INT0

查询W78C374供应商

Preliminary W78E378/W78C378/W78C374

MONITOR CONTROLLER

GENERAL DESCRIPTION

The W78E378, W78C378 and W78C374B are ASIC which is a stand-alone high-performance

microcontroller specially designed for monitor control applications. The device integrates the

embedded 80C31 microcontroller core, on-chip MTP or Mask ROM, 576 bytes of RAM, and a number

of dedicated hardware monitor functions. Additional special function registers are incorporated to

control the on-chip peripheral hardware. The chip is used to control the interface signal of other

devices in the monitor and to process the video sync signals. Because of the highly integration and

Flash cell for program memory, the device can offer users the competitive advantages of low cost

and reduced development time.

FEATURES

• 80C31 MCU Core Embedded

• 32K Bytes MTP-ROM (W78E378)

• 32K Bytes Mask-ROM (W78C378)

• 16K Bytes Mask-ROM (W78C374B)

• Total 576 Bytes of On-chip Data RAM

− 256 bytes accessed as in the 80C32

−

320 bytes accessed as external data memory via "MOVX @Ri"

• PWM DACs

− Eight 8-bit Static PWM DACs: DAC0−DAC8

− Three 8-bit Dynamic PWM DACs: DAC9−DAC10

• Sync Processor

−

Horizontal & Vertical Polarity Detector

−

Sync Separator for Composite Sync

− 12-bit Horizontal & Vertical Frequency Counter

−

Programmable Dummy Frequency Generator

− Programmable H-clamp Pulse Output

−

SOA Interrupt

−

Hsync/2 Output

• Serial Ports:

− DDC1 Port- support DDC1

−

SIO1 & SIO2 Ports - each can support DDC2B/2B+/2Bi/2AB (each has 2 slave addresses)

• Two 16-bit Timer/Counters (8031's Timer0 & Timer1)

• One External Interrupt Input (8031's

• One Parabola Interrupt Generator

• One ADC with 7 Multiplexed Analog Inputs

• Two 12 mA(min) Output Pins for Driving LEDs

• Watchdog Timer (2

• Power Low Reset

• Frequency: 10 MHz max. (with the same performance as a normal 8051 that uses 20 MHz)

• Packaged in 40/32-pin 600 mil DIP & 44-pin PLCC

22

/Fosc = 0.42s @Fosc = 10 MHz)

)

Publication Release Date: December 1999

- 1 - Revision A1

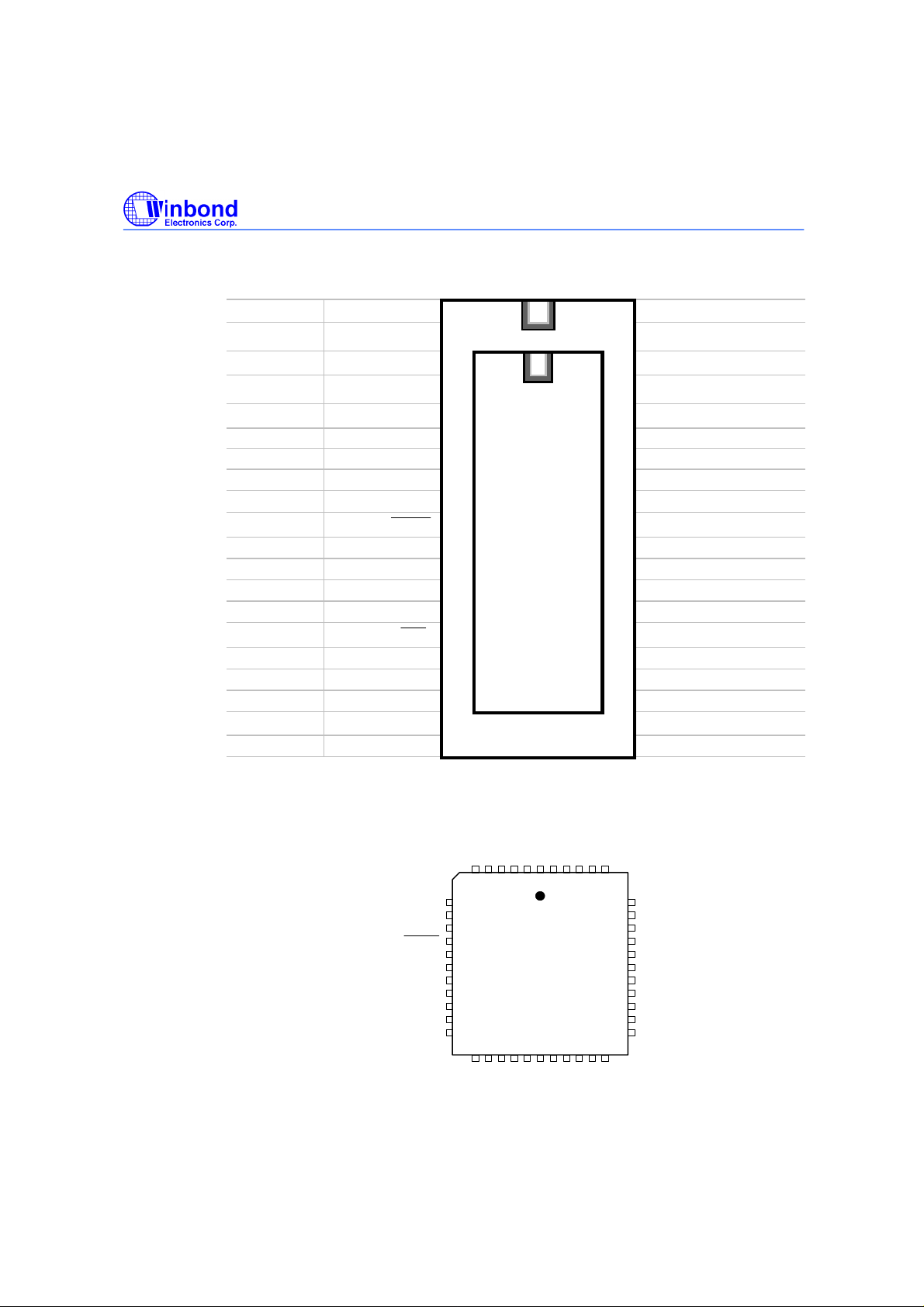

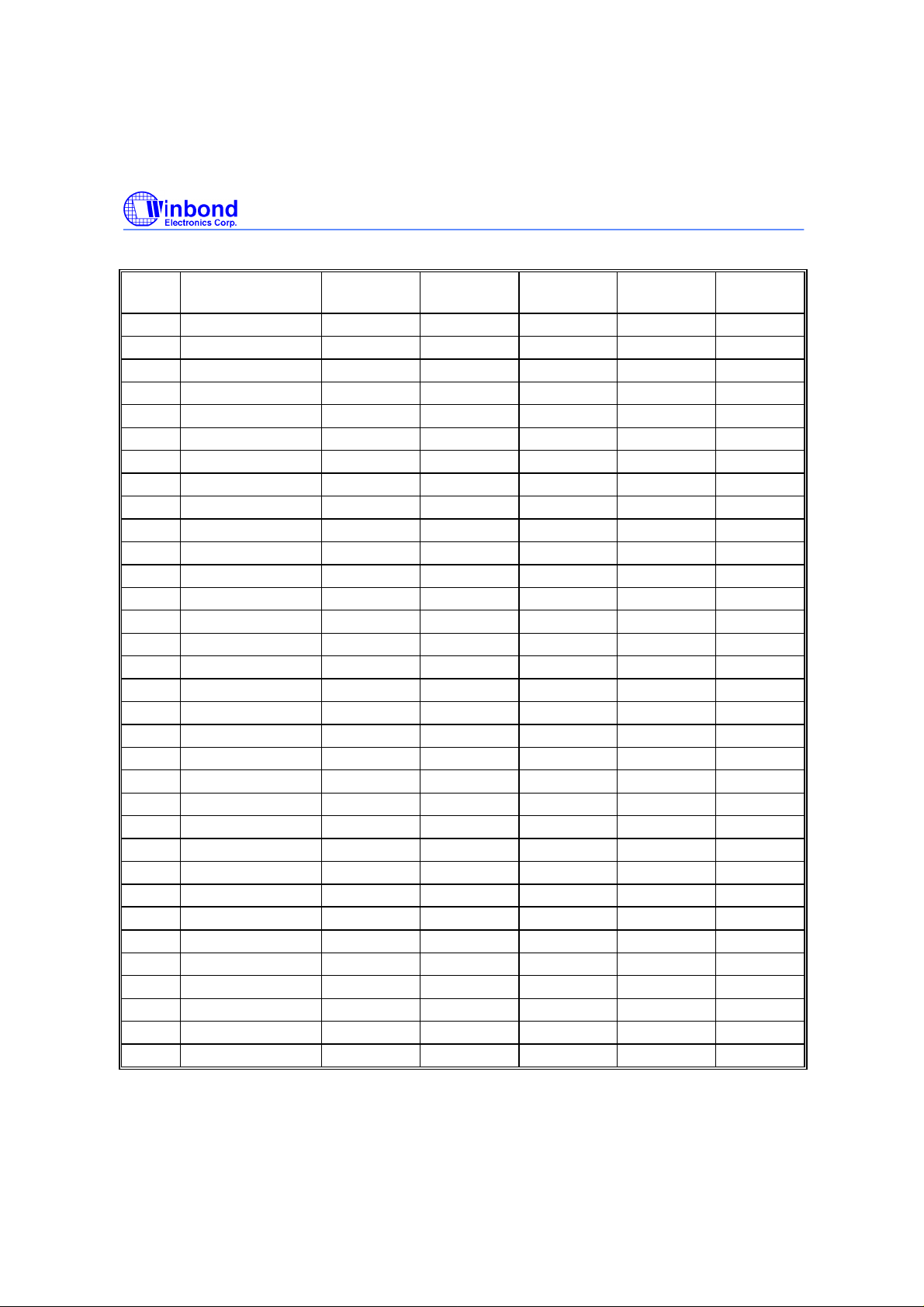

PIN CONFIGURATIONS

40-pin DIP:

32-pin DIP:

44-pin PLCC

W78E378E

W78C378E

W78C374E

W78E378

W78C378

W78C374

Preliminary W78E378/W78C378/W78C374

P4.1

40-pin DIP

40 P4.2

1

32-pin DIP

1

39 P4.3

32 38 P3.6 (ADC5, T1)*

HIN 8 6 27 33 P1.6 (DAC6)*

VIN 9 7 26 32 P1.7 (DAC7)*

10 8 25 31 P2.0 (DAC8)

VDD 11 9 24 30 P2.1 (DAC9)

VSSA 12 10 23 29 P2.2 (DAC10)

OSCIN 14 12 21 27 P2.4 (ADC0)

15 13 20 26 P2.5 (ADC1)

)

INT0

VSS 18 16 17 23 P3.7 (ADC6)*

P4.6 20 21 P4.5 (SDA2)*

P4.0 (HFI) 2

P3.5 (ADC4, T0)* 3

P1.1 (DAC1)* 4 2 31 37 P1.2 (DAC2)*

P1.0 (DAC0)* 5 3 30 36 P1.3 (DAC3)*

P3.4 (VOUT) 6 4 29 35 P1.4 (DAC4)*

P3.3 (HOUT) 7 5 28 34 P1.5 (DAC5)*

RESET

OSCOUT 13 11 22 28 P2.3 (Hclamp)

P3.2 (

P3.1 (SCL)* 16 14 19 25 P2.6 (ADC2)

P3.0 (SDA)* 17 15 18 24 P2.7 (ADC3)

P4.7 (HFO) 19 22 P4.4 (SCL2)*

P3.3

H

V

RESET

V

DD

VDDA

V

DD

VSSA

OSCOUT

OSCIN

P3.2

IN

IN

P

3

.

4

7

8

9

10

11

12

13

14

15

16

17

1819202

P

3

.

1

- 2 -

P

P

1

1

.

.

0

1

P

V

3

S

.

S

0

P

P

P

P

3

4

4

4

.

.

.

.

5

2

1

0

123456 404142434

4

W78E378P

W78C378P

W78C374P

2

2

3

1

V

P

P

P

S

4

4

4

S

.

.

.

6

5

7

P

P

P

P

3

1

4

1

.

.

.

.

6

2

3

3

P1.4

39

NC

38

P1.5

37

P1.6

36

P1.7

35

P2.0

34

P2.1

33

P2.2

32

P2.3

31

P2.4

30

P2.5

29

2625242

2

2

8

7

P

P

P

P

3

4

2

2

.

.

.

.

7

4

7

6

Preliminary W78E378/W78C378/W78C374

RESET

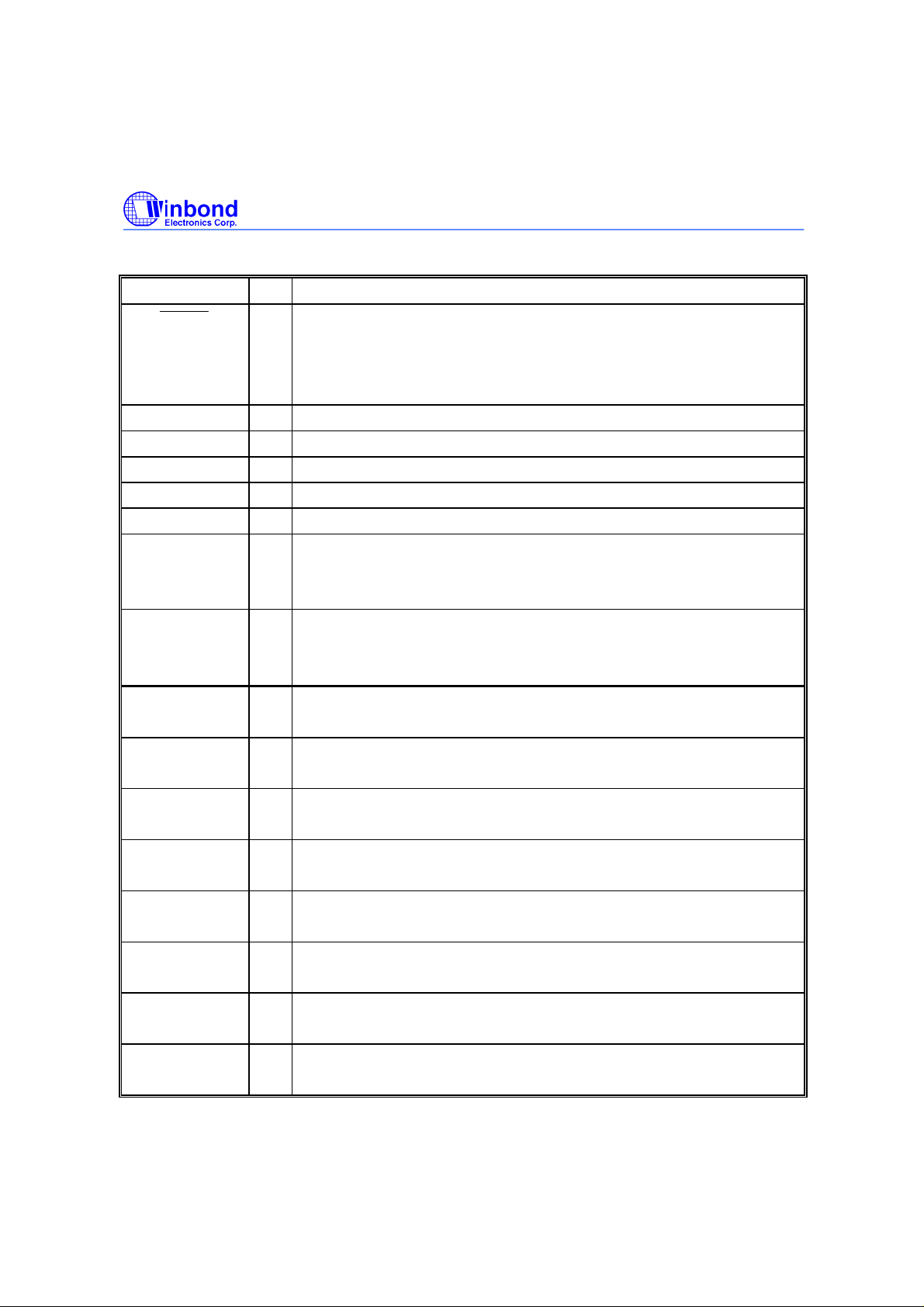

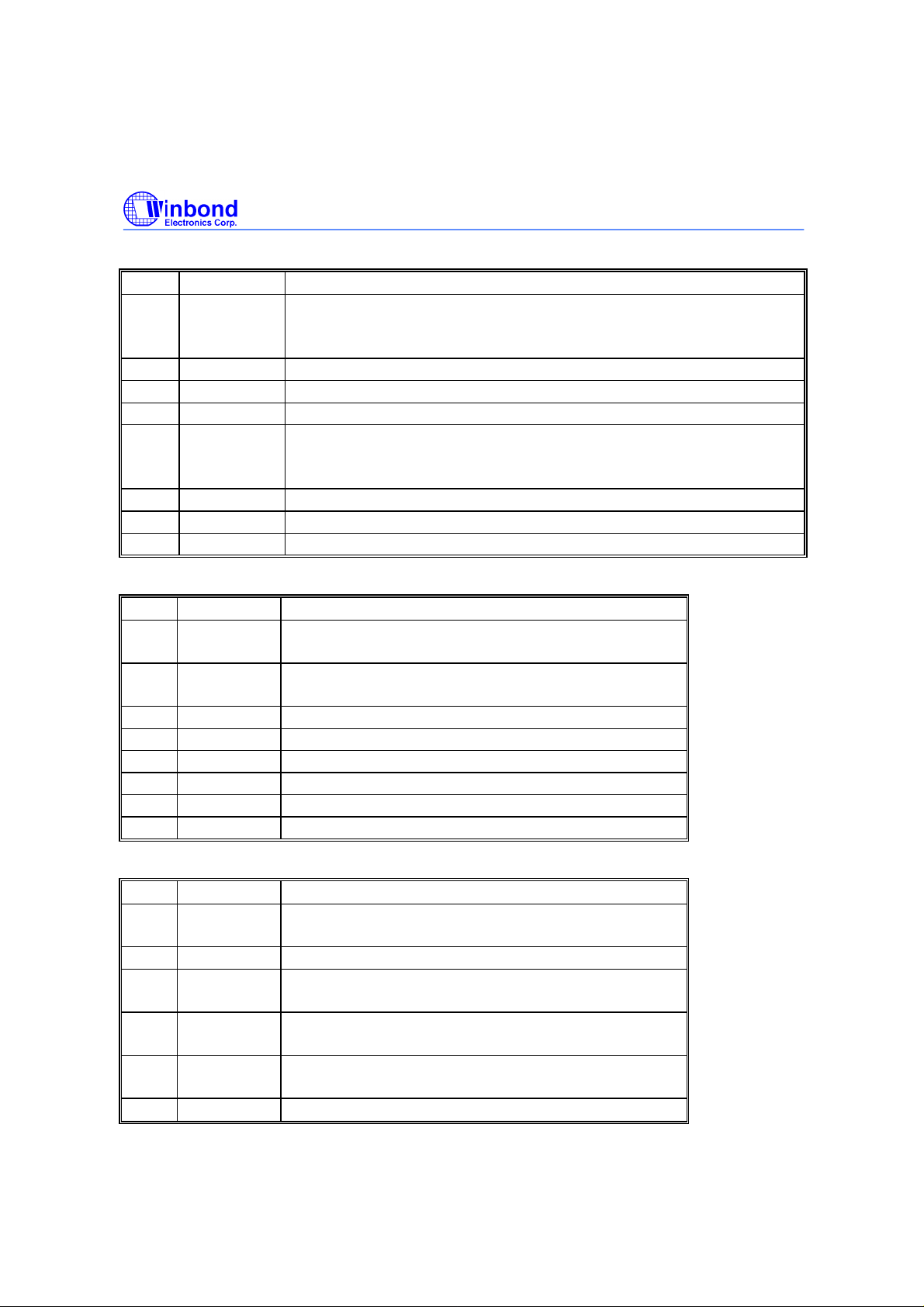

PIN DESCRIPTION

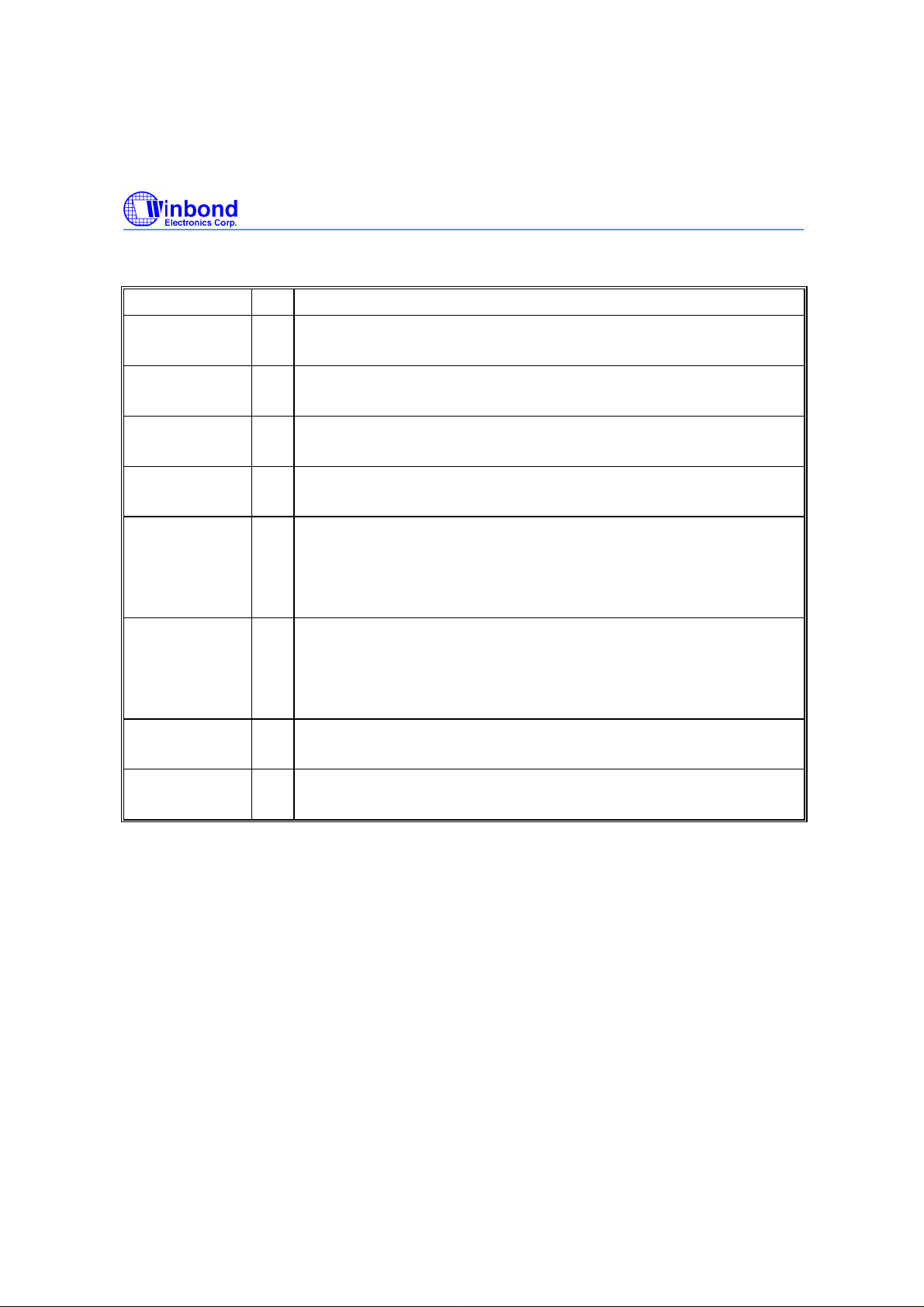

PIN NAME I/O DESCRIPTION

VDD - Positive power supply

VSS - Ground

VSS - Ground

OUT

OSC

OSCIN I Input to the inverting oscillator amplifier, 10 MHz max.

HIN I Hsync input

VIN I Vsync i nput

P1.0 (DAC0) I/O General purpose I/O, DAC0 special function output

P1.1 (DAC1) I/O General purpose I/O, DAC1 special function output

P1.2 (DAC2) I/O General purpose I/O, DAC2 special function output

P1.3 (DAC3) I/O General purpose I/O, DAC3 special function output

P1.4 (DAC4) I/O General purpose I/O, DAC4 special function output

P1.5 (DAC5) I/O General purpose I/O, DAC5 special function output

P1.6 (DAC6) I/O General purpose I/O, DAC6 special function output

P1.7 (DAC7) I/O General purpose I/O, DAC7 special function output

I/O Chip reset input (active low) input &

Internal reset output (generated by WDT or power low)

TTL Schmitt trigger input, internal pull-up ~30 KΩ

IOL = +12 mA @VOL = 0.45V

O Output from the inverting oscillator amplifier

TTL Schmitt trigger input , w/o PMOS

IL

VIH/V

TTL Schmitt trigger input, w/o PMOS

VIH/V

Open-drain output

Open-drain output

Open-drain output

Open-drain output

Open-drain output

Open-drain output

Open-drain output

Open-drain output

= 2.0V/0.8V, V+/ V- = ~1.6V/ 1.1V

IL

= 2.0V/0.8V, V+/ V- = ~1.6V/ 1.1V

, sink current: 15 mA

, sink current: 15 mA

, sink current: 4 mA

, sink current: 4 mA

, sink current: 4 mA

, sink current: 4 mA

, sink current: 4 mA

, sink current: 4 mA

Publication Release Date: December 1999

- 3 - Revision A1

Preliminary W78E378/W78C378/W78C374

INT0

INT0

Pin Description, Continued

PIN NAME I/O DESCRIPTION

P2.0 (DAC8) I/O General purpose I/O, DAC8 Special Function output

Sink/Source current: 4 mA/-100 µA (-4 mA for SF output)

P2.1 (DAC9) I/O General purpose I/O, DAC9 Special Function output

Sink/Source current: 4 mA/-100 µA (-4 mA for SF output)

P2.2 (DAC10) I/O General purpose I/O, DAC10 Special Function output

Sink/Source current: 4 mA/-100 µA (-4 mA for SF output)

P2.3 (Hclamp) I/O General purpose I/O, Hclamp Special Function output

Sink/Source current: 4 mA/-100 µA (-4 mA for SF output)

P2.4 (ADC0) I/O General purpose I/O, ADC input channel 0

Sink/Source current: 4 mA/-100 µA

P2.5 (ADC1) I/O General purpose I/O, ADC input channel 1

Sink/Source current: 4 mA/-100 µA

P2.6 (ADC2) I/O General purpose I/O, ADC input channel 2

Sink/Source current: 4 mA/-100 µA

P2.7 (ADC3) I/O General purpose I/O, ADC input channel 3

Sink/Source current: 4 mA/-100 µA

P3.0 (SDA) I/O General purpose I/O, DDC port serial data I/O

Schmitt trigger input

VIH/VIL = 0.7 VDD/0.3 VDD, V+/V- = ~0.6 VDD/ 0.4 V

Open-drain output

P3.1 (SCL) I/O General purpose I/O, DDC port serial clock I/O

Schmitt trigger input

VIH/VIL = 0.7 VDD/0.3 VDD, V+/V- = ~0.6 VDD/ 0.4 VDD

Open-drain output

P3.2 (

P3.3 (H

P3.4 (V

P3.5 (ADC4, T0) I/O General purpose I/O, ADC input channel 4

P3.6 (ADC5, T1) I/O General purpose I/O, ADC input channel 5

P3.7 (ADC6) I/O General purpose I/O, ADC input channel 6

OUT

OUT

I/O

)

) I/O General purpose I/O, H

) I/O General purpose I/O, V

General purpose I/O,

Sink/Source current: 1 mA/ -100 µA

Sink/Source current: 4 mA/-100 µA (-4 mA for SF output)

Sink/Source current: 4 mA/-100 µA (-4 mA for SF output)

Open-drain output

Open-drain output

Open-drain output

, sink current: 8 mA

, sink current: 8 mA

input

OUT

special function output

OUT

special function output

, sink current: 4 mA

, sink current: 4 mA

, sink current: 4 mA

DD

- 4 -

Preliminary W78E378/W78C378/W78C374

Pin Description, Continued

PIN NAME I/O DESCRIPTION

P4.0 (HFI) I/O P4.0 Output, HFI Input

Sink/Source current: 4 mA/-4 mA

P4.1 O P4.1 Output

Sink/Source current: 4 mA/-4 mA

P4.2 O P4.2 Output

Sink/Source current: 4 mA/-4 mA

P4.3 O P4.3 Output

Sink/Source current: 4 mA/-4 mA

P4.4 (SCL2) I/O P4.4 Output, SIO2 port serial clock I/O

Schmitt trigger input

VIH/VIL = 0.7 VDD/0.3 VDD, V+/V- = ~0.6 VDD/0.4 V

Open-drain output

P4.5 (SDA2) I/O P4.5 Output, SIO2 port serial data I/O

Schmitt trigger input

VIH/VIL = 0.7 VDD/0.3 VDD, V+/V- = ~0.6 VDD/0.4 V

Open-drain output

P4.6 O P4.6 Output

Sink/Source current: 4 mA/-4 mA

P4.7 (HFO) O P4.7 Output, HFO Output

Sink/Source current: 4 mA/-4 mA

, sink current: 8 mA

, sink current: 8 mA

DD

DD

Publication Release Date: December 1999

- 5 - Revision A1

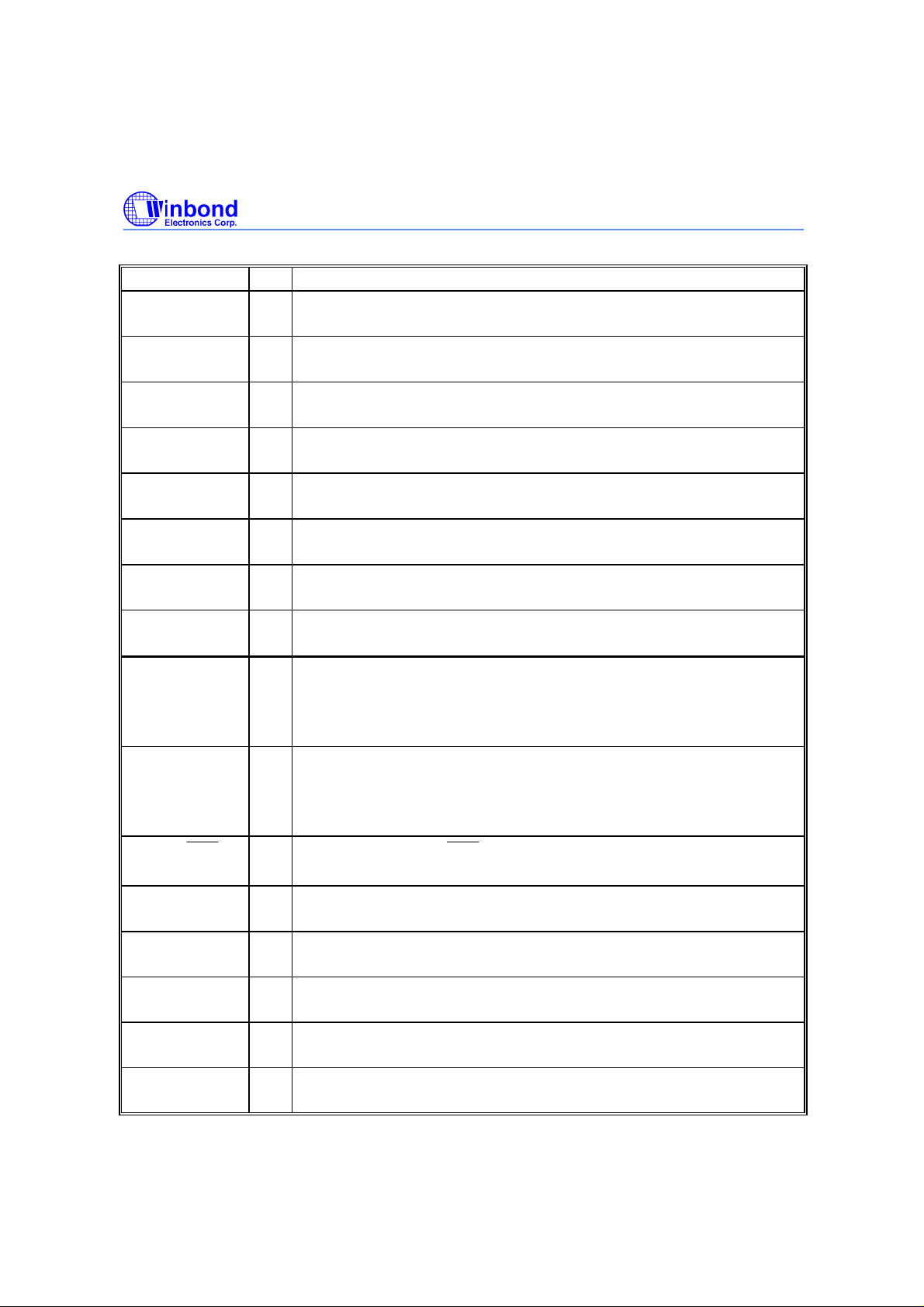

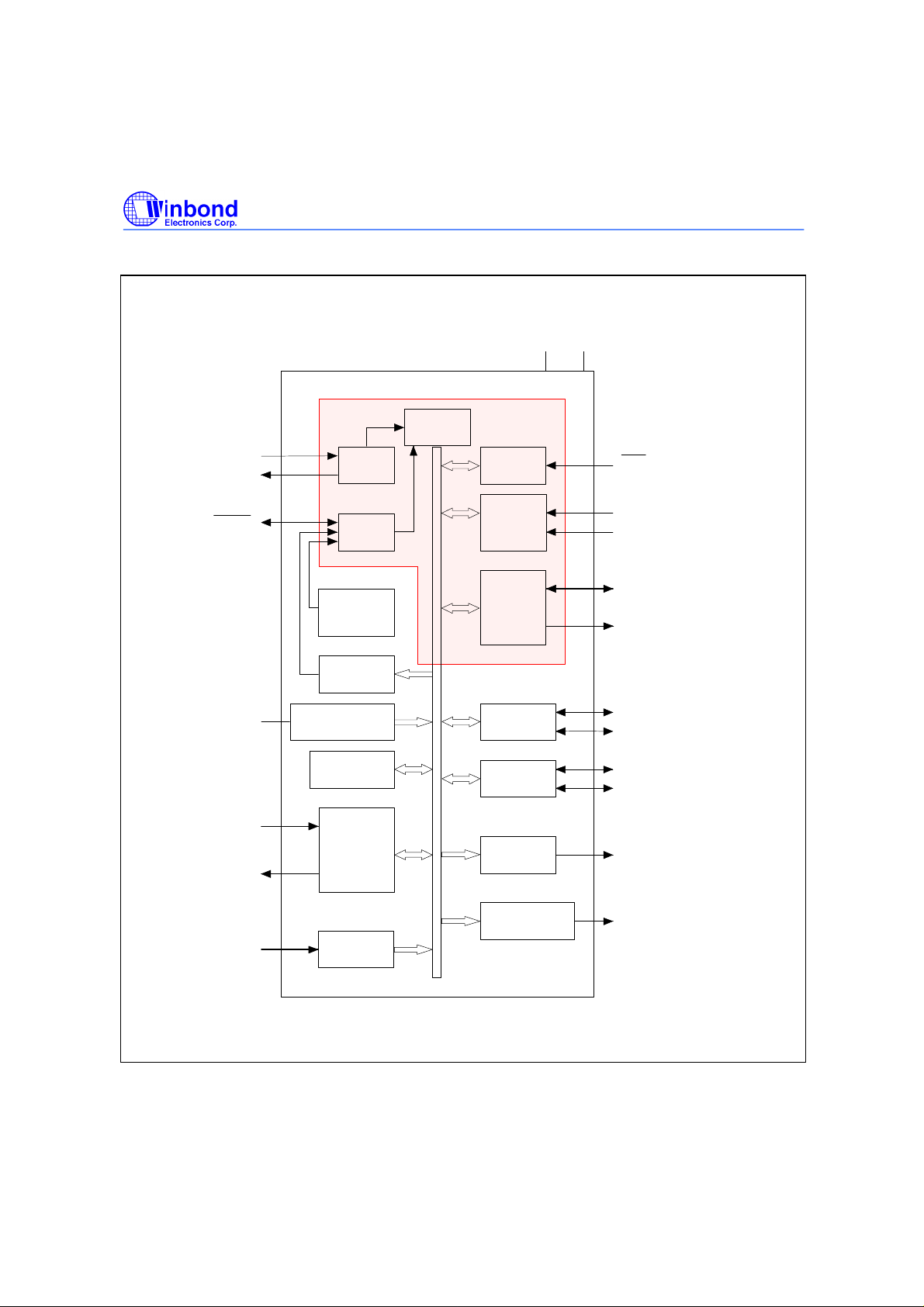

BLOCK DIAGRAM

Preliminary W78E378/W78C378/W78C374

V V

SS

DD

80C31 Core excluding internal RAM

OSCIN

OSCOUT

RESET

VPP (P3.2)

HIN, VIN

HFI (P4.0)

VOUT (P3.4)

HOUT (P3.3)

Hclamp (P2.3)

HFO (P4.7)

ADC0 (P2.4)

ADC1 (P2.5)

ADC2 (P2.6)

ADC3 (P2.7)

ADC4 (P3.5)

ADC5 (P3.6)

ADC6 (P3.7)

Note:

freq1 = freq2

freq1

Program Memory

Osc.

Circuit

Reset

Circuit

Power Low

Detection

Watch Dog

Timer

Data Memory

RAM: 576 Bytes

Sync.

Processor

ADC

freq2

CPU

8-bit Internal Bus

Interrupt

Processor

Timer 0

Timer 1

I/O Port

SIO1

SIO2

Static DACs

Dynamic DACs

INT0 (P3.2)

T0 (P3.5)

T1 (P3.6)

P1, P2, P3

P4

Note:

P1, P4.4~P4.5

P3.0~P3.1 & P3.5~P3.7

are open-drain.

SCL (P3.1)

SDA (P3.0)

SCL2 (P4.4)

SDA2 (P4.5)

DAC0~7 (P1.0~P1.7)

DAC8~10 (P2.0~P2.2)

- 6 -

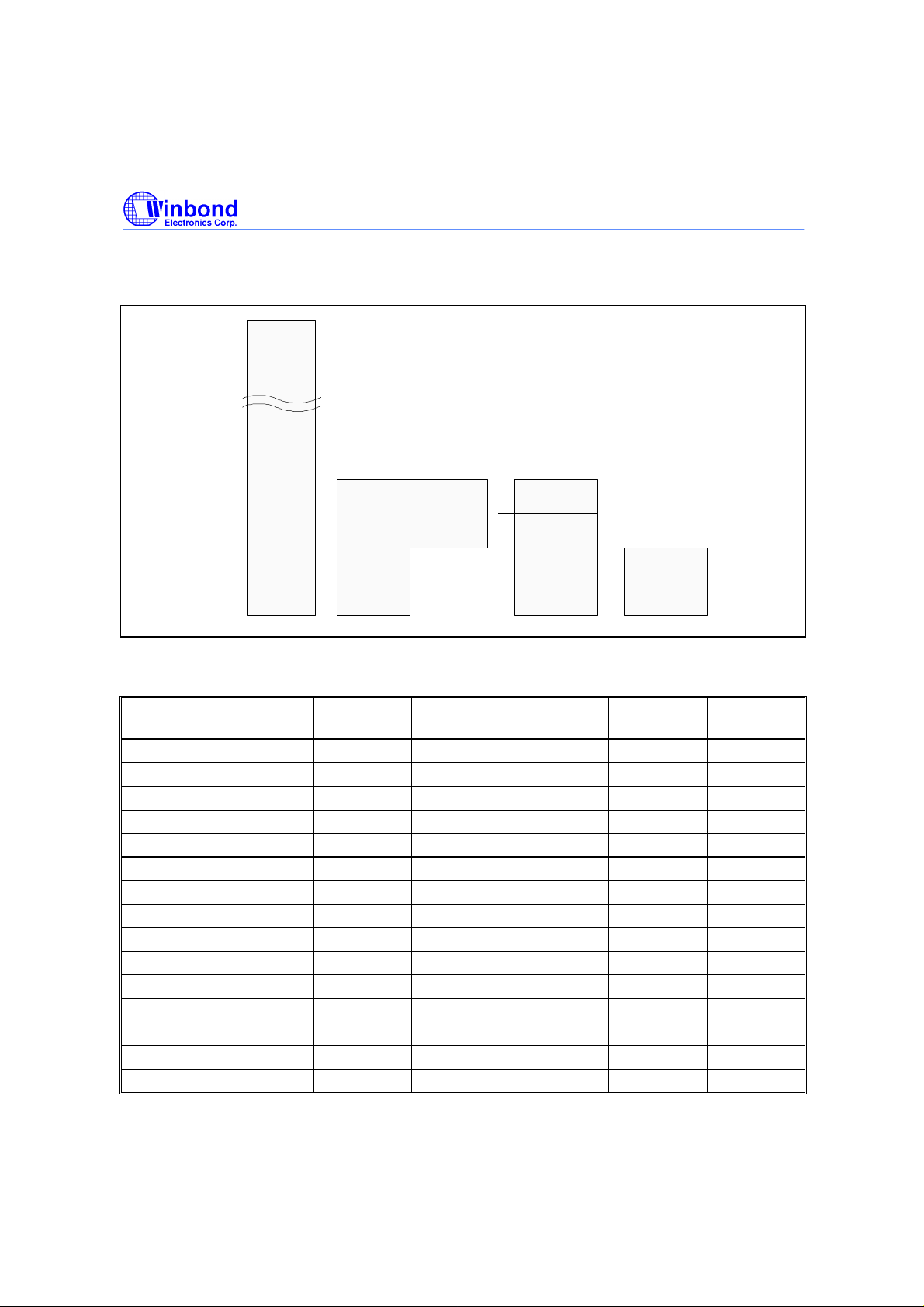

Preliminary W78E378/W78C378/W78C374

BANK0

BANK1

FUNCTIONAL DESCRIPTION

Address Space

7FFFh

Internal

(3FFFh)

Program Memory

0000h

FFh

Internal RAM

256 Bytes

Indirect Addressing

"MOV @Ri"

80h

Direct or Indirect

Addressing

"MOV" or "MOV @Ri"

00h

8051SFRs &

Serial Ports SFRs

Direct Addressing

"MOV"

FFh

On-Chip Data Memory

64 Bytes

External Access

C0h

"MOVX @Ri"

BFh

new SFRs

External Access

External Access

"MOVX @Ri"

"MOVX @Ri"

80h

On-Chip Data Memory

128 Bytes

External Access

"MOVX @Ri"

00h

7Fh7Fh7Fh

00h

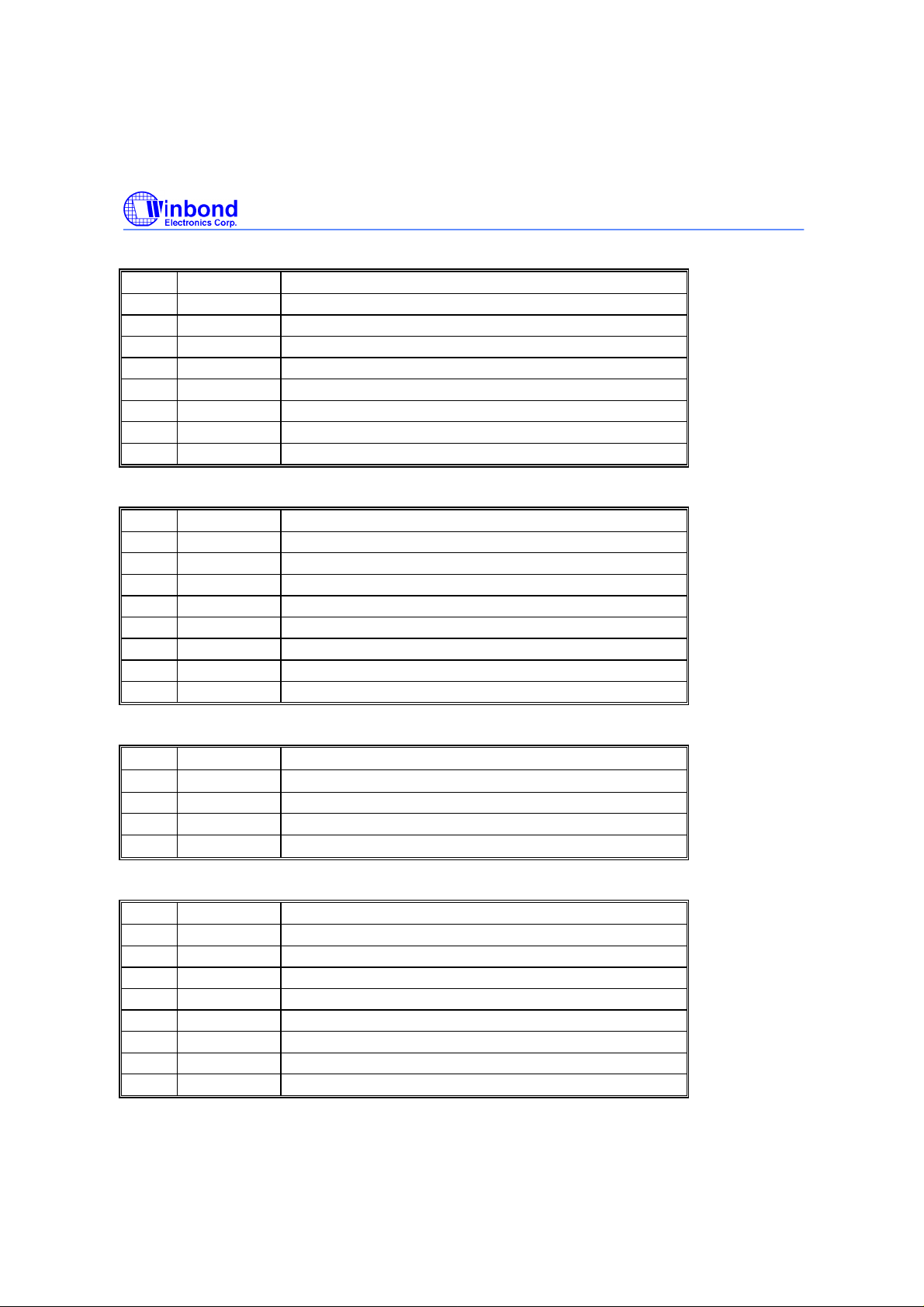

Program/Data/SFRs Address Space

SFRs accessed using 'Direct Addressing'

REGISTER ADDRESS BITS POWER

ON RESET

1

A* E0h

2

B* F0h 8 00h 00h

3 PSW* D0h

SP 81h 8 00h 00h R/W

4

DPL 82h 8 00h 00h R/W

5

8 00h 00h R/W

8 00h 00h R/W

6 DPH 83h 8 00h 00h

7 IE* A8h

8 IP* B8h

9 TCON* 88h

8 00h 00h R/W

8 00h 00h R/W

8 00h 00h R/W

10 TMOD 89h 8 00h 00h

11 TL0 8Ah

12 TH0 8Ch

13 TL1 8Bh

14 TH1 8Dh

15 PCON 87h

8 00h 00h R/W

8 00h 00h R/W

8 00h 00h R/W

8 00h 00h R/W

8 00h x0h R/W

On-Chip Data Memory

128 Bytes

External Access

"MOVX @Ri"

RESET R/W

R/W

R/W

R/W

Publication Release Date: December 1999

- 7 - Revision A1

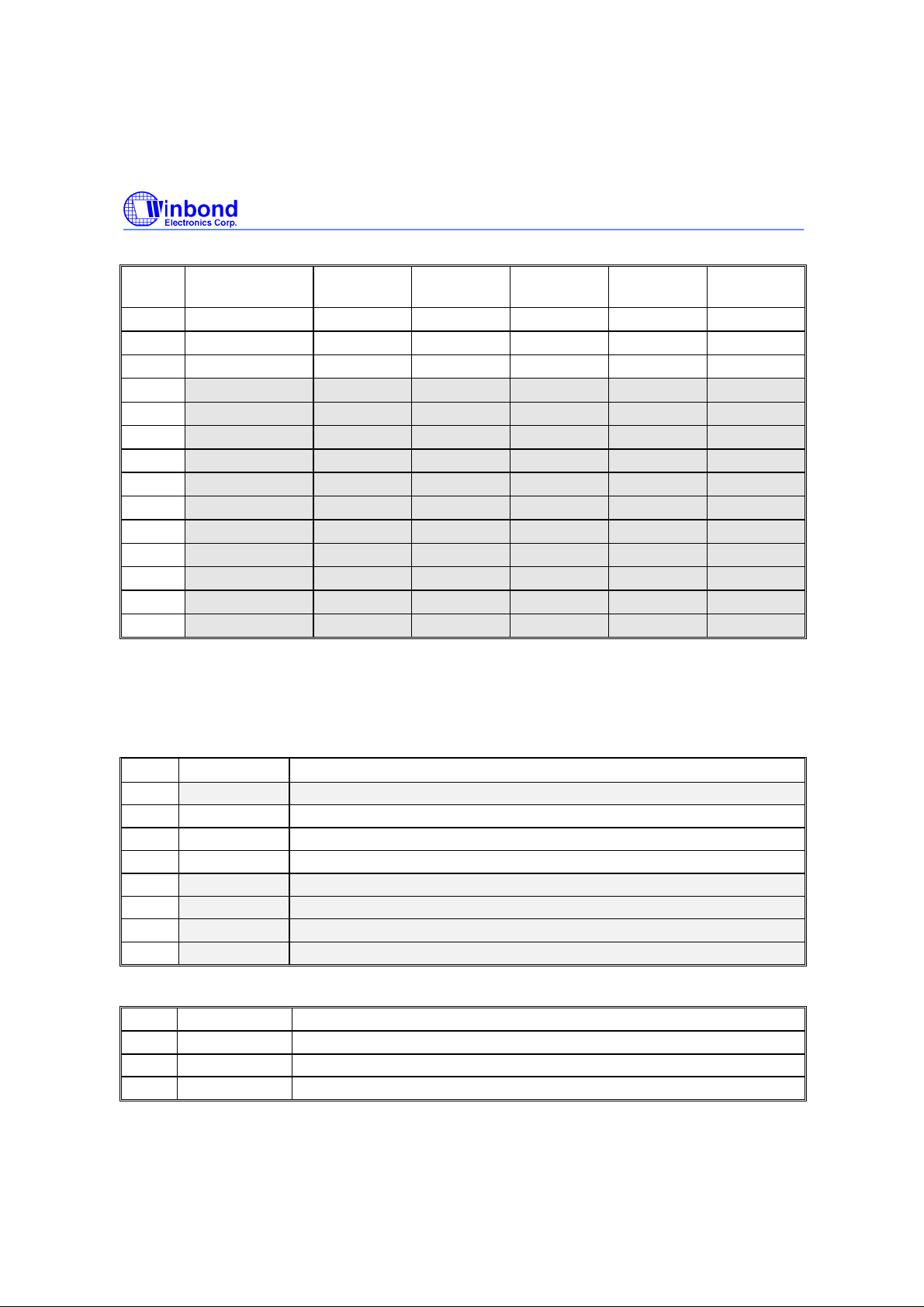

Preliminary W78E378/W78C378/W78C374

SFRs accessed using 'Direct Addressing', continued

REGISTER ADDRESS BITS POWER

ON RESET

16 P1* 90h 8 00h 00h

17 P2* A0h

18 P3* B0h 8 1Fh 1Fh

19 TMREG* C0h 3 00h xxh

20 S1CON* D8h 8 00h 00h

21 S1STA D9h

22 S1DAT DAh

23 S1ADR1 DBh 8 00h 00h

24 S1ADR2 DCh

25 S2CON* E8h 8 00h 00h

26 S2STA E9h

27 S2DAT EAh

28 S2ADR1 EBh 8 00h 00h

28 S2ADR2 ECh

Notes:

1. The SFRs marked with an asterisk (*) are both bit- and byte-addressable.

2. Port 1 and P3.5−P3.7 outputs low during & after reset.

3. "x" means no reset action.

4. The SFRs in the shaded region are new-defined.

8 FFh FFh R/W

8 F8h F8h R

8 FFh FFh R/W

8 00h 00h R/W

8 F8h F8h R

8 FFh FFh R/W

8 00h 00h R/W

RESET R/W

R/W

R/W

R/W

R/W

R/W

R/W

R/W

* Modified PCON

BIT NAME FUNCTION

0 ADCS2 ADC channel Select bit 2

1 PD Power Down bit

2 GF0 General purpose flag bit

3 GF1 General purpose flag bit

4 TEST0 Test purpose flag bit

5 TEST1 Test purpose flag bit

6 ADCcal Set 0/1 to select 1.0V/3.0V for ADC calibration

7 CPUhalt Set to let CPU halt when the chip runs internally

* TMREG: Test Mode Register

BIT NAME FUNCTION

0 TM1 Test Mode1

1 TM2 Test Mode2

2 TM3 Test Mode3

- 8 -

Preliminary W78E378/W78C378/W78C374

SFRs accessed using 'MOVX @Ri'

REGISTER ADDRESS BITS POWER

ON RESET

1 CTRL1 80h 8 00h 00h W

2 CTRL2 81h 8 00h 00h W

3 P1SF 82h 8 00h xxh W

4 P2SF 83h 8 00h xxh W

5 P3SF 84h 8 00h 00h W

6 PARAL 85h 8 00h 00h R/W

7 PARAH 86h 5 00h 00h R/W

8 HFCOUNTL 87h 8 x x R

9 HFCOUNTH 88h 8 x x R

10 VFCOUNTL 89h 8 x x R

11 VFCOUNTH 8Ah 8 x x R

12 WDTCLR 8Bh - x x W

13 SOARL 8Ch 8/6 x x R/W

14 SOARH 8Dh 8/6 x x R/W

15 SOACLR 8Eh - x x W

16 INTMSK 8Fh 6 00h 00h R/W

17 INTVECT 90h 6 00h 00h R

18 INTCLR 91h 6 x x W

19 DDC1 92h 8 x x W

20 ADC 93h 8 x x R

21 DAC0 94h 8 00h x R/W

22 DAC1 95h 8 00h x R/W

23 DAC2 96h 8 00h x R/W

24 DAC3 97h 8 00h x R/W

25 DAC4 98h 8 00h x R/W

26 DAC5 99h 8 00h x R/W

27 DAC6 9Ah 8 00h x R/W

28 DAC7 9Bh 8 00h x R/W

29 DAC8 9Ch 8 00h x R/W

30 DAC9 9Dh 8 00h x R/W

31 DAC10 9Eh 8 00h x R/W

32 P4 9Fh 8 FFh FFh W

33 CTRL3 A0h 0 00h 00h W

Note: "x" means no reset action.

RESET R/W

TYPE

Publication Release Date: December 1999

- 9 - Revision A1

Preliminary W78E378/W78C378/W78C374

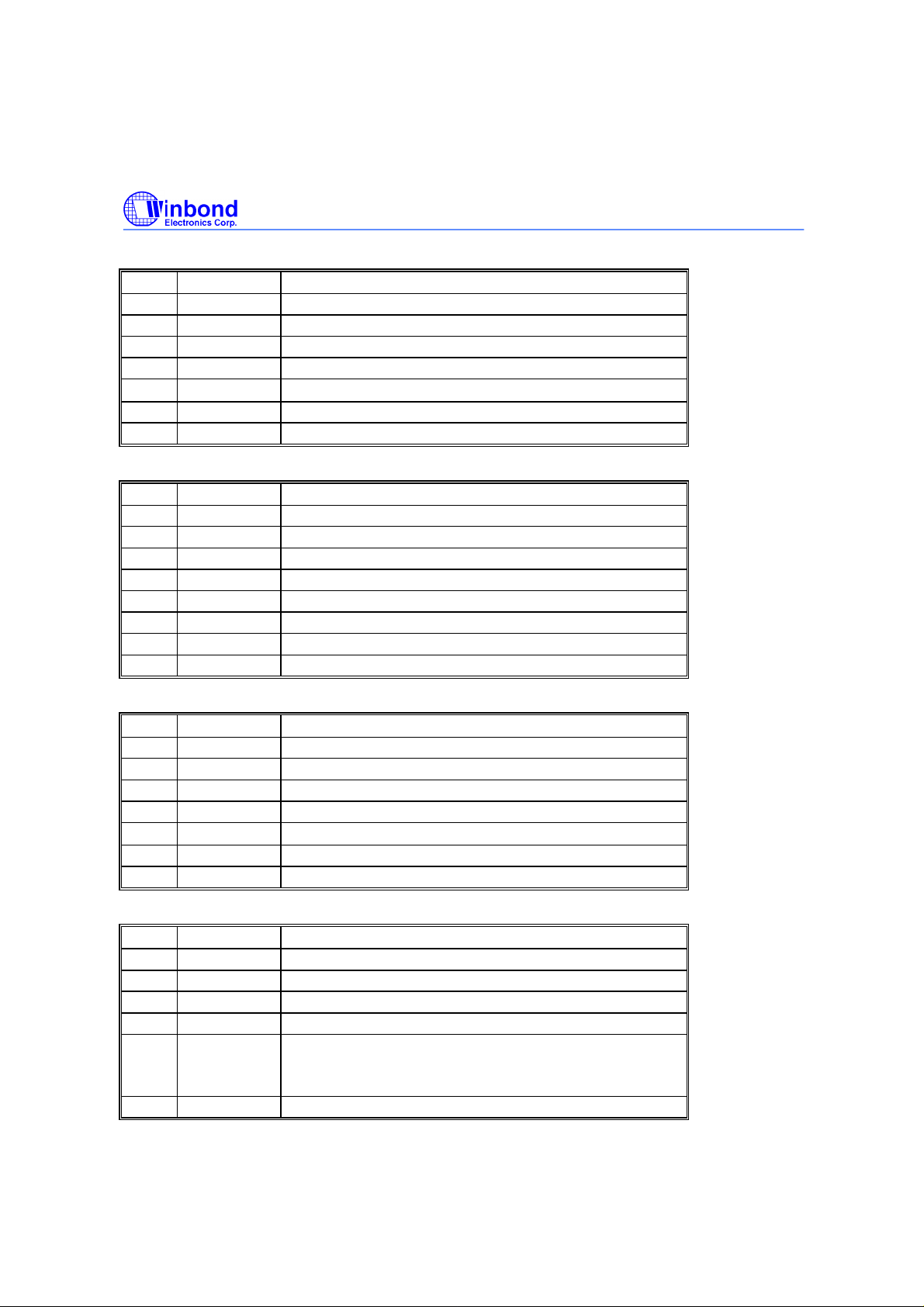

* CTRL1: Control Register 1 (Write Only)

BIT NAME FUNCTION

0 ADCSTRT A-to-D Conversion START control

Set by S/W to start conversion.

Cleared by H/W while conversion completed (read SOARH.6 to check).

1 ADCS0 ADC channel Select bit 0

2 ADCS1 ADC channel Select bit 1

3 ENDDC1 Enable DDC1

4 HCES H-Clamp Edge Select

0: Select leading edge of restored Hsync

1: Select trailing edge of restored Hsync

5 HCWS H-Clamp Width Select bit

6 DUMMYEN Dummy signal Enable

7

VSDIS Vsync Separator Disable, 0: Enable, 1: Disable

* CTRL2: Control Register 2 (Write Only)

BIT NAME FUNCTION

0 HSPS HSync Polarity Select

0: Positive, 1: Negative

1 VSPS VSync Polarity Select

0: Positive, 1: Negative

2 HDUMS0 H Dummy frequency Select 0

3 VDUMS V Dummy frequency Select

4 DDC1B9 Bit 9 in DDC1 mode

5 WDTEN Enable Watch Dog Timer

6 SOAHDIS Disable SOA low to high detection

7 OSCHI OSC freq. Higher than 10 MHz

* CTRL3: Control Register 3 (Write Only)

BIT NAME FUNCTION

0 ENHFO Enable HF input/output for P4.0/P4.7, respectively

0: Disable, 1: Enable

1 HDUMS1 H Dummy frequency Select 1

2 HFO_POL Select HFO polarity

0: Positive, 1: Negative

3 HFO_HALF Select HFO output freq.

0: the same as HFI, 1: half of the HFI

4 ENBNK1 Select on-chip ext. RAM bank

0: Bank 0, 1: Bank 1

5−7

- -

- 10 -

Preliminary W78E378/W78C378/W78C374

*P1SF: Port1 special function output enable register (Write Only)

BIT NAME FUNCTION

0 P10SF Port 1.0 Special Function enable (DAC0 output)

1 P11SF Port 1.1 Special Function enable (DAC1 output)

2 P12SF Port 1.2 Special Function enable (DAC2 output)

3 P13SF Port 1.3 Special Function enable (DAC3 output)

4 P14SF Port 1.4 Special Function enable (DAC4 output)

5 P15SF Port 1.5 Special Function enable (DAC5 output)

6 P16SF Port 1.6 Special Function enable (DAC6 output)

7 P17SF Port 1.7 Special Function enable (DAC7 output)

*P2SF: Port2 special function output enable register (Write Only)

BIT NAME FUNCTION

0 P20SF Port 2.0 Special Function enable (DAC8 output)

1 P21SF Port 2.1 Special Function enable (DAC9 output)

2 P22SF Port 2.2 Special Function enable (DAC10 output)

3 P23SF Port 2.3 Special Function enable (Hclamp output)

4 P24SF Port 2.4 Special Function enable (ADC0 input)

5 P25SF Port 2.5 Special Function enable (ADC1 input)

6 P26SF Port 2.6 Special Function enable (ADC2 input)

7 P27SF Port 2.7 Special Function enable (ADC3 input)

*P3SF: Port3 special function output enable register (Write Only)

BIT NAME FUNCTION

0−2

3 P33SF Port 3.3 Special Function enable (H

4 P34SF Port 3.4 Special Function enable (V

5−7

*HFCOUNTL: Horizontal frequency counter register, low byte (Read Only)

BIT NAME FUNCTION

0 HF0 H frequency count bit 0

1 HF1 H frequency count bit 1

2 HF2 H frequency count bit 2

3 HF3 H frequency count bit 3

4 HF4 H frequency count bit 4

5 HF5 H frequency count bit 5

6 HF6 H frequency count bit 6

7 HF7 H frequency count bit 7

- -

- -

OUT

)

OUT

)

Publication Release Date: December 1999

- 11 - Revision A1

Preliminary W78E378/W78C378/W78C374

*HFCOUNTH: Horizontal frequency counter register, high byte (Read Only)

BIT NAME FUNCTION

0 HF8 H frequency count bit 8

1 HF9 H frequency count bit 9

2 HF10 H frequency count bit 10

3 HF11 H frequency count bit 11

4−5

6 NOH Set by hardware if no Hin signal

7 HPOL Hin polarity. 0: Positive, 1: Negative

*VFCOUNTL: Vertical frequency counter register, low byte (Read Only)

BIT NAME FUNCTION

0 VF0 V frequency count bit 0

1 VF1 V frequency count bit 1

2 VF2 V frequency count bit 2

3 VF3 V frequency count bit 3

4 VF4 V frequency count bit 4

5 VF5 V frequency count bit 5

6 VF6 V frequency count bit 6

7 VF7 V frequency count bit 7

- -

*VFCOUNTH: Vertical frequency counter register, high byte (Read Only)

BIT NAME FUNCTION

0 VF8 V frequency count bit 8

1 VF9 V frequency count bit 9

2 VF10 V frequency count bit 10

3 VF11 V frequency count bit 11

4−5

6 NOV Set by hardware if no VIN signal

7 VPOL VIN polarity. 0: Positive, 1: Negative

* INTVECT: Interrupt Vector Register (Read Only)

BIT NAME FUNCTION

0 SCLINT SCL pin pulled low detected

1 ADCINT ADC conversion completed

2 DDC1INT DDC1 port buffer empty

3 SOAINT SOA condition happen

4 VEVENT Vsync pulse detected or NOV = 1 (V counter overflow)

5 PARAINT Parabola Interrupt generated

- -

(The VEVENT is designed to be generated only 'one' time

if no Vsync input.)

- 12 -

Preliminary W78E378/W78C378/W78C374

* INTMSK: Interrupt Mask Register (Read/Write)

BIT NAME FUNCTION

0 MSCLINT Set/clear to enable/disable SCLINT

1 MADCINT Set/clear to enable/disable ADCINT

2 MDDC1INT Set/clear to enable/disable DDC1INT

3 MSOAINT Set/clear to enable/disable SOAINT

4 MVEVENT Set/clear to enable/disable VEVENT

5 MPARAINT Set/clear to enable/disable PARAINT

* INTCLR (Write Only)

BIT NAME FUNCTION

0 CSCLINT Write 1 to this bit to clear SCLINT in INTVECT

1 CADCINT Write 1 to this bit to clear ADCINT in INTVECT

2 CDDC1INT Write 1 to this bit to clear DDC1INT in INTVECT

3 CSOAINT Write 1 to this bit to clear SOAINT in INTVECT

4 CVEVENT Write 1 to this bit to clear VEVENT in INTVECT

5 CPARAINT Write 1 to this bit to clear PARAINT in INTVECT

*PARAL: Parabola interrupt generator register, low byte (Read/Write)

BIT NAME FUNCTION

0 PARA0 PARAINT period register bit 0

1 PARA1 PARAINT period register bit 1

2 PARA2 PARAINT period register bit 2

3 PARA3 PARAINT period register bit 3

4 PARA4 PARAINT period register bit 4

5 PARA5 PARAINT period register bit 5

6 PARA6 PARAINT period register bit 6

7 PARA7 PARAINT period register bit 7

*PARAH: Parabola interrupt generator register, high byte (Read/Write)

BIT NAME FUNCTION

0 PARA8 PARAINT period register bit 8

1 PARA9 PARAINT period register bit 9

2 PARA10 PARAINT period register bit 10

3 PARA11 PARAINT period register bit 11

4 PARA12 PARAINT period register bit 12

Publication Release Date: December 1999

- 13 - Revision A1

Preliminary W78E378/W78C378/W78C374

*SOARL: SOA register, low byte (Read/Write)

BIT NAME FUNCTION

0 SL0 SOA Low register bit 0

1 SL1 SOA Low register bit 1

2 SL2 SOA Low register bit 2

3 SL3 SOA Low register bit 3

4 SL4 SOA Low register bit 4

5 SL5 SOA Low register bit 5

6 (OVL) OVL = 1: current H count larger than SOARL, for test

7 (OVH) OVH = 1: current H count smaller than SOARH, for test

*SOARH: SOA register, high byte (Read/Write)

BIT NAME FUNCTION

0 SH0 SOA High register bit 0

1 SH1 SOA High register bit 1

2 SH2 SOA High register bit 2

3 SH3 SOA High register bit 3

4 SH4 SOA High register bit 4

5 SH5 SOA High register bit 5

6 (ADCSTRT) ADCSTRT bit status, for test

7 (WDTQ10) Watch Dog Timer, bit 10, for test

* ADC

* DAC0~DAC8

* DAC9~DAC10

* WDTCLR

* SOACLR Safe-Operation-Area Clear register, without real hardware but an address.

* DDC1

* S1CON SIO1 control register.

* S1STA SIO1 status register.

* S1DAT SIO1 data register.

* S1ADR1, S1ADR2 SIO1 address registers.

* S2CON SIO2 control register.

* S2STA SIO2 status register.

* S2DAT SIO2 data register.

* S2ADR1, S2ADR2 SIO2 address registers.

Result of the A-to-D conversion.

8-bit PWM static DAC register.

8-bit PWM dynamic DAC register.

Watchdog-timer-clear register, without real hardware but an address.

Writing any value to WDTCLR will clear the watchdog timer.

Writing any value to SOACLR will clear the SOAINT.

DDC1 latch buffer.

- 14 -

Preliminary W78E378/W78C378/W78C374

Modified Timer 0 & Timer 1

OSC 6

T0 pin

(P3.5)

GATE

INT0 pin

(P3.2)

Modified point in Timer 0

(Not divided by 12)

.

.

C/T = 0

To TL0

C/T = 1

TR0

Modified point in Timer 1

(Not divided by 12)

.

6

OSC

T1 pin

(P3.6)

GATE

.

C/T = 0

To TL1

C/T = 1

TR1

Modified point in Timer 1

DD

V

(No INT1 pin)

Publication Release Date: December 1999

- 15 - Revision A1

Preliminary W78E378/W78C378/W78C374

DDC1/SIO1 and SIO2 Ports

1. DDC1/SIO1 port

DDC Port

SIO1

SCL

IN

OUT

SCL

ENDDC1

SDA

Support DDC2B/2B+

DDC1

SDA

SCL

Support DDC1

IN

OUT

0

1

OUT

Vsync

SDA

• ENDDC1 = 1, used as DDC1 (Display Data Channel) port:

To support DDC1, use Vsync signal for shift clock and P3.0 (SDA) for data output.

•

ENDDC1 = 0, used as SIO1 port:

To support DDC2B/2B+/2Bi/2AB, use P3.1 (SCL) for serial clock and P3.0 (SDA) for serial data.

SCLINT interrupt is generated when SCL (P3.1) has a high-to-low transition and then keeps at low for

16 × 1/Fosc.

Fosc 8 MHz 10 MHz

SCL low

2. SIO2 port:

2 µS 1.6 µS

•

To support DDC2B/2B+/2Bi/2AB, use P4.4 (SCL) for serial clock and P4.5 (SDA) for serial data.

DDC1 Port

The DDC1 is a serial output port that supports DDC1 communication. To enable the DDC1 port,

ENDDC1 (bit 3 of CTRL1) should be set to '1'. Once previous eight data bits in the shift register and

one null bit (the 9th bit) are shifted out to the SDA sequentially on each rising edge of the VIN signal,

the DDC1 control circuit loads the next data byte from the latch buffer (the DDC1 register) to the shift

register and generates a DDC1INT signal to the CPU. In the interrupt service routine, the S/W should

fetch the next byte of EDID data and write it to the DDC1 register. If ENDDC1 is cleared, the shift

register is stopped, and the SDA output is kept high. The bit DDC1B9 (bit 4 of CTRL2) decides the 9th

bit in a DDC transmission. If DDC1B9 is set, the 9th bit will be '1', otherwise '0'.

- 16 -

Preliminary W78E378/W78C378/W78C374

To use DDC1 port, a user should pay attention to the following items:

(1) When the chip is powered-on or after reset , the 8-bit shift register in DDC1 H/W contains all 0s. If

you write a data to the latch buffer (the DDC1 register), it will be loaded to the shift register at the

9th clock (on VIN), so from the 10th clock, the real data bit begins to shift out.

(2) Because there is no reset signal to the latch buffer, it contains a random data after power-on. If

you enable DDC1 without writing data to the latch buffer, SDA will have the random data shifted

out after 9 clocks. The shift register is reset to 00H during CPU reset.

(3) The DDC1 H/W has a counter that counts how many bits shifted out. This counter is initialized to 0

when power-up or reset. When you firstly enable DDC1 after power-on, the first bit is already

shifted out without clock, so the first clock triggers the second data bit (D6) to shift out and "0000

0001 1" will be got. After the first 9 clocks that shift out an invalid byte, the counter counts from 1

to 9 cyclically according to the clock pulse on VIN-pin. See the following illustration.

After power on, the

counter count:

0 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 ...

shifted-out data bit:

VIN clock pulse:

(4) The interrupt happens on the failing edge of the following first clock. The next data, which is about

to be shifted out, in the latch buffer is loaded into the shift register at the rising edge of the

following first clock. At the same time, data bit D7 is shifted out and the counter value is "1".

SIO1 Port (with two slave addresses)

The SIO1 port is a serial I/O port, which supports all transfer modes from and to the I2C bus. The

SIO1 port handles byte transfers autonomously. To enable this port, the bit ENDDC1 in CTRL1

should be cleared to '0'. The CPU interfaces to the SIO1 port through the following five special

function registers:

register, DAh) and

I2C bus via two pins: SDA (P3.0, serial clock line) and SCL (P3.1, serial data line). The output latches

of P3.0 and P3.1 must be set to "1" before using this port.

SIO2 Port (with two slave addresses)

The function of this port is the same as SIO1 port. The CPU interfaces to the SIO2 port through the

following five special function registers:

S2DAT

interfaces to the I2C bus via two pins: SDA2 (P4.5, serial clock line) and SCL2 (P4.4, serial data line).

The output latches of P4.5 and P4.4 must be set to "1" before using this port.

(data register, EAh) and

S1ADR1/S1ADR2

0 0 0 0 0 0 0 0 1 1 D7 D6 D5 D4 D3 D2 D1 D0 ack D7 D6 D5 D4 D3 D2 D1 D0 ack …

1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 ...

|--> invalid data |--> normal data

S1CON

(control register, D8h),

(address registers, DBh/DCh). The SIO1 H/W interfaces to the

S2CON

S2ADR1/S2ADR2

S1STA

(control register, E8h),

(address registers, EBh/ECh). The SIO2 H/W

(status register, D9h),

S2STA

(status register, E9h),

S1DAT

(data

Operation of SIO1 Port:

(SIO2 has the same function except their addresses of control registers)

Publication Release Date: December 1999

- 17 - Revision A1

a) Control Registers

Preliminary W78E378/W78C378/W78C374

a-1) The Address Registers, S1ADR1, S1ADR2

The SIO1 is equipped with two address registers: S1ADR1 & S1ADR2. The CPU can read from and

write to these two 8-bit, directly addressable SFRs. The content of these registers are irrelevant when

SIO1 is in master modes. In the slave modes, the seven most significant bits must be loaded with the

MCU's own address. The SIO1 hardware will react if either of the addresses is matched.

7 6 5 4 3 2 1 0

X X X X X X X -

|------------------------ Own Slave Address -----------------------|

a-2) The Data Register, S1DAT

This register contains a byte of serial data to be transmitted or a byte which has just been received.

The CPU can read from or write to this 8-bit directly addressable SFR while it is not in the process of

shifting a byte. This occurs when SIO1 is in a defined state and the serial interrupt flag (SI) is set.

Data in S1DAT remains stable as long as SI is set. While data is being shifted out, data on the bus is

simultaneously being shifted in; S1DAT always contains the last data byte present on the bus. Thus,

in the event of lost arbitration, the transition from master transmitter to slave receiver is made with

the correct data in S1DAT.

7 6 5 4 3 2 1 0

SD7 SD6 SD5 SD4 SD3 SD2 SD1 SD0

|<---------------------------- Shift direction -----------------------------

S1DAT and the acknowledge bit form a 9-bit shift register, the acknowledge bit is controlled by the

SIO1 hardware and cannot be accessed by the CPU. Serial data is shifted through the acknowledge

bit into S1DAT on the rising edges of serial clock pulses on the SCL line. When a byte has been

shifted into S1DAT, the serial data is available in S1DAT, and the acknowledge bit (ACK or NACK) is

returned by the control logic during the ninth clock pulse. Serial data is shifted out from S1DAT on the

falling edges of SCL clock pulses, and is shifted into S1DAT on the rising edges of SCL clock pulses.

a-3) The Control Register, S1CON

The CPU can read from and write to this 8-bit, directly addressable SFR. Two bits are affected by the

SIO1 hardware: the SI bit is set when a serial interrupt is requested, and the STO bit is cleared when

a STOP condition is present on the bus. The STO bit is also cleared when ENS1 = "0".

7 6 5 4 3 2 1 0

CR2 ENS1 STA STO SI AA CR1 CR0

ENS1, the SIO1 Enable Bit

ENS1 = "0": When ENS1 is "0", the SDA and SCL outputs are in a high impedance state. SDA and

SCL input signals are ignored, SIO1 is in the not addressed slave state, and STO bit in S1CON is

forced to "0". No other bits are affected. P3.0 (SDA) and P3.1 (SCL) may be used as open drain I/O

ports.

ENS1 = "1": When ENS1 is "1", SIO1 is enabled. The P3.0 and P3.1 port latches must be set to logic

1.

- 18 -

Preliminary W78E378/W78C378/W78C374

STA, the START Flag

STA = "1": When the STA bit is set to enter a master mode, the SIO1 hardware checks the status of

I2C bus and generates a START condition if the bus is free. If the bus is not free, then SIO1 waits for

a STOP condition and generates a START condition after a delay. If STA is set while SIO1 is already

in a master mode and one or more bytes are transmitted or received, SIO1 transmits a repeated

START condition. STA may be set at any time. STA may also be set when SIO1 is an addressed

slave.

STA = "0": When the STA bit is reset, no START condition or repeated START condition will be

generated.

STO, the STOP Flag

STO = "0": When the STO bit is set while SIO1 is in a master mode, a STOP condition is transmitted

to the I2C bus. When the STOP condition is detected on the bus, the SIO1 hardware clears the STO

flag. In a slave mode, the STO flag may be set to recover from an bus error condition. In this case, no

STOP condition is transmitted to the I2C bus. However, the SIO1 hardware behaves as if a STOP

condition has been received and switches to the defined not addressed slave receiver mode. The

STO flag is automatically cleared by hardware. If the STA and STO bits are both set, then a STOP

condition is transmitted to the I2C bus if SIO1 is in a master mode (in a slave mode, SIO1 generates

an internal STOP condition which is not transmitted). SIO1 then transmits a START condition.

SI, the Serial Interrupt Flag

SI = "1": When a new SIO1 state is present in the S1STA register, the SI flag is set by hardware, and,

if the EA and ES bits (in IE register) are both set, a serial interrupt is requested. The only state that

does not cause SI to be set is state F8H, which indicates that no relevant state information is

available. When SI is set, the low period of the serial clock on the SCL line is stretched, and the serial

transfer is suspended. A high level on the SCL line is unaffected by the serial interrupt flag. SI must

be cleared by software.

SI = "0": When the SI flag is reset, no serial interrupt is requested, and there is no stretching on the

serial clock on the SCL line.

AA, the Assert Acknowledge Flag

AA = "1": If the AA flag is set, an acknowledge (low level to SDA) will be returned during the

acknowledge clock pulse on the SCL line when: 1) The own slave address has been received. 2) A

data byte has been received while SIO1 is in the master receiver mode. 3) A data byte has been

received while SIO1 is in the addressed slave receiver mode.

AA = "0": If the AA flag is reset, a not acknowledge (high level to SDA) will be returned during the

acknowledge clock pulse on SCL when: 1) A data has been received while SIO1 is in the master

receiver mode. 2) A data byte has been received while SIO1 is in the addressed slave receiver mode.

CR0, CR1 and CR2, the Clock Rate Bits

These three bits determine the serial clock frequency when SIO1 is in a master mode. It is not

important when SIO1 is in a slave mode. In the slave modes, SIO1 will automatically synchronize

with any clock frequency up to 100 KHz.

Publication Release Date: December 1999

- 19 - Revision A1

Preliminary W78E378/W78C378/W78C374

Bit Freq. (KHz) @Fosc

CR2 CR1 CR0 8 MHz 10 MHz Fosc Divided

By

0 0 0 31.25 39.1 256

0 0 1 35.7 44.6 224

0 1 0 41.7 52.1 192

0 1 1 50.0 62.5 160

1 0 0 8.3 10.4 960

1 0 1 66.7 83.3 120

1 1 0 133.3 166.7 60

a-4) The Status Register, S1STA

S1STA is an 8-bit read-only register. The three least significant bits are always 0. The five most

significant bits contain the status code. There are 23 possible status codes. When S1STA contains

F8H, no serial interrupt is requested. All other S1STA values correspond to defined SIO1 states.

When each of these states is entered, a status interrupt is requested (SI = 1). A valid status code is

present in S1STA one machine cycle after SI is set by hardware and is still present one machine

cycle after SI has been reset by software.

In addition, state 00H stands for a Bus Error. A Bus Error occurs when a START or STOP condition is

present at an illegal position in the format frame. Examples of illegal positions are during the serial

transfer of an address byte, a data byte or an acknowledge bit.

b) Operating Modes

The four operating modes are: Master/Transmitter, Master/Receiver, Slave/Transmitter and

Slave/Receiver. Bits STA, STO and AA in S1CON decide the next action the SIO1 hardware will take

after SI is cleared. When the next action is completed, a new status code in S1STA will be updated

and SI will be set by hardware in the same time. Now, the interrupt service routine is entered (if the

SI_interrupt is enabled), the new status code can be used to decide which appropriate service routine

the software is to branch. Data transfers in each mode are shown in the following figures.

*** Legend for the following four figures:

Last state

Last action is done

Next setting in S1CON

Expected next action

New state

Next action is done

08H

A START has been

transmitted.

(STA,STO,SI,AA)=(0,0,0,X)

SLA+W will be transmitted;

ACK bit will be received.

18H

SLA+W has been transmitted;

ACK has been received.

Software's access to S1DAT with respect to "Expected next action":

1) "Data byte will be transmitted":

Software should load the data byte (to be transmitted) into S1DAT

before new S1CON setting is done.

2) "SLA+W (R) will be transmitted":

Software should load the SLA+W/R (to be transmitted) into S1DAT

before new S1CON setting is done.

3) "Data byte will be received":

Software can read the received data byte from S1DAT

while a new state is entered.

- 20 -

Preliminary W78E378/W78C378/W78C374

Master/Transmitter Mode

(STA,STO,SI,AA)=(0,0,0,X)

Data byte will be transmitted;

ACK will be received.

28H

Data byte in S1DAT has been transmitted;

ACK has been received.

or

30H

Data byte in S1DAT has been transmitted;

NOT ACK has been received.

From Slave Mode (C)

(STA,STO,SI,AA)=(1,0,0,X)

A repeated START will be transmitted.

10H

A repeated START has been

transmitted.

Set STA to generate

a START.

08H

A START has been

transmitted.

(STA,STO,SI,AA)=(0,0,0,X)

SLA+W will be transmitted;

ACK bit will be received.

18H

SLA+W has been transmitted;

ACK has been received.

or

20H

SLA+W has been transmitted;

NOT ACK has been received.

(STA,STO,SI,AA)=(0,1,0,X)

A STOP will be transmitted;

STO flag will be reset.

From Master/Receiver (B)

(STA,STO,SI,AA)=(1,1,0,X)

A STOP followed by a START will be

transmitted;

STO flag will be reset.

Send a STOP Send a STOP

followed by a START

(STA,STO,SI,AA)=(0,0,0,X)

SLA+R will be transmitted;

ACK bit will be received;

SIO1 will be switched to MST/REC mode.

To Master/Receiver (A)

- 21 - Revision A1

38H

Arbitration lost in SLA+R/W

or Data bytes.

(STA,STO,SI,AA)=(0,0,0,X)

I2C bus will be released;

Not addressed SLV mode will be entered.

Enter NAslave Send a START

Publication Release Date: December 1999

(STA,STO,SI,AA)=(1,0,0,X)

A START will be transmitted when

the bus becomes free.

when bus becomes free

Preliminary W78E378/W78C378/W78C374

Master/Receiver Mode

From Master/Transmitter (A)

48H

SLA+R has been transmitted;

NOT ACK has been received.

Set STA to generate

a START.

08H

A START has been

transmitted.

(STA,STO,SI,AA)=(0,0,0,X)

SLA+R will be transmitted;

ACK will be received.

From Slave Mode (C)

40H

SLA+R has been transmitted;

ACK has been received.

(STA,STO,SI,AA)=(0,0,0,0)

Data byte will be received;

NOT ACK will be returned.

58H

Data byte has been received;

NOT ACK has been returned.

(STA,STO,SI,AA)=(0,0,0,1)

Data byte will be received;

ACK will be returned.

50H

Data byte has been received;

ACK has been returned.

(STA,STO,SI,AA)=(1,1,0,X)

A STOP followed by a START will

be transmitted;

STO flag will be reset.

Send a STOP

followed by a START

38H

Arbitration lost in NOT ACK bit.

(STA,STO,SI,AA)=(1,0,0,X)

A START will be transmitted

when the bus becomes free.

Send a START

when bus becomes free

(STA,STO,SI,AA)=(0,1,0,X)

A STOP will be transmitted;

STO flag will be reset.

Send a STOP

(STA,STO,SI,AA)=(0,0,0,X)

I2C bus will be released;

Not addressed SLV mode will be entered.

Enter NAslave

- 22 -

(STA,STO,SI,AA)=(1,0,0,X)

A repeated START will be transmitted.

10H

A repeated START has been

transmitted.

(STA,STO,SI,AA)=(0,0,0,X)

SLA+W will be transmitted;

ACK will be received;

SIO1 will be switched to MST/TRX mode.

To Master/Transmitter (B)

Preliminary W78E378/W78C378/W78C374

Slave/Transmitter Mode

C8H

Last data byte in S1DAT has been transmitted;

ACK has been received.

(STA,STO,SI,AA)=(0,0,0,0)

Last data byte will be transmitted;

ACK will be received.

C0H

Data byte or Last data byte in S1DAT has

been transmitted;

NOT ACK has been received.

Set AA

A8H

Own SLA+R has been received;

ACK has been returned.

or

B0H

Arbitration lost in SLA+R/W as master;

Own SLA+R has been received;

ACK has been returned.

(STA,STO,SI,AA)=(0,0,0,1)

Data byte will be transmitted;

ACK will be received.

B8H

Data byte in S1DAT has been transmitted;

ACK has been received.

(STA,STO,SI,AA)=(0,0,0,0)

Last data byte will be transmitted;

ACK will be received.

(STA,STO,SI,AA)=(0,0,0,1)

Data byte will be transmitted;

ACK will be received.

(STA,STO,SI,AA)=(1,0,0,1)

Switch to not addressed SLV mode;

Own SLA will be recognized;

A START will be transmitted when

the bus becomes free.

Send a START

when bus becomes free

To Master Mode (C)

(STA,STO,SI,AA)=(1,0,0,0)

Switch to not addressed SLV mode;

No recognition of own SLA;

A START will be transmitted when

the bus becomes free.

(STA,STO,SI,AA)=(0,0,0,1)

Switch to not addressed SLV mode;

Own SLA will be recognized.

Enter NAslave

`

(STA,STO,SI,AA)=(0,0,0,0)

Switch to not addressed SLV mode;

No recognition of own SLA.

Publication Release Date: December 1999

- 23 - Revision A1

Preliminary W78E378/W78C378/W78C374

Slave/Receiver Mode

A0H

A STOP or repeated START has been

received while still addressed as SLV/REC.

(STA,STO,SI,AA)=(0,0,0,0)

Data byte will be received;

NOT ACK will be returned.

88H

Previously addressed with own SLA address;

Data has been received;

NOT ACK has been returned.

Set AA

60H

Own SLA+W has been received;

ACK has been returned.

or

68H

Arbitration lost in SLA+R/W as master;

Own SLA+W has been received;

ACK has been returned.

(STA,STO,SI,AA)=(0,0,0,0)

Data will be received;

NOT ACK will be returned.

(STA,STO,SI,AA)=(0,0,0,1)

Data byte will be received;

ACK will be returned.

80H

Previously addressed with own SLA address;

Data has been received;

ACK has been returned.

(STA,STO,SI,AA)=(0,0,0,1)

Data will be received;

ACK will be returned.

(STA,STO,SI,AA)=(1,0,0,1)

Switch to not addressed SLV mode;

Own SLA will be recognized;

A START will be transmitted when

the bus becomes free.

Send a START

when bus becomes free

To Master Mode (C)

(STA,STO,SI,AA)=(1,0,0,0)

Switch to not addressed SLV mode;

No recognition of own SLA;

A START will be transmitted when

the bus becomes free.

- 24 -

(STA,STO,SI,AA)=(0,0,0,1)

Switch to not addressed SLV mode;

Own SLA will be recognized.

(STA,STO,SI,AA)=(0,0,0,0)

Switch to not addressed SLV mode;

No recognition of own SLA.

Enter NAslave

`

Preliminary W78E378/W78C378/W78C374

Parabola Interrupt Generator

The parabola interrupt generator is a 13-bit auto-reload timer, which generates an interrupt to the

CPU periodically for software to load the parabola waveform data to the dynamic DACs

(DAC8−DAC10). The software should calculate the value of the PARAH and PARAL registers by:

(Vcount × 16) ÷ segment number. The segment number is the number of integration segments

between two Vsync pulses. The interrupt interval is programmable:

•

Time base = 1/Fosc

•

Programmable interrupt period = Time base × (PARAH × 256 + PARAL + 1)

•

Maximum period = Time base × 8192

Note: Zero value in [PARAH, PARAL] is inhibited.

A-to-D Converter

(ref. Application Note in Appendix A.)

One 4-bit Analog-to-Digital Converter.

• Conversion time = (6/Fosc) × 128 sec.

• 7 channels selected by an analog multiplexer

(ADCS2, ADCS1, ADCS0) (0, 0, 0) (0, 0, 1) (0, 1, 0) (0, 1, 1) (1, 0, 0) (1, 0, 1) (1, 1, 0)

Selected Channel ADC0 ADC1 ADC2 ADC3 ADC4 ADC5 ADC6

The conversion of the ADC is started by setting bit ADCSTRT in CTRL1 by software. When the

conversion is completed, the ADCSTRT bit is cleared by hardware automatically, and the ADCINT bit

in INTVECT is set by hardware at the same time if MADCINT in INTMSK is set.

PWM DACs

Eight 8-bit Static DACs: DAC0−DAC7

•

The PWM frequency F

•

The duty cycle of the PWM output = Register value ÷ 255

•

The DC voltage after the low pass filter = V

PWM

= Fosc ÷ 255

CC

×

duty cycle

Static DAC application circuit:

Low-pass filter

Static DAC

R

C

- 25 - Revision A1

V

OUTPUT

T = RC

V

OUTPUT

= V

¡Ñ

n/255, if T >> T

CC

PWM

Publication Release Date: December 1999

Preliminary W78E378/W78C378/W78C374

Three 8-bit Dynamic DACs: DAC8−DAC10

The dynamic DACs are especially used to generate parabola waveform for geometric compensation,

or to be used as static DACs. Dynamic DAC application circuit:

10K

4.7u/16V

470

100K

10K

0.022u

470

10u/50V

470

V

output

Dynamic DAC

+Vsync

VDD

The following types of distoration can be compensated:

1. H size distortion:

a. PinCushion Correction (Amplitude)

b. Trapezoid (Keystone)

25%

c. CBOW (Quarter Width)

25%

d. PinCushion Correction (Corner)

e. S Curve

The PCC amplitude can be compensated against V size adjustment automatically.

The Trapzoid can be compensated against V center adjustment automatically.

2. H center distortion:

a. Pin balance (Bow)

b. Key balance (Tilt)

c. Corner balance

- 26 -

Preliminary W78E378/W78C378/W78C374

Sync Processor

Polarity Detector

The H/V polarity is detected automatically and can be known from HPOL bit (HFCOUNTH.7) and

VPOL bit (VFCOUNTH.7).

Fosc 10 MHz

Max. H+V width

Max. V width

Sync Separator

The Vsync is separated from the composite sync automatically, without any software effort.

Fosc 10 MHz

Min. V width & Max. H width

Horizontal & Vertical Frequency Counter

There are two 12-bit counters which can count H and V frequency automatically. When VEVENT

(Vsync frequency counter timeout) interrupt happens, the count value values are latched into the

counter registers (HFCOUNTH, HFCOUNTL, VFCOUNTH and VFCOUNTL). And then the S/W may

read the count value (H

COUNT

and V

frequency by the formulas listed below.

(64/Fosc) × 62 (counter overflow) = 396.8 µS

(2048/Fosc) × 2 = 409.6 µS

(1/Fosc) × 64 = 6.4 µS

) from the counter registers to calculate the H and V

COUNT

V frequency:

The resolution of V frequency counter: V

The V frequency: V

RESOL

= (1/Fosc) × 64.

FREQ

= 1/(V

COUNT

×

V

RESOL

).

The lowest V frequency can be detected: Fosc ÷ 262144. (38.1Hz @Fosc =10 MHz)

H frequency:

The resolution of H frequency counter: H

The H frequency: H

RESOL

= (1/Fosc) ÷ 8.

FREQ

= 1/(H

COUNT

×

RESOL

H

).

The lowest H frequency can be detected: Fosc ÷ 512. (19.5 KHz @Fosc = 10 MHz)

Dummy Frequency Generator

The Dummy H and V frequencies are generated for factory burn-in or showing warning message

while there are no input frequency.

(HDUMS1, HDUMS0) (0, 0) (0, 1) (1, 0) (1, 1)

dummyH

F

Hsync width

Fosc/(8 × 4 × 8) Fosc/(8 × 2 × 8) Fosc/(8 × 3 × 8) Fosc/(8 × 5 × 8)

(8 × 4)/Fosc (8 × 2)/Fosc (8 × 3)/Fosc (8 × 5)/Fosc

VDUMS 0 1

dummyV

F

F

Vsync width 8/ F

dummyH

dummyH

/ 512 F

16/ F

dummyH

dummyH

/1024

Publication Release Date: December 1999

- 27 - Revision A1

Preliminary W78E378/W78C378/W78C374

1/FdummyH

Hsync width

Hdummy

Vdummy

Vsync width

For Fosc = 10 MHz:

(HDUMS1,

(0, 1) (1, 0) (0, 0) (1, 1)

HDUMS0)

dummyH

F

Hsync width

VDUMS

F

dummyV

78.125 KHz 52.083 KHz 39.063 KHz 31.250 KHz

1.6 µS 2.4 µS 3.2 µS 4.0 µS

0 1 0 1 0 1 0 1

152.6 Hz 76.3 Hz 101.7 Hz 50.9 Hz 76.3 Hz 38.1 Hz 61.0 Hz 30.5 Hz

H-clamp Pulse Generator

1. Leading edge/Trailing edge selectable.

* HCES = 0: select leading edge

* HCES = 1: select trailing edge

..... .....

..... .....

1/FdummyV

.....

.....

Negative polarity Hsync Postive polarity Hsync

HsyncHsync

Hclamp

(Leading-edge)

Hclamp

(Trailing-edge)

Hclamp

(Leading-edge)

Hclamp

(Trailing-edge)

- 28 -

Preliminary W78E378/W78C378/W78C374

2. Pulse width selectable.

For Fosc = 10 MHz:

HCWS = 0 HCWS = 1

Pulse Width

Safe Operation Area (SOA) Interrupt

500−600 nS 900−1000 nS

Upper boundary frequency = F

Lower boundary frequency = F

Function description:

•

If the condition, H

happens twice continuously, the SOAINT will be activated.

•

If the HIN is stopped for a certain period, the SOAINT will also be generated.

The no Hsync response time is 512/F

•

If SOAHDIS = 1, then no upper boundary frequency.

Half Hsync Output

When ENHFO (bit 0 of CTRL3) is set, P4.7 (HFO) will output the same or half frequency from P4.0

(HFI). The divide-by-two operation is done at the falling edge of HFI signal when HFO_HALF (bit 3 of

CTRL3) is set. The polarity of HFO is specified by HF_POL (bit 2 of CTRL3).

lower than the lower boundary freq. or higher than the upper boundary freq.,

FREQ

HFI

HFO

(HFO_HALF=0)

(HF_POL=1)

/ [8 × SOARH]

OSC

/ [8 × (SOARL + 1)]

OSC

. (e.x., 51.2us for 10 MHz)

OSC

HFO

(HFO_HALF=0)

(HF_POL=0)

HFO

(HFO_HALF=1)

Publication Release Date: December 1999

- 29 - Revision A1

Preliminary W78E378/W78C378/W78C374

Interrupts

The five interrupt sources are listed as below.

SOURCE VECTOR ADDRESS

1 IE0 0003H Interrupt 0 edge detected Highest

2 TF0 000BH Timer 0 overflow

3 IE1 0013H Miscellaneous interrupts*1

4 TF1 001BH Timer 1 overflow

5 SI1+SI2 002BH SIO1 or SIO2 interrupt Lowest

Note: *1: SCLINT + ADCINT + DDC1INT + SOAINT + VEVENT + PARAINT.

The miscellaneous interrupts at vector address 0013H is driven by the following six sources, which

are:

(1) SCLINT: when high-to-low transition on SCL-pin,

(2) ADCINT: when A-to-D conversion completion,

(3) DDC1INT: when DDC1 data byte transmitted (after 9 clock pulses from VIN) in the DDC port,

(4) SOAINT: when SOA activated,

(5) VEVENT: on every Vsync pulse or vertical frequency counter overflow,

(6) PARAINT: when parabola timer timeout.

If IE1 interrupt occurs, it is necessary for the programmer to read the INTVECT register to tell where

the interrupt request comes. These sources can be masked individually by clearing their

corresponding bits in the INTMSK register. To clear any of these interrupt flags, just write a '1' to the

corresponding bit in the INTCLR.

The interrupt enable bits and priority control bits for these five main sources are listed as below.

DESCRIPTON PRIORITY WITHIN A LEVEL

INTERRUPT FLAG ENABLE BIT PRIORITY CONTROL BIT

1 IE0 IE.0 & IE.7 IP.0

2 TF0 IE.1 & IE.7 IP.1

3 IE1 IE.2 & IE.7 IP.2

4 TF1 IE.3 & IE.7 IP.3

5 SI+SI2 IE.5 & IE.7 IP.5

- 30 -

Preliminary W78E378/W78C378/W78C374

Vector Address

IE0

TF0

IE1

TF1

SI1+SI2

SCL Interrupt

ADC Interrupt

DDC1 Interrupt

SOA Interrupt

VEVENT Interrupt

PARA Interrupt

IE

0003H

000BH

IE.0

IE.1

0013H

IE.2

001BH

002BH

IE.3

IE.5

IE.7

INTMSK INTVECT

Bit 0

Bit 1

Bit 2

Bit 3

Bit 4

Bit 5

SCLINT

0

ADCINT

1

DDC1INT

2

SOAINT

3

VEVENT

4

PARAINT

5

IP

IP.0

IP.1

IP.2

IP.3

IP.5

High Priority

Low Priority

Interrupt Polling

Sequence

0

IT1

1

IE1

Publication Release Date: December 1999

- 31 - Revision A1

Preliminary W78E378/W78C378/W78C374

RESET

Reset Circuit- Power-low Detector & Watchdog Timer

The reset signals come from the following three sources:

1. External reset input (active low)

2. Power low detect

3. Hardware Watchdog Timer

.

3.5V

for above 10

The power-low detection circuit generates a reset signal once the VCC falls below

µ

S or falls below

1.8V

, and the reset signal is released after VCC goes up to

4.3V

4.3V

3.8V

1.8V

VCC

Power-low Reset

10uS

The purpose of a watchdog timer is to reset the CPU if the user program fails to reload the watchdog

timer within a reasonable period of time known as the "watchdog interval". The clock source of the

watchdog timer comes from the internal system clock. It can be enabled/disabled by set/clear

WDTEN (bit 5 of CTRL2). For debug purpose, if the WDT reset or power low reset occur, the

pin will be pulled low internally. The pulled-low duration due to WDT reset is about 60/Fosc sec. The

block diagram of the reset circuitry is shown as below.

R:100K

C:0.01u

External Reset

/RESET

Watchdog

Timer

WDTEN

Iol=12mA @Vol=0.45V

EN

Power-low

Supervisor

- 32 -

Reset Logic

Preliminary W78E378/W78C378/W78C374

RESET

RESET

ELECTRICAL CHARACTERISTICS

Absolute Maximum Ratings

PARAMETER SYMBOL MIN. MAX. UNIT

DC Power Supply V

Input Voltage V

Input Current I

Operating Temperature T

Storage Temperature

Note: Exposure to conditions beyond those listed under Absolute Maximum Ratings may adversely affect the life and reliability of the

device.

D.C. Characteristics

VDD-VSS= 5V ± 10%, TA = 25°C, Fosc = 10 MHz, unless otherwise specified.

DD

IN

IN

A

TST

-0.3 +7.0 V

VSS -0.3 VDD +0.3 V

-100 +100 mA

0 70

-55 150

°C

°

C

PARAMETER SYM.

MIN. TYP. MAX.

SPECIFICATION UNIT

TEST CONDITIONS

Operating Voltage VDD 4.5 5 5.5 V All function must pass!

Operating Current IDD - - 30 mA No load, VDD = 5.5V

Power-down Current IPD - - 100

µ

No load, VDD = 5.5V

A

Input

Input Current

P2, P3.2−P3.4, P4.0

Input Current

Input Leakage Current

P1, P2.4−P2.7(

S.F. enabled)

IN1

I

-75

-10

IN2

I

-300

-10

ILK -10 - +10

-

-

-

-

-10

+10

-100

+10

VDD = 5.5V, V

µ

A

VDD = 5.5V, VIN = 5.5V

VDD = 5.5V, VIN = 0V

µ

A

VDD = 5.5V, VIN = 5.5V

µA

VDD = 5.5V, 0V<VIN<

VDD

IN

= 0V

P3.0, P3.1, P3.5−P3.7,

P4.4, P4.5 HIN, VIN

Logical 1-to-0 Transition

Current

ITL -650 - -100

µ

VDD = 5.5V, V

A

IN

= 2.0V

P2, P3.2−P3.4

Input Low Voltage

IL1

V

0 - 0.8 V VDD = 4.5V

P1, P2, P3 (except P3.0 &

P3.1), P4.0, HIN, VIN,

, OSCIN

Publication Release Date: December 1999

- 33 - Revision A1

Preliminary W78E378/W78C378/W78C374

RESET

D.C. Characteristics, continued

PARAMETER SYM.

Input Low Voltage

MIN. TYP. MAX.

IL2

V

P3.0, P3.1, P4.4, P4.5

Input High Voltage

IH1

V

P1, P2, P3 (except P3.0 &

P3.1), P4.0, HIN, VIN,

Input High Voltage

RESET

IH2

V

P3.0, P3.1, P4.4, P4.5

Input High Voltage

IH3

V

OSCIN

Output

Output Low Voltage

P1.0, P1.1,

Output Low Voltage

V

OL1

V

OL2

P3.0, P3.1, P4.4, P4.5

Output Low Voltage

V

OL3

P1 (except P1.0 & P1.1)

P2, P3 (except P3.0−P3.2)

P4 (except P4.4 & P4.5)

Output Low Voltage

V

OL4

P3.2, OSCOUT

Output High Voltage

V

OH1

P2, P3.2−P3.4

Output High Voltage

V

OH2

P4 (except P4.4 & P4.5)

Special Function Output

V

OH3

High Voltage

P2.0−P2.3, P3.3, P3.4

Output High Voltage

V

OH4

OSCOUT

Notes:

*1.

*2. P2 and P3.2−P3.4 can source a transition current when they are being externally driven from 1 to 0. The transition current

reaches its maximum value when VIN is approximately 2V.

*3. P3.0, P3.1, P4.4, P4.5, HIN, VIN and

has an internal pull-up resistor of about 30 KΩ.

RESET

RESET

SPECIFICATION UNIT

0 - 0.3

V VDD = 4.5V

TEST CONDITIONS

VDD

2.0 - V

DD

V VDD = 5.5V

+0.2

0.7

- V

VDD

3.5 - VDD

DD

+0.2

V VDD = 5.5V

V VDD = 5.5V

+0.2

- - 0.45 V VDD = 4.5V

OL

I

= +12 mA

- - 0.45 V VDD = 4.5V

OL

I

= +8 mA

- - 0.45 V VDD = 4.5V

OL

I

= +4 mA

- - 0.45 V VDD = 4.5V

OL

I

= +0.8 mA

2.4 - - V VDD = 4.5V

OH

I

= -100 µA

2.4 - - V VDD = 4.5V

OH

I

= -4 mA

2.4 - - V VDD = 4.5V

OH

I

= -4 mA

2.4 - - V VDD = 4.5V

OH

I

= -3 mA

are Schmitt trigger inputs.

- 34 -

Preliminary W78E378/W78C378/W78C374

ADC input voltage

Appendix A. Application Note for Usage of ADC

To use the ADC, users should pay attention to the following points:

(1) According to the absolute maximum ratings, the input voltage should not exceed V

especially for the ADC channel pins (P2.4−P2.7 & P3.5−P3.7). If a voltage over V

on any of these ADC channel pins, the AD conversion will fail.

(2) Owing to the CMOS process, the ADC curve of some chip might differ from those of the others.

So, before using the ADC, the S/W should do the ADC calibration described below.

Step 1. Set (ADCS2, ADCS1, ADCS0, ADCcal) = (1, 1, 1, 0) and then do AD coversion to get

the ADC value for the on-chip

0.948V

input. Suppose it is A.

Step 2. Set (ADCS2, ADCS1, ADCS0, ADCcal) = (1, 1, 1, 1) and then do AD coversion to get

the ADC value for the on-chip

2.924V

input. Suppose it is B.

Step 3. Because the ADC curve in the usable range is linear, any V and X should meet the

formula:

(X-A)/(V-0.948) = (B-A)/(2.924-0.948),

where V is the key voltage (designed by users and thus known) and X is its predicted

ADC value. Then, we can get X = A + (V-0.948)(B-A)/(2.924-0.948), regardless of V >

0.948V or < 0.948V. (

Of course, some effort should be paid in S/W to find X.)

Step 4. Suppose there are N keys used, the N predicted ADC values for these keys can be

found.

DD

DD

+0.3V exists

+0.3V,

ADC value

B

X

A

1.0 2.0 3.0 4.0 5.0

V

Usable range

(is linear)

After finding these N predicted ADC values, the S/W can recognize which key is pressed by

comparing the ADC value of this key with the set of predicted values (found previously).

** Note: To get the exact on-chip calibration voltages (0.948V and 2.924V), the VDD should be 5.0V as close as possible.

Publication Release Date: December 1999

- 35 - Revision A1

Preliminary W78E378/W78C378/W78C374

Test strategy before shipping:

(1) Vi = 0V => ADC < 20

(2) Vi = 0.8V => ADC > 25

(3) Vi = 3.2V => ADC < 248

(4) Vi = 4.4V => ADC = 255

(5) 0.8V < Vi < 3.2V, 25 points (step 0.1V) will be tested. All test points should be recognized

correctly.

Comment:

a. (1) guarantees 0V input can be recognized (ADC value < 20).

b. (4) guarantees 5V input can be recognized (ADC value = 255).

c. (2), (3) and (5) guarantee linear (with 4 bits at least) within the usable range (0.8V to 3.2V).

25

20

ADC value

0.8

Usable range

248

3.2

4.4

Analog voltage (V)

- 36 -

Preliminary W78E378/W78C378/W78C374

3. Dimensions D & E1 include mold mismatch and

6. General appearance spec. should be based on

A

PACKAGE DIMENSIONS

32-pin P-DIP

32

E

1

1

S

2

A

A

L

D

B

1e

1B

Dimension in inches Dimension in mm

Symbol

17

16

1A

Base Plane

Seating Plane

E

e

a

Notes:

1. Dimensions D Max. & S include mold flash or

c

2. Dimension E1 does not include interlead flash.

4. Dimension B1 does not include dambar

5. Controlling dimension: Inches

Nom.

Min.

A

0.010

A

1

0.150

0.155

A

2

0.016

0.018

B

0.050 1.27

B

1

0.010

c

0.008

1.650 1.660 41.91 42.16

D

0.6000.590 0.610

E

E1

e

1

0.120

0.130

L

0 15

a

0.6500.630 16.00 16.51

e

A

S

Nom.

Max. Max.

Min.

0.210

0.25

0.160

3.81

3.94

0.41

0.46

0.022

0.0540.048

0.20

0.014

0.25

15.2414.99

13.84

13.97

0.5550.5500.545

0.110

2.29 2.54 2.790.090 0.100

0.140

3.05

3.30

0.670

0.085

tie bar burrs.

are determined at the mold parting line.

protrusion/intrusion.

final visual inspection spec.

5.33

4.06

0.56

1.371.22

0.36

15.49

14.10

3.56

17.02

2.16

150

40-pin DIP

40 21

1

E

1

S

A

2

A

L

Dimension in inch Dimension in mm

Symbol

Min. Nom. Max. Max.Nom.Min.

A

0.010

1

A

0.150

A

2

0.016

B

1

B

0.008

D

20

Base Plane

1

A

B

e

1

B

1

Seating Plane

E

eA

a

c

D

E

0.540

E1

e

1

0.120

L

a

0.630 16.00

A

e

S

Notes:

1. Dimension D Max. & S include mold flash or

tie bar burrs.

c

2. Dimension E1 does not include interlead flash.

3. Dimension D & E1 include mold mismatch and

are determined at the mold parting line.

4. Dimension B1 does not include dambar

protrusion/intrusion.

5. Controlling dimension: Inches.

6. General appearance spec. should be based on

final visual inspection spec.

0.210

0.155

0.160

0.018

0.022

0.050 1.27

0.0540.048

0.010

0.014

2.055 2.070

0.610

0.6000.590

0.545

0.550

0.110

0.130

0.140

0 15

0.670

0.650

0.090

.

0.254

3.81

0.406

0.203

14.986

13.72

2.286 2.54 2.7940.090 0.100

3.048

3.937

0.457

0.254

52.20

15.24

3.302

16.51

5.334

4.064

0.559

1.3721.219

0.356

52.58

15.494

13.9713.84

3.556

17.01

2.286

150

Publication Release Date: December 1999

- 37 - Revision A1

Package Dimensions, continued

44-pin PLCC

D

H

6 1

7

17

L

θ

Seating Plane

D

e

DG

Preliminary W78E378/W78C378/W78C374

44 40

b

b

1

39

E

E H

29

2818

2

A

A

1

A

y

E

G

c

Dimension in inches Dimension in mm

Symbol

Min. Nom.

A

0.020

1

A

0.145

A

2

0.026

b 1

0.016

b

0.008

c

0.648

D

E

e

0.590

D

G

0.590

E

G

0.680

D

H

0.680

H E

0.090

L

y

Notes:

1. Dimension D & E do not include interlead flash.

2. Dimension b1 does not include dambar

protrusion/intrusion.

3. Controlling dimension: Inches

4. General appearance spec. should be based

on final visual inspection spec.

0.050

0.150

0.028

0.018

0.010

0.653

0.610

0.690

0.690

0.100

BSC

Max.

0.185

0.155

0.032

0.022

0.014

0.658

0.6580.6530.648

0.630

0.6300.610

0.700

0.700

0.110

0.004

0.51

3.68

0.66

0.41

0.20

16.46

14.99

17.27

17.27

2.29

1.27

Nom.Min.

3.81

0.71

0.46

0.25

16.59

15.49

17.53

2.54

BSC

Max.

4.70

3.94

0.81

0.56

0.36

16.71

16.7116.5916.46

16.00

16.0015.4914.99

17.78

17.7817.53

2.79

0.10

Headquarters

No. 4, Creation Rd. III,

Science-Based Industrial Park,

Hsinchu, Taiwan

TEL: 886-3-5770066

FAX: 886-3-5792766

http://www.winbond.com.tw/

Voice & Fax-on-demand: 886-2-27197006

Winbond Electronics (H.K.) Ltd.

Rm. 803, World Trade Square, Tower II,

123 Hoi Bun Rd., Kwun Tong,

Kowloon, Hong Kong

TEL: 852-27513100

FAX: 852-27552064

Taipei Office

11F, No. 115, Sec. 3, Min-Sheng East Rd.,

Taipei, Taiwan

TEL: 886-2-27190505

FAX: 886-2-27197502

Note: All data and specifications are subject to change without notice.

Winbond Electronics North America Corp.

Winbond Memory Lab.

Winbond Microelectronics Corp.

Winbond Systems Lab.

2727 N. First Street, San Jose,

CA 95134, U.S.A.

TEL: 408-9436666

FAX: 408-5441798

- 38 -

Loading...

Loading...