29

Page 30

7. Loosen mounting bolts on one wheel assembly.

DP116

WARNING

DP13

8. Slide assembly along the frame tube to new

position (see Figure 32).

9. Tighten mounting bolts to specified torque level.

5. Loosen and remove the worn knife and its opposite

on the other side of the rotor. Discard worn knives

and their mounting hardware.

6. Replace with new knives and mounting hardware

(see Figure 33).

Figure 33. Flail Replacement

Figure 32. Positioning Wheel Assembly

10. Remove safety stands or blocks.

11. Lower and remove jack.

12. Repeat with other wheel assemblies.

REPLACING FLAIL KNIVES

Do not handle knives with bare hands. Careless

or improper handling may result in serious injury.

■ Read Balance Statement, page 5, before replac-

ing any knives.

The flail knives in pairs swing on a hardened bushing,

designed to reduce wear, and are sandwiched between

two steel spacers. The hardened bushing is bolted to

the clip with a 1/2" NC carriage bolt and a flange lock

nut.

NOTICE

■ To maintain rotor balance, always replace oppo-

site (180°) pairs of knives and mounting hardware.

7. Tighten flail mounting flange lock nut.

8. Replace additional worn flails following step 5 and

step 6.

9. Remove safety stands or blocks from under frame.

10. Lower unit and remove jack.

11. Attach driveline and hydraulic line to tractor.

12. Refer to Balance Statement, page 5, for balance

issues.

REPLACING RUBBER SHIELD FLAPS

Rubber shield flaps on the front of the unit deflect or

prevent stones or debris from being ejected when operating unit. Replace if damaged or missing to provide a

safe work environment. To replace, follow this procedure:

1. Clear the area of bystanders, especially children.

1. Clear the area of any bystanders.

2. Shut off tractor, place all controls in neutral, set

parking brake, remove key, and wait for all moving

parts to stop.

3. Disconnect driveline and hydraulic lines from the

tractor.

4. Place safety stands or large blocks under the

frame.

2. Lower the unit to the ground, place all controls in

neutral, shut off engine, set park brake, remove

key, and wait for all moving parts to stop before

dismounting.

NOTE: For 3-point hitch units, unhook to gain access

to center flaps.

3. Remove 3/8" nut, washer and carriage bolt from

each worn flap. (Replace any worn or damaged

hardware. See page 51 for hardware sizes.)

30 Service & Maintenance

MAN0943 (07/12/2011)

Page 31

Figure 34. Front Rubber Shield Flaps

DP117

WARNING

CAUTION

4. Replace damaged flap with new flap and secure

with correct hardware.

NOTE: Use only genuine Woods parts when replacing

flaps.

SERVICING ROTORS (FLAIL TUBES)

Do not handle knives with bare hands. Careless

or improper handling may result in serious injury.

■ Any excessive vibration caused by worn or

missing knives or damaged drive components can

cause damage to the shredder and personal injury.

Excessive vibration can also be transmitted

through the hitch mounts and PTO to the tractor

resulting in tractor damage.

Factory balanced replacement rotors are available

through your local Woods dealer. Contact Woods Technical Service for re-balance options or further details.

Follow the procedure below if rotor removal or replacement is required.

Use a suitable lifting device of sufficient capacity. Use adequate personnel to handle heavy components.

1. Clear the area of any bystanders.

2. Shut off tractor, place all controls in neutral, set

parking brake, remove key, and wait for all moving

parts to stop.

3. Remove PTO driveline from the shredder.

4. Fully disconnect the shredder from the tractor.

5. Remove wheel arms.

6. Use a hoist, crane, or frame of sufficient capacity to

raise the front of the unit and allow the back of the

unit to rest on a solid surface (blocks).

7. Leave lifting device attached while working on

rotors to prevent tipping.

Removing Components

Refer to Replacing knives, page 30, for knife or knife

component replacement.

■ Once field operation has been started, it is the

responsibility of the owner/operator to monitor and

maintain acceptable rotor balance. Refer to Balance Statement, page 5, for details.

NOTICE

■ Read Balance Statement, page 5, before replac-

ing any knives.

Refer to Replacing Knives, page 30, for knife or knife

component replacement.

The Woods Center Drive Flail Shredder has been

designed for durability when shredding any type of

crop. Some operating conditions will shorten the life of

the shredder or components. These include operating

too low to the ground or in frequent contact with the

ground, and contact with large rocks or other foreign

objects. Over time, some types of soils and crops can

cause wear or damage to rotor components and affect

rotor balance, leading to increased vibration. Continued operation with excessive vibration can damage the

shredder, requiring rotor service, removal, or replacement.

Refer to Servicing Rotors, page 31, before proceeding

with these steps.

1. Follow steps in the previous section to prepare and

position shredder. Support each end of the rotor

(flail tube) to be removed with a crane or hoist.

2. Remove bearing locking collar (see Figure 35).

3. Remove the six bolts holding the bearing plate to

the body assembly.

4. Slide rotor out to disengage from the center drive

coupling.

5. Thoroughly clean and inspect gearbox drive

couplings for wear and replace if any wear is

detected. Also inspect the rubber O-ring for wear or

tears and replace if any wear or tears are detected.

6. Remove crossmember from the underside of the

shredder, providing access for the removal of the

gearbox.

7. Remove gearbox, if damaged. This will require

removal of the second rotor (repeat steps 1-5

above).

MAN0943 (07/12/2011)

Service & Maintenance 31

Page 32

P E E R

F S 2 1 1

LOCKING COLLAR SET SCREW

DP15

LOCKING COLLAR

SHAFT

FOR REMOVAL: TAP

WITH A HAMMER AND

PUNCH AFTER LOOSENING

SET SCREW.

FOR INSTALLATION:

REVERSE PROCEDURE

MAN0506003

Figure 35. Locking Collar

Replacing Components

NOTE: When re-installing rotors, the gear coupling

grease fitting will need to be temporarily removed

to allow for air to purge from the coupler assembly

during installation. After successful installation,

reinstall grease fitting and re-service.

7. Reinstall bearing plate assembly and bolts, and

apply appropriate torque.

8. Reinstall bearing locking collar and tighten (see

Figure 35).

NOTICE

■ If removing rotor drive coupling, use Loctite No.

271 or equivalent and special high collar lock

washers to keep bolts from loosening.

1. Place new stud bolts into gearbox using Loctite

No. 271 or equivalent.

2. Remount gearbox. The gearbox oil dipstick should

protrude out the top panel of the shredder for

checking and servicing. Reinstall the nuts and lock

washers securing the top of the gearbox to the

shredder gearbox mount plate and torque to

specifications in Bolt Torque Chart, page 59.

3. Remount the crossmember securing the bottom of

the gearbox and torque to specifications in Bolt

Torque Chart, page 59.

4. Install drive couplings and reapply new grease

around entire O-ring and gear teeth surfaces.

5. Install rotors (flail tubes) in the opposite fashion as

removal. Position rotors with each end supported

by a crane or hoist so that it is aligned with the gear

coupling and gearbox output shaft center lines.

The bearing (stub shaft) end of the rotor will

protrude out of the hole in the end sheet.

6. With gentle care not to damage gear coupler teeth

or O-ring, provide pressure to align gear teeth and

slide the rotor back into its original position.

®

Figure 36. Rotor Direction of Rotation

REPLACING STUB SHAFT

1. Remove rotor (see Servicing Rotors (Flail Tubes),

page 31).

2. Remove three 1/2 x 2-1/2 hex bolts in taper lock

hub and re-install bolts in three threaded holes

(see Figure 37).

3. Tighten bolts evenly to release taper lock hub from

stub shaft. NOTE: You may have to give a sharp

blow directly to each bolt head to help the hub

disengage.

4. Unscrew stub shaft from the rotor tube.

5. Install new stub shaft, reversing Steps 1-3.

32 Service & Maintenance

MAN0943 (07/12/2011)

Page 33

Figure 37. Stub Shaft Assembly

Removing the Driveline

1. Shut off tractor and disengage PTO.

2. Disconnect driveline from PTO shaft.