Page 1

Wilbur Curtis Co., Inc.

Rev. 8/16/00

ALPHA DIGITAL

COFFEE BREWERS

S E R V I C E M A N U A L

Included in this service manual is information on the Alpha 1D, Alpha 2D, Alpha 3D, Alpha

3DL, Alpha 3DR, Alpha 5DL, Alpha 5DR and Alpha 6D. The information is common to all

Alpha digital brewers except where noted.

INCLUDES THE FOLLOWING UNITS:

––

– ALPHA 1D

––

––

– ALPHA 3DR

––

––

– ALPHA 5DL

––

C

––

– ALPHA 2D

––

––

– ALPHA 3DL

––

––

– ALPHA 6D

––

––

– ALPHA 3D

––

––

– ALPHA 5DR

––

CONTENTS

Alpha Digital . . . . . . . . .

Setup . . . . . . . . . . . . . . . .

Setup Steps . . . . . . . . . .

Brewing . . . . . . . . . . . . .

Coffee Requirements .

Programming . . . . . . . . .

Trouble Shooting . . . . . .

Replacing Membrane .

Care & Maintenance .

Illustrated Parts Lists

Wiring Diagrams

Alpha 1D . . . . . . . . .

Alpha 2D . . . . . . . . .

Alpha 3D . . . . . . . . .

Alpha 3DR . . . . . . . .

Alpha 3DL . . . . . . . .

Alpha 5D . . . . . . . . .

Alpha 3D-61/63 . . . .

Alpha 6D . . . . . . . . .

Alpha 3D - Export . .

Warranty . . .

9 - 15

Back Cover

1

1

2

2

2

3

5

7

8

16

17

18

19

20

21

22

23

24

Carton Contents

All products manufactured by the

Wilbur Curtis Company are thoroughly

inspected at the factory and are

warranted to be free of all defects and

faulty workmanship. The Alpha unit is

packaged for maximum protection for

shipping.

Make sure the shipping carton is not damaged or punctured. Unpack the carton carefully , inspecting the

contents for any damage that may have occurred in transit.

Report any damage immediately to the freight company .

9/6/00 12.2 f-2068 revA.p65.p1

Qty Item

1

1

25

1

Automatic Coffee Brewer . . . . . . . . .

Brewcone . . . . . . . . . . . . . . . . . . . . . . .

Paper Filters . . . . . . . . . . . . . . . . . . . . . .

Elbow Fitting, 3/8 X 1/4 Flare . . . . . . . .

Part Nº

Alpha

WC-3621

CR-10

WC-2401

Page 2

ALPHA DIGITAL

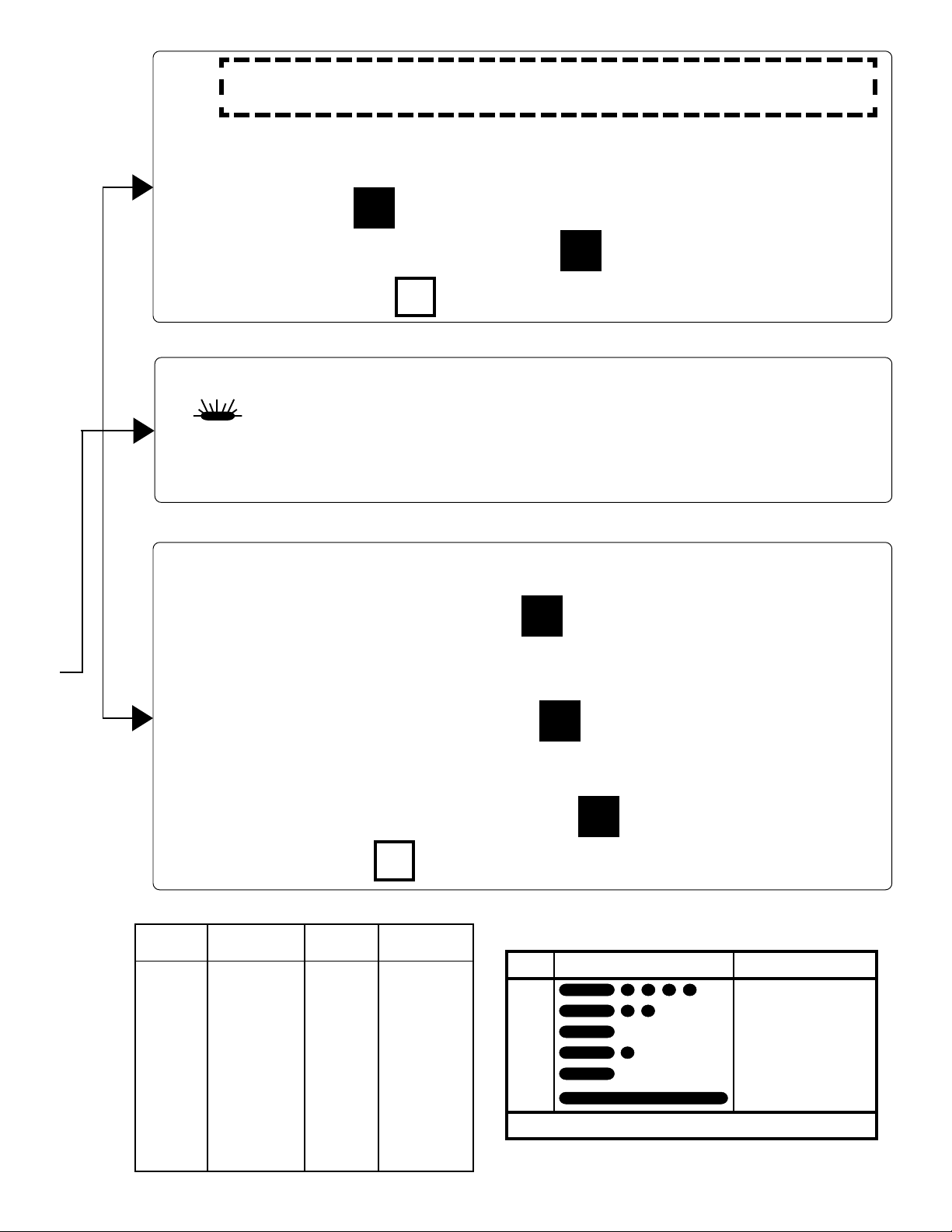

The Alpha Digital series of automatic coffee brewers require installation to be in compliance

with all local water and electrical power codes. The Alpha is designed to brew 12 cups at a

time. The Alpha 3D, 3DL and 3DR have three warmer plates that allow up to three decanters to

be kept at serving temperature. The hot water faucet lets you draw hot water for tea, instant

soups, chocolate drinks or cup meals - even during the brew cycle.

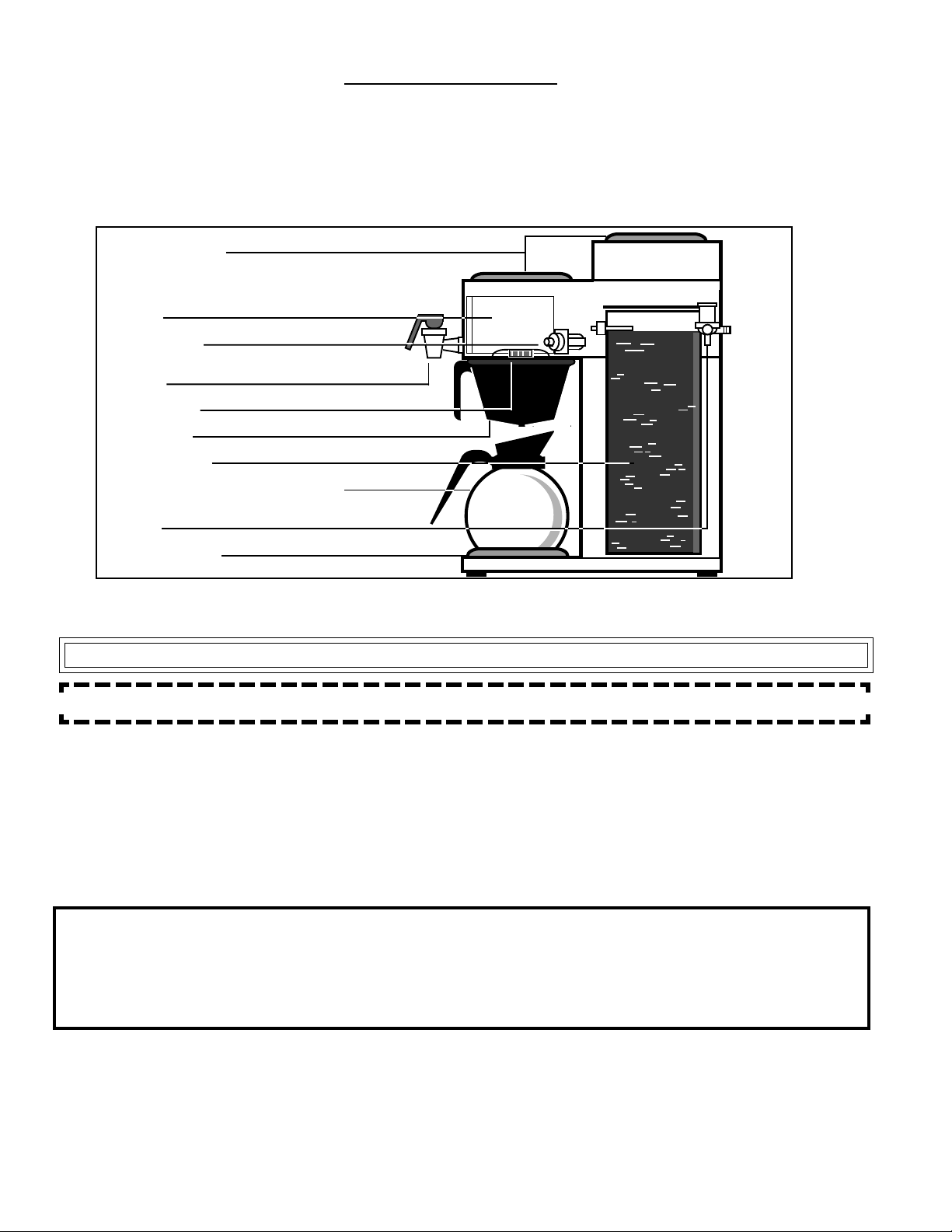

WARMER PLATES

z

ELECTRONIC CONTROL

BOARD

DUMP VALVE

HOT WATER

FAUCET

SPRAY HEAD

BREW CONE

HEATING TANK

12 CUP DECANTER (NOT INCLUDED)

WATER INLET

VALVE

WARMER PLATE

Figure 1. Alpha Brewing System, Basic Components.

THIS EQUIPMENT IS TO BE INSTALLED TO COMPLY WITH THE APPLICABLE FEDERAL, STATE, OR LOCAL PLUMBING CODES HAVING JURISDICTION.

z

z

z

z

z

z

z

z

z

z

CAUTION DO NOT connect this brewer to hot water. Inlet valve not rated for hot water.

SETUP

The Alpha unit should be located on a solid counter top. The counter top should be level. Connect

the water line from the water filter to the unit using ¼" copper tubing with a flare fitting at the end.

Some type of water strainer must be used to maintain a trouble-free operation. In areas with extremely hard water, we suggest that an Everpure QC7-MH water filter be installed. W ater filters may

be ordered from the Wilbur Curtis Company . For customer service call (800) 421-6150.

The National Sanitation Foundation (NSF), requires the following water hookup:

1. A quick disconnect water connection or enough extra coiled tubing (at least 2x the depth of the

unit) so that the machine can be moved for cleaning underneath.

2. An approved flow back prevention device, such as a double check valve to be installed between

the machine and the water supply .

Alpha decanter brewers are shipped with the power cord connected inside the machine. The

power cord ends with an electric plug having two flat blades with a round grounding pin, 120V AC

current and 20 amp rating. Some units are rated for 220 volts. Check the serial plate on the side

of the machine to make sure of the electrical requirements for your unit.

1

Page 3

Setup Steps

1. Connect a ¼" copper water line from your facility to the ¼" flare water inlet fitting on the valve, behind

the machine. Water pressure going to the machine must be stable. Use a water regulator to maintain

constant pressure. This brewer works perfectly when water pressures are from 20 to 90 psi.

2. Plug the power cord into an electrical outlet rated at 20A.

3. Turn on the toggle switch behind the unit. The heating t ank will st art to fill. When the water reaches the

probe, the heating element will turn on automatically .

4. The heating tank will require 20 to 30 minutes to reach operating temperature (200ºF). The READY TO

BREW indicator will light at this time.

5. When water reaches operating temperature, dispense about 12 ounces of hot water through the hot

water faucet to lower the water level in the heating tank. You can also dispense only enough water to

activate the liquid level control.

BREWING

STEPS FOR BREWING COFFEE:

1. Place a paper filter into the brew cone. Pour ground coffee into the filter.

2. Slide the brew cone into place. When pushed in against the stop, the brew cone fits into the slide rails

and centers it under the sprayhead (see Figure 1. illustrating basic components).

3. Place a clean coffee decanter on the warmer plate.

CAUTION - Always use an empty decanter before starting a brew cycle.

4. To start brewing, push in the momentary brew switch, located on the front panel. The brew cycle will

take approximately three minutes to complete. To stop a brew cycle press the ON/OFF button.

CAUTION - Wait for hot coffee to stop dripping from brew cone before lifting decanter.

5. To stop a brew cycle press the ON/OFF button.

COFFEE REQUIREMENTS

The Alpha coffee brewer will produce excellent results using most grades of

coffee available from your coffee distributor. Coffee suppliers can provide coffee

in convenient pre-measured envelopes.

The Alpha coffee brewer is designed for ground coffee; Freeze Dried or Liquid

coffee products will not work.

The Wilbur Curtis Company manufactures bulk coffee dispensers (Models

MCD-7 or MCD-7G) that consistently dispense ground coffee in selected

amounts.

2

Figure 2. MCD-7 Coffee

Dispenser

Page 4

PROGRAMMING

(ONLY REQUIRED IF FACTORY SETTINGS MUST BE CHANGED)

IMPORTANT These digital brewers are thoroughly tested and programmed at

the time of manufacture.

A few brew cycles may be required for unit to normalize.

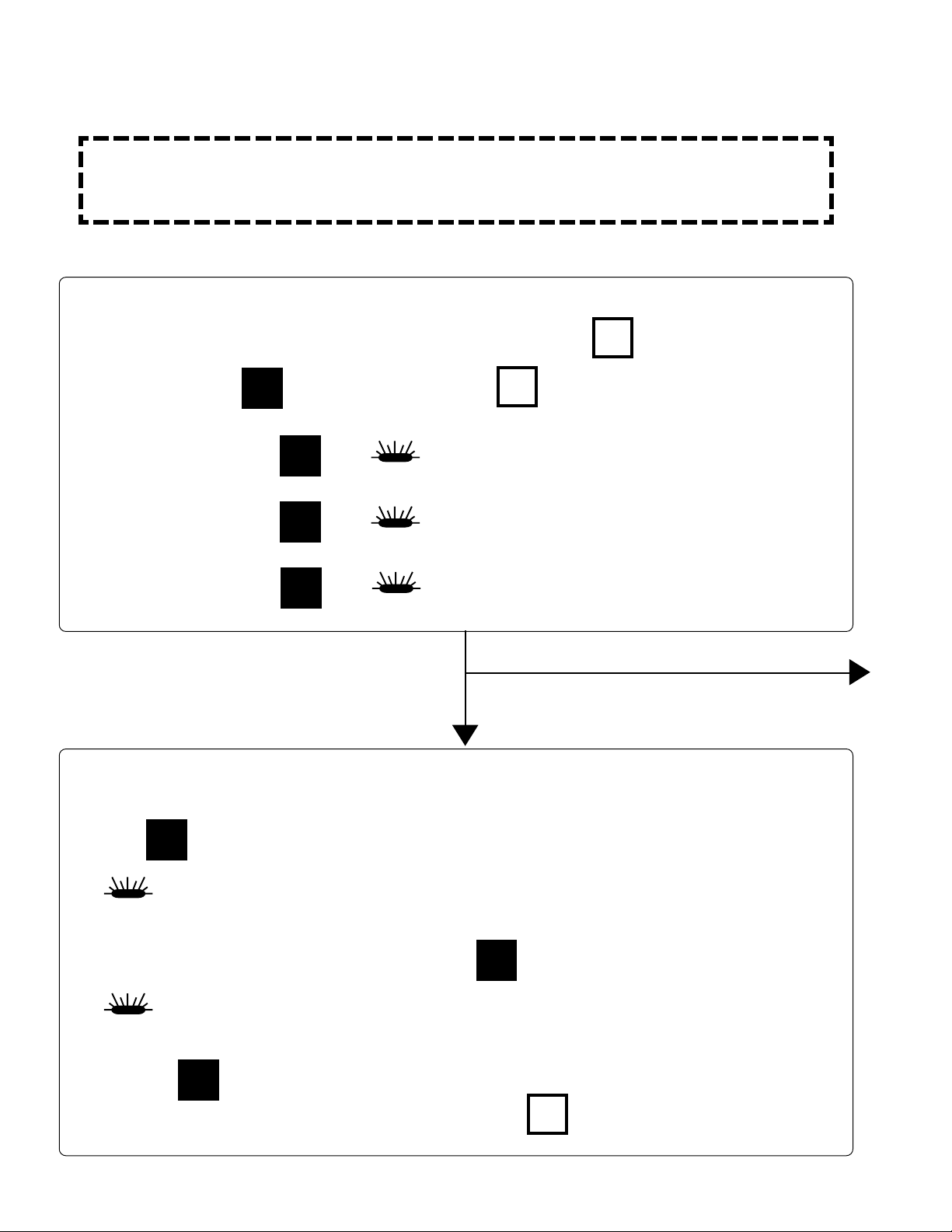

ENTERING THE PROGRAM MODE

For all programming functions you must first enter the programming mode as follows:

z Turn OFF the power from the Control Panel by pressing .

z Press and HOLD and press and RELEASE .

BREW

ON/OFF

ON/OFF

MODE #1

z Continue HOLDING until starts blinking; RELEASE.

BREW

READY TO BREW

MODE #2

z Continue HOLDING until stops blinking; RELEASE.

BREW

READY TO BREW

MODE #3

z Continue HOLDING until stops blinking and remains on; RELEASE.

BREW

READY TO BREW

CONFIRM/RESET BREW TEMPERATURE

ENTER THE PROGRAMMING MODE #1:

(PRE-PROGRAMMED FOR 200º F)

(Over)

z Press for two seconds, then RELEASE.

z will start blinking. Each blink equals 2º F, starting at 170º (max. temp. 204º F

BREW

READY TO BREW

or 18 blinks).

z To change Temperature, press and HOLD .

z will start QUICK flashing. Each QUICK flash equals 2º F. After reaching 204º,

READY TO BREW

BREW

temperature starts over at 170º.

z RELEASE when the desired temperature is reached. The newly set tempera-

ture will now be displayed. To set and exit, press .

BREW

ON/OFF

3

Page 5

CHANGE BREW VOLUME

IMPORTANT - Before changing the brew volume, place a measuring

container on the brew deck and insert the brew cone.

ENTER THE PROGRAMMING MODE #1:

(PRE-PROGRAMMED FOR APPROXIMATELY 64 OUNCES)

z Press and HOLD until hot water starts running, then RELEASE.

z When desired volume is reached, press again to stop the flow.

z To set and exit, press .

BREW

BREW

ON/OFF

TO ACCESS PREVENTATIVE MAINTENANCE BREW CYCLE COUNTER

ENTER THE PROGRAMMING MODE #2:

z will now start a pattern of LONG and SHORT blinks.

READY TO BREW

This pattern identifies the number of brew cycles. SHORT blinks indicate

the brew number from 1 to 9. LONG blinks separate 1's, 10's, 1,000's and

10,000's.

WARMER QUALITY TIMER - Factory Preset to OFF

TO DETERMINE WARMER SETTING AND CHANGE TIME

z Warmer must be ON. Press and HOLD until light goes OFF, RELEASE.

WARMER

z The light will start blinking. Count the blinks. Each blink=5 minutes

(maximum 50 minutes).

z At the end of the cycle, press and hold until the light begins quick

WARMER

flashing. The cycle will start over after 11 flashes (a setting of 11 flashes is the

OFF position).

z When the desired time is reached, RELEASE .

10

11

12

13

14

15

16

17

18

ON/OFF

TEMPERA-

TURE

188º F

190º F

192º F

194º F

196º F

198º F

200º F

202º F

204º F

Table 2. Exa mple of Brew Counting Code

SETS BLINKING LIGHT PATTERN

1ST

2ND

3RD

4TH

5TH

END

4

z To set and exit, press .

Table 1 . Temper ature S e ttings

NUMBER

OF BLINKS

1

2

3

4

5

6

7

8

9

TEMPERA-

TURE

170º F

172º F

174º F

176º F

178º F

180º F

182º F

184º F

186º F

NUMBER

OF BLINKS

WARMER

TOTAL BREWS

NUMBER OF BREWS

4 x 1

2 x 10

0 x 100

1 x 1,000

0 x 10,000

01024

= 4

= 20

= 0

= 1,000

= 0

Page 6

TROUBLE SHOOTING

ERROR CODES: All Alpha Digital brewers contain various safety features in the electronic circuitry that shut down the

functions of the unit in the event of a system failure. Error codes are signalled by the BREW READY light blinking. Deciphering the code:

WATER LEVEL PROBLEM 3 LONG AND 1 SHORT

TEMPERATURE SENSOR PROBLEM 3 LONG AND 2 SHORT

ANY SERVICE DONE ON THIS UNIT MUST BE PERFORMED BY A QUALIFIED SERVICE TECHNICIAN.

PROBLEM: WATER DOES NOT FLOW INTO HEATING TANK

POSSIBLE CAUSE SOLUTION

1. Water line turned off

or water filter needs

changing

2. Water inlet valve coil

burned out

3. Grounded probe

4. Defective or burned

out control board

Make sure the unit is receiving enough water pressure. Open

the water line. Change the filter or filter element.

Turn the brewer off. Disconnect wires from water inlet coil

terminals and connect a power cord to the terminals. Plug cord

into a 120V outlet and verify if water flows when plugged in

and stops when power is disconnected. If valve fails this test,

replace valve.

When the water level gets below the probe tip, water should

automatically refill the tank. If not, pull wire off the probe

terminal. Water should now start flowing into the tank. If not,

check the control board of the microprocessor assembly (see

step 4), or inlet valve (step 5, below).

Pull wire out of probe terminal. With a voltmeter, check voltage

at the water inlet coil terminals. This should read 110-120

volts. If no voltage is present, check control board. Make sure

the control board is energized on terminals WHT & BLK. Lack of

power to these terminals will indicate a defect within the

circuit board. Replace the microprocessor assembly.

Check for loose connections at terminals.

CODE:

PROBLEM: WATER IN HEATING TANK OVERFLOWING

POSSIBLE CAUSE SOLUTION

5. Defective water inlet

valve

6. Probe limed up

7. Non-grounded or loose

terminal connections at

control board

Unplug the unit and observe water level. If water continues to

flow into tank, clean or replace valve.

Pull wire off from probe terminal. Touch the metal body of the

heating tank with the end of this wire (to ground the wire). If

water stops flowing, try cleaning the probe. Probe may have to

be replaced.

The control board must be grounded. Check for loose connections at the terminals. Make sure the grounding wire is securely

fastened to the chassis.

CODE:

5

Page 7

TROUBLE SHOOTING, CONTINUED

PROBLEM: WATER IN TANK DOES NOT GET HOT

OR WATER TEMPERATURE TOO LOW

CODE:

POSSIBLE CAUSE

8. Power is off

9. Defective or loose heat

sensor

10. Burned out heating

element

11. Defective control

board

PROBLEM: WATER NOT FLOWING FROM SPRAYHEAD

POSSIBLE CAUSE

Make sure unit is on; power cord plugged in. Toggle switch is

on. Breaker is on.

Remove the sensor and squeeze a dab of silicone compound

(part no. WC-5229) between the sensor and the tank body.

Make sure the fastening nut is secure. Check the wire for

damage.

Check element for continuity and or check with clamp ammeter. This should show a reading of approximately 15 amps

(depending on element wattage). If no power is going through

element, replace the heating element.

If checks #8, #9 and #10 are normal, the control board is not

operating correctly. Replace the microprocessor assembly (#8,

figure 6.).

SOLUTION

CODE:

SOLUTION

12. Sprayhead clogged

13. Water level is too low

in heating tank

14. Defective control board

15. Defective dump valve

or coil

Remove sprayhead and clean. Clean the sprayhead fitting.

Check water level in tank. If water is not flowing into the tank,

review steps 1 thru 4, previous page.

Check the continuity between terminals WHT & BREW VLV.

When the BREW button is pressed, there should be solid continuity between these two terminals. If not, replace the membrane control panel (see the instructions below).

Make sure the board is receiving 110 to 120 volts at terminals

BREW VLV and WHITE when BREW switch has been pressed.

There should be 110 to 120V going to the dump valve. If not,

then the control board is faulty.

If the control board is functioning properly (step 14), check the

dump valve. Measure voltage across the two terminals of the

valve coil. You should read 110 to 120 volts. Check also for

clogging or lime deposits. Clean if possible. Replace valve or

coil.

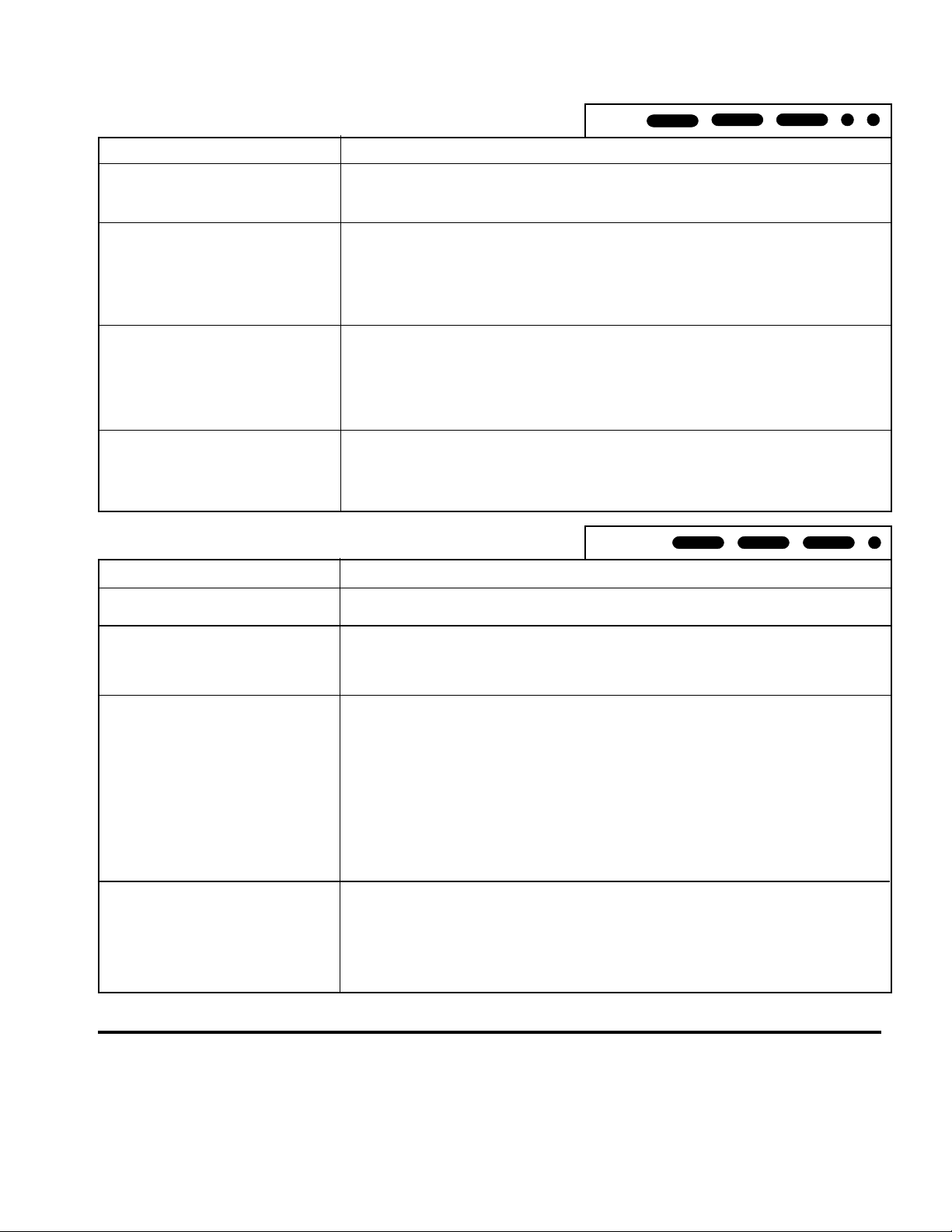

REPLACING THE MEMBRANE CONTROL PANEL

IMPORTANT - This procedure requires careful positioning of the membrane control panel. Improper

application of the new part will ruin the membrane when you try to lift it again. You will have to acquire an

additional panel to complete the task.

TEST

Before you actually remove the old membrane, test the old one by using your new membrane. Your old

one may be okay.

6

Page 8

1. Unplug the machine from your power source.

2. Remove the cover accessing the control board.

3. Unplug the ribbon connector from the control board then take the new

membrane and plug the connector into the control board. Place it on a hard

surface outside the unit.

CAUTION Do not bend the new membrane.

When pressing the buttons always have a hard, flat, surface to push

against. The tiny dome switches within the membrane may become

inverted unless you have something solid behind it.

WARNING TO HELP AVOID PERSONAL INJURY

Do not place objects or reach your hands into the open unit.

4. Return power to the unit and press the ON/OFF button on the new membrane control panel.

5. If your unit still does not function normally, your problem may not be with the membrane panel, but in

another component. If your unit runs okay, then proceed with the replacement of the membrane

control panel.

REPLACE THE MEMBRANE CONTROL PANEL

1. Unplug the machine from your power source or switch off at the circuit breaker.

2. Remove the cover accessing the control board.

3. On this unit there is a hot water faucet over part of the membrane control panel that must be removed.

Open the faucet and let the hot water pour out until the flow stops.

WARNING TO HELP AVOID PERSONAL INJURY

Allow faucet to cool before proceeding. Components may be hot.

Figure 3. Testing

Membrane, Typical

4. Disconnect the ribbon cable plug from the control board.

5. Remove the old membrane control panel by lifting one of the corners and peeling it from the front of the

unit. Pull the flex cable through the hole.

6. With acetone, remove any adhesive left on the stainless surface. Clean and dry the surface.

7. Take your new panel and insert the flex cable through the opening in front of the unit and connect the

flex cable to the control board.

8. Peel off the paper backing on the new membrane panel and carefully position the panel. Line it up

correctly with the switches and LEDs. Press onto the surface of the unit. You must get this right the

first time. Any attempt to reposition the membrane control panel will damage the small switches within

the membrane.

9. Reinstall the faucet. Turn on the water. Return the top cover and front cover. Plug the power cord into

and outlet.

CLEANING AND PREVENTIVE MAINTENANCE

1. Slide out the brew cone and clean around the sprayhead and dome using a nontoxic cleaner.

2. Remove the sprayhead from the brewer and clean it. This should be done at least once a week, more

often in heavy lime areas.

3. Wipe any spills, dust or debris from the exterior surfaces.

CAUTION: Do not use cleansers, bleach liquids, powders or any other substance that contains chlorine.

These products promote corrosion and will pit the stainless steel.

THE USE OF THESE PRODUCTS WILL VOID YOUR WARRANTY.

4. Clean the brew cone slide rails with a brush or damp cloth.

5. The outside surfaces should be cleaned with a stainless steel polish only, to prevent scratches.

6. The inside of the heating tank may occasionally require deliming. The frequency is determined by

local water conditions.

7

Page 9

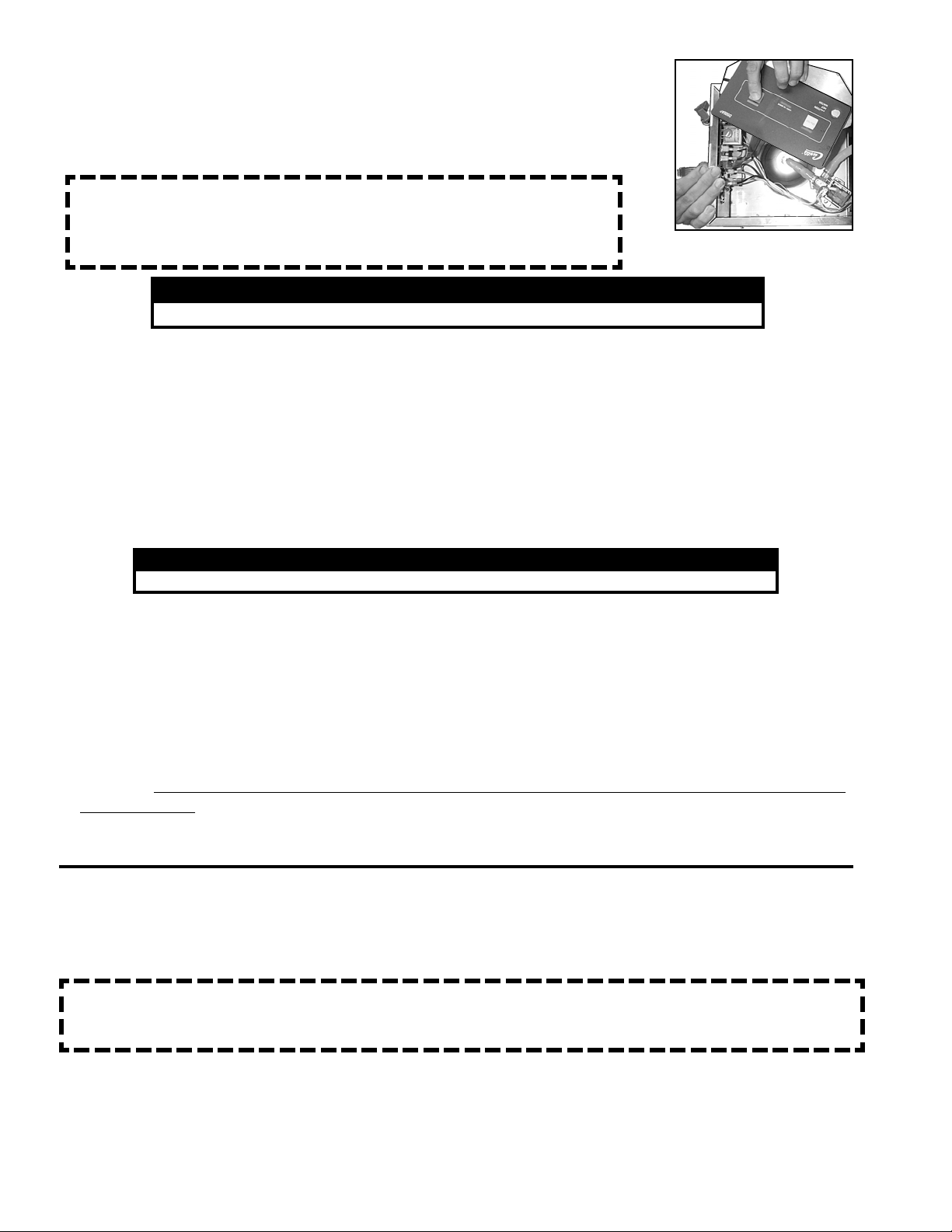

ALPHA 3D

1

1

ILLUSTRATED PARTS

THIS FIGURE (AND FIG. 4.) SHOW THE

ALPHA 3D. ALL OTHER ALPHAS ARE

SIMILAR EXCEPT WHERE DETAILED

(SEE FIGURES 9, 10, 11, 12).

A

E

A

~

Figure 4. Illustrated Parts List, Main View (Alpha 3D Shown).

8

Page 10

ALPHA

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

3

ILLUSTRATED PARTS

44

4

E

49

52

48

53

49

55

43

F

50

46

54

48

49

54

47

49

42

57

49

B

64

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

2

58

57

50

55

Figure 8. Alpha Tank.

29

F

Figure 5. Illustrated Parts List, Detail Bubbles.

9

Page 11

ALPHA DIGITAL Parts List

INDEX

NUMBER

1

2

3

4

5

6

8

9

10

11

12

13

14

15

16

17

18

19

20

22

23

24

25

26

27

28

29

30

31

32

33

35

36

37

39

42

43

44

46

47

48

49

50

52

PART

NUMBER

WC-38310

WC-6205

WC-6826

WC- 889

WC-2977

WC-4320

WC-37015

WC-4436

WC-39173

WC-3029

WC-43041

WC-4238

WC-43045

WC-1809

WC-1806

WC-5477

WC-4213

WC-2936

WC-1411

WC-3323

WC-3317

WC-3503

WC-1408

WC-1200

WC-2401

WC-4616

WC- 826L

WC-5819

WC- 102

WC-5231

WC-4426

WC-37102

WC- 947

WC-4201

WC-6234

WC-5851

WC-43062

WC-4543

WC-4211

WC-1438

WC-29015

WC-29009

WC-5502-01

WC-4394

DESCRIPTION

LABEL, "CAREFUL HOT SURFACE"

WARMER DECK, UPPER ALPHA

COVER, WARMER ALPHA

VALVE, DUMP LEFT 120V 12W

FITTING ASSEMBLY SPRAYHEAD PLATED

O' RING, 1/2" I.D.

KIT, MICROPROCESSOR ASSY, ALPH-D W/BRD, HT SNK .

SCREW, 4x3/8 PHIL PAN HEAD

MEMBRANE CONTROL PANEL ALPHA 3D

INSULATION, HEAT SLEEVE ALPHA

WASHER, TANK LID

NUT, 6-32, HEX S.S.

SPACER, BOARD .25 DIA x .264

FAUCET, HOT WATER

SEAT CUP, SILICONE

COVER, FRONT ALPHA 1D, -2D, -3D

NUT, LOCK 5/8" BRASS

SPRAYHEAD, RED (.131 DIA.)

BUSHING, 5/8" SNAP-IN

BREW CONE, 7 1/8" ASSEMBLY, STAINLESS

BREW BASKET, WIRE

LEG, SCREW BUMPER, 3/8-16 STD

GRIP, CORD 7/8"

CORD, POWER 6' 14/3 BLK SJTO

ELBOW, 1/4 x 3/8, FLARE

SCREW, MACHINE, 1/4 - 20 x 1/2" PH HEAD S/S

VALVE, INLET 1 GPM 120V 10W

COVER, BOTTOM ALPHA 3

TOGGLE SWITCH, 120V

COMPOUND, SILICONE 5 OZ.

SCREW, PAN HEAD, 8-32 x 1/4"

PLATE WARMER ALPHA

WARMER ELEMENT, 90W 120V

NUT, KEP, 8-32, ZINC

WARMER ASSEMBLY 90W 120V

LID, HEATING TANK

GASKET, TANK LID

SCREW, 8-32x 1" SLOTTED HEX SS

NUT, JAM 5/8" NPT BRASS

SENSOR, HEATING TANK

FITTING, ASSEMBLY OVERFLOW

FITTING, ASSEMBLY INLET

PROBE, WATER LEVEL

SHOCK GUARD FOR HEATING ELEMENT

10

Page 12

ALPHA DIGITAL Parts List

INDEX

NUMBER

53

54

55

56

57

58

59

60

61

63

64

65

PART

NUMBER

WC-4306

WC- 917-04

WC- 522

WC-43058

WC-3685

WC-5310

WC-3765L

WC- 829

WC-43055

WC-3763

WC-29018

WC-4320

DESCRIPTION

WASHER, 9/16" TEFLON . . . . . . . . . . . . . . . . . . . . . . .

ELEMENT, HEATING 1.45KW 120V W/JAM NUTS & SILICONE WSHR

THERMOSTAT RST . . . . . . . . . . . . . . . . . . . . . . . . . .

PLUG, TANK DRAIN PP RED

INSULATION, WRAP ALPHA-D

TUBE, SILICONE, 5/16" I.D. . . . . . . . . . . . . . . . . . . . .

KIT, INLET VALVE REPAIR USE ON WC- 826L

WASHER, FLOW .35GPM .5" . . . . . . . . . . . . . . . . . . .

SHOCK GUARD, RESET THERM . . . . . . . . . . . . . . . .

KIT, DUMP VALVE FOR WC866, WC889, WC816, WC817 & WC818

PLASTIC TEE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

O' RING, 3/4" I.D. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

ITEMS SPECIFIC TO ALPHA 1D, 2D, 3DR, 3DL, 5D, 6D (SEE IPB, PAGES 14, 15 & 16)

66

67

68

69

70

71

72

73

74

WC-6206

WC-5820

WC-6224

WC-39174

WC-39175

WC-6642

WC-6666

WC-5896

WC- 129

COVER, TOP ALPHA 1D, 3DR & 3DL . . . . . . . . . . . . . .

COVER, BOTTOM ALPHA 3DR & 3DL, 5DR & 5DL . . . . .

COVER, TOP ALPHA 2D . . . . . . . . . . . . . . . . . . . . . . .

MEMBRANE CONTROL PANEL ALP-2D . . . . . . . . . . . . .

MEMBRANE CONTROL PANEL ALP-1D . . . . . . . . . . . . .

COVER, TOP ALPHA 6D . . . . . . . . . . . . . . . . . . . . . . .

COVER, CENTER WRAP ALPHA 6D . . . . . . . . . . . . . . .

COVER, BOTTOM ALPHA 6D . . . . . . . . . . . . . . . . . . . .

SWITCH, WARMER RED ALPHA 5D . . . . . . . . . . . . . . .

75

WC-3621

BREWCONE, UNIVERSAL PLASTIC STD. . . . . . . . . . . . . . . . .

ALPHA EXPORT COMPONENTS

76

77

78

79

80

81

82

WC- 103

WC- 305

WC- 701

WC- 856

WC- 860

WC- 922-04

WC-37163

TOGGLE SWITCH, 220V . . . . . . . . . . . . . . . . . . . . . . .

POWER BLOCK . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

TRANSFORMER, 220V - 120V . . . . . . . . . . . . . . . . . .

VALVE, INLET 220V . . . . . . . . . . . . . . . . . . . . . . . . . .

VALVE, DUMP 220V . . . . . . . . . . . . . . . . . . . . . . . . .

ELEMENT, HEATING 3.5KW 220V W/JAM NUTS, SILICONE WSHR

KIT, WARMER ELEMENT 100W 220V

11

Page 13

ALPHA 3DR &

ALPHA 3DL

THIS FIGURE ILLUSTRATES THE DIFFERENCES

BETWEEN THE ALPHA 3DR/L AND THE ALPHA

3D. THE ALPHA 3DR/L HAS A PLAIN TOP

COVER AND A WIDE BOTTOM COVER..

ALPHA 3DL

ALPHA 3DR

Figure 6. Illustrated Parts, Alpha 3DR & 3DL.

12

Page 14

ALPHA 2D

1

1

1

1

THIS FIGURE ILLUSTRATES THE DIFFERENCES

BETWEEN THE ALPHA 2D AND THE ALPHA 3D.

THE ALPHA 2D HAS ONLY TWO WARMERS, A

DIFFERENT TOP COVER AND TWO WARMER

SWITCHES ON THE SWITCH PANEL.

Figure 7. Illustrated Parts, Alpha 2D.

ALPHA 1D

THIS FIGURE ILLUSTRATES THE DIFFERENCE

BETWEEN THE ALPHA 1D AND THE ALPHA 3D.

THE ALPHA 1D HAS A PLAIN TOP COVER. THE

ALPHA 1D HAS ONLY ONE WARMER AND ONE

WARMER SWITCH ON THE SWITCH PANEL.

Figure 8. Illustrated Parts, Alpha 1D.

13

Page 15

ALPHA 6D

THE ALPHA 6D IS BASICALLY

AN ALPHA 3DR AND AN ALPHA

3DL LINKED TOGETHER.

THIS FIGURE ILLUSTRATES THE

DIFFERENCES BETWEEN THE

ALPHA 6D AND THE ALPHA 3D.

THE ALPHA 6D HAS A TOTAL

OF SIX WARMERS, A LARGER

TOP COVER, CENTER COVER,

AND BOTTOM COVER.

73

71

72

Figure 9. Illustrated Parts, Alpha 6D.

ALPHA 5DL &

ALPHA 5DR

THIS FIGURE ILLUSTRATES THE

DIFFERENCES BETWEEN THE ALPHA 5Ds

AND THE ALPHA 3D. THE ALPHA 5D HAS

TWO ADDITIONAL SIDE WARMERS, AS

WITH THE ALPHA 3DL & 3DR BUT WITH

TWO SEPERATE WARMER SWITCHES.

Figure 10. Illustrated Parts, Alpha 5D.

14

74

Page 16

15161718192021

Page 17

Page 18

Page 19

Page 20

Page 21

Page 22

Page 23

22

Page 24

23

Page 25

Product Warranty Information

The Wilbur Curtis Company certifies that its products are free from defects in material and workmanship under normal use. The following limited

warranties and conditions apply:

3 Years, Parts and Labor , from Original Date of Purchase on digital control boards.

2 Years, Parts, from Original Date of Purchase on all other electrical components, fittings and tubing.

1 Y ear , Labor , from Original Date of Purchase on all electrical components, fittings and tubing.

Additionally, the W ilbur Curtis Company warrants its Grinding Burrs for Forty (40) months from date of purchase or 40,000 pounds of coffee, whichever

comes first. Stainless Steel components are warranted for two (2) years from date of purchase against leaking or pitting and replacement parts are

warranted for ninety (90) days from date of purchase or for the remainder of the limited warranty period of the equipment in which the component is

installed.

All in-warranty service calls must have prior authorization. For Authorization, call the T echnical Support Department at 1-800-995-0417. Effective date

of this policy is April 1, 2003.

Additional conditions may apply. Go to www.wilburcurtis.com to view the full product warranty information.

CONDITIONS & EXCEPTIONS

The warranty covers original equipment at time of purchase only. The Wilbur Curtis Company , Inc., assumes no responsibility for substitute replacement parts installed on Curtis equipment that have not been purchased from the

Wilbur Curtis Company, Inc. The Wilbur Curtis Company will not accept any responsibility if the following conditions are not met. The warranty does

not cover and is void under the following circumstances:

1) Improper operation of equipment: The equipment must be used for its designed and intended purpose and function.

2) Improper installation of equipment: This equipment must be installed by a professional technician and must comply with all local electrical,

mechanical and plumbing codes.

3) Improper voltage: Equipment must be installed at the voltage stated on the serial plate supplied with this equipment.

4) Improper water supply: This includes, but is not limited to, excessive or low water pressure, and inadequate or fluctuating water flow rate.

5) Adjustments and cleaning: The resetting of safety thermostats and circuit breakers, programming and temperature adjustments are the

responsibility of the equipment owner. The owner is responsible for proper cleaning and regular maintenance of this equipment.

6) Damaged in transit: Equipment damaged in transit is the responsibility of the freight company and a claim should be made with the carrier.

7) Abuse or neglect (including failure to periodically clean or remove lime accumulations): Manufacturer is not responsible for variation

in equipment operation due to excessive lime or local water conditions. The equipment must be maintained according to the manufacturer’s

recommendations.

8) Replacement of items subject to normal use and wear: This shall include, but is not limited to, light bulbs, shear disks, “0” rings, gaskets,

silicone tube, canister assemblies, whipper chambers and plates, mixing bowls, agitation assemblies and whipper propellers.

9) Repairs and/or Replacements are subject to our decision that the workmanship or parts were faulty and the defects showed up under normal

use. All labor shall be performed during regular working hours. Overtime charges are the responsibility of the owner. Charges incurred by

delays, waiting time, or operating restrictions that hinder the service technician’s ability to perform service is the responsibility of the owner of the

equipment. This includes institutional and correctional facilities. The Wilbur Curtis Company will allow up to 100 miles, round trip, per inwarranty service call.

RETURN MERCHANDISE AUTHORIZA TION: All claims under this warranty must be submitted to the Wilbur Curtis Company Technical

Support Department prior to performing any repair work or return of this equipment to the factory . All returned equipment mus t be repackaged

properly in the original carton. No units will be accepted if they are damaged in transit due to improper packaging. NO UNITS OR PARTS

WILL BE ACCEPTED WITHOUT A RETURN MERCHANDISE AUTHORIZATION (RMA). RMA NUMBER MUST BE MARKED ON THE

CARTON OR SHIPPING LABEL. All in-warranty service calls must be performed by an authorized service agent. Call the Wilbur Curtis

T echnical Support Department to find an agent near you.

Printed in U.S.A. 8/06 1M F - 2068 Rev B

WILBUR CURTIS CO., INC.

6913 Acco St., Montebello, CA 90640 Web Site: www.wilburcurtis.com Customer Service Tel: 800/421-6150

Technical Service Tel: 800/995-0417 E-Mail: techsupport@wilburcurtis.com

Loading...

Loading...