Wilo MVIL 100, MVIL 300, MVIL, MVIL 500, MVIL 900 Installation And Operating Instructions Manual

Page 1

Wilo-MVIL

D Einbau- und Betriebsanleitung

GB Installation and operating instructions

F Notice de montage et de mise en service

NL Inbouw- en bedieningsvoorschriften

E Instrucciones de instalación y funcionamiento

I Istruzioni di montaggio, uso e manutenzione

P Manual de instalação e funcionamento

TR Montaj ve Kullanma Kılavuzu

GR Οδηγίες εγκατάστασης και λειτουργίας

DK Monterings- og driftsvejledning

S Monterings- och skötselinstruktioner

PL Instrukcja montażu i obsługi

FIN Huolto- ja käyttöohje

RO Instrukcja montazu i obslugi

DK Monterings- og driftsvejledning

Návod k montáži a obsluze

H Beépítési és üzemeltetési utasítás

Montaj ve Kullanma K›lavuzu

PL Instrukcja montażu i obsługi

CZ Návod k montáži a obsluze

RUS Инструкция по монтажу и эксплуатации

EST Paigaldus- ja kasutusjuhend

LV Instalēšanas un ekspluatācijas instrukcijas

LT Montavimo ir naudojimo instrukcija

SK Návod na montáž a obsluhu

SLO Navodila za vgradnjo in vzdrževanje

RO Instrukcja montazu i obslugi

BG Инструкция за монтаж и експлоатация

4.086.201-Ed.1-03/06

Page 2

8

F

B

4Ø13

H

ig. 1

F

ig. 2

Fig. 3

Fig. 4

Fig. 5

Page 3

D Einbau- und Betriebsanleitung 5

GB Installation and operating instructions 11

F Notice de montage et de mise en service 17

NL Inbouw- en bedieningsvoorschriften 23

E Instrucciones de instalación y funcionamiento 29

I Istruzioni di montaggio, uso e manutenzione 35

P Manual de instalação e funcionamento 41

TR Montaj ve Kullanma Kılavuzu 47

GR Οδηγίες εγκατάστασης και λειτουργίας 53

S Monterings- och skötselinstruktioner 59

FIN Huolto- ja käyttöohje 65

DK Monterings- og driftsvejledning 71

H Beépítési és üzemeltetési utasítás 77

PL Instrukcja montażu i obsługi 83

CZ Návod k montáži a obsluze 89

RUS Инструкция по монтажу и эксплуатации 95

EST Paigaldus- ja kasutusjuhend 101

LV Instalēšanas un ekspluatācijas instrukcijas 107

LT Montavimo ir naudojimo instrukcija 113

SK Návod na montáž a obsluhu 119

SLO Navodila za vgradnjo in vzdrževanje 125

RO Instrukcja montazu i obslugi 131

BG Инструкция за монтаж и експлоатация 137

Page 4

1

. General

These installation and operating instructions are

an integral part of the product. They must be

ept readily available at the place where the

k

product is installed. Strict adherence to these

instructions is a precondition for the proper use

and correct operation of the product.

These installation and operating instructions

conform to the relevant version of the product

and the underlying safety standards valid at the

ime of going to press.

t

1.1 Applications

Pumps aimed at clear liquids in building, agriculture and industry areas … (water supply – water

ower - sprinkling, irrigation, high pressure

t

ashing , fire protection, – Lifting of conden-

w

sates – air conditioning – Industrial circuits and

integration in all modular systems.).

- boiler supply (with mandatory by-pass kit).

1.2 Technical characteristics

• Maximum operating pressure (Depending on

types):

102 - 105 Mechanical seal 10 bars

302 - 304 Pump casing 16 bars

502 - 504 Maximum suction

802 - 804 pressure: 6 bars

106 - 112 Mechanical seal 16 bars

305 - 312 Pump casing 16 bars

505 - 512 Maximum suction

805 - 807 pressure: 10 bars

• Temperature range:

(EPDM O’ring and mechanical seal) - 15° to + 90°C

• Ambient temperature (standard): + 40°C maxi

• Maximum suction head: according to NPSH of the

pump

Sound level: Depends on pump size, rotation

speed, working point, motor type: it can exceed

70 dB(A) in 50 Hz and 75 dB(A) in 60 Hz.

2. Safety

These instructions contain important information

which must be followed when installing and

operating the pump. It is therefore imperative

that they be read by both the installer and the

operator before the pump is installed or operated. Both the general safety instructions in this

section and the more specific safety points in

the following sections should be observed.

2.1 Instruction symbols used in this operating man

ual

Symbols

General danger symbol.

Hazards from electrical causes.

NOTE: ...

.

nglish

E

ignal words:

S

DANGER ! Imminently hazardous situation. Will

result in death or serious injury if not avoided.

WARNING ! Risk of (serious) injury. 'Warning'

mplies that failure to comply with the safety

i

instructions is likely to result in (severe) personal injury.

AUTION ! Risk of damage to the pump/instal-

C

lation. ‘Caution’ alerts to user to potential

product damage due to non-compliance with

the safety instructions.

OTE ! Useful information on the handling of the

N

product.

It alerts the user to potential difficulties.

2.2 Personnel qualification

The personnel installing the pump must have the

appropriate qualification for this work.

2.3 Risks incurred by failure to comply with the

safety instructions

Failure to comply with the safety precautions

could result in personal injury or damage to the

pump or installation. Failure to comply with the

safety precautions could also invalidate any claim

for damages.

In particular, failure to comply with these safety

instructions could give rise, for example, to the

following risks:

• Failure of important pump or system functions,

• Failure of specified maintenance and repair

methods

• Personal injury due to electrical, mechanical and

bacteriological causes.

• Damage to property.

2.4 Safety instructions for the operator

The relevant accident precaution regulations

must be observed.

Potential dangers caused by electrical energy

must be excluded. Local or general regulations

[e.g. IEC, VDE, etc.] and directives from local

energy supply companies are to be followed.

2.5 Safety instructions for inspection and assembly

The operator must ensure that all inspection and

assembly work is carried out by authorised and

qualified specialists who have carefully studied

these instructions.

Work on a pump or installation should only be

carried out once the latter has been brought to a

standstill.

-

2.6 Unauthorised modification and manufacture of

spare parts

Changes to the pump/machinery may only be

made in agreement with the manufacturer. The

use of original spare parts and accessories

authorised by the manufacturer will ensure safe

ty. The use of any other parts may invalidate

claims invoking the liability of the manufacturer

for any consequences.

-

11WILO AG 02/2006

Page 5

English

.7 Improper use

2

The operating safety of the pump or installation

can only be guaranteed if it is used in accordance

with paragraph 4 of the operating instructions.

All values must neither exceed nor fall below the

limit values given in the catalogue or data sheet.

3. Transport and interim storage

FREQUENCY 50Hz 60Hz

Speed RPM 2900 3500

Winding* TRI ≤4

* Standard voltage motors: on network (50Hz) ± 10%

- (60Hz) ± 6%

aximun number of starts per hour

M

Motor Power (kW) 0,37 0,55 0,75 1,1 1,5 1,85 2,2 2,5

Direct 100 90 75 60 50 45 40 40

30/400 V220/380V to 254/440V

2

When receiving the material, check that there has

been no damage during the transport. If any defect

has been stated, take the required steps with the

carrier within the allowed time. If the delivered

material is to be installed later on, store it in a dry

place and protect it from impacts and any outside

nfluences (humidity, frost etc...).

i

DANGER ! Due to high position of centre of gravity

and small ground surface of this type of pumps,

beware of unstability during handling to avoid any

falling down and take necessary means to avoid

injuries or damaging.

CAUTION ! Handle the pump carefully so as not to

alter the geometry and the alignment of the

hydraulic unit.

4. Products and accessories

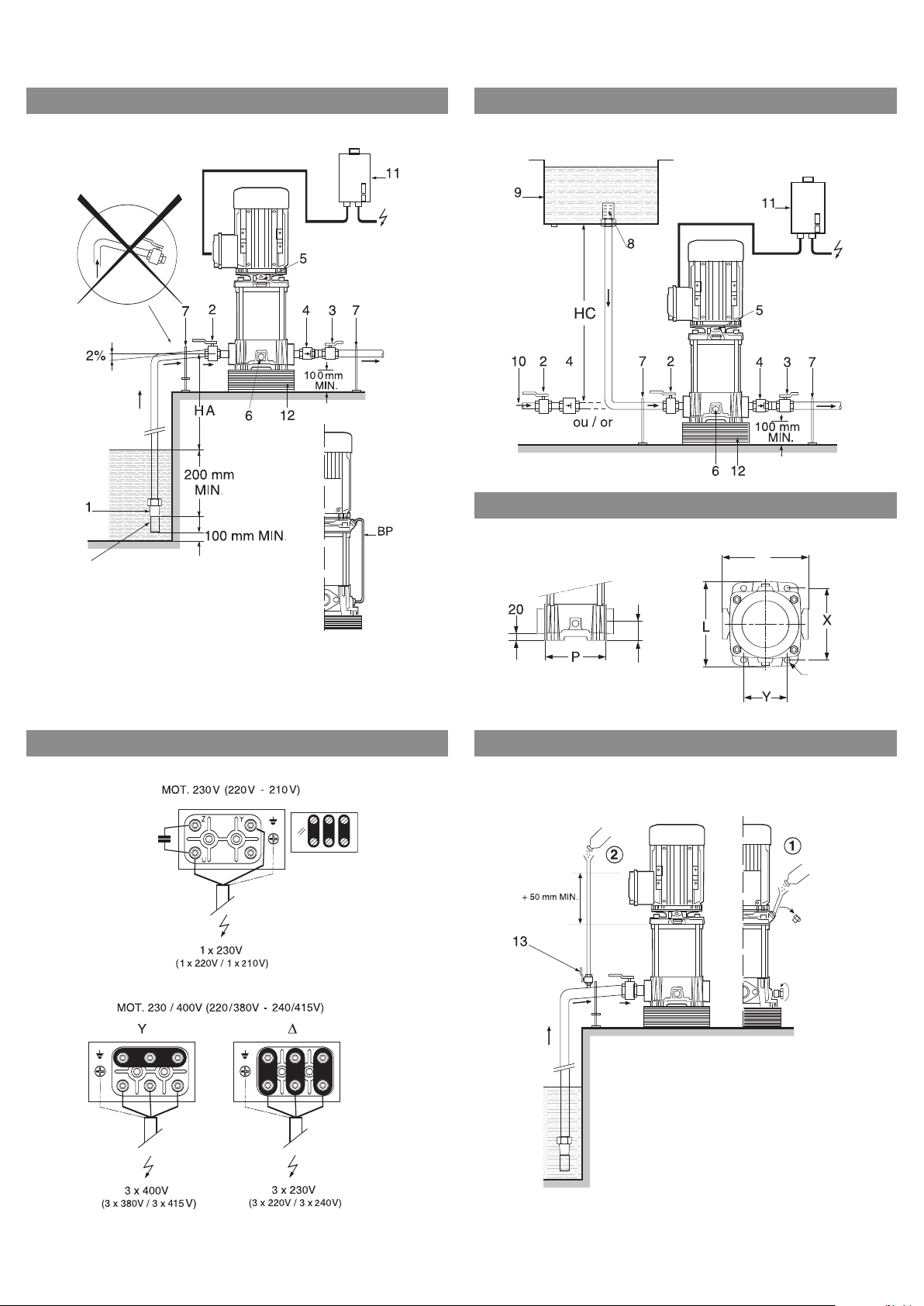

4.1 Description (fig. 1, 2, 5):

1 - Strainer-foot valve

2 - Pump suction valve

3 - Pump discharge valve

4 - Non-return valve

5 - Venting and filling plug

6 - Drain-priming plug

7 - Pipe supports

8 - Strainer

9 - Storage tank

10 - Town water supply

11 - Motor overload release

12 - Foundation block

13 - Cock

HA - Maximum suction head

HC - Minimum inlet pressure

4.2 The pump

Vertical multistage pump (2 to 12 stages) not

self-priming, with ports in line on the same axis

at the bottom part.

Shaft tightness with standard mechanical seal.

Oval Flanges for PN 16 pump casing: pump delivered with oval counterflanges in cast iron for

screw-on tube, gaskets and bolts.

4.3 The motor

Dry motor - 2 poles.

Protection index: IP 54

Insulation class: F

Single phase motor:

- With integrated thermal protection, automatic

reset.

- Capacitor integrated inside the terminal box.

4.4 Accessories (as option)

• By-pass kit • isolating valves • bladder or galvanised tank • tank for antihammer blow effect •

ontrol box • PN 25 weld-on counter-flange

c

(steel) or tapped (stainless steel) • tapped oval

counter-flange PN 16 in stainless steel - motor

overload release • non-return valves • strainer-

oot valve • vibrationless sleeves • dry-running

f

protection kit • flexible collar type Victaulic style

77 • threaded muff joint (stainless steel)…

5. INSTALLATION

Two standard cases:

• fig. 1: pump in suction

• fig. 2: pump under pressure on storage tank (9) or

town water supply (10) with dry-running protection

system.

5.1 Montage

Install the pump in a place easy to reach,protected against frost and as close as possible from the

drawing point.

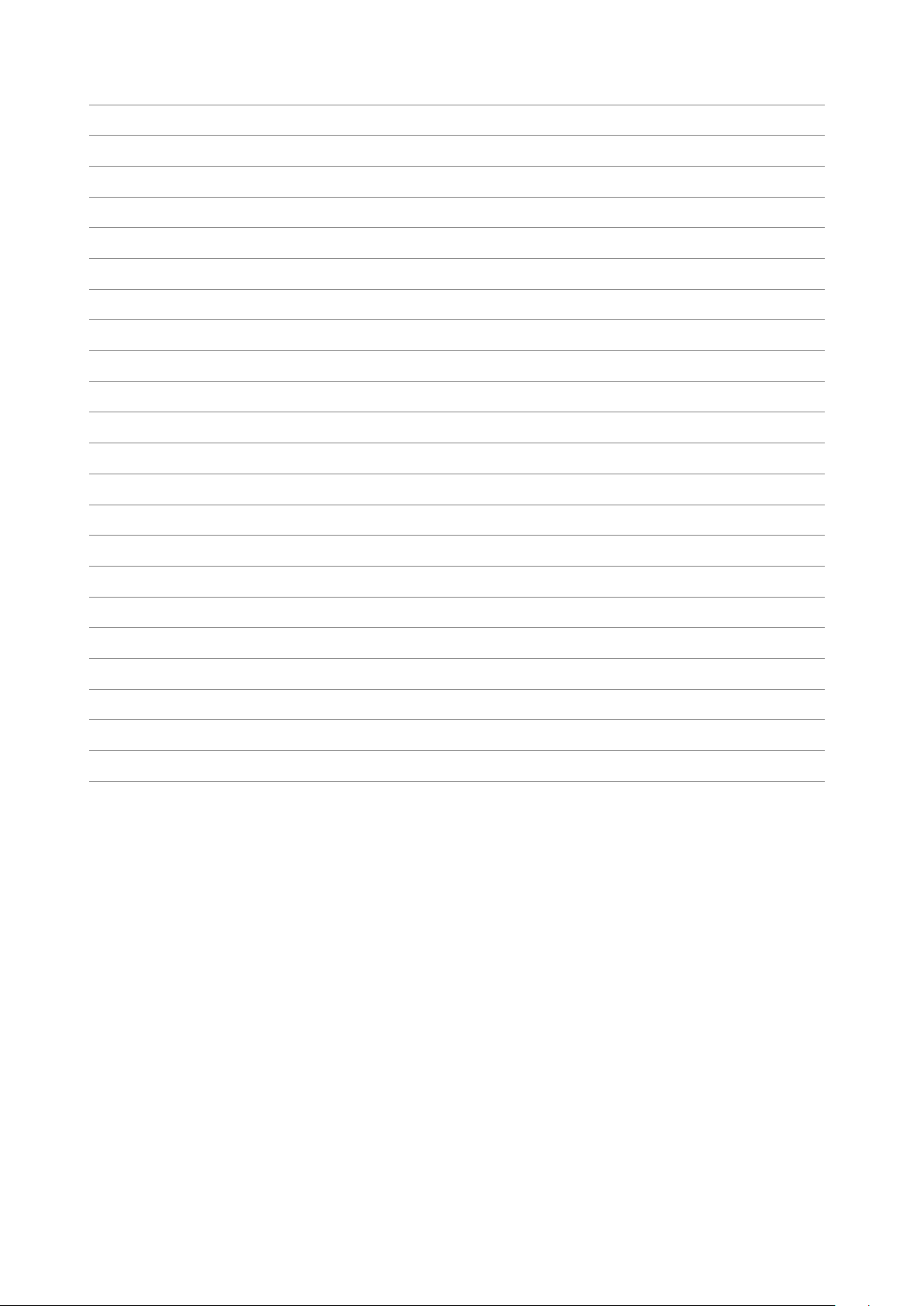

Install the pump on a concrete block (at least 10

cm high) (fig. 12) and fix with anchor bolts

(installation plan fig. 3).

Foresee an isolating material under the concrete

block (cork or reinforced rubber) to avoid any

noise and vibration transmission into the instal

lation.

Before final tightening of anchor bolts, ensure

that the pump axis is vertical: use shims if necessary.

Bear in mind that the altitude of the installation

place and water temperature may reduce the

suction head of the pump.

Altitude Loss of head Temperature Loss of head

0 m 0 mCL 20 °C 0,20 mCL

500 m 0,60 mCL 30 °C 0,40 mCL

1000 m 1,15 mCL 40 °C 0,70 mCL

1500 m 1,70 mCL 50 °C 1,20 mCL

2000 m 2,20 mCL 60 °C 1,90 mCL

2500 m 2,65 mCL 70 °C 3,10 mCL

3000 m 3,20 mCL 80 °C 4,70 mCL

90 °C 7,10 mCL

100 °C 10,30 mCL

CAUTION !

When the conveyed fluid is above 80°C, plan to

install the pump under pressure.

-

12 WILO AG 02/2006

Page 6

nglish

E

.2 Hydraulic connections

5

By threaded tubes to screw directly on the oval

tapped counterflanges delivered with the pump.

The diameter of the pipe must never be smaller

than the one of the counterflange.

Limit the length of the suction pipe and avoid all

features that cause losses of head (bends, valves,

tapers...).

AUTION ! Connections has to correctly sealed:

C

No air entrance is allowed on the suction pipe

which is showing a mounting declivity (2 %)

(fig. 1).

Use supports or collars so that the pump does

not bear the weight of the pipes.

- The circulation sense of the fluid is indicated on

he identification label of the pump.

t

- Connect the non-return valve to the pump

discharge to protect it from hammer blow

effects.

To pump water with a large content of air or hot

water,we recommend installing the by-pass kit

(fig. 1).

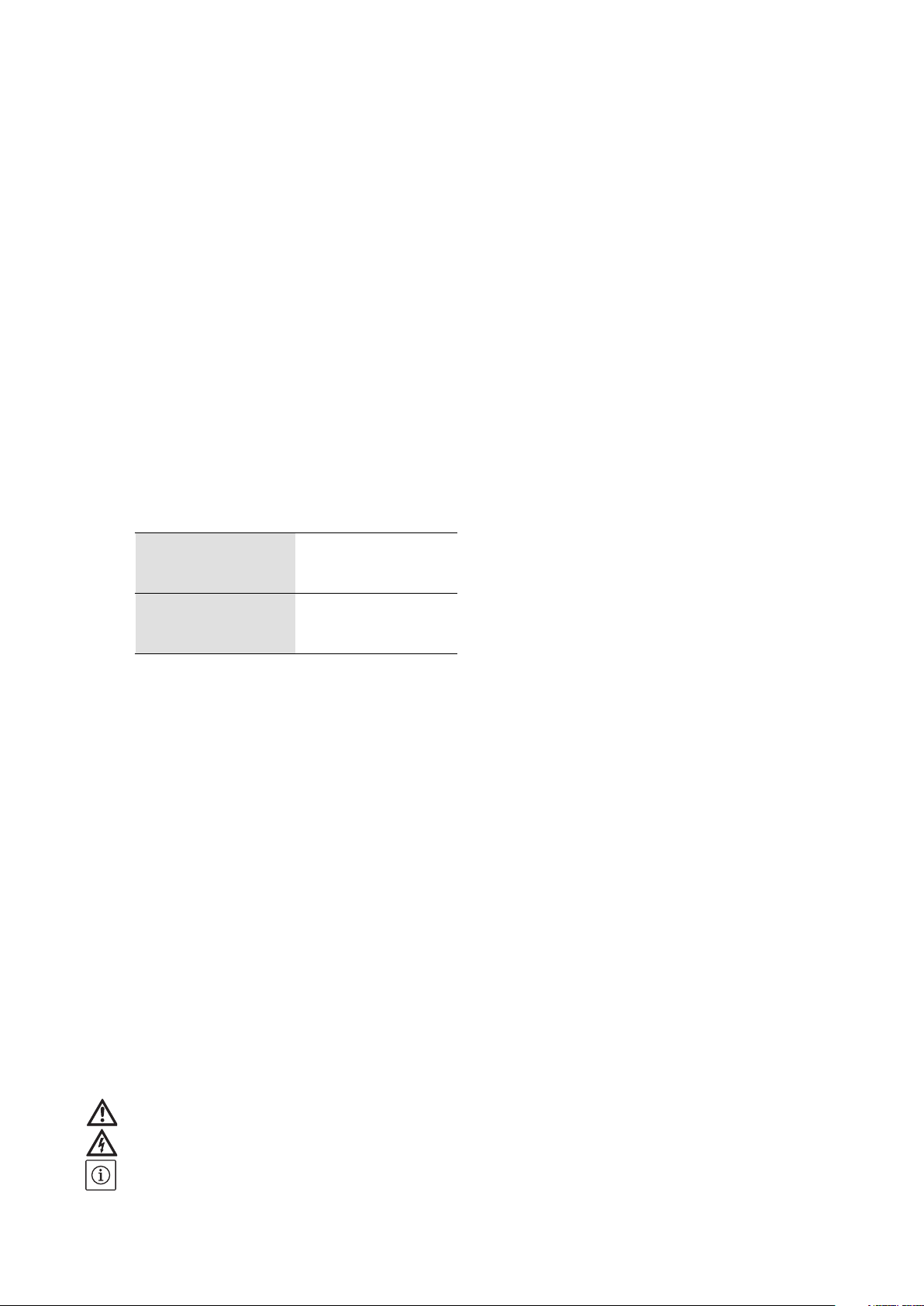

5.3 Electrical connections

The electrical connections and the inspections

have to be done by a qualified electrician and

comply with the applicable local standards.

- The electrical characteristics (frequency, voltage,

nominal current) of the motor are mentionned on

the name plate).

- check if the motor it complies with the mains

supply used.

- The motors must be protected by a circuitbreaker set to the current mentionned on the

name plate of the motor.

- Provide a fuse disconnecting switch (type aM) to

protect the mains supply.

Supply network

- Use an electrical cable conforming with the

National Electric Supply Company.

Three-phase: 4 conductors (3 phases + earth).

If necessary, cut an opening in the terminal box,

fit the cable gland stuffing box and connect the

motor as shown by the diagram inside the cover

of the terminal box (fig. 4).

DO NOT FORGET TO CONNECT TO EARTH.

CAUTION ! A connection error would damage

the motor. The power cable must never touch

the pipe or the pump; make sure that it is sheltered from any humidity.

The electric motors used on the pumps can be

connected to a frequency converter. Strictly follow the instructions given by the data sheet of

the converter's manufacturer.

The converter must not generate voltage peaks

at the motor terminals higher than 850 V and

dU/dt (Voltage/Time variation) higher than

2500 V/µs. If the value of the voltage signal are

higher than those, risk of damage the motor are

to forecast.

n the contrary provide a LC filter (inductance –

I

capacitor) between the converter and the motor.

It must be connected to the motor with a minimum length cable, armoured if necessary.

. Starting up

6

.1 Prior cleaning

6

n hydraulic test is carried out for each pump in

A

our factory. If some water stays inside them. It is

recommended for hygien reasons to clean the

pump before using it with potable water supply.

6.2 Filling - degassing

CAUTION !

riefly.

b

Pump under pressure (fig. 2)

- Close the discharge valve (3),

- Open the venting plug (5), and the suction valve

(2) and completely fill the pump.

Close the venting plug only after water flows out

and complete air exit.

WARNING ! In hot water, a stream of water

may escape from the venting port. Take all

required precautions as regards persons and

motor.

Pump in suction

Two possible cases:

1st CASE (fig. 5-1):

- Close the discharge valve (3), open the suction

valve (2).

- Remove the venting plug (5).

- Unscrew the bottom drain-priming plug (6)

located on the pump casing 4 to 5 turns.

- Put a funnel into the venting plug port and completely fill the pump and the suction pipe.

- After water flows out and total air exit, filling is

complete.

- Screw the venting plug and the bottom drainpriming plug back in.

2nd CASE (fig. 5-2):

Filling can be made easier by fitting on the suction pipe of the pump, a vertical pipe fitted with

a Ø

The length of the pipe must be at least 50 mm

taller than the venting level.

- Close the discharge valve (3), open the suction

valve (2).

- Open the stopcock and the venting plug.

- Unscrew 4 to 5 turns the drain-priming plug (6).

- Fill the pump and the suction pipe completely

until water flows out of the venting plug (5).

- Close the stopcock (which can be left in place),

remove the pipe and close the bleed device (5)

and screw again the drain-priming plug (6).

Never operate the pump dry, even

1/2” stopcock and a funnel.

13WILO AG 02/2006

Page 7

English

ry-running protection

D

To ensure that the pump is always primed,we

recommend to protect it with a pressure switch

or a float switch.

6.3 Check the motor sense of rotation

- With an open-end screwdriver placed in the slot

of the shaft on fan side,make sure that the pump

urns freely without sticking.

t

Three-phase motor

- Switch on the motor by short pressing on the

motor-overload release and check that it turns in

he direction indicated by the arrow located on

t

the identification label of the pump.

- In the opposite case and if the motor had three

phase, cross two phase wires on motor terminal

block or on the switch.

Single-phase motor

The single-phase motors and motors variatiors

are designed for operating in the correct sense of

rotation.

The sense of rotation is adjusted when assem

bling the product and is independent from the

network connection.

6.4 Starting

WARNING ! Depending on conveyed fluid and

running of pump, surface temperature can

exceed 68°C. Take necessary means to avoid

injuries.

7

. Maintenance

ANGER ! Before any operation, switch off the

D

pump(s).

o special maintenance in operation.

N

Keep the pump and the motor perfectly clean.

In case of prolonged stopping, if there is no risk

of frost, it is best not to drain the pump.

The bearing holding the coupling is lubricated for

its total lifetime and does not require any lubrication.

Motors

The bearings are lubricated for their lifetime and

do not require any lubrication.

Mechanical seals

The mechanical seal does not require any main-

enance in operation.

t

It must never operate dry.

Replacement frequencies

The replacement frequency of the mechanical

seal depends on the operating conditions of the

-

pump:

- Temperature and pressure of the conveyed fluid

for the mechanical seal.

- Starting frequency: continuous or intermittent

running.

The replacement frequency of the other components depends on the operating conditions of

the pump like load and ambient temperature.

CAUTION !

flow (closed discharge valve) for more than 10

minutes with cold water (T° C < 40° C) and more

than 5 minutes above 60° C.

We recommend to ensure a minimum flow of

about 10 % of the nominal flow of the pump to

avoid the formation of a vapour lock at the top

of the pump.

- Keep the discharge valve closed.

- Start the pump.

- Open draining plug to drain air. If no water leaks

within 20', close the plug and stop the pump,

then wait 20' to allow air to settle.

- Start again the pump.

- If necessary (particularly if the suction height

exceeds 5 m) repeat these operations.

- If water leaks at draining plug (it means the

pump delivers its pressure), slowly open the dis

charge valve. The pump has to be primed.

- Check pressure stability at discharge with a

manometer, if instability, perfect air draining.

- In case of failure, do the filling in again and start

the operation again.

- To perfect air draining, close the discharge valve

and the draining plug, then stop the pump 20',

start the pump again and open the draining plug.

Do it as long as air comes out.

- Open the discharge valve in order to have the

wished working point.

- Check that the current input does not exceed

the value indicated on the motor data plate.

The pump must not operate at zero

-

14 WILO AG 02/2006

Page 8

8

. Problems, causes and remedies

Faults Causes Remedies

he pump turns but not delivery

T

The pump vibrate Loose on its foundation Check and tighten completely the nuts

The motor overheats Voltage too low Check voltage on terminals of the motor,

The pump delivers insufficient pressure The motor fails to run at its normal

The circuit-breaker device is on The setting of the thermal relay is not

The flow is irregular The suction head (Ha) is not adequate Study again the installation conditions

he internal parts are obstructed by

T

particles

Suction pipe obstructed Clean all the pipes

Air in suction pipes Check tightness of the whole pipe up to

Pump is no more primed Fill the pump to prime again

uction pressure is too low, it causes

S

cavitation noise

he supply voltage of the motor is too

T

low

Particles obstructing the pump Dismantle the pump and clean it

Difficult rotation of the pump Check the pump turns freely without

Bad electrical connection Check the connections to the pump motor

Pump obstructed by particles Dismantle the pump and clean it

Ambient temperature above + 40°C The motor is aimed at operating at a

Coupling failure in the terminal box Be in conformity with the motor plate

speed (particles...)

The motor is defective Replace the motor

Bad filling of the pump Open the bleeding device and drain until

The motor turns in the wrong way

(three-phase motor)

The drain-priming plug is not correctly

tightened

The supply voltage of the motor is too

low

adequate (too low)

The voltage is too low Check the adequate cross-section of the

A phase is cut Check it and change the electrical cable

The thermal relay of the circuit-breaker

is defective

A fuse is off Replace it

The suction pipe has a lower diameter

than the one of the pump

The strainer and the suction pipe are

partially obstructed

ismantle the pump and clean it

D

the pump and make it tight

Check foot valve is tight

oo high loss of head on suction or suc-

T

tion head (check the NPSH of the pump

installed and of the installation)

heck the voltage on the terminals of

C

the motor and the cross-section of the

conductors

of the stud bolts

abnormal sticking

it should be within ± 10 % in 50 Hz or ± 6

% in 60 Hz of the rated voltage

maximum ambient temperature of

+ 40°C

and see figure 4

Dismantle the pump and solve the defect

there are no more air bubbles

Reverse the sense of rotation by interchanging the two phase wires on the

motor terminal box

Check it and screw it again

Check the voltage on the terminals of

the motor and the cross-section of the

conductors

Check the current with an ammeter or

set the value of the current rating on the

motor data plate

conductors of the electrical cable

if necessary

Replace it

and the recommendations described in

this instruction

The suction pipe must have the same

diameter as the suction pump port

Remove and clean

nglish

E

If no solution can be found, please contact your

plumbing and heating specialist or your nearest

Wilo Customer Service or representative.

15WILO AG 02/2006

Page 9

English

9

. Spare parts

Spare parts are ordered via a local specialist dealer and/or Wilo customer service.

In order to avoid queries and incorrect orders,

ake sure to mention all data indicated on the

m

rating plate when placing your order.

Subject to technical alterations !

16 WILO AG 02/2006

Page 10

D EG - Konformitätserklärung

GB EC – Declaration of conformity

F Déclaration de conformité CEE

Hiermit erklären wir, dass die Bauarten der Baureihe :

MVIL 100

Herewith, we declare that this product:

MVIL 300

Par le présent, nous déclarons que cet agrégat :

MVIL 500

MVIL 900

in der gelieferten Ausführung folgenden einschlägigen Bestimmungen entspricht:

in its delivered state comply with the following relevant provisions:

est conforme aux dispositions suivants dont il relève:

EG-Maschinenrichtlinie 98/37/EG

EC-Machinery directive

Directives CEE relatives aux machines

Elektromagnetische Verträglichkeit - Richtlinie 89/336/EWG

Electromagnetic compatibility - directive

i.d.F/ as amended/ avec les amendements suivants:

Compatibilité électromagnétique- directive

91/263/EWG

92/31/EWG

93/68/EWG

Niederspannungsrichtlinie 73/23/EWG

Low voltage directive

i.d.F/ as amended/ avec les amendements suivants :

Direction basse-tension

93/68/EWG

Angewendete harmonisierte Normen, insbesondere:

EN 809

Applied harmonized standards, in particular:

EN 60034-1

Normes harmonisées, notamment:

Dortmund, 25.05.2005

Erwin Prieß

Quality Manager

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Document: 2058815.2

Page 11

N

L

EG-verklaring van overeenstemming

Hiermede verklaren wij dat dit aggregaat in de

g

eleverde uitvoering voldoet aan de volgende

bepalingen:

E

G-richtlijnen betreffende machines 98/37/EG

Elektromagnetische compatibiliteit 89/336/EEG

als vervolg op 91/263/EEG, 92/31/EEG, 93/68/EEG

EG-laagspanningsrichtlijn 73/23/EEG als vervolg

o

p 93/68/EEG

Gebruikte geharmoniseerde normen, in het

bijzonder: 1)

I

Dichiarazione di conformità CE

Con la presente si dichiara che i presenti prodotti

s

ono conformi alle seguenti disposizioni e

direttive rilevanti:

D

irettiva macchine 98/37/CE

Compatibilità elettromagnetica 89/336/CEE e

seguenti modifiche 91/263/CEE, 92/31/CEE,

9

3/68/CEE

D

irettiva bassa tensione 73/23/CEE e seguenti

modifiche 93/68/CEE

Norme armonizzate applicate, in particolare: 1)

E

Declaración de conformidad CE

Por la presente declaramos la conformidad del

p

roducto en su estado de suministro con las

disposiciones pertinentes siguientes:

D

irectiva sobre máquinas 98/37/CE

Directiva sobre compatibilidad electromagnética

89/336/CEE modificada por 91/263/CEE,

9

2/31/CEE, 93/68/CEE

D

irectiva sobre equipos de baja tensión

73/23/CEE modificada por 93/68/CEE

Normas armonizadas adoptadas, especialmente: 1)

P

Declaração de Conformidade CE

Pela presente, declaramos que esta unidade no

s

eu estado original, está conforme os seguintes

requisitos:

Directivas CEE relativas a máquinas 98/37/CE

Compatibilidade electromagnética 89/336/CEE

com os aditamentos seguintes 91/263/CEE,

92/31/CEE, 93/68/CEE

Directiva de baixa voltagem 73/23/CEE com os

aditamentos seguintes 93/68/CEE

Normas harmonizadas aplicadas, especialmente: 1)

S

CE- försäkran

Härmed förklarar vi att denna maskin i levererat

u

tförande motsvarar följande tillämpliga

bestämmelser:

EG–Maskindirektiv 98/37/EG

EG–Elektromagnetisk kompatibilitet – riktlinje

89/336/EWG med följande ändringar

91/263/EWG, 92/31/EWG, 93/68/EWG

EG–Lågspänningsdirektiv 73/23/EWG med

följande ändringar 93/68/EWG

Tillämpade harmoniserade normer, i synnerhet: 1)

N

EU-Overensstemmelseserklæring

Vi erklærer hermed at denne enheten i utførelse

som levert er i overensstemmelse med følgende

r

elevante bestemmelser:

EG–Maskindirektiv 98/37/EG

EG–EMV–Elektromagnetisk kompatibilitet

8

9/336/EWG med senere tilføyelser:

91/263/EWG, 92/31/EWG, 93/68/EWG

EG–Lavspenningsdirektiv 73/23/EWG med senere

tilføyelser: 93/68/EWG

A

nvendte harmoniserte standarder, særlig:

1)

FIN

CE-standardinmukaisuusseloste

Ilmoitamme täten, että tämä laite vastaa

seuraavia asiaankuuluvia määräyksiä:

EU–konedirektiivit: 98/37/EG

Sähkömagneettinen soveltuvuus 89/336/EWG

seuraavin täsmennyksin 91/263/EWG 92/31/EWG,

93/68/EWG

Matalajännite direktiivit: 73/23/EWG seuraavin

täsmennyksin 93/68/EWG

Käytetyt yhteensovitetut standardit, erityisesti: 1)

DK

EF-overensstemmelseserklæring

Vi erklærer hermed, at denne enhed ved levering

overholder følgende relevante bestemmelser:

EU–maskindirektiver 98/37/EG

Elektromagnetisk kompatibilitet: 89/336/EWG,

følgende 91/263/EWG, 92/31/EWG, 93/68/EWG

Lavvolts-direktiv 73/23/EWG følgende

93/68/EWG

Anvendte harmoniserede standarder, særligt: 1)

H

EK. Azonossági nyilatkozat

Ezennel kijelentjük,hogy az berendezés az

alábbiaknak megfelel:

EK Irányelvek gépekhez: 98/37/EG

Elektromágneses zavarás/türés: 89/336/EWG és

az azt kiváltó 91/263/EWG, 92/31/EWG,

93/68/EWG

Kisfeszültségü berendezések irány-Elve:

73/23/EWG és az azt kiváltó 93/68/EWG

Felhasznált harmonizált szabványok, különösen: 1)

CZ

Prohlášení o shodě EU

Prohlašujeme tímto, že tento agregát v dodaném

provedení odpovídá následujícím příslušným

ustanovením:

Směrnicím EU–strojní zařízení 98/37/EG

Směrnicím EU–EMV 89/336/EWG ve sledu

91/263/EWG, 92/31/EWG, 93/68/EWG

Směrnicím EU–nízké napětí 73/23/EWG ve sledu

93/68/EWG

Použité harmonizační normy, zejména: 1)

PL

Deklaracja Zgodności CE

Niniejszym deklarujemy z pełną odpowiedzialnoscią

że dostarczony wyrób jest zgdony z następującymi

dokumentami:

EC–dyrektywa dla przemysłu maszynowego

98/37/EG

Odpowiedniość elektromagnetyczna 89/336/EWG

ze zmianą 91/263/EWG, 92/31/EWG, 93/68/EWG

Normie niskich napięć 73/23/EWG ze zmianą

93/68/EWG

Wyroby są zgodne ze szczegółowymi normami

zharmonizowanymi:

1)

RUS

Деклация о соответствии Европейским

нормам

Настоящим документом заявляем, что данный

агрегат в его объеме поставки соответствует

следующим нормативным документам:

Директивы EC в отношении машин 98/37/EG

Электромагнитная устойчивость 89/336/EWG с

поправками 91/263/EWG, 92/31/EWG,

93/68/EWG

Директивы по низковольтному напряжению

73/23/EWG с поправками 93/68/EWG

Используемые согласованные стандарты и

нормы, в частности : 1)

GR

∆ήλωση προσαρ ογής της Ε.Ε.

∆ηλώνου ε ότι το προϊόν αυτό σ’ αυτή την

κατάσταση παράδοσης ικανοποιεί τις ακόλουθες

διατάξεις :

Οδηγίες EG για ηχανή ατα 98/37/EG

Ηλεκτρο αγνητική συ βατότητα EG-89/336/EWG

όπως τροποποιήθηκε 91/263/EWG 92/31/EWG,

93/68/EWG

Οδηγία χα ηλής τάσης EG–73/23/EWG όπως

τροποποιήθηκε 93/68/EWG

Εναρ ονισ ένα χρησι οποιού ενα πρότυπα,

ιδιαίτερα: 1)

TR

CE Uygunluk Teyid Belgesi

Bu cihazın teslim edildiği ºekliyle aºağıdaki

standartlara uygun olduğunu teyid ederiz:

AB-Makina Standartları 98/37/EG

Elektromanyetik Uyumluluk 89/336/EWG ve takip

eden, 91/263/EWG, 92/31/EWG, 93/68/EWG

Alçak gerilim direktifi 73/23/EWG ve takip eden,

93/68/EWG

Kısmen kullanılan standartlar: 1)

1)

EN 809,

EN 60034-1

Erwin Prieß

Quality Manager

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Page 12

Page 13

Loading...

Loading...