Page 1

Pioneering for You

Wilo-Sevio AIR

de Einbau- und Betriebsanleitung

US Installation and operating instructions

hu Beépítési és üzemeltetési utasítás

6068088 Ed.0.5-11/2012 no ofcial version

Page 2

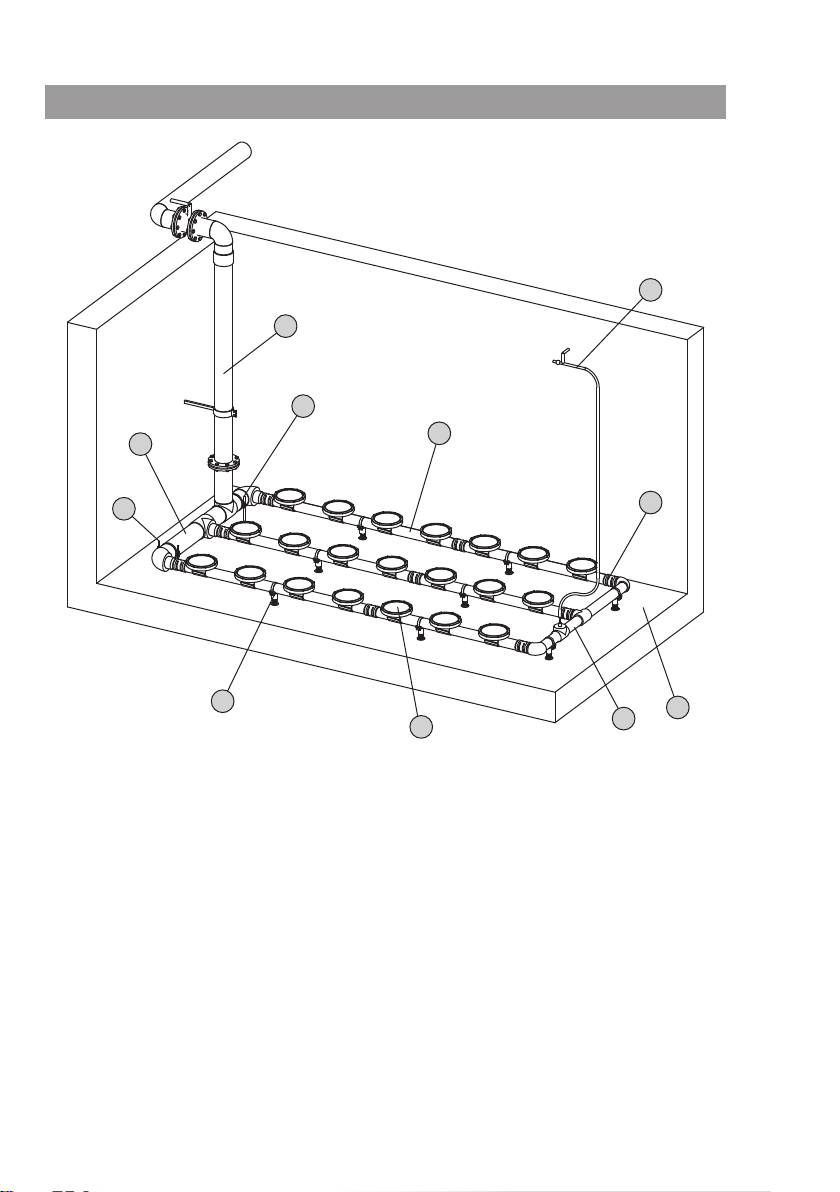

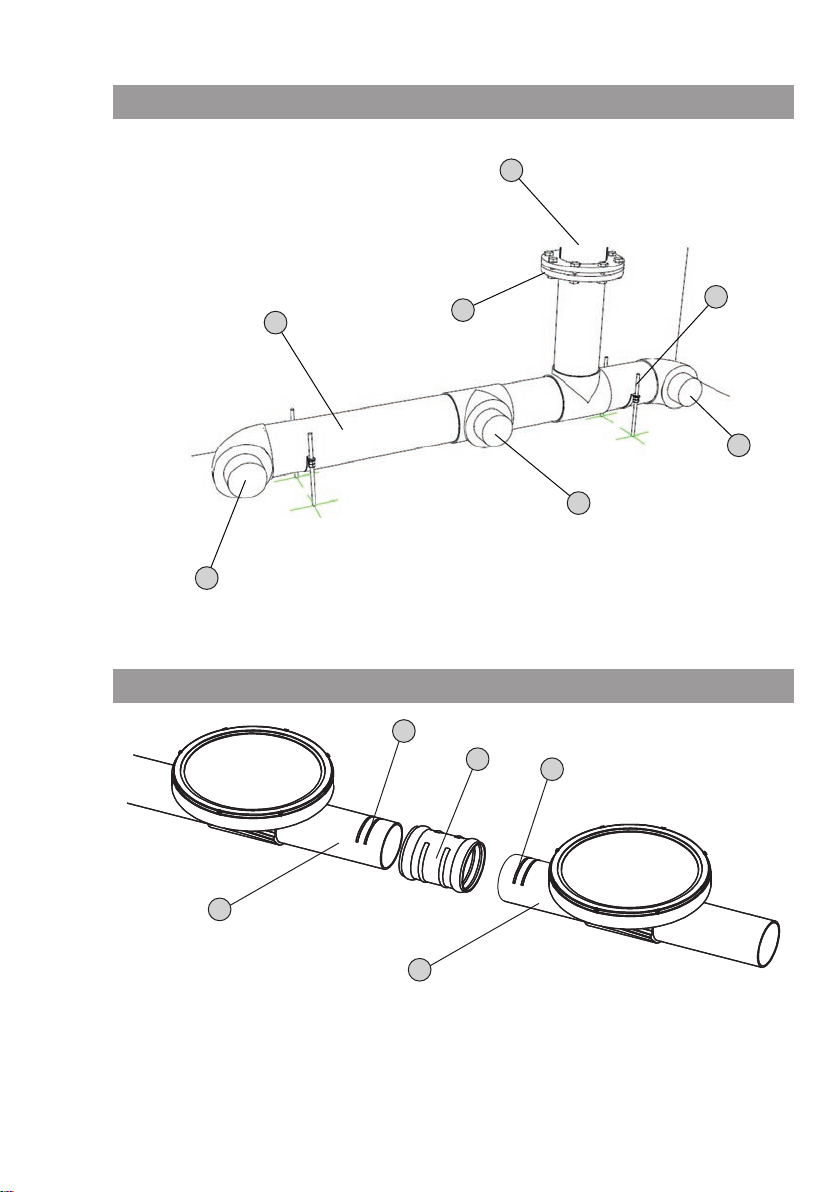

Fig. 1

10

3

2

1

4

2

5

6

8

7

9

Page 3

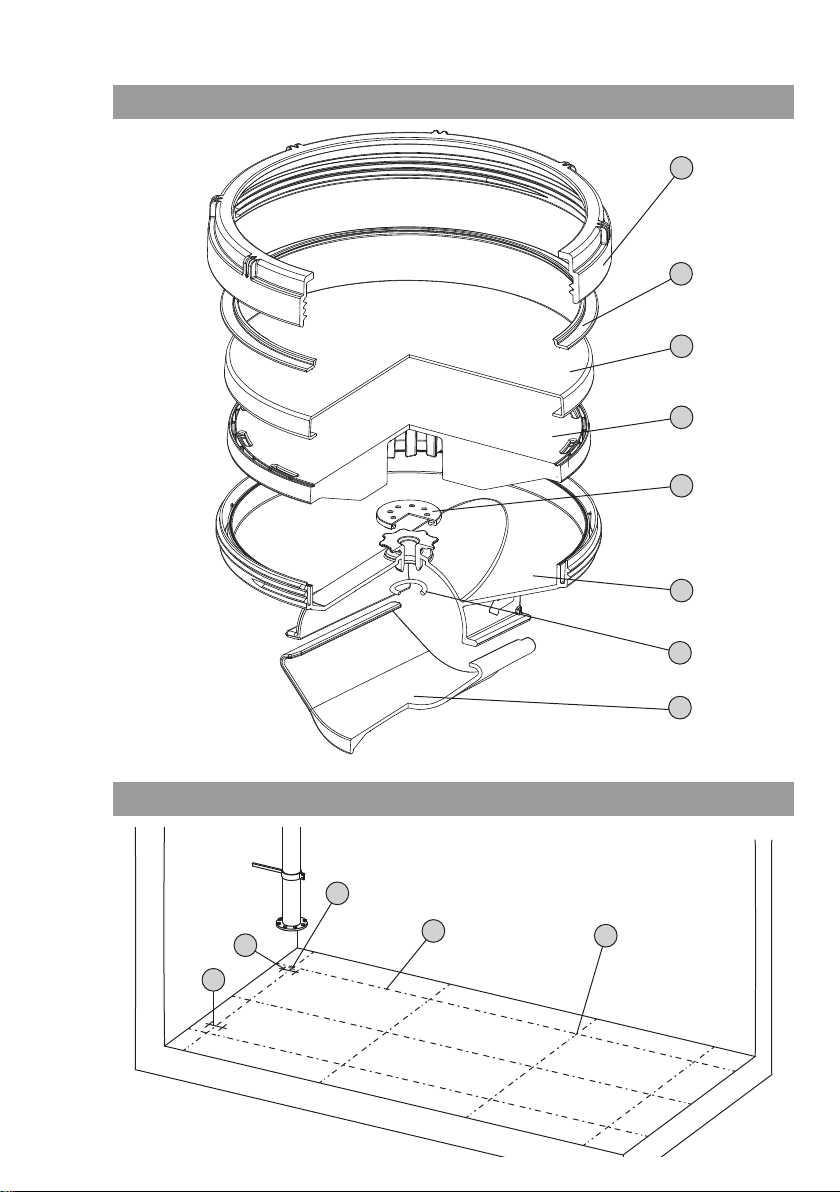

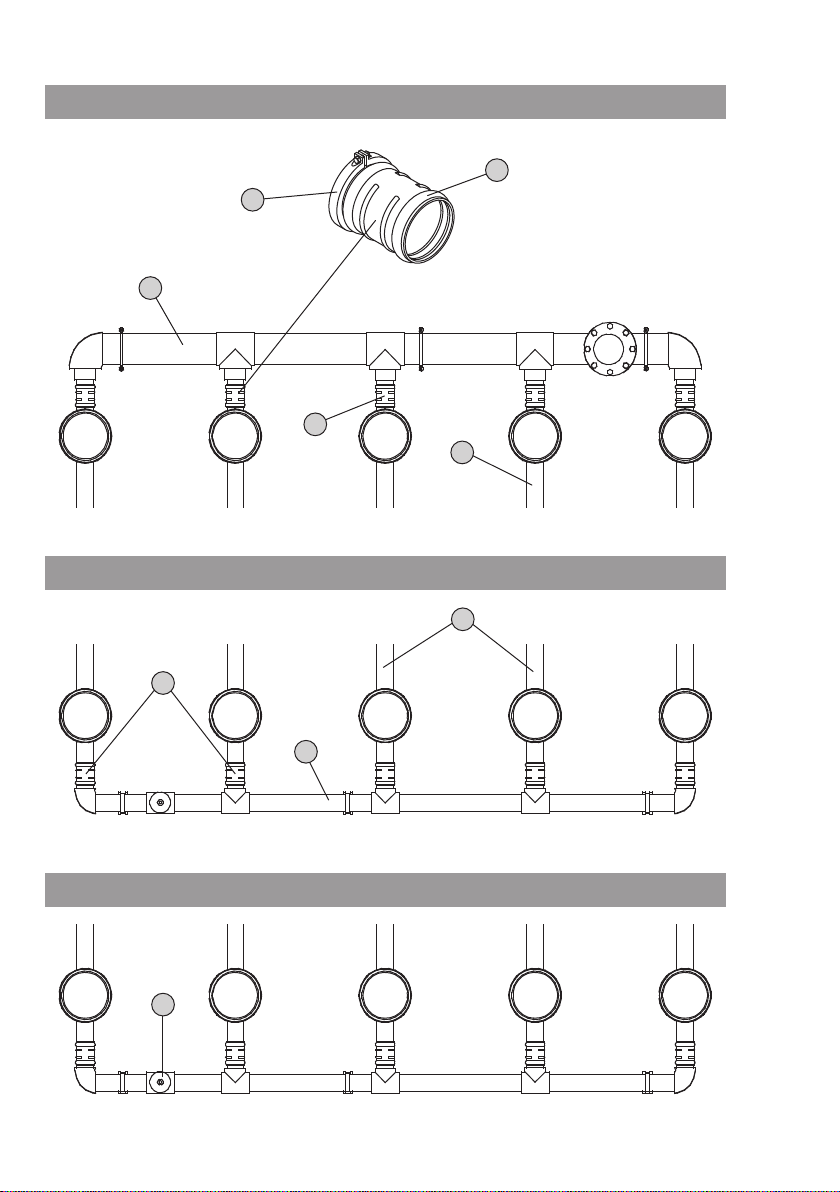

Fig. 2

1

2

3

4

5

6

7

Fig. 3

8

1

2

3

4

2

Page 4

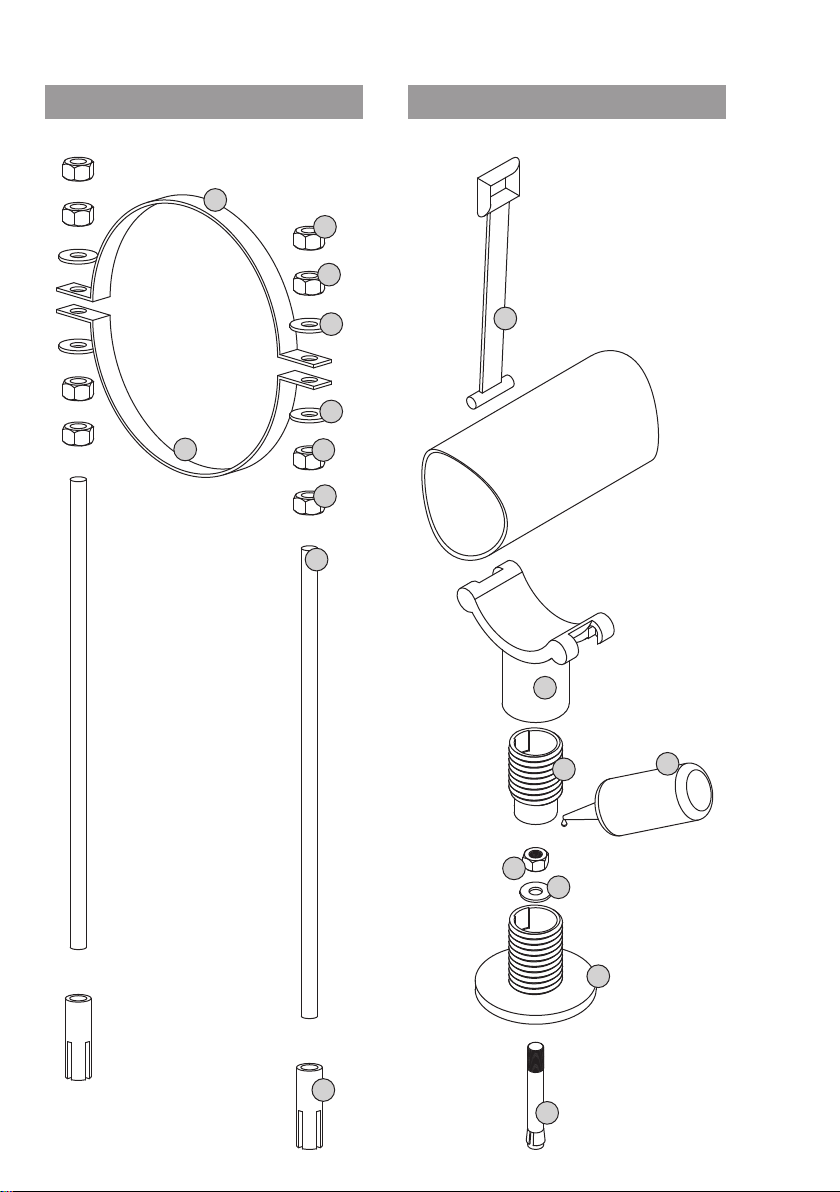

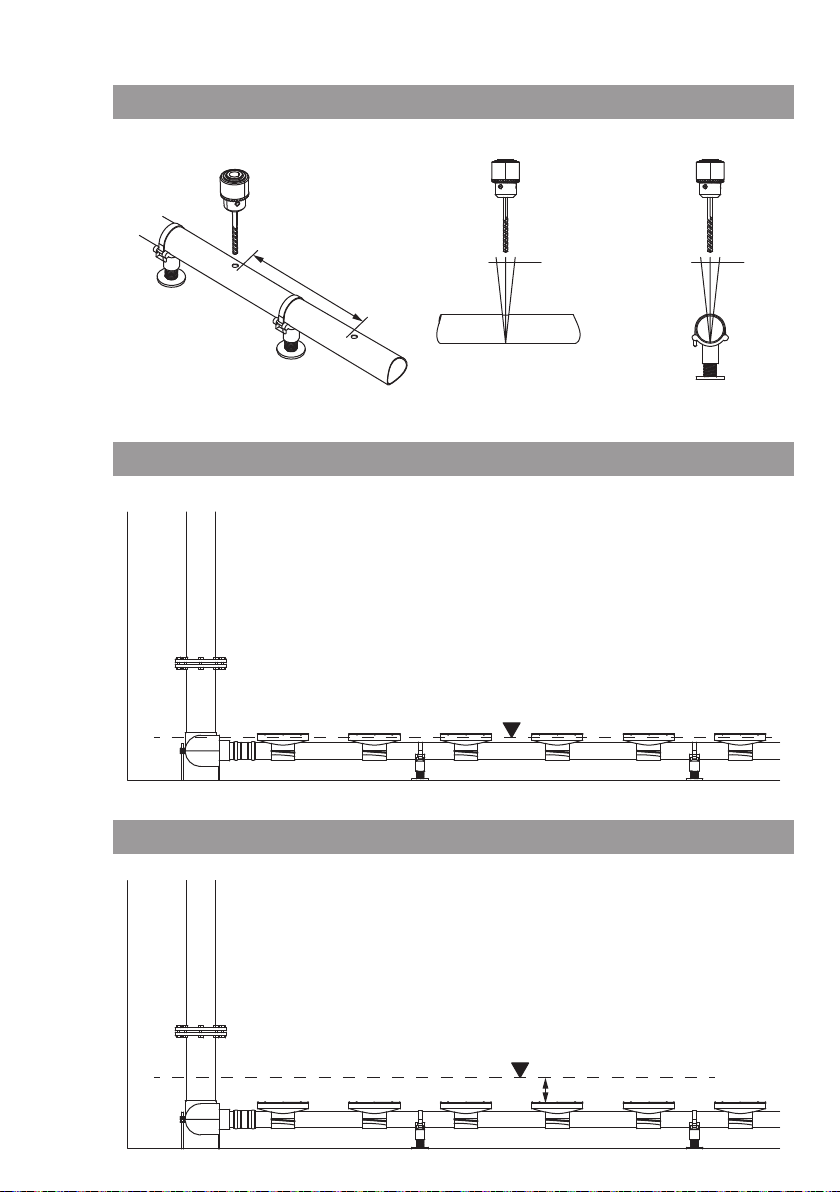

Fig. 5Fig. 4

6

8

7

5

7

5

6

4

3

2

6

5

8

4

3

2

1

1

Page 5

Fig. 6

2

Fig. 7

1

4

3

5

5

5

3

1

3

2

2

Page 6

Fig. 8

Fig. 9

4

5

2

1

3

1

Fig. 10

3

2

1

Page 7

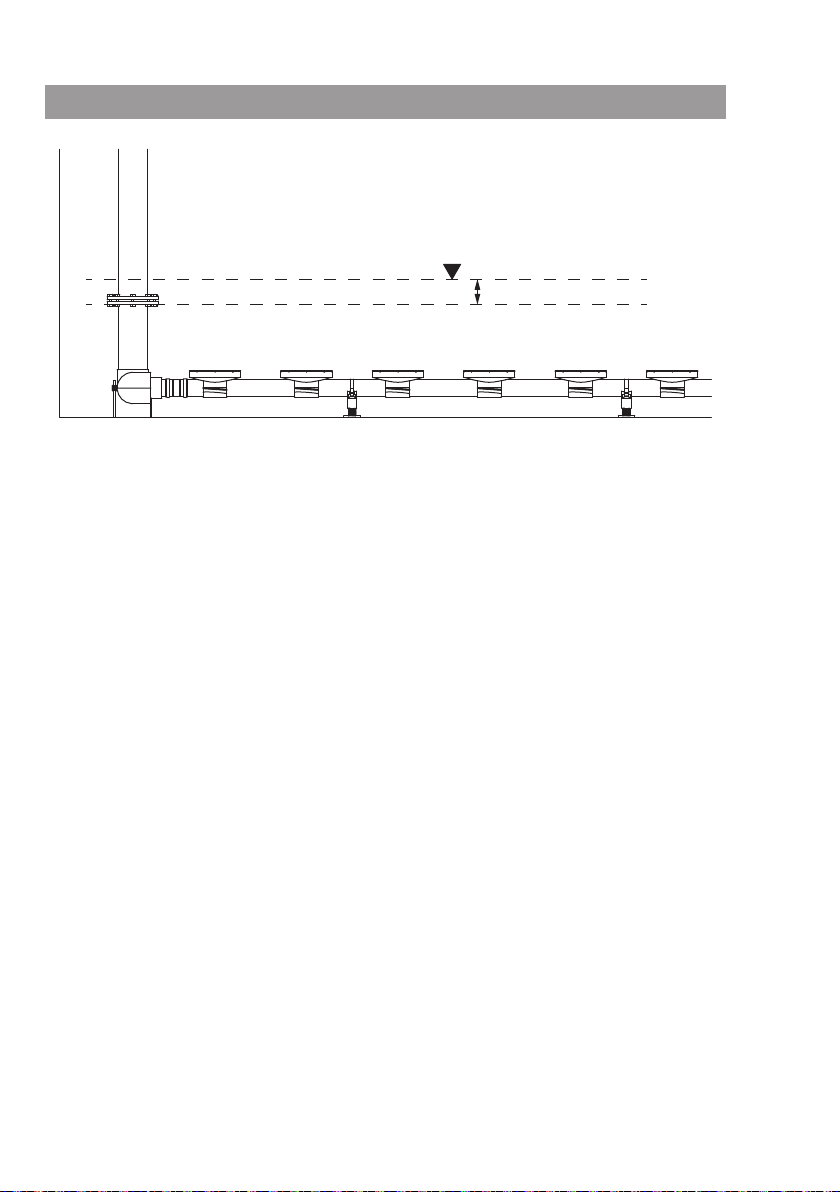

Fig. 11

Fig. 12.1

min. 800 mm

±5° ±1°

Fig. 12.2

10 cm

Page 8

Fig. 12.3

10 cm

Page 9

English

1. Introduction 44

1.1. About this document 44

1.2. Structure of the manual 44

1.3. Personnel qualications 44

1.4. Abbreviations 44

1.5. Illustrations 45

1.6. Copyright 45

1.7. Rights of alteration 45

1.8. Warranty 45

2. Safety 46

2.1. Instructions and safety information

47

2.2. General safety information 48

2.3. CE marking 49

2.4. Ground connection 49

2.5. Safety rules during operation 49

2.6. Liquids 49

2.7. Sound pressure 50

3. Transport and storage 50

3.1. Delivery 50

3.2. Transport 50

3.3. Storage 50

6. Start-up 63

6.1. Initial start-up 63

6.2. Before switching on 65

6.3. Starting up the aeration 65

6.4. After switching on 65

7. Shutdown/disposal 66

7.1. Temporary shutdown 66

7.2. Shutdown for maintenance work or

storage 66

7.3. Starting up again 67

7.4. Disposal 67

8. Maintenance 68

8.1. Maintenance intervals 69

8.2. Maintenance tasks 70

8.3. Repairs 71

4. Product description 51

4.1. Proper use 51

4.2. Construction 51

4.3. Function 53

4.4. Technical data 53

4.5. Scope of delivery 53

5. Installation 54

5.1. General requirements 54

5.2. Types of installation 55

5.3. The operating area 55

5.4. Work steps 56

Installation and operating instructions Wilo-Sevio AIR 43

Page 10

English INTRODUCTION

1. Introduction

1.1. About this document

The language of the original operating manual is German. All other language versions

are translations of the original German manual.

The operating manual contains a copy of the EC Declaration of Conformity.

Any unauthorized or unapproved changes made to the design specied in it will nullify

this declaration.

1.2. Structure of the manual

The manual is divided into individual sections. Each section has a heading which clearly

describes its content.

The table of contents also serves as a brief reference, since all the important sections

have their own headers.

All the important operating and safety instructions are highlighted. For detailed information on the structure of these texts, see “Safety” in section 2.

1.3. Personnel qualications

All personnel who work on or with the product must be qualied for such work; electrical work, for example, may only be carried out by a qualied electrician. All personnel

must be of legal age.

Operating and maintenance personnel must also observe national accident prevention

regulations.

It must be ensured that the personnel have read and understood the instructions in this

operating and maintenance handbook; if necessary, this manual must be ordered from

the manufacturer in the required language.

This product is not intended to be used by persons (including children) with limited

physical, sensory or mental capacities or without the relevant experience or knowledge,

unless they are supervised by a person responsible for their safety and receive instructions from this person on how to use the product.

Children must be supervised in order to ensure that they do not play with the product.

1.4. Abbreviations

• p.t.o. = please turn over

• re. = regarding

• approx. = approximately

• i.e. = that means

• incl. = including

• min. = minimum

• max. = maximum

• etc. = and so on

• s.a. = see also

• e.g. = for example

44 WILO SE 11/2012 Ed.03 DIN A5

Page 11

INTRODUCTION English

1.5. Illustrations

Dummies and original drawings of the products are used in the illustrations. This is the

only sensible solution given our wide range of products and the differing sizes offered

by the modular system. More exact drawings and specications can be found on the

dimension sheet, the planning information and the installation plan.

1.6. Copyright

This operation and maintenance manual has been copyrighted by the manufacturer.

The operation and maintenance handbook is intended for use by assembly, operating

and maintenance personnel. It contains technical specications and diagrams which

may not be reproduced or distributed, either completely or in part, or used for any other

purpose without the express consent of the manufacturer.

1.7. Rights of alteration

The manufacturer reserves the right to make technical alterations to systems or components. This operating and maintenance manual refers to the product indicated on the

title page.

1.8. Warranty

This section contains the general information on the warranty. Contractual agreements

have the highest priority and are not superseded by the information in this section.

The manufacturer is obliged to correct any defects found in the products it sells, provided that the following requirements have been fullled:

1.8.1. General requirements

• The defects are caused by the materials used or the way the product was manufactured

or designed.

• The defects were reported in writing to the manufacturer within the agreed warranty

period.

• The product was used only as prescribed.

• All safety and control devices were connected and inspected by qualied personnel.

1.8.2. Warranty period

If no other provisions have been made, the warranty period covers the rst 12 months

after initial start-up or up to 18 months after the delivery date. Other agreements must

be made in writing in the order conrmation. These remain valid at least until the agreed

warranty period of the product has expired.

1.8.3. Spare parts, add-ons and modications

Only genuine spare parts from the manufacturer may be used for repairs, replacements,

add-ons and modications. These are the only parts that guarantee a long service life

and maximum safety. These parts have been specially designed for our products. Unau-

Installation and operating instructions Wilo-Sevio AIR 45

Page 12

English SAFETY

thorized add-ons and modications or the use of non-original spare parts can seriously

damage the product and injure personnel.

1.8.4. Maintenance

The prescribed maintenance and inspection work should be carried out regularly. This

work may only be carried out by qualied, trained and authorized personnel. Maintenance not listed in this operation and maintenance manual, and any type of repair work

may only be performed by the manufacturer and authorized service centers.

1.8.5. Damage to the product

Damage and malfunctions that endanger safety must be eliminated immediately by

trained personnel. The product may only be operated if it is in proper working order.

During the agreed warranty period, the product may only be repaired by the manufacturer or an authorized service center. The manufacturer reserves the right to ask the

operator to return the damaged product to the factory for inspection.

1.8.6. Exclusion from liability

No liability will be assumed for product damage if any of the following items apply:

• The manufacturer deems that information provided by the operator or customer is

insufcient or incorrect

• Failure to observe the safety instructions, the regulations and requirements of German

law or the applicable local laws, or of this operating and maintenance manual

• Improper use

• Incorrect storage and transport

• Improper assembly or dismantling

• Insufcient maintenance

• Improper repairs

• Inadequate construction site or construction work

• Chemical, electrochemical and electrical inuences

• Wear

This means the manufacturer’s liability excludes all liability for personal, material or

nancial injury.

2. Safety

This section lists all the generally applicable safety instructions and technical information.

All instructions and information must be observed and followed during the various

phases of the product’s life cycle (installation, operation, maintenance, transport, etc.)!

The operator is responsible for ensuring that personnel follow these instructions and

guidelines.

46 WILO SE 11/2012 Ed.03 DIN A5

Page 13

SAFETY English

2.1. Instructions and safety information

This manual uses instructions and safety information to prevent injury and damage to

property. To clearly identify them for personnel, the instructions and safety information

are distinguished as follows:

2.1.1. Instructions

Instructions are displayed in bold type. Instructions contain text that refers to the previous text or particular sections, or highlights short instructions.

Example:

Note that products stored with drinking water must be protected from frost.

2.1.2. Safety information

Safety information is slightly indented and displayed in bold type. It always commences

with a signal word.

Information that only refers to material damage is printed in gray, without safety symbols.

Information that refers to personal injury is printed in black and is always accompanied by a safety symbol. Danger, prohibition or instruction symbols are used as safety

symbols.

Example:

DANGER symbol: General hazard

DANGER symbol, for example, electrical current

PROHIBITION symbol, for example, Keep out!

INSTRUCTION symbol, for example, wear protective equipment

The safety symbols used conform to the generally valid directives and regulations, such

as DIN and ANSI.

Each safety instruction begins with one of the following signal words:

• Danger

Serious or fatal injuries can occur!

Installation and operating instructions Wilo-Sevio AIR 47

Page 14

English SAFETY

• Warning

Serious injuries can occur!

• Caution

Injuries can occur!

• Caution (instruction without symbol)

Substantial material damage can occur. Irreparable damage is possible!

Safety instructions begin with a signal word and description of the hazard, followed by

its cause and potential consequences, and end with advice on prevention.

Example:

Beware of rotating parts!

The moving impeller can crush and sever limbs. Switch off the device and let the

impeller come to a halt.

2.2. General safety information

• When installing or removing the product, never work alone in rooms and shafts. A second person must always be present.

• Sufcient ventilation must be provided in enclosed rooms.

• When welding or working with electrical devices, make sure there is no risk of explosion.

• During work in environments hazardous to health (liquid containing fecal matter, acti-

vated sludge with bacteria, etc.), special caution is required:

• Open wounds must be immediately cleaned and treated.

• Eating and drinking are strictly prohibited.

• Proper protective equipment must be worn!

• Upon leaving the system, disinfect persons and tools.

• The product must always be switched off before any work is performed on it (assembly,

dismantling, maintenance, installation). The product must be secured against being

switched back on.

• The person operating the product must notify his or her supervisor immediately should

any defects or irregularities occur.

• Tools and other objects should be kept in a place reserved for them so that they can be

found quickly.

• Only use lashing equipment which is legally dened as such and ofcially approved.

• The lashing equipment must be kept safely and must be suitable for the conditions of

use (weather, hooking device, load, etc).

• Mobile equipment for lifting loads should be used in such a way that it always remains

stable during operation.

• When using mobile equipment for lifting non-guided loads, take action to prevent

tipping, sliding, etc.

• Measures should be taken to ensure that no person is ever directly beneath a suspended

load. Furthermore, it is also prohibited to move suspended loads over workplaces where

people are present.

48 WILO SE 11/2012 Ed.03 DIN A5

Page 15

SAFETY English

• If mobile equipment is used for lifting loads, a second person should be present to coordinate the procedure if required (for example, if the operator’s eld of vision is blocked).

• The load to be lifted must be transported in such a manner that nobody can be injured

in the event of a power outage. Additionally, when working outdoors, such procedures

must be stopped immediately if weather conditions worsen.

These instructions must be strictly observed. Non-observance can result in injury or

substantial material damage.

2.3. CE marking

If the product is obliged to carry a CE marking,

• the marking is attached to the product and

• a copy of the EC declaration of conformity is enclosed or is part of this operating man-

ual.

2.4. Ground connection

Products with metallic and/or conductive surfaces must be grounded. If there is a possibility that people can come into contact with the product and the pumped liquid, the

connection must be additionally equipped with a residual current circuit breaker.

2.5. Safety rules during operation

When operating the product, always follow the locally applicable laws and regulations

for accident prevention and securing the worksite. To help to ensure safe working

practice, the responsibilities of employees should be clearly set out by the owner. All

personnel are responsible for ensuring that regulations are observed.

2.6. Liquids

Each liquid differs in terms of its composition, corrosiveness, abrasiveness and dry matter content, as well as in many other aspects. Generally, our products can be used for

many applications. Please note that if requirements change (density, viscosity or general

composition), this can also affect many operational parameters of the product.

When using or replacing the product in a different liquid, observe the following points:

• When used in drinking water applications, all the parts that come into contact with the

uid must be approved for use with drinking water.

Before being used in drinking water, the corresponding products must be checked to

ensure that they have been approved for such use.

• Products that have been operated in dirty waste water must be cleaned thoroughly

before being used for other liquids.

• Products that have been operated in sewage water and/or uids that are hazardous to

health must be decontaminated before being used with other liquids.

It must be claried whether the product can be used with another liquid.

Installation and operating instructions Wilo-Sevio AIR 49

Page 16

English TRANSPORT AND STORAGE

• If the product is to be used with highly ammable, explosive and/or aggressive uids,

the manufacturer must be consulted.

2.7. Sound pressure

The product itself is generally operated under water and only with air. This means that

the sound pressure cannot be measured.

However, the air is supplied using a compressor. Depending on its power and environmental conditions, this compressor can have elevated sound pressure.

For this reason we recommend that the operator carry out an the additional measurement in the workplace when the product is operating.

CAUTION: Wear ear protectors!

In terms of the applicable laws and regulations, ear protection must be worn if the

sound pressure is greater than 85 dB (A). The owner is responsible for ensuring

compliance with these regulations.

3. Transport and storage

3.1. Delivery

On delivery, immediately check that the product is complete and undamaged. If any

parts are damaged or missing, the transport company or the manufacturer must be notied on the day of delivery. Claims made after this date cannot be recognized. Damage

to parts must be noted on the delivery or freight documentation.

3.2. Transport

Before transport, the product must be packaged in such a way that it is protected from

moisture, frost and other damage. It is important to keep the original packaging.

3.3. Storage

• The components must be stored in the original packaging.

• The store room must be dry and frost-proof. We recommend storage in a room with a

temperature between 10°C and 25°C. The temperature may not exceed +50°C.

• The product must be protected from direct sunlight, heat, dust and frost. Furthermore,

the product may not be stored in rooms where welding takes place. Heat and cold, as

well as the gas and radiation given off during welding, can damage the plastic parts.

• New disc aerators may not be stored for more than three months. If they are stored for

more than three months, there is a risk that the membranes will become porous and

leaky.

50 WILO SE 11/2012 Ed.03 DIN A5

Page 17

PRODUCT DESCRIPTION English

4. Product description

4.1. Proper use

The Wilo-Sevio AIR disc aerator and aerator systems are used for ne-bubble air

inclusion in liquids such as water, waste water or sludges, for the purpose of supplying

oxygen to the liquids.

The temperature of the liquid must be between +5°C and 30°C. If the products are to

be used in liquid with higher temperatures, the manufacturer must be consulted. The

surrounding liquid must also be free of objects with sharp edges. We recommend that

the liquid be pre-cleaned with a lter.

The supplied air must be free of oil, dust and solvents. Dust lters must correspond to

lter class EU4 according to DIN24185 (degree of separation >90%).

All lters and insulating materials in use may not be made of berglass, mineral bers or

other materials consisting of ne bers. Rotary slide valves with graphite ns must be

equipped with an air lter on the pressure side.

These materials can lead to clogging of or damage to the membranes.

4.2. Construction

A Wilo-Sevio AIR aerator system consists of one or more aerator groups. An aerator

group forms the base unit and consists of several components:

Fig. 1.: Aerator system component overview

Air distributor with connecting ange for

1

the intake line (down pipe)

2 Base support for air distributor 7 Basin bottom

Intake line (down pipe); must be installed

3

by the customer.

Aerator pipe with pre-assembled disc

4

aerators

5 Base support for aerator pipe 10

6 Disc aerators

Pipe coupling for connecting the individ-

8

ual components

9 Drainage connection

Drainage line; must be installed by the

customer.

4.2.1. Piping

The pipes are pre-fabricated in components that can be easily used:

• PVC air distributors in the diameters of 90mm, 160mm and 200mm with central or

lateral DN80 to DN200 ange connection for the intake line. Larger diameters are

available in stainless steel with DN125 to DN350 ange connections.

• PVC aerator pipes with 90mm external diameter or made from stainless steel with

88.9mm external diameter with pre-assembled disc aerator

Installation and operating instructions Wilo-Sevio AIR 51

Page 18

English PRODUCT DESCRIPTION

• Drainage connection as the terminating connection of all aerator pipes with a connection for the drainage line. This can be used to drain off the condensate that can form

during aeration.

• Pipe coupling with rubber ring seal as a plug connection for connecting the individual

PVC components. The pipe coupling for securing the aerator pipes on the air distributor

must also be equipped with a stainless steel clamping ring.

4.2.2. Base support

All pipes on the basin bottom are secured by the base supports. They also make it possible to level the aerator group.

There are two different base supports:

• For securing the stainless steel air distributor

• For securing the aerator pipes and the PVC drainage connection

4.2.3. Disc aerators

The disc aerators introduce the supplied air into the liquid. The air is distributed across

the entire membrane surface and released through the perforated membrane. The disc

aerator consists of several components.

Fig. 2.: Disc aerator component overview

1 Threaded ring 5 Non-return valve

2 Separation ring 6 Aerator housing

3 Membrane 7 O ring

4 Membrane support 8 Slide closure

• Fiberglass-reinforced plastic threaded ring for securing the membrane to the membrane

support. The threaded ring and aerator housing are matched to each other in such a

way that the threaded ring can be easily loosened even after years of use, allowing the

membrane to be replaced.

• The polyacetal separation ring prevents the membrane from sticking to the threaded

ring. This ensures that the membrane can be easily replaced.

• The EPDM membrane with perforations across its entire surface for optimal air inclusion.

• Fiberglass-reinforced plastic membrane support, which holds the membrane in place.

• The EPDM non-return valve protects the aerator system from penetration of the liquid if

the membrane is defective.

• Fiberglass-reinforced plastic aerator housing with integrated anti-rotation lock

• NBR O ring for sealing the disc aerator against the aerator pipe

• Fiberglass-reinforced sliding closure for easy installation and removal of the disc aerator

52 WILO SE 11/2012 Ed.03 DIN A5

Page 19

PRODUCT DESCRIPTION English

4.3. Function

A blower or compressor is used to pump air through the intake line into the air distributor. The air is evenly distributed into the aerator pipes through the air distributor and

fed to the disc aerators. The disc aerators distribute the air across the entire membrane

surface and introduce this air into the liquid.

4.4. Technical data

• Disc aerators

• External diameter: 280mm

• Membrane diameter: 237mm

• Membrane surface: 0.044m²

• Oxygen utilization: 6.5 ... 8.5%/m

• Size of the air bubbles: 1–3mm

• Pressure loss: 22 ... 43mbar

• Connection size: 88.9 ... 90mm

• Max. air temperature in the system / disc aerator: 100°C

• Pressurization range

• Air volume range: 1–8Nm³/h*

• Min. pressurization: 1.5Nm³/h*

• Standard pressurization: 4.0Nm³/h*

• Max. pressurization: 6.0Nm³/h*

Pressurization of 7.5Nm³/h* is possible for a brief period (no more than 15 minutes).

*The values for the pressurization apply to standardized conditions: 0°C and 1013hPa.

4.5. Scope of delivery

The scope of delivery differs according to whether a complete aerator system or only

disc aerators (with the pipes provided by the customer) were ordered.

4.5.1. “Aerator system” scope of delivery

• Air distributor with ange connection for intake line

• Aerator pipes with pre-assembled disc aerator

• Drainage connection

• Pipe connections

• Base support

• Fastening material

• Drilling plan for the base supports

• Overview and position diagram of the individual components

• Special key for easy installation/removal of the threaded ring on the disc aerator

• Rubber mallet

4.5.2. “Disc aerator” scope of delivery

• Disc aerators

• Drilling plan for the connection holes on the pipes for the disc aerators

Installation and operating instructions Wilo-Sevio AIR 53

Page 20

English INSTALLATION

4.5.3. Material to be provided by the customer

• Intake line for the air supply

• Blower or compressor

• Drainage line with shut-off valve

• All pipes if only disc aerators were ordered

5. Installation

In order to prevent damage to the product or serious injury during installation, the

following points must be observed:

• Installation work – assembly and installation of the machine – may only be carried out

by qualied persons. The safety instructions must be followed at all times.

• The machine must be inspected for transport damage before carrying out any installation work.

5.1. General requirements

For planning and operation of technical waste water systems, pay attention to the pertinent local regulations and directives for wastewater technology (such as those of the

German Association for Water, Wastewater and Waste).

The following information must be observed when installing the product:

• This work must be carried out by qualied personnel.

• Check that the available planning documentation (installation plans, layout of the oper-

ating area, drilling plan) is complete and correct.

• Observe all regulations, rules and legal requirements for working with and underneath

heavy suspended loads.

• Wear appropriate protective equipment.

• During all work, a second person must always be present. If there is a risk of poisonous

or asphyxiating gases forming, the necessary precautions must be taken.

• Please also observe the applicable national accident prevention regulations and trade

association safety provisions.

DANGER of falling!

Work may be necessary directly at the edge of the shaft and/or basin during installation. Carelessness or wearing inappropriate clothing could result in a fall. There is

a risk of fatal injury! Take all necessary safety precautions to prevent this.

54 WILO SE 11/2012 Ed.03 DIN A5

Page 21

INSTALLATION English

BEWARE of poisonous substances!

During work in environments hazardous to health, such as waste water or sewage

treatment plants, there is an increased hazard from bacteria and viruses. In order to

counteract this elevated risk, please keep the following points in mind:

• Open wounds must be immediately cleaned and treated.

• Eating and drinking are strictly prohibited.

• Proper protective equipment must be worn.

• Upon leaving the system, disinfect persons and tools.

5.2. Types of installation

• Aerator group securely xed to the basin bottom

5.3. The operating area

• The operating area must be clean, with coarse solid particles removed, dry, frost-free

and, if necessary, decontaminated.

• During all work, a second person must be present for safety reasons.

• If there is a risk of poisonous or asphyxiating gases forming, the necessary precautions

must be taken.

• Safe, truck-accessible access must be available to the operating area.

• A storage location of sufcient size and with a solid subsurface must be available so

that the complete load can be unloaded and stored in accordance with the specications in the “Transport and storage” section.

• Provisioning of the electricity, water and compressed air supply for the installation.

• It must be ensured that hoisting gear can be tted without any trouble, since this is re-

quired for assembly and removal of the product. It must be possible to reach the product

safely in its operating and storage locations using the hoisting gear.

• For transport of the product, load-carrying equipment must be secured to the pipes

with approved fastening devices. Here it is necessary to ensure that the load does not

shift during transport.

• The structural components and foundations must be of sufcient stability in order to

allow the product to be anchored securely and functionally. The operator or the supplier

is responsible for the provision of the foundations and their suitability in terms of dimensions, stability and strength.

5.3.1. Material to be provided by the customer

• Intake line for the air supply

The aerator group is connected through the air distributor to the intake line. The position of the intake line may not change after the order is placed, since this can otherwise

lead to problems during installation.

The intake line also needs to be self-supporting. The weight of the intake line may not

be transferred to the air distributor.

We also recommend installation of a compensating joint between the intake pipe and

Installation and operating instructions Wilo-Sevio AIR 55

Page 22

English INSTALLATION

the rest of the pipelines, as well as installation of a manometer in the intake line. These

measures allow tension and transmissions of vibration to be reduced and the current air

inclusion to be checked.

• Blower or compressor

The blower or compressor must have sufcient output for introducing the required air

volume into the aerator group(s).

• Drainage line with shut-off valve

In order to channel off any liquid that has penetrated into the aeration system or condensate that has formed during operation.

• All pipes if only disc aerators were ordered

If only disc aerators were ordered, the complete pipe system must be installed in advance.

5.4. Work steps

Installation takes place in the following steps:

1. Checking the operating area

2. Unpacking and checking the components

3. Installing the base supports

4. Aligning the contact surface for the pipes

5. Installing the air distributor

6. Installing the aerator pipes

7. Installing the drainage connection

8. Securing the pipes

9. Installing the drainage line

10. Installing the disc aerators

When a complete aerator system is being installed, the disc aerators are already pre-assembled. In this case, item 10 is omitted during installation. If the pipe system is being

provided by the customer and only disc aerators were ordered, items 3 to 9 are omitted

during installation.

5.4.1. Checking the operating area

Before you begin with installation, check the operating area to ensure that it is prepared

for installation:

• The design of the system as well as the installation and drilling plan match the current

conditions.

• The operating area is clean and the components to be provided by the customer are

appropriately prepared/installed.

• PVC becomes brittle when subjected to cold temperatures. For this reason, the ambient

temperature must be over +10°C during installation.

Installation with an ambient temperature below +5°C is strictly prohibited.

56 WILO SE 11/2012 Ed.03 DIN A5

Page 23

INSTALLATION English

5.4.2. Unpacking and checking the components

The pipes are packed in wooden crates, and the installation parts are packed in cardboard boxes. Carefully open the packaging so that you do not injure yourself or damage

the components.

The individual components must be unpacked in a clean, dry and frost-free place near

the installation location.

The following components must be included in the scope of delivery:

• “Aerator system” scope of delivery

• Air distributor with ange connection for intake line

• Aerator pipes with pre-assembled disc aerator

• Drainage connection

• Pipe connections

• Base support

• Fastening material

• Drilling plan for the base supports

• Overview and position diagram of the individual components

• Special key for easy installation/removal of the threaded ring on the disc aerator

• Rubber mallet

• “Disc aerator” scope of delivery

• Disc aerators

• Drilling plan for the air escape holes on the pipes for the disc aerators

Check all components for damage. Do not install defective parts. In this case, contact

the manufacturer.

5.4.3. Installing the base supports

The base supports on the bottom of the basin are used to secure and align the aerator

group. The drilling plan contains information regarding the position as well as the design

(support for air distributor or aerator pipe) of the individual base supports, along with

information on the borehole (depth, diameter).

The center of the intake pipe is used as a reference point. The air distributor must be

placed here precisely in order to ensure a problem-free connection to the supply line.

Applying borehole markings to the bottom of the basin

Fig. 3.: Applying markings

1 Center of the intake pipe 3 Marking lines for the aerator pipes

Boreholes for the air distributor base

2

support

Boreholes for the base support for the

4

aerator pipes

1. Mark the center of the intake pipe on the bottom of the basin.

2. Mark the boreholes for the air distributor base supports on the bottom of the basin.

Installation and operating instructions Wilo-Sevio AIR 57

Page 24

English INSTALLATION

3. Using a colored line, mark the center of the individual disc aerators on the bottom of the

basin and measure the boreholes for the base supports of the aerator pipes.

The boreholes of the base supports must be precisely on the marking line and match

the supplied drilling plan, since there can otherwise be twisting during installation.

4. Before you begin drilling the holes, check the distances of the aerator group to the

basin wall. The distances must match the design, since the calculated air inclusion can

otherwise not be ensured.

Installation of the stainless steel base supports with drop-in anchors and threaded

rods (for the air distributor)

Fig. 4.: Stainless steel base support component overview

1 Drop-in anchor 5 Flat washer

Pipe clamp:

2 Threaded rod 6

1x support for the air distributor

1x securing of the air distributor

Locknut for securing the height adjust-

3

ment

7 Hexagon nut for securing the pipe clamps

4 Hexagon nut for height adjustment 8 Locknut for securing the attachment

• The drop-in anchor may only be used in reinforced or unreinforced normal concrete with

a strength class between C20/25 and C50/60 (according to EN206:2000-12).

• The drop-in anchor is only suitable for crack-free concrete.

• Before the drop-in anchors are used, the strength of the structure must be ascertained

in order to ensure that the reaction forces can be absorbed.

1. Drill the individual holes for the corresponding base supports. Use a drill with a borehole

depth marking.

2. Thoroughly clean the boreholes, such as by vacuuming them out.

3. Place the drop-in anchor into the borehole and carefully drive it into the hole using a

rubber mallet. The anchor and foundation must be ush with each other.

4. Rotate the threaded rods completely into the anchor.

5. Twist on two hexagon nuts per anchor rod, place one at washer on each, and attach a

pipe clamp with the bend pointing downwards.

Installation of the PVC base support with anchor bolt (for the aerator pipes)

Fig. 5.: Stainless steel base support component overview

1 Anchor bolt 5 Extension

2 Foot 6 Upper part with pipe support

58 WILO SE 11/2012 Ed.03 DIN A5

Page 25

INSTALLATION English

3 Flat washer 7 Elastic band for securing pipe

4 Hexagon nut for attachment 8 PVC adhesive

• The anchor bolt may only be used in reinforced or unreinforced normal concrete with a

strength class between C20/25 and C50/60 (according to EN206:2000-12).

• The anchor bolt is only suitable for crack-free concrete.

• Before the anchor bolts are used, the strength of the structure must be ascertained in

order to ensure that the reaction forces can be absorbed.

1. Drill the individual holes for the corresponding base supports. Use a drill with a borehole

depth marking.

2. Thoroughly clean the boreholes, such as by vacuuming them out.

3. Place the anchor bolt into the borehole and carefully use a rubber mallet to drive it into

the hole until it reaches the insertion depth marking. The threaded rod for securing the

components must protrude out of the foundation.

4. Place the foot of the base support onto the threaded rod and secure it with the washer

and hexagon nut.

Important: When tightening the hexagon nuts, make sure that the foot doesn’t

break.

5. Turn the upper part of the base support with the pipe support onto the foot.

5.4.4. Aligning the contact surface for the pipes

In order to ensure proper aeration, the individual aerator groups must be aligned so that

they are precisely horizontal and all aerator groups are the same height. The recommended distance between bottom of the basin and the pipe support is 70mm. Within

an aerator group, a deviation of no more than ±10mm is permitted. The height of each

support can be adjusted between 70mm and 100mm. The precise height can be measured and adjusted using a leveling device (laser).

When carrying out leveling work, also keep in mind the height of the air distributor.

The air distributor must be connected to the intake line so that it is free of strain.

Height adjustment of the stainless steel base support with drop-in anchor and

threaded rod

The height is adjusted using the two hexagon nuts. The top hexagon nut is used to set

the desired height, and the bottom nut is used to secure the adjustment (locknut).

Height adjustment of the PVC base support with anchor bolt

The height is adjusted by turning the pipe support. If this height adjustment is not

sufcient, an extension can be installed.

1. Rotate the extension onto the foot and secure the connection using PVC adhesive.

2. Rotate the upper part of the support onto the extension and set the desired height.

Installation and operating instructions Wilo-Sevio AIR 59

Page 26

English INSTALLATION

5.4.5. Installing the air distributor

Fig. 6.: Installing the air distributor

1 Air distributor 4

Air distributor / intake line ange connection

2 Intake line 5 Connection ange of the aerator pipes

3 Base support

1. Place the air distributor into the pipe clamp of the base support so that the ange connection is pointing straight upwards.

2. Slide the air distributor to the left or right until the ange connection is positioned

directly under the connection ange of the intake line.

Important: The air distributor must be easily slid under the supply pipe. The two

anges may not twist, and the distance between them may not be larger than 1mm.

The height of the base support may need to be adjusted.

3. Screw the two anges onto each other and tighten the screws securely.

4. The connections for the aerator pipes must be precisely horizontal so that the connected aerator pipes run horizontally.

5.4.6. Installing the aerator pipes

The aerator pipes are installed using pipe couplings. A differentiation must be made

here between the installations “aerator pipe / aerator pipe” and “aerator pipe / air distributor.” For connecting two aerator pipes, the pipe couplings are used purely as plug

connections. When connecting the aerator pipes to the air distributor, the pipe coupling

is additionally secured on the side of the air distributor using a pipe clamp.

Aerator pipe / aerator pipe installation

Fig. 7.: Connecting the aerator pipes

1 Pipe coupling 3 Slide-in marking

2 Aerator pipe with disc aerator

1. Clean the outside of the pipe ends of the aerator pipe as well as the inside of the pipe

coupling.

2. Check the round sealing rings in the pipe coupling for damage. Defective seals must be

replaced.

3. Wet the outside of the pipe ends of the aerator pipe as well as the inside of the pipe

coupling with a liquid soap solution (do not use grease or oil).

4. Fit the pipe coupling onto an aerator pipe. Slide the pipe coupling up to the rst marking

on the aerator pipe.

60 WILO SE 11/2012 Ed.03 DIN A5

Page 27

INSTALLATION English

5. Slide the other aerator pipe into the pipe coupling also up to the rst marking.

6. Continue until the corresponding aerator pipes have all been joined in accordance with

the overview diagram.

7. In each case place a line of aerator pipes onto the base supports.

Aerator pipe / air distributor installation

Fig. 8.: Installing the aerator pipes with the air distributor

1 Pipe coupling with pipe clamp 4

2 Air distributor 5

Pipe coupling: aerator pipe connection

side

Pipe coupling: connection side with pipe

clamp for securing to the air distributor

3 Aerator pipe with disc aerator

1. Clean the outside of the pipe end of the aerator pipe, the outside of the connection

ange of the air distributor and the inside of the pipe coupling.

2. Check the round sealing rings in the pipe coupling for damage. Defective seals must be

replaced.

1. Wet the outside of the pipe end of the aerator pipe, the outside of the connection

ange of the air distributor and the inside of the pipe coupling with a liquid soap solution (do not use grease or oil).

2. Fit the pipe coupling onto the aerator pipe. Slide the pipe coupling up to the rst marking on the aerator pipe. Ensure that the pipe clamp is not needed on this side.

3. Slide the pipe coupling with pipe clamp onto the connection ange of the air distributor

and secure the pipe coupling with the pipe clamp.

4. Also attach the other aerator lines to the air distributor in this manner.

5.4.7. Installing the drainage connection

Fig. 9.: Installing the drainage connection

1 Aerator pipes with disc aerators 3 Pipe connections

2 Drainage connection

The drainage connection forms the end piece of an aerator group. Accordingly, all aerator lines must also be connected to it. The connection for the drainage line is also here.

The drainage connection is installed on an aerator pipe in the same way as the “aerator

pipe / aerator pipe” installation.

5.4.8. Securing the pipes

After the entire pipe system has been assembled, the aerator group can be afxed to

the base supports.

Installation and operating instructions Wilo-Sevio AIR 61

Page 28

English INSTALLATION

1. Check whether the aerator group is complete and resting horizontally on the base supports. It may be necessary to adjust the height of some base supports.

2. Use the elastic bands to secure the aerator pipes to the base support. The elastic bands

are hooked into the support using the eyelets.

Important: If the ambient temperature is below 15°C, it is recommended that the

elastic bands be placed in warm water before installation. This allows the elastic to

be more easily stretched and simplies installation.

3. Use the second pipe clamp to secure the air distributor. Fit this onto the anchor rod, put

on a at washer, and screw on two hexagon nuts per anchor rod. The pipe clamp is secured using the bottom hexagon nut; the attachment is secured using the top hexagon

nut (locknut).

5.4.9. Installation of the drainage line (supplied by the customer)

Fig. 10.: Connecting the drainage line

1 Connection for the drainage line

Once the aerator group has been completely installed, the drainage line needs to be

connected. The drainage connection is located at the end of the pipe system, or, in case

of aerator systems that are not connected, the drainage connection is located on the air

distributor.

The drainage line must be attached outside of the basin and equipped with a valve.

5.4.10. Installing the disc aerators with customer-supplied aerator systems

If the aerator system has already been provided by the customer, only the disc aerators

can be installed. To do this, it is only necessary to drill the connection holes into the

existing pipe system. The corresponding drilling diagram can be found in the included

drilling plan.

Fig. 11.: Installing the disc aerators

1. Clean the pipes.

2. Mark the boreholes according to the included drilling plan. The minimum distance be-

tween two connection holes may not be smaller than 800mm.

3. Drill the connection holes:

• Size: 20mm; +5/-0mm

• Horizontal tolerance: ±5°

• Vertical tolerance: ±1°

4. Fit the disc aerator onto the pipe. Ensure that the connection of the disc aerator is completely inserted into the connection hole.

62 WILO SE 11/2012 Ed.03 DIN A5

Page 29

START-UP English

5. Place the slide closure laterally into the guide and slide it up in the direction of the

arrow.

6. Start-up

The “Start-up” section contains all the important instructions for the operating personnel for starting up and operating the product safely.

The following conditions must be adhered to and monitored:

• The compressor/blower has sufcient output for the required air supply.

• The pressure in the intake line corresponds to the specication and remains constant.

• The pipes are absolutely tight.

• The drainage line is connected.

If the machine has not been operated for an extended period, also check these con-

ditions and rectify any identied faults.

Always keep this manual either by the product or in a place specially reserved for it,

where it is accessible to all operating personnel.

In order to prevent damage or serious injury when starting up the product, the following

points must always be observed:

• The product may only be started up by qualied, trained persons. The safety advice

must be followed at all times.

• All persons working on or with the product must have received, read and understood

this operating and maintenance manual.

• The product is suitable for use under the specied operating conditions.

• The work area of the product is not a recreational area and is to be kept free of people!

No persons are allowed in the work area during start-up or operation.

• During all work, a second person must be present. Adequate ventilation must be ensured if there is danger of poisonous gases forming.

6.1. Initial start-up

The following points must be checked before the initial start-up:

• Inspecting the installation as described in the “Installation” section.

• Basic cleaning of the operating area.

• Function test / clear water test

6.1.1. Inspecting the installation as described in the “Installation” section

Before a function test of the aerator system is conducted, the complete installation

needs to be checked to ensure that it is correct (tightness, horizontal installation, base

support securely anchored to the oor, etc.). Any defects must be rectied before a

function test is conducted.

Installation and operating instructions Wilo-Sevio AIR 63

Page 30

English START-UP

6.1.2. Basic cleaning of the operating area

The operating area can be heavily soiled during installation. This soiling can negatively

inuence the air inclusion or damage the disc aerator. For this reason you should clean

the entire operating area with clear water and remove soiling. Course soiling and foreign

bodies must be removed by hand.

The stream of water must not directly impact the membrane, since this can lead to

damage.

6.1.3. Function test / clear water test

A function test is used to ensure that all components are tight and that the aerator

groups are working awlessly. A function test is conducted with clear water.

During the function test, people must be in the basin to inspect the aerator groups.

Inspection from the corners or from outside of the operating area is not permitted.

Fig. 12.: Function test in three steps

12.1 Tightness test of the pipes and of the disc aerator

12.2 Function test of the membranes

12.3 Tightness test of the intake line

1. Before the water is introduced into the operating area for the function test, air must

be introduced into the aerator system. This prevents water from penetrating into the

aerator system if there are any leaks.

2. Once the air supply is ensured, the operating area is slowly ooded with clear water.

3. In the rst step, the water level must extend up to the halfway point of the threaded

ring on the disc aerator. If air bubbles emerge, the corresponding location must be

disassembled and the fault rectied. This can be caused by the following:

• Incorrect installation of the pipe coupling

• Defective sealing ring in the pipe coupling

• Defective sealing ring on the connection of the disc aerator

• Material fault

4. In the second step, the water level is increased to approx. 10cm above the membranes.

With this water level, you can see whether all disc aerators are functioning awlessly.

For this test, air pressurization of 1.5Nm³/h to 6Nm³/h must be present. If the pressurization is too low, the disc aerators do not operate awlessly.

If there are defective disc aerators in the system, they need to be replaced. Before a

replacement can be made, the water must be completely pumped out so that no water

penetrates into the pipes.

If several disc aerators within a line are operating erratically, it is likely that water has

penetrated into the pipes. Open the drainage line to press out the water that has penetrated into the pipes.

64 WILO SE 11/2012 Ed.03 DIN A5

Page 31

START-UP English

5. In the third step, the water level must be increased to approx. 10cm above the ange

connection of the air distributor / intake pipe. Check the air distributor as well as the

intake connection for tightness. Leaky spots must be xed.

6. To complete the test, check the drainage line. To do this, open the valve on the drainage

line. If the aerator system is tight, only air or an air/water mixture may escape.

7. After the test is complete, a retest must be conducted after 24 hours. The system can

only be placed into operation if this test also results in no faults.

After the second function test is completed successfully, the operating area must be

ooded.

If it is not yet possible to place the system into operation, provision must be made

to ensure a water level >1m. In this way the disc aerators are protected from falling

objects and the membranes are protected from UV light.

Before the system is placed into operation at a later point in time, an additional function

test must be conducted. The relevant maintenance measures in accordance with the

“Maintenance” section must be taken into account starting at this point.

6.2. Before switching on

• Check the operating area to ensure that it is completely ooded.

• If the start-up procedure was not yet conducted in full, an additional function test must

be conducted.

6.3. Starting up the aeration

After the function test has been successfully conducted, the system can be placed into

operation. For this the aeration is switched on using a separate, customer-provided

control station. It is standard that a differentiation is only made between the operational states of On and Off.

Additional operational states such as intermittent operation or time-based control must

be arranged on an individual basis.

6.4. After switching on

During operation, check the formation of air bubbles on the surface of the liquid on a

regular basis. If individual aerators or entire aerator groups fail, you can recognize this

from the appearance of the bubbles.

We also recommend checking the air inclusion into the aeration system using a manometer in the intake line. The pressure in the intake line changes due to deposits (the

pressure increases) or defects (the pressure falls).

Note that when there is a pressure increase of 20mbar, the maintenance measure

“Cleaning the membrane surface” must be carried out. The highest permitted pressure

increase in the system is 50mbar. Higher deviations can damage the disc aerators.

Installation and operating instructions Wilo-Sevio AIR 65

Page 32

English SHUTDOWN/DISPOSAL

7. Shutdown/disposal

• All work must be carried out with the greatest care.

• Proper protective equipment must be worn.

• When carrying out work in basins or containers, the local protection measures must be

observed in all cases.

• During all work, a second person must be present.

• Only hoisting gear that is in a technically perfect condition and load-carrying equipment

that has been ofcially approved may be used for lowering and raising the product.

7.1. Temporary shutdown

With this type of shutdown, the product remains completely installed and is ready to

operate at all times.

While the system is shut down, a minimum water level of >1m must be maintained in

the operating area. Also ensure that the temperature of the liquid and in the operating

area does not fall below +3°C.

During down times, it is also necessary to ensure that a 10-minute function run is conducted on a weekly basis.

7.2. Shutdown for maintenance work or storage

Switch off the system and secure it against being switched on again without permission. The operating area must be completely drained and cleaned. Work on removing

the product and storage can then commence.

During basin drainage, we recommend that the aerator system be allowed to continue

to run. This prevents deposits on the bottom of the basin and foul odors.

BEWARE of poisonous substances!

During work in environments hazardous to health, such as waste water or sewage

treatment plants, there is an increased hazard from bacteria and viruses. In order to

counteract this elevated risk, please keep the following points in mind:

• Open wounds must be immediately cleaned and treated.

• Eating and drinking are strictly prohibited.

• Proper protective equipment must be worn!

• Upon leaving the system, disinfect persons and tools.

7.2.1. Removal

Removal takes place in the reverse order to installation:

1. Remove the drainage line

2. Remove the base support attachment

3. Remove the drainage connection

4. Remove the aeration pipes

5. Remove the air distributor

66 WILO SE 11/2012 Ed.03 DIN A5

Page 33

SHUTDOWN/DISPOSAL English

7.2.2. Return delivery / storage

Return delivery

For shipping, the parts must be packed and sealed in sufciently large, non-tearing

plastic sacks to prevent leakages. Shipping must be performed by carriers who have

been briefed accordingly.

Please also refer to the “Transport and storage” section.

Storage

• Thoroughly clean all components, decontaminating them if necessary.

• Store them in a clean, dry place protected from frost.

• Place them on a rm foundation and secure them against falling.

• Protect components from direct sunshine to prevent the plastic parts from becoming

brittle.

Please also refer to the “Transport and storage” section.

7.3. Starting up again

Clean the product of dust and soiling before starting up again. During operation and

storage, the membrane is subject to natural wear and thus must be checked for cracks

and elasticity before it is installed. The product can then be installed in accordance

with the Installation section. After it is installed, a function test in accordance with the

“Start-up” section must be conducted.

7.4. Disposal

7.4.1. Protective clothing

Protective clothing worn for installation and dismantling as well as cleaning and maintenance work is to be disposed of in accordance with German Waste Code TA 524 02 and

EC Directive 91/689/EEC.

7.4.2. Product

Proper disposal of this product avoids damage to the environment and risks to personal

health.

• Make use of the services or the advice of public or private waste disposal companies for

the disposal of the product or parts of it.

• More information about proper disposal can be obtained from the urban administration, the waste disposal authorities or from the supplier from whom the product was

purchased.

Installation and operating instructions Wilo-Sevio AIR 67

Page 34

English MAINTENANCE

8. Maintenance

Maintenance or repair work must be carried out by an authorized service center, Wilo

customer service or a qualied specialist.

Maintenance or repair work and/or constructional changes that are not listed in this

operating and maintenance manual may only be carried out by the manufacturer or

by authorized service centers.

Note the following:

• This manual must be available to the maintenance personnel and its instructions must

be followed.

• All maintenance, inspection and cleaning work on the product and system may only be

carried out by trained specialists exercising extreme care. Proper protective clothing is

to be worn.

• When carrying out work in basins or containers, the local protection measures must be

observed in all cases. A second person must be present for safety reasons.

• Only hoisting gear that is in a technically perfect condition and load-carrying equipment

that has been ofcially approved may be used for lowering and raising the product. The

maximum load-carrying capacity must never be exceeded.

Make sure that all fastening devices, ropes and safety devices of the hoisting gear

are in a technically perfect condition. Work may only commence if the hoisting gear

has been checked and found to be in perfect working order. If it is not inspected,

fatal injuries may result.

• Electrical work on the system must be carried out by an electrician.

• When working with ammable solvents and cleaning agents, res, naked lights and

smoking are prohibited.

• Products that operate in uids that are hazardous to your health must be decontaminated. It must be ensured that no dangerous gases can form or are present.

BEWARE of poisonous substances!

During work in environments hazardous to health, such as waste water or sewage

treatment plants, there is an increased hazard from bacteria and viruses. In order to

counteract this elevated risk, please keep the following points in mind:

• Open wounds must be immediately cleaned and treated.

• Eating and drinking are strictly prohibited.

• Proper protective equipment must be worn!

• Upon leaving the system, disinfect persons and tools.

• If injuries involving hazardous liquids or gases occur, rst-aid measures

must be performed in accordance with the notices in the workplace and a

doctor should be called immediately.

• Ensure that all necessary tools and materials are available. Tidiness and cleanliness

guarantee safe and trouble-free operation of the product. After working on the unit, all

68 WILO SE 11/2012 Ed.03 DIN A5

Page 35

MAINTENANCE English

cleaning materials and tools should be removed from it. All materials and tools should be

stored in an appropriate place.

• Appropriate protective clothing must be worn for cleaning and maintenance jobs. This

is to be disposed of in accordance with waste code TA 524 02 and EC Directive 91/689/

EEC.

• Only use genuine parts made by the manufacturer.

8.1. Maintenance intervals

To ensure reliable operation, various maintenance tasks must be carried out regularly.

The maintenance intervals should be decided according to the demands placed on the

product. If strong vibrations occur during operation, the product or installation must be

checked, regardless of the maintenance intervals.

8.1.1. Intervals for normal operating conditions

Weekly during a brief period of shutdown

• Function run

• Drainage of the aerator system

Weekly during regular operation

• Cleaning the membrane surface

Annually during regular operation

• Leak check of the aerator group(s)

• Maintenance measures of the compressors/blower

• Changing the lter

8.1.2. Intervals for difcult operating conditions

For difcult operating conditions, the maintenance intervals stated should be shortened

accordingly. In this case, please contact Wilo customer service. If the products are to

be used in difcult conditions, we also recommend that you take out a maintenance

contract.

The following are considered difcult operating conditions:

• Large quantities of brous materials or sand in the uid

• Heavily corrosive liquids

• Very aggressive liquids

• For industrial applications

8.1.3. Measures recommended to ensure smooth operation

We recommend installation of a manometer in the intake line for the aerator group.

The current pressure allows small defects to be immediately detected and rectied as

necessary.

Installation and operating instructions Wilo-Sevio AIR 69

Page 36

English MAINTENANCE

Deposits on the aerator membranes reduce the air inclusion into the liquid and increase

the pressure in the aerator system. This reduces the efciency of the system. This

becomes visible due to a changed appearance of the bubbles on the surface of the

liquid. In this case, the maintenance measure “Cleaning the membrane surface” must be

carried out.

If the aerator system is not tight or if a membrane cracks, the pressure drops in the

aerator system. This leads to uncontrolled air inclusion and causes the efciency of the

aeration to drop. This also becomes visible on the surface of the liquid, where large air

bubbles will be escaping. In this case, the plant needs to be taken out of operation and a

function test with clear water must be conducted in order to nd the leak.

Regular checks can therefore prevent greater damage from occurring later and reduce

the risk of a total failure. For monitoring on a regular basis, we recommend remote monitoring of the air inclusion. Please contact Wilo customer service about this.

8.2. Maintenance tasks

8.2.1. Function run

To prevent damage to the membrane, a function run lasting 10 minutes must be conducted. Here it must be ensured that a minimum water level >1m exists in the operating

area. The air inclusion must be between 1.5Nm³/h and 6Nm³/h.

8.2.2. Drainage of the aerator system

During the function run, open the valve of the drainage line. Supplying air into the

aeration system causes any water/condensate that is present to be channeled through

the drainage line.

8.2.3. Cleaning the membrane surface

During operation, the membrane surface can be clogged by deposits. This leads to

reduced air inclusions into the uid and decreases the efciency of the aeration system.

To counteract this, the membrane must be blown off in brief intervals under peak load

in accordance with the maintenance intervals.

1. Increase the pressure in the system to the max. permitted value of 7.5Nm³/h for ve

minutes.

2. Switch off the aeration for two minutes.

3. Repeat these steps 3 to 4 times.

The max. permitted value for pressurization of 7.5Nm³/h may not be exceeded.

Since this maintenance measure makes a major contribution to the functional safety

and efciency of the system, we recommend that the maintenance interval be carried

out automatically. This can be accomplished using a control station. Contact the manufacturer of the control station in this regard.

70 WILO SE 11/2012 Ed.03 DIN A5

Page 37

MAINTENANCE English

8.2.4. Leak check of the aerator group(s)

Leaks become visible on the surface of the liquid through a change in the appearance of

the bubbles. Check the operating area from all sides for unusual bubble formation.

For this maintenance measure, we recommend carrying out a function test with clear

water and an inspection of the operating area.

8.2.5. Maintenance measures of the compressors/blower

Carry out maintenance work according to the manufacturer’s specications for the

devices.

8.2.6. Changing the lter

If lters are used in the air intake, they need to be cleaned or replaced on a regular basis.

You can nd more information in the respective lter documentation.

8.3. Repairs

When carrying out repairs, you must:

• Switch off the system and make sure it cannot be switched on accidentally.

• Drain the operating area, thoroughly clean all components, and decontaminate them if

necessary.

• Never use brute force during any of this work.

8.3.1. What repairs may be carried out?

• Membrane replacement, including the non-return valve

• Disc aerator replacement

8.3.2. Membrane replacement, including the non-return valve

1. Use the special key to loosen and unscrew the threaded ring on the disc aerator.

2. Remove the separation ring and membrane support.

3. Remove the non-return valve.

4. Pull off the membrane from the membrane support.

5. Attach a new membrane to the membrane support.

6. Attach a new non-return valve.

7. Fit the membrane support and separation ring.

8. Screw the threaded ring back on and tighten it securely using the special key.

Before the system is started up again, a function test must be conducted.

8.3.3. Disc aerator replacement

1. Use a rubber mallet to push down the slide closure on the underside of the disc aerator

against the direction of the arrow.

2. Remove the disc aerator.

3. Fit the new disc aerator onto the connection hole in the aerator pipe.

Important The connection of the disc aerator must be completely on the connection

hole and the O ring must seal the connection!

Installation and operating instructions Wilo-Sevio AIR 71

Page 38

English MAINTENANCE

4. Slide the slide closure up in the direction of the arrow using a rubber mallet.

Before the system is started up again, a function test must be conducted.

72 WILO SE 11/2012 Ed.03 DIN A5

Page 39

Wilo–International(Subsidiaries)

Argentina

WILO SALMSON

Argentina S.A.

C1295ABI Ciudad Autónoma

de Buenos Aires

T+ 54 11 4361 5929

info@salmson.com.ar

Australia

WILO Australia Pty Limited

Murrarrie, Queensland, 4172

T +61 7 3907 6900

chris.dayton@wilo.com.au

Austria

WILO Pumpen

Österreich GmbH

2351 Wiener Neudorf

T +43 507 507-0

office@wilo.at

Azerbaijan

WILO Caspian LLC

1014 Baku

T +994 12 5962372

info@wilo.az

Belar

us

ILO Bel OOO

W

220035 Minsk

T +375 17 2535363

wilo@wilo.by

Belgium

WILO SA/NV

1083 Ganshoren

T +32 2 4823333

info@wilo.be

Bulgaria

WILO Bulgaria Ltd.

1125 Sofia

T +359 2 9701970

info@wilo.bg

Brazil

WILO Brasil Ltda

Jundiaí – SP – CEP

13.201-005

T + 55 11 2817 0349

wilo@wilo-brasil.com.br

Canada

WILO Canada Inc.

Calgary, Alberta T2A 5L4

T +1 403 2769456

bill.lowe@wilo-na.com

China

WILO China Ltd.

101300 Beijing

T +86 10 58

w

041888

ilobj@wilo.com.cn

Croatia

WILO Hrvatska d.o.o.

10090 Zagreb

T +38 51 3430914

wilo-hrvatska@wilo.hr

CzechRepublic

WILO Praha s.r.o.

25101 Cestlice

T +420 234 098711

info@wilo.cz

Denmark

WILO Danmark A/S

2690 Karlslunde

T +45 70 253312

wilo@wilo.dk

Estonia

WILO Eesti OÜ

12618 Tallinn

T +372 6 509780

info@wilo.ee

Finland

WILO Finland OY

02330 Espoo

T +358 207401540

wilo@wilo.fi

France

WILO S.A.S.

78390 Bois d'Arcy

T +33

1

30050930

info@wilo.fr

GreatBritain

WILO (U.K.) Ltd.

DE14 2WJ BurtonUpon-Trent

T +44 1283 523000

sales@wilo.co.uk

Greece

WILO Hellas AG

14569 Anixi (Attika)

T +302 10 6248300

wilo.info@wilo.gr

Hungary

WILO Magyarország Kft

2045 Törökbálint

(Budapest)

T +36 23 889500

wilo@wilo.hu

India

WILO India Mather and Platt

Pumps Ltd.

Pune 411019

T +91 20 27442100

service@

pun.matherplatt.co.in

Indonesia

WILO Pumps Indonesia

Jakart

a S

elatan 12140

T +62 21 7247676

citrawilo@cbn.net.id

Ireland

WILO Ireland

Limerick

T +353 61 227566

sales@wilo.ie

Italy

WILO Italia s.r.l.

20068 Peschiera Borromeo

(Milano)

T +39 25538351

wilo.italia@wilo.it

Kazakhstan

WILO Central Asia

050002 Almaty

T +7 727 2785961

info@wilo.kz

Korea

WILO Pumps Ltd.

621-807 Gimhae

Gyeongnam

T +82 55 3405890

wilo@wilo.co.kr

Latvia

WILO Baltic SIA

1019 Riga

T +371 7 145229

mail@wilo.lv

Leb

anon

ILO SALMSON

W

Lebanon

12022030 El Metn

T +961 4 722280

wsl@cyberia.net.lb

Lithuania

WILO Lietuva UAB

03202 Vilnius

T +370 5 2136495

mail@wilo.lt

Morocco

WILO Maroc

SARLQUARTIER

INDUSTRIEL AIN SEBAA

20250

CASABLANCA

T +212 (0) 5 22 660 924

contact@wilo.ma

TheNetherlands

WILO Nederland b.v.

1551 NA Westzaan

T +31 88 9456 000

info@wilo.nl

Norway

WILO Norge AS

0975 Oslo

T +47 22 804570

wilo@wilo.no

Poland

WILO Polska Sp.

0

5-090 Raszyn

T +48 22 7026161

wilo@wilo.pl

Portugal

Bombas Wilo-Salmson

Portugal Lda.

4050-040 Porto

T +351 22 2080350

bombas@wilo.pt

Romania

WILO Romania s.r.l.

077040 Com. Chiajna Jud.

Ilfov

T +40 21 3170164

wilo@wilo.ro

Russia

WILO Rus ooo

123592 Moscow

T +7 495 7810690

wilo@wilo.ru

SaudiArabia

WILO ME - Riyadh

Riyadh 11465

T +966 1 4624430

wshoula@wataniaind.com

SerbiaandMontenegro

WILO Beograd d.o.o.

11000 Be

+381 11 2851278

T

office@wilo.co.yu

Slovakia

WILO Slovakia s.r.o.

83106 Bratislava

T +421 2 33014511

wilo@wilo.sk

Slovenia

WILO Adriatic d.o.o.

1000 Ljubljana

T +386 1 5838130

wilo.adriatic@wilo.si

z.o.o.

ograd

SouthAfrica

Salmson South Africa

1610 Edenvale

T +27 11 6082780

errol.cornelius@

salmson.co.za

Spain

WILO Ibérica S.A.

28806 Alcalá de Henares

(Madrid)

T +34 91 8797100

wilo.iberica@wilo.es

Sweden

WILO Sverige AB

35246 Väx

jö

T

+46 470 727600

wilo@wilo.se

Switzerland

EMB Pumpen AG

4310 Rheinfelden

T +41 61 83680-20

info@emb-pumpen.ch

Taiwan

WILO-EMU Taiwan Co. Ltd.

110 Taipeh

T +886 227 391655

nelson.wu@

wiloemutaiwan.com.tw

Turkey

WILO Pompa Sistemleri

San. ve Tic. A.S¸.

34956 İstanbul

T +90 216 2509400

wilo@wilo.com.tr

Ukraina

WILO Ukraina t.o.w.

01033 Kiew

T +38 044 2011870

wilo@wilo.ua

UnitedArabEmirates

WILO Middle East FZE

Jebel Ali F

- Dubai

T +971 4 880 91 77

info@wilo.ae

USA

WILO USA LLC

Rosemont, IL 60018

T +1 866 945 6872

info@wilo-usa.com

Vietnam

WILO Vietnam Co Ltd.

Ho Chi Minh City, Vietnam

T +84 8 38109975

nkminh@wilo.vn

e Zone - South

re

Loading...

Loading...