Page 1

FIND OUT MORE

ON

THE WEB.

WILBURCURTIS.COM

W W

W

W W

ILBURILBUR

ILBUR

ILBURILBUR

C C

C

C C

URTISURTIS

URTIS

URTISURTIS

C C

C

C C

OMPOMP

OMP

OMPOMP

ANYANY

ANY

ANYANY

, I, I

, I

, I, I

NCNC

NC

NCNC

MCD-7 & MCD-7G Instructions & Service Information

Revised: May 2002

..

.

..

MCD-7

MCD-7G

MEASURED COFFEE DISPENSERS

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Technical Service Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techservice@wilburcurtis.com

Web Site: www.wilburcurtis.com

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

1

Page 2

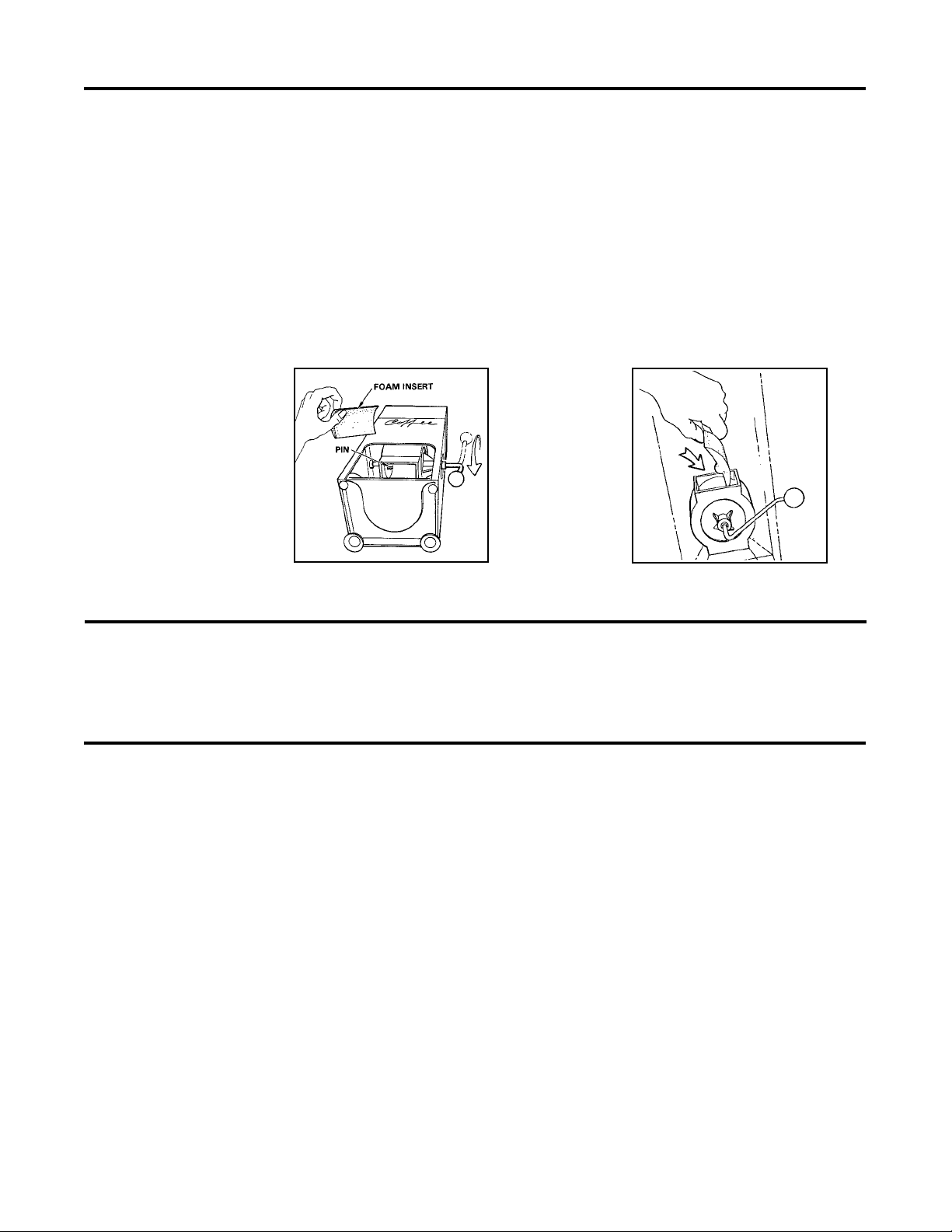

FOAM INSERTS —

INSTALLATION

1. Remove lid. Remove bag of inserts.

2. Looking down into the hopper, observe the small nylon pin piercing the left side of the measuring drum.

3. Now turn unit on its back (see Figure 1.).

4. Using a knife blade or thin screw driver, slide the blade under the head of the pin and pry out the nylon pin.

5. Pull handle to DOWN position and carefully, place into drum opening, one of the foam inserts (as shown in Figure

2.). Each insert is marked with the quantity, in ounces, that it will dispense (the smaller the insert, the more coffee

dispensed from the unit).

6. Replace nylon pin. Press firmly on the head until it snaps into place.

7. Turn the unit upright and fill the hopper with ground coffee. The coffee dispenser is now ready for use.

OPERA TION OF MCD-7

REPLACING THE HANDLE

RETURN SPRING

Figure 1. View of MCD-7, looking

into drum from beneath.

1. Place a coffee filter or a Brew Basket with filter already inserted. Fit it, into the front opening of the MCD-7.

2. Pulling the handle will dispense the amount of coffee you have selected with the foam insert. If you need to change

the quantity of ground coffee that is dispensed (see FOAM INSERTS INSTALLATION, above) choose a different

size of insert.

With use, the handle return spring occasionally breaks. If this happens, the handle will no longer automatically lift after

pulling down. When this happens, the MCD-7 is still usable by simply by lifting up the handle to the top position after

each dispense stroke. The spring can be replaced. Using the illustrated parts breakdown as a guide will help identify the

parts referred to in these instructions. The index numbers in parentheses ( ) will match those in the parts breakdown.

1. Remove the hopper. The hopper is held in place by a screw (5) and nut (6) on both sides of the upper of hopper.

2. Remove the round black knob (21) on the handle. Unthread it , twisting counterclockwise.

3. Remove the bottom screw (9) on the side plate (don't lose the arm stop (7) that it screws into). Also, on the side

plate (8), remove the top screw and the other stop (7) that it is threaded into. Take off the side plate.

4. The next step is to remove the drum and shaft assembly (10). To do this, lay the unit on it's side with the handle

pointing up. Grab the handle (20) with your right hand. Reach inside the MCD-7 and push against the opposite wall

with the flat of your left hand while with your right hand you pull up on the handle (figure 3.). The walls are flexible

enough so that with a little tugging you can dislodge the shaft from the hole in the left side of the wall.

Figure 2. View placing foam inserts

into drum.

5. Once free, pull the handle through the hole on the right side of the MCD-7 (fig 4.) and lift out the drum and shaft.

6. To get off the broken return spring (17), you will have to separate the handle from the plastic drum. The easiest way

is to clamp the metal handle in a vise, grab the drum with both hands; then just yank off the drum with a firm tug.

2

Page 3

REPLACING THE HANDLE

RETURN SPRING, CONT'D

7. Take off the collar by loosening the set screw with an Allen wrench.

Take notice of the spring position.

9. Replace with a new spring and reverse steps 4 through 7 to reinstall the drum.

10. The drum assembly should be in place with the handle sticking out from the

hole on the right side of the MCD-7. Slide the side plate through the handle

and align the screw holes. Rotate the handle so that it is pointing down.

Reaching in from the top, push the end of the spring though the side hole on

the spring retainer (7). Hold on to these while rotating them (put tension on the

spring) to align with the top screw hole. Insert the screw from the outside,

though the plate and into the threaded retainer. Thread the screw into the

spring retainer loosely (not tight).

11. Rotate the handle counter clockwise until the stop bar (19) hits the spring

retainer. Hold the handle in this position while replacing the arm stop standoff

and screw on the bottom hole of the plate. Release the handle. The return

spring will now have the proper tension to return the handle when pulled. The

travel of the handle is also limited by the stop bar between the standoff and the

spring retainer. Tighten the screw on the spring retainer.

12. Replace the knob on the handle and put the hopper back on.

Figure 3.

Figure 4

ILLUSTRA TED PARTS

LIST

3

18

1

17

16

2

8

7

6

4

4

15

10

14

13

12

11

9

5

Note: This parts list contains parts that are common to both

the MCD-7 and MCD-7G units, except where noted,

indication in bold type.

NO.

1

1A

2

2A

3

4

5

6

6A

7

8

8A

9

10

11

12

13

14

15

16

17

18

PART

NO.

WC-3612

WC-3666

WC-3610

WC-3667

WC-3606

WC-4004

WC-5408

WC-3673

WC-3674

WC-4806

WC-3601

WC-3671

WC-3400

WC-3614

WC-3622

WC-3623

WC-3624

WC-3625

WC-3626

WC-3627

WC-3628

WC-3629

DESCRIPTION

COVER, COFFEE HOPPER MCD-7

COVER, GRAY HOPPER MCD-7G

HOPPER, COFFEE MCD-7

HOPPER, GRAY COFFEE MCD-7G

GUARD, HEAT MCD-7

STOP, ARM

PLATE, SIDE

DRUM & HANDLE REG COMPLETE MCD-7

DRUM & HNDL LG GRAY COMPL MCD-7G

PIN, CANOE (10 PER PKG.)

DRUM ASSY W/SHAFT & RINGS MCD-7

DRUM ASSY GRAY MCD-7G

SPRING, RETURN

DRUM INSERTS (SET OF 8)

FOAM INSERT (1.25 oz.) #125

FOAM INSERT (1.50 oz.) #150

FOAM INSERT (1.75 oz.) #175

FOAM INSERT (2 oz.) #200

FOAM INSERT (2.25 oz.) #225

FOAM INSERT (2.50 oz.) #250

FOAM INSERT (2.75 oz.) #275

FOAM INSERT (3 oz.) #300

INDEX

3

Page 4

WARRANTY We hereby certify that the products manufactured by the Wilbur Curtis Company, Inc., are, to thebest of our knowledge, free from all defects and faulty workmanship.

The following warranties and conditions are applicable:

• 90 Days for Labor and 1 Year Parts from Date of Purchase from Factory: This warranty covers all electrical parts, fittings and tubing.

• 40 Months or 40, 000 Pounds of Coffee on a set of Grinding Burrs. (ADS Grinders)

• 2 Years from Date of Purchase: This warranty covers electronic control boards and leaking or pitting of a stainless steel body of a Brewer or Urn.

• 90 Days from Date of Purchase: On replacement parts that have been installed on out of warranty equipment

All in-warranty service calls must have prior authorization from the manufacturer. For an RMA (Return Merchandise Authorization) number, call the Technical Service Department at 1-800-995-0417.

The Wilbur Curtis Company will allow up to 100 miles, round trip, per in-warranty service call.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc., assumes no responsibility for substitute replacement parts installed on Curtis equipment that have

not been purchased from the Wilbur Curtis Company. Inc The Wilbur Curtis Company will not accept any responsibility if the following conditions are not met. The warranty does not cover and is

void under these circumstances:

1) Improper operation of equipment. The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment. This equipment must be installed by a professional, certified technician and must comply with all local electrical, mechanical and plumbing

codes.

3) Wilbur Curtis Company will not be responsible for the operation of equipment at other than the stated voltages on the serial plate.

4) Abuse or neglect (including failure to periodically clean or remove lime accumulations). Manufacturer is not responsible for variation in equipment operation due to excessive lime

or local water conditions.

5) Replacement of items subject to normal use and wear. This shall include, but is not limited to, light bulbs, shear disks, “0” rings, gaskets, canister assemblies. whipper chambers

and plates, mixing bowls, agitation assemblies and whipper propellers.

6) Any faults resulting from inadequate water supply. This includes, but is not limited to, excessive or low water pressure, and inadequate or fluctuating water flow rate.

7) All repairs and/or replacements are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal use.

8) All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner.

9) Charges incurred by delays, waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner of the

equipment.

This includes institutional and correctional facilities.

10) All claims under this warranty must be submitted to the Wilbur Curtis Company Technical Service Department before return of the unit to the factory.

11) All equipment returned to us must be repackaged properly in the original carton. No units will be accepted if they are damaged in transit due to improper packaging.

12) Damaged in transit.

13) The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the responsibility of the equipment owner.

NO UNITS OR PARTS WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LABEL.

All in-warranty service calls must be performed by an authorized service center, where service is available. Call the factory for location near you.

4

2/21/02. 10.0 . edr 3335 rev NC

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Technical Service Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techservice@wilburcurtis.com

Web Site: www.wilburcurtis.com

Printed in U.S.A. 4/02 F-1988 Rev B

Loading...

Loading...