Page 1

Pioneering for You

Wilo-Control ESK, PSK

de Einbau- und Betriebsanleitung

en Installation and operating instructions

fr Notice de montage et de mise en service

Instrucciones de instalación y funcionamiento

es

2 543 184-Ed.01 / 2015-12-Wilo

it

Istruzioni di montaggio, uso e manutenzione

ru Инструкцияпомонтажуиэксплуатации

Page 2

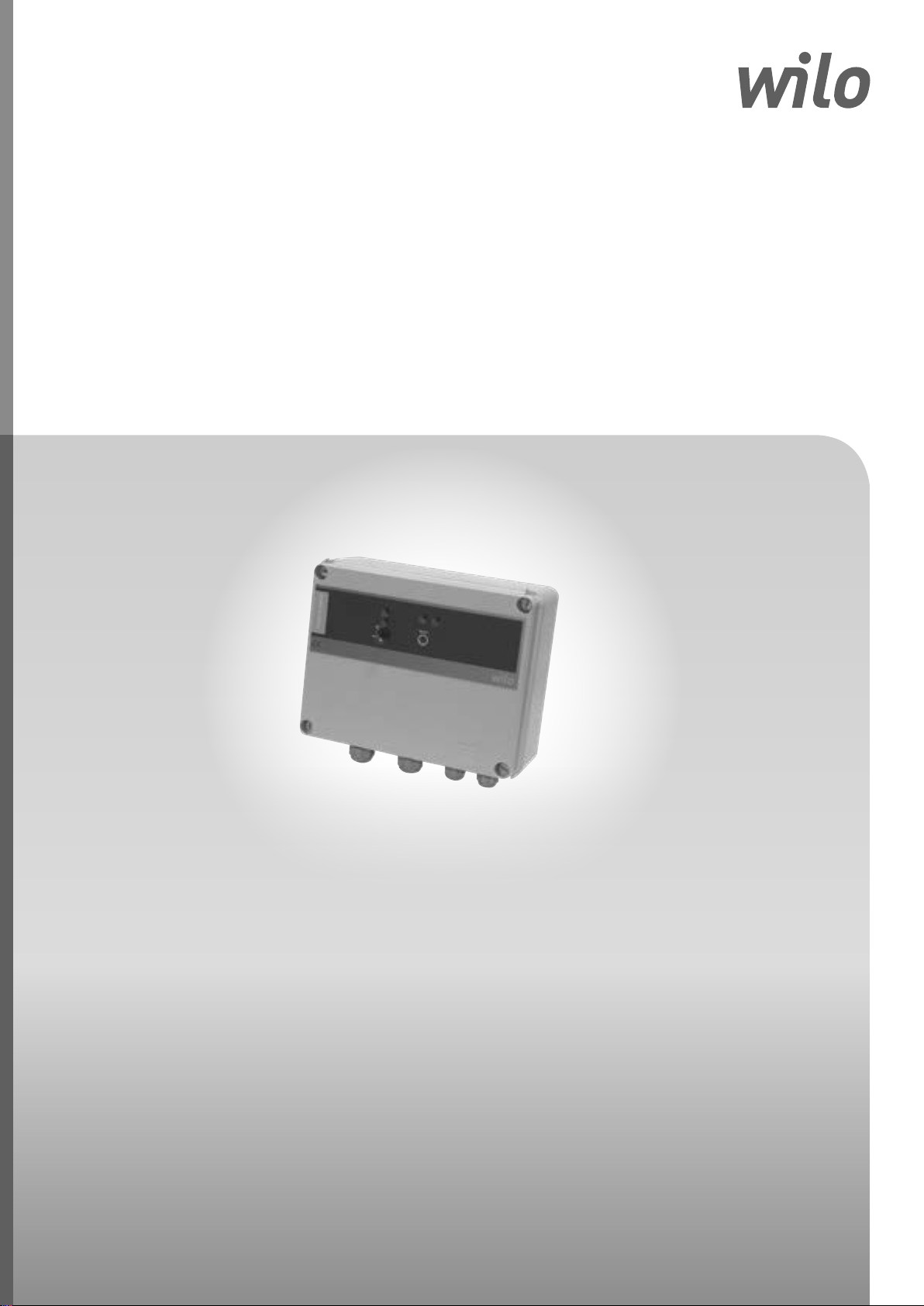

Fig. 1:

Fig. 2:

Page 3

Fig. 3:

Page 4

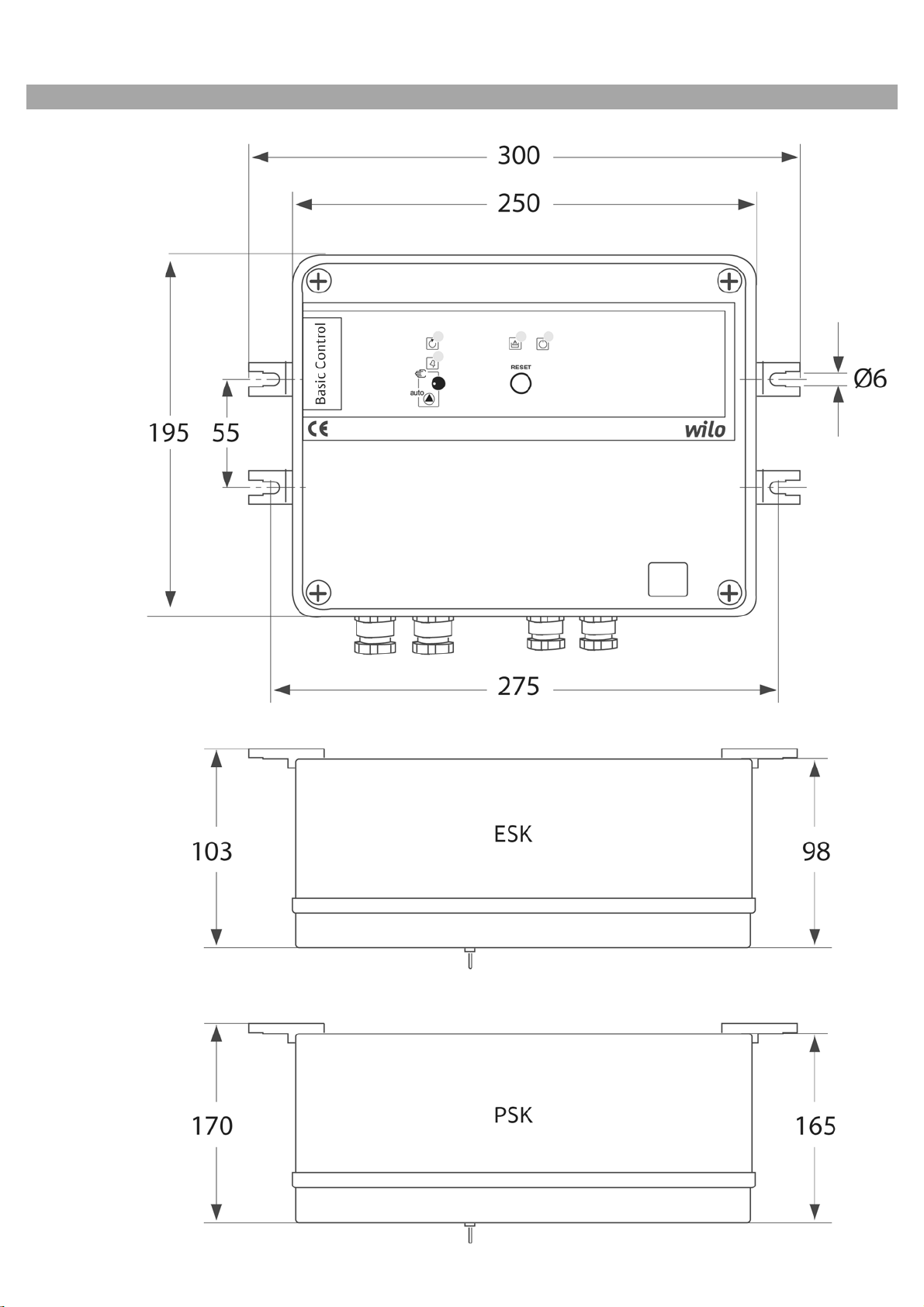

Fig. 4a: Fig. 4b: Fig. 4c:

Fig. 4d: Fig. 4e:

Fig. 4f:

Page 5

English

1 General ..................................................................................................................................................11

2 Safety.....................................................................................................................................................11

2.1 Symbols and signal words in the operating instructions ................................................................................11

2.2 Personnel qualifications.......................................................................................................................................11

2.3 Danger in the event of non-observance of the safety instructions ..............................................................11

2.4 Safety consciousness on the job ........................................................................................................................ 11

2.5 Safety instructions for the operator .................................................................................................................12

2.6 Safety instructions for installation and maintenance work ...........................................................................12

2.7 Unauthorised modification and manufacture of spare parts ..........................................................................12

2.8 Improper use ........................................................................................................................................................12

3 Transport and interim storage ...........................................................................................................12

4 Intended use .........................................................................................................................................12

5 Product information ..........................................................................................................................13

5.1 Technical data ....................................................................................................................................................13

5.2 Scope of delivery .................................................................................................................................................. 13

5.3 Accessories (optional) .........................................................................................................................................13

6 Description ...........................................................................................................................................13

6.1 Front side of the switchgear ..............................................................................................................................13

6.2 Single components in the housing ................................................................................................................... 13

7 Installation and electrical connection ...............................................................................................14

7.1 Installation ............................................................................................................................................................14

7.2 Electrical connection ...........................................................................................................................................14

7.2.1 Connection of the pump engine .........................................................................................................................14

7.2.2 Connection of external elements ......................................................................................................................14

7.2.3 Mains connection .................................................................................................................................................14

8 Commissioning .....................................................................................................................................14

8.1 Selecting the operating mode ............................................................................................................................14

8.2 Settings and tests ................................................................................................................................................14

8.2.1 Overload protection ............................................................................................................................................14

8.2.2 Check direction of rotation (3-phase motor only) ..........................................................................................15

8.3 Selecting the operating mode ............................................................................................................................15

8.3.1 Installation with two electrodes ........................................................................................................................ 15

8.3.2 Installation with one electrode ..........................................................................................................................15

8.3.3 Installation with flow meter ...............................................................................................................................15

8.3.4 Pumping operation ..............................................................................................................................................15

8.3.5 Pressure boosting................................................................................................................................................. 16

9 Maintenance..........................................................................................................................................16

10 Faults, causes and remedies................................................................................................................16

11 Spare parts ............................................................................................................................................17

10 WILO SE 12/2015

Page 6

English

1 General information

About this document

The language of the original operating instructions is German. All other language versions are

translations of the original German manual.

These installation and operating instructions are

an integral part of the product. They must be kept

readily available at the place where the product is

installed. Strict adherence to these instructions is

a precondition for the proper use and correct

operation of the product.

These installation and operating instructions correspond to the relevant version of the product and

the underlying safety standards valid at the time

of going to print.

EC declaration of conformity:

A copy of the EC declaration of conformity is a

component of these operating instructions.

If a technical modification is made on the designs

named there without our agreement or the declarations made in the installation and operating

instructions on product/personnel safety are not

observed, this declaration loses its validity.

2Safety

These operating instructions contain basic information which must be adhered to during installation, operation and maintenance. For this reason,

these operating instructions must, without fail, be

read by the service technician and the responsible

specialist/operator before installation and commissioning.

It is not only the general safety instructions listed

under the main point “safety” that must be

adhered to but also the special safety instructions

with danger symbols included under the following

main points.

2.1 Symbols and signal words in the operating

instructions

Symbols:

General danger symbol

CAUTION!

There is a danger of damaging the product/unit.

‘Caution’ implies that damage to the product is

possible if this information is disregarded.

NOTE:

Useful information on handling the product. It

draws attention to possible problems.

Information that appears directly on the product,

such as:

• Direction of rotation arrow

• Identifiers for connections,

• Rating plate

• Warning sticker

must be strictly complied with and kept in legible

condition.

2.2 Personnel qualifications

The installation, operating and maintenance personnel must have the appropriate qualifications

for this work. Area of responsibility, terms of reference and monitoring of the personnel are to be

ensured by the operator. If the personnel are not in

possession of the necessary knowledge, they are

to be trained and instructed. This can be accomplished if necessary by the manufacturer of the

product at the request of the operator.

2.3 Danger in the event of non-observance of the

safety instructions

Non-observance of the safety instructions can

result in risk of injury to persons and damage to

the environment and the product/unit. Nonobservance of the safety instructions results in

the loss of any claims to damages.

In detail, non-observance can, for example, result

in the following risks:

• Danger to persons from electrical, mechanical and

bacteriological influences,

• Damage to the environment due to leakage of

hazardous materials

• Property damage

• Failure of important product/unit functions

• Failure of required maintenance and repair

procedures

Danger due to electrical voltage

NOTE

Signal words:

DANGER!

Acutely dangerous situation.

Non-observance results in death or the most

serious of injuries.

WARNING!

The user can suffer (serious) injuries. ‘Warning’

implies that (serious) injury to persons is probable if this information is disregarded.

Installation and operating instructions Wilo-Control ESK1, PSK1 11

2.4 Safety consciousness on the job

The safety instructions included in these installation and operating instructions, the existing

national regulations for accident prevention

together with any internal working, operating and

safety regulations of the operator are to be complied with.

Page 7

English

2.5 Safety instructions for the operator

This appliance is not intended for use by persons

(including children) with reduced physical, sensory

or mental capabilities, or lack of experience and

knowledge, unless they have been given supervision or instruction concerning use of the appliance

by a person responsible for their safety.

Children should be supervised to ensure that they

do not play with the appliance.

• If hot or cold components on the product/the unit

lead to hazards, measures must be taken onsite to

guard them against touching.

• Guards protecting against touching moving components (such as the coupling) must not be

removed whilst the product is in operation.

• Leakages (e.g. from the shaft seals) of hazardous

fluids (which are explosive, toxic or hot) must be

led away so that no danger to persons or to the

environment arises. National statutory provisions

are to be complied with.

• Highly flammable materials are always to be kept

at a safe distance from the product.

• Danger from electrical current must be eliminated.

Local directives or general directives [e.g. IEC, VDE

etc.] and instructions from local energy supply

companies must be adhered to.

2.6 Safety instructions for installation and

maintenance work

The operator must ensure that all installation and

maintenance work is carried out by authorised and

qualified personnel, who are sufficiently informed

from their own detailed study of the operating

instructions.

Work on the product/unit must only be carried out

when at a standstill. It is mandatory that the procedure described in the installation and operating

instructions for shutting down the product/unit

be complied with.

Immediately on conclusion of the work, all safety

and protective devices must be put back in position and/or recommissioned.

2.8 Improper use

The operating safety of the supplied product is

only guaranteed for conventional use in accordance with Section 4 of the operating instructions.

The limit values must on no account fall under

or exceed those specified in the catalogue/

data sheet.

3 Transport and interim storage

Immediately after receiving the product:

• Check the product for transport damage.

• In the event of damage in transit, take the necessary steps with the forwarding agent within the

respective time limits.

CAUTION! Risk of property damage!

Incorrect transport and interim storage can

cause damage to the product.

• The switchgear is to be protected against moisture and mechanical damage.

• It must not be exposed to temperatures outside

the range of -10 °C to +55 °C.

4 Intended use

Switchgear for use as an

• automatic control of single pumps

• Water level control

• Overload protection

• Dry-running protection

Fields of application using electrodes, float

switches and pressure switches.

No other devices for other purposes may be

installed in the switchgear.

Intended use includes compliance with this

manual.

Any other use is regarded as improper use.

2.7 Unauthorised modification and manufacture of

spare parts

Unauthorised modification and manufacture of

spare parts will impair the safety of the product/

personnel and will make void the manufacturer’s

declarations regarding safety.

Modifications to the product are only permissible

after consultation with the manufacturer. Original

spare parts and accessories authorised by the

manufacturer ensure safety. The use of other

parts will absolve us of liability for consequential

events.

12 WILO SE 12/2015

Page 8

5 Product information

5.1 Technical data

Mains supply voltages

Max. current consumption

Wilo-Control

— ESK1:

— PSK1:

Protection class:

Mains fuses

Control (230/400 V):

Low-voltage component:

Ambient temperature: -10 to +55 °C

1~ 230 V, 50/60 Hz

3~ 230 V, 50/60 Hz

3~ 400 V, 50/60 Hz

1-12 A

10-23 A

IP 54

0.1 A

0.8 A

English

5.2 Scope of delivery

• Switchgear

• Installation and operating instructions

• 2 electrodes

• 4 holders for installation of the switchgear

• Plastic clips and ribbons for the mounting of a

capacitor in the cover of the switchgear

(for version 1~230 V)

Item Element Function

1 Signal lamp - green lights up continuously when mains voltage is available

2 Signal lamp - yellow

Depends on the selected operating mode:

– Displays “low water status”

– Lower level reached

3 Signal lamp - red

Pump fault

4 Signal lamp - green

Pump in operation

5 Three-way switch

Operating mode

6 Pushbutton Resets the thermal overload protection

lights up continuously when the electrodes are triggered

lights up continuously when the pump is stopped due to an error.

lights up permanently while the pump is running

Selecting the operating mode:

AUTO Automatic operation with all safety functions,

0Off

MANU button function

5.3 Accessories (optional)

• Connection cable for electrodes

• External displays (clock, pressure gauge, etc.)

• Direction-of-rotation sensor

6Description

6.1 Front of the switchgear (Fig. 1)

electronic motor protection, low-water protection

6.2 Single components in the housing (Fig. 2)

Item Element

1 Thermo-magnetic circuit breaker

2 12 V transformer for low voltage part

3 Motor protection

4 Terminal strip for external sensors (electrode, pressure switch, float switch, external control)

5 Earth contact

6 Variable adjustment of rated motor power in accordance with pump motor rating plate

7 Variable adjustment of electrode sensitivity to the hardness of the water

8 Variable adjustment of time delay for “low water status” display

9 Variable adjustment of time delay for pressure switch/flow meter

10 Fuse (0.1 A) for pre-selected voltage in accordance with pump motor rating plate

11 Protection class selector switch for low water protection

12 On/off switch for time delay when using pressure switch or flow meter

13 Connector for control panel circuit board

14 Fuse holder low voltage fuse (0.8 A)

Installation and operating instructions Wilo-Control ESK1, PSK1 13

Page 9

English

7 Installation and electrical connection

7.1 Installation

Wall-mounted installation: Dimensions, see Fig. 3

7.2 Electrical connection (Fig. 4a-f)

DANGER! Risk of fatal injury!

When working on the open switchgear, there is

a danger of electric shock from touching the live

components.

Have the electrical connection established by an

electrician approved by the local electricity supply company only and in accordance with applicable regulations.

The current and voltage of the mains connection

must correspond to the details on the rating

plate of the pump to be connected / of the

motor.

• Adhere to regulations for accident prevention!

• Earth the pump/installation in accordance with

the regulations.

• Mains connection cable for three-phase:

4 x 1.5 mm², for single-phase: 3 x 1.5 mm².

• Remove the case cover.

• 0.1 A Insert fuse into the corresponding holders for

the used voltage: 230 V or 400 V (Fig. 2, item 10).

7.2.1 Connection of the pump motor (Fig. 2)

DANGER! Risk of fatal injury!

Poor earthing can lead to electric shock.

• Connect the earthing cable with the terminal

strip (Fig. 2, item 5)

7.2.3 Mains connection

DANGER! Risk of fatal injury!

Poor earthing can lead to electric shock.

• Connect the earthing cable with the terminal

strip (Fig. 2, item 5)

Three-phase 400 V (230 V):

Four-core cable (3 phases + earth) Ø 1.5 mm

terminals R-S-T.

Single-phase 230 V:

Three-core cable (1 phase + neutral + earth)

Ø 1.5 mm

2

to terminals L-N.

8 Commissioning

CAUTION! Risk of malfunctions!

If power consumption falls below 1 A during

operation, (idling power), reset the device by

pressing the 'RESET' button (Fig. 1, item 6).

8.1 Selecting the operating mode

A 3-way selector switch (button) is used to select

the operating mode on the front of the switchgear

(Fig. 1; item 5):

“MANU” (button) position: the system is manually controlled, regardless of the level setting or

external control components.

Position “0”: the pump cannot operate. It remains

deactivated in all circumstances.

Position “AUTO”: the pump operates automatically based on the selected system.

8.2 Settings and tests

2

to

Three-phase 400 V:

Four-core cable (3 phases + earth) on contact

(item 3) to terminals 2-4-6

Single-phase 230 V:

Three-core cable (1 phase + neutral + earth) on

contact (item 3) to terminals 2-4

7.2.2 Connect external elements

DANGER! Risk of fatal injury!

Poor earthing can lead to electric shock.

• Connect the earthing cable with the terminal

strip (Fig. 2, item 5)

• Do not connect an external voltage to terminal

strip (Fig. 2, item 4).

It is possible to perform remote control using an

external control element (pressure switch, control, level control, etc.). Connection via a two-core

cable Ø 0.75 mm

2

to the terminals 5 + 6 of the terminal strip (see Fig. 2; item 4); beforehand,

remove the bridge between terminals 5 + 6.

Connect the cable to the terminal strip based on

the intended application (see Fig. 2, item 4 and

Fig. 4;. see Chapter 6.3).

8.2.1 Overload protection

DANGER! Risk of fatal injury!

Make all settings when the pump is deactivated.

• Set the potentiometer (Fig. 2, item 6) to the rated

motor power specified on the rating plate (or for

submersible pumps, on the equipment label near

the switchgear).

• Set three-way switch (Fig. 1, item 5) to 'AUTO' the green signal lamp lights up and the pump

starts.

If the fault light comes on within 3 minutes, the

rated power is set too low.

• Before changing settings, check the motor

power consumption and the connections.

• Reset the rated power based on the determined

values.

14 WILO SE 12/2015

Page 10

English

8.2.2 Check direction of rotation

(3-phase motor only)

Keep three-way switch (Fig. 1, item 5) at the position 'MANU' (the 'Mains voltage' signal lamp lights

up). When there is a signal (float switch, electrode,

etc.), the pump starts.

For direction-of-rotation control, follow the

instructions for commissioning the pump.

If the direction of rotation is incorrect:

• Switch off the plant

• Switch two phases in the switchgear.

8.3 Selecting the operating mode

Depending on the application, an operating mode

must be set.

8.3.1 Installation with two electrodes (Fig. 4a)

• Select low-water protection (Fig. 2, item 11)

• Configure the sensitivity of the electrodes

Before the pump is started, set the water conductivity potentiometer (Fig. 2, item 7) to the minimum value.

Make sure that the electrodes are immersed and

the three-way switch (Fig. 1, item 5) is set to position 'AUTO'. Slowly turn the potentiometer (Fig. 2,

item 7) clockwise until the pump starts.

• Applying the electrodes

(see the pump operating instructions)

NOTE:

The lower electrode reports low water. The upper

electrode must be immersed in order to reset this

error.

8.3.2 Installation with one electrode (Fig. 4b)

CAUTION! Risk of malfunctions!

Select low-water protection (Fig. 2, item 11)!

• Configure the sensitivity of the electrode

Before the pump is started, set the water hardness

potentiometer (Fig. 2, item 7) to the minimum

value.

Make sure that the electrodes are immersed and

the three-way switch (Fig. 1, item 5) is set to position 'AUTO'. Slowly turn the potentiometer (Fig. 2,

item 7) clockwise until the yellow signal lamp

(Fig. 1, item 2) starts to flash.

• Set the time delay before restarting

After stopping due to low water, the pump will

start with a delay (1 to 30 minutes).

The delay is preset in the potentiometer (Fig. 2,

item 8).

During the waiting period, the yellow signal lamp

flashes (Fig. 1, item 2).

• Applying the electrode

(see the pump operating instructions)

8.3.3 Installation with flow meter (Fig. 4c)

CAUTION! Risk of malfunctions!

Set water hardness potentiometer to its maximum value (Fig. 2, item 7)!

• Select low-water protection (Fig. 2, item 11).

• Set the time delay before restarting

After stopping due to low flow rates, the pump will

start with a delay (1 to 30 minutes). This delay

allows for sufficient filling of the water tank

before a restart.

The delay is preset in the potentiometer (Fig. 2,

item 8).

During the waiting period, the yellow signal lamp

flashes (Fig. 1, item 2).

• Configure the time delay before a restart (Fig. 2,

item 9)

To provide the flow meter with enough time to

record a sufficient flow rate, a minimum period

operating time (5 seconds to 3 minutes) is configured for the pump. If the flow meter has not been

activated after this time has elapsed, the pump

will stop.

• Activating the time delay functions

(Fig. 2, item 12)

“AUT” position:

Both delays are active

“MAN” position:

The restart is triggered by pressing the 'Reset'

button (Fig. 1, item 6).

CAUTION! Risk of malfunctions!

Make sure that the bridge between terminals 5 + 6

on the terminal strip (Fig. 2, item 4) is correctly

positioned.

8.3.4 Pumping operation

CAUTION! Risk of malfunctions!

Set water conductivity potentiometer to its

maximum value (Fig. 2, item 7)!

Operation with one float switch (Fig. 4d)

• Select low-water protection (Fig. 2, item 11).

In this position, the float switch is connected to

terminals 5 + 6 of the terminal strip (Fig. 2, item 4).

• Connect a protection switch (as dry running protection) to terminals 1 + 3 of the terminal strip.

• Set the time delay before restarting

After stopping due to low water, the pump will

start with a delay (1 to 30 minutes).

The delay is preset in the potentiometer (Fig. 2,

item 8).

During the waiting period, the yellow signal lamp

flashes (Fig. 1, item 2).

Installation and operating instructions Wilo-Control ESK1, PSK1 15

Page 11

English

Operation with two float switches (Fig. 4e)

• Select low-water protection (Fig. 2, item 11).

In this position, the device only activates the

pump and the yellow signal lamp (Fig. 1, item 2)

displays the filling phase.

CAUTION! Risk of malfunctions!

Make sure that the bridge between terminals 5 + 6

on the terminal strip (Fig. 2, item 4) is correctly

positioned.

8.3.5 Pressure boosting (Fig. 4f)

CAUTION! Risk of malfunctions!

Set water hardness potentiometer to its

maximum value (Fig. 2, item 7)!

Float switch in the tank + pressure switch

• Select low-water protection (Fig. 2, item 11).

In this position, the pressure switch is connected

to terminals 5 + 6 of the terminal strip (Fig. 2,

item 4).

• Set the time delay before restarting

After stopping due to low water, the pump will

start with a delay (1 to 30 minutes).

The delay is preset in the potentiometer (Fig. 2,

item 8).

During the waiting period, the yellow signal lamp

flashes (Fig. 1, item 2).

Pressure switch in the inlet pipe + pressure

switch

• Select low-water protection (Fig. 2, item 11).

In this position, the pressure switch is connected to

terminals 5 + 6 of the terminal strip (Fig. 2, item 4).

• Set the time delay before restarting

After stopping due to low water, the pump will

start with a delay (1 to 30 minutes).

The delay is preset in the potentiometer (Fig. 2,

item 8).

During the waiting period, the yellow signal lamp

flashes (Fig. 1, item 2).

9 Maintenance

DANGER! Risk of fatal injury!

When working on the open switchgear, there is

a danger of electric shock from touching the live

components.

• Before maintenance and repair work, disconnect

the system from the power supply and make

sure it cannot be switched on by unauthorised

persons.

10 Faults, causes and remedies

Have faults remedied by qualified personnel

only! Follow the safety instructions in

Chapter “Safety”!

Fault Causes Remedy

The pump does not start or constantly

stops working

Pump fault at pump start)

Pump fault

Continuous fault indication

Faulty automation

The pump starts up but the flow rate is

too low

• Faulty mains connection

• The fuse for the pre-selected voltage

(Fig. 2, item 11) has been inserted

incorrectly or is defective

• Operating mode in position '0'

• The circuit for external control has

been interrupted

• No electrodes, float switches or

bridges are connected

• Contactor problem

• Faulty cabling/wiring

• Thermal protection switch (Fig. 2,

item 1) triggered

• Faulty earthing connection

• Exceptionally soft water

• Time delay set to '0'

• The rotation speed is too low

• Incorrect direction of rotation

• Reconnect a mains connection with

the appropriate available voltage.

• Insert fuse into the correct holder. If

necessary, replace the fuse.

• Place the switch (Fig. 1, item 5) into

position 'AUTO'.

• Close the circuit or check for presence

of the bridge (terminals 5 + 6 of the

terminal strip)

• Connect electrodes, float switch or

bridge, depending on the application

(Figs. 4a-f)

• Check relays.

• Check cabling/wiring.

• Check whether the configured rating

matches the rating specified on the

motor rating plate.

• Reset the fault using the “RESET”

switch.

If the fault remains, contact the

Service contact.

• Check the earthing connections and

mass contacts of the pump

• Check setting (see § 6.3.1.1).

• Check the operation and setting of

time delay.

• Check the power supply and motor

connection.

• Switch two phases!

16 WILO SE 12/2015

Page 12

11 Spare parts

All spare parts must be ordered directly from the

Wilo customer service.

To avoid queries and incorrect orders, all data from

the rating plate must be specified with every

order.

The spare parts catalogue can be found at the

following address: www.wilo.com.

Subject to change without prior notice.

English

Installation and operating instructions Wilo-Control ESK1, PSK1 17

Page 13

Page 14

3LRQHHULQJIRU<RX

:,/26(

1RUWNLUFKHQVWUDH

''RUWPXQG

*HUPDQ\

7

)

ZLOR#ZLORFRP

ZZZZLORFRP

Loading...

Loading...