Page 1

Operating Instructions — Parts Manual

15-Inch Vari-Speed Drill Press

Models: A5816, A5818, A3816, A3818

Manufactured after Serial No. 807137 Part No.

5507564

Revision B6

WMH Tool Group, Inc.

2420 Vantage Dr.

Elgin, IL 60123

Ph: 847-649-3010

Fax:

847-851-1144

Page 2

Page 3

Table of Contents

Cover Page.......................................................................................................................... 1

General Specifications....................................................................................................... 4

Operating Precautions....................................................................................................... 5

Set-up and Operation......................................................................................................... 7

Maintenance........................................................................................................................ 9

Wiring Diagrams............................................................................................................... 10

Troubleshooting ................................................................................................................11

Replacement Parts ........................................................................................................... 12

3

Page 4

General Specifications

The Wilton 15-Inch Vari-Speed Drill Presses, Models

A5816, A5818, A5836, and A5838 provide drilling

speeds from 400 to 5,000 rpm. Simple handwheel

adjustment sets the speeds with an LED speed

display on the faceplate of the machine.

Wilton's 15-inch vari-speed drill press provides a solid

base for drilling and offers a wide range of spindle

speeds. The large quill provides greater accuracy.

The large worktable provides the operator with room

to work and ample support for the workpiece. The

drill press has a 3-inch diameter column for head and

table support. The 15-Inch Vari-Speed Drill Press is

equipped with a standard table raiser.

Specifications

Model............................ A5816 ..................... A5818....................... A5836 .......................A5838

A3816 A3818 A3836 A3838

Type .............................. Floor Model............. Floor Model .............. Bench Model ............. Bench Model

4

Motor:

Motor Speed (rpm) .... 1,725 rpm................ 1,725 rpm ................. 1,725 rpm..................1,725 rpm

HP ............................. 1 HP ........................ 3 HP ......................... 1 HP ..........................3 HP

Power Rating............. 1 Ph, 115/220V........ 3 Ph, 220/440V......... 1 Ph, 115/220V .........3 Ph, 220/440V

Spindle speed (rpm) ...... 400 to 5,000rpm...... 400 to 5,000 rpm ...... 400 to 5,000 rpm....... 400 to 5,000rpm

Capacity:

Cast iron.................... up to 5/8-in. ............. up to 5/8-in. .............. up to 5/8-in. .............. up to 5/8-in.

Steel .......................... up to 1/2-in. ............. up to 1/2-in. .............. up to 1/2-in...............up to 1/2-in.

Drills to center ............... 15 in. ....................... 15 in. ........................ 15 in. .........................15 in.

Quill diameter ................ 2-1/4 in. ................... 2-1/4 in. .................... 2-1/4 in......................2-1/4 in.

Quill travel ..................... 6 in. ......................... 6 in. .......................... 6 in. ...........................6 in.

Spindle taper ................. #2 MorseTaper ........ #2 MorseTaper ......... #2 MorseTaper .......... #2 MorseTaper

Dimensions:

Table (overall)............ 15-1/4 x 17-3/4 in. ... 15-1/4 x 17-3/4 in. .... 15-1/4 x 17-3/4 in. .....15-1/4 x 17-3/4 in.

Table (working area).. 12-1/2 x 14-1/2 in. ... 12-1/2 x 14-1/2 in. .... 12-1/2 x 14-1/2 in. .....12-1/2 x 14-1/2 in.

T-slot ......................... 1/2-in....................... 1/2-in. ....................... 1/2-in.........................1/2-in.

Spindle to table.......... 41 in. ....................... 41 in. ........................ 41 in. .........................41 in.

Spindle to base .......... 47-1/2 in. ................. 47-1/2 in. .................. 47-1/2 in. ...................47-1/2 in.

Overall height ............ 67-1/2 in. .................67-1/2 in.

Page 5

- Misuse of this machine can cause serious injury.

- For safety, machine must be set up, used and

serviced properly.

- Read, understand and follow instructions in the

Operating Instructions and Parts Manual which

was shipped with your machine.

supply while servicing.

- Always follow instructions in Operating Instructions and Parts Manual when changing accessory

tools or parts.

- Never modify the machine without consulting

Wilton Corporation.

You—the stationary power tool user—

When setting up machine:

- Always avoid using machine in damp or poorly

lighted work areas.

- Always be sure the machine support is securely

anchored to the floor or the work bench.

When using machine:

- Always wear safety glasses with side shields

(See ANSI Z87.1)

- Never wear loose clothing or jewelry.

- Never overreach—you may slip and fall.

When servicing machine:

- Always disconnect the machine from its electrical

hold the key to safety.

Read and follow these simple rules for best results

and full benefits from your machine. Used properly,

Wilton’s machinery is among the best in design and

safety. However, any machine used improperly can

be rendered inefficient and unsafe. It is absolutely

mandatory that those who use our products be

properly trained in how to use them correctly. They

should read and understand the Operating Instructions and Parts Manual as well as all labels affixed

to the machine. Failure in following all of these

warnings can cause serious injuries.

Machinery general safety warnings

1. Always wear protective eye wear when operat-

ing machinery. Eye wear shall be impact resistant, protective safety glasses with side shields

which comply with ANSI Z87.1 specifications.

Use of eye wear which does not comply with

ANSI Z87.1 specifications could result in severe

injury from breakage of eye protection.

2. Wear proper apparel. No loose clothing or

jewelry which can get caught in moving parts.

Rubber soled footwear is recommended for best

footing.

3. Do not overreach. Failure to maintain proper

working position can cause you to fall into the

machine or cause your clothing to get caught —

pulling you into the machine.

4. Keep guards in place and in proper working

order. Do not operate the machine with guards

removed.

5. Avoid dangerous working environments. Do not

use stationary machine tools in wet or damp

locations. Keep work areas clean and well lit.

6. Avoid accidental starts by being sure the start

switch is “OFF” before plugging in the machine.

7. Never leave the machine running while unat-

tended. Machine shall be shut off whenever it is

not in operation.

8. Disconnect electrical power before servicing.

Whenever changing accessories or general

maintenance is done on the machine, electrical

power to the machine must be disconnected

before work is done.

9. Maintain all machine tools with care. Follow all

maintenance instructions for lubricating and the

changing of accessories. No attempt shall be

made to modify or have makeshift repairs done to

the machine. This not only voids the warranty but

also renders the machine unsafe.

10. Machinery must be anchored to the floor.

11 . Secure work. Use clamps or a vise to hold work,

when practical. It is safer than using your hands

and it frees both hands to operate the machine.

12. Never brush away chips with machine in operation.

13. Keep work area clean. Cluttered areas invite

accidents.

14. Remove adjusting keys and wrenches before

turning machine on.

15. Use the right tool. Don’t force a tool or attachment

to do a job it was not designed for.

16. Use only recommended accessories and follow

manufacturers instructions pertaining to them.

17. Keep hands in sight and clear of all moving parts

and cutting surfaces.

18. All visitors should be kept at a safe distance from

the work area. Make workshop completely safe

by using padlocks, master switches, or by

removing starter keys.

19. Know the tool you are using — its application,

limitations, and potential hazards.

5

Page 6

General electrical cautions

The drill press should be grounded in accordance

with the National Electrical Code and local codes

and ordinances. This work should be done by a

qualified electrician. The drill press should be

grounded to protect the user from electrical shock.

Wire sizes

Caution: for circuits which are far away from the

electrical service box, the wire size must be

increased in order to deliver ample voltage to the

motor. To minimize power losses and to prevent

motor overheating and burnout, the use of wire sizes

for branch circuits or electrical extension cords

according to the following table is recommended.

AWG (American wire gauge) number

Conductor length 240 volt lines 120 volt lines

0-50 feet No. 14 No. 14

50-100 feet No. 14 No. 12

Over 100 feet No. 12 No. 8

Safety Instructions for Drill

Presses

1. All work shall be secured using either clamps or a

vise to the drill press table. It is unsafe to use your

hands to hold any workpiece being drilled.

2. Drill press head and table shall be securely

locked to the column before operating the drill press.

This must always be checked prior to starting the

machine.

3. Always use the correct tooling. Tooling shall

always be maintained and properly sharpened. All

tooling must be run at the proper speeds and feeds

as they apply to the job. Use only recommended

accessories and follow those manufacturers instructions pertaining to them. Tooling shall be not be

forced in to any workpiece but fed according to the

6

proper specifications. Failure to follow these instructions will not only ruin the tooling as well as the

machine, but can cause serious injury.

4. Never brush away any chips while the machine is

in operation. All clean up should be done when the

machine is stopped.

5. Keep hands in sight. Do not put hands or fingers

around, on, or below any rotating cutting tools.

Leather safety gloves should be used when handling

any sharp objects or cutting tools. See Figure A.

6. Always wear protective eye wear when operating,

servicing or adjusting machinery. Eyewear shall be

impact resistant, protective safety glasses with side

shields complying with ANSI Z87.1 specifications.

Use of the eye wear which does not comply with

ANSI Z87.1 specifications could result in severe

injury from breakage of eye protection. See Figure

B.

7. When drilling in material which causes dust, a

dust mask shall be worn. See Figure C.

8. Avoid contact with coolant, especially guarding

the eyes.

9. Non-slip footwear and safety shoes are recommended. See Figure D.

10. Wear ear protectors (plugs or muffs) during

extended periods of operation. See Figure E.

A B C

D E

Page 7

Introduction

Set-up and Operation

This manual includes operating and maintenance

instructions for the Wilton 15-Inch Vari-Speed Drill

Presses, Models A5816, A5818, A5836, and A5838.

This manual also includes parts listings and illustrations of replaceable parts.

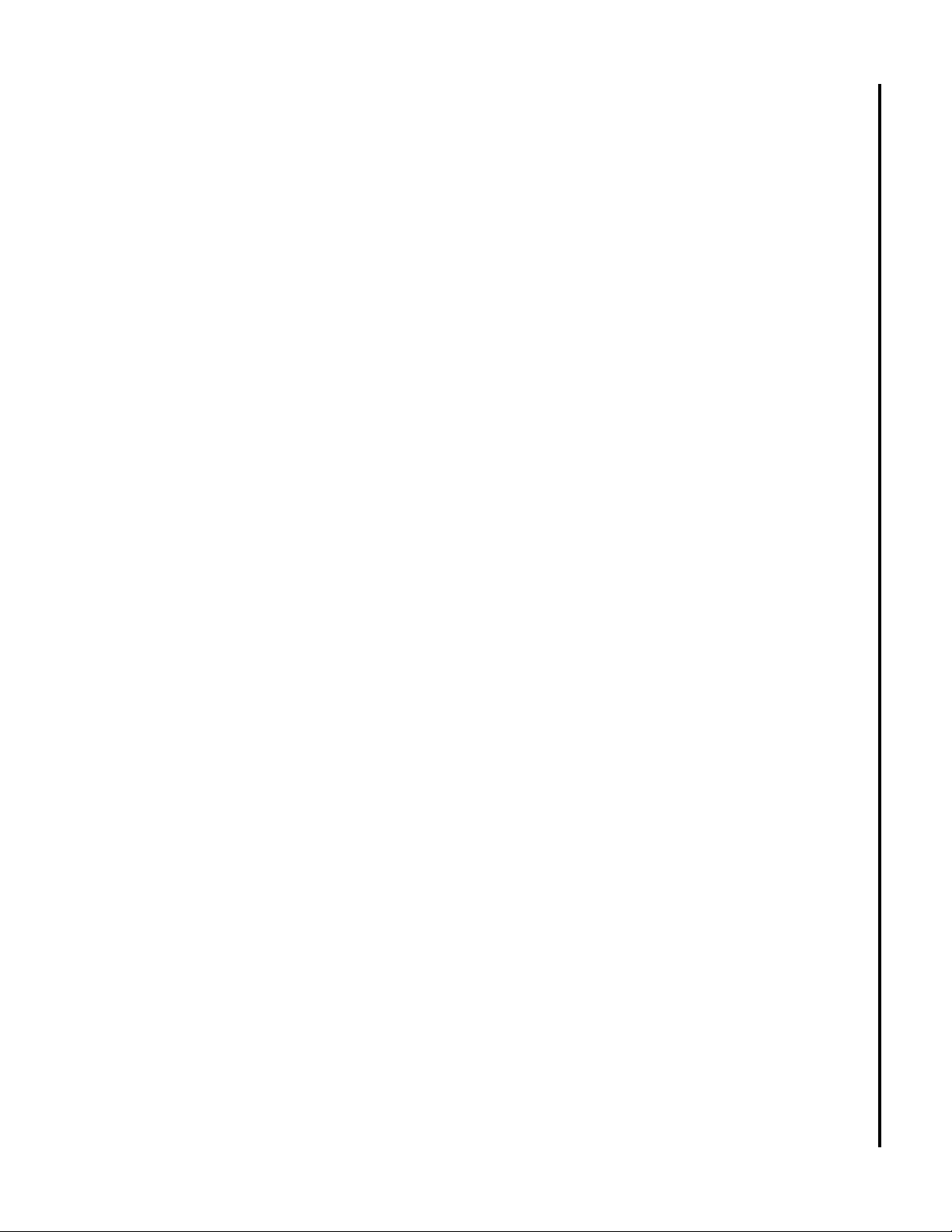

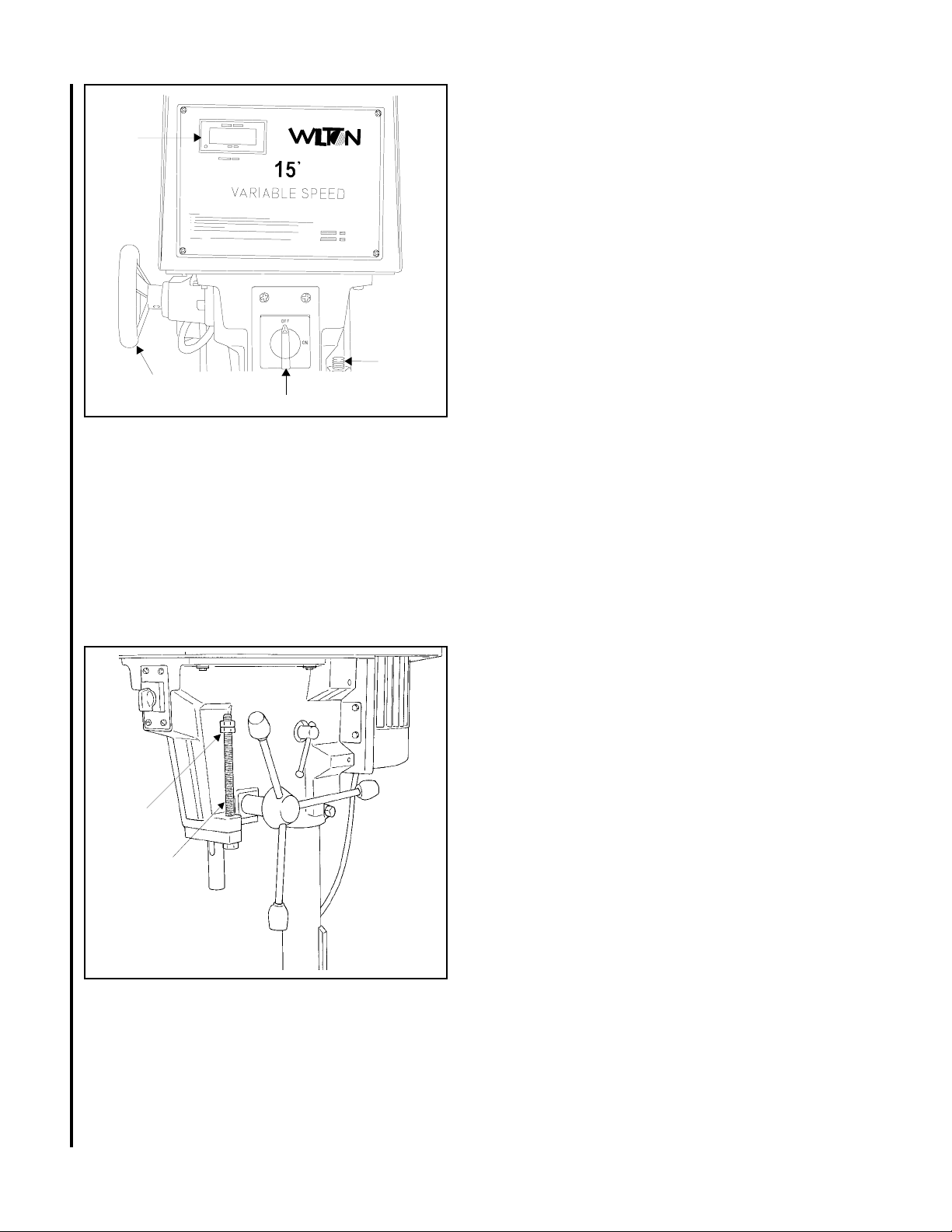

Refer to Figure 1 for key features of the drill press.

LED Speed

Display

Speed

setting

handwheel

On/Off

switch

Depth stop

Spindle

Feed

handle

Motor

Head

locking

handle

Column

Securing the Base

The base of the drill press has four mounting holes.

The drill press should be level and rest solidly on the

floor. Place shims under the four mounting holes in

the base as required to level the drill press.

Cleaning

Clean off any protective grease with solvent. After

cleaning, lubricate the base, table, and column with

a light coating of medium weight machine oil.

Repeat at six months intervals.

Internal parts of the drill press are lubricated at the

factory. No further lubrication is required at the time

of installation.

Electrical Connection

Refer to the Wiring Diagram section for wiring

information. Connection to electrical power should

be made by a qualified electrician. Observe local

electrical codes when connecting the machine.

The motor should be protected with a time delay

fuse or circuit breaker with a amperage rating

slightly higher than the full load current of the motor.

Work

table

Base

Figure 1: Drill Press Features

Table

height

adjustment

Rack

Operating Controls

(Refer to Figure 2)

ON/OFF Switch

The ON/OFF switch is located at the front of the drill

head.

Speed Control Handwheel

CAUTION: TO AVOID DAMAGE TO THE SPEED

ADJUSTMENT MECHANISM, THE MOTOR MUST

BE OPERATING BEFORE ATTEMPTING TO

ADJUST THE SPEED SETTING.

The speed control handwheel is located on the left

side of the drill head. An LED speed indicator is

provided on the face plate on the drill head.

7

Page 8

LED

Speed

Display

Depth

Speed control

handwheel

Figure 2. Operating Controls

On/Off switch

stop

Depth Stop

A drilling depth stop (refer to Figure 3) is provided on

the right side of the drill head. The depth stop

consists of a threaded rod with depth setting jam

nuts. The front side of the threaded rod has a depth

scale. The jam nuts are loosened and moved to the

desired depth on the scale. The upper jam nut is

then tightened against the lower nut.

Operating Precautions

The following operating and safety precautions must

be observed in order to avoid harm to the operator

or damage to the drill press.

1. The head assembly must be locked to the

column so the thrust produced by drilling will

not force the head assembly up the column.

2. The work table must be locked to the column

so it will not be forced down the column.

3. Be sure the belt is tightened to the proper

tension.

4. DO NOT start to drill the workpiece until

making certain the workpiece is held down

securely.

5. MAKE SURE THE DRIVE MOTOR IS RUN-

NING BEFORE turning the speed control

handwheel in either direction.

6. Point of operation protection is required for

maximum safety. This remains the responsibility of the user/purchaser since conditions differ

between jobs.

7. Make sure the drill is secured in the spindle or

check before attempting to use the drill press.

8. Make sure the spindle taper is clean and free

of burrs, scoring, and galling to assure maximum gripping.

Drilling Recommendations

Speeds for Drilling

The speed of a drill is usually measured in terms of

the rate at which the outer periphery of the tool

moves in relation to the work being drilled. The

Jam

nuts

8

Depth scale

(on threaded

rod)

Figure 3. Depth Stop

common term for this is Surface Feet per Minute

(SFM). The relationship of SFM is expressed in the

following formulas:

SFM = 0.26 X rpm X Drill Diameter (in inches)

RPM = 3.8 x ________SFM__________

Drill diameter (in inches)

In general, the higher the speed the shorter the drill

life. Operating at the low end of the speed range for

a particular material will result in longer life. The

most efficient speed for operating a drill depends on

many variables:

1. Composition and hardness of material.

2. Depth of the hole.

3. Efficiency of the cutting fluid.

4. Type and condition of the drilling machine.

5. Desired quality of the hole.

Page 9

6. Difficulty of set-up.

Indication of Extreme Speeds and Feeds

A drill that splits up the web is evidence of too much

feed or insufficient tip clearance at the center as a

result of improper grinding. The rapid wearing away

of the extreme outer corners of the cutting edges

indicates that the speed is too high. A drill chipping

or braking out at the cutting edges indicates that

either the feed is too heavy or the drill has been

ground with too much tip clearance.

3. Remove head cover.

4. Remove belt. (With speed control setting at the

highest speed, the belt should be loose enough

to remove.)

5. Install the replacement belt. Install the head

cover.

6. Connect electrical power to the drill press.

7. Operate the drill press to verify correct operation.

Replacement of Motor

Speeds for High Speed Steel Drills

Speed

Material In SFM

Alloy Steel — 300 to 400 Brinell .....................20 - 30

Stainless Steel................................................30 - 40

Automotive Steel Forgings .............................40 - 50

Tool Steel, 1.2C ..............................................50 - 60

Steel, .4C to .5C .............................................70 - 80

Mild Machinery Steel, .2C to .3C..................80 - 110

Hard Chilled Cast Iron ....................................30 - 40

Medium Hard Cast Iron ................................70 - 100

Soft Cast Iron .............................................100 - 150

Malleable Iron.................................................80 - 90

High Nickel Steel or Monel .............................40 - 50

High Tensile Bronze ......................................70 -150

Ordinary Brass and Bronze ........................200 - 300

Aluminum and its Alloys .............................200 - 300

Magnesium and its Alloys...........................250 - 400

Slate, Marble, and Stone.................................15 -25

Plastics and similar material (Bakelite).......100 - 150

Wood...........................................................300 -400

Titanium Alloys ...............................................10 - 25

Titanium Alloy Sheet.......................................50 - 60

WARNING: MAKE SURE TO DISCONNECT

ELECTRICAL POWER TO THE DRILL PRESS TO

AVOID THE POSSIBILITY OF INADVERTENT

OPERATION AND EXPOSURE TO POTENTIALLY

LETHAL VOLTAGE LEVELS.

1. Disconnect electrical power to drill press.

2. Remove drive belt (refer to Replacement of

Drive Belt).

3. Disconnect electrical wiring from motor junction

box.

4. Remove nuts and washers from bolts securing

motor to drill head. Remove motor.

5. Remove pulleys and related components from

motor shaft.

6. Install pulleys and related components on

replacement motor shaft.

7. Install motor on mounting bolts and secure with

nuts and washers.

8. Connect electrical wiring (refer to Wiring

Diagram section for wiring details).

9. Install drive belt (refer to Replacement of

Drive Belt).

10. Operate drill press to verify proper operation.

In cases where carbon steel drills are applicable, the

drill should be run at speeds of from 40 to 50

percent of those given above.

Maintenance

Replacement of Drive Belt

WARNING: MAKE SURE TO DISCONNECT

ELECTRICAL POWER TO THE DRILL PRESS TO

AVOID THE POSSIBILITY OF INADVERTENT

OPERATION AND EXPOSURE TO POTENTIALLY

LETHAL VOLTAGE LEVELS.

1. Start drill press. Set speed control to highest

speed. Stop drill press.

2. Disconnect electrical power to drill press.

9

Lubrication

Following are lubrication recommendations for drill

press components.

1. Spindle pulley drive: Lubricate spindle splines

occasionally with light grease.

2. Quill, Table, and Column: Lubricate with light

film of oil.

3. Table lift rack: Lubricate regularly with SAE20

oil (clean rack with solvent before applying oil.)

4. Variable speed drive fork: Lubricate contact

points occasionally with grease.

Page 10

Adjustments

Table Adjustment

The table can be raised or lowered to accommodate

the height of the component being drilled (refer to

Figure 4). To raise or lower the table, loosen the

lock handle. Then use the hand crank to move the

table to the desired height. Then retighten the lock

handle.

Figure 4. Table Adjustment

Head Adjustment

WARNING: CHANGE THE RADIAL POSITION OF

THE DRILL HEAD ONLY IF THE DRILL PRESS

BASE IS SECURED TO THE FLOOR. SWINGING

THE DRILL HEAD WITHOUT THE BASE BEING

SECURED TO THE FLOOR WILL CAUSE THE

DRILL PRESS TO BECOME UNSTABLE AND TIP

OVER RESULTING IN INJURY AND/OR DAMAGE

TO THE MACHINE.

The radial position of the drill head can be changed

Motor

1 Phase 115/230 Volts

Motor

3 Phase 220/440 Volts

Switch

Switch

Green

Line

White

Black

Green

Line

10

Table lock

(handle on

opposite side)

Table

height

adjustment

Work table

to accommodate the drilling of a hole that may be

offset from the center of the table. Reposition the

drill head by loosening the locking handles and

swinging the drill head to the desired position. Then

retighten the locking handles.

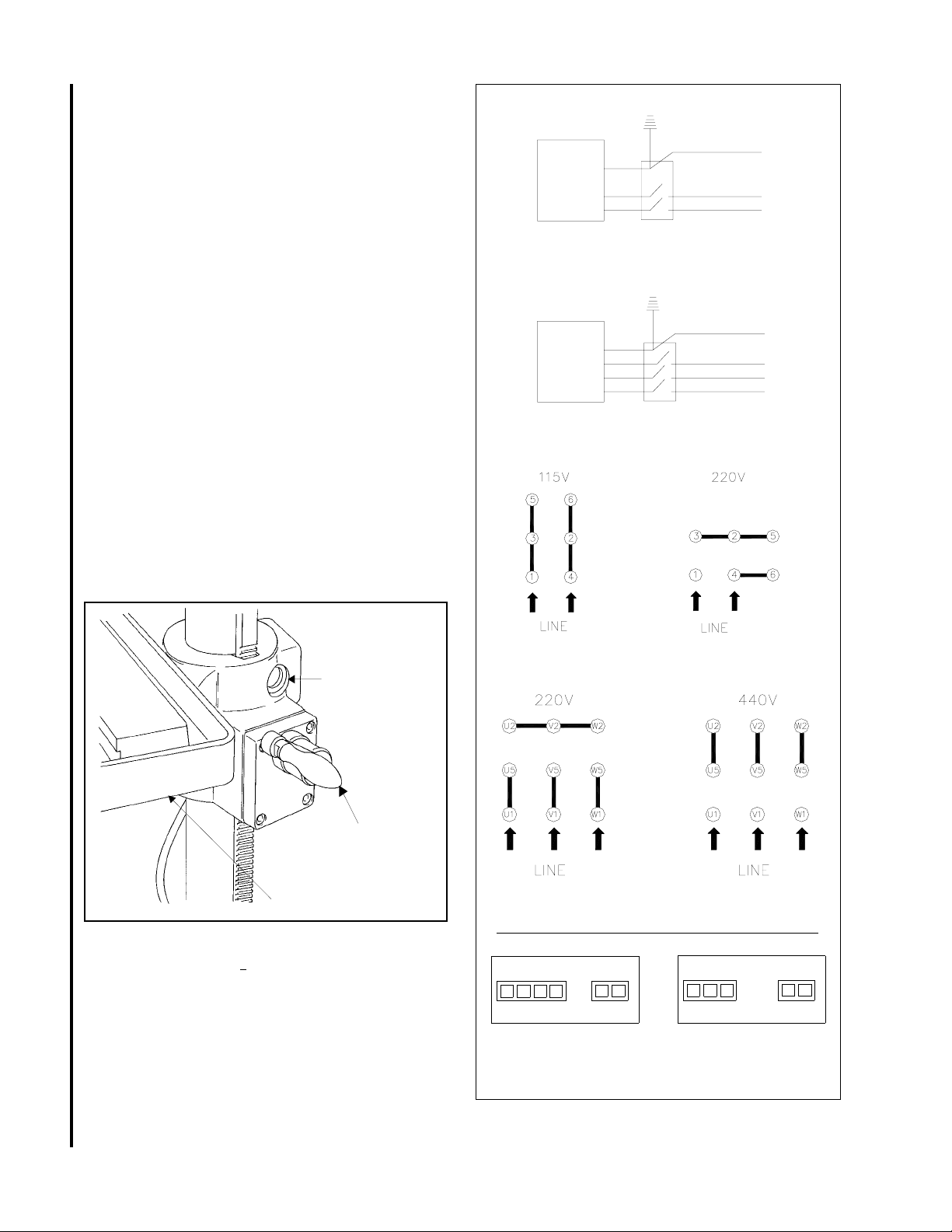

Wiring Diagrams

Refer to Figure 5 for wiring information. The drive

motor is115/230 volt single phase or 220/440 volt

three phase. Notice: When converting machine

voltage, it is necessarry to re-wire the LED display

connection accordingly. Refer to figure 5.

1 phase Motor Connection

3 phase Motor Connection

AC Power Sensor

0 110 220 24

Volts

1 Phase 115/220

Figure 5. Wiring Diagrams

- +

Input

LED Display Connection

AC Power Sensor

0 220 440

Volts

3 Phase 220/440

- +

Input

Page 11

Troubleshooting

Problem Possible Cause Remedy

Spindle does not turn. 1. Circuit breaker tripped. 1. Reset circuit breaker.

2. Branch circuit breaker tripped or 2. Reset branch circuit breaker/replace

fuse blown. fuse.

3. Open wire in switch circuit. 3. Repair open circuit.

4. Defective switch. 4. Repair switch.

5. Broken drive belt. 5. Replace drive belt.

Spindle noisy. 1. Damaged spindle bearings. 1. Replace bearings.

2. Worn spline. 2. Replace spline.

Drill stalls. 1. Worn drive belt. 1. Check condition of belt. Replace

glazed or slipping on pulleys.

2. Excessive feed rate for size of drill and material 2. Reduce feed pressure or use

being drilled. cutting fluid.

3. No cutting fluid or improper cutting fluid. 3. Use correct cutting fluid.

Poorly drilled holes. 1. Drill dull. 1. Sharpen drill.

2. Lack of rigidity in hold-down method. 2. Check that all T-slot hold-downs are

tight and that table-lock and drill

head bolts are tight.

3. Speed too fast for material and drill size. 3.

Check spindle speed recommendations.

Reduce speed if

necessary.

4. Feed too fast for material and drill size. 4. Reduce feed rate.

5. No or improper cutting fluid or coolant 5. Use cutting fluid, or change to

being used. proper fluid or coolant for material

being drilled.

6. Improperly ground drill bit. 6. Check for proper angles and reliefs.

Regrind to proper geometry.

Motor overheating. 1. Electrical circuit fault. 1. Check current draw in circuit.

Make sure current draw is the

same as rating on motor plate.

2. Oversize drill. 2. Reduce drill size.

3. Excessive feed. 3. Reduce feed rate.

4. No cutting fluid, or wrong fluid. 4. Use correct cutting fluid for the

material and drill.

if

11

Table can not be 1. Lack of lubrication. 1. Lubricate.

raised.

No speed readout. 1. Speed pickup out of adjustment or failed. 1. Adjust gap between speed pickup

and post spindle pulley. If there is

no readout on the speed indicator,

replace the speed pickup.

Page 12

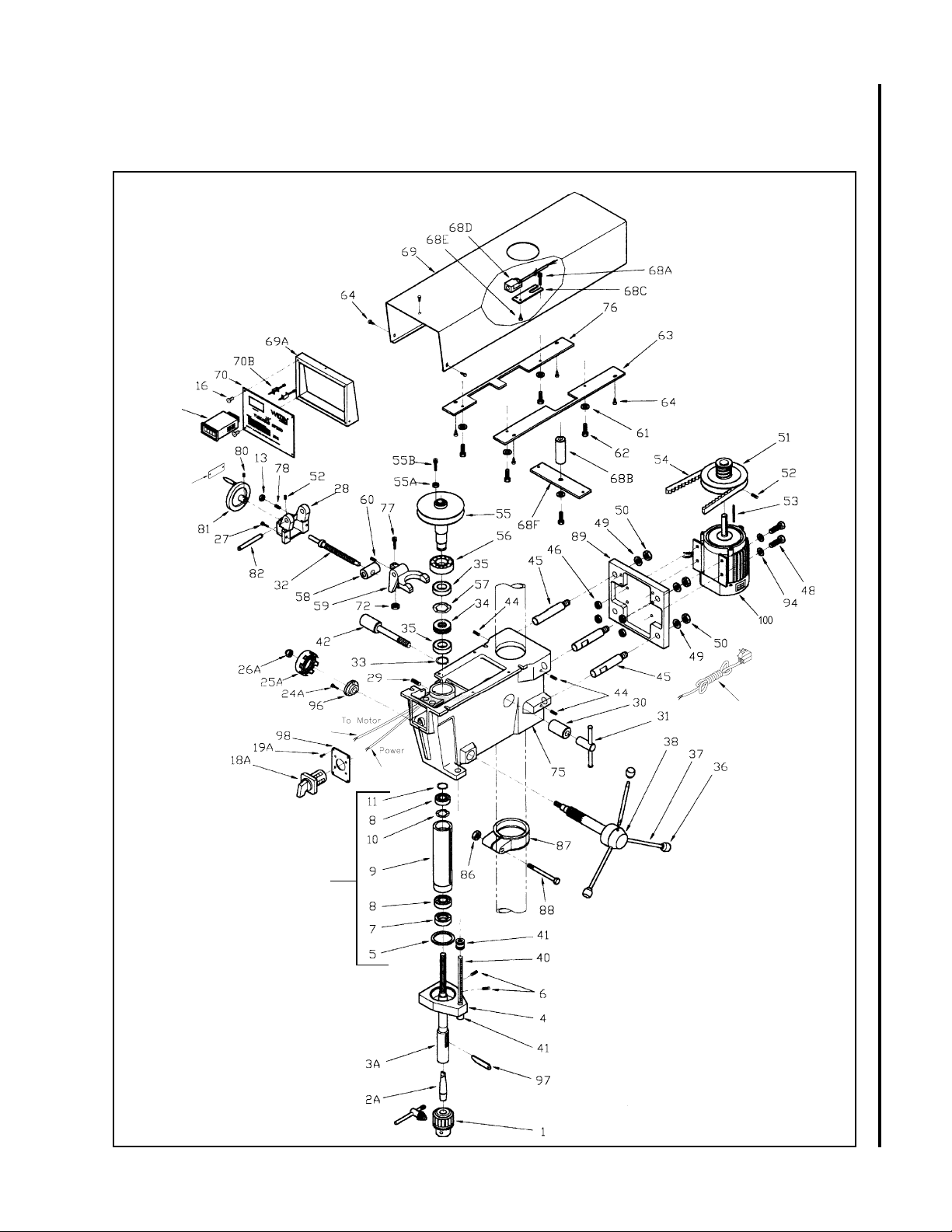

Replacement Parts

This section provides exploded view illustrations that show the replacement parts for the Wilton 15-Inch VariSpeed Drill Presses, Models A58 and A38 series. Also provided are parts listings that provide part number,

description, and quantity. The item numbers shown on the illustration relate to the item number on the facing

page of the parts listing.

Order replacement parts from:

Wilton Corporation

300 South Hicks Road

Palatine, IL 60067

TEL: 1-888-594-5866

FAX: 1-800-626-9676

Identify the replacement part by the part number shown in the parts listing. Be sure to include the model

number and serial number of your machine when ordering replacement parts to assure that you will receive the

correct part.

12

Page 13

Exploded View — Head

Models: A5816, A5818, A5836, & A5838

70A

39

21

99

(Note 1)

17

17A

13

Page 14

Parts List - Head

Models A5816, A5818, A5836 and A5838

14

Item Part

No. Number Description Qty

1 5507580 Chuck (with Key) 1

2A 5507495 #2 MT x JT3 Arbor 1

3A 5507496 Spindle Assembly 1

4 5053070 Quill Band 1

5 9010541 O-Ring 1

6 905451 1 Set Screw 2

5/16-18 x 3/8

7 5032611 Bearing Retainer 1

8 9100331 Bearing 2

9 5041010 Quill 1

10 9058561 Wavy Spring Washer 1

11 9074081 Truarc Retainer 1

13 9056981 Hex Jam Nut 3

1/4-20

16 5518170 Sloted self taping Screw 5

3/16-24 x 3/8

17 5518157 Power Cord (1-Phase) 1

17A 5517463 Power Cord (3-Phase) 1

18A 5507500 Switch (Single Phase) 1

5507497 Switch (3-Phase) 1

19A 5507501 Slotted Machine Screw 4

1/4-20 x 1

21 5518158 Wiring Harness (1-Phase) 1

5517457 Wiring Harness (3-Phase) 1

24A 5507502 Socket Head Cap Screw 3

25A 5507503 Return Spring Assemlby 1

26A 5507504 Nylon Nut 1

27 9135311 Lock Screw 1/4-20 x 1 2

28 5041050 Speed Change Housing 1

29 9127731 Socket Set Screw 1

5/16-18 x 5/16

30 5024541 Head Lock (Plain Side) 1

31 1000771 Lock Nut Assembly 1

32 5041071 Speed Change Shaft 1

33 9053661 Retainer 1

34 5041201 Bearing Spacer 1

35 9100321 Bearing 2

36 9070291 Knob 3

37 5053000 Spoke 3

38 5507827 Feed Shaft Assembly 1

39 5513378 Hi/Lo Speed Direction Plate 1

40 5053100 Rod, Graduated 1

41 9056381 Jam Nut 5/8-11 3

42 9128611 Hex Head Cap Screw 1

1/2-12 x 4

44

TS-0270031 set Screw 4

5/16-18 x 3/8

45 5032781 Motor Plate Bar 4

46 9057111 Whiz Flange Locknut 4

47 TS-0152051 Carriage Bolt 5/16-18 x 2 4

48 9056171 Carriage Bolt 4

5/16-18 x 1-1/2

49 9058051 Split Lock Washer 1/2 ID 2

50 9056841 Hex Nut 1/2-12 2

51 5041170 Variable Speed Pulley (Motor) 1

52 9054621 Socket Set Screw 1/4-20 x 1/2 2

Item Part

No. Number Description Qty

53 5042011 Key (Motor) 1

54 9077101 Variable Speed Belt 1

55 5041140 Vaiable Speed Pulley (Spindle) 1

55A 5513510 Hex Nut 1

55B 5513511 SHCS 1

56 9100421 Bearing 1

57 9058571 Spring Washer 1

58 5041761 Speed Change Nut 1

59 5041040 Speed Change Lever 1

60 9127951 Socket Set Screw 1

1/4-20 x 1/2

61 9057461 Washer 1/4 3

62 9052101 Hex Head Cap Screw 4

1/4-20 x 1

63 5041271 Right Mounting Plate 1

64 5518170 Self T apping Screw 7

3/16-24 x 3/8

68A

68B 5513513 Spacer, Threaded 1

68C 5513514 Plate, Bracket 1

68D 5513515 Pickup, Magnetic 1

68E 5513516 Screw 2

68F 5513521 Plate 1

69 5041320 Cover, Pulley 1

69A 5513517 Bracket, Face Plate 1

70 5513518 Plate, Face 1

70A 5513519 LED Display 1Ph 1

70B 5513520 Screw, Locking 1

72 9056771 Hex Jam Nut 3/8-16 1

75 5041000 Head Casting 1

76 5518172 Left Mounting Plate 1

77 9052831 Socket Set Screw 1

78

80 9052971 Socket Set Screw 1

81 5034111 Hand Wheel 1

82 5513737 Shaft speed change lever 1

86 9129051 Hex Nut 7/16-14 1

87 5041470 Collar 1

88 9128071 Hex Head Cap Screw 1

89 5032560 Motor Mounting Bracket 1

94 TS-0680032 Washer 5/16 4

96 5507505 Return Spring Bracket 1

97 5507507 Drift Pin 1

98 5507506 Switch Mounting Plate 1

99 5507527 Quill Assembly (Note 1) 1

100 5507812 Motor, 1 PH 115/220

TS-0208041 SHCS 5/16-18x3/4 2

5513736 LED Display 3 Ph

3/8-16 x 1

TS-0267101 Socket Set Screw 1

1/4-20 x 1-1/4

5/16-18 x 5/16

7/16-14 x 3-1/2

1725 RPM 60 Hz 1

5514604 Motor, 1PH 115/220

1725 RPM 50 Hz 1

5507813 Motor, 3 PH 220/440

1725 RPM 50/60 Hz 1

Note 1: Quill assembly includes items 5, 7, 8, 9,10 and 11.

Page 15

Exploded View — Head

Models: A3816, A3818, A3836 & A3838

A

15

Page 16

Parts List - Head

Models: A3816, A3818, A3836 & A3838

16

Item Part

No. Number Description Qty

1 5507580 Chuck (with Key) 1

2A 5507495 #2 MT x JT3 Arbor 1

3A 5507496 Spindle Assembly 1

4 5053070 Quill Band 1

5 9010541 O-Ring 1

6 9054511 Set Screw 2

5/16-18 x 3/8

7 5032611 Bearing Retainer 1

8 9100331 Bearing 2

9 5041010 Quill 1

10 9058561 Wavy Spring Washer 1

11 9074081 Truarc Retainer 1

16 9052711 Self Tapping Screw 4

8-32 x 3/8

17 5518157 Power Cord (Single Phase) 1

17A 5517463 Power Cord (3-Phase) 1

18A 5507500 Switch (Single Phase) 1

5507497 Switch (3-Phase) 1

19A 5507501 Slotted Machine Screw 4

21 5518158 Wiring Harness (1-Phase) 1

5517457 Wiring Harness (3-Phase) 1

24A 5507502 Socket Head Cap Screw 3

25A 5507503 Return Spring Assemlby 1

26A 5507504 Nylon Nut 1

27 5518159 Phillips Screw 1/4-20 x 5/16 2

28 5518160 Cover Plate 1

29 9127731 Socket Set Screw 1

5/16-18 x 5/16

30 5024541 Head Lock (Plain Side) 1

31 1000771 Lock Nut Assembly 1

33 9053661 Retainer 1

34 5041201 Bearing Spacer 1

35 9100321 Bearing 2

36 9070291 Knob 3

37 5053000 Spoke 3

38 5507827 Feed Shaft Assembly 1

40 5053100 Rod, Graduated 1

41 9056381 Jam Nut 5/8-11 3

42 9128611 Hex Head Cap Screw 1

1/2-13 x 4

44 9052191 Socket Set Screw 4

5/16-18 x 1/2

45 5032781 Motor Plate Bar 4

46 9057111 Whiz Flange Locknut 4

48 9056171 Carriage Bolt 4

5/16-18 x 1-1/2

49 9058051 Split Lock Washer 1/2 ID 4

50 9056841 Hex Nut 1/2-13 4

51 5518161 Step Pulley (Motor) 1

52 5518162 Socket Set Screw 2

1/4-20 x 5/16

53 5042011 Key (Motor) 1

54 5518163 Drive Belt 1

55 5518164 Step Pulley (Spindle) 1

55A 5518165 Spindle Pulley Shaft 1

55B 5518166 Key 5 x 45 1

Item Part

No. Number Description Qty

57 9058571 Spring Washer 2

61 9057461 Washer 1/4 3

62 9052101 Hex Head Cap Screw 4

1/4-20 x 1

63 5518167 Mounting Plate 2

64 9138011 Self Tapping Screw 4

#10 x 3/4 Type A

69 5518168 Pulley Cover (w/door & latch) 1

70 5518169 Face Plate 1

75 5041000 Head Casting 1

86 9129051 Hex Nut 7/16-14 1

87 5041470 Collar 1

88 9128071 Hex Head Cap Screw 1

7/16-14 x 3-1/2

89 5032560 Motor Mounting Bracket 1

94 9055281 Rubber Washer 4

96 5507505 Return Spring Bracket 1

97 5507507 Drift Pin 1

98 5507506 Switch Mounting Plate 1

99 5507527 Quill Assembly (Note 1) 1

100 5507812 Motor, 1 PH 115/220

1725 RPM 60 Hz 1

5514604 Motor, 1PH 115/220

1725 RPM 50 Hz 1

5507813 Motor, 3 PH 220/440

1725 RPM 50/60 Hz 1

Note 1: Quill assembly includes items 5, 7, 8, 9, 10

and 11.

Page 17

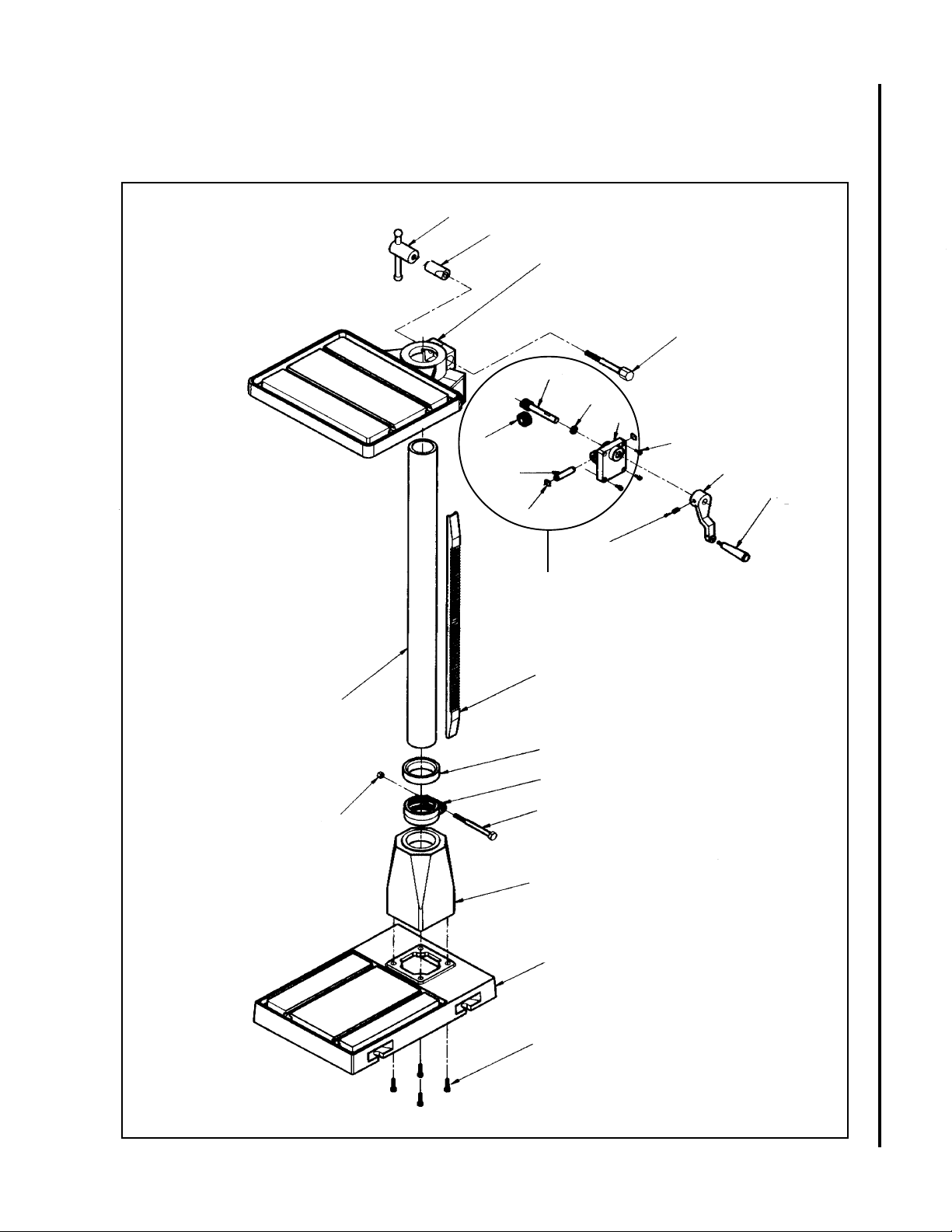

Exploded View - Base

(Floor Models A5816, A5818, A3816 & A3818)

1

2

3

14

13

12

15

18

4

16

17

19

25

22

9

23

6

5

7

20

21

17

10

11

8

Page 18

Parts List - Base

(Floor Models A5816, A5818, A3816 & A3818)

Item Part

No. Number Description Qty

1 1000771 Locknut 1

2 5003751 Table Lock (Plain Side) 1

3 5507508 Table 1

4 5507509 Hex Head Cap Screw 1

5 TS-0061091 Cap Screw 1

7/16-14 x 3-1/2

6 5041470 Collar 1

7 9129051 Hex Nut 7/16-14 1

8 5507528 Base 1

9 5507510 Standard Column 1

5511850 Short Column 1

10 5507511 Flange (Base/Column) 1

11 5630771 HHCS 1/2-12 x 1-1/2 4

12 5507571 Cover Plate 1

13 5507570 Bushing 1

14 5507513 Worm, Table Raiser 1

15 5507514 Gear, Table Raiser 1

16 5507515 Shaft, Table Raiser 1

17 5507516 C-Ring, Table Raiser 2

18 TS-0050051 SHCS 1/4 x 1 4

19 5507518 Socket Head Set Screw 1

5/16-18 x 3/8

20 5507519 Crank, T able Raiser 1

21 5507520 Handle, Table Raiser 1

22 5507521 Rack 1

23 5507522 Rack Ring 1

25 5507816 Table Raiser Assembly 1

18

Page 19

Page 20

WMH Tool Group, Inc.

2420 Vantage Dr.

Elgin, IL 60123

Ph: 847-649-3010

Fax:

847-851-1144

Loading...

Loading...