Wilo PBI-L203MA, PBI-L205MA, PBI-L404MA, PBI-L405MA, PBI-L803MA Installation, Operation And Maintenance Manual

...Page 1

INVERTER PUMP

Installation, Operation, and Maintenance Manual

Models

PBI-L203MA

PBI-L205MA

PBI-L404MA

PBI-L405MA

PBI-L802MA

PBI-L803MA

♣

Before installing and operating the pump, the Safety Instructions must be

thoroughly read for the proper use of the pump.

♣ Before installation, this manual should be completely studied. / Read this

manual completely before any work on your unit.

♣ Keep this manual handy for future reference.

♣ Product warranty is attached to this manual.

♣ ATTENTION: To keep the pump at top efficiency, this manual

should be thoroughly studied.

Page 2

THANK YOU FOR PURCHASING THIS PUMP.

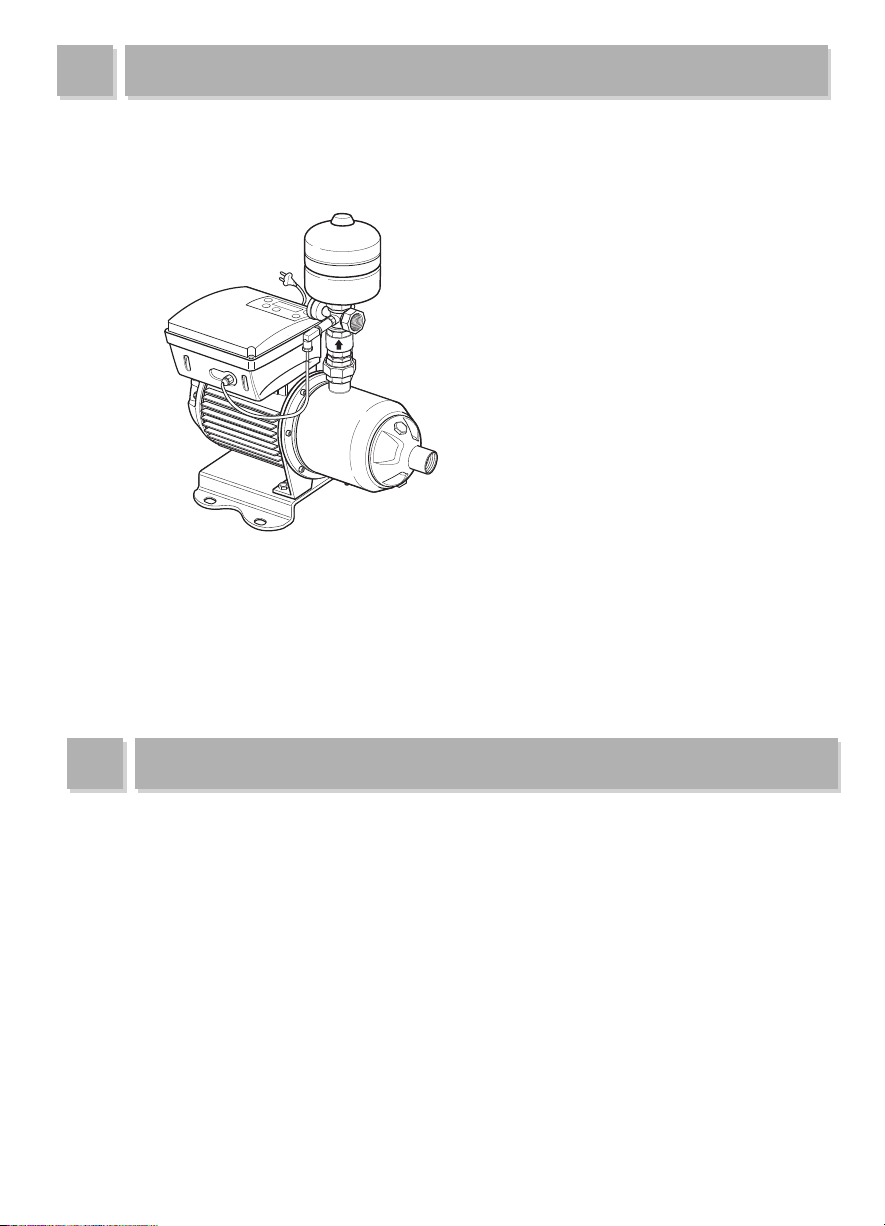

INVERTER PUMP

<PBI-L>

▶ This manual includes installation and operation instructions for PBL-L Model of WILO Pumps.

▶ To keep the pump at top efficiency, follow the recommended instructions in this manual.

▶ In case of lending the pump, this manual should be attached.

I

mproper operation not outlined in this manual may cause defects or physical damage that users are liable for.

▶

▶ The WILO Pumps Customer Service Department is available for customers to ask any questions and to

give an advice on errors on this manual. Call our dealers or headquarter.

▶ Keep this manual handy for future reference.

FEATURES OF THE PUMP

▶ Constant Pressure: The inverter equipped with PID Controller and high-speed digital filter guarantee

constant pressure.

▶ Energy cost saving: AVR(automatic voltage regulator) embedded in the hybrid inverter allows customers

to save energy cost.

▶ Absorption of water hammer shock: The inverter designed to control revolution count absorbs water

hammer shock.

▶ User-friendly handling: Optimized input value reduces customer’s input values.

▶ Low-noise, low-vibration: The pump makes low-noise and low-vibration.

▶ Stainless steel pump: The pump guarantees supply of clean water due to its material, ALL STS304.

▶ Easy installation and maintenance: Package of accessories including piping helps customers easily

install and maintain the pump.

▶ Light weight: Lighter net weight makes installation and transportation easy.

▶ Sophisticated design: The plastic case of the inverter has a sophisticated design.

2

Page 3

APPLICATION OF THE PUMP

▶

The pump is suitable for boosting low water pressure in apartment houses, apartments, weekend

cottages, inns, houses, small sprinklers, school buildings, dormitories, and other buildings,

providingconstant water pressure.

SPECIFICATIONS OF THE PUMP

▶

The embedded converter for constant pressure enables control of the operating pressure depending

on the height of a building.

▶

Pressure gauge is engaged to show pump pressure.

▶

Pressure tank is attached to prevent rapid change of pressure in piping.

▶

The stainless steel pump and brass piping will remain free of rust stains.

※ Water flow rate, water pressure(head), voltage, motor output are referred to on the nameplate.

Basic conditions are:

Ambient temperature

Ambient humidity

Power consumption

Liquid Temperature

0~40°C (32~104°F) Location Indoors

A relative humidity under

90% (no condensation)

Single phase

220V 60Hz

Up to 80°C

Suction condition

Inverter control

Pump

Pressurized condition

centrifugal pump (horizontal

multi-stage stainless steel pump)

VVVF

FEATURES

▶ Adjusting pressure setting

▶ Overpressure protection

▶ Auto restart after electricity failure

▶ Auto restart after correcting errors

▶ Dry running protection and zero flow detection

▶ Optional operating modes: Pressure regulation mode, Constant speed mode, External signal control

▶ Information and alarm signs are indicated on the display, helping easy search

STAINLESS HORIZONTAL MULTI-STAGE PUMP

▶ The pump forms block-typed structure and every pump parts in contact with water is corrosion

resistant. (Approved by KTW and WRC)

▶ The pump is equipped with Mono-Shaft, general-purpose mechanical seal, and plugs for suction and

discharge.

3

Page 4

CONTENTS

Thank you for purchasing our pump.

Follow the recommended instructions in this manual.

Thank you for

purchasing our pump

Features

Application

Contents

Safety Instructions

Transportation and

Installation instructions

Operating instructions

Maintenance

Dimension and Parts

Specifications

Wiring Diagram

Performance Curve

Dimensions

Specifications of the Pump

Connecting Sensors with the Pump

...................................................

................................................

....................................................

..................................

........................................

...........................................

...........................

................................

...................

................

..........................

....................................

............................

..............

10~12

12~13

........

5~9

14

14

15

15

16

17

17

Changing Operating Mode

2

2

3

4

5

Reversing the Rotation of the Pump

Keypad and Display

Indicators

Set Value

Notifying Errors

Default Value for Inverter

Remote control of the pump

Trouble shooting

...............................................

.........................................

.....................................

..............................

.................

.......

...........................

21~22

.................

..............

25~27

18

19

19

20

23

23

24

4

Page 5

SAFETY INSTRUCTIONS

These instructions contain important information which must be followed when installing and operating the

pump. These operating instructions must therefore be read before assembly and commissioning by the installer

and the responsible operator. Both the general safety instructions in the "Safety precautions" section and those

in subsequent sections indicated with danger symbols should be carefully observed.

●

Indication of instructions in the Operating instructions

Safety precautions in these operating instructions which if not followed could cause personal injury are

indicated by the symbol: electrical warnings are indicated with:

The following symbol is used to indicate that by ignoring the relevant safety instructions, damage could be

caused to the pump/machinery and its functions:

ATTENTION!

●

Staff training

The personnel installing the pump must have the appropriate qualifications.

●

Risks incurred by failure to comply with the safety precautions

Failure to comply with the safety precautions could result in personal injury, damage to the pump, or damage

to the installation. Failure to comply with the safety precautions could also invalidate any claim for damages.

In particular, lack of care may lead to problems such as:

-

Failure of important pump or machinery functions,

-P

ersonal injury due to electrical, mechanical and bacteriological causes.

●

Safety precautions for the operator

Existing regulations for accident prevention must be followed. Dangers caused by electrical energy

are to be excluded. Directives issued by the VDE German Association of Electrical Engineers and the local

electricity supply companies are to be observed.

●

Safety information for inspection and assembly

The operator must ensure that all inspection and installation work is carried out by authorized and qualified

specialists who have carefully studied these instructions. Work on the pump/machinery should only be

carried out when the machine has been brought to a standstill.

●

Unauthorized modification and manufacture of spare parts

Alterations to the pump or installation may only be carried out with the manufacturer's consent. The use of

original spare parts and accessories authorized by the manufacturer will ensure safety. The use of any other

parts may invalidate claims invoking the liabilitty of the manufacturer for any consequences.

●

Unauthorized operating methods

The operating safety of the pump or installation supplied can only be guaranteed if it is used in accordance

with paragraph 1 of the operating instructions. The limiting values given in the catalogue or data sheet must

neither be exceeded nor allowed to fall below those specified.

5

Page 6

TRANSPORTATION AND INSTALLATION

over 30cm

over 30cm over 30cm

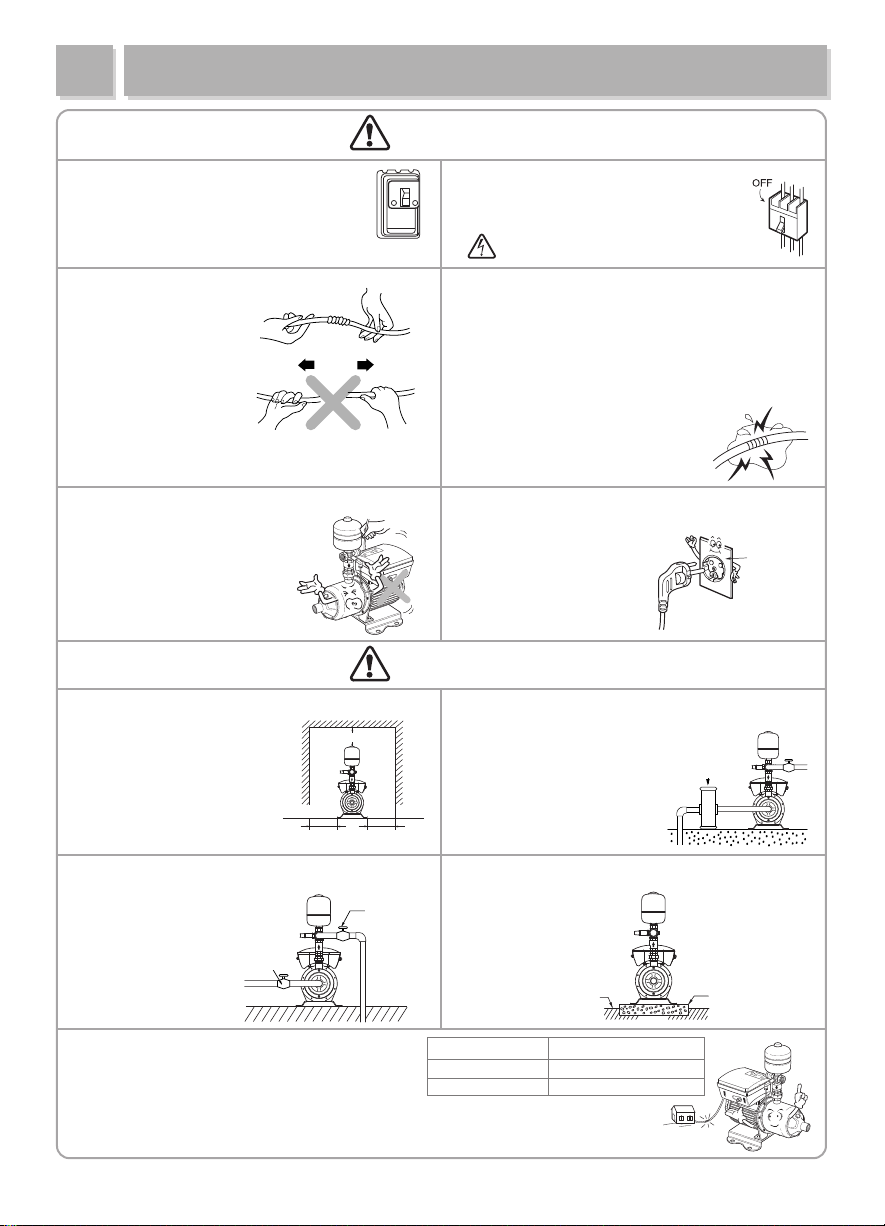

●

Install a breaker of electric leakage

of under 30mA of rated sensitivity

to prevent electric shock.

●

The power cord must not be

bent, tied, pulled

or twisted by force.

Electric leakage,

electric shock, or fire

can occur.

●

Don’t clasp the power cord in transportation

and installation.

The damaged cord may cause

electric leakage or shock.

WARNING!

Breaker

●

Before installation, repair or removal

of the pump, the power supply must be

disconnected.

Breaker

●

Pay special attention to extensions of the power cord.

Any electric leakage or disconnection in the extension

may cause electric shock.

●

How to extend the power cord.

①

Peel off the rubber/plastic insulation of the cable

as long as the connection terminal is.

② Insulate the connection and cover it with rubber tape.

Then tightly cover it over four times

with friction tape.

●

Use a rated outlet with

voltage (220V) fluctuation

of less than

●

To prevent electric shock,

never plug in a power

cord under wet

±

10%.

AC220V

power cord

or plug

conditions.

●

Install the pump where the pump can be

conveniently checked or

repaired after installation.

If the space for the pump

is narrow, make the room

as described on the figure.

●

Install a stop valve on the suction side and the

discharge side of the pump

for easier pump maintenance.

●

When the power cord is extended, a voltage drop

that keeps the pump from operation may be caused.

Refer to the table for extended power cord.

Stop valve

CAUTION!

Stop valve

●

When the pump is highly likely to suck in dust

or foreign material, install a sand filter.

Failure to do so may cause a decline

in pressure and quantity

Sand filter

of pumped water, and

malfunction of the inverter.

●

Concrete the foundation with cement to avoid

pump slant.

Foundation

Length of power cable

shorter than 10

shorter than 200

nominal dimension of the cable

m

larger than 1.5

m

larger than 2.0

㎟

㎟

6

Concrete

Page 7

TRANSPORTAION AND INSTALLATION

drinking

water

CAUTION!

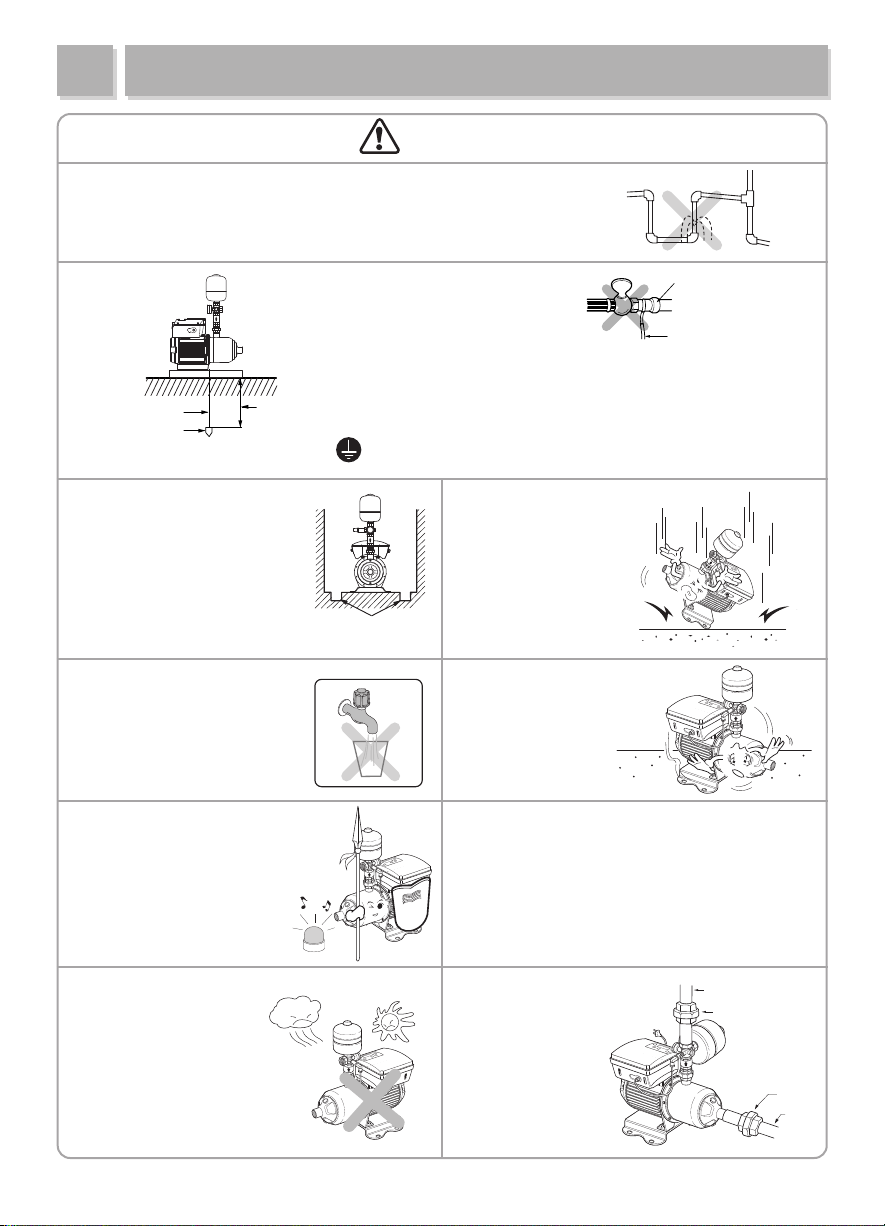

●

Minimize the number of elbows to prevent water leakages in the piping

and to decrease water resistance.

ore than 75cm

m

embed a cooper plate

r rod deeply in moist ground.

o

●

When installing the pump,

make waterways to prevent

damage caused by water

leakage. Pay special

attention to a

basement, kitchen, and attic.

●

When the pump is used for

drinking water, a water purifier

must be installed.

※ The pump has no

purification ability.

●

Set an alarm system to notify

the malfunction of the pump.

●

Connect the earth wire before

operation to prevent electric shock

when the electric insulation is faulty.

●

Never get the power plug strained

with water, to prevent electric shock.

ore than 75cm

m

●

Handle the pump with care.

Do not drop.

waterway

●

Set an anti-vibration plate

to absorb the vibration

of the pump.

●

The permitted voltage fluctuation is within 10%

of the rated voltage. Otherwise contact a power

company.

●

The pump should not be connected directly to

public waterworks. Permission from the authority

Gas Pipe

Earth wire

※

NOTE!

• Disconnect the power supply

before connecting the earth wire.

• Gas pipe must not be connected

with earth wire. Otherwise

an explosion may occur.

Damage may occur.

should be granted. This could shorten the life of

the pump.

●

Don’t expose the pump

to direct sunrays or

to rain, otherwise

faulty parts or an electric

shock may be caused.

●

Install unions on the

suction side and

discharge side of the

pump for convenient

maintenance and

repair.

7

Pipe

Union

Union

Pipe

Page 8

운반·설치상의 주의사항

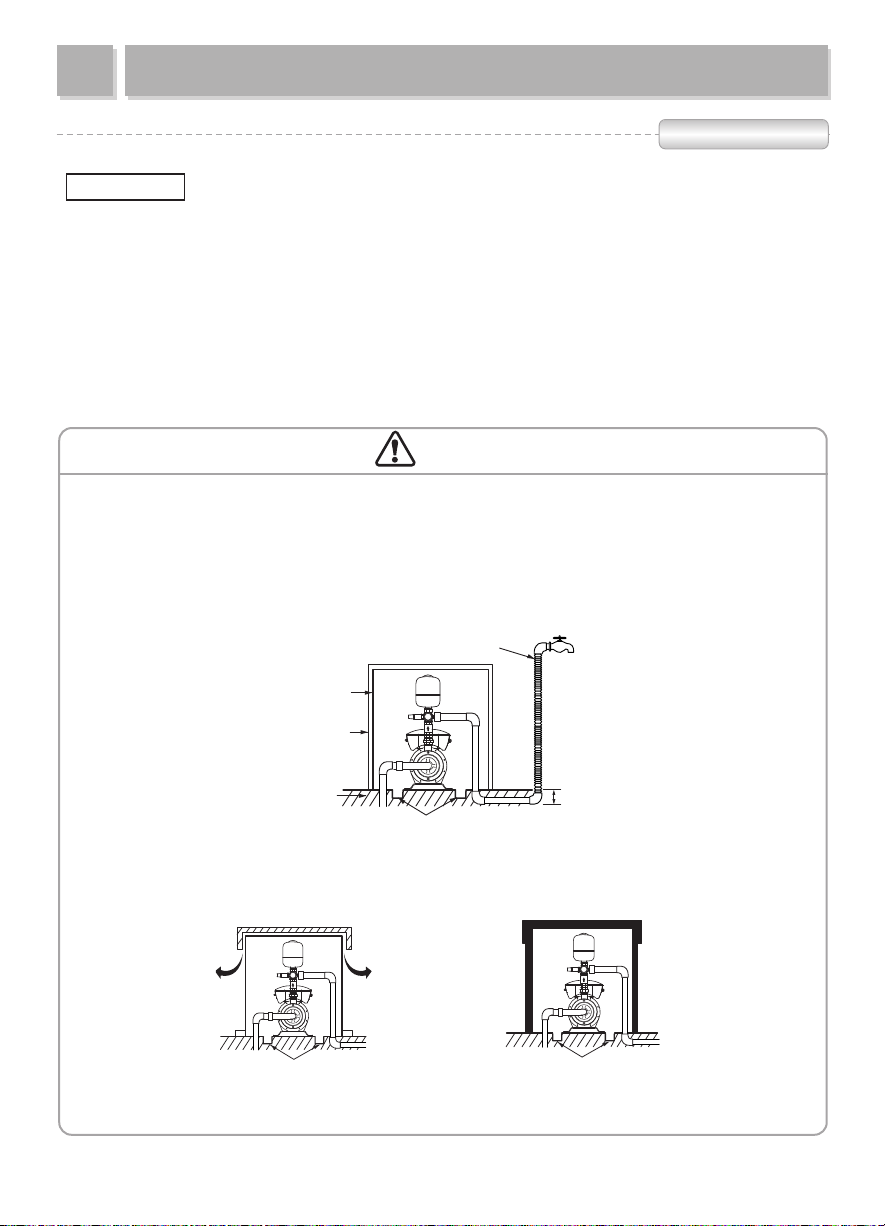

INSTALLATION

Installation process

- The pump should be installed indoors. In case of installing outdoors, set eaves to avoid exposure to wind

and rain, and prevent the pump from freezing.

- The pump should be in pressurized condition. (Recommended suction pressure: 0.2kgf/cm

To prevent dry running, the water tank should always be higher than the suction port of

ATTENTION!

the pump. Keep the minimum suction pressure at all times.

Vent air out from the suction side tank after cleaning it.

Even in a pressurized condition, running the pump with air in the tank or with suction

condition, the mechanical seal may be worn and consequently the rotational part may fall

down upon the stationary part.

Piping

2

)

ATTENTION!

- An elbow close to the pump suction flange should be avoided. Abnormal noise and vibration may occur.

- The piping should be adequately supported on both sides to reduce mechanical stress on the pump

- Make the piping run as short as possible and minimize the number of elbows

- Attach a strainer for filtering foreign objects to the end of the suction piping.

- Install a stop valve on the suction side and the discharge side of the pump to make pump maintenance

easier.

- Install the bypass on the discharge side to make pump maintenance easier.

- When the pressure tank is damaged, the discharge pressure can fluctuate or the piping can leak.

- To minimize noise of the pump, install a flexible joint on the suction piping and the discharge piping, and use

an anti-vibration rubber.

Piping direction

-Piping direction can vary depending on circumstances.

-Piping direction can be adjusted by loosening the union on discharge side.

-Tank is separately packed in shipping.

Pic.1 Pic.2 Pic.3 Pic.4

- Even in a pressurized condition, if an elbow is used, the suction piping should never be

of smaller diameter than the pump suction.

8

Page 9

운반·설치상의 주의사항

over 30cm

INSTALLATION

Wiring

Only a qualified electrician should connect cables. Install a circuit breaker and connect

ATTENTION!

earth wire to prevent any electrical accidents including electric shock.

- The wiring of major parts including the motor and the pressure sensor is already finished. Wiring of earth

and other optional parts should be conducted according to the wiring diagram.

- The power sup ply sh ould be i n a cco rdan ce wit h the rat ed val ue mar ked on th e n ame plat e.

- Before supplying power, check the following:

①

if the circuit breaker at power is suitable (under 30mA of rated sensitivity).

②

if the wiring is correct (connection and wire size).

③

If the connections with motor terminal are tightened (No operation with missing phase).

CAUTION!

In winter, install protections against cold weather.

●

When the pump remains inactive for a long time at temperatures lower than 0°C, the pump body must

be completely empty through the drain valve to prevent possible cracking of the hydraulic components.

●

Bury the horizontal piping at least 30cm under ground.

CAUTION! To prevent a fire, don’t cover the motor or pump with a blanket.

Cover the exposed piping.

lagging

wooden plate

ground

waterway

summer / not humid

waterway waterway

9

winter

Page 10

운반·설치상의 주의사항

USAGE

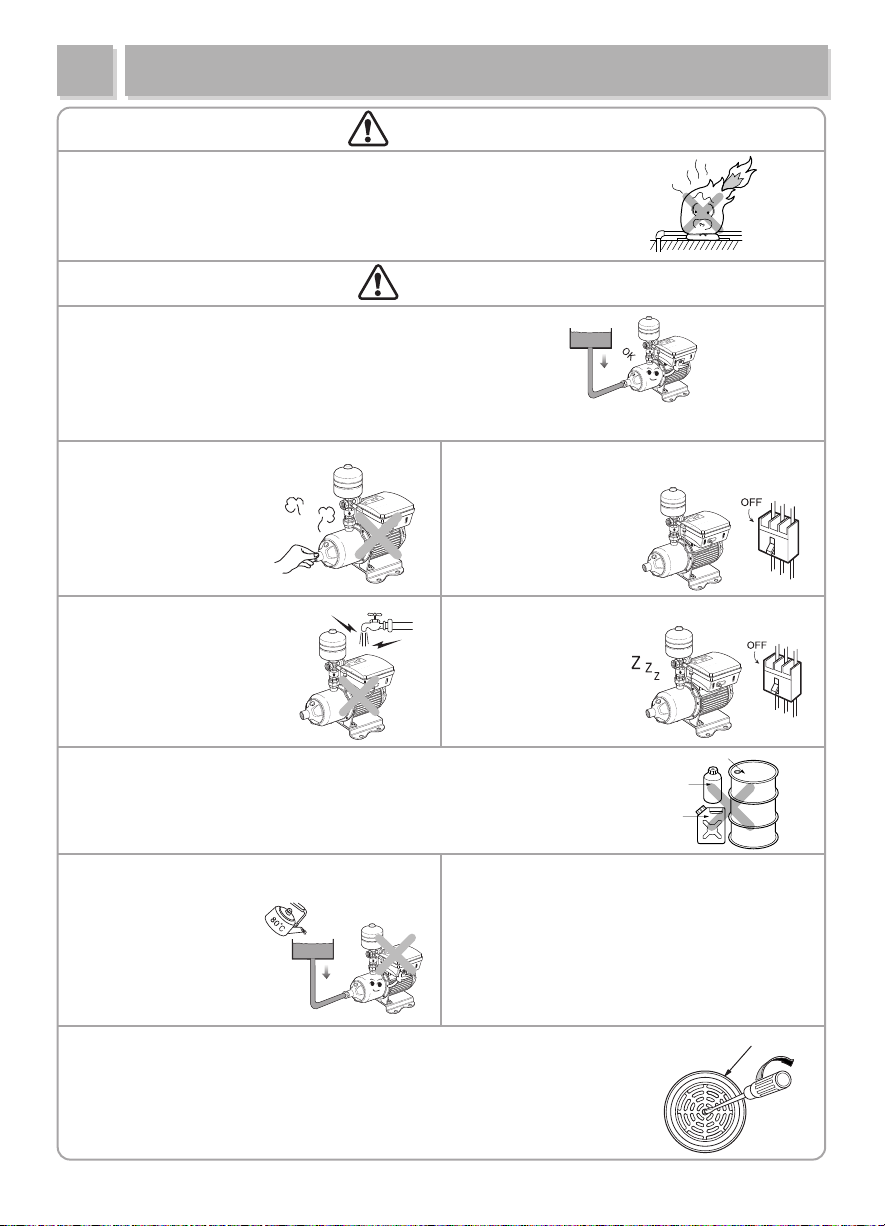

WARNING!

●

To prevent a fire, never wrap the motor of the pump head in a blanket or a cloth

to prevent freezing in cold weather.

The customers are liable for any damage caused by improper wrapping.

CAUTION!

●

Never conduct a shut-off operating under dry running condition

and delivering no water.

The life of the parts may be shortened and explosion may occur.

●

●

Never touch the pump with

a bare hand when the pump

is operating or just stops

operating.

●

If water penetrates into the

motor, malfunction or electric

leakage may occur.

In electricity failure, disconnect the pump with the

power supply. Sudden start up may cause

physical damage.

●

Disconnect the pump if it is unused for a long time.

Otherwise old insulation

may cause electric

shock or fire.

electricity

failure

●

Never use the pump with liquids other than water. A fire may be caused,

when chemicals or flammable liquids including petroleum, alcohol, or

gasoline are used. In addition, the service life of the pump may be

shortened and malfunctions are highly likely to occur.

●

●

Never use hot water over 80°C in the pump.

Rubber parts and packing may be deformed,

and motor may

be damaged.

●

When staring up the pump after a long time of inactivity, check if the rotating

parts turn freely. Turn off the power and insert a screwdriver

in the notch on the motor shaft from the fan side.

Never alter an automatic item into non-automatic

Reconstruction of the pump is prohibited.

●

Any physical damage and property losses

cannot be compensated in this case.

10

Oil

Alcohol

Gasoline

one.

Motor

Page 11

운반·설치상의 주의사항

USAGE

Piping

The suction pipe should be larger than the discharge pipe.

Make the piping run as short as possible and minimize the number of elbows.

The piping should be adequately supported on both sides to reduce mechanical stress on the pump.

Install a stop valve on the suction side and the discharge side of the pump.

*

Test running

① Priming the pump: The pump must not be run dry.

Part Description

1. Foot valve, strainer

2. Stop valve on the

suction side

3. Stop valve on the

discharge side

4. Check valve

5. Air vent screw

6. Drain cap

7. Pipe support

8. Strainer

9. Water tank

10. Piping

11. Monitor protector

12. Union

2

10

9

2 4

HC

MIN

7

3

2 12

6

12

5

8

7

11

1-phase

220V

60Hz

※

Recommended suction pressure : 0.2kgf/cm

※

Maximum suction pressure : 6kgf/cm

- Close the discharge valve (3) and open the air vent screw (5).

- Open the suction valve (2) to fill the pump with water.

- Close the suction valve when water comes out from the air vent screw.

- Close the air vent screw.

② Start-up of the pump

1. Make sure the pump has been primed and open the discharge valve.

2.

Switch on the power and verify that the motor rotates in right direction. Then turn on the power to pump up water.

3. If water is not primed up, power off and reprime the pump.

Make sure that the pump operates without any problem. Then open and close the water tap to verify no leakage.

4.

●

Check the pressure gauge to confirm stable suction and discharge pressure. If the pressure fluctuates,

Reprime the pump.

●

Verify the electronic current flow doesn’t exceed the rated value marked on the nameplate.

2

11

Page 12

MAINTENANCE

WARNING!

●

At first running, if you notice abnormal vibration, noise, or strange smell, turn off and disconnect the

pump from its source and contact the dealer or service center. Continuous operating in this case may

cause fire or electric shock.

●

Don’t ever disassemble or alter the product.

- Fire, electric shock, or physical injury may occur.

- The pump must not be dismantled and repaired except by qualified skilled personnel.

- Contact our service center or dealer to have the pump repaired.

●

When the power cord is broken, the replacement should be carried out by our dealer or other qualified

personnel.

CAUTION!

●

After assembled, the pump should be put to test running.

Incorrect assembly may cause malfunction, electric leakage, or water leakage.

12

Page 13

운반·설치상의 주의사항

MAINTENANCE

Refilling Pressure Tank

WARNING!

- The pressure in the tank must not exceed the rated maximum.

- Regularly check pre-charged gas pressure in the pressure tank.

When checking the pressure, stop the pump and drain the tank. Otherwise the pre-charged gas pressure

cannot be accurately measured.

- Check the pre-charged gas pressure every six months when using proper tank. When refilling the tank,

follow the instructions below:

Completely drai n the tank and open the ca p. R efill the tan k wi th an injector or a compressor.

2

The injected pressure should be 90% of operating pressure or lower by 0.5 kgf/cm

than the pressure.

If it is difficult to drain the tank, stop the pump and start refilling the pressure when pre-charged gas pressure

is far less than needed.

- If the refilled pressure is much lower than operating pressure, the pressure tank may work abnormally.

If the refilled pressure is much higher than operating pressure, the pump may shutdown and restart frequently.

-

Checking Inverter

The wiring and setting of the inverter is already finished before delivery.

WARNING!

Never change any setting except data related to the operation.

The inverter is a semiconductor device that can be damaged by ambient temperature, humidity, and vibration.

To prevent malfunctions, pay attention to following:

①

If there is any problem in wiring connections

③

If there is overheating, discoloration, or abnormal smell

②

If there is abnormal vibrations or noise

- To prerent destruction of IC components, do not preform a voltage test or insulation resistance(mega test).

-

The electronic circuit is embedded in the inverter, so any contact with the inverter may cause static electricity

that can damage parts of the inverter.

Never touch the electronic circuit when repairing and checking the inverter. Otherwise use a ground

connection and earth Chassis when touching it.

- If the bolts and nuts are loosened or rusted, disconnect the power supply, and tighten or replace them.

- If there is a connection defect in the electromagnetic switch or abnormal noise, replace the part.

The timetable below shows how often a part should be replaced.

What to replace How often replace Whenever

Every one year it leaks

-

Every three years abnormal noise occurs.

Every three years

Every three years operation is not certain.

Every three years

Every three years operation is not certain.

it is checked

discrepancy between pressure values

occurs, or value is uncertain.

connection is critically damaged

or malfunction occurs.

Pump/ Motor

Machinery

Control

panel

Mechanical seal

O-ring/ Casket

Motor bearing

Input transmitter

Pressure tank

Relays

PCBs

13

Maintenance time table

NOTE: The timetable is based on the assumption that

after s tartup , the unit has been opera ted at

rated load. So the schedule can be adjusted in

accordance with circumstance and operating

conditions.

Disposal of PCB or electronic parts must be carried

out in accordance with related laws and regulations.

This product includes PCB, so never dispose it in a

general waste collection.

Page 14

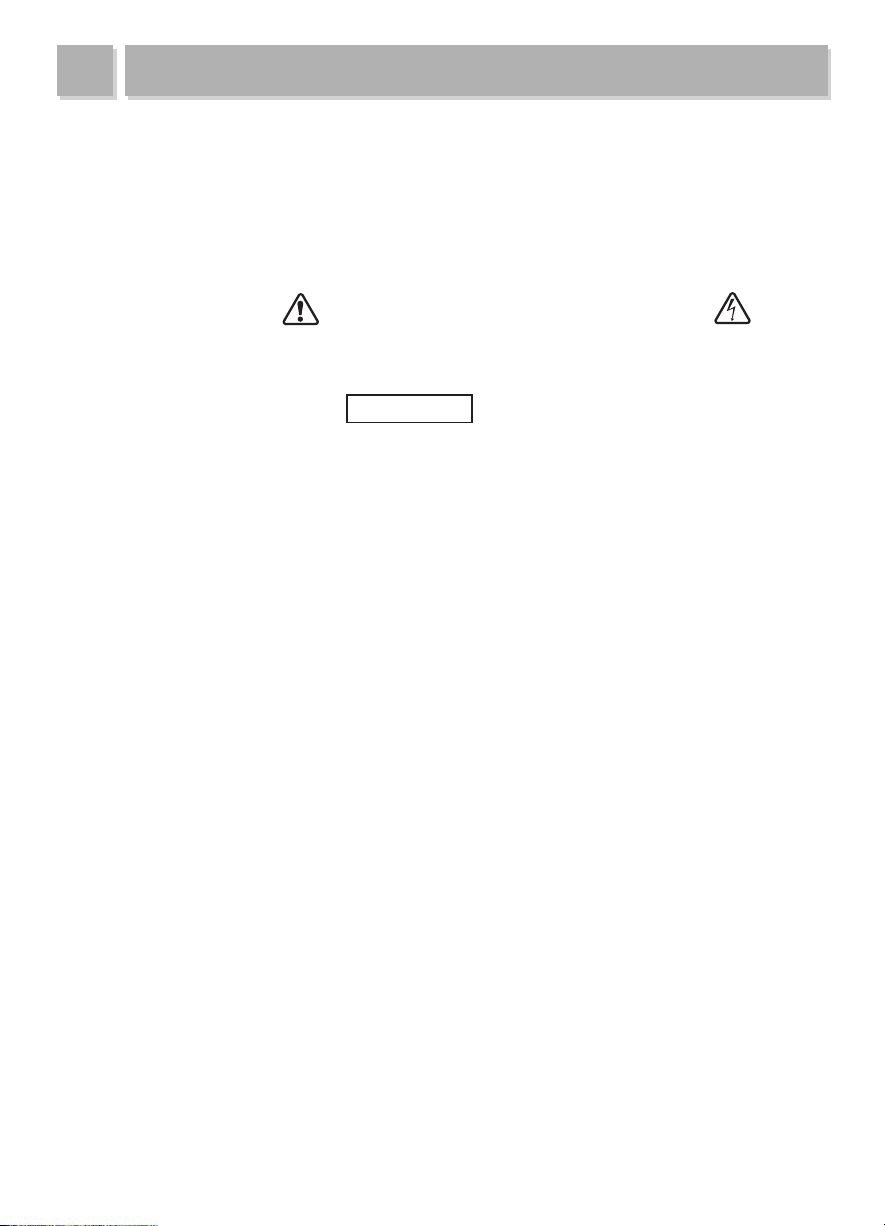

DIMENSION AND PARTS

Display

Inverter Cover

Inverter Base

Fan Cover

Motor

Base Plate

운반·설치상의 주의사항

SPECIFICATIONS

Power Cord

Pressure Gauge

Casing

Drain Plug

Pressure Tank

Cross Nipple

Pressure Sensor

Check Valve

Union

Priming Plug

Inverter specifications

Rating output

1.1kW

1.1kW

1.85kW

1.85kW

1.85kW

1.85

kW

kW

Rating capacity

3.0KVA

3.0KVA

4.5KVA

4.5KVA

4.5KVA

4.5KVA

i

Impeller

stage

3

5

4

5

2

3

l

PBI Model Pump

PBI-L203MA

PBI-L205MA

PBI-L404MA

PBI-L405MA

PBI-L802MA

PBI

-

L803MA

※ Pressure transmitter (pressure sensor): rated pressure 16bar, input voltage 5 VDc, output 0~5VCD(Voltage)

※ The volume of pressure tank : 2

MHI203i

MHI205i

MHI404i

MHI405i

MHI802i

MHI803

Motor

output

0.75kW

1.1kW

1.5kW

1.85kW

1.5kW

1.85

Pipe demension

Suction

Discharge

25A 25A

25A 25A

32A 25A

32A 25A

40A

40A

32A

32A

Operation

Pressure

2㎏f/㎠

4㎏f/㎠

4㎏f/㎠

4㎏f/㎠

2㎏f/㎠

2㎏

f

/

㎠

14

Page 15

운반·설치상의 주의사항

WIRING DIAGRAM

Pump

운반·설치상의 주의사항

PERFORMANCE CURVE

(Red, Green, Black)

RS232(Black, Blue, Yellow)

15

Page 16

DIMENSIONS

Model

PBI-L

PBI-L

PBI-L

203MA

205MA

404MA

H

580

580

580

Dimension(mm)

H

1 H2 H3 LL1 L2 ØD1 ØD2

90

120

435

90

90

120

120

435

435

360

425

425

204

252

252

109.5

157.5

157.5

1”

1”

1

1

/4”

Unit(mm)

Weight

(kg)

1”

1”

1”

13

14

19.5

PBI-L

PBI-L

PBI-L

405MA

802MA

803MA

580

5809090

580

90 120

120

435

120

435

435 360 204

16

425

360

252

204

157.5

109.5

109.5

1 1/4

1 1/2

1 1/2

”

”1”1 1/4”

1 1/4”

”

20

18

19

Page 17

운반·설치상의 주의사항

INVERTER DISPLAY

For avoiding electric accidents by high voltage and hazards caused by the leakage of

inverter and condensers, please pull-out the power cord and wait more than 5 minutes.

Every connections (include with potential-free connections) check the poles.

1. Display

Easy display for user

2. Control Button

Use to change the system information

or check.

운반·설치상의 주의사항

SENSOR CONNECTION OF INVERTER PUMP

Keep the power off before connection

- Sensor connection

Pressure auto control mode : Should connect sensor for pressure control

Pressure manual control mode : Sensor is assist function of checking pressure and display

Sensor input

1. Sensor input

Need the qualified person’s help to install the relative pressure for measure the pressure of suction and discharge pipes

17

Page 18

운운·운운운운 운운운운

INVERTER CONTROL BUTTEN EXPLANATION

운운·운운운운 운운운운

STATUS DISPLAY EXPLANATION

Status display when pump stop

Set the pressure in a auto control mode, change the motor

frequency in a manual mode

Pump run, parameter save in a setting mode

Pump stop, parameter cancel in a setting mode

parameter increase in a setting mode, change the status in a

status display menu

parameter decrease in a setting mode, change the status in a

status display menu

pump stop

Current pressure display setting pressure display

Current mode display

Status display when pump running

Current pressure display setting pressure display

18

saved error check

Current frequency display

Page 19

운운·운운운운 운운운운

AUTO CONTROL MODE PRESSURE SETTING

Warning!

운운·운운운운 운운운운

PARAMETER SETTING

Stop the pump before pressure setting

Press the stop button and pump stop

Press the “P” button, display will change the pressure setting

menu.

Press the Auto button and save.

Press the stop button and display will change initial screen.

Ex) How to change setting pressure 2.0 to 3.0 bar

- Open the cover and press the “menu” button in a back of

PCB when change the parameter setting

Press the + or - , change the setting.

Press the + or – move “Mode”,

and press the auto button.

19

Press the + or – move

“Manu”, and press the

auto button.

Press the + or – change

the frequency and press

auto button(save).

Press the stop button, display

will change initial screen.

Page 20

운운·운운운운 운운운운

PARAMETER MENU

※ MENU button is not in front

interface. Open the inverter cover,

menu button is located in back of

interface PCB.

Pump power

Move the

menu by + or -

Rotation of motor

Warming up time

Sensor offset

Press the “stop”

button, move to stop

status in each menu

Dry run pressure setting

Running mode setting

Stop flow time setting

Hi-pressure setting

20

Page 21

운운·운운운운 운운운운

PARAMETER FUNTOIN MENU

1. Pump power

Display Range 750W~1.8KW

Initial setting value

How to check pump power status.

Press auto is move.

~

“750W” or “1.8kW” Blinking.

Press “+” or “-” can change status.

Press “Auto” is save and stop blinking.

Press “Stop” is move to stop status.

2. Motor rotation change

Display Range CCW or CW

Initial setting value

1.1KW

CW

How to change motor rotation.

Press auto is move.

“CW” or “CCW” Blinking.

Press “+” or “-” can change status.

Press “Auto” is save and stop blinking.

Press “Stop” is move to stop status.

21

Page 22

운운·운운운운 운운운운

PARAMETER FUNTOIN MENU

3. Warming-up time change

Display Range 000~999

Initial setting value

Time unit minute

How to change warming-up time.

Press auto is move.

“0” Blinking.

Press “+” or “-” can change status.

Press “Auto” is save and stop blinking.

Press “Stop” is move to stop status.

60

4. Sensor Offset change

How to change sensor offset.

Press auto is move.

“0” Blinking.

Press “+” or “-” can change status.

Press “Auto” is save and stop blinking.

Press “Stop” is move to stop status.

Display Range -0.9 ~ 0.9

Initial setting value

Pressure unit bar

0

22

Page 23

운운·운운운운 운운운운

PARAMETER FUNTOIN MENU

5. Dry-run protection pressure change

How to change dry-run protection pressure.

Press auto is move.

“0.5” Blinking.

Press “+” or “-” can change status.

Press “Auto” is save and stop blinking.

Press “Stop” is move to stop status.

Display Range 0 ~ 9.9

Initial setting value

Pressure unit bar

0.5

6. Running mode change

How to change running mode.

Press auto is move.

Press “+” or “-” can change status.

Press “Auto” is save and stop blinking.

Press “Stop” is move to stop status.

“Auto” or “Manu” Blinking.

Display Range Auto or Manu

Initial setting value

23

Auto

Page 24

운운·운운운운 운운운운

PARAMETER FUNTOIN MENU

7. Stop flow time change

How to change stop flow time.

Press auto is move.

“0” Blinking.

Press “+” or “-” can change status.

Press “Auto” is save and stop blinking.

Press “Stop” is move to stop status.

Display Range 0 ~ 99

Initial setting value

Time unit second

10

8. Abnormal high pressure change

How to change abnormal high pressure.

Press auto is move.

“0” Blinking.

Press “+” or “-” can change status.

Press “Auto” is save and stop blinking.

Press “Stop” is move to stop status.

Display Range

Initial setting value

Pressure unit bar

설정값+ 1.0~15

24

10.0

Page 25

운운·운운운운 운운운운

TROUBLE SHOOTING(INVERTER)

abnormal

high

pressure

Inverter

Error

Over

current

Inverter

oveload

High

voltage

Low

voltage

Error descriptionType

Make an error for protect valve or pipe. When

discharge pressure is higher than abnormal pressure,

inverter make an error.

Make an error for protect inverter. When inverter

hardware alarm is occur(short, earth leakage, or hard

fault), inverter make an error.

Make an error for protect inverter and prevent from

fire by over-current. When impeller bound, overload

are occur, inverter make an error.

Make an error for protect inverter. When alarm is

occur(software trip, pump rated load 130% over),

inverter make an error.

Make an error for safe. When high voltage occur in

DC-Link, inverter make an error.

Make an error for safe and protect inverter. When low

voltage is occur in DC-Link(or AC power voltage),

inverter can’t make control power source and over

current can flow. Inverter make an error.

detecting

delay time

4m sec

4m sec

4m sec --

60m Sec

4m sec

4m sec

delay time

for re-run

10sec after

normal

pressure

return

10sec after

normal

status return

10sec after

normal

status return

10sec after

normal

voltage

return

10sec after

normal

status return

repetition

time

-

-

-

-

-

Code

E-02

E-24

E-23

E-22

E-05

E-04

Dry-run

Bad

suction

Sensor

fault

Communic

ation fault

Make an error for protect pump. When dry-running is

occur, inverter make an error.

Make an error only auto running mode. When bad

suction is occur, inverter make an error.

Make an error only auto running mode. When nosignal or abnormal pressure is occur, inverter make

an error.

When bad communication is occur(control board to

power board), inverter make an error.

30 Sec - 10

10 min -3

4m sec

1 Sce

10sec after

normal

status return

10sec after

normal

status return

-

-

25

E-00

E-06

E-42

E-49

Page 26

운반·설치상의 주의사항

TROUBLE SHOOTING (PUMP)

Trouble

The motor does not

run.

The pump runs, but

doesn’t deliver

water.

Or the suction and

discharge pressure

is too low.

Water delivery is

unstable

The pump

abnormally vibrates

Overheating of the

pump

Motor stopped

due to overload

Cause

Connections are faulty. Tighten loose terminals and repair damaged wire.

Broken power cord Replace the cord.

Motor malfunction Fix or change the motor.

Low voltage

The suction piping leaks.

The mechanical seal leaks. Replace the mechanical seal.

Foreign material clogged the

pump parts.

The suction piping is clogged. Clean the piping.

The pump is not primed.

Low suction pressure and cavitation

Power supply doesn’t reach to the

motor.

The suction piping leaks.

Loosened anchor.

Foreign material clogged the pump.

The pump doesn’t smoothly run. Clean the sticking around the pump.

Power connection failure Check the power of the pump.

Power supply is too low.

Foreign material clogged the

pump.

The ambient temperature is over

40℃.

The input value of the

temperature relay is too low.

Input voltage is too low.

Missing phase

Temperature relay malfunction of

circuit breaker.

The diameter of suction piping is

smaller than that of suction plug.

Strainer or suction piping is partly

clogged.

In case of lower than regulated voltage, contact an

electric power company

Check the connections of piping and completely

cover them up.

Disassemble the pump and clean it.

Reprime the pump. Check the check valve and tighten it.

Compare the piping losses with NPSHa.

Measure the voltage of the motor terminal or

the size of cable wire.

Check the connections of piping and completely

cover them up.

Check anchor bolt / nut and tighten them.

Disassemble the pump and clean it.

Check the voltage of the motor terminal.

Make sure that the voltage varies less than10%.

Disassemble the pump and clean it.

The ambient temperature for the motor should be

lower than

Check the input current and regulate the value as

plated.

Check the power cable and replace it if needed.

Check the power cable and replace it if needed.

Check the terminal of power switch.

Replace it.

The diameter of suction piping should be equal to

that of suction plug.

Disassemble the pump and clean it.

Trouble shooting

40℃.

26

Page 27

운반·설치상의 주의사항

SWITCHING-OF TROUBLE SHOOTING (PUMP)

Trouble

The pump does not

deliver water even

when the water tap is

opened.

The pump does not

stop when the tap is

turned off.

The pump runs even

when water is not

flowing

The pump vibrates

irregolarly (The pump

stops and starts too

often.)

Cause

• Main valve is closed.

• Air is in the pump or piping.

• Pump or motor malfunction

• The motor reverses.

• Water tank is too low.

• Pressure sensor malfunction.

• No power supply.

• The pump is in “STOP” mode.

•Main power, motor, sensors, or

connections are faulty or disconnected.

• Missing phase

• Operating pressure is too low.

•

Input switching off pressure is too high

• Pressure sensors or switches

malfunction.

• Control board malfunction.

• The piping leaks.

• Worn pump or pump backlash

• The piping leaks.

• The check valve leaks.

• The range between the working

pressure and the switching off

pressure is too narrow.

•

Pressure tank malfunction or low pressure

• DFR(Dynamic Flow Range) by piping

Trouble shooting

• Open the main valve.

•

Extract air out from the pump or piping.

• Check and repair the pump.

• In case of three wire connections,

exchange the connection of two wires

each other.

• Fill the tank.

• Move to Pressure regulation mode.

• Check and repair the pump.

• Remove the cause of missing phase.

• Adjust the operating pressure.

.

•

Adjust the input switching-off pressure.

• Check and repair the pump.

• Check and repair the pump.

• Check and repair the pump.

• Check and repair the pump.

• Check and repair the pump.

• Check and repair the pump.

• Adjust the working pressure and

switching off pressure.

•

Check and repair the pump. Fill air into

pressure tank up to rated value.

•

Repair the piping (remove the airpocket).

The pump runs but

does not deliver

expected flow.

The pump does not run in

Pressure regulation

mode.

Th ecircuit breakers trip.

• Input pressure is too low

• Capacity lack of the pump

• Worn pump

• The pump is in Constant speed mode.

• Control board malfunction.

•

Pressure sensors or switches malfunction.

• Pump or motor malfunction.

• Electrical wiring short

• Circuit short or breaker short

• Power short

27

• Adjust the working pressrue.

• Check the specifications of the pump.

• Check and repair the pump.

• Move to Pressure regulation mode.

• Check and repair the pump.

• Check and repair the pump.

• Check and repair the pump.

• Check and repair the pump.

• Check and repair the pump.

• Check and repair the pump.

Page 28

MEMO

Page 29

MEMO

Page 30

MEMO

Page 31

MEMO

Page 32

P/NO. : 3057884 ( Rev.0 )

NOV., 2014 Printed in Korea.

Loading...

Loading...