Page 1

Wilo-MVIE 11 --> 22 kW / Wilo-HELIX-VE 11 --> 22 kW

D Einbau- und Betriebsanleitung

GB Installation and operating instructions

F Notice de montage et de mise en service

NL Inbouw- en bedieningsvoorschriften

E Instrucciones de instalación y funcionamiento

I Istruzioni di montaggio, uso e manutenzione

P Manual de instalação e funcionamento

S Monterings- och skötselinstruktioner

DK Monterings- og driftsvejledning

CZ Návod k montáži a obsluze

RUS Инструкция по монтажу и эксплуатации

4093679 – Ed.04-09/08/9704 Ba.

Page 2

Page 3

L

X

P

Y

4 x Ø D

E

1

606 1610

3203 3205

3203 3207

5203 5205

5203 5205

TYPE

2

5

PN

L

PXY

corps

mm mm mm mm

235 235 195 195 35 14

260 260 220 220 35 14

16

25

16

25

16

1606

2

52 190 215 130

260 260 220 220 30 14

E

ØD

mm mm

2

0 12

2207 2209

25

162205

270 190 215 130 5 12

7002 7004

7002 7004

25

16

350 261 280 199 45 14

9501 9503

9501 9503

25

16

350 261 280 199 45 14

5

1

1

7

6

1

13

327

100 mm Min.

200 mm Min.

100 mm

Min.

HA

2%

BP

8

9

12

5

11

3

2

7

74

613

2

4

10

100 mm

Min.

HC

ou / or

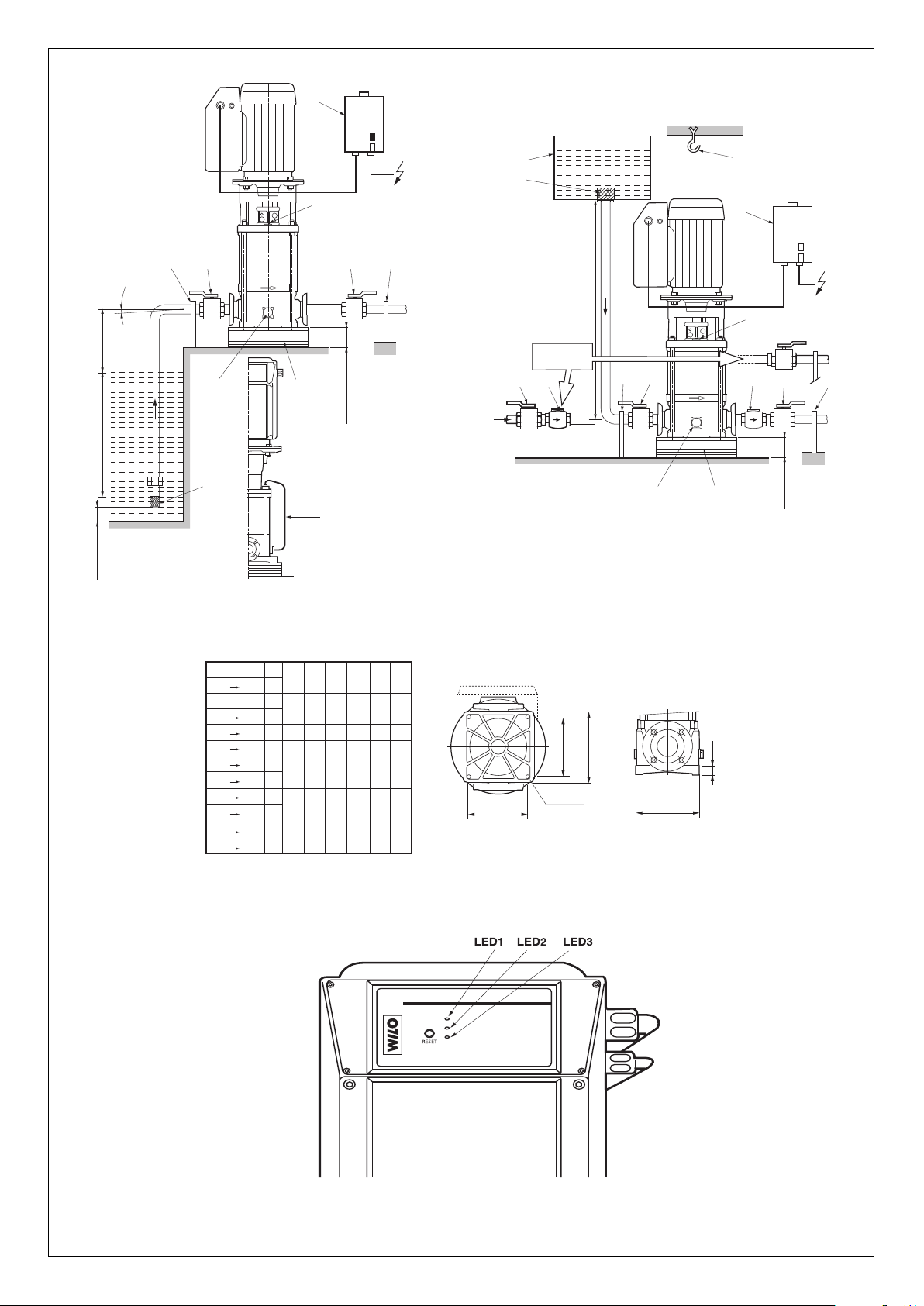

Fig. 1

Fig. 2

Fig. 3

Fig. 4

Page 4

2

1

+ 50 mm

Min.

14

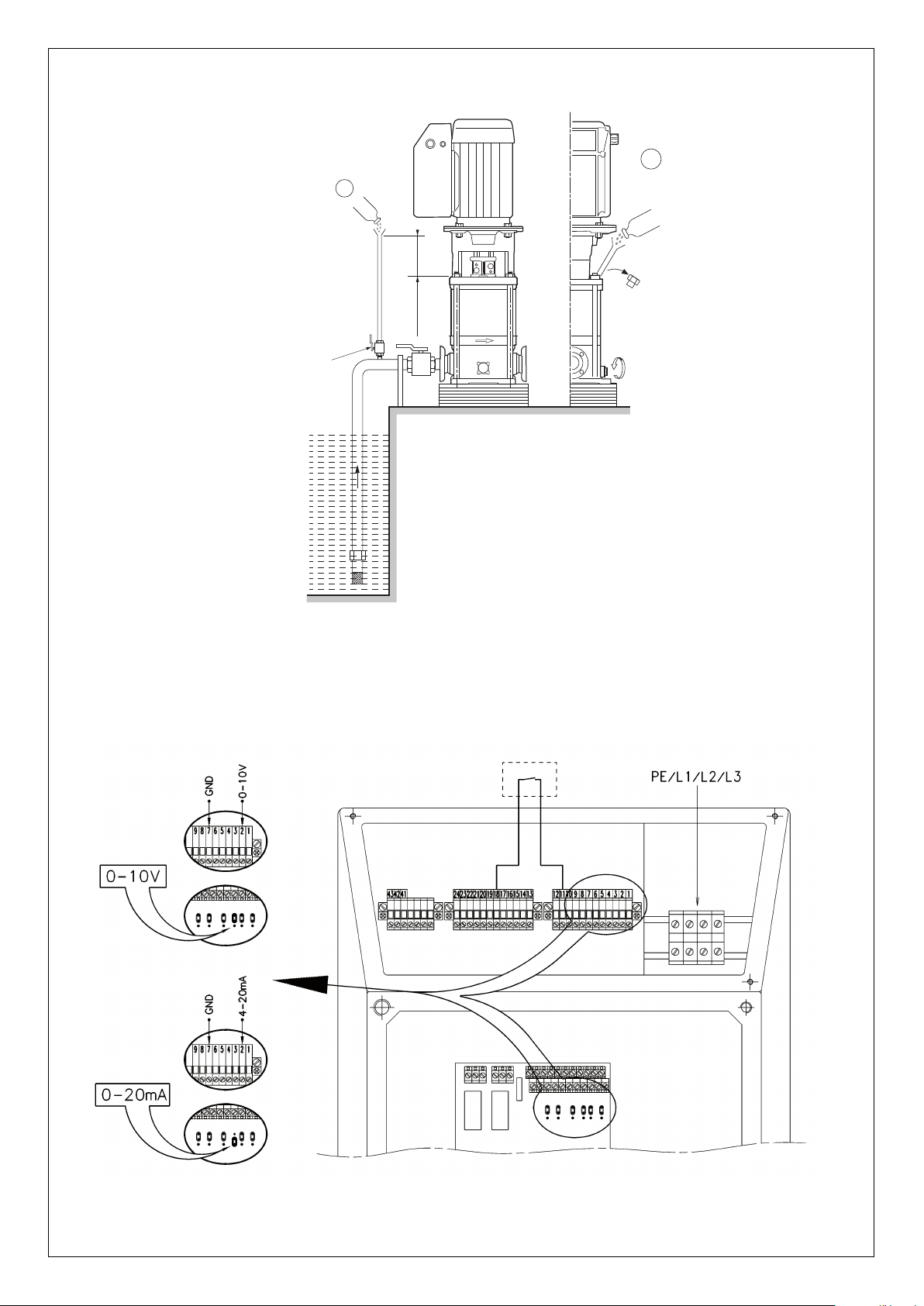

Fig. 5

Fig. 6

Page 5

Fig. 7

Page 6

D

1. Allgemeines . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2. Sicherheit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3. Transport und Zwischenlagerung . . . . . . . . . . . . . . . . . . . . . . 8

4. Beschreibung von Produkt und Zubehör . . . . . . . . . . . . . . . . 8

5. Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

6. Inbetriebnahme . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

7. Wartung . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

8. Störungen, Ursachen und Beseitigung . . . . . . . . . . . . . . . . . . 12

GB

1. General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

2. Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

3. Transport and interim storage . . . . . . . . . . . . . . . . . . . . . . . . . 15

4. Description and function . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

. Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

5

6. Starting Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

7. Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

8. Defaults-Causes-Remedies . . . . . . . . . . . . . . . . . . . . . . . . . . 19

F

1. Généralités . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

2. Sécurité . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

3. Transport et stockage momentané . . . . . . . . . . . . . . . . . . . . . 22

4. Descriptif et fonctionnement . . . . . . . . . . . . . . . . . . . . . . . . . . 22

5. Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6. Mise en route . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

7. Entretien . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

8. Anomalies-Détection-Réparation . . . . . . . . . . . . . . . . . . . . . . 26

Page 7

1. General

Installation and service by qualified personnel only

1.1 Uses

Pumps aimed at pumping clear liquids in building, agriculture and

ndustry areas …

i

Water supply, water tower, sprinkling, high pressure washing, boiler

supply (with mandatory by-pass kit) – lifting of condensates – air conditioning – industrial networks and integration in all modular systems.

1.2 Product Data

1.2.1 Connection and electrical data (table 1)

ENGLISH

Temperature range : versions EPDM O’ring and mechanical seal (KTW/WRAS approved versions)

1

) –15 °C to +120 °C

Viton O'ring and mechanical seal (agressiv water) –15 °C to +90 °C

Maximum ambient temperature (standard product) +40 °C maxi

Maximum permissible working pressure : Maximum suction pressure 10 bars

Pump casing PN 16 16 bars

Pump casing PN 25 25 bars

Mains voltages 3~ 400 V (±10%) - 50Hz

3~ 380 V (±6%) - 60Hz

Maximum suction head according NPSH of the pump

Ambient humidity <90 %

Protection index IP 54

Insulation class F

Pump acoustic level tolerance + 3dB (A) : 11 kW 78

15 kW 78

18,5 kW 81

22 kW 81

1

) (WRAS : according to British standard - KTW : according to German standard).

EEMMC

C

This product complies with the standard EN 61800-3 (2nd environment).

WWAARRNNIINNG

G

: in domestic environment this product may cause radio interferences in which case the user may be required to take adequate measures.

Principal dimensions and connection dimensions

(table 2, see also fig. 3)

Types

PN 16 version PN 25 version

LPXYPXY

MVIE mm mm mm

1606 252 190 215 130

1606 to 1610 252 190 215 130

2205 270 190 215 130

2207 to 2209 270 190 215 130

3203 to 3205 235 235 195 195

3203 to 3207 260 260 220 220

5203 to 5205 260 260 220 220 260 220 220

7002 to 7004 350 264 280 199 261 280 199

9501 to 9503 350 264 280 199 261 280 199

When ordering spare parts, please give all the information on the pump/rotor rating plate.

14

Page 8

ENGLISH

1.2.2 Type key

Pump family

(Centrifugal pump,

Multistage vertical,

electronic)

3

Flow rate (m

2 poles/50 Hz)

(

Number of

impellers in row

Power for

MVIE 3203 only

Steel grade :

1 = 1.4301 (AISI 304)

= 1.4404 (AISI 316L)

2

3 = corps GJL-250

+ coating + hydraulics 1.4301 (AISI 304)

Maximum permissible working

ressure (bars)

p

Gaskets – E

Gaskets – V

Mains voltage

3 = 3 400 V

2 = 2 poles

Index of technical evolution

/h)

PDM (KTW/WRAS)

ITON

MVIE 32 03 -11 1 16 E32B

- / / /-/

In particular, failure to comply with these safety precautions could

lead, for example, to risks such as :

• Significant failure of the pump or installation.

• Personal injury due to electrical, mechanical or bacteriological causes.

• Damage to property.

2.4 Safety precautions for the operator

Existing regulations for the prevention of accidents must be followed.

Dangers caused by electrical energy (electric shock or electrocution)

are to be excluded. Safety precautions issued by the local electricity

supply company are to be observed.

2.5 Safety precautions for the installation

The operator must ensure that all inspection and installation work is

carried out by authorised and qualified specialists who have carefully

studied these instructions.

Work on the pump or installation should only be carried out when the

pump is OFF.

2.6 Unauthorized alterations and manufacture of spare parts

Alterations to the pump or installation may only be carried out with the

manufacturer's consent. The use of original spare parts and accessories authorized by the manufacturer will ensure safety. The use of any

other parts may invalidate claims invoking the liability of the manufacturer for any consequences.

2.7 Improper use

The operating safety of the pump or installation supplied can only be

guaranteed if it is used in accordance with paragraph 1 of the operating

instructions.

The limiting values given in the catalogue or data sheet must under no

circumstances be exceeded.

2. Safety

These instructions contain major information, which must be observed

when installing and operating the pump.

These instructions must therefore be by the installer and the responsible operator before the pump is installed or started up.

Both the general safety instructions in the «safety precautions» section

and those in subsequent sections indicated by danger symbols should

be carrefully observed.

2.1 Symbols used in the instruction

Safety precaution which if not followed could cause personal injury:

Safety precaution concerning electrical risks which if not followed could

cause personal injury:

Safety precaution which if not followed could cause damages to the

pump or installation and cause it to malfunction:

CAUTION !

Useful hint to give suggestions and helps the work to be carried out:

NOTE!

2.2 Qualified personnel

The personnel installing the pump must have the appropriate qualifications for this work.

2.3 Risks incurred by failure to comply with the safety precautions

Failure to comply with the safety precautions could result in personal

injury or damage to the pump or installation. Failure to comply with the

safety precautions could also invalidate any claim for damages.

3. Transport and interim storage

When receiving the material, check that there has been no damage

during the transport. If any defect has been stated, take all necessary

steps with the carrier within the allowed time

During transport and in storage the pump must be protected against

moisture, frost and mechanical damage.

Due to high position of centre of gravity and small ground

surface of this type of pumps, beware of instability during

handling to avoid any falling down and take necessary means

to avoid injuries or damaging.

Handle the pump carefully so as not to alter the geometry

and the alignment of the unit.

CAUTION !

In no case the pump must be lifted by the converter,

use some lifting hooks for any handling.

4. Description and function

4.1 Description (fig. 1-2-5)

1 : Strainer-foot valve

2 : Pump suction valve

3 : Pump discharge valve

4 : Non-return valve

5 : Venting and filling plug

6 : Drain-priming plug

7 : Pipe supports or brackets

8 : Strainer

9 : Storage tank

10 : Town water supply

11 : Switch and section switch with fuses

12 : Lifting hook

13 : Foundation block

14 : Cock

BP: By-pass

HA : Maximum suction head

HC : Minimum inlet pressure

15

Page 9

ENGLISH

4.2 Design of pump and motor

• Multistage vertical pump not self-priming, with ports in line on the same

axis in bottom part.

• Asynchronous motor with standardized flange and shaft end for vertical

operation fitted with its converter.

• Motor-pump linked by a coupling with safety guards.

• Shaft sealing by standardized mechanical seal.

• Hydraulic connection:

Round flanges: pump delivered with rings and bolts without counter

flanges (accessories as option).

4.3 Accessories as option

See catalogue or data sheet.

5. Assembly

nstallation and service by qualified personnel only.

CAUTION !

5.1 Installation

Two standard types :

Fig. 1: pump in suction.

Fig. 2: pump under pressure on storage tank (item9) or town water supply (item10).

– Install the pump in a place easy to reach, protected against extrema

conditions (rain and sun in excess, frost) and as close as possible

from the drawing point.

– For heavy pumps provide a point of attachment (lifting hook) in the

pump axis (item12) to facilitate removal.

– Install the pump on a concrete block (at least 10 cm high) (item13)

and fix with anchor bolts (installation plan see fig.3).

– Foresee an insulating material under the concrete block (cork or rein-

forced rubber) to avoid any noise and vibration transmission into the

installation.

– Before final tightening of anchor bolts, ensure that the pump axis is

vertical : use shims if necessary.

CAUTION !

AAllttiittuuddee

0 m 0 mCL 20 °C 0,20 mCL

500 m 0,60 mCL 30 °C 0,40 mCL

1000 m 1,15 mCL 40 °C 0,70 mCL

I

Bear in mind that the altitude of the installation place

and the water temperature may reduce the suction

possibilities of the pump.

Loss of head

TTeemmppeerraattuurree

50 °C 1,20 mCL

60 °C 1,90 mCL

70 °C 3,10 mCL

80 °C 4,70 mCL

90 °C 7,10 mCL

100 °C 10,30 mCL

110 °C 14,70 mCL

120 °C 20,50 mCL

Loss of head

• The direction of the fluid flow is indicated on the identification label of

the pump.

• Limit the length of the suction pipe and avoid all features that cause

losses of head (bends, valves, tapers). Connections have to be

correctly sealed : no air entrance is allowed on the suction

pipe which is showing a mounting declivity of at least 2% (fig.

1).

• Use supports or collars (fig.1 & 2 - item 7) so that the pump does not

CAUTION !

ded to connect the non-return valve to the pump discharge to protect

NOTE!

water, we recommend to install the by-pass kit (fig.1-item BP).

5.3 Electrical connections

The electric connections and inspections have to be carried out by a

qualified electrician and have to comply with the relevant local standards.

• The electric characteristics (frequency, voltage, nominal current) of

he motor-converter are mentioned on the name plate. Check that the

t

motor-converter complies with the mains supply used.

• The electric protection of the motors is integrated into the converter.

The parameters take into account the characteristics of the pump

and must ensure its protection and the one of the motor.

• In case of impedance between earth and neutral point, install a protection before motor-converter.

• Provide a fuse disconnecting switch (type GF) to protect the mains

installation (fig.1 & 2-item11).

• If you have to install a differential circuit-breaker for users protection,

it must have a delay effect. Adjust it according to the current mentioned on the converter label.

• Use power cables conforming with standards

DO NOT FORGET TO CONNECT TO EARTH.

• The electric connection of the converter (fig.6) has to comply with the

ear the weight of the pipes.

b

When the pump is under pressure, it is recommen-

it against hammer blow effects.

To pump water with a large content of air or hot

schemes of the following table :

CAUTION !

A connection error would damage the converter.

The power cable must never touch the pipe or the pump ;

make sure that it is sheltered from any humidity.

• You can change the orientation of the motor-converter by quarter turn

when removing the fixing screws of the motor and reorientating the

motor to the wished position.

Place the screws back.

CAUTION !

sure.

5.2 Hydraulic connections

CAUTION !

runs at maximum frequency and zero flow rate.

• Pump with round flange pump casing : with weld-on or screw-on

tube in the counterflanges (counterflanges available as accessories).

• The diameter of the pipe must never be smaller than the one of the

counter flange.

16

Possible damage of the pump! (cavitation).

Above 80° C, plan to install the pump under pres-

Possible damage of the pump! The installation

has to bear the pressure reached when the pump

Page 10

ENGLISH

Details of electrical connections

– Loosen the screws and remove the converter cover.

CONNECTION TO MAINS SUPPLY POWER TERMINALS

– Connect the cable 4 wires wires ≥ ø4 mm2 No special order

(3 phases + earth)

CONNECTION OF INPUTS/OUTPUTS TERMINAL FOR INPUTS/OUTPUTS (1 to 10)

– Control of the converter by an external (see fig. 6) (See chapter 6 : starting up)

system with a signal (0-10V) or 0-20mA)

A removable jumper has to be placed

according to the type of signal.

- Control with a current signal............................ 0-20mA

put the bridge in low position.

L1 L2 L3 PE

zero volt

urrent input 0-20mA

c

emovable bridge

r

of the phases

654321

7

GND

0-20MA

7654321

GND

- Control with a voltage signal ........................... 0-10V

by default the bridge is in high position,

if not carry out the change.

- Possibility to have a remote control ................ Accessories

(free contact).

zero volt

oltage input 0-10V

v

removable bridge

18 17 16 15 14 12 11

Float switch, pressure gauge for dry-running...

ex :

Remote control

CONNECTION OF THE SERIES CONTACTS TERMINAL FOR SERIES CONTACTS

The speed variator is fitted with an output relay with

free contact aimed for an interface to centralized control

For example : control box, pumps control…

«Available transfer» relay : See fig.6

Bornes : 41 - 42 - 43 Example : 6 defects with a variable time limit on 10 sliding

- feature of the contact .....................................

The relay is actived when the pump runs or

is in a position to run.

When a first defect appears or by mains supply

min12V/10mA

max250V/1A

active relay

minutes according to the following scale :

Final

Stop

cutoff (the pump stops), the relay is no more

active. Information are given to the control box,

regarding the availability of the pump permanently.

transfer ”

“ available

0-10V

The number of defects is stored thanks to a

counter.

If the number of defects is lower than 6 and if

after 10 sliding minutes no new defect has been

detected, so the number of defects of the

counter is reduced of 1.

The pump is permanently stopped the counter

count 6 defects. An impulse on the RESET

button initialize the counter.

rest relay

Defect

appearance

123456

10 sliding minutes

17

Page 11

ENGLISH

Control laws

Control signal 0-20mA

100%

Frequency

n % of

i

he pump

t

rotation

40%

0

2 4

Pump

top

s

ecurity

s

rea

a

Input in current (mA)

20

6. Starting up

CAUTION !

guration mode is the external control 0-10V.

6.1 Configurations

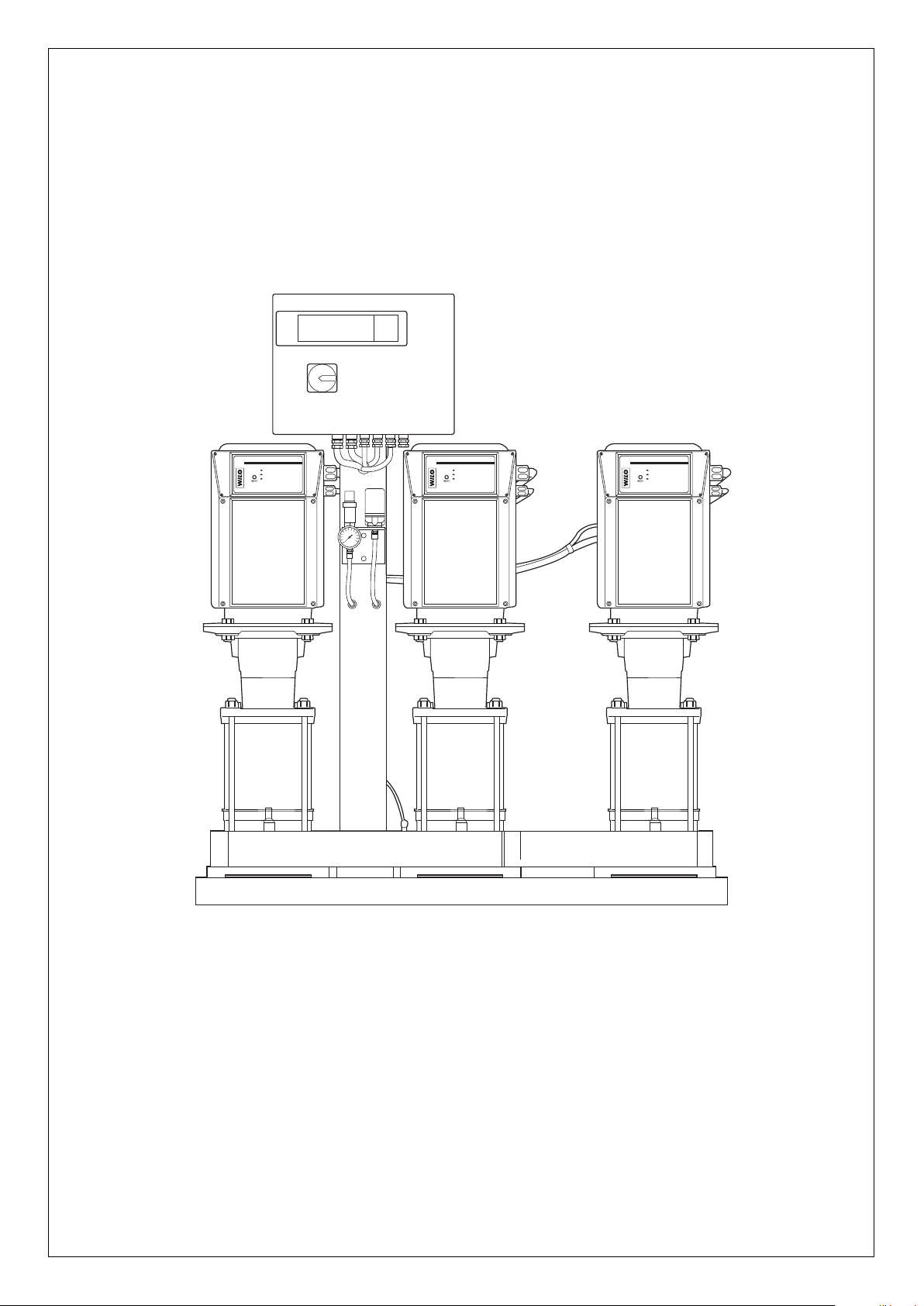

The pump is controlled with an external system (see fig.7)

If the pump is integrated in a booster assembled by ourselves, consult

the booster instructions.

In normal operation the state of the leds is as follows (see fig.4) :

State of Function

LED Light on Flashing Switched off

LED1

RED

LED2 The pump

GREEN turns

LED3 Pump

GREEN alive

6.2 Preliminary rinsing

Each of our pumps is tested regarding hydraulic features in factory,

some water may remain in them. It is recommended for hygien purposes, to carry out a rinsing of the pump before any using with potable

water supply.

6.3 Filling - degassing

CAUTION !

Pump under pressure (see fig. 2)

- Close the discharge valve (item3).

- Open the venting plug (item5), the suction valve (item2) and completely fill the pump.

- Close the venting plug only after water flows out and complete aeration.

- In hot water, a stream of water may escape from the venting plug port.

- Take all required precautions as regards persons and motor-converter.

If the pump is delivered as separate part, not integrated into a system we mounted, the standard confi-

Failure

Detected failure Limit No failure

alarm

The motor is in

acceleration or

deceleration phase

The motor

is stopped

Pump

/

dead

Never operate the pump dry,

even briefly.

Control signal 0-10V

100%

Frequency

n % of

i

he pump

t

rotation

40%

0

1 2

Pump

top

s

ecurity

s

rea

a

Input in a voltage (V)

10

Pump in suction (see fig.1) : two possible cases.

1st case (see fig.5.1)

- Close the discharge valve (fig.1-item3), open the suction valve (fig.1item2).

- Remove the venting plug (fig.1-item5)

- Unscrew about 4 turns the bottom drain-priming plug (fig.1-item 6)

located on the pump casing.

- Put a funnel into the venting plug port and completely fill the pump

and the suction pipe.

- After water flows out and total air exit, filling is achieved.

- Screw the venting plug and the bottom drain-priming plug back in.

2nd case (see fig.5.2)

- Filling can be made easier by fitting on the suction pipe of the pump, a

vertical pipe (fig.5-item14) fitted with a Ø 1/2" stopcock and a funnel.

- The length of the pipe must be at least 50 mm taller than the venting

plug level.

- Close the discharge valve (fig.1-item3), open the suction valve (fig.1item2).

- Open the stopcock (fig.5-item14) and the venting device (fig.1-item5).

- Unscrew about 4 turns the drain-priming plug (fig.1-item 6).

- Completely fill the pump and the suction pipe until water flows out of

the venting plug (fig.1-item5).

- Close the stopcock (fig.5-item14) (which can be left in place), remove

the pipe, close the venting device (fig.1-item5) and screw again the

drain-priming plug (fig.1-item6).

6.4 Starting up

Depending on conveyed fluid and running of pump, surface

temperature can exceed 68°C. Take necessary means to

avoid injuries.

The pump must not operate at zero flow (closed dis-

CAUTION !

charge valve) for more than 10 minutes with cold water

(T°C < 40°C) and more than 5 minutes above 60° C.

- We recommend to ensure a minimum flow of about 10 % of the nominal

flow of the pump to avoid the formation of a vapour lock at the top

of the pump.

- Keep the discharge valve closed.

- Start the pump.

- Open draining plug to drain air. If no water leaks within 20s, close the

plug and stop the pump, then wait 20s to allow air to settle.

18

Page 12

ENGLISH

GR

E

A

SE

- Start again the pump.

- If necessary (particularly if the suction height exceeds 5 m) repeat

these operations.

- If water leaks at draining plug (it means the pump delivers its pressure),

slowly open the discharge valve.

- The pump has to be primed.

- Check pressure stability at discharge with a manometer, if instability,

perfect air draining.

- In case of failure, do the filling in again and start the operation again.

- To perfect air draining, close the discharge valve and the draining plug,

hen stop the pump 20s, start the pump again and open the draining

t

plug. Do it as long as air comes out.

- Open the discharge valve in order to have the wished working point.

- Check that the current input does not exceed the value indicated on

he identification pump plate.

t

7. Maintenance

CAUTION !

Before any operation,

switch off the pump(s).

8. Defaults-Causes-Remedies

Before carrying out any maintenance work, switch off the

pump and ensure that it cannot be switched on again by

unauthorised people.

CAUTION !

Never carry out work on a running pump.

No special maintenance in operation.

Keep the pump and the motor-converter perfectly clean.

In case of prolonged stopping, if there is no risk of frost, it is best not

to drain the pump.

The bearing holding the coupling and the motor bearings are lubricated

for their total lifetime and do not require any lubrication.

On pumps equipped with greaser under bearing box, see regreasing

instructions written on sticker put on it.

MVIE 7004

MVIE 9503/2

On other models, the bearing holding the coupling is lubricated for its

total lifetime.

It is recommended to grease the shaft end as well as the coupling

boring with a high adhering grease (type type D321R Molikote or 8191

Loctite for example) to facilitate any further diassembling.

The mechanical seal does not require any maintenance in operation. It

must never operate dry.

DEFECTS DETECTED BY THE SPEED VARIATOR

All incidents hereafter mentioned give rise to :

- The resting of the ”available transfer” relay.

- The activation of the ”failure transfer” relay when the maximum quantity of defect is reached.

- ligthening of a red LED.

INCIDENTS

8.1 THE PUMP IS

OVERLOADED

8.2 ELECTRICAL

INCIDENTS

8.3 THE MOTOR /

CONVERTER HEATS

CAUSES

a) The Ventilation of the converter

is uncertain :

b) The pump is obstructed

by foreign matters :

c) The pump is locked :

d) The fluid density is too important :

a) The supply of the converter is in

over-or under-voltage :

b) A supply phase is missing :

c) The converter or the motor is

in short-circuit :

a) The ventilation of the converter is uncertain :

b) The motor cooling is uncertain :

REMEDIES

a) Check that the cooling channel is not obstructed.

b) Dismantle the pump, replace the defective

components or clean.

c) Dismantle the pump, clean it and replace the

defective parts.

Possibly mechanical defect of the motor (bearings).

Clean all the pipework.

d) Limit the maximum loading point of the pump

according to the type of fluid.

a) Check the voltage at the converter terminals.

b) Check the supply.

c) Dismantle the motor-converter of the pump and

check it or replace it.

a) Check that the cooling channel is not obstructed

and that fans run correctly.

b) Clean the cooling ribs of the motor.

c) The pump is used in the ambient

temperature higher 40 °C :

-The ”failure transfer” relay is active when the counter reaches 6 failures.

1) If the pump is completely stopped and an intervention on this one is

necessary, cut the supply ; correct the failure, switch on the supply

again.

c) The motor / converter is foreseen to run at a

maximum ambient temperature of + 40 °C.

2) If the failure cause has been suppressed without cutting the converter supply ; the pump must start again after an impulse on the ”reset”

button (See FIG. 4).

- If the defect is major, the action of an after-sales technician is required.

19

Page 13

ENGLISH

Other defects, not detected by the speed variator, due to the

safety to the repairing man.

8.4 THE PUMP TURNS

8.5 THE PUMP IS VIBRATING

pump.

Before any operation, SWITCH OFF the pump(s).

If the liquid is toxic, corrosive or dangerous for human being,

WILO or the qualified person in charge of the repairing must

be informed. In this case, clean the pump to ensure a complete

DEFAULTS

BUT NO DELIVERY

CAUSES

a) The pump does not run quickly enough :

b) The internal parts are obstructed

by particles :

c) Suction pipe are obstructed :

d) Air in suction piping :

e) Suction pressure is too low,

it causes generally

cavitation noise :

a) Loose on its foundation :

REMEDIES

a) Check the adequate adjustment of the po-

tentiometer (conformity to the required points).

b) Let dismantle the pump and clean it.

c) Clean all the pipes.

d) Check tightness of the whole pipe up to be

pump an make it tight.

e) Too high losses of load on suction or suction

head is too high.

(Check the NPSH of the pump installed and

of the installation).

a) Check and tighten completely the nuts of

the stud bolts.

b) Particles obstrucing the pump :

c) Difficult rotation of the pump :

8.6 NO SUFFICIENT

PRESSURE FOR THE

PUMP

8.7 THE FLOW IS

IRREGULAR

If the fault cannot be remedied, please contact your plumbing and heating specialist or

your nearest WILO customer services or representative.

a) The motor speed is not high enough :

b) The motor is defective :

c) Bad filling of the pump :

d) The drain-priming plug is not

fully tightened :

a) The suction head (HA) is not

respected :

b) The suction pipe has a lower

diameter than the one of the pump :

c) The strainer and the suction

pipe are partially obstructed :

b) Have the pump dismantled and clean it.

c) Check the pump turns freely without

abnormal sticking.

a) Check the reference is correctly adjusted

(conformity of the reference points).

b) Replace Motor-converter.

c) Open the venting device and venty until

there are no more air bubbles.

d) Check it and screw it again.

a) Study again the installation conditions and the

recommendations described in this manual.

b) The suction pipe must have the same

diameter as the suction pump port.

c) Remove and clean.

Subject to technical alterations!

20

Page 14

D EG - Konformitätserklärung

GB EC – Declaration of conformity

F Déclaration de conformité CEE

Hiermit erklären wir, dass die Bauarten der Baureihe :

MVIE 11-22 kW

Herewith, we declare that this product:

Par le présent, nous déclarons que cet agrégat :

in der gelieferten Ausführung folgenden einschlägigen Bestimmungen entspricht:

in its delivered state comply with the following relevant provisions:

est conforme aux dispositions suivants dont il relève:

EG-Maschinenrichtlinie 98/37/EG

EC-Machinery directive

Directives CEE relatives aux machines

Elektromagnetische Verträglichkeit - Richtlinie 2004/1008/EG

Electromagnetic compatibility - directive

Compatibilité électromagnétique- directive

Niederspannungsrichtlinie 2006/95/EG

Low voltage directive

Direction basse-tension

Angewendete harmonisierte Normen, insbesondere:

EN 809

Applied harmonized standards, in particular:

EN 50178

Normes harmonisées, notamment:

EN 61800-3

Dortmund, 14.09.2007

Erwin Prieß

Quality Manager

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Document: 2060374.2

Page 15

Page 16

NL

EG-verklaring van overeenstemming

H

iermede verklaren wij dat dit aggregaat in de

g

eleverde uitvoering voldoet aan de volgende

bepalingen:

EG-richtlijnen betreffende machines 98/37/EG

E

lektromagnetische compatibiliteit

2004/1008/EG

EG-laagspanningsrichtlijn 2006/95/EG

Gebruikte geharmoniseerde normen, in het

b

ijzonder:

1)

I

Dichiarazione di conformità CE

C

on la presente si dichiara che i presenti prodotti

s

ono conformi alle seguenti disposizioni e

direttive rilevanti:

Direttiva macchine 98/37/CE

C

ompatibilità elettromagnetica 2004/1008/EG

Direttiva bassa tensione 2006/95/EG

Norme armonizzate applicate, in particolare: 1)

E

Declaración de conformidad CE

P

or la presente declaramos la conformidad del

p

roducto en su estado de suministro con las

disposiciones pertinentes siguientes:

Directiva sobre máquinas 98/37/CE

D

irectiva sobre compatibilidad electromagnética

2004/1008/EG

Directiva sobre equipos de baja tensión

2

006/95/EG

N

ormas armonizadas adoptadas, especialmente:

1

)

P

Declaração de Conformidade CE

Pela presente, declaramos que esta unidade no

seu estado original, está conforme os seguintes

requisitos:

Directivas CEE relativas a máquinas 98/37/CE

Compatibilidade electromagnética 2004/1008/EG

D

irectiva de baixa voltagem 2006/95/EG

N

ormas harmonizadas aplicadas, especialmente:

1)

S

CE- försäkran

Härmed förklarar vi att denna maskin i levererat

utförande motsvarar följande tillämpliga

bestämmelser:

EG–Maskindirektiv 98/37/EG

EG–Elektromagnetisk kompatibilitet –

2004/1008/EG

E

G–Lågspänningsdirektiv 2006/95/EG

Tillämpade harmoniserade normer, i synnerhet: 1)

N

EU-Overensstemmelseserklæring

Vi erklærer hermed at denne enheten i utførelse

s

om levert er i overensstemmelse med følgende

r

elevante bestemmelser:

E

G–Maskindirektiv 98/37/EG

EG–EMV–Elektromagnetisk kompatibilitet

2

004/1008/EG

E

G–Lavspenningsdirektiv 2006/95/EG

Anvendte harmoniserte standarder, særlig: 1)

FIN

CE-standardinmukaisuusseloste

Ilmoitamme täten, että tämä laite vastaa

seuraavia asiaankuuluvia määräyksiä:

EU–konedirektiivit: 98/37/EG

Sähkömagneettinen soveltuvuus 2004/1008/EG

Matalajännite direktiivit: 2006/95/EG

Käytetyt yhteensovitetut standardit, erityisesti: 1)

DK

EF-overensstemmelseserklæring

Vi erklærer hermed, at denne enhed ved levering

o

verholder følgende relevante bestemmelser:

EU–maskindirektiver 98/37/EG

Elektromagnetisk kompatibilitet: 2004/1008/EG

Lavvolts-direktiv 2006/95/EG

Anvendte harmoniserede standarder, særligt: 1)

H

EK. Azonossági nyilatkozat

Ezennel kijelentjük,hogy az berendezés az

alábbiaknak megfelel:

EK Irányelvek gépekhez: 98/37/EG

Elektromágneses zavarás/türés: 2004/1008/EG

Kisfeszültségü berendezések irány-Elve:

2006/95/EG

Felhasznált harmonizált szabványok, különösen: 1)

CZ

Prohlášení o shodě EU

Prohlašujeme tímto, že tento agregát v dodaném

provedení odpovídá následujícím příslušným

ustanovením:

Směrnicím EU–strojní zařízení 98/37/EG

Směrnicím EU–EMV 2004/1008/EG

Směrnicím EU–nízké napětí 2006/95/EG

Použité harmonizační normy, zejména: 1)

PL

Deklaracja Zgodności CE

Niniejszym deklarujemy z pełną odpowiedzialnoscią

że dostarczony wyrób jest zgdony z następującymi

dokumentami:

EC–dyrektywa dla przemysłu maszynowego

98/37/EG

Odpowiedniość elektromagnetyczna

2004/1008/EG

Normie niskich napięć 2006/95/EG

Wyroby są zgodne ze szczegółowymi normami

zharmonizowanymi: 1)

RUS

Деклация о соответствии Европейским

нормам

Настоящим документом заявляем, что данный

агрегат в его объеме поставки соответствует

следующим нормативным документам:

Директивы EC в отношении машин 98/37/EG

Электромагнитная устойчивость

2004/1008/EG

Директивы по низковольтному напряжению

2006/95/EG

Используемые согласованные стандарты и

нормы, в частности : 1)

GR

∆ήλωση προσαρ ογής της Ε.Ε.

∆ηλώνου ε ότι το προϊόν αυτό σ’ αυτή την

κατάσταση παράδοσης ικανοποιεί τις ακόλουθες

διατάξεις :

Οδηγίες EG για ηχανή ατα 98/37/EG

Ηλεκτρο αγνητική συ βατότητα -2004/1008/EG

Οδηγία χα ηλής τάσης 2006/95/EG

Εναρ ονισ ένα χρησι οποιού ενα πρότυπα,

ιδιαίτερα: 1)

TR

CE Uygunluk Teyid Belgesi

Bu cihazın teslim edildiği ºekliyle aºağıdaki

standartlara uygun olduğunu teyid ederiz:

AB-Makina Standartları 98/37/EG

Elektromanyetik Uyumluluk 2004/1008/EG

Alçak gerilim direktifi 2006/95/EG

Kısmen kullanılan standartlar: 1)

1)

EN 809

EN 50178

EN 61800-3

Erwin Prieß

Quality Manager

WILO AG

Nortkirchenstraße 100

44263 Dortmund

Page 17

WILO SE

Nortkirchenstraße 100

44263 Dortmund

Germany

T +49 231 4102-0

F +49 231 4102-7363

wilo@wilo.de

www.wilo.com

Algeria

Bad Ezzouar, Dar El Beida

T +213 21 247979

chabane.hamdad@salmson.fr

Armenia

375001 Yerevan

T +374 10 544336

info@wilo.am

Bosnia and Herzegovina

71000 Sarajevo

T +387 33 714510

zeljko.cvjetkovic@wilo.ba

Georgia

0177 Tbilisi

T +995 32317813

info@wilo.ge

Macedonia

1000 Skopje

T +389 2 3122058

valerij.vojneski@wilo.com.mk

Moldova

2012 Chisinau

T +373 2 223501

sergiu.zagurean@wilo.md

Rep. Mongolia

Ulaanbaatar

T +976 11 314843

wilo@magicnet.mn

Tajikistan

734025 Dushanbe

T +992 37 2232908

farhod.rahimov@wilo.tj

Turkmenistan

744000 Ashgabad

T +993 12 345838

wilo@wilo-tm.info

Uzbekistan

700046 Taschkent

sergej.arakelov@wilo.uz

August 2008

Wilo – International (Subsidiaries)

Wilo – International (Representation offices)

Argentina

W

ILO SALMSON

A

rgentina S.A.

C1270ABE Ciudad

Autónoma de Buenos Aires

T +54 11 43015955

info@salmon.com.ar

A

ustria

WILO Handelsges. m.b.H.

1

230 Wien

T

+43 507 507-0

office@wilo.at

Azerbaijan

WILO Caspian LLC

1065 Baku

T +994 12 5962372

info@wilo.az

Belarus

WILO Bel OOO

220035 Minsk

T +375 17 2503393

wilobel@wilo.by

Belgium

WILO SA/NV

1083 Ganshoren

T +32 2 4823333

info@wilo.be

Bulgaria

WILO Bulgaria Ltd.

1125 Sofia

T +359 2 9701970

info@wilo.bg

Canada

WILO Canada Inc.

Calgary, Alberta T2A 5L4

T +1 403 2769456

bill.lowe@wilo-na.com

China

WILO China Ltd.

101300 Beijing

T +86 10 80493900

wilobj@wilo.com.cn

C

roatia

WILO Hrvatska d.o.o.

10090 Zagreb

T

+38 51 3430914

w

ilo-hrvatska@wilo.hr

Czech Republic

WILO Praha s.r.o.

25101 Cestlice

T +420 234 098711

info@wilo.cz

Denmark

WILO Danmark A/S

2690 Karlslunde

T +45 70 253312

wilo@wilo.dk

Estonia

WILO Eesti OÜ

12618 Tallinn

T +372 6509780

info@wilo.ee

Finland

WILO Finland OY

02330 Espoo

T +358 207401540

wilo@wilo.fi

France

WILO S.A.S.

78390 Bois d'Arcy

T +33 1 30050930

info@wilo.fr

Great Britain

WILO (U.K.) Ltd.

DE14 2WJ BurtonUpon-Trent

T +44 1283 523000

sales@wilo.co.uk

Greece

WILO Hellas AG

14569 Anixi (Attika)

T +302 10 6248300

wilo.info@wilo.gr

Hungary

WILO Magyarország Kft

2

045 Törökbálint

(Budapest)

T

+36 23 889500

wilo@wilo.hu

I

reland

W

ILO Engineering Ltd.

Limerick

T

+353 61 227566

sales@wilo.ie

Italy

WILO Italia s.r.l.

20068 Peschiera

Borromeo (Milano)

T +39 25538351

wilo.italia@wilo.it

Kazakhstan

WILO Central Asia

050002 Almaty

T +7 727 2785961

in.pak@wilo.kz

Korea

WILO Pumps Ltd.

621-807 Gimhae

Gyeongnam

T +82 55 3405800

wilo@wilo.co.kr

Latvia

WILO Baltic SIA

1019 Riga

T +371 67 145229

mail@wilo.lv

Lebanon

WILO SALMSON

Lebanon

12022030 El Metn

T +961 4 722280

wsl@cyberia.net.lb

Lithuania

W

ILO Lietuva UAB

03202 Vilnius

T +370 5 2136495

m

ail@wilo.lt

The Netherlands

WILO Nederland b.v.

1948 RC Beverwijk

T +31 251 220844

i

nfo@wilo.nl

Norway

WILO Norge AS

0901 Oslo

T +47 22 804570

wilo@wilo.no

Poland

WILO Polska Sp. z.o.o.

05-090 Raszyn

T +48 22 7026161

wilo@wilo.pl

Portugal

Bombas Wilo-Salmson

Portugal Lda.

4050-040 Porto

T +351 22 2080350

bombas@wilo.pt

Romania

WILO Romania s.r.l.

077040 Com. Chiajna

Jud. Ilfov

T +40 21 3170164

wilo@wilo.ro

Russia

WILO Rus ooo

123592 Moscow

T +7 495 7810690

wilo@orc.ru

Saudi Arabia

WILO ME - Riyadh

Riyadh 11465

T +966 1 4624430

wshoula@wataniaind.com

S

erbia and Montenegro

WILO Beograd d.o.o.

11000 Beograd

T +381 11 2851278

o

ffice@wilo.co.yu

Slovakia

WILO Slovakia s.r.o.

8

2008 Bratislava 28

T

+421 2 45520122

w

ilo@wilo.sk

Slovenia

WILO Adriatic d.o.o.

1000 Ljubljana

T +386 1 5838130

wilo.adriatic@wilo.si

South Africa

Salmson South Africa

1610 Edenvale

T +27 11 6082780

errol.cornelius@

salmson.co.za

Spain

WILO Ibérica S.A.

28806 Alcalá de Henares

(Madrid)

T +34 91 8797100

wilo.iberica@wilo.es

Sweden

WILO Sverige AB

35246 Växjö

T +46 470 727600

wilo@wilo.se

Switzerland

EMB Pumpen AG

4310 Rheinfelden

T +41 61 83680-20

info@emb-pumpen.ch

Taiwan

WILO-EMU Taiwan Co. Ltd.

1

10 Taipeh

T +886 227 391655

n

elson.wu@

w

iloemutaiwan.com.tw

Turkey

W

ILO Pompa Sistemleri

S

an. ve Tic. A.S¸.

3

4530 Istanbul

T +90 216 6610211

wilo@wilo.com.tr

Ukraina

WILO Ukraina t.o.w.

01033 Kiew

T +38 044 2011870

wilo@wilo.ua

Vietnam

Pompes Salmson Vietnam

Ho Chi Minh-Ville Vietnam

T +84 8 8109975

nkm@salmson.com.vn

United Arab Emirates

WILO ME - Dubai

Dubai

T +971 4 3453633

info@wilo.com.sa

USA

WILO-EMU USA LLC

Thomasville,

Georgia 31792

T +1 229 5840097

info@wilo-emu.com

USA

WILO USA LLC

Melrose Park, Illinois 60160

T +1 708 3389456

mike.easterley@

wilo-na.com

Page 18

WILO SE

Nortkirchenstraße 100

44263 Dortmund

Germany

T 0231 4102-0

F 0231 4102-7363

wilo@wilo.de

www.wilo.de

G1 Nord

WILO SE

Vertriebsbüro Hamburg

Beim Strohhause 27

20097 Hamburg

T 040 5559490

F 040 55594949

hamburg.anfragen@wilo.de

G2 Ost

WILO SE

Vertriebsbüro Berlin

Juliusstraße 52–53

12051 Berlin-Neukölln

T 030 6289370

F 030 62893770

berlin.anfragen@wilo.de

G3 Sachsen/Thüringen

WILO SE

Vertriebsbüro Dresden

Frankenring 8

01723 Kesselsdorf

T 035204 7050

F 035204 70570

dresden.anfragen@wilo.de

G4 Südost

WILO SE

Vertriebsbüro München

Landshuter Straße 20

85716 Unterschleißheim

T 089 4200090

F 089 42000944

muenchen.anfragen@wilo.de

G5 Südwest

WILO SE

Vertriebsbüro Stuttgart

Hertichstraße 10

71229 Leonberg

T 07152 94710

F 07152 947141

stuttgart.anfragen@wilo.de

G6 Rhein-Main

WILO SE

Vertriebsbüro Frankfurt

An den drei Hasen 31

61440 Oberursel/Ts.

T 06171 70460

F 06171 704665

frankfurt.anfragen@wilo.de

G7 West

WILO SE

Vertriebsbüro Düsseldorf

Westring 19

40721 Hilden

T 02103 90920

F 02103 909215

duesseldorf.anfragen@wilo.de

Kompetenz-Team

Gebäudetechnik

WILO SE

Nortkirchenstraße 100

44263 Dortmund

T 0231 4102-7516

T 01805 R•U•F•W•I•L•O*

7•8•3•9•4•5•6

F 0231 4102-7666

Kompetenz-Team

Kommune

Bau + Bergbau

WILO EMU GmbH

Heimgartenstraße 1

95030 Hof

T 09281 974-550

F 09281 974-551

Werkskundendienst

Gebäudetechnik

Kommune

Bau + Bergbau

Industrie

WILO SE

Nortkirchenstraße 100

44263 Dortmund

T 0231 4102-7900

T 01805 W•I•L•O•K•D*

9•4•5•6•5•3

F 0231 4102-7126

Erreichbar Mo–Fr von

7–17 Uhr.

Wochenende und feiertags

9–14 Uhr elektronische

Bereitschaft mit

Rückruf-Garantie!

–Kundendienst-Anforderung

–Werksreparaturen

–Ersatzteilfragen

–Inbetriebnahme

–Inspektion

–Technische Service-Beratung

–Qualitätsanalyse

Wilo-International

Österreich

Zentrale Wien:

WILO Handelsgesellschaft mbH

Eitnergasse 13

1230 Wien

T +43 507 507-0

F +43 507 507-15

Vertriebsbüro Salzburg:

Gnigler Straße 56

5020 Salzburg

T +43 507 507-13

F +43 507 507-15

Vertriebsbüro Oberösterreich:

Trattnachtalstraße 7

4710 Grieskirchen

T +43 507 507-26

F +43 507 507-15

Schweiz

EMB Pumpen AG

Gerstenweg 7

4310 Rheinfelden

T +41 61 83680-20

F +41 61 83680-21

Standorte weiterer

Tochtergesellschaften

Argentinien, Aserbaidschan,

Belarus, Belgien, Bulgarien,

China, Dänemark, Estland,

Finnland, Frankreich,

Griechenland, Großbritannien,

Irland, Italien, Kanada,

Kasachstan, Korea, Kroatien,

Lettland, Libanon, Litauen,

Niederlande, Norwegen,

Polen, Portugal, Rumänien,

Russland, Saudi-Arabien,

Schweden, Serbien und

Montenegro, Slowakei,

Slowenien, Spanien,

Südafrika, Taiwan,

Tschechien, Türkei, Ukraine,

Ungarn, Vereinigte Arabische

Emirate, Vietnam, USA

Die Adressen finden Sie unter

www.wilo.de oder

www.wilo.com.

Stand August 2008

Erreichbar Mo–Fr von 7–18 Uhr.

–Antworten auf

– Produkt- und Anwendungsfragen

– Liefertermine und Lieferzeiten

–Informationen über Ansprechpartner vor Ort

–Versand von Informationsunterlagen

* 14 Cent pro Minute aus dem deutschen Festnetz

der T-Com. Bei Anrufen aus Mobilfunknetzen

sind Preisabweichungen möglich.

Wilo-Vertriebsbüros in Deutschland

Loading...

Loading...