Page 1

Pioneering for You

Wilo-Control SC-Fire Diesel A2P

en Installation and operating instructions

4 206 382-Ed.02 / 2016-11-Wilo

Page 2

English

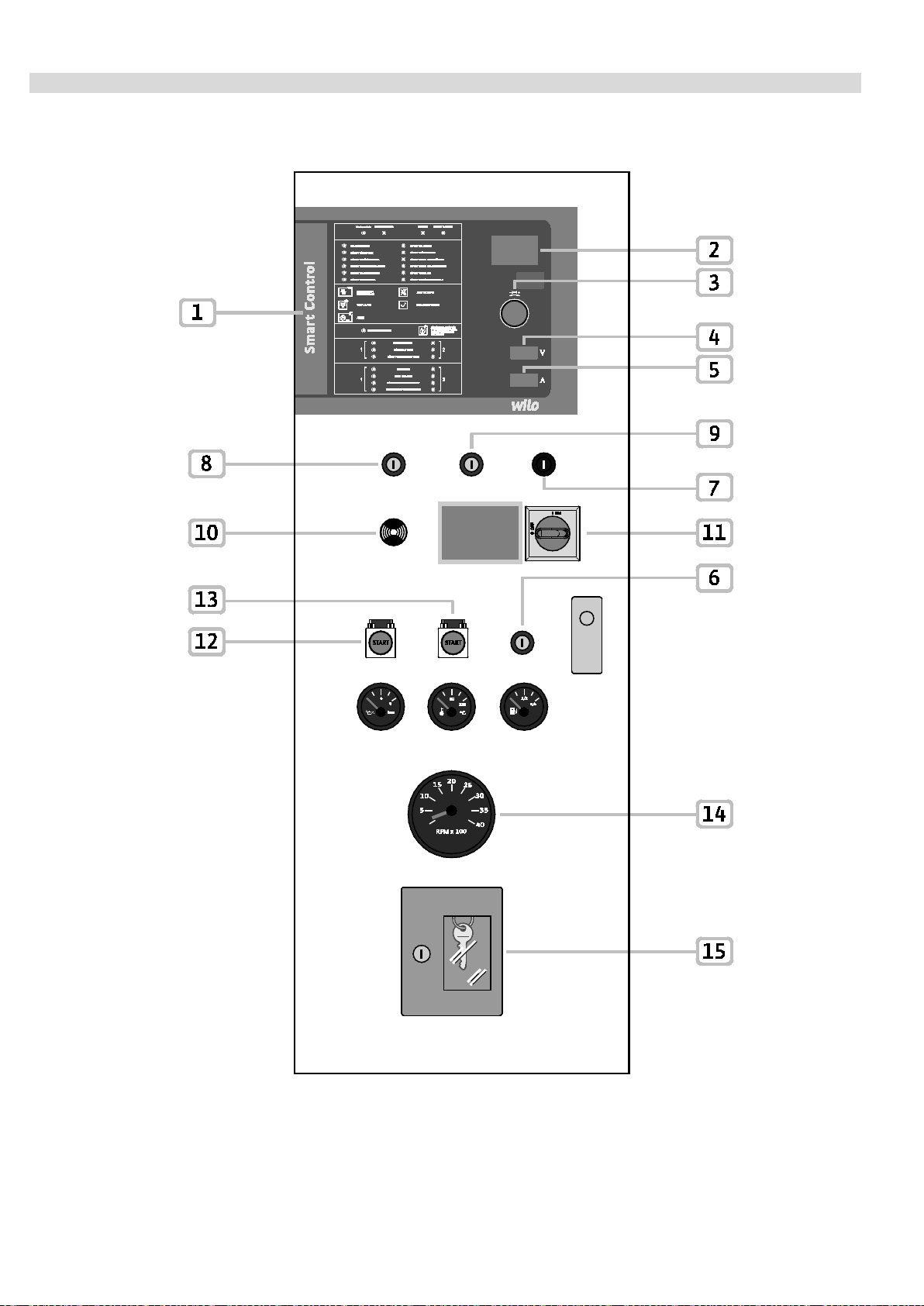

Fig. 1

WILO SE 11/2016 2

Page 3

English

Fig. 1

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 3

Page 4

English

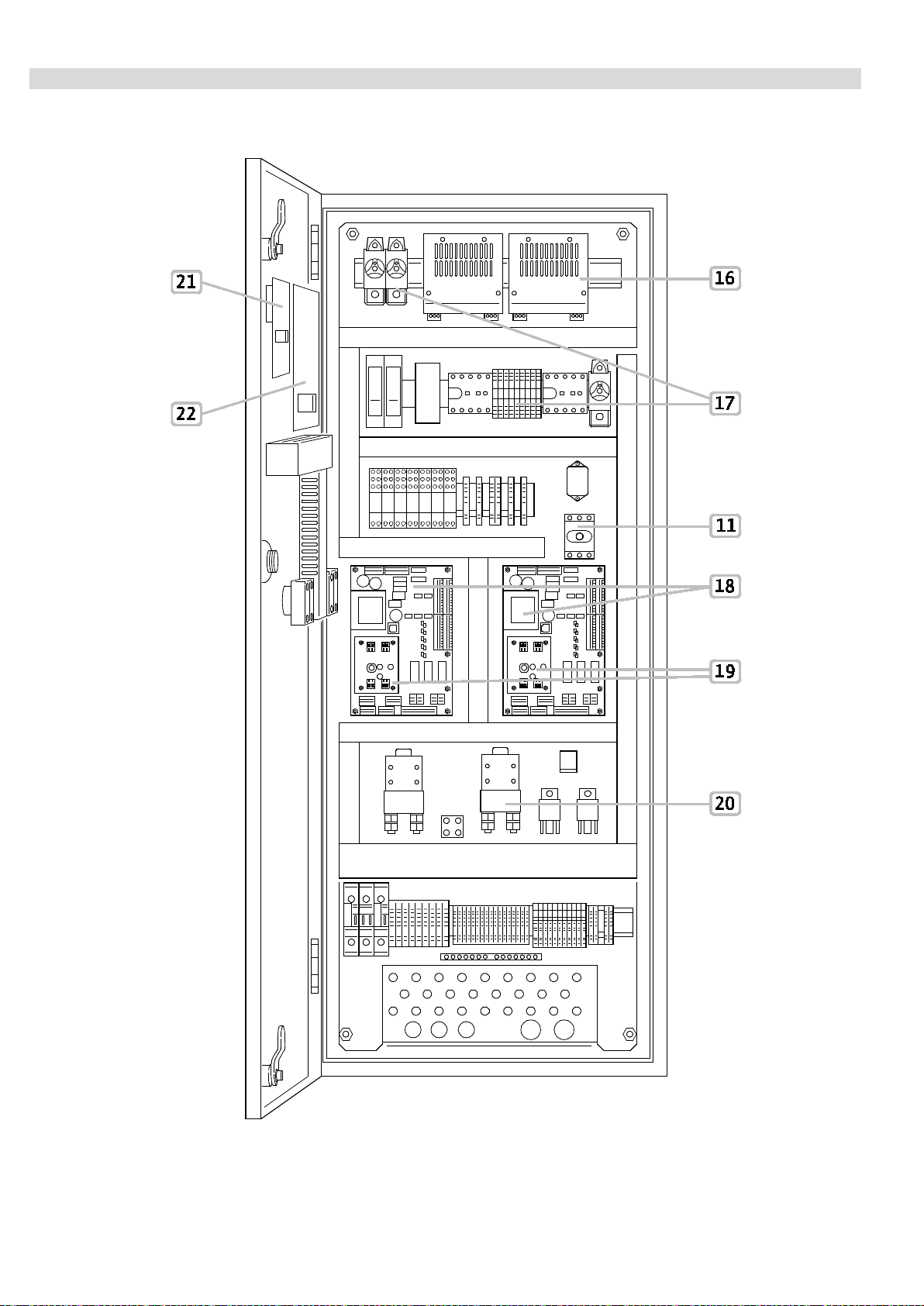

Fig. 2

WILO SE 11/2016 4

Page 5

English

1 General

About this document

The language of the installation and original operating instructions is German. All other languages of these

instructions are translations of the original installation and operating instructions.

The installation and operating instructions are an integral part of the product. They must be kept close to the

product and be ready for use if necessary. Strict adherence to these instructions is a precondition for the proper

use and correct operation of the product.

These installation and operating instructions correspond to the relevant version of the product and the

underlying safety standards valid at the time of going to print.

EC-Declaration of conformity:

A copy of the EC-Declaration of conformity is an integral part of these installation and operating instructions.

If a technical modification is made on the designs listed therein without prior approval or the declarations made

in the installation and operating instructions on product/personnel safety are not observed, this declaration loses

its validity.

2 Safety

These installation and operating instructions contain important information which must be adhered to during

installation, operation and maintenance. For this reason, these instructions must, without fail, be read by the

service technician and the responsible specialist/operator before installation and commissioning.

It is not only the general safety instructions listed under the main point “safety” that must be adhered to but also

the special safety instructions with danger symbols included under the following main points.

2.1 Symbols and signal words used in the installation and operating instructions

Symbols:

Danger: Imminent hazardous situation.

Non-observance may result in death or severe injury.

Danger: Danger due to electrical voltage.

Non-observance may result in death or severe bodily injuries by electric shock.

Useful or important information

WARNING!

Non-observance may result in severe injury.

WARNING!

Non-observance may result in a risk of damage of material or of the unit.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 5

Page 6

English

NOTE:

Useful information on handling the product. It draws attention to possible problems.

Infor mation that appears directly on the product, such as:

• Direction of rotation arrow

• Identification for connections

• Rating plate

• Warni ng stickers

must be strictly complied with and kept in legible condition.

2.2 Personnel qualifications

The installation, operating and maintenance personnel must have the appropriate qualifications for this work.

Area of responsibility, terms of reference and monitoring of the personnel are to be ensured by the operator. If

the personnel are not in possession of the necessary knowledge, they are to be trained and instructed. This can

be accomplished if necessary by the manufacturer of the product at the request of the operator.

2.3 Danger in the event of non-observance of the safety instructions

Non-observance of the safety instructions can result in risk of injury to persons and damage to the environment

and the product/unit. Non-observance of the safety instructions results in the loss of any claims to damages.

In detail, non-observance can, for example, result in the following risks:

• Danger to persons due to electrical, mechanical and bacteriological influences.

• Damage to the environment due to leakage of hazardous materials.

• Property damage.

• Failure of important product/unit functions.

• Failure of required maintenance and repair procedures.

2.4 Safety consciousness on the job

The safety instructions included in these installation and operating instructions, the existing national regulations

for accident prevention together with any internal working, operating and safety regulations of the operator are

to be complied with.

2.5 Safety instructions for the operator

This appliance is not intended for use by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have been given supervision or instruction

concerning use of the appliance by a person responsible for their safety.

Children should be supervised to ensure that they do not play with the appliance.

• If the product/unit poses a threat due to components being too hot or too cold, these components must

be protected by the customer against touching.

• Guards that protect against coming into contact with moving components (such as the coupling) must

not be removed whilst the product is in operation.

• Hazardous fluids (e.g. from the shaft seals) which have leaked (which are explosive, toxic or hot) must

be eliminated so that no danger to persons or to the environment arises. National statutory provisions

are to be complied with.

• Highly flammable materials are always to be kept at a safe distance from the product.

• Danger from electrical current must be eliminated. Local directives or general directives

[e.g. IEC, VDE etc.] and instructions from energy supply companies must be adhered to.

WILO SE 11/2016 6

Page 7

English

2.6 Safety instructions for installation and maintenance work

The operator must ensure that all maintenance and installation work is carried out by authorised and qualified

personnel, who are sufficiently informed based on their own detailed study of the installation and operating

instructions.

Work on the product/unit must only be carried out when at a standstill. It is mandatory that the procedure

described in the installation and operating instructions for shutting down the product/unit be complied with.

Immediately on conclusion of the work, all safety and protective devices must be put back in position and/or

recommissioned.

2.7 Unauthorised modification and manufacture of spare parts

It is strictly forbidden to use batteries for any other purpose than to start the diesel motor.

3 Transport and interim storage

Upon receipt of the product:

• Check for any damage that may have occurred during transit.

• In the event of damage in transit take the necessary steps within the period defined by the transport

company within the time constraints.

WARNING! Risk of material damage!

Non-compliant transport and interim storage may cause material damage to the product.

• The switchgear must be protected against humidity and any mechanical damage.

• The product must not be exposed to temperatures lower than -10 °C and higher than

+50 °C.

4 Intended use

The SC-Fire A2P Diesel switchgear controls pumps in automatic pumping installations used for fire-fighting

purposes (sprinkler systems).

The design of this switchgear adheres to the technical regulations defined in the T1-1 of the A2P trademark.

The installation, functioning and maintenance are also defined in these technical regulations.

The relevant fields of application are habitable buildings, offices, hospitals, hotels, administrative and industrial

buildings.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 7

Page 8

5 Product information

W

W = WIL O

CTRL

Operation

SC

Smart Control = Control unit

F

F = Fire fighting application

1x

Number of pumps

197 – 246 kW

M

Power supply: 1 x 230 V/50 Hz

FM

Frame mounted

ND

New design of the electrical/control cabinet

D

Diesel cabinet

FR

France – box conforms to A2P

Technical data

Mains connection voltage [V]:

Frequency [Hz]:

50/60 Hz

12/24 V DC

Absorbed current max [A]:

See the rating plate

Protection class:

IP44

Fuse protection max on mains side [A]:

See circuit diagram

Room temperature [°C]:

0 °C to +50 °C

Electrical safety:

Pollution degree II

Alarm/signal contact:

250 V AC, 1 A

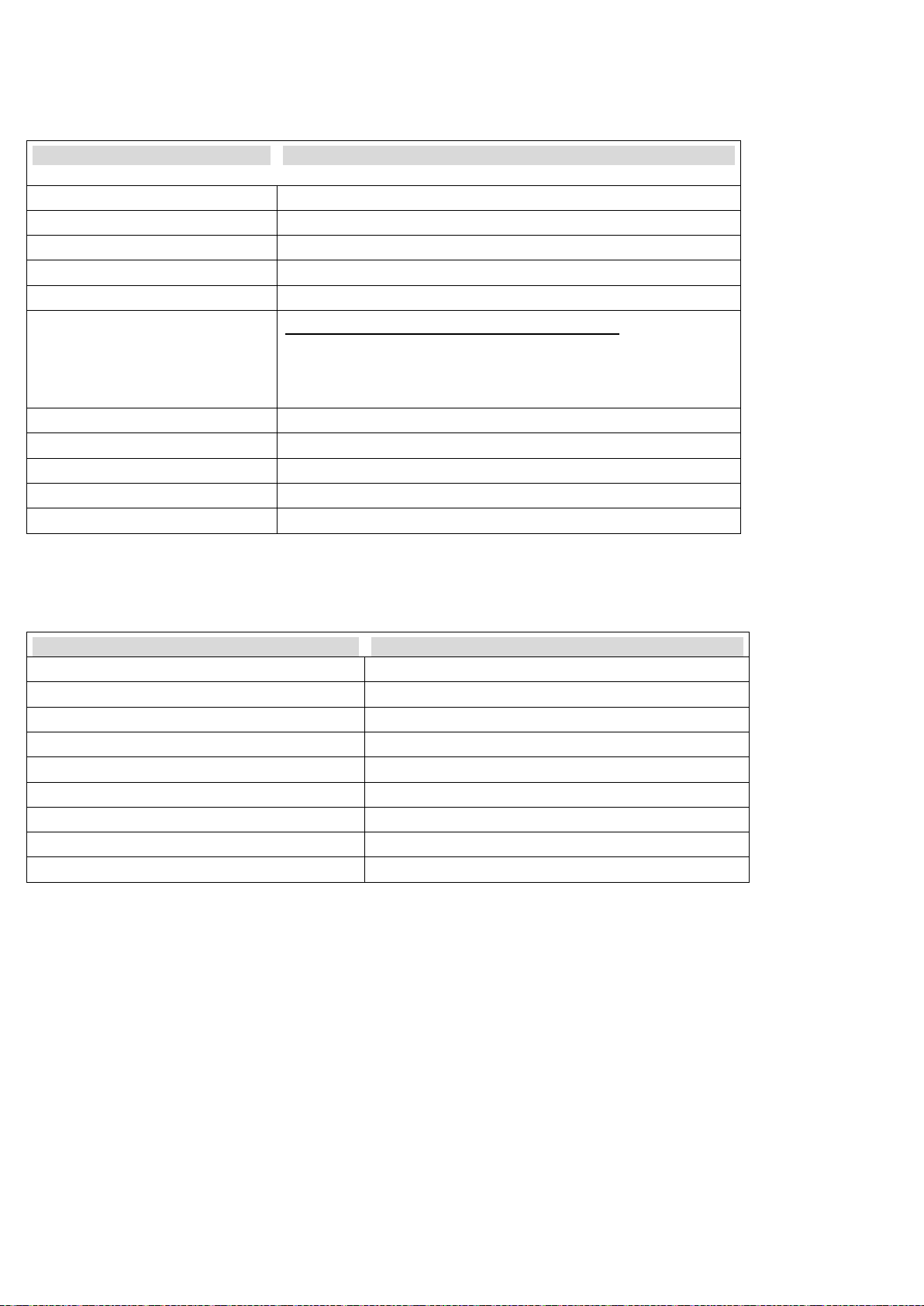

5.1 Type key

Example: W-CTRL-SC-F-1x(2)KW-M-FM-ND-D-FR

(2) Rated power range of the diesel motor [kW]:

4.25 – 47.7 kW

66 – 145 kW

English

Table 1 - Type key

5.2 Technical data (standard execution)

Control voltage [V]:

Table 2 - Technical data

5.3 Scope of delivery

• Switchgear

• Circuit diagram

• Installation and operating Instructions

• Check log in accordance with EN 60204-1

1~230 V (L, N, PE)

5.4 Accessories

WILO SE 11/2016 8

Page 9

English

6 Description and function

6.1 Product description

6.1.1 Function

The switchgear is used to operate a diesel motor pump in the sprinkler system in accordance with A2P (T1-1).

The manual start-up of the diesel motor is done from the HMI of the switchgear.

Contrary to automatic start-up which is generated by a lack of pressure in one of the 2 pressure switches.

Each pump has 2 pressure switches and each pressure switch has an Auto/0/Manu key switch.

The automatic start-up of the diesel motor follows a start-up sequence which allows for the generation of 6 startup attempts, the 2 batteries are used in the course of this sequence.

The status of the unit can be seen on the front of the support box:

- From the LED panel

- From the LCD

- From the audible warning

The operation is performed by means of the rotary knobs, key switches and screen pushbuttons also located on

the front of the box.

It is possible to perform an emergency start by means of the 2 buttons on the front of the cabinet. In this way,

the battery voltage is directly applied to the terminals of the diesel starter, without going through the control.

The water level in the start-up tank is monitored at all times. If the level in the tank goes under 2/3 of the “full

tank” level, then the diesel motor starts up to supplement the level.

Potential-free contacts are ready to transmit the collective run/malfunction signals to the BMS device.

6.1.2 Structure of the switchgear

The structure of the switchgear may vary according to the performance of the pump to be connected.

The switchgear includes the following components:

• Main switch (Fig. 1, pos. 11): Power supply of the switchgear

• Human Machine Interface (HMI):

o LCD screen enabling operational data to be displayed (see menus) (Fig. 1, pos. 2),

o LED indication of the status of the system (functioning/malfunctioning) (Fig. 1, pos. 1),

o Control button enabling menu navigation, menu selection and entering of parameters

(Fig. 1, pos. 1, 2, 3).

• Key switch (Fig. 1, pos. 8 and 9): Operation mode (Auto/0/Manu) of pressure switches 1 and 2

• Screen display indicating the voltage and battery charging current (Fig. 1, pos. 4, 5)

• Key switch (Fig. 1, pos. 6): access to level 2

• Battery selection switch (Fig. 1, pos. 7): selection of the battery for the voltage and current displays

(Fig. 1, pos. 4, 5)

• Audible warning: Activated in case of an alarm (Fig. 1, pos. 10)

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 9

Page 10

• Base printed circuit board: printed circuit board with micro-controller. (Fig. 1, pos. 18)

• Printed circuit board of the converter: conversion of the voltage from 12 V DC to 24 V DC, conversion

of the speed rotation signal (Fig. 1, pos. 19)

• Fuse protection of components: fuse protection of the control and connected components

(Fig. 1, pos. 17)

• Contactors/relay: contactors/relay to activate the starter and the electromagnets (Fig. 1, pos. 20)

• Chargers: To automatically charge and keep the diesel batteries charged (Fig. 1, pos. 16)

• Emergency start button: start-up of the diesel motor with battery 1 or 2, carried out independent of the

control (Fig. 1, pos. 12, 13)

• Diesel indicators (Fig. 1, pos. 14): display showing the fuel level, temperature of the cooling water, oil

pressure and speed of the diesel motor

• Key box: enables the storage of the keys from the key switches (Fig. 1, pos. 15)

• Printed circuit board “SC Display”: printed circuit board with display and rotary knob (Fig. 1, pos. 21)

• Printed circuit board “SC I/O”: printed circuit board with control/operating console (Fig. 1, pos. 22)

6.2 Function and operation

English

DANGER! Risk of fatal injury!

When working on an open switchgear, there is a risk of electrocution in the event of contact

with the conductor components.

Only authorised and qualified personnel may carry out the work!

Following connection of the switchgear to the connection voltage as well as after each network cutoff, the switchgear reverts to the operating mode set before the voltage cut-off.

6.2.1 Operating modes of the switchgear

Activation/deactivation of the switchgear

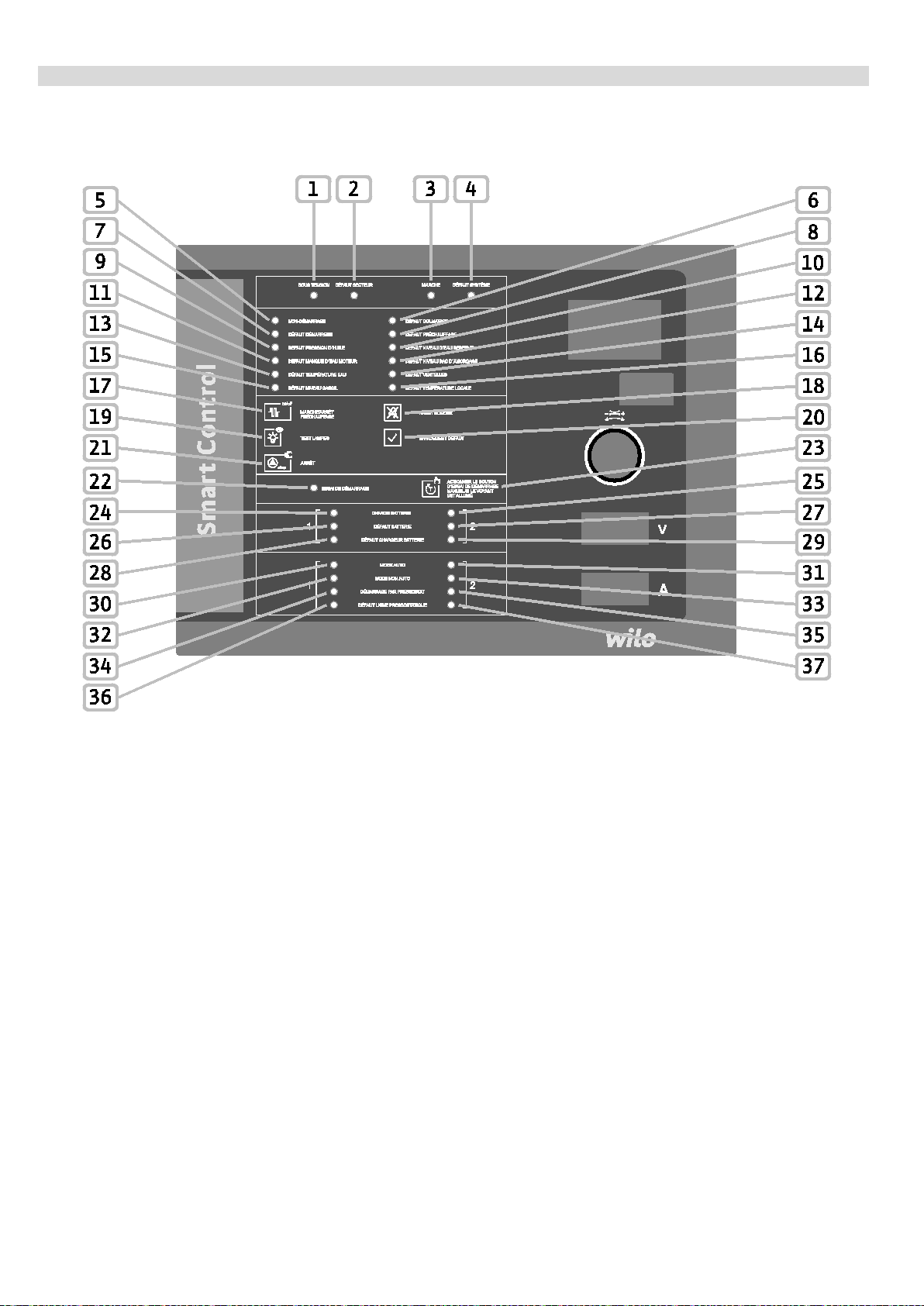

Once the batteries are connected to the switchgear and the voltage supply has been established, the control is

operational after a few seconds. The green LED indicating the operational readiness (Fig. 2, pos. 1) is turned

on.

By default, the remaining time before changeover to the other battery and charger is indicated on the LCD.

The chargers and the heating which maintain the temperature of the motor oil constant can be switched on or

off via the main switch.

To stop the operation, the terminals of connected batteries and the main switch must be disconnected.

WILO SE 11/2016 10

Page 11

English

Key switch no. 1 (for the pressure switch no. 1)

AUTO

OFF

MANUAL

the start-up tank

the start-up tank

the start-up tank

Operating mode

The operating mode of the switchgear is configurable via the 2 key switches, simply select one of the three

positions on the key switches “Auto”, “0” or “Manual”.

Diesel motor start-up in

case of

...

Activation of pressure

AUTO

switch no. 1

or

Malfunction of pressure

switch no. 1

or

Activation of pressure

switch no. 2

or

Malfunction of pressure

switch no. 2

or

Detection of a low level of

Activation of pressure

switch no. 2

or

Malfunction of pressure

switch no. 2

or

Detection of a low level

of the start-up tank

Activation of pressure

switch no. 2

or

Malfunction of pressure

switch no. 2

or

Detection of a low level of

the start-up tank

or

Key switch no. 1 in

“Manual” position

Key switch

no. 2

(for the

pressure

switch

OFF

no. 2)

MANUAL

Table 3: Operating modes

Activation of pressure

switch no. 1

or

Malfunction of pressure

switch no. 1

or

Detection of a low level of

Activation of pressure

switch no. 1

or

Malfunction of pressure

switch no. 1

or

Key switch no. 2 in

“Manual” position

or

Detection of a low level of

-

Key switch no. 2 in

“Manual” position

Key switch no. 1 in

“Manual” position

Key switch no. 1 in

“Manual” position

or

Key switch no. 2 in

“Manual” position

Automatic mode

To operate the unit in automatic mode, put the key switches (Fig. 1, pos. 8, 9) in the “Auto” position, the “Auto”

position is thus confirmed by the 2 green LEDs on the HMI (Fig. 2, pos. 30, 31).

The unit starts up automatically once the pressure switch no. 1 activates (drop in pressure, contact opening

width) and the key switch no. 1 is in the “Auto” position or once the pressure switch no. 2 activates and the key

switch no. 2 is in the “Auto” position.

The status of the pressure switches is signalled by a green or yellow LED (Fig. 2, pos. 34, 35).

In the event of a cable cut or connection malfunction of one of the 2 pressure switches, a red LED is activated

(Fig. 2, pos. 36, 37). This malfunction causes the diesel motor to start up automatically.

In automatic mode, the diesel motor also starts up if the level of the start-up tank is less than 2/3 full. The motor

only stops through the intervention of a technician.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 11

Page 12

English

Automatic start-up process

The automatic start-up consists of a sequence of six consecutive start-up attempts. Each attempt lasts

15 seconds and is followed by a pause of 10 to 15 seconds. After each start-up attempt, the other battery is

used for the following attempt. Even if there is no additional need on the float or key switch level, start-up

attempts continue. The number of attempts with each battery will be constantly indicated on the LCD.

All successful start-ups are signalled by a green LED (Fig. 2, pos. 3) and the output “running” is activated.

After six unsuccessful start-up attempts, an alarm signal is emitted, the output “failure to start” is activated and

the red “failure to start” LED is turned on (Fig. 2, pos. 5) as well as the yellow LED which signifies “attempt at

manual start-up” (Fig. 2, pos. 22) (see test of start-up device 6.2.1).

After a successful start-up sequence or after a phase of “failure to start”, the yellow LED named “Operat e the

test button for manual start-up if the indicator light is turned on” is turned on. (see device start-up test 6. 2.1).

Non-automatic mode

The key switch is not in the “Auto” position. Consequently, the corresponding pressure switch cannot activate

automatic start-up.

If neither of the two key switches is in the “Auto” position, then the start-up tank also cannot activate automatic

start-up. This operating mode is signalled by the red LEDs (Fig. 2, pos. 32, 33). Furthermore, the output

“NON-AUTO MODE 1/2” is active.

Manual mode

To perform a manual start-up, place one of the key switches in the “Man” position. The manual start-up (like the

automatic start-up) consists of a sequence of six consecutive start-up attempts. Each attempt lasts 15 seconds

and is followed by a pause of 10 to 15 seconds. After each start-up attempt, the other battery is used for the

following attempt.

Even when the key switch is not in the “Man” position, the start-up attempts continue.

Deactivation mode

To switch off the diesel motor, at least one of the key switches must be in the “0” position. As soon as the

pressure switch (or the float switch) is no longer activated, the diesel motor can be switched off by means of

the “OFF” button (Fig. 2, pos. 21).

Emergency start

Start by lifting the emergency start button protection cap (Fig. 1, pos. 12 et 13).

Subsequently, to start the diesel motor with battery no. 1, press the button “battery 1 emergency start”, and

keep the button pressed until start-up.

To start the diesel motor with battery no. 2, press the button “battery 2 emergency start”. In this start-up mode,

the starter is fed directly from the batteries.

Manual start-up device test

After a start-up sequence (manual or automatic) or after a failure to start, the yellow LED (Fig. 2, pos. 22)

recognised by the following indication is turned on: “OPERATE THE MANUAL START TEST BUTTON IF THE

INDICATOR LIGHT IS TURNED ON”.

In this case, the corresponding button must be pressed (Fig. 2, pos. 23) to perform the start-up device test.

WILO SE 11/2016 12

Page 13

English

Pump demand

If the set pressure configured is not reached for at least one of the two pressure on/off switches, the green or

yellow LED signals this (Fig. 2, pos. 34, 35). If these LEDs flash, this signifies that a configured dwell time has

elapsed (see menu 1.2.5.1). Once the set dwell time has elapsed, the corresponding LED remains turned on

while the pr essure switch is activated. The automatic start-up test run of the diesel motor is launched with a

maximum of 6 start-up attempts. The running-in period (menu 1.2.2.1) as well as the pause time (menu 1.2.2.2)

can be set using the software. After each start-up attempt, a switch to the other battery takes place. Any noncoupled pinions in the ring gear of the motor are detected. Connection is achieved by means of additional

attempts.

Successful start-up of the diesel motor is signalled by the green LED (Fig. 2, pos. 3). This lights up when the

measured rotation speed exceeds the threshold of the cut-in adjusted for “motor in operation” (menu 1.2.1.3).

The LCD displays the symbol of the pump and the battery currently being charged with the remaining time

before passing to the next charging system. The pinion for engaged starter is automatically disengaged. The

diesel motor can only be manually switched off with the “OFF” button (Fig. 2, pos. 21), if at least one of the key

switches is in the “Stop” position and if the change-over switch is not engaged. The green LED (Fig. 2, pos. 3)

turns off if the cut-in threshold for “motor in operation” is not reached. The LCD displays once more the

remaining time until passing to the other charging system.

Filling device

If the start-up tank level falls below 2/3 of its full level, then the “START-UP TANK MALFUNCTION” LED

(Fig. 2, pos. 12) is activated.

If the LED flashes, this signifies that a follow-up time is elapsing (see menu 1.2.5.2). Once the set follow-up time

has elapsed, the LED remains turned on while the float switch is activated.

This detection of a lack of water in the start-up tank launches the automatic start-up sequence of the diesel

motor, with a maximum of 6 start-up attempts. The running-in period (menu 1.2.2.1) as well as the time between

2 attempts (menu 1.2.2.2) can be adjusted. After each start-up attempt, a switch to the other battery takes

place. Any non-coupled pinions in the ring gear of the motor are detected.

A successful start-up of the diesel motor is signalled by a green LED (Fig. 2, pos. 3). This lights up when the

measured rotation speed exceeds the threshold of the cut-in adjusted for “motor in operation” (menu 1.2.1.3).

The LCD displays the symbol of the pump and the battery being charged with the remaining time before

passing to the next charging system. The diesel motor can be manually switched off with the “OFF” button

(Fig. 2, pos. 21), if at least one of the key switches is in the “Off” position and if the float switch is not engaged.

The green LED (Fig. 2, pos. 3) turns off if the cut-in threshold for “motor in operation” is not reached. The LCD

displays the remaining time before passing to the next charging system.

Monitoring of battery voltage

The cabinet is fitted with two battery chargers which are fed by the 230 V AC network.

The chargers deliver 12 V DC or 24 V DC, depending on the type of starter to be fed.

To maintain continuous service, the network voltage as well as the battery charges are constantly monitored.

Battery monitoring is ensured by the controller which constantly receives information from the two chargers.

The chargers can signal the following malfunctions to the controller:

- a rupture of the wire, coupling or connection,

- a short-circuit,

- a battery malfunction,

- a connection voltage error.

The malfunctions are analysed by the controller and displayed in the malfunction menu (Fig. 1, pos . 2).

Furthermore, it is possible to adjust the minimal battery voltage in the menu 5.4.1.0. If this voltage is not

achieved by one of the connected batteries, an error message is displayed on the screen.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 13

Page 14

English

Monitoring of motor start-up

Once the pressure switch/float switch is activated, or after a successful manual start-up, the automatic start-up

cycle of the motor is l aunched.

During the start-up phase, the controller monitors to ensure that the diesel motor is triggered.

The diesel motor is triggered when the start-up pinion is engaged in the gear ring of the motor.

If the diesel motor is not triggered after the first attempt, an error message appears on the screen. After each

start-up attempt, the other battery is used for the following attempt. After 6 unsuccessful start-up attempts, the

process is interrupted, the yellow LED “ATTEMPT START-UP” turns on (Fig. 2, pos. 22), an error message is

displayed on the screen and the malfunction signal contacts are active.

Duty cycling of the battery chargers

From the menu 5.3.1.0, it is possible to force the duty cycling of the active charger.

To do this, go to the menu 5.3.1.0, accessible from level 3, change the value “Auto” and select “Man”. The value

automatically reverts to “Auto”.

The battery charger which was active has swapped. The duty cycling countdown has also been reset to 0.

6.2.2 Application of the switchgear

Levels of access

• Level of access 1: Allows access to the functions without particular restrictions, such as for stopping

the buzzer (Fig. 2, pos. 18) or to proceed to a light test (Fig. 2 pos. 19).

• Level of access 2, intended for operators/owners, is accessible only after activation of the key switch

(Fig. 1, pos. 6). It enables access to certain functions such as the resetting of error messages (Fig. 2,

pos. 20) and the commissioning/decommissioning of the pre-heating diesel device (Fig. 2, pos. 17).

• Level of access 3, intended for the commissioner, is accessible with a code, given in the menu 7.0.0.0.

It enables access to all configurations of the menu.

Control elements

• Main switch (Fig. 1, pos. 11) On/Off (lockable in “Off” position).

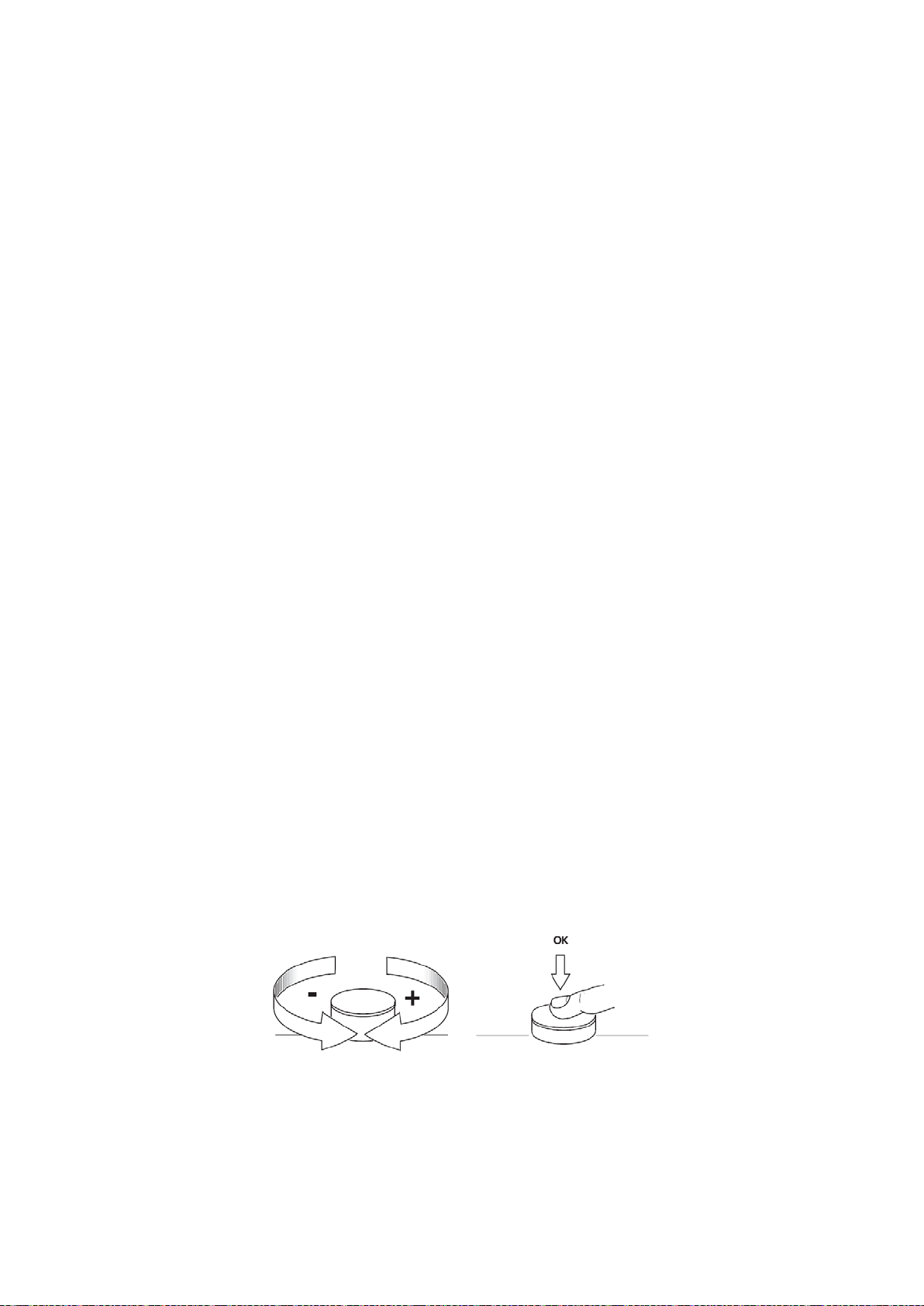

• The LCD (Fig. 1, pos. 2) displays the pump operating status and the settings menu. The control button

(Fig. 1, pos. 3) allows menu selection and the entering of parameters (level 3 access required). To

modify the values or to scroll through a menu level, turn the knob and to select and confirm, press it:

WILO SE 11/2016 14

Page 15

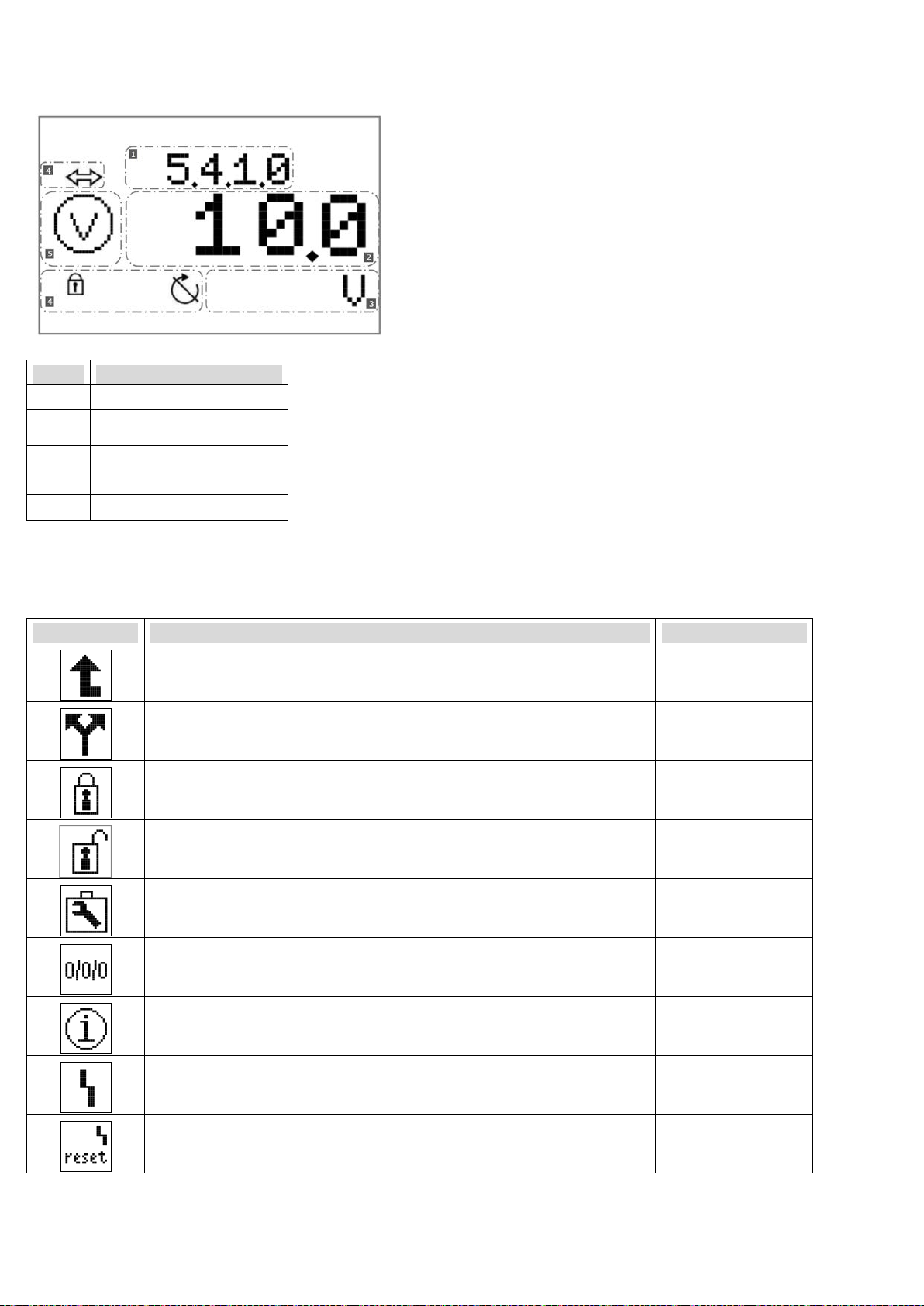

The information display is performed on the screen according to the following model:

Pos.

Description

1

Menu number

3

Unit display (text)

4

Standard symbols

5

Graphic symbols

Symbol

Function/description

Availability

2 Value display (text)

English

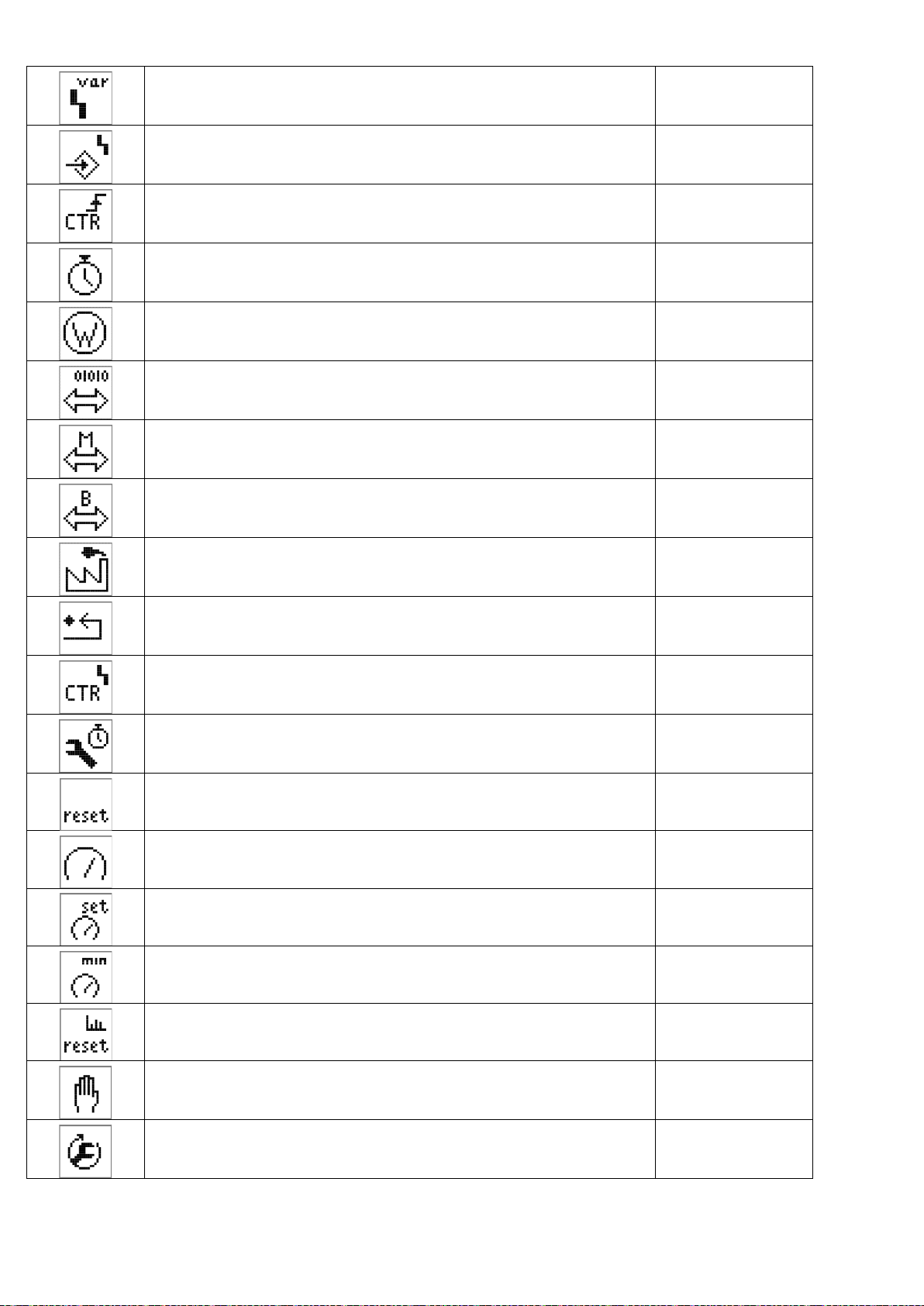

The following graphic symbols are used:

Return (brief press: a menu level; long press: main screen) All

EXPERT menu All

1. Notification: not connected

2. Notification: display value – no entry possible

Active/unlocked

Service menu All

Parameters All

All

Information All

Malfunction All

Reset malfunction All

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 15

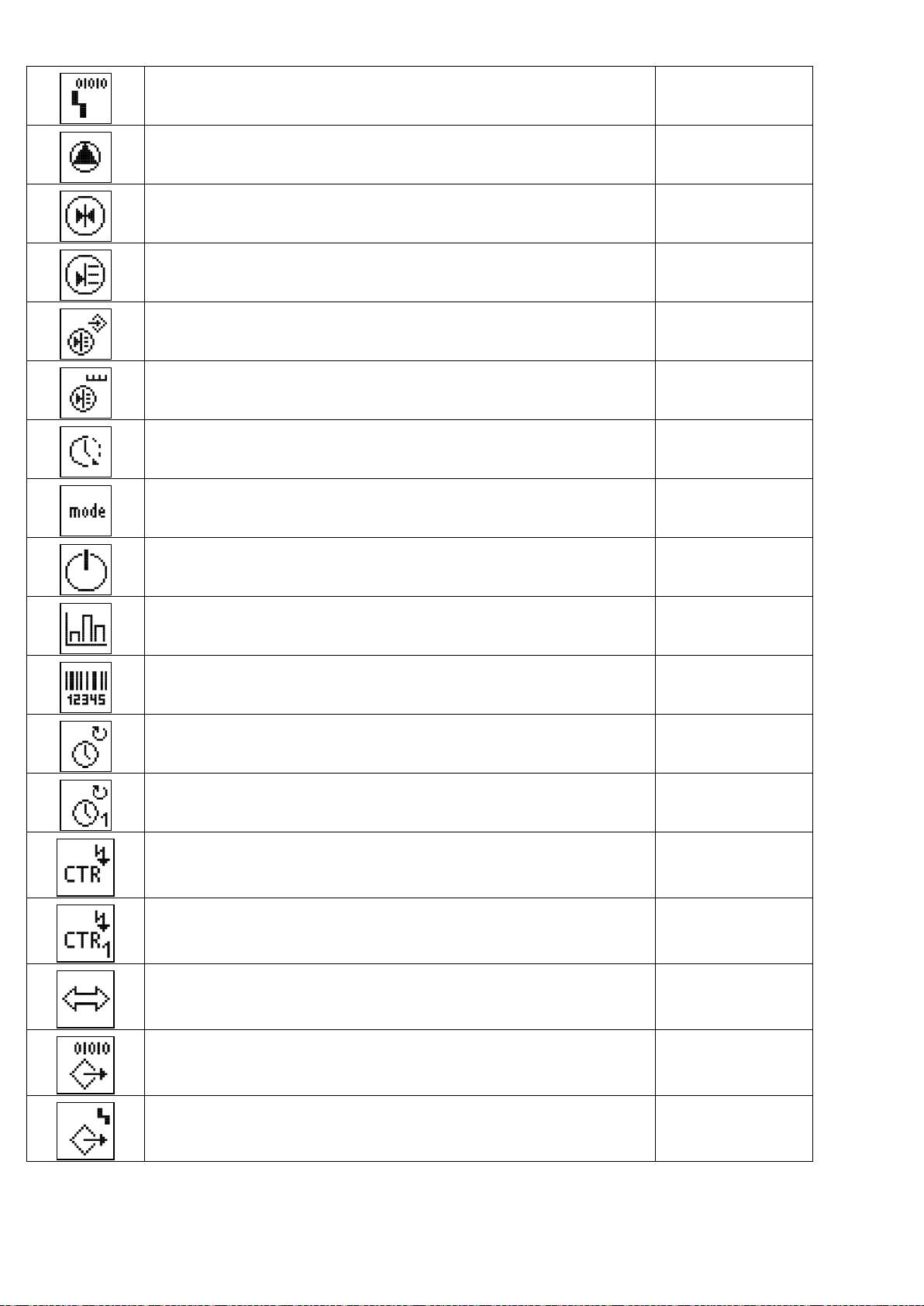

Page 16

Alarm settings All

Pump All

Setpoint All

Actual value All

Sensor signal All

Measurement sensor range Electric

Follow-up time All

English

Operating mode/application All

Stand-by All

Operational data All

Switchgear data:

All

Controller type; ID number; software/firmware

Operating hours All

Pump operating hours All

Switchgear operating cycles All

Pump operating cycles All

Communication All

Output parameters All

SSM parameters All

WILO SE 11/2016 16

Page 17

Definition of the motor rotation speed Diesel

Running-in period via start-up attempt Diesel

Pause between start-up attempts Diesel

Fuel Diesel

Battery 1 (A) Diesel

Battery 2 (B) Diesel

Sprinkler (pressure switch) All

English

Pump filling tank (float switch) All

Heating Diesel

Motor oil Diesel

Thermostat temperature of the motor Diesel

(Temperature of the water) for cooling Diesel

Belt rupture Diesel

Start-up interruption Electric

Pressure Electric

Power supply (mains) Electric

Voltmeter All

Ammeter All

Cut-in star-delta Electric

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 17

Page 18

Malfunction signal freely configurable All

Malfunction input All

Start-up attempts counter Diesel

Duration All

Power indicator Electric

Communication parameters All

Modbus All

English

BACnet All

Factory setting All

Reset to the factory setting All

Alarm counter All

Maintenance interval All

Reset All

Motor rotation speed Diesel

Definition of the motor rotation speed Diesel

Minimum rotation speed for the signal “motor in operation” Diesel

Start-up counter reset Diesel

Manual Diesel

Commissioning Diesel

WILO SE 11/2016 18

Page 19

Menu structure:

The menu structure of the control system has 4 levels.

Navigation in the individual menus as well as the parameter input are described in the example of the

modification of the minimum battery voltage (level of access 3 required):

English

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 19

Page 20

Refer to the following table for a description of the individual menu items.

When the motor is running, the pump

“Services” menu

Menu

no.

Menu accessible from the level of access no. 1

1.1.1.1 Screen 1.1.2 Description

English

Parameter range

Factory setting

The main screen displays the ba ttery

currently being charged a nd th e rem a ining

time before switching to the other ba ttery

charger [hh.mm].

symbol appears on the screen ( in the place

of the stand-by s ymbol) on the main

screens.

To access level 3 an access code must be

entered.

After 5 minutes of inactivity on HMI or after

a main supply malfunction, access is

blocked and the code must be re-entered.

“Malfunctions” menu

0…9999

WILO SE 11/2016 20

Page 21

English

6.1.0.1

History memory of m a lfunctions

the error counter can be reset via th e m enu

The main screen displays the ba ttery

The EXPERT menu contains other settings

which enable a detailed configur a tion of the

to

6.1.1.6

Menu accessible from the level of access no. 3

from 1 to 16

Remarks:

The history memor y of malfunctions and

7599 accessible on level 3.

currently being charged a nd th e rem a ining

time before switching to the other battery

charger [hh.mm].

The remaining time [in secs] before

deactivation of the level of access 3 in case

of inactivity on the HMI is also indicat ed on

the main screen (alternating every

5 seconds with the previous screen).

On the main screen, and when the motor is

running, the pump symbol a ppea r s in the

place of the stand-by symbol.

Menu unlocked with the correct access code

switchgear.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 21

Page 22

Access to the parameter menu enablin g

modification of the system operation.

Settings of the mot or r otation speed:

100 … 3000 … 4000

Once the preceding action has finished,

Finished

Minimum rotation speed from whic h the

200 … 800 … 3000

The parameter menu for a ll timer

English

The settings menu for the para meter s of

rotation speed.

When the diesel motor is running, and with

the aid of a tachome ter , (not provided), the

actual speed must be entered in order to

set parameters f or the controller.

validate the procedure by selecting “start”

from the menu, w hich will automatically

return to “finished”.

Start

controller deems that the “motor is in

operation”.

parameters influencing the operation.

WILO SE 11/2016 22

Page 23

English

Duration of each motor start-up atte m pt

5 … 15

Activation delay from the malfun ction

0 … 3 … 5

Pause duration be tween two start-up

attempts

Delays

Start-up delay in case of pressure switch

activation

5 … 10 … 15

1 … 10

Start-up delay in case of float switch

activation

“Empty fuel tank”

1 … 10

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 23

Page 24

English

Communication

Pump menu

Information me nu

Display of active c om m unication bus No bus (no active bu s),

Modbus,

BACnet

Display of the au tom a tic mode status:

ON or OFF

Remarks: Th is information is the image of

the change-over switch status on the front

of the cabinet.

Service parameters

WILO SE 11/2016 24

Page 25

English

Battery voltage

Instantaneous voltage battery A

Instantaneous load current battery A

Instantaneous voltage battery B

Load currents

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 25

Instantaneous load current battery B

Page 26

Counter for start-up attempts of the diesel

motor

English

Total start-up attem pt counter from

battery A

Total start-up attem pt counter from

battery B

Status of sensors

Status of pressure switch

Contact open

Or

Contact closed

Status of start-up tank float switch

(low level)

Contact open

Or

Contact closed

WILO SE 11/2016 26

Page 27

Status of float switch in the fuel tank

(low level)

Status of the the r m o c ontact of the diesel

Values of the sensors

Contact open

Or

Contact closed

English

Status of thermo contact of the dies e l

pre-heating device

Contact open

Or

Contact closed

oil

Contact open

Or

Contact closed

Status of the the r m o c ontact of the cooling

water of the diesel motor

Contact open

Or

Contact closed

Display of the oil pr e s s ure

Remarks:

At menu 5250 this sensor is deac tiv a ted as

not installed in th e s ystem.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 27

Page 28

Oil temperature

Temperature of the cooling water (external)

Display of instantaneous rotation speed of

Remarks:

At menu 5260 this sensor is deac tiv a ted as

not installed in th e s ystem.

English

Temperature of the cooling water

Remarks:

This sensor is not installed in the s ystem.

Remarks:

This sensor is not installed in the s ystem.

Rotation speed menu

the diesel motor

Display of the minimum rotation speed to

deem that the “mot or is in operation”

WILO SE 11/2016 28

Page 29

English

Operational data

Total hour coun ter of operation of the diesel

operation of the dies el

Number counter of cabinet pow er ups

Total hour coun ter of operation of the

SC-FIRE Diesel cabinet

motor

Total hour coun ter of

motor since the last s ta rt-up

Remarks:

Activation of the m ain switch or con nection

of batteries

Number counter of pump start-ups

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 29

Page 30

English

System characteristics

Firmware version display

System type SC Diesel APSAD

Serial number display

Remarks: Text scrolling

Software version display

Adjustments

WILO SE 11/2016 30

Page 31

English

Communication

Parity

Even

Modbus

Baud delivery rate 9.6

19.2

38.4

76.8

Slave address

1 … 4 … 247

No (none)

Odd

Stop bits 1

2

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 31

Page 32

English

BACnet

Stop bits

1

Baud delivery rate 9.6

19.2

38.4

76.8

Slave address 1 … 4 … 255

Parity Even

No (none)

Odd

2

BACnet Device Instance ID 0 … 24 … 9999

WILO SE 11/2016 32

Page 33

English

Adjustments of the sensors

Correspondence values for the oil

5.2.6.1

Input of resistance values for a

0 … 3000 (in ohms)

to

5.2.6.9

Oil pressure sensor activation OFF

ON

temperature sensor

temperature of 10 °C

Remarks:

The adjustment of the resistance p r ofile

continues in the menus 5.2.6. 2 to 5. 2. 6.9.

Activation of the m onitoring of belt failure OFF

ON

Forced cut-in of battery charger

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 33

Page 34

English

Immediate duty cycling of a c tiv e c harger

Auto

Minimum battery voltage

0 … 30

Control of the commissioning sta r t -up

Finished, Start

Remarks:

By selecting the parameter “Man”, the

battery charger curren tly a c tiv e is r eversed.

And the countdown bef ore duty cycling is

reset to 0, visible on the main sc reen.

Limit values

Man

Control of the commissioning

Remarks:

Menu dedicated to the commission er.

Malfunction messages

WILO SE 11/2016 34

Page 35

Resetting of malfunction messages

Services menu

Adjustment of the serial nu m ber :

0…9999

This menu is equivalent to the reset button

malfunction on the front of the cabinet.

English

6.1.0.1

to

6.1.1.6

History memory of m a lfunctions

from 1 to 16

Access to the para m ete risation of the

cabinet

Designation of the cabinet

Adjustment of th e first 4 numbers of the

serial number

These numbers are adjusted in the factory

and cannot be modified.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 35

Page 36

Adjustment of the serial nu m ber :

Adjustment of th e last 4 numbers of the

0…9999

Software version display

Restoring of factor y parameters:

serial number

These numbers are adjusted in the factory

and cannot be modified.

English

Controller desig nation

Factory setting menu:

Possibility to res et the cabinet to factory

configuration

By pressing the red button, th e s ymbol

“factory” flas hes, turn the red button to the

right, the symbol “reverse arrow” appears ,

press the button a s e c ond time to launch

the resetting of the cabinet to factory

configuration.

Alarm menu

WILO SE 11/2016 36

Page 37

Error counter dis play, showing the number

of times that the error Exx.x has occ urred.

Additional menu functions

Modification of a ccess code to level 3:

Scroll through th e er ror codes with the red

button.

English

Resetting of the m a lfunction histor y and

error counter:

By pressing the red button, th e s ymbol

flashes, turn the red button to the right,

press the button a second time.

The malfunction history and the error

counter are now reset.

Activation code:

Enter the activa tion code, for example, to

activate a field bus c onnection.

To reset the access code, please call the

technical service.

Operational data of the menu reset

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 37

Page 38

Resetting to zero of the total hour c ounter

of pump operation tim e and start-up

Resetting to zero of the total hour c ounter

Activation/deactivation of th e m aintenance

number counter:

By pressing the red button, th e s ymbol

flashes, then press the button a second

time.

English

Resetting to zero of the total hour c ounter

of operation time of battery 1

of operation time of battery 2

Maintenance and repair menu

interval

OFF

Or

ON

Adjustment of th e d uration in days for the

maintenance interval

0…92…1000

WILO SE 11/2016 38

Page 39

Resetting to zero of the maintenance

message:

Diesel mode display

Activation/deactivation of th e RIA

By pressing the r ed button, it is possible to

reset the maintena nce countdown

English

Application menu

RIA menu

application:

Protected access: To gain access, please

call the technical service.

Activation/deactivation of th e a p plication of

the hydrants:

Once access has been granted by the

technical service.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 39

Page 40

English

Adjust the time in minutes for the

1…20

automatic stop of the pump.

Operation levels:

Levels of use:

The parameterisation of the switchgear is divided into the menu areas EASY and EXPERT. Access to level 1

allows consultation of the breakdown history in the menu level 6.0.0.0 and the identification/connection sector

from menu 7.0.0.0. Access to level 3 allows consultation and parameterisation of the whole menu.

For rapid commissioning using the factory presets, it is enough to set the speed values and the speed

adjustment in the EASY area.

• Key switch (Fig. 1, pos. 48 et 49)

Pressure switch 1 and pressure switch 2 each have a key switch. The key switches can be locked in the

“Auto” position and their keys can only be withdrawn if the key switches are in the “Auto” position. Once the

“0” or “Manual” position has been selected, no automatic start-up with the pressure switch or float switch can

take place. The status corresponding to the “Auto” position is signalled by the green LEDs (Fig. 2, pos. 30,

31) and that which corresponds to the “0” or “Manual” position by the red LEDs (Fig. 2, pos. 32, 33).

If you turn one of the key switches in “Manual” mode, the diesel motor starts up manually with battery 1 or 2,

and six attempts maximum.

• Key switch (Fig. 1, pos. 6)

By turning the key switch into the “On” position, you will access the level 2 functions.

• Change-over switch (Fig. 1, pos. 7)

The change-over switch enables selection of battery 1 or 2. For the chosen battery, the voltage and current

are displayed on the screen (Fig. 1, pos. 4, 5).

• Emergency start button (Fig. 1, pos. 12, 13)

This button allows you to manually start the diesel motor with the corresponding battery and without

intervention of the control.

• “PRE-HEATING ON/OFF” (Fig. 2, pos. 17)

The heating ensuring a constant temperature of the motor oil turns on automatically as soon as the system is

powered up. This button enables the heating to be switched off and restarted (Level of access 2 required).

Once the heating is switched off, this malfunction is signalled by a red LED (Fig. 2, pos. 8) and a buzzer

signal.

• “BUZZER OFF” (Fig. 2, pos. 18)

This button allows an audible signal emitted in case of alarm to be cleared separately (level of access 1

required). As soon as a new malfunction arises, the buzzer signal sounds once again.

WILO SE 11/2016 40

Page 41

English

• “LAMP TEST” (Fig. 2, pos. 19)

If you press this button (level of access 1 required), all the control lamps and the alarm buzzer turn on for the

duration of the actuation, which allows you to check their good functioning. Once the button is released, the

control lamps and the alarm buzzer turn off once again or remain turned on only if the functioning demands

it.

• “CLEAR MALFUNCTION” (Fig. 2, pos. 20)

By pressing the button (level of access 2 required), all the error messages/control lamps are reset insofar as

the cause of the error has been eliminated.

• “OFF” (Fig. 2, pos. 21)

This button serves to switch off the motor. To do this, at least one of the switches must be in the “0” position.

The motor cannot be switched off if the pressure switch or float switch are not emitting anything. Once the

motor is switched off, the control lamp “ON” turns off (Fig. 2, pos. 3).

• “START-UP ATTEMPT BUTTON” (Fig. 2, pos. 23)

This attempt button and its control lamp (Fig. 2, pos. 22) are intended for the manual and regular test of the

electric start-up device. The button is used when an automatic motor start-up has taken place followed by a

manual stop, and following six consecutive failed start-up attempts. For these two operation statuses, the

control lamp turns on and the button must be pressed.

6.2.3 Display elements of the switchgear

“LIVE” (Fig. 2, pos. 1)

The control lamp turns on green as soon as the power supply is established.

“MAINS MALFUNCTION” (Fig. 2, pos. 2)

In case of malfunction in the level of connection voltage (charger, heating) or inactive switch, the LED turns on

yellow with a follow-up time of 180 seconds.

“RUNNING” (Fig. 2, pos . 3)

The control lamp turns on green as soon as the diesel motor starts and when the rotation speed increased by

the rotation speed sensor has reached or exceeded the value pre-set for “motor in operation” (menu 1.2.1.3).

“SYSTEM MALFUNCTION” (Fig.2, pos. 4)

The yellow LED signals a software malfunction if the communication between the “printed circuit board I/O” and

the 2 printed circuit boards “SC controller” is interrupted or if the software routine (the programme) does not

function correctly.

“START-UP FAILURE” (Fig. 2, pos. 5)

The control lamp turns on red following six consecutive failed start-up attempts.

“CLOGGING MALFUNCTION” (Fig. 2, pos. 6)

The measurement of the differential pressure at the filter level has detected a clogged filter. This malfunction is

thus signalled by the LED turning on red.

“STARTER MALFUNCTION” (Fig. 2, pos. 7)

As soon as the switchgear no longer receives a response from the starter, the LED turns on red.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 41

Page 42

English

“PREHEATING MALFUNCTION” (Fig. 2, pos. 8)

The LED turns on red if the heating switches off or if the heating temperature switch or fuse is triggered.

“OIL PRESSURE MALFUNCTION” (Fig. 2, pos. 9)

The control lamp turns on red as soon as the oil pressure is detected to be too low by the automatic control of

the oil pressure. This error message can only be transmitted during diesel motor operation.

“WAT ER TANK LEV EL MALFUNCTION” (Fig. 2, pos. 10)

If the water tank level is too low, this LED turns on red.

“LACK OF MOTOR WATER MALFUNCTION” (Fig. 2, pos. 11)

The level of the cooling water is monitored. If the level is too low, this LED turns on red.

“START-UP TANK LEVEL MALFUNCTION” (Fig. 2, pos. 12)

The control lamp flashes red as soon as the level of the pump filling tank corresponds to 2/3 of the tank and

when the float switch is triggered. Once the start-up delay has elapsed (menu 1.2.5.2), the control lamp is

permanently turned on red. If at least the key switch is in the “Auto” position, the diesel motor starts

automatically.

“WATER TEMPERATURE MALFUNCTION” (Fig. 2, pos. 13)

The control lamp turns on red as soon as the temperature is detected to be too high by the connected

thermostatic valve. This error message can only be transmitted during diesel motor operation.

“VENT MALFUNCTION” (Fig. 2, pos. 14)

Once the diesel motor starts up, the aeration valves must open within 10 seconds. If no signal is emitted after

10 seconds, the LED turns on red.

“DIESEL LEVEL MALFUNCTION” (Fig. 2, pos. 15)

The control lamp turns on red as soon as the float switch of the fuel tank is triggered.

“ROOM TEMPERATURE MALFUNCTION” (Fig. 2, pos. 16)

As soon as the room temperature drops below 10 °C, the control lamp turns on red.

“START-UP ATTEMPT” (Fig. 2, pos. 22)

The control lamp turns on yellow when an automatic start-up of the motor has been triggered by the pressure

switch, followed by manual switch off, as well as after six consecutive failed start-up attempts.

“BATTERY LOAD 1/2” (Fig. 2, pos. 24, 25)

The two batteries are recharged alternately, every 24 hours. The corresponding green LED indicates the battery

which is being recharged.

“BATTERY MALFUNCTION 1/2” (Fig. 2, pos. 26, 27)

The voltage of the batteries is monitored. Furthermore, any absence of short-circuit or line break is checked. As

soon as a malfunction occurs, the LED turns on yellow.

“BATTERY CHARGER 1/2 MALFUNCTION” (Fig. 2, pos. 2 8, 29)

The connection voltage of the battery chargers is monitored. Furthermore, any absence of error or

communication malfunction is checked. As soon as a malfunction occurs, the LED turns on yellow.

WILO SE 11/2016 42

Page 43

English

“AUTO MODE 1/2 ” (Fig. 2, pos. 30, 31)

The green LED turns on if the corresponding key switch is in the “Auto” po sition. In the automatic mode, the

automatic start-up of the diesel motor is possible either via the intermediary of the float switch or the

corresponding pressure switch.

“NON-AUTO MODE 1/2” (Fig. 2, pos. 32, 33)

The green LED turns on if the corresponding key switch is in the “0” or “Manual” position. In the non-automatic

mode, no automatic start-up of the diesel motor is possible via the intermediary of the float switch or the

corresponding pressure switch.

“START-UP VIA PRESSURE SWITCH 1/2” (Fig. 2, pos. 34, 35)

The control lamp flashes green as soon as the pressure of the unit drops below the set/requested pressure and

when pressure switch 1 or 2 is triggered. Once the start-up delay has elapsed (menu 1.2.5.1), the control lamp

is permanently turned on. If the pressure increases as a consequence, the control lamp turns off once again. If

the key switch 1 or 2 is in the “Auto” position, the diesel motor starts automatically. If the pressure increases

and the output button (Fig. 2, pos. 20) is activated (level of access 2 required), the indicator light turns back on.

“PRESSURE SWITCH LINE 1/2 M ALFUNCTION” (Fig. 2, pos. 36, 37)

The connection of the pressure switches is monitored. Any short-circuit or cable rupture is signalled by the LED

turning on red. If the corresponding key switch is in the “Auto” position, the diesel motor starts up automatically.

Even in the absence of problems, the number of start-up attem pts is limited t o 6.

7 Installation and electri ca l c onne c t ion

Installation and electrical connection must be carried out in accordance with local regulations and only

by qualified personnel!

WARNING! Risk of personal injury!

Comply with applicable accident prevention regulations.

Warning! Danger of electric shock!

Danger from electrical current must be eliminated.

Local directives or general directives [e.g. IEC] and instructions from local energy supply

companies must be adhered to.

7.1 Installation

Install the switchgear/unit in a dry location.

Protect the place of installation from direct exposure to sunlight.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 43

Page 44

7.2 Electrical connection

DANGER! Risk of fatal injury!

In case of non-compliant electrical connection, there is a danger of death by electrocution.

• Have the electrical connection established by an electrician approved by the local energy

supply company only and in accordance with local regulations.

• Observe the installation- and operating instructions for the pumps and accessories.

• Disconnect the power supply before any work!

Warning! Danger of electric shock!

There is a potentially fatal voltage on the supply side, even when the main switch is turned

off.

• The type of mains, current type and voltage of the mains connection must match the details on the

rating plate of the control device.

English

NOTE:

• Fuse on mains side in accordance with the information in the wiring diagram.

• Feed the ends of the mains cable through the threaded cable connections and cable inputs and wire

them according to the markings on the terminal strips.

• Earth the pump/system in accordance with the regulations.

7.2.1 Power supply connection

Connect the on-site 3-wire cable (L, N, PE) for the power supply network to the main switch, in accordance with

the wiring diagram.

7.2.2 Battery connection

The batteries must be connected by means of the cables provided for that purpose. The screws of the hose

clamps must be fully tightened.

7.2.3 Connection of the malfunction signals/run signals

A signal can be withdrawn via a potential-free contact on the terminal strip for the malfunction/running

messages in order to signal a malfunction/operation (see wiring diagram).

Potential-free, contact load max. 250 V ~/1 A

WILO SE 11/2016 44

Page 45

English

“GENERAL MALFUNCTION”

Activation of the signal output if the following malfunctions occur:

• “MAINS MALFUNCTION”

• “PRE-HEATING MALFUNCTION”

• “OIL PRESSURE MALFUNCTION”

• “WATER TEMPERATURE MALFUNCTION”

• “BATTERY 1/2 MALFUNCTION”

• “BATTERY CHARGER 1/2 MALFUNCTIO N”

“RISK OF FAILURE”

Activation of the signal output if the following malfunctions occur:

• “SYSTEM MALFUNCTION”

• “CLOGGING MALFUNCTION”

• “STARTER MALFUNCTION”

• “WATER TANK LEVEL MALFUNCTION”

• “LACK OF MOTOR WATER MALFUNCTION”

• “START-UP TANK LEVEL MALFUNCTION”

• “VENT MALFUNCTION”

• “DIESEL LEVEL MALFUNCTION”

• “ROOM TEMPERATURE MALFUNCTION”

• “PRESSURE SWITCH LINE 1/2 MALFUNCTION”

“NON-AUTO MODE 1”

The signal output is activated if the corresponding key switch is in the “0” or “Manual” position. In the nonautomatic mode, no aut omatic s tart-up of the diesel motor is possible via the intermediary of the float switch or

the corresponding pressure switch.

“NON-AUTO MODE 2”

The signal output is activated if the corresponding key switch is in the “0” or “Manual” position. In the nonautomatic mode, no automatic start-up of the diesel motor is possible via the intermediary of the float switch or

the corresponding pressure switch.

“ON”

The signal output is activated as soon as the diesel motor has started and when the rotation speed increased

by the rotation speed sensor has reached or exceeded the pre-set value for a “motor in operation”

(menu 1.2.1.3).

“START-UP FAILURE”

The output signal is activated following six consecutive failed start-up attemp ts.

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 45

Page 46

English

MALFUNCTION”

Colour of the LED

Buzzer

“GENERAL

“RISK OF FAILURE”

“NON-AUTO MODE 1/2”

“ON”

“LIVE” green

“MAINS MALFUNCTION” yellow x

“ON” green x

“SYSTEM MALFUNCTION” yellow x x

“START-UP FAILURE” red x x

“CLOGGING MALFUNCTION” red x x

“STARTER MALFUNCTION” red x x

“PRE-HEATING MALFUNCTION” red x x

“OIL PRESSURE MALFUNCTION” red x x

“WATER TANK LEVEL MALFUNCTION” red x x

“LACK OF MOTOR WATER MALFUNCTIO N” red x x

“START-UP TANK LEVEL MALFUNCTION” red x x

“WATER TEMPERATURE MALFUNCTION” red x x

“VENT MALFUNCTION” red x

“DIESEL LEVEL MALFUNCTION” red x x

“START-UP FAILURE”

“ROOM TEMPERATURE MALFUNCTIO N” red x

“START-UP ATTEMPT” yellow

“BATTERY LOAD 1/2” green

“BATTERY 1/2 MALFUNCTION” yellow x

“BATTERY CHARGER 1/2 MALFUNCTI ON” yellow x x

“AUTO MODE 1/2” green

“NON-AUTO MODE 1/2” red x

“START-UP VIA PRESSURE SWITCH 1/2” green/yellow

“PRESSURE SWITCH LINE 1/2 MALFUNCTION” red x x

Table 4: Malfunctio n signals and run signals

Warning! Danger of electric shock!

There is a potentially fatal voltage on these terminals, even when the main switch is turned

off.

WILO SE 11/2016 46

Page 47

8 Commissioning

WARNING! Risk of fatal injury!

Commissioning by qualified personnel only!

Improper commissioning poses a risk of fatal injury.

Have commissioning performed by qualified personnel only.

DANGER! Risk of fatal injury!

When working on an open switchgear, there is a risk of electrocution in the event of contact

with the conductor components.

This work must only be carried out by qualified personnel!

We recommend that you have the switchgear commissioned by Wilo customer service.

Before switching on for the first time, the on-site wiring must be checked, in particular the earthing.

Tighten all connection terminals prior to commissioning!

English

8.1 Factory setting

The control is pre-set at the factory.

The factory setting can be restored by Wilo customer service.

8.2 Rotation speed correction control

The motor rotation speed is fixed at the factory. To check it, the motor is to be started up by a manual function.

Once the motor is running, increase the rotation speed by means of a portable tachometer and compare it to

the rotation speed displayed on the screen. If the two rotation speeds match, no correction is required.

In case of significant difference, a further correction must be carried out. To do this, proceed as follows. Set the

motor at a constant and known rotation speed. Enter this value in the menu 1.2.1.1 and confirm. Move on to the

following menu item. In the menu 1.2.1.2, modify the setting by selecting “Start”, then confirm. Once the

correction is performed, the message “Finished” is displayed on the screen. The rotation speed correction was

successful and has been recorded. The motor can be switched off with the “OFF” button if at least one of the

key switches is in the “0” position.

8.3 Rotation speed correction control

Commissioning at the place of installation requires the automatic device test of the diesel motor start-up. To do

this, the fuel supply must be interrupted. In the menu 5.9.1.0, set “Start”, then confirm. Then push the button

“CLEAR FAULT” (Fig. 2, pos. 20) in the following 10 seconds. 6 automatic start-up attempts thus take place.

After 6 start-up attempts, the yellow LED (Fig. 2, pos. 22) signifies a failed start-up. The fuel supply must be

restored and the motor must start up as soon as the button is pushed (Fig. 2, pos. 23).

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 47

Page 48

9 Maintenance

Have maintenance and repair work carried out by qualified skilled personnel only!

DANGER! Risk of fatal injury!

There is a risk of fatal injury from electric shock when working on electrical equipment.

• The switchgear should be electrically isolated and secured against unauthorised switch-

on during any maintenance or repair work.

• Any damage to the connection cable should only ever be eradicated by a qualified

electrician.

• The switchgear must remain clean.

• Visual inspection of the electrical components of the system in the switchgear.

10 Malfunctions, causes and remedies

English

DANGER! Risk of fatal injury!

There is a risk of fatal injury from electric shock when working on electrical equipment.

Have malfunctions remedied by qualified skilled personnel only! Observe the safety

instructions under Fehler! Verweisquelle konnte nicht gefunden werden.

Before performing any work to remedy malfunctions, disconnect the unit from the power

supply, and make sure it cannot be switched back on by unauthorised persons.

10.1 Malfunction indication

When a malfunction is observed, the corresponding LED malfunction indicator turns on, the contact of the

corresponding malfunction signal is activated and the malfunction is displayed on the LCD (malfunction code

number). An additional buzzer sounds for certain malfunctions. This alarm can be switched off with the button

“BUZZER OFF” (Fig. 2, pos. 18) (level of access 1 required).

It is possible to clear the malfunction by pushing the button “CLEAR FAULT” (Fig. 2, pos. 20) (level of access 2

required) or by following the steps described in the menu 6.1.0.0 (level of access 3 required):

WILO SE 11/2016 48

Page 49

English

Code

Fault description

Causes

Remedies

Main switch off

Switch on the main switch

it if necessary

Main switch off

Switch on the main switch

it if necessary

A interrupted

it if necessary

B interrupted

it if necessary

it if necessary

Check charger

required

it if necessary

Check charger

required

switch 1

Check connection

switch 2

Check connection

circuit board

interrupted

battery 1

10.2 Malfunction history

A history which works according to the FIFO (First In First Out) principle has been created for the switchgear.

The memory is configured for 16 malfunctions. The malfunction memory can be called up using

menus 6.1.0.1 – 6.1.1. 6 (level of access 1 req uired).

E04.1 No connection voltage

charger 1

E04.2 No connection voltage

charger 2

Blown fuse

Blown fuse

Check the fuse and replace

Check the fuse and replace

E04.3 No connection voltage

battery 1

E04.4 No connection voltage

battery 2

E04.5 Undervoltage battery 1 Voltage dropped below the

E04.6 Undervoltage battery 2 Voltage dropped below the

E40.1 Malfunction of the

connection to pressure

Connection with the battery

Blown fuse

Connection with the battery

Blown fuse

value set in the menu

5.4.1.0

value set in the menu

5.4.1.0

Cable rupture or shortcircuit

Check connection

Check the fuse and replace

Check connection

Check the fuse and replace

Check battery A and replace

Check the settings in the

menu 5.4.1.0 and correct as

Check battery B and replace

Check the settings in the

menu 5.4.1.0 and correct as

Request customer service

E40.2 Malfunction of the

connection to pressure

E54.0 No bus communication

with the HMI printed

E54.1 No bus communication

with the charger of

battery 1

E54.2 No bus communication

with the charger of

battery 2

E54.3 Incorrect transfer of data

from the charger of

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 49

Cable rupture or shortcircuit

Connection with the HMI

printed circuit board

Connection with charger 1

interrupted

Connection with charger 2

interrupted

Malfunction on the data line Request customer service

Request customer service

Check connection

Request customer service

Check connection

Request customer service

Check connection

Request customer service

Page 50

English

battery 2

interrupted

Software integrity error

Request customer service

level in the storage tank

core

under 10 °C

it if necessary

Request customer service

it if necessary

Request customer service

it if necessary

Request customer service

it if necessary

battery 1

Request customer service

battery 2

Request customer service

minimum

triggered

required

Request customer service

cooling water

Request customer service

Check the starter

Check the fuse

Request customer service

Check the fuse

Request customer service

replace it in necessary

E54.4

Incorrect transfer of data

Malfunction on the data line Request customer service

from the charger of

E54.5 No bus communication

with the printed circuit

Connection with the printed

circuit board of slave control

Check connection

board of slave control

E62.0 Low water level Level below minimum filling

Filling the storage tank

Leakage Check the impermeability of

the storage tank and of the

E64.0 Room temperature

Room not heated Heat the room

E100.1 Battery 1 malfunction Battery 1 defective Check battery 1 and replace

E100.2 Battery 2 malfunction Battery 2 defective Check battery 2 and replace

E105.1 Short-circuit battery 1 Batt er y 1 defective Check battery 1 and replace

E105.2 Short-circuit battery 2 Batt er y 2 defective Check battery 2 and replace

E106.1 Cable rupture battery 1 Connection with battery 1

Check the connection of

interrupted

E106.2 Cable rupture battery 2 Connection with battery 2

Check the connection of

interrupted

E130.0 Insufficient fuel Fuel level lower than the

E131.0 Heating malfunction The heating thermostat is

E132.0 Low oil pressure The oil pressure switch is

Add fuel

Check heating

Check the oil level and fill it if

triggered

E133.0 Excessive motor

temperature

E134.0 Pinion of the non-

engaged star ter

The motor thermostat is

triggered

No response from starter

pinion

Check the level of the

E135.0 Pinion circuit interrupted No response from starter

pinion

E136.0 Start-up failure 6 failed start-up attempts Request customer service

E137.0 Belt rupture No alternator voltage Check the V-belt and

WILO SE 11/2016 50

Page 51

Request customer service

the cooling water system

diesel motor start-up

the aeration valves

aeration valves

English

E138.0 Insufficient cooling water Leakage in the cooling

water system

E139.0 Clogged filter of the

cooling water system

E150.0 Aeration valve

malfunction

If you cannot manage to eliminate a malfunction, please contact Wilo customer service or its nearest

representative.

Contaminated cooling water Eliminate clogging

The aeration valves have

not opened in the

10 seconds following the

Malfunction of the signal

allowing outlet opening of

Add the cooling water

Check the impermeability of

Clean the filter

Request customer service

Check the operation of the

aeration valves

Check the signal allowing

outlet opening of the

11 Spare parts

Spare parts may be ordered via a local specialist retailer and/or Wilo customer service. To avoid queries and

incorrect orders, all data on the rating plate should be submitted with each order.

Subject to change without prior notice

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 51

Page 52

12 Annexes

Standby consumption without

230 V AC power supply

Wiring

designation

7K2

BC6-22-00, 24 V DC

8G1

Signal converter SC-Fire

15 mA under 12.6 V DC

11G1

Signal converter SC-Fire

15 mA under 12.6 V DC

0.19 W

0.19 W

2U1

CPU SC-Fire ED

390 mA under 24 V DC

9.36 W

9.36 W

2U2

CPU SC-Fire ED

390 mA under 24 V DC

9.36 W

9.36 W

10K1

2xUM, 24 V DC, 240 V AC, 6 A

10K2

2xUM, 24 V DC, 240 V AC, 6 A

10K3

2xUM, 24 V DC, 240 V AC, 6 A

10K4

2xUM, 24 V DC, 240 V AC, 6 A

10K5

2xUM, 24 V DC, 240 V AC, 6 A

10K6

2xUM, 24 V DC, 240 V AC, 6 A

10H1

Buzzer 24 V DC

0.008 A under 24 V DC

10K7

BC6-30-10, 24 VDC

3.50 W

3.50 W

14P1

199.9 V

14P2

19.99 V

15P1

06000002, 12 V, Ø 56 mm

2.00 W

2.00 W

15P2

Ø 56 mm

15P3

06000006, 0 – 8 bar, 12 V,

Ø 56 mm

15P4

12 V, Ø 90.5 mm

Total:

(29 W)

supply 230 V

h = 72 h

Time required for independent operation

on 2 batteries

on 2 batteries

2 x 111 Ah

2 x 56 Ah

under 12 V

under 24 V

𝐼 =

37𝑊

𝑄 =

12𝑉

∗ 72ℎ = 222𝐴ℎ

𝐼 =

37𝑊

𝑄 =

24𝑉

∗ 72ℎ = 111𝐴ℎ

Calculation of battery capacity

English

diagram

Component designation Measurement

2xUM, 12 V DC, 240 V AC, 6 A

2xUM, 12 V DC, 240 V AC, 6 A

2xUM, 12 V DC, 240 V AC, 6 A

2xUM, 12 V DC, 240 V AC, 6 A

2xUM, 12 V DC, 240 V AC, 6 A

2xUM, 12 V DC, 240 V AC, 6 A

Buzzer 12 V DC

LCD panel meter, EX2071, 0 –

0.019 A under 12 V DC

Consumption

(under 12 V)

3.50 W 3.50 W

0.19 W 0.19 W

0.40 W 0.40 W

0.40 W 0.40 W

0.40 W 0.40 W

0.40 W 0.40 W

0.40 W 0.40 W

0.40 W 0.40 W

0.23 W 0.19 W

0.04 W 0.08 W

Consumption

(under 24 V)

LCD panel meter, EX2070, 0 –

06000003, 40 – 120 °C, 12 V,

P = 28 W

U = 12 V

(24 V DC) Battery voltage

Consumption without power

0.04 W 0.08 W

2.00 W 2.00 W

2.00 W 2.00 W

2.00 W 2.00 W

37 W 37 W

37𝑊

12𝑉

222 Ah required

37𝑊

111 Ah required

24𝑉

WILO SE 11/2016 52

Page 53

Details of the diesel cabinet terminal blocks

block no.

no.

Designation

Signal type

X0 1

2

X1 1

2

X4 1

2

3

4

5

6

7

8

10

malfunction

temperature is too high)

11

AI (Pressure sensor with resistor,

12

13

14

15

AI (Temperature sensor with resistor,

16

17

18

Motor speed (used by the

tachometer)

20

21

22

23

24

25

26

27

28

Terminal

Terminal

English

9

Connection voltage

cabinet

Diesel oil pre-heating Power supply performance (230 V, max 10 A)

Pressure switch 1 DI

Pressure switch 2 DI

Fuel malfunction

Pre-heating diesel

malfunction

Motor oil malfunction

Motor temperature

Power supply performance (230 V)

DI (Float switch, contact closed when the ta nk

level is lo w , i.e. malfunction)

DI (Thermostat, contact closed when operation

OK)

DI (Pressure switch, ground contact when low

pressure malfunctio n)

DI (Thermostat, ground contact when the

19

Motor oil pressure

Cooling liquid temperature

Motor oil temperature

External water

temperature

controller but not for the

Cooling water malfunction DI (F loat switch, closed in case of low leve l)

Motor cooling line filter

malfunction

Aeration vent malfunction DI (position contact, closed if the vents are open)

270…30 Ω ≙ 0…8 bars)

AI (Temperature sensor with resistor,

1805…110 Ω ≙ 10…90 °C)

1805…43 Ω ≙ 10…130 °C)

AI (Temperature sensor with resistor,

1805…110 Ω ≙ 10…90 °C)

AI (Frequency sensor, 0…10 kHz)

DI (Differential pressure sensor, closed if the filter

is not clogged)

Technical room

temperature malfunction

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 53

DI (Thermostat, open when the temperature is

too low)

Page 54

English

29

30

31

32

33

34

8 V when the wire is cut or H S f use)

36

Belt malfunction

DI (Motor signal, signal 12/24 V DC when the belt

is OK)

37

38

39

40

Motor speed (only for the

the cabinet)

42

X7 1

2

3

4

5

6

7

8

9

10

11

12

13

15

16

17

18

19

20

21

22

23

35

41

Pump pressure switch in

demand

Start-up tank malfunction DI (Float switch, contact closed a t low leve l)

Water tank malfunction DI (Float switch, contact closed at low leve l)

Diesel motor pinion

malfunction

Valve status of bypass

filter line of cooling

Fuel level AI (Resistor level sensor)

countdown on the front of

DI (Pressure switch, contact closed when the

pump is running)

DI (Starter signal, 12/24 V DC when the pinion is

engaged, 0 V when the pinion is not engaged and

DI (signal when the v alve is open)

AI (Alternator signal of the diesel motor)

14

General malfunction

(2 contacts no/nc)

Pump running

(2 contacts no/nc)

Start-up failed

(2 contacts no/nc)

Risk o f failure

(2 contacts no/nc)

Automatic mode

deactivated on battery 1

(2 contacts no/nc)

DO (NO)

DO (NC)

DO (NO)

DO (NC)

DO (NO)

DO (NC)

DO (NO)

DO (NC)

DO (NO)

DO (NC)

Automatic mode

deactivated on battery 2

(2 contacts no/nc)

WILO SE 11/2016 54

DO (NO)

DO (NC)

Page 55

English

24

25

Motor active

DO (12/24 V DC signal during die sel mo tor

operation)

26

27

28

29

30

X8 1

2

X10

1 Battery 1

Input performance (positive pole of battery 1,

in 12 or 24 V DC)

2 Battery 2

Input performance (positive pole of battery 2,

in 12 or 24 V DC)

3 Starter performance

diesel starter, in 12 or 24 V DC)

4

5

6

(auxiliary)

coil, in 12 or 24 V DC)

7

8

generator and switchgear during pump opera tion)

Motor fan active

Bypass valve of the

cooling filter

RS485 Modbus or Bacnet Connection of communication b us

GND

Operation relay starter

DO (contact NO, closed when the diesel motor is

running)

DO (contact NO in terminals 28-30, contact NC in

terminals 29-30)

Performanc e ou tp u t (starting current for the

Ground connection of the batteries and diese l

motor

Auxiliary voltage output (operation o f the relay

9

Electric switch off of the

diesel motor

Load current (alternator)

Control voltage output (for the electric shut-off

device, in 12 or 24 V DC)

Performance input (load current between the

Installation and operating instructions: Wilo-SC-Fire Diesel A2P 55

Page 56

External connection of the diesel cabinet

Pressure switch no. 1

Pressure switch no. 2

Low fu el level malfunction

Pre-heating malfunction

English

Digita l input

Low oil pressure malfunction

Overheating motor cooling water

malfunction

Low level of cooling liquid malfunction

Detection of clogged filter cooling wate r

Vent malfunction

Technical room low temperature

malfunction

Bypass valve of the cooling filter

Pressure switch “pump in demand”

Low level start-up tank malfunction -

float switch

Low water level

Start-up pinion malfunction

Diesel cabinet

Analogue inputs

Activated outputs

V-belt rupture

Oil pressure

Cooling liquid temperature

Oil temperature

External water temperature

Fuel level

Motor rotation speed (sensor)

Motor rotation speed (alternator)

Motor activated

Cooling bypass valve

WILO SE 11/2016 56

Page 57

English

Potential-free

contact (NO)

Communication bus RS485 Modbus or Bacnet

Potential-free

contact (NO/NC)

Power supply input

performance

Fan motor active

General malfunction

Pump running

Start-up failed

Risk of error

Automatic stop 1

Automatic stop 2

Connection voltage 230 V AC

Battery 1

Battery 2

Load current of the diesel motor

Oil pre-heating

Output

performance

Mass GND

Starter - Starting current

Starter - Auxiliary voltage