Page 1

Instruction Manual

VERTEBRIS lumbar-thoracic

Full endoscopic spinal instrument set

GA-B 223 / USA / 2012-10 V5.0 / ECO 2012-0519

(RW: 07-09-7.0

/ PDZ 09-3602)

Page 2

Important general notes and instructions for use

Make sure that this product is used only as intended and described in this instruction manual, by

adequately trained and qualified medical personnel, and that maintenance and repair are only car

ried out by authorized experts.

Use the product only in the combinations and with the accessories and spare parts specified in this

instruction manual. Use other combinations, accessories and replacement parts only if they are

expressly intended for the planned application and if the performance characteristics and safety

requirements are met. The product must not be altered in any way.

Reprocess the products in accordance with the manual before every use and before return ship

ment to protect the patient, user and third parties.

Immediately upon receipt, check the product and its accessories for completeness and possible

damage. Should the shipment give right to complaints, please inform the manufacturer or supplier

immediately.

Subject to technical changes!

Due to ongoing developments, the illustrations and technical data may deviate slightly.

CAUTION :

Federal law restricts this device to sale by or on the order of a physician.

Safety instructions and levels of danger

Symbols Level of danger

WARNING!

Failure to observe can result in death or serious injury.

CAUTION!

Failure to observe can result in slight injury or damage to the product.

.

.

IMPORTANT!

Failure to observe can result in damage to the product or surroundings.

NOTE!

Tips for optimum use and other useful information.

USA

RICHARD WOLF

Medical Instruments Corporation

353 Corporate Woods Parkway

Vernon Hills, Illinois 60061

Toll Free: 001 (800) 323 - 9653

Phone: 001 (847) 913 - 1113

Fax: 001 (847) 913 - 1488

MANUFACTURER

sales@richardwolfusa.com

www.richardwolfusa.com

BELGIUM / NETHERLANDS

N.V. Endoscopie

RICHARD WOLF Belgium S.A.

Industriezone Drongen

Landegemstraat 6

9031 Gent Drongen

Telephone: +32 92 80 81 00

Telefax: +3292829216

endoscopy@richard-wolf.be

www.richard-wolf.be

Marketing Office

U.A.E

RICHARD WOLF Middle East

P.O. Box 500283

AL Thuraya Tower 1

th

Floor,

9

Room 904, Dubai

Telephone: + 9 71 43 68 19 20

Telefax: + 9 71 43 68 61 12

middle.east@richard-wolf.com

www.richard-wolf.com

GERMANY

RICHARD WOLF GmbH

75438 Knittlingen

Pforzheimerstr. 32

Telephone: +49 70 43 35-0

Telefax: +49704335-300

info@richard-wolf.com

www.richard-wolf.com

FRANCE

RICHARD WOLF France S.A.R.L.

Rue Daniel Berger

Z.A.C. La Neuvillette

F-51100 Reims

Telephone: +33 3 26 87 02 89

Telefax: +33 3 26 87 60 33

france@richard-wolf.com

INDIA

RICHARD WOLF India Private Ltd.

JMD Pacific Square

No. 211 A, Second Floor

Behind 32

Gurgaon - 122 001

National Capitol Region

Telephone: + 91 12 44 31 57 00

Telefax: +911244315705

india@richard-wolf.com

www.richard-wolf.com

nd

Milestone

UK

RICHARD WOLF UK Ltd.

Waterside Way

Wimbledon

SW17 0HB

Telephone: + 44 20 89 44 74 47

Telefax: +442089441311

admin@richardwolf.uk.com

www.richardwolf.uk.com

AUSTRIA

RICHARD WOLF Austria

Ges.m.b.H.

Wilhelminenstraße 93 a

A-1160 Vienna

Telephone: +43 14 05 51 51

Telefax: +431405515145

austria@richard-wolf.com

www.richard-wolf.com

0

GA-B 223

Page 3

Contents

1 Intended use 1..............................................................

1.1 Endoscopes, endoscope accessories 1.........................................

1.2 Suction- and Irrigation instruments 1............................................

1.2.1 Irrigation adapters, adapter 1..................................................

1.2.2 Suction connector, suction tube 1..............................................

1.3 Access instruments 1.........................................................

1.3.1 Positioning rod 1.............................................................

1.3.2 Spinal Cannula Set 1.........................................................

1.3.3 Dilators 1...................................................................

1.3.4 Working sleeves 1...........................................................

1.3.5 Attachable handles 1.........................................................

1.3.6 Trephines 1.................................................................

1.3.7 Spongiosa pusher / funnel 1...................................................

1.4 Hand and auxiliary instruments 1...............................................

1.4.1 Rasp / Trocar / Spoon / Anulotome / Dissector / Curette / Face cutter 1.............

1.5 Forceps instruments, punches, scissors 2.......................................

1.5.1 Punches, micro rongeurs 2....................................................

1.5.2 Micro punches 2.............................................................

1.5.3 Scissors 2..................................................................

1.5.4 Tubular sheath punches, bone punches 2.......................................

1.6 Motorized instruments 2......................................................

1.6.1 Abrader 2...................................................................

1.6.2 Rotary blades / Nucleus resector 2.............................................

1.7 HF / RF instruments 2........................................................

1.8 Accessories 2...............................................................

1.8.1 Deflector 2..................................................................

1.8.2 Extractor instrument ”X-tractor” 2...............................................

2 Indications and field of use 2..................................................

3 Contraindications 2...........................................................

4 Combinations 3..............................................................

5 Illustration 4.................................................................

5.1 Endoscopes, endoscopic accessories 4.........................................

5.1.1 Endoscope A 4..............................................................

5.1.2 Endoscope B 5..............................................................

5.2 Suction‐ and irrigation instruments 6............................................

5.2.1 Stopcock‐, irrigation connectors, adapters 6.....................................

5.2.2 Suction tube, suction connector 6..............................................

5.3 Access instruments 7.........................................................

5.3.1 Positioning rod 7.............................................................

5.3.2 Disposable Spinal Cannula Set 7...............................................

5.3.3 Dilators 8...............................................................

5.3.4 Working sleeve 8............................................................

5.3.5

5.3.6 Trephines 9.................................................................

5.3.7 Spongiosa pusher and funnel 9................................................

Attachable handles ......................................................... 9

....

GA-B 223

I

Page 4

5.4 Hand and auxiliary instruments 10...............................................

5.4.1 Anulotome / Dissector / Curette / Spoon / Rasp / Trocar / Face cutter 10.............

5.5 Forceps instruments, punches, scissors 11.......................................

5.6 Motorized instruments 12......................................................

5.6.1 Abraders 12..................................................................

5.6.2 Rotary blades 12..............................................................

5.7 HF / RF Instruments 13........................................................

5.7.1 Bipolar coagulations instruments and bipolar electrodes 13.........................

5.7.2 Bipolar Micro Grasping Forceps 14..............................................

5.8 Accessories 15...............................................................

5.8.1 Deflector 15..................................................................

5.8.2 Extractor instrument ”X-tractor” 15...............................................

5.9 Packaging identification 16.....................................................

6Use 17......................................................................

6.1 Preparation 17................................................................

6.1.1 Assembling the endoscopes 17.................................................

6.1.2 Attaching access instruments 20................................................

6.1.3 Motorized instruments 21......................................................

6.2 Additional notes and instructions for use 21.......................................

6.2.1 Light 21......................................................................

6.2.2 Current 22...................................................................

6.2.3 Image quality 22..............................................................

6.2.4 Irrigation fluid 22..............................................................

6.2.5 Irrigation and suction power 22..................................................

6.2.6 HF application 23.............................................................

6.3 Laser application 24...........................................................

6.3.1 Forceps instruments, punches, scissors 24.......................................

7 Checks 27...................................................................

7.1 Visual check 27...............................................................

7.2 Functional check 28...........................................................

7.2.1 Endoscopes 28...............................................................

7.2.2 Suction- and irrigation instruments 28............................................

7.2.3 Forceps instruments, punches, scissors 28.......................................

8 Reprocessing and maintenance 29..............................................

8.1 Disassembly before cleaning 29.................................................

8.1.1 Endoscopes 29...............................................................

8.1.2 Access instruments 30.........................................................

8.1.3 Forceps instruments, punches, scissors 31.......................................

8.1.4 Motorized instruments 31......................................................

8.2 Manual reprocessing 31........................................................

8.2.1 Endoscopes

8.2.2 Forceps instruments, punches, scissors 31.......................................

8.2.3 Motorized instruments 31......................................................

8.3 Machine reprocessing 32.......................................................

8.3.1 Endoscopes 32...............................................................

8.3.2 Forceps instruments, punches, scissors, nucleus resector with luer connector 33......

8.4 Checks 33...................................................................

31...............................................................

II

GA-B 223

Page 5

Contents

8.5 Assembly before sterilization 34.................................................

8.5.1 Endoscopes 34...............................................................

8.6 Sterilization 35................................................................

8.6.1 Steam sterilization 36..........................................................

8.6.2 Gas sterilization 36............................................................

8.6.3 Alternate sterilization methods 36...............................................

8.6.4 Short Endoscope Tray, Item # 88090.0007 36....................................

9 Technical data and order data 37................................................

9.1 Spare parts and accessories 37.................................................

10 Operating, storage, transport and shipping conditions. 38...........................

11 Disposal of product, packaging material and accessories. 38........................

12 Warranty and Customer Service 39..............................................

GA-B 223

III

Page 6

1 Intended use

The instruments and endoscopes serve to create the surgical passages, visualize

the operating area, manipulate and dissect tissue in endoscopic or endoscopically

supported spinal surgery.

For this purpose the instruments described in the following are used:

1.1 Endoscopes, endoscope accessories

For visualizing the operating area and the surgical instruments. The surgical instruments are introduced through the working channel or insertion port with stopcock.

Irrigation is carried out via a separate irrigation channel or the working channel.

1.2 Suction-- and Irrigation instruments

1.2.1 Irrigation adapters, adapter

For connecting the endoscopes or working sleeves to the suction and irrigation

environment.

1.2.2 Suction connector, suction tube

They allow additional or inproved aspiration of irrigation fluid, blood or ablated

particles. If necessary the suction connector can also be attached directly to the

distal end of the endoscope.

1.3 Access instruments

1.3.1 Positioning rod

The positioning rod is used to define the optimum entry point when establishing

access under image converter control.

1.3.2 Spinal Cannula Set

The spinal cannula set is used for creating primary access and injecting local

anesthetic, as well as for applying discography media.

1.3.3 Dilators

Dilators are used for blunt preparation of the access channel. The cannulated

dilators can be inserted via a guide wire.

1.3.4 Working sleeves

The working sleeves are used to secure the passage during the operation. Working sleeves are inserted via a suitable dilator.

1.3.5 Attachable handles

For intraoperative manipulation of working sleeves, without suction or irrigation

function.

1.3.6 Trephines

The trephine is used to create a window in the fibrous ring of the intervertebral

disc.

1.3.7 Spongiosa pusher / funnel

This instrument is used for implanting spongiosa.

1.4 Hand and auxiliary instruments

1.4.1 Rasp / Trocar / Spoon / Anulotome / Dissector / Curette / Face cutter

For palpating, exposing and dissecting soft tissue.

1

GA-B 223

Page 7

1.5 Forceps instruments, punches, scissors

1.5.1 Punches, micro rongeurs

are used for manipulating and withdrawing soft and cartilaginous tissue.

1.5.2 Micro punches

are used for dissecting soft and cartilaginous tissue.

1.5.3 Scissors

for the dissection of soft and cartilaginous tissue.

1.5.4 Tubular sheath punches, bone punches

are used for dissecting strong ligaments, cartilaginous tissue and osseous structures.

1.6 Motorized instruments

1.6.1 Abrader

Abraders are used for the resection of osseous structures under simultaneous aspiration of severed tissue chips.

1.6.2 Rotary blades / Nucleus resector

Resect disc core material (nucleus pulposus) under simultaneous aspiration of severed tissue chips.

They serve to palpate, expose and dissect tissue.

1.7 HF / RF instruments

For tissue coagulation, vessel coagulation, hemostasis and tissue reduction under

endoscopic view. The use of suction applicators allows additional irrigation or suction.

1.8 Accessories

1.8.1 Deflector

The deflector is used for deflecting flexible auxiliary instruments.

1.8.2 Extractor instrument ”X--tractor”

The ”X--tractor” serves to manipulate cylindrical access instruments.

2 Indications and field of use

For use in endoscopic or endoscopically supported operations of the spine.

Mainly for removing tissue, (such as prolapse material, bones, cartilage, etc.) in

order to decompress neural structures.

3 Contraindications

CJD -- Creutzfeldt--Jakob Disease or

vCJD -- Variant of the Creutzfeldt--Jakob Disease

BSE -- Bovine Spongiform Encephalopathy; the so--called mad cow disease

TSE -- Transmissible spongiform Encephalopathy

On the basis of the patient’s general condition the physician / surgeon in charge

must decide whether the planned use is possible or not.

The regulations and laws valid in your country must be adhered to.

For further information see the latest medical literature.

Contraindications directly related to the product are presently unknown.

(e.g. Creutzfeldt--Jakob disease)

GA-B 223

2

Page 8

4 Combinations

The instrument set is used in conjunction with:

Z Light sources and fiber light cables

Z Cameras and objective lenses

Z Pumps for irrigation and suction

Z HF surgical devices

Z Laser

Z Motor systems / Motorized handles

Z Endoscopic accessories

CAUTION!

Do not combine products incorrectly!

Injuries of the patient, user or third parties as well as damage to the product

are possible.

The different products can only be combined and used together if the in-

tended use and the relevant technical data (working length, diameter, peak

voltage etc.) are the same.

Follow the instruction manuals of the products used in combination with

this product.

' System Overview VERTEBRIS lumbar -thoracic BB -B 223

' Overview of motorized instruments BB- B 223- 1

' POWER CONTROLE 2303 GA- A 202

' POWER DRIVE ART1 2304 GA- A 238

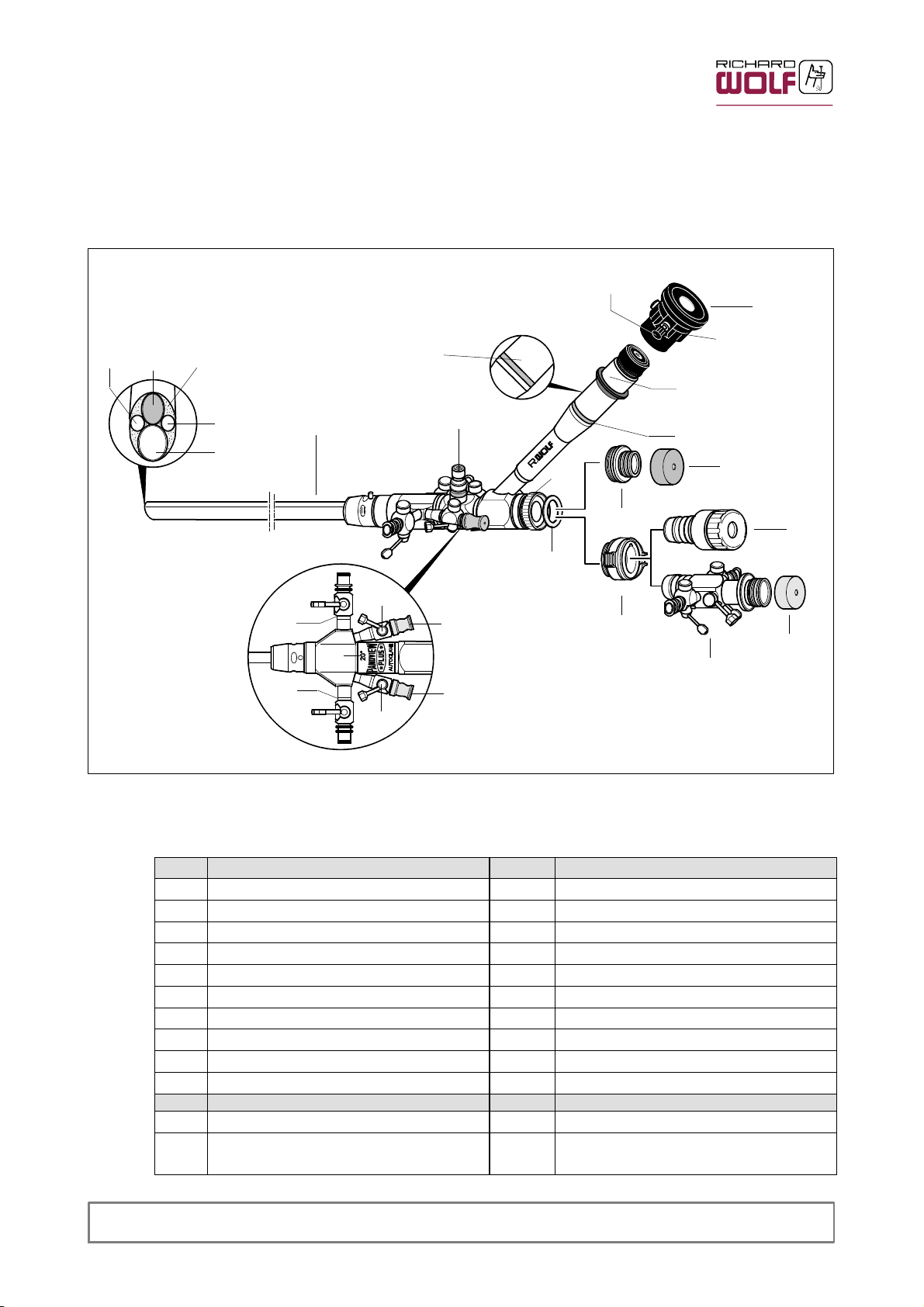

Fig. 1

1.5

The cold--light connector (1.5) can be unscrewed and replaced with suitable

adapters to connect fiber light cables made by other manufacturers (Fig. 1).

' The same applies to endoscope A.

' For order information please refer to the current catalog sheets.

3

GA-B 223

Page 9

5 Illustration

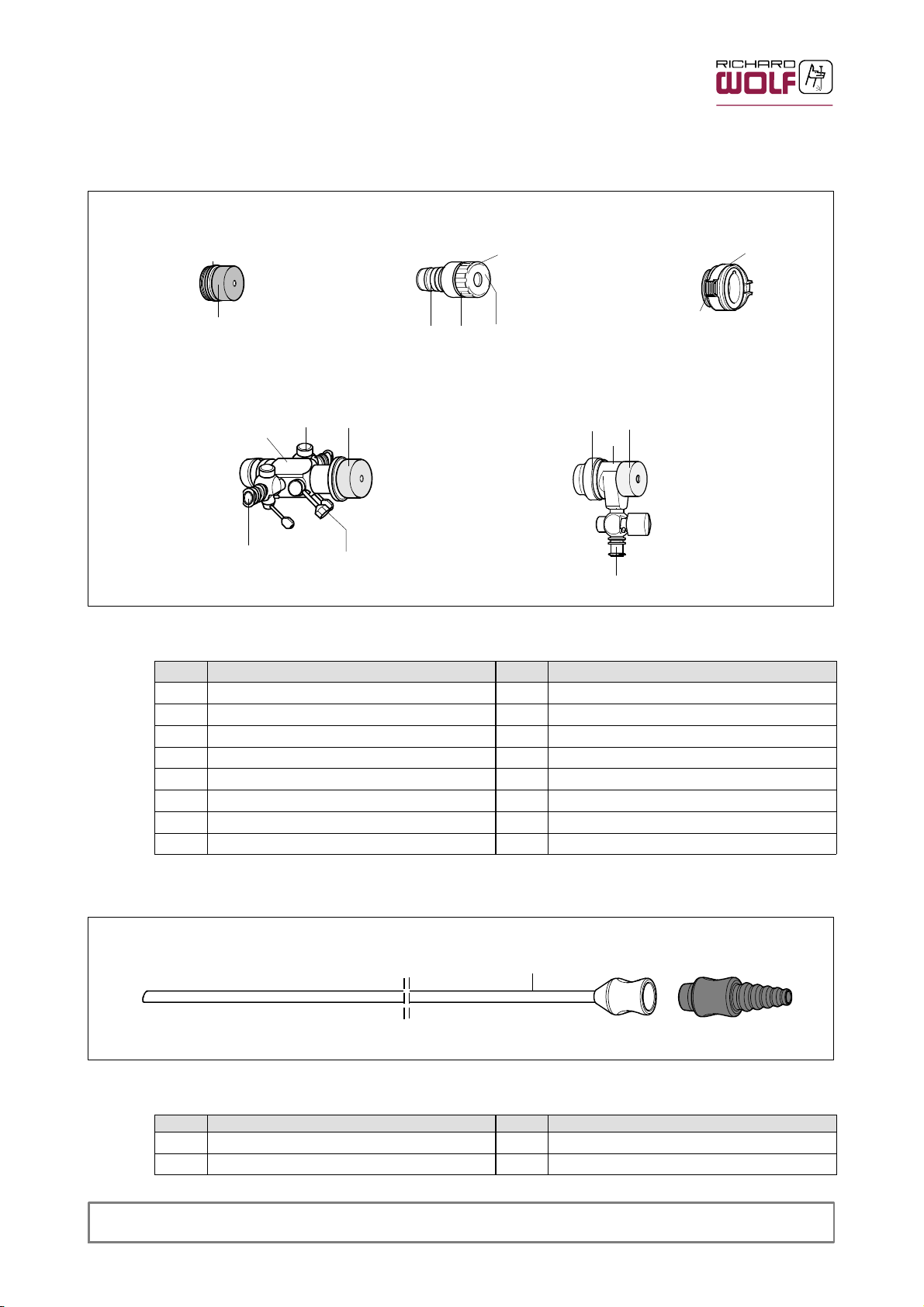

5.1 Endoscopes, endoscopic accessories

5.1.1 Endoscope A

1.1 1.2

1.3

1.1

1

1.4

2.1

2

#

#

*

1.5

1.12

3

1.6

Fig. 2

4

1.7

1.9

1.10

1.11

1.10

1.8

1.8

6

7

1.9

Legend and identification

Item Designation Item Designation

1 Endoscope 1.9 Insertion stopcock / port

1.1 Irrigation channel 1.10 Irrigation stopcock

1.2 Objective lens 2 Snap--on eyepiece with eyecup

1.3 Light exit 2.1 Locking screw

1.4 Working channel 3 Sealing cap

1.5 Cold--light adapter 4 Sealing cap adapter

1.6 Locking collar 5 Membrane adapter

1.7 Sealing membrane 6 Cone adapter

1.8 Rubber cap, red 7 Stopcock adapter

# Product no. * Serial no.

Item Designation Colour Meaning

1.1 1 Indication of viewing direction

1.12 Colored ring

red

blue

Viewing direction 20

Viewing direction 0

5

3

GA-B 223

4

Page 10

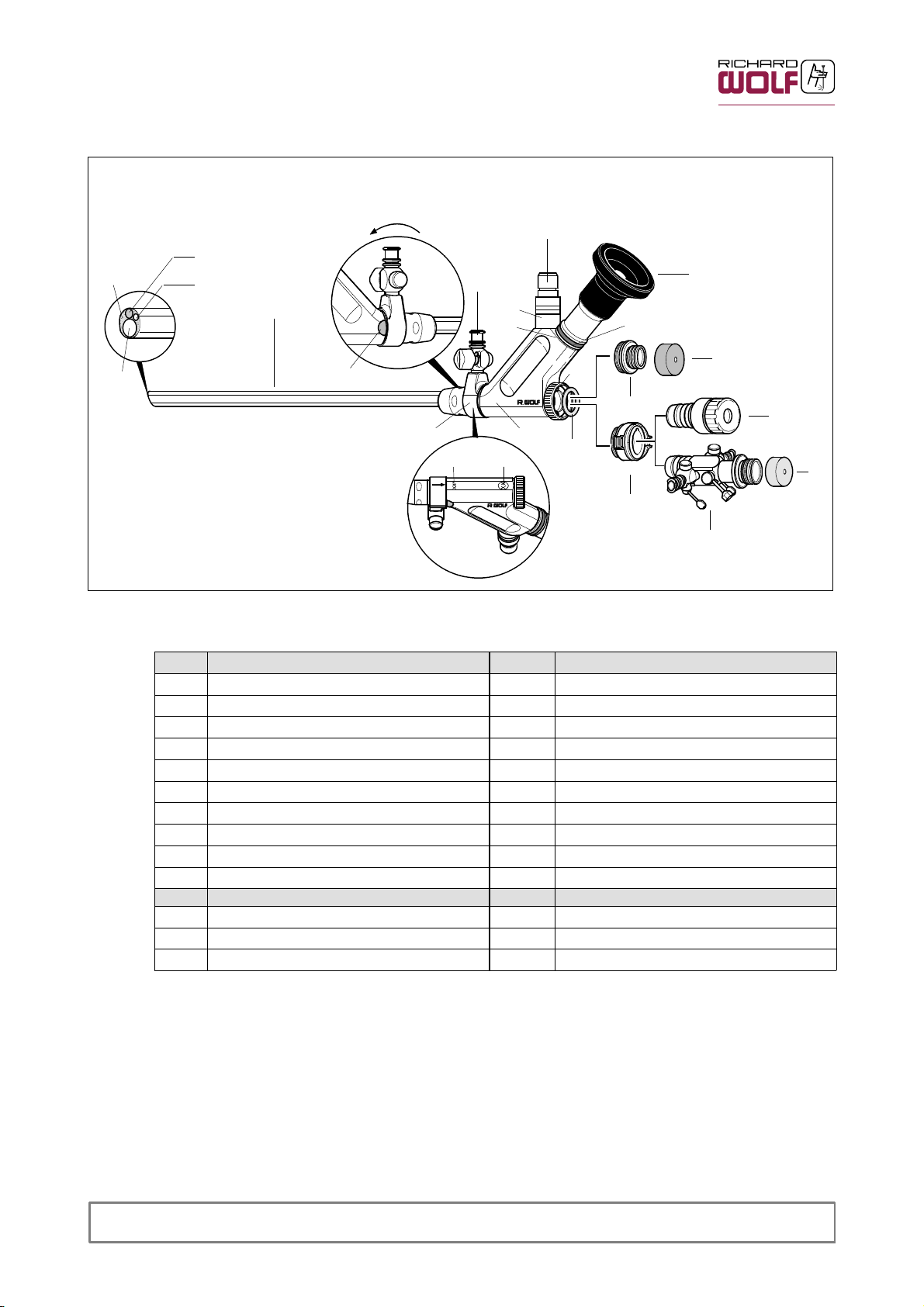

5.1.2 Endoscope B

1.3

1.4

Fig. 3

180°

1.5

1.2

1.1

1

1.14

8.1

1.15

*

35

1.12

1.6

4

8

1.11 1.13

#

1.7

6

Legend and identification

Item Designation Item Designation

1 Endoscope 2 Eyepiece with eyecup

1.1 Irrigation channel 3 Sealing cap

1.2 Objektive lens 4 Sealing cap adapter

1.3 Light exit 5 Membrane adapter

1.4 Working channel 6 Cone adapter

1.5 Cold--light adapter 7 Stopcock adapter

1.6 Locking collar 8 Irrigation adapter, rotatable

1.7 Sealing membrane 8.1 Irrigation stopcock

1.14 Locking tab # Product no.

1.15 Size of fiber core diameter * Serial no.

Item Designation Color Meaning

1.1 1 Indication of viewing direction

1.12 Colored ring red Viewing direction 25

1.13 Maximum capacity (lumen) in mm

2

3

5

3

7

5

GA-B 223

Page 11

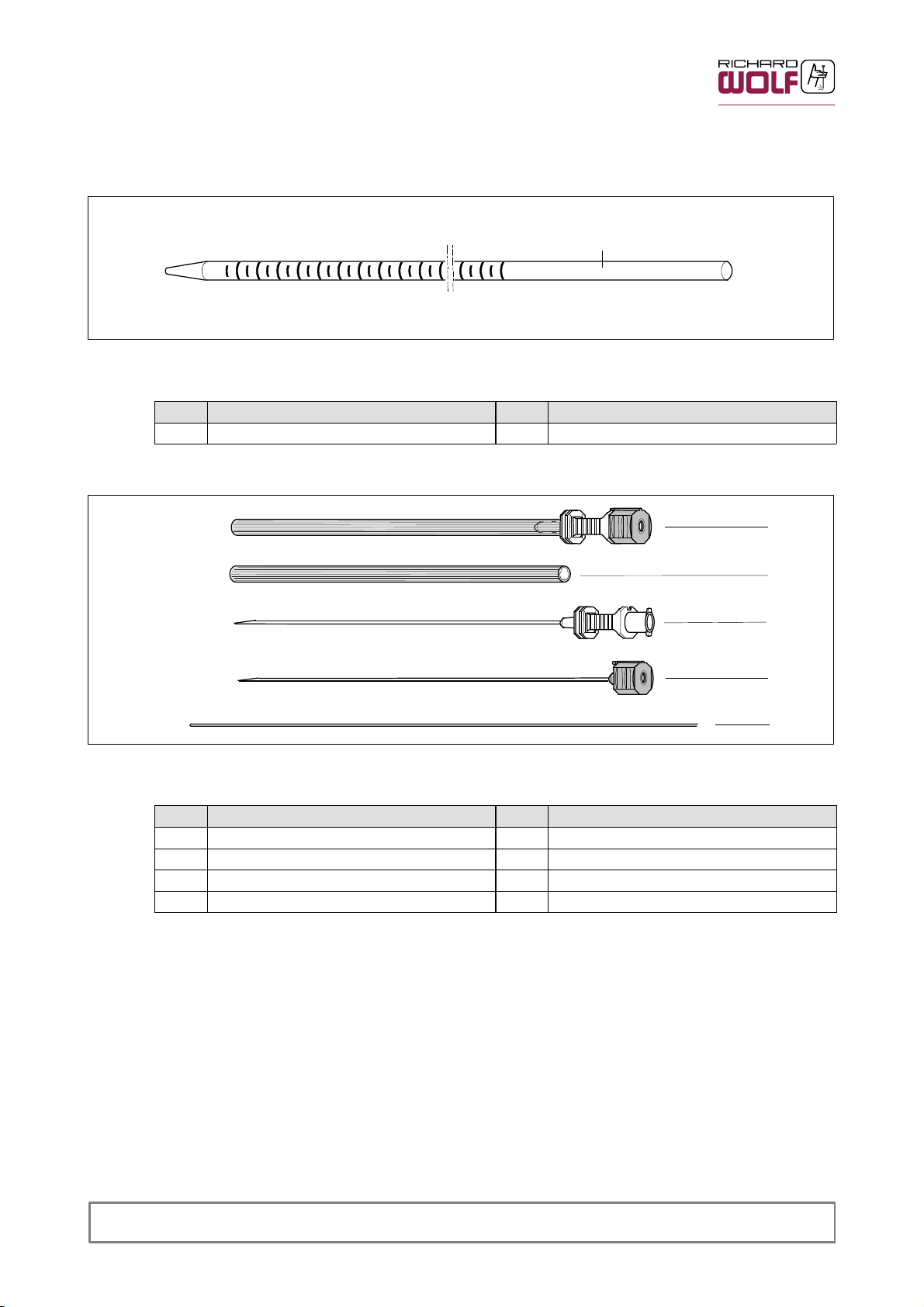

5.2 Suction- and irrigation instruments

5.2.1 Stopcock-, irrigation connectors, adapters

4 56

#

5.1

#

Fig. 4

3

7

7.1

3

#

5.25.3

#

9

9.2

3

6.1

#

7.27.1

9.1

Legend and identification

Item Designation Item Designation

3 Sealing cap 7 Stopcock adapter

4 Sealing cap adapter 7.1 Insertion stop cock

5 Membrane adapter 7.2 Irrigation stopcock

5.1 Sealing insert 9 Irrigation adapter for workling sleeves

5.2 Membrane valve 9.1 Irrigation stopcock

5.3 Adapter 9.2 Locking sleeve

6 Cone adapter

6.1 Tab # Product no.

5.2.2 Suction tube, suction connector

Fig. 5

Legend and identification

Item Designation Item Designation

10 Suction tube 11 Suction connector

GA-B 223

10

11

#

# Product no.

6

Page 12

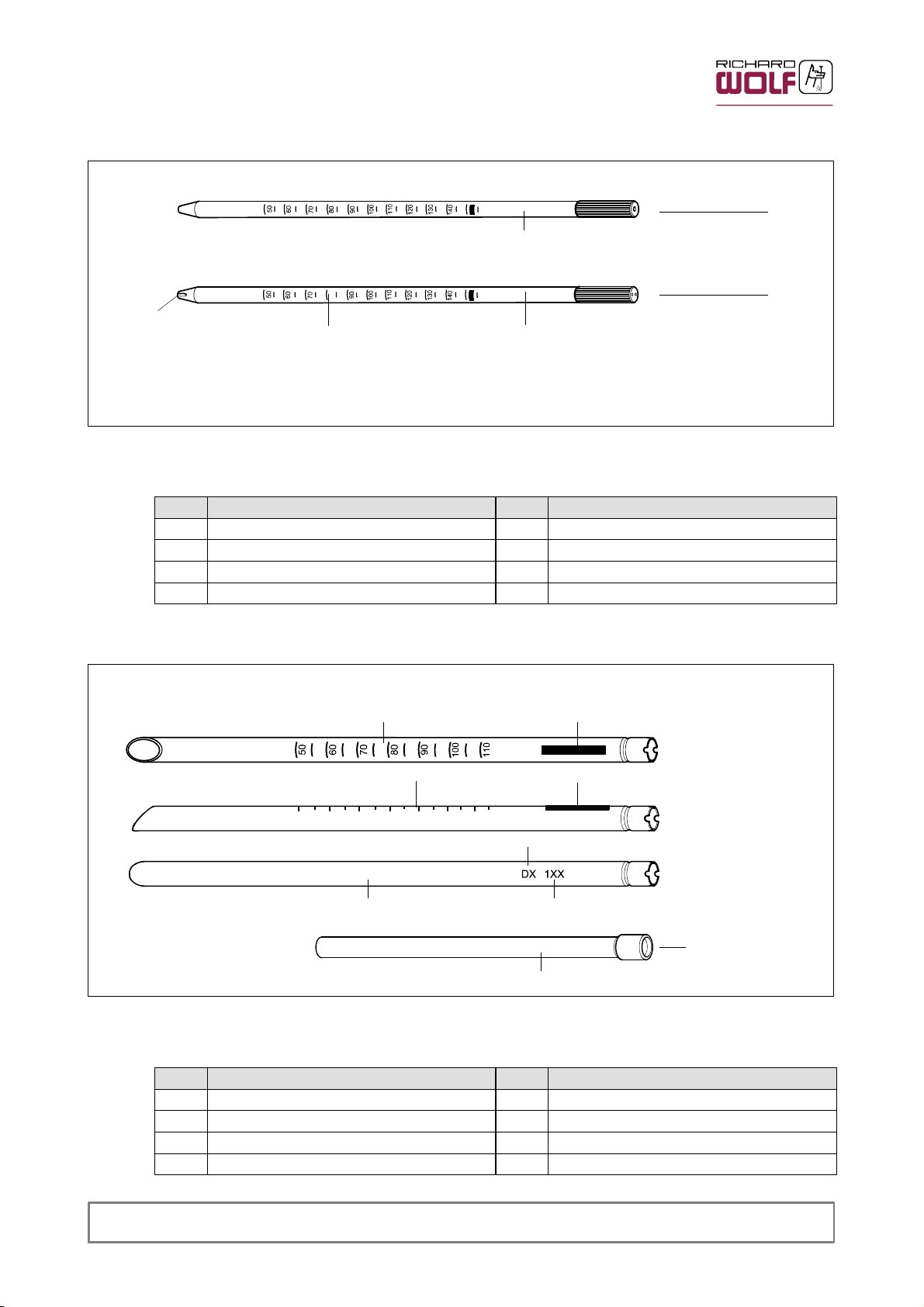

5.3 Access instruments

5.3.1 Positioning rod

Fig. 6

Legend and identification

Item Designation Item Designation

12 Positioning rod # Product no.

5.3.2 Disposable Spinal Cannula Set

12

#

13

13.1

Fig. 7

Legend and identification

Item Designation Item Designation

13 Disposable Spinal Cannula Set 14 Guide wire

13.1 Protection sleeve

13.2 Spinal cannula

13.3 Internal needle

For more information see instruction manual GA--B 175

13.2

13.3

14

7

GA-B 223

Page 13

5.3.3 Dilators

15

15.1

#

15.2

15.2.1

Fig. 8

Legend and identification

Item Designation Item Designation

15 Dilators # Product no.

15.1 Dilator, single--channel * Scale, graduation in mm

15.2 Dilator, dual--channel

15.2.1 Eccentric bore for second channel

5.3.4 Working sleeve

*

#

16

*

*

16.1

16.1

Fig.9

Legend and identification

GA-B 223

##

#

###

#

Item Designation Item Designation

16 Working sleeves # Product no.

16.1 Identification of window position * Scale, graduation in mm

16.2 Extension sleeve ## External diameter in mm

### Length in mm

16.2

8

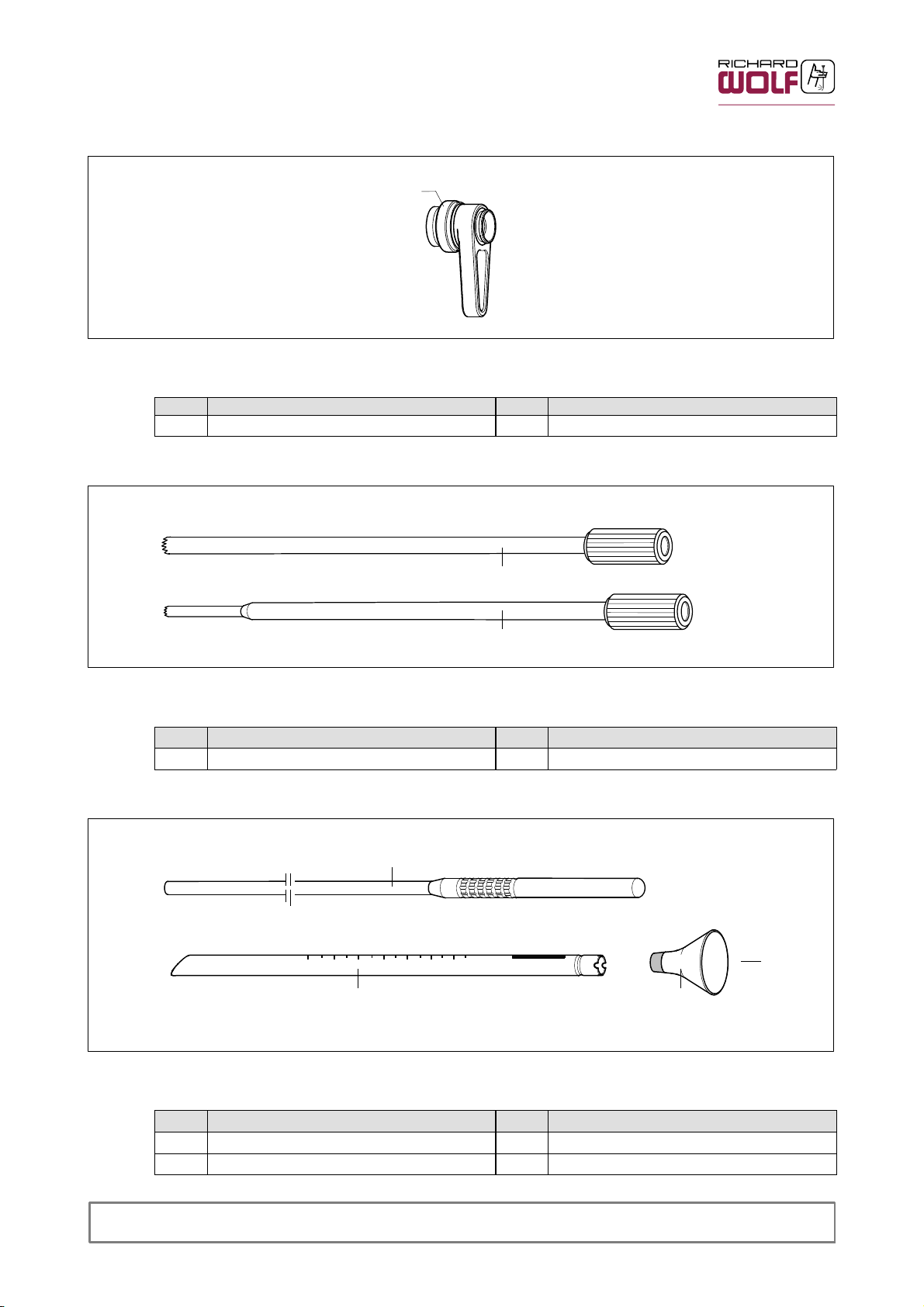

Page 14

5.3.5

Fig. 10

5.3.6 Trephines

Attachable handles

Legend and identification

Item Designation Item Designation

17 Attachable handle # Product no.

17

#

18

#

Fig. 11

Legend and identification

Item Designation Item Designation

18 Trephines # Product no.

5.3.7 Spongiosa pusher and funnel

Fig. 12

#

19

#

16

20

#

#

Legend and identification

Item Designation Item Designation

19 Spongiosa pusher

20 Spongiosa funnel # Product no.

9

GA-B 223

Page 15

5.4 Hand and auxiliary instruments

5.4.1 Anulotome / Dissector / Curette / Spoon / Rasp / Trocar / Face cutter

#

Fig. 13

21

22

23

24

25

26

27

Legend and identification

Item Designation Item Designation

21 Spoon 25 Dissector

22 Curette 26 Anulotome

23 Trocar 27 Face cutter

24 Rasp # Product no.

#

GA-B 223

10

Page 16

5.5 Forceps instruments, punches, scissors

28

#

28.1

28.2

29.2

29

#

30.1

30

30.2

29.2

30.3

30.5

30.4

31.1

32.2

32

32.3

30.6

29.1

32.1

31

31.2 31.3

#

33

33.1 33.2 33.3 33.4

Fig. 14

Legend and identification

Item Designation Item Designation

28--32 Handle versions

28 Suction forceps handle 30.5 Locking screw

28.1 Adjusting wheel 30.6 Thrust plate

28.2 Suction connector 31 Bone punch

Handle with ring--shaped grips with/

29

without finger support

29.1 Finger support 31.2 Sheath (tube)

29.2 Grip 31.3 Knurled nut

30 Intradiscal forceps, hinged 32 Forceps handle with strain relief

30.1 Luer--lock cap 32.1 Strain relief

30.2 Luer connector 32.2 Luer connector

30.3 Locking mechanism 32.3 Luer--lock cap

30.4 Deflection lever # Product no.

33 Jaw versions

33.1 Scissors 33.5 Micro rongeur, with two movable jaws

33.2 Grasping / holding forceps 33.6 Micro rongeur

33.3 Micro punch 33.7 Intradiscal grasping forceps, hinged

33.4 Micro bone punch / tubular sheath punch

33.7

33.6

31.1 Internal part (forceps actuator)

33.5

For more informations see instruction manuals GA--S 003 and BB-- S 003--1 / BB--S 003--2

11

GA-B 223

Page 17

5.6 Motorized instruments

5.6.1 Abraders

34

#

35

36

#

37

Fig. 15

Legend and identification

Item Designation Item Designation

34 Oval Burr, laterally hooded 36 Round Burr

35 Oval Burr, frontally hooded 37 Diamond Burr

# Product no.

For more information see instruction manual GA--A 202 and GA--A 238

5.6.2 Rotary blades

Fig. 16

Legend and identification

Item Designation Item Designation

38 Nucleus Resector

39 Nucleus Resector with Luer connector

39.1 Luer connector

39.2 Luer lock cap # Product no.

38

39

#

#

#

39.

1

39.2

For more information see instruction manual GA--A 202 and GA--A 238

GA-B 223

12

Page 18

5.7 HF / RF Instruments

5.7.1 Bipolar coagulations instruments and bipolar electrodes

40.1

41.1

41.2

41.3

41.4

41.5

41.6

*

40.2

40

#

41

#

*

#

42

Fig. 17

Legend and identification

Item Designation Item Designation

40 Coagulation instruments, bipolar 41.4 Stepped spherical electrode

40.1 Button Electrode 41.5 Ring electrode

40.2 Bipolar connection adapter, long 41.6 Stepped needle electrode

41 Bipolar electrodes 42 Bipolar needle by Biner

41.1 Hook electrode 43 Bipolar tweezers, bayonet--shaped

41.2 Needle electrode # Product no.

41.3 Spherical electrode *

For more informations see instruction manual GA--S 011

13

#

43

Identification of electrode insert on

packaging

GA-B 223

Page 19

5.7.2 Bipolar Micro Grasping Forceps

47

#

44

45

44

46

44.1

45

consisting of:

46.1

46.4

46.2

46

#

45.1

46.3

Fig. 18

Legend and identification

Item Designation Item Designation

44 Jaw insert 46 Spring handle

44.1 Jaws 46.1 Linking rod

45 Sheath 46.2 Receptable

45.1 Grip 46.3 Bipolar HF connector

For more information see instruction manual GA--B 210

GA-B 223

46.4 Handle guide

47 Rubber cap

# Product no.

14

Page 20

5.8 Accessories

5.8.1 Deflector

48

Fig. 19

Legend and identification

Item Designation Item Designation

48 Deflector # Product no.

5.8.2 Extractor instrument ”X--tractor”

49.2

#

49.349.1

49

#

50.1 50.150.2

Fig. 20

Legend and identification

Item Designation Item Designation

49 Handle 50 Clamping device

49.1 Recesses 50.1 Fastening pins

49.2 Spring 50.2 Fastening straps

49.3 Grip # Product no.

For more information see instruction manual GA--B 227.

##

50

**

* Size data

15

GA-B 223

Page 21

5.9 Packaging identification

Symbols Meaning

Attention, consult ACCOMPANYING DOCUMENTS

15

REF

SN

Order number

Lot identification number

Series number

Manufacturing date

Manufacturer

Units, pieces

Use--by date:

Do not reuse (for single use only)

Sterilized with ethylene oxide

25

Permissible temperature range

Keep away from heat

<60

<60%

Keep dry, atmospheric humidity below 60 %

Identification in conformity with Medical Devices Directive 93/42/EEC only valid if the product and/or

packaging is marked with this symbol. Products of category IIa and above, as well as sterile

products or products with measuring function of category I, are additionally marked with the code

number of the notified body (0124).

GA-B 223

16

Page 22

6Use

WARNING!

Do not reprocess disposable items!

Products marked ”disposable”, i.e. for single use only, have been designed

for only one use on or in a single patient.

If disposable items are reprocessed to be used again, product quality may

deteriorate, which will endanger the patient, user and others.

In this case the manufacturer can no longer guarantee the product’s safety

and performance.

CAUTION!

The products have only limited strength!

Exerting excessive force will cause damage, impair the function and there-

fore endanger the patient.

Immediately before and after each use, check the products for damage,

loose parts and completeness.

Ensure that no missing instrument parts remain in the patient.

Do not use products which are damaged, incomplete or have loose parts.

6.1 Preparation

Z Perform a visual check: section 7.1

Z Tighten the cold--light connector (1.5) (Fig. 1, page 3).

6.1.1 Assembling the endoscopes

Sealing cap adapter (Fig. 21)

Z Place the sealing membrane (1.7) into the locking collar.

Z Firmly tighten the sealing cap adapter (4).

Z Install the sealing cap (3).

Fig. 21

1.7

4 3

NOTE!

.

The sealing membrane (1.7) amd membrane valve (5.2) should be replaced after each use.

Membrane adapter (Fig. 22)

Z Place the sealing membrane (1.7) into the locking collar.

Z Firmly tighten the cone adapter (6).

Z Place the membrane valve (5.2) into sealing insert (5.1).

Z Screw the sealing insert (5.1) into connector (5.3).

Z Introduce the membrane adapter (5) in cone adapter (6) until the locking mech-

anism snaps into place.

NOTE!

.

If locking mechanism won’t engage, push release button (6.1) as far as it will go,

then repeat the procedure.

6.1

17

Fig. 22

1.7

6 5.3 5.2 5.1

GA-B 223

Page 23

Stopcock adapter (Fig. 23)

Z Place the sealing membrane (1.7) into the locking collar.

Z Firmly tighten the cone adapter (6).

Z Introduce the stopcock adapter (7) into cone adapter (6) until the locking mech-

anism snaps into place.

NOTE!

.

If locking mechanism won’t engage, push release button (6.1) as far as it will go,

then repeat the procedure.

Z Attachthesealingcap(3).

6.1

Fig. 24

2.1

Fig. 23

Endoscope A

For connecting endoscope A to objective lenses with C--mount thread, use the

plug--on eyepiece.

Z Attaching the plug--on eyepiece (2) (Fig. 24):

2

-- Unscrew the locking screw (2.1) turning in direction of arrow “a” as far as it

will go before you attach the eyepiece.

-- Install the plug--on eyepiece (2) and tighten the locking screw (2.1) in direction

of arrow “b”.

Fig. 25

Z Install the rubber caps (1.8).

Z Connect the irrigation tubes (A) to the irrigation stopcocks (1.10).

Z Connect the fiber light cable (B) to the cold--light connector (1.5) and to a suit-

able light source.

1.7

6 3

GA-B 223

Fig. 25

B

A

1.5

A

1.8

1.10

18

Page 24

Endoscope B (Fig. 26)

NOTE!

.

The eyepiece with eyecup of endocope B cannot be removed.

When mounting the irrigation adapter (8) make sure that you overcome the resist-

ance of the 0--rings and keep the irrigation adapter perfectly aligned.

Z Push the irrigation adapter (8) in direction of arrow as far as it will go.

' The irrigation adapter snaps into place.

Z Connect the irrigation tube (A) to the irrigation stopcock (8.1).

Z Connect the fiber light cable (B) to the cold--light connector (1.5) and to a suit-

able light source.

B

Fig. 27

1.15

1.5

A

8.1

8

1.5

xxxxx.xxxx

Fig. 26

Fig. 27

NOTE!

.

To achieve optimum light transmission the fiber bundle diameters of the endoscope and of the fiber light cable must be the same.

Possible consequences when using a fiber light cable with

' excessive diameter:

excessive heating at the coupling point with the endoscope

' insufficient diameter:

reduced light output

The model / type no. of the fiber light cable is an indicator for the suitable

fiber bundle diameter (1.15).

' The code number on the cold light connector (1.5) must be the same as

the last 2 digits to the right of the decimal point of the product number

(type number).

Exception: Fiber light cable 8061.933 has a fiber bundlediameter

of 3.5 mm.

19

CAUTION!

Intense heat due to high light energy!

Under unfavourable conditions the use of the high temperature resistant

fiber light cable 8063.353 can cause a temperature increase at the coupling

point between the fiber light cable and the endoscope.

Danger of burns for the user and risk of damage to the endoscope.

Reduce the light output, or use fiber light cable product no. 8061.xxx /

8062.xxx if necessary.

Z Carry out a function check: section 7.2

GA-B 223

Page 25

6.1.2 Attaching access instruments

Inserting working sleeve (16) into irrigation adapter (9) or attachable

handle (17)

NOTE!

.

The working sleeves (16) can be inserted in 4 working positions, i.e. in every 90

position.

Z Install the sealing cap (3) [not with attachable handle (17)] (Fig. 28).

3

Fig. 28

Fig. 29

Z Retract the locking sleeve (9.2) and hold it in the retracted position.

Z Insert working sleeve (16) in irrigation adapter (9).

Z Let go of the clamping sleeve (9.2).

Z Pull slightly to check that the connection is securely locked.

Z Connect the irrigation tube (A) to the irrigation stopcock (9.1)

' The clamping sleeve (9.2) returns to its home position.

[not with attachable handle (17)].

10

16

9

9.1

9.2

Fig. 29

Z Releasing the connection:

Retract the locking sleeve (9.2) and while holding it in this position, remove the

working sleeve (16).

Connecting suction connector (11) to suction tube (10).

Fig. 30

Z Plug the suction connector (11) under slight rotation into suction tube (10).

Z Connect the suction tube to the suction connector (11).

A

Fig. 30

GA-B 223

11

NOTE!

.

If on a short--term basis increased aspiration is required, the suction connector (11) can also be be directly attached to the distal end of the endoscope.

20

Page 26

6.1.3 Motorized instruments

NOTE!

.

In intadiscal use with the nucleus resector we recommend additional irrigation via

the luer connector or working sleeve.

Advantages:

' It improves cutting performance

' It facilitates the removal of tissue fragments

' It minimizes the risk of a possible clogging of the nucleus resectors

37.1

A

Fig. 31a

Fig. 31b

9.1

37

Irrigation through luer connector

Fig. 31a

Z Remove luer lock cap (37.2).

Z Connect irrigation tube (A) to luer connector (37.1) of nucleus resector (37).

IMPORTANT!

.

If the luer connector (37.1) is not required, it should be closed with the luer

37.2

38

9

A

lock cap (37.2) to avoid reduced suction power.

Irrigation through working sleeve

Fig. 31b

Z Install the sealing cap (3) as shown in Fig. 28.

Z Insert working sleeve (16) into irrigation adapter (9) and connect the irrigation

supply tube (A) to the luer connector (9.1) as shown in Fig. 29.

Z With the resector blade (38) connected to the shaver handpiece, insert the

resector blade (38) into the working sleeve (Fig. 31b).

Z Operate the resector blade (38) with irrigation supplied through the working

sleeve and suction connected to the shaver handpiece.

6.2 Additional notes and instructions for use

6.2.1 Light

IMPORTANT!

.

Use only products with type BF or CF applied parts in conjunction with the endoscope.

WARNING!

Intense heat due to high light energy!

Danger of inadvertent tissue damage

' due to insufficient distance between the light exit area and the tissue

' due to soiling / contamination in the light exit area

' when using high performance light projectors.

Do not touch the light exit area and avoid direct contact with the tissue.

Remove any soiling / contamination.

WARNING!

Fire hazard!

When placing the endoscope onto heat -sensitive flammable surfaces (dark

drapes etc.) the high light energy at the light exit area of the endoscope can

cause high temperatures or even ignition.

Store the endoscope at a safe place.

Switch off the light source if you do not use the endoscope for a prolonged

period of time.

21

GA-B 223

Page 27

6.2.2 Current

6.2.3 Image quality

6.2.4 Irrigation fluid

CAUTION!

Danger of burns!

Due to the high energy of the light source the cold light connector will be

hot when disconnecting it from the light source.

Burns may result from unintentional contact with the connector.

Do not touch the light connector, allow it to cool down.

WARNING!

Danger from electric shock!

Patient leakage currents can add up if the endoscope is combined with

powered endoscopic accessories.

Make sure that the combinations do not exceed the permissible patient leak-

age currents.

CAUTION!

Increased risk potential if the image is blurred!

Danger of injuring the patient.

Stop the intervention for safety reasons if the image is blurred.

Check the image quality of the endoscope before use (section 7.2).

CAUTION!

Irrigation fluid can be electrically conductive!

Depending on the application, a suitable low - conductivity irrigation fluid

must be selected by the user.

Do not use saline (NaCl) solution for HF applications.

6.2.5 Irrigation and suction power

CAUTION!

Determine the irrigation and suction rates!

Due to the differing anatomical conditions the irrigation and suction rates

cannot be quantified. The user must adapt these rates to the patient and to

the situation.

CAUTION!

In the case of motor - driven instruments!

Do not apply any suction during extradiscal application of the instruments!

To prevent inadvertent aspiration of other types of tissue (e.g. nerves),

suction is not permissible when the instruments are applied extradiscally.

GA-B 223

22

Page 28

6.2.6 HF application

Fig. 32

Follow the ”Notes and instructions on HF applications”, order no.: GA--S 002

as well as the HF device manufacturer’s instructions.

WARNING!

Danger of injury if the HF instrument is not visible through the scope!

Inadvertent tissue damage as well as damage to the distal end of the endo-

scope and instrument parts are possible.

Use HF instruments only within the scope of their specifications (voltage

strength, duty factor).

Activate HF instruments only after the part conducting HF current has be-

come fully visible through the scope and contact is made with the desired

area of use.

WARNING!

HF arcing!

Danger of injury due to incorrect HF application and insufficient distance

between parts conducting live HF current and other conductive parts.

Parts of HF instruments that conduct live HF current must maintain a safety

distance of at least 10 mm from the distal end of the endoscope or working

sleeve during activation (Fig. 32)

CAUTION!

Danger of burns due to leackage currents when using high- frequency current.

Burns on the surgeon’s eye or face may occur.

Use the endoscope only with the eyepiece (2) attached (Fig. 33).

Fig. 33

2

CAUTION!

Careful if HF output power is incorrectly selected!

Injuries to the patient as well as damage to the product are possible.

The power should be set on the basis of the surgeon’s experience / training

regarding the corresponding indication.

NOTE!

.

For determining the optimal power setting we recommend starting with a low

power setting.

23

GA-B 223

Page 29

6.3 Laser application

C

When applying a laser make sure you follow the laser device manufacturer’s instructions as well as the general regulations on the use of lasers.

Wear the required personal protection equipment.

CAUTION!

Do not work outside the scope’s field of view!

Inadvertent tissue damage as well as damage to the distal end of the endo -

scope and to instrument parts are possible.

Activate the laser only after

' the tip of the laser fiber is fully visible through the endoscope and

' the pilot beam makes contact with the intended area to be treated.

CAUTION!

High temperatures due to highly coherent laser beam!

The heat generated by the laser beam reduces the strength of instrument

parts.

Do not direct the laser beam at instrument parts, in particular not at plastic

parts.

Keep a safe distance.

CAUTION!

Highly coherent light beams!

Danger of eye injuries!

When using the product in conjunction with laser devices make sure you wear

adequate personal safety gear.

When using an ND -YAG laser while working through the endoscope under

direct view, use the additional filter attachment (C) (Fig. 34).

Keep a safe distance.

Fig. 34

6.3.1 Forceps instruments, punches, scissors

The following is a description of the special intradiscal grasping forceps:

NOTE!

.

For information about further forceps, punches and scissors, see GA--S003 and

B B -- S 0 0 3 -- 1 .

CAUTION!

Danger of injury as well as possible damage to the endoscope when

introducing or withdrawing instruments in open condition!

Inadvertent tissue damage, damage to the distal end of the endoscope as

well as loss of particles from the jaws are possible.

Introduce and withdraw the instrument only in closed condition and under

visual control (Fig. 35).

Fig. 35

GA-B 223

24

Page 30

CAUTION!

Danger of injury if the intradiscal grasping forceps is not used under visual

control!

Inadvertent manipulations may result in injuries.

Limit the use to the intradiscal space and ensure this by image converter

control if necessary.

Z Angling the jaw section (Fig. 36):

actuate either deflection lever (30.4) or thrust plate (30.6).

' The jaw section is deflected in upward direction.

30.4

30.6

Fig. 36

NOTE!

.

The jaws (29.7) can be rotated through 360

Z Changing the position of the jaws (Fig. 37):

-- Loosen locking screw (30.5) by turning as indicated by the arrow ”open”.

-- Turn the jaws (33.7) to the required position.

-- Tighten locking screw (30.5) by turning as indicated by the arrow ”close”.

' The jaws are locked in this position.

33.7

Fig. 37

to any position which suits the surgeon.

open

close

30.5

25

GA-B 223

Page 31

Z Locking the forceps handle (Fig. 38):

Push the handle grips together and turn the locking mechanism (26.3) in the

direction indicated by the arrow.

' The jaws (33.7) are closed and locked.

33.7

Fig. 38

NOTE!

.

The deflection lever can be mounted on the left or right--hand side.

IMPORTANT!

.

Deflection lever (30.4) is only functional if mounted parallel to the sheath.

Z Assembling the deflection lever (Fig. 39):

-- Insert the square section of the deflection lever in the square bore.

-- Push the deflection lever in the square bore as far as it will go.

' The deflection lever (30.4) clicks into place.

30.3

Fig. 39

30.4

GA-B 223

26

Page 32

Z Disassembly of deflection lever (Fig. 40):

-- Push onto the square of the deflection lever (30.4) from the opposite side until it

disengages from the square bore (Fig. 40a).

-- Remove the deflection lever (30.4) (Fig. 40b).

7 Checks

7.1 Visual check

Fig. 40a

Fig. 40b

30.4

Fig. 40

CAUTION!

Be careful if products are damaged or incomplete!

Injuries of the patient, user or others are possible.

Run through the checks before and after each use.

Do not use the products if they are damaged, incomplete or have loose parts.

Return damaged products together with any loose parts for repair.

Do not attempt to do any repairs yourself.

Z Check the instruments, in particular their distal areas, and the accessories for

' damage

' sharp edges

' loose or missing parts

' possible surface changes (e.g. corrosion)

' rough surfaces

' hairline cracks.

Z Replace sealing membrane (1.7) and membrane valve (5.2) after each use.

Z Replace any torn or damaged rubber caps (1.8 / 47), sealing caps (3) and O--

rings.

Z Check the jaws for defective cutting edges and corroded parts. (Fig. 41)

30.4

Fig. 41

27

CAUTION!

Danger of injury!

Check for surface changes, such as hairline cracks, around the hinge pin

(Fig. 41).

Caution if surface in the hinge area of the forceps is damaged.

The hinge pin can loosen.

Z Any lettering, labeling or identification necessary for the safe intended use

must be legible.

' Missing or illegible lettering, labeling or identifications leading to incorrect

handling and reprocessing must be reinstated.

GA-B 223

Page 33

7.2 Functional check

7.2.1 Endoscopes

Z Check image quality and light output in conjunction with the system compo-

nents.

Z Check the glass surfaces for any deposits.

' Deposits on the glass surfaces can cause a spotted or blurred field of view

and thus impair light transmission considerably.

' Wipe the glass surfaces with a swab soaked with alcohol (wood swab car-

rier, not metal or plastic), remove hard--to--remove deposits with instrument

cleaner.

35

Fig. 42

Z Check the light output without the system components.

Z Hold the distal end of the endoscope towards a light source.

' Broken fibers appear as black dots at the cold light connector. If approx. 30%

of the fibers are broken the light output is no longer sufficient (Fig. 43).

Fig. 43

7.2.2 Suction-- and irrigation instruments

Z Before use, check for proper irrigation flow, leak tightness and patency (free

passage) of the entire system.

Z Check the suction power of the working sleeve (16) with the irrigation adapter (9)

attached as well as that of the suction connector (11) and suction tube (10).

7.2.3 Forceps instruments, punches, scissors

Z Check the ratchet unit and handle grip locking mechanism.

Z Check the hinges.

Z Check the jaws for easy operation while you open and close them.

35

GA-B 223

28

Page 34

8 Reprocessing and maintenance

WARNING!

Creutzfeldt Jakob Disease!

If the patient is suspected of having the Creutzfeldt Jakob Disease (CJD) or a

variant of the Creutzfeldt Jakob Disease (vCJD) or the latter have been diagnosed, adequate measures must be taken to prevent possible transmission

to other patients, users and third parties.

For this purpose apply the country- specific reprocessing guidelines and

regulations.

8.1 Disassembly before cleaning

8.1.1 Endoscopes

1.5

Fig. 44

Z Unscrew the cold--light connector (1.5) (Fig. 44).

Fig. 45

4

1.7 3

Sealing cap adapter (Fig. 45)

Z Removethesealingcap(3).

Z Unscrew the sealing cap adapter (4).

Z Remove the sealing membrane (1.7).

NOTES!

.

Remove and replace the sealing membrane (1.7) and membrane valve (5.2)

after each use.

Membrane adapter (Fig. 46)

Z Unscrew the sealing adapter (5.1).

Z Remove the membrane valve (5.2).

Z Push the tab (6.1) and remove the membrane adapter (5.3).

Z Unscrew the cone adapter (6).

Z Remove the sealing membrane (1.7).

6.1

5.1

29

Fig. 46

1.7

6

5.3 5.2

GA-B 223

Page 35

Stopcock adapter (Fig. 47)

Z Removethesealingcap(3).

Z Push the tab (6.1) and remove the stopcock adapter (7).

Z Unscrew the cone adapter (6).

Z Remove the sealing membrane (1.7).

6.1 7

1.7

Fig. 47

Endoscope A

Z Remove the plug--on eyepiece (2) (Fig. 24, page 18).

Endoscope B

Z Push the locking tab (1.14) and remove the irrigation adapter (8) in direction of

arrow (Fig. 48).

6 3

8.1.2 Access instruments

35

1.14

8

Fig. 48

Working sleeve and irrigation adapter or attachable handle (17) (Fig. 49)

Z Separate the working sleeve (16) from the irrigation adapter (9) .

Z Remove the sealing cap [not with attachable handle (17)] (3).

16 9

9.2

3

Fig. 49

GA-B 223

30

Page 36

8.1.3 Forceps instruments, punches, scissors

ZUnscrew the luer--lock s

30.1

ZRemoving the deflection lever: see Fig. 40

Fig. 50

8.1.4 Motorized instruments

Z Remove the internal blade of the abraders (34) (35) and nucleus resectors (36)

(37) from the external blades.

8.2 Manual reprocessing

8.2.1 Endoscopes

Z Wet preparation at the point of use

Z Disassembly before cleaning: see section 8.1

Z Manual cleaning with an approved enzymatic cleaner.

8.2.2 Forceps instruments, punches, scissors

Z Wet preparation at the point of use

Z Disassembly before cleaning: see section 8.1

Z Manual cleaning with an approved enzymatic cleaner.

' Rinse out the intradiscal grasping forceps from the luer connector (30.2) us-

ing a cleaning gun (Fig. 51).

ealing cap (30.1) (Fig. 50).

8.2.3 Motorized instruments

37.2

37

Fig. 52

30.2

Fig. 51

Z Wet preparation at the point of use.

Z Disassembly before cleaning: Section 8.1

Z Manual cleaning with an approved enzymatic cleaner.

' Rinse out the nucleus resector with luer connector (37) from luer connector

port (37.2) with a cleaning gun (fig. 52)

31

GA-B 223

Page 37

8.3 Machine reprocessing

8.3.1 Endoscopes

.

.

Z Dry preparation at the point of use

Z Disassembly before cleaning: see section 8.1

Z Machine cleaning with an approved enzymatic cleaner.

Loading of reprocessing basket

Endoscope B

IMPORTANT!

Before machine reprocessing, preclean the rotatable irrigation adapter (8) manually.

IMPORTANT!

Before you place endoscope B into the reprocessing basket, install the rotatable

irrigation adapter (8) (section 6.1.1).

Endoscopes A and B (Fig. 53 / Fig. 54)

Z Screw on the supplied irrigation adapter (C).

' Before, clean the endoscope’s contact surfaces manually.

Z Place the parts used into the small items basket:

-- Rubber caps (1.8)

-- Sealing cap (3)

-- Sealing cap adapter (4)

-- Membrane adapter (5)

-- Cone adapter (6) and

-- New sealing membrane (1.7)

-- Snap--on eyepiece (2), only in the case of endoscope A

Z Place the cold--light connector (1.5) onto the corresponding holder.

Z Pass the irrigation tubes through the meshes, connect all connectors and open

the stopcocks (8.1) / (1.9) / (1.10).

IMPORTANT!

.

For machine cleaning do not place the stopcock adapter (7) into the reprocessing

basket but store it securely in the corresponding holders in the rinsing basket.

Endoscope B (Fig. 53)

4

1.7

= rinsing tube

1.5

8

B

C

Fig. 53

38044.411

GA-B 223

32

Page 38

Endoscope A (Fig. 54)

1.5

2

4

6

38044.111

= rinsing tube

B

Fig. 54

8.3.2 Forceps instruments, punches, scissors, nucleus resector with luer connector

Z Dry preparation at the point of use

Z Disassembly before cleaning: see section 8.1

Z Machine cleaning with an approved enzymatic cleaner.

' To prevent damage in the washer/disinfector, place the products in special

holders or in a reprocessing basket.

' Connect forceps / nucleus resector with luer connector (37) via luer connec-

tors (30.2 / 32.2), (37.1) to the washer/disinfector.

Z Oil all movable parts sparingly with instrument oil.

Wipe off/remove any excess oil.

8.4 Checks

Z Perform a visual check: see section 7.1

C

33

GA-B 223

Page 39

8.5 Assembly before sterilization

NOTE!

.

Before sterilization screw on the threaded connections only loosely:

' to allow a sufficient flow of sterilization medium.

' to prevent stress cracks.

Tighten all threaded connections before use.

IMPORTANT!

.

Do not screw on the luer lock caps (30.1 / 32.3), (37.2) to allow a sufficient flow

of sterilization medium.

Screw on the luer lock caps after sterilization and before use.

8.5.1 Endoscopes

Z Attach the cold--light connector (1.5) and screw it home (Fig. 1, page 3).

Z Oil all movable parts sparingly with endoscope oil.

Wipe off/remove any excess oil.

Endoscope B

Z Disassemble the rotatable irrigation adapter (8) (section 8.1.1) and oil the slid-

ing surfaces on the endoscope sparingly with instrument oil. Remove any excess oil.

Z Attach the rotatable irrigation adapter (8) see section 6.1.1.

Cone adapter (Fig. 55)

Z Place a new sealing membrane (1.7) into the locking collar.

Z Fasten the cone adapter (6) by means of the locking collar and tighten.

For better handling hold the locking collar with your thumb.

Fig. 55

5.3 5.2 5.1

1.7 6

Fig. 56

Sealing cap adapter (Fig. 21, page 17)

Z Place a new sealing membrane (1.7) into the locking collar.

Z Firmly tighten the sealing cap adapter (4).

Membrane adapter (Fig. 56)

Z Place a new membrane valve (5.2) into the sealing insert (5.1).

Z Screw the sealing insert (5.1) into the adapter (5.3)

GA-B 223

34

Page 40

8.6 Sterilization

Loading of reprocessing basket

Endoscopes A and B

Z Before sterilization, assemble endoscope B or A, as described under section

8.5.1.

Z Screw on the sealing cap attachment (4) only loosely.

Endoscope B (Fig. 57)

C

Fig. 57

Endoscope A (Fig. 58)

7

C

8

1.5

B

1.5

38044.411

4

38044.111

35

4

Fig. 58

Z For sterilization wrap the reprocessing basket/tray in compliance with the stan-

dards in your country or use a suitable sterilization container.

A

GA-B 223

Page 41

8.6.1 Steam sterilization

Z Steam sterilization at 132 C(270 F) using a Pre--Vac cycle at an exposure

time of 4 minutes with a 20 -- 30 minute dry time.

8.6.2 Gas sterilization

Z Gas sterilization using ethylene oxide (EtO).

8.6.3 Alternate sterilization methods

For possible alternate sterilization methods, refer to the Sterilization Guides posted

on our website, www.richardwolfusa.com.

8.6.4 Short Endoscope Tray, Item # 88090.0007

Loading the Tray

Z Assemble the short endoscope (B) and adapters as described under section 8.5.1.

Z Place the components into the reprocessing tray as shown in Fig. 59. Place loose

parts in the container at the center of the tray.

Z For sterilization, wrap the reprocessing tray in compliance with the standards in

your country, e.g., ISO 11607.

GA-B 223

Fig. 59

Steam Sterilization

Z Steam sterilization at 132 C(270 F) using a Pre-Vac cycle at an exposure

time of 4 minutes with a 20 -- 30 minute dry time.

36

Page 42

9 Technical data and order data

For additional information on the reprocessing, see Manual GA--J020 “Reprocessing of RICHARD WOLF Heat Stable Instruments”.

For technical data, order data and combinations of the following instruments see

”System overview VERTEBRIS lumbar--thoracic”, order no. BB--B 223.

Z Endoscopes, endoscopic accessories

Z Suction and irrigation instruments

Z Access instruments

Z Manual and auxiliary instruments

Z Motorized instruments

' see “Overview of motorized instruments” order no. BB--B 223--1.

For further information see the respective manuals.

9.1 Spare parts and accessories

Item Illustration Product no. Designation

2 8885.901 Snap--on eyepiece with eyecup

4 8792.452 Sealing cap adapter

5 8792.451 Membrane adapter

6 8791.751 Cone adapter

7 8791.951 Stopcock adapter

8 15461.034 Irrigation adapter, rotatable

-- 9500.113

5.2 89.103 Membrane valve

1.7 15 479.006 Sealing membrane

3 89.00 Sealing cap, black (10/pkg)

1.8 88.01 Rubber cap, red (10/pkg)

-- 887.00 Luer--Lock sealing cap

1.5 8095.00 Cold--light connector

O--rings serving as a seal between irrigation adapter

15461.034 and endoscope , 10/pkg

37

GA-B 223

Page 43

Item Illustration Product no. Designation

-- 200.532 Instrument oil

--

--

-- 64164.039

The products can be combined as required provided their relevant technical data and intended uses are observed. For the general overview please refer to the latest catalog sheets and brochures, or contact Richard

Wolf or your Richard Wolf representative.

--

--

38044.411 Reprocessing basket for endoscope B

38044.111 Reprocessing basket for endoscope A

Rinsing adaper for machine reprocessing in reprocessing

basket

10 Operating, storage, transport and shipping conditions.

Operating conditions

Storage, transport and shipping conditions

IMPORTANT!

.

Store sterile products in their original packaging until use.

Incorrect storage may lead to loss of sterility.

NOTE!

.

To prevent damage during transport or shipment of the products we recommend

using the original packaging material.

+10Cto+40C , 30% to 75% rel. humidity,

atmospheric pressure 700 hPa to 1060 hPa

-- 2 0 Cto+60C , 10% to 90% rel. humidity,

atmospheric pressure 700 hPa to 1060 hPa

11 Disposal of product, packaging material and accessories.

For the disposal observe the regulations and laws valid in your country.

' For further information please contact the manufacturer.

GA-B 223

38

Page 44

12 Warranty and Custome r Service

Richard Wolf guarantees ourinstrumentsto be free from any defectsin materialsand workmanshipunder

normal use and service for one year. Richard Wolf general terms and conditions may be found on the

back of our invoice.

Parts delivered separately by Richard Wolf are subject to all of the same general terms and conditions for

our products, including the limitations of warranty and liability.

All products should be returned to Richard Wolf for any necessary or desired repair or partreplacement.

No product repair or part replacement should be done other than by Richard Wolf unless the care and

instruction manual or other written information indicates that repair or part replacement is authorized. If

authorized,parts must be replaced onlyby partssupplied or specified by Richard Wolf, and productrepair

and part replacement must be done in strict conformance with Richard Wolf specifications and

instructions forrepair and part replacement, including post replacement testing and recalibration. Failure

to follow this requirement in any way can be dangerous to you, your personnel and your patients and

voids the warranty for the product repaired or the product in which the part was replaced and if the part

was supplied by Richard Wolf, for that part.

Delivery by Richard Wolf of technical documents such as circuit or other design diagrams does not

constitute authorization for product repair or part replacement. Richard Wolf instruments and other

products should never be modified or altered under any circumstances.

Contact Richard Wolf if you have any question (1) whether replacement of a part or a repair is authorized

by Richard Wolf, or (2) whether you have complete instructions and specifications forpart replacement or

repair.

These instructions do not attempt to cover all details or variations in equipment, nor to provide for every

possible contingency to be met in connection with installation, operation, or maintenance. Shouldfurther

information be required or should problems arise which are not covered sufficiently for the purchaser’s

purpose, the matter should be referred to Richard Wolf Medical Instruments Corporation.

Our national salesand service offices, as wellas our manufacturing facility, are located in Illinois. Trained

manufacturer’s representatives are located throughout the U.S. to serve you. For any questions

regarding these instruments, or to place an order, contact Richard Wolf c ustomer service department at

847-- 913--1113 or 800--323--WOLF (9653).

INSTRUMENT ORDERING POLICY

Richard Wolf reserves the right to make substitutions, if necessary, without prior notice.

REPAIR POLICY

Defective merchandise will be repaired or replaced at no charge to the customer, provided thecustomer

delivers such defective merchandise prepaid. Any repairs, maintenance or servicing of Richard Wolf

merchandise by anyone other than a factory authorized representative will render our warranty null and

void.

REPAIR SHIPMENTS

When returning your instrument for repair, we suggest that you prevent shipping damage to the

instrument by reusing the box that it was originally shipped in. Richard Wolf also recommends that the

instrument be insured for an amount to cover the cost of replacement.

IMPORTANT

For general safety and health reasons, Richard Wolf requires that you clean and sterilize all instruments

before returning them for repair. If instruments are received in an unsanitary condition, Richard Wolf will

clean and sterilize each instrument and add a $ 100.00 cleaning charge for each instrument requiring

cleaning.

39

GA-B 223

Loading...

Loading...