Page 1

ROTARY MOWER

L59 & L306 AC/B & C

For use on Allis Chalmers B & C Tractors

29936

Rev. 5/18/2007

Tested. Proven. Unbeatable.

Page 2

TO THE DEALER:

®

Assembly and proper ins tallation of this product is the r esponsibility of the Woods

and safety rules. Make su re all item s on the Dealer ’s Pr e-Delivery and Delivery Check L ists in the O perator ’s Ma nual

are completed before releasing equipment to the owner.

The dealer must complete the Produc t Registrati on included with the Oper ator ’s Manual. The cust omer must si gn the

registration which cer tifies that all Dealer Check List items have been completed. The de aler is to return the prepaid

postage portion to Woods, give one co py to th e custo mer, and retain one co py. Failure to complete and return this

card does not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your W oods equipm ent. The informa tion presented will prepare you to do a better and

safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and become

acquainted with all adjustment and operating procedures before attempting to operate. Replacement manuals can be

obtained from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in

the United States and Canada call 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your author ized Woods dealer has trained me chanics, genuine Woods serv ice parts, and the necessary

tools and equipment to handle all your needs.

Use only genuine Woods service parts. Substitute parts will void the warranty and may not meet standards required for

safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

dealer. Read manual instructions

Model:_______________________________ Date of Purchase: _____________________

Serial Number: (see Safety Decal section for location) ____________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term IMPORTANT is used to indicate that failure to observe can cause damage to

equipment. The ter ms CAUTION, WARNING, and DANGER are used in co njunction with the Sa fety-Alert Symbol (a

triangle with an exclamation mark) to indicate the degree of hazard for items of personal safety.

2 Introduction

Gen’l (Rev. 2/5/2007)

Page 3

TABLE OF CONTENTS

INTRODUCTION. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

ASSEMBLY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

PARTS LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

BOL T TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

BOLT SIZE CHART. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . INSIDE BACK COVER

REPLACEMENT PARTS WARRANTY . . . . . . . . . . . . . . . . . . BACK COVER

GENERAL INFORMATION

The purpose of this manual is to assist you in operating

and maintaining your cutter. Read it carefully. It furnishes information and instructions that will help you

achieve years of dependable performance. These

instructions have been compiled from extensive field

experience and engineering data. Some information

may be general in nature due to unknown and vary ing

operating conditions. However, through experience

and these instruction s, you should be able to deve lop

procedures suitable to your particular situation.

!

LEA EL INSTRUCTIVO!

alguien que si lo lea para que le

traduzca las medidas de seguridad.

The illustrations and data used in this manual were current at the time of printing but, due to possible inline

production changes, your cutter may vary slightly in

detail. We reserve the right to redesign and change the

cutters as may be necessary without notification.

Throughout this m anual, references are made to right

and left directions. Th ese are determined by standing

behind the cutter facing the direction of forward travel.

Si no lee Ingles, pida ayuda a

29936 (Rev. 5/18/2007)

This Operator’s Manual should be regarded as part of the machine.

Suppliers of both new and second-hand machines must make sure

that this manual is provided with the machine.

Introduction 3

Page 4

S

AFETY RULE

S

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Safety is a primary concern in the design and

manufacture of our p roducts. Unfortunately, our

efforts to provide safe equipm ent can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident p revention are dependent upon the awareness, concern, judgement, and proper training of

personnel involved in the operation, transport,

maintenance, and storage of equipment.

It has been said, “The best safety device is an

informed, careful operator.” We ask you to be

that kind of operator.

TRAINING

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

If you do not understand any part of this manual

and need assistance, see your dealer.

Know your controls and how to stop engine and

attachment quickly in an emergency.

Operators must be instruct ed in and be capable

of the safe operation of t he equipment, its attachments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Never allow children or untrained persons to

operate equipment.

PREPARATION

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Remove accumulated debris from this equipment, power unit, and engine to avoid fire hazard.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

OPERATION

You may not be able to stop the tractor safely if

the clutch or brake pedal mechanisms are improperly adjusted, a llowing them to contact mower

components.

When the mower lift stops are installed as

instructed in t his manu al, prop erly adj usted cl utch

and brake pedal mechanisms will not contact

mower components. You should frequently check

that the tractor clutch and brake pedal mechanisms

are in adjustment.

If the clutch or brake pedal mechanisms can

contact mower components, do not put mower into

service until properly adjusted.

Do not put mower into service unless discharge

chute is installed and in good condition. Replace if

damaged.

Keep bystanders away from equipment.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Never direct discharg e toward people, animals,

or property.

Operate only in daylight or good artificial light.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Always comply with all state and local lighting

and marking requirements.

Never allow riders on power unit or attachment.

Always sit in power unit seat when operating

controls or starting engine. Place transmission in

neutral, engage brak e, and ensure all othe r controls are disengaged before starting power unit

engine.

Look down and to the rear and make sure area

is clear before operating in reverse.

Do not operate or transport on steep slopes.

4 Safety

L59 Safety Rules (Rev. 9/1/2006)

Page 5

S

AFETY RULE

S

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Do not stop, start, or change directions suddenly on slopes.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Watch for hidden hazards on the terrain during

operation.

Stop power unit and equipment immediately

upon striking an obstruction. Turn off engine,

remove key, inspect, and repair any damage before

resuming operation.

TRANSPORTATION

Always comply with all state and local lighting

and marking requirements.

Never allow riders on power unit or attachment.

Do not operate PTO during transport.

Watch for hidden hazards on the terrain.

Do not operate or transport on steep slopes.

Do not operate auxiliary hydraulics during

transport.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

MAINTENANCE

Before dismounting power unit or pe rforming

any service or maintenance, follow these steps:

disengage power to equipment, lower the 3-point

hitch and all raised c omponents to the ground,

operate valve levers to release any hydraulic pressure, set parking brake, stop engine, rem ove key,

and unfasten seat belt.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its components in any way.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Never go underneath equipment (lowered to the

ground or raised) unless it is properly blocked and

secured. Never place any part of the body under-

neath equipment or between moveable parts even

when the engine has been turned off. Hydraulic

system leak down, hydraulic system failures,

mechanical failures, or movement of control levers

can cause equipment to drop or rotate unexpectedly and cause severe injury or death. Follow Operator's Manual instructions for working underneath

and blocking require ments or have work done by a

qualified dealer.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

Make certain all movement of equipmen t components has stopped before app roaching fo r service.

Frequently check blades. They should be sharp,

free of nicks and cracks, and securely fastened.

Do not handle blades with bare hands. Careless

or improper handling may result in serious injury.

Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter pins ar e

installed secu rely to ensu re eq uipme nt is i n a sa fe

condition before putting unit into service.

Make sure all safety decals are installed.

Replace if damaged. (See S afet y Deca ls se ctio n f or

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Wear gloves when installing belt. Be careful to

prevent fingers from being caught between belt

and pulley.

STORAGE

Block equipment securely for storage.

Keep children and bystanders away from stor-

age area.

L59Safety Rules (Rev. 9/1/2006)

Safety 5

Page 6

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

MODEL NO. SER IAL NO.

Woods Equipment Company

Oregon, Illinois, U.S.A.

3 - SERIAL NUMBER PLATE

BE CAREFUL!

Use a clean, damp cloth to clean saf ety

decals.

Avoid sprayi ng too close to decal s when usin g

a pressure washer; high-pressure water can

enter through very small scratches or under

edges of decals causing them to peel or come

off.

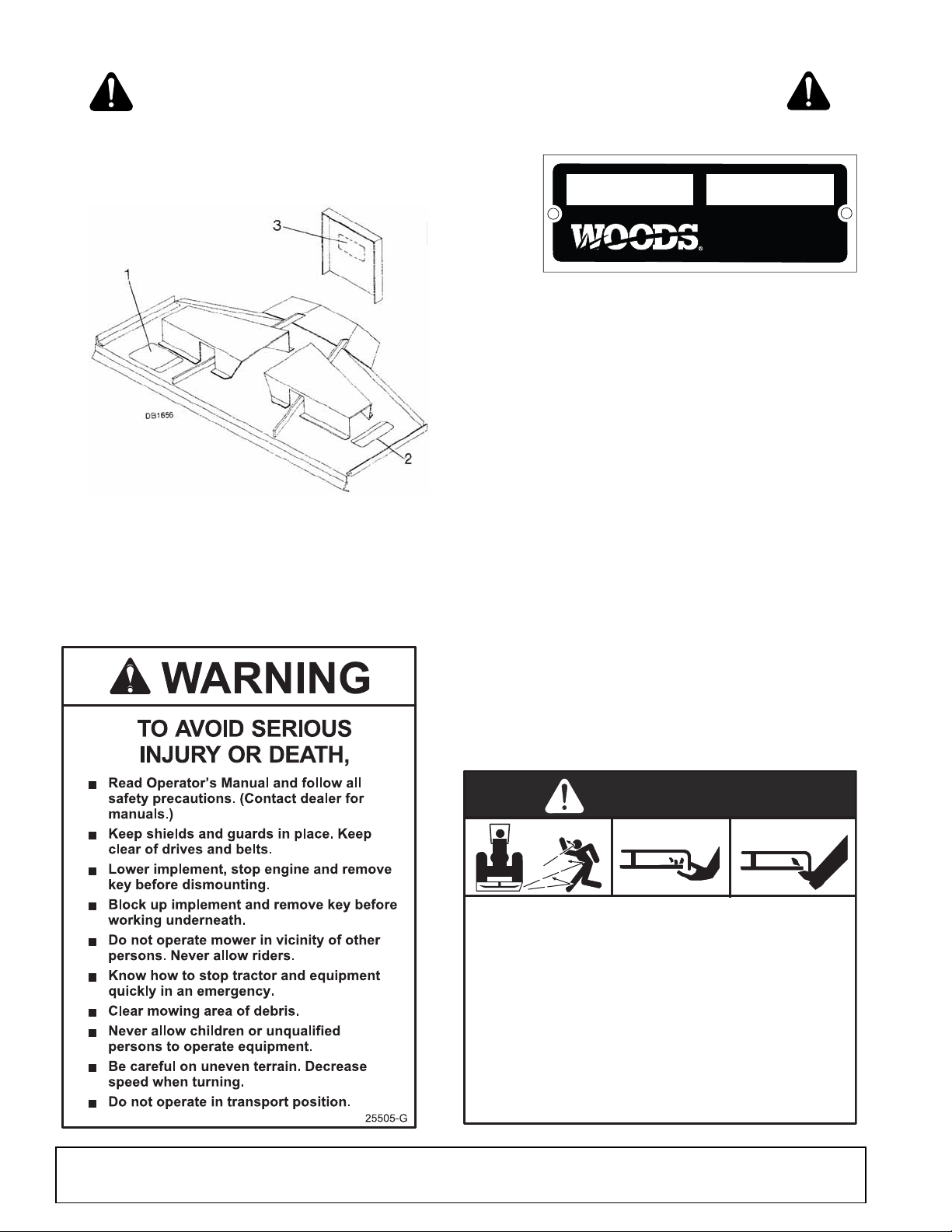

1 - 25505

Replacement safety decals can be ordered

free from your Woods dealer. To locate your

nearest dealer, check the Dealer Locator at

www.WoodsEquipment.com, or in the United

States and Canada call 1-800-319-6637.

2 - 53425

DANGER

ROTATING BLADES AND

THROWN OBJECTS

Do not put hands or feet under or into mower when

engine is running.

Before mowing, clear area of objects that may be

thrown by blade.

Keep bystanders away.

Keep discharge chute and guards in place and in good

condition.

BLADE CONTACT OR THROWN OBJECTS CAN

CAUSE SERIOUS INJURY OR DEATH.

53425-B

6 Safety

29936 (Rev. 5/18/2007)

Page 7

OPERATION

A WARNING

■ Do not a llow c hildren or unqualified persons to

operate equipment.

■ Kee p bystanders away from equipment while it

is in operation.

A CAUTION

■ Stop mower and tractor immediately upon

striking an obstruction. Turn off engine, remove

key, inspect and repair any damage before resuming operation.

■ Alway wear relatively tight and belted clothing

to avoid entanglement in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hands, hearing and head.

MOWING GRASS

Woods model 59, L59, and L306 series mowers are

equipped with suction-type blades which make them

ideal for finish mowing large areas of lawn. The

machine should be run level when mowing, and the

uncut area should be kept to the left side (right s ide o n

left-handed machine). This prevents a small windrow

that might otherwise occur .

Streaking

clear the ground. The side skid s will minimize sc alping

by lifting the mower over bumps.

Height Adjustment (With Casters)

Adjustments for 59 and L59 casters are made by p lacing the axle in th e uppe r and low er hol e in the yo ke, or

by moving spacers to top o r bottom of the pivot shaft.

On L306, adjust by using variou s holes in caster arm.

Adjust side skids 1/2" above the ground.

Raise mower off the ground when b acking and tur ning

at same time.

Mower Attitude

Position front of mowe r level with or slightly bel ow the

rear of mower to provid e a closer cutting . Mowing with

the front end high will produ ce rag ged cuts with a s calloped look, exces sive shreddi ng, and will require extr a

power.

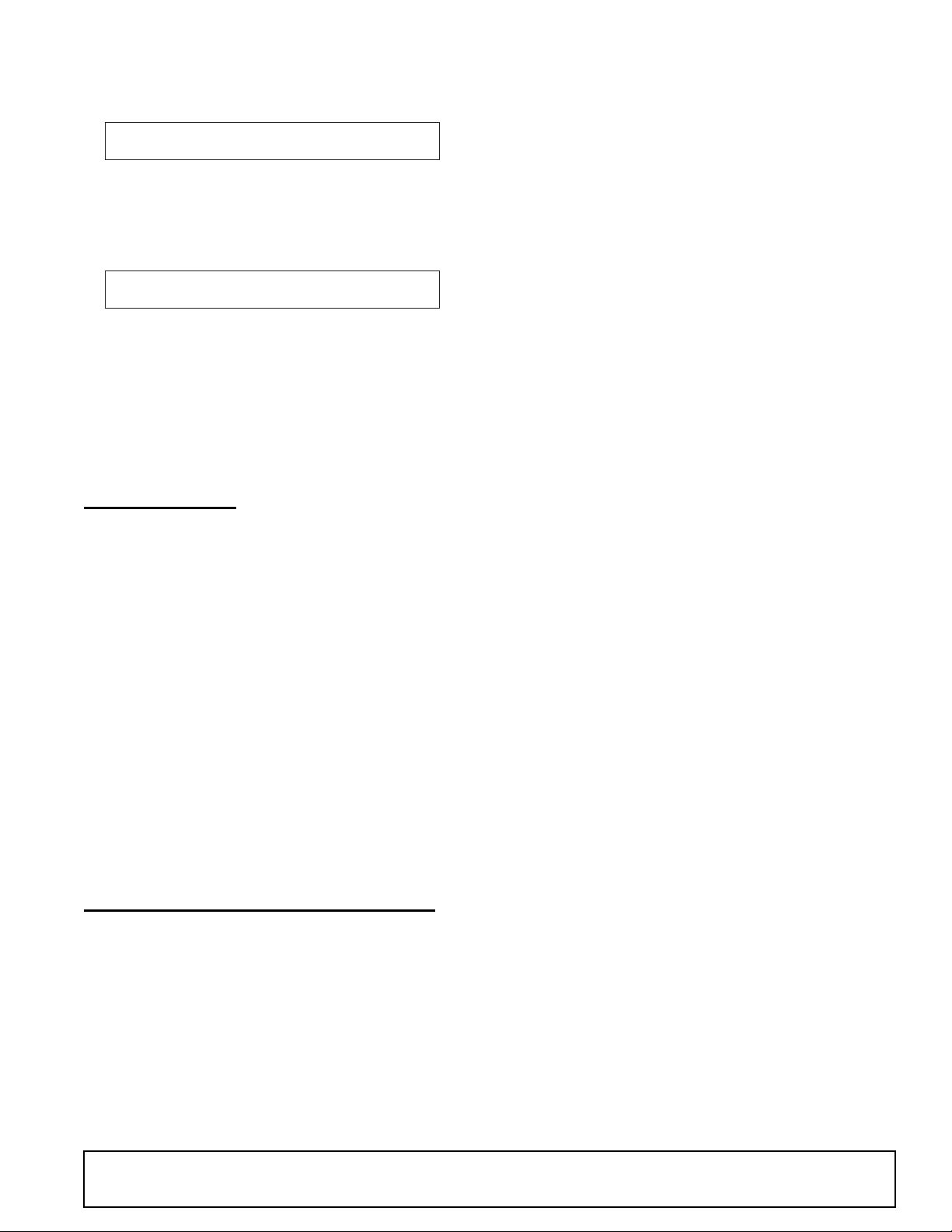

Attitude Adjustment (Figure 1)

For best mowing results, dimension “A” should not be

more than 1/2" higher, and never lower, than dimension

“B”.

Dimension “B” is set by adjusting casters, gauge

wheels, or lift chains.

Dimension “A” is set by raisin g or lowering pu sh channel arms in idler bracket.

With certain types of grass and under certain sea sonal

conditions, the fro nt caster wheels may roll the grass

down enough that it will no t come all the way back up

and will not be cut as short as the surrounding area.

This may appear to be a streak left by the spindle, but it

is not. The only solution, under these conditions, is to

carry the weight of the machine on the lift chains with

the caster wheels adj usted up s o they c arry the we ight

when riding a high ridge or high spot.

TRACTOR OPERATING INSTRUCTIONS

Operate the tractor at full governed rpm when doing

normal mowing. If the forward speed is too high, a

lower gear can be used.

Height Adjustment (Without Casters)

The mower is raised or lowered and the mowing height

is maintained by the tractor hydraulic system.

Set the hydraulic control lever stop for the desired

mowing level. Adjust the side skids so that they just

NOTICE

■ Any adjustment to either dimension “A” or “B”

will require adjustment to the other.

Check cutting height and attitude by placing a straight

edge along the outside edge of the mower frame as

shown in Figure 1.

Measure from the bottom edge of the straight edge at

the front and rear at least 32" apart. The front measurement should be approximately 1/2" lower than the rear.

To det ermine cutting hei ght, it is necessa ry to subtract

the distance the blade is below mower frame from the

front measurement. On the L59, the blade is 4-5/8"

below the mower frame. On the L306, it is 4-7/8" below.

When checking cutting height, be sure to take measurements on both sides of the mower. Be sure the

mower is level from side to side usi ng these m easurements.

When changes are made to cutti ng height or attitude,

be sure to check belt alignment and tension.

29936 (Rev. 5/18/2007)

Operation 7

Page 8

Figure 1. Attitude Adjustment

NOTICE

■ Improper belt alignment or tension can cause

premature belt failure.

LUBRICATION

Grease caster pivot a nd wh eel ever y 8 hours of oper ation. There are grease fittings on each of the three

blade spindles. These are accessible without shield

removal. Grease every 24 hours of operation with a

good grade light to medium grease gun.

NOTICE

■ Do not over grease spindles. Excess grease

could be transferred to the belt and cause slippage

or premature failure.

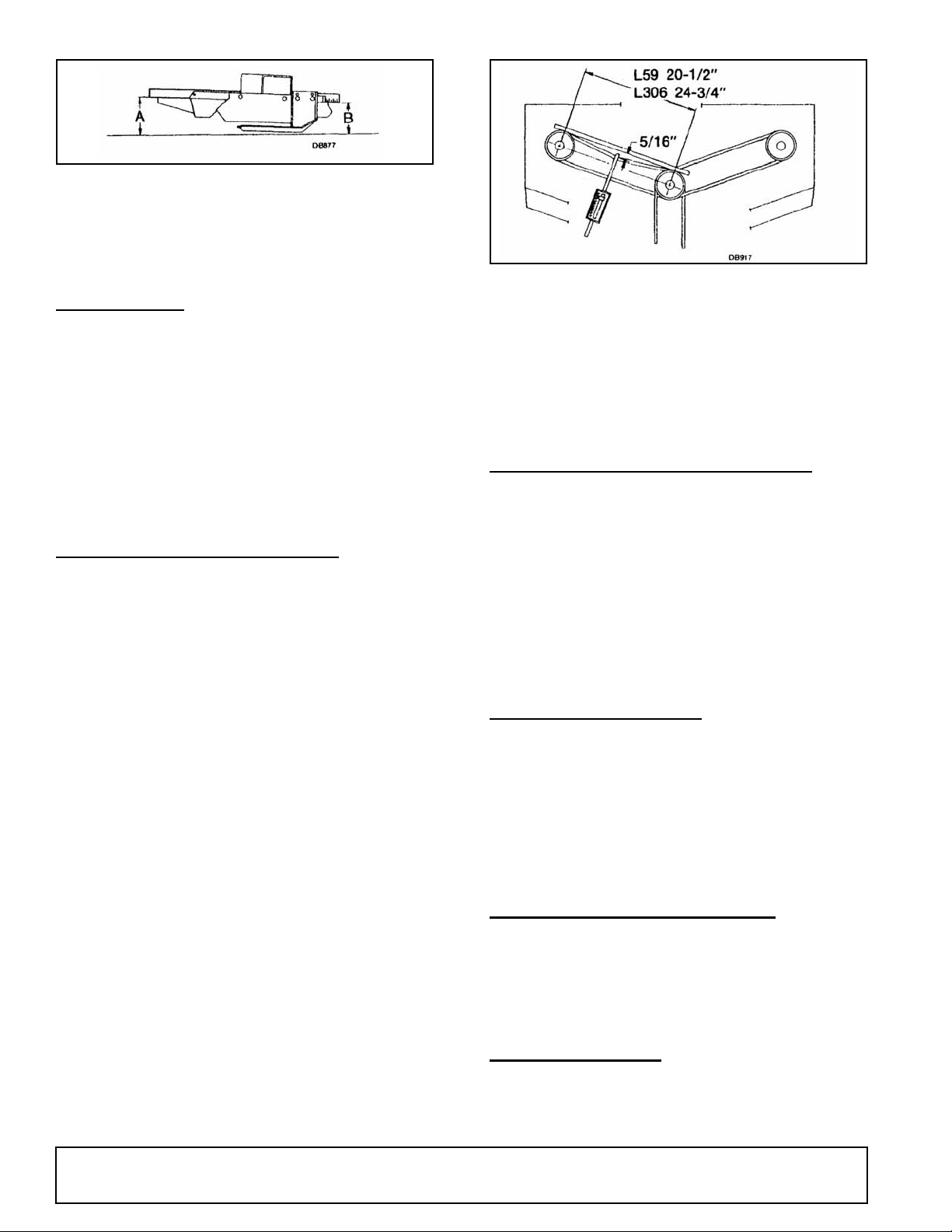

BELT TENSION (SEE FIGURE 2)

Set belt tension using a spring scale or other force

measuring d evic e. Remo ve l eft bel t shie ld. At t ach sca le

between cutter and left pulley. Apply between three

and four pounds of force. Belt deflection should measure 5/16" for normal conditions.

Te nsion may be in creased if nec essary to prevent belt

from slipping in heavy mowing conditions.

When checking tension without a force measuring

device, the belt, when properly set, should feel very

tight.

Cycle belt through at least two revolutions after any

adjustment before checking tension. These belts are

very strong and need to be adjusted very tight. Belts

are more likely to b e damaged by excessive slippage

then from being overtightened.

Figure 2. Proper Belt Tension

NOTICE

■ Alig nment must b e rechecked if it is necessar y

to move idler pulleys to get proper belt tension.

■ Tension on a new belt should be readjusted

every half hour for the first two hours and then

checked every eight hours of operation.

SIDE SHIELD & DISCHARGE CHUTE

Side shield and discharge chute are provided fo r discharge end of mower (left end on white frames and

right end on yellow frames ). Use s ide shiel d for n ormal

mowing and in areas where other persons may be

present. Use discharge chute for very heavy mowing

conditions.

NOTICE

■ Always use either side shield or discharge

chute.

OPTIONAL EQUIPMENT

Optional equipment a vailable includes casters for cutting height control, front roller to minimi ze s calpi ng, low

and extra suction blades , and a leaf m ulche r. Low suction blades are for sa ndy areas where abras ive action

could cause excessive blade wear. Extra suction

blades are design ed to lift up fragile downed grass es

for better cutting results and are also recommended for

use with Woods leaf mulcher attachment.

NOTICE

■ Belt must not rub deck or crosswise support.

Te nsion ad ju stments m ay be mad e b y movi ng the idler

pulleys up or down.

8 Operation

MOWER SPINDLE ASSEMBLIES

Mower spindle assemblies are equipped with two

tapered roller bearings. Bearing adjustment is held by a

roll pin. Adjustment should not be necessary. Repair

requires special skills and tools. You may save time

and money by using a new spindle assembly.

BLADE SERVICING

Keep blades sharp for a good mowing job. Sharpen

both ends of the blade the same amount to maintain

balance. Do not sharpen blade to a razor edge, but

29936 (Rev. 5/18/2007)

Page 9

leave a 1/16" blunt edge . Do not sharpen back si de of

blade. When replacing blades, do not substitute any

bolt for the special Ny lok blade bo lt. The Nyl ock bolt is

self-locking, meeting the non-loosening requirements

for this application.

NOTICE

■ O n mowers with white frames, the blade bolts

have left hand threads.

Both 59 and 306 mowers use cup washers under

blades. These washers wil l burn and lose their clamping force if excess slippage occurs. Inspect and replace

as necessary. The L306 mower incorpo rates a friction

clutch disc which is de signed to slip o nly when strikin g

a solid object. Should blade slip during mowing, tighten

by adding thin shim washers over bushing, between

top cup washer and blade, until blades will hold desired

load. Blade bolts should be torqued to 170 lbs-ft.

HOW TO SOLVE BELT PROBLEMS

Assemble as shown on mower decal. If not installed

correctly, more twist will result than is allowable.

Belt whip is c aus ed by be lt m isa l ig nme nt unl e ss m owe r

is driven by a rough-running or 2-cylinder engine.

Proper position of L59 and L306: Adjust mower forward and back to suc h a position tha t the rear take-u p

idlers are near the bottom of their slots when the belt

lines up with the proper groove in the center pulley and

is tight. Never run the id ler s hig h in the s lo ts as thi s will

cause misalignment.

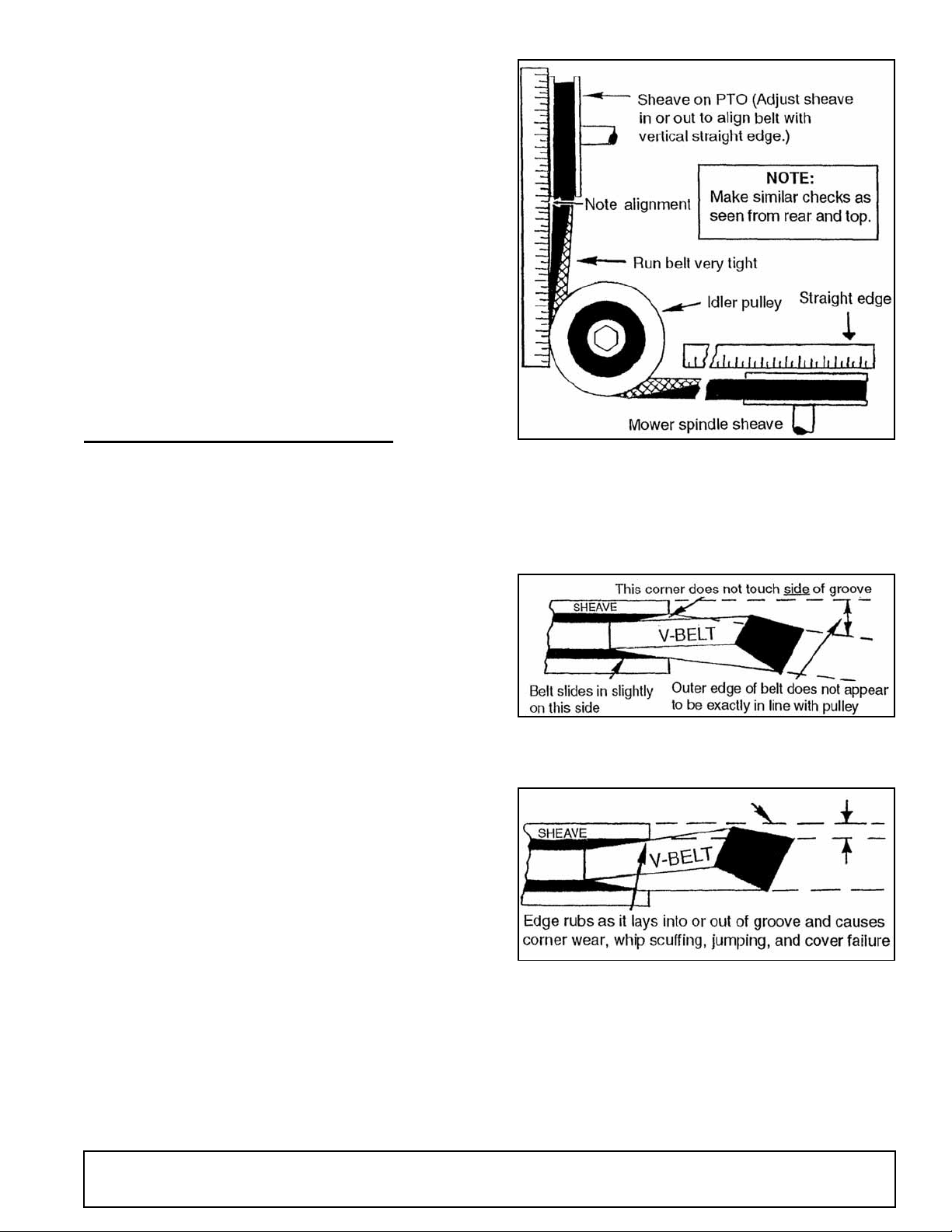

Figure 3. Use of Straight Edge (Side View)

How to Align a Twisted Belt

Right: Inside edge of belt are approximately lined up

with the sheave.

It is assumed that the mower is adjusted to run approximately level. If the front of the mower is down, the

idlers will have to be rais ed. If the bac k of the m ower is

down, the idlers will have to be down further. Belts

must be in proper alignment with sheave grooves as

shown in Figure 4 and Figure 5.

PTO pulleys must be moved in or ou t to c ause the belt

to be in alignment with the idlers.

Belt Tension: Run belts very tight. Present belt

designs are much strong er tha n we are a ccustom ed to

and will stand more tensi on. Slip ping will hea t and rui n

a belt but tension i s not h armful. You can minimize the

amount of change in belt length as mower is raised and

lowered by keeping the rear idlers adjusted to a low

position.

Figure 4

Wrong: Outer edge of belt appears to be in line.

Figure 5

29936 (Rev. 5/18/2007)

Operation 9

Page 10

ASSEMBLY

Center Shield

To allow more lift on tractors with minimum ground

clearance, such as Fords, IH LoBoy, Kubotas, Satohs,

etc., a center belt shield is not offered. Refer to

page 24. If the box of parts has a center belt shield, bolt

center belt shield bracket (34) to deck with 3/8 x 1" bolt.

Bolt center shield (10) to bolts welded in deck and

bracket (34).

To provide clearance between tractor muffler and left

belt shield on L306, see page 24.

Side Skids

Bolt skids in such a position that they will be carried

close to the ground, b ut so they do not ride c ontinual ly

on the ground when mower is operated at desired

mowing height.

On 59’s, use 3/8 x 1" heat-tr eated bolts (torque to 35

lbs-ft), lock washer and nuts. On L306’s, use 1/2 x

1-1/4" heat treated bolts, lock washers and nuts.

Front Toe Guard

Refer to page 24. Front toe guards (6) are furnished for

some mowers. When provided, bolt them to the front of

the mower, using 3/8 NC x 3/4" carriage bo lts and 3/8"

flange lock nuts. (NOTE: On 59 and L59 where casters

are installed on outer deck rails, bolt toe guards to

mower so outer ends are abo ut 2" in from end of dec k.

Otherwise, end of toe guard will be about 1/2" in from

end of deck.) End of L306 toe guard will be 3/4" in from

end of deck.

Crosswise Rear Support

Casters

If casters are used, see page 27 or page 28, except for

the L59 mower on Ford 1000, 1600, 1700, 1900, and

Satoh S650. (Se e moun ting f rame drawing in ma nual.)

L306 caster assembly will not fit on IH424, 2424, 444,

2444, 454 and 2400; John Deere 1010 & 1020 ; Deutz

2506, 3006 and other tractors with swept back front

axle as they will hit front tires. Caster wheels cannot be

used on GM4 mounting.

L306 Casters

On Ford 8N, Massey 135, Deutz 4006, IH 354, and

2300 with straight front axle, etc., the right caster

should be put on side ang le, bolting it ov er side shield

and between side angle and right skid. Left caster

should attach to short bar on deck so casters will be

inside of left front tire. Left front tr actor tire should be

moved out to clear caster wheel. On Ford 1000, Kubota

tractors, etc., both arms will bolt to the outer de ck r ai ls.

Caster wheels cannot be used on GM4 mounting.

Front Roller Assembly Instructions

Refer to page 24. O n 59 mowers, put it em (28) on left

side and item (27) on right side of mower using 3/8"

carriage bolts and nuts.

On L306 mowers, item (28) goes on right side and item

(27) on left. This will put the highest hole in brackets

rearward on 59 and the next to the hi ghest hole rearward on L306.

Assemble roller and roller rod (26) in rear holes in

brackets (27 & 28). Se cure with 3 /16" cotte r pins. Turn

roller by hand to see that it turns freely.

Refer to page 24. Ins tall bushing (16) into center h ole

in crosswise rear s upport and bolt it to back of mo wer

deck with short bar forward and offset up using 1/2 x 2"

hex head cap screw and 1/2" flange lock nut. NOTE:

On L59, L306F10-2, “S”, JD85, JD95, and GM4 mountings, a special crosswise rear support is provided. If

tractor is equipped with turf tires, use upper center hole

in crosswise supp ort, and for Ag tires, us e lower hole.

See mounting frame drawing in those manuals.

Channel Arms

Refer to page 24. Slide mower under tractor. Attach

channel arms (12 ) to mower frame using 5/8 x 1-1/2"

clevis pin and safe ty pins. Pin crosswise rear supp ort

bar (15) between channel arms and bolt center to

frame angle bracket as shown.

10 Assembly

MOUNTING FRAME ASSEMBLY

Refer to page 18.

Idler & Mounting Bracket Assembly

Remove bolts holding front end of drawbar in place.

Slide idler brac ket (6) betw een tract or wheel h ousings,

with idler slides rearward, and bolt to the center set of

holes in rear wheel housings, using holes in idler

bracket.

Use two 7/16" thick shims at eac h front hole between

the end plates and the tractor whe el housings. If necessary, also use 5/8" flat washers. Assembly using

either 1/2" or 5/8 x 2-1/4 bolts and lock washers.

Idler Assembly to Idler Bracket

Install one V-groove idler (2) to left side of front verticl e

slot by installing three 5/ 8" flat washers between idler

29936 (Rev. 5/18/2007)

Page 11

and idler bracket. Install 5/8 x 2-1/2 carriage bolt

through slot and idler , and secure with 5/8" nut and lock

washer.

Install a 5/8 x 3" bolt through second idler. Put these

5/8" flat washers over bolt, and install assembly to right

side of rear vertical slot in idler bracket. Secure with a

5/8" flat washer and nut.

After drive belt has been installed, install rear belt

shield (19) ov er bolt installed in rear id ler and secure

with another 5/8" nut and two 5/8" flat washers.

longer chain ( 17), and sec ure by in stalling 3/1 6" sa fety

pin (16) through end of link in chain (15).

Adjust chain s so t he mow er r ais es le vel w itho ut pull in g

sideways or hitting rear tires. Also adjust chain so

mower does not hit bo ttom of t ractor or tires when ful ly

raised.

Check to make sure the lift triangle does not hit the

tractor starter. If it does, use washers to sh im lift triangle or lift support frame away from tractor.

If manual height adjustment is used, refer to page 22.

Drive Sheave

Remove paint from bo re of drive sheave. Install lar ge

drive sheave onto tractor belt pulley s haft using tractor

key and nut. A flat washer is provided to be installed

between nut and sheave. If your trac tor has a tapered

shaft which is too small for this sheav e (made prior to

1939), it will be necessa ry to install a late model belt

pulley shaft (AC part 208959) or to build up the old

shaft with shims or weld to fit.

Belt Assembly and Adjustment

Slide mower under tractor and pin push channel to idler

bracket with 5/8 x 1-3/4 clevi s pi n. Put bel t on, see Bel t

Assembly and Adjustment. Make major adjustments by

sliding mower fore and aft using 6 holes in channel arm

as required. Make minor adjustments with idlers.

Lift Assembly

Attach the lift frame (11) to tractor using upper right

hand clutch housing hole for front end of the bracket

and 1/2" vertical hole i n square tubing on tractor foot

rest for the rear attaching point.

T rac tor Whe el Adjustment

On model “B” tractors, the right tire may be fully

extended and the mow er will cut bey ond it, but th e left

rear tire must be moved in if the mower is to cut clear.

For model “C” tractors, the right tir e must be pu t within

four inches of its most inward position for the mower to

cut beyond the tire track. With the left tire in its most

inward position, the mower will still not quite cut

beyond the tire track.

Belt Assembly and Adjustment

Models used on: 59C, L59, and L306 model AC52,

AC54, BMC, B-25, D, D10-D12, F, F10, H3, GM2,

GM4, JD85, JD95, JM, K17, K2 2, K28, KD, KL, K210,

K260, MF, M25, S, S55, VC, U, etc.

First put belt on the bottom groove, right hand side of

the center sheave. Then thread it to left, around the left

hand sheave.

For hydraulic lift, assemble triangular plate (12) onto lift

frame using 5/8 x 2- 1/4 b olt ( 39), bush ing (13) , two flat

washers, and lock nut with forked end rearward and

down.

Remove cylinder from rear of trac tor, remove hose and

install longer hose provided, using 45° swivel a daptor

between valve and hose. In stall 90° swi vel en d of h os e

in cylinder and st raight end in 45° adaptor previous ly

installed.

Install cylinder onto attaching frame on ins ide of frame

at the threaded hole using a 5/8 x 3" bolt. Put bolt

through cylinder, then run a nut up on the bolt, screw

bolt through the plate, install a nut on outside and

tighten. Use a 7/16" c levis pin and cotter pin to attach

the cylinder to the triangular plate.

Attach 33-link chain (17) to keyhole lug on mower deck

and secure with pla stic c aplug (14). A ttach 7-li nk ch ain

(15) to triangular plate with 3/8 x 1-1/4 " bolt and flange

lock nut. Connect the cha ins together by installing the

lower end of 7-link chain (15) through the middle of

29936 (Rev. 5/18/2007)

Figure 6.

Assembly 11

Page 12

Bring the belt back across the center sheave in the

center groove over to the right outside sheave.

Figure 7.

Then thread it back across the front of the center

sheave in the top groove.

leave a 1/4 twist in th e section of belt extending fro m

the right V-idler to lower groove of the center mower

sheave.

Adjust the mower to p roper cutting heig ht. The front of

the mower should be slightly lower than the rea r of the

best cutting and least power requirement.

Idler Adjustment: Make minor belt adjustment with

idlers but keep left idler about 1" above being in line

with the groove in which the belt runs on the center

sheave of the mower and right idler about 1" below.

Move mower fore and aft for major adjustments. On

L306K210, K260, S, and F10, use bel t takeup id lers on

mower deck for major adjustment.

LEAF MULCHER (OPTIONAL)

1. Turn the mower upside down on saw horses. If

mower has a bolt-on front shie ld, adjust shield all

the way down in l ong slots. Remove side sh ields.

Leave side skids on. If optional front roller has

been installed, it must be removed.

2. On mowers with bent-down front frame, remove

center baffle and drill three 7/16 diameter holes

(two on 59’s) in front of mower at the diameter

shown on drawing.

3. Attach slotted angles (2) or (3 & 4) to lea f mulcher

as shown on drawing.

Figure 8.

Proper Twist: The belt then follows with a 3/4 twist

back under the left V-idler, up over the drive sheave

and back down under the right idler pulley. This will

4. Place leaf mulc her over blades on mower. Attach

angles (2) or ( 3 & 4) and mower side shiel d to s id e

frame angle on mower. All 59 mowers and L306

mowers with bolt-on front shield will use front

shield hole to attach angles (2) or (3 & 4). L306

mowers with bent-down front frame will use 2nd

hole behind skid to attach angl es (3 & 4). Bolt side

shields to mower using 3/8 flat washers for spacers.

5. On mowers with bolt-on front shield, bolt front of

leaf mulcher to bottom of slots in front shield with

3/8 x 1" bolts and flat washers. On mowers with

bent-down front frame, bol t leaf mulcher to inside

of mower in holes drilled in front frame using 3/8 x

1" bolts on L306, and on L59’s use 3/8 x 1-1/2

bolts and 5/8 long pipe spacers between leaf

mulcher and mower. On some mo wers where 5/8"

pipe may be too long, substitute 3/8 flat washers.

6. Drill 7/16 holes in rear of mower deck through

holes in leaf mulcher rear plates and bolt rear of

leaf mulcher to deck using 3/8 x 1" bolts.

7. Tighten all bolts securely. Turn each blade individually inside the l eaf mulc her to see that it clears th e

leaf mulcher ri ngs. If necessary, the rings may be

re-shaped with a hammer to clear the le af mulcher

rings.

12 Assembly

29936 (Rev. 5/18/2007)

Page 13

Figure 9. L59-AC/C & L306-AC/C Mounting Frame Assembly Photo

29936 (Rev. 5/18/2007)

Assembly 13

Page 14

Figure 10. L59-AC/C & L306-AC/C Mounting Frame Assembly Photo

14 Assembly

29936 (Rev. 5/18/2007)

Page 15

Figure 11. L59-AC/B&C & L306-AC/B&C Hydraulic Lift Assembly Photo

29936 (Rev. 5/18/2007)

Assembly 15

Page 16

Figure 12. L59-AC/B&C & L306-AC/B&C Manual Lift Assembly Photo

16 Assembly

29936 (Rev. 5/18/2007)

Page 17

NOTES

29936 (Rev. 5/18/2007)

Assembly 17

Page 18

L59-AC/B & C & L306-AC/B & C Mounting Frame

18 Parts

29936 (Rev. 5/18/2007)

Page 19

L59-AC/B & C & L306-AC/B & C Mounting Frame

REF PART QTY DESCRIPTION

10

11

12

13

14

15

16

17

18

19

1

1

2

3

4

5

6

6

7

8

9

3652

10859

4336

4335

6095

7451

9201

9376

7453

----7444

7443

10750

7445

1791

18336

6911

18270 *

4154

13006

25558

V-belt, special W188 (for L59) -or-

1

V-belt, special W205 (for L306)

1

V-idler sheave with bearing

2

V-idler sheave less bearing

2

Bearing

2

Drive sheave 8B P.D.

1

Idler and mounting frame to fit Allis

1

“C” -or-

Idler and mounting frame to fit Allis

1

“B”

5/8 x 1-3/8 x 7/16 Thick flat washer

4

Manual lift (see page 22)

-

1/4 x 1/4 x 45° Swivel street ell (opt)

1

1/4 x 42 One wire braid hyd hos e

1

(opt)

Lift support frame

1

Hyd lift triangular assembly (opt)

1

5/8 x 1 x 9/16 Hard steel sleeve

1

Plastic caplug

2

7 Link chain

1

3/16 Safety pin

1

33 Link 3/0 Chain

1

Lift holder spring (u sed on L306 only)

1

Rear belt shield

1

REF PART QTY DESCRIPTION

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

1256 * 3/16 x 1 Cotter pin

7468 7/16 x 1-3/4 Clevis pin

25474 * 1/2 NC x 2-1/4 HHCS GR5 (used on

older Allis “B”)

3489 * 1/2 NC x 3 HHCS GR5

855 * 1/2 Lock washer

1093 * 1/2 NC Hex nut

6268 * 5/8 NC x 1-1/4 HHCS GR5 (used on

L59’s)

4548 * 5/8 NC x 1-3/4 HHCS GR5 (used on

L306’s)

12274 * 5/8 NC x 2-1/4 HHCS GR5

5836 * 5/8 NC x 2-1/2 Carriage bolts

34473 * 5/8 NC x 3 HHCS GR5

1286 * 5/8 Lock washer

692 * 5/8 Flat washer

230 * 5/8 NC Hex nut

6239 * 5/8 NC Deformed thread hex nut

1598 * 5/8 NC Hex jam nut

832 1 x 2-1/2 x 7 Washer

12169 * 3/8 NC x 1-1/4 HHCS GR5

14350 * 3/8 NC Flange lock nut

Standard hardware, obtain locally

*

29936 (Rev. 5/18/2007)

Parts 19

Page 20

REF PART QTY DESCRIPTION

1

2

3

4

5

6

7

8

9

10

10

5081KT

11

26875KT †

11

23825KT

11

25997KT †

11

13404KT

11

28328KT †

11

1015826

12

13

14

14

15

15

16

17

18

19

20

22

22

23

3761

5089

4114

4115

4107

4117

4106

1972

28897

4110

13409

692

10635

13401

10718

24184

13402

13403

13405

12313

13451

4902

2974

3490 ‡

Spindle assembly (for left hand rota-

1

tion)

Seal

2

Sleeve

1

Sel-lock pin

1

Bearing cone

2

Housing with cups

1

Bearing cup

2

Grease fitting

1

Spindle shaft with left hand thread

1

Shoulder washer 2-1/4 diameter (for

1

L59 & FM48) -or-

Shoulder washer 3 diameter (for

1

L306)

16-13/16 medium suction blade (std

1

on RM48 and FM48) -or-

16-13/16 Low suct ion bl ade (optio nal

1

on RM48) -or-

20-1/4 Medium suction blade ( stan-

1

dard on L59) -or-

20-1/4 Low su ction blade (optional

1

on L59) -or-

24-1/2 Blade (Std on L306) -or-

1

24-1/2 Low su ction blade (optional

1

on L306)

Blade bolt and washer kit (For FM48

1

& L59)

5/8 Flat washer

1

5/8 ID Cup washer (for FM48 & L59)

2

1" ID x 2-3/4 OD Cup washer (For

2

L306)

Special 1-1/2 Long bolt (for FM48 &

1

L59) -or-

Special 2-3/8 Long bolt (for L306)

1

Clutch disk 3" diameter

1

Blade stop

1

Shim washer

1

5/8 ID x 1" OD x 13/16 sleeve, hear

1

treated

Special heat treated washer

1

Spind le lo ck wre nc h (us ed on FM4 8)

1

-or-

Spindle lock wrench (used on L59 &

1

L306)

Blade bolt wrench

1

Spindles and Blades

NOTE: Repair shaft 9 and repair sleev e 3 do not have a

hole drilled in them for pin 4. After new parts have been

assembled and prop er bearing adju stment obtaine d, drill

a 3/16" diameter hole throu gh sleeve and shaft. Drive in

Sel-lock pin to hold proper bearing adjustment.

NOTE: Left hand blade r otation for “ L” series. (See page

_ for right hand rotation 59’s and yellow RM48’s.)

For maximum suction for diffi cult

*

mowing.

For use in sandy areas or where high

†

abrasive wear occurs on fin of standard blade.

Used on mower prior to 1964.

‡

20 Parts

29936 (Rev. 5/18/2007)

Page 21

Lift Chain Hook-Up Table

Mower Model

Number

42A, HB

L42AC, B&C

42C

L42U

L42VAC

L42VC

L59A, 59HB,

& L306A

59HC

L59AC, B&C

L306AC, B&C

59C

L59U, L306U

L59VAC,

L306VAC

L59VC,

L306VC

Chains Used Lift Chain Attach Plt Holes Used for Spring

Part No No Used Description

4154 1 33 Link Chain

4154 1 33 Link Chain

4154 1 33 Link Chain

17477 1 84" Twisted

cut off excess

6673 1 78" Twisted

4154 1 33 Link Chain

4154

18264

18264 3 13 Link Chain

4154

18264

4154 2 33 Link Chain

17477

18264

17477 1 84" Twisted

4154

18264

1

1

1

1

1

1

1

1

33 Link Chain

13 Link Chain

33 Link Chain

13 Link Chain

84" Twisted

13 Link Chain

33 Link Chain

13 Link Chain

To Lift

Lever Hole

B

B

B

B

B

B

A or B

Opt

A or B

Opt

A

A

A

B

B

B

B

B

B

Special

Notes

T o Ho les in

Mower

H&G O See note 4 (10)

GPH(5)

L&M See note 8 Z (8)

HTH

HRJ

GSJ

E

E

E N C&D (1, 3, 8, 9)

C&D

C&D

C&D See note 8 See note 1,3 (8)

C&D

C&D

E

U

E

U

Upper End to

Hole Let-

tered:

N

N

Q

Q

T

T

R

R

S

S

Lower End to

Hole Let-

tered:

C&D

C&D

E

E

See note 3

See note 3

E

E

C&D

C&D

(1, 3, 8, 10)

(1, 3, 8, 10)

(1, 3, 8, 9)

(5)

(5)

(1)

(7)

(7)

(1, 3, 8)

(7)

Special Notes (Refer to numbers in parentheses in above table)

1. Hook one 13-link chain between holes “C” & “D”.

2. Fasten one 10-link and one 7-link chain together.

3. Hook lower end of spring in crotch chain.

4. Hook spring into chain just above hole “H”.

5. Clamp offset end spring under flat washer on out-of-way side of bracket, where indicated.

6. Fasten two 10-link chains together for lift chain.

7. O n L306 models, u se heavy spring f urnished with m ower rather than lighter spring furn ished with manua l lift kit.

Hook to a point on tractor so most of mower weight is held by spring which will allow lift to work easier.

8. Hook upper end of spring over bushing (4). Bolt lift chain to lift lever with 3/8 x 2 bolt and nut.

9. Bolt two 13-link chains together for lift chain.

10. On IH “A” lift lever (3) goes ins ide st eering r od. On IH “B” it g oes outside s teeri ng rod. For IH "B " shim at tachmen t

plate (10) out away from tr actor us in g spacer (11), four washers (56) and b ol ts (38 ). Lift le ver may have to be bent

out slightly to clear steering rod.

29936 (Rev. 5/18/2007)

Parts 21

Page 22

Manual Height Adjustment

22 Parts

29936 (Rev. 5/18/2007)

Page 23

Manual Height Adjustment

REF PART QTY DESCRIPTION

10

11

12

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

-----

4155

10693

484

10706

10701

3597 *

10699

10702

9045 NS

10708

10707

13006

10750

409

1256 *

10735

9046

-----

-----

-----

11445

11446

11489

13450

Chain (see chart for chain used on

-

your mounting)

1/4 Cold shut repair link

2-3

Manual height adjustment lever

1

assembly

5/8 x 1 x 7/16 HT Sleeve

1-2

3-3/8 Long compression spring

1

Manual height adjustment cli p

1

1/8 x 1 Cotter pin

1

Manual height adjustment rod

1

Manual lift sector assembly

1

IHC Manual lift att a ch ment plate

1

(includes hardware & spacer)

IHC Manual height adjustment

1

spacer (used on IHC “B” & “C”)

8-1/8 Long extension spring (used on

1

42’s & 59’s) -or-

13-1/4 Long extension spring (used

1

on L306’s)

Allis Chalmers “B” & “C” lift mounting

1

frame assembly

1/2 x 2 Clevis pin

1

3/16 x 1 Cotter pin

1

Lift attachment assembly

1

Case VAC manual lift moun ting

1

Case VC lift mounting lug (no longer

1

available)

Case VC manual lift bracket (no

1

longer available)

Case VC manual lift weldment (no

1

longer available)

Manual lift radius bracket

1

Manual lift bar

1

John Deere “B” offset manual lift

1

brace

1/4 Keystone connecting link

1

REF PART QTY DESCRIPTION

17410

25

18336

26

30

31

32

32

33

34

35

36

37

38

39

40

41

42

43

45

46

47

48

49

50

51

52

53

54

55

56

2457 * 1/4 NC x 3/4 HHCS GR5

6128 * 1/4 NC Hex lock nut

12735 * 1/2 NC x 1-3/4 Carriage bolt GR5

10284 * 1/2 NC x 2 Carriage bolt

3489 * 1/2 NC x 3 HHCS GR5

855 * 1/2 Extra-heavy lock washer

1093 * 1/2 NC Heavy hex nut

3598 * 1/2 SAE Flat washer

6268 * 5/8 NC x 1-1/2 HHCS GR5

12274 * 5/8 NC x 2-1/4 HHCS GR5

11854 * 5/8 NC x 2-1/2 HHCS GR8

986 * 5/8 x 2-3/4 HHCS GR5

1286 * 5/8 Heavy lock washer

230 * 5/8 NC Hex nut

692 * 5/8 Standard flat washer

24576 * 1/2 NC x 1-3/4 HHCS GR5

7832 * 5/8 NC x 1-1/2 HHCS GR5

4616 3/4 NC x 1-1/2 HHCS GR5

2522 * 3/4 Standard lock washer

1257 * 3/4 Standard flat washer

902 * 5/8 NC x 2 HHCS GR5

1450 * 3/4 NC Hex nut

3231 * 3/8 NC x 2 HHCS GR5

565 * 3/8 Standard flat washer

838 * 3/8 Standard lock washer

835 * 3/8 NC Hex nut, plated

25728 5/8 x 2 x 1/2 Flat washer (for IH “B”

IH Cub manual lift mounting plate

1

Caplug, 1-1/16 - 121D SAE thread

2+

-or-

only)

Obtain locally

*

29936 (Rev. 5/18/2007)

Parts 23

Page 24

59, L59, & L306 Mower Frame Assembly

24 Parts

29936 (Rev. 5/18/2007)

Page 25

REF

1

2

3

4

4

5

59, L59, & L306 Mower Frame Assembly

Model

Red &

Yellow

Mowers

25513 25511 24189 13426

25512 25510 24188 13426

26559 25997 28328 28328

26520 26521 26522 -----

Model

L59

White

Mowers

9700 9701 9702 9702

6950

23825

-or-

-or-

L306

Mowers

1976 &

Later

13404

-or-

Mowers

Prior to

L306

1976 QTY DESCRIPTION

Frame only

1

Left side shield

1

Right side shield

1

13404

-or-

Blade, medium suction (std.)

3

Blade, low suction (opt)

3

Side discharge chute

1

(a) For all 59, L59 models except: GM2, LB,

F10, F13, F15, H284, JD85, JD95, K17,

K18, K210, K260, S, S55, S-BL, TB, YM;

For all L306 models except

: AC54, GM2,

GM4, H284, JD85, JD95, K22, K24, K210,

K260 & S-BL.

(b) For use on 59, L59 models

: LB, K17,

K18, K210, K260, S55 , S-BL, TB, YM; For

use on L306 models: AC54, GM2, K22,

K24, K210, K260 & S-BL.

(c) For F10, F13, F15, GM4, H284, JD85,

JD95, S; See mounting frame assembly

drawing for items 12 & 15.

REF

6

7

8

9

10

10

11

11

12

12

13

14

15

15

16

17

18

18

19

20

21

22

23

23

24

59 & L59

3-Spindle

5’ Swath

3-Spindle

6’ Swath QTY DESCRIPTION

26516 25623

----- -----

4141 13428

25506 25528

25555 25555

4130 4130

25507 25529

----- 25547

13314 23942

18241 23928

4097 4097

410 410

3485 3485

18245 18245

3504 3504

----- -----

5753 13421

52311 52311

6126 13417

4227 4227

3885 3885 *

4226 12622

----- -----

----- -----

4142 13429

L306

Front toe guard

2

Casters (opt) (see page 27)

1pr

Right side skid

1

Right belt shield

1

Center belt shiel d (use wh en

1

front of mower is bent down)

-or-

Center belt shiel d (use wh en

1

front shield is bolted on

mower)

Left belt shield -or-

1

L306 Left belt shield, short

1

Channel arms (see a & b)

2

-or-

Channel arms (see b & c)

2

5/8 x 1-1/2 Clevis pin

4

5/8 x 1-3/4 Clevis pin

2

Crosswise rear support (se e

1

a & c) -or-

Crosswise rear support ( see

1

b & c)

1/2 x 5/8 x 1-1/16 Sleeve, HT

1

Leaf mulcher (opt)( see pg

1

26)

Complete decal set -or-

1

French safety decal set

1

Sheave (3-groove)

1

H3/4 St bushing with bolts

3

3/16 x 3/16 x 1-1/4 Key

3

Sheave (single-groove)

2

Spindle, blade & wrench kit

3

(white, left-hand blade rotation) (see pg 20) -or-

Spindle, blade & wrench kit

3

(red or yellow, right hand

blade rotation) (see pg 20)

Left side skid

1

59 & L59

3-Spindle

REF

5’ Swath

25

26

27

28

29

30

31

32

33

34

REF PART DESCRIPTION

40

41

42

43

44

45

24650 24650

24583 24583

24587 24587

24586 24586

5818 -----

25508 ----- †

25509 25533

25532 25532

25531 25530

25557 25557

2688 * 1/8 Safety pin

1256 * 3/16 x 1 Cotter pin

10378 * 1/4 NC x 1 HHCS GR5

1985 * 1/4 Standard lock washer

24597 *3/8 NC x 3/4 Carriage bolt

6697 * 3/8 NC x 1 Carriage bolt

46

47

48

14350 3/8 NC Flange hex lock nut

49

50

51

52

4119 1/2 NF x 1 HHCS GR5

6100 * 1/2 NC x 1-1/4 HHCS GR5

3699 * 1/2 NC x 2 HHCS GR5

53

54

55

1093 1/2 NC Heavy hex nut

11900 1/2 NC Flange hex lock nut

L306

3-Spindle

6’ Swath QTY DESCRIPTION

Front roller complete (opt)

1

Front roller, bearing & rod

1

Left front roller bracket

1

Right front roller bracket

1

Front shield (for mowers

1

prior to 1976)

Front corne r baffle

1

Center baffle

1

Rear mounting angle

1

Front mounting lug

1

Center belt shield bracket

1

839 * 3/8 NC x 1 HHCS GR5

838 * 3/8 Standard lock washer

835 * 3/8 NC Hex nut, plated

855 * 1/2 Extra-heavy lock washer

* Standard hardware, obtain locally

† For mowers sold after 1976. Mower frame

will have front of mower formed down.

Before this time, mower ha d a bolt-o n front

shield.

29936 (Rev. 5/18/2007)

Parts 25

Page 26

REF PART DESCRIPTION

59 & L306 Leaf Mulcher

A

A

1

2

3

4

5

7

8

9

10

11

Operation: To do a satisfactory job of leaf

mulching, the mower should be adjusted so

blades are about

1-1/2" above ground and the back of the

mower slightly lower than the front. The

mower should be run at ful l rpm w ith tra ctor

in first or second gear.

7080 Model 59 Leaf mulcher -or-

13482 Model L306 Leaf mulcher

-----

7076 Angle lug (for model 59)

13224 Right attachment bracket (for model

13225 Left attachment bracket (for model

23218 3/8 Schedule 40 pipe 5/8 long (for

839 * 3/8 NC x 1 HHCS GR5

976 * 3/8 NC x 1-1/2 HHCS GR5

565 * 3/8 Flat washer

838 * 3/8 Lock washer

835 * 3/8 NC Hex nut

leaf mulcher weldment

N/S

L306)

L306)

use only on 59 w/bent down frt frm)

* Standard hardware, obtain locally

26 Parts

29936 (Rev. 5/18/2007)

Page 27

REF PART QTY DESCRIPTION

1

2

3

3

4

4

5

7

7

8

8

9

10

11

12

13

14

15

15

16

16

16

16

17

18

29750

12243

29746 a

6761 a

29747 a

18424 a

19703

----- *

195 *

21020

1285 *

12296 *

12169 *

838 *

835 *

765 *

23479

29368 c

12242 c

29375 b

4228 b

2905 b

65578 b

22240

4181

59 & L59 Right and left caster bun dle

1

Caster yoke (includes bolt, nut & 2

1

sleeves)

Right caster arm asy, 13-5/32" long

1

-or-

Right caster arm, 16-5/32" long

1

Left caster arm asy, 13-5/32" long

1

-or-

Left caster arm, 16-5/32" long

1

8" HD Caster wheel with sleeve

1

Straigh t 1/4 self-tapping grea se fitting

1

(for steel wheel) -or-

Straight 1/8P thread grease fitting

1

(for polyethylene wheel)

1/4 x 1-1/4 Spirol pin -or-

1

1/4 x 1-1/2 Co tter pin

1

1/4 - 28 Str aight grease fit ting, 15/32"

1

long

3/8 NC x 1-1/4 HHCS GR5

2

3/8 Standard lock washer

2

3/8 NC Hex nut, plated

2

1/2 NC Hex lock nut

1

1/2 NC x 5 HHCS GR5

1

1/2 x 3/4 OD x 3-3/8 Sleeve -or-

1

17 GA Wall x 5/8 OD x 3-3/8 tube

1

3/4 Bore flanged bearing for 1-1/8

2

hole -or-

5/8 Bore flanged bearing for 1-3/8

2

hole -or-

5/8 Bore flanged bearing for 1-1/8

2

-or-

3/4 Bore x 1.385 flanged wheel bear-

2

ing with groove

3/4 x 1-3/16 x 10 GA Washer

2

25/32 x 1 x 1/2 Heat-treated sleeve

2

59 Casters

*

29936 (Rev. 5/18/2007)

Standard hardware, obtain locally

Parts 27

Page 28

REF PART QTY DESCRIPTION

A

1

2

3

4

5

6

7

8

8

9

9

10

11

12

13

14

15

16

16

17

17

17

17

24095

13400

15638

23857

13435

13444

13444

1972 *

21020

1285 *

----- *

195 *

976 *

838 *

835 *

11900 *

24576

23479

29368 c

12242 c

29375 b

4228 b

2905 b

65578 b

L306 Caster assembly bundle

-

Caster assembly

1

10" Caster wheel with sleeve

1

Caster wheel yoke assembly

1

Caster arm assembly

1

Left caster adjustment bracket

1

Right caster adjustment brack et

1

1/4 - 28 Straig ht thread grease fit ting,

1

15/32" L

1/4 x 1-1/4 Spirol pin -or-

1

1/4 x 1-1/2 Cotter pin

1

Straight 1/4 self-t apping greas e fitting

1

(for steel wheel) -or-

Straight 1/8P thread grease fitting

1

(for polyethylene wheel)

3/8 NC x 1-1/2 HHCS GR5

1

3/8 Standard lock washer

1

3/8 NC Hex nu t, plated

1

1/2 NC Flanged hex lock nut

3

1/2 NC x 1-3/4 HHCS GR5

2

1/2 NC x 5 HHCS GR5

1

1/2 x 3/4 OD x 3-3/8 Sleeve, HT -or-

1

17 GA Wall x 5/8 OD x 3-3/8 tube

1

3/4 Bore flanged bearing for 1-1/8

2

hole -or-

5/8 Bore flanged bearing for 1-3/8

2

hole -or-

5/8 Bore flanged bearing for 1-1/8

2

hole -or-

3/4 Bore x 1.385 flanged wheel bear-

2

ing with groove

L306 Casters

Standard hardware, obtain locally

*

For proper caster arm identification,

a

refer to dimension “L” as shown on

drawing. The caster arms may be

used on either side to obtain best fit.

Measure old bearing.

b

Measure outside diameter of old

c

sleeve.

28 Parts

29936 (Rev. 5/18/2007)

Page 29

BOLT TORQUE CHART

Always tighten hardware to these values unless a different torque value or tightening procedure is listed for a specific

application.

Fasteners must always be replaced with the same grade as specified in the manual parts list.

Always use the proper tool for tightening hardware: SAE for SAE hardware and Metric for metric hardware.

Make sure fastener threads are clean and you start thread engagement properly.

All torque values are given to specifications used on hardware defined by SAE J1701 MAR 99 & J1701M JUL 96.

SAE SERIES

A

A

Diameter

(Inches)

1/4" 7/16" 6 8 10 13 14 18

5/16"1/2"121719262737

3/8"9/16"233135474967

7/16"5/8"3648557578106

1/2" 3/4" 55 75 85 115 120 163

9/16" 13/16" 78 106 121 164 171 232

5/8" 15/16" 110 149 170 230 240 325

3/4" 1-1/8" 192 261 297 403 420 569

7/8" 1-5/16" 306 416 474 642 669 907

1" 1-1/2" 467 634 722 979 1020 1383

TORQUE

CHART

Wrench

Size

SAE Grade 2

(No Dashes)

SAE 2 SAE 5 SAE 8

lbs-ft N-m lbs-ft N-m lbs-ft N-m

METRIC SERIES

A

TORQUE

CHART

COARSE THREAD FIN E THREAD

A A

Diameter &

Thread Pitch

(Millimeters)

6 x 1.0 10 mm 8 6 11 8 8 6 11 8 6 x 1.0

8 x 1.25 13 mm 20 15 27 20 21 16 29 22 8 x 1.0

10 x 1.5 16 mm 39 29 54 40 41 30 57 42 10 x 1.25

12 x 1.75 18 mm 68 50 94 70 75 55 103 76 12 x 1.25

14 x 2.0 21 mm 109 80 151 111 118 87 163 120 14 x 1.5

16 x 2.0 24 mm 169 125 234 173 181 133 250 184 16 x 1.5

18 x 2.5 27 mm 234 172 323 239 263 194 363 268 18 x 1.5

20 x 2.5 30 mm 330 244 457 337 367 270 507 374 20 x 1.5

22 x 2.5 34 mm 451 332 623 460 495 365 684 505 22 x 1.5

24 x 3.0 36 mm 571 421 790 583 623 459 861 635 24 x 2.0

30 x 3.0 46 mm 1175 867 1626 1199 1258 928 1740 1283 30 x 2.0

Wrench

Size

N-m lbs-ft N-m lbs-ft N-m lbs-ft N-m lbs-ft

MARKING ON HEAD MARKING ON HEAD

Metric 8.8 Metric 10.9 Metric 8.8 Metric 10.9

SAE Bolt Head

Identification

8.8

Metric

Grade 8.8

SAE Grade 5

(3 Radial Dashes)

MARKING ON HEAD

Metric Bolt Head

Identification

SAE Grade 8

(6 Radial Dashes)

10.9

Metric

Grade 10.9

Diameter &

Thread Pitch

(Millimeters)

Typical Washer

Installations

Lock W ash er

Bolt

Bolt Torque & Size Charts (Rev. 3/28/2007)

Flat Washer

8/9/00

Appendix 29

Page 30

BOLT SIZE CHART

NOTE: Chart shows bolt thread sizes and corresponding head (wrench) sizes for standard SAE and metric bolts.

SAE Bolt Thread Sizes

5/16 3/8 1/2 5/8 3/4 7/8

IN 1 7

2

34

5

6

MM 25 50 75 100 125 150 175

Metric Bolt Thread Sizes

8MM 18MM14MM12MM10MM 16MM

ABBREVIATIONS

AG.............................................................. Agriculture

ASABE ....................American Society of Agricultural &

Biological Engineers (formerly ASAE)

ASAE ... . ... American Society of Agricultural Engineers

ATF................................Automatic Transmission Fluid

BSPP.............................British Standard Pipe Parallel

BSPTM................ British Standard Pi pe Tapered Male

CV ....................................................Constant Velocity

CCW.............................................. Counter-Clockwise

CW .............................................................. Clockwise

F.......................................................................Female

FT................... ........................................... Full Thread

GA.....................................................................Gauge

GR (5, etc.)........................................... Grade (5, etc.)

HHCS........................................Hex Head Cap Screw

HT ...........................................................Heat-Treated

JIC.................Joint Industry Council 37° Degree Flare

LH.................................................................Left Hand

LT ...........................................................................Left

m ........................................................................Meter

mm ...............................................................Millimeter

M ..........................................................................Male

MPa ........................................................Mega Pascal

N......................................................................Newton

NC...................................................... National Coarse

NF...........................................................National Fine

NPSM .................... National Pipe Straight Mechanical

NPT...........................................National Pipe Tapered

NPT SWF......... National Pipe Tape red Swivel Female

ORBM...........................................O-Ring Boss - Male

P ..........................................................................Pitch

PBY.......................................................Power-Beyond

psi.........................................Pounds per Square Inch

PTO............. .........................................Power Take Off

QD ...................................................Quick Disconnect

RH..............................................................Right Hand

ROPS........................... Roll-Over Protective Structure

RPM........................................Revolutions Per Minute

RT........................................................................Right

SAE..........................Society of Automotive Engineers

UNC.....................................................U nified Coarse

UNF ..........................................................Unified Fine

UNS.....................................................Unified Special

30 Appendix

Bolt Torque & Size Charts (Rev. 3/28/2007)

Page 31

WARRANTY

(All Models Except Mow’n MachineTM Zero-Turn Mowers and Woods BoundaryTM Utility Vehicles)

Please Enter Information B elow and Save for Future R eference.

Date Purchased: ____________________________ From (Dealer): ___________________________________________

Model Number: _ ___________________ ________ Serial Num ber:__________________________________________ _

Woods Equipment Company (“WOODS”) warrants t his produc t to be free fro m defect in material and workm anship. Exc ept as oth erwise set

forth below, the duration of this Wa rranty shall be for TWELVE (12) MONTHS COMMENCING ON THE DATE OF DELIVERY OF THE

PRODUCT TO THE ORIGINAL PURCHASER.

Woods backhoe models BH70-X, BH80- X , and BH90-X are warranted for two ( 2) years from the date of delivery to the orig in al purchaser.

The warranty peri ods for specific parts or condi t ions are listed below:

Part or

Condition

Warranted

BW1260, BW1800 8 years

BB48X, BB60X, BB72X, BB84X, BB600X, BB720X, BB840X, BB6000X,

BB7200X, BB840 0X, D S1260, DSO1260, DS1440, TS1680, BW126-2, BW180-2

Gearbox

components

Blade spindles

Rust-through

Under no circumstances will this Warranty apply in the event that the product, in the good faith opinion of WOODS, has been subjected to

improper operat ion, improper maintenance, misu se, or an accident. This Warranty does not apply in the event that the product has been

materially modified or repaired by someone other than WOODS, a WOODS authorized dealer or distributor, and/or a WOODS authorized

service center. This Warranty does not cover normal wear or tear, or normal maintenance items. This Warranty also does not cover repair s ma de

with parts other than those obtainable through WOODS.

This W arranty is extended solely to th e original purchaser of the product. Should th e original purchaser sell or other wise transfer this product to

a third party, this Warranty does not transfer to the third party purchaser in any way. There are no third party beneficiaries of th is Warranty.

WOODS makes n o warranty, express or implied, w ith respect to e ngines, batteries, tires or other par ts or accessories not manufactured by

WOODS. Warranties for these item s, if any, are provided separately by their respective manufacturers.

WOODS’ obligation under this Warranty is limited to, at WOODS’ option, the repair or replace ment, free of charge, of the product if W OODS,

in its sole discretion, deems it to be defective or in noncompliance with this Warranty. The pro duct must be returned to WOO D S with proof

of purchase within thirty (30) days after such defect or noncompliance is discovered or should have been discovered, routed through the

dealer and distributor from whom the purchase w as made, transportation charges prepaid. WOODS shall complete such repair or

replacement within a reasonable time after WOODS receives the product. THERE ARE NO OTHER REMEDIES UNDER THIS

WARRANTY. THE REMEDY OF REPAIR OR REPLACEMENT IS THE SOLE AND EXCLUSIVE REMEDY UNDER THIS

WARRANTY.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE OF THIS WARRAN TY. WOODS

MAKES NO OTHER WARRAN TY, EXPRESS OR IMPLIED, AND WOODS SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY

OF MERCHANTABILITY AND/OR ANY IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

WOODS shall not be l iable for any incidental or conseque ntial losses, damages or expe nses, arising directly or indirectly from the

product, whether su ch cl aim is b ased u po n breach of co ntra ct, b reach of w arr an ty, negligence, stri ct lia bil ity in t or t or an y o the r le ga l

theory. Without limiting the generality of the foregoing, Woods specifically disclaims any damages relating to (i) lost profits, business,

revenues or goodwill ; (ii) loss of crops; (iii) loss because of delay in harvesting; (iv) any expense or loss incurred for labor, supplies, substitute

machinery or rental; or (v) any other type of dam age to property or economic l oss.

This Warranty is subject to any existing conditions of supply which may directly affect WOODS’ ability to obtain materials or manufacture

replacement parts.

No agent, repr esentative, dealer, distri butor, serviceperso n, salesp erson, or employee of any comp any, including without l imitation, WOODS,

its authorized dealers, distr ibutors, and service centers, is authoriz ed to alter, modify, or enlarge this Warranty.

Answers to any questions regarding warranty service and locations may be obtained by contacting:

PHD25, PHD35, PH D65, PHD95, 2162, 3240, DS96, DS 120, RCC42, RM550-2,

RM660-2, RM990-3, PRD6000, PRD7200, PRD8400, 7144RD-2, 9180RD-2,

9204RD-2, S15CD, S20CD, S22CD, S25CD, S27CD

RDC54, RD60, RD72

RM550-2, RM660-2, RM990-3, PRD6000, PRD7200, PRD8400, 7144RD-2,

9180RD-2, 9204RD-2

BB600, BB720, BB840, BB6000, BB7200, BB8400, BW126-2, BW180-2,

BW1260, BW1800, 2162, 3240, DS1260, DSO1260 , DS1440, TS1680

Model Number

Duration (fr om dat e of deliv ery

to the original purchase r)

6 years

5 years

3 years (1 year if used in rental or

commercial applications)

3 years

10 years

Woods Equipment

Company

2606 South Illinois Route 2

Post Office Box 1000

Oregon, Illinois 61061

800-319-6637 tel

800-399-6637 fax

www.WoodsEquipment.com

F-3079 (Rev. 6/1/2007)

Page 32

WARRANTY

(Replacement Parts For All Models Except Mow’n Machine

Zero-Turn Mowers and Woods BoundaryTM Utility Vehicles)

Woods Equipment Company (“WOODS”) warrants this product to be free from defect in material and

workmanship for a period of ninety (90) days from the date of delivery of the product to the original purchaser

with the exception of V-belts, which will be free of defect in material and workmanship for a period of 12 months.

Under no circumstances will this Warranty apply in the event that the product, in the good faith opinion of

WOODS, has been subjected to improper operation, improper maintenance, misuse, or an accident. This Warranty

does not cover normal wear or tear, or normal maintenance items.

This Warranty is extended solely to the original purchaser of the pr oduct. Should the original purchaser sell or

otherwise transfer this product to a third party, this Warranty does not transfer to the th ird party purchaser in any

way. There are no third party beneficiaries of this Warranty.

WOODS’ obligation under this Warranty is limited to, at WOODS’ option, the repair or replacement, free of

charge, of the product if WOODS, in its sole discretion, deems it to be defective or in noncompliance with this

Warranty. The product must be returned to WOODS with proof of purchase within thirty (30) days after

such defect or noncomplian ce is di scovered or should have been d iscovered, routed through the dealer and

distributor from whom the purchase was made, transportation charges prepaid. WOODS shall complete

such repair or replacement within a reasonable time after WOODS receives the product. THERE ARE NO

OTHER REMEDIES UNDER THIS WARRANTY. THE REMEDY OF REPAIR OR REPLACEMENT IS THE

SOLE AND EXCLUSIVE REMEDY UNDER THIS WARRANTY.

THERE ARE NO WARRANTIES WHICH EXTEND BEYOND THE DESCRIPTION ON THE FACE OF THIS

WARRANTY. WOODS MAKES NO OTHER WARRANTY, EXPRESS OR IMPLIED, AND WOODS

SPECIFICALLY DISCLAIMS ANY IMPLIED WARRANTY OF MERCHANTABILITY AND/OR ANY

IMPLIED WARRANTY OF FITNESS FOR A PARTICULAR PURPOSE.

TM

WOODS shall not be liable for any incidental or con sequential losses, damages or expenses, arising directly

or indirectly from the product, whether such claim is based upon breach of contract, breach of warranty,

negligence, strict liability in tort or any other legal theory. Without limiting the generality of the foregoing,

Woods specifically disclaims any dama ges relating to (i) l ost profits, business, revenues or goodwill; (ii) loss of

crops; (iii) loss because of delay in harvesting; (iv) any expense or loss incurred for labor, supplies, substitute

machinery or rental; or (v) any other type of damage to property or economic loss.

This Warranty is subject to any existing conditions of supply which may directly affect WOODS’ ability to obtain

materials or manufacture replacement parts.

No agent, representative, dealer, distributor, service person, salesperson, or employee of any company, including

without limitation, WOODS, its authorized dealers, distributors, and service centers, is authorized to alter, modify,

or enlarge this Warranty.

Answers t o any questions regarding warranty se rvice and locations may be obtained by contacting:

Woods Equipment

Company

2606 South Illinois Route 2

Post Office Box 1000

Oregon, Illinois 61061

800-319-6637 tel

800-399-6637 fax

www.WoodsEquipment.com

©2007 Woods Equipment Company. All rights reserved. WOODS, the Woods logo, and "Tested. Proven. Unbeatable." are trademarks of Woods

Equipment Company. All other trademarks, trade names, or service marks not owned by Woods Equipment Company that appear in this manual are

the property of their respective companies or mark holders. Specifications subject to change without notice.

F-8494 (Rev. 6/23/2005)

Loading...

Loading...