Page 1

Operating Instructions

Betriebsanleitung

D

GB

Head Mounting Version Rail Mounting Version

Model T19.10 Model T19.30

Temperature Transmitter Model T19

Temperatur-Transmitter Typ T19

Page 2

2

2143014.04 05/2010 GB/D

WIKA Operating Instructions Temperature Transmitter T19

D

GB

Operating Instructions Model T19

Page 3 - 12

Betriebsanleitung Typ T19

Seite 13 - 21

Page 3

3

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

1. Safety instructions 4

2. Before mounting 4

3. Conguration 5

4. Mounting 7

5. Electrical connections 8

6. Maintenance 9

7.

Adjustment of transmitter 10

Contents

Contents

Warning!

This symbol warns you against actions that can cause

injury to people or damage to the instrument.

Page 4

4

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

1. Safety instructions

When mounting, initiating and operating these transmitters

it is important to observe the respective national safety

precautions and regulations in eect (e.g. VDE 100).

Nonobservance of the applicable regulations may cause

severe injury to persons or damage to equipment. Only sta

with suitable qualication should work with these transmitters.

Before initial operation check the suitability for the intended application.

In particular, it is important to fulll the ambient and operation conditions

as specied in the WIKA data sheet TE 19.03. Use only congured

transmitters.

2. Before mounting

2.1 Transmitters with standard measuring ranges

Series T19 transmitters with standard measuring ranges are congurable

by means of solder bridges. Access to the solder bridges is gained after

removing the bottom of the casing. Mounted transmitters have to be

dismantled rst before they can be congured.

To work properly, the transmitter has to be congured. Make

sure that the transmitter is congured before mounting.

Conguration is to be carried out as described in section 3.

As an option standard measuring ranges can be congured at the factory

and in this case the appropriate measuring range is printed on the rating

plate. Transmitters with standard measuring range congured at the

factory can be immediately tted at the measuring point and put into

operation.

1. Safety instructions / 2. Before mounting

Page 5

5

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

2.2 Transmitters with special measuring ranges

Series T19 transmitters with special measuring ranges cannot be

recongured. Special measuring ranges can be recognised by a 9 as last

digit in the model designation: T19.x0-xx0-9

Special measuring ranges are congured at the factory and can be

immediately tted at the measuring point and put into operation.

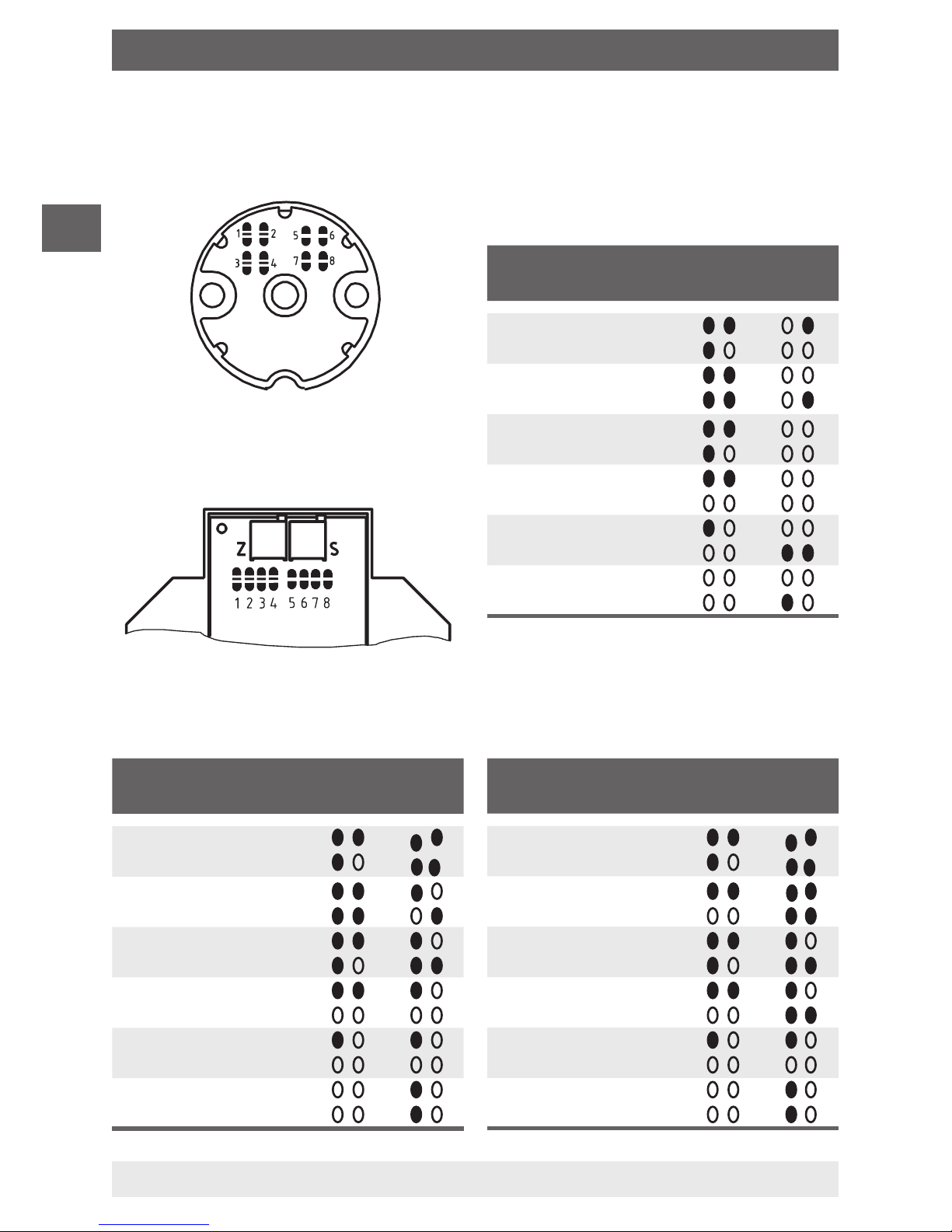

3. Conguration

3.1 Working sequence

Model T19.10 head mounting:

Remove case bottom

Model T19.30 rail mounting:

Remove case lid

Set the solder bridges for the

desired measuring range in

accordance with tables 1 – 7. The

measuring ranges to be selected

depend on the model of the

transmitter.

Model T19.10: Snapt the bottom to the case again

Model T19.30: Snapt the lid to the case again. Insert lid with its long

side into the case, then press lid to the case until it locks into place

Adjust zero point and span by means of potentiometer as described

in section 7!

Note the measuring range on the rating plate (for example, with

waterproof bretip pen)

2. Before mounting / 3. Conguration

Demonstration: Model T19.30

use a small screwdriver:

to prick the marking

unlook both locks of the snap-in

connection

Page 6

Pt100 measuring ranges small

Measuring range Bridge

-50 ... +50 °C

0 ... +50 °C

0 ... +100 °C

0 ... +120 °C

0 ... +150 °C

0 ... +200 °C

Pt100 measuring ranges large

Measuring range Bridge

-50 ... +200 °C

0 ... +200 °C

0 ... +250 °C

0 ... +300 °C

0 ... +350 °C

0 ... +400 °C

Pt100 measur. ranges for HVAC

Measuring range Bridge

-30 ... +30 °C

-30 ... +50 °C

0 ... +60 °C

0 ... +80 °C

0 ... +100 °C

0 ... +120 °C

6

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

3.2 Position of solder bridges with Pt100

Head mounting:

Table 1: Model T19.10-1P0-1

Model T19.30-1P0-1

Table 2: Model T19.10-1P0-2

Model T19.30-1P0-2

Table 3: Model T19.10-1P0-3

Model T19.30-1P0-3

Rail mounting:

3. Conguration

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1

2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

Page 7

7

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

4. Mounting

4.1 Mounting for head mounting version

The transmitters for head mounting (Model T19.10) are designed to be

mounted on a measuring insert in a DIN connecting head with form B.

The connecting wires of the measuring insert must be approx. 50 mm

long and insulated.

Insert the measuring insert with the mounted transmitter in the protective

sheath and ax in the connecting head using screws in pressure springs.

2257521.022257521.03

4. Mounting

Mounting example:

Page 8

8

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

4.2 Mounting for rail mounting version

The transmitters for rail mounting (Model T19.30) are designed for

mounting on a standard rail or for wall mounting.

■

Rail mounting

The transmitter is axed without the use of auxiliary parts by sliding

onto a 35 mm top hat rail (DIN EN 50022-35).

De-mounting is done by freeing the snap parts.

■

Wall mounting

Lever the snap parts outwards with a screwdriver until they lock into

place. Mount case to the wall by means of two screws.

5. Electrical connections

In the case of the transmitters described here there is an

internal galvanic connection between the sensor input and

analogue output.

No external conducting is to be made (for example, by

earthing) between the connected temperature sensor and

analogue output!

We recommend the use of crimped connector sleeves in the

case of exible leads.

For Model T19.30 the connection cable of a temperature

probe must be shielded and grounded.

To connect a Pt100 sensor in a 2-wire connecting circuit:

Set a jumper between the input terminals 2 and 3 in accordance with

section 5.1.!

4. Mounting / 5. Electrical connections

Page 9

9

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

5.1 Sensor input Pt100/Pt1000

Head mounting version: Rail mounting version:

5.2 Connect 4 ... 20 mA-loop

The electrical connection of Model T19.10 (head mounting version) is

made through the ⊕ and ⊖ terminals, while Model T19.30 (rail mounting

version) is connected through the terminals 4 and 5 (please refer to

page 10).

■

Maximum permissible terminal voltage: 30 V

■

Maximum permissible load RA (dependent upon the loop power

supply voltage U

B

) 1000 Ω at 30 V power supply U

B

700 Ω at 24 V power supply U

B

RA ≤ (UB - 10 V ) / 0.02 A with RA in Ω and UB in V

6. Maintenance

The temperature transmitters described here are maintenance-free!

The electronics incorporate no components which could be repaired or

replaced. Depending upon operating conditions, it may be advisable to

check the adjustment yearly. Adjustment as per section 7.

InputInput

4 ... 20 mA-loop

5. Electrical connections / 6. Maintenance

Page 10

10

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

7. Adjustment of transmitter

The adjustment of the zero point and the span is carried out with

potentiometers. In order to adjust the transmitter output to optimal values

please adjust to the desired value by turning the potentiometer in one

direction only.

Example

Adjust the potentiometer in a clockwise direction.

The potentiometer has to be turned clockwise (the output current gets

higher) until the signal shows the desired value.

If the potentiometer is turned too much (the output current is too high),

the potentiometer must be turned back again until a value below the

desired value is reached (output current is too low). Adjust the potentiometer in a clockwise direction again until the desired value is reached.

Repeat steps as necessary.

Head mounting version: Rail mounting version:

Z S

Potentiometer

Z for zero point

S for span

7. Adjustment of transmitter

Page 11

11

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

7.1 Preparation

■

Connect a suitable simulation source to the input of the T19 (Pt100).

When simulating a Pt100 connect the simulator in a 3-wire connecting

circuit. We recommend the use of passive resistances. Electronical

simulation sources can cause incorrect measurement values.

■

Connect a mA meter in 4 ... 20 mA-loop according to section 5 (with

R

i

≤ max. permissible load!) to measure the output signal.

■

Connect a suitable power supply to the transmitter.

7.2 Adjustment

Carry out steps

through in the order given.

Set the lower value of the measurement range with the simulator, e.g.

-30 °C for measurement range -30 ... +50 °C.

Turn the zero potentiometer Z, until the output signal shows the

desired value.

Set the end value of the measurement range with the simulator, e.g.

+50 °C for measurement range -30 ... +50 °C.

Turn the span potentiometer S, until the output signal shows the

desired value.

High output currents (for example 20 mA) should therefore not exist

longer than 1 minute (in total) when doing adjustment. If adjustment

has to be repeated then allow the transmitter to cool down for approx.

20 minutes (disconnect the transmitter from the power supply).

Repeat step and check output signal of zero point.

Repeat step and check output signal of span.

7.3 Closing steps

Disconnect the simulator, the mA meter, and the power supply.

7. Adjustment of transmitter

Page 12

12

2143014.04 05/2010 GB/D

GB

WIKA Operating Instructions Temperature Transmitter T19

Page 13

D

WIKA Betriebsanleitung Temperatur-Transmitter T19

13

2143014.04 05/2010 GB/D

1. Sicherheitshinweise 14

1

2. Vor der Montage 14

3. Kongurieren 15

4. Montage 17

5. Elektrische Anschlüsse 18

6. Wartung 19

7.

Justieren 20

Inhalt

Inhalt

Warnung!

Dieses Symbol warnt Sie vor Handlungen, die Schäden an

Personen oder am Gerät verursachen können.

Page 14

D

WIKA Betriebsanleitung Temperatur-Transmitter T19

14

2143014.04 05/2010 GB/D

1. Sicherheitshinweise

Beachten Sie unbedingt bei Montage, Inbetriebnahme und

Betrieb dieser Transmitter die jeweils gültigen nationalen

Sicherheitsvorschriften (z. B.: VDE 100). Bei Nichtbeachten

der entsprechenden Vorschriften können schwere Körperverletzungen und/oder Sachschäden auftreten.

Nur entsprechend qualiziertes Personal darf an diesem

Gerät arbeiten.

Überprüfen Sie vor Inbetriebnahme die Eignung für die jeweilige

Anwendung. Beachten Sie insbesondere die im WIKA Datenblatt

TE 19.03 genannten zulässigen Umgebungs- und Betriebsbedingungen.

Verwenden Sie nur kongurierte Transmitter.

2. Vor der Montage

2.1 Transmitter mit Standardmessbereichen

Transmitter der Serie T19 mit Standardmessbereichen sind kongurierbar durch Lötbrücken. Die Lötbrücken sind zugänglich nach Abnahme

des Gehäusebodens. Montierte Transmitter müssen erst demontiert

werden, bevor konguriert werden kann.

Damit der Transmitter ordnungsgemäß arbeitet, muss er

konguriert sein. Bitte vergewissern Sie sich vor der Montage,

dass der Transmitter konguriert ist. Gegebenenfalls Konguration durchführen nach Kapitel 3.

Standardmessbereiche können optional werkseitig konguriert sein,

dann ist auf dem Typenschild der entsprechende Messbereich aufgedruckt. Werkseitig kongurierte Transmitter mit Standardmessbereich

können sofort an der Messstelle eingebaut und in Betrieb genommen

werden.

1. Sicherheitshinweise / 2. Vor der Montage

Page 15

D

WIKA Betriebsanleitung Temperatur-Transmitter T19

15

2143014.04 05/2010 GB/D

2.2 Transmitter mit Sondermessbereich

Transmitter der Serie T19 mit Sondermessbereich können nicht umkonguriert werden. Sondermessbereiche sind gekennzeichnet durch eine 9

an der letzten Stelle der Typbezeichnung: T19.x0-xx0-9

Sondermessbereiche sind werkseitig konguriert und können sofort an

der Messstelle eingebaut und in Betrieb genommen werden.

3. Kongurieren

3.1 Reihenfolge der Arbeitsschritte

Typ T19.10 Kopfversion:

Gehäuseboden abnehmen

Typ T19.30 Schienenversion:

Gehäusedeckel abnehmen

Lötbrücken für gewünschten

Messbereich setzen gemäß der

Tabellen 1 – 7. Die wählbaren

Messbereiche sind abhängig vom

Typ des Transmitters.

Typ T19.10: Gehäuseboden wieder aufsetzen

Typ T19.30: Gehäusedeckel wieder aufsetzen, Deckel mit seiner

Längsseite in das Gehäuse einsetzen, dann Deckel bis zum Einrasten aufdrücken

Nullpunkt und Spanne mit Potentiometer justieren gemäß Kapitel 7!

Messbereich auf Typenschild notieren (z. B. mit wasserfestem

Faserschreiber)

2. Vor der Montage / 3. Kongurieren

Darstellung: Typ T19.30

Mit kleinem Schraubendreher:

in Markierung einstechen

beide Einrastungen der Snap-In

Verbindung entriegeln

Page 16

Pt100-Messbereiche klein

Messbereich Lötbrücke

-50 ... +50 °C

0 ... +50 °C

0 ... +100 °C

0 ... +120 °C

0 ... +150 °C

0 ... +200 °C

Pt100-Messbereiche groß

Messbereich Lötbrücke

-50 ... +200 °C

0 ... +200 °C

0 ... +250 °C

0 ... +300 °C

0 ... +350 °C

0 ... +400 °C

Pt100-Messbereiche für HKL

Messbereich Lötbrücke

-30 ... +30 °C

-30 ... +50 °C

0 ... +60 °C

0 ... +80 °C

0 ... +100 °C

0 ... +120 °C

D

WIKA Betriebsanleitung Temperatur-Transmitter T19

16

2143014.04 05/2010 GB/D

3.2 Lage der Lötbrücken bei Pt100

Kopfversion:

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

Tabelle 1: Typ T19.10-1P0-1

Typ T19.30-1P0-1

Tabelle 2: Typ T19.10-1P0-2

Typ T19.30-1P0-2

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

1 2 5 6

3 4 7 8

Tabelle 3: Typ T19.10-1P0-3

Typ T19.30-1P0-3

Schienenversion:

3. Kongurieren

Page 17

D

WIKA Betriebsanleitung Temperatur-Transmitter T19

17

2143014.04 05/2010 GB/D

4. Montage

4.1 Montage bei Ausführung Kopfversion

Die Transmitter in Ausführung Kopfversion (Typ T19.10) sind vorgesehen

zur Montage auf einem Messeinsatz im DIN-Anschlusskopf der Form B.

Die Anschlussdrähte des Messeinsatzes müssen ca. 50 mm lang und

isoliert ausgeführt sein.

Messeinsatz mit montiertem Transmitter in die Schutzarmatur einstecken

und im Anschlusskopf mit Schrauben federnd befestigen.

2257521.022257521.03

4. Montage

Montagebeispiel:

Page 18

D

WIKA Betriebsanleitung Temperatur-Transmitter T19

18

2143014.04 05/2010 GB/D

4.2 Montage bei Ausführung Schienenversion

Die Transmitter in Ausführung Schienenversion (Typ T19.30) sind vorgesehen zur Montage auf einer Normschiene.

■

Montage auf Normschiene

Das Befestigen erfolgt ohne Hilfsmittel durch Aufrasten auf eine

35 mm Hutschiene (DIN EN 50022-35).

Demontage durch Entriegeln der Rastelemente.

■

Wandmontage

Mit Schraubendreher die Rastelemente bis zum Einrasten nach außen

hebeln. Gehäuse mit zwei Schrauben an der Wand montieren.

5. Elektrische Anschlüsse

Bei den hier beschriebenen Transmittern besteht intern

eine galvanische Verbindung von Sensoreingang und

Analogausgang.

Es darf keine äußere leitende Verbindung (z. B. über Erde)

zwischen angeschlossenem Temperatursensor und Analogausgang geben!

Bei Litzenadern empfehlen wir das Verwenden von

gecrimpten Adernendhülsen.

Das Anschlusskabel des Temperaturfühlers muss bei Typ

T19.30 geschirmt und geerdet sein.

Bei Anschluss eines Pt100-Sensors in 2-Leiter-Anschlussschaltung:

Setzen Sie eine Drahtbrücke zwischen den Eingangsklemmen 2 und 3

gemäß Kapitel 5.1!

4. Montage / 5. Elektrische Anschlüsse

Page 19

D

WIKA Betriebsanleitung Temperatur-Transmitter T19

19

2143014.04 05/2010 GB/D

5.1 Sensoreingang Pt100/Pt1000

Kopfversion: Schienenversion:

5.2 Anschluss der 4 ... 20 mA-Schleife

Der elektrische Anschluss erfolgt bei der Kopfversion Typ T19.10 über

die Anschlussklemmen ⊕ und ⊖ bzw. bei der Schienenversion Typ

T19.30 über die Klemmen 4 und 5 (siehe Seite 20).

■

Maximal zulässige Klemmenspannung: 30 V

■

Maximal zulässige Bürde RA (abhängig von Spannung UB der

Schleifenversorgung) 1000 Ω bei 30 V Hilfsenergie U

B

700 Ω bei 24 V Hilfsenergie U

B

RA ≤ (UB - 10 V) / 0,02 A mit RA in Ω und UB in V

6. Wartung

Die hier beschriebenen Temperatur-Transmitter sind wartungsfrei!

Die Elektronik enthält keinerlei Bauteile, welche repariert oder ausgetauscht werden könnten. Je nach Einsatzbedingungen empfehlen wir

eine jährliche Überprüfung der Justage gemäß Kapitel 7.

EingangEingang

4 ... 20 mA - Schleife

5. Elektrische Anschlüsse / 6. Wartung

Page 20

D

WIKA Betriebsanleitung Temperatur-Transmitter T19

20

2143014.04 05/2010 GB/D

7. Justieren der Transmitter

Die Justage von Nullpunkt und Spanne wird mit Potentiometern durchgeführt. Um die Transmitter optimal zu justieren empfehlen wir, den Sollwert

einseitig anzufahren.

Beispiel

Potentiometer im Uhrzeigersinn anfahren:

Potentiometer in Uhrzeigersinn drehen (Ausgangsstrom wird größer), bis

Ausgangssignal den gewünschten Wert hat.

Wurde das Potentiometer zu weit gedreht (Ausgangsstrom zu

groß), dann zuerst das Potentiometer wieder deutlich zurück drehen

(Ausgangsstrom ist jetzt wieder deutlich zu klein), anschließend den

gewünschten Ausgangsstrom erneut durch Drehen im Uhrzeigersinn

anfahren.

Kopfversion: Schienenversion:

Z S

Potentiometer

Z für Nullpunkt

S für Spanne

7. Justieren der Transmitter

Page 21

D

WIKA Betriebsanleitung Temperatur-Transmitter T19

21

2143014.04 05/2010 GB/D

7.1 Vorbereiten

■

An den Eingang des T19 eine geeignete Sensor-Simulationsquelle

anschließen (Pt100).

Bei Simulaton eines Pt 100-Sensors den Simulator in 3-Leiter-technik

anschließen. Wir empfehlen hierzu passive Widerstandsdekaden.

Elektronische Simulationsquellen können zu einer Verfälschung der

Messwerte führen.

■

In die 4 ... 20 mA-Schleife gemäß Kapitel 5 ein mA-Meter (mit

R

i

≤ max. zulässige Bürde!) zum Messen des Ausgangssignals

anschließen.

■

Transmitter mit Hilfsenergie versorgen.

7.2 Justieren

Arbeitsschritte

bis nacheinander durchführen.

Anfangswert des Messbereiches am Simulator einstellen, z. B. -30 °C

bei Messbereich -30 ... +50 °C.

Nullpunkts-Potentiometer Z solange drehen, bis Ausgangssignal den

gewünschten Wert hat.

Endwert des Messbereiches am Simulator einstellen, z. B. +50 °C bei

Messbereich -30 ... +50 °C.

Spanne-Potentiometer S solange drehen, bis Ausgangssignal den

gewünschten Wert hat.

Große Ausgangsströme (z. B. 20 mA) sollen bei der Justage nicht

länger als 1 Minute (in Summe) vorliegen. Muss die Justage wiederholt werden, so ist eine Abkühlzeit von ca. 20 Minuten einzuhalten

(Transmitter von der Hilfsenergie abklemmen).

Schritt wiederholen und Ausgangssignal des Nullpunktes

kontrollieren.

Schritt

wiederholen und Ausgangssignal der Spanne kontrollieren

.

7.3 Nachbereiten

Simulator, mA-Meter und Hilfsenergie abklemmen.

7. Justieren der Transmitter

Page 22

22

WIKA Operating Instructions Temperature Transmitter T19

2143014.04 05/2010 GB/D

WIKA Global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand

GmbH & Co. KG

1230 Vienna

Tel. (+43) 1 86916-31

Fax: (+43) 1 86916-34

E-Mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX Echt

Tel. (+31) 475 535-500

Fax: (+31) 475 535-446

E-Mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

Bul. „Al. Stamboliiski“ 205

1309 Soa

Tel. (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-Mail: t.antonov@wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovicka 19

10250 Zagreb-Lucko

Tel. (+385) 1 6531034

Fax: (+385) 1 6531357

E-Mail: info@wika.hr

www.wika.hr

Finland

WIKA Finland Oy

00210 Helsinki

Tel. (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-Mail: info@wika.

www.wika.

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Tel. (+33) 1 343084-84

Fax: (+33) 1 343084-94

E-Mail: info@wika.fr

www.wika.fr

Germany

WIKA Alexander Wiegand

SE & Co. KG

63911 Klingenberg

Tel. (+49) 9372 132-0

Fax: (+49) 9372 132-406

E-Mail: info@wika.de

www.wika.de

Italy

WIKA Italia Srl & C. sas

20020 Arese (Milano)

Tel. (+39) 02 9386-11

Fax: (+39) 02 9386-174

E-Mail: info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

87-800 Wloclawek

Tel. (+48) 542 3011-00

Fax: (+48) 542 3011-01

E-Mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments

Romania S.R.L.

Bucuresti, Sector 5

Calea Rahovei Nr.

266-268

Corp 61, Etaj 1

Tel. (+40) 21 4048327

Fax: (+40) 21 4563137

E-Mail: m.anghel@wika.ro

Russia

ZAO WIKA MERA

127015 Moscow

Tel. (+7) 495-648 01 80

Fax: (+7) 495-648 01 81

E-Mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika

d.o.o.

Sime Solaje 15

11060 Belgrade

Tel. (+381) 11 2763722

Fax: (+381) 11 753674

E-Mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

C/Josep Carner, 11-17

08205 Sabadell

(Barcelona)

Tel. (+34) 902 902577

Fax: (+34) 933 938666

E-Mail: info@wika.es

www.wika.es

Page 23

23

WIKA Operating Instructions Temperature Transmitter T19

2143014.04 05/2010 GB/D

WIKA Global

Switzerland

Manometer AG

6285 Hitzkirch

Tel. (+41) 41 91972-72

Fax: (+41) 41 91972-73

E-Mail:

info@manometer.ch

www.manometer.ch

Turkey

WIKA Instruments Istanbul

Basinc ve Sicaklik Ölcme

Cihazlari

Ith. Ihr. ve Tic. Ltd. Sti.

Bayraktar Bulvari No. 21

34775 Yukari Dudullu Istanbul

Tel. (+90) 216 41590-66

Fax: (+90) 216 41590-97

E-Mail: info@wika.com.tr

www.wika.com.tr

Ukraine

WIKA Pribor GmbH

83016 Donetsk

Tel. (+38) 062 34534-16

Fax: (+38) 062 34534-17

E-Mail: info@wika.ua

www.wika.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill

RH13LG

Tel. (+44) 1737 644-008

Fax: (+44) 1737 644-403

E-Mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Oce

Edmonton, Alberta,

T6N 1C8

Tel. (+1) 780 46370-35

Fax: (+1) 780 46200-17

E-Mail: info@wika.ca

www.wika.ca

Mexico

Instrumentos WIKA

Mexico S.A.

de C.V.

01210 Mexico D.F.

Tel. (+52) 55 55466329

E-Mail: ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument

Corporation

Lawrenceville, GA 30043

Tel. (+1) 770 5138200

Fax: (+1) 770 3385118

E-Mail: info@wika.com

www.wika.com

WIKA Instrument Corp.

Electrical Temperature

Division

950 Hall Court

Deer Park, TX 77536

Tel. (+1) 713 47500-22

Fax (+1) 713 47500-11

E-Mail:

info@wikaetemp.com

www.wika.com

Mensor Corporation

201 Barnes Drive

San Marcos, TX 78666

Tel. (+1) 512 3964200-15

Fax (+1) 512 3961820

E-Mail:

sales@mensor.com

www.mensor.com

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Tel. (+54) 11 47301800

Fax: (+54) 11 47610050

E-Mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e

Com. Ltda.

CEP 18560-000 Iperó - SP

Tel. (+55) 15 34599700

Fax: (+55) 15 32661650

E-Mail:

marketing@wika.com.br

www.wika.com.br

Page 24

24

WIKA Alexander Wiegand SE & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Tel. (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

2143014.04 05/2010 GB/D

WIKA Operating Instructions Temperature Transmitter T19

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

Asia

China

WIKA International

Trading (Shanghai)

Co., Ltd.

200001 Shanghai

Tel. (+86) 21 538525-72

Fax: (+86) 21 538525-75

E-Mail: info@wika.com.cn

www. wika.com.cn

India

WIKA Instruments India

Pvt. Ltd.

Village Kesnand, Wagholi

Pune - 412 207

Tel. (+91) 20 66293-200

Fax: (+91) 20 66293-325

E-Mail: sales@wika.co.in

www.wika.co.in

Japan

WIKA Japan K. K.

Tokyo 105-0023

Tel. (+81) 3 543966-73

Fax: (+81) 3 543966-74

E-Mail:

t-shimane@wika.co.jp

Weitere WIKA Niederlassungen weltweit nden Sie online unter

www.wika.de.

Further WIKA subsidiaries worldwide can be found online at

www.wika.de.

WIKA Global

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Tel. (+7) 32 72330848

Fax: (+7) 32 72789905

E-Mail: info@wika.kz

www.wika.kz

Korea

WIKA Korea Ltd.

#569-21 Gasan-dong

Seoul 153-771 Korea

Tel. (+82) 2 869 05 05

Fax (+82) 2 869 05 25

E-Mail: info@wika.co.kr

www.wika.co.kr

Loading...

Loading...