Page 1

Operating Instructions

& Service Parts Manual

Hydraulic

Strut Cutter

# ESP1100

Record purchase information for quick reference:

427 New Sanford Road

LaVergne, Tennessee 37086

Ph.: 800-373-8206

www.wiltontools.com

WILTON

Manual No. M-ESP1100

Edition 2

04/2017

Copyright © 2017 WILTON

Page 2

1.0 IMPORTANT SAFETY INSTRUCTIONS

WARNING – To reduce risk of injury:

1. Read and understand all warnings posted on

the tool and in this manual. Failure to comply

with all of these warnings may c ause serious

injury.

2. Do not use this strut cutter for other than its

intended use.

3. Replace warning labels if they become

obscured or removed.

4. Make sure the Wilton Strut Cutter is properly

supported by the rods or handle pieces, so

that it will not tip over during use.

5. Keep ground or floor around the tool

uncluttered and free of scrap material, oil and

grease. Wear non-slip footwear.

6. Always wear protective eye wear when

operating machinery. Eye wear shall be

impact resistant, protective safety glasses

with side shields which comply with ANSI

Z87.1 specifications. Use of eye wear which

does not comply with ANSI Z87.1

specifications could result in severe injury

from breakage of eye protection.

7. Wear gloves when handling steel work pieces

to prevent possible injury from sharp edges.

8. Keep hands away from cutting area during

operation.

9. CALIFORNIA PROPOSITION 65 WARNING:

This product contains chemicals known to the

State of California to cause cancer, or birth

defects or other reproductive harm.

10. Thi s product, when used for welding, cutting,

or working with metal, produces fumes,

gases, or dusts which contain chemicals

known to the State of California to cause birth

defects and, in some cases, cancer.

(California Health and Safety Code Section

25249.5 et seq.)

11. Always inspect the Strut Cutter before use.

Check for misalignment of moving parts,

binding of moving parts, breakage of parts,

mounting and any other conditions that may

affect the tool’s operation. If damage is found,

repair the tool immediately or replace it.

12. Disconnect from power/hydraulic source

before performing any maintenance or

cleaning.

13. Have tool serviced only by qualified

personnel, using authorized replacement

parts.

14. Provide for adequate space surrounding work

area and sufficient lighting.

15. Do not use this tool while tired or under the

influence of drugs, alcohol or medication.

16. Keep bystanders, especially children, away

from the area while using the tool.

17. Give your work undivided attention. Looking

around, carrying on a conversation and

“horse-play” are careless acts that can result

in serious injury.

18. Maintain a balanced stance at all times. Do

not overreach while performing the work.

19. Do not use power tools in damp or wet

location, or expose them to rain.

Familiarize yourself with the following safety notices used in this manual:

This means that if precautions are not heeded, it may result in serious, or even

fatal, injury.

This means that if precautions are not heeded, it may result in minor injury and/or

possible tool damage.

2

WILTON Strut Cutter

Page 3

2.0 About this tool

The WILTON Strut Cutter is a portable hydraulic t ool designed to quickly cut common U.S. manufactured

brand struts in 12-, 14-, and 16-gauge mild steel. A single set of blades will provide thousands of clean,

even cuts, eliminating the need for deburri ng. Cont act WILTON for special appl ication bl ade and hydraulic

sets. This product has been designed and constructed to provide consistent long-term operation, if used in

accordance with instructions as set forth in this document. NOTE: This tool is not designed for use with

fiberglass, aluminum, or stainl ess st eel struts.

Register your product using the mail-in card provi ded, or regi st er onl ine:

http://www.wiltontools.com/us/en/service-and-support/warranty/registration/

3.0 About this manual

This manual covers operation and maintenance procedures for the WILTON Strut Cutter. It contains

instructions on setup, safety precautions, general operating procedures, maintenance instructions and parts

breakdown.

If there are questions or comments, please contact your local supplier or WILTON. WILTON can also be

reached at our web site: www.wiltontools.com.

Retain this manual for future reference. If the tool transfers ownership, the manual should accompany it.

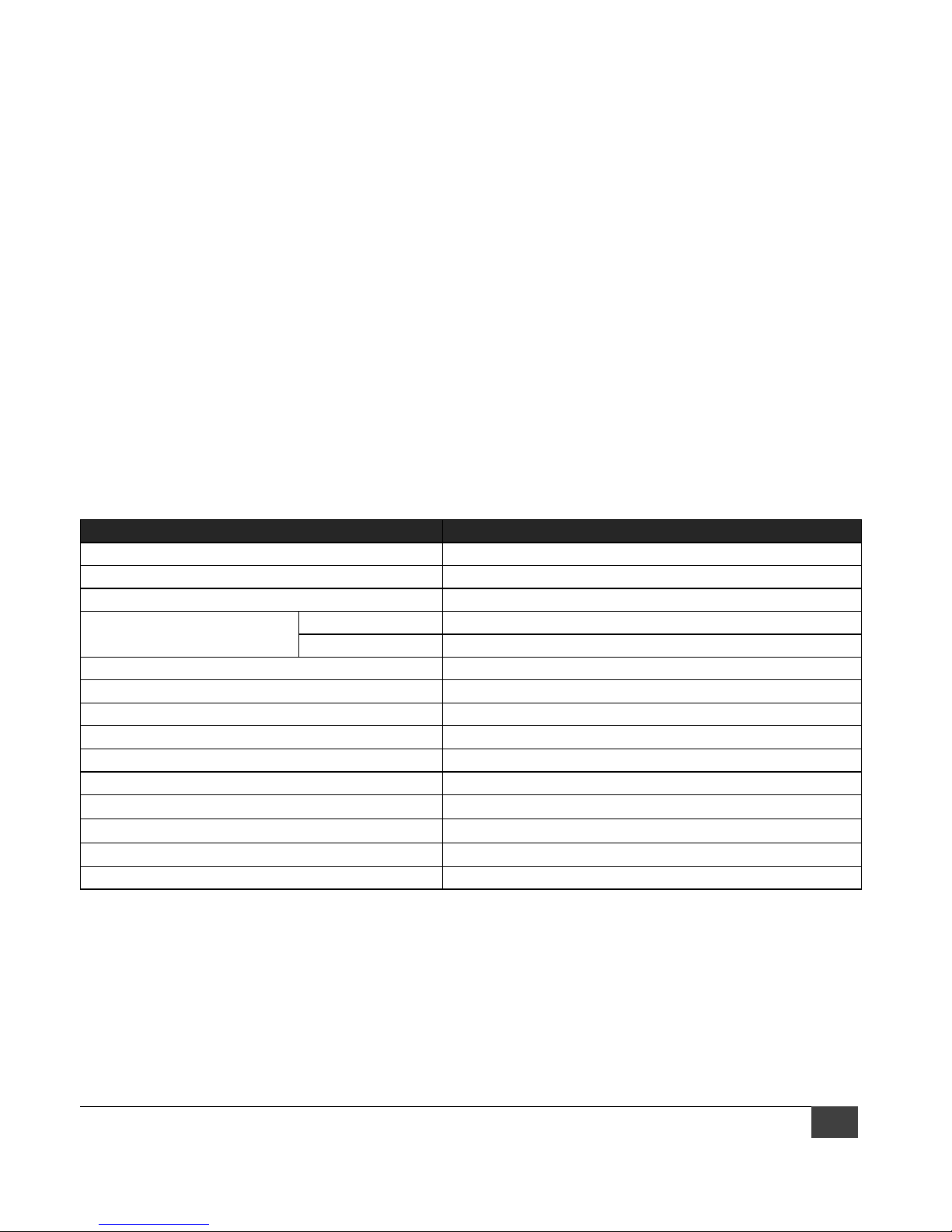

4.0 Specifications

Model Wilton Strut Cutter

Stock number ESP1100

Cutting cycle 3 seconds

Required power supply (not provided) 10,000 PSI hydraulic

Standard die set

Maximum capacity 12 gauge mild steel

Cylinder linear force 25 tons

Cylinder stroke 1 in. (25.4 mm)

Main unit material 7075-T651 Black anodized aluminum

Bade set material S7 heat treated steel

Recommended hydraulic fluid (not provided) ASTM 215, or equivalent

Assembled dimensions with handle (LxWxH) 17 x 5.5 x 13 in. (431.8 x 139.7 x 330.2 mm)

Shipping dimensions (LxWxH) 18 x 15 x 9 in. (8.1 x 6.8 x 4 kg)

Net weight 63.5 lb. (28.8 kg)

Shipping weight 67 lb. (30.4 kg)

L = length, W = width, H = height

Deep strut 1-5/8 x 1-5/8 in. (41.3 x 41.3 mm)

Shallow strut 1-5/8 x 13/16 in. (41.3 x 20.6 mm)

Table 1

The specifications in this manual were current at time of publication, but because of our policy of continuous

improvement, Wilton reserves the right to change specifications at any time and without prior notice, without

incurring obligations.

WILTON

3

Page 4

Read and understand the

entire contents of this manual before

attempting setup or operation of the Strut

Cutter. Failure to comply may cause serious

injury.

5.0 Setup and Assembly

5.1 Shipping contents

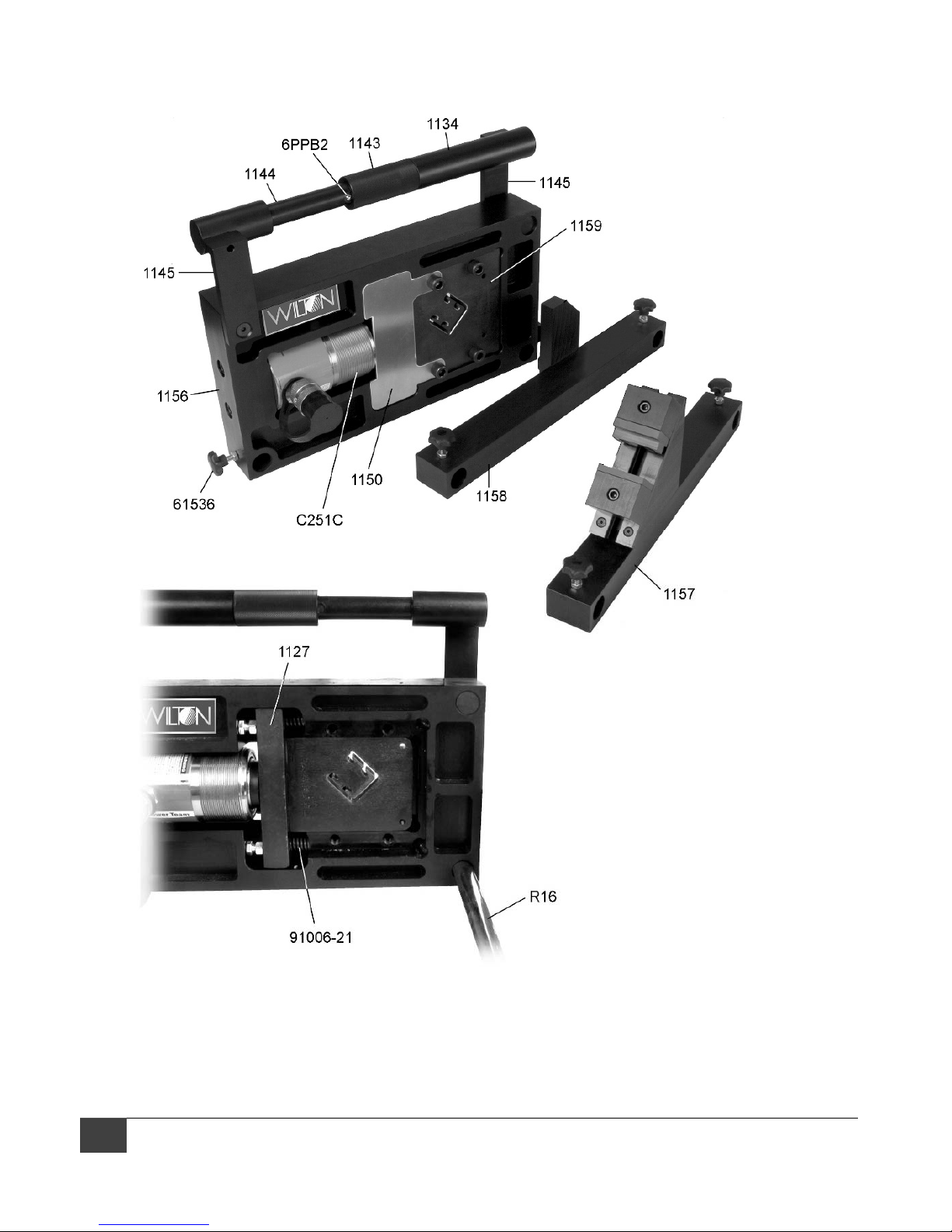

See Figure 1.

1 Main unit with hydraulic cylinder and

coupling

1 Collapsible handle system

1 Material rest assembly

1 Back stop assembly

1 Blade set (installed on main unit)

7 Star knobs

2 Guide rods 16 in.

1 Instructions and parts manual

1 Product registration card

Remove all contents from shipping carton, and

check for shipping damage or missing parts. If

either of these is discovered, contact your dealer

or Wilton at the phone number on the cover.

To install handle assembly for carrying, place pins

of long and short handles into holes on main unit,

as shown in Figure 1. Slide knurled collar past ball

plunger onto opposite handle to secure. Reverse

procedure to collapse handle assembly.

For supports during cutting of lighter gauge

(16ga.) material, position handle pieces on

opposite sides as shown in Figure 2. Install knobs

securely and tighten hex nuts against main unit to

prevent knobs from backing out.

Supports must be used while

operating the Wilton Strut Cutter, to prevent

unit from tipping.

Figure 1: contents

5.2 Handle system

The handle system can be used for carrying the

main unit (Figure 1), or as supports during cutting

(Figure 2).

Figure 2: handles used as supports

5.3 Support rods

For cutting heavier 14- or 12-gauge struts, or for

cutting multiple pieces to the same length:

1. Slide material rest onto the two rods, and

insert rods through holes in main unit, as

shown in Figure 3. Position material rest

about 6 to 8 inches from, and perpendicular

to, the cutting die.

2. Adjust height of material rest guide block

(1/4-inch hex wrench required) to allow

smooth, straight line entry into cutting die.

Insert strut through cutting die to test the

adjustment. When satisfied, securely tighten

screws and knobs.

3. For making multiple cuts to identical length,

install back stop (see Figure 3). Measure

from surface of cutting die to back stop; then

add 3/4-inch (19mm) for final cut length.

4

WILTON Strut Cutter

Page 5

Figure 3: setup for larger materials

4. Adjust to desired cut length, and activate

hydraulic power source. Wait approximately

3 seconds for strut to separate.

5. Releas e hydraul i c press ure to allow blade to

return to rest position. Remove cutoff piece

from back of unit before making additional

cuts.

7.0 User-maintenance

Disconnect from power/

hydraulic source before performing any

cleaning or maintenance of the unit.

NOTE: If longer support is required, use 1-inch

O.D. pipe or tube of greater length (not provided)

and move material rest and/or back stop farther

from cutting die.

6.0 Operation

1. Connect hydraulic power source (not

provided) to the universal coupling on the

tool. Use clean ASTM 215 or equivalent

hydraulic fluid.

2. Turn on hydraulic power source and observe

the tool’s operation without a strut inserted.

The blade set consists of a stationary blade

in front and a moving shear blade in back.

Watch shear blade motion from rear of tool –

it should have smooth movement. When

shear blade has returned to rest position,

both blades should remain aligned.

3. When correct operation is verified, place

strut upon material rest and slide through

cutting die. See Figure 4. Make sure strut is

clean and straight.

Periodically apply a light coat of machine oil to

exposed metal areas, such as rods, to inhibit rust.

Periodically inspect tightness of socket head

screws which secure cutting die to main unit.

If cutting becomes diffic ult, remove stationary di e

and clear away any shavings from cutting area,

using vacuum or brush. Do not use bare hands.

7.2 Additional servicing

Any additional servicing should be performed by

authorized service personnel.

Figure 4: operation

WILTON

5

Page 6

8.0 Compatibility chart

The Wilton Strut Cutter is compatible with the following products. Contac t Wi lton for custom blade sets.

Brand Blade part no. Compatible strut

Unistrut®

B-Line®

Powerstrut® custom

Superstrut® custom

Kindorf® Custom blade sets available

Erico® Custom blade sets available

ESP1159

(standard)

ESP1160

ESP1161 4D21

ESP1162 4D22

P1000, P1000T, P1000SL, P1000HS, P1000H3, P4100, P4100T,

P4100SL, P4100HS, PA158

B22, B22SH, B22S, B22H17/8, B22TH, B22S58, B24, B24SH,

B24S, B24H17/8, B24TH, B24S58, B52, B52S H, B52S, B52H17/8,

B52TH, B52S58, B54, B54SH, B54S, B54H17/8, B54TH, B54S58,

PS200, PS200H, PS200S, PS200EH, PS210, PS210H, PS210S,

PS210EH, PS500, PS500H, PS500S, PS500EH, PS520, PS520H,

PS520S, PS520EH

A1200, A1200HS, A1200P, A1200S, A1400, A1400HS, A1400P,

A1400S, B1200, B1200HS, B1200P, B1200S, B1400, B1400HS,

B1400P, B1400S

Table 2

6

WILTON Strut Cutter

Page 7

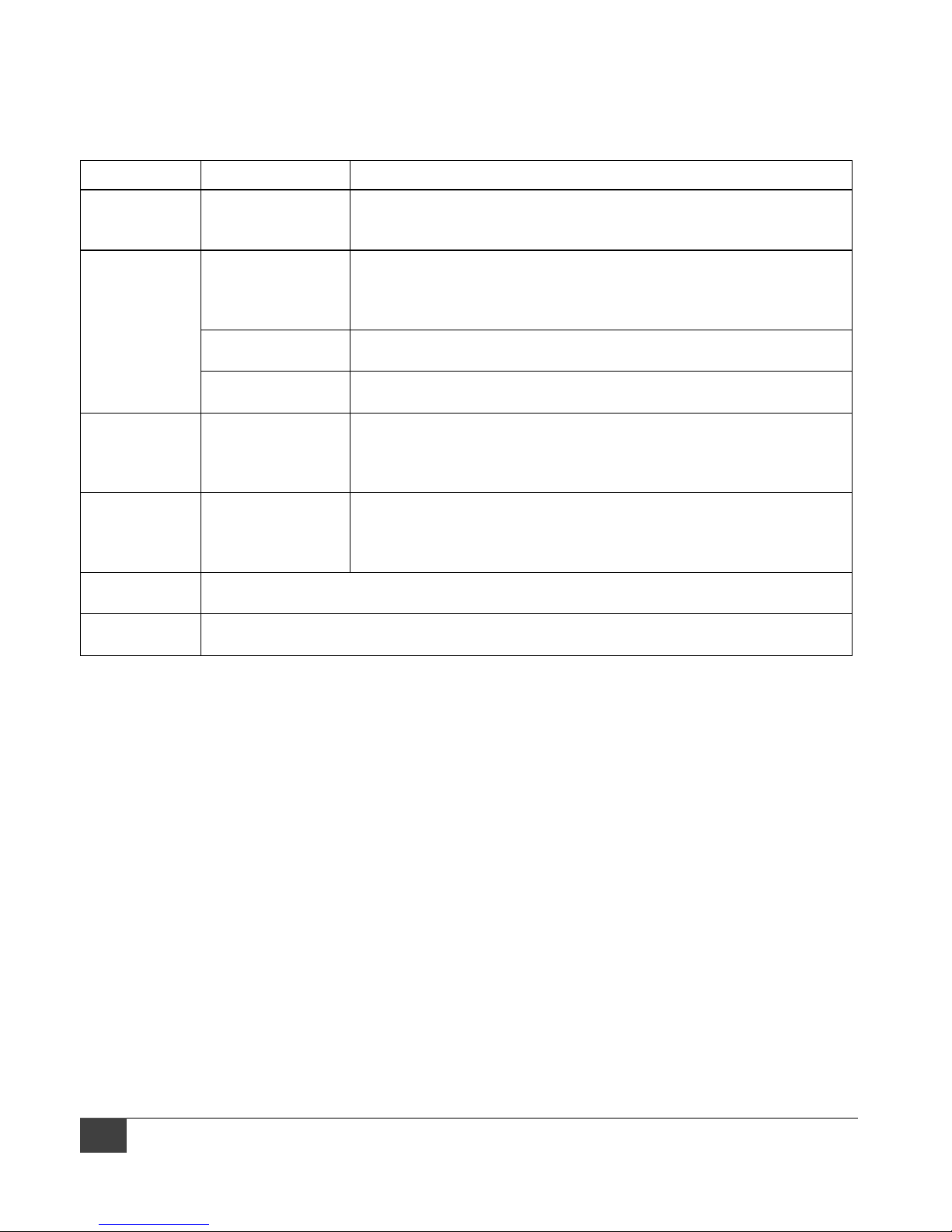

9.0 Troubleshooting Wilton Strut Cutter

Problem Possible cause Remedy

Irregular cut. Material rest not adjusted properly. Adjust material rest so that strut is

perpendicular to cutting die

surface. Ensure that knobs are

tightened down on rods.

Bolts which hold blade die in frame of

main unit have loosened (possibly

from vibration over long-term use).

Shear blade won’t

return to rest position.

Hydraulic dump valve not functioning. Inspect and correct dump valve

Blade movement blocked by

obstruction.

Blade return springs worn or

damaged.

10.0 Replacement Parts

Check tightness of bolts after about

every 500 cuts (3/8 in. hex wrench

required).

function on hydraulic system.

Clean debris from blade area.

Inspect and replace if needed.

Table 3

To order parts or reach our service department, call 1-800-373-8206 Monday through Friday, 8AM to 5PM

CST. Having the Model Number and Serial Number of your tool available w hen you call will allow us to se rve

you quickly and accurately.

Some parts are shown for reference only, and may not be available individually.

Non-proprietary parts, such as fasteners, can usually be found at local hardware stores or may be ordered

from Wilton.

WILTON

7

Page 8

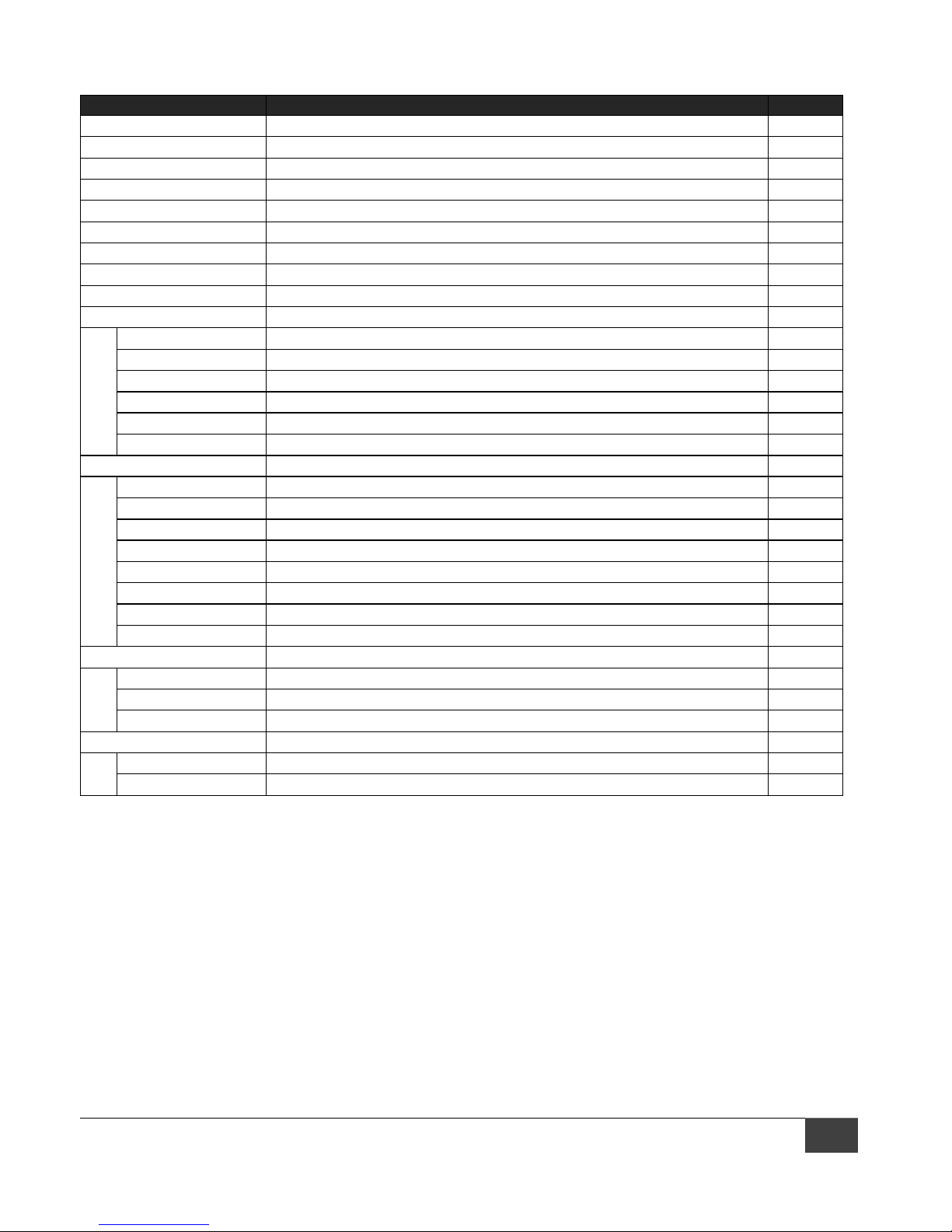

10.1 ESP1100 Wilton Strut Cutter – parts breakdown

8

WILTON Strut Cutter

Page 9

10.2 ESP1100 Wilton Strut Cutter – parts list

Part No. Description Qty

ESP1156

ESP1127

ESP1150

Main Body

Push Block

Safety Cover

ESP-91006-21 Die Spring

ESP-C251C Cylinder SPX 25T

ESP-CL-6-PBP-2 Spring Plunger

LM000275 WILTON Decal

ESP-61536 Star Knob

ESP1100-R16 Guide rod Ø1 x 16 in.

ESP1152

Handle Set Assem bly

ESP1133 Handle Standoff Pin

ESP1134 Handle Long

ESP1143 Knurled Slider

ESP1144 Handle Short

ESP1145 Standoff L Bracket

ESP-6PPB2 Ball Plunger Press Fit

ESP1157

Material Rest Assembly

---- Bottom Rail, Slotted

---- Angle Bl oc k 45- D e gr ee

---- Guide Bl oc k To p/ B o tt om

---- Plastic Sli de Ra il 45 De g re e

---- Plastic G ui d e P l ate

---- Plastic T-Guide

---- Star Knob ( wi th hex nu t)

---- T-Nut

ESP1158 Back Stop Assembly

---- Plastic Stop

---- Bottom Rail

---- Star Knob ( wi th hex nu t)

ESP1159 Blade Set Standard

---- Blade Stationary

---- Blade Moving

1

1

1

2

1

2

1

7

2

1

2

1

1

1

2

1

1

1

1

1

1

1

1

2

2

1

1

1

3

1

1

1

Table 4

WILTON

9

Page 10

10.3 Optional accessories

Part No. Description

ESP-9754 Hose Kit 6'

ESP-PE302S Power Pack SPX (includes 6’ hose)

ESP1163 Material Rest Assembly 4D 21/4 D22

---- T-Guide Ki t 4 D 21/ 4 D 2 2

---- Guide Bl oc k To p/ B o tt om 4D21/4 D22

---- Plastic G ui d e P l ate 4 D21/4D 2 2

---- Plastic G ui de T 4D21/4 D22

ESP1160 Blade Set B22/B52

---- Blade Stationary B 22/ B52

---- Blade Moving B22/B52

ESP1161 Blade Set 4D21

ESP1162 Blade Set 4D22

---- Blade Stationary 4 D21

---- Blade Moving 4D21

---- Blade Stationary 4 D22

---- Blade Moving 4D22

Table 5

10

WILTON Strut Cutter

Page 11

11.0 Warranty and Service

Wilton® warrant s e very pro duct they sell again st manu facturer s’ d efect s. If one o f our tool s n eeds ser vice or r epair,

please contact Technical Service by calli ng 1-800-373-8206, 8AM to 5PM CST, Monday thro ugh Friday.

Warranty Period

The general warranty lasts for the ti me period specified in th e literature included with your product o r o n the official

Wilton branded website.

• W ilton products carry a limited warranty which varies in duration based upon the product. (See chart

below)

• Accessories carry a limited warranty of one year from the date of receipt.

• Consumable items are defined as expendable parts or accessories expected to become inoperable

within a reasonable amou nt o f use a nd ar e co vered by a 90 day limite d w arranty ag ain st man ufacture r’s

defects.

Who is Covered

This warranty covers only the initial purchaser of the product from the date of delivery.

What is Co vered

This warranty covers any defe cts in w orkmansh ip or materials subjec t to the l imita tions sta ted bel ow . This w arranty

does not cover failures due directly or indirectly to misuse, abuse, negligence or accidents, normal wear-and-tear,

improper repair, alterations or lack of maintenance.

How to Get Technical Support

Please contact Technical Service by calling 1-800-373-8206. Please note that you will be asked to provide

proof of initial purchase when calling. If a product requires further inspection, the Technical Service

representative will explain and assist with any additional action needed. Wilton has Authorized Service Centers

located throughout the United States. For the name of an Authorized Service Center in your area call 1-800-2746846 or use the Service Center Locator on the Wilton website.

More Information

Wilton is consistently adding new products. For complete, up-to-date product information, check with your local

distrib u tor or visit the Wilto n website.

How State Law Applies

This warranty gives you specific legal rights, subject to applicable state law.

Limitations on This Warranty

WILTON LIMITS ALL IMPLIED WARRANTIES TO THE PERIOD OF THE LIMITED WARRANTY FOR EACH

PRODUCT. EXCEPT AS STATED HEREIN, ANY IMPLIED WARRANTIES OF MERCHANTABILITY AND

FITNESS FOR A PARTICULAR PURPOSE ARE EXCLUDED. SOME STATES DO NOT ALLOW LIMITATIONS

ON HOW LONG AN IMPLIED WARRANTY LASTS, SO THE ABOVE LIMITATION MAY NOT APPLY TO YOU.

WILTON SHALL IN NO EVENT BE LIABLE FOR DEATH, INJURIES TO PERSONS OR PROPERTY, OR FOR

INCIDENTAL, CONTINGENT, SPECIAL, OR CONSEQUENTIAL DAMAGES ARISING FROM THE USE OF OUR

PRODUCTS. SOME STATES DO NOT ALLOW THE EXCLUSION OR LIMITATION OF INCIDENTAL OR

CONSEQUENTIAL DAMAGES, SO THE ABOVE LIMITATION OR EXCLUSION MAY NOT APPLY TO YOU.

Wilton sells through distributors only. The specifications listed in Wilton printed materials and on official Wilton

branded website are given as general information and are not binding. Wilton reserves the right to effect at any

time, without prior notice, those alterations to parts, fittings, and accessory equipment which they may deem

necessary for any reason whatsoever.

Product Listing with Warranty Period

90 Days – Parts; Consumable items

1 Year – Wilton Strut Cutter

NOTE: Wilton is a division of JPW Industries, Inc. References in this document to Wilton also apply to JPW

Industries, Inc., or any of its successors in interest to the Wilton brand.

WILTON

11

Page 12

427 New Sanford Road

LaVergne, Tennessee 37086

Phone: 800-373-8206

www.wiltontools.com

12

WILTON Strut Cutter

Loading...

Loading...