Wolf DF484FLP, DF606CGLP, DF486CLP, DF364G, DF364CLP Installation manual

...

Dual Fuel Ranges Installation Guide

DUAL FUEL RANGES

Contents

3 Safety Precautions

4 Specications

7 Installation

11 Troubleshooting

Features and specications are subject to change at any

time without notice. Visit wolfappliance.com/specs for the

most up-to-date information.

Important Note

To ensure this product is installed and operated as safely

and efciently as possible, take note of the following types

of highlighted information throughout this guide:

IMPORTANT NOTE highlights information that is especially

important.

CAUTION indicates a situation where minor injury or product

damage may occur if instructions are not followed.

WARNING states a hazard that may cause serious injury or

death if precautions are not followed.

IMPORTANT NOTE: Throughout this guide, dimensions in

parentheses are millimeters unless otherwise specied.

IMPORTANT NOTE: Save these instructions for the local

electrical inspector.

2 | Wolf Customer Care 800.222.7820

SAFETY PRECAUTIONS

Product Information

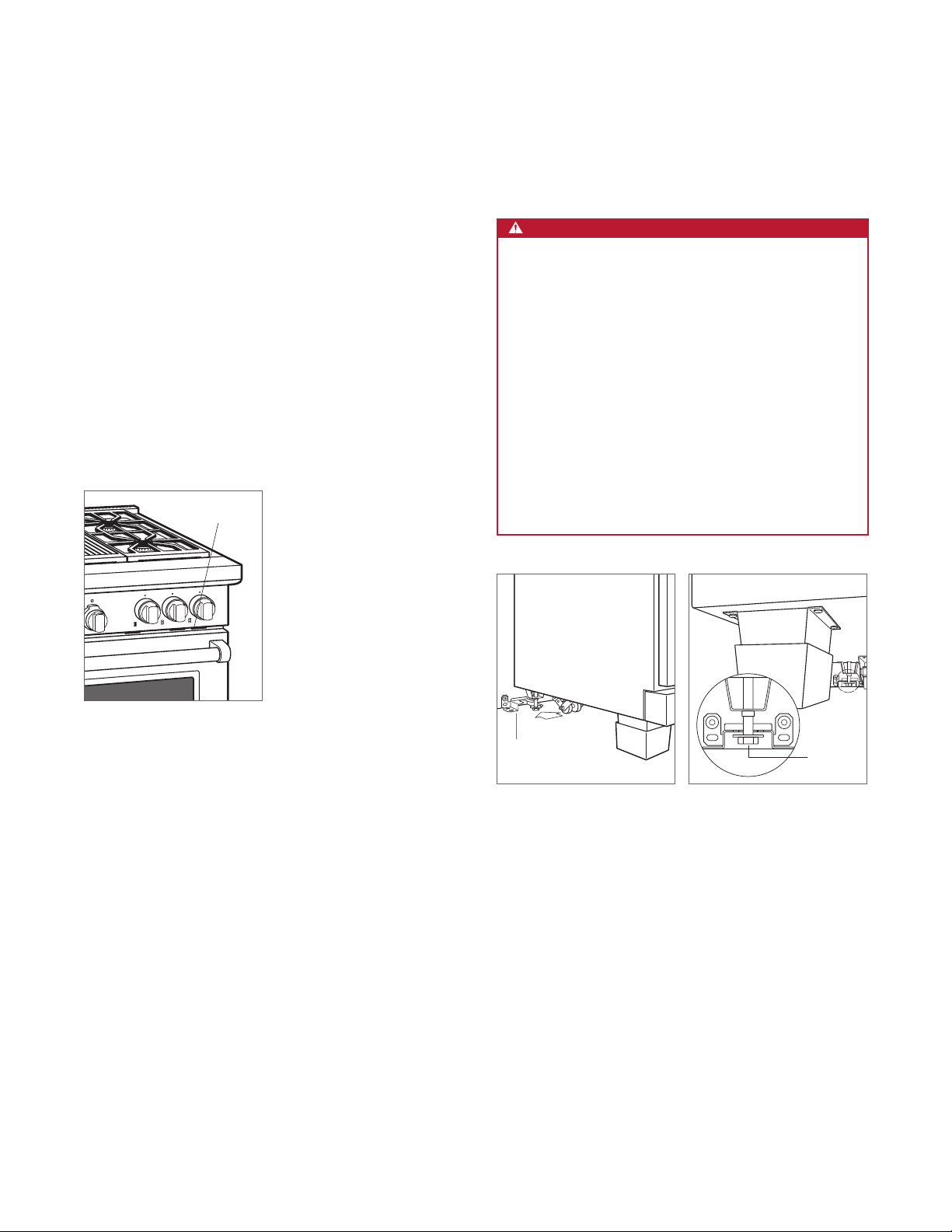

Important product information including the model and

serial number are listed on the product rating plate. The

rating plate is located on the bottom of the control panel

assembly, at the far right, just above the oven door. Refer

to the illustration below.

If service is necessary, contact Wolf factory certied service

with the model and serial number. For the name of the

nearest Wolf factory certied service or for questions

regarding the installation, visit the contact & support section

of our website, wolfappliance.com or call Wolf customer

care at 800-222-7820.

RATING PLATE

IMPORTANT INSTRUCTIONS

WARNING

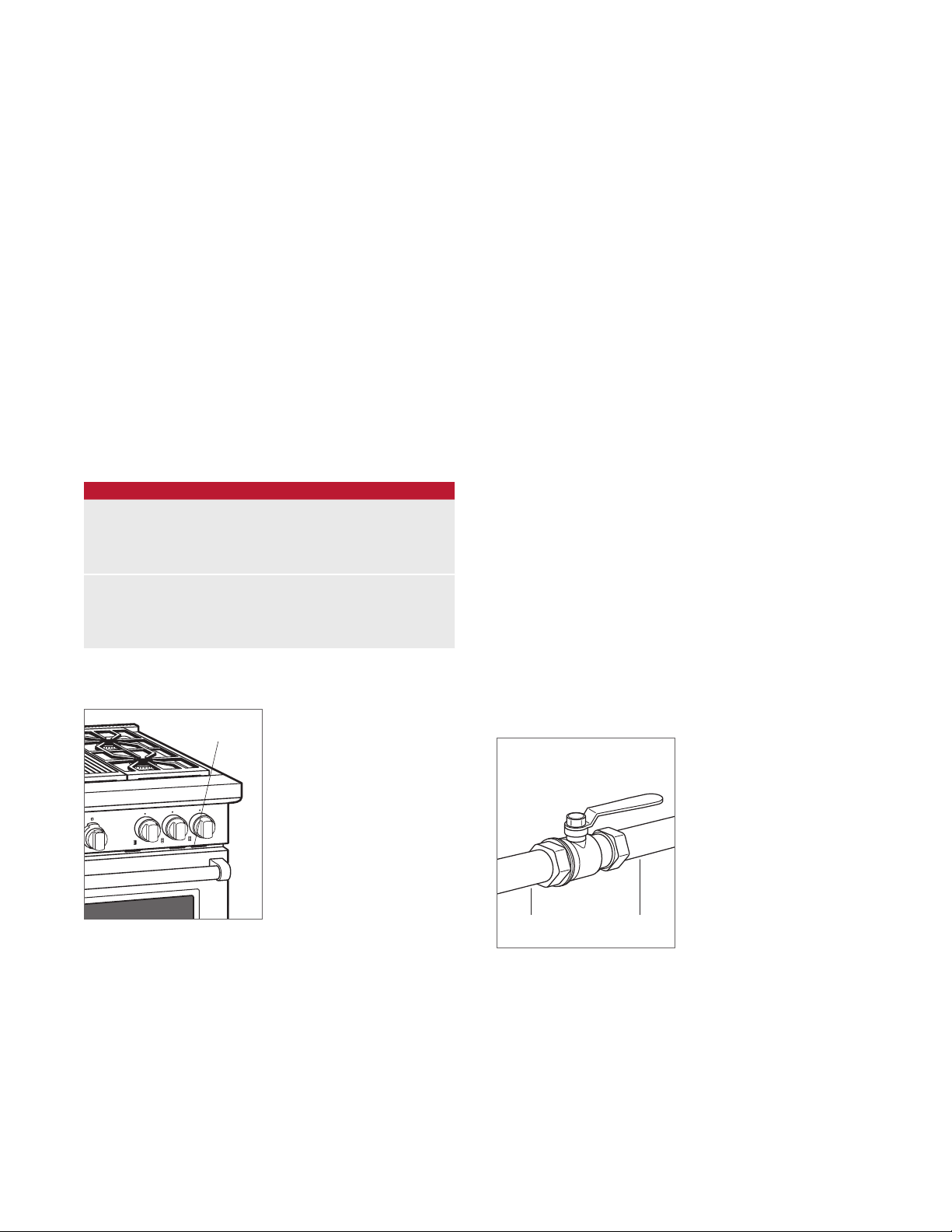

A child or adult can tip this appliance and be

killed.

Verify the anti-tip device has been properly

installed and engaged. Ensure the anti-tip device

is re-engaged when this appliance is moved. Refer

to the illustrations below for how to verify correct

installation.

Do not operate this appliance without the anti-tip

device in place and engaged. Failure to do so

can result in death or serious burns to children or

adults.

To reduce the risk of burns, do not move this

appliance while hot.

Rating plate location.

ANTI-TIP

DEVICE

Anti-tip device location.

Anti-tip device engaged.

ANTI-TIP

DEVICE

ENGAGED

• This appliance is equipped with casters on two

or more legs and must be installed on 1/8" (3) thick

commercial grade vinyl composition oor nishing

materials or equivalent.

• This appliance is not approved for downward air-

ow ventilation or air curtain equivalent.

wolfappliance.com | 3

SPECIFICATIONS

Installation Requirements

IMPORTANT NOTE: When installing against a combustible

surface, a minimum 10"

fuel range with charbroiler or griddle and all 48" and 60"

models. Follow all minimum clearances to combustible surfaces shown in the illustration on the following pages.

(254) riser is required for a 36" dual

Electrical

Installation must comply with all applicable electrical codes.

Locate the electrical supply ush with the wall or oor

and within the shaded area shown in the illustration on the

following pages. A separate circuit, servicing only this appliance is required.

If a power supply cord is being used, the cord must be

designated for use with ranges and rated for 240 V, 30 or

50 amps (refer to the chart below), and must include 3 or 4

conductors. A 4-conductor cord is required for installations

where grounding through the neutral is prohibited.

Performance may be compromised if the electrical supply is

less than 240 volts.

ELECTRICAL REQUIREMENTS

SINGLE OVEN RANGE

Electrical Supply grounded, 240/208 VAC, 60 Hz

Service 30 amp dedicated circuit

Total Amps 21

Max Connected Load 5.2 kW

Min Supply Wire L1, L2, ground—12 AWG

neutral—16 AWG

DOUBLE OVEN RANGE

Electrical Supply grounded, 240/208 VAC, 60 Hz

Service 50 amp dedicated circuit

Total Amps 42.5

Max Connected Load 10.2 kW

Min Supply Wire L1, L2—8 AWG, ground—10 AWG

neutral—12 AWG

4 | Wolf Customer Care 800.222.7820

SPECIFICATIONS

Gas Supply

Installation must conform with local codes or, in the absence

of local codes, with the National Fuel Gas Code.

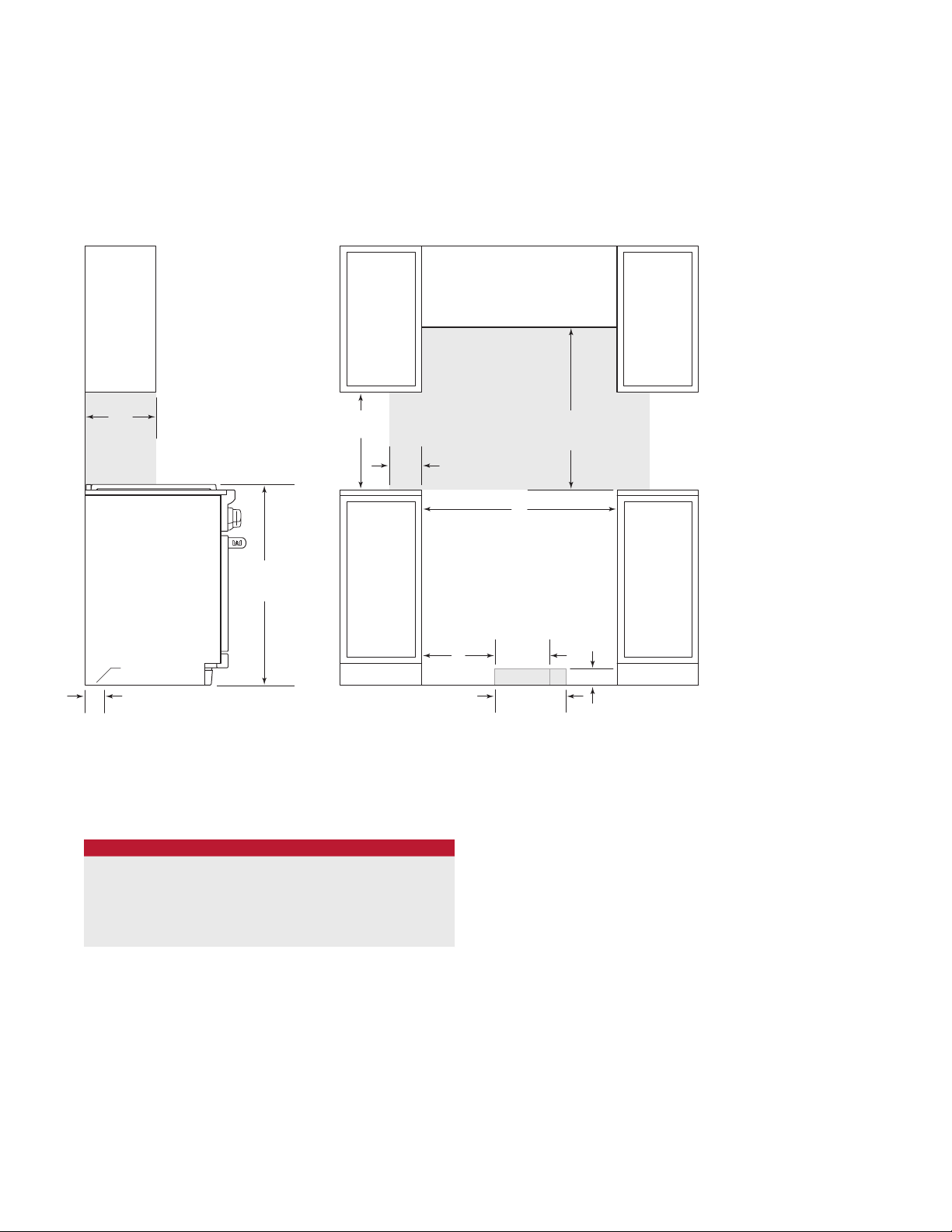

Locate the gas supply within the shaded area shown in the

illustration on the following page.

The range is equipped for use with natural or liquid propane

(LP) gas. It is design certied by the Canadian Standards

Association (CSA) for natural or LP gases. The product

rating plate has information on the type of gas that should

be used. For rating plate location, refer to the illustration

below. If this information does not agree with the type of gas

available, check with the local gas supplier The gas pressure regulator is built into the unit.

GAS REQUIREMENTS

NATURAL GAS WC

Supply Pressure 5" (12.5 mb)

Min Line Pressure 7" (17.5 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

LP GAS WC

Supply Pressure 10" (25 mb)

Min Line Pressure 11" (27.4 mb)

Max Regulator Pressure 14" (34.9 mb), .5 psi (3.5 kPa)

The range must be connected to a regulated gas supply.

The supply line must be equipped with an approved external

gas shut-off valve located near the range in an accessible

location. Do not block access to the shut-off valve. Refer to

the illustration below.

3

A gas supply line of

the range. If local codes permit, a certied, 3'

1

/2" (13) or 3/4" (19) ID exible metal appliance connector is

recommended to connect the units

/4" (19) rigid pipe must be provided to

(.9 m) long,

1

/2" NPT female inlet to

the gas supply line. Pipe joint compounds, suitable for use

with natural or LP gas should be used.

The appliance and its shut-off valve must be disconnected

from the gas supply piping system during any pressure

testing of the system at test pressures in excess of .5 psi

(3.5 kPa)

. The appliance must be isolated from the gas

supply piping system by closing its individual manual shutoff valve during any pressure testing of the system at test

pressures equal to or less than .5 psi

Wolf natural gas ranges will function up to 10,250'

(3.5 kPa).

(3124 m)

in altitude without adjustment and LP gas ranges will function up to 8,600'

(2621 m). If the installation exceeds these

elevations, contact an authorized Wolf dealer for a high

altitude conversion kit.

RATING PLATE

Rating plate location.

SHUT-OFF VALVE

OPEN POSITION

Gas shut-off valve.

GAS SUPPLYTO APPLIANCE

wolfappliance.com | 5

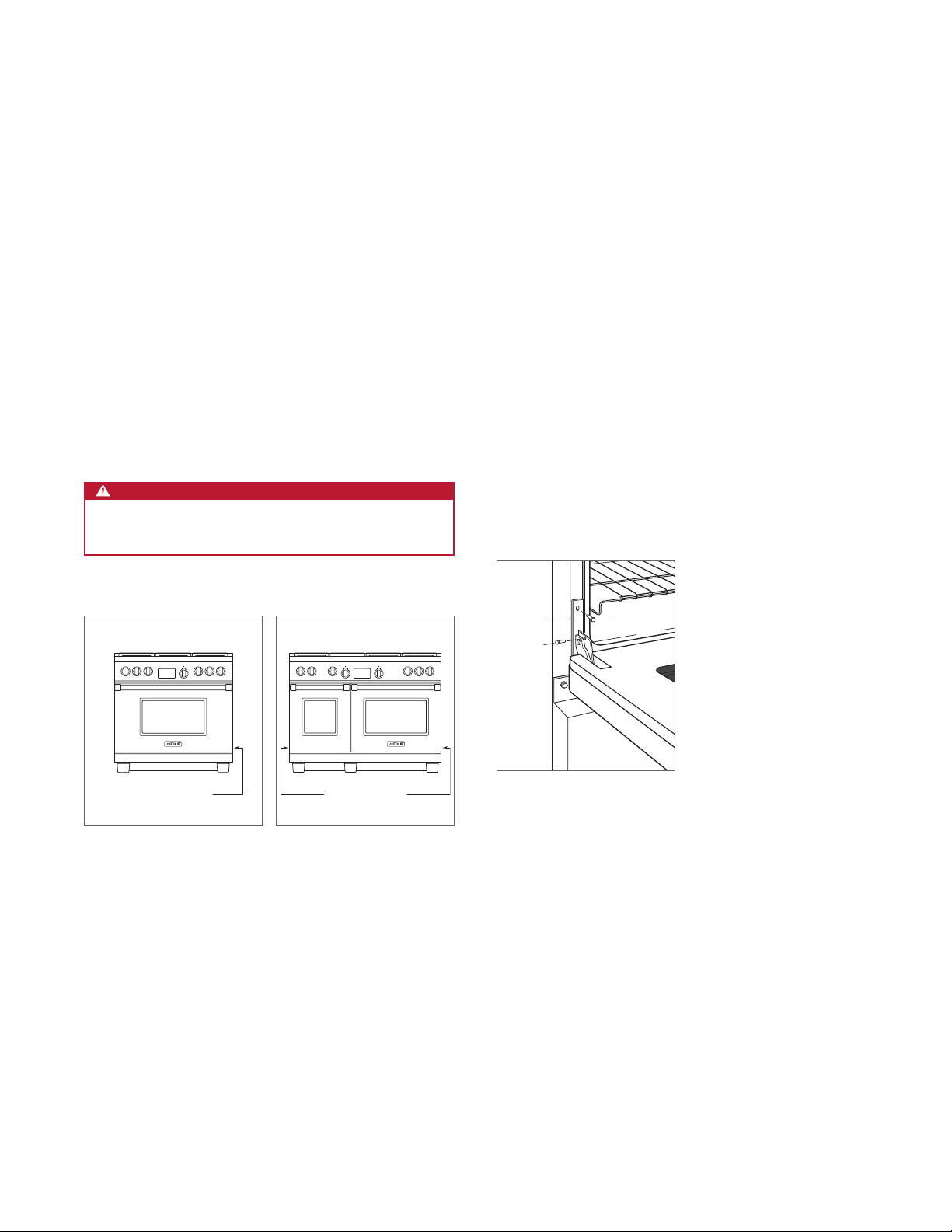

SPECIFICATIONS

Dual Fuel Range

INSTALLATION

13"

(330)

367/8" (937)

TO COOKING

SURFACE

LOCATION OF GAS AND

ELECTRICAL EXTENDS

ON FLOOR

21/4"

(57)

*Without ventilation hood, 36" (914) minimum clearance countertop to combustible materials, 44" (118) for charbroiler.

NOTE: Shaded area above countertop indicates minimum clearance to combustible surfaces,

combustible materials cannot be located within this area.

For island installation, 12"

(305) minimum clearance back of range to combustible rear wall above countertop.

FRONT VIEWSIDE VIEW

18"

(457)

6"

(152)

OPENING WIDTH

A

30" (762) TO 36" (914)

TO BOTTOM OF

VENTILATION HOOD

W

10" (254)

GAS

G E

13" (330)

ELECTRICAL

31/4" (83)

OPENING WIDTH

DUAL FUEL RANGE W A

30" Model 30" (762) 81/2" (216)

36" Model 36" (914) 131/2" (343)

48" Model 48" (1219) 24" (610)

60" Model 601/4" (1530) 31" (787)

*

6 | Wolf Customer Care 800.222.7820

INSTALLATION

SPRING HINGES

SPRING HINGES

Preparation

Before moving the range, protect any nished ooring and

secure oven door(s) closed to prevent damage.

To lighten the load or to t through a door way, the oven

door(s) can be removed. Only remove if necessary. Do not

remove griddle or any other component. Door removal

should only be done by a certied installer or service

technician.

For removal, a hinge pin will be inserted into the appropriate

hinge shown in the illustrations below. The pin(s) are located

inside the oven door. For single oven ranges, the hinge pin

must be inserted in the right hinge. For double oven ranges,

the pins must be placed in the outer two hinges.

CAUTION

Failure to insert the hinge pin in the appropriate hinge

arm will cause damage to the range.

OVEN DOOR REMOVAL

1 Insert the hinge pin into the appropriate hinge.

2 Remove the lower kickplate assembly to access the

lower hinge retainer mounting screws.

3 Open the oven door and remove both upper and lower

hinge retainer mounting screws. The oven gasket may

have to be moved slightly to access the bottom screws.

4 Move the hinge retainer plate forward slightly. The hinge

retainer plate will remain on the door hinge after the

mounting screws have been removed.

5 Carefully close the oven door to approximately 60°, then

lift the door up and out. A slight rocking motion may be

required for removal.

HINGE

RETAINER

PLATE

HINGE

PIN

UPPER

MOUNTING

SCREW

Single oven ranges.

SPRING HINGE

Double oven ranges.

KICKPLATE

Oven door removal.

wolfappliance.com | 7

INSTALLATION

Placement

Do not lift or carry the oven door by the door handle. The

range has rear casters which allow for easy movement by

lifting the front of the unit.

Use an appliance dolly to move the unit near the opening.

Remove and recycle packing materials. Do not discard the

anti-tip bracket supplied with the range.

If a riser has been specied, refer to the installation instructions packaged with the riser. The riser must be installed

before the range is installed.

Leveling

Raise the unit to its desired height by adjusting the front

legs and rear casters. Use a

casters. The front legs can be adjusted by rotating the

hexagonal leg clockwise to raise and counterclockwise to

lower.

3

/4" socket to adjust the rear

8 | Wolf Customer Care 800.222.7820

INSTALLATION

7/8" (22) MAX

ANTI-TIP

BOLT

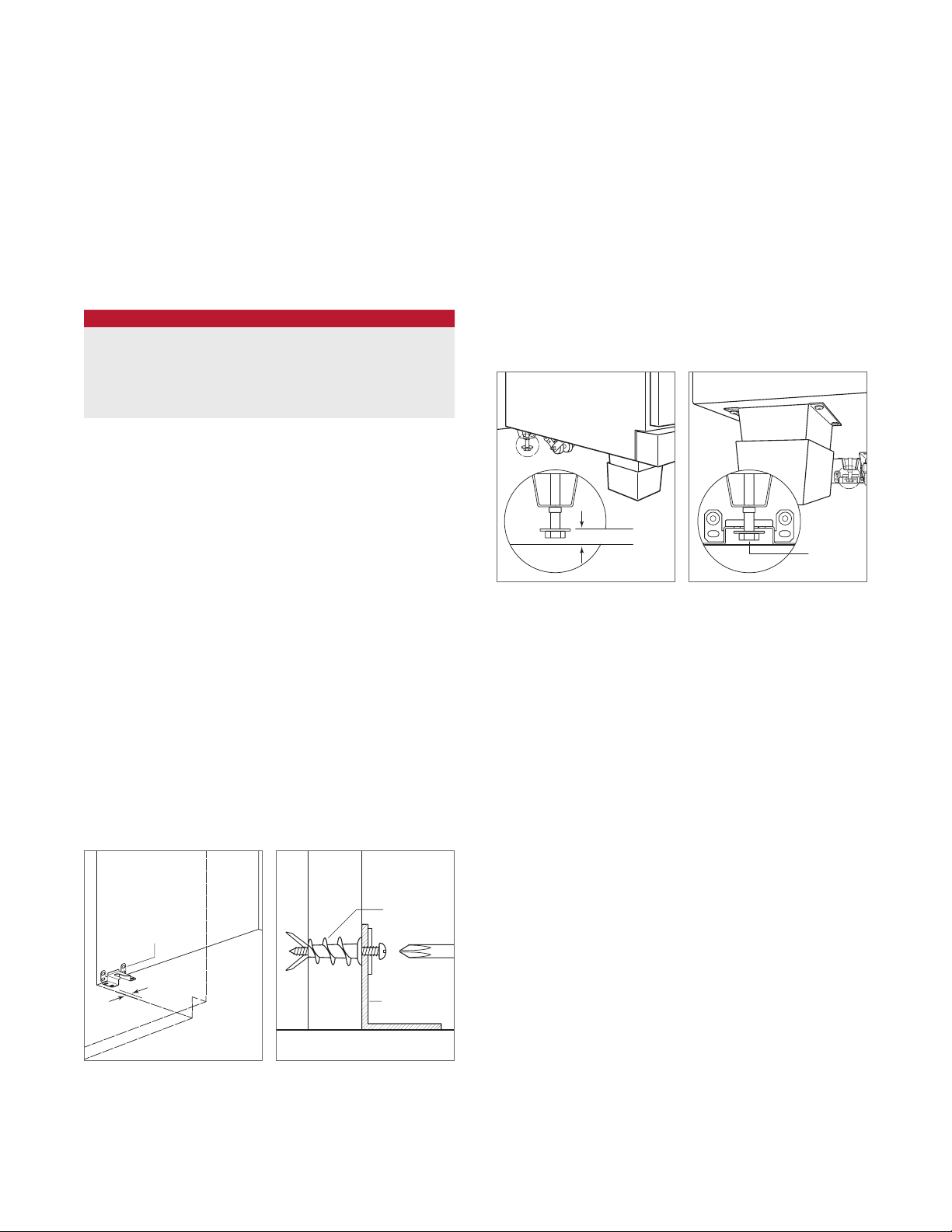

Anti-Tip Bracket

To prevent the unit from tipping forward, the anti-tip bracket

must be installed. To ensure the anti-tip bolt engages the

bracket, refer to the chart and illustration below to determine proper placement.

ANTI-TIP BRACKET

WIDTH A

30" Range

36" Range

48" Range

60" Range

3

/16" (5)

9

/16" (14)

3

/16" (5)

5

/16" (8)

INSTALL BRACKET

Drywall application | After properly positioning the anti-tip

bracket, mark holes, then use a Phillips screwdriver or a low

rpm power drill to drive the wall anchor into the surface of

the wallboard until ush. Pre-drill holes if needed. For hard

1

wallboard or double-board construction, use a

7

For solid plaster, use a

/16" drill bit. Refer to the illustration

/4" drill bit.

below. Use #8 screws and at washers to fasten the bracket

to the wall.

Wood oor application | After properly positioning the

3

anti-tip bracket, drill

/16" (5) pilot holes through the oor.

Use #12 screws and at washers to secure the bracket to

the oor.

ANTI-TIP BOLT ADJUSTMENT

Once the bracket is secure, adjust the anti-tip bolt so the

7

top of the washer is

/8" (22) maximum from the oor. Slide

the range into the opening and verify the anti-tip bolt is

engaged. Refer to the illustrations below.

ANTI-TIP

DEVICE

ENGAGED

Anti-tip bolt adjustment.

Anti-tip bolt engaged.

Concrete oor application | After properly positioning

3

the anti-tip bracket drill

1

minimum of 1

/2" (38) deep. Use 3/8" wedge anchors to

/8" (10) holes into the concrete a

secure the bracket to the oor.

WALL

ANTI-TIP

BRACKET

A

Anti-tip bracket location.

Wall anchor installation.

ANCHOR

ANTI-TIP

BRACKET

wolfappliance.com | 9

INSTALLATION

Electrical Connection

The terminal block on the back of the range allows for a

3-wire or 4-wire installation. For a 4-wire installation, the

ground strap from the unit to the terminal block must be cut.

Two concentric knockouts are provided to allow for permanent or cordset wiring of the unit.

THREE-WIRE ELECTRICAL SYSTEM

1 Where local codes permit, connect the ground appliance

wire to the neutral (white) supply wire.

2 Connect the ground and white appliance wires to the

neutral (white) supply wire in the electrical box.

3 Connect the black appliance wire to the black (L1) power

supply wire in the electrical box.

4 Connect the red appliance wire to the red (L2) power

supply wire in the electrical box.

FOUR-WIRE ELECTRICAL SYSTEM

1 Separate the ground and white appliance wires.

2 Connect the white appliance wire to the neutral (white)

supply wire in the electrical box.

Gas Supply Connection

All connections to the gas piping must be wrench-tightened.

Do not overtighten or allow pipes to turn when tightening.

If a exible metal connector is being used, verify it is not

kinked, then attach the gas supply line to the regulator on

the range. Open the valve and check for leaks by placing a

liquid detergent solution onto all gas connections. Bubbles

around connections indicate a gas leak. If a leak appears,

close the shut-off valve and adjust connections.

3 Connect the black appliance wire to the black (L1) power

supply wire in the electrical box.

4 Connect the red appliance wire to the red (L2) power

supply wire in the electrical box.

5 Connect the ground appliance wire to the green/ground

house grounding wire in the electrical box.

10 | Wolf Customer Care 800.222.7820

Loading...

Loading...