Page 1

CAUTION:

DO NOT

connect this brewer to hot

water. The inlet valve is

not rated for ho

t wa

ter.

FIND OUT MORE

Models Included

MWMGT-10

MWMGT-12

CAUTION:

Please use

this setup procedure

before attempting to use

this brewer. Failure to follow the

instructions

can result in injury or the

voiding of the

warranty.

Important Safeguards/Conventions

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO WWW.WILBURCURTIS.COM

by an authorized Wilbur Curtis service center.

inside. Repair should be done only by authorized service personnel.

•

Keep hands and other items away from hot parts of unit during operation.

Never clean with scouring powders, bleach or harsh implements.

Important Notes/Cautions – from the factory

Sanitation Requirements

Following are the Factory Settings for your Mercury™ GT

• Brew Volume = 3 Gallon, 6 Gallon, 10 Gallon

adjustments to meet your brewing needs, programming instructions are provided later in this

manual.

• Horizontal wall space of 57 inches and vertical clearance of 84 inches.

• Electrical Service: 208 or 240 VAC Three Phase, 3 Wire Plus Ground, 50 Amp.

• Duplex outlet: 115 VAC, 20 Amp, immediate area of installation.

• Water connection: Minimum 3/8” O.D. tube for lengths less than 6¾”. Otherwise 1/2” O.D. tube with gate or ball

shut off valve at the supply pipe. Minimum fl ow rate of 1 GPM.

SYSTEM REQUIREMENTS

SETUP STEPS

2. Mounting holes are provided on both top and lower fl anges of the rear panel, 1/4” or 5/16” lag screws or toggle

bolts may be used depending on the wall structure.

3. It is essential that the Wall Mount unit (MWMGT) be positioned so that the center line of the bottom screw holes are

exactly 33¼” from the fl oor. This measurement is critical and will allow the wall unit to properly mate with the

coffee vessel..

4. Once mounted, the access plate, left side of the machine, must be removed to make the electrical connections.

Remove the four screws attaching the access plate to the wrap. Remove the plate to reveal the wiring connections

to the power block.

5. A qualifi ed electrician should make the electrical connections using #8 wire. The connection block is located on the

left rear of the frame with cable access through the bottom.

manual shut-off valve and a good water fi lter be installed in the water line close to the wall unit.

8. Place the hot water delivery tube assembly on the pipe extending from the top of the wall mounted unit. Press

down, gently guiding the swivel fi tting through the grommet in the top panel and further until it bottoms out.

Wrap the control cable once around the swivel fi tting in the direction of the ¼” O.D. conduit and press the plug

into the receptacle.

9. Mount the coffee vessel over the positioning lugs, located on top of push cart, with the faucet squarely over the

drip tray. Insert the knobbed anchor bolt into the hole underneath the table

top and thread it into the coffee vessel

bottom. Tighten securely.

NOTE:

Some type of wa-

ter fi ltration device must

be used to maintain a

trouble-free operation.

(In areas with extremely hard wa-

ter, we suggest that a sedimentary

and taste & odor fi lter be installed.)

This will prolong the life of your

brewing system and enhance

coffee quality.

approved backfl ow prevention

device may be required between

the brewer

and water supply.

WILBUR CURTIS COMPANY

Page 2

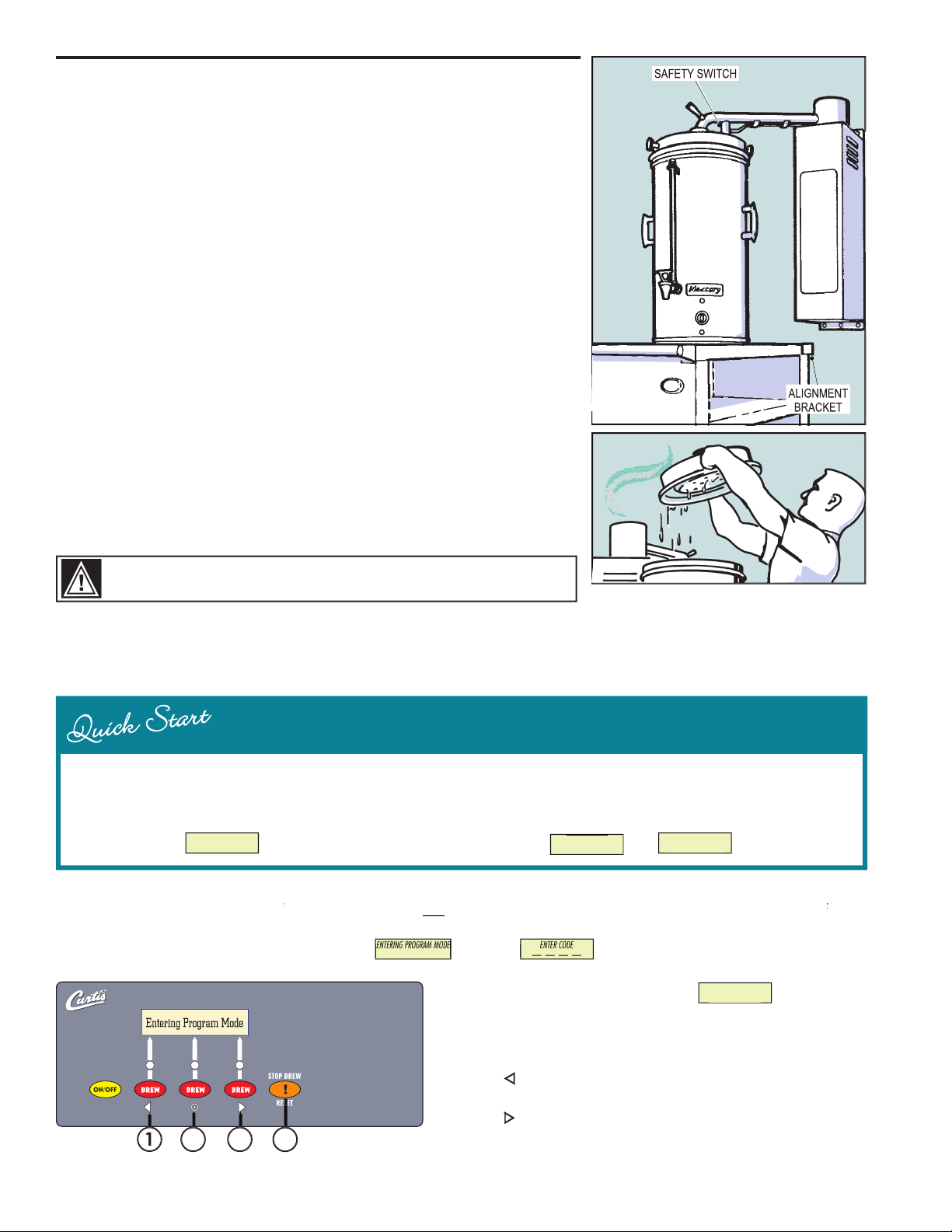

affi xed to the wall, the cart will be aligned to allow for the mating of the wall unit with the

vessel.

2. Nest the fi lter paper into the brew basket and add appropriate ground coffee for the

anticipated brew selection.

3. With the fi lter brew basket in place and with the coffee vessel cover positioned, insert the

hot water delivery tube into the center receptacle of the vessel cover. Make sure the tube

is pushed down into the vessel cover and the safety switch is pushed in by the nut locator

on top of the lid. If the safety switch is not pressed fi rmly by this locator, the wall mount

unit will not operate.

4. Push one of the three selector buttons and after a minute or so, hot water will start to

pour out over the ground coffee.

the dial to around 5. Check occasionally for proper temperature.

unit has now shut do

Remove the fi lter basket and discard the used coffee grounds. Replace the lid.

9. Make sure to unplug the electrical cord before moving the vessel to another location. To maintain the temperature of the coffee, park the

cart by an electrical outlet where the vessel can be plugged in.

BREWING

After connection to water and power; the STANDBY/ON toggle switch must be on. You will hear a beep sound, indicating power is available

to the controller.

3 GL 6 GL 10 GL

READY TO BREW

3 GL 6 GL 10 GL

button (yellow). Press and

hold

STOP BREW/RESET

button (orange) and then press and release

button

3

4

All programming selections are performed with the three center buttons.

Scroll LEFT

SELECTION or ENTER to save new parameter

Scroll RIGHT

Exit

Press

to select, exits program mode and returns unit to o

pera

tion.

2

STOP BREW

button. Display will read , wait until is displayed Enter the 4-digit access code, the digits

ENTER CODE

ENTER CODE

ENTERING PROGRAM MODE

ENTERING PROGRAM MODE

played.

WARNING

HOT LIQUID, Scalding may occur. Avoid splashing.

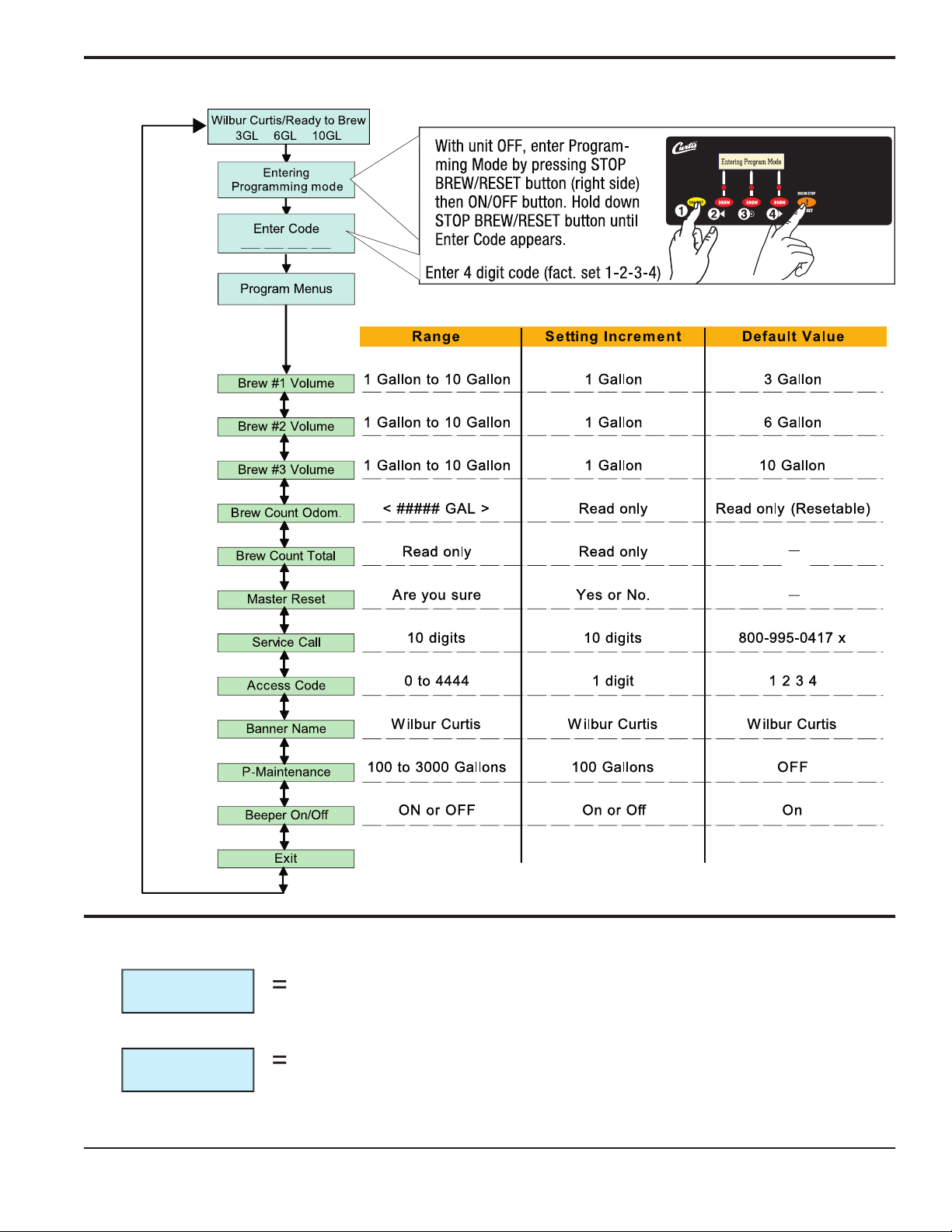

PROGRAM MENUS

< SELECT >

Page 3

3

PROGRAM MENUS

Entering

Programming mo de

Enter Code

Program Menus

SAFETY STOP

VESSEL ERROR

3 GAL

6GAL

charge arm is improperly inserted over the acorn nut protrusion on top of the lid.

offee

Page 4

ILLUSTRATED PARTS LIST

26

27

28

29

30

31

32

33

34

35

36

37

38

394043

45

46

48

49

50

51

KIT, INLET VALV REPAIR

HOT WATER DELIVERY ARM (MWM-10)

PLUG, MALE #05DL-5M MERCURY

HANDLE, SPRAY ARM BLACK PLASTIC

SWITCH, SAFETY WATER DELIVERY ARM W/CAP

FITTING, COLD WATER TANK PLTD

ELBOW, 1/2 x 3/8 FLRE-FPT PLTD

DEFUSER, WATER MWM

PROBE, WATER LEVEL ASSY MWM-10

FITTING, WATER INLET UPPER TANK

ELEMENT, HEATING 5KW 208V MERCURY

NUT, 1-3/8 - 12 HEX UNS PLATED

HOT WTR LIFT TUBE ASSY MWM-10

FITTING, 3/8 X 5/8 HOSE BARB 90

º

HEATING TANK ONLY MWM

FITTING, ASSY OVERFLOW RESERVOIR TANK

DESCRIPTION

2

3

4

5

6

7

8

9

20

22

23

25

LABEL, CAUTION USE ONLY W/MCV

LABEL, BREWING INSTRUCTIONS ENGLISH

LABEL, 208V POWER BLOCK WIRING DIAG.

LABEL, BREWING INSTRUCTIONS SPANISH

LABEL, POWER ON/OFF

LABEL, CAUTION RESET THERMOSTAT

KIT, UCM & LABEL MWMGT

LABEL, UCM PANEL MERCURY

PLUG, FEMALE #57GB-5F MERCURY

POWER BLOCK, 3 STA 175A 600V

SWITCH, TOGGLE NON-LIT DPST

SOCKET, SAFETY CIRC.RELAY MERC

RELAY, SAFETY CIRCUIT MERCURY

DESCRIPTION

PART N

ITEM

Page 5

ILLUSTRATED

PARTS LIST

4

3

2

7

6

5

9

8

24

232226

27

20

25

31

30

29

28

5

Page 6

ILLUSTRATED

PARTS LIST

34

33

50

32

49

37

38

35

36

43

4039454746

44

48

51

CAUTION:

When clean-

ing, DO NOT use pow-

ders, liquids, cleansers, or

any substance containing chlorine.

These products promote corrosion,

cause pitting of stainless steel and

will void the warranty.

Regular cleaning of the Mercury wall mount brewer, Mercury coffee vessel and cart is essential in maintaining the highest standards of

coffee that your equipment is capable of producing.

cleaned with stainless steel polish only, to prevent scratches.

2. On the vessel, clean the water spreader with a detergent solution and scrub well to remove coffee residue. Rinse with and

clear water. Dry with clean cloth.

3. Remove the wire fi lter holder from the vessel and wash both parts with a detergent solution or put these parts through a

dishwasher.

4. Remove the faucet assembly. Unscrew the handle assembly from the faucet and remove. Clean the faucet shank with a

gage glass brush (circular bristle) by pushing the brush through the shank. Using the same brush clean the faucet body inlet

and outlet. Clean the faucet cap and silicone seat cup.

5. After the cleaning, place the parts (water spreader, basket and faucet parts) into a sink to be sanitized.

To sanitize the disassembled parts:

A. Use a clean container to submerge all parts. Wear rubber gloves for protection.

B. Immerse in commerical Bar Tabs/Sani-Tabs sanitizing solution

The solution must be warm (75°F.) Let the parts soak for at least one minute.

6. Thoroughly rinse parts with hot water. Air dry, all parts that were sanitized.

6

Page 7

ELECTRICAL

7

Page 8

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

8/28/06 . 14.5 . ECN 8488 Rev A

Phone: 800/421-6150

Fax: 323-837-2410

Web Site: www.wilburcurtis.com

3

2

Additionally, the Wilbur Curtis Company warrants its Grinding Burrs for Forty (40) months from date of purchase or 40,000 pounds of coffee,

ment parts are warranted for ninety (90) days from date of purchase or for the remainder of the limited warranty period of the equipment in which

the component is installed.

All in-warranty service calls must have prior authorization. For Authorization, call the Technical Support Department at 1-800-995-0417. Effective

date of this policy is April 1, 2003.

Additional conditions may apply. Go to

to view the full product warranty information.

ment parts installed on Curtis equipment that have not been purchased from the

does not cover and is void under the following circumstances:

2) Improper installation of equipment:

This equipment must be installed by a professional technician and must comply with all local electrical,

mechanical and plumbing codes.

3) Improper voltage:

Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply:

re

sponsibility of the equipment owner. The owner is responsible for proper cleaning and regular maintenance of this equipment.

Equipment damaged in transit is the responsibility of the freight company and a claim should be made with the carrier.

Manufacturer is not responsible for variation in

equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s

recommendations.

silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and whipper propellers.

9) Repairs and/or Replacements

are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal

use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner. Charges incurred by

delays, waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner

of the equipment. This includes institutional and correctional facilities. The Wilbur Curtis Company will allow up to 100 miles, round trip, per

in-warranty service call.

RETURN MERCHANDISE AUTHORIZATION:

All claims under this warranty must be submitted to the Wilbur Curtis Company Technical Sup-

port Department prior to performing any repair work or return of this equipment to the factory. All returned equipment must be repackaged

properly in the original carton. No units will be accepted if they are damaged in transit due to improper packaging.

NO UNITS OR PARTS WILL

BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE CARTON OR

All in-warranty service calls must be performed by an authorized service agent. Call the Wilbur Curtis Technical Support

Department to fi nd an agent near you.

Product Warranty Information

8

Loading...

Loading...