Page 1

Pioneering for You

Wilo-Control SC-Fire Electric A2P

en Installation and operating instructions

4 206 383-Ed.01 / 2017-01-Wilo

Page 2

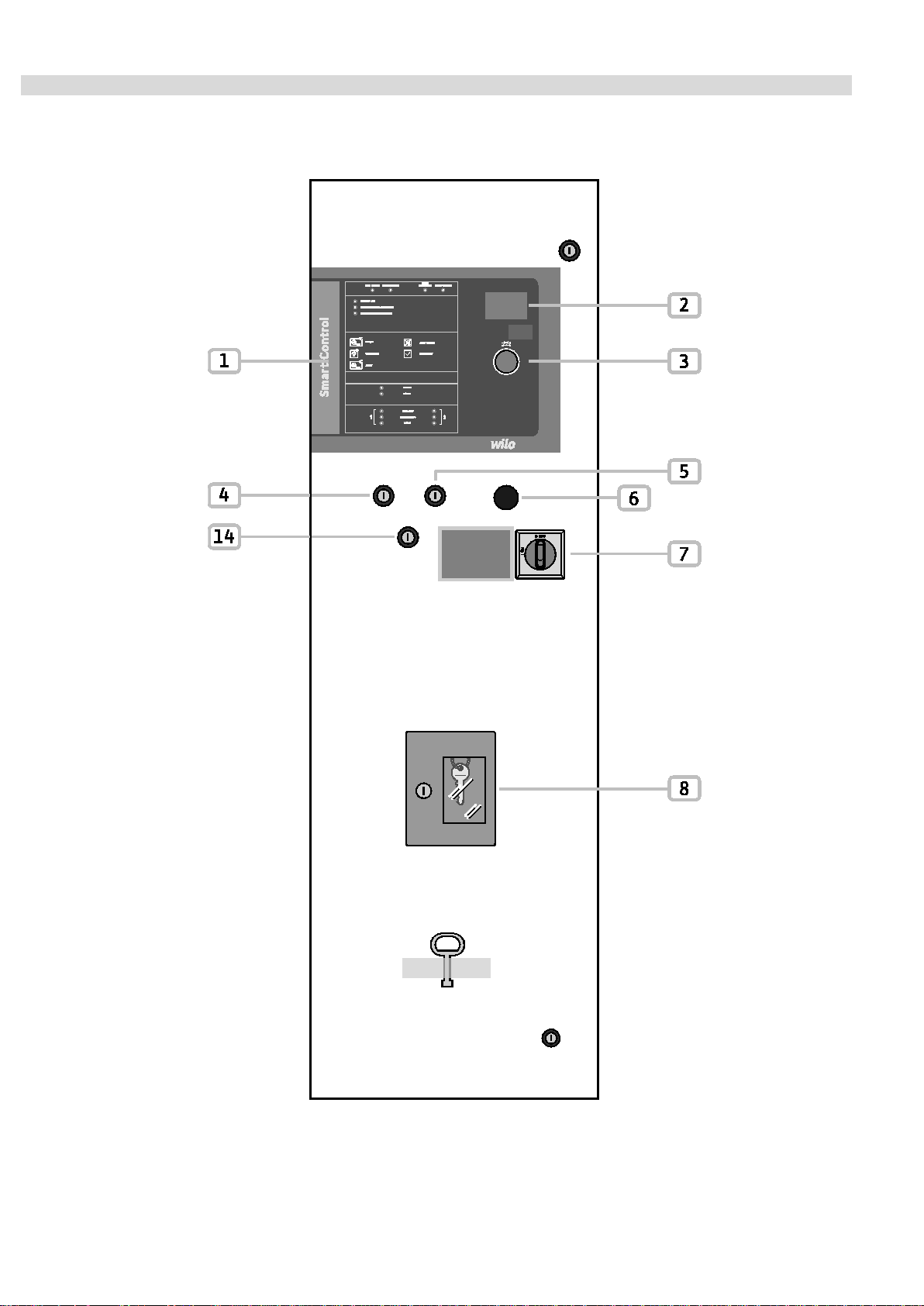

Fig. 1

English

WILO SE 01/2017 2

Page 3

Fig. 1

English

Installation and operating instructions Wilo-SC-Fire Electric A2P 3

Page 4

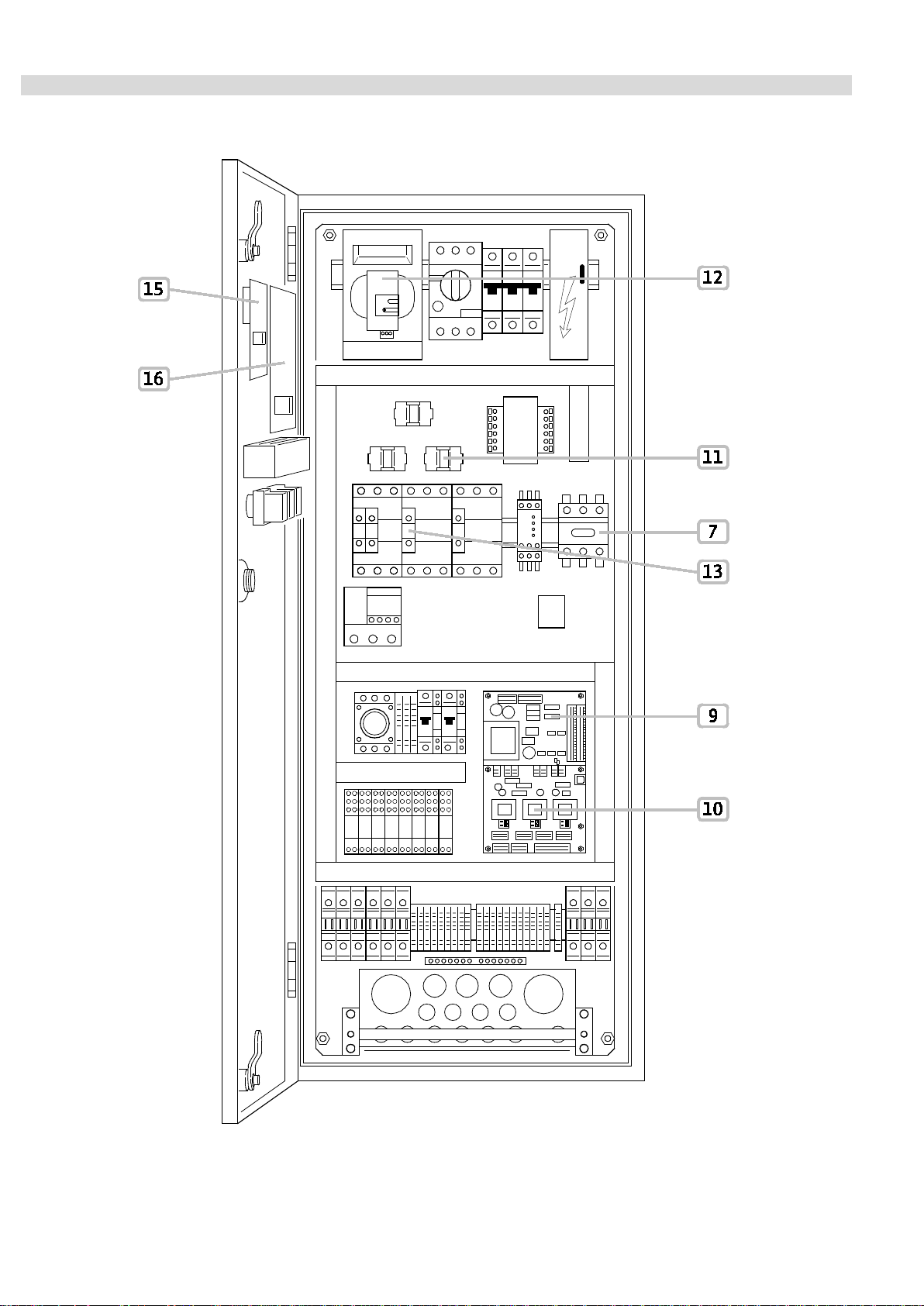

Fig. 2

English

WILO SE 01/2017 4

Page 5

English

1 General

About this document

The language of the original installation and operating instructions is German. All other lan guages of these

instructions are translations of the original installation and operating instructions.

The installation and operating instructions are an integral part of the product. They must be kept close to the

product and be ready for use if necessary. Strict adherence to these instructions is a precondition for the

proper use and correct operation of the product.

These installation and operating instructions correspond to the relevant version of the product and the

underlying safety standards valid at the time of going to print.

EC declaration of conformity: A copy of the EC declaration of conformity is a key component of these installation and operating instructions. If a technical modification is made on the designs listed therein without prior approval or the declarations made

in the installation and operating instructions on product/personnel safety are not observed, this declaration

loses its validity.

2 Safety

These installation and operating instructions contain important information which must be adhered to during

installation, operation and maintenance. For this reason, these instructions must, without fail, be read by the

service technician and the responsible specialist/operator before installation and commissioning.

It is not only the general safety instructions listed under the main point “safety” that must be adhered to but also

the special safety instructions with danger symbols included under the following main points.

2.1 Symbols and signal words used in the installation and operating instructions

Symbols:

HELPFUL NOTE

Signal words:

DANGER!

Acutely dangerous situation.

Non-observance results in death or the most serious of injuries.

WARNING!

The user may suffer (serious) injuries. “Warning” implies that (serious) injury to persons is

probable if this information is disregarded.

CAUTION!

There is a risk of damaging the pump/system. “Caution” implies that damage to the product is

likely if this information is disregarded.

General danger symbol

Danger due to electrical voltage

Installation and operating instructions Wilo-SC-Fire Electric A2P 5

Page 6

English

NOTE:

Useful information on handling the product. It draws attention to possible problems.

2.2 Personnel qualifications

The installation, operating and maintenance personnel must have the appropriate qualifications for this work.

Area of responsibility, terms of reference and monitoring of the personnel are to be ensured by the operator.

If the personnel are not in possession of the necessary knowledge, they are to be trained and instructed.

This can be accomplished if necessary by the manufacturer of the product at the request of the operator.

2.3 Danger in the event of non-observance of the safety instructions

Non-observance of the safety instructions can result in risk of injury to persons and damage to the

environment and the product/unit. It also results in the loss of any claims to damages.

In detail, non-observance can, for example, result in the following risks:

• Danger to persons due to electrical, mechanical and bacteriological influences.

• Damage to the environment due to leakage of hazardous materials.

• Property damage.

• Failure of important product/unit functions.

• Failure of required maintenance and repair procedures.

2.4 Safety instructions for the operator

This device is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the device.

• If the product/unit poses a threat due to components being too hot or too cold, these components must

be protected by the customer against touching.

• Guards which protect personnel from coming into contact with moving components (e.g. the coupling)

must not be removed while the product is in operation.

• Hazardous fluids (e.g. from the shaft seals) which have leaked (which are explosive, toxic or hot) must

be eliminated so that no danger to persons or to the environment arises. National statutory provisions

are to be complied with.

• Highly flammable materials are always to be kept at a safe distance from the product.

• Danger from electrical current must be eliminated. Local directives or general directives

[e.g. IEC, VDE etc.] and instructions from energy supply companies must be adhered to.

2.5 Safety instructions for installation and inspection work

The operator must ensure that all maintenance and installation work is carried out by authorised and qualified

personnel, who are sufficiently informed based on their own detailed study of the installation and operating

instructions.

Work on the product/unit must only be carried out when at a standstill. It is mandatory that the procedure

described in the installation and operating instructions for shutting down the product/unit be complied with.

Immediately on conclusion of the work, all safety and protective devices must be put back in position and/or

recommissioned.

WILO SE 01/2017 6

Page 7

English

2.6 Unauthorised modification and manufacture of spare parts

Unauthorised modification and manufacture of spare parts will impair the safety of the product/personnel and

will make void the manufacturer's declarations regarding safety.

Product modifications are exclusively authorised following the agreement of the manufacturer. Original spare

parts and accessories authorised by the manufacturer ensure safety. The use of other parts will absolve the

company of liability.

2.7 Improper use

The operating safety of the supplied product is only guaranteed for conventional use in accordance with

Section 4 of the installation and operating instructions. The limit values must on no account fall under or

exceed those values specified in the catalogue/data sheet.

3 Transport and interim stora ge

Upon receipt of the product:

• Check for any damage that may have occurred during transit.

• In the event of damage in transit take the necessary steps within the period defined by the transport

company within the time constraints.

CAUTION! Risk of property damage!

Non-compliant transport and interim storage may cause material damage to the

product.

• The switchgear must be protected against humidity and any mechanical damage.

• The product must not be exposed to temperatures lower than -10 °C and higher

than +50 °C.

Installation and operating instructions Wilo-SC-Fire Electric A2P 7

Page 8

Example:

CTRL

Fixed

Operation

SC

Fixed

Smart Control = control unit

F

Fixed

F = application of protection against fire

1x

Fixed

Number of pumps

T4

Fixed

T = three-phase ; 4 = 400 V

BM: Base mounted (mounted on feet)

ND

Fixed

Switchgear type “New Design”

E

Fixed

Switchgear for electric pump

English

4 Applications (application)

The switchgear SC Fire A2P controls a single electric pump in automatic sprinkler systems in accordance with

APSAD (T1-2).

The relevant fields of application are habitable buildings, offices, hospitals, hotels, administrative and

industrial buildings.

The pump is switched according to the pressure or level when it is used with the right signal sensors.

Compliance with this manual is also part of correct use.

Any use which does not meet this criteria is considered to be non-compliant.

5 Product information

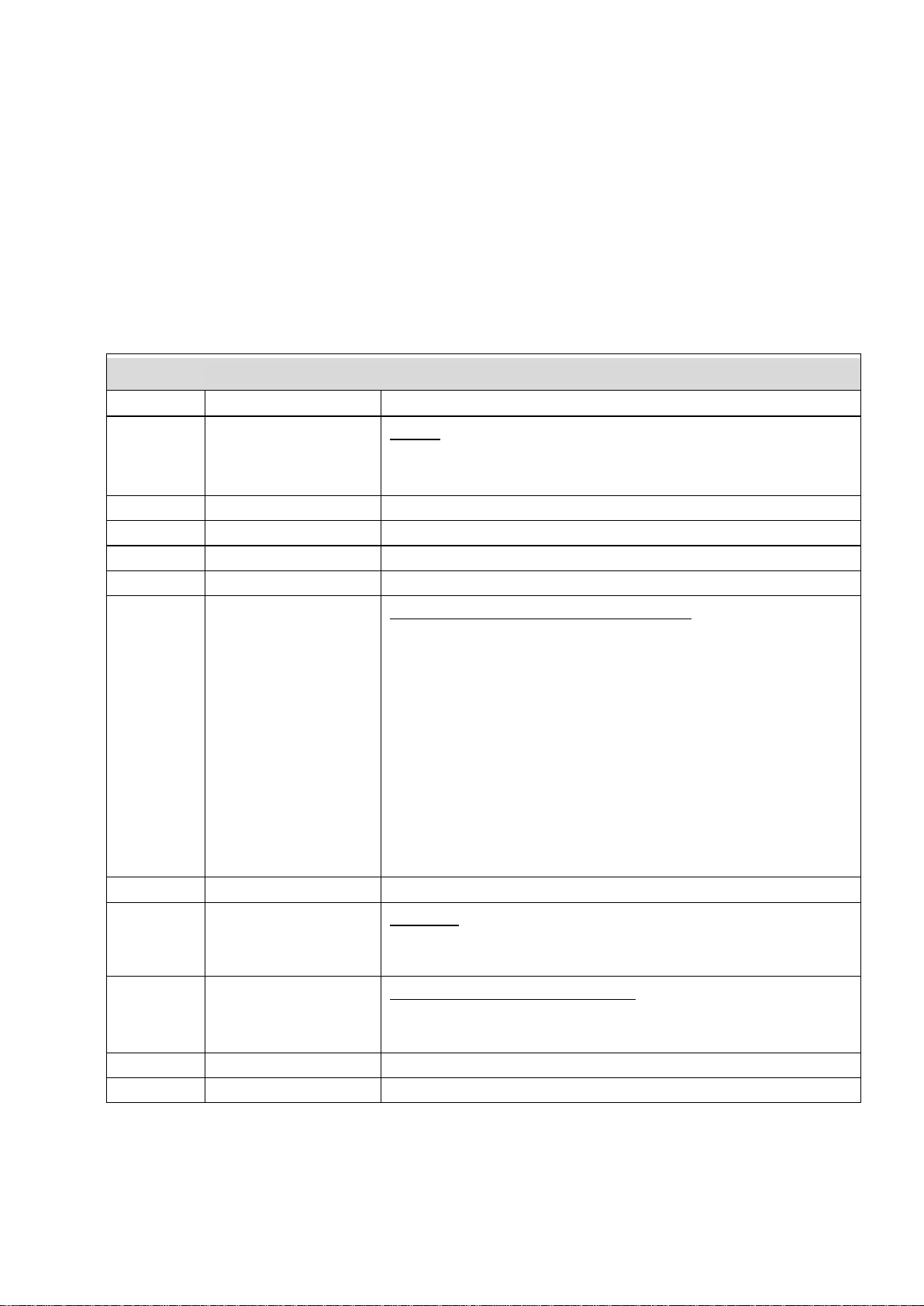

5.1 Type key

W-CTRL-SC-F-1x(2)A-T4-(3)-(4)-ND-E

W

Multiple choice

Brand:

W: Wilo

(2) Multiple choice

(3)

(4)

Multiple choice

Multiple choice

Maximum rated current of the motor [A]:

14.1A

20.4A

27.6A

33.7A

39.1A

53.6A

65.8A

78.0A

95.0A

129.0A

On state:

DOL: Direct online (direct starting)

SD: Star Delta (start star-delta)

Type of installation of switchbox:

FM: Frame mounted (placed on a baseplate)

Table 1 – Type key

WILO SE 01/2017 8

Page 9

Technical data

Mains connection voltage [V]:

Frequency [Hz]:

50/60 Hz

230 V AC ; 24 V AC/DC

Absorbed current max [A]:

See the rating plate

Protection class:

IP44

Fuse protection max on mains side [A]:

See circuit diagram

Room temperature [°C]:

0 °C to +50 °C

Electrical safety:

Pollution degree II

Alarm/signal contact:

250 V AC, 1 A

English

5.2 Technical data

3~ 400 V (L1, L 2, L3, PE)

Control voltage [V]:

Table 2 – Technical data

5.3 Scope of delivery

• Switchgear

• Circuit diagram

• Installation and operating instructions

• Check log in accordance with EN 60204-1

5.4 Accessories

6 Description and function

6.1 Product description

6.1.1 Function description

The switchgear is used to control a single electric pump in “sprinkler systems” in accordance with APSAD (T1-2).

In automatic mode the pump is switched on according to the unit pressure. Each pump has 2 pressure switches

at its pressure connection to monitor the pressure. Each pressure switch is controlled by a key switch.

When the pump is started, it can only be switched off manually and only when the pressure has been reached in

the unit.

In manual mode the start of the pump is activated from the HMI.

The st art-up of the pump is done by means of a start-up tank, the filling of which is controlled by a float switch.

States of system operation such as availability, pump operation, malfunctions, etc. are visually indicated by

LEDs on the front of the switchbox and equally by a buzzer. Operating parameters such as current or voltage

values are displayed on the screen. The operation is performed by means of the rotary knob, key switches and

buttons accessible on the front of the switchbox.

Potential-free contacts are available for transmitting the collective run or malfunction signals to a possible

BMS (building management system).

Installation and operating instructions Wilo-SC-Fire Electric A2P 9

Page 10

English

6.1.2 Structure of the switchgear (Fig. 1) The installation of components in the switchbox depends on the performance of the pump connected.

The switchgear includes the following main components:

• Main on/off switch: Power supply of the switchgear (pos. 7)

• Human-machine interface (HMI): signal lamps or screen for displaying the state of operation (for example

availability, malfunction and rated current of the pump), user test of the pump and function allowing error

messages to be acknowledged (pos. 1, 2, 3)

• Key switch: selection of operating mode (manual, deactivation, automatic) of the pressure switches

(pos. 4, 5)

• Change-over switch (pos. 14): access to level 2

• Buzzer signal: additional buzzer for certain error messages (pos. 6)

• “SC controller” PCB: printed circuit board with microcontroller (pos. 9)

Warni ng: There are 2 “SC controller” PCBs, fixed with spacer sleeves to superimpose them.

• “SC U/I” PCB: Measurement/acquisition voltage/current (pos. 10)

• Current converter: pump current measurement (pos. 11)

• Fuse protection: protection of the pump motor (pos. 12)

• Contactor: Contactor of the motor of the pump (pos. 13)

• “SC Display” PCB: printed circuit board with display and rotary button (pos. 14)

• “SC I/O” PCB: printed circuit board with control/operating console (pos. 15)

• Key box: enables the storage of the keys from the key switches (pos. 8)

6.2 Function and operation

DANGER! Risk of death!

When working on an open switchgear, there is a risk of electrocution in the event of

contact with active conductors.

This work must only be carried out by qualified personnel!

After connecting the switchgear to the connection voltage as well as after each network cut-off, the

switchgear reverts to the operating mode set before the voltage cut-off.

6.2.1 Switchgear operating modes of the start/deactivation After connection to the power supply, the switchgear can be switched on or off using the main switch.

Once the main switch has been activated, the system is instantly ready for operation. After several seconds,

the green signal lamp (Fig. 2, pos. 1) lights up.

WILO SE 01/2017 10

Page 11

Key switch 1

AUTO

OFF

MANUAL

Float switch

Float switch

Float switch

Float switch

-

Float switch

English

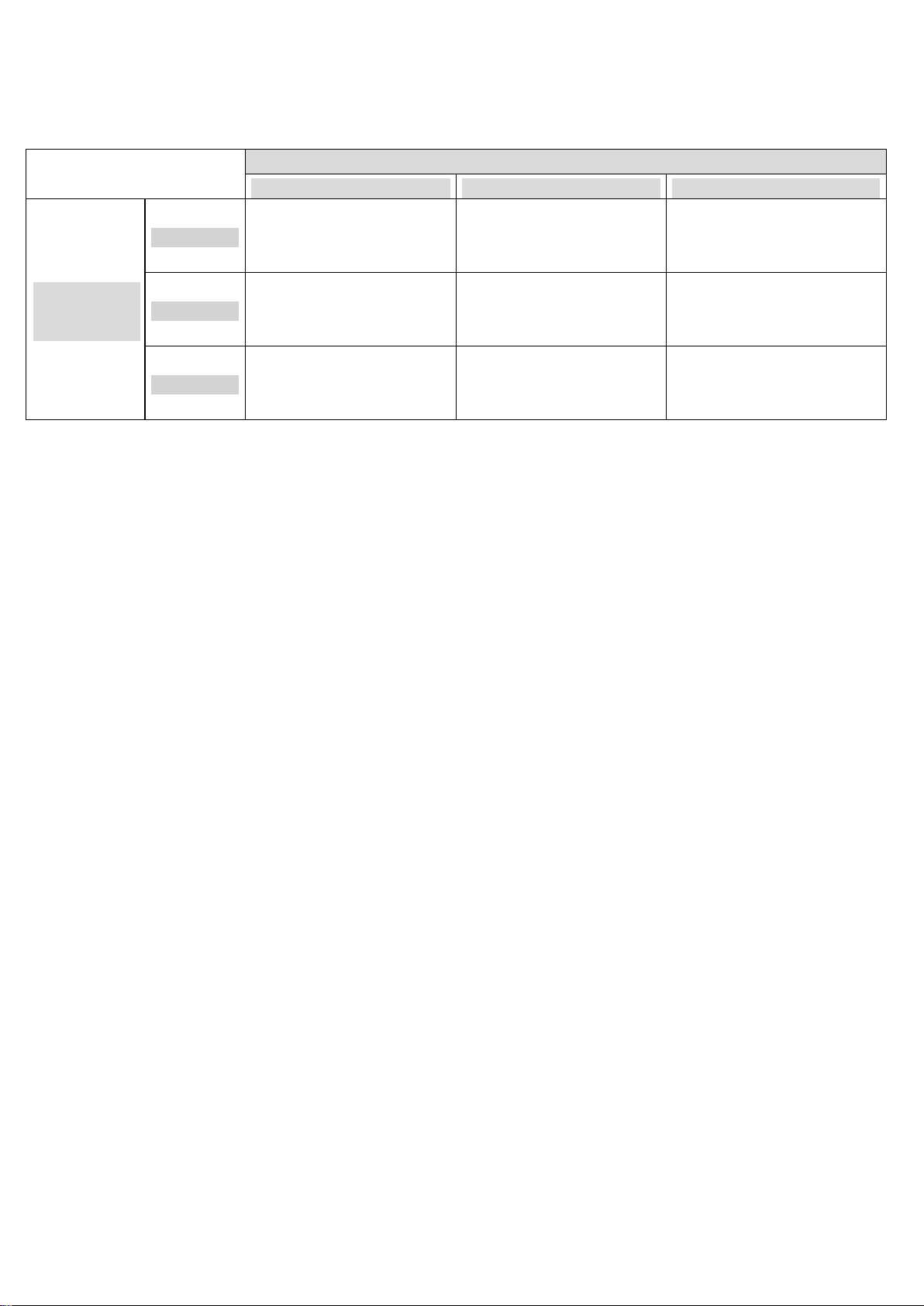

Operating mode You can define the operating mode of the switchgear by selecting one of the three positions of the key

switch “Auto”, “0” or “Manual”.

Starting the

motor with...

Table 3: Operating modes

Automatic mode

The key switch (Fig. 1, pos. 4, 5) is placed in the “Auto” position, the “Auto” position is thus confirmed by the

corresponding green LEDs (Fig. 2, pos. 15, 16) .

The unit starts up automatically once the pressure switch no. 1 opens and the key switch no. 1 is in the “Auto”

position or once the pressure switch no. 2 activates and the key switch no. 2 is in the “Auto” position.

Any open pressure switch is signalled by a green LED for pressure switch 1 or a yellow LED for the pressure

switch 2 (Fig. 2, pos. 19, 20). Triggering of the float switch (low level of start-up tank) st arts the pump if at least

one of the 2 key switches is in the “Auto” position.

Non-automatic mode

This mode is activated when the key switches are not in the “Auto” position.

This operating mode is signalled by the red LEDs (Fig. 2, pos. 17, 18).

Furthermore, the output “NON-AUTO MODE 1/2” is activated.

Manual mode To perform a manual start-up, place one of the key switches in the “Man” position. The manual start button “ON”

(Fig. 2, pos. 8) enables start-up of th e pump. Deactivation mode

To switch off the pump, at least one of the key switches must be in the “0” position.

As soon as the pressure switch or the float switch is no longer activated, the pump can be switched off by

means of the “OFF” button (Fig. 2, pos. 12).

Key

switch 2

AUTO

OFF

MANUAL

Pressure switch 1

Pressure switch 2

Pressure switch 1

Pressure switch 1

“ON” button

Pressure switch 2

“ON” button

“ON” button

Pressure switch 2

“ON” button

“ON” button

Pump start-up In auto mode, if the pressure measured by at least one of the two pressure switches is below the switch-on

threshold, the LED/LEDs (“active” Fig. 2, pos. 19 and pos. 20) turn/s on green for pressure switch 1 or yellow

for pressure switch 2. Once the follow-up time has elapsed (see menu 1.2.5.1) the pump starts.

Note: If the follow-up time (menu 1.2.5.1) is quite long, it is possible to see the LED flashing while the follow-up

time elapses.

The LED (“on” Fig. 2, pos. 13) turns on green and signals the operation of the pump. Throughout pump

operation, the instantaneous current of the pump is monitored and displayed on the screen. When a malfunction

arises, and even if the pump continues to function, the error code of the malfunction is displayed for

30 seconds.

Installation and operating instructions Wilo-SC-Fire Electric A2P 11

Page 12

English

Once the set pressure is reached or exceeded it is possible to switch off the LED/LEDs (“active” Fig. 2,

pos. 19 and pos. 20) previously turned on by pressing the malfunction acknowledgement. The pump is

still running and must be switched off manually.

Start-up tank

If the level of water in the start-up tank of the pump is less than 2/3 of the full level, the float switch closes and the

red indicator light is activated (Fig. 2, pos. 6). Following a configurable follow-up time (see menu 1.2.5.2) the

pump switches on and the green indicator light (Fig. 2, pos. 13) is activated.

Note: As the follow-up time expires, the indicator light flashes

As soon as the tank is full, the float switch opens and the error message can be acknowledged. The indicator light

turns off (Fig. 2, pos. 6) and the pump can be switched off manually. The audible warning (Fig. 2, pos. 13)

deactivates also.

Control of the voltage

To increase operational safety, the power supply voltage of the switchbox is subject to permanent control.

The power supply voltage is configured in the menu 1.2.1.1 (400 V by default), the 3 phases are controlled.

When the pump is on standby, the 3 phase-to-phase voltages are displayed one after another.

As soon as the power supply voltage is lower or higher than the defined tolerance level (see menus 5.4.1.0

and 5.4.2.0), an error code is displayed after a certain time lag (see menu 1.2.5.3).

When the pump is in operation, and in case of a malfunction, the pump continues to function.

Protection against excess currents

During pump functioning, the current is subject to permanent monitoring.

The rated current motor is configurable in the menu 1.2.1.2.

The current is monitored over the three phases. When the pump is functioning, the current is indicated on the

screen. The green indicator light (“on” Fig. 2, pos. 13) turns on as soon as the current of the pump reaches a

predefined minimum level (see menu 5.4.3.0).

As soon as the current of the pump exceeds the maximum threshold (see menu 5.4.4.0), the red indicator light

(“malfunction” see menu 1.2.5.5) (Fig. 2, pos. 14) turns on.

Despite the presence of an error, this does not prevent the pump from starting or continuing to function. As soon

as the current level of the pump returns to within the range of the levels permitted, you can acknowledge the

error. And the indicator light (Fig. 2, pos. 14) deactivates.

Monitoring of the “pump in demand”

As soon as the pump switches on, a pressure switch located at the pressure connection monitors whether the

pressure at the pump outlet is correct.

After a certain predefined time (see menu 1.2.2.2), if the pressure at the pump outlet is not reached, the red

indicator light turns on (“pump in demand” Fig. 2, pos. 3).

When the pressure exceeds the configured threshold, the error message can be acknowledged and the indicator

light will change to green (Fig. 2, pos. 3).

Monitoring of failed start-up

When the pump is in operation, and after a certain predefined time in the menu 1.2.2.1, the electrical power

consumption is monitored.

The power is monitored against the following parameterisation: 1.2.1.1 and 1.2.1.2.

During the monitoring period, and after a certain configured lag time (see menu 1.2.5.6), if the minimum value has

not been reached (see menu 5.4.5.0), the indicator light will turn yellow (Fig. 2, pos. 2).

When the power consumed is reached again, the error message can be acknowledged. And the indicator light will

change from yellow to green (Fig. 2, pos. 2).

WILO SE 01/2017 12

Page 13

Pos.

Description

1

Menu number

2

Value display

3

Unit display

4

Standard symbols

5

Graphic symbols

English

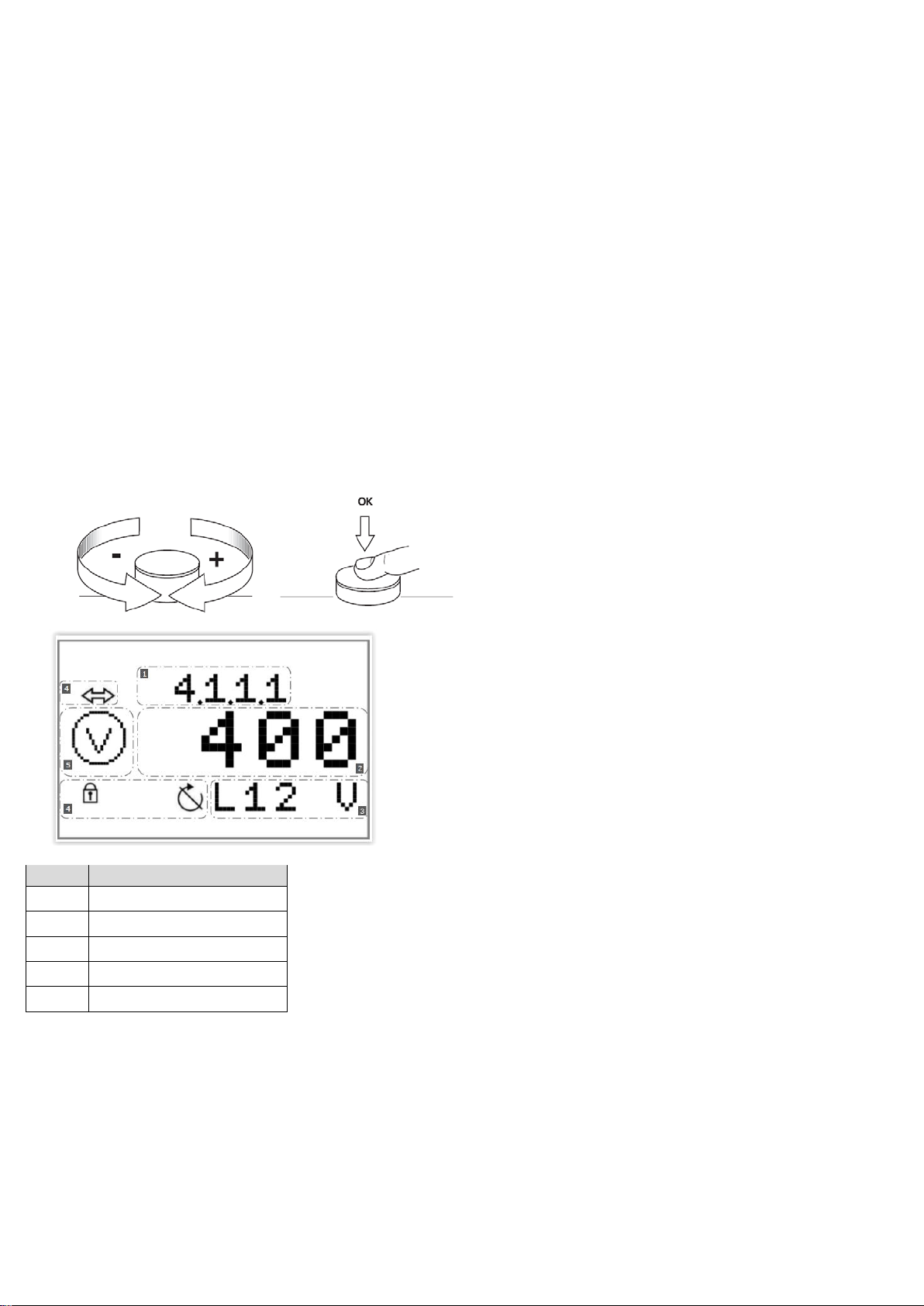

6.2.2 Application of the switchgear

Operation elements

Levels of access

• The level of access 1 allows access to the function test of the lamp (Fig. 2, pos. 2) without intervention in

addition.

• The level of access 2 is performed using a key switch (Fig. 1, pos. 7) and enables access to the reset

function in the event of error messages (Fig. 2, pos. 4).

• The level of access 3 is performed using a ciphered code encoded in the menu 7.0.0.0, enabling access to all

menu items.

Functions and application elements

• Main switch On/Off (lockable in “Off” position) (Fig. 1, pos. 7)

• LCD screen (Fig. 1, pos. 2) The LCD screen displays the pump operating status and the settings menu.

Thanks to the control button (Fig. 1, pos. 3) you can select the menus and enter the parameters (level 3

access required). To alter the values and scroll through the menu levels, turn the function. To select and

confirm your input, press the button:

Installation and operating instructions Wilo-SC-Fire Electric A2P 13

Page 14

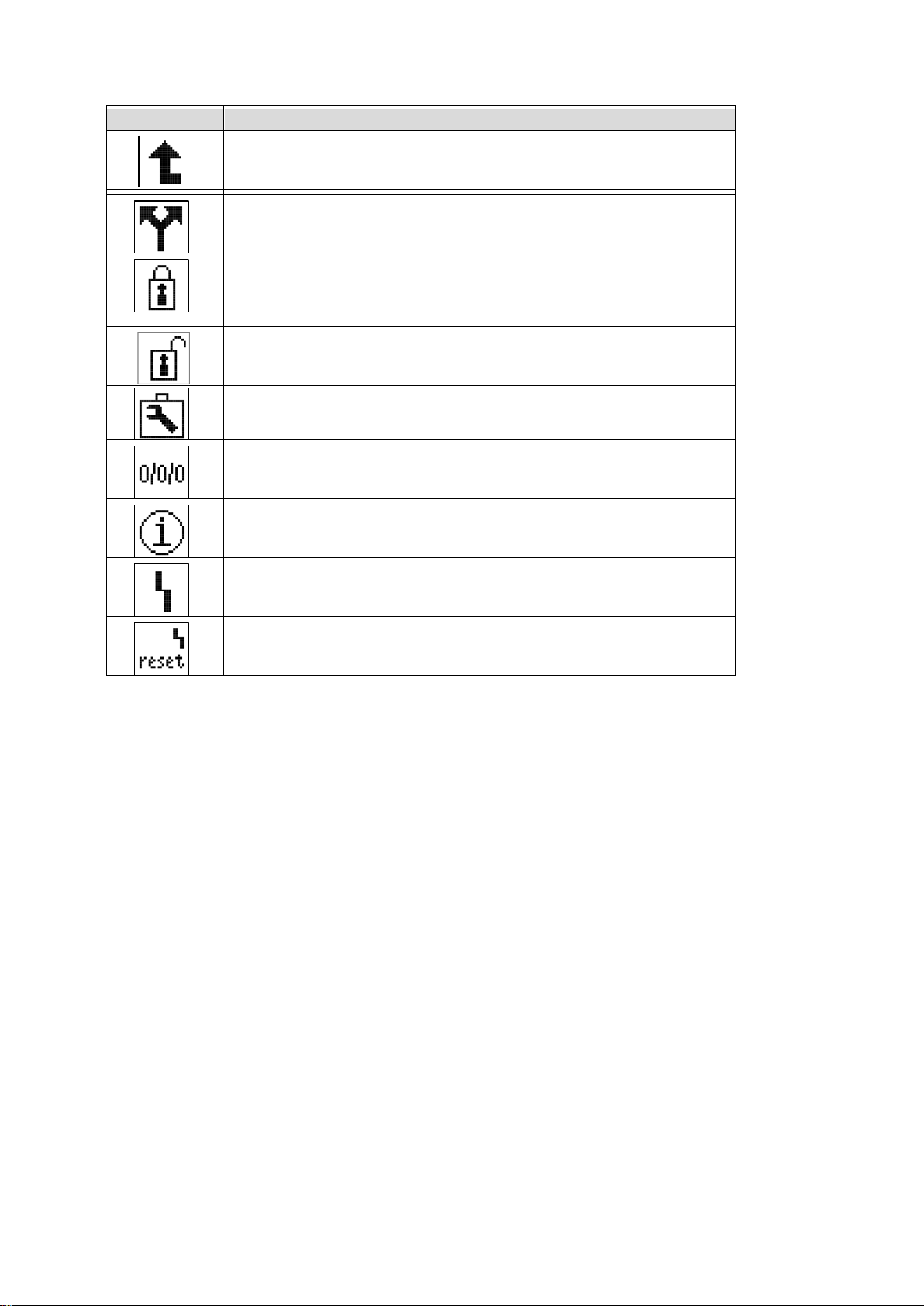

Symbol

Function/description

Brief press: Return to the previous menu

EXPERT menu

1. Notification: service not connected

Unlocked

Service menu

Parameters

Information

Malfunction

Reset malfunction

English

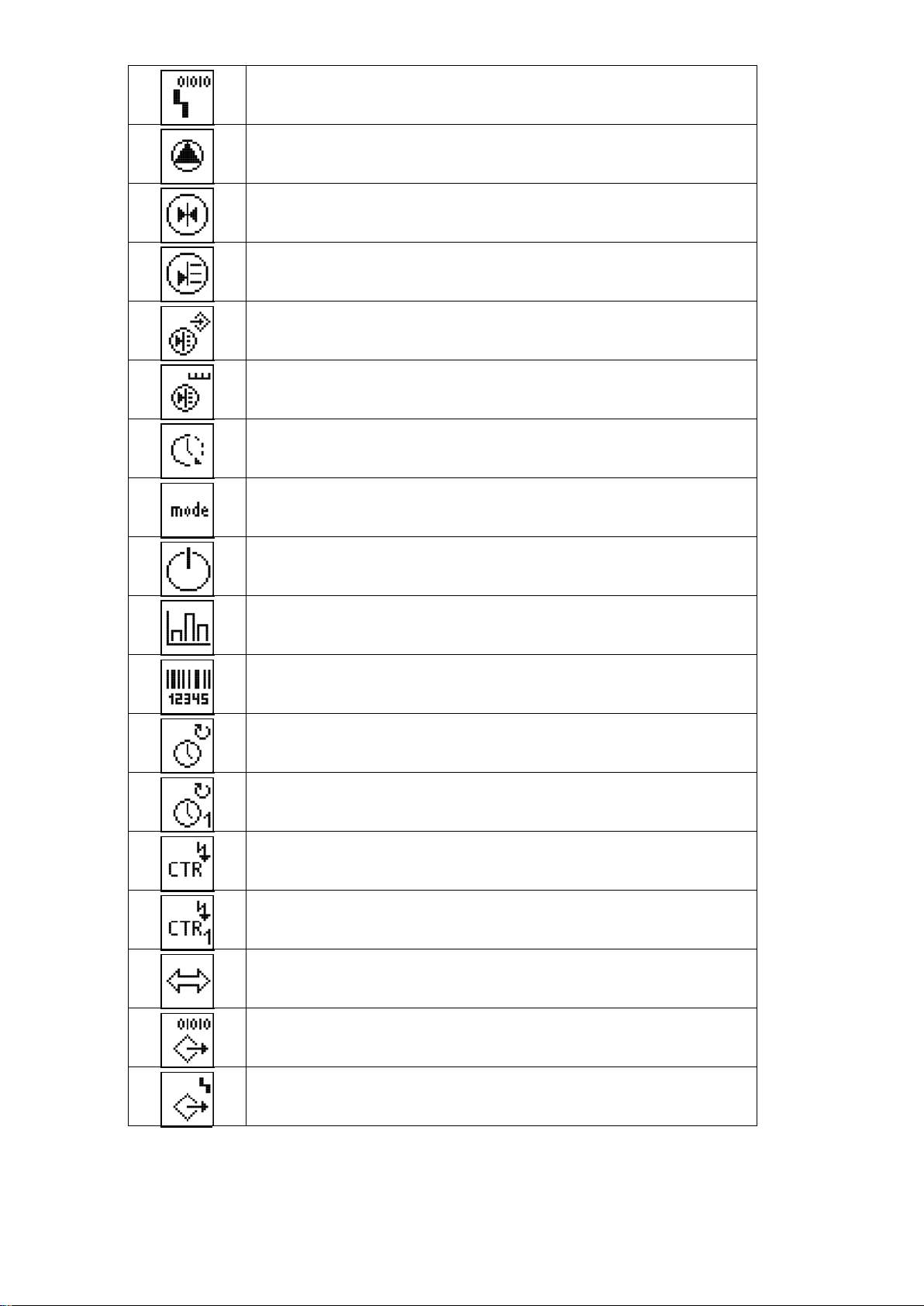

The following graphic symbols are used:

Long press: Return to the main screen

2. Notification: display value – no entry possible

WILO SE 01/2017 14

Page 15

Alarm settings

Pump

Setpoint

Actual value

Sensor signal

Measurement range sensor

Follow-up time

Operating mode/application

Stand-by

Operational data

Switchgear data:

Operating hours

Pump operating hours

Switchgear operating test runs

Pump operating test runs

Communication

Output parameters

SSM parameters

English

Controller type; ID number; software/firmware

Installation and operating instructions Wilo-SC-Fire Electric A2P 15

Page 16

English

Sprinkler (pressure switch)

Pump filling tank (float switch)

Activation failed

Pressure

Power supply (mains)

Voltmeter

Ammeter

Cut-in star-delta

Malfunction signal freely configurable

Malfunction input

WILO SE 01/2017 16

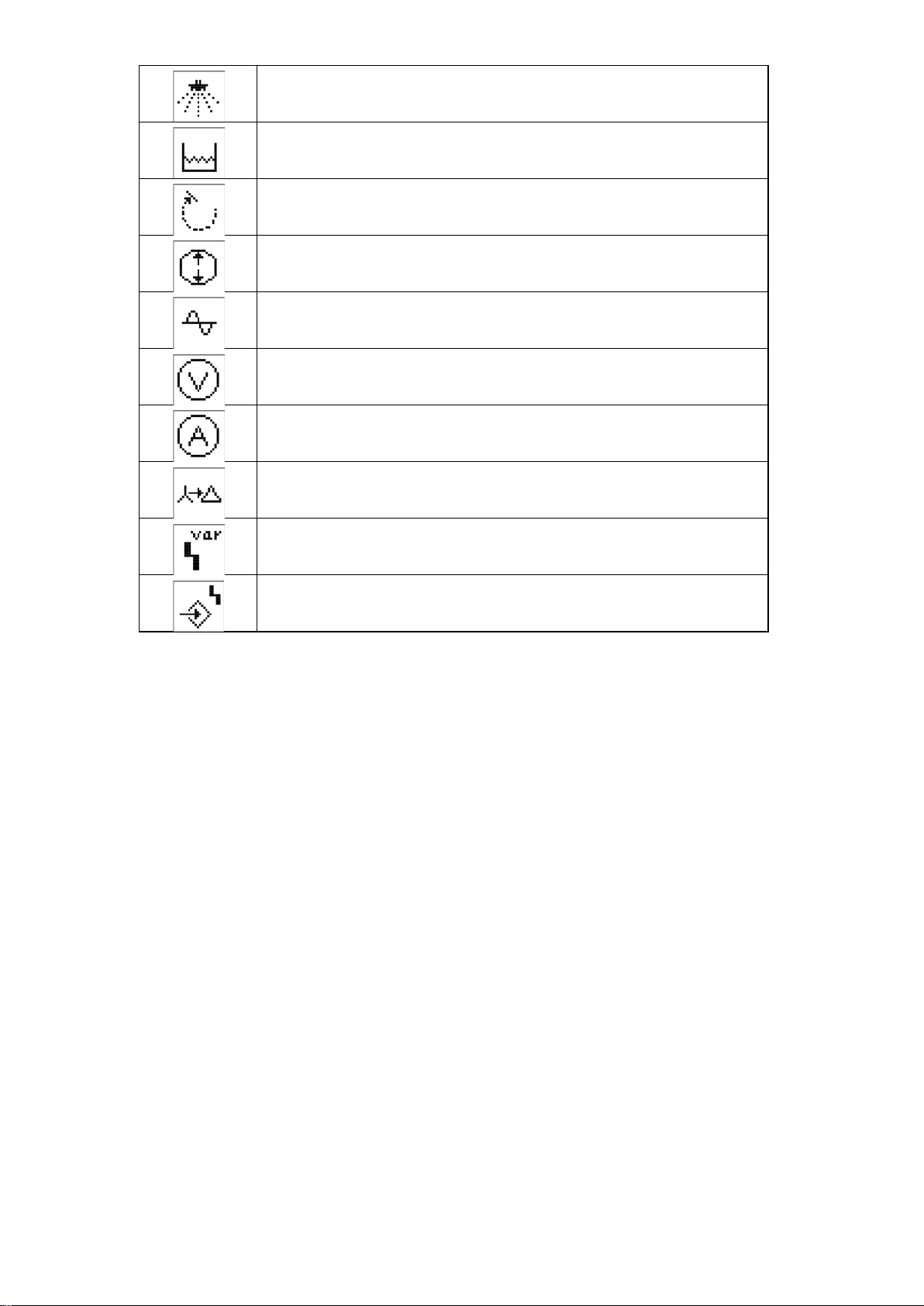

Page 17

English

Duration

Power indicator

Communication parameters

Modbus

BACnet

Factory setting

Reset to the factory setting

Alarm counter

Maintenance interval

Reset

Installation and operating instructions Wilo-SC-Fire Electric A2P 17

Page 18

English

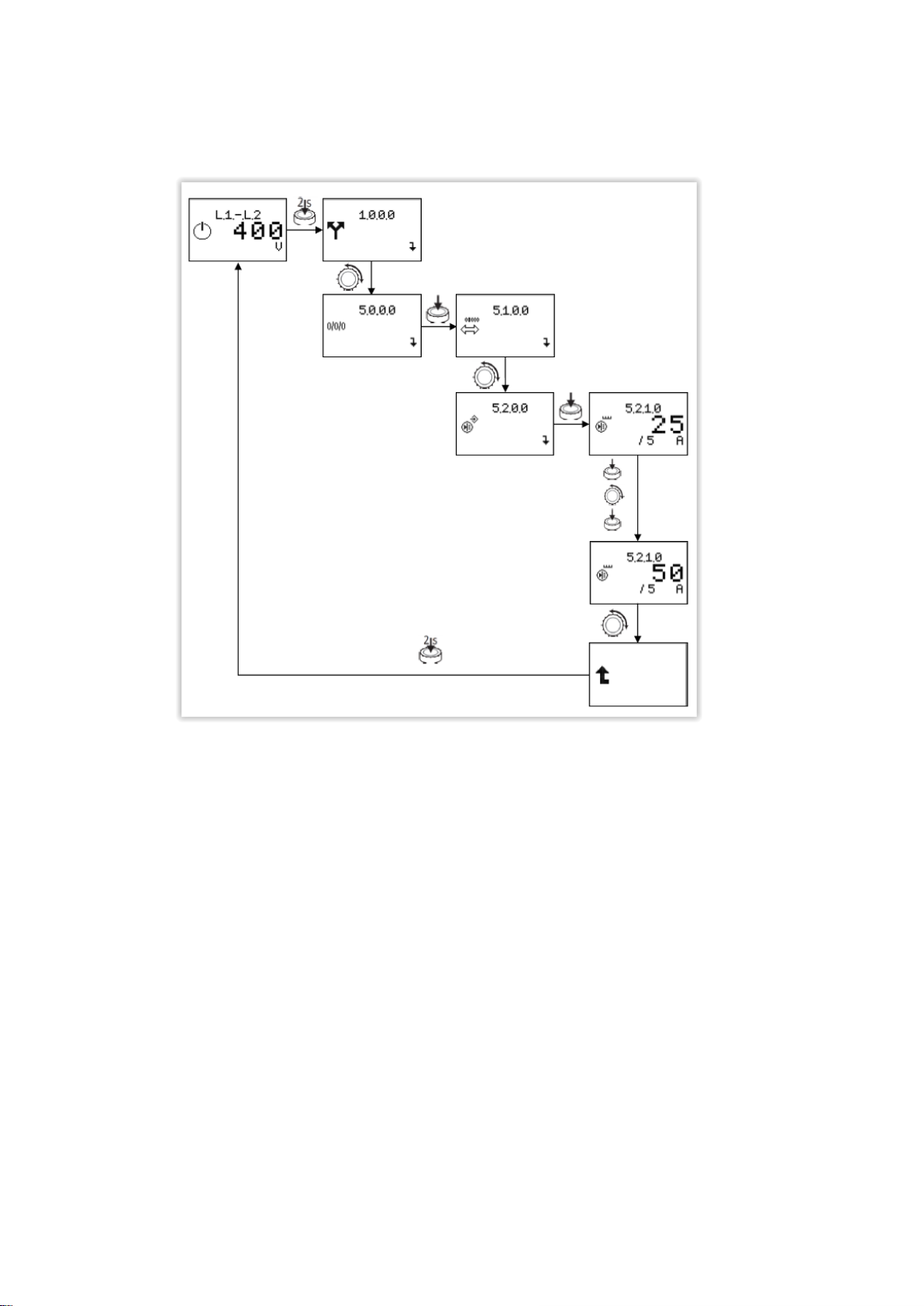

Menu structure: The menu structure of the control system is organised into 4 levels. Navigation in the individual menus as well as the parameter input are described in the example

below – selection of transformers (level 3 required):

WILO SE 01/2017 18

Page 19

Menu accessible from the level of access 1

The main screen indicates the status of the unit.

The display constantly switches from one voltage

“Malfunctions” menu

English

Refer to the following table for a description of the individual menu items.

No.

menu/

1.1.1.1 Screen 1.1.2 Description

to another (alternating between L1-L2, L1-L3 and

L2-L3).

When the pump is in operation, the

instantaneous current on the three phases

and the voltages ar e d is played in turn s on

the screen.

Parameter range

Factory setting

“Services” menu

To access level 3 an access code must be entered.

After 5 minutes of inactivity on HMI or after a main

supply malfunction, access is blocked and the code

must be re-entered.

0…9999

Installation and operating instructions Wilo-SC-Fire Electric A2P 19

Page 20

6.1.0.1

error

7.5.9.9, accessible

The EXPERT menu contains other settings

which enable a detailed configuration of the

English

to

6.1.1.6

Menu accessible from the level of access 3

History memory of m a lfunctions from 1 to 16

Note:

The history memory of malfunctions and the

counter can be reset via menu

on level 3.

Menu unlocked after entering the access

code.

The remaining time [in secon ds ] before

deactivation of the level of acce s s 3 in

case of inactivity on the HMI is also

indicated on the m a in screen.

switchgear.

Access to the parameter menu

enabling modific a tion of the sys tem

operation

Access to the settin gs menu of the

electrical parameters of the pump

WILO SE 01/2017 20

Page 21

English

Adjustment of th e connection voltage 400

Adjustment of the rated cur rent of the pump 0.1..7.8..500.0

Display of the mot or power of the

pump

The parameter menu for all timer

parameters influencing the operation

Adjustment of the follow-up time for the

0..40..120

monitoring of the electrical power of the

pump (electrical error at start-up)

Adjustment of th e follow-up time for th e

0..5..120

monitoring of th e pr es s ure at the pump

outlet (error “pump in demand”)

Installation and operating instructions Wilo-SC-Fire Electric A2P 21

Page 22

English

The settings menu for the follow-up tim es

and delays

Start-up delay of the pump upon

1..120

activation of the pressure switch

Start-up delay upon activation of the

1..120

float switch

Follow-up time of the error message for

0..1..10

the monitoring of the voltage

Follow-up time of the error message

5..10..20

“electrical error a t start-up”

Follow-up time in th e event of error

5..10..20

message through current monitoring

WILO SE 01/2017 22

Page 23

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Parameter range

Factory setting

Cut-in time star-delta 0..5..60

Buffer time between the activati on of the

0.00..0.05..1.0

star contactor an d the interlocking of the

delta contactor

Communication

Display of the field bus temporarily

activated

Number bus, Modbus,

BACnet

Pump menu

Display of the au tom a tic mode of operation:

ON or OFF

Installation and operating instructions Wilo-SC-Fire Electric A2P 23

Page 24

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Information

Present operation values

Voltage values

Parameter range

Factory setting

Voltage display b etween conductors L 1

and L2

Voltage display b etween conductors L 1

and L3

Voltage display b etween conductors L 2

and L3

WILO SE 01/2017 24

Page 25

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Current values

Current display of pump in L1

Current display of pump in L2

Parameter range

Factory setting

Current display of pump in L3

Performance values

Performance display L1

Installation and operating instructions Wilo-SC-Fire Electric A2P 25

Page 26

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Performance display L2

Performance display L3

Status informa tion

Parameter range

Factory setting

Display of the status of the

system/availability

Display of the status of the pr e s s ure

switches

Display of the status of the float sw itc h

WILO SE 01/2017 26

Page 27

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Operational data

Total hour coun ter of operation of

the switchbox SC-FIRE Electric

Total hour coun ter of operation of the

pump

Parameter range

Factory setting

Total hour coun ter of operation of the

pump since the last start-up

Number counter of power-ups of the

switchbox SC-FIRE electric

Note: Activation of the main switch

Number counter of p ump start-ups

Installation and operating instructions Wilo-SC-Fire Electric A2P 27

Page 28

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Unit characteristics

Type of switchbox

Serial number display

Note: Text scrolling

Parameter range

Factory setting

Software version

Firmware version

Adjustments

WILO SE 01/2017 28

Page 29

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Communication

Modbus

Baud delivery rate 9.6 19.2 38.4 76.8

Parameter range

Factory setting

Slave address 1..4…247

Parity even not odd

Stop bits 1 2

Installation and operating instructions Wilo-SC-Fire Electric A2P 29

Page 30

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

BACnet

Baud delivery rate 9.6 19.2 38.4 76.8

Slave address 1...128...255

Parameter range

Factory setting

Parity even not odd

Stop bits 1 2

BACnet Device Instance ID 0...128...9999

WILO SE 01/2017 30

Page 31

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Adjustments of the sensors

Selection curr ent transformer 25..1000

Limit values

Parameter range

Factory setting

Lower tolerance limit of the connection

voltage

Higher tolerance l im it of the connec tion

voltage

0..10..20

0..10..20

Installation and operating instructions Wilo-SC-Fire Electric A2P 31

Page 32

Acknowledgemen t b ehaviour for m alfunction

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Lower tolerance limit of the rated

current of the pump

Higher tolerance limit of the rated

current of the pump

Adjustment for m inimum performance of

detection of the s tart of the pump

Parameter range

Factory setting

0..10..100

0..10..100

0..50..100

Output parameters

Malfunction s ignal freely configurable

Not store, ON store

messages

WILO SE 01/2017 32

Page 33

English

No.

menu/

1.1.1.1 Screen 1.1.2 Description

Logic reversal sig nal of input Fall, Raise

Activation malfunction messages to

configure

Malfunction a c tive:

Always

or

Only with pump in operation

Parameter range

Factory setting

OFF, ON

Ever, Pump

Response delay 0..60

Malfunction messages

Resetting of malfunction messages

Installation and operating instructions Wilo-SC-Fire Electric A2P 33

Page 34

Access to the para m ete risation of the c a binet

English

6.1.0.1

to

6.1.1.6

Malfunction messages 1 to 16

Service menu

Designation of the cabinet

Adjustment of the serial nu m ber :

Adjustment of th e first 4 numbers of the

serial number

These numbers are adjusted in the factory

and cannot be modified.

Adjustment of the serial nu m ber :

Adjustment of th e last 4 numbers of the

serial number

These numbers are adjusted in the factory

and cannot be modified.

0…9999

0…9999

WILO SE 01/2017 34

Page 35

Alarm menu

Error counter dis play, showing the number of

English

Controller desig nation

Software version display

Factory setting menu:

Possibility to res et the cabinet to factory

configuration

Restoring of factor y parameters:

By pressing the red button, th e s ymbol

“factory” flas hes, turn the red button to the

right, the symbol “reverse a r r ow ” appears,

press the button a s e c ond time to launch the

resetting of the cabinet to fa ctory

configuration.

times that the error E xx.x has occurred.

Scroll through th e er ror codes with th e r ed

button.

Installation and operating instructions Wilo-SC-Fire Electric A2P 35

Page 36

Resetting of the m a lfunction histor y and error

flashes, turn the red button on the r ight side,

The malfunction history and the error c ounter

Operational data of the menu reset

Resetting to zero of the total hour counter of

flashes, then press the button a se c ond time.

English

counter:

By pressing the red button, th e s ymbol

press the button a second time.

are now reset.

Additional menu functions

Activation code:

Enter the activa tion code, for example, to

activate a field bus c onnection.

Modification of a ccess code to level 3:

To reset the access code, please call the

technical service.

pump operation time and start-up number

counter:

By pressing the red button, th e s ymbol

WILO SE 01/2017 36

Page 37

Application menu

Diesel mode display

English

Maintenance and repair menu

Activation/deactivation of th e maintenance

interval

OFF

Or

ON

Adjustment of th e d uration in days for the

maintenance interval

0…92…1000

Resetting to zero of the maintenanc e

message:

By pressing the r ed button, it is possible to

reset the maintena nce countdown .

Installation and operating instructions Wilo-SC-Fire Electric A2P 37

Page 38

Activation/deactivation of th e RIA application:

English

RIA menu

Protected access: To gain access, please call

the technical service.

Activation/deactivation of th e application of

the hydrants:

Once access has been granted by the

technical service.

Adjust the time in minutes for the automatic

stop of the pump

1…20

WILO SE 01/2017 38

Page 39

English

Description of cabinet components:

• Key switches (Fig. 1, pos. 4 and 5)

Pressure switch no. 1 and pressure switch no. 2 each have a key switch.

The 3 positions available are: Auto / Off / Manual.

The keys can only be withdrawn if the key switches are in the “Auto” position. Once the “0” or “Manual”

position has been selected, it is not possible to launch an automatic start-up of the pump, even if the

pressure switch or the float switch are active.

The status corresponding to the “Auto” position is signalled by the green LEDs (Fig. 2, pos. 15, 16) and

that which corresponds to the “0” or “Manual” position by the red LEDs (Fig. 2, pos. 17, 18).

• Key change-over switch (Fig. 1, pos. 14)

Enables access to the functions of level of access 2.

• “ON” (Fig. 2, pos. 8)

By pressing this button, the pump starts manually. To do this, at least one of the two key switches must be

in the “Manual” position. Pump operation is signalled by the green signal lamp (Fig. 2, pos. 13). The pump

must be switched off manually and the signal lamp (Fig. 2, pos. 13) turns off also.

• “BUZZER OFF” (Fig. 2, pos. 9)

This button (level 1) allows an audible signal emitted in case of alarm to be cleared separately. As

soon as a new malfunction arises, the buzzer signal sounds once again.

• “OFF” (Fig. 2, pos. 12)

By pressing this button, the pump switches off manually. To do this, at least one of the two key switches

must be in the “0” position and neither the pressure switch nor the float switch must be activated. The

pump can only be switched off with this button.

• “LAMP TEST” (Fig. 2, pos. 10)

By pressing this button (level 1), all the signal lamps (Fig. 2, pos. 1 to 20) and the buzzer activate and remain

activated while the button is pressed down. This allows for the control of correct operation of all of the LEDs.

Once the button is released, the signal lamps and the alarm buzzer turn off or remain turned on if the

functioning demands it.

• “RESET” (Fig. 2, pos. 11)

By pressing this button (level 2 required), all the error messages/signal lamps are reset insofar as the

cause of the error has been eliminated.

6.2.3 Display elements of the switchgear

“LIVE”

The signal lamp (Fig. 2, pos. 1) turns on green if the power supply is established and if it has been activated

with the main on/off switch.

“ON” The signal lamp (Fig. 2, pos. 13) turns on green if the pump is running and the current consumed by the

pump motor falls within the tolerance limits set (see menu 5.4.3.0).

Installation and operating instructions Wilo-SC-Fire Electric A2P 39

Page 40

English

“START-UP FAILURE” When the pump is running, the power consumed by the pump is permanently monitored. At pump start-up and after a set follow-up time (see menu 1.2.2.1), if the power consumed by the pump is

below the threshold set (see menu 5.4.5.0), the LED (Fig. 2, pos. 2) turns on.

“PUMP IN DEMAND” As soon as the pump is operating and the matching pressure switch does not close after a defined period (see

menu 1.2.2.2), the signal lamp (Fig. 2, pos. 3) lights up red.

“SYSTEM MALFUNCTION” The yellow signal lamp (Fig. 2, pos. 4) signals a software malfunction if the communication between the

control board and the display board is disrupted and the software routine can no longer take place.

“TANK EMPTY” If the water tank level is too low, the LED (Fig. 2, pos. 5) turns on red.

“START-UP TANK LEVEL MALFUNCTION” The signal lamp (Fig. 2, pos. 6) turns on red as soon as the level of the pump start-up tank falls below 2/3 and

when the float switch is triggered. If at least one key switch is in the “Auto” position, the pump starts

automatically. If the level rises sufficiently, the signal lamp (Fig. 2, pos. 6) turns off again. The pump must be

switched off manually.

“LEVEL MINI GLYCOL TANK” If the glycol tank level is too low, the LED (Fig. 2, pos. 7) turns on red. If the malfunction occurs when the pump is in operation the pump continues to function. You can acknowledge the error message and the indicator light (Fig. 2, pos. 7) when the level of the glycol tank

is once again above the low level.

“MALFUNCTION” A signal lamp (Fig. 2, pos. 14) turns on red:

- upon activation of the pump protection device,

- if the thermistor of the motor is triggered,

- if the fuse switch amplifier is open,

- if the fuses have been triggered,

- if a phase sequence malfunction occurs,

- or if a malfunction is detected at the control voltage.

“AUTO MODE” The signal lamp (Fig. 2, pos. 15/16) is turned on green if the matching key switch is in the “Auto” position. In the

automatic mode, the automatic start-up of the pump is possible either via the intermediary of the float switch or

the corresponding pressure switch.

“NON-AUTO MODE” The signal lamp (Fig. 2, pos. 17/18) is turned on red if the matching key switch is in the “0” or “Manual”

position. In the non-automatic mode, no automatic start-up of the pump is possible via the intermediary of the

float switch or the corresponding pressure switch.

WILO SE 01/2017 40

Page 41

English

“ACTIVE” When the pressure in the unit falls below the threshold set on the pressure switches, the pressure switch(es)

becomes active. The LED flashes green (for pressure switch 1) or yellow (for pressure switch 2).

After the elapsed follow-up time (menu 1.2.5.1), the LED remains turned on permanently.

If key switch 1 or 2 is in the “Auto” position, the pump starts automatically.

When the pressure rises and exceeds the threshold set, the pressure switch passes to the passive state. It is

possible to turn off the LED by pressing the acknowledgement button (Fig. 2, pos. 11).

The acknowledgement is only accessible if the user has previously connected to level 2.

7 Installation and electri ca l c onne c t ion

Installation and electrical connection must be carried out in accordance with local regulations and only by qualified personnel!

WARNING! Risk of personal injury!

Comply with applicable accident prevention regulations.

Warning! Risk of electric shock!

Danger from electrical current must be eliminated.

Local directives or general directives [e.g. IEC] and instructions from local energy

supply companies must be adhered to.

7.1 Installation

Install the switchgear/unit in a dry location.

Protect the place of installation from direct exposure to sunlight.

7.2 Electrical connection

DANGER! Risk of death!

In case of non-compliant electrical connection, there is a danger of death by electrocution.

• Have the electrical connection established by an electrician approved by the local energy

supply company only and in accordance with local regulations.

• Observe the installation and operating instructions for the pumps and accessories.

• Disconnect the power supply before any work!

Warning! Risk of electric shock!

There is a potentially fatal voltage on the supply side, even when the main switch is turned

off.

Installation and operating instructions Wilo-SC-Fire Electric A2P 41

Page 42

English

• The power supply configuration, current type and the mains connection voltage must be in accordance

with the indications given on the rating plate of the device.

NOTE:

• Fuse on mains side in accordance with the information in the wiring diagram.

• Feed the ends of the mains cable through the threaded cable connections and cable inputs and wire

them according to the markings on the terminal strips.

• Earth the pump/system in accordance with the regulations.

NOTE:

In accordance with the standard EN/IEC 61000-3-11 (see the following table), the switchgear and

a pump of a performance of ... kW (column 1) are planned to be used within a power supply

network of an impedance system of Z

for a maximum number of ... connections (column 3).

If the mains impedance and the number of connections per hour are higher than the values shown

in the table, the switchgear related to the pump can, in the presence of unfavourable network

conditions, lead to temporary decreases in voltage as well as disruptive variations in voltage

(“flickers”).

It may require the implementation of measures before the switchgear and the pump can function in

a compliant way regarding this connection. Contact the local electrical energy supply company

and the manufacturer to obtain the necessary information.

max at the particular connection of. ... Ohm max (column 2)

WILO SE 01/2017 42

Page 43

Performance [kW]

System impedance [Ω]

Connections per hour

Three-phase 400 V

2.2

0.257

12

2 poles 2.2

0.212

18

Direct starting

2.2

0.186

24

2.2

0.167

30

3.0

0.204

6

3.0

0.148

12

3.0

0.122

18

3.0

0.107

24

4.0

0.130

6

4.0

0.094

12

4.0

0.077

18

5.5

0.115

6

5.5

0.083

12

5.5

0.069

18

7.5

0.059

6

7.5

0.042

12

9.0 – 11.0

0.037

6

9.0 – 11.0

0.027

12

15.0

0.024

6

15.0

0.017

12

Three-phase 400 V

5.5

0.252

18

2 poles

5.5

0.220

24

Starting S-D

5.5

0.198

30

7.5

0.217

6

7.5

0.157

12

7.5

0.130

18

7.5

0.113

24

9.0 – 11.0

0.136

6

9.0 – 11.0

0.098

12

9.0 – 11.0

0.081

18

9.0 – 11.0

0.071

24

15.0

0.087

6

15.0

0.063

12

15.0

0.052

18

18.5

0.059

6

18.5

0.043

12

18.5

0.035

18

22.0

0.046

6

22.0

0.033

12

22.0

0.027

18

English

(Column 1)

(Column 2)

(Column 3)

15.0

0.045

24

Installation and operating instructions Wilo-SC-Fire Electric A2P 43

Page 44

English

7.2.1 Power supply connection

The 4-wire cable (L1, L2, L3, PE) provided by the customer for the power supply network must be connected to

the main switch in accordance with the wiring diagram.

7.2.2 Connection of the malfunction/operating messages

On the terminal strip on the lower part of the switchbox, potential-free contacts are available to allow a

possible malfunction/operating information message (see diagram).

Potential-free contacts, contact load max. 250 V ~/1 A

“ALARM LACKS VOLTAGE” Activation of the output upon onset of one of the following malfunctions:

• Loss of connection voltage

• Malfunction of phase sequence

• Main on/off switch open

• Activation failed

• System malfunction

“MALFUNCTION” Activation of the output upon onset of one of the following malfunctions:

• Overload

• Pump protection fuse holder open

• Pump protection fuse holder activated

• Pressure too low during pump operation (malfunction pump in demand)

“NON-AUTO MODE 1” The output is activated if the corresponding key switch 1 is in the “0” or “Manual” position. In the non-automatic

mode, no automatic start-up of the pump is possible via the intermediary of the float switch or the corresponding

pressure switch.

“NON-AUTO MODE 2” The output is activated if the corresponding key switch 2 is in the “0” or “Manual” position. In the non-automatic

mode, no automatic start-up of the pump is possible via the intermediary of the float switch or the corresponding

pressure switch.

“ON” The output is activated if the pump starts and the pump current falls within the tolerance limits set (see

menu 5.4.3.0).

“START-UP TANK LEVEL MALFUNCTION” The output is activated when the level of the pump start-up tank is below 2/3 and when the float switch is

triggered.

“TANK EMPTY” If the level of the water tank is too low, the output is activated.

WILO SE 01/2017 44

Page 45

x

red

red

red

red

x

English

“LEVEL MINI GLYCOL TANK” If the level of the glycol tank is too low, the output is activated.

Error message freely configurable The message output is activated according to the corresponding input signal and the configuration of

malfunctions in the menu.

Colour of the LED

“LIVE” green

“START-UP FAILURE” yellow x

“PUMP IN DEMAND” red x x

“SYSTEM MALFUNCTION” yellow x

“TANK EMPTY” red x

“START-UP TANK LEVEL MALFUNCTION” red x

“LEVEL MINI GLYCOL TANK” red x

“ON” green

Undervoltage “MALFUNCTION”

Control voltage error “MALFUNCTION”

Excess current pump “MALFUNCTION”

Fault pump “MALFUNCTION”

“AUTO MODE ½” green

“NON-AUTO MODE ½” red

“ACTIVE ½” green/yellow

Buzzer

x x

x x

x x

x x

“MALFUNCTION”

“ALARM LACKS VOLTAGE”

x

“NON-AUTO MODE ½”

“ON”

x

x

“START-UP TANK

LEVEL MALFUNCTION”

x

“TANK EMPTY”

“LEVEL MINI GLYCOL

x

Table 4: Malfunctio n signals and run signals

Warning! Risk of electric shock!

Installation and operating instructions Wilo-SC-Fire Electric A2P 45

There is a potentially fatal voltage on these terminals,

even when the main switch is turned off.

Page 46

English

8 Commissioning

WARNING! Risk of death!

Commissioning by qualified personnel only!

Improper commissioning poses a risk of fatal injury.

Have commissioning performed by qualified personnel only.

DANGER! Risk of death!

When working on an open switchgear, there is a risk of electrocution

in the event of contact with conductor components.

This work must only be carried out by qualified personnel!

We recommend that you have the switchgear commissioned by Wilo customer service.

Before switching on for the first time, the wiring provided by the customer, especially the earth, must be

subjected to a detailed control.

Tighten all connection terminals prior to commissioning!

8.1 Adjustments to the switchgear

Once the main on/off switch is turned on and the start sequence of the screen and the signal lamps has

elapsed, the switchgear is ready to operate and displays the adjustments performed in the factory.

The factory setting can be restored by Wilo customer service.

To ensure correct operation it is necessary to proceed to the following adjustments in the menu:

- Menu 1.2.1.1: Adjustment of the connection voltage in volts.

- Menu 1.2.1.2: Adjustment of the rated current of the pump. The rated current of the pump is indicated on the rating plate of the pump.

- Menu 5.2.1.0: Adjustment of the type of current transformer (primary field of measurement of the current). The type of current transformer is indicated on the rating plate of the current transformer.

NOTE:

If the measurement line which passes into the current transformer is coiled, the current value of the transformer

is to be halved for each wrapping.

Example:

A measurement line has been wrapped twice around a 100/5 A transformer.

2 circuits transformer 25/5 A

Therefore, a current transformer 25/5 A must be indicated in the menu.

Menu 3.1.0.0: Displaying the operating mode

WILO SE 01/2017 46

Page 47

English

If “Auto off” is set, it is not possible to launch the automatic mode. The pump can only be switched on

manually.

8.2 Checking the motor direction of rota tion

Briefly activate the pump to verify whether the direction of rotation of the pump is correct. When switching off

the pump motor, compare the direction of rotation of the fan wheel and the direction specified on the pump

housing.

If the direction of rotation of the pump is wrong, swap over any two phases of the mains connection.

9 Maintenance

Have maintenance and repair work carried out by qualified skilled personnel only!

DANGER! Risk of death!

There is a risk of fatal injury from electric shock when working on electrical devices.

• The switchgear should be electrically isolated and secured against unauthorised

switch-on during any maintenance or repair work.

• Any damage to the connection cable should only ever be eradicated by a qualified

electrician.

• The switchgear must remain clean.

• Visual inspection of the electrical components of the system in the switchgear.

Installation and operating instructions Wilo-SC-Fire Electric A2P 47

Page 48

Code

Fault

Causes

Remedies

control board interrupted

Software integrity error

Request customer service

the fuses

English

10 Faults, causes and remedies

DANGER! Risk of death!

There is a risk of fatal injury from electric shock when working on electri cal devices. Have

faults remedied by qualified skilled personnel only! Follow the safety instructions under

chapter 2.

Before performing any work to remedy malfunctions, disconnect the device from the power

supply, and make sure it cannot be switched back on by unauthorised persons.

10.1 Fault indication

When a fault is observed, the corresponding LED fault indicator turns on, the contact of the corresponding

fault signal is activated and the fault is displayed on the LCD (fault code number). An additional buzzer

sounds for certain faults. This alarm can be switched off with the button “BUZZER OFF” (Fig. 2, pos. 9).

It is possible to clear the fault by pushing the button “RESET” (Fig. 2, pos. 11) (level 2 required) or by following

the steps described in the menu 6.1.0.0 (level 3 required):

10.2 Fault history

The fault history works according to the FIFO (First In First Out) principal and it allows the consultation of the

previous 16 arising faults.

The fault history can be consulted using menus 6.1.0.1 to 6.1.1.6 (level of access 1).

E54.0 No bus communication

with the HMI PCB

E54.5 No bus communication

with the slave control

board

E4.0 Undervoltage Connection voltage on mains side

Connection with the HMI PCB

interrupted

Connection with the slave

too low

Check connection

Request customer service

Check connection

Check the connection

voltage/network voltage, verify

WILO SE 01/2017 48

Page 49

switch

core

core

malfunction

defective fuse

replace the defective fuse

following the starting of the pump

connection voltage

during operation

pump/the impeller

Control board defective

Check the control board

operation

configurable

error

configuration of the error

English

E5.0 Overvoltage Connection voltage on mains side

too high

E61.0 Pump in demand

(Hydraulic error at

start)

E62.0 Low water level Level below minimum filling

E62.1 Lack of glycol Level below minimum filling

E80.1 Pump fuse

The pressure switch of the signal

pump signals a lack of pressure

while the pump is in operation

level in the storage tank

Leakage Check the impermeability of

level in the glycol tank

Leakage Check the impermeability

Fuse switch amplifier open,

Check the connection

voltage/power supply

Check the pump/the impeller,

check for leakages in the core,

check the direction of rotation of

the pump, adjust the pressure

Filling the storage tank

the storage tank and of the

Filling the glycol tank

of the glycol tank and of the

Close the fuse switch amplifier,

E11.0 Electric false start The minimum electrical performance

of the motor has not been reached

E23.0 Excess current Rated current of the pump too

high during operation

E25.0 Undercurrent Rated current of the pump too low

E106.0 Malfunction

operation fuse

E109.0 Error freely

If you cannot manage to eliminate a fault, please contact Wilo customer service or its nearest representative.

Replace the defective fuse of

Depends on the configuration of the

Check the settings, check the

pump/the impeller

The pump is blocked or

impeded, check the

Check the settings, check the

Reactivate the fuse

Depends on the

11 Spare par t s

Spare parts or repair orders may be ordered via a local specialist retailer and/or Wilo customer service. To

avoid queries and incorrect orders, all data on the rating plate should be submitted with each order.

Subject to change without prior notice

Installation and operating instructions Wilo-SC-Fire Electric A2P 49

Page 50

block no.

no.

Designation

Signal type

X0

L1

L2

L3

PE

X1 1

2

3

PE

4

5

6

X4 1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

configurable

18

X7 1

2

3

4

5

6

7

8

English

12 Annex

Details of the ele ctr i cal cab in et ter m in al blo cks

Terminal

Terminal

7

Connection voltage

cabinet

Pump motor

Pump pressure switch

in demand

Thermal protection

pump

Malfunction level of

cooling liquid

Pressure switch 1 DI (contact closed when the pressure is high)

Power supply performance (three-phase current

400 V, 50 Hz)

Output performance (three-phase current 400 V,

50 Hz, start star-delta)

DI (Pressure switch, contact closed when the pump

is running correctly)

DI (Auxiliary contact of the thermal relay, contact

closed when no malfunction)

DI (float switch, close d in case of low level of glycol

tank)

Pressure switch 2 DI (contact closed when the pressure is high)

Malfunction level startup tank

Malfunction level of

tank

Contact freely

configurable

Contact freely

General malfunction

(2 contacts NO/NC)

Pump in operation

(2 contacts NO/NC)

DI (Float switch, contact open when the tank is full)

DI (Float switch, contact open when the storage tank

is full)

DI (logic adjustable in the menu)

DI (state of the DI searchable via modbus)

DO (NO, contact open when an error exists)

DO (NC, contact closed when an error exists)

DO (NO, contact closed when the pump is running)

DO (NC, contact open when the pump is running)

WILO SE 01/2017 50

Page 51

9

10

11

12

13

14

15

16

17

18

19

20

21

the menu)

22

23

24

25

26

27

29

switch 2 is not positioned on the automatic mode)

30

31

32

33

34

35

36

39

40

41

42

43

44

X8 1

2

English

28

Malfunction level startup tank

(2 contacts NO/NC)

Malfunction level of

tank

(2 contacts NO/NC)

Malfunction level of

cooling liquid

(2 contacts, NO/NC)

Contact freely

configurable

(2 contacts, NO/NC)

(logic configurable in

Non-automatic mode 1

(2 contacts NO/NC)

DO (NO, contact open whe n t he tank level is low)

DO (NO, contact closed when the tank level is low)

DO (NO, contact open whe n t he tank level is low)

DO (NC, contact closed when the tank level is low)

DO (NO, contact open in the case of lack of glycol)

DO (NC, contact closed in the case of lack of glycol)

DO (NO)

DO (NC)

DO (NO, contact open whe n t he change-over

switch 1 is not positioned on the automatic mode)

DO (NC, contact closed when the change-over

switch 1 is not positioned on the automatic mode)

DO (NO, contact open whe n t he change-over

Non-automatic mode 2

(2 contacts NO/NC)

Malfunction of the

connection voltage

(2 contacts, NO/NC)

Activation failed DO (NO, contact closed in the case of failed start)

Malfunction connection

of communication bus

Availability of the

connection voltage

RS485 Modbus or

Bacnet

DO (NC, contact closed when the change-over

switch 2 is not positioned on the automatic mode)

DO (NO, contact open following a delay of

20 seconds in case of a power failure)

DO (NC, contact closed following a delay of

20 seconds in case of a power failure)

DO (NO, contact closed in the case of malfunction of

communication bus)

DO (NC, contact closed when the connection voltage

is available)

Connection of commu ni cation bus

Installation and operating instructions Wilo-SC-Fire Electric A2P 51

Page 52

Number of

English

External connections of t he el e c tr ic cabinet

wires per

Function

Pressure switch no. 1 PG7 2 x 1 mm² 10 m

Pressure switch no. 2 PG7 2 x 1 mm² 10 m

Size of the

cable gland

shroud and

cross-section of

the wires

N07VK

Max

length

Pressure switch “pump in

demand”

Motor protection switch

Digita l inputs

Digital outputs

(contact NO)

Digital outputs

(contact NC)

Connection bus RS485 Modbus or Bacnet Unused 2 x 1 mm² 10 m

pump

Float switch level gly c ol PG7 2 x 1 mm² 20 m

Float switch start-up tank PG7 2 x 1 mm² 20 m

Float switch storage tank PG7 2 x 1 mm² 20 m

Contact freely configurable PG7 2 x 1 mm² 10 m

Malfunction start-up fa iled Unused 2 x 1 mm² 10 m

Malfunction connection of

communication bus

Malfunction availability of

the connection voltage

PG7 2 x 1 mm² 10 m

PG7 2 x 1 mm² 10 m

Unused 2 x 1 mm² 10 m

Unused 2 x 1 mm² 10 m

Electrical

switchgear

General malfunction Unused 2 x 1 mm² 10 m

Pump in operation Unused 2 x 1 mm² 10 m

Low level of start-up tank Unused 2 x 1 mm² 10 m

Digital outputs

(contacts NO/NC)

Low water level Unused 2 x 1 mm² 10 m

Lack of glycol Unused 2 x 1 mm² 10 m

Contact freely configurable Unused 2 x 1 mm² 10 m

Non-auto mode 1 Unused 2 x 1 mm² 10 m

Non-auto mode 2 Unused 2 x 1 mm² 10 m

Connection voltage

availability malfunction

Unused 2 x 1 mm² 10 m

WILO SE 01/2017 52

Page 53

pump

pump

English

Performance input

Performanc e ou tp u t Pump mo tor

Mass GND PG7 1 x 6 mm² 20 m

Connection voltage threephase 400 V AC

Cross-section of cable

according to the size of the

Cross-section of cable

according to the size of the

10 m

20 m

Installation and operating instructions Wilo-SC-Fire Electric A2P 53

Page 54

English

Details of the terminal bloc k s of the PCB mas t er/slave

WILO SE 01/2017 54

Page 55

PCB 2U1 (Master)

PCB 2U2 (Slave)

C

C

400 V

400 V

X901

Used for:

X901

Used for:

L3

L3

L2(N)

L2(N)

X100

Used for:

X100

Used for:

54

CAN_H

54

CAN_H

56

Analog In 0

Voltage measurement U1-U2

56

Analog In 0

58

Analog In 2

Voltage measurement U2-U3

58

Analog In 2

60

Analog In 4

Current measurement I2

60

Analog In 4

1

1

68

RS485_B_L

68

RS485_B_L

70

RS485_B_R

RS485: Output Modbus or Bacnet

70

RS485_B_R

CAN: towards LED/button PCB and

towards master PCB (2U1)

CAN: towards LED/button PCB and

73

Field Bus1

73

Field Bus1

75

Field Bus3

75

Field Bus3

77

Temp In 2

77

Temp In 2

79

GND

GND of the PCB 2U1

79

GND

GND of the PCB 2U2

English

Specification SC-Commande Electric

X900 Used for: X900 Used for:

Selection by means of a shunt of

230 V 230 V

the connection voltage

(400 V only)

Selection by means of a shunt of

the connection voltage

(400 V only)

PE

Connection voltage

L1(L) L1(L)

53 Temp In 1 53 Temp In 1

55 CAN_L 55 CAN_L

57 Analog In 1 Voltage measurement U1-U3 57 Analog In 1

59 Analog In 3 Current measurement I1 59 Analog In 3

61 Analog In 5 Current measurement I3 61 Analog In 5

62

63

64

Analog Out

0

Analog Out

Analog Out

2

(400 V only)

62

63

64

PE

Analog Out

0

Analog Out

Analog Out

2

Connection voltage

(400 V only)

X101 Used for: X101 Used for:

65

66

67 RS485 A_L 67 RS485 A_L

69 RS485_A_R RS485: Output Modbus or Bacnet 69 RS485_A_R

71 CAN_ISO_H CAN: towards slave PCB (2U2) 71 CAN_ISO_H

72 CAN_ISO_L CAN: towards slave PCB (2U2) 72 CAN_ISO_L

74 Field Bus2 74 Field Bus2

76 Field Bus4 76 Field Bus4

X102 Used for: X102 Used for:

78 GND GND for digital outputs 78 GND GND for digital outputs

Analog Out

3

Analog Out

4

65

66

Analog Out

3

Analog Out

4

towards master PCB (2U1)

Installation and operating instructions Wilo-SC-Fire Electric A2P 55

Page 56

81

VCC24V

Power supply 24 V DC of PCB

81

VCC24V

83

VCC24V

83

VCC24V

85

GND

85

GND

GND of transform e r of L ED

87

GND

87

GND

89

GND

89

GND

LED/button PCB

LED/button PCB

93

GND

93

GND

94

GND

94

GND

95

GND

95

GND

LED/button PCB

97

Field Bus5

97

Field Bus5

98

Field Bus6

98

Field Bus6

99

Field Bus7

99

Field Bus7

100

Field Bus8

100

Field Bus8

X600

Used for:

X600

Used for:

21

Digital In 0

Pressure switch 1

21

Digital In 0

Signalling trip circuit malfunction

22

COM 0

GND

22

COM 0

GND

X601

Used for:

X601

Used for:

23

Digital In 1

Pressure switch 2

23

Digital In 1

Trip c ircuit operation malfunction

24

COM 1

GND

24

COM 1

GND

X602

Used for:

X602

Used for:

26

COM 2

GND

26

COM 2

GND

X603

Used for:

X603

Used for:

27

Digital In 3

Main water tank – Low level

27

Digital In 3

Pump in operation

28

COM 3

GND

28

COM 3

GND

X604

Used for:

X604

Used for:

12

Digital In 5

Motor protection switch pump

12

Digital In 5

Free error message

14

Digital In 7

Float switch – Lack of glycol

14

Digital In 7

English

80 VCC24V

82 VCC24V 82 VCC24V

84 VCC24V 84 VCC24V

86 GND GND towards PCB 2U2 86 GND

88 GND 88 GND

X103 Used for:

90 GND

91 GND

92 VCC24V

96 GND

Power supply 24 V DC for digital

outputs

Power supply of CAN: towards

80 VCC24V

X103 Used for:

90 GND

91 GND

92 VCC24V

96 GND

Power supply 24 V DC for digital

outputs

Power supply of CAN: towards

LED/button PCB

Power supply of CAN: towards

CAN shielding: towards

25 Digital In 2

11 Digital In 4 Pressure switch “pump in demand”

13 Digital In 6 Key switch level 2

15 COM 4-7 GND

X605 Used for:

Float switch of the start-up tank –

Low level

25 Digital In 2 Pump fuse malfunction

11 Digital In 4

13 Digital In 6

15 COM 4-7 GND

X605 Used for:

Monitoring availability of the

connection voltage 400 V

WILO SE 01/2017 56

Page 57

17

Digital In 9

Key switch no. 1 in Auto position

17

Digital In 9

Digital In 10

position

Digital In 11

20

COM 8-11

GND

20

COM 8-11

GND

X700

Used for:

X700

Used for:

42

Relay 0 NC

42

Relay 0 NC

44

Relay 1 NO

Communication bus ma l function

44

Relay 1 NO

Key switch in non-auto mode 2

47

Relay 2 NO

47

Relay 2 NO

COM

COM

51

Relay 3 NC

51

Relay 3 NC

COM

COM

X702

Used for:

X702

Used for:

32

Relay 5 NO

Delta contactor

32

Relay 5 NO

Pump in operation

34

Relay 6 NO

Star contactor

34

Relay 6 NO

36

Relay 8 NO

36

Relay 8 NO

Low level start-up tank

English

16 Digital In 8

18

19

41 Relay 0 NO Activation failed

43

45 Relay 1 NC

46

48 Relay 2 NC

49

Relay 0

COM

Relay 1

COM

Relay 2

Key switch no. 1 in Manual

position

Key switch no. 2 in Manual

Key switch no. 2 in Auto position

COM (voltage EXT.)

COM (voltage EXT.)

16 Digital In 8

18 Digital In 10 Empty

19 Digital In 11

41 Relay 0 NO Key switch in non-auto mode 1

43

45 Relay 1 NC

46

48 Relay 2 NC Buzzer

49

Relay 0

COM

Relay 1

COM

Relay 2

230 V AC

230 V AC

230 V AC

50 Relay 3 NO

52

31 Relay 4 NO Main contactor

33

35 Relay 7 NO

X703 Used for:

37 Relay 9 NO

38

39 Relay 10 NO

40 Relay 11 NO

Relay 3

Relay 4-7

COM

Relay 8-11

COM

Connection voltage availability

malfunction

COM (voltage EXT.)

230 V AC

50 Relay 3 NO Connection voltage malfunction

52

31 Relay 4 NO General malfunction

33

35 Relay 7 NO

X703 Used for:

37 Relay 9 NO Low level main water tank

38

39 Relay 10 NO Low level glycol tan k source A

40 Relay 11 NO Free error message

Relay 3

Relay 4-7

COM

Relay 8-11

COM

230 V AC

230 V AC

230 V AC

Installation and operating instructions Wilo-SC-Fire Electric A2P 57

Page 58

Pioneering for You

WILO SE

Nortkirchenstraße 100

D-44263 Dortmund

Germany

T +49(0)231 4102-0

F +49(0)231 4102-7363

wilo@wilo.com

www.wilo.com

Loading...

Loading...