Woods Equipment M8200 User Manual

111868 LOADER MOUNTING KIT

Loaders

1020

1027

Includes

Valve Kits

56037

56038

56042

Hose Kits

40542

40547

mounting to

Kubota Tractor Models

M8200

M9000

46047

46018

PN-46018 (Rev. 3/15/02)

TO THE DEALER:

Assembly and proper i nstallation of thi s product is the responsibil ity of the WOODS dealer. Read manual instructi ons

and safety rules. Make su re all item s on the Dealer ’s Pre- Delivery and Delivery Check L ists in the O perator ’s Ma nual

are completed before releasing equipment to the owner.

TO THE OWNER:

Read this manual before operating your WOODS equipment. The information presented will prepare you to do a better

and safer job. Keep thi s manual handy for ready referenc e. Require all operators to read this m anual carefully and

become acquainted with all the adjustment and operating procedures before attempting to operate. Replacement

manuals can be obtained from your dealer or, in the United States and Canada, by calling 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your authorized WOODS dealer has trained mechanics, genuine WOODS service parts, and the

necessary tools and equipment to handle all your needs.

Use only genuine WOODS serv ice parts. Substitute parts will void the warranty and may not m eet s tandards r equi red

for safe and satisfactory operation. Record the model number and serial number of your equip ment in the spaces

provided:

Model: 111868 Loader Mounting Kit

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to

equipment. The terms CAUTION, WARNING and DANGER are used in conjunctio n with the Safety-Aler t Symbol, (a

triangle with an exclamation mark), to indicate the degree of hazard for items of personal safety.

NOTE

This Safety-Alert Symbol indicates a hazard and means

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Indicates an imminently hazardous situation that, if not avoided, will

result in death or serious injury.

Indicates a potentially hazardous situation that, if not avoided,

could result in death or serious injury, and includes hazards that are

exposed when guards are removed.

Indicates a potentially hazardous situation that, if not avoided, may

result in minor or moderate injury.

Indicates that failure to observe can cause damage to equipment.

Indicates helpful information.

ii

Introduction (2/9/01)

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped out

by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, co ncern,

judgement, and proper training of personnel

involved in the o peration, transport, mainten ance

and storage of equipment.

It has been said “The best safety device is an

informed, careful ope rator.” We ask you to be that

kind of operator.

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

INSTALLATION

SAFETY RULES

Know your controls and how to stop engine and

attachment quickly in an emergency.

Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

Make sure that all operating and service personnel know that if hyd raulic flui d penetrat es skin, it

must be surgically removed as soon as possible by

a doctor familiar with this form of injury or gangrene, serious injury, or death will result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

Never allow children or untrained persons to

operate equipment.

During installation, the tractor engine should be

off, the key removed and th e bra kes l oc ked. D o no t

disconnect hydraulic lines until attachments are

removed or lowered to the ground and system

pressure is released by operating valve levers.

Never operate any hydraulic cylinders during any

phase of the installation process.

This Loader Mounting Kit is to be used only for

the loaders and tractors specified in the Loader

Mount Installation section of this manual. Any

other use or modificat ion of this m ounting kit m ay

result in serious injury or death.

Hydraulics must be connected as instructed in

this manual. Do not substitute parts, modify, or

connect in any other way.

After connecting hoses, check that all control

lever positions func tion a s in s truct ed in th e O per ator’s Manual. Do not put into service until control

lever and equipment movements are correct.

TRAINING

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals are available from dealer or, in the

United States and Canada, call 1-8 00-319-6637.)

Failure to follo w instructio ns or safety rules can

result in serious injury or death.

If you do not understand any part of this manual

and need assistance, see your dealer.

Loader Mounting Kit (9/11/00)

PREPARATION

Check that all hardware is properly installed.

Always tighten to torque chart specif ications

unless instructed otherwise in this manual.

Air in hydraulic systems ca n cause erratic operation and allows loads or equipment components

to drop unexpectedly. When connecting equipment

or hoses or performing any hydraulic maintenance,

purge any air in hydraulic system by operating all

hydraulic functions several times. Do this before

putting into service or allowing anyo ne to

approach the equipment.

After connecting hoses, check that all control

lever positions func tio n as instructed in the Oper ator’s Manual. Do not put into service until control

lever and equipment movements are correct.

Protective hose slee ves must cover all hydraulic hoses and be secured onto metal hose fittings.

Replace hoses or sleeves if damaged or if protective sleeve cannot be properly positioned or

secured.

Make sure all hydraulic hoses, fittings, and

valves are in good condition and not leaking bef ore

starting power unit or using equipment. Check and

route hoses carefully to prevent damage. Hoses

must not be twisted, bent sharply, kinked, frayed,

pinched, or come into c ontact with any moving

parts. Operate moveable components through full

operational range to check clearances. Replace

any damaged hoses immediately.

(Safety Rules continued on next page)

SAFETY 1

S

AFETY RULE

S

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

(Safety Rules continued from previous page)

Do not connect a low-pressure hydraulic hose

into a high-pressure system—it will burst the hose.

Do not use a high-pressure hose in place of a lowpressure hose—it is possible to rupture the valve.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt securely

fastened. Fallin g off power unit can re sult in death

from being run over or crushed. Keep foldable

ROPS systems in “locked up” position at all times.

Whenever 3-point implements are attached to

tractor, always check full range of operation for

mechanical or hydraulic hose interferenc e.

Make sure all safety decals are installed.

Replace if damaged. (See S af ety D ecal s se ct ion for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

OPERATION

Do not allow bystanders in the area when o perating, attaching, removing, assembling, or servicing equipment.

Keep bystanders away from equipment.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Always comply with all state and local lighting

and marking requirements.

Never allow riders. Do not lift or carry anybody

on the loader or in the bucket or attachments.

Power unit must be equipped with ROPS or

ROPS cab and seat belt. Keep seat belt securely

fastened. Fallin g off power unit can re sult in death

from being run over or crushed. Keep foldable

ROPS systems in “locked up” position at all times.

Always sit in power unit seat when operating

controls or startin g engine. Se curely faste n seat

belt, place transmission i n neutral, engage brake,

and ensure all other controls are disengaged

before starting power unit engine.

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Never work under a raised loader. Always lower

loader to the ground with b ucket or loader attachment in full roll-back position. Shut off tractor, set

parking brake, and remove key. Operate valve

levers to release any hydr aulic pressur e. If loader

obstructs tractor maintenance, loader must be

removed from tractor.

MAINTENANCE

Before dismounting power unit or performing

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised components to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, remove key,

and unfasten seat belt.

Never work under a raised loader. Always lower

loader to the ground with b ucket or loader attachment in full roll-back position. Shut off tractor, set

parking brake, and remove key. Operate valve

levers to release any hydr aulic pressur e. If loader

obstructs tractor maintenance, loader must be

removed from tractor.

Refer to loader manual and follow all maintenance safety rules and instructions.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of i ts components in any way.

Your dealer can supply original equipment

hydraulic accessories and repair parts. Substitute

parts may not meet original equipment specifications and may be dangerous.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head.

Do not allow bystanders in the area when operating, attaching, removing, assembling, or servicing equipment.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

2 SAFETY

Loader Mounting Kit (9/11/00)

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Tighten all bolts, nuts and screws to torque

chart specifications. Check that all cotter pins ar e

installed securely to ensure equipment is in a safe

condition before putting unit into service.

Make sure all safety decals are installed.

Replace if damaged. (See S af ety D ecal s se ct ion for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Do not disconnect hydrauli c lines until all system pressure is relieved. Lower unit to gr ound,

stop engine, and operate all hydraulic control

levers.

Loader Mounting Kit (9/11/00)

SAFETY 3

9

56053-A

DANGER

ROLLOVERS CAN

RESULT IN INJURY

OR DEATH

n

Always use ROPS and

seat belt.

n

Add rear tractor

ballast.

n

Move wheels to widest

setting.

n

Avoid slope operation.

n

Operate at low speeds.

n

Carry load low.

Serious injury or death

can result from contact

with electrical lines.

DANGER

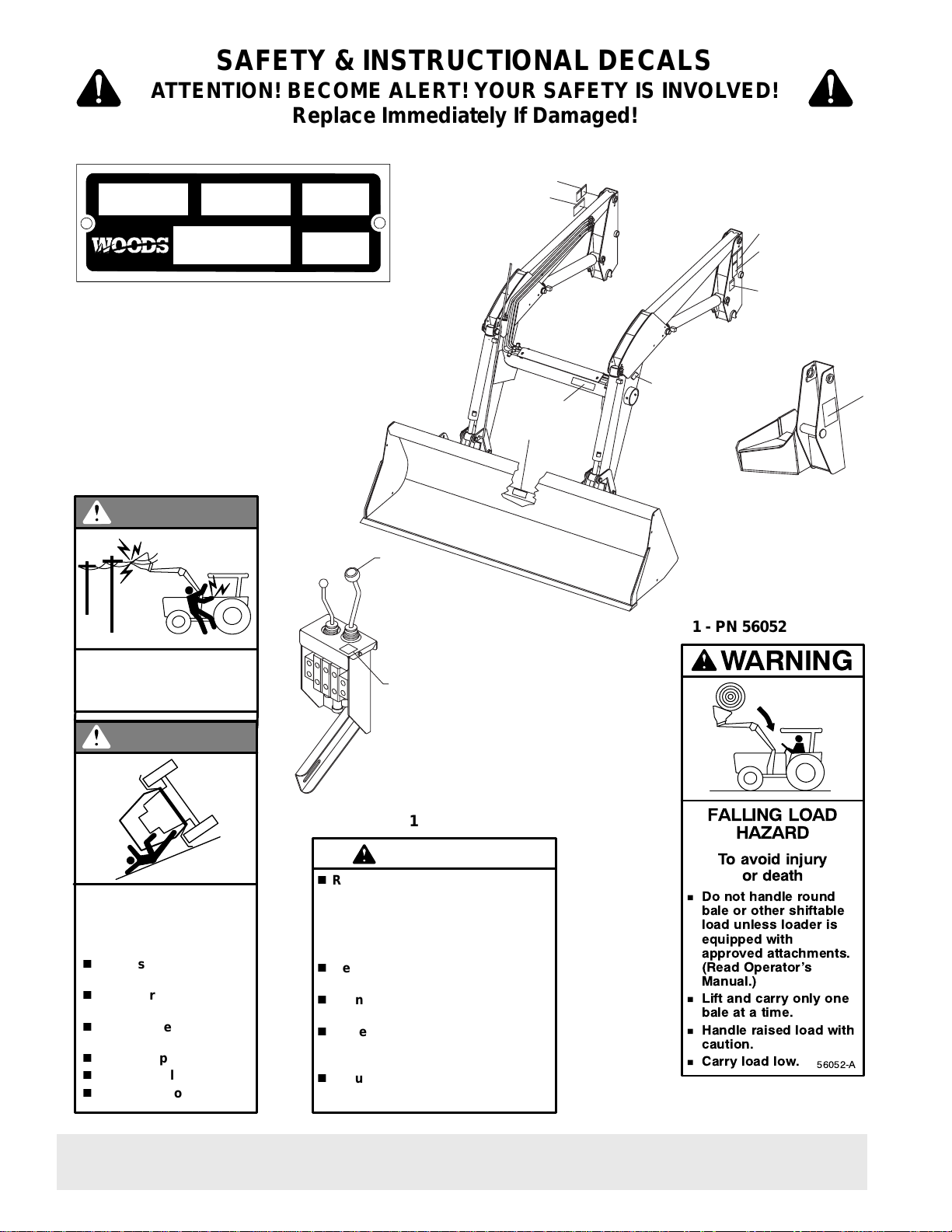

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

MODELNO. SERIALNO. MASS (KG)

ID NO.

OREGON, IL U.S.A.

4 - SERIAL NUMBER PLATE

2 - PN 56053

YR OF MFG.

8

Optional Loader

Control Valv e

10

6

5

1

2

3

4

7

11

Loader Mount

(Left Side)

1 - PN 56052

WARNING

4 SAFETY

3 - PN 56051

W ARNING

n

Read and understand Operator’s

Manual before operating.

(Replacement manuals are

available from dealer or, in the

United States and Canada, call

1-800-319-6637.)

n

Keep others away when operating

loader.

n

Do not allow children or untrained

persons to operate equipment.

n

Lower loader to ground, stop engine, set park brake and remove

key before leaving tractor seat.

n

Failure to follow safety rules can

result in serious injury or death.

56051-A

FALLING LOAD

n

n

n

n

(Safety Decals continued on next page)

HAZARD

To avoid injury

or death

Do not handle round

bale or other shiftable

load unless loader is

equipped with

approved attachments.

(Read Operators

Manual.)

Lift and carry only one

bale at a time.

Handle raised load with

caution.

Carry load low.

PN-46018 (Rev. 11/10/00)

56052-A

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

(Safety Decals continued from previous page)

6 - PN 56050

WARNING

CRUSHING HAZARD

To avoid injury

or death:

n

Do not walk or work underneath a raised loader.

n

Lower loader to ground

before leaving tractor

seat.

5 - PN 19924

HIGH-PRESSURE HYDRAULIC OIL LEAKS CAN PENETRATE SKIN

RESULTING IN SERIOUS INJURY, GANGRENE OR DEA TH.

n

Check for leaks with cardboard; never use hand.

n

Before loosening fittings: lower load, release pressure, and

be sure oil is cool.

n

19924-B

Consult physician immediately if skin penetration occurs.

WARNING

FALLING HAZARD

To avoid injury

n

Do not work from or

allow riders on loader or

its attachments.

WARNING

or death:

56050-A

LOADER MOUNTING INSTRUCTIONS

Read Operator’s Manual instructions before proceding.

To Remove Loader

1. Park tractor on level surface with bucket flat on

ground.

2. Dump bucket to take weight off mount pins and

allow for stand installation. Set brake and shut off

tractor.

3. Remove stands from crosstube and pinintobrackets.

(Pin location noted in mounting manual.)

4. Remove mount pins from loader upright.

5. Roll back bucket completely to raise uprights from

mounts.

6. Shut off engine. Disconnect hydraulics. Back tractor

away. Store mount pins in loader uprights.

To Mount Loader

1. Remove mount pins from uprights.

2. Drive tractor into loader slowly.

3. Shut off tractor. Connect hydraulics.

4. Dump bucket to lower upright into mounts.

5. Continue dumping bucket until uprights settle into

mounts, pins can be installed and stands can be

removed. Set brake and shut off tractor.

6. Install mount pins andclips. Remove stands andpin

into crosstube.

56059-A

9 - PN 56059

8 - PN 45002

(WHEN EQUIPPED)

W ARNING

LOADER ATTACHMENT CAN FALL OFF IF NOT PROPERLY ATTACHED.

n

Read operator’s manuals for instructions.

n

Position and align loader to attachment.

n

Rotate coupler handles to full locked position. Lockpins must fully extend and

engage into attachment retaining slots.

n

Attachment mechanism must be functional and in good repair.

n

Only use loader manufacturer approved attachments.

n

For information on approved attachments, call 1-800-319-6637.

Failure to follow these instructions can result in serious injury or death.

7 - PN 56055

11 - PN 45024

WARNING

LOADER ATTACHMENT CAN FALL OFF IF NOT PROPERLY ATTACHED.

Only use loader manufacturer approved attachments.

Failure to do so can cause serious injury or death.

PN-46018 (Rev. 11/10/00)

45024-A

56055-B

10 - PN 56889

(WHEN EQUIPPED)

AUXILIARY

CONTROL

56889

SAFETY 5

#

"

8 - PN 260274

(WHEN EQUIPPED)

LOADER

CONTROL

260274-C

LOADER MOUNT INSTALLATION

WARNING

■ Only use 111868 Loader Mounting Kit for mount-

ing Woods 1020/1027 loaders to Kubota M8200 and

M9000 tractors. Any other use or modification of

this kit may result in serious injury or death.

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals are available from dealer or, in the

United States and Canada, call 1-800-319-6637.)

Failure to follo w instructions or safety rules ca n

result in serious injury or death.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its components in any way.

CAUTION

If you do not understand any part of this manual

and need assistance, see your dealer.

Always wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head.

IMPORTANT

■ A front wheel track settin g of 60.6” is th e widest

setting allowed by the tractor manufacturer for

2WD models using front end loaders.

TRACTOR PREPARATION

For installing this mounting kit, references to right,

left, forward, and rearw ard directions are determine d

from the operator’s position in the tractor seat.

1. Shut off engine and set parking brake during

installation.

2. Remove the tractor front wei ghts a nd fro nt we igh t

bracket if equipped. R emove to ol box on tracto rs with

cab.

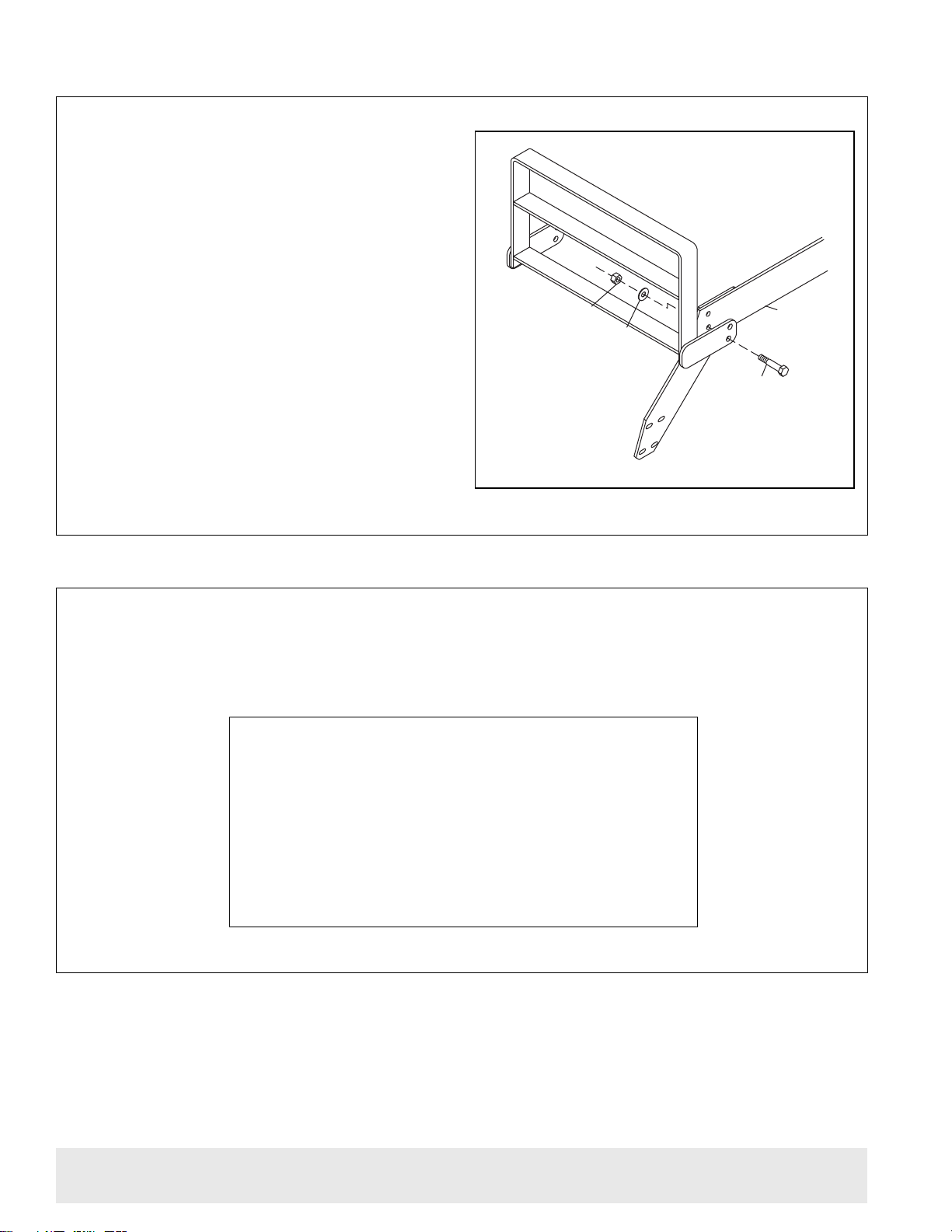

3. Cab tractors only – Remove four bolts (Figure 1)

for cab tractor mountings.

IMPORTANT

■ Clean threaded holes in the tractor chassis

thoroughly, using a tap of the proper size. Paint,

rust, or debris in the threads may not permit cap

screws to be installed and tightened correctly.

6 Mount Installation

Figure 1 Remove 4 bolts on each side

PN-46018 (Rev. 3/15/02)

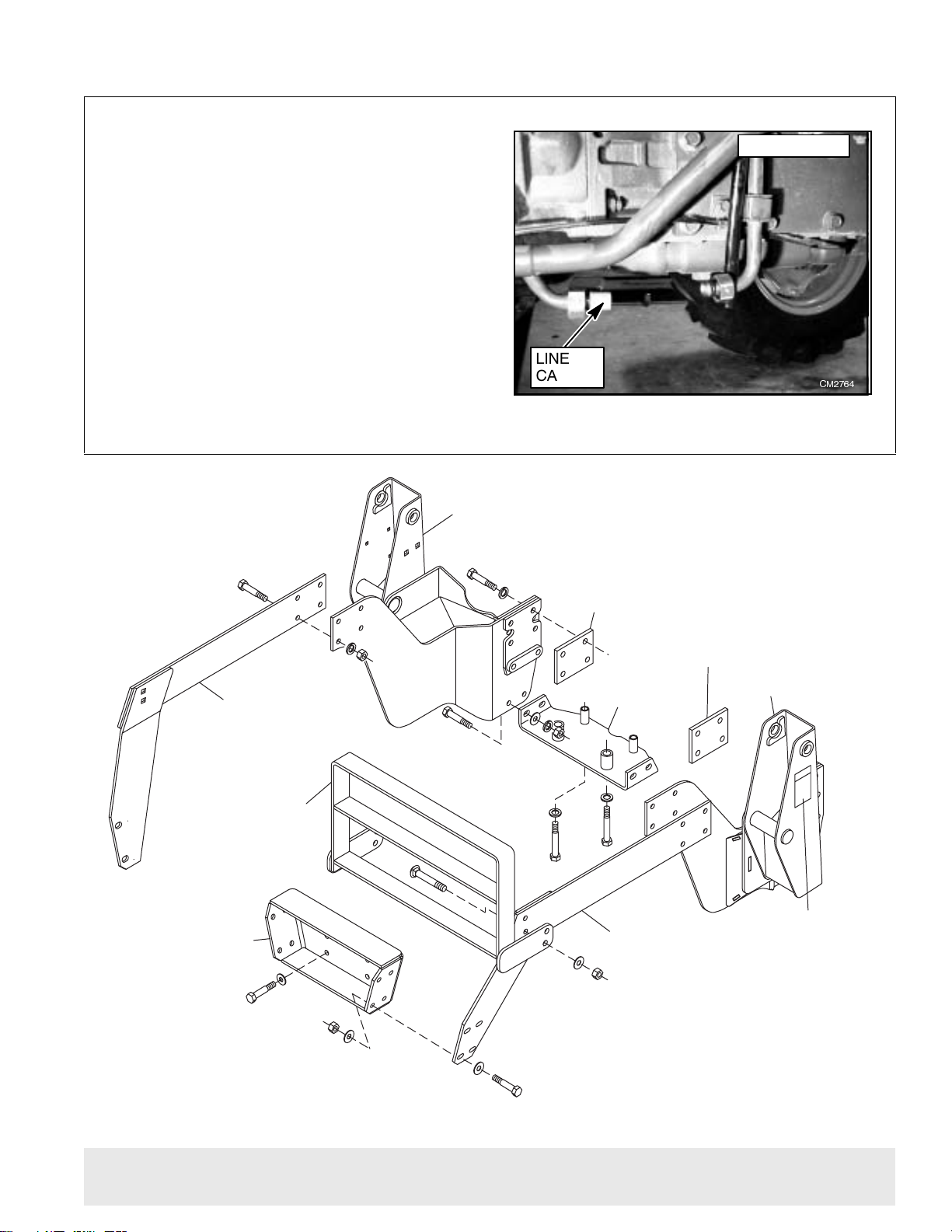

LOADER MOUNT INSTALLATION Cont’d

Remove Tractor Connector Tube or

Adapter Block

Follow this procedure only if using #40547 or

#46047 Hose Kits.

NOTE: It is easier to remove the connector tube or

adapter block before installing the right mount.

1. Remove tractor hydraulic line connector tube or

adapter block (if equipped) as shown in Figure 2.

2. To prevent the line from leaking during installation

of the loader mounts, be sure to plug the fitting. A 3/4”

plastic cap taken from an a dapter in the ho se kit may

be used.

RH Rear Mount

44490

(1*,1( (1'

/,1(

&$33('

Figure 2 Hydraulic connector Tube Removed

(Rear line capped with 3/4” plastic cap)

&0

RH Side Rail

59628

Grill Guard

1000545

Front Support

1002896

Spacer

Plate

46015

Crossmember

46000

LH Side Rail

59631

Spacer

Plate

46015

LH Rear Mount

44491

Loader

Mounting

Instruction

Decal

56059

PN-46018 (3/15/02)

Figure 3

CD5612C-Var

111868 Loader Mounting Kit

Mount Installation 7

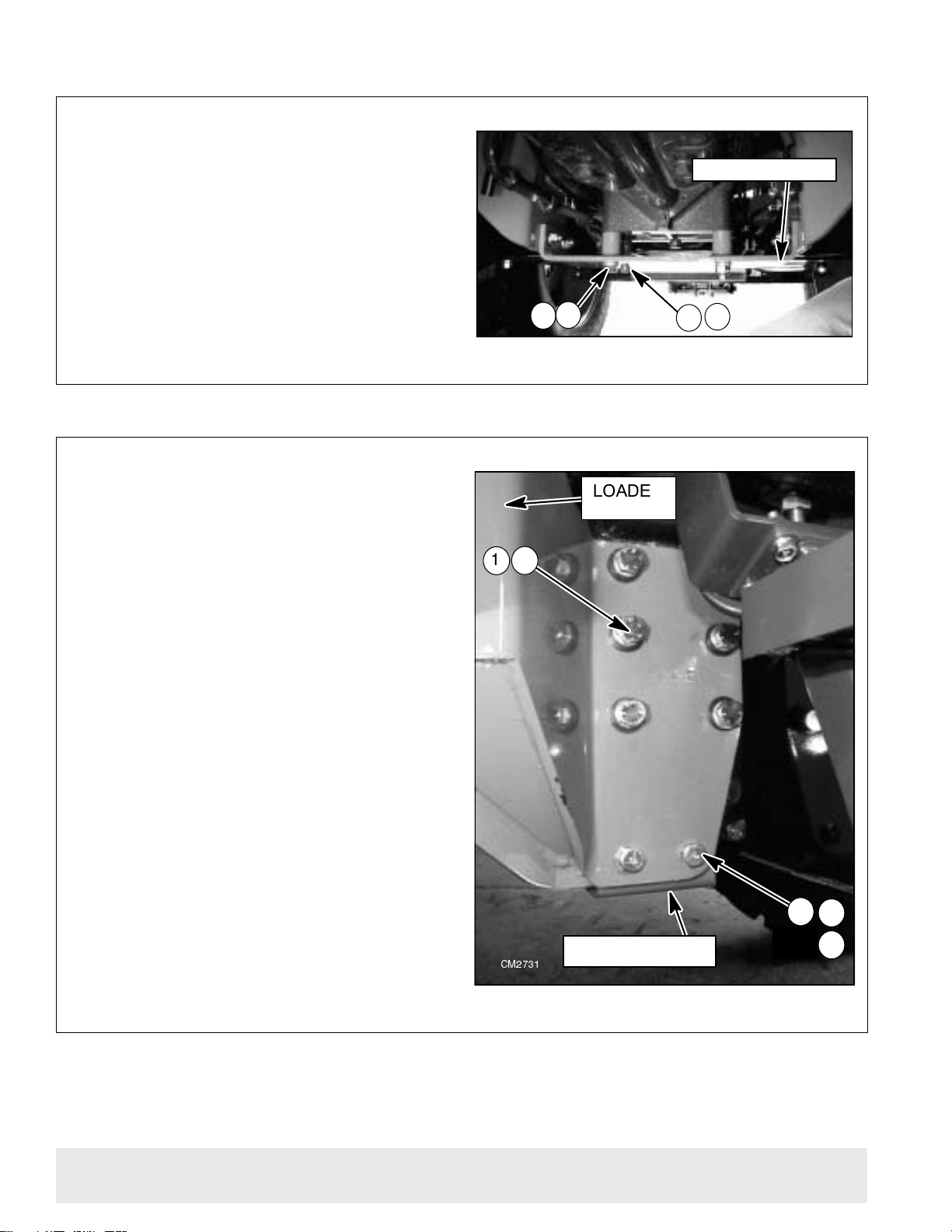

LOADER MOUNT INSTALLATION Cont’d

Install Crossmember

NOTE: Leave all cap screws loose until loader

mounts are completely installed.

1. Install #46000 cross member to the underside of

the tractor clutch housing, using cap screws and

hardened flat washers as shown in Figure 4.

1. 307502 M18 x 1.5 x 85mm Cap screw

2. 57798 3/4 Hardened flat washer

3. 67376 M12 x 1.25 x 80mm Cap screw

4. 57816 1/2 Hardened flat washer

Install Rear Loader Mounts

1. Install #44490 right rear mount and #44491 left

rear mount to tractor chassis and crossmember.

NOTE: Non-cab tractors will need #46015 spacer

plate installed between t he rear mounts an d the tractor.

&52660(0%(5

Figure 4 Crossmember Installed

/2$'(5

02817

2. Use cap screws (1) and hardened flat washers (2)

at tractor clutch housing as shown in Figure 5.

3. Use cap screws (3) and hardened flat washers (4)

to attach mount to crossmember.

1. 46019 M18 x 1.5 x 70mm Cap screw

2. 57798 3/4 Hardened flat washer

3. 12274 5/8 x 2-1/4 Cap screw

4. 57817 5/8 Hardened flat washer (hidden)

6. 230 5/8 Hex nut (hidden)

&0

&52660(0%(5

Figure 5 Left Rear Mount Installed

8 Mount Installation

PN-46018 (Rev. 3/15/02)

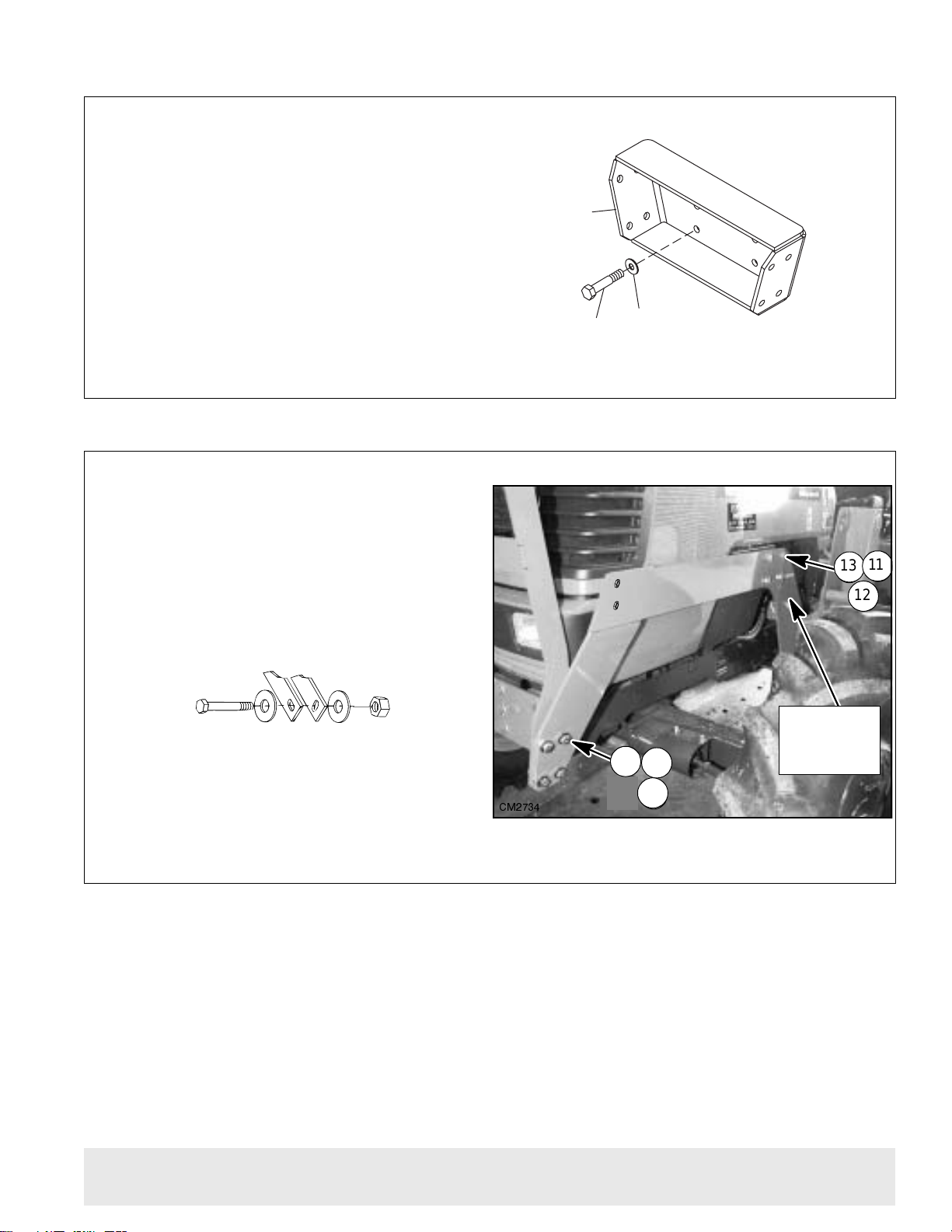

LOADER MOUNT INSTALLATION Cont’d

Install Front Mount Bracket

1. Install front mount bracket (3) to tractor steerin g

housing, using cap screws (17) and hardened flat

washers (11) as shown in Figure 6.

3. 1002896 Front mount bracket

11. 57817 5/8 Hardened flat washer

17. 307425 M16 x 1.5 x 35mm Cap screw

3

Install Side Rails

1. Install #59628 right side r ail and #59631 le ft side

rail to outside of rear mounts as s hown in Figure 7.

Secure with cap sc rews (13), hardened flat washers

(11), and hex nuts (12).

2. Secure at front suppor t with cap screws (13), flat

washers (11), and hex nuts (12). Flat washers are

installed over the slot as shown below.

11. 57817 5/8 Hardened flat washer

12. 230 5/8 Hex nut

13. 4548 5/8 NC x 1-3/4 Cap screw

17

Figure 6 Front Mount Bracket

&0

Figure 7 Side Rails Installed to Rear Mounts

11

13

11

12

& Front Support

13

/()7

/2$'(5

02817

12

11

PN-46018 (3/15/02)

Mount Installation 9

LOADER MOUNT INSTALLATION Cont’d

Install Grill Guard

1. Install grill guard outside the left and right side

rails as shown in Figure 8.

5. 59628 Right side rail (not shown)

6. 59631 Left side rail

11. 57817 5/8 Hardened flat washer

12. 230 5/8 Hex nut

13. 4548 5/8 NC x 1-3/4 Cap screw

12

11

13

CD5612C-Var

Figure 8 Grill Guard Installed

6

Torque Hardware

1. Tighten all hardware to specifications given.

TORQUE SPECIFICATIONS

Cap Screw Qty Size Required Torque

M12 x 1.25 x 80mm 2 18mm 76 lbs.-ft.(103 N-m)

M16 x 1.50 x 35mm 6 24mm 133 lbs.-ft.(181 N-m)

M18 x 1.50 x 85mm 2 27mm 194 lbs.-ft.(263 N-m)

M18 x 1.50 x 70mm 12 27mm 194 lbs.-ft.(263 N-m)

5/8 NC x 1-3/4 8 15/16” 170 lbs.-ft.(230 N-m)

5/8 NC x 2-1/4 12 15/16” 170 lbs.-ft.(230 N-m)

Wrench

10 Mount Installation

PN-46018 (Rev. 3/15/02)

CONTROL VA LVE & HOSE KIT INSTALLATION

WARNING

WARNING

■ Keep hands and body away from pressurized

lines. Use paper or cardboard, not hands or other

body parts to check for leaks. Wear safety goggles.

Hydraulic fluid under pressure can easily penetrate

skin and will cause serious injury or death.

■ Make sure that all operating and service per-

sonnel know that if hydraulic fluid penetrates skin,

it must be surgically removed as soon as possible

by a doctor familiar with this form of injury or gangrene, serious injury, or death will result. CONTACT A PHYSICIAN IMMEDIATELY IF FLUID

ENTERS SKIN OR EYES. DO NOT DELAY.

■ Air in hydraulic systems can cause erratic

operation and allow loads or equipment components to drop unexpectedly. When connecting

equipment or hoses or performing any hydraulic

maintenance, purge any air in hydraulic system by

operating all hydraulic functions several times. Do

this before operating or allowing anyone to

approach the equipment.

WARNING

WARNING

■ Make sure all hydraulic hoses, fittings, and

valves are in good condition and not leaking bef ore

starting power unit or using equipment. Check and

route hoses carefully to prevent damage. Hoses

must not be twisted, b ent sharply, kinked, frayed,

pinched, or come into contact with any moving

parts. Operate moveable components through full

operational range to check clearances. Replace

any damaged hoses immediately.

■ Protective hose slee ves must co ver all hydrau-

lic hoses and be secured onto metal hose fittings.

Replace hoses or sleeves if damaged or if protective sleeve cannot be properly positioned or

secured.

IMPORTANT

■ Hydraulic valves must be connected to the

tractor hydraulic system as shown in this loader

mounting kit manual.

■ If hydraulic lines are not con nected as shown

in the mounting kit manual, the loader control valve

may be damaged. A blocked outlet (Return) or

improper hose connection will cause pressurized

oil to enter the return circuit and damage the valve.

COMPLETION OF THIS INSTALLATION REQUIRES CONNECTION TO THE LOADER,

ASSEMBLED ACCORDING TO INSTRUCTIONS IN MANUAL #56060.

SHUT OFF ENGINE AND LOCK PARKING BRAKE BEFORE INSTALLING HOSE KITS.

CHECK ALL PARTS IN HOSE KIT AGAINST PACKING LIST.

THE FOLLOWING INSTRUCTIONS ARE FOR OPERATING THE LOADER USING THE

TRACTOR HYDRAULIC REMOTE CONTROL LEVERS:

1

#40542 Hose Kit

(For use with tractor remotes). . . . . . . . . . . . . . . . . . . . . . . . . . . Page 12

2

#56037 Control Valve Kit & #40547 Hose Kit

(For use with loader joystick) . . . . . . . . . . . . . . . . . . . . . . . . . . .Page 15

3

#56038 Cable Control Valve Kit & #46047 Hose Kit (For use

on cab tractors with cable-operated control valve). . . . . . . . . . Page 21

PN-46018 (Rev. 3/15/02)

Hydraulic Installation 11

#40542 Hose Kit

1

NOTE: To use this hydraulic connection, the tractor

must be equipped with two hydraulic levers and four

tractor hydraulic couplers.

(For use with tractor remotes)

Install Hose Clamp Bracket & Channel

1. Install #40539 hose clamp bracket to right l oader

mount, using carriage bolts (3), flat washers (4), lock

washers (5), and nuts as shown in Figure 9.

NOTE: Bracke t must be installed befo re the loader is

mounted to the tractor.

2. With loader in mounti ng position, connect load er

supply hoses to the l oader feedli nes as s hown in Fi gure 11.

3. Install #40548 hose clamp ch anne l to hos e cl am p

bracket. Clamp hoses as shown in Figure 10.

5. 40539 Hose clamp bracket

6. 40548 Hose clamp channel

10. 35735 3/8 NC x 2-1/2 Carriage bolt

11. 66840 3/8 NC Knob

12. 3632 5/8 Flat washer

13. 1286 5/8 Lock washer

14. 230 5/8 NC Hex nut

15. 5607 5/8 NC x 1-1/2 Carriage bolt

Figure 9 Hose Clamp Assembly

+26( &/$03 &+$11(/

Figure 10 Hose Clamp Bracket & Channel Installed

$

%

5+

/2$'(5

'

$ %8&.(7 &</ %$6( (1'

% %8&.(7 &</ 52' (1'

& %220 &</ 52' (1'

' %220 &</ %$6( (1'

Figure 11 Loader Feedline Identifications

&

'803

52//%$&.

'2:1

83

(viewed from rear)

%220

FP

12 Hydraulic Installation

PN-46018 (Rev. 3/15/02)

Loading...

Loading...