Page 1

815897

Wolf Gas Cooktop-3 LP High Altitude Conversion Kit

818164 / Rev A / December, 2010Page 1 of 2

CONTAINS: QTY DESCRIPTION

1 Orifice, 15K Burner

2 6-Lobe Screws

QTY

DESCRIPTION

1 High Altitude Conversion Label

1 High Altitude Conversion Instructions

INST

ALLATION PROCEDURE:

15,000 Btu/hr Orifice Replacement

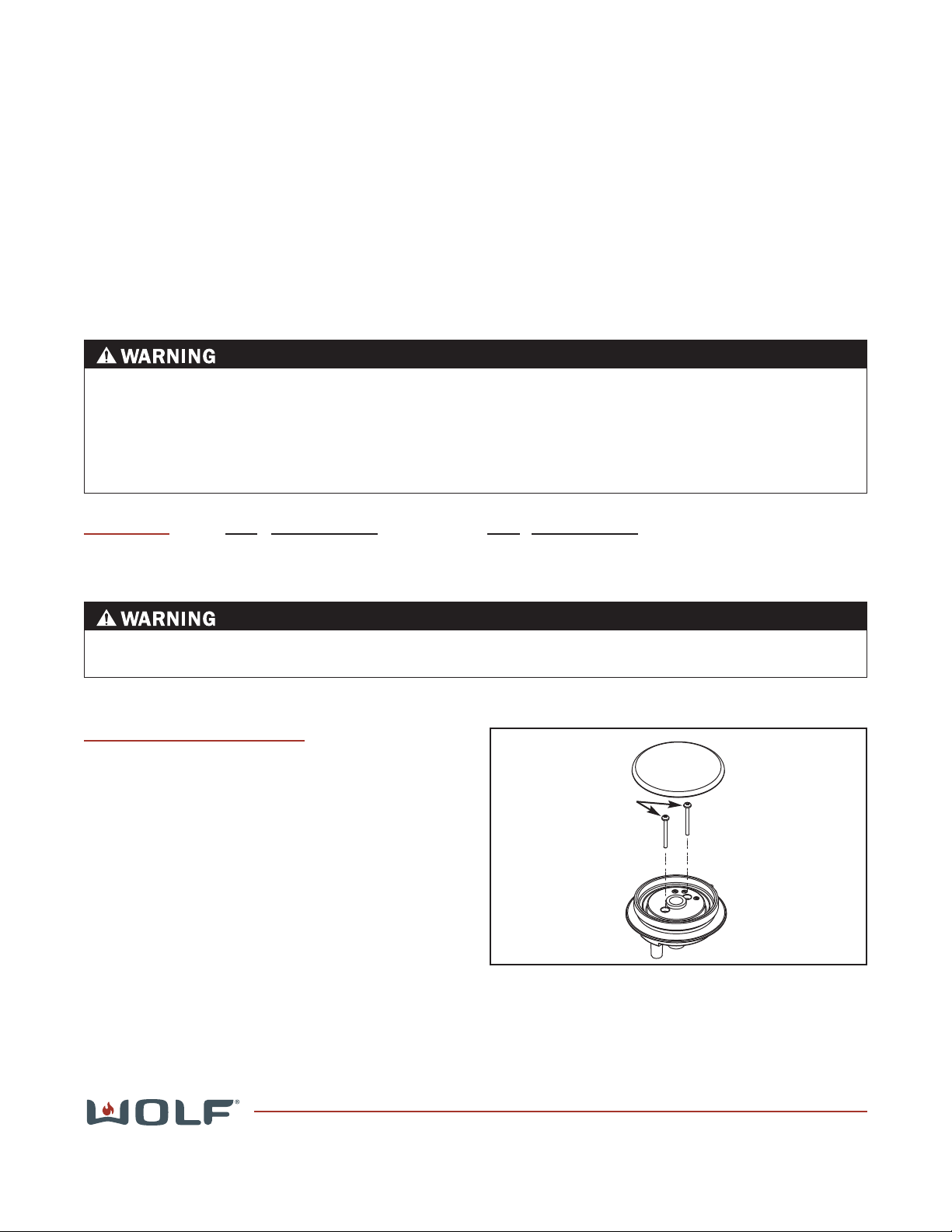

1. Remove the two T-15, 6-Lobe screws from the

15,000 Btu/hr burner. (See Figure 1)

2. Once screws are removed, gently lift up on burner

head. Using a needle nose pliers unplug

Electrode and set this aside (placing inside orifice

holder helps to keep it in correct relative position).

3. Set burner head aside.

NOTES:

• For use on models CT30G/S - LP, CT30G/P - LP, CT36G/S - LP, CT36G/P - LP

• These instructions pertain to the conversion of the above listed conventional LP Gas Wolf Cooktop to a high

altitude unit - anything between 8,600 and 10,250 feet above sea level.

• Some units may not contain all the burners combinations this package contains conversion components and

information for.

THIS CONVERSION KIT MUST BE INSTALLED BY A QUALIFIED SERVICE TECHNICIAN IN ACCORDANCE

WITH THESE INSTRUCTIONS AND ALL APPLICABLE LOCAL CODES AND REQUIREMENTS. IF THESE

INSTRUCTIONS ARE NOT FOLLOWED AS WRITTEN A FIRE, EXPLOSION OR PRODUCTION CARBON

MONOXIDE COULD OCCUR CAUSING PROPERTY DAMAGE, PERSONAL INJURY OR DEATH! THE CONVERSION IS NOT COMPLETE UNTIL THE APPLIANCE IS CHECKED FOR PROPER OPERATION AS SPECIFIED IN THESE INSTRUCTIONS.

TOOLS NEEDED: T-15 Torx Driver, 7mm Nut Driver, Torque Wrench – inch/lbs, Needle-nose Pliers

BEFORE PROCEEDING, SHUT OFF GAS SUPPLY TO APPLIANCE BEFORE DISCONNECTING ELECTRICAL POWER!

Figure 1. Burner Removal

T-15 6-Lobe Screws

Page 2

815897

Wolf Gas Cooktop-3 LP High Altitude Conversion Kit

818164 / Rev A / December, 2010Page 2 of 2

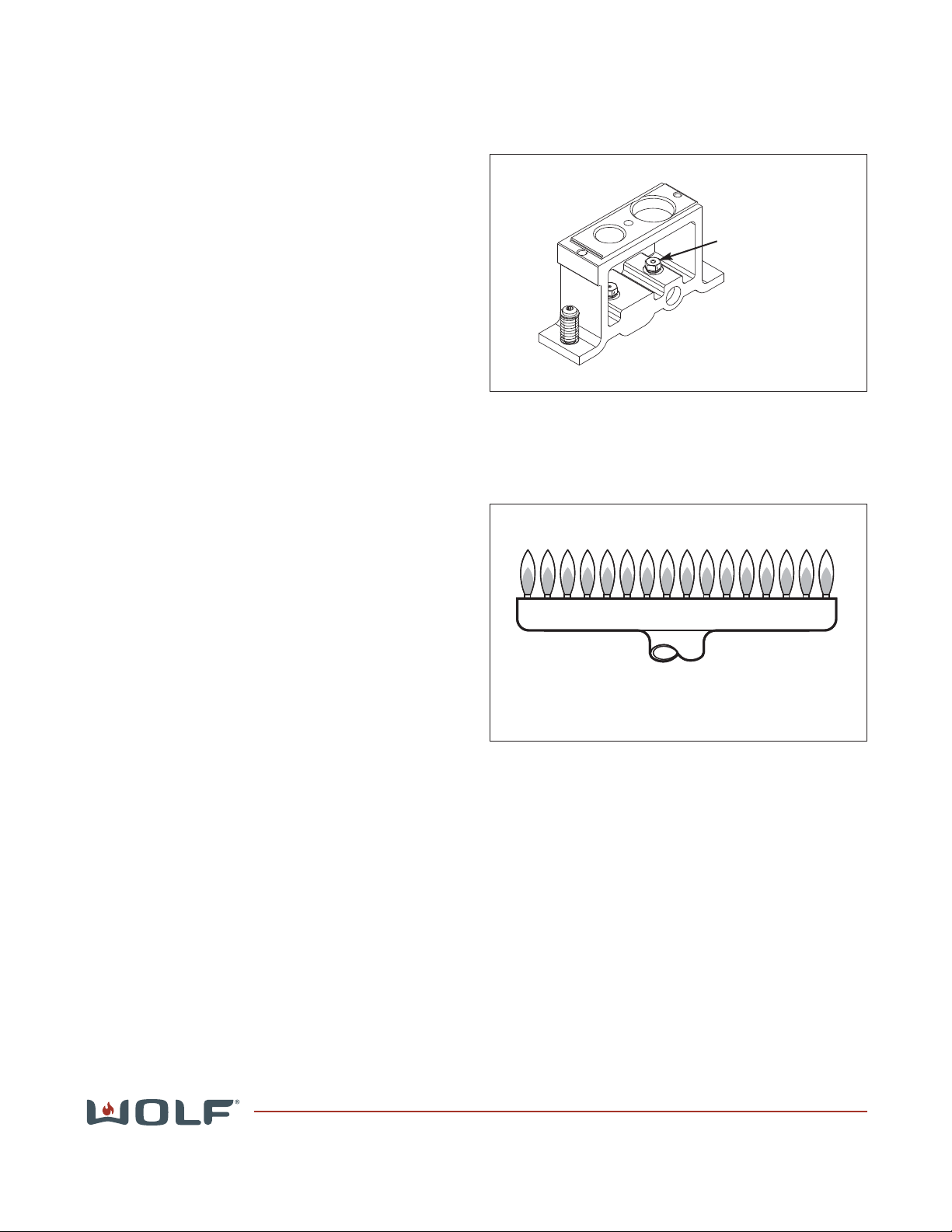

Figure 2.

4. Using the 7mm nut driver, remove the main orifice

and set aside (See Figure 2).

5. Replace the 15,000 Btu/hr main orifice, stamped

119, with orifice stamped 105 from package.

6. Re-assemble the burner head by plugging in the

electrode and inserting the burner back into the jet

holder

NOTE: Watch that the electrode wire does not

get caught between the burner and the jet holder.

Also make sure the burner is sitting down completely. You may need to pull forward slightly to

allow the electrode bracket to clear the burner

pan.

7. New screws are available in the package if needed. Tighten down the burner head screws to 24

inch-lbs.

Flame Characteristics:

The flame produced by the burner should be a quiet,

blue flame, exhibiting no lifting or blowing. The following illustration shows a desirable flame.

Figure 3 shows a desirable flame.

No modifications should need to be made to the

flame, but if the burner is not exhibiting a proper flame

and modifications need to be made, the CO level

should be monitored at all times during modification.

Ignition System:

If the unit is operating properly after conversion, the

burners should ignite within 4 seconds of the gas flowing out of the burner ports. If the flame is extinguished, the unit should also automatically re-ignite

within 4 seconds. When the burner is operating correctly, with a proper, hard flame, the unit should not be

sparking.

Leak Testing:

With all orifices converted, apply soapy water to all

joints and fittings. Turn on all burners and check thoroughly for leaks. Then turn off all the burners and

recheck for leaks.

Labels:

Once installation of all orifices is complete, and all the

appropriate tests have been satisfied, fill out all applicable information and affix the High Altitude Gas

Cooktop Rating Label as close as possible to the

existing rating plate.

Figure 3.

Main Orifice

NORMAL HARD FLAME

Loading...

Loading...