Page 1

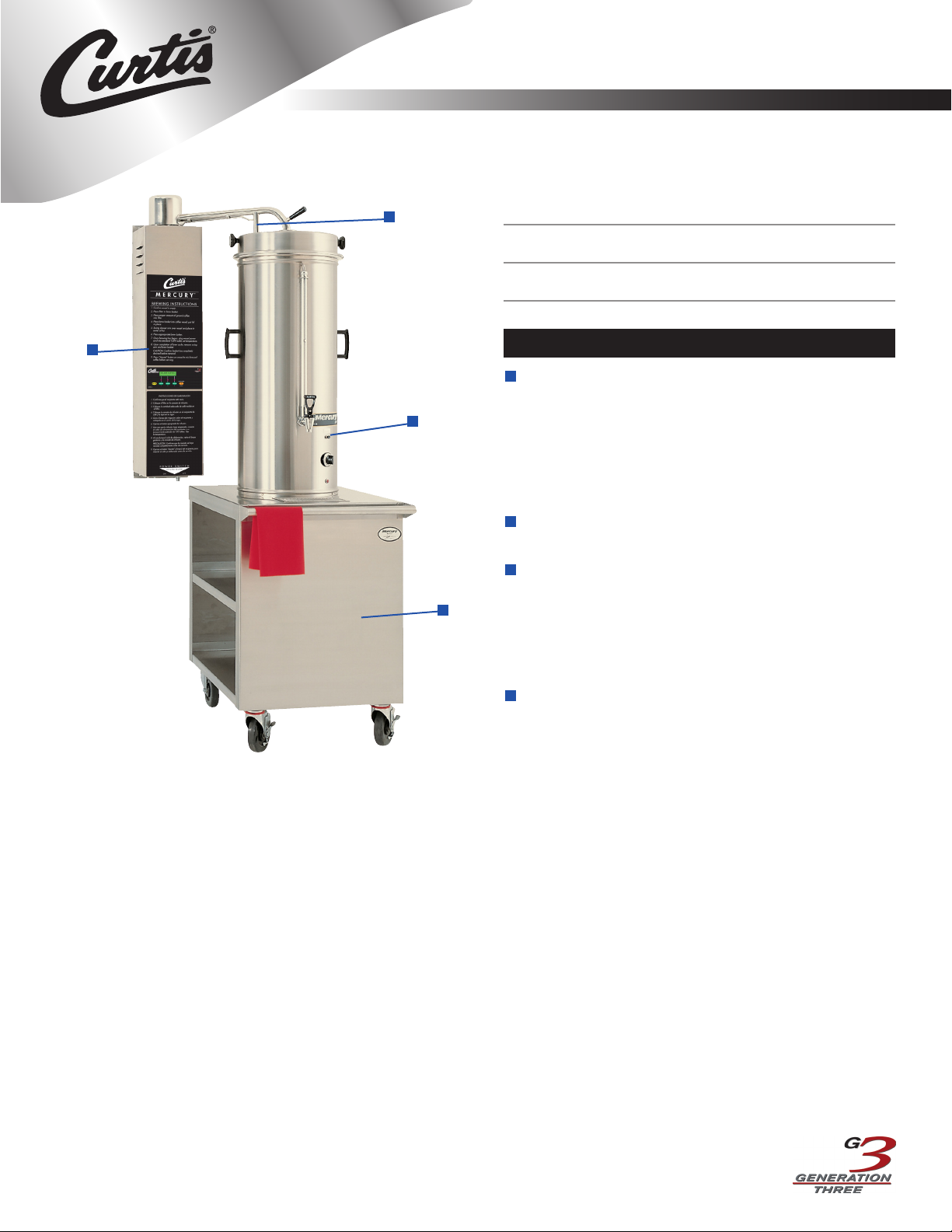

MERCURY HIGH-VOLUME COFFEE BREWING SYSTEM

MODEL: MWMGT

2

ITEM NO

PROJECT

DATE

1

1

High Output Brewing Module with G3 Control

FEATURES AT A GLANCE

— Quickly brews up to ten gallons.

3

— Three separate brew buttons – 3, 6, and 10 gallon brews.

— Digital display provides “scroll-through” programming.

— Easy to use. Simple color coded buttons.

Instructions in English and Spanish.

— Safety heater lockout system provides fail safe heater control

2

Safety Interlocking Brew Spout – Brews only when properly

connected to its SuperSatellite.

3

10 Gallon SuperSatellite Vessel

— Thermostatically controlled warming element maintains

4

ideal serving temperature.

— Self contained aerator keeps coffee fresh

— Integral drip tray

— Vessel secured to cart for safety

4

Integral Serving Cart – Wide stance provides stability. Shelves

offer storage for transportation

The G3 Mercury Advantage . . . gourmet brewing brains and brawn.

Now brew hundreds of cups of gourmet quality coffee and keep

each hot, fresh and delicious while serving with the G3 Mercury

Coffee Brewing System. Mercury is designed from the ground up to

simplify volume coffee production and service.

Coffee Where You Need It Most!

Working as a complete integrated system, the Mercury brews

up to 800 cups of coffee per hour, then lets you move it precisely

where it’s most convenient for service.

Meeting rooms, banquets, convention halls, pool-side receptions

— there’s no end to where Mercury’s portable ten gallon

SuperSatellite can be placed.

Gourmet Flavor From Practically Every Roast.

The key to the Mercury System is its powerful wall-mounted brewing

module. At the touch of a button, it instantly delivers up to ten

gallons of “brew temperature” water.

The Mercury brewing module features Curtis’ advanced G3

digital control. G3 simplifies the complex process of extracting

great “gourmet” coffee flavor. It’s pre-programmed for “out of the

carton” use, and can be adjusted to fine tune flavor with easy

to program features including digital brew temperature and brew

volume control, preventive maintenance alerts and much more.

Safety That Makes Sense.

Mercury incorporates proven protection features designed for

large volume coffee service. Wall-mounted guide brackets position

the vessel precisely in place during the brew cycle. A brew-interlock

safety switch allows brewing only when the spout is correctly

positioned, preventing the possibility of spills or burns.

The SuperSatellite vessel is securely fastened to the service cart,

which features a wide-wheel base for extra stability.

Plus, Mercury forever ends the dangerous practice of hand

carrying large trays, laden with pots of hot, scalding coffee from

the brewer to the service area.

Get the MERCURY ADVANTAGE.

Curtis puts over 50 years of foodservice coffee brewing experience

into the high-volume Mercury System. Put that expertise to work

in your operation and start enjoying the benefits

of a more efficient, more profitable high-volume

coffee service today.

Page 2

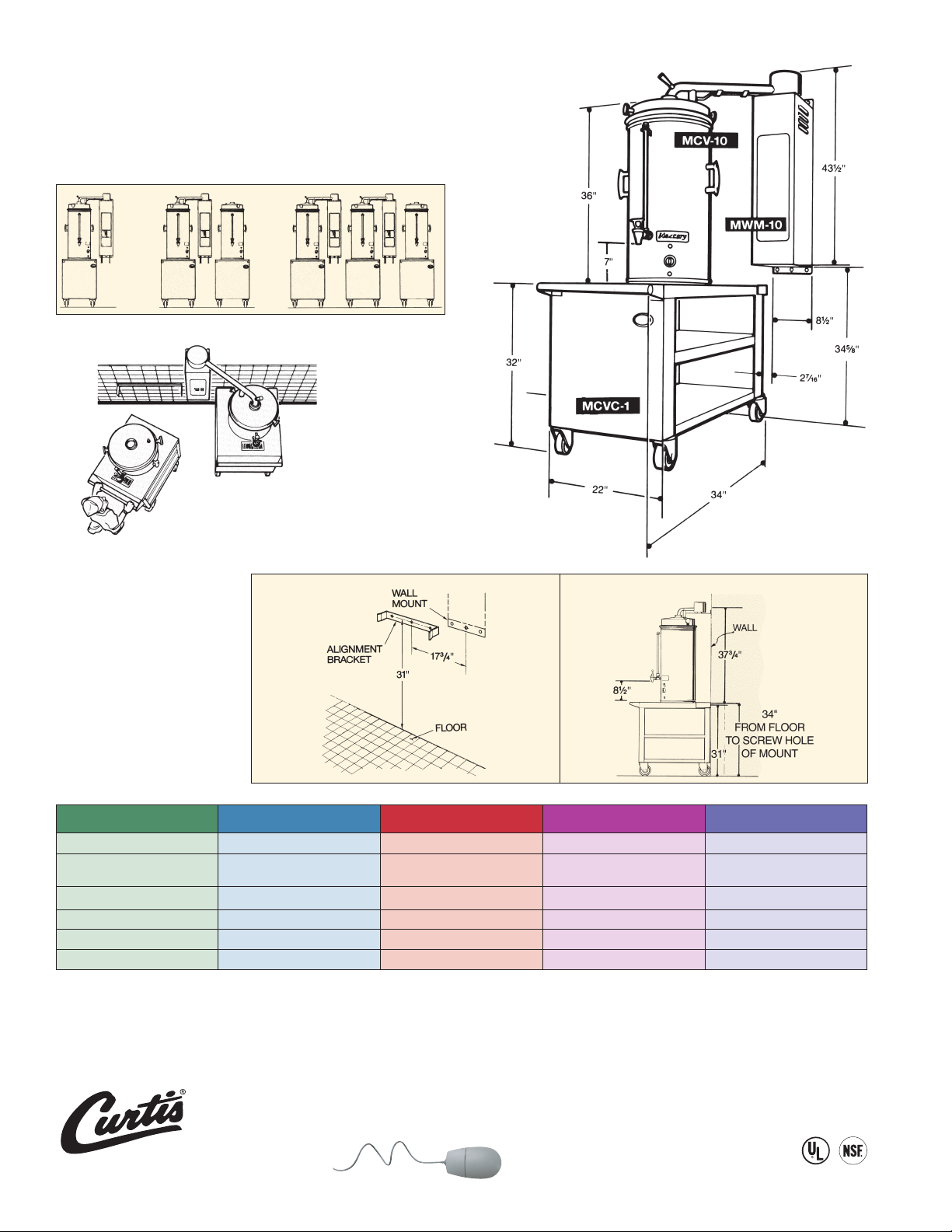

Design Mercury to Fit Your Specific Needs.

The Mercury coffee brewing system’s modularity lets you design a

configuration to fit your exact needs. By integrating the individual

modular units, your system can produce the quantities of coffee you

need in the most efficient, productive manner.

COMMON CONFIGURATIONS:

Cart Alignment

Bracket Installation

and Brewing Module

Installation

Specifications

Capacity Up to 800 Cups/hr. 10 gal. N/A N/A

Electrical (Three Phase Only) 208VAC/60Hz/3-Phase 120VAC/60Hz N/A N/A

Three Wire Plus Ground Standard Duplex Outlet

Power Requirements 15kw/42A 3A N/A N/A

Plumbing 3/8” Water Inlet N/A N/A N/A

Dimensions H x W x D 43.5” x 8.5” x 10.5” 36” High 32” x 34” x 22” N/A

Shipping Weight (lbs.) 60 54 89 2

WILBUR CURTIS COMPANY, INC.

6913 Acco Street, Montebello, CA 90640-5403

Telephone: 800-421-6150 · 323-837-2300

Fax: 323-837-2406

www.wilburcurtis.com

Brewing Module

(MWMGT-10)

COffee Vessel

(MCV-10)

Cart

(MCVC-1)

Wall Bracket

Guides

© 2010 Wilbur Curtis Company, Inc. Printed In U.S.A · MAR/10 – 13114 F-1866 rev. B

Loading...

Loading...