Page 1

Safety manual

Sicherheitshandbuch

Manuel de sécurité

Manual de seguridad

Information on functional safety

for temperature transmitter model T32.xS

Hinweise zur funktionalen Sicherheit

für Temperatur-Transmitter Typ T32.xS

Indications relatives à la sécurité fonctionnelle

pour transmetteur de température type T32.xS

Notas acerca de la seguridad funcional

para transmisores de temperatura modelo T32.xS

Full assessment per IEC 61508

certied by TÜV Rheinland

GB

D

F

E

Head mounting version Rail mounting version

model T32.1S model T32.3S

Page 2

Safety manual model T32.xS

GB

Page 3 - 18

Sicherheitshandbuch Typ T32.xS

D

Manuel de sécurité type T32.xS

F

E

Manual de seguridad modelo T32.xS

Seite 19 - 32

Page 33 - 46

Página 47 - 59

11583631.02 11/2010 GB/D/F/E

2

WIKA safety manual temperature transmitter T32.xS

Page 3

Contents

Contents

1. General information 4

1.1 History of this document 4

1.2 Other applicable instrument documentation 4

1.3 Relevant standards 4

1.4 Abbreviations 5

2. Safety 6

2.1 Intended use in safety applications 6

2.2 Labelling / safety labels 7

2.3 Restrictions to operating modes 8

2.4 Error signaling 9

2.5 Write protection 10

GB

2.6 Accuracy of the safe measuring function 11

2.7 Conguration changes 12

2.8 Commissioning and periodic tests 13

2.8.1 Proof Test of the transmitter's complete signal processing chain 13

2.8.2 Reduced proof test - limited testing of the transmitter's signal

conditioning chain 14

2.9 Information on the determination of safety-relevant parameters 15

2.10 Decommissioning the transmitter 15

Appendix 1: SIL Declaration of Conformity 16

11583631.02 11/2010 GB/D/F/E

WIKA safety manual temperature transmitter T32.xS

3

Page 4

1. General information

1. General information

1.1 History of this document

Documentation changes (compared with the previous issue)

GB

Issue Remarks Firmware

April 2010

May 2010

November

2010

This safety manual on functional safety covers the WIKA temperature transmitter

T32.1S/T32.3S (from Firmware Rev. 2.2.1) solely as part of a safety-related system.

This safety manual is valid with the documentation mentioned in chapter "1.1 Other

applicable instrument documentation". Please also note the safety instructions listed in

the operating manual.

These operating instructions contain important information on working with the Model

T32.1S/T32.3S temperature transmitter. Working safely requires that all safety instructions and work instructions are observed.

First issue

4 languages

(+ French, + Spanish)

Monitoring of the output limits

(optional, not activated by default for

SIL versions starting from 01.01.2011)

T32.1S/ T32.3S

(from Firmware Rev. 2.2.1)

T32.1S/ T32.3S

(from Firmware Rev. 2.2.1)

T32.1S/ T32.3S

(from Firmware Rev. 2.2.1)

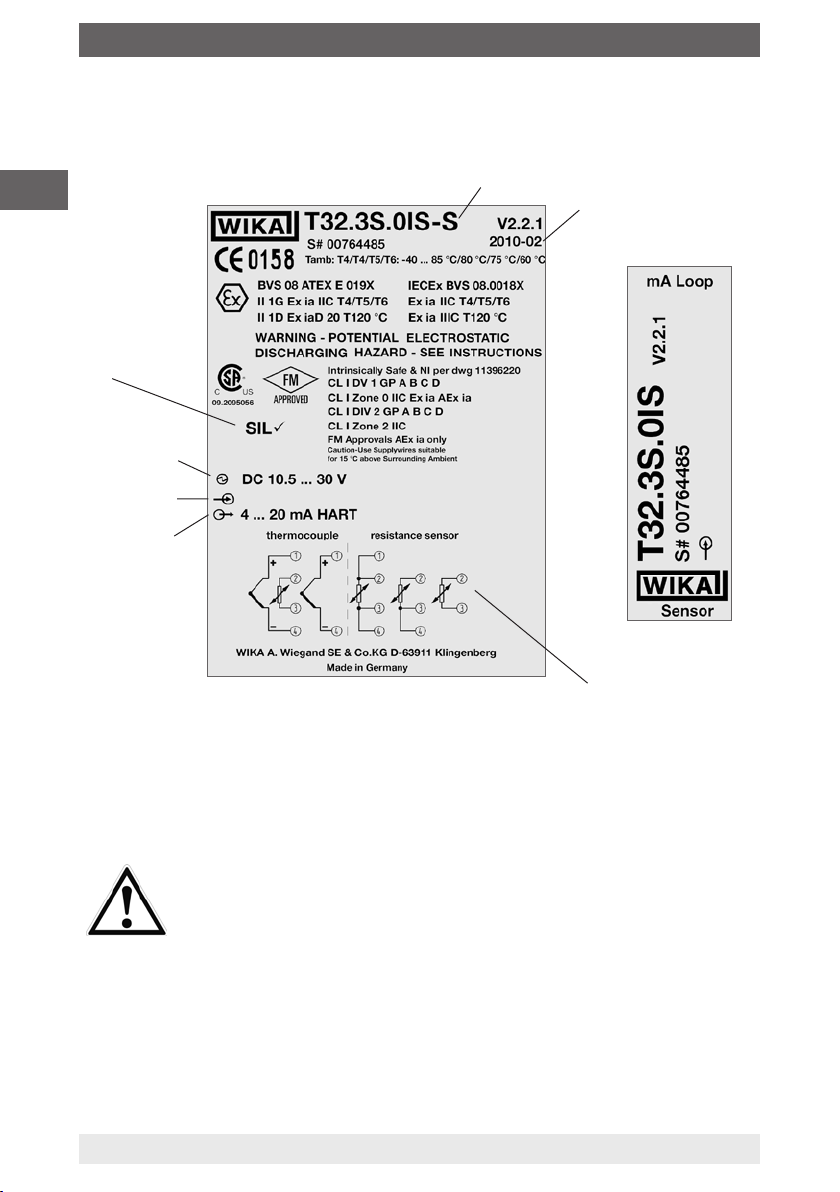

The marking on the product label for the instrument with SIL design is

shown in the following illustration. Only the model T32.xS.0xx-S is suitable

for operation in safety-related applications!

The model T32.xS.0xx-S can be combined with the optional Ex version.

1.2 Other applicable instrument documentation

In addition to this safety manual the operating instructions for model T32.xS

(S-No.: 11258421) and the data sheet TE 32.04 are applicable.

1.3 Relevant standards

Standard Model T32.xS

IEC 61508 Safety-related systems for the process industry

Target groups: Manufacturers and suppliers of instruments

IEC 61511

4

Functional safety safety-related electrical/electronic/ programmable

electronic systems

Target groups: designers, integrators, users

WIKA safety manual temperature transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 5

1. General information

1.4 Abbreviations

Abbreviation

HFT Hardware Fault Tolerance, capability of a functional unit to continue

MTBF Mean interval between two failures

MTTR Mean interval between the occurrence of the failure in a device or

PFD Likelihood of dangerous safety function failures occurring on

PFD

avg

SIL Safety Integrity Level, the international standard IEC 61508

SFF Safe Failure Fraction, the proportion of failures without the potential

T

Proof

XooY Classication and description of the safety-related system with

und λ

λ

sd

λdd +λ

du

λ

du

Description

the execution of the demanded function when faults or anomalies

exist.

system and its repair

demand

Average likelihood of dangerous safety function failures occurring

on demand

denes four discrete safety integrity levels (SIL1 to SIL4). Each

level corresponds to a specic probability range with respect to

the failure of a safety function. The higher the integrity level of the

safety-related system, the lower the likelihood of the demanded

safety functions not occurring.

to put the safety-related system into a dangerous or impermissible

functional state.

In accordance with IEC 61508-4, chapter 3.5.8, TProof is dened

as the periodic testing to expose errors in a safety-related system.

respect to redundancy and the selection procedure used. "Y"

indicates how often the safety function is carried out (redundancy).

"X" determines how many channels must work properly.

λsd Safe detected + λsu Safe undetected

su

Safe failure (IEC 61508-4, chapter 3.6.8):

A safe failure is present when the measuring system switches to the

dened safe state or the fault signalling mode without the process

demanding it.

λdd Dangerous detected + λdu Dangerous undetected

Unsafe failure (IEC 61508-4, chapter 3.6.7):

Generally a dangerous failure occurs if the measuring system

switches into a dangerous or functionally inoperable condition.

λdu Dangerous undetected

A dangerous undetected failure occurs if the measuring system does

not switch into a safe condition or into the error mode on a demand

from the process.

GB

For further relevant abbreviations, see IEC 61508-4.

11583631.02 11/2010 GB/D/F/E

WIKA safety manual temperature transmitter T32.xS

5

Page 6

2. Safety

2. Safety

2.1 Intended use in safety applications

All safety functions relate exclusively to the analogue output signal (4 … 20 mA). The

GB

device is certied to SIL2 (IEC 61508) . The device software fullls the criteria for SIL3

(IEC 61508). The use of the device in homogeneous reduntant systems is therefore

possible.

The following sensor connections achieve an SFF (Safe Failure Fraction) of >90 %,

sucient for SIL2:

■

Thermocouple (internal cold junction, Pt100)

■

Thermocouple (external cold junction, Pt100)

■

Resistance thermometer with 4-wire connection

■

Resistance thermometer with 3-wire connection

WIKA sensors Model TRxx (see WIKA manufacturer's declaration

Document No. 3011701)

■

Duplex thermocouple and/or duplex resistance thermometer (only in "redundant"

operating mode and when both sensors are used for monitoring the same

measurement point (2 channel)).

The following sensor connections achieve an SFF (Safe Failure Fraction) of >60 % for

SIL1:

■

Resistance thermometers with 3-wire connection

- universal sensors -

■

Resistance thermometers with 2-wire connection

The device generates a current signal in the approved measuring mode of a nominal

4 … 20 mA, that is dependent upon the sensor signal. The eective range of the output

signal limited to a minimum of 3.8 mA and a maximum of 20.5 mA (factory setting in

basic conguration).

WARNING!

Do not exceed the specications for the model T32.xS given in the data

sheets and operating instructions. In order to ensure a safe functionality

of the current output, the correct terminal voltage must be present in the

device.

The following terminal voltage limits apply:

Instrument model Terminal voltage limits

T32.1S.000-S

T32.3S.000-S

T32.1S.0IS-S

T32.3S.0IS-S

6

DC 10,5 ... 42 V

DC 10,5 ... 30 V

WIKA safety manual temperature transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 7

2. Safety

WARNING !

The following sensors and oerating modes are NOT allowed for operation

in a safety-relevant application:

■

Potentiometer

■

Resistance sensor

■

mV-Sensor

■

Dierential mode in duplex sensor operation

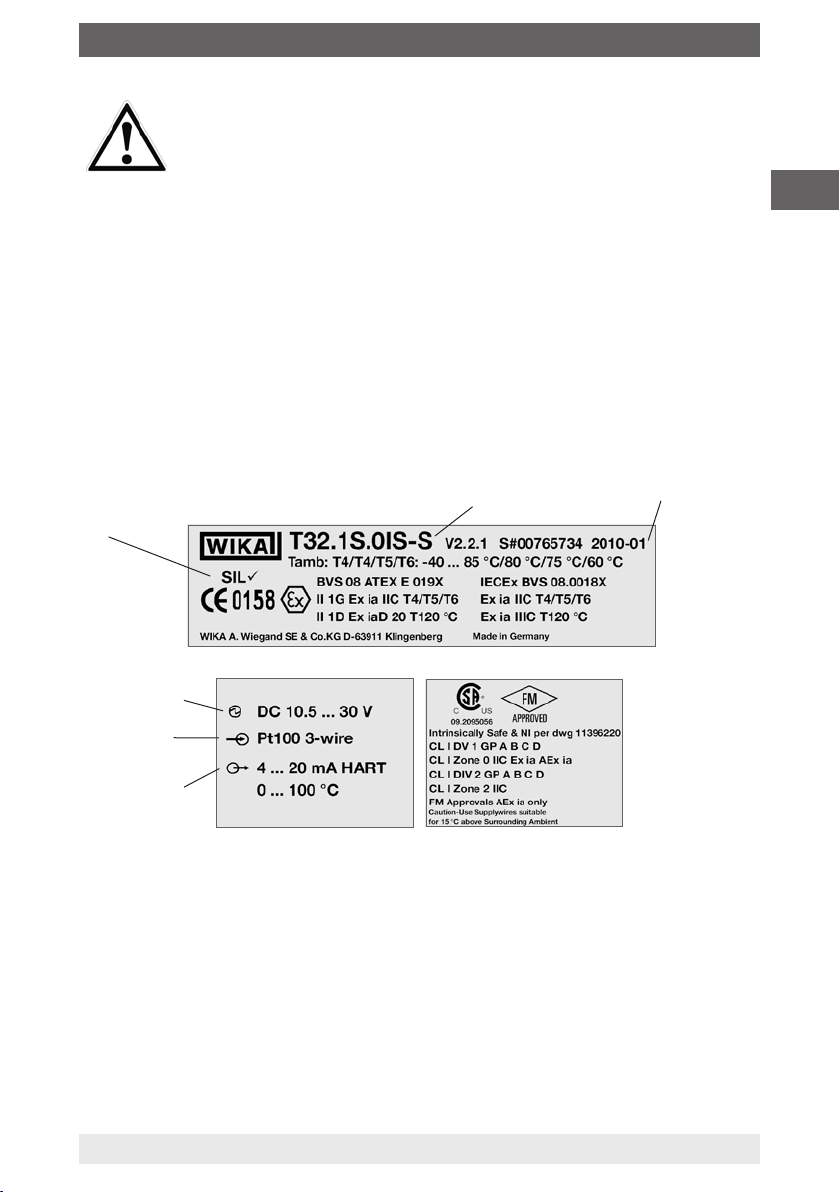

2.2 Labelling / safety labels

Product label

■

Head mounting version, model T32.1S

GB

SIL version

(only at SIL)

Power supply

Sensor, Pt100

or RTD

Output signal

Model

with SIL: T32.1S.0IS-S

without SIL: T32.1S.0IS-Z

Date of manufacture

(year-month)

11583631.02 11/2010 GB/D/F/E

WIKA safety manual temperature transmitter T32.xS

7

Page 8

GB

2. Safety

■

Rail mounting version, model T32.3S

SIL version

(only at SIL)

Power supply

Sensor, Pt100

or RTD

Output signal

Model

with SIL: T32.1S.0IS-S

without SIL: T32.1S.0IS-Z

Date of manufacture

(year-month)

2.3 Restrictions to operating modes

WARNING!

Under the following operating conditions, the safety function of the device

is not guaranteed:

■

During conguration

■

When the write-protection is deactivated

■

When the HART® multi drop mode is activated.

■

Measured value transmission via HART® protocol

■

During a simulation

■

During the Proof Tests

■

When the write-protection is deactivated

8

Pin assignment

11583631.02 11/2010 GB/D/F/E

WIKA safety manual temperature transmitter T32.xS

Page 9

2. Safety

2.4 Error signaling

The model T32.xS temperature transmitter monitors the connected sensors and its

own hardware for errors. In the event of a known error condition the device generates

an error signalling current.

The response time from the sensor is a maximum of 90 seconds.

This implies the discovery of the following potential errors:

■

Sensor burnout

■

Sensor short circuit (only for resistance temperature sensors, not for thermocouples)

■

Inadmissably high lead resistance (not with duplex resistance temperature sensors)

The online diagnosis-test interval of the instrument should be a maximum of

35 minutes. This implies the discovery of the following potential device errors:

■

ROM error

■

EEPROM error

■

RAM error

■

Program-counter error

■

Stack-pointer error

Furthermore, the following monitoring functions are carried out continuously:

■

Logical program ow control

■

Internal communications error

■

Over sensor upper limit

■

Under sensor lower limit

■

Cold junction temperature outside permissible limits (only for thermocouples)

■

Duplex sensor drift monitoring (activated optionally)

■

Conguration error

■

Monitoring of the permissible device temperature (optional, activated by default for

SIL versions)

■

Monitoring of the output limits (optional, not activated by default for SIL versions

starting from 01.01.2011)

GB

CAUTION!

The device's error signalling current (error current) is congured in

accordance with the following requirements:

■

Error current fail high (high alarm value):

settable in the range ≥ 21.0 mA to ≤ 23.0 mA (upscale)

■

Error current fail low (low alarm value) :

settable in the range ≥ 3.5 mA to ≤ 3.6 mA (downscale)

11583631.02 11/2010 GB/D/F/E

WIKA safety manual temperature transmitter T32.xS

9

Page 10

2. Safety

WARNING!

With certain device-side diagnosed hardware errors, the device gives a

downscale error signal with a loop current of < 3.8 mA, and can however,

GB

With certain inadmissible congurations (e.g. with deactivated write-protection) the

transmitter likewise generates an error signal. In order to nd the reason behind the

error signal, the diagnostic functions available over HART

functions are oered, for example, in the WIKA_T32 conguration software (free

download from www.wika.com).

2.5 Write protection

The T32.xS oers a write protection functionality in order to prevent accidental

conguration changes. The write-protection password is factory set to "0".

for technical reasons, also ensure no signal ≤ 3.6 mA with the appropriate

conguration. The evaluation system must therefore interpret a loop

current of < 3.8 mA as a fault condition.

®

should be used. Such

A T32.xS temperature transmitter with SIL option will only work once the

write protection has been activated. Without write protection activated,

such a transmitter will signal an error.

2.5.1 Operation of the write protection

The write protection function is activated via a passsword (numbers in the range 0 to

65535 are allowed) and through a switch (write protection activate/deactivate).

A change in the state of the write protection switch is only possible after the successful

input of the password. The password can be altered via its own menu.

CAUTION!

There is absolutely NO possibility of retrieving a forgotten password! The

only possibility is for the password to be reset at the factory!

Also, activation of the write protection is only possible through the input of

the correct password!

10

WIKA safety manual temperature transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 11

2. Safety

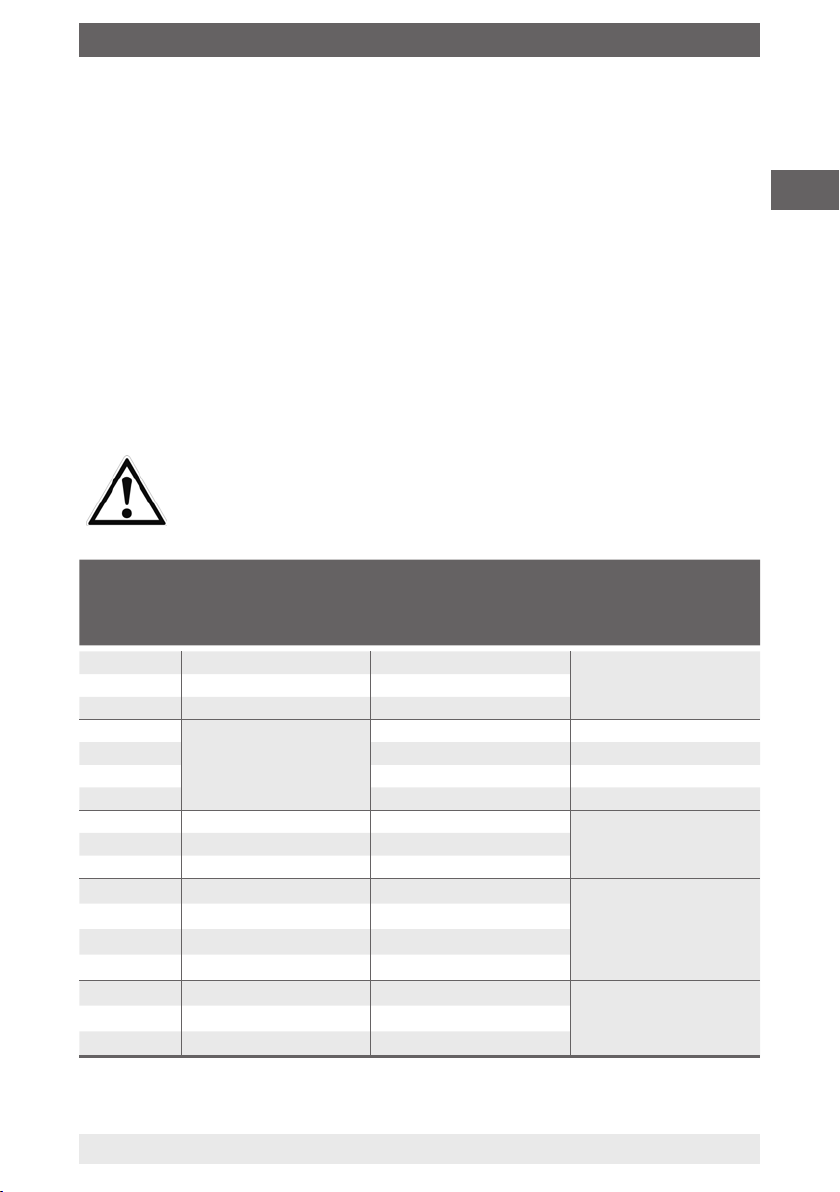

2.6 Accuracy of the safe measuring function

The following information on the Total Safety Accuracy contains the following components:

■

Basic accuracy (measuring deviation from input and output, and the linearity error

of the transmitter)

■

In addition, for thermocouples, the internal cold-junction compensation (CJC),

except for type B thermocouples

■

Inuence of the ambient temperature in the range -50 ... +85 °C

The dened value for the Total Safety Accuracy for this instrument depends on the

chosen sensor type, and the congured measuring span (see following table).

Up to the minimum spans given in the table, the Total Safety Accuracy is 2 % of the

measuring range with respect to the current output signal of 16 mA.

Otherwise, the absolute values given directly in the table are valid.

CAUTION!

The measuring span is the dierence between the full scale value and the

initial value of a measuring range.

GB

Sensor

type

Permissible

sensor range

for the accuracy

Min. span for

2 % total safety

accuracy

specications

Pt100 -200 ... +850 °C 84 K

JPt100 -200 ... +500 °C 50 K

Ni100 -60 ... +250 °C 21 K

Pt1000

Pt500 70 K 2 K

Pt25 134 K 3 K

Pt10 241 K 5 K

TC type T -150 ... +400 °C 134 K

TC typeL -150 ... +900 °C 138 K

TC type U -150 ... +600 °C 136 K

TC type E -150 ... +1000 °C 164 K

TC type J -150 ... +1200 °C 176 K

TC type K -140 ... +1200 °C 197 K

TC type N -150 ... +1300 °C 154 K

TC type R +50 … +1600 °C 255 K

TC type S +50 … +1600 °C 273 K

TC type B +500 …+1820 °C 283 K

11583631.02 11/2010 GB/D/F/E

WIKA safety manual temperature transmitter T32.xS

-200 ... +850 °C

69 K 2 K

Absolute total

safety accuracy for

small measuring

spans

2 K

3 K

4 K

6 K

11

Page 12

2. Safety

Application (see table page 11):

■

Example 1

Sensor type Pt100, congured measuring range = -50 … +100 °C, so congured

GB

measuring span = 150 K.

This is not smaller than 84 K. Thus the Total Safety Accuracy is 2 % FS,

thus 2 % * 150 K = 3 K,

and/or 2 % * 16 mA = 320 μA in terms of the current output

■

Example 2

Sensor type Pt100, congured measuring range = 0 … 50 °C, so congured

measuring span = 50 K

This is smaller than 84 K, thus the total safety accuracy is 2 K,

thus 2 K / 50 K = 4 %, and 4 % * 16 mA = 640 μA in terms of the current output

2.7 Conguration changes

WARNING!

During the conguration change, the safety function is not active! Safe

operation is only admissible with activated write protection (password).

Carry out conguration changes within the permissible specications in accordance

with chapter "2.1 Intended use in safety applications".

With the supplied conguration tools, the write protection, and other items, for the

model T32.xS is settable:

■

WIKA T32 Conguration Software

■

AMS

■

SIMATIC PDM

■

DTM (from Version DTM Beta version V1.0.2, January 2003) in conjunction with

operating software to the FDT/DTM Standard, e.g. PACTware, FieldMate

■

HART® hand-held terminal FC475, FC375, MFC4150

WARNING!

The safety function must be checked following any conguration

procedure.

12

WIKA safety manual temperature transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 13

2. Safety

2.8 Commissioning and periodic tests

The operability and error current of the model T32.xS temperature transmitter must

be tested both during commissioning and at reasonable intervals. Both the nature of

the tests as well as the chosen intervals are the responsibility of the user. The interval

usually conforms to the PFDavg value given in the standard (Values and key data see

"Appendix 1: SIL declaration of conformity"). Normally the repeated test happens every

year.

2.8.1 Proof test of the transmitter's complete signal processing chain

1. If required, bypass the safety controller system and/or take the appropriate action,

to prevent an alarm being triggered unintentionally.

2. Deactivate the device's write protection

3. With the aid of the HART

high alarm value (≥ 21.0 mA). (HART

4. Test whether the current output signal reaches this value.

5. With the aid of the function in simulation mode, set the current output of the

transmitter to a low alarm value (≤ 3.6 mA)

6. Test whether the current output signal reaches this value.

7. Activate the write protection and wait for a minimum of 5 seconds.

8. Switch the device o, or disconnect from the power supply.

9. Restart the device and wait at least 15 seconds from the switch-on time.

10. Check the current output with reference temperature 1) at 2 points. Select for the

initial value, (4 mA to +20 % of the span) and for the nal value (20 mA up to –20 %

of the span).

11. When using a customer-specic linearisation, this must be checked at a minimum

of three points.

12. Remove the bypass on the safety controller system or return to a normal operating

condition for other measures.

13. Following the tests, the results must be documented and archived accordingly.

®

function in simulation mode, set the current output to a

®

command 40: Enter Fixed Current-Mode)

GB

1) checking transmitters without sensors can also be achieved with an appropriate sensor

simulator (Simulator, ref. voltage source, etc.). Here the sensor must be tested to the SIL

demands of the customer's application. The measuring or setting accuracy of the test

instruments used should be at least 0.2 % of the span of the current output (16 mA).

With the testing described above a diagnostic cover of 99% will be

achieved.

11583631.02 11/2010 GB/D/F/E

WIKA safety manual temperature transmitter T32.xS

13

Page 14

2. Safety

2.8.2 Reduced proof test - limited testing of the transmitter's signal

conditioning chain

1. Bypass the safety controller system and/or take the appropriate action, to prevent

GB

an alarm being triggered unintentionally.

2. Deactivate the device's write protection

3. With the aid of the HART

®

function in simulation mode, set the current output to a

high alarm value (≥ 21.0 mA).

4. Test whether the current output signal reaches this value.

5. With the aid of the function in simulation mode, set the current output of the

transmitter to a low alarm value (≤ 3.6 mA)

6. Test whether the current output signal reaches this value.

7. Activate the write protection and wait for a minimum of 5 seconds.

8. Switch the device o, or disconnect from the power supply.

9. Restart the device and wait at least 15 seconds from the switch-on time.

10. Read the device status

11. Evaluate the device status and check it for conformity with the specications in the

operating instructions.

12. Read the device diagnostics

13. Evaluate the device diagnostics and check it for conformity with the specications

in the operating instructions.

14. Remove the bypass on the safety controller system or return to a normal operating

condition for other measures.

15. Following the tests, the results must be documented and archived accordingly

In contrast to the procedures described in 2.8.1., the signal conditioning chain is not tested here.

Its operational reliability should be ensured through reading and evaluating the device status and

device diagnostics.

With the testing described above, a diagnostic cover of 73 % will be

achieved.

WARNING!

Following the checking of the safety function, the device should be

secured against interference through write protection, since any change

in parameter can prejudice the safety function. The write protection should

be checked as follows: send a write instruction to the model T32.xS via a

®

HART

command. The temperature transmitter must acknowledge this

instruction with the message "Instrument is write protected".

WARNING!

The methods and procedures used for these tests (test scenarios) must

also be documented like the test results

. If the outcome of the function test

is negative, the whole system must be shut down. The process must be

put into a safe condition using appropriate procedures.

14

WIKA safety manual temperature transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 15

2. Safety

WARNING!

After the proof test of the device, start a functional check of the entire

safety function (safety loop) in order to test whether the transmitter

ensures the safety function of the system. Function tests are intended

to demonstrate the correct function of the whole safety-related system,

including all instruments (sensor, logic unit, and actuator).

2.9 Information on the determination of safety-relevant parameters

The failure rates of the electronics were determined using FMEDA in accordance

with IEC 61508. The calculations were based upon the component failure rates in

accordance with SN 29500.

The following assumptions have been made:

■

The transmitter are only operated in low demand mode applications.

■

The mean ambient temperature during the period of operation is 40 °C.

■

The MTTF following a device failure is 8 hours.

In accordance with ISO 13849-1 a maximum service life for the transmitter of 20 years

is assumed. Replace the device after this time.

2.10 Decommissioning the transmitter

GB

WARNING!

Ensure dvices that have been taken out of service are not accidentally

recommissioned (e.g. through marking the instrument). After

decommissioning the temperature transmitter, a functional test of the

entire safety function (safety loop) should be initiated, in order to test

whether the safety function of the system is still ensured. Function tests

are intended to demonstrate the correct function of the whole safetyrelated system, including all instruments (sensor, logic unit, and actuator).

11583631.02 11/2010 GB/D/F/E

WIKA safety manual temperature transmitter T32.xS

15

Page 16

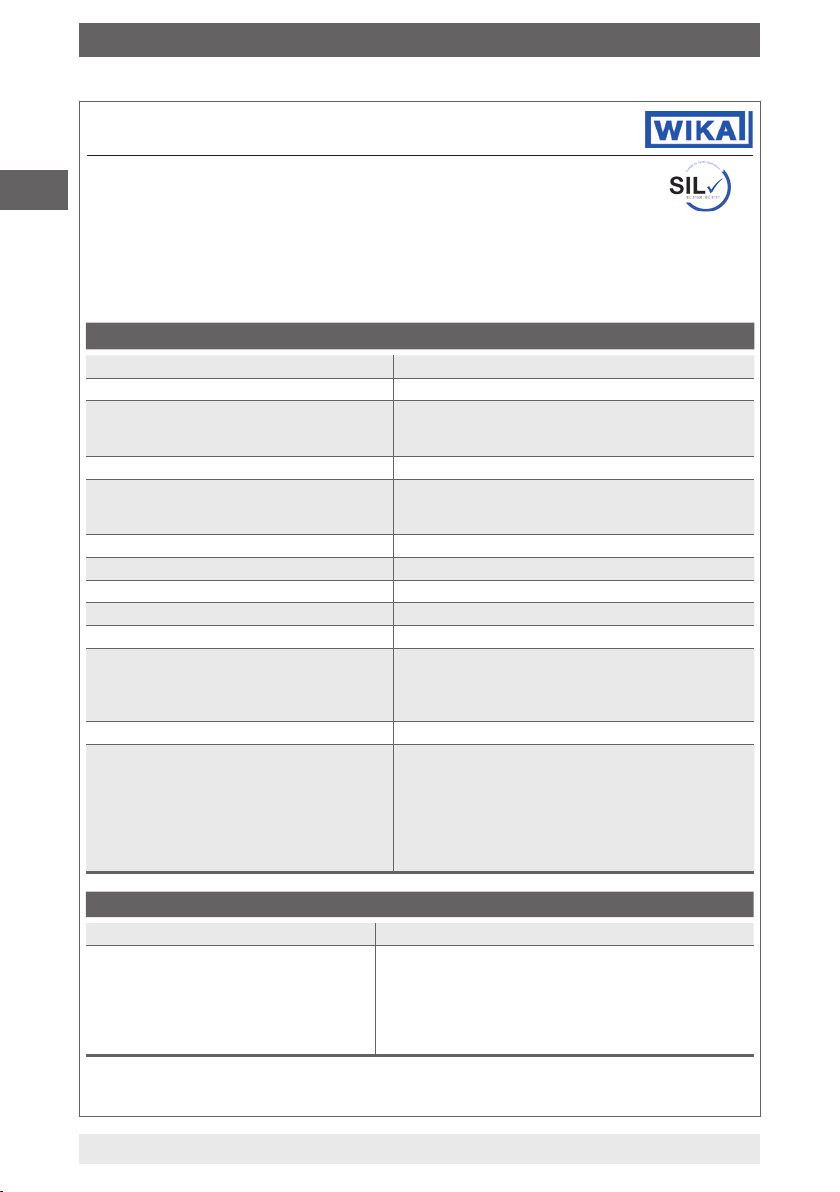

Appendix 1: SIL Declaration of Conformity

GB

SIL Declaration of Conformity

Functional safety per DIN EN 61508 / DIN EN 61511

WIKA Alexander Wiegand SE & Co. KG, Alexander Wiegand Straße 30, 63911 Klingenberg

declares as the manufacturer the accuracy of the following information.

1. General information

Permissible options

Safety-relevant output signal 4 … 20 mA

Error current Adjustable: ≤ 3.6 mA and ≥ 21.0 mA

Evaluated measurands /function Temperature in °C, °F, K, R

Safety function Single sensor

Device type per IEC 61508-2 B (complex components)

Operating mode Low Demand Mode

Current hardware version 6

Current software version (Firmware) 2.2.1

Safety handbook Issue 05/2010

Type of evaluation Complete evaluation, in parallel with development,

Evaluation through Report No. TÜV Rheinland 968/EL 632.01/10

Test documents Safety-Product Requirement Specication

T32.1S.xxx-S / T32.3S.xxx-S (xxx = 000/0IS/0NI)

(Factory settings: 3.5 mA and 21.5 mA to NAMUR

NE43)

Duplex sensor, Redundant, Minimum value,

Maximum value, Average value

of hardware and software incl. FMEDA on a

component level and change process to

IEC 61508-2,3

Product Requirements Specication

Functional Safety Management Plan

Product verication plan

Data Sheet TE 32.04

FMEA at component level

Safety handbook

2. SIL Integrity

Systematic safety integrity SIL3-capable software

Integrity against "random, dangerous

hardware errors"

(Type B components)

16

Single channel operation (HFT = 0, e.g. 1v1); SIL2

Two channel operation SIL3: to IEC 61508-6 Annex D

must determine a β-factor for the two channel (redundant) application, in order to incorporate the 'Common

Cause Failure Probability'.

For further information, see WIKA contact data

WIKA safety manual temperature transmitter T32.xS

Page 1/3

11583631.02 11/2010 GB/D/F/E

Page 17

Appendix 1: SIL Declaration of Conformity

SIL Declaration of Conformity

Functional safety per DIN EN 61508 / DIN EN 61511

3.1 FMEDA Pt100 3-wire (safety function for 4 … 20 mA output)

λ

du

λ

dd

λsu +λ

sd

SFF – Safe Failure Fraction 98.6 %

MTTR 8 h

PFD for T

1 year 1.316 x 10

proof

DC proof-test-coverage

incl. signal conditioning chain

3.2 FMEDA Pt100 4-wire (safety function for 4 … 20 mA output)

λ

du

λ

dd

λsu +λ

sd

SFF – Safe Failure Fraction 98.6 %

MTTR 8 h

PFD for T

1 year 1.482 x 10

proof

DC proof-test-coverage

incl. signal conditioning chain

3.3 FMEDA Pt100 2-wire (safety function for 4 … 20 mA output)

λ

du

λ

dd

λsu +λ

sd

SFF – Safe Failure Fraction 81.2 %

MTTR 8 h

PFD for T

DC proof-test-coverage

incl. signal conditioning chain

1 year 1.815 x 10

proof

30 FIT

2037 FIT

118 FIT

99 %

34 FIT

2037 FIT

119 FIT

99 %

414 FIT

1657 FIT

118 FIT

99 %

1)

1)

1)

-4

1)

1)

1)

-4

1)

1)

1)

-3

GB

2)

3.4 FMEDA thermocouple with internal cold junction

(safety function for 4 … 20 mA output)

λ

du

λ

dd

λsu +λ

sd

SFF – Safe Failure Fraction 94.9 %

MTTR 8 h

PFD for T

1 year 1.162 x 10

proof

DC proof-test-coverage

incl. signal conditioning chain

1) FIT = Failure in time, Unit: Quantity of failures per 10

2) Determine the distribution of error patterns in WIKA TRxx Sensors

11583631.02 11/2010 GB/D/F/E

265 FIT

4807 FIT

116 FIT

99 %

9

h

WIKA safety manual temperature transmitter T32.xS

1)

1)

1)

-3

Page 2/3

17

Page 18

Appendix 1: SIL Declaration of Conformity

GB

SIL Declaration of Conformity

Functional safety per DIN EN 61508 / DIN EN 61511

3.5 FMEDA thermocouple with external cold junction

(safety function for 4 … 20 mA output)

λ

du

λ

dd

λsu +λ

sd

SFF – Safe Failure Fraction 90.7 %

MTTR 8 h

PFD for T

1 year 2.91 * 10

proof

DC proof-test-coverage

incl. signal conditioning chain

3.6 FMEDA duplex sensor Pt100 (safety function for 4 … 20 mA output)

λ

du

λ

dd

λsu +λ

sd

SFF – Safe Failure Fraction 98.8 %

MTTR 8 h

PFD for T

1 year 2.495 * 10

proof

DC proof-test-coverage

incl. signal conditioning chain

3.7 FMEDA duplex sensor thermocouple with internal cold junction

(safety function for

λ

du

λ

dd

λsu +λ

sd

SFF – Safe Failure Fraction 95.3 %

MTTR 8 h

PFD for T

DC proof-test-coverage

incl. signal conditioning chain

1) FIT = Failure in time, Unit: Quantity of failures per 10

proof

4 … 20 mA output

)

1 year 2.262 * 10

664 FIT

6407 FIT

118 FIT

99 %

57 FIT

4017 FIT

119 FIT

99 %

516 FIT

9557 FIT

117 FIT

99 %

9

h

1)

1)

1)

-3

1)

1)

1)

-4

1)

1)

1)

-3

18

Page 3/3

WIKA safety manual temperature transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 19

Inhalt

Inhalt

1. Allgemeines 20

1.1 Historie dieses Dokumentes 20

1.2 Mitgeltende Gerätedokumentationen 20

1.3 Relevante Normen 20

1.4 Abkürzungen 21

2. Sicherheit 22

2.1 Bestimmungsgemäße Verwendung in Sicherheitsanwendungen 22

2.2 Beschilderung / Sicherheitskennzeichnungen 23

2.3 Einschränkung der Betriebsarten 24

2.4 Fehlersignalisierung 25

2.5 Schreibschutz 26

2.6 Genauigkeit der sicheren Messfunktion 27

2.7 Kongurationsänderungen 28

2.8 Inbetriebnahme und wiederkehrende Prüfungen 29

2.8.1 Proof Test der kompletten Signalverarbeitungskette des Transmitters 29

2.8.2 Reduzierter Prooftest - eingeschränkte Prüfung der Signalverarbeitungskette des Transmitters 30

2.9 Hinweise zur Ermittlung sicherheitstechnischer Kenngrößen 31

D

2.10 Außerbetriebnahme des Transmitters 31

Anlage 1: SIL Konformitätserklärung 16

11583631.02 11/2010 GB/D/F/E

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

19

Page 20

1. Allgemeines

1. Allgemeines

1.1 Historie dieses Dokumentes

Dokumentationsänderungen (verglichen mit der vorherigen Ausgabe)

Ausgabe Bemerkung Firmware

April 2010 Erstausgabe T32.1S/ T32.3S

D

Mai 2010 4 Sprachen

(+ Französisch, + Spanisch)

November

2010

Dieses Sicherheitshandbuch zur funktionalen Sicherheit behandelt die WIKA Temperatur-Transmitter Typ T32.1S/T32.3S (ab Firmware Rev. 2.2.1) lediglich als Teil einer

Sicherheitsfunktion. Dieses Sicherheitshandbuch gilt im Zusammenhang mit den unter

„1.2 Mitgeltende Gerätedokumentationen“ genannten Dokumentationen. Zusätzlich

die Sicherheitshinweise in der Betriebsanleitung beachten.

Die Betriebsanleitung enthält wichtige Hinweise zum Umgang mit dem TemperaturTransmitter Typ T32.1S/T32.3S. Voraussetzung für sicheres Arbeiten ist die Einhaltung

aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

Überwachung der Ausgangsgrenzen

(optional, bei SIL Ausführung ab

01.01.2011 als default nicht aktiviert)

(ab Firmware Rev. 2.2.1)

T32.1S/ T32.3S

(ab Firmware Rev. 2.2.1)

T32.1S/ T32.3S

(ab Firmware Rev. 2.2.1)

Die Kennzeichnung der Geräte mit SIL-Ausführung auf den

Typenschildern ist in den folgenden Darstellungen erläutert. Nur der Typ

T32.xS.0xx-S ist für den Einsatz in sicherheitsgerichteten Anwendungen

geeignet!

Der Typ T32.xS.0xx-S ist beliebig mit den verfügbaren Ex-Ausführungen

kombinierbar.

1.2 Mitgeltende Gerätedokumentationen

Ergänzend zu diesem Sicherheitshandbuch gelten die Betriebsanleitung für

Typ T32.xS (S-Nr.: 11258421) sowie das Datenblatt TE 32.04.

1.3 Relevante Normen

Norm Typ T32.xS

IEC 61508 Sicherheitstechnische Systeme für die Prozessindustrie

Zielgruppe: Hersteller und Lieferanten von Geräten

IEC 61511

20

Funktionale Sicherheit sicherheitsbezogener elektrischer/elektronischer/

programmierbarer elektronischer Systeme

Zielgruppe: Planer, Errichter Nutzer

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 21

1. Allgemeines

1.4 Abkürzungen

Abkürzung

HFT Hardware Fehlertoleranz; Fähigkeit einer Funktionseinheit, eine

MTBF Mittlere Zeitdauer zwischen zwei Ausfällen

MTTR Mittlere Zeitdauer zwischen dem Auftreten eines Fehlers in einem

PFD Wahrscheinlichkeit gefahrbringender Ausfälle einer Sicherheits-

PFD

avg

SIL Safety Integrity Level; Die internationale Norm IEC 61508 deniert

SFF Anteil ungefährlicher Ausfälle, Anteil von Ausfällen ohne Poten-

T

Proof

XooY Klassizierung und Beschreibung des sicherheitsbezogenen

und λ

λ

sd

λdd +λ

du

λ

du

Beschreibung

geforderte Funktion bei Bestehen von Fehlern oder Abweichungen

weiter auszuführen.

Gerät oder System und der Reparatur

funktion im Anforderungsfall

Mittlere Wahrscheinlichkeit gefahrbringender Ausfälle einer Sicher-

heitsfunktion im Anforderungsfall

vier diskrete Safety Integrity Level (SIL1 bis SIL4). Jeder Level

entspricht einem Wahrscheinlichkeitsbereich für das Versagen einer

Sicherheitsfunktion. Je höher der Safety Integrity Level der sicherheitsbezogenen Systeme ist, umso geringer ist die Wahrscheinlichkeit, dass sie die geforderten Sicherheitsfunktionen nicht ausführen.

tial, das sicherheitsbezogene System in einen gefährlichen oder

unzulässigen Funktionszustand zu versetzen.

Nach IEC 61508-4, Abschnitt 3.5.8 wird TProof deniert als wiederkehrende Prüfung zur Aufdeckung von Ausfällen in einem sicherheitsbezogenen System.

Systems hinsichtlich Redundanz und angewandtem Auswahlverfahren. "Y" gibt an, wie oft die Sicherheitsfunktion ausgeführt

wird (Redundanz). "X" bestimmt, wie viele Kanäle korrekt arbeiten

müssen.

λsd Safe detected + λsu Safe undetected

su

Ungefährlicher Ausfall (IEC 61508-4, Abschnitt 3.6.8):

Ein ungefährlicher Ausfall (safe failure) liegt vor, wenn das Messsystem ohne Anforderung des Prozesses in den denierten sicheren

Zustand oder in den Fehler-Signalisierungsmodus wechselt.

λdd Dangerous detected + λdu Dangerous undetected

Gefährlicher Ausfall (IEC 61508-4, Abschnitt 3.6.7):

Generell liegt ein gefährlicher Ausfall dann vor, wenn das Messystem

in einen gefährlichen oder funktionsunfähigen Zustand versetzt wird.

λdu Dangerous undetected

Ein gefährlicher unentdeckter Ausfall liegt vor, wenn das Messsystem

bei einer Anforderung des Prozesses weder in den denierten

sicheren Zustand, noch in den Fehler-Signalisierungsmodus wechselt.

D

Weitere relevante Abkürzungen siehe IEC 61508-4.

11583631.02 11/2010 GB/D/F/E

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

21

Page 22

2. Sicherheit

2. Sicherheit

2.1 Bestimmungsgemäße Verwendung in Sicherheitsanwendungen

Sämtliche Sicherheitsfunktionen beziehen sich ausschließlich auf das analoge

Ausgangsignal (4 … 20 mA). Das Gerät ist nach SIL2 (IEC 61508) zertiziert. Die

Software des Gerätes erfüllt die Kriterien für SIL3 (IEC 61508). Der Einsatz des

Gerätes in homogen redundanten Systemen ist damit möglich.

D

Folgende Sensoranschlüsse erreichen eine für SIL2 ausreichende SFF (Safe Failure

Fraction) von >90 %:

■

Thermoelement (Vergleichsstelle intern, Pt100)

■

Thermoelement (Vergleichsstelle extern, Pt100)

■

Widerstandsthermometer mit 4-Leiter Anschluss

■

Widerstandsthermometer mit 3-Leiter Anschluss

WIKA-Sensoren Typ TRxx (siehe WIKA-Herstellererklärung Dokument Nr. 3011701)

■

Doppel-Thermoelement bzw. Doppel-Widerstandsthermometer

(Nur in der Betriebsart „redundant“ und wenn beide Sensoren für die Überwachung

der gleichen Messstelle verwendet werden (2-kanalig)).

Folgende Sensoranschlüsse erreichen eine für SIL1 ausreichende SFF (Safe Failure

Fraction) von >60 %:

■

Widerstandsthermometer mit 3-Leiter Anschluss

- Universelle Sensoren -

■

Widerstandsthermometer mit 2-Leiter Anschluss

Das Gerät erzeugt ein vom Sensorsignal abhängiges Stromsignal im zulässigen

Messbetrieb von nominal 4 … 20 mA. Der gültige Bereich des Ausgangssignals ist auf

ein Minimum von 3,8 mA und ein Maximum von 20,5 mA begrenzt (Werkseinstellung

bei Grundkonguration).

WARNUNG!

Die im Datenblatt bzw. in der Betriebsanleitung angegebenen Spezikationen des Typs T32.xS nicht überschreiten. Um eine sichere Funktion

des Stromausgangs zu gewährleisten, muss insbesondere die korrekte

Klemmenspannung am Gerät anliegen.

Folgende Klemmenspannungsgrenzen einhalten:

Geräte-Typ Klemmenspannungsgrenzen

T32.1S.000-S

T32.3S.000-S

T32.1S.0IS-S

T32.3S.0IS-S

22

DC 10,5 ... 42 V

DC 10,5 ... 30 V

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 23

2. Sicherheit

WARNUNG !

Folgende Sensoren und Betriebsarten sind für den Einsatz in einer sicherheitsgerichteten Anwendung NICHT zulässig:

■

Potentiometer

■

Widerstandssensor

■

mV-Sensor

■

Dierenzmodus im Doppelsensorbetrieb

2.2 Beschilderung / Sicherheitskennzeichnungen

Typenschild

■

Kopfversion, Typ T32.1S

D

SIL-Ausführung

(nur bei SIL)

Hilfsenergie

Sensor, Pt100

oder RTD

Ausgangssignal

Typ

mit SIL: T32.1S.0IS-S

ohne SIL: T32.1S.0IS-Z

Herstellungsdatum

(Jahr-Monat)

11583631.02 11/2010 GB/D/F/E

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

23

Page 24

2. Sicherheit

■

Schienenversion, Typ T32.3S

D

SIL-Ausführung

(nur bei SIL)

Hilfsenergie

Sensor, Pt100

oder RTD

Ausgangssignal

Typ

mit SIL: T32.1S.0IS-S

ohne SIL: T32.1S.0IS-Z

Herstellungsdatum

(Jahr-Monat)

2.3 Einschränkung der Betriebsarten

WARNUNG!

Unter folgenden Betriebsbedingungen wird die Sicherheitsfunktion des

Gerätes nicht gewährleistet:

■

Während der Konguration

■

Bei deaktiviertem Schreibschutz

■

Bei aktiviertem HART®-Multidrop-Modus

■

Messwertübertragung mittels HART®-Protokoll

■

Während einer Simulation

■

Während des Proof-Tests

■

Bei deaktiviertem Schreibschutz

24

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

Anschlussbelegung

11583631.02 11/2010 GB/D/F/E

Page 25

2. Sicherheit

2.4 Fehlersignalisierung

Der Temperatur-Transmitter Typ T32.xS überwacht den angeschlossenen Fühler und

die eigene Hardware auf Fehler. Im Falle eines erkannten Fehlerzustands erzeugt das

Gerät einen Fehlersignalisierungsstrom.

Die Reaktionszeit auf Sensorfehler beträgt maximal 90 Sekunden.

Dies beinhaltet die Aufdeckung folgender potentieller Fehler:

■

Fühlerbruch

■

Fühlerkurzschluss (nur bei Widerstandstemperatursensoren, nicht für Thermo-

elemente)

■

Unzulässig hoher Zuleitungswiderstand (nicht bei Doppel-Widerstandstemperatur-

sensoren)

Das online Diagnose-Test-Intervall des Geräts beträgt maximal 35 Minuten.

Dies beinhaltet die Aufdeckung folgender potentieller Gerätefehler:

■

ROM-Fehler

■

EEPROM-Fehler

■

RAM-Fehler

■

Programm-Counter-Fehler

■

Stack-Pointer-Fehler

Weiterhin werden permanent folgende Überwachungsfunktionen durchgeführt:

■

Logische Programmlaufkontrolle

■

Interne Kommunikationfehler

■

Sensor-Obergrenze überschritten

■

Sensor-Untergrenze unterschritten

■

Vergleichsstellentemperatur außerhalb erlaubter Grenzen (nur bei Thermoelementen)

■

Doppelsensor Drift-Überwachung (optional zuschaltbar)

■

Kongurationsfehler

■

Überwachung der zulässigen Gerätetemperatur (optional, bei SIL Ausführung als

default aktiviert)

■

Überwachung der Ausgangsgrenzen (optional, bei SIL Ausführung ab 01.01.2011

als default nicht aktiviert)

D

VORSICHT!

Der Fehler-Signalisierung-Strom (Störstrom) des Gerätes entsprechend

den nachfolgenden Anforderungen kongurieren:

■

Störstrom Fail High (Hoch-Alarmwert):

einstellbar im Bereich ≥ 21,0 mA bis ≤ 23,0 mA (Upscale)

■

Störstrom Fail Low (Tief-Alarmwert) :

einstellbar im Bereich ≥ 3,5 mA bis ≤ 3,6 mA (Downscale)

11583631.02 11/2010 GB/D/F/E

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

25

Page 26

2. Sicherheit

WARNUNG!

Bei bestimmten geräteseitig diagnostizierten Hardwarefehlern wird das

Gerät eine zusteuernde Fehlersignalisierung mit einem Schleifenstrom

< 3,8 mA vornehmen, kann jedoch technisch bedingt auch bei entsprechender Konguration keine Signalisierung ≤ 3,6 mA sicherstellen. Das

Auswertesystem muss daher Schleifenströme < 3,8 mA als Fehlerfall

D

Der Transmitter erzeugt bei bestimmten unzulässigen Kongurationen (z. B. bei

deaktiviertem Schreibschutz) ebenfalls eine Fehlersignalsierung. Um den Grund einer

Fehlersignalisierung herauszunden empehlt sich die Nutzung von über HART

abrufbaren Diagnose Funktionen. Derartige Funktionen bietet z. B. die KongurationsSoftware WIKA_T32 an (kostenfreier Download unter www.wika.de).

2.5 Schreibschutz

Der T32.xS verfügt über eine Schreibschutzfunktionalität um versehentliche Kongurationsänderungen zu verhindern. Ab Werk ist das Passwort des Schreibschutzes auf „0“

eingestellt.

interpretieren.

Ein T32.xS Temperatur Transmitter mit SIL Option geht erst in den aktiven

Betrieb nachdem der Schreibschutz aktiviert wurde. Ohne aktiven

Schreibschutz signalisiert ein solcher Transmitter einen Fehler.

®

2.5.1 Bedienung des Schreibschutzes

Die Funktion Schreibschutz wird bedient durch ein Passwort (Zahlen im Bereich 0 bis

65535 sind zulässig) und durch einen Schalter (Schreibschutz aktivieren/deaktivieren).

Eine Änderung des Zustandes des Schreibschutzschalters ist jeweils nur nach erfolgreicher Eingabe des Passwortes möglich. Das Passwort kann über ein eigenes Menü

geändert werden.

VORSICHT!

Es besteht absolut KEINE Möglichkeit ein in Vergessenheit geratenes

Passwort wieder auszulesen! Es besteht ausschließlich die Möglichkeit

das Passwort im Werk wieder zurückzusetzen!

Auch das Aktivieren des Schreibschutzes ist nur durch die korrekte

Passworteingabe möglich!

26

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 27

2. Sicherheit

2.6 Genauigkeit der sicheren Messfunktion

Die nachfolgenden Angaben zur Gesamtsicherheitsgenauigkeit beinhalten jeweils

folgende Komponenten:

■

Grundgenauigkeit (Messabweichung von Ein- und Ausgang, sowie Linearisierungs-

fehler des Transmitters)

■

Für Thermoelemente zusätzlich die interne Vergleichsstellen-Kompensation

(engl.: CJC), außer bei Thermoelement Typ B

■

Einuss der Umgebungstemperatur im Bereich -50 ... +85 °C

Der denierte Wert für die Gesamtsicherheits-Genauigkeit der Sicherheitsfunktion

dieses Gerätes richtet sich nach dem gewählten Sensortyp, sowie der kongurierten

Messspanne (siehe nachfolgende Tabelle).

Bis zu den in der Tabelle angegebenen minimalen Spannen beträgt die Gesamtsicherheitsgenauigkeit 2 % der Messspanne bzgl. des Stromausgangssignals von 16 mA.

Ansonsten gelten die in der Tabelle direkt angegebenen absoluten Werte.

VORSICHT!

Die Messspanne ist die Dierenz zwischen Endwert und Anfangswert

eines Messbereiches.

D

Sensortyp

Pt100 -200 ... +850 °C 84 K

Ni100 -60 ... +250 °C 21 K

Pt1000

Pt500 70 K 2 K

Pt25 134 K 3 K

Pt10 241 K 5 K

TE Typ T -150 ... +400 °C 134 K

TE Typ U -150 ... +600 °C 136 K

TE Typ E -150 ... +1000 °C 164 K

TE Typ J -150 ... +1200 °C 176 K

TE Typ K -140 ... +1200 °C 197 K

TE Typ N -150 ... +1300 °C 154 K

TE Typ R +50 … +1600 °C 255 K

TE Typ B +500 …+1820 °C 283 K

11583631.02 11/2010 GB/D/F/E

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

Zulässiger Sensorbereich für die

Genauigkeitsangaben

-200 ... +850 °C

Min. Spanne für 2 %

Gesamtsicherheitsgenauigkeit

69 K 2 K

Absolute Gesamtsicherheitsgenauigkeit für kleinere

Messspannen

2 KJPt100 -200 ... +500 °C 50 K

3 KTE Typ L -150 ... +900 °C 138 K

4 K

6 KTE Typ S +50 … +1600 °C 273 K

27

Page 28

2. Sicherheit

Anwendung (siehe Tabelle Seite 27):

■

Beispiel 1

Sensortyp Pt100, kongurierter Messbereich = -50 … +100 °C, also kongurierte

Messspanne = 150 K.

Diese ist nicht kleiner als 84 K. Damit beträgt die Gesamtsicherheitsgenauigkeit

2 % FS, also 2 % * 150 K = 3 K,

bzw. 2 % * 16 mA = 320 μA bzgl. des Stromausgangs

D

■

Beispiel 2

Sensortyp Pt100, kongurierte Messbereich = 0 … 50 °C, also kongurierte

Messspanne = 50 K

Diese ist kleiner als 84 K, damit beträgt die Gesamtsicherheitsgenauigkeit 2 K, also

2 K / 50 K = 4 %, bzw. 4 % * 16 mA = 640 μA bzgl. des Stromausgangs

2.7 Kongurationsänderungen

WARNUNG!

Während der Kongurationsänderung ist die Sicherheitsfunktion nicht

aktiv! Der Safety-Betrieb ist nur mit aktiviertem Schreibschutz (Passwort)

erlaubt.

Kongurationsänderungen innerhalb der zulässigen Spezikationen gemäß

„2.1 Bestimmungsgemäße Verwendung in Sicherheitsanwendungen“ durchführen.

Mit den aufgeführten Kongurations-Werkzeugen ist u.a. der Schreibschutz für Typ

T32.xS einstellbar:

■

Kongurations-Software WIKA_T32

■

AMS

■

SIMATIC PDM

■

DTM (ab Version DTM Betaversion V1.0.2, Januar 2003) in Verbindung mit einer

Bediensoftware nach dem FDT/DTM-Standard, z. B. PACTware, FieldMate

■

HART®- Handterminal FC475, FC375, MFC4150

WARNUNG!

Die Sicherheitsfunktion muss nach einem Kongurationsvorgang durch

einen Test überprüft werden.

28

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 29

2. Sicherheit

2.8 Inbetriebnahme und wiederkehrende Prüfungen

Die Funktionsfähigkeit und der Fehlersignalisierungs-Strom des Temperatur-Transmitters TypT32.xS ist bei der Inbetriebnahme sowie in angemessenen Zeitabständen, zu

prüfen. Sowohl die Art der Überprüfung als auch die gewählten Zeitabstände liegen

in der Verantwortung des Anwenders. Die Zeitabstände richten sich gewöhnlich

nach dem in Anspruch genommenen PFDavg-Wert (Werte und Kennzahlen siehe

„Anlage 1: SIL-Konformitätserklärung“). Üblicherweise wird von einer Wiederholungsprüfung von 1 Jahr ausgegangen.

2.8.1 Proof Test der kompletten Signalverarbeitungskette des Transmitters

1. Wenn notwendig, das Sicherheitssteuerungs-System überbrücken bzw. geeignete

Maßnahmen ergreifen, die ein nicht beabsichtigtes Auslösen des Alarms verhindern.

2. Den Schreibschutz des Gerätes deaktivieren

3. Der Stromausgang ist mit Hilfe der HART

einen Hochalarmwert (≥ 21,0 mA) einzustellen.(HART

Fixed Current-Mode)

4. Prüfen, ob das Stromausgangssignal diesen Wert erreicht.

5. Den Stromausgang des Messumformers mithilfe der Funktion im Simulation-

Modus auf einen Tiefalarmwert (≤ 3,6 mA) einstellen

6. Prüfen, ob das Stromausgangssignal diesen Wert erreicht.

7. Den Schreibschutz aktivieren und min. 5 Sekunden warten.

8. Das Gerät abschalten bzw. von der Stromversorgung trennen.

9. Das Gerät neu starten und mindestens die Einschaltzeit von 15 Sekunden abwarten.

10. Den Stromausgang mit Referenztemperatur 1) an 2 Punkten überprüfen. Für den

Messanfang, (4 mA bis +20 % der Spanne) und für das Meßende (20 mA bis zu

–20 % der Spanne) wählen.

11. Bei Verwendung der kundenspezischen Kennlinie ist diese an mindestens drei

Punkten zu prüfen.

12. Die Überbrückung des Sicherheitssteuerungs-Systems entfernen oder den

normalen Betriebszustand auf eine andere Weise wiederherstellen.

13. Nach Durchführung der Tests müssen die Ergebnisse dokumentiert und entspre-

chend archiviert werden.

®

-Funktion im Simulation-Modus auf

®

-Kommando 40: Enter

D

1) die Überprüfung des Messumformers ohne Sensor kann auch mit einem entsprechenden Sen-

sorsimulator (Simulator, Ref. Spannungsquellen, etc.) erfolgen. Hierbei ist der Sensor gemäß

den SIL Anforderungen der Kundenapplikation zu prüfen. Die Mess- oder Stellgenauigkeit der

eingesetzten Prüfmittel soll mindestens 0,2 % bezogen auf die Spanne des Stromausgangs

(16 mA) betragen.

Mit der oben beschriebenen Prüfung wird ein Diagnosedeckungsgrad von

99 % erreicht.

11583631.02 11/2010 GB/D/F/E

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

29

Page 30

2. Sicherheit

2.8.2 Reduzierter Prooftest - eingeschränkte Prüfung der Signalverarbeitungs-

kette des Transmitters

1. Das Sicherheitssteuerungs-System überbrücken bzw. eine geeignete Maßnahme

ergreifen, die ein nicht beabsichtigtes Auslösen des Alarms verhindert.

2. Den Schreibschutz des Gerätes deaktivieren.

3. Den Stromausgang des Gerätes mit Hilfe der HART

Modus auf einen Hochalarmwert (≥ 21,0 mA) einstellen

4. Prüfen, ob das Stromausgangssignal diesen Wert erreicht.

D

5. Den Stromausgang des Messumformers mithilfe der HART®-Funktion im Simulati-

on-Modus auf einen Tiefalarmwert (≤ 3,6 mA) einstellen

6. Prüfen, ob das Stromausgangssignal diesen Wert erreicht.

7. Den Schreibschutz aktivieren und min. 5 Sekunden warten.

8. Das Gerät abschalten bzw. von der Stromversorgung trennen.

9. Das Gerät neu starten und mindestens die Einschaltzeit von 15 Sekunden abwarten.

10. Den Gerätestatus auslesen

11. Den Gerätestatus bewerten und auf Konformität gegenüber den Vorgaben in der

Betriebsanleitung überprüfen.

12. Die Gerätediagnose auslesen

13. Die Gerätediagnose bewerten und auf Konformität gegenüber den Vorgaben in

der Betriebsanleitung überprüfen.

14. Die Überbrückung des Sicherheitssteuerungs-Systems entfernen oder den

normalen Betriebszustand auf eine andere Weise wiederherstellen.

15. Nach der Durchführung des Tests müssen die Ergebnisse dokumentiert und

entsprechend archiviert werden.

®

-Funktion im Simulation-

Im Gegensatz zu dem in 2.8.1. beschriebenen Verfahren wird hier die Signalverarbeitungskette

nicht getestet. Deren Funktionstüchtigkeit soll durch Auslesen und Bewertung des Gerätestatus

bzw. der Gerätediagnose gewährleistet werden.

Mit der oben beschriebenen Prüfung wird ein Diagnosedeckungsgrad von

73 % erreicht.

WARNUNG!

Nach der Überprüfung der Sicherheitsfunktion ist das Gerät gegen Bedienung per Schreibschutz zu sichern, da jede Änderung der Parameter die

Sicherheitsfunktion beeinträchtigen kann. Der Schreibschutz sollte wie

folgt überprüft werden: Einen Schreibbefehl per HART

®

-Kommando an

den Typ T32.xS senden. Der Temperatur-Transmitter muss diesen Befehl

mit der Meldung „Gerät ist schreibgeschützt“ quittieren.

WARNUNG!

Die bei den Tests verwendeten Methoden und Verfahren (Prüfszenarien)

sind, ebenso wie die Prüfergebnisse, zu dokumentieren.

Verläuft ein

Funktionstest negativ, ist das gesamte Messsystem außer Betrieb zu

nehmen. Der Prozess ist durch geeignete Maßnahmen im sicheren

Zustand zu halten.

30

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

11583631.02 11/2010 GB/D/F/E

Page 31

2. Sicherheit

WARNUNG!

Nach dem Proof-Test des Gerätes einen Funktionstest der gesamten

Sicherheitsfunktion (Sicherheitsloop) starten um zu prüfen, ob der Transmitter die Sicherheitsfunktion des Systems gewährleistet. Die Funktionstests dienen dazu, die einwandfreie Funktion der Sicherheitseinrichtung

SIS im Zusammenwirken aller Komponenten (Sensor, Logikeinheit, Aktor)

nachzuweisen.

2.9 Hinweise zur Ermittlung sicherheitstechnischer Kenngrößen

Die Ausfallraten der Elektronik wurden durch eine FMEDA nach IEC 61508 ermittelt.

Den Berechnungen wurden Bauelemente-Ausfallraten nach SN29500 zugrunde

gelegt.

Dabei gelten die folgenden Annahmen:

■

Der Transmitter wird nur in Anwendungen niedriger Anforderungsrate eingesetzt

(Low Demand Mode)

■

Die mittlere Umgebungstemperatur während der Betriebszeit beträgt 40 °C

■

Die MTTR nach einem Gerätefehler beträgt 8 Stunden

In Anlehnung an die ISO 13849-1 wird von einer maximalen Gebrauchsdauer für den

Transmitter in einer Sicherheitsanwendung von 20 Jahren ausgegangen. Ersetzen Sie

das Gerät nach dieser Zeit.

D

2.10 Außerbetriebnahme des Transmitters

WARNUNG!

Außer Betrieb genommene Geräte gegen versehentliche Inbetriebnahme

(z. B. durch Kennzeichnung der Geräte) sichern. Nach der Außerbetriebnahme des Temperatur-Transmitters sollte ein Funktionstest der gesamten

Sicherheitsfunktion (Sicherheitsloop) gestartet werden, um zu prüfen, ob

die Sicherheitsfunktion des Systems immer noch gewährleistet ist. Die

Funktionstests dienen dazu, die einwandfreie Funktion der Sicherheitseinrichtung SIS im Zusammenwirken aller Komponenten (Sensor, Logikeinheit, Aktor) nachzuweisen.

11583631.02 11/2010 GB/D/F/E

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

31

Page 32

D

32

11583631.02 11/2010 GB/D/F/E

WIKA Sicherheitshandbuch Temperatur-Transmitter T32.xS

Page 33

Sommaire

Sommaire

1. Généralités 34

1.1 Historique du présent document 34

1.2 Autres documentations relatives à l'appareil 34

1.3 Normes pertinentes 34

1.4 Abréviations 35

2. Sécurité 36

2.1 Utilisation conforme à l'usage prévu dans des applications de sécurité 36

2.2 Etiquetage / Marquages de sécurité 37

2.3 Limitation des modes opératoires 38

2.4 Signalement des erreurs 39

2.5 Protection en écriture 40

F

2.6 Exactitude de la fonction de mesure sûre 41

2.7 Modications de la conguration 42

2.8 Mise en service et contrôles récurrents 43

2.8.1

Essai relatif à la chaîne complète de traitement des signaux du transmetteur

2.8.2 Essai réduit - contrôle restreint de la chaîne de traitement du signal du

transmetteur 44

2.9 Remarques relatives à la détermination de paramètres relevant de la

sécurité 45

2.10 Mise hors service du transmetteur 45

Annexe 1: Déclaration de conformité SIL 16

11583631.02 11/2010 GB/D/F/E

WIKA manuel de sécurité transmetteur de température T32.xS

43

33

Page 34

1. Généralités

1. Généralités

1.1 Historique du présent document

Modications apportées à la documentation

(par comparaison à l'édition précédente)

Édition Remarque Firmware

Avril 2010 Première édition T32.1S/ T32.3S

(à partir de la révision 2.2.1 de

F

Mai 2010

Novembre

2010

Ce manuel de sécurité relative à la sécurité fonctionnelle concerne les transmetteurs

de température WIKA type T32.1S/T32.3S (à partir de la révision 2.2.1 de la rmware)

uniquement en tant que partie d'une fonction de sécurité. Le manuel de sécurité est

valable en rapport avec les documentations désignées au point "1.2 Autres documentations relatives à l'appareil". Observer en plus les consignes de sécurité contenues

dans le mode d'emploi.

4 langues

(+ français, + espagnol)

Surveillance de la température

admissible de l'appareil (en option, non

activée en standard sur le modèle SIL à

partir du 01.01.2011)

la rmware)

T32.1S/ T32.3S

(à partir de la révision 2.2.1 de

la rmware)

T32.1S/ T32.3S

(à partir de la révision 2.2.1 de

la rmware)

Ce mode d'emploi comporte des indications importantes relatives au maniement du

transmetteur de température type T32.1S/T32.3S. Il est possible de travailler en toute

sécurité avec ce produit en respectant toutes les consignes de sécurité et d'utilisation.

Le marquage des appareils avec Type SIL sur les plaques signalétiques

est expliqué dans les exposés suivants. Seul le type T32.xS.0xx-S est

approprié pour l'utilisation dans des applications de sécurité !

Le type T32.xS.0xx-S peut être combiné avec la version Ex optionnelle .

1.2 Autres documentations relatives à l'appareil

Le mode d'emploi pour le type T32.xS (Réf. : 11583615) ainsi que la che technique

TE 32.04 sont valables en complément au présent manuel de sécurité.

34

WIKA manuel de sécurité transmetteur de température T32.xS

11583631.02 11/2010 GB/D/F/E

Page 35

1. Généralités

1.3 Normes pertinentes

Norme Type T32.xS

IEC 61508 Systèmes de sécurité pour les procédés industriels

Groupe cible : fabricants et fournisseurs d'appareils

IEC 61511

1.4 Abréviations

Abréviation

HFT Tolérance matérielle ; capacité d'un module fonctionnel de

MTBF Temps moyen entre deux défaillances

MTTR Temps moyen entre la survenance d'une erreur dans un appareil ou

PFD Probabilité de défaillances menaçantes d'une fonction de sécurité

PFD

avg

SIL Safety Integrity Level (niveau d'intégrité de sécurité) ; la norme

SFF Partie de défaillances non dangereuses, partie de défaillances ne

T

Proof

XooY Classication et description du système de sécurité en termes

und λ

λ

sd

11583631.02 11/2010 GB/D/F/E

Sécurité fonctionnelle des systèmes électriques/électroniques/

électroniques programmables relatifs à la sécurité

Groupe cible : concepteurs, constructeurs, utilisateurs

Description

continuer l'exécution d'une fonction sollicitée en présence d'erreurs

ou de tolérances.

un système et la réparation

en cas de sollicitation

Probabilité moyenne de défaillances menaçantes d'une fonction de

sécurité en cas de sollicitation

internationale IEC 61508 dénit quatre Safety Integrity Level

discrets (SIL1 à SIL4). Chaque niveau correspond à une plage

de probabilité pour la défaillance d'une fonction de sécurité. Plus

le Safety Integrity Level des systèmes de sécurité est élevé, plus

la probabilité qu'ils n'exécutent pas les fonctions de sécurité

sollicitées est faible.

présentant pas de potentiel pour mettre le système de sécurité

dans un état de fonctionnement dangereux ou inadmissible.

Selon IEC 61508-4, section 3.5.8, T

répétitif permettant de détecter des défaillances dans un système

de sécurité.

de redondance et de procédé de sélection appliqué. "Y" indique

la fréquence à laquelle la fonction de sécurité est exécutée

(redondance). "X" détermine le nombre de canaux qui doivent

fonctionner correctement.

λsd Safe detected + λsu Safe undetected

su

Défaillance ne présentant aucun danger (IEC 61508-4, section

3.6.8) : Une défaillance ne présentant aucun danger (safe failure)

est donnée quand le système de mesure passe à l'état sûr déni

ou au mode de signalisation d'erreurs sans sollicitation émanant du

procédé.

est déni comme contrôle

Proof

F

WIKA manuel de sécurité transmetteur de température T32.xS

35

Page 36

2. Sécurité

λdd +λ

du

λdd Dangerous detected + λdu Dangerous undetected

Défaillance dangereuse (IEC 61508-4, section 3.6.7) :

Généralement, une défaillance dangereuse est donnée quand le

système de mesure est mis dans un état dangereux ou entravant le

fonctionnement.

λ

du

λdu Dangerous undetected

Une défaillance dangereuse non détectée est donnée lorsque le

système de mesure ne passe ni à l'état sûr déni, ni au mode de

signalisation d'erreurs en cas de sollicitation émanant du procédé.

Vous trouverez d'autres abréviations pertinentes en vous reportant à IEC 61508-4.

F

2. Sécurité

2.1 Utilisation conforme à l'usage prévu dans des applications de sécurité

Toutes les fonctions de sécurité se rapportent exclusivement au signal de sortie

analogique (4 … 20 mA). L'appareil est certié selon SIL2 (IEC 61508). Le logiciel de

l'appareil remplit les critères de SIL3 (IEC 61508). L'utilisation de l'appareil dans des

systèmes redondants de manière homogène est ainsi possible.

Les branchements pour capteurs suivants atteignent une SFF (Safe Failure Fraction)

susante pour SIL2 de >90 % :

■

Thermocouple (soudure froide interne, Pt100)

■

Thermocouple (soudure froide externe, Pt100)

■

Sonde à résistance avec raccordement 4 ls

■

Sonde à résistance avec raccordement 3 ls

Capteurs WIKA type TRxx (voir déclaration du fabricant WIKA, document n° 3011701)

■

Thermocouple double ou sonde à résistance double

(seulement en mode opératoire "redondant" et si les deux capteurs sont utilisés

pour la surveillance du même point de mesure (à 2 canaux)).

Les branchements pour capteurs suivants atteignent une SFF (Safe Failure Fraction)

susante pour SIL1 de >60 % :

■

Sonde à résistance avec raccordement 3 ls

- capteurs universels -

■

Sonde à résistance avec raccordement 2 ls

L'appareil génère un signal électrique dépendant du signal du capteur en mode de

mesure admissible en courant nominal de 4 … 20 mA. La plage valable du signal

de sortie est limitée à un minimum de 3,8 mA et un maximum de 20,5 mA (réglage

standard pour la conguration de base).

36

WIKA manuel de sécurité transmetteur de température T32.xS

11583631.02 11/2010 GB/D/F/E

Page 37

2. Sécurité

AVERTISSEMENT !

Ne pas dépasser les spécications indiquées dans la che de données ou

dans le mode d'emploi du type T32.xS. Pour assurer un fonctionnement

sûr de la sortie tension, il faut particulièrement appliquer la tension

correcte aux bornes.

Respecter les limites suivantes de tension sur les bornes :

Type d'appareil Limites de tension sur les bornes

T32.1S.000-S

T32.3S.000-S

T32.1S.0IS-S

T32.3S.0IS-S

AVERTISSEMENT !

Les capteurs et modes opératoires suivants NE SONT PAS admissibles

pour l'utilisation dans une application de sécurité:

■

Potentiomètre

■

Capteur à résistance

■

Capteur mV

■

Mode diérentiel en mode double capteur

DC 10,5 ... 42 V

DC 10,5 ... 30 V

F

2.2 Etiquetage / Marquages de sécurité

Plaque signalétique

■

Version tête de canne, type T32.1S

Type

version SIL

(seulement pour SIL)

Alimentation

Capteur Pt100

ou RTD

Signal de sortie

11583631.02 11/2010 GB/D/F/E

WIKA manuel de sécurité transmetteur de température T32.xS

avec SIL: T32.1S.0IS-S

sans SIL: T32.1S.0IS-Z

Date de fabrication

(année-mois)

37

Page 38

2. Sécurité

■

Version rail, type T32.3S

version SIL

F

(seulement

pour SIL)

Alimentation

Capteur Pt100

ou RTD

Signal de sortie

Type

avec SIL: T32.1S.0IS-S

sans SIL: T32.1S.0IS-Z

Date de fabrication

(année-mois)

2.3 Limitation des modes opératoires

AVERTISSEMENT !

Dans les conditions de services décrites ci-dessous, la fonction de

sécurité de l'appareil n'est pas garantie :

■

Pendant la conguration

■

Lorsque la protection en écriture est désactivée

■

En mode HART® Multidrop activé

■

Transmission des valeurs de mesures au moyen du procès-verbal HART

■

Pendant une simulation

■

Pendant l'essai

■

Lorsque la protection en écriture est désactivée

38

WIKA manuel de sécurité transmetteur de température T32.xS

Conguration du raccordement

®

11583631.02 11/2010 GB/D/F/E

Page 39

2. Sécurité

2.4 Signalement des erreurs

Le transmetteur de température du type T32.xS surveille le capteur branché et le

propre matériel pour détecter des erreurs. En cas de détection d'un état d'erreur,

l'appareil génère un courant de signalisation d'erreurs.

Le temps de réaction à des erreurs du capteur est au maximum de 90 secondes.

Ceci inclut la détection des erreurs potentielles suivantes :

■

Rupture du capteur

■

Court-circuit dans le capteur (seulement pour des capteurs de température à

résistance, pas pour les thermoéléments)

■

Niveau de résistance de l'alimentation inadmissible (pas pour des capteurs de

température à résistance doubles)

L'intervalle du test diagnostic en ligne de l'appareil est au maximum de 35 minutes.

Ceci inclut la détection des erreurs potentielles suivantes de l'appareil :

■

Erreur ROM

■

Défaut EEPROM

■

Erreur RAM

■

Erreur du compteur ordinal

■

Erreur du stack pointer

De plus, les fonctions de surveillance suivantes sont exécutées en permanence :

■

Contrôle logique du déroulement du logiciel

■

Erreur interne de communication

■

Limite supérieure du capteur dépassée

■

Limite inférieure du capteur dépassée

■

Température de la soudure froide hors des limites permises (seulement pour les

thermocouples)

■

Capteur double surveillance de la dérive (commutable en option)

■

Erreur de conguration

■

Surveillance de la température admissible de l'appareil (en option, activée en

standard sur le modèle SIL)

■

Surveillance des limites de sortie (en option, non activée en standard sur le modèle

SIL à partir du 01.01.2011))

F

ATTENTION !

Congurer le courant de signalisation d'erreurs (courant parasite) de

l'appareil en fonction des exigences suivantes :

■

Courant parasite Fail High (valeur d'alarme élevée) :

réglable sur la plage ≥ 21,0 mA à ≤ 23,0 mA (Upscale)

■

Courant parasite Fail Low (valeur d'alarme basse) :

réglable sur la plage ≥ 3,5 mA à ≤ 3,6 mA (Downscale)

11583631.02 11/2010 GB/D/F/E

WIKA manuel de sécurité transmetteur de température T32.xS

39

Page 40

2. Sécurité

AVERTISSEMENT !

Dans le cas de certaines erreurs matérielles diagnostiquées par l'appareil,

l'appareil procédera à une signalisation d'erreur avec un courant de trac

< 3,8 mA, mais, pour des raisons techniques, il ne peut pas assurer la

signalisation ≤ 3,6 mA, même pour une conguration correspondante.

C'est pourquoi le système d'évaluation doit interpréter des courants de

trac < 3,8 mA comme erreur.

Pour certaines congurations inadmissibles (par ex. quand la protection en écriture est

désactivée), le transmetteur génère également une signalisation d'erreur. Pour trouver

F

la raison d'une signalisation d'erreur, il est recommandé d'utiliser les fonctions de

diagnostic pouvant être appelées via HART

par le logiciel de conguration WIKA_T32 (téléchargement gratuit sur www.wika.de).

2.5 Protection en écriture

Le T32.xS dispose d'une fonctionnalité de protection en écriture empêchant les modications non intentionnelles de la conguration. Le mot de passe de la protection en

écriture est réglé en standard sur "0".

Un transmetteur de température T32.xS avec option SIL ne passe en mode

actif qu'une fois que la protection en écriture a été activée. Si la protection

en écriture n'est pas activée, un tel transmetteur signale une erreur.

®

. De telles fonctions sont oertes par ex.

2.5.1 Commande de la protection en écriture

La fonction de protection en écriture est commandée par un mot de passe (les chires

sur la plage de 0 à 65535 sont admissibles) et par un interrupteur (activer/désactiver la

protection en écriture).

Une modication de l'état de l'interrupteur de protection en écriture n'est possible

qu'une fois que le mot de passe a été entré avec succès. Le mot de passe peut être

modié via un menu spécique.

ATTENTION !

Il n'existe absolument AUCUNE possibilité de récupérer un mot de passe

oublié ! Il est seulement possible de réinitialiser le mot de passe en usine !

La protection en écriture ne peut, elle aussi, être activée que par saisie du

mot de passe correct !

40

WIKA manuel de sécurité transmetteur de température T32.xS

11583631.02 11/2010 GB/D/F/E

Page 41

2. Sécurité

2.6 Exactitude de la fonction de mesure sûre

Les indications suivantes relatives à l'exactitude de la sécurité globale incluent les

composants suivants :

■

Exactitude de base (tolérance de mesure de l'entrée et de la sortie, ainsi que les

erreurs de linéarisation du transmetteur)

■

Pour les thermocouples en plus la compensation soudure froide interne (CSF, en

anglais : CJC), sauf pour le thermocouples du type B

■

Inuence de la température ambiante sur la plage -50 ... +85 °C

La valeur dénie pour l'exactitude de la sécurité globale de la fonction de sécurité

de cet appareil est fonction du type de capteur choisi ainsi que de la fourchette de

mesure congurée (voir tableau ci-dessous).

Jusqu'aux fourchettes minimales indiquées dans le tableau, l'exactitude de la sécurité

globale est de 2 % de la fourchette de mesure relative au signal de sortie tension

de 16 mA. Dans les autres cas, les valeurs absolues indiquées directement dans le

tableau sont applicables.

ATTENTION !

La fourchette de mesure est la diérence entre la valeur nale et la valeur

initiale d'une plage de mesure.

Type de

capteur

Plage admissible

du capteur pour

les indications

d'exactitude

Fourchette

mini. pour 2 %

d'exactitude de la

sécurité globale

Exactitude de la

sécurité globale

absolue pour les

petites fourchettes

de mesure

Pt100 -200 ... +850 °C 84 K

2 KJPt100 -200 ... +500 °C 50 K

Ni100 -60 ... +250 °C 21 K

Pt1000

Pt500 70 K 2 K

Pt25 134 K 3 K

Pt10 241 K 5 K

TC Type T -150 ... +400 °C 134 K

TC Type U -150 ... +600 °C 136 K

TC Type E -150 ... +1000 °C 164 K

TC Type J -150 ... +1200 °C 176 K

TC Type K -140 ... +1200 °C 197 K

TC Type N -150 ... +1300 °C 154 K

TC Type R +50 … +1600 °C 255 K

TC Type B +500 …+1820 °C 283 K

11583631.02 11/2010 GB/D/F/E

-200 ... +850 °C

69 K 2 K

3 KTC Type L -150 ... +900 °C 138 K

4 K

6 KTC Type S +50 … +1600 °C 273 K

F

WIKA manuel de sécurité transmetteur de température T32.xS

41

Page 42

2. Sécurité

Application (voir tableau page 43):

■

Exemple 1

Type de capteur Pt100, plage de mesure congurée = -50 … +100 °C, donc

fourchette de mesure congurée = 150 K.

Elle n'est pas inférieure à 84 K. Ainsi, l'exactitude de la sécurité globale est de

2 % FS, donc 2 % * 150 K = 3 K,

ou 2 % * 16 mA = 320 μA relativement à la sortie tension

■

Exemple 2

Type de capteur Pt100, plage de mesure congurée = 0 … 50 °C, donc fourchette

F

de mesure congurée = 50 K

Elle est inférieure à 84 K, l'exactitude de la sécurité globale est donc de 2 K, donc

2 K / 50 K = 4 %, ou 4 % * 16 mA = 640 μA relativement à la sortie tension

2.7 Modications de la conguration

AVERTISSEMENT !

Pendant la modication de la conguration, la fonction de sécurité n'est

pas active ! Le mode Safety n'est autorisé qu'avec protection en écriture

activée (mot de passe).

Eectuer les modications de la conguration en restant dans les limites des

spécications admissibles selon "2.1 Utilisation conforme à l'usage prévu dans des

applications de sécurité".

Entre autres, la protection en écriture peut être réglée pour le type T32.xS avec les

outils de conguration mentionnés :

■

Logiciel de conguration WIKA_T32

■

AMS

■

SIMATIC PDM

■

DTM (à partir de la version bêta V1.0.2 de DTM, janvier 2003) en rapport avec un

logiciel de commande selon le standard FDT/DTM, par ex. PACTware, FieldMate

■

Terminal manuel HART® FC475, FC375, MFC4150

AVERTISSEMENT !

La fonction de sécurité doit être vériée par un test après une procédure

de conguration.

42

WIKA manuel de sécurité transmetteur de température T32.xS

11583631.02 11/2010 GB/D/F/E

Page 43

2. Sécurité

2.8 Mise en service et contrôles récurrents

La capacité de fonctionnement et le courant de signalisation d'erreurs du transmetteur

de température du type T32.xS doit être soumis à un contrôle lors de la mise en service

et à des intervalles adéquats. Le type de contrôle tout comme les intervalles choisis

relèvent de la responsabilité de l'utilisateur. Les intervalles dépendent habituellement

de la valeur PFDavg utilisée (valeurs et indices, voir "Annexe 1 : Déclaration de conformité SIL"). Selon l'usage, un intervalle d'un an entre les contrôles annuel est approprié.

2.8.1 Essai relatif à la chaîne complète de traitement des signaux du transmetteur

1. Si nécessaire, ponter le système de l'automate de sécurité ou prendre des

mesures adaptées empêchant un déclenchement intempestif de l'alarme.

2. Désactiver la protection en écriture de l'appareil

3. En mode simulation, la sortie tension doit être réglée à une valeur d'alarme

élevée (≥ 21,0 mA) (ordre HART

fonction HART

®

4. Vérier si le signal de sortie tension atteint cette valeur.

5. Régler la sortie tension du transmetteur au moyen de la fonction en mode

simulation sur une valeur d'alarme basse (≤ 3,6 mA)

6. Vérier si le signal de sortie tension atteint cette valeur.

7. Activer la protection en écriture et attendre au moins 5 secondes.

8. Déconnecter l'appareil ou le séparer de l'alimentation.

9. Redémarrer l'appareil et attendre au moins 15 secondes qui correspondent à la

période de mise en marche.

10. Contrôler la sortie tension avec la température de référence 1) sur 2 points. Pour le

début de la mesure, sélectionner (4 mA jusqu'à +20 % de la fourchette) et pour la

n de la mesure (20 mA jusqu'à –20 % de la fourchette).

11. En cas d'utilisation de la courbe de réponse spécique du client, elle doit être

contrôlée sur au moins trois points.

12. Éliminer le pontage du système de l'automate de sécurité ou rétablir l'état normal

de service d'une autre manière.

13. Après le test, il convient de documenter les résultats et de les archiver de manière

adéquate.