Page 1

F

IND OUT MORE

FIND OUT MORE

THE WEB.

ON

ON

THE WEB.

WILBURCURTIS.COM

WILBURCURTIS.COM

WW

W

WW

ILBURILBUR

ILBUR

ILBURILBUR

C C

C

C C

URTISURTIS

URTIS

URTISURTIS

C C

C

C C

OMPOMP

OMP

OMPOMP

ANYANY

ANY

ANYANY

, I, I

, I

, I, I

NCNC

NC

NCNC

..

.

..

Models Included

SLG

ISLG

CAUTION: CAUTION:

CAUTION: Please

CAUTION: CAUTION:

use this setup

attempting to use this grinder.

Failure to follow the instructions

can result in injury or the voiding

of the warranty.

procedure before

InstallaInstalla

Installa

InstallaInstalla

Important Safeguards/ConventionsImportant Safeguards/Conventions

Important Safeguards/Conventions

Important Safeguards/ConventionsImportant Safeguards/Conventions

This appliance is designed for commercial use. Any servicing other than cleaning and maintenance should be performed by an

authorized Wilbur Curtis service center.

Conventions

QUICK START & SETUP - SLG

1. Install the grinder on a firm, level base in a location where it can be connected to a grounded electrical outlet of 120VAC,

rated at 15 amps.

2. Test the unit by running some whole bean coffee through the grinder. If any problems are encountered, refer to the

troubleshooting section complete at www.wilburcurtis.com or call Technical Service at 800-995-0417.

SETUP INSTRUCTIONS - ISLG

1. Turn both units OFF.

2. Place the grinder close enough to the brewer so the InterLock cable will reach the brewer.

tion Instructions,tion Instructions,

tion Instructions,

tion Instructions,tion Instructions,

• Do NOT immerse the unit in water or any other liquid

• To reduce the risk of fire or electric shock, do NOT open top panel. No user serviceable parts inside. Repair should be done

only by authorized service personnel.

• Keep hands and other items away from hot parts of unit during operation.

• Never clean with scouring powders or harsh implements.

WW

ARNINGS – ARNINGS –

W

ARNINGS –

WW

ARNINGS – ARNINGS –

TT

o help ao help a

void personal injurvoid personal injur

T

o help a

void personal injur

TT

o help ao help a

void personal injurvoid personal injur

OPERATING INSTR UCTIO NS - SLG

The SLG grinder is adjusted at the factory to grind 2 - 2.5 ounces of medium roast coffee.

Ser Ser

Ser

Ser Ser

yy

y

yy

vice & vice &

vice &

vice & vice &

Important Notes/Cautions – from the factorImportant Notes/Cautions – from the factor

Important Notes/Cautions – from the factor

Important Notes/Cautions – from the factorImportant Notes/Cautions – from the factor

WW

arranty Informaarranty Informa

W

arranty Informa

WW

arranty Informaarranty Informa

tiontion

tion

tiontion

yy

y

yy

WARNING TO AVOID

SCALDING, Do not

remove brewcone

while brew light is flashing.

C

ISO 9001 REGISTERED

WILBUR CURTIS COMPANY

Montebello, CA 90640

1. Lift off the clear hopper lid and fill the hopper with whole coffee beans.

2. Place a new filter into your brew cone. Slide the brew cone into the brew cone rails on the grinder.

3. Push the START switch on the front panel. The SLG will start to grind coffee into the brew cone.

4. Wait for the grinder motor to stop before removing the brew cone.

OPERATING INSTR UCTIONS - ISLG

Factory settings: SMALL grind button, set for 5 seconds (1.3 oz). LARGE grind

button, set at 15 seconds (3.8 oz). ISLG -13, has additional MEDIUM button set

for 10 seconds.

1. Place the brew cone into the rails on the grinder. Press one of the grind

buttons on the switch panel. Ground coffee will start to fill the brew cone.

2. When the grinder motor stops, remove the brew cone and slide it into the rails

on the brewer.

3. Press the brew switch that displays the blinking indicator light. This starts a brew cycle.

To cancel a brew cycle, press the ON/OFF switch on the brewer. Brew cycles in process will be

cancelled.

ADJUSTING THE GRINDS

Refer to illustration page 2.

1. Empty hopper of coffee beans. Run grinder to clear grinding burrs of coffee.

2. Open housing cover to locate adjustment screw (8) and lock nut (7). Loosen lock nut.

3. Run motor during adjustment. Turning adjustment screw clockwise will result in a finer grind (if, while turning, you hear the

grinding burrs starting to touch, immediately, back off 1/8th turn). Turning counter clockwise will produce a coarser grind.

4. With a screwdriver holding the adjustment screw in place, tighten the locknut.

5. Run some coffee beans through the machine to check the grind adjustment.

6. Replace front cover on machine.

*This adjustment may change the amount of ground coffee dispensed.

FOR THE LATEST SPECIFICATIONS AND INFORMATION GO TO

WWW.WILBURCURTIS.COM

1

Page 2

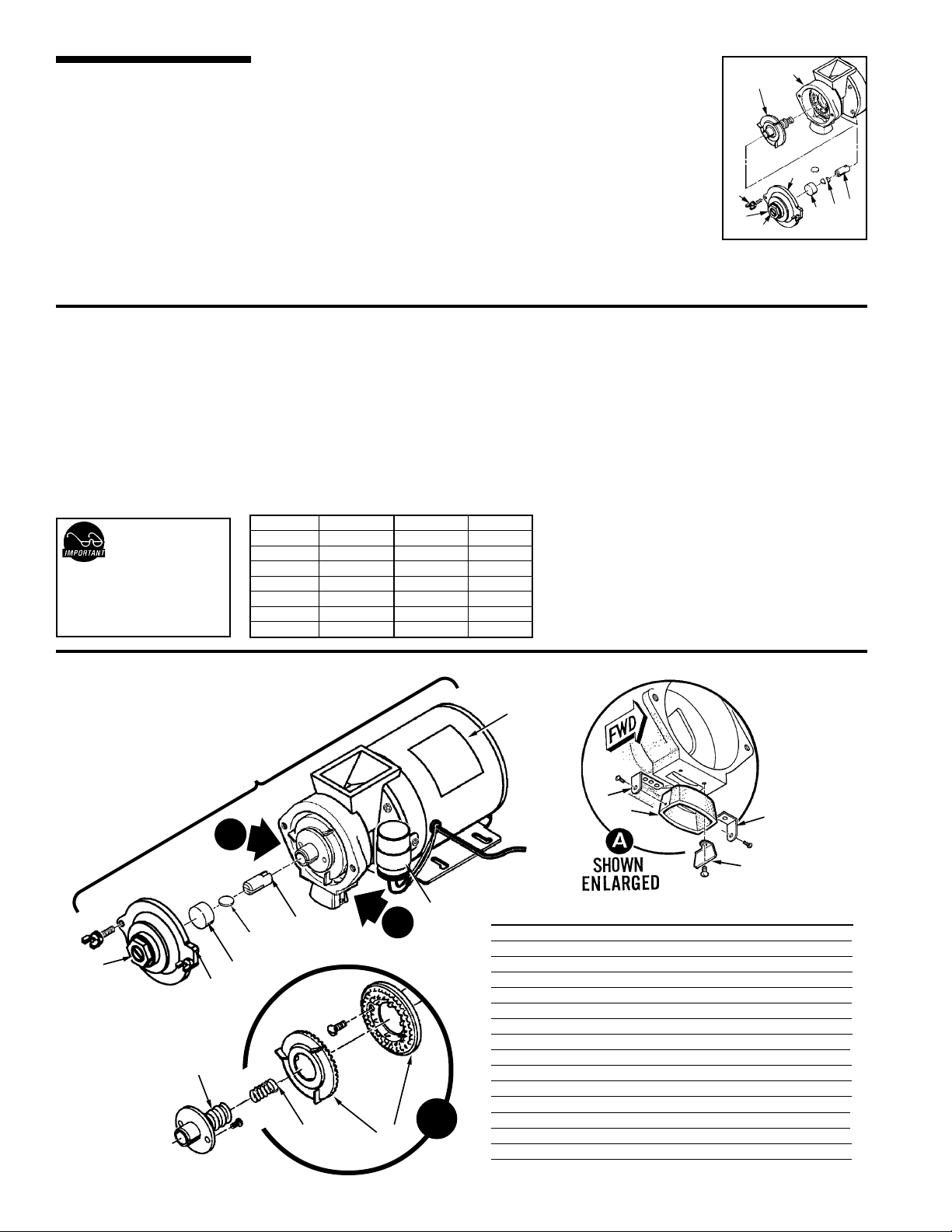

CHANGING A BROKEN SHEAR DISK

1. Unplug power cord.

2. Open hopper and remove beans, then open front cover.

3. On grind motor assembly, take out two thumb screws (10) and remove grind cap (6).

4. Pull out grinding burr/feed worm assembly (2). Inner half of grinding burrs will remain with

housing.

5. Separate shear cap (5) and shear drive (3). Broken shear disk (4) should fall out of slot in

drive.

6. Inspect and clean housing (1) of coffee or debris. Especially, look for something that could

have snapped shear disk.

7. Re-insert feed worm and grinding burr on motor shaft.

8. Push shear drive through burr/feed worm assembly and align large slot with tongue on

motor shaft.

9. Rotate burr/feed worm assembly to align slot with narrow slot on shear drive.

10. Insert a new shear disk into slot. Cover with the shear cap. Replace grind cap and thumb screws.

11. Return power to unit.

1010

10

1010

11

1

11

22

2

22

66

6

66

33

3

33

44

4

44

55

5

88

8

88

77

7

77

55

PROGRAMMING THE ISLG

NOTE:NOTE:

NOTE: Time settings in

NOTE:NOTE:

this table are only

will vary with grind texture and

specific coffee bean. Weigh your

output, then make adjustments as

necessary

ILLUSTRAILLUSTRA

ILLUSTRA

ILLUSTRAILLUSTRA

LISTLIST

LIST

LISTLIST

approximate. Amounts

TED PTED P

TED P

TED PTED P

ARAR

AR

ARAR

TSTS

TS

TSTS

PROGRAMMING THE ISLG

NOTE:NOTE:

NOTE: Before reprogramming the ISLG, the factory timer settings may be all you need.

NOTE:NOTE:

The factory settings: The SMALL grind button is set for 5 seconds (1.3 oz). The LARGE grind button is set at 15 seconds (3.8

oz). On the ISLG -13, there is an additional MEDIUM button that is set for 10 seconds.

1. Open timer cover (behind hopper). Find timer and move the switch from RUN to PROGRAM.

2. Use a stopwatch (recommended) or sweep second hand to time your batches. It is usually quicker to optimize the SMALL

button first. You will then have a more accurate start point for optimizing the other grind button[s].

3. Place an empty filter and cone under the grinder. With your stopwatch ready, press and

button for the desired number of seconds. Weigh the grounds. Record the time and weight. If you are below your target

weight, you can reinsert the filter and add time in small increments by pressing and holding the same button.

Weigh again and add time as desired to reach your target weight. When you are satisfied with the amount, switch the timer

back to RUN and re-grind to test the time and weight. Write down the results.

4. When the time/weight programming is completed, install the front cover.

4

5

6

7

8

10

12

GRINDER MOTORGRINDER MOTOR

GRINDER MOTOR

GRINDER MOTORGRINDER MOTOR

1.0

1.3

1.5

1.8

2.0

2.5

3.0

Seconds OuncesSeconds Ounces

15

20

25

29

34

39

43

10.0

11.3

SETTING TIMER ON SLG GRINDER

3.8

1. Take off timer cover (behind hopper) removing four screws.

5.0

Locate timer.

6.3

2. Timer controls are one high/low switch, allowing you to select a

7.5

scale on timer dial; outside scale range is .5 through 15, inside

8.8

scale range is 2 to 60.

3. Test adjustment by grinding some coffee. When amount is

satisfactory, reinstall timer cover.

hold the

SMALLSMALL

SMALL front panel

SMALLSMALL

2

1

9

12

10

B

11

Item Part No.Item Part No.

Item Part No.

3

4

5

8

6

A

7

15

B

14

2

13

Item Part No.Item Part No.

WC-9135

1

WC-91022

2

WC-91026

3

WC-91024

4

WC-91025

5

WC-91016

6

WC-91017

7

WC-91015

8

WC-91029

9

WC-91027

10

WC-91028

11

WC-91023

12

WC-91045

13

WC-91021

14

WC-91020

15

DescriptionDescription

Description

DescriptionDescription

MOTOR CRUSHING GRINDER ASSY 120VAC

MOTOR, GRINDER 120VAC

CAPACITOR, COFFEE GRINDER ASSY

SHEAR DRIVE COFFEE GRINDER

SHEAR DISK

CAP, SHEAR DISK GRINDERS

COVER, GRINDER HOUSING W/LABEL

SCREW & THRUST PIN ADJUSTING ASSY

SPRINGBAFFLE LONG, NITRIC ACID COLORING

SPRING BAFFLE SHORT, NITRIC ACID COLORING

BAFFLE, SPOUT

SPOUT, GRINDER HOUSING

BURRS, SET CRUSH HIGH FLOW

SPRING, TENSION COFFEE GRINDER

WORM FEEDING ASSY CCG

Page 3

PARTS

DIAGRAMS

SLG Hopper &SLG Hopper &

SLG Hopper &

SLG Hopper &SLG Hopper &

CoversCovers

Covers

CoversCovers

11

1

11

22

2

22

SLG Motor AssemblySLG Motor Assembly

SLG Motor Assembly

SLG Motor AssemblySLG Motor Assembly

77

7

77

33

3

33

44

4

44

1010

10

1010

99

9

88

8

88

99

66

6

66

Item Part No. DescriptionItem Part No. Description

Item Part No. Description

Item Part No. DescriptionItem Part No. Description

WC-9178

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

15A

WC-9169

WC- 628

WC-1504

WC-3502

WC-6550

WC-9135

WC-38027

WC-3796

WC- 101

WC- 652

WC-6470

WC- 122

WC- 121

WC-39062

WC-39048

HOPPER COVER, CLEAR PLASTIC

HOPPER

TIMER

CIRCUIT BREAKER

FOOT, RUBBER WITH 8-32 STUD

RAILS, BREW CONE

MOTOR, 120V

LABEL, FRONT COVER SLG

LABEL, INSIDE FRONT COVER ADJ GRIND & SHEAR DISK

SWITCH, START

TIMER, INTERLOCK

COVER, FRONT FOR INTERLOCK

SWITCH, 12 CUP, 24 CUP, OR 36 CUP

SWITCH, ON/OFF

LABEL, SWITCH PANEL TWO BATCH (ISLG -10)

LABEL, SWITCH PANEL THREE BATCH (ISLG -13)

Illustrated Parts -Illustrated Parts -

Illustrated Parts -

55

5

55

Illustrated Parts -Illustrated Parts ISLGISLG

ISLG

ISLGISLG

1111

11

1111

1212

12

1212

1313

13

1313

1515

15

1515

1414

14

1414

illustrated Parts Breakdown - ISLG

The parts called out on this illustration are for the ISLG grinder and are the only parts that are different from the SLG

grinder. All other parts are identical. Illustrated, is the ISLG -10 (a two batch grinder). The ISLG -13 uses a slightly

different switch panel and has an additional switch (a three batch grinder).

3

Page 4

ELECTRICAL SCHEMAELECTRICAL SCHEMA

ELECTRICAL SCHEMA

ELECTRICAL SCHEMAELECTRICAL SCHEMA

TICTIC

TIC

TICTIC

WARRANTY We hereby certify that the products manufactured by the Wilbur Curtis Company, Inc., are, to the best of our knowledge, free from all defects and faulty workmanship.

The following warranties and conditions are applicable:

• 90 Days for Labor and 1 Year Parts from Date of Purchase from Factory: This warranty covers all electrical parts, fittings and tubing.

• 40 Months or 40, 000 Pounds of Coffee on a set of Grinding Burrs. (ADS Grinders)

• 2 Years from Date of Purchase: This warranty covers electronic control boards and leaking or pitting of a stainless steel body of a Brewer or Urn.

• 90 Days from Date of Purchase: On replacement parts that have been installed on out of warranty equipment

All in-warranty service calls must have prior authorization from the manufacturer. For an RMA (Return Merchandise Authorization) number, call the Technical Service Department at 1-800-995-0417. The Wilbur Curtis

Company will allow up to 100 miles, round trip, per in-warranty service call.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company, Inc., assumes no responsibility for substitute replacement parts installed on Curtis equipment that have not been purchased

from the Wilbur Curtis Company. Inc The Wilbur Curtis Company will not accept any responsibility if the following conditions are not met. The warranty does not cover and is void under these circumstances:

1) Improper operation of equipment. The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment. This equipment must be installed by a professional, certified technician and must comply with all local electrical, mechanical and plumbing codes.

3) Wilbur Curtis Company will not be responsible for the operation of equipment at other than the stated voltages on the serial plate.

4) Abuse or neglect (including failure to periodically clean or remove lime accumulations). Manufacturer is not responsible for variation in equipment operation due to excessive lime or local water

conditions.

5) Replacement of items subject to normal use and wear. This shall include, but is not limited to, light bulbs, shear disks, “0” rings, gaskets, canister assemblies. whipper chambers and plates, mixing

bowls, agitation assemblies and whipper propellers.

6) Any faults resulting from inadequate water supply. This includes, but is not limited to, excessive or low water pressure, and inadequate or fluctuating water flow rate.

7) All repairs and/or replacements are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal use.

8) All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner.

9) Charges incurred by delays, waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner of the equipment.

This includes institutional and correctional facilities.

10) All claims under this warranty must be submitted to the Wilbur Curtis Company Technical Service Department before return of the unit to the factory.

11) All equipment returned to us must be repackaged properly in the original carton. No units will be accepted if they are damaged in transit due to improper packaging.

12) Damaged in transit.

13) The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the responsibility of the equipment owner.

NO UNITS OR PARTS WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE CARTON OR SHIPPING LABEL.

All in-warranty service calls must be performed by an authorized service center, where service is available. Call the factory for location near you.

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640-5403 USA

Phone: 800/421-6150 Fax: 323-837-2410

Technical Service Phone: 800/995-0417 (M-F 5:30A - 4:00P PST) E-Mail: techservice@wilburcurtis.com

Web Site: www.wilburcurtis.com

FOR THE LATEST SPECIFICATION INFORMATION GO TO WWW.WILBURCURTIS.COM

4

Printed in U.S.A. 10/01 F-3217-S Rev NC

10/16/01 . 10.6 . edr 3167 Rev NC

Loading...

Loading...