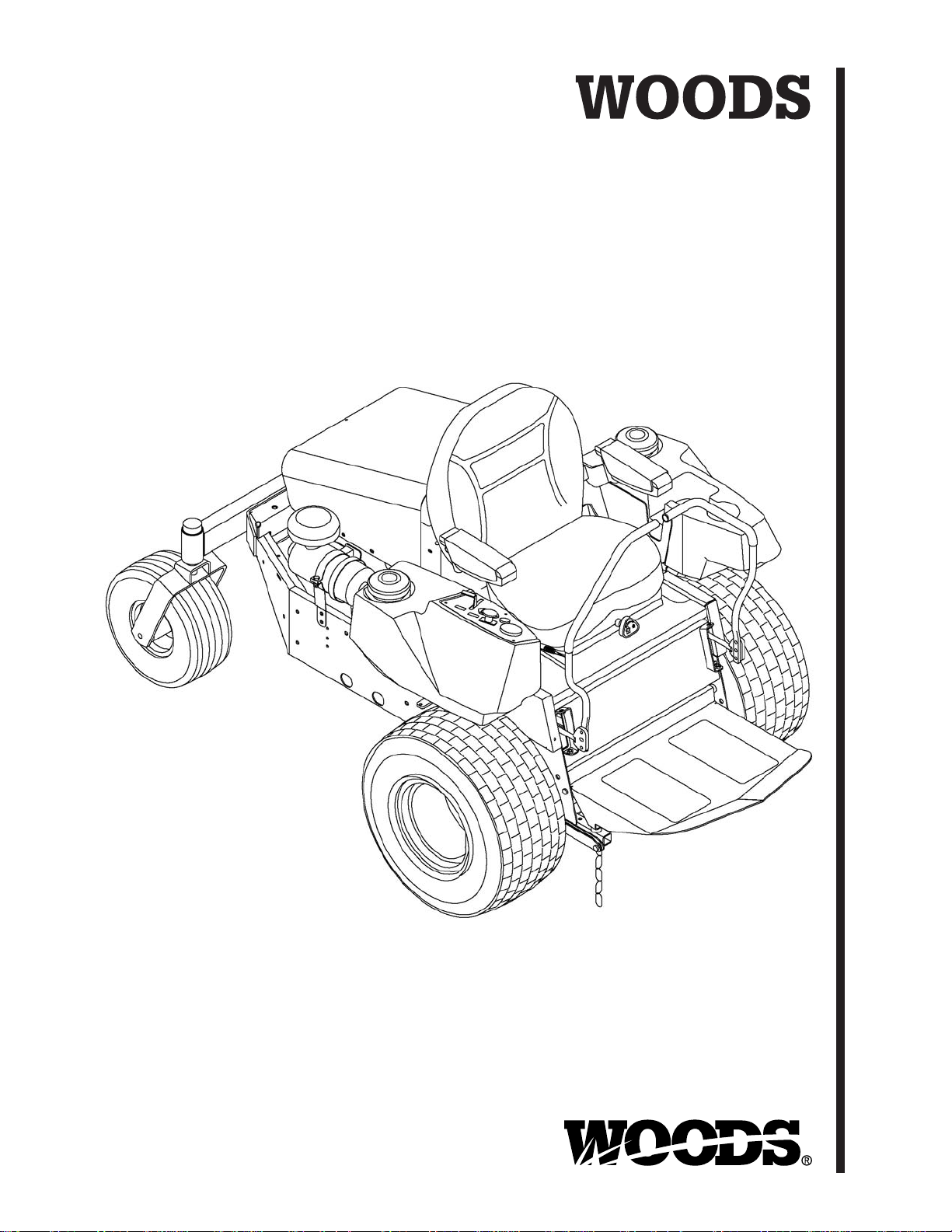

Woods Equipment FZ25D User Manual

MOW’N MACHINE

FZ25D

Power Unit

(Rev. 3/7/2012)

MAN0646

TO THE DEALER:

®

Assembly and proper installation of this product is the responsibility of the Woods

and safety rules. Make sure all items on the Dealer’s Pre-Delivery and Delivery Check Lists in the Operator’s Manual

are completed before releasing equipment to the owner.

The dealer must complete the online Product Registration form at the Woods Dealer Website which certifies that

all Dealer Check List items have been completed. Dealers can register all Woods product at

dealer.WoodsEquipment.com under Product Registration.

Failure to register the product does not diminish customer’s warranty rights.

TO THE OWNER:

Read this manual before operating your Woods equipment. The information presented will prepare you to do a better and

safer job. Keep this manual handy for ready reference. Require all operators to read this manual carefully and become

acquainted with all adjustment and operating procedures before attempting to operate. Replacement manuals can be

obtained from your dealer. To locate your nearest dealer, check the Dealer Locator at www.WoodsEquipment.com, or in

the United States and Canada call 1-800-319-6637.

The equipment you have purchased has been carefully engineered and manufactured to provide dependable and

satisfactory use. Like all mechanical products, it will require cleaning and upkeep. Lubricate the unit as specified.

Observe all safety information in this manual and safety decals on the equipment.

For service, your authorized Woods dealer has trained mechanics, genuine Woods service parts, and the necessary

tools and equipment to handle all your needs.

Use only genuine Woods service parts. Substitute parts will void the warranty and may not meet standards required for

safe and satisfactory operation. Record the model number and serial number of your equipment in the spaces

provided:

dealer. Read manual instructions

Model: _______________________________ Date of Purchase: _____________________

Serial Number: (see Safety Decal section for location) ____________________________________

Provide this information to your dealer to obtain correct repair parts.

Throughout this manual, the term NOTICE is used to indicate that failure to observe can cause damage to equipment.

The terms CAUTION, WARNING, and DANGER are used in conjunction with the Safety-Alert Symbol (a triangle with

an exclamation mark) to indicate the degree of hazard for items of personal safety.

2 Introduction

Gen’l (Rev. 12/5/2011)

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

SPECIFICATIONS. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

GENERAL INFORMATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

SAFETY RULES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 - 8

SAFETY DECALS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9 - 10

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .11

OWNER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DEALER SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

ASSEMBLY INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

DEALER CHECK LIST . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

INDEX TO PARTS LISTS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

BOLT TORQUE CHART . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

BOLT SIZE CHART & ABBREVIATIONS . . . . . . . . . . . . . . . . . . . . . . . . . . 50

INDEX . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

PRODUCT WARRANTY . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

REPLACEMENT PARTS WARRANTY . . . . . . . . . . . . INSIDE BACK COVER

WARNING

The engine exhaust from this product

contains chemicals known to the State

of California to cause cancer, birth

defects or other reproductive harm.

WARNING

This product contains chemicals,

including lead, known to the State of

California to cause cancer, and birth

defects or other reproductive harm.

Wash hands after handling.

MAN0646 (7/6/2007)

Introduction 3

SPECIFICATIONS

WARNING

Engine . . . . . . . . . . . . . . . . . . . . . . . . . . . Kubota 3-cylinder, 4-cycle, liquid cooled

(See engine manual for complete specifications)

Horsepower . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25 HP

Fuel Type. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . Diesel

Standard Tire Size: Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23 x 10.50 - 12

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . .15 x 6.00 - 6 Rib

Recommended Tire Pressure:

Front . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12 psi

Rear . . . . . . . . . . . . . . . . . . . . . . . . . . . Maximum 18 psi

Power Unit Dimensions: Width . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50"

Overall Length . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 87"

Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1020 lbs

Fuel Tank Capacity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11.0 Gallons

Recommended Mower Decks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52", 61", 72"

GENERAL INFORMATION

Some illustrations in this manual show the

equipment with safety shields removed to provide

a better view. This equipment should never be

operated with any necessary safety shielding

removed.

The purpose of this manual is to assist you in operating

and maintaining your Mow’n Machine. Read it carefully.

It furnishes information and instructions that will help

you achieve years of dependable performance. These

instructions have been compiled from extensive field

experience and engineering data. Some information

may be general in nature due to unknown and varying

operating conditions. However, through experience

and these instructions, you should be able to develop

procedures suitable to your particular situation.

The illustrations and data used in this manual were current at the time of printing but, due to possible inline

production changes, your machine may vary slightly in

detail. We reserve the right to redesign and change the

machines as may be necessary without notification.

Throughout this manual, references are made to right

and left directions. These are determined by standing

behind the equipment facing the direction of forward

travel.

4 Introduction

(Rev. 11/5/2007)

MAN0646 (7/6/2007)

Safety is a primary concern in the design and

manufacture of our products. Unfortunately, our

efforts to provide safe equipment can be wiped

out by an operator’s single careless act.

In addition to the design and configuration of

equipment, hazard control and accident prevention are dependent upon the awareness, concern, judgement, and proper training of

personnel involved in the operation, transport,

maintenance, and storage of equipment.

It has been said, “The best safety device is an

informed, careful operator.” We ask you to be

that kind of operator.

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

TRAINING

Safety instructions are important! Read all

attachment and power unit manuals; follow all

safety rules and safety decal information. (Replacement manuals and safety decals are available from

your dealer. To locate your nearest dealer, check

the Dealer Locator at www.WoodsEquipment.com,

or in the United States and Canada call 1-800-319-

6637.) Failure to follow instructions or safety rules

can result in serious injury or death.

Data indicates that those operators age 60 years

and above are involved in a large percentage of

riding mower-related injuries. Those operators

should evaluate their ability to operate the riding

mower safely enough to protect themselves and

others from injury.

If you do not understand any part of this manual

and need assistance, see your dealer.

Know your controls and how to stop engine and

attachment quickly in an emergency.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Never allow children or untrained persons to

operate equipment.

FE-Series Mow”n Machine (12/23/2005)

SAFETY RULES

PREPARATION

Check that all hardware is properly installed.

Always tighten to torque chart specifications

unless instructed otherwise in this manual.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Make sure spring-activated locking pin or collar

slides freely and is seated firmly in tractor PTO

spline groove.

The safety interlock system was installed for

your protection. Do not disconnect, disable, override, or execute any action that would cause this

system to malfunction. If malfunction occurs, stop

all operation and contact dealer for repair.

Remove accumulated debris from this equipment, power unit, and engine to avoid fire hazard.

Keep children out of the mowing area and under

the watchful care of a responsible adult other than

the operator.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Be sure either the discharge chute, mulching

end cap, or complete vacuum attachment is

installed and in good condition. Replace if damaged.

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

The machine is not intended for highway or

street use.

Do not mow on wet grass.

While fueling, extinguish all cigarettes, cigars,

pipes, and other sources of ignition.

Never fuel the machine indoors.

(Safety Rules continued on next page)

Safety 5

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Never fill fuel containers inside a vehicle or a

truck or trailer bed with a plastic liner. Always

place container on the ground away from the vehicle before filling.

Remove gas-powered equipment from the truck

or trailer and refuel on the ground. If this is not

possible, then refuel such equipment on a trailer

with a portable container, rather than from a

gasoline dispenser nozzle.

Keep the nozzle in contact with the rim of the

fuel tank opening at all times until fueling is complete. Do not use a nozzle lock-open device.

If fuel is spilled on clothing, change clothing

immediately.

Never over-fill tank. Replace gas cap and tighten

securely.

Handle fuel carefully; it is highly flammable.

Always use an approved container. Never remove

fuel cap or add fuel while engine is running. Allow

engine to cool before refueling. Wipe up all spilled

fuel before starting engine.

TRANSPORTATION

Use extra care when loading or unloading the

machine onto a trailer or truck.

Transport power unit facing rearward when

equipped with a sunshade.

Do not operate or transport on steep slopes.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Do not operate PTO during transport.

OPERATION

Keep bystanders away from equipment.

Keep children out of the mowing area and under

the watchful care of a responsible adult other than

the operator.

Be alert and turn machine off if a child enters

the mowing area.

Before and while backing, look behind and

down for children.

Never direct discharge toward people, animals,

or property.

Operate only in daylight or good artificial light.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Because a ROPS is not offered with this unit, a

seat belt must not be used.

Use extreme care when approaching blind corners, shrubs, trees, or other objects that may block

your vision.

Use care when operating with ROPS or sunshade around shrubs, trees or other objects that

can become entangled with power unit.

Always comply with all state and local lighting

and marking requirements.

Never allow riders on power unit or attachment.

Start engine from operator's seat after disen-

gaging power unit PTO and placing steering levers

in neutral.

Do not mow in reverse unless absolutely necessary.

Slow down before turning.

Do not operate on slopes greater than 15

degrees (27% grade).

Mow up and down slopes, not across.

If the tires lose traction on a slope, disengage

the blade(s) and proceed slowly straight down the

slope.

Do not stop, start, or change directions suddenly on slopes.

Do not make sudden changes in speed or direction which could cause the machine to roll over.

Use extreme care and reduce ground speed on

slopes and rough terrain.

Installation of a grasscatcher assembly will

reduce the stability and maneuverability of the

Mow'n Machine when operating on sloping terrain.

Watch for hidden hazards on the terrain during

operation.

Watch for traffic when operating near or crossing roadways.

Uneven terrain could overturn the machine.

Do not try to stabilize the machine by putting

your foot on the ground.

6 Safety

(Rev. 8/22/2008)

FE-Series Mow’n Machine (12/23/2005)

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Stop power unit and equipment immediately

upon striking an obstruction. Turn off engine,

remove key, inspect, and repair any damage before

resuming operation.

Do not drive or operate mower in tilt-up position. Power unit stability is not adequate and resulting loads can damage or cause failure of tilt-up

mechanism.

Never leave a running machine unattended.

Moving steering levers rapidly from forward to

reverse or reverse to forward could cause loss of

control.

Do not operate power unit with attachment

removed. Attachment is required for power unit

stability.

Before dismounting power unit, follow these

steps: lower attachment to ground, shut off PTO,

set parking brake, shut off engine, position steering levers to neutral swing-out position, and

remove key.

This machine is not equipped for towing. Do not

tow any loads.

To avoid burns, DO NOT TOUCH the engine or

muffler immediately after operation.

Do not modify or alter or permit anyone else to

modify or alter the equipment or any of its components in any way.

Do not work on mower in tilt-up position unless

deck is in a stable position.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate

Do not work on mower in tilt-up position unless

lock-up mechanism is in good condition. Replace if

damaged.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Do not put Mow’n Machine into service unless

clutch is working properly. When the engine is at

full throttle, PTO-driven accessories must stop

within five seconds after the PTO switch is turned

to “OFF.” See your dealer for replacement

clutches.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

MAINTENANCE

Before dismounting power unit, follow these

steps: lower attachment to ground, shut off PTO,

set parking brake, shut off engine, position steering levers to neutral swing-out position, and

remove key.

Before attempting to unplug vacuum hoses, disengage PTO, stop power unit, and remove key.

Before performing any service or maintenance,

lower attachment to ground, turn off power unit

engine, remove key, and disconnect battery ground

cable (negative -).

Before working underneath, read manual

instructions, securely block up, and check stability.

Secure blocking prevents equipment from dropping due to hydraulic leak down, hydraulic system

failure, or mechanical component failure.

Do not change engine governor settings or

overspeed engine.

Frequently check blades. They should be sharp,

free of nicks and cracks, and securely fastened.

Do not handle blades with bare hands. Careless

or improper handling may result in serious injury.

Your dealer can supply genuine replacement

blades. Substitute blades may not meet original

equipment specifications and may be dangerous.

Tighten all bolts, nuts, and screws to torque

chart specifications. Check that all cotter pins are

installed securely to ensure equipment is in a safe

condition before putting unit into service.

Use care to prevent battery acid from contacting

skin.

Make sure all safety decals are installed.

Replace if damaged. (See Safety Decals section for

location.)

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

(Safety Rules continued on next page)

(Rev. 8/22/2008)

FE-Series Mow”n Machine (12/23/2005)

Safety 7

SAFETY RULES

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Battery posts, terminals, wiring insulation, and

related accessories contain lead and lead compounds, chemicals known to the State of California

to cause cancer and birth defects or other reproductive harm. WASH HANDS AFTER HANDLING.

STORAGE

Keep children and bystanders away from storage area.

Never store the machine or fuel container near

an open flame, spark or pilot light such as on a

water heater or other appliance.

Do not run engine indoors. Exhaust gases contain carbon monoxide, an odorless and deadly poison.

Remove key and store in a secure location to

prevent unauthorized persons from operating

8 Safety

(Rev. 8/22/2008)

FE-Series Mow’n Machine (12/23/2005)

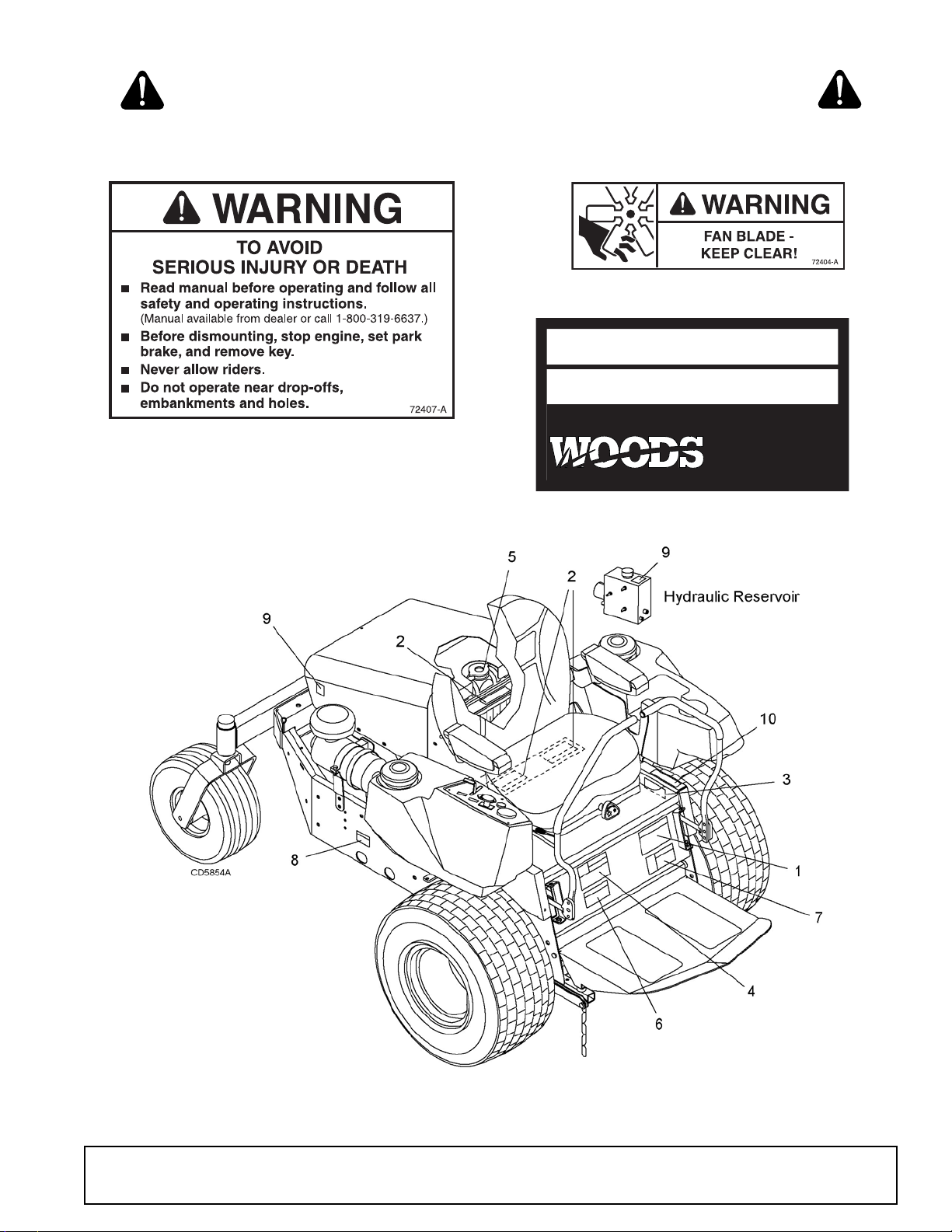

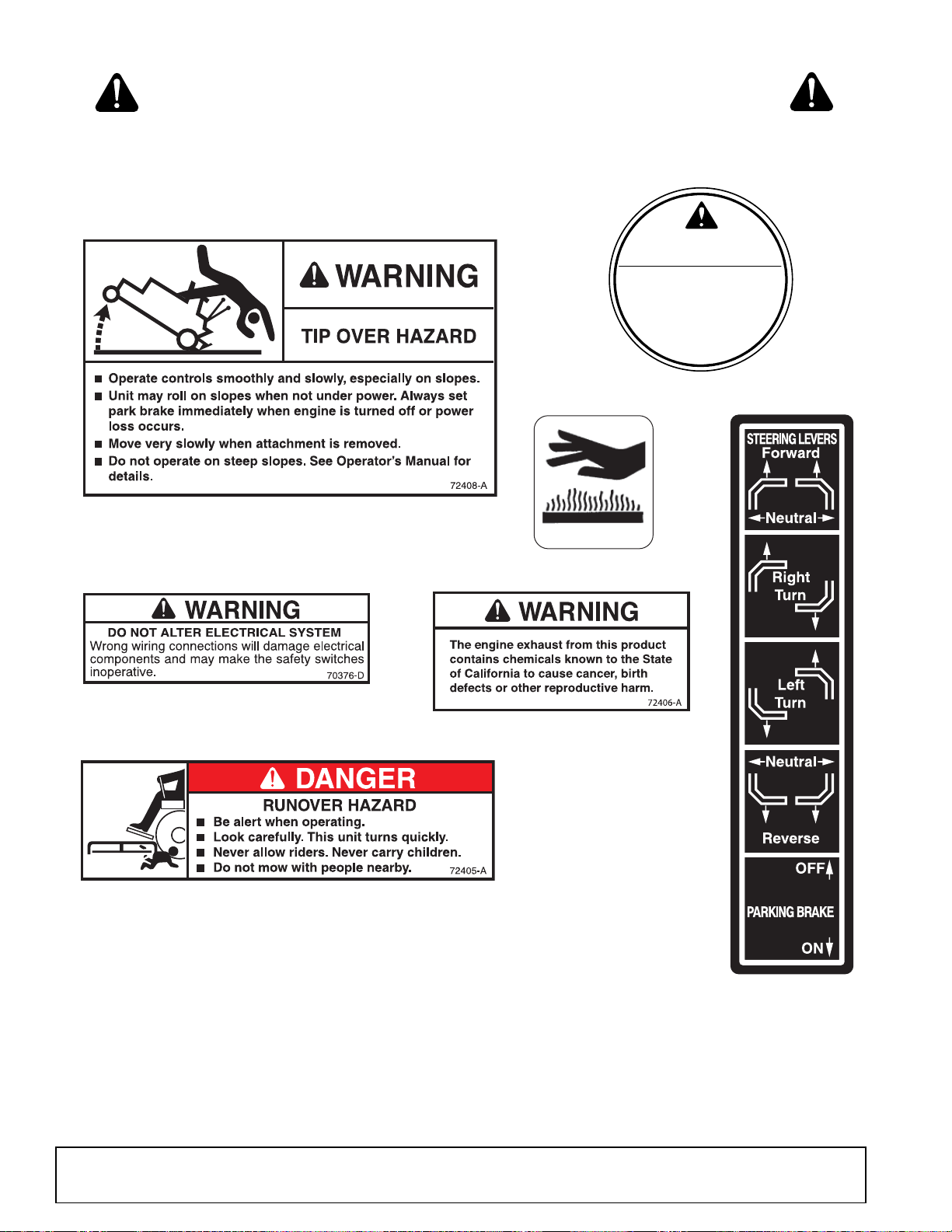

SAFETY & INSTRUCTIONAL DECALS

1 - PN 72407

2 - PN 72404

3 - SERIAL NUMBER PLATE

(Safety Decals continued on next page)

W

oods Equipment Company

Oreg

.

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

MODEL NO.

SERIAL NO.

Woods Equipment

Company

Oregon, Illinois, U.S.A.

on, Illinois, U.S.A

MAN0646 (7/6/2007)

Safety 9

7 - PN 72405

4 - PN 72408

8 - PN 72406

(Safety Decals continued from previous page)

BE CAREFUL!

Use a clean, damp cloth to clean safety decals. Avoid spraying too close to decals when using a pressure washer;

high-pressure water can enter through very small scratches or under edges of decals causing them to peel or come

off. Replacement safety decals can be ordered free from your Woods dealer. To locate your nearest dealer, check

the Dealer Locator at www.woodsequipment.com, or in the United States and Canada call 1-800-319-6637.

6 - PN 70376

CAUTION

ENGINE COOLANT

(SEE ENGINE MANUAL)

DO NOT OPEN

WHEN HOT

72648

5 - PN 72648

9 - PN 07754100 10 - PN 72801

SAFETY & INSTRUCTIONAL DECALS

ATTENTION! BECOME ALERT! YOUR SAFETY IS INVOLVED!

Replace Immediately If Damaged!

07754100

10 Safety

MAN0646 (7/6/2007)

OPERATION

WARNING

WARNING

CAUTION

The operator is responsible for the safe operation of

this Mow’n Machine. The operator must be properly

trained. Operators should be familiar with the power

unit, all attachments that will be used, and all safety

practices before starting operation. Read the safety

rules and safety decals on page 5 through page 10.

Operators must be instructed in and be capable

of the safe operation of the equipment, its attachments, and all controls. Do not allow anyone to

operate this equipment without proper instructions.

Make sure attachment is properly secured,

adjusted, and in good operating condition.

Inspect and clear area of stones, branches, or

other hard objects that might be thrown, causing

injury or damage.

Do not operate power unit with attachment

removed. Attachment is required for power unit

stability.

Make sure shields and guards are properly

installed and in good condition. Replace if damaged.

Handle fuel carefully; it is highly flammable.

Always use an approved container. Never remove

fuel cap or add fuel while engine is running. Allow

engine to cool before refueling. Wipe up all spilled

fuel before starting engine.

Keep bystanders away from equipment.

Do not operate or transport equipment while

under the influence of alcohol or drugs.

Keep hands, feet, hair, and clothing away from

equipment while engine is running. Stay clear of all

moving parts.

Never allow riders on power unit or attachment.

Never direct discharge toward people, animals,

or property.

Moving steering levers rapidly from forward to

reverse or reverse to forward could cause loss of

control.

Look down and to the rear and make sure area

is clear before operating in reverse.

Do not stop, start, or change directions suddenly on slopes.

Before dismounting power unit, follow these

steps: lower attachment to ground, shut off PTO,

set parking brake, shut off engine, position steering levers to neutral swing-out position, and

remove key.

Do not drive or operate mower in tilt-up position. Power unit stability is not adequate and resulting loads can damage or cause failure of tilt-up

mechanism.

Do not operate PTO during transport.

Remove accumulated debris from this equip-

ment, power unit, and engine to avoid fire hazard.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

Start engine from operator's seat after disengaging power unit PTO and placing steering levers

in neutral.

Stop power unit and equipment immediately

upon striking an obstruction. Turn off engine,

remove key, inspect, and repair any damage before

resuming operation.

MAN0646 (7/6/2007)

Operation 11

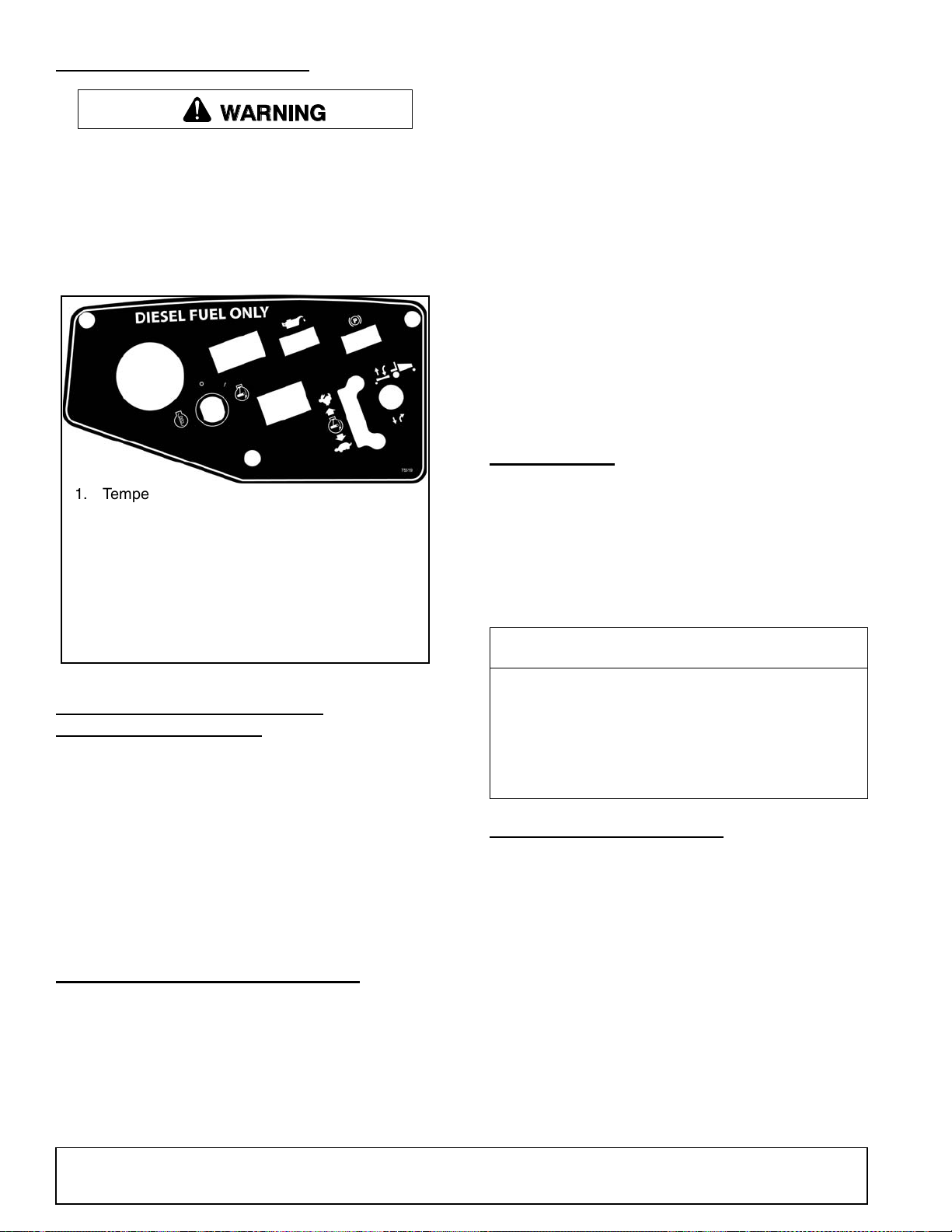

CONTROLS AND SWITCHES

WARNING

1. Temperature gauge

2. PTO switch

3. Brake light

4. Oil light

5. Ignition switch

6. Hour meter

7. Throttle control

8. Deck height switch

1

2

3

4

5

6

7

8

brake and turn ignition key switch to the “ON” position.

Control panel brake light (3) should be on.

Temperature Light

Know your controls and how to stop engine and

attachment quickly in an emergency.

Control and indicator console is located on the right

fuel tank. This console contains controls needed to

operate this unit. PTO switch (2) is used to engage

attachments: pull up to engage, push down to disengage.

NOTICE

■ For overheating, clean radiator grill and check

engine coolant level.

The temperature light will alert you when the engine

temperature is excessive. The temperature light system is not intended to shut the engine off or prevent

operation; it is designed to provide notification. If temperature light starts to flash during operation, discontinue operation. The light is programed to flash at 220°

fahrenheit and above.

NOTE: The radiator and prescreen require regular

cleaning to prevent engine overheating. Clean the prescreen daily and the radiator fins every 40 hours. Do

not use high pressure on radiator fins to avoid radiator

damage.

HOUR METER

The hour meter is programed to alert the operator at

various service intervals. The change oil light will flash

at 20 hours (initial break in) and every 100 hours after.

The light will flash for a period of 4 hours (alternating

between hours & change oil) and than resume normal

mode. The hour glass will flash every second indicating

it’s in running mode.

Figure 1. Console Control Locations

DECK HEIGHT/POWER TILT™

ADJUSTMENT SWITCH

The deck height and Power Tilt™ switch is used with

MXT or MX deck equipped with the Power Tilt™ Kit.

Push the toggle switch forward to raise the deck and

pull back to lower the deck to the desired cutting

height. For Power Tilt™ operation, pull back and hold

the toggle switch to lower the deck and cycle through to

the tilt position. Release switch when deck reaches

maximum tilt position. To lower the deck, push and hold

toggle switch until it cycles to the desired cutting

height. NOTE: Power Tilt™ feature must not be used

when sitting in the seat.

BRAKE & TEMPERATURE LIGHTS

Brake Light

NOTICE

■ Do not operate with parking brake engaged or

damage to the brake adjustment will occur.

The brake light indicates when the brake is engaged.

To ensure light is operating properly, engage parking

12 Operation

Service Intervals

20 hrs Engine oil change (break in)

100 hrs Engine oil change & filter

500 hrs Hydraulic oil change & filter (see

hydraulic transmission - change oil

& filter, page 19)

SAFETY SWITCH SYSTEM

Several safety switches are incorporated in the unit’s

design to prevent it from being started out of NEUTRAL

(handles pivoted outward) or with PTO engaged.

The PTO control must be in the “OFF” position and the

steering handles in the NEUTRAL position before unit

can be started.

A safety switch behind the operator’s seat will cause

the engine to stop if the operator leaves the seat with

the PTO or steering handles engaged. The engine will

also stop if the steering handles are moved from NEUTRAL while the parking brake is engaged. It will not run

if the deck jumper wire (for Power Tilt™ operation) is

not connected to the wire harness or the deck safety

switch is disengaged.

(Rev. 1/7/2010)

MAN0646 (7/6/2007)

STARTING ENGINE

DANGER

WARNING

WARNING

WARNING

Do not run engine indoors. Exhaust gases contain carbon monoxide, an odorless and deadly poison.

To enhance starter life, use short starting cycles not

exceeding 10 seconds. If engine does not start within

10 seconds, stop cranking for 30 seconds; then repeat

starting procedures.

1. Position yourself on the power unit seat.

2. Place steering control handles in the NEUTRAL

position (pivoted outward).

3. Place PTO switch in the “OFF” position (down).

4. Place throttle approximately 1/3 open.

5. Turn key counter-clockwise to “PRE-HEAT” the

glow plugs.

NOTICE

■ Never engage PTO if the mower blades are

plugged with grass or other material. This may

cause damage to the electric clutch.

1. With engine running, position throttle at half speed.

2. Engage PTO by pulling up on the PTO switch.

3. Move throttle to full speed and begin operation.

NOTE: Starting attachment at lower engine speed will

help prolong the life of the clutch and transmission

components.

STOPPING MOWER OR ATTACHMENT

Push down on PTO switch.

NOTE: If attachment does not stop in five seconds, the

unit requires service.

NOTE: Standard pre-heating time is 5 to 10 seconds. Pre-heat is not required if engine has been

running and warmed up.

6. Turn key to “START”. Release key immediately

when engine starts.

7. Ensure that the oil pressure light is off.

8. Warm up engine several minutes at medium

throttle.

NOTE: Allow engine a warm-up period regardless of

the season. Loading a cold engine will shorten its life.

If engine does not start after refueling or has been sitting for a prolonged period, refer to “bleeding the fuel

system” in the engine manual.

COLD WEATHER STARTING TIPS

1. Use proper oil grade for temperature expected.

(Refer to engine manual for oil grade.)

2. Set throttle half way open.

3. A warm battery has better starting capacity than a

cold one.

4. Use fresh fuel (winter grade for diesel model); it is

better for starting than leftover fuel.

PRACTICE OPERATION

Never allow children or untrained persons to

operate equipment.

Operating this unit is not difficult once you are familiar

with the use of the controls. Equip the power unit with

the attachment you will be using and practice in a flat

open area at half throttle setting until you are comfortable with the controls.

Do not operate attachment until you become proficient

with controls.

UNEVEN TERRAIN OPERATION

Uneven terrain could overturn the machine.

Do not operate on slopes greater than 15

degrees (27% grade).

Do not stop, start, or change directions suddenly on slopes.

STARTING MOWER OR ATTACHMENT

Make sure people and objects are clear of

attachment and discharge area before engaging

PTO.

MAN0646 (7/6/2007)

Use extreme care and reduce ground speed on

slopes and rough terrain.

Watch for hidden hazards on the terrain during

operation.

Installation of a grasscatcher assembly will

reduce the stability and maneuverability of the

Mow'n Machine when operating on sloping terrain.

Operation 13

Mow up and down slopes, not across.

CAUTION

WARNING

forward. Pulling handles to the rear will move the

power unit in reverse. The further forward or rearward

the steering handles are moved, the faster the machine

will move.

If the tires lose traction on a slope, disengage

the blade(s) and proceed slowly straight down the

slope.

Practice steering maneuvers at half throttle.

STEERING HANDLE OPERATION

Moving steering levers rapidly from forward to

reverse or reverse to forward could cause loss of

control.

Do not operate power unit with attachment

removed. Attachment is required for power unit

stability.

NOTE: Speed and direction are controlled with steering

handles. Pushing handles forward will move power unit

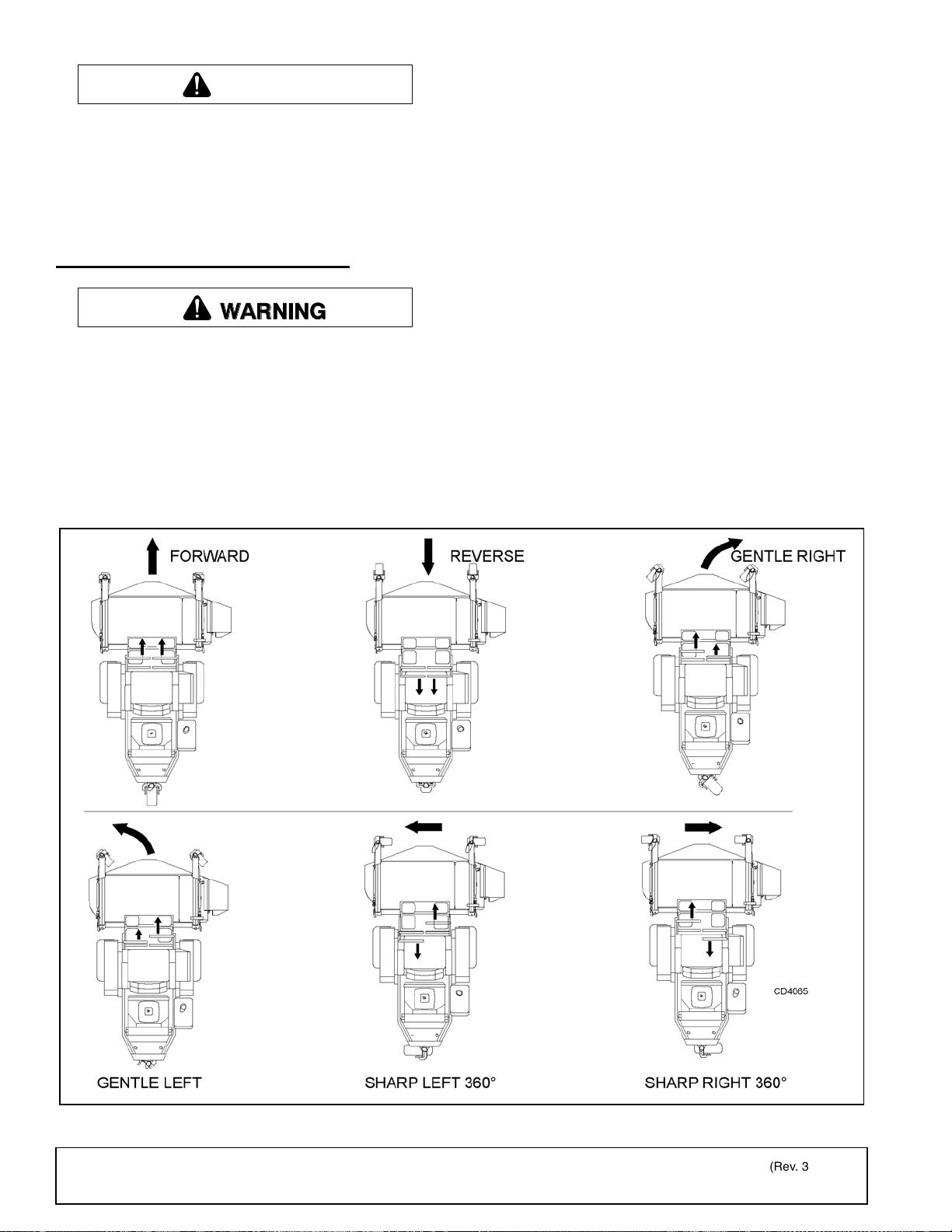

Steering Handle Positions

NOTICE

■ If you become confused during operation,

return both handles to the center neutral position

and the power unit will stop.

Forward Both handles forward

Reverse Both handles rearward

Gentle Right Left handle further forward than right

Gentle Left Right handle further forward than left

360° Left Left full rearward; right full forward

360° Right Right full rearward; left full forward

NOTE: Moving one handle forward with the other handle in neutral will also result in a 360° circle. However

this will cause one drive wheel to dig into the turf and

should be avoided.

14 Operation

Figure 2. Steering Handle Operation

(Rev. 3/7/2012)

MAN0646 (7/6/2007)

STOPPING ENGINE

CAUTION

DP2

DUMP VALVE

WARNING

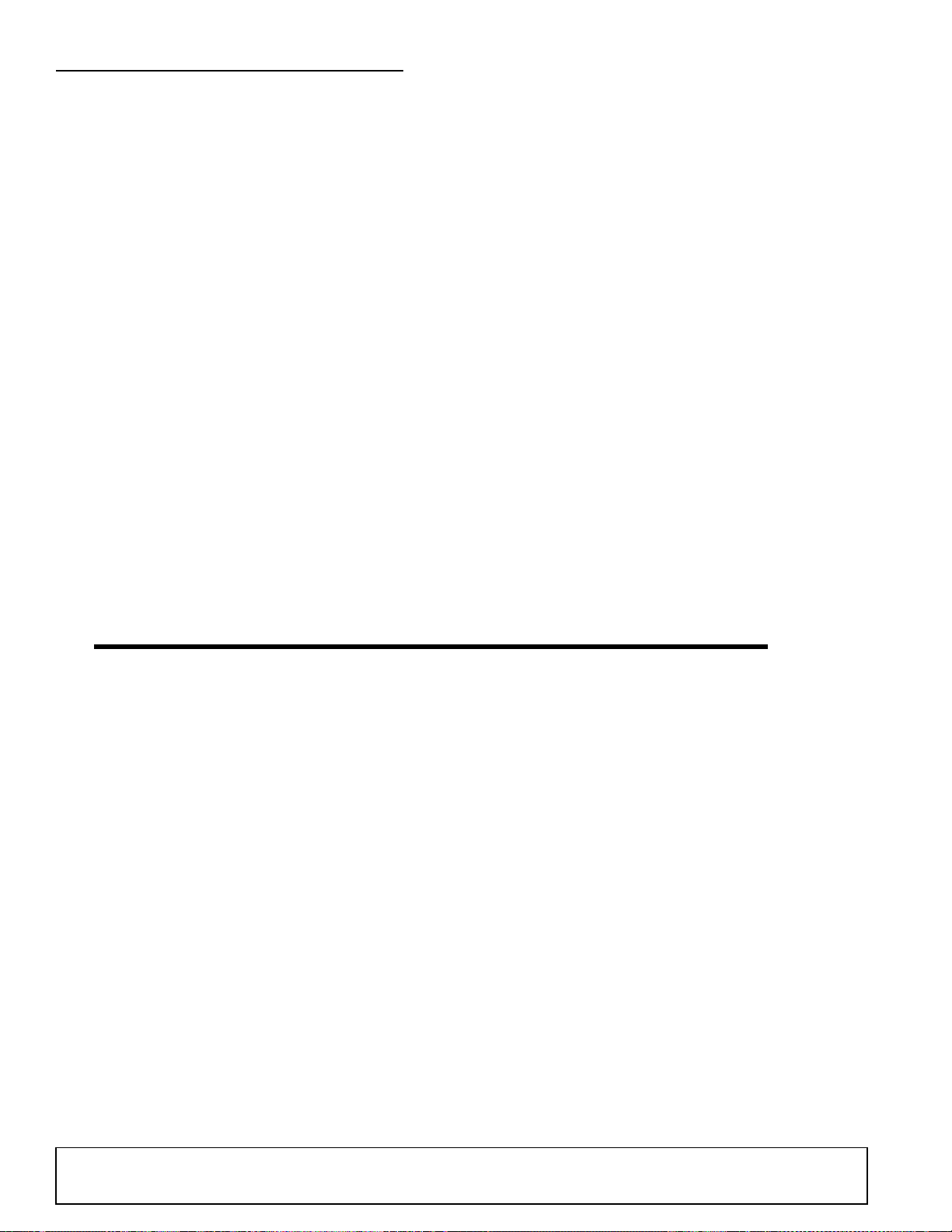

Mower

FZ25D

With

ROPS

With

ROPS &

Sun

Shade

Grass

Catcher

52" Deck 0 lbs 50 lbs 100 lbs 0 lbs

61" Deck 0 lbs 50 lbs 100 lbs 0 lbs

72" Deck 50 lbs 100 lbs 150 lbs N/A

Snow Thrower 0 lbs 50 lbs 100 lbs N/A

Dozer Blade 0 lbs 50 lbs 100 lbs N/A

60" Sweeper 50 lbs 100 lbs 150 lbs N/A

1. Move throttle to 1/3 setting.

Manually move a disabled power unit by following

these steps.

2. Allow engine to idle for several minutes.

3. Turn key to OFF position and remove.

Remove key and store in a secure location to

prevent unauthorized persons from operating

equipment.

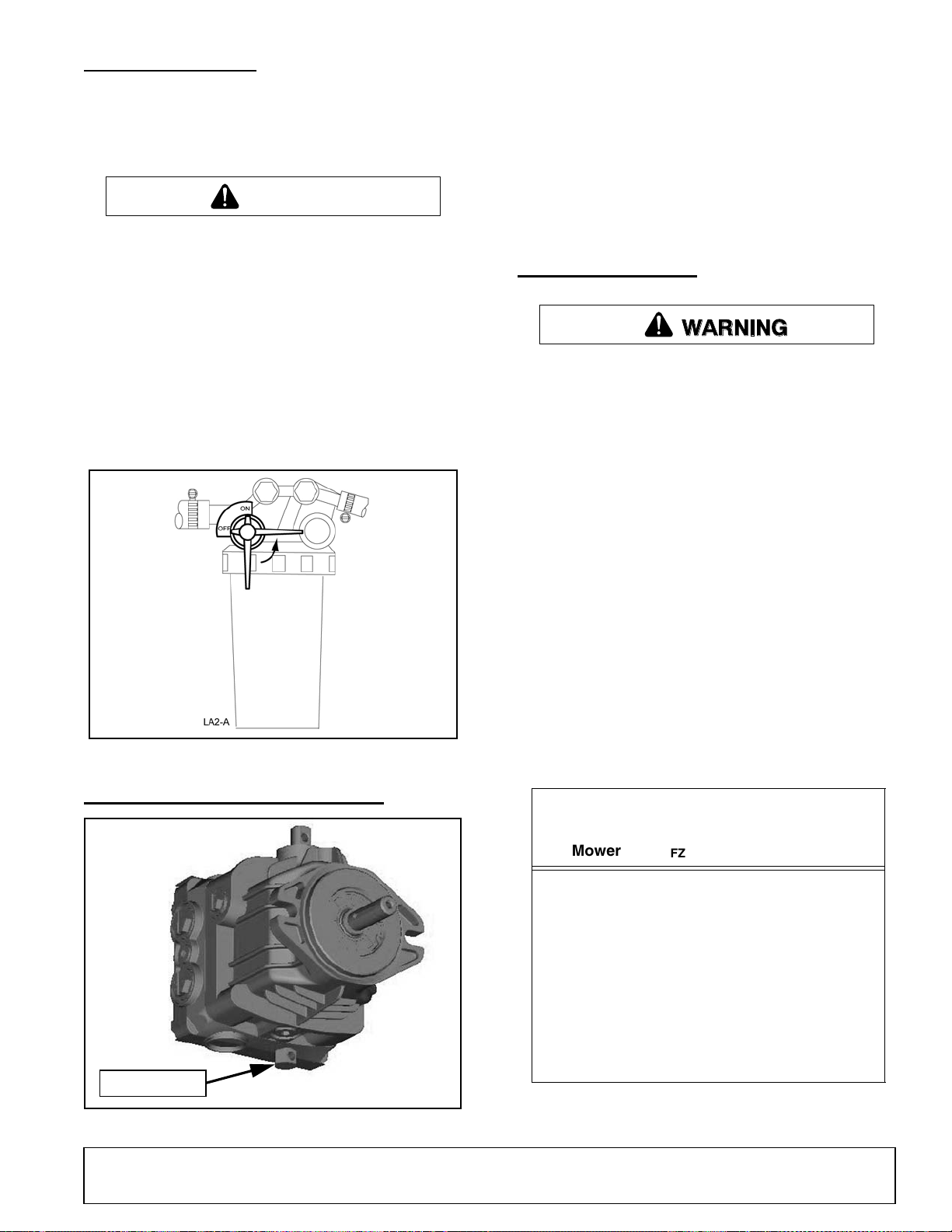

Manual Fuel Shut-Off Valve

A manual fuel shut-off valve is located on top of the fuel

filter, on the right side of engine.

1. Place valve in the “ON” position before attempting

to start engine.

2. Place valve in the “OFF” position when changing or

cleaning the fuel filter.

1. Locate dump valves on bottom of both hydraulic

pumps.

2. Turn hex head two full revolutions counter-clock

wise to open valve, using a 5/8" wrench or round

punch.

WEIGHT TRANSFER

When using weight transfer system, correct

counterweight must be used to maintain stability.

See counterweight chart in power unit manual or

contact dealer.

The weight transfer is designed to place an additional

load on the drive wheels, providing additional traction.

1. Attach mower to power unit and set to desired

cutting height.

Figure 3. Manual Shut-Off Valve

MOVING DISABLED POWER UNIT

2. Torque bolt on both sides to 35 lbs-in.

NOTE: Counterweight is needed to provide adequate

stability. Refer to the chart to determine your power

unit/mower combination, and the amount of counterweight required.

Counterweights are not required when power unit is

equipped with a grass catcher system.

(Rev. 8/22/2008)

MAN0646 (7/6/2007)

Figure 4. Left Pump Dump Valve

Figure 5. Counterweight Requirement Chart

Operation 15

OWNER PRE-OPERATION CHECK LIST

(OWNER'S RESPONSIBILITY)

___ Review and follow all safety rules and safety

decal instructions on pages 5 through 10.

___ Check that all safety decals are installed and in

good condition. Replace if damaged.

___ Check to make sure all shields and guards are

properly installed and in good condition. Be sure

that either the discharge shield or complete vacuum attachment is installed.

___ Check that all hardware and cotter pins are prop-

erly installed and secured.

___ Check that equipment is properly and securely

attached to power unit.

___ Make sure driveline spring-activated locking pin

or collar slides freely and is seated firmly in

power unit PTO spline groove and in gearbox

spline groove.

___ Check for grass wrap on PTO shaft. When mow-

ing long grass, remove key and check for grass

wrap around PTO shaft every 30 minutes of operation.

___ Check to be sure engine is free of dirt and debris.

Pay particular attention to the cooling fins, governor parts and muffler.

___ Do not allow riders.

___ Inspect area and remove stones, branches or

other hard objects that might be thrown, causing

injury or damage.

___ Clean air intake screen. Check air cleaner; ser-

vice if necessary.

___ Clean area around oil fill dipstick. Remove dip-

stick and check to be sure oil is in operating

range (between marks on dipstick). Add oil if necessary but Do Not Overfill. Install dipstick

assembly firmly until cap bottoms out on tube.

Dipstick assembly must always be secured into

fill tube when engine is running. Avoid touching

exhaust manifold if unit has been running.

___ Check all lubrication points and grease as

instructed. See “Lubrication Service Intervals” on

page 18.

___ Check hydrostatic fluid level (refer to Owner Ser-

vice section). Check to be sure cooling fins on

hydrostat are clean.

___ Perform a functional check of the safety interlock

system each time you operate the unit. Place

both steering levers outward, start engine,

engage PTO and then rise up out of the seat; the

engine should die. If it does not, do not operate

unit until the safety interlock system has been

repaired and operates properly.

16 Operation

MAN0646 (7/6/2007)

OWNER SERVICE

WARNING

CAUTION

The information in this section is written for operators

who possess basic mechanical skills. If you need help,

your dealer has trained service technicians available.

For your protection, read and follow the safety information in this manual.

Before performing any service or maintenance,

lower attachment to ground, turn off power unit

engine, remove key, and disconnect battery ground

cable (negative -).

■ Before working underneath, read manual

instructions, securely block up, and check stability.

Secure blocking prevents equipment from dropping due to hydraulic leak down, hydraulic system

failure, or mechanical component failure.

Keep all persons away from operator control

area while performing adjustments, service, or

maintenance.

1. Park power unit on a level surface.

2. Stop engine and clean off dirt and dust from around

dipstick.

3. Remove dipstick, check oil level. Oil level should

be between marks on dipstick. Avoid touching

exhaust manifold if unit has been running.

4. Add oil as necessary.

Change Engine Oil

NOTICE

■ Use care to prevent hot oil from contacting bare

skin.

1. Run engine to allow oil to become hot. This will

ensure that most foreign materials are in

suspension and will be flushed out with the oil.

2. Remove drain plug and drain crankcase.

3. Remove oil filter.

4. Install new oil filter.

Always wear relatively tight and belted clothing

to avoid getting caught in moving parts. Wear

sturdy, rough-soled work shoes and protective

equipment for eyes, hair, hands, hearing, and head;

and respirator or filter mask where appropriate.

RADIATOR AND PRESCREEN

NOTICE

■ Clean the prescreen daily and the radiator fins

every 40 hours or annually, which ever is less. Do

not use high pressure on radiator fins to avoid radiator damage.

ENGINE SERVICE

NOTE: Follow engine manufacturer recommendations

in engine manual.

Check Engine Oil Level

NOTE: Never attempt to check oil level while engine is

running. Serious injury or damage to equipment could

result.

5. Install drain plug and add oil.

NOTE: Refer to the engine manual for oil specifica-

tions, capacity, service rating, and proper grade.

Engine Coolant

Refer to the engine manual for the coolant specifications, coolant capacity, service rating, and proper mixture.

LUBRICATION INFORMATION

1. Do not let excess grease collect on or around

parts, particularly when operating in sandy areas.

2. See Figure 6 for lubrication points and frequency or

lubrication based on normal operating conditions.

Severe or unusual conditions may require more

frequent lubrication.

3. Use a lithium grease of #2 consistency with a

MOLY (molybdenum disulfide) additive for all

locations unless otherwise noted. Be sure to clean

fittings thoroughly before attaching grease gun.

One good pump of most guns is sufficient when the

lubrication schedule is followed.

(Rev 1/7/2010)

MAN0646 (7/6/2007)

Owner Service 17

Loading...

Loading...