Page 1

DESIGN GUIDE

REVISED 7/ 2018

Page 2

TABLE OF CONTENTS

3 BUILT-IN OVENS

42 MICROWAVE OVENS

58 WARMING DRAWERS

64 COOKTOPS | MODULES

90 COFFEE SYSTEMS | CUP WARMING DRAWERS

100 RANGES | RANGETOPS

124 OUTDOOR GRILLS | MODULES

132 COOKTOP VENTILATION

146 DOWNDRAFTS

154 PRO VENTILATION

166 WOLF WARRANTIES

Features and specications are subject to change at any

time without notice. Visit wolfappliance.com/specs for the

most up-to-date information.

Throughout this guide, dimensions may vary by ±

1

/8" (3).

Dimensions in parentheses are millimeters unless otherwise

specied.

Page 3

Page 4

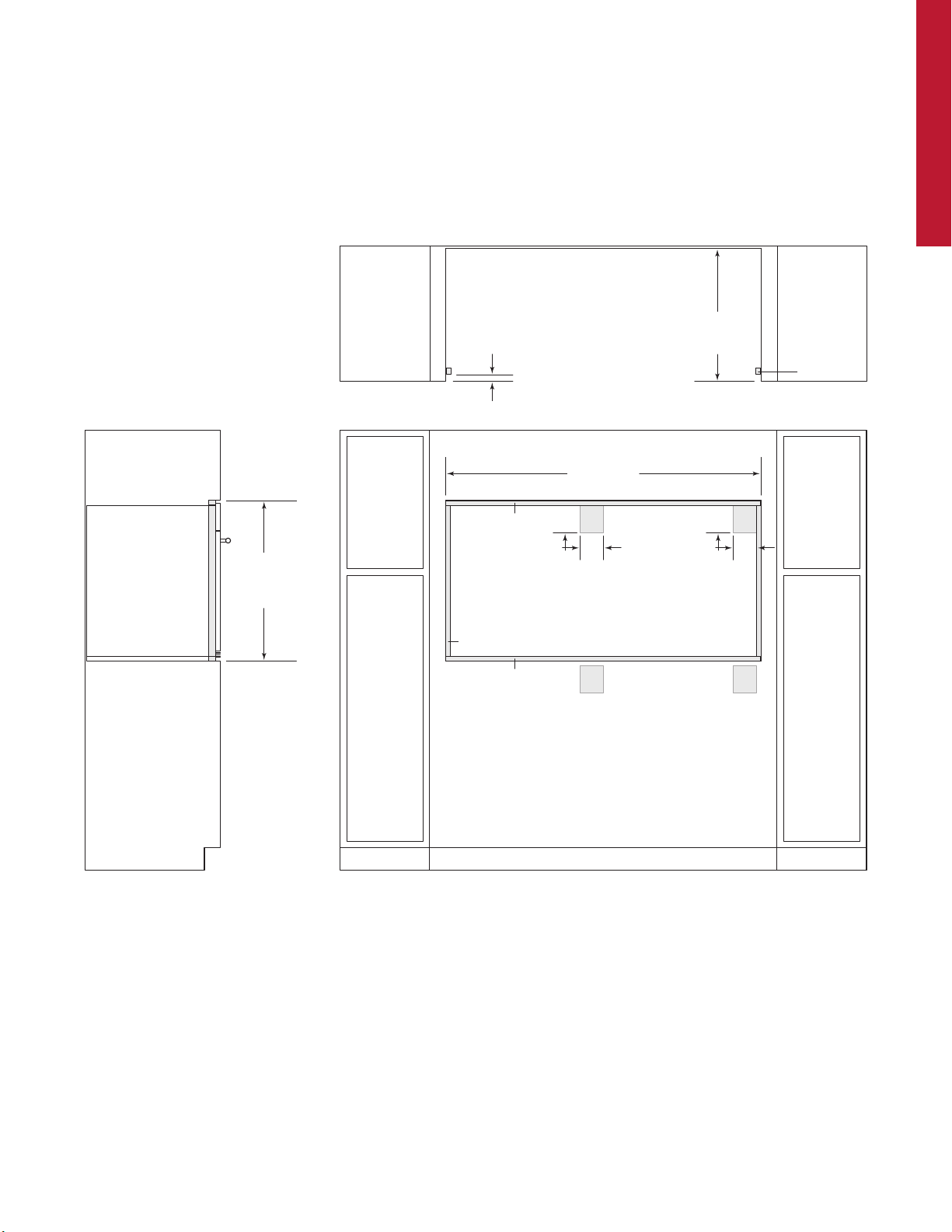

UPPER OVEN LOWER OVEN

M SERIES OVENS

M Series Built-In Ovens

Four striking new looks are just the beginning. Contemporary M series ovens include stainless steel and black glass

models. Superior performance features include a more

advanced dual vertical convection fan system, touchscreen controls, convenient preset cooking programs, and

improved interior lighting. There is more usable space inside

for deliciousness on a grand scale. M series ovens can be

installed in a standard or ush inset application.

M SERIES OVENS

TRANSITIONAL

SO30TM/S/TH

DO30TM/S/TH

PROFESSIONAL

SO30PM/S/PH

DO30PM/S/PH

CONTEMPORARY

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

4 | Wolf Customer Care 800.222.7820

SO30CM/S

DO30CM/S

SO30CM/B

DO30CM/B

Page 5

M SERIES OVENS

30" M Series Built-In Ovens

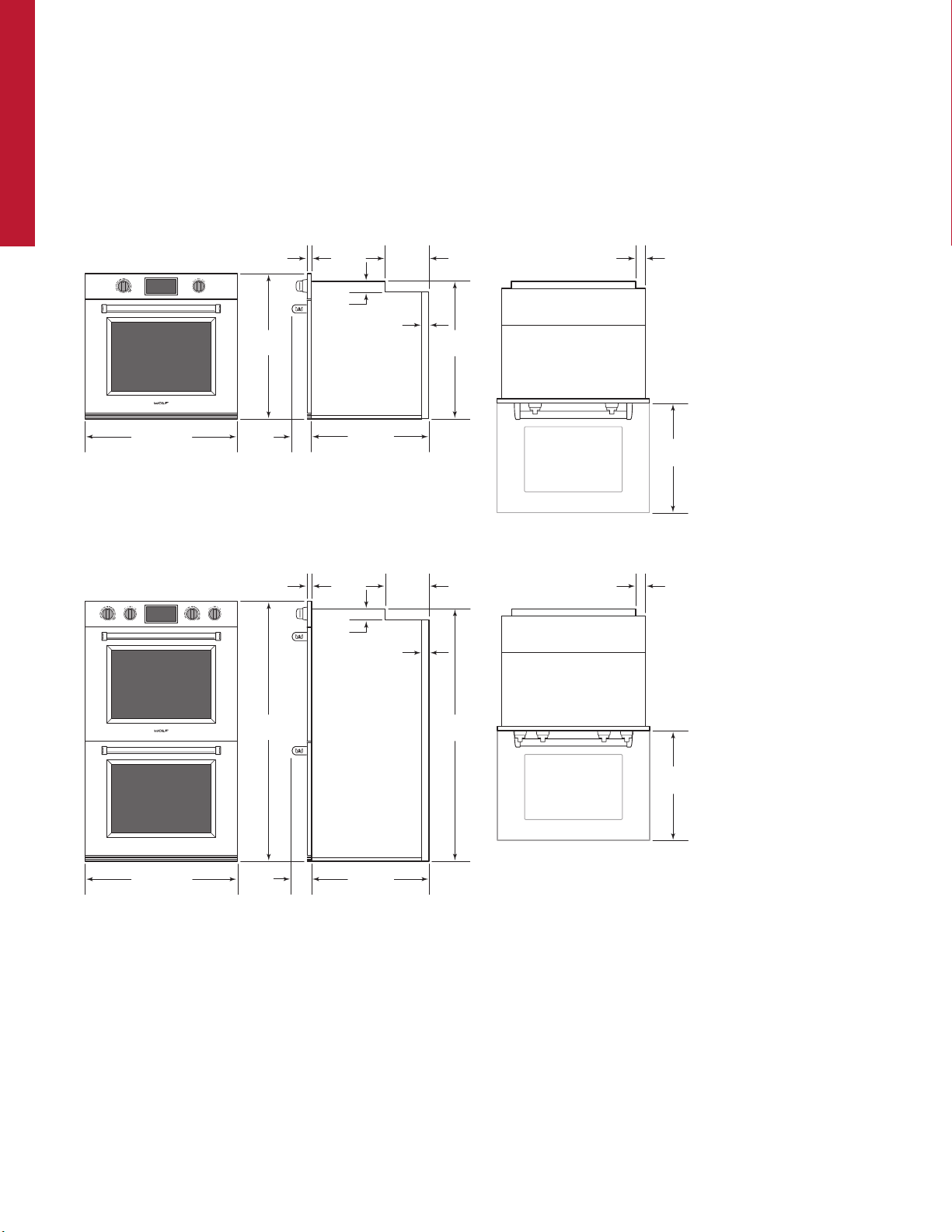

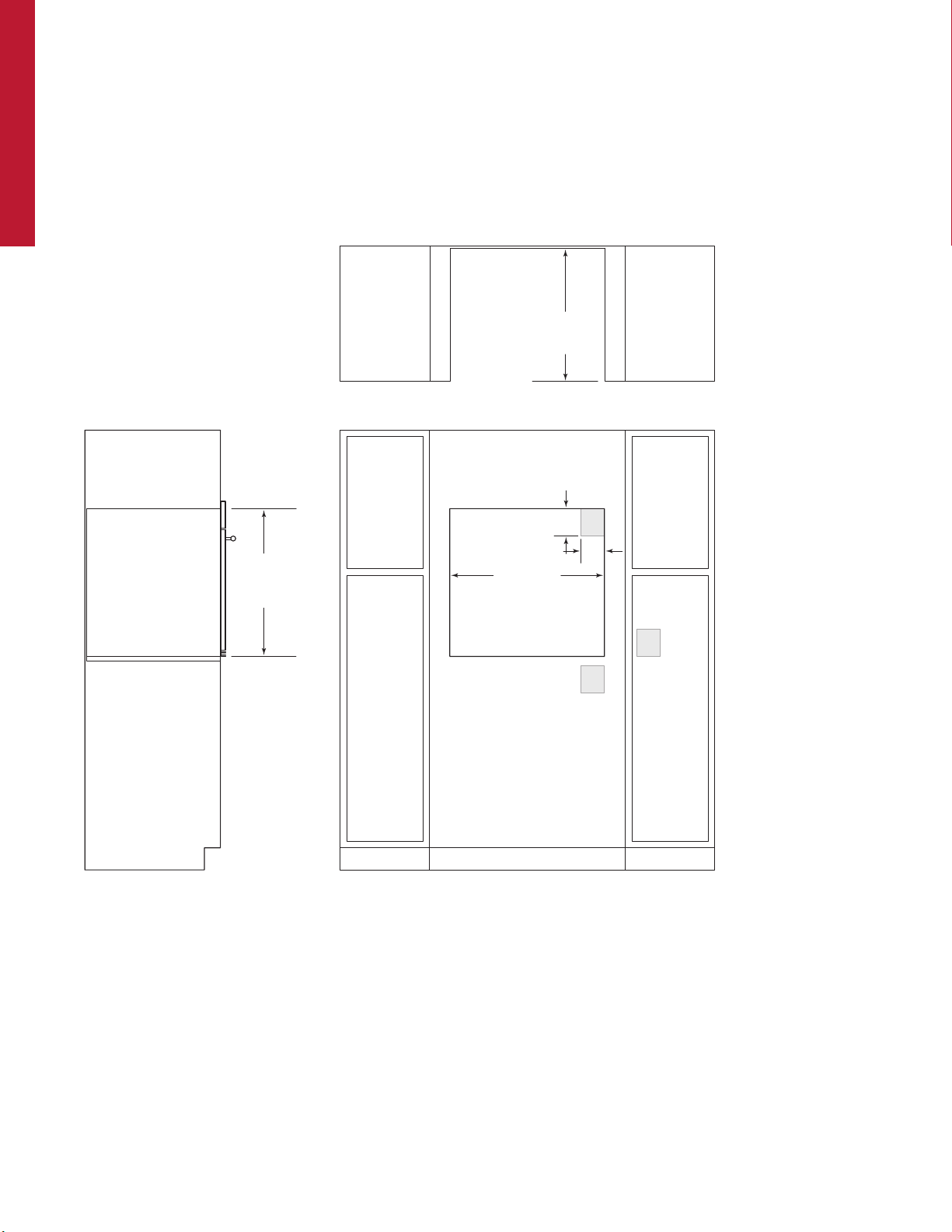

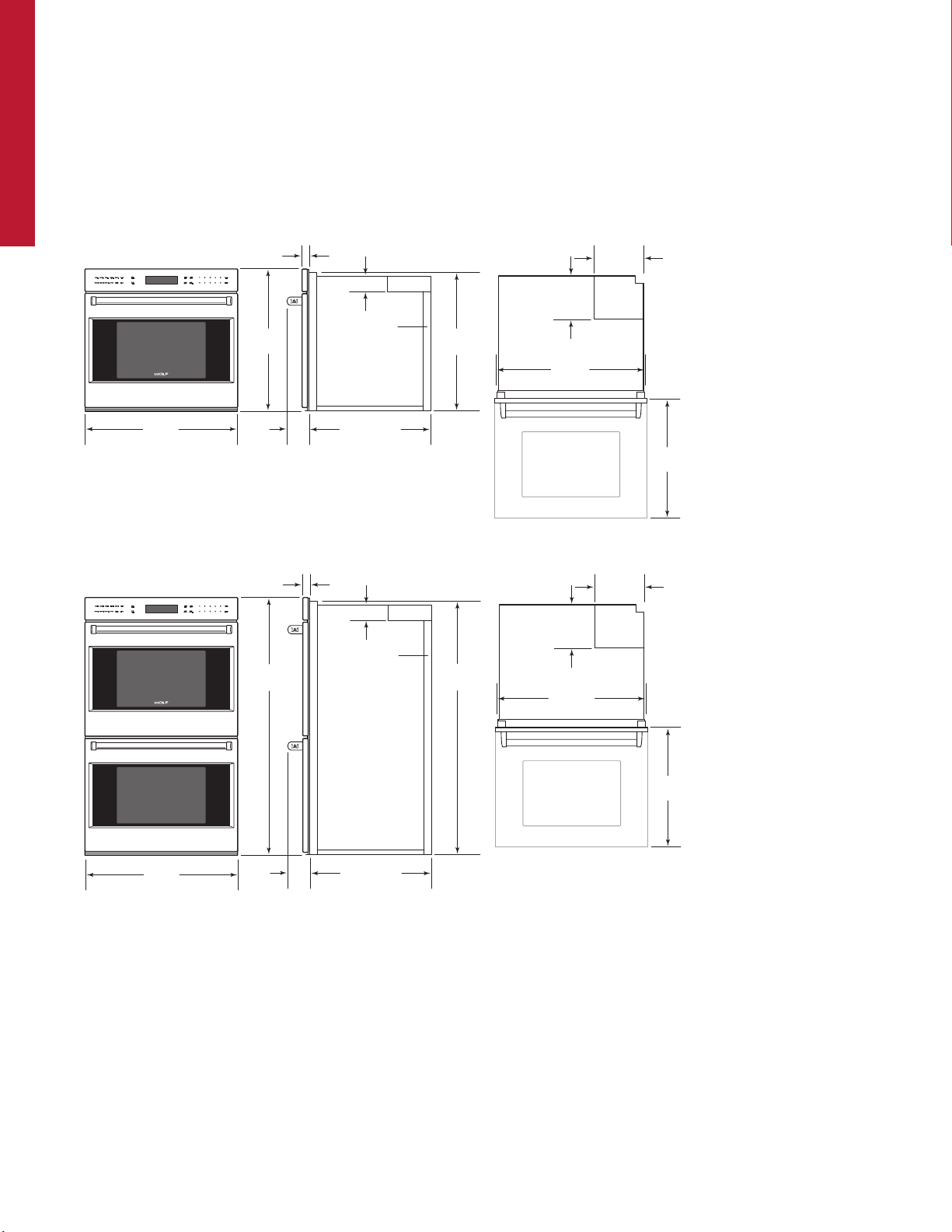

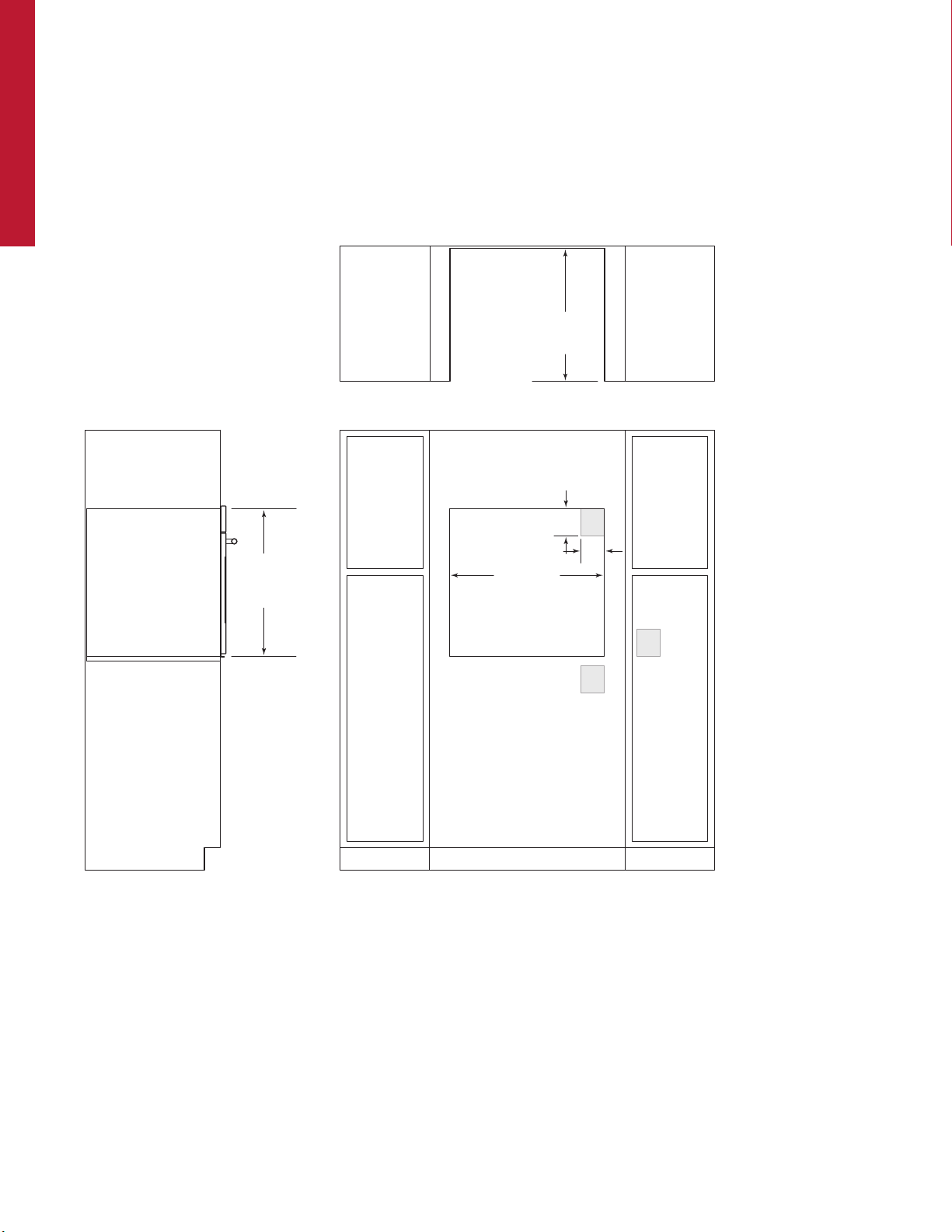

TRANSITIONAL SINGLE OVEN

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

281/2"

(723)

297/8" (759)

21/2"

(65)

TRANSITIONAL DOUBLE OVEN

7

/8"

(22)

2" (51)

CHANNEL

23" (584)

BEHIND FRAME

7

/8"

(22)

2" (51)

13/8"

CHANNEL

(36)

13/8"

CONDUIT

(36)

CONDUIT

85/8"

(218)

85/8"

(218)

27"

(686)

17/8"

(46)

OPEN OVEN DOOR

17/8"

(46)

213/8"

(543)

297/8" (759)

507/8"

(1291)

21/2"

(65)

23" (584)

BEHIND FRAME

493/8"

(1254)

OPEN OVEN DOOR

213/8"

(543)

wolfappliance.com | 5

Page 6

M SERIES OVENS

30" M Series Built-In Ovens

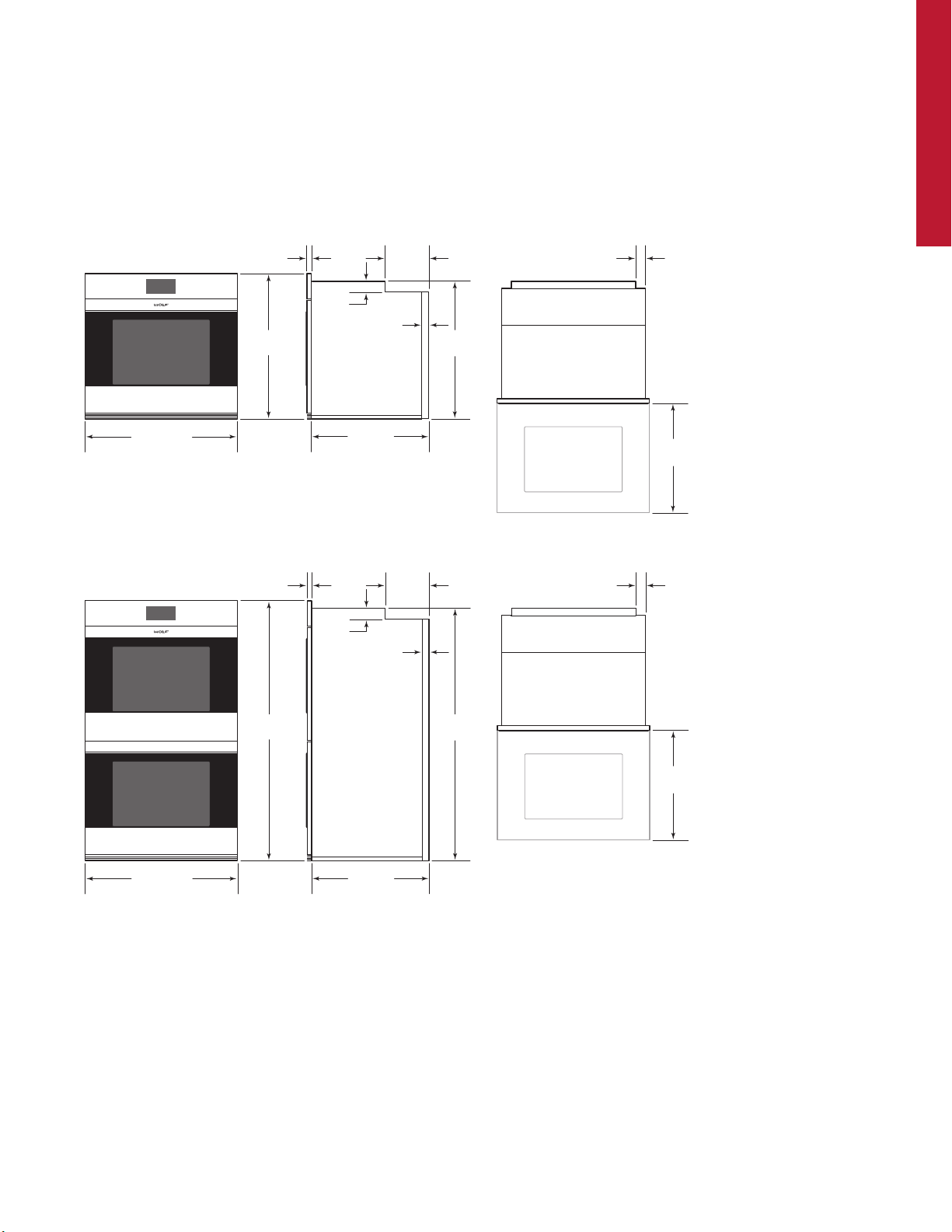

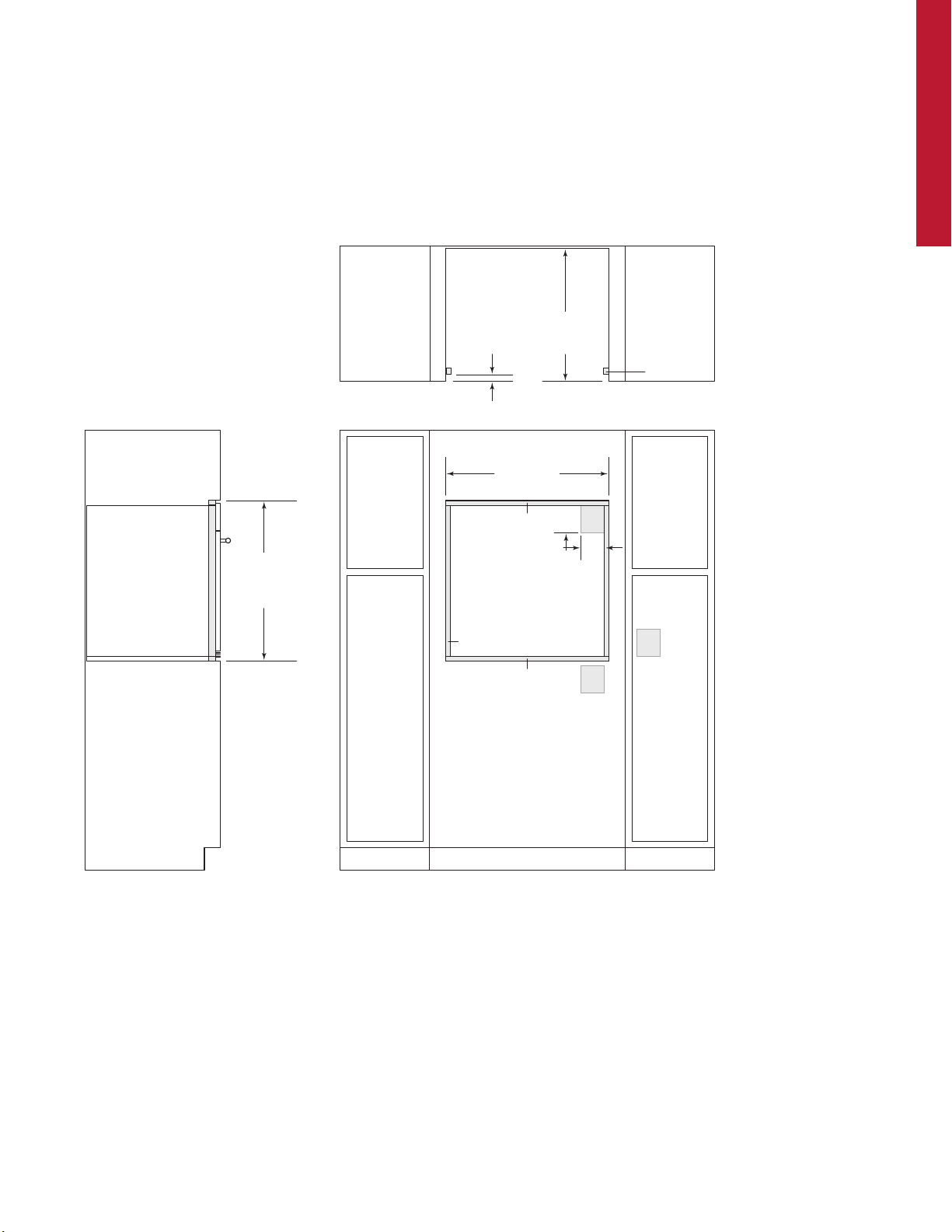

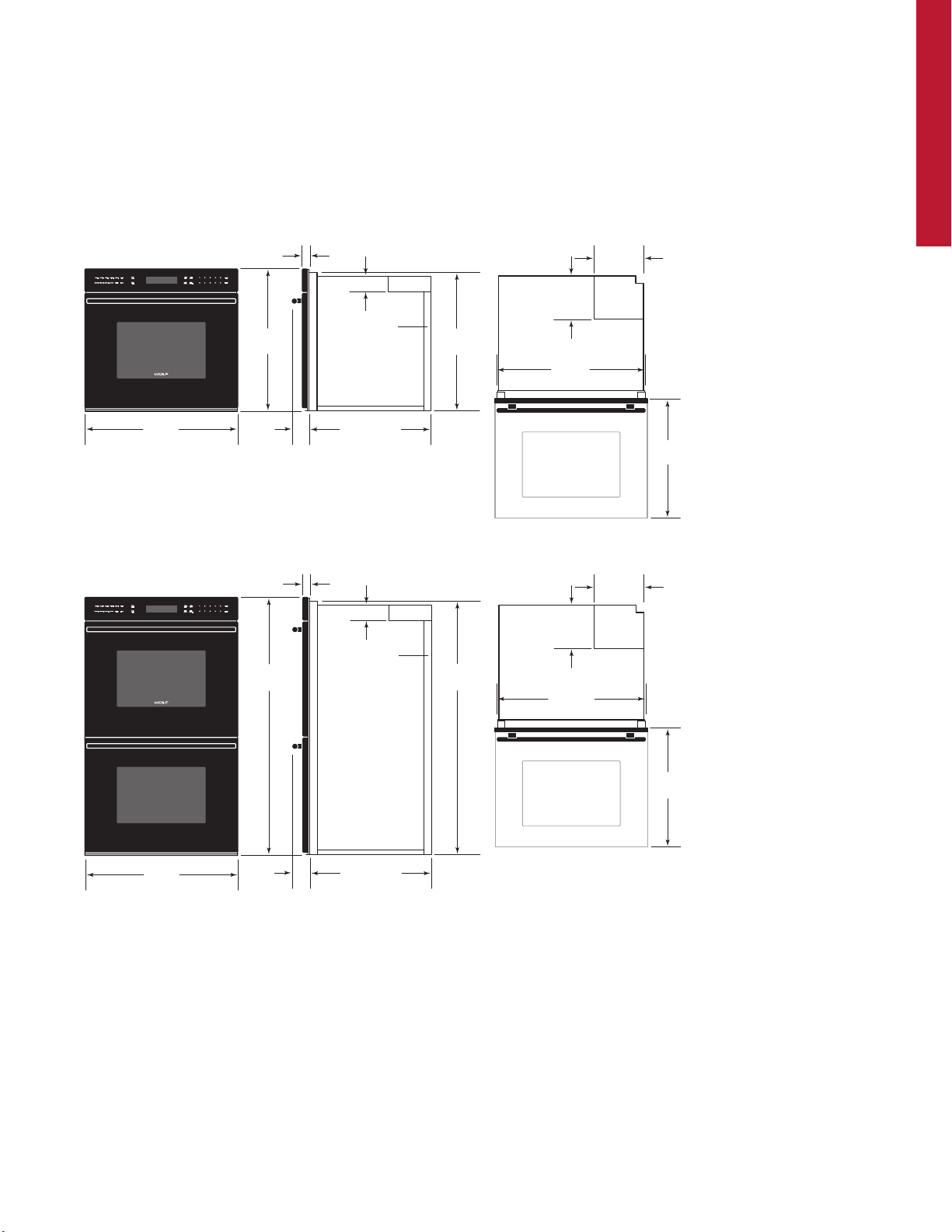

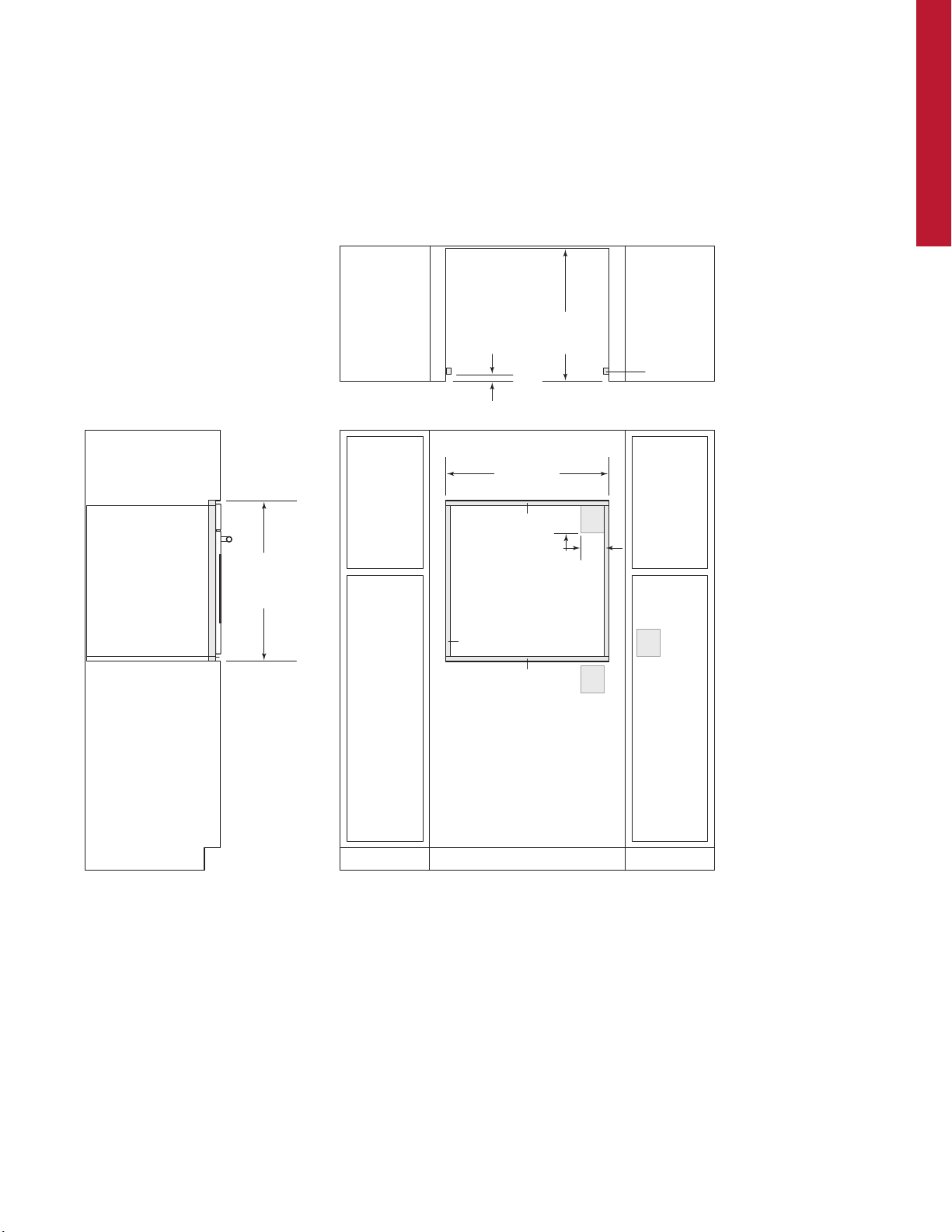

PROFESSIONAL SINGLE OVEN

281/2"

(723)

297/8" (759)

31/4"

(83)

PROFESSIONAL DOUBLE OVEN

UPPER OVEN LOWER OVEN

7

/8"

(22)

2" (51)

13/8"

CONDUIT

CHANNEL

23" (584)

BEHIND FRAME

7

/8"

(22)

2" (51)

13/8"

CHANNEL

(36)

(36)

CONDUIT

85/8"

(218)

85/8"

(218)

27"

(686)

17/8"

(46)

OPEN OVEN DOOR

17/8"

(46)

213/8"

(543)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

6 | Wolf Customer Care 800.222.7820

297/8" (759)

507/8"

(1291)

31/4"

(83)

23" (584)

BEHIND FRAME

493/8"

(1254)

OPEN OVEN DOOR

213/8"

(543)

Page 7

M SERIES OVENS

30" M Series Built-In Ovens

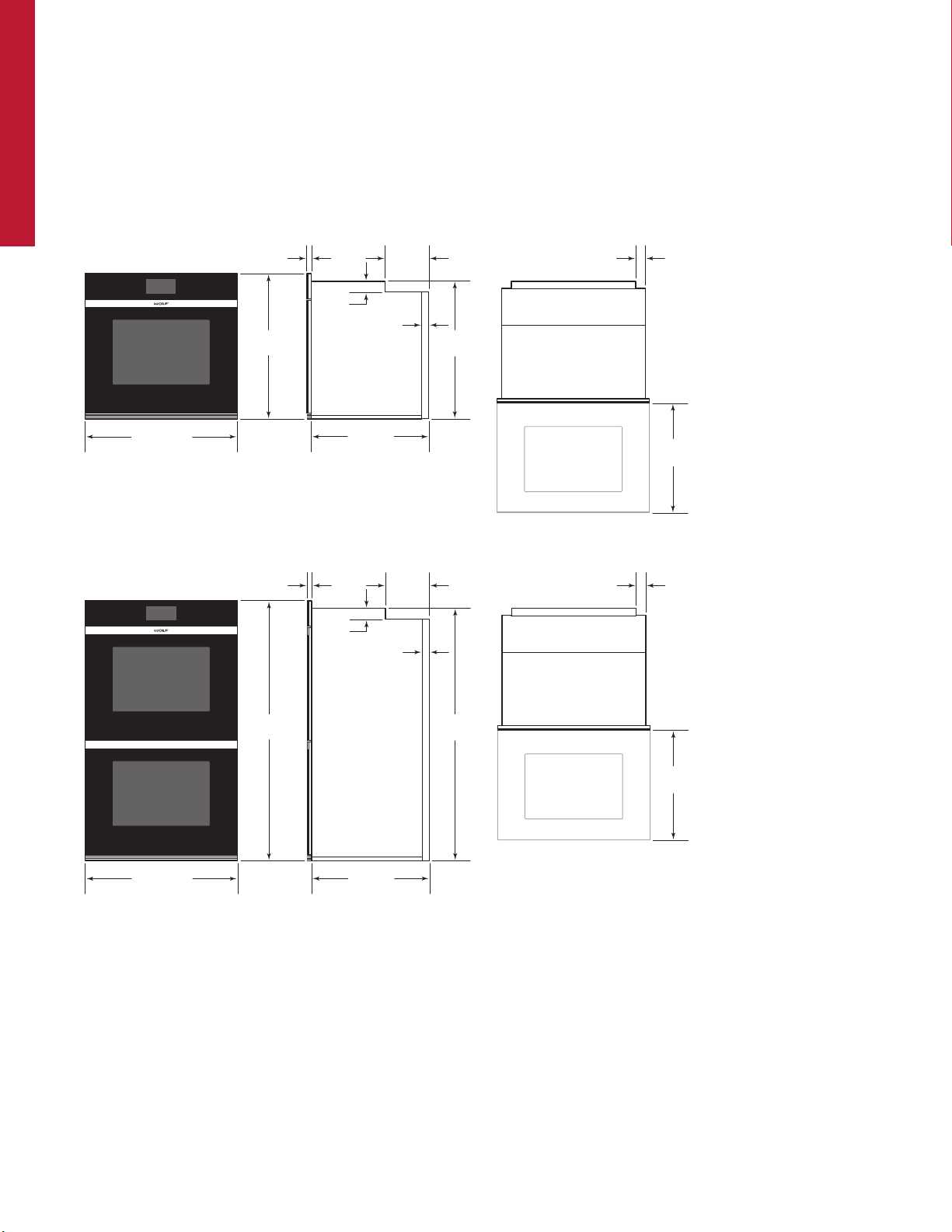

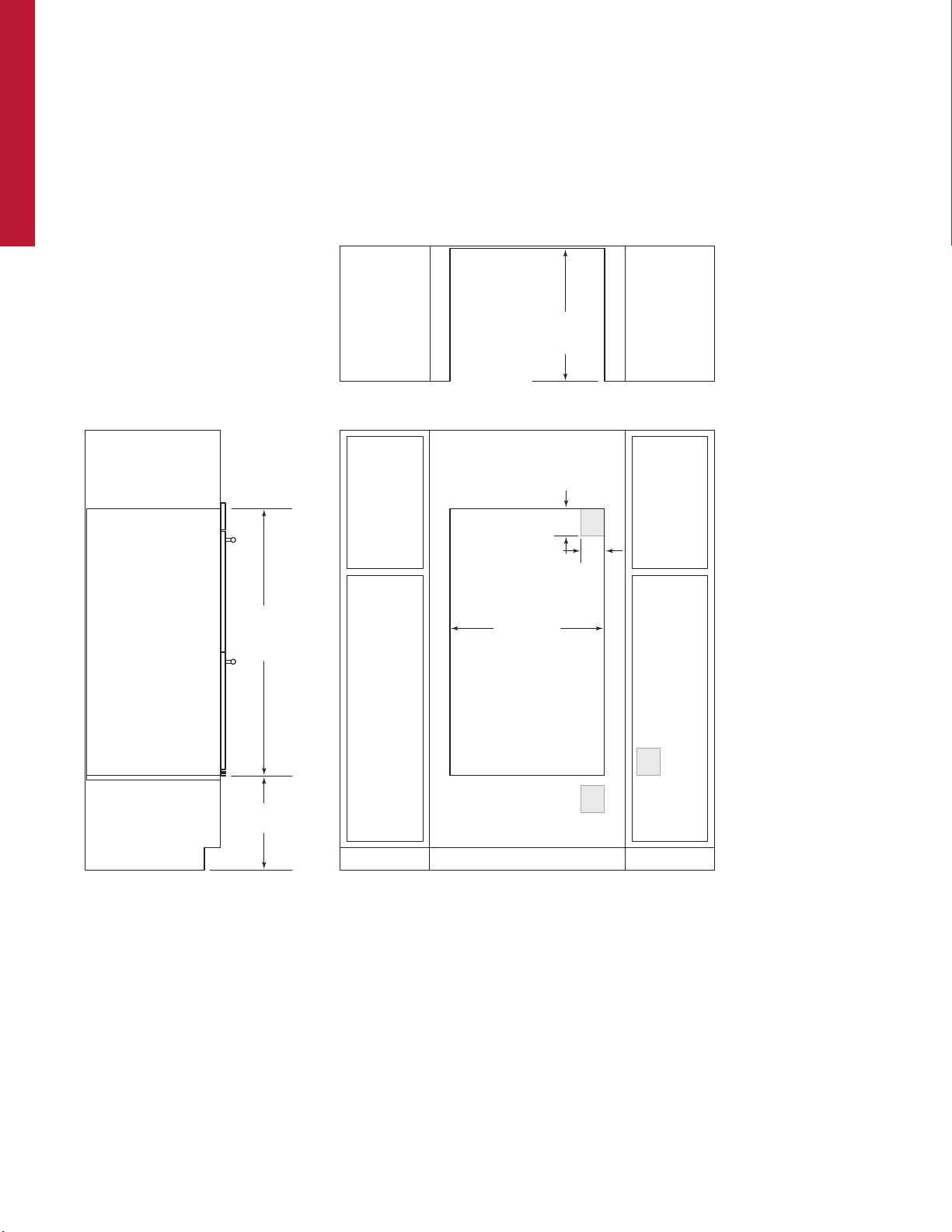

CONTEMPORARY STAINLESS STEEL SINGLE OVEN

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

7

(22)

/8"

85/8"

(218)

2" (51)

(36)

13/8"

297/8" (759)

281/2"

(723)

CONDUIT

CHANNEL

23" (584)

BEHIND FRAME

27"

(686)

CONTEMPORARY STAINLESS STEEL DOUBLE OVEN

7

(22)

2" (51)

/8"

(36)

13/8"

CONDUIT

CHANNEL

85/8"

(218)

17/8"

(46)

OPEN OVEN DOOR

17/8"

(46)

213/8"

(543)

297/8" (759)

507/8"

(1291)

23" (584)

BEHIND FRAME

493/8"

(1254)

OPEN OVEN DOOR

213/8"

(543)

wolfappliance.com | 7

Page 8

M SERIES OVENS

30" M Series Built-In Ovens

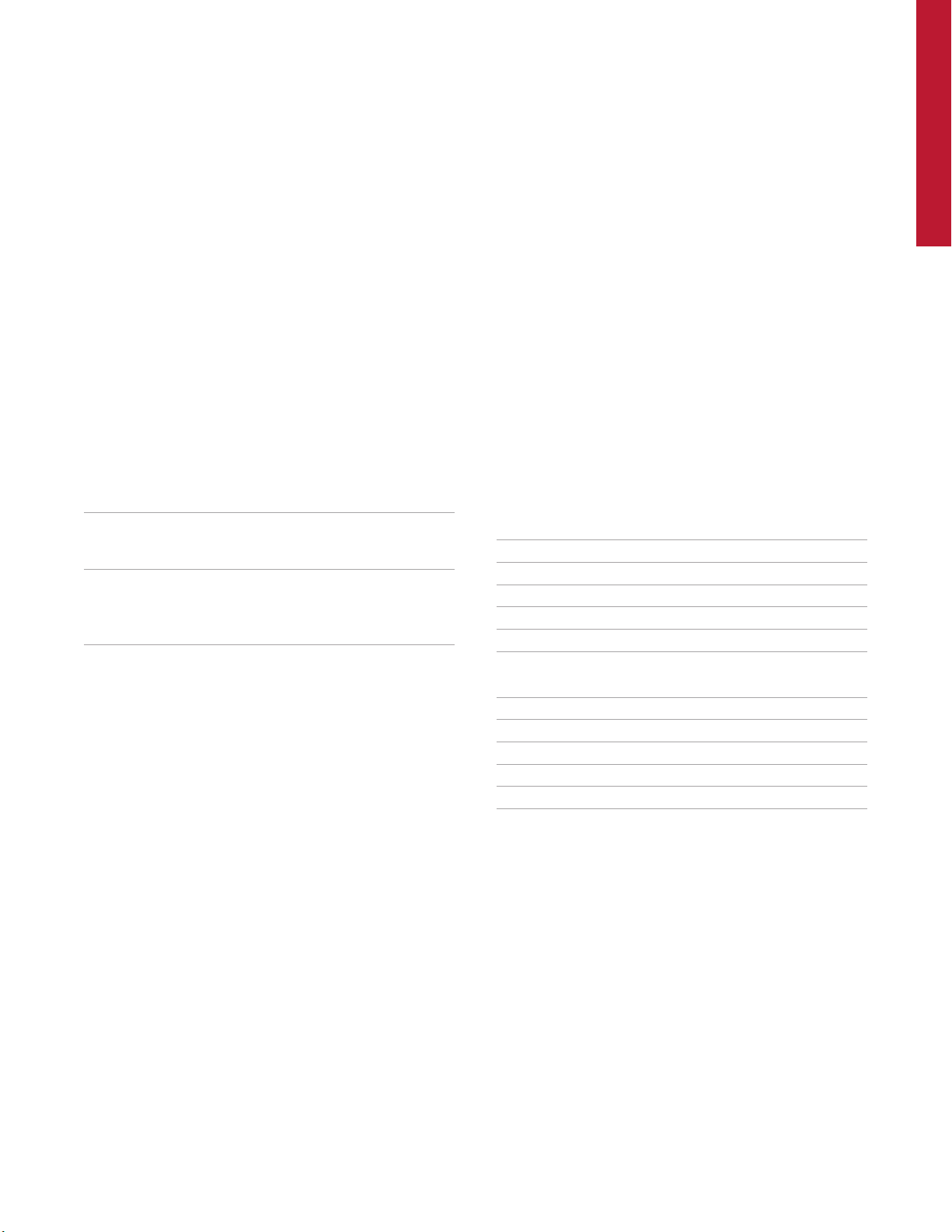

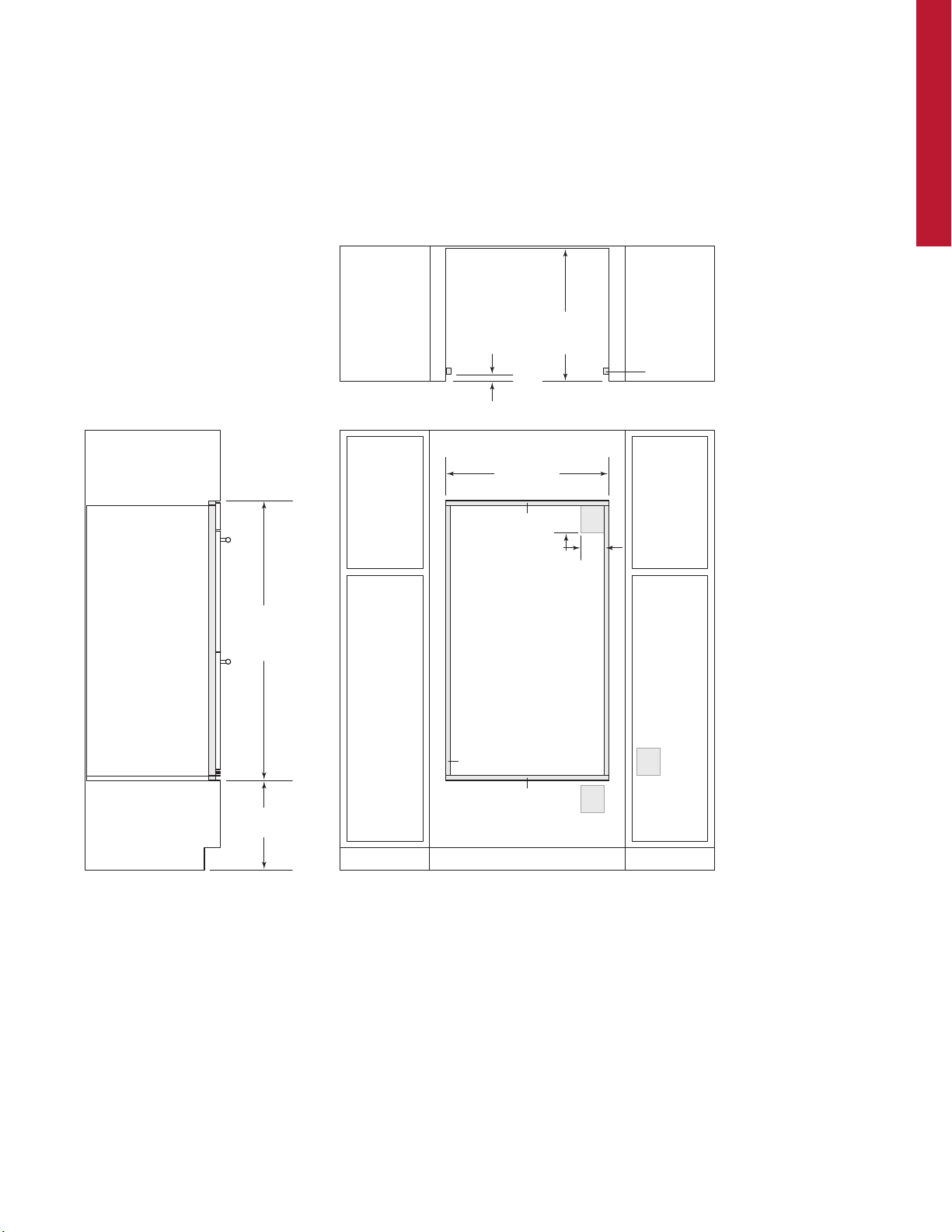

CONTEMPORARY BLACK GLASS SINGLE OVEN

(25)

1"

85/8"

(218)

2" (51)

(36)

13/8"

CONDUIT

CHANNEL

23" (584)

BEHIND FRAME

297/8" (759)

281/2"

(723)

CONTEMPORARY BLACK GLASS DOUBLE OVEN

(36)

13/8"

CONDUIT

CHANNEL

85/8"

(218)

(25)

2" (51)

1"

27"

(686)

17/8"

(46)

OPEN OVEN DOOR

17/8"

(46)

213/8"

(543)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

8 | Wolf Customer Care 800.222.7820

297/8" (759)

507/8"

(1291)

23" (584)

BEHIND FRAME

493/8"

(1254)

OPEN OVEN DOOR

213/8"

(543)

Page 9

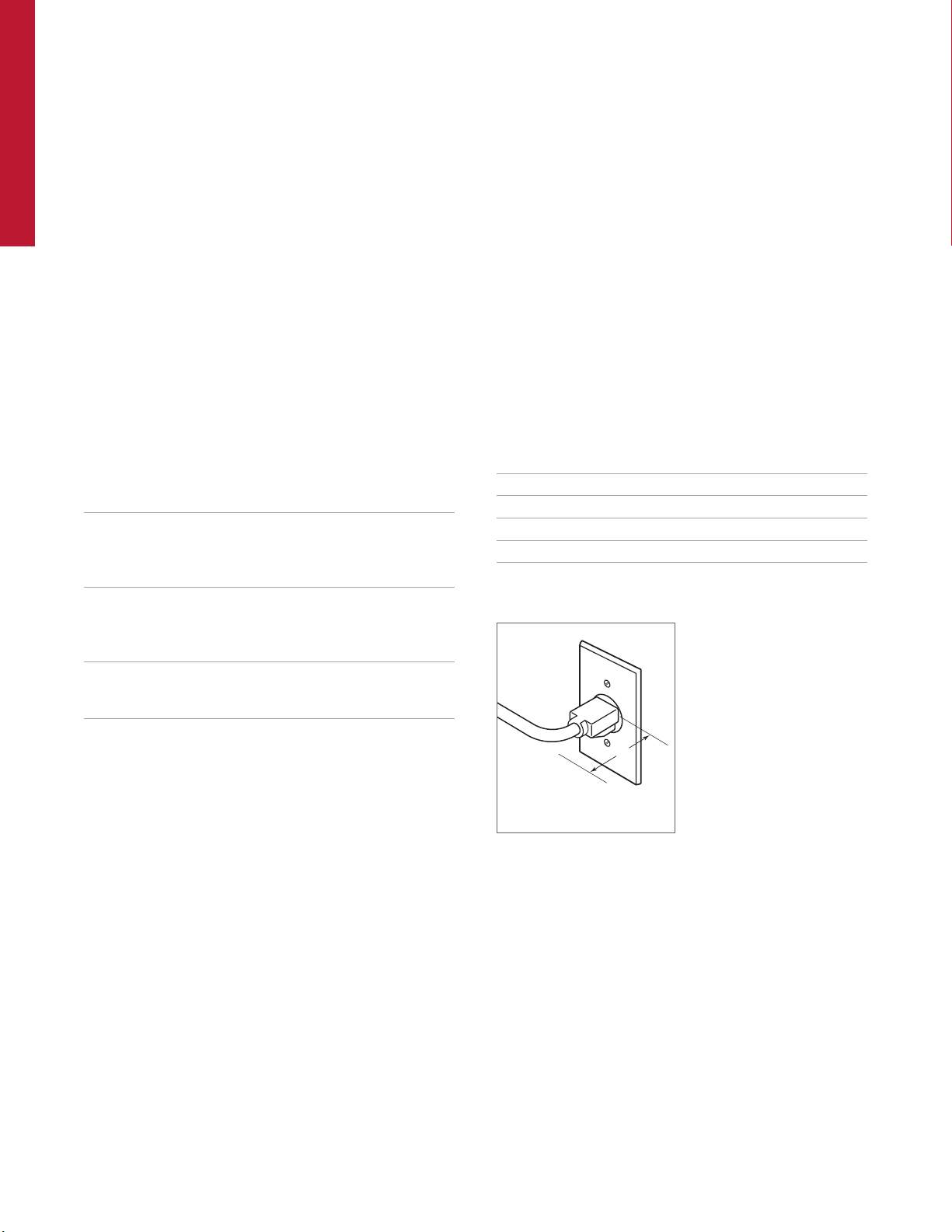

M SERIES OVENS

Planning Information

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

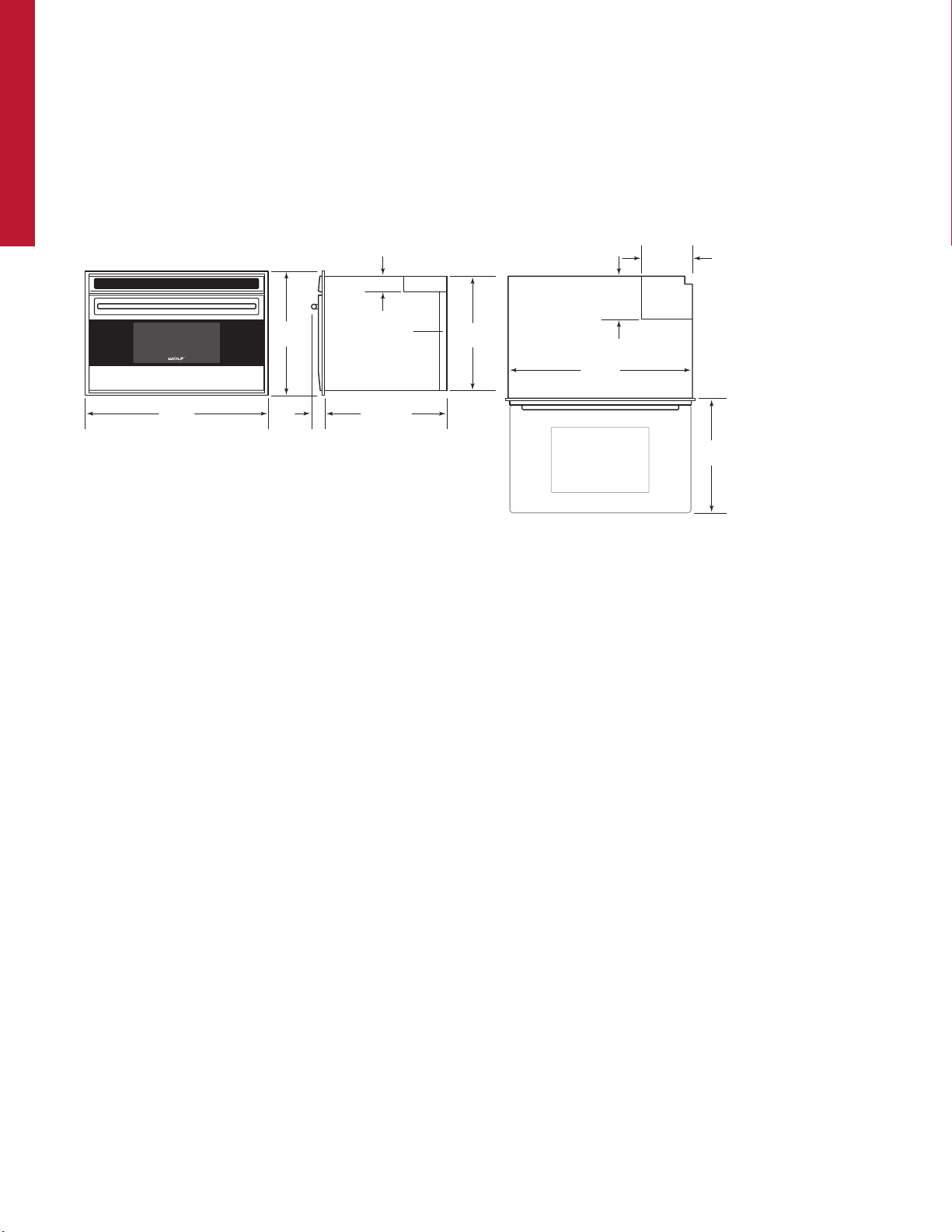

The M series oven can be installed in a standard or ush

inset application. If a cooktop is being installed above an

1

oven, a minimum of

/4" (6) is required between the units.

The location of the electrical supply within the oven opening

may require additional cabinet depth.

Finish the edges of the opening. They may be visible when

the door is open.

For standard installations, the face trim will overlap stiles

and rails. Refer to the chart below.

1

For ush inset installations, a minimum

/8" (3) reveal is

required on all sides. To ensure consistent reveals, each

corner of the opening must be exactly 90°.

INSTALLATION REQUIREMENTS

BASE SUPPORT MIN

Single Oven 250 lb (115 kg)

Double Oven 400 lb (181 kg)

TRIM OVERLAP

Top 1" (25)

Bottom 0" (0)

Sides

11

/16" (18)

ELECTRICAL REQUIREMENTS

Installation must comply with all applicable electrical codes.

Locate the electrical supply ush with the back wall and

within the shaded area shown in the illustrations on the

following pages. For ease of installation, the electrical

supply for the oven can be placed in an adjacent cabinet

within reach of the conduit.

Performance may be compromised if the electrical supply is

less than 240 volts.

The oven is supplied with a conduit consisting of two

insulated hot lead conductors and a bare ground conductor.

The wiring diagram covering the control circuit is provided

with the oven.

ELECTRICAL REQUIREMENTS—SINGLE OVEN

Electrical Supply grounded, 240/208 VAC, 60 Hz

Service 30 amp dedicated circuit

Conduit 4'

Total Amps 22

Max Connected Load 5.4 kW

(1.2 m)

DUAL INSTALLATION

Two 30" single M series ovens can be installed side by side

in a standard or ush inset application. A dual installation kit

is required. To maintain appropriate airow, the ovens must

be installed into one opening. Any cosmetic or structural

material placed between the ovens will impede airow and

is not recommended. Refer to the illustrations on pages

14–15.

The dual installation kit is available through an authorized

Wolf dealer. For local dealer information, visit the nd a

showroom section of our website, wolfappliance.com.

ELECTRICAL REQUIREMENTS —DOUBLE OVEN

Electrical Supply grounded, 240/208 VAC, 60 Hz

Service 50 amp dedicated circuit

Conduit 5'

Total Amps 45

Max Connected Load 10.8 kW

(1.5 m)

wolfappliance.com | 9

Page 10

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth.

M SERIES OVENS

30" M Series Single Oven

STANDARD INSTALLATION

231/4" (591)

TOP VIEW

OPENING

DEPTH

VIEW

271/2"

(699)

OPENING

HEIGHT

281/2" (724)

OPENING WIDTH

FRONT VIEW

5"

(127)

E

4"

(102)

E

E

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

10 | Wolf Customer Care 800.222.7820

Page 11

*1

**

**

NOTE: Location of electrical supply within opening may require additional cabinet depth.

SIDE

M SERIES OVENS

30" M Series Single Oven

FLUSH INSET INSTALLATION

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

283/4"

(730)

FLUSH INSET

HEIGHT***

7

(22)

/8"

OR

(25)**

1"

FLUSH INSET WIDTH***

24" (610)

FLUSH INSET

TOP VIEW

301/8" (765)

DEPTH

11/8" (29)

13

/16" (21)

1

/8" (3)

5"

(127)

E

4"

(102)

E

FINISHED

CLEATS*

E

VIEW

" (25) minimum depth. Shaded areas will be visible and should be finished to match cabinetry.

7

/8" (22) for transitional, professional and contemporary stainless steel models and 1" (25) for contemporary black glass model.

*Dimension provides minimum reveals.

FRONT VIEW

wolfappliance.com | 11

Page 12

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth.

M SERIES OVENS

30" M Series Double Oven

STANDARD INSTALLATION

231/4" (591)

TOP VIEW

OPENING

DEPTH

VIEW

497/8"

(1267)

OPENING

HEIGHT

17" (432)

TYPICAL

281/2" (724)

OPENING WIDTH

FRONT VIEW

5"

(127)

E

4"

(102)

E

E

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

12 | Wolf Customer Care 800.222.7820

Page 13

*1

**

**

NOTE: Location of electrical supply within opening may require additional cabinet depth.

SIDE

M SERIES OVENS

30" M Series Double Oven

FLUSH INSET INSTALLATION

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

511/8"

(1299)

FLUSH INSET

HEIGHT***

7

(22)

/8"

OR

(25)**

1"

FLUSH INSET WIDTH***

24" (610)

FLUSH INSET

TOP VIEW

301/8" (765)

DEPTH

11/8" (29)

13

/16" (21)

5"

(127)

E

4"

(102)

FINISHED

CLEATS*

E

(432)

17"

TYPICAL

VIEW

" (25) minimum depth. Shaded areas will be visible and should be finished to match cabinetry.

7

/8" (22) for transitional, professional and contemporary stainless steel models and 1" (25) for contemporary black glass model.

*Dimension provides minimum reveals.

1

/8" (3)

FRONT VIEW

E

wolfappliance.com | 13

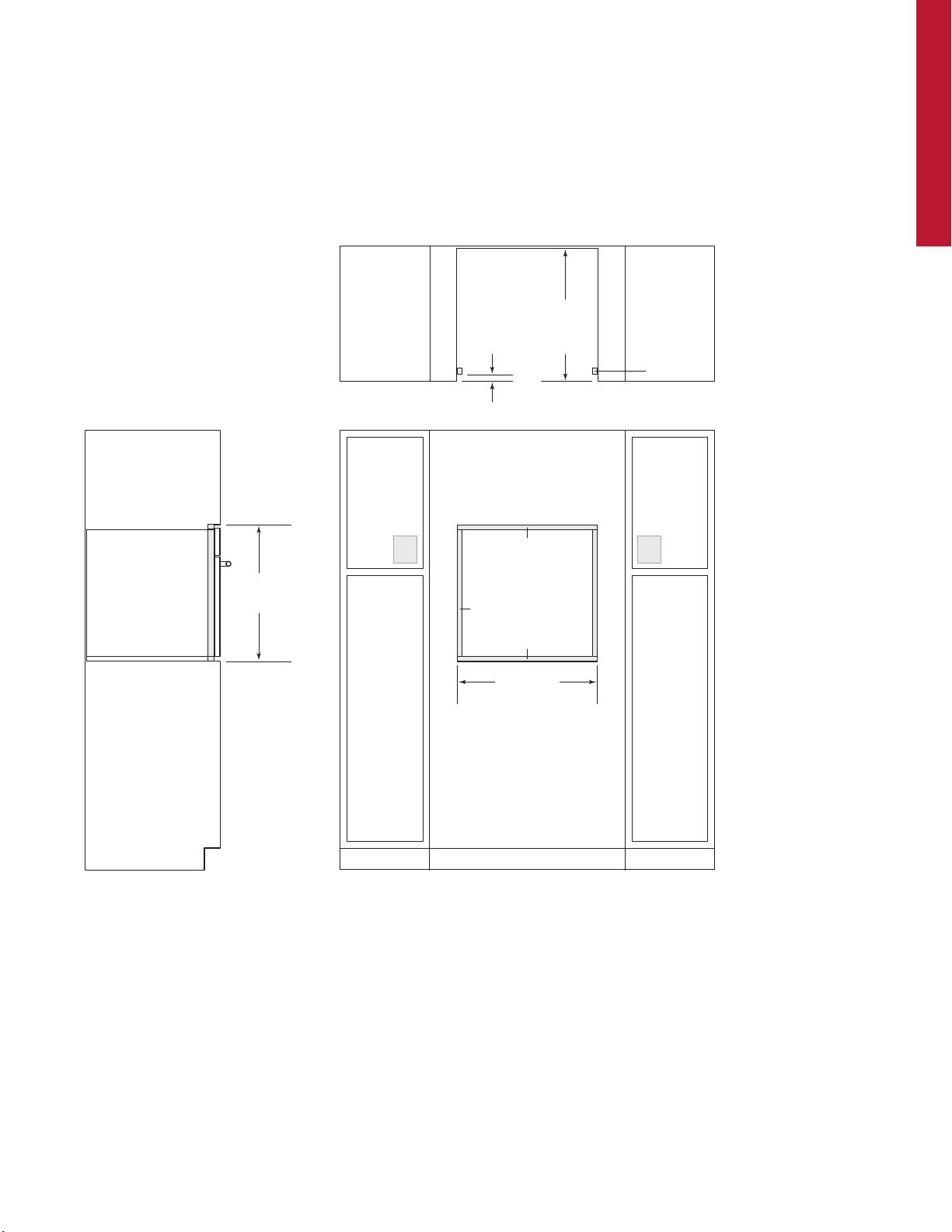

Page 14

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth. A dual installation kit is required fo

M SERIES OVENS

30" M Series Single Oven

DUAL STANDARD INSTALLATION

TOP VIEW

231/4" (591)

OPENING

DEPTH

VIEW

271/2"

(699)

OPENING

HEIGHT

5"

E

(127)

4"

(102)

581/2" (1486)

OPENING WIDTH

E E

FRONT VIEW

r this installation.

5"

(127)

E

4"

(102)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

14 | Wolf Customer Care 800.222.7820

Page 15

SIDE

*1

**

**

NOTE: Location of electrical supply within opening may require additional cabinet depth. A dual installation kit is required fo

M SERIES OVENS

30" M Series Single Oven

DUAL FLUSH INSET INSTALLATION

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

283/4"

(730)

FLUSH INSET

HEIGHT***

7

1"

13

/16" (21)

(22)

/8"

OR

(25)**

11/8" (29)

1

/8" (3)

TOP VIEW

601/8" (1527)

FLUSH INSET WIDTH***

5"

E

(127)

4"

(102)

24" (610)

FLUSH INSET

DEPTH

5"

(127)

(102)

FINISHED

CLEATS*

E

4"

EE

VIEW

" (25) minimum depth. Shaded areas will be visible and should be finished to match cabinetry.

7

/8" (22) for transitional, professional and contemporary stainless steel models and 1" (25) for contemporary black glass model.

*Dimension provides minimum reveals.

FRONT VIEW

r this installation.

wolfappliance.com | 15

Page 16

16 | Wolf Customer Care 800.222.7820

Page 17

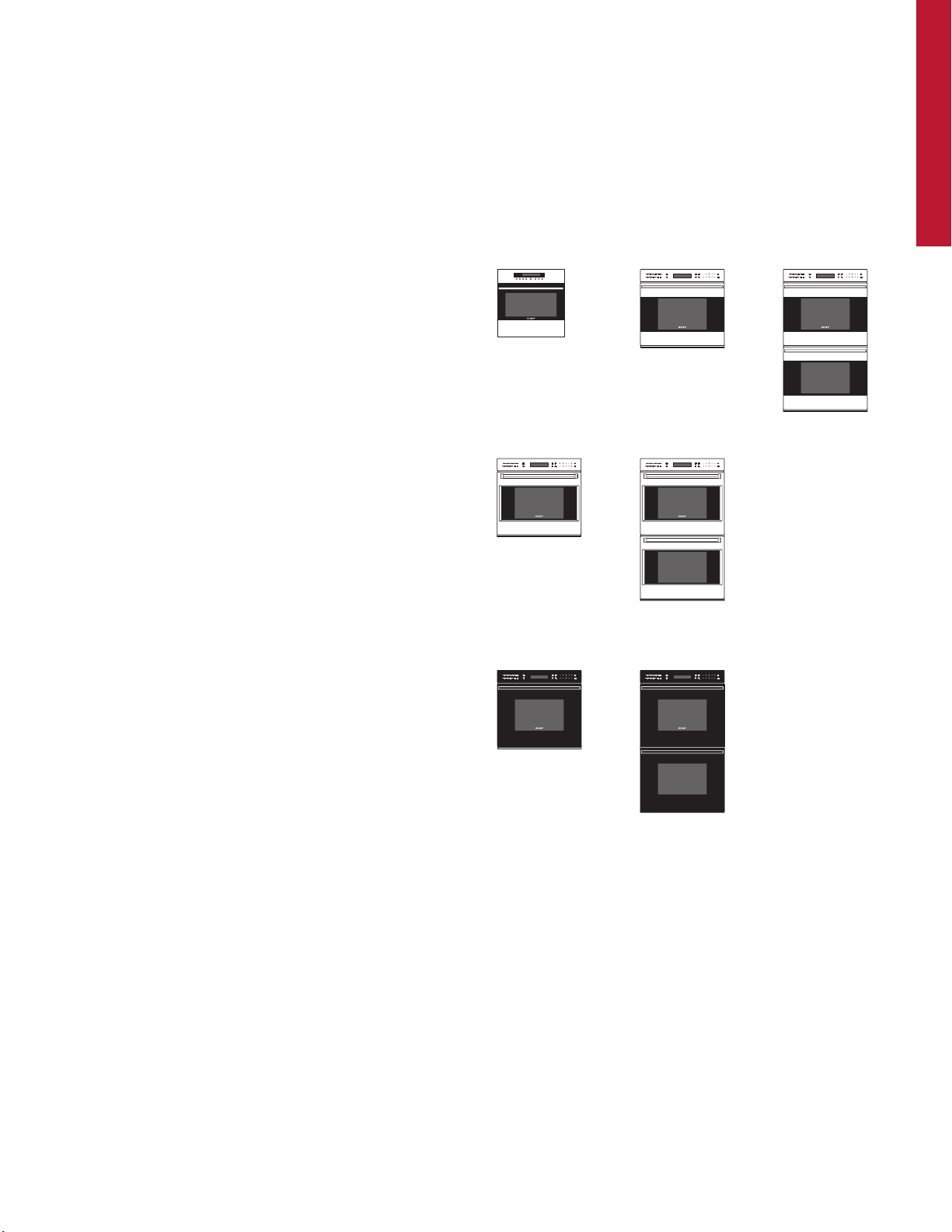

E SERIES OVENS

E Series Built-In Ovens

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

Wolf E series ovens are crafted of stainless steel. The

handles match the rest of the new Wolf cooking appliance

offering, providing a more cohesive look. E series ovens can

be installed in a standard or ush inset application.

E SERIES OVENS

TRANSITIONAL

OK

WARM LIGHTTEMPMODETIMER TIME OFF

SO24TE/S/TH

PROFESSIONAL

SO30PE/S/PH

CONTEMPORARY

SO30TE/S/TH

DO30TE/S/TH

DO30PE/S/PH

SO30CE/B/TH

DO30CE/B/TH

wolfappliance.com | 17

Page 18

E SERIES OVENS

24" E Series Built-In Oven

TRANSITIONAL SINGLE OVEN

OK

WARM LIGHTTEMPMODETIMER TIME OFF

7

(22)

/8"

22"

(559)

231/2"

(597)

231/2"

(597)

21/2"

(64)

211/2" (546)

BEHIND FRAME

231/4"

(591)

OPEN OVEN DOOR

181/8"

(460)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

18 | Wolf Customer Care 800.222.7820

Page 19

E SERIES OVENS

30" E Series Built-In Ovens

TRANSITIONAL SINGLE OVEN

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

1" (25)

277/8"

(708)

297/8"

(759)

23/4"

(70)

TRANSITIONAL DOUBLE OVEN

1" (25)

503/8"

(1280)

(76)

3"

CONDUIT

CHANNEL

233/4" (603)

BEHIND FRAME

(76)

3"

CONDUIT

CHANNEL

271/8"

(689)

495/8"

(1261)

87/8"

(225)

281/4"

(718)

OPEN OVEN DOOR

87/8"

(225)

281/4"

(718)

95/8"

(244)

95/8"

(244)

22"

(559)

297/8"

(759)

23/4"

(70)

233/4" (603)

BEHIND FRAME

OPEN OVEN DOOR

22"

(559)

wolfappliance.com | 19

Page 20

E SERIES OVENS

30" E Series Built-In Ovens

PROFESSIONAL SINGLE OVEN

1" (25)

277/8"

(708)

297/8"

(759)

33/8"

(86)

PROFESSIONAL DOUBLE OVEN

1" (25)

503/8"

(1280)

(76)

3"

CONDUIT

CHANNEL

233/4" (603)

BEHIND FRAME

(76)

3"

CONDUIT

CHANNEL

271/8"

(689)

495/8"

(1261)

87/8"

(225)

281/4"

(718)

OPEN OVEN DOOR

87/8"

(225)

281/4"

(718)

95/8"

(244)

95/8"

(244)

22"

(559)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

20 | Wolf Customer Care 800.222.7820

297/8"

(759)

33/8"

(86)

233/4" (603)

BEHIND FRAME

OPEN OVEN DOOR

22"

(559)

Page 21

E SERIES OVENS

30" E Series Built-In Ovens

CONTEMPORARY SINGLE OVEN

(32)

11/4"

277/8"

(708)

(76)

3"

CONDUIT

CHANNEL

271/16"

(687)

87/8"

(225)

281/4"

(718)

95/8"

(244)

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

297/8"

(759)

3"

(76)

CONTEMPORARY DOUBLE OVEN

11/4" (32)

503/8"

(1280)

297/8"

(759)

3"

(76)

233/4" (603)

BEHIND FRAME

(76)

3"

CONDUIT

CHANNEL

233/4" (603)

BEHIND FRAME

491/2"

(1257)

OPEN OVEN DOOR

87/8"

(225)

281/4"

(718)

OPEN OVEN DOOR

95/8"

(244)

22"

(559)

22"

(559)

wolfappliance.com | 21

Page 22

E SERIES OVENS

Planning Information

E series ovens can be installed in a standard or ush inset

application. If a cooktop is being installed above an oven, a

1

minimum of

/4" (6) is required between the units. The location of the electrical supply within the oven opening may

require additional cabinet depth.

Finish the edges of the opening. They may be visible when

the door is open.

For standard installations, the face trim will overlap stiles

and rails. Refer to the chart below.

For ush inset installations, a minimum reveal is required

on all sides. Refer to the chart below. To ensure consistent

reveals, each corner of the opening must be exactly 90°.

INSTALLATION REQUIREMENTS

BASE SUPPORT MIN

24" Oven 150 lb (68 kg)

30" Single Oven 250 lb (113 kg)

30" Double Oven 400 lb (181 kg)

TRIM OVERLAP 24" OVEN 30" OVEN

Top

Bottom 0" (0)

Sides

REVEAL MIN

24" Oven

30" Oven

1

11

/16" (17)

/4" (6)

1

/2" (13)

1

11

/16" (17)

1

1

/8" (3)

/8" (3)

/4" (6)

ELECTRICAL REQUIREMENTS—24" OVEN

Installation must comply with all applicable electrical codes.

Locate the electrical supply as shown in the illustrations

on the following pages. A separate circuit servicing only

this appliance is required. A ground fault circuit interrupter

(GFCI) is not recommended and may cause interruption of

operation. Refer to the illustration below for minimum power

cord plug clearance.

Performance may be compromised if the electrical supply is

less than 240 volts.

ELECTRICAL REQUIREMENTS—24" OVEN

Electrical Supply grounded, 240/ 208 VAC, 60 Hz

Service 20 amp dedicated circuit

Receptacle NEMA 6-20R grounding-type

Power Cord 6'

(1.8 m)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

22 | Wolf Customer Care 800.222.7820

MINIMUM CORD

CLEARANCE

Power cord clearance

3"

(76)

Page 23

E SERIES OVENS

Planning Information

ELECTRICAL REQUIREMENTS—30" OVEN

Installation must comply with all applicable electrical codes.

Locate the electrical supply ush with the back wall and

within the shaded area shown in the illustrations on the following pages. For ease of installation, the electrical supply

for the oven can be placed in an adjacent cabinet within

reach of the conduit.

Performance may be compromised if the electrical supply is

less than 240 volts.

The oven is supplied with a conduit consisting of two

insulated hot lead conductors and a bare ground conductor.

The wiring diagram covering the control circuit is provided

with the oven.

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

ELECTRICAL REQUIREMENTS—30" SINGLE OVEN

Electrical Supply grounded, 240/ 208 VAC, 60 Hz

Service 30 amp dedicated circuit

Conduit 4'

Total Amps 21

Max Connected Load 5.1 kW

ELECTRICAL REQUIREMENTS—30" DOUBLE OVEN

Electrical Supply grounded, 240/ 208 VAC, 60 Hz

Service 50 amp dedicated circuit

Conduit 5'

Total Amps 37

Max Connected Load 8.9 kW

(1.2 m)

(1.5 m)

wolfappliance.com | 23

Page 24

E SERIES OVENS

SIDE

NOTE: Electrical supply must be located in adjacent cabinet within 3'

24" E Series Single Oven

STANDARD INSTALLATION

OPENING

TOP VIEW

221/2"

(572)

DEPTH

VIEW

231/4"

(591)

OPENING

HEIGHT

(.9 m) of opening.

(562)

221/8"

OPENING WIDTH

FRONT VIEW

EE

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

24 | Wolf Customer Care 800.222.7820

Page 25

SIDE

*W

**

NOTE: Electrical supply must be located in adjacent cabinet within 3'

E SERIES OVENS

24" E Series Single Oven

FLUSH INSET INSTALLATION

7

/8"

(22)

TOP VIEW

23" (584)

FLUSH

INSET

DEPTH

FINISHED

CLEATS*

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

233/4" (603)

FLUSH INSET

HEIGHT**

VIEW

ill be visible and should be finished to match cabinetry.

Dimension provides minimum reveals.

(.9 m) of opening.

3

/8" (10)

13

/16" (21)

1

/8" (3)

(603)

233/4"

FLUSH INSET WIDTH**

FRONT VIEW

EE

wolfappliance.com | 25

Page 26

E SERIES OVENS

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth.

30" E Series Single Oven

STANDARD INSTALLATION

TOP VIEW

24" (610)

OPENING

DEPTH

VIEW

271/4"

(692)

OPENING

HEIGHT

281/2" (724)

OPENING WIDTH

FRONT VIEW

5"

(127)

E

4"

(102)

E

E

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

26 | Wolf Customer Care 800.222.7820

Page 27

E SERIES OVENS

SIDE

*W

**

**

NOTE: Location of electrical supply within opening may require additional cabinet depth.

30" E Series Single Oven

FLUSH INSET INSTALLATION

1" (25)

OR

11/4" (32)**

FLUSH INSET WIDTH***

FLUSH INSET

TOP VIEW

303/8" (772)

25"

DEPTH

(635)

FINISHED

CLEATS*

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

283/8"

(721)

FLUSH INSET

HEIGHT***

15

VIEW

ill be visible and should be finished to match cabinetry.

1" (25) for professional and transitional models and 11/4" (32) for contemporary model.

*Dimension provides minimum reveals.

(24)

/16"

FRONT VIEW

3

/4"(19)

3

/8" (10)

5"

(127)

E

4"

(102)

E

E

wolfappliance.com | 27

Page 28

E SERIES OVENS

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth.

30" E Series Double Oven

STANDARD INSTALLATION

TOP VIEW

24" (610)

OPENING

DEPTH

VIEW

493/4"

(1264)

OPENING

HEIGHT

17" (432)

TYPICAL

281/2" (724)

OPENING WIDTH

FRONT VIEW

5"

(127)

E

4"

(102)

E

E

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

28 | Wolf Customer Care 800.222.7820

Page 29

E SERIES OVENS

SIDE

*W

**

**

NOTE: Location of electrical supply within opening may require additional cabinet depth.

30" E Series Double Oven

FLUSH INSET INSTALLATION

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

507/8"

(1292)

FLUSH INSET

HEIGHT***

1" (25)

OR

11/4" (32)**

FLUSH INSET WIDTH***

15

/16" (24)

FLUSH INSET

TOP VIEW

303/8" (772)

3

/4"(19)

25" (635)

DEPTH

5"

(127)

E

4"

(102)

FINISHED

CLEATS*

E

17" (432)

TYPICAL

VIEW

ill be visible and should be finished to match cabinetry.

1" (25) for professional and transitional models and 11/4" (32) for contemporary model.

*Dimension provides minimum reveals.

3

/8" (10)

FRONT VIEW

E

wolfappliance.com | 29

Page 30

Page 31

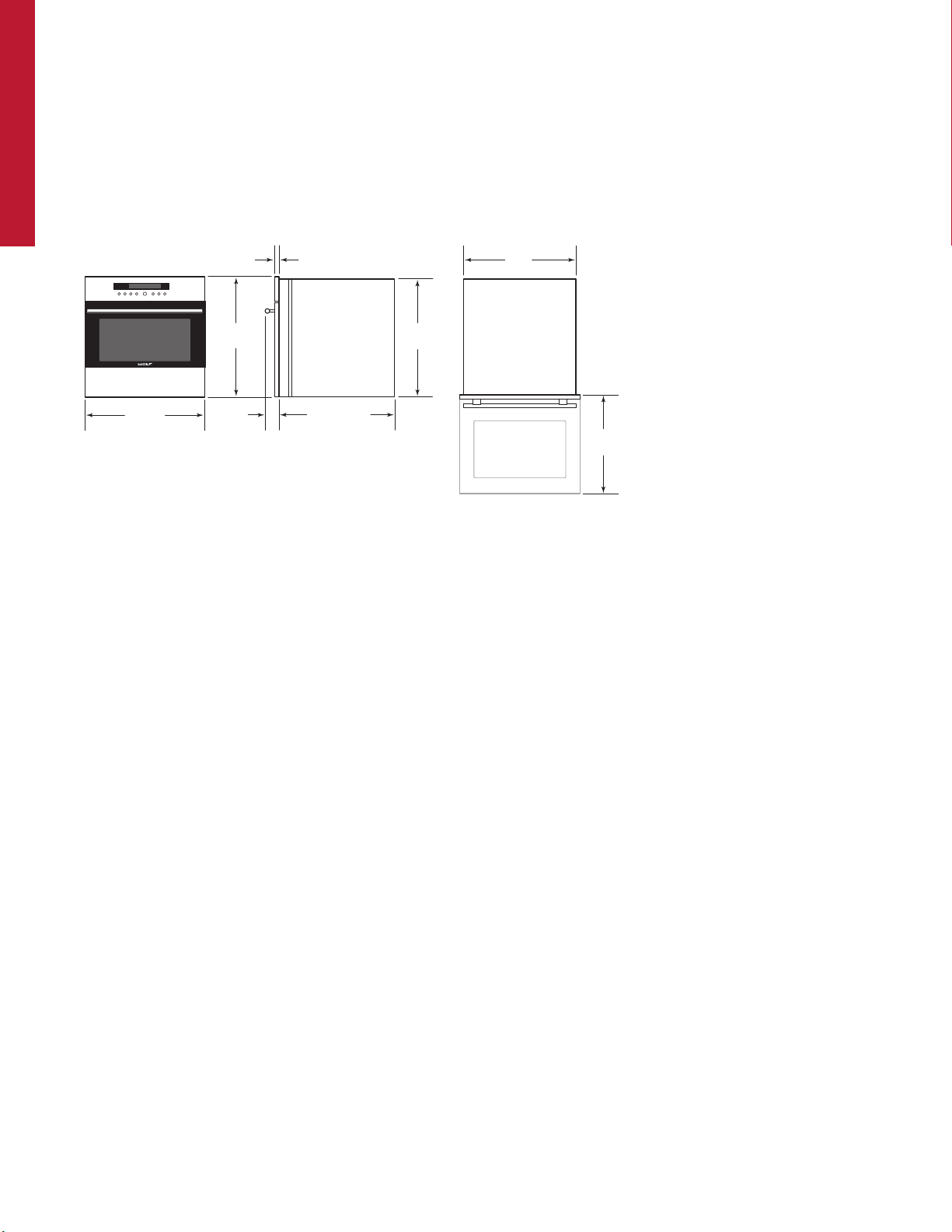

L SERIES OVEN

L Series Built-In Oven

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

Since their introduction, Wolf L series built-in ovens have

taken the culinary world by storm—and not just for their

stylish cobalt blue interior and 10 cooking modes. Thanks

to a Wolf innovation called dual convection, the L series

delivers faster, more consistent results for baking, roasting,

broiling—even drying fruits. The Wolf L series oven is offered

in the 36" width with unframed door style and tubular

handle.

L SERIES OVEN

UNFRAMED

SO36U

wolfappliance.com | 31

Page 32

L SERIES OVEN

L Series Built-In Oven

36" SINGLE OVEN

243/8"

(619)

(76)

3"

CONDUIT

CHANNEL

23"

(584)

341/8"

(867)

87/8"

(225)

95/8"

(244)

355/8"

(905)

3"

(76)

24" (610)

BEHIND FRAME

OPEN OVEN DOOR

173/4"

(451)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

32 | Wolf Customer Care 800.222.7820

Page 33

L SERIES OVEN

Planning Information

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

If a cooktop is being installed above an oven, a minimum

1

/4" (6) is required between the units. The location of the

of

electrical supply within the oven opening may require additional cabinet depth.

Finish the edges of the opening. They may be visible when

the door is open.

For standard installations, the face trim will overlap stiles

and rails. Refer to the chart below.

INSTALLATION REQUIREMENTS

BASE SUPPORT MIN

36" Single Oven 250 lb (113 kg)

TRIM OVERLAP

Top

Bottom

Sides

3

/16" (5)

1

/8" (3)

9

/16" (14)

ELECTRICAL REQUIREMENTS

Installation must comply with all applicable electrical codes.

Locate the electrical supply ush with the back wall and

within the shaded area shown in the illustration on the following page. For ease of installation, the electrical supply for

the oven can be placed in an adjacent cabinet within reach

of the conduit.

Performance may be compromised if the electrical supply is

less than 240 volts.

The oven is supplied with a conduit consisting of two

insulated hot lead conductors and a bare ground conductor.

The wiring diagram covering the control circuit is provided

with the oven.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 240/ 208 VAC, 60 Hz

Service 30 amp dedicated circuit

Conduit 3'

Total Amps 21

Max Connected Load 5.1 kW

(.9 m)

wolfappliance.com | 33

Page 34

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth.

L SERIES OVEN

36" L Series Single Oven

STANDARD INSTALLATION

TOP VIEW

24" (610)

OPENING

DEPTH

VIEW

241/16"

(611)

OPENING

HEIGHT

341/2" (876)

OPENING WIDTH

FRONT VIEW

5"

(127)

E

4"

(102)

E

E

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

34 | Wolf Customer Care 800.222.7820

Page 35

L SERIES OVEN

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

wolfappliance.com | 35

Page 36

Page 37

CONVECTION STEAM OVENS

Convection Steam Ovens

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

The legacy of the “combination oven” goes back decades,

to innovative chefs in America and Europe who embraced

the combination of air movement with superheated steam

to achieve superior results—from breads and roasts to

delicate shes, seafood, and vegetables. Wolf combines the

benets of convection and steam for the most innovative

steam oven on the market today. Virtually any dish prepared

in a conventional oven, range, or microwave can also be

prepared in the Wolf convection steam oven—with more

control. Two widths and three distinct styles compliment

the look of Wolf ovens, ranges, and cooktops. Convection

steam ovens can be installed in a standard or ush inset

application.

CONVECTION STEAM OVENS

TRANSITIONAL

CSO24TE/S/TH

PROFESSIONAL

CSO30PM/S/PH

CONTEMPORARY

CSO30CM/B/TH

CSO30TM/S/TH

CSO30PE/S/PH

CSO30TE/S/TH

wolfappliance.com | 37

Page 38

CONVECTION STEAM OVENS

Convection Steam Ovens

TRANSITIONAL

7

/8"

(22)

171/2"

W

WIDTH

177/8"

(454)

21/2"

(64)

211/2" (546)

BEHIND FRAME

WIDTH

24" Transitional 231/2" (597)

30" Transitional 297/8" (759)

PROFESSIONAL

7

/8"

(22)

177/8"

(454)

171/2"

(446)

W

(446)

213/16"

(538)

OPEN OVEN DOOR

213/16"

(538)

143/16"

(360)

CONTEMPORARY

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

38 | Wolf Customer Care 800.222.7820

297/8"

(759)

297/8"

(759)

31/4"

(83)

177/8"

(454)

21/2"

(64)

211/2" (546)

BEHIND FRAME

7

/8"

(22)

211/2" (546)

BEHIND FRAME

171/2"

(446)

OPEN OVEN DOOR

213/16"

(538)

OPEN OVEN DOOR

143/16"

(360)

143/16"

(360)

Page 39

CONVECTION STEAM OVENS

Planning Information

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

The convection steam oven can be installed in a standard

or ush inset application. The electrical supply for the oven

must be located in an adjacent cabinet.

Finish the edges of the opening. They may be visible when

the door is open.

For standard installations, the face trim will overlap stiles

and rails. Refer to the chart below.

1

For ush inset installations, a minimum

/8" (3) reveal is

required on all sides. To ensure consistent reveals, each

corner of the opening must be exactly 90°.

INSTALLATION REQUIREMENTS

BASE SUPPORT MIN

Convection Steam Oven 100 lb (45 kg)

TRIM OVERLAP 24" MODEL 30" MODEL

Top

Bottom 0" (0) 0" (0)

Sides

3

/16" (5)

11

/16" (18) 37/8" (98)

3

/16" (5)

ELECTRICAL REQUIREMENTS

Installation must comply with all applicable electrical codes.

Locate the electrical supply as shown in the illustrations

on the following pages. A separate circuit servicing only

this appliance is required. A ground fault circuit interrupter

(GFCI) is not recommended and may cause interruption of

operation. Refer to the illustration below for minimum power

cord plug clearance.

Performance may be compromised if the electrical supply is

less than 240 volts.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 240/ 208 VAC, 60 Hz

Service 20 amp dedicated circuit

Receptacle NEMA 6-20R grounding-type

Power Cord 6'

(1.8 m)

MINIMUM CORD

CLEARANCE

Power cord clearance

3"

(76)

wolfappliance.com | 39

Page 40

SIDE

NOTE: 24"

Electrical supply must be located in adjacent cabinet within 3'

CONVECTION STEAM OVENS

Convection Steam Oven

STANDARD INSTALLATION

OPENING

TOP VIEW

219/16"

(548)

DEPTH

1711/16"

(449)

OPENING

HEIGHT

VIEW

(610) and 30" (762) models require the same opening dimensions.

(.9 m) of opening.

W

OPENING WIDTH

FRONT VIEW

EE

OPENING WIDTH

24" Model 221/8" (562)

30" Model 221/8" (562)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

40 | Wolf Customer Care 800.222.7820

W

Page 41

SIDE

*W

**

NOTE: Electrical supply must be located in adjacent cabinet within 3'

CONVECTION STEAM OVENS

Convection Steam Oven

FLUSH INSET INSTALLATION

7

/8" (22)

FLUSH INSET

TOP VIEW

23" (584)

DEPTH

FINISHED

CLEATS*

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

181/8"

(460)

FLUSH INSET

HEIGHT**

VIEW

ill be visible and should be finished to match cabinetry.

Dimension provides minimum reveals.

A

(.9 m) of opening.

5

/16"(8)

1

/8" (3)

FLUSH INSET WIDTH**

W

FRONT VIEW

EE

FLUSH INSET WIDTH

24" Model 233/4" (603)

30" Model 301/8" (765) 4" (102)

W A

13

/16" (21)

wolfappliance.com | 41

Page 42

Page 43

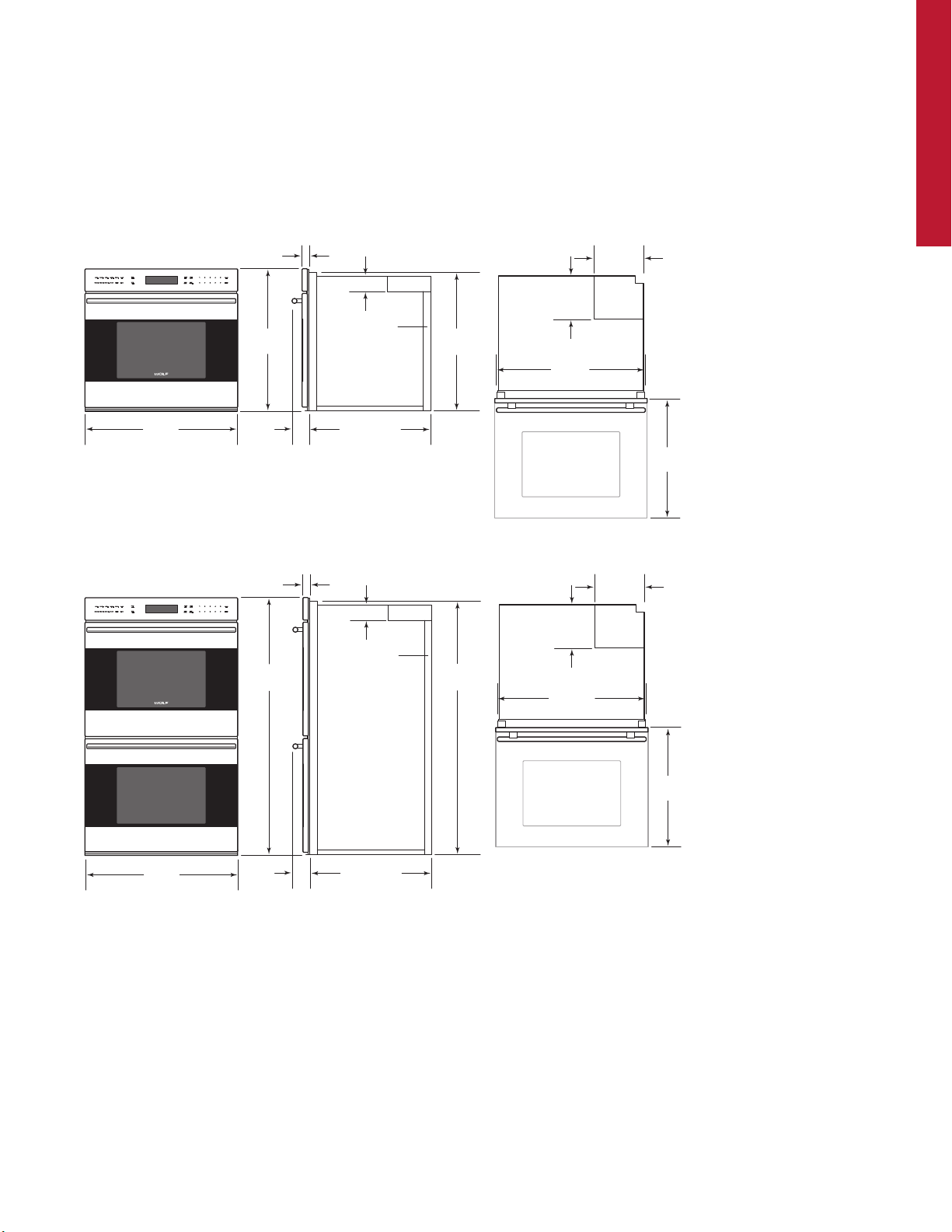

MICROWAVE OVENS

Microwave Ovens

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

As true cooking instruments, Wolf microwave ovens have

features that make fast meals better meals. The new dropdown door microwaves feature a door that hinges at the

bottom for easier access to foods. Available in 24" and

30" widths, they are designed to match Wolf transitional,

professional, and contemporary products. Drawer microwave ovens can be conveniently located undercounter, in

a corner, or below an oven. Wolf also offers both a roomy,

powerful standard microwave and a convection model that

can microwave, broil, and cook in three convection modes.

Trim kits to match Wolf ovens are available through an

authorized Wolf dealer. Microwave ovens can be installed in

a standard or ush inset application.

DROP-DOWN DOOR MICROWAVES

TRANSITIONAL

MDD24TE/S/TH

PROFESSIONAL

MDD30PM/S/PH

CONTEMPORARY

MDD30CM/B/TH

MDD30TM/S/TH

MDD30PE/S/PH

DRAWER MICROWAVE

TRANSITIONAL

MDD30TE/S/TH

MD24TE/S

PROFESSIONAL

MD30PE/S

MD30TE/S

CONVECTION MICROWAVE

MC24 (M

/E TRIM)

MC24 (L TRIM)

STANDARD MICROWAVE

MS24 (M

/E TRIM)

MS24 (L TRIM)

wolfappliance.com | 43

Page 44

MICROWAVE OVENS

Drop-Down Door Microwave Ovens

TRANSITIONAL

7

/8"

(22)

213/16"

(538)

171/2"

W

WIDTH

177/8"

(454)

21/2"

(64)

20" (508)

BEHIND FRAME

WIDTH

24" Transitional 231/2" (597)

30" Transitional 297/8" (759)

PROFESSIONAL

7

/8"

(22)

171/2"

297/8"

(759)

177/8"

(454)

31/4"

(83)

20" (508)

BEHIND FRAME

(446)

W

(446)

OPEN

OVEN DOOR

213/16"

(538)

143/16"

(360)

CONTEMPORARY

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

44 | Wolf Customer Care 800.222.7820

297/8"

(759)

177/8"

(454)

21/2"

(64)

7

/8"

(22)

20" (508)

BEHIND FRAME

171/2"

(446)

OPEN

OVEN DOOR

213/16"

(538)

OPEN

OVEN DOOR

143/16"

(360)

143/16"

(360)

Page 45

MICROWAVE OVENS

Drawer Microwave Ovens

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

TRANSITIONAL / PROFESSIONAL

WIDTH

297/8" (759)

151/8"

(384)

11/4"

(32)

217/8" (556)

BEHIND FRAME

13/4"

POWER CORD

(45)

CHANNEL

24" Model 237/8" (606)

30" Model 297/8" (759)

145/8"

(372)

W

215/8" (549)

45/8"

(118)

OPEN DRAWER

161/2"

(419)

wolfappliance.com | 45

Page 46

MICROWAVE OVENS

*1

147/8"

(378)

FREE-

STANDING

243/4" (629)

FREESTANDING

197/8"

(505)

WITH

TRIM

TRIM WIDTH

18"

(457)

BEHIND TRIM

*11/4" (32) for contemporary E series trim only.

1" (25) OR

11/4" (32)*

Convection Microwave Oven

M/E SERIES TRIM

243/4" (629)

FREESTANDING

TRIM WIDTH

1

/4" (32) for contemporary E series trim only.

TRIM WIDTH

M SERIES E SERIES L SERIES

197/8"

(505)

WITH

TRIM

1" (25) OR

11/4" (32)*

(457)

18"

BEHIND TRIM

147/8"

(378)

FREE-

STANDING

27" Trim NA 267/8" (683) NA

30" Trim 297/8" (759) 297/8" (759) 297/8" (759)

36" Trim NA NA 355/8" (905)

L SERIES TRIM

243/4" (629)

FREESTANDING

TRIM WIDTH

197/8"

(505)

WITH

TRIM

13/8"

(35)

(448)

175/8"

BEHIND TRIM

147/8"

(378)

FREE-

STANDING

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

46 | Wolf Customer Care 800.222.7820

Page 47

MICROWAVE OVENS

*1

TRIM WIDTH

133/8"

(340)

FREE-

STANDING

24" (610)

FREESTANDING

181/4"

(464)

WITH

TRIM

18" (457)

BEHIND TRIM

*11/4" (32) for contemporary E series trim only.

1" (25) OR

11/4" (32)*

Standard Microwave Oven

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

M/E SERIES TRIM

24" (610)

FREESTANDING

TRIM WIDTH

1

/4" (32) for contemporary E series trim only.

TRIM WIDTH

M SERIES E SERIES L SERIES

181/4"

(464)

WITH

TRIM

1" (25) OR

11/4" (32)*

18" (457)

BEHIND TRIM

133/8"

(340)

FREE-

STANDING

27" Trim NA 267/8" (683) NA

30" Trim 297/8" (759) 297/8" (759) 297/8" (759)

L SERIES TRIM

24" (610)

FREESTANDING

TRIM WIDTH

181/4"

(464)

WITH

TRIM

13/8"

(35)

175/8" (448)

BEHIND TRIM

133/8"

(340)

FREE-

STANDING

wolfappliance.com | 47

Page 48

MICROWAVE OVENS

Planning Information

DROP-DOWN DOOR MICROWAVE

The drop-down door microwave oven can be installed in a

standard or ush inset application.

Finish the edges of the opening. They may be visible when

the door is open.

For standard installations, the face trim will overlap stiles

and rails. Refer to the chart below.

1

For ush inset installations, a minimum

/8" (3) reveal is

required on all sides. To ensure consistent reveals, each

corner of the opening must be exactly 90°.

INSTALLATION REQUIREMENTS

BASE SUPPORT MIN

Drop-Down Door Microwave 125 lb (57 kg)

TRIM OVERLAP 24" MODEL 30" MODEL

Top

Bottom 0" (0) 0" (0)

Sides

3

/16" (5)

11

/16" (18) 37/8" (98)

3

/16" (5)

DRAWER MICROWAVE

The drawer microwave oven can be installed in a standard

or ush inset application. The location of the electrical

supply within the oven opening may require additional

cabinet depth.

Finish the edges of the opening. They may be visible when

the drawer is open.

For standard installations, the face trim will overlap stiles

and rails. Refer to the chart below.

1

For ush inset installations, a minimum

required on the top and sides and

/8" (3) reveal is

11

/16" (18) on the bottom.

To ensure consistent reveals, each corner of the opening

must be exactly 90°. A sales accessory is required to direct

air away from the unit. Accessories are available through an

authorized Wolf dealer. For local dealer information, visit the

nd a showroom section of our website, wolfappliance.com.

INSTALLATION REQUIREMENTS

BASE SUPPORT MIN

24" Drawer Microwave 125 lb (57 kg)

30" Drawer Microwave 125 lb (57 kg)

TRIM OVERLAP 24" MODEL 30" MODEL

Top

Bottom

Sides

5

/16" (8)

1

/16" (2)

7

/8" (22) 37/8" (98)

5

/16" (8)

1

/16" (2)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

48 | Wolf Customer Care 800.222.7820

Page 49

MICROWAVE OVENS

Planning Information

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

CONVECTION / STANDARD MICROWAVES

Convection and standard microwave ovens can be installed

in a standard or ush inset application using accessory

trim to match Wolf ovens. Trim kits are avail able through an

authorized Wolf dealer. For local dealer information, visit the

nd a showroom section of our website, wolfappliance.com.

For standard installations, the face trim will overlap stiles

and rails. Refer to the chart below.

Convection and standard microwave ovens can also be

used freestanding. For freestanding applications, a minimum

(51) space is required at the top, rear, and sides of the

2"

microwave oven for air circulation.

INSTALLATION REQUIREMENTS

BASE SUPPORT MIN

Convection Microwave 125 lb (57 kg)

Standard Microwave 125 lb (57 kg)

27" E SERIES TRIM OVERLAP CONV STAN

Top

Bottom

Sides

30" M/E/L TRIM OVERLAP CONV STAN

Top

Bottom

Sides 13/16" (30) 13/16" (30)

36" L SERIES TRIM OVERLAP CONV STAN

Top

Bottom

Sides 1

1

/4" (6)

3

/4" (19)

13

/16" (21)

1

/4" (6)

3

/4" (19)

3

/16" (5) NA

13

/16" (21) NA

1

/4" (32) NA

9

/16" (14)

11

/16" (17)

13

/16" (21)

9

/16" (14)

11

/16" (17)

ELECTRICAL REQUIREMENTS

Installation must comply with all applicable electrical codes.

Locate the electrical supply as shown in the illustrations on

the following pages. The receptacle may also be located

in an adjacent cabinet within reach of the power cord. A

separate circuit servicing only this appliance is required. A

ground fault circuit interrupter (GFCI) is not recommended

and may cause interruption of operation. Refer to the illustration below for minimum power cord plug clearance.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 120 VAC, 60 Hz

Service 15 amp dedicated circuit

Receptacle 3-prong grounding-type

Power Cord 4'

3"

(76)

MINIMUM CORD

CLEARANCE

(1.2 m)

Power cord clearance

wolfappliance.com | 49

Page 50

MICROWAVE OVENS

SIDE

NOTE: 24"

Drop-Down Door Microwave Oven

STANDARD INSTALLATION

OPENING

TOP VIEW

219/16"

(548)

DEPTH

1711/16"

(449)

OPENING

HEIGHT

VIEW

(610) and 30" (762) models require the same opening dimensions.

OPENING WIDTH

24" Model 221/8" (562)

30" Model 221/8" (562)

W

E

OPENING WIDTH

FRONT VIEW

W

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

50 | Wolf Customer Care 800.222.7820

Page 51

MICROWAVE OVENS

SIDE

*W

**

Drop-Down Door Microwave Oven

FLUSH INSET INSTALLATION

7

/8" (22)

FLUSH INSET

TOP VIEW

23" (584)

DEPTH

FINISHED

CLEATS*

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

181/8"

(460)

FLUSH INSET

HEIGHT**

VIEW

ill be visible and should be finished to match cabinetry.

Dimension provides minimum reveals.

FLUSH INSET WIDTH

24" Model 233/4" (603)

W A

13

/16" (21)

30" Model 301/8" (765) 4" (102)

5

E

/16"(8)

A

1

/8" (3)

FLUSH INSET WIDTH**

W

FRONT VIEW

wolfappliance.com | 51

Page 52

MICROWAVE OVENS

SIDE

NOTE: All dr

Drawer Microwave Oven

STANDARD INSTALLATION

22" (559)

OPENING

DEPTH

TOP VIEW

ANTI-TIP BLOCK

(375)

143/4"

OPENING

HEIGHT

VIEW

awer microwave ovens require the same opening dimensions.

OPENING WIDTH

24" Model 221/8" (562)

30" Model 221/8" (562)

W

E

W

OPENING WIDTH

FRONT VIEW

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

52 | Wolf Customer Care 800.222.7820

Page 53

MICROWAVE OVENS

SIDE

*W

**

Drawer Microwave Oven

FLUSH INSET INSTALLATION

11/4" (32)

231/4"

FLUSH INSET

TOP VIEW

DEPTH

(591)

FINISHED

CLEATS*

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

ANTI-TIP BLOCK

1515/16"

VIEW

ill be visible and should be finished to match cabinetry.

Dimension provides minimum reveals.

FLUSH INSET WIDTH

(405)

FLUSH INSET

HEIGHT**

W A

24" Model 241/8" (613) 1" (25)

30" Model 301/8" (765) 4" (102)

7

E

/16"(11)

A

3

/4" (19)

FLUSH INSET WIDTH**

W

FRONT VIEW

wolfappliance.com | 53

Page 54

MICROWAVE OVENS

SIDE

Convection Microwave Oven

STANDARD INSTALLATION WITH TRIM

201/8" (511)

TOP VIEW

OPENING

DEPTH

187/8" (479)

OPENING

HEIGHT

VIEW

OPENING WIDTH

27" Trim 251/4" (641)

30" Trim 271/2" (699)

36" Trim 333/8" (854)

E

W

W

OPENING WIDTH

FRONT VIEW

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

54 | Wolf Customer Care 800.222.7820

Page 55

MICROWAVE OVENS

*W

**

**

SIDE

Convection Microwave Oven

FLUSH INSET INSTALLATION WITH TRIM

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

201/8" (511)

FLUSH INSET

HEIGHT***

(25)

1"

OR

11/4" (32)**

TOP VIEW

3

E

/8"

A

7

/8" (22)

FLUSH INSET WIDTH***

231/4"

FLUSH INSET

DEPTH

(10)

W

(591)

FINISHED

CLEATS*

VIEW

ill be visible and should be finished to match cabinetry.

11/4" (32) for contemporary E series trim only.

*Dimension provides minimum reveals.

FLUSH INSET WIDTH

27" Trim 271/8" (689)

W A

15

/16" (24)

30" Trim 301/8" (765) 13/16" (30)

FRONT VIEW

wolfappliance.com | 55

Page 56

MICROWAVE OVENS

SIDE

Standard Microwave Oven

STANDARD INSTALLATION WITH TRIM

TOP VIEW

20" (508)

OPENING

DEPTH

17" (432)

OPENING

HEIGHT

VIEW

OPENING WIDTH

27" Trim 251/4" (641)

30" Trim 271/2" (699)

E

W

W

OPENING WIDTH

FRONT VIEW

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

56 | Wolf Customer Care 800.222.7820

Page 57

MICROWAVE OVENS

SIDE

*W

**

**

Standard Microwave Oven

FLUSH INSET INSTALLATION WITH TRIM

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

181/2" (470)

FLUSH INSET

HEIGHT***

(25)

1"

OR

11/4" (32)**

TOP VIEW

11

E

/16"

A

13

/16" (21)

FLUSH INSET WIDTH***

231/4"

FLUSH INSET

DEPTH

(17)

W

(591)

FINISHED

CLEATS*

VIEW

ill be visible and should be finished to match cabinetry.

11/4" (32) for contemporary E series trim only.

*Dimension provides minimum reveals.

FLUSH INSET WIDTH

27" Trim 271/8" (689)

W A

15

/16" (24)

30" Trim 301/8" (765) 13/16" (30)

FRONT VIEW

wolfappliance.com | 57

Page 58

Page 59

WARMING DRAWERS

Warming Drawers

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

Wolf warming drawers are designed to take care of prepared foods until it’s time to serve them. You can adjust the

temperature, keeping moist foods moist, and crisp foods

crisp. Warming drawers are ideal for proong dough. They

can also be used to warm robes and towels. Drawer fronts

are available to match the look of Wolf ovens, sealed burner

rangetops, and outdoor grills. The integrated drawer front

allows for a custom panel and handle. Model WWD30O,

approved for outdoor installations, is ideal for any outdoor

kitchen.

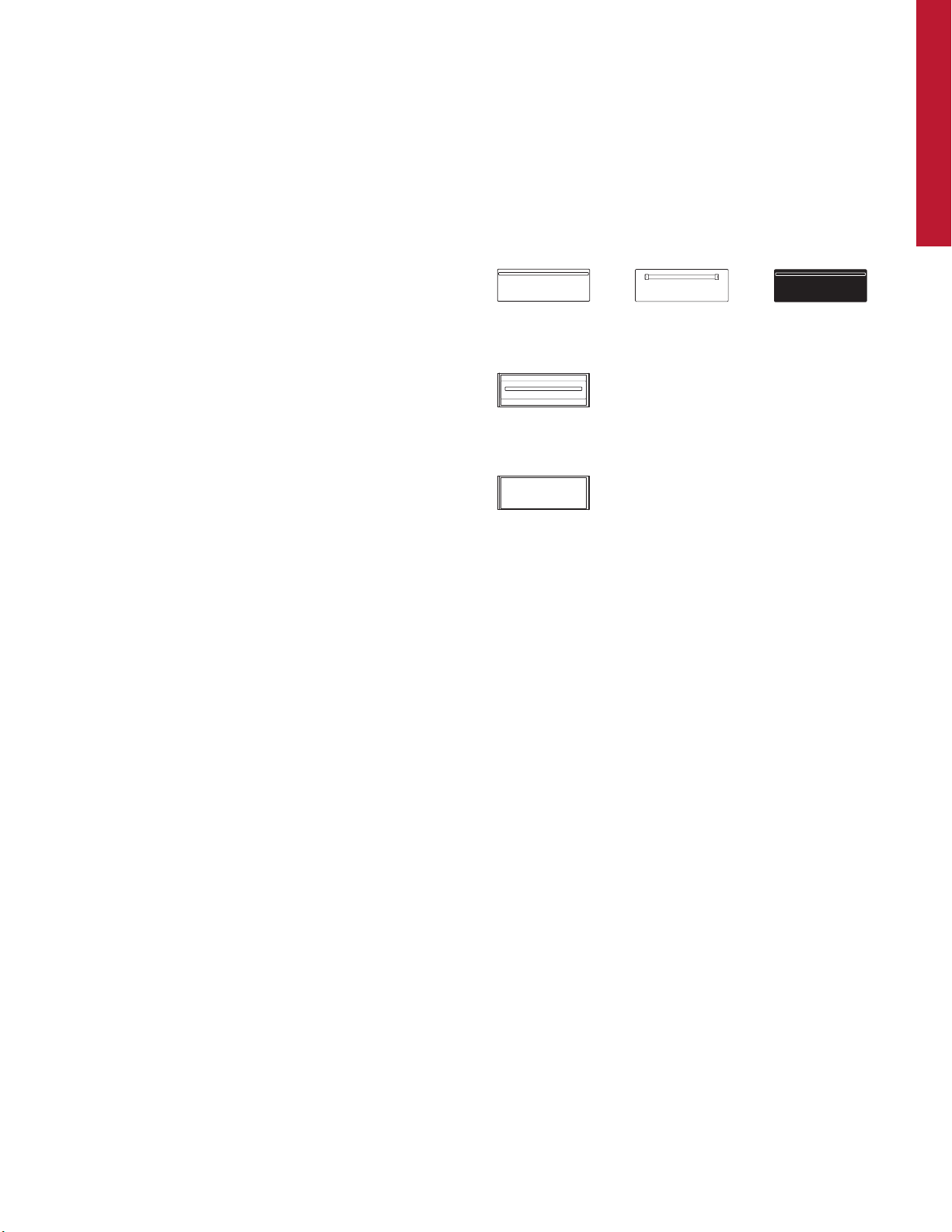

WARMING DRAWER FRONTS

M/E SERIES

TRANSITIONAL

L SERIES

TRANSITIONAL

INTEGRATED

CUSTOM PANEL

PROFESSIONAL

CONTEMPORARY

wolfappliance.com | 59

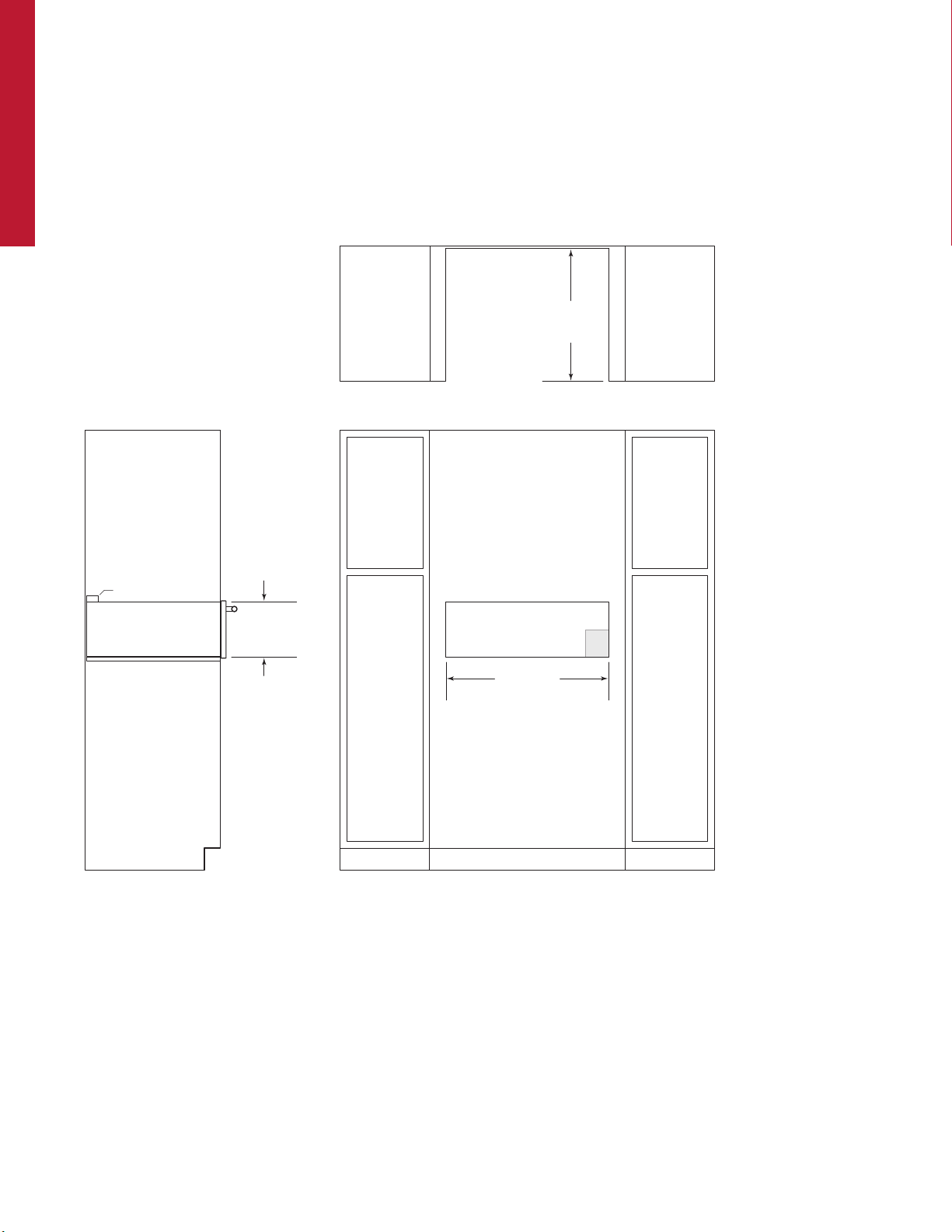

Page 60

WARMING DRAWERS

Warming Drawers

DRAWER FRONT OPTIONS

Wolf warming drawer fronts allow for many design options,

but the warming drawer itself will be the same for all applications. A panel mounting kit is required when installing a

custom panel. The panel mounting kit is available through

an authorized Wolf dealer. For local dealer information,

visit the nd a showroom section of our website,

wolfappliance.com.

(51) thick drawer front, in 30" and 36" widths, is

The 2"

designed to be installed below a sealed burner rangetop or

outdoor gas grill, so the panel aligns properly with the front

of the rangetop or grill. Dimensions for the warming drawer

remain the same, even though the drawer front may be

wider to match a Wolf 36" oven, sealed burner rangetop,

or outdoor grill.

DIMENSIONS

W

WIDTH

281/4" (718)

OPEN DRAWER

103/8"

(264)

211/2"

(546)

B

A

223/4" (578)

9"

(229)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

60 | Wolf Customer Care 800.222.7820

STAINLESS STEEL DRAWER FRONT

WIDTH W

30" Drawer Front 297/8" (759)

36" Drawer Front 357/8" (911)

M SERIES A B

Transitional/Professional

Contemporary Stainless

7

/8" (22) 31/4" (83)

7

/8" (22) 31/4" (83)

Contemporary Black 1" (25) 33/8" (86)

E SERIES A B

Transitional/Professional 11/8" (29) 31/2" (89)

Professional (2" thick) 21/8" (54) 41/2" (114)

Contemporary 11/4" (32) 35/8" (92)

L SERIES A B

Transitional

INTEGRATED DRAWER FRONT

CUSTOM PANEL W H D

Dimensions (typical) 297/8" (759) 103/8" (264)

Min Thickness

7

/8" (22) 31/2" (89)

3

/4" (19)

5

/8" (16)

Page 61

WARMING DRAWERS

Planning Information

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

The warming drawer must be installed with a Wolf drawer

front, avail able through an authorized Wolf dealer. For local

dealer information, visit the nd a showroom section of our

website, wolfappliance.com. Specic installation instructions are included with the drawer front.

The warming drawer can be installed in a standard or ush

inset application (excludes L series drawer front).

For a standard installation, the drawer collar and front panel

sit proud of the cabinet face frame. A recessed installation

3

requires the cabinetry be recessed by

/16" (5) so the collar

is ush with the cabinet face frame but the drawer front

will sit proud. A ush inset installation (excludes L series)

requires the drawer collar and front panel be recessed to be

ush with surrounding cabinetry. Refer to illustrations on the

following pages for minimum cabinet dimensions for your

specic installation.

Finish the edges of the opening. They may be visible when

the drawer is open.

For standard installations, the face trim will overlap stiles

and rails. Refer to the chart below.

1

For ush inset installations, a minimum

/8" (3) reveal is

required on all sides. To ensure consistent reveals, each

corner of the opening must be exactly 90°.

ELECTRICAL REQUIREMENTS

Installation must comply with all applicable electrical codes.

Locate the electrical supply ush with the back wall and

within the shaded area shown in the illustrations on the

following pages. For ease of installation, the electrical

supply for the warming drawer can be placed in an adjacent

cabinet within reach of the power cord.

IMPORTANT NOTE: When installed outdoors, a ground fault

circuit interrupter (GFCI) is required to reduce the risk of

electrical shock.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 120 VAC, 60 Hz

Service 15 amp dedicated circuit

Receptacle 3-prong grounding-type

Power Cord 3'

(.9 m)

Model WWD30O is CSA approved for outdoor installations.

INSTALLATION REQUIREMENTS

Min Base Support 200 lb (90 kg)

Trim Overlap (top, bottom, sides)

5

/8" (16)

wolfappliance.com | 61

Page 62

WARMING DRAWERS

SIDE

NOTE: Location of electrical supply within opening may require additional cabinet depth.

Warming Drawer

STANDARD INSTALLATION

TOP VIEW

23" (584)

OPENING

DEPTH

ANTI-TIP BLOCK

91/8" (232)

OPENING

HEIGHT

VIEW

285/8" (727)

OPENING WIDTH

FRONT VIEW

E

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

62 | Wolf Customer Care 800.222.7820

Page 63

SIDE

*W

**

**

NOTE: Location of electrical supply within opening may require additional cabinet depth.

WARMING DRAWERS

Warming Drawer

FLUSH INSET INSTALLATION

A

DRAWER

FRONT

DEPTH

FLUSH INSET

TOP VIEW

24" (610)

DEPTH***

FINISHED

CLEATS*

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

ANTI-TIP BLOCK

105/8"

(270)

FLUSH INSET

HEIGHT**

VIEW

ill be visible and should be finished to match cabinetry.

Dimension provides minimum reveals.

*241/8" (613) for E series contemporary drawer front.

DRAWER FRONT DEPTH (A)

Transitional/Professional

Professional (2" thick) NA 21/8" (54)

Contemporary Stainless

Contemporary Black 1"

Custom front panel depth is dependent on panel thickness. Add

the panel thickness to determine the drawer front depth.

M SERIES E SERIES

7

/8" (22) 11/8" (29)

7

/8" (22) NA

(25) 1

3

/8" (35)

1

/4" (6) to

3

/4"(19)

3

/4"(19)

3

/4"(19)

301/8" (765)

FLUSH INSET WIDTH**

FRONT VIEW

E

E

wolfappliance.com | 63

Page 64

Page 65

INDUCTION COOKTOPS

Induction Cooktops

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

Almost instantaneous temperature response. Practically no

wasted heat. Induction cooking has been popular among

European chefs and homeowners for decades. Now Wolf

leads the way in bringing this remarkable technology to

North American kitchens. Its secret is magnetism. Electromagnetic elements cause iron and magnetic stainless cookware to heat up instantly and with perfectly distributed heat.

Heat generation stops the instant you turn off the element or

remove the pan. The cooktop’s surface remains cool. Your

kitchen stays cooler too.

Transitional models have a brushed stainless steel trim.

Contemporary models can be mounted ush with the

countertop. The following models have the same stainless

steel frame as our module cooktops for paired installations:

CI243TF/S, CI304TF/S, and CI365TF/S.

INDUCTION COOKTOPS

TRANSITIONAL FRAMED

CI243TF/S

TRANSITIONAL

CI304T/S

CONTEMPORARY

CI243C/B

CI304TF/S

CI365T/S

CI304C/B

CI365TF/S

CI365C/B

wolfappliance.com | 65

Page 66

INDUCTION COOKTOPS

Induction Cooktops

24" TRANSITIONAL

21"

(533)

235/8" (600)

11/4" (32)

CONDUIT

7

/8"

(22)

2" (51)

24" CONTEMPORARY

21"

(533)

235/8" (600)

30" TRANSITIONAL

30" (762)

CONDUIT

7

/8"

11/4" (32)

(22)

30" CONTEMPORARY

30" (762)

21"

(533)

2" (51)

21"

(533)

36" TRANSITIONAL

36" (914)

CONDUIT

7

11/4" (32)

(22)

36" CONTEMPORARY

36" (914)

21"

(533)

2" (51)

/8"

21"

(533)

ELEMENT RATING

24" COOKTOP W

11" (279) 2600/3150 boost

8"

8"

30" COOKTOP W

11" (279) 2600/3150 boost

8"

8" (203) 2100

6"

36" COOKTOP W

11" (279) 2600/3700 boost

(2) 8"

(2) 8"

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

66 | Wolf Customer Care 800.222.7820

CONDUIT

7

11/4" (32)

(203) 2100/3000 boost

(203) 2100

(203) 2100/3000 boost

(152) 1400

(203) 2100/3000 boost

(203) 2100

(22)

21/2" (64)

/8"

11/4" (32)

CONDUIT

7

/8"

(22)

21/2" (64)

11/4" (32)

CONDUIT

7

/8"

(22)

21/2" (64)

Page 67

ELECTRIC COOKTOPS

Electric Cooktops

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

New generation electric cooktops use high-frequency

pulsation technology for the most exceptional performance and control ever in a Wolf electric cooktop, with

blazing hot sears at the high end and steady simmers and

melts at the low end—a low-end nesse that is unusual in

an electric cooktop. The updated element conguration

accommodates a wide variety of cooking vessels and dish

preparation.

ELECTRIC COOKTOPS

TRANSITIONAL

CE304T/S

CONTEMPORARY

CE304C/B

CE365T/S

CE365C/B

wolfappliance.com | 67

Page 68

ELECTRIC COOKTOPS

Electric Cooktops

30" TRANSITIONAL

30" (762)

CONDUIT

7

/8"

11/4" (32)

(22)

21"

(533)

31/2" (89)

36" TRANSITIONAL

36" (914)

11/4" (32)

CONDUIT

7

(22)

30" CONTEMPORARY 36" CONTEMPORARY

21"

(533)

30" (762)

36" (914)

21"

(533)

31/2" (89)

/8"

21"

(533)

ELEMENT RATING

30" COOKTOP W

101/2" (267) Triple 1050/1950/2700

(2) 5

1

6

36" COOKTOP W

101/2" (267) Triple 1050/1950/2700

8"

51/2" (140) Single 1200

(2) 7"

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

68 | Wolf Customer Care 800.222.7820

CONDUIT

7

11/4" (32)

1

/2" (140) Singles 1200

(22)

4" (102)

/8"

/2" (165) Single with Oval 2400

(203) Dual 700/2200

(178) Singles with Bridge 4400

11/4" (32)

CONDUIT

7

/8"

(22)

4" (102)

Page 69

INDUCTION | ELECTRIC COOKTOPS

Planning Information

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

A minimum 2" (51) is required from the bottom of the

cooktop to combustible materials.

Contemporary induction and electric cooktops can be

mounted ush with the top of the countertop, or as a frameless standard installation sitting on top of the countertop

surface. If the cooktop is to be mounted ush with the

countertop, a recessed area surrounding the cooktop cutout

must be provided.

IMPORTANT NOTE: Flush mount installations are intended

for granite, solid surface, or stone countertop surfaces only.

ELECTRICAL REQUIREMENTS

Installation must comply with all applicable electrical codes.

Locate the electrical supply as shown in the illustrations on

the following pages. A separate circuit servicing only this

appliance is required.

ELECTRICAL REQUIREMENTS

INDUCTION

Electrical Supply grounded 3-wire, 240/208 VAC, 60 Hz

Conduit exible 4'

ELECTRIC

Electrical Supply grounded 3-wire, 240 VAC, 60 Hz

Electrical Supply (208 V) grounded 3-wire, 208 VAC, 60 Hz

Conduit exible 4'

SERVICE

24" Induction 30 amp dedicated circuit

30" Induction/Electric 40 amp dedicated circuit

36" Induction/Electric 50 amp dedicated circuit

(1.2 m)

(1.2 m)

wolfappliance.com | 69

Page 70

INDUCTION | ELECTRIC COOKTOPS

SIDE

NO

combus

El

24" / 30" / 36" Cooktop

STANDARD INSTALLATION

21/2"

(64)

13"

(330)

36" (914) min

FLOOR TO

COUNTERTOP

18"

(457)

2"

(51)

W

WIDTH

COUNTERTOP CUTOUT

30"

(762)

41/2" (114)

31/2" (89)

10" (254)

191/2"

(495)

21/2" (64)

E

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

VIEW

TE: Shaded area above countertop indicates minimum clearance to combustible surfaces,

tible materials cannot be located within this area.

ectrical supply location only applies to installations with built-in oven.

CUTOUT WIDTH

W

24" Induction 221/8" (562)

30" Induction/Electric 29" (737)

36" Induction/Electric 35" (889)

70 | Wolf Customer Care 800.222.7820

FRONT VIEW

Page 71

INDUCTION | ELECTRIC COOKTOPS

SIDE

NO

combus

El

Outsid

24" / 30" / 36" Cooktop

FLUSH INSTALLATION

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

13"

(330)

COUNTERTOP

7

/8"

(22) MAX

PROFILE

5

(8)

/16"

36" (914) min

FLOOR TO

COUNTERTOP

211/8"

(537)

RECESS

19/16" (40) min

18"

(457)

2"

(51)

W

CUTOUT WIDTH

A

RECESS

COUNTERTOP CUTOUT

30"

(762)

41/2" (114)

31/2" (89)

10" (254)

21/2" (64)

191/2"

(495)

21/2" (64)

E

VIEW

TE: Shaded area above countertop indicates minimum clearance to combustible surfaces,

tible materials cannot be located within this area.

ectrical supply location only applies to installations with built-in oven.

e corner radius 7/16" (11).

CUTOUT WIDTH

W A

24" Induction 221/8" (562) 233/4" (603)

30" Induction/Electric 29" (737) 301/8" (765)

36" Induction/Electric 35" (889) 361/8" (918)

FRONT VIEW

wolfappliance.com | 71

Page 72

Page 73

GAS COOKTOPS

Gas Cooktops

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

Like their oven counterparts, the new generation of Wolf gas

cooktops features three new looks—transitional, professional, and contemporary. New performance enhancements

make delicious results even more of a certainty than ever.

Multiple sizes, choice of knob colors, and distinctly different

grates—the new gas cooktops offer exceptional design

exibility. For a striking, low-prole look, the contemporary

gas cooktop ts ush to the countertop with front-mounted

controls that integrate directly into cabinetry below.

Model CG243TF/S has the same stainless steel frame as

our module cooktops for paired installations.

GAS COOKTOPS

TRANSITIONAL FRAMED

CG243TF/S

TRANSITIONAL

CG304T/S

PROFESSIONAL

CG304P/S

CONTEMPORARY

CG365T/S

CG365P/S

CG365C/S

wolfappliance.com | 73

Page 74

GAS COOKTOPS

Gas Cooktops

24" TRANSITIONAL 36" TRANSITIONAL

21"

(533)

235/8" (600)

4" (102)

3

/8"

(10)

30" PROFESSIONAL

21"

(533)

30" (762)

30" TRANSITIONAL

30" (762)

7

/8"

(22)

36" PROFESSIONAL

36" (914)

21"

(533)

4" (102)

21"

(533)

36" (914)

7

(22)

21"

(533)

4" (102)

/8"

36" CONTEMPORARY

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

74 | Wolf Customer Care 800.222.7820

3515/16" (913)

7

(22)

4" (102)

/8"

2015/16"

(532)

7

(22)

4" (102)

/8"

63/4" (171)

7

/8"

(22)

Page 75

GAS COOKTOPS

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

Gas Cooktops

BURNER RATING—BTU (kW)

24" TRANSITIONAL SIM HI

18K Burner 300 (.1) 18,000 (5.3)

12K Burner 300 (.1) 12,000 (3.5)

9.2K Burner 300 (.1) 9,200 (2.7)

30" TRANSITIONAL/PROFESSIONAL SIM HI

18K Burner 300 (.1) 18,000 (5.3)

12K Burner 300 (.1) 12,000 (3.5)

9.2K Burner (2) 300 (.1) 9,200 (2.7)

36" TRANSITIONAL/PROFESSIONAL SIM HI

18K Burner 300 (.1) 18,000 (5.3)

12K Burner 300 (.1) 12,000 (3.5)

9.2K Burner (3) 300 (.1) 9,200 (2.7)

36" CONTEMPORARY SIM HI

20K Burner 300 (.1) 20,000 (5.9)

12K Burner (2) 300 (.1) 12,000 (3.5)

9.2K Burner (2) 300 (.1) 9,200 (2.7)

Planning Information

A minimum 2" (51) is required from the bottom of the

cooktop to combustible materials. If the cooktop is installed

above an oven, a minimum of

units.

The contemporary gas cooktop can be mounted ush with

the top of the countertop, or as a standard installation

sitting on top of the countertop surface. If the cooktop is

to be mounted ush with the countertop, a recessed area

surrounding the cooktop cutout must be provided. The

countertop must be able to withstand temperatures up to

(149°C).

300°F

Control knobs for the contemporary gas cooktop are

designed to be mounted on the front face of cabinetry

below the unit. Mounting holes must be drilled through the

cabinet face. Refer to the illustrations on pages 78–79 for

the hole location.

1

/4" (6) is required between the

wolfappliance.com | 75

Page 76

GAS COOKTOPS

Planning Information

ELECTRICAL REQUIREMENTS

Installation must comply with all applicable electrical codes.

Locate the electrical supply as shown in the illustrations

on the following pages. A separate circuit servicing only

this appliance is required. A ground fault circuit interrupter

(GFCI) is not recommended and may cause interruption of

operation.

ELECTRICAL REQUIREMENTS

Electrical Supply grounded, 120 VAC, 60 Hz

Service 15 amp dedicated circuit

Receptacle 3-prong grounding-type

Power Cord 6'

(1.8 m)

GAS SUPPLY

Installation must comply with all applicable gas codes.

If local codes permit, a certied, 3'

(19)

ID exible metal appliance connector is recommended.

(.9 m) long,

Wolf natural gas cooktops will function up to 10,250'

(3124 m)

will function up to 8,600'

in altitude without adjustment and LP gas cooktops

(2621 m). If the installation exceeds

1

/2" (13) or 3/4"

these elevations, contact an authorized Wolf dealer for a

high altitude conversion kit.

GAS REQUIREMENTS

Gas Supply

Gas Inlet

NATURAL GAS WC

Supply Pressure 5" (12.5 mb)

Min Line Pressure 7" (17.5 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

LP GAS WC

Supply Pressure 10" (25 mb)

Min Line Pressure 11" (27.4 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

3

/4" ID line

1

/2" NPT male

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

76 | Wolf Customer Care 800.222.7820

Page 77

SIDE

NO

combus

El

GAS COOKTOPS

24" / 30" / 36" Transitional / Professional Gas Cooktop

STANDARD INSTALLATION

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

21/2" (64)

13"

(330)

18"

(457)

9"

(229)

W

WIDTH

COUNTERTOP CUTOUT

30"

(762)

4" (102)

31/2" (89)

E G

10"

(254)

191/2"

(495)

21/2"

(64)

VIEW

TE: Shaded area above countertop indicates minimum clearance to combustible surfaces,

tible materials cannot be located within this area.

ectrical and gas supply location only applies to installations with built-in oven.

CUTOUT WIDTH

W

24" Transitional 23" (584)

30" Transitional/Professional 29" (737)

36" Transitional/Professional 35" (889)

FRONT VIEW

wolfappliance.com | 77

Page 78

GAS COOKTOPS

SIDE

NOTE:

combus

Ma

36" Contemporary Gas Cooktop

STANDARD INSTALLATION

21/2" (64)

13"

(330)

2" (51) MIN–

5"

(127) MAX

18"

(457)

9"

(229)

35" (889)

CUTOUT WIDTH

COUNTERTOP CUTOUT

30"

(762)

5"

11/4" (32)

(127)

10"

(254)

DIAMETER

C

L

4" (102)

37/8"

E G

(98) MIN

20"

(508)

–51/8"

(130) MAX

C

L

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

VIEW

Shaded area above countertop indicates minimum clearance to combustible surfaces,

tible materials cannot be located within this area.

ximum facade thickness 1" (25). 1" (25) thickness extends 17 " (432) left and right and 2" (51) above and below centerlines.

FRONT VIEW

78 | Wolf Customer Care 800.222.7820

Page 79

GAS COOKTOPS

SIDE

NOTE:

combus

Ma

Outsid

36" Contemporary Gas Cooktop

FLUSH INSTALLATION

COUNTERTOP

PROFILE

1

/2"

(13) MAX

5

(2)

/64"

21"

(533) MIN

RECESS

(889)

35"

CUTOUT WIDTH

36" (914) MIN

RECESS

COUNTERTOP CUTOUT

21/2"

20"

(508)

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

(64)

13"

(330)

18"

(457)

9"

(229)

2" (51) MIN–

5"

(127) MAX

VIEW

Shaded area above countertop indicates minimum clearance to combustible surfaces,

tible materials cannot be located within this area.

ximum facade thickness 1" (25). 1" (25) thickness extends 17 " (432) left and right and 2" (51) above and below centerlines.

e corner radius 3/8" (10).

30"

(762)

5"

(127)

10"

(254)

C

L

FRONT VIEW

(102)

4"

37/8" (98) MIN–51/8" (130) MAX

11/4" (32)

DIAMETER

E G

C

L

wolfappliance.com | 79

Page 80

Page 81

MODULE COOKTOPS

Module Cooktops

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

Wolf modules have been redesigned to match the updated

lines of Sub-Zero and Wolf. Controls, grates, and trim allow

them to integrate perfectly with their larger counterparts and

deliver equal performance. Combine modules à la cartestyle to create a custom cooktop, or add specialty functions

alongside an existing cooktop.

Full-size cooktops including CI243TF/S, CG243TF/S,

CI304TF/S, and CI365TF/S feature the same brushed stainless frame, making them ideal for pairing with modules.

MODULE COOKTOPS

CI152TF/S

INDUCTION

GM15TF/S

GRILL

CE152TF/S

ELECTRIC

TM15TF/S

TEPPANYAKI

SM15TF/S

STEAMER

CG152TF/S

GAS

FM15TF/S

FRYER

MM15TF/S

MULTIFUNCTION

wolfappliance.com | 81

Page 82

MODULE COOKTOPS

Module Cooktops

INDUCTION ELECTRIC STEAMER

21"

(533)

31/2" (89)

21"

(533)

7

(22)

/8"

15"

(381)

DRAIN

OUTLET

4"

(102)

11/4"

(32)

15"

(381)

CONDUIT

7

/8"

(22)

21"

(533)

2" (51)

21"

(533)

11/4"

(32)

15"

(381)

CONDUIT

7

/8"

(22)

21"

(533)

83/4"

(222)

21"

(533)

FRYER

15"

(381)

7

/8"

(22)

DRAIN

OUTLET

MULTIFUNCTIONGRILL TEPPANYAKI GAS

4"

(102)

21"

(533)

83/4"

(222)

21"

(533)

11/4"

(32)

VENTILATION OUTDOOR GRILLS RANGES | RANGETOPS COOKTOPS | COFFEE BUILT-IN OVENS

82 | Wolf Customer Care 800.222.7820

15"

(381)

7

(22)

15"

(381)

6"

(152)

7

/8"

(22)

/8"

4" (102)

15"

(381)

7

(22)

4" (102)

/8"

15"

(381)

7

(22)

5" (127)

/8"

Page 83

MODULE COOKTOPS

Planning Information

BUILT-IN OVENS COOKTOPS | COFFEE RANGES | RANGETOPS OUTDOOR GRILLS VENTILATION

IMPORTANT NOTE: Wolf does not recommend the use

of downdraft ventilation with the steamer, fryer, or grill

modules.

A minimum 2"

(51) is required from the bottom of the module

to combustible materials. For the teppanyaki module, a

7

minimum

/8" (22) is required from the bottom of the unit to

any material.

Refer to the illustrations on the following pages for installation of modules.

MULTIPLE COOKTOPS

When multiple cooktops or modules are installed side by

side, refer to the chart and illustration below for typical

congurations. The cutout dimensions provided will accommodate the use of an optional ller strip if desired.

For specic multiple cooktop and module conguration

options or the installation of more than six modules, contact

Wolf Customer Care at 800-222-7820.

COUNTERTOP CUTOUT

(2) 15" Modules* 29" (737)

(3) 15" Modules* 44" (1118)

(4) 15" Modules* 591/4" (1505)

(5) 15" Modules* 741/4" (1886)

(6) 15" Modules* 891/4" (2267)

24" Cooktop**/15" Module* 375/8" (956)

30" Cooktop/15" Module* 44" (1118)

30" Cooktop/(2) 15" Modules* 59" (1473)

36" Cooktop/15" Module* 50" (1270)

*Dimensions apply to CI152TF/S, CE152TF/S, CG152TF/S, SM15TF/S,

FM15TF/S, GM15TF/S, TM15TF/S and MM15TF/S.

5

**23

/8" actual product width.

W

21/2"

(64) min

21/2"

(64) min

Countertop cutout

W

CUTOUT

WIDTH

FRONT OF COUNTERTOP

wolfappliance.com | 83

191/2"

(495)

CUTOUT

DEPTH

Page 84

MODULE COOKTOPS

Planning Information

ELECTRICAL

Installation must comply with all applicable electrical codes.

Locate the electrical supply as shown in the illustrations on

the following pages. A separate circuit servicing only this

appliance is required.