Page 1

Operating instructions

Betriebsanleitung

EN

DE

Digital temperature transmitter, model T16

Digitaler Temperaturtransmitter, Typ T16

Head mounting version, model T16.H Rail mounting version, model T16.R

Page 2

EN

DE

2

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

Operating instructions model T16 Page 3 - 36

Betriebsanleitung Typ T16 Seite 37 - 65

Further languages can be found at www.wika.com.

© 06/2017 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA

®

is a registered trademark in various countries.

WIKA

®

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Page 3

EN

Contents

Contents

1. General information 5

2. Design and function 6

2.1 Description. . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Dimensions in mm . . . . . . . . . . . . . . . . . . . . . . . . 6

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Safety 8

3.1 Explanation of symbols . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Responsibility of the operator . . . . . . . . . . . . . . . . . . . . 9

3.4 Personnel qualification. . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Labelling, safety marks . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Ex marking. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4. Transport, packaging and storage 12

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.2 Packaging and storage . . . . . . . . . . . . . . . . . . . . . . 12

5. Commissioning, operation 13

5.1 Grounding . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

5.2 Mounting . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2.1 Transmitter in head mounting version (model T16.H) . . . . . . . . . . . 15

5.2.2 Transmitter in rail mounting version (model T16.R) . . . . . . . . . . . . 16

5.3 Electrical connection . . . . . . . . . . . . . . . . . . . . . . . 16

5.3.1 Power supply, 4 ... 20 mA current loop . . . . . . . . . . . . . . . . 17

5.3.2 Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

5.4 Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . 19

5.4.1 Configurable monitoring functionality . . . . . . . . . . . . . . . . . 19

5.4.2 Configuration via the PC . . . . . . . . . . . . . . . . . . . . . 19

5.4.3 Programming unit model PU-548 . . . . . . . . . . . . . . . . . . 20

5.4.4 Configuration software WIKAsoft-TT . . . . . . . . . . . . . . . . . 20

6. Special conditions for safe use (X conditions) 21

6.1 Approval ATEX und IECEx . . . . . . . . . . . . . . . . . . . . . 21

6.1.1 Models T16.x-AC, T16.x-AI . . . . . . . . . . . . . . . . . . . . 21

6.1.2 Model T16.x-AN . . . . . . . . . . . . . . . . . . . . . . . . 21

6.1.3 Model T16.x-AE . . . . . . . . . . . . . . . . . . . . . . . . 21

6.2 Approval FM . . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.1 Models T16.x-AC, T16.x-AI . . . . . . . . . . . . . . . . . . . . 22

6.2.2 Model T16.x-AN . . . . . . . . . . . . . . . . . . . . . . . . 22

6.2.3 Model T16.x-AE . . . . . . . . . . . . . . . . . . . . . . . . 22

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

3

Page 4

EN

Contents

Declarations of conformity can be found online at www.wika.com.

7. Conguration software WIKAsoft-TT 23

7.1 Starting the software . . . . . . . . . . . . . . . . . . . . . . . 23

7.2 Configuration procedure . . . . . . . . . . . . . . . . . . . . . . 24

7.3 Fault diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . 24

7.4 Measured values. . . . . . . . . . . . . . . . . . . . . . . . . 24

7.5 Configuring several instruments identically . . . . . . . . . . . . . . . . 24

8. Faults 25

9. Maintenance 27

10. Return and disposal 27

10.1 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

10.2 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

11. Specications 28

11.1 Safety-related characteristic values for models T16.x-AI, T16.x-AC. . . . . . . . 29

11.2 Safety-related characteristic values for models T16.x-AN, T16.x-AE . . . . . . . 30

11.3 Versioning per NAMUR NE53 . . . . . . . . . . . . . . . . . . . . 31

12. Accessories 31

Appendix 1: Control drawing CSA/FM 32

Appendix 2: EU declaration of conformity 36

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

4

Page 5

EN

1. General information

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

5

1. General information

■

The temperature transmitter described in the operating instructions has been designed

and manufactured using state-of-the-art technology. All components are subject

to stringent quality and environmental criteria during production. Our management

systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time. Pass

the operating instructions on to the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet:

TE 16.01

- Application consultant:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Page 6

EN

2. Design and function

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

6

2. Design and function

2.1 Description

The model T16 temperature transmitter is used for converting a thermoelectric voltage into

a proportional current signal (4 ... 20 mA). Thus the sensors are permanently monitored for

their fault-free operation.

The temperature transmitter meets the requirements for:

■

Explosion protection (depending on the version)

■

Electromagnetic compatibility in accordance with NAMUR recommendation NE21

■

Signalling at the analogue output in accordance with NAMUR recommendation NE43

■

Sensor break signalling in accordance with NAMUR recommendation NE89 (corrosion

monitoring sensor connection)

2.2 Dimensions in mm

■

Head mounting version, model T16.H

14263238.01

Page 7

EN

2. Design and function

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

7

■

Rail mounting version, model T16.R

14263238.01

2.3 Scope of delivery

Cross-check scope of delivery with delivery note.

Page 8

EN

3. Safety

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

8

3. Safety

3.1 Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury

or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or

damage to property or the environment, if not avoided.

DANGER!

... identifies hazards caused by electrical power. Should the safety

instructions not be observed, there is a risk of serious or fatal injury.

DANGER!

... indicates a potentially dangerous situation in the hazardous area that can

result in serious injury or death, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and

trouble-free operation.

3.2 Intended use

The model T16 temperature transmitter is a universal transmitter, configurable via a PC, for

use with thermocouples.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specifications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specifications

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

Page 9

EN

3. Safety

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

9

3.3 Responsibility of the operator

The instrument is used in the industrial sector. The operator is therefore responsible for

legal obligations regarding safety at work.

The safety instructions within these operating instructions, as well as the safety, accident

prevention and environmental protection regulations for the application area must be

maintained.

The operator is obliged to maintain the product label in a legible condition.

The responsibility for classification of zones lies with the plant operator and not the

manufacturer/supplier of the equipment.

3.4 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to

equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled electrical personnel who have the qualifications

described below.

Skilled electrical personnel

Skilled electrical personnel are understood to be personnel who, based on their technical

training, know-how and experience as well as their knowledge of country-specific

regulations, current standards and directives, are capable of carrying out work on

electrical systems and independently recognising and avoiding potential hazards. The

skilled electrical personnel have been specifically trained for the work environment they

are working in and know the relevant standards and regulations. The skilled electrical

personnel must comply with current legal accident prevention regulations.

Special knowledge for working with instruments for hazardous areas:

The skilled electrical personnel must have knowledge of ignition protection types,

regulations and provisions for equipment in hazardous areas.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

Page 10

EN

3. Safety

T16.H-AIZZZ

0158

S# 1106FIDB159

V 1.0.0 2015-12

DC 8 ... 30 V

TAG-NR.

WIKA A. Wiegand SE & Co. KG D-63911 Klingenberg

Pt100/3 -150 ... +180 °C

Made in Germany

BVS 15 ATEX E 139 X

IECEx BVS 15.0112X

II 1 G Ex ia IIC T6...T4 Ga

II 1 D Ex ia IIIC T135 °C Da

Tamb T4/T5/T6: -40 ... +85/70/55 °C

T16.R-AIZZZ

S# 1106FIDB159

V 1.0.0

DC 8 ... 30 V

TAG-NR.

Pt100/3 -150 ... +180 °C

Sensor

mA-Loop

T16.H-AIZZZ

0158

S# 1106FIDB159

V 1.0.0 2015-12

DC 8 ... 30 V

TAG-NR.

WIKA A. Wiegand SE & Co. KG D-63911 Klingenberg

Pt100/3 -150 ... +180 °C

Made in Germany

BVS 15 ATEX E 139 X

IECEx BVS 15.0112X

II 1 G Ex ia IIC T6...T4 Ga

II 1 D Ex ia IIIC T135 °C Da

Tamb T4/T5/T6: -40 ... +85/70/55 °C

T16.H-AIZZZ

0158

S# 1106FIDB159

V 1.0.0 2015-12

DC 8 ... 30 V

TAG-NR.

WIKA A. Wiegand SE & Co. KG D-63911 Klingenberg

Pt100/3 -150 ... +180 °C

Made in Germany

BVS 15 ATEX E 139 X

IECEx BVS 15.0112X

II 1 G Ex ia IIC T6...T4 Ga

II 1 D Ex ia IIIC T135 °C Da

Tamb T4/T5/T6: -40 ... +85/70/55 °C

T16.R-AIZZZ

S# 1106FIDB159

V 1.0.0

DC 8 ... 30 V

TAG-NR.

Pt100/3 -150 ... +180 °C

Sensor

mA-Loop

T16.R-AIZZZ

0158

S# 1106FIDB159

V 1.0.0 2015-12

DC 8 ... 30 V

TAG-NR.

WIKA A. Wiegand SE & Co. KG D-63911 Klingenberg

Pt100/3

-150 ... +180 °C

Made in Germany

BVS 15 ATEX E 139 X

IECEx BVS 15.0112X

II 2(1)G Ex ia [ia Ga] IIC T6...T4 Ga

II 2(1)D Ex ia [ia Da] IIIC T135 °C Da

Tamb T4/T5/T6: -40 ... +85/70/55 °C

1

2

3

4

2

3

4

2

3

Resistance sensor

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

10

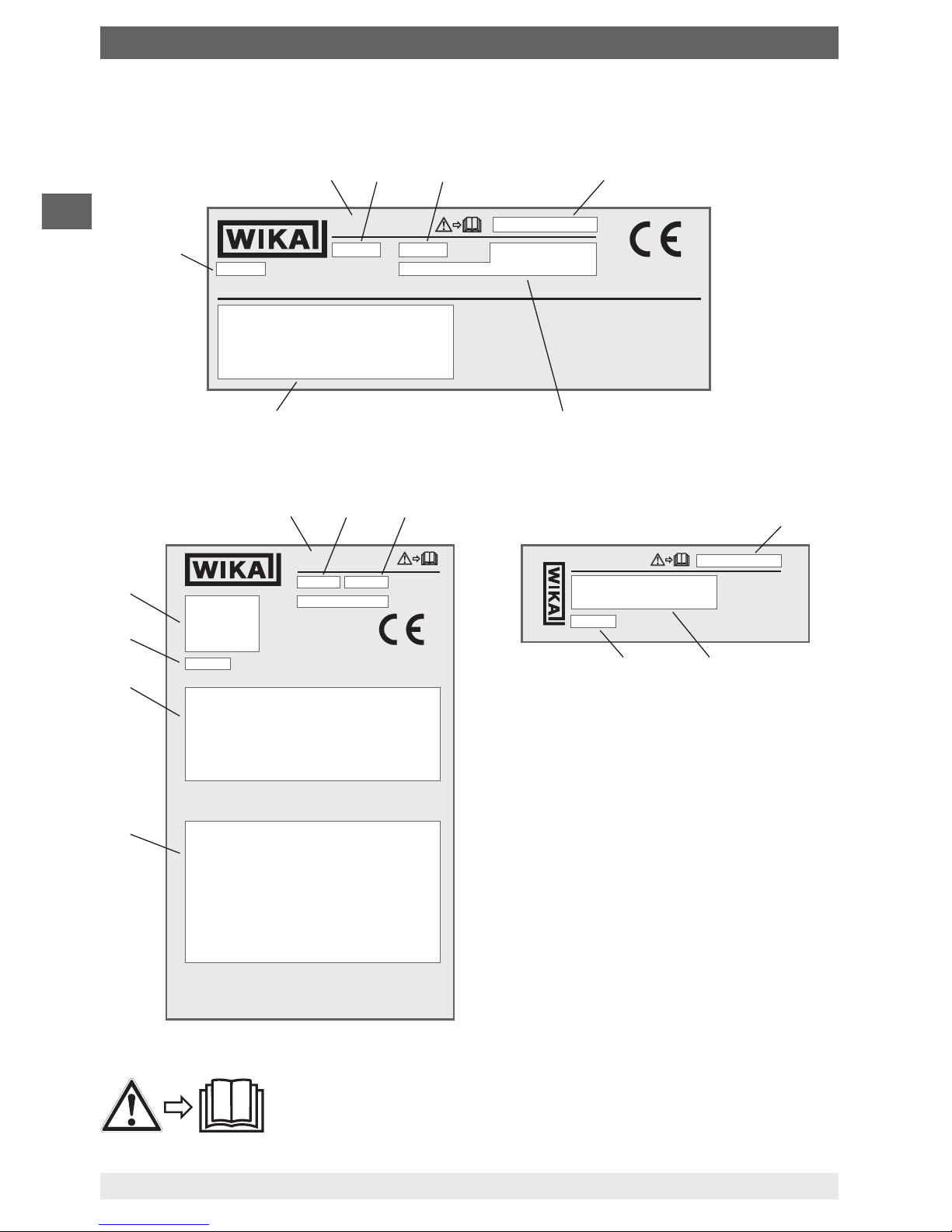

3.5 Labelling, safety marks

■

Head mounting version, model T16.H

■

Rail mounting version, model T16.R

Before mounting and commissioning the instrument, ensure you

read the operating instructions!

Model

Firmware

Date of manufacture (year-month)

Serial number

Sensor information (model, connection

method, power supply, measuring range)

Approval-related data

TAG no.

Pin assignment

Page 11

EN

3. Safety

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

11

3.6 Ex marking

DANGER!

Danger to life due to loss of explosion protection

Non-observance of these instructions and their contents may result in the

loss of explosion protection.

▶

Observe the safety instructions and further explosion instructions in these

operating instructions.

▶

Follow the requirements of the ATEX directive.

▶

Observe the information given in the applicable type examination

certificate and the relevant country-specific regulations for installation and

use in hazardous areas (e.g. IEC 60079-14, NEC, CEC).

Check whether the classification is suitable for the application. Observe the relevant

national regulations.

Model overview of European approvals

Model Ex marking Ignition protection type

BVS 17

ATEX E039 X

IECEx BVS 17.0033X

T16.H-AI

(Head mounting version)

II 1G

II 1D

Ex ia IIC T6 ... T4 Ga

Ex ia IIIC T135 °C Da

Intrinsically safe equipment

T16.R-AI

(Rail mounting version)

II 2(1)G

II 2(1)D

Ex ia [ia Ga] IIC T6 ... T4 Gb

Ex ia [ia Da] IIIC T135 °C Db

Intrinsically safe equipment

T16.x-AC II 3G Ex ic IIC T6 ... T4 Gc X Intrinsically safe equipment

T16.x-AN II 3G Ex nA IIC T6 ... T4 Gc X Non-incendive equipment

T16.x-AE II 3G Ex ec IIC T6 ... T4 Gc Non-incendive equipment

Page 12

EN

4. Transport, packaging and storage

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

12

4. Transport, packaging and storage

4.1 Transport

Check the instrument for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, damage to property can occur.

▶

Do not use transmitters with any damage to the exterior!

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Permissible conditions at the place of storage:

■

Storage temperature: -40 ... +85 °C

■

Humidity: 95 % r. h. (condensation permitted)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

Page 13

EN

5. Commissioning, operation

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

13

5. Commissioning, operation

Personnel: Skilled electrical personnel

Tools: Screwdriver (see chapter 5.3 “Electrical connection”)

DANGER!

Danger to life from explosion!

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Only carry out set-up work in non-hazardous environments!

▶

In hazardous areas, only use temperature transmitters that are approved

for those hazardous areas. Observe the approvals on the product label.

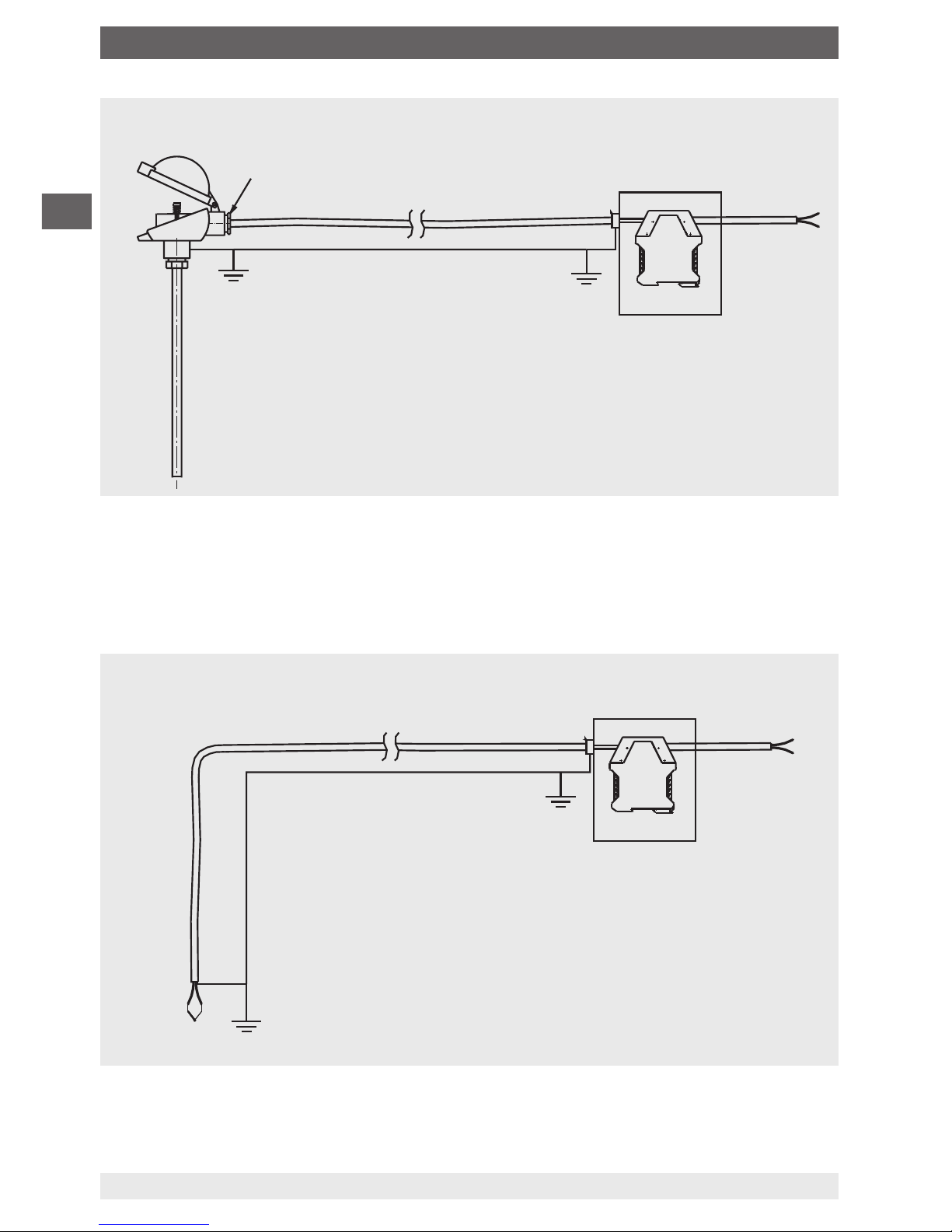

5.1 Grounding

WARNING!

Prevention of electrostatic discharge

When working during a running process operation, measures to prevent

electrostatic discharge from the connection terminals should be taken, as a

discharge could lead to temporary corruption of the measured value.

▶

Only use model T16.H temperature transmitters in grounded thermometer

heads!

▶

Connection of a thermocouple (e.g. type K) to the T16.R with a shielded

cable. The shield must be electrically connected to the case of the

grounded thermometer.

Connection head BSZ

grounded

Loop cable

Only use the model T16

temperature transmitter in

grounded thermometers!

Page 14

EN

5. Commissioning, operation

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

14

In applications with higher EMC requirements, using a shielded cable between the

transmitter and the sensor is recommended, especially in connection with long leads to the

sensor. For an exemplary illustration, see drawing.

With the rail mounting version (T16.R) and cable lengths greater than 30 m, shielded cable

must be used.

grounded

grounded shield

Sensor wire

Equipotential bonding

Field case/

Control cabinet

Sensor

T16

Connection head BSZ

grounded

grounded shield

Thermowell

with sensor

grounded

Sensor wire

Equipotential bonding

T16

Field case/

Control cabinet

Page 15

EN

5. Commissioning, operation

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

15

5.2 Mounting

5.2.1 Transmitter in head mounting version (model T16.H)

When fitting the head-mounted version of the transmitter, do not exceed a

torque of 1 Nm!

The transmitters for head mounting version are designed to be mounted on a measuring

insert within a form B, DIN connection head. The connection wires of the measuring insert

must be approx. 50 mm long and insulated.

Mounting in connection head

Insert the measuring insert with the mounted transmitter into the protective components

and secure into the connection head using screws in pressure springs.

Mounting in the connection head cover

When mounting in the cover of a connection head, use suitable screws and matching

washers.

Installing with DIN rail adapter

With the mechanical adapter, available as an accessory, the T16.H head-mounted

transmitters can also be fixed on a DIN rail (see chapter 12 “Accessories”).

Mounting example

14139114.01

14139114.01

Page 16

EN

5. Commissioning, operation

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

16

5.2.2 Transmitter in rail mounting version (model T16.R)

The rail mounting case will fasten onto a 35 mm DIN rail (EN 60175) by simply locking it

into place without the need for any tools.

Disassembly involves unlocking the detent element.

5.3 Electrical connection

DANGER!

Danger to life caused by electric current

Upon contact with live parts, there is a direct danger to life.

▶

The instrument may only be installed and mounted by skilled personnel.

▶

Operation using a defective power supply unit (e.g. short circuit from the

mains voltage to the output voltage) can result in life-threatening voltages

at the instrument!

▶

Carry out mounting work only with power disconnected.

▶

The connected wires must be checked to ensure they are connected

properly. Only well-secured wires can guarantee a fault-free operation.

This is protection class 3 equipment for connection at low voltages, which are separated

from the power supply or voltages of greater than AC 50 V or DC 120 V. Preferably, a

connection to an SELV or PELV circuit is recommended; alternatively protective measures

from HD 60346-4-41 (DIN VDE 0100-410).

Alternatively for North America

The connection can be made in line with “Class 2 Circuits” or “Class 2 Power Units” in

accordance with CEC (Canadian Electrical Code) or NEC (National Electrical Code).

The functional galvanic isolation present in the instrument does not ensure sufficient

protection against electrical impulses in the sense of EN 61140.

Recommended tool for screw terminals

Model Screwdriver Tightening torque

T16.H Cross head (Pozidriv tip), size 2 (ISO 8764) 0.5 Nm

T16.R Slotted, 3 x 0.5 mm (ISO 2380) 0.5 Nm

Page 17

EN

5. Commissioning, operation

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

17

5.3.1 Power supply, 4 ... 20 mA current loop

The model T16 is a 2-wire, powered temperature transmitter. Depending on the version, it

can be supplied with various types of power supply.

With flexible leads we recommend the use of crimped connector sleeves.

The integrated reverse polarity protection (wrong polarity on the terminals ⊕ and ⊖)

prevents the transmitter from being damaged.

Maximum values

■

Model T16.x-ZZ: DC 35 V

■

Model T16.x-AI: DC 30 V

■

Model T16.x-AC: DC 30 V

■

Model T16.x-AN: DC 35 V

■

Model T16.x-AE: DC 35 V

Minimum terminal voltage

DC 10 V

The load must not be too high, as otherwise, in the case of relatively high currents, the

terminal voltage at the transmitter will be too low.

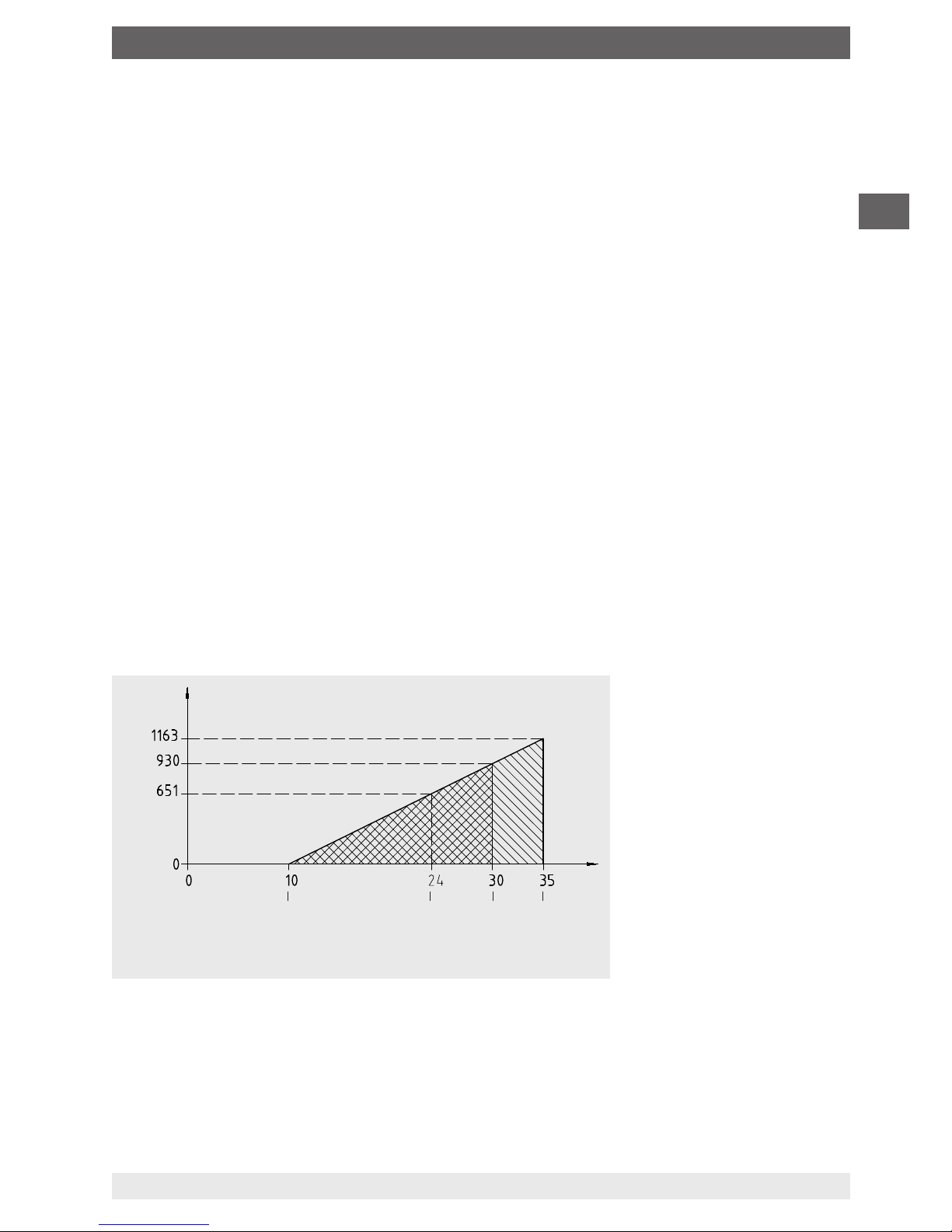

Maximum permissible load depending on the supply voltage

Load diagram

Voltage UB in V

Load R

A

in Ω

14222396.01

Min. voltage

Operating

voltage

Ex instruments

Non-Ex

instruments

Page 18

EN

5. Commissioning, operation

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

18

5.3.2 Sensors

Designation of connection terminals

Thermocouples (TC)

It is possible to connect a thermocouple in a 2-wire connection.

The T16 transmitter always uses the internal cold junction.

For the safety-relevant maximum values for the connection of the voltage

supply and the sensors, see chapter 11 “Specifications”.

Thermocouples

Input

Output

4 ... 20 mA loop

T16.H T16.R

Connection of the

PU-548 programming unit

14151201.01

Page 19

EN

5. Commissioning, operation

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

19

5.4 Configuration

Configurable are

■

Sensor type

■

Measuring range

■

Unit

■

Signalling

■

Measuring range monitoring

■

Damping

■

Write protection

■

“Several” TAG numbers

■

2-point scaling

The temperature transmitters are delivered with a basic configuration (see data sheet

TE 16.01) or configured according to customer specifications. If the configuration is

changed afterwards, the modifications must be noted on the product label using a waterresistant fibre-tip pen.

A simulation of the input value is not required to configure the T16. A sensor

simulation is only required for the functional test.

5.4.1 Configurable monitoring functionality

Measuring range monitoring:

If this function is activated, an error is signalled on the current loop if the measured value is

either below or over the limits of the measuring range.

5.4.2 Configuration via the PC

Configuration is carried out using a USB interface with a PC via the model PU-548

programming unit (see chapter 12 “Accessories”) and the WIKAsoft-TT configuration

software.

The required Windows device driver for the PU-548 is a component of the

current Windows

®

operating system.

Windows® is a registered trademark of Microsoft Corporation in the United States and other countries.

Page 20

EN

5. Commissioning, operation

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

20

5.4.3 Programming unit model PU-548

■

Easy to use

■

LED status indicator

■

Compact design

■

No further voltage supply is needed for either the

programming unit or for the transmitter

■

No driver installation needed (Windows® standard drivers are used)

(replaces programming unit model PU-448)

Connection of the PU-548

5.4.4 Configuration software WIKAsoft-TT

The WIKAsoft-TT configuration software is regularly updated and adapted to the firmware

extensions of the T16. Thus, full access to all functionalities and parameters of the

transmitter is permanently ensured (see chapter 7 “Configuration software WIKAsoft-TT”).

Free download of the current version of the WIKAsoft-TT software at

www.wika.com.

Head mounting version,

model T16.H

Rail mounting version, model T16.R

Page 21

EN

6. Special conditions for safe use (X conditions)

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

21

6. Special conditions for safe use (X conditions)

The influence of power dissipation of other devices placed beside the transmitter has

to be taken into account with regard to a temperature rise of the transmitter’s ambient

temperature.

General information:

Transmitters with “ia” marking may also be used in supply circuits of type “ib” with the same

connection parameters. Thus the entire measuring circuit (including the sensor circuit) is an

“ib” circuit. Transmitters were operated with supply circuits of type “ib” may not be re-used

with supply circuits of type “ia”.

6.1 Approval ATEX and IECEx

6.1.1 Models T16.x-AC, T16.x-AI

■

The transmitter shall be mounted in an enclosure in accordance with IEC 60079-11

suitable for the relevant installation area. The enclosure has to fulfil at least IP20 for

areas requiring EPL Ga, Gb or Gc and IP54 in accordance with IEC 60079-0 for areas

requiring EPL Db or Dc.

■

During the installation internal wiring, clearances, creepage distances and separations

have to be considered according to IEC 60079-11.

6.1.2 Model T16.x-AN

■

The transmitter shall be mounted in an enclosure fulfilling at least IP54 in accordance

with IEC 60079-0 and IEC 60079-15.

■

During the installation clearances, creepage distances and separations have to be

considered according to IEC 60079-15.

■

The equipment shall only be used in an area of at least pollution degree 2, as defined in

IEC 60664-1.

■

Maximum overvoltage category II according to IEC 60664-1 is permitted for the circuits.

6.1.3 Model T16.x-AE

■

The transmitter shall be mounted in an enclosure fulfilling at least IP54 in accordance

with IEC 60079-0 and IEC 60079-7.

■

During the installation clearances, creepage distances and separations have to be

considered according to IEC 60079-7.

■

The equipment shall only be used in an area of at least pollution degree 2, as defined in

IEC 60664-1.

■

Maximum overvoltage category II according to IEC 60664-1 is permitted for the circuits.

Page 22

EN

6. Special conditions for safe use (X conditions)

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

22

6.2 Approval FM

6.2.1 Models T16.x-AC, T16.x-AI

■

The transmitters shall be mounted in an enclosure in accordance with

ANSI/ISA 60079-11 suitable for the relevant installation area. The enclosure has to fulfil

at least IP20.

■

During the installation internal wiring, clearances, creepage distances and separations

have to be considered according to ANSI/ISA 60079-11.

6.2.2 Model T16.x-AN

■

The transmitters shall be mounted in an enclosure fulfilling at least IP54 in accordance

with ANSI/ISA 60079-0 and ANSI/ISA 60079-15.

■

During the installation clearances, creepage distances and separations have to be

considered according to ANSI/ISA 60079-15.

■

The equipment shall only be used in an area of at least pollution degree 2, as defined in

ANSI/ISA 61010-1 resp. IEC 60664-1.

■

Maximum overvoltage category II in accordance with ANSI/ISA 61010-1 resp.

IEC 60664-1 is permitted for the circuits.

6.2.3 Model T16.x-AE

■

The transmitters shall be mounted in an enclosure fulfilling at least IP54 in accordance

with ANSI/ISA 60079-0 and ANSI/ISA 60079-7.

■

During the installation clearances, creepage distances and separations have to be

considered according to ANSI/ISA 60079-7.

■

The equipment shall only be used in an area of at least pollution degree 2, as defined in

ANSI/ISA 61010-1 resp. IEC 60664-1.

■

Maximum overvoltage category II in accordance with ANSI/ISA 61010-1 resp.

IEC 60664-1 is permitted for the circuits.

Page 23

EN

7. Configuration software WIKAsoft-TT

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

23

7. Configuration software WIKAsoft-TT

For installation please follow the instructions of the installation routine.

7.1 Starting the software

Start the configuration software by double-clicking on the WIKAsoft TT icon.

After starting the software, the language

can be changed by selecting the flag of the

country in question.

The selection of the COM port is made

automatically.

After the connection of a transmitter (using

the PU-548), on pressing the “Start” button,

the configuration interface is loaded.

The configuration interface can only be loaded when an instrument is

connected.

Page 24

EN

7. Configuration software WIKAsoft-TT

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

24

7.2 Configuration procedure

Steps 1 and 2 are carried out automatically when starting the software

1. “Loading instrument data”

2. “Loading configuration”

3. [optional] Cancel write protection (“key” symbol at the bottom right)

4. Change the required parameters

→ Sensor/Measuring range/Error signalling etc.

5. “Save to the instrument”

6. [optional] Activate write protection

7. [optional] Print configuration history

8. [optional] Test: “Loading configuration” → Check configuration

7.3 Fault diagnosis

Here, in the event of an “error detected by the transmitter”, the error message is displayed.

Examples: Sensor break, permitted highest temperature exceeded, etc.

In normal operation, “No fault - No maintenance requirement” is displayed here.

7.4 Measured values

Line recorder - Here the measured value progression is represented in the format of a

chart recorder with a constant sampling rate in a defined time interval (180 seconds) and a

variable temperature axis.

The display purely serves as a functional check and for information.

An export of the data is not possible.

7.5 Configuring several instruments identically

■

First instrument

1. “Loading configuration”

2. [optional] Cancel write protection (“key” symbol at the bottom right)

3. Change the required parameters

4. “Save to the instrument”

5. [optional] Activate write protection

■

All following instruments

1. “Loading instrument data”

2. [optional] Cancel write protection

3. [optional] Change the required parameters, e.g. TAG number

4. “Save to the instrument”

5. [optional] Activate write protection

For further information see chapter 1 “General information” “Contact data” or

the back page of these operating instructions

Page 25

EN

8. Faults

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

25

8. Faults

DANGER!

Danger to life from explosion

Through working in flammable atmospheres, there is a risk of explosion

which can cause death.

▶

Only rectify faults in non-flammable atmospheres!

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the instrument

must be taken out of operation immediately.

▶

Ensure that there is no longer any signal present and protect against being

put into operation accidentally.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter 10.1

“Return” and enclose a short description of the problem, details of ambient

conditions as well as the time of use before the problem occurred with the

temperature transmitter.

For contact details see chapter 1 “General information” or the back page of

the operating instructions.

Page 26

EN

8. Faults

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

26

Fault tree

Current loop disconnected

Voltage supply connected

incorrectly (wrong polarity)

Transmitter not connected

Wrong sensor type

Thermocouple

reversed

Wrong temperature

range

Wrong compensation

Sensor

= TC

Sensor

= TC

l > 20 mA

l < 4 mA

Current value is correct, but a temperature

drift is noticeable while transmitter is heating

up or cooling down

Process temperature out of

measuring range

Sensor break

Capacitive or inductive

coupling via the sensor

Capacitive or inductive

coupling via the current loop

4 mA < l < 20 mA

but wrong values

l = 0 mA

Sensor connected incorrectly

Wrong transmitter

configuration

Wrong polarity of

thermocouple

Load too high

Electromagnetic

interferences

Current value falls while the measured

temperature rises (and the other way around)

Current value is okay at low temperature

values, but too low at higher temperatures

Current value is unstable and changes within

seconds

Page 27

EN

9. Maintenance / 10. Return and disposal

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

27

9. Maintenance

For contact details see chapter 1 “General information” or the back page of

the operating instructions.

The temperature transmitter described in these operating instructions is maintenance-free.

The electronics are completely encapsulated and incorporate no components which could

be repaired or replaced.

Repairs must only be carried out by the manufacturer.

Only use original parts.

10. Return and disposal

10.1 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.) and must therefore be cleaned before being returned.

When returning the instrument, use the original packaging or a suitable transport

packaging.

To avoid damage:

1. Place the instrument, along with shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

2. If possible, place a bag containing a desiccant inside the packaging.

3. Label the shipment as carriage of a highly sensitive measuring instrument.

Information on returns can be found under the heading “Service” on our local

website.

10.2 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

Do not dispose of with household waste. Ensure a proper disposal in accordance with national regulations.

Page 28

EN

11. Specifications

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

28

11. Specifications

DANGER!

Danger to life due to loss of explosion protection

The non-observance of the instructions for use in hazardous areas can lead

to the loss of the explosion protection.

▶

Adhere to the following limit values and instructions.

Specifications Model T16

Permissible ambient temperature range {-50} -40 ... +85 {+105} °C

{-58} -40 ... +185 {+221} °F

Climate class per IEC 654-1:1993 Cx (-40 ... +85 °C / -40 ... +185 °F, 5 ... 95 % r. h.)

Maximum permissible humidity

■

Model T16.H

per IEC 60068-2-38:2009

■

Model T16.R

per IEC 60068-2-30:2005

Test max. temperature variation 65 °C (177 °F) /

-10 °C (-18 °F), 93 % ±3 % r. h.

Test max. temperature 55 °C (131 °F), 95 % r. h.

Vibration resistance

per IEC 60068-2-6:2008

Test Fc: 10 ... 2,000 Hz; 10 g,

amplitude 0.75 mm (0.03 in)

Shock resistance

per IEC 68-2-27:2009

Acceleration / Shock width

Model T16.H: 100 g / 6 ms

Model T16.R: 30 g / 11 ms

Salt fog

per IEC 68-2-52:1996, IEC 60068-2-52:1996

Severity level 1

Condensation Model T16.H: Acceptable

Model T16.R: Acceptable in vertical mounting

position

Free fall

in line with IEC 60721-3-2:1997,

DIN EN 60721-3-2:1998

Drop height 1.5 m (4.9 ft)

Electromagnetic compatibility (EMC)

per DIN EN 55011:2010, DIN EN 61326-2-3:2013,

NAMUR NE21:2012, GL 2012 VI Part 7

EN 61326 emission (group 1, class B) and

interference immunity (industrial application)

[HF field, HF cable, ESD, Burst, Surge]

{ } Items in curved brackets are options for an additional price, not for ATEX versions of the head mounting version and not for

T16.R rail mounting version

Page 29

EN

11. Specifications

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

29

11.1 Safety-related characteristic values for models T16.x-AI, T16.x-AC

Intrinsically safe connection values for the current loop (4 ... 20 mA)

Protection level Ex ia IIC/IIB/IIA, Ex ia IIIC or Ex ic IIC/IIB/IIA

Parameters Models T16.x-AI, T16.x-AC Models T16.x-AI

Gas hazardous application Dust hazardous

application

Terminals + / - + / -

Voltage U

i

DC 30 V DC 30 V

Current l

i

130 mA 130 mA

Power P

i

800 mW 750/650/550 mW

Effective internal capacitance C

i

18.4 nF 18.4 nF

Effective internal inductance L

i

800 µH 800 µH

Sensor circuit

Parameters Models T16.x-AI Model T16.x-AC

Ex ia IIC/IIB//IIA

Ex ia IIIC

Ex ic IIC/IIB//IIA

Terminals 1 - 2 1 - 2

Voltage U

o

DC 6.6 V DC 6.6 V

Current I

o

4 mA 4 mA

Power P

o

10 mW 10 mW

Max. external

capacitance C

o

IIC 21 µF

1)

280 µF

1)

IIB IIIC 495 µF

1)

995 µF

1)

IIA 995 µF

1)

995 µF

1)

Max. external

inductance L

o

IIC 95 mH 95 mH

IIB IIIC 95 mH 95 mH

IIA 95 mH 95 mH

Characteristics Linear

Comments:

U

o

: Maximum voltage of any conductor against the other three conductors

I

o

: Maximum output current for the least favourable connection of the internal current limiting resistors

P

o

: Uo x Io divided by 4 (linear characteristic)

1) Internal L and C have already been considered

Due to distance requirements of the applied standards, the IS power and signal circuit as well

as the IS sensor circuit shall be considered as being galvanically connected to each other.

The electrical parameters of the head and rail mounting versions are identical.

Page 30

EN

11. Specifications

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

30

Models T16.x-AI

The intrinsically safe sensor circuit (optional 2-wire, 3-wire or 4-wire configuration) for both

versions is intended for the supply of equipment in areas with 1G or 1D requirements.

The version T16.H-AI has been designed for installation in cases or connection heads in

areas with 1G, 2G or 1D, 2D requirements.

The version T16.R-AI is intended for installation in a case which guarantees at least IP20

ingress protection (2G application or installation outside the hazardous area) or IP6X

(2D application).

Ambient temperature range

Application Ambient temperature range Temperature class Power P

i

Group II

-40 °C (-40 °F) ≤ T

a

≤ +85 °C (+185 °F)

T4 800 mW

-40 °C (-40 °F) ≤ T

a

≤ +70 °C (+158 °F)

T5 800 mW

-40 °C (-40 °F) ≤ T

a

≤ +55 °C (+131 °F)

T6 800 mW

Group IIIC

-40 °C (-40 °F) ≤ T

a

≤ +40 °C (+104 °F)

N / A 750 mW

-40 °C (-40 °F) ≤ T

a

≤ +75 °C (+167 °F)

N / A 650 mW

-40 °C (-40 °F) ≤ T

a

≤ +85 °C (+185 °F)

N / A 550 mW

N / A = not applicable

11.2 Safety-related characteristic values for models T16.x-AN, T16.x-AE

Power and signal circuit (4 ... 20 mA loop)

Protection level Ex nA IIC/IIB/IIA

Parameters Models T16.x-AN, T16.x-AE

Gas hazardous application

Terminals + / -

Voltage U

i

DC 35 V

Current I

i

21.5 mA

Sensor circuit

Protection level Ex nA IIC/IIB/IIA

Parameters Models T16.x-AN, T16.x-AE

Terminals 1 - 2

Power P

o

2.575 V x 0.1 mA → 0.256 mW

DC 2.575 V

0.1 mA

Page 31

EN

11. Specifications / 12. Accessories

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

31

Ambient temperature range

Application Ambient temperature range Temperature class

Group II -40 °C (-40 °F) ≤ Ta ≤ +85 °C (+185 °F) T4

-40 °C (-40 °F) ≤ T

a

≤ +70 °C (+158 °F) T5

-40 °C (-40 °F) ≤ T

a

≤ +55 °C (+131 °F) T6

N / A = not applicable

11.3 Versioning per NAMUR NE53

Firmware version Comments WIKAsoft-TT Modem

V 1.0.0 First “Launch” version

of the T16

v 1.5 PU-448 (S. no. >10000) or

PU-548

For further specifications see WIKA data sheet TE 16.01 and the order documentation.

12. Accessories

Model Special features Order no.

Programming unit

Model PU-548

■

Simple operation

■

LED status display

■

Compact design

■

No further voltage supply is needed for either the

programming unit or for the transmitter

■

No driver installation needed (Windows® standard

drivers are used)

■

2 mm banana plug

■

Incl. 1 model magWIK magnetic quick connector

(replaces programming unit model PU-448)

14231581

Magnetic quick

connector

magWIK

■

Replacement for fine alligator clips and HART® terminals

■

Fast, safe and tight electrical connection

■

For all configuration and calibration processes

■

2 mm socket

■

Incl. 2 adapters (2 mm to 4 mm socket)

14026893

Adapter

■

Suitable for TS 35 per DIN EN 60715 (DIN EN 50022)

or TS 32 per DIN EN 50035

■

Material: Plastic / stainless steel

■

Dimensions: 60 x 20 x 41.6 mm (2.3 x 0.7 x 1.6 in)

3593789

Adapter

■

Suitable for TS 35 per DIN EN 60715 (DIN EN 50022)

■

Material: Steel, tin-plated

■

Dimensions: 49 x 8 x 14 mm (1.9 x 0.3 x 0.5 in)

3619851

Page 32

EN

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

32

Appendix 1: Control drawing CSA/FM

Page 33

EN

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

33

Appendix 1: Control drawing CSA/FM

Page 34

EN

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

34

Appendix 1: Control drawing CSA/FM

Page 35

EN

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

35

Appendix 1: Control drawing CSA/FM

Page 36

EN

Appendix 2: EU declaration of conformity

14147933.02 10/2018 EN/DE

WIKA operating instructions model T16

36

Page 37

DE

Inhalt

Inhalt

1. Allgemeines 39

2. Aufbau und Funktion 40

2.1 Beschreibung . . . . . . . . . . . . . . . . . . . . . . . . . . 40

2.2 Abmessungen in mm . . . . . . . . . . . . . . . . . . . . . . . 40

2.3 Lieferumfang . . . . . . . . . . . . . . . . . . . . . . . . . . 41

3. Sicherheit 42

3.1 Symbolerklärung. . . . . . . . . . . . . . . . . . . . . . . . . 42

3.2 Bestimmungsgemäße Verwendung . . . . . . . . . . . . . . . . . . 42

3.3 Verantwortung des Betreibers . . . . . . . . . . . . . . . . . . . . 43

3.4 Personalqualifikation . . . . . . . . . . . . . . . . . . . . . . . 43

3.5 Beschilderung, Sicherheitskennzeichnungen . . . . . . . . . . . . . . . 44

3.6 Ex-Kennzeichnung . . . . . . . . . . . . . . . . . . . . . . . . 45

4. Transport, Verpackung und Lagerung 46

4.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

4.2 Verpackung und Lagerung . . . . . . . . . . . . . . . . . . . . . 46

5. Inbetriebnahme, Betrieb 47

5.1 Erdung . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

5.2 Montage . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

5.2.1 Transmitter in Kopfversion (Typ T16.H) . . . . . . . . . . . . . . . . 49

5.2.2 Transmitter in Schienenversion (Typ T16.R). . . . . . . . . . . . . . . 50

5.3 Elektrischer Anschluss. . . . . . . . . . . . . . . . . . . . . . . 50

5.3.1 Hilfsenergie, 4 ... 20 mA-Stromschleife . . . . . . . . . . . . . . . . 51

5.3.2 Sensoren . . . . . . . . . . . . . . . . . . . . . . . . . . 52

5.4 Konfiguration . . . . . . . . . . . . . . . . . . . . . . . . . . 53

5.4.1 Konfigurierbare Überwachungsfunktionen . . . . . . . . . . . . . . . 53

5.4.2 Konfigurieren mit dem PC. . . . . . . . . . . . . . . . . . . . . 53

5.4.3 Programmiereinheit Typ PU-548 . . . . . . . . . . . . . . . . . . 54

5.4.4 Konfigurationssoftware WIKAsoft-TT . . . . . . . . . . . . . . . . . 54

6. Besondere Bedingungen für die sichere Anwendung (X-Conditions) 55

6.1 Zulassung ATEX und IECEx . . . . . . . . . . . . . . . . . . . . . 55

6.1.1 Typen T16.x-AC, T16.x-AI. . . . . . . . . . . . . . . . . . . . . 55

6.1.2 Typ T16.x-AN . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.1.3 Typ T16.x-AE . . . . . . . . . . . . . . . . . . . . . . . . . 55

6.2 Zulassung FM . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.2.1 Typen T16.x-AC, T16.x-AI. . . . . . . . . . . . . . . . . . . . . 56

6.2.2 Typ T16.x-AN . . . . . . . . . . . . . . . . . . . . . . . . . 56

6.2.3 Typ T16.x-AE . . . . . . . . . . . . . . . . . . . . . . . . . 56

WIKA Betriebsanleitung Typ T16

37

14147933.02 10/2018 EN/DE

Page 38

DE

Inhalt

Konformitätserklärungen finden Sie online unter www.wika.de.

7. Konfigurationssoftware WIKAsoft-TT 57

7.1 Starten der Software . . . . . . . . . . . . . . . . . . . . . . . 57

7.2 Ablauf Konfiguration . . . . . . . . . . . . . . . . . . . . . . . 58

7.3 Fehlerdiagnose . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.4 Messwerte . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

7.5 Mehrere Geräte identisch konfigurieren . . . . . . . . . . . . . . . . . 58

8. Störungen 59

9. Wartung 61

10. Rücksendung und Entsorgung 61

10.1 Rücksendung . . . . . . . . . . . . . . . . . . . . . . . . . . 61

10.2 Entsorgung . . . . . . . . . . . . . . . . . . . . . . . . . . 61

11. Technische Daten 62

11.1 Sicherheitstechnische Kennwerte Typen T16.x-AI, T16.x-AC . . . . . . . . . . 63

11.2 Sicherheitstechnische Kennwerte Typen T16.x-AN, T16.x-AE . . . . . . . . . 64

11.3 Versionierung nach NAMUR NE53 . . . . . . . . . . . . . . . . . . 65

12. Zubehör 65

Anlage 1: Control drawing CSA/FM 32

Anlage 2: EU-Konformitätserklärung 36

WIKA Betriebsanleitung Typ T16

38

14147933.02 10/2018 EN/DE

Page 39

DE

1. Allgemeines

WIKA Betriebsanleitung Typ T16

39

14147933.02 10/2018 EN/DE

1. Allgemeines

■

Der in der Betriebsanleitung beschriebene Temperaturtransmitter wird nach dem aktuellen Stand der Technik konstruiert und gefertigt. Alle Komponenten unterliegen während

der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme

sind nach ISO 9001 und ISO 14001 zertifiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise

und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden. Betriebsanleitung an nachfolgende Benutzer oder Besitzer des Gerätes weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt:

TE 16.01

- Anwendungsberater:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.de

Page 40

DE

2. Aufbau und Funktion

WIKA Betriebsanleitung Typ T16

40

14147933.02 10/2018 EN/DE

2. Aufbau und Funktion

2.1 Beschreibung

Der Temperaturtransmitter Typ T16 dient zur Umwandlung einer Thermospannung in ein

proportionales Stromsignal (4 ... 20 mA). Dabei werden die Sensoren permanent auf ihre

einwandfreie Funktion überwacht.

Der Temperaturtransmitter erfüllt die Anforderungen an:

■

Explosionsschutz (je nach Version)

■

Elektromagnetische Verträglichkeit nach NAMUR-Empfehlung NE21

■

Die Signalisierung am Analogausgang gemäß NAMUR-Empfehlung NE43

■

Eine Fühlerbruchsignalisierung gemäß NAMUR-Empfehlung NE89 (Korrosionsüberwachung Sensoranschluss)

2.2 Abmessungen in mm

■

Kopfversion, Typ T16.H

14263309.01

Page 41

DE

2. Aufbau und Funktion

WIKA Betriebsanleitung Typ T16

41

14147933.02 10/2018 EN/DE

■

Schienenversion, Typ T16.R

14263309.01

2.3 Lieferumfang

Lieferumfang mit dem Lieferschein abgleichen.

Page 42

DE

3. Sicherheit

WIKA Betriebsanleitung Typ T16

42

14147933.02 10/2018 EN/DE

3. Sicherheit

3.1 Symbolerklärung

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod oder

zu schweren Verletzungen führen kann, wenn sie nicht gemieden wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen kann,

wenn sie nicht gemieden wird.

GEFAHR!

... kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder tödlicher

Verletzungen.

GEFAHR!

... weist auf eine möglicherweise gefährliche Situation im explosionsgefährdeten Bereich hin, die zum Tod oder zu schweren Verletzungen führen kann,

wenn sie nicht gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

effizienten und störungsfreien Betrieb hervor.

3.2 Bestimmungsgemäße Verwendung

Der Temperaturtransmitter Typ T16 ist ein universeller, via PC konfigurierbarer Transmitter

für Thermoelemente.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Die technischen Spezifikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der technischen

Spezifikationen macht die sofortige Stilllegung und Überprüfung durch einen autorisierten

WIKA-Servicemitarbeiter erforderlich.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

Page 43

DE

3. Sicherheit

WIKA Betriebsanleitung Typ T16

43

14147933.02 10/2018 EN/DE

3.3 Verantwortung des Betreibers

Das Gerät wird im gewerblichen Bereich eingesetzt. Der Betreiber unterliegt daher den

gesetzlichen Pflichten zur Arbeitssicherheit.

Die Sicherheitshinweise dieser Betriebsanleitung, sowie die für den Einsatzbereich des

Gerätes gültigen Sicherheits-, Unfallverhütungs- und Umweltschutzvorschriften einhalten.

Der Betreiber ist verpflichtet das Typenschild lesbar zu halten.

Die Verantwortung über die Zoneneinteilung unterliegt dem Anlagenbetreiber und nicht

dem Hersteller/Lieferanten der Betriebsmittel.

3.4 Personalqualifikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualifikation

Unsachgemäßer Umgang kann zu erheblichen Personen- und Sachschäden

führen.

▶

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch

Elektrofachpersonal nachfolgend beschriebener Qualifikation durchführen

lassen.

Elektrofachpersonal

Das Elektrofachpersonal ist aufgrund seiner fachlichen Ausbildung, Kenntnisse und

Erfahrungen sowie Kenntnis der landesspezifischen Vorschriften, geltenden Normen

und Richtlinien in der Lage, Arbeiten an elektrischen Anlagen auszuführen und mögliche Gefahren selbstständig zu erkennen und zu vermeiden. Das Elektrofachpersonal ist

speziell für das Arbeitsumfeld, in dem es tätig ist, ausgebildet und kennt die relevanten

Normen und Bestimmungen. Das Elektrofachpersonal muss die Bestimmungen der

geltenden gesetzlichen Vorschriften zur Unfallverhütung erfüllen.

Besondere Kenntnisse bei Arbeiten mit Geräten für explosionsgefährdete Bereiche:

Das Elektrofachpersonal muss Kenntnisse haben über Zündschutzarten, Vorschriften und

Verordnungen für Betriebsmittel in explosionsgefährdeten Bereichen.

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

Page 44

DE

3. Sicherheit

T16.H-AIZZZ

0158

S# 1106FIDB159

V 1.0.0 2015-12

DC 8 ... 30 V

TAG-NR.

WIKA A. Wiegand SE & Co. KG D-63911 Klingenberg

Pt100/3 -150 ... +180 °C

Made in Germany

BVS 15 ATEX E 139 X

IECEx BVS 15.0112X

II 1 G Ex ia IIC T6...T4 Ga

II 1 D Ex ia IIIC T135 °C Da

Tamb T4/T5/T6: -40 ... +85/70/55 °C

T16.R-AIZZZ

S# 1106FIDB159

V 1.0.0

DC 8 ... 30 V

TAG-NR.

Pt100/3 -150 ... +180 °C

Sensor

mA-Loop

T16.H-AIZZZ

0158

S# 1106FIDB159

V 1.0.0 2015-12

DC 8 ... 30 V

TAG-NR.

WIKA A. Wiegand SE & Co. KG D-63911 Klingenberg

Pt100/3 -150 ... +180 °C

Made in Germany

BVS 15 ATEX E 139 X

IECEx BVS 15.0112X

II 1 G Ex ia IIC T6...T4 Ga

II 1 D Ex ia IIIC T135 °C Da

Tamb T4/T5/T6: -40 ... +85/70/55 °C

T16.H-AIZZZ

0158

S# 1106FIDB159

V 1.0.0 2015-12

DC 8 ... 30 V

TAG-NR.

WIKA A. Wiegand SE & Co. KG D-63911 Klingenberg

Pt100/3 -150 ... +180 °C

Made in Germany

BVS 15 ATEX E 139 X

IECEx BVS 15.0112X

II 1 G Ex ia IIC T6...T4 Ga

II 1 D Ex ia IIIC T135 °C Da

Tamb T4/T5/T6: -40 ... +85/70/55 °C

T16.R-AIZZZ

S# 1106FIDB159

V 1.0.0

DC 8 ... 30 V

TAG-NR.

Pt100/3 -150 ... +180 °C

Sensor

mA-Loop

T16.R-AIZZZ

0158

S# 1106FIDB159

V 1.0.0 2015-12

DC 8 ... 30 V

TAG-NR.

WIKA A. Wiegand SE & Co. KG D-63911 Klingenberg

Pt100/3

-150 ... +180 °C

Made in Germany

BVS 15 ATEX E 139 X

IECEx BVS 15.0112X

II 2(1)G Ex ia [ia Ga] IIC T6...T4 Ga

II 2(1)D Ex ia [ia Da] IIIC T135 °C Da

Tamb T4/T5/T6: -40 ... +85/70/55 °C

1

2

3

4

2

3

4

2

3

Resistance sensor

WIKA Betriebsanleitung Typ T16

44

14147933.02 10/2018 EN/DE

3.5 Beschilderung, Sicherheitskennzeichnungen

■

Kopfversion, Typ T16.H

■

Schienenversion, Typ T16.R

Vor Montage und Inbetriebnahme des Gerätes unbedingt die

Betriebsanleitung lesen!

Typ

Firmware

Herstellungsdatum (Jahr-Monat)

Seriennummer

Sensorangaben (Typ, Schaltungsart,

Hilfsenergie, Messbereich)

Zulassungsrelevante Daten

TAG-Nr.

Anschlussbelegung

Page 45

DE

3. Sicherheit

WIKA Betriebsanleitung Typ T16

45

14147933.02 10/2018 EN/DE

3.6 Ex-Kennzeichnung

GEFAHR!

Lebensgefahr durch Verlust des Explosionsschutzes

Die Nichtbeachtung dieser Inhalte und Anweisungen kann zum Verlust des

Explosionsschutzes führen.

▶

Sicherheitshinweise sowie Explosionshinweise in dieser Betriebsanleitung

beachten.

▶

Die Anforderungen der ATEX-Richtlinie beachten.

▶

Die Angaben der geltenden Baumusterprüfbescheinigung sowie die jeweiligen landesspezifischen Vorschriften zur Installation und Einsatz in explosionsgefährdeten Bereichen (z. B. IEC 60079-14, NEC, CEC) einhalten.

Überprüfen, ob die Klassifizierung für den Einsatzfall geeignet ist. Die jeweiligen nationalen

Vorschriften und Bestimmungen beachten.

Typenübersicht der europäischen Zulassungen

Ty p Ex-Kennzeichnung Zündschutzart

BVS 17

ATEX E039 X

IECEx BVS 17.0033X

T16.H-AI

(Kopfversion)

II 1G

II 1D

Ex ia IIC T6 ... T4 Ga

Ex ia IIIC T135 °C Da

Eigensicheres Betriebsmittel

T16.R-AI

(Schienenversion)

II 2(1)G

II 2(1)D

Ex ia [ia Ga] IIC T6 ... T4 Gb

Ex ia [ia Da] IIIC T135 °C Db

Eigensicheres Betriebsmittel

T16.x-AC II 3G Ex ic IIC T6 ... T4 Gc X Eigensicheres Betriebsmittel

T16.x-AN II 3G Ex nA IIC T6 ... T4 Gc X Nicht-funkende Einrichtung

T16.x-AE II 3G Ex ec IIC T6 ... T4 Gc Nicht-funkende Einrichtung

Page 46

DE

4. Transport, Verpackung und Lagerung

WIKA Betriebsanleitung Typ T16

46

14147933.02 10/2018 EN/DE

4. Transport, Verpackung und Lagerung

4.1 Transport

Gerät auf eventuell vorhandene Transportschäden untersuchen.

Offensichtliche Schäden unverzüglich mitteilen.

VORSICHT!

Beschädigungen durch unsachgemäßen Transport

Bei unsachgemäßem Transport können Sachschäden entstehen.

▶

Äußerlich beschädigte Transmitter nicht verwenden!

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

4.2 Verpackung und Lagerung

Verpackung erst unmittelbar vor der Montage entfernen.

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -40 ... +85 °C

■

Feuchtigkeit: 95 % r. F. (Betauung zulässig)

Folgende Einflüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

Page 47

DE

5. Inbetriebnahme, Betrieb

WIKA Betriebsanleitung Typ T16

47

14147933.02 10/2018 EN/DE

5. Inbetriebnahme, Betrieb

Personal: Elektrofachpersonal

Werkzeuge: Schraubendreher (siehe Kapitel 5.3 „Elektrischer Anschluss“)

GEFAHR!

Lebensgefahr durch Explosion!

Durch Arbeiten in entzündlichen Atmosphären besteht Explosionsgefahr, die

zum Tod führen kann.

▶

Rüstarbeiten nur in nicht-explosionsgefährdeter Umgebung durchführen!

▶

Im explosionsgefährdeten Bereich nur Temperaturtransmitter einsetzen,

die für diesen explosionsgefährdeten Bereich zugelassen sind. Zulassungen auf dem Typenschild beachten.

5.1 Erdung

WARNUNG!

Vermeidung elektrostatischer Entladung

Bei Arbeiten während eines laufenden Prozessbetriebes Maßnahmen zur

Vermeidung elektrostatischer Entladung auf die Anschlussklemmen treffen,

da Entladungen zu vorübergehenden Verfälschungen des Messwertes

führen können.

▶

Den Temperaturtransmitter Typ T16.H nur in geerdeten ThermometerKöpfen einsetzen!

▶

Anschluss eines Thermoelementes (z. B. Typ K) an den T16.R mit einem

geschirmten Kabel. Der Schirm muss elektrisch leitend mit dem Gehäuse

des geerdeten Thermometers verbunden werden.

Anschlusskopf BSZ

geerdet

Schleifenleitung

Den Temperaturtransmitter

Typ T16 nur in geerdeten

Thermometern einsetzen!

Page 48

DE

5. Inbetriebnahme, Betrieb

WIKA Betriebsanleitung Typ T16

48

14147933.02 10/2018 EN/DE

In Applikationen mit erhöhten EMV-Anforderungen empfiehlt sich, v. a. in Verbindung mit

langen Zuleitungen zum Sensor, der Einsatz einer geschirmten Leitung zwischen Transmitter und Sensor. Beispielhafte Darstellung siehe Zeichnung.

Bei der Schienenversion (T16.R) und Zuleitungslängen größer 30 m ist eine geschirmte

Leitung zwingend erforderlich.

geerdet

Schirm geerdet

Sensorleitung

Potentialausgleich

Feldgehäuse/

Schaltschrank

Sensor

T16

Anschlusskopf BSZ

geerdet

Schirm geerdet

Schutzrohr

mit Sensor

geerdet

Sensorleitung

Potentialausgleich

T16

Feldgehäuse/

Schaltschrank

Page 49

DE

5. Inbetriebnahme, Betrieb

WIKA Betriebsanleitung Typ T16

49

14147933.02 10/2018 EN/DE

5.2 Montage

5.2.1 Transmitter in Kopfversion (Typ T16.H)

Bei der Montage des Transmitters in Kopfversion ein Drehmoment von 1 Nm

nicht überschreiten!

Die Transmitter in Ausführung Kopfversion sind vorgesehen zur Montage auf einem

Messeinsatz im DIN-Anschlusskopf der Form B. Die Anschlussdrähte des Messeinsatzes

müssen ca. 50 mm lang und isoliert ausgeführt sein.

Montage im Anschlusskopf

Messeinsatz mit montiertem Transmitter in die Schutzarmatur einstecken und im

Anschlusskopf mit Schrauben federnd befestigen.

Montage im Anschlusskopfdeckel

Bei der Montage im Deckel eines Anschlusskopfes entsprechende Schrauben und

passende Unterlegscheiben verwenden.

Montage mit Hutschienenadapter

Mit dem als Zubehör erhältlichen mechanischen Adapter können auch die Kopftransmitter

T16.H auf einer Hutschiene befestigt werden (siehe Kapitel 12 „Zubehör“).

Montagebeispiel

14139114.01

14139114.01

Page 50

DE

5. Inbetriebnahme, Betrieb

WIKA Betriebsanleitung Typ T16

50

14147933.02 10/2018 EN/DE

5.2.2 Transmitter in Schienenversion (Typ T16.R)

Das Schienengehäuse wird ohne Hilfsmittel durch einfaches „Aufrasten“ auf eine 35 mm

Hutschiene (EN 60175) befestigt.

Die Demontage erfolgt durch das Entriegeln des Rastelementes.

5.3 Elektrischer Anschluss

GEFAHR!

Lebensgefahr durch elektrischen Strom

Bei Berührung mit spannungsführenden Teilen besteht unmittelbare

Lebensgefahr.

▶

Einbau und Montage des Gerätes dürfen nur durch Fachpersonal

erfolgen.

▶

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von Netzspannung zur Ausgangsspannung) können am Gerät lebensgefährliche

Spannungen auftreten!

▶

Montagen im spannungslosen Zustand durchführen.

▶

Die angeschlossenen Drähte auf festen Sitz kontrollieren. Nur fest

angeschlossene Leitungen gewährleisten eine volle Funktionalität.

Dies ist ein Betriebsmittel der Schutzklasse 3 zum Anschluss an Kleinspannungen, die

von der Netzspannung oder Spannung größer AC 50 V bzw. DC 120 V getrennt sind. Zu

bevorzugen ist ein Anschluss an SELV- oder PELV-Stromkreise; alternativ ist eine Schutzmaßnahme aus HD 60346-4-41 (DIN VDE 0100-410) zu empfehlen.

Alternativ für Nordamerika

Der Anschluss kann auch an „Class 2 Circuits“ oder „Class 2 Power Units“ gemäß CEC

(Canadian Electrical Code) oder NEC (National Electrical Code) erfolgen.

Die im Gerät vorhandene funktionale galvanische Trennung ist nicht geeignet einen Schutz

gegen elektrischen Schlag im Sinne der EN 61140 sicherzustellen.

Empfohlenes Werkzeug für Schraubklemmen

Ty p Schraubendreher Anzugsdrehmoment

T16.H Kreuzschlitz (Pozidriv-Spitze), Größe 2 (ISO 8764) 0,5 Nm

T16.R Schlitz, 3 x 0,5 mm (ISO 2380) 0,5 Nm

Page 51

DE

5. Inbetriebnahme, Betrieb

WIKA Betriebsanleitung Typ T16

51

14147933.02 10/2018 EN/DE

5.3.1 Hilfsenergie, 4 ... 20 mA-Stromschleife

Der Typ T16 ist ein in 2-Leiter gespeister Temperaturtransmitter und kann je nach Ausführung, mit unterschiedlicher Hilfsenergie versorgt werden.

Empfohlen wird bei Litzenadern die Verwenden von Crimpkontakten.

Der integrierte Verpolungsschutz (verpolte Spannung an den Klemmen ⊕ und ⊖) verhindert die Zerstörung des Transmitters.

Maximale Werte

■

Typ T16.x-ZZ: DC 35 V

■

Typ T16.x-AI: DC 30 V

■

Typ T16.x-AC: DC 30 V

■

Typ T16.x-AN: DC 35 V

■

Typ T16.x-AE: DC 35 V

Minimale Klemmenspannung

DC 10 V

Die Bürde darf nicht zu groß sein, da sonst die Klemmenspannung am Transmitter bei

höheren Strömen zu klein wird.

Maximal zulässige Bürde in Abhängigkeit der Speisespannung

Bürdendiagramm

Spannung UB in V

Bürde R

A

in Ω

14222396.01

min. Spannung

Betriebsspannung

ExGeräte

Nicht-ExGeräte

Page 52

DE

5. Inbetriebnahme, Betrieb

WIKA Betriebsanleitung Typ T16

52

14147933.02 10/2018 EN/DE

5.3.2 Sensoren

Belegung der Anschlussklemmen

Thermoelemente (TC)

Möglich ist der Anschluss eines Thermoelementes in 2-Leiter-Anschlussschaltung.

Der Transmitter T16 verwendet immer die interne Vergleichsstelle.

Sicherheitstechnische Maximalwerte für den Anschluss der Spannungsversorgung und der Sensoren siehe Kapitel 11 „Technische Daten“.

Thermoelemente

Eingang

Ausgang

4 ... 20 mA-Schleife

T16.H T16.R

Anschluss Programmiereinheit

PU-548

14151201.01

Page 53

DE

5. Inbetriebnahme, Betrieb

WIKA Betriebsanleitung Typ T16

53

14147933.02 10/2018 EN/DE

5.4 Konfiguration

Konfigurierbar sind

■

Sensortyp

■

Messbereich

■

Einheit

■

Signalisierung

■

Messbereichsüberwachung

■

Dämpfung

■

Schreibschutz

■

„Mehrere“ TAG-Nummern

■

2-Punkt-Skalierung

Ausgeliefert werden die Temperaturtransmitter mit einer Grundkonfiguration (siehe Datenblatt TE 16.01) oder konfiguriert nach Kundenvorgabe. Nachträgliche Änderungen der

Konfiguration mit einem wasserfesten Faserschreiber auf dem Typenschild notieren.

Zur Konfiguration des T16 ist eine Simulation des Eingangswertes nicht

erforderlich. Lediglich zur Funktionsüberprüfung ist eine Simulation des

Sensors notwendig.

5.4.1 Konfigurierbare Überwachungsfunktionen

Messbereichsüberwachung:

Ist diese aktiviert, erfolgt im Falle einer Messbereichsüberschreitung/-unterschreitung eine

Fehlersignalisierung auf der Stromschleife.

5.4.2 Konfigurieren mit dem PC

Das Konfigurieren erfolgt über die USB-Schnittstelle eines PC‘s via Programmiereinheit

Typ PU-548 (siehe Kapitel 12 „Zubehör“) und der Konfigurationssoftware WIKAsoft-TT.

Der benötigte Windows-Gerätetreiber für die PU-548 ist Bestandteil jedes

aktuellen Windows

®

-Betriebssystems.

Windows® ist eine eingetragene Marke der Microsoft Corporation in den Vereinigten Staaten und weiteren Ländern.

Page 54

DE

5. Inbetriebnahme, Betrieb

WIKA Betriebsanleitung Typ T16

54

14147933.02 10/2018 EN/DE

5.4.3 Programmiereinheit Typ PU-548

■

Einfache Bedienung

■

LED-Statusanzeige

■

Kompakte Bauform

■

Keine zusätzliche Spannungsversorgung notwendig, weder

für die Programmiereinheit noch für den Transmitter

■

Keine Treiberinstallation notwendig (Windows® Standardtreiber werden genutzt)

(ersetzt Programmiereinheit Typ PU-448)

Anschluss der PU-548

5.4.4 Konfigurationssoftware WIKAsoft-TT

Die Konfigurationssoftware WIKAsoft-TT wird ständig aktualisiert und den FirmwareErweiterungen des T16 angepasst. Somit ist immer der volle Zugriff auf alle Funktionalitäten und Parameter des Transmitters gewährleistet (siehe Kapitel 7 „Konfigurationssoftware WIKAsoft-TT“).

Kostenfreier Download der aktuellen Version der WIKAsoft-TT Software unter

www.wika.de.

Kopfversion, Typ T16.H

Schienenversion, Typ T16.R

Page 55

DE

6. Besondere Bedingungen für die sichere Anwendung ..

WIKA Betriebsanleitung Typ T16

55

14147933.02 10/2018 EN/DE

6. Besondere Bedingungen für die sichere Anwendung

(X-Conditions)

Der Einfluss der Verlustleistung anderer Geräte, welche neben dem Transmitter installiert

werden, müssen im Hinblick auf eine Temperaturerhöhung der Umgebungstemperatur des

Transmitters berücksichtigt werden.

Allgemeine Hinweise:

Transmitter mit „ia“-Markierung können auch in Versorgungsstromkreisen des Typs „ib“ mit

den gleichen Anschlussparametern verwendet werden. Somit ist der gesamte Messstromkreis (inklusive dem Sensorkreis) ein „ib“-Stromkreis. Transmitter, die in Versorgungsstromkreisen vom Typ „ib“ betrieben wurden, dürfen nicht in Versorgungsstromkreisen vom

Typ „ia“ wiederverwendet werden.

6.1 Zulassung ATEX und IECEx

6.1.1 Typen T16.x-AC, T16.x-AI

■

Der Transmitter muss in einem für den jeweiligen Installationsbereich geeigneten

Gehäuse nach IEC 60079-11 eingebaut werden. Das Gehäuse muss mindestens IP20

erfüllen für Bereiche, die EPL Ga, Gb oder Gc erfordern und IP54 nach IEC 60079-0 für

Bereiche, die EPL Ga, Gb oder Gc erfordern.

■

Bei der Montage die innere Verdrahtung, Luft- und Kriechstrecken, sowie Trennabstände nach IEC 60079-11 berücksichtigen.

6.1.2 Typ T16.x-AN

■

Der Transmitter muss in ein Gehäuse eingebaut werden, das mindestens IP54 nach

IEC 60079-0 und IEC 60079-15 erfüllt.

■

Bei der Montage Luft- und Kriechstrecken und Trennabstände nach IEC 60079-15

berücksichtigen.

■

Wie in IEC 60664-1 festgelegt, darf das Gerät nur in einem Bereich mit mindestens

Verschmutzungsgrad 2 eingesetzt werden.

■

Die Stromkreise dürfen maximal die Überspannungskategorie II nach IEC 60664-1

besitzen.

6.1.3 Typ T16.x-AE

■

Der Transmitter muss in ein Gehäuse eingebaut werden, das mindestens IP54 nach

IEC 60079-0 und IEC 60079-7 erfüllt.

■

Bei der Montage Luft- und Kriechstrecken und Trennabstände nach IEC 60079-7

berücksichtigen.

■

Wie in IEC 60664-1 festgelegt, darf das Gerät nur in einem Bereich mit mindestens

Verschmutzungsgrad 2 eingesetzt werden.

■

Die Stromkreise dürfen maximal die Überspannungskategorie II nach IEC 60664-1

besitzen.

Page 56

DE

6. Besondere Bedingungen für die sichere Anwendung ...

WIKA Betriebsanleitung Typ T16

56

14147933.02 10/2018 EN/DE

6.2 Zulassung FM

6.2.1 Typen T16.x-AC, T16.x-AI

■

Die Transmitter müssen in einem für den jeweiligen Installationsbereich geeigneten

Gehäuse nach ANSI/ISA 60079-11 eingebaut werden. Das Gehäuse muss mindestens

IP20 erfüllen.

■

Bei der Montage die innere Verdrahtung, Luft- und Kriechstrecken, sowie Trennabstände nach ANSI/ISA 60079-11 berücksichtigen.

6.2.2 Typ T16.x-AN

■

Die Transmitter müssen in ein Gehäuse eingebaut werden, das mindestens IP54 nach

ANSI/ISA 60079-0 und ANSI/ISA 60079-15 erfüllt.

■

Bei der Montage Luft- und Kriechstrecken und Trennabstände nach ANSI/ISA 60079-15

berücksichtigen.

■

Wie in ANSI/ISA 61010-1 bzw. IEC 60664-1 festgelegt, darf das Gerät nur in einem

Bereich mit mindestens Verschmutzungsgrad 2 eingesetzt werden.

■

Die Stromkreise dürfen maximal die Überspannungskategorie II nach ANSI/ISA 61010-1

bzw. IEC 60664-1 besitzen.

6.2.3 Typ T16.x-AE

■

Die Transmitter müssen in ein Gehäuse eingebaut werden, das mindestens IP54 nach

ANSI/ISA 60079-0 und IEC 60079-7 erfüllt.

■

Bei der Montage Luft- und Kriechstrecken und Trennabstände nach ANSI/ISA 60079-7

berücksichtigen.

■

Wie in ANSI/ISA 61010-1 bzw. IEC 60664-1 festgelegt, darf das Gerät nur in einem

Bereich mit mindestens Verschmutzungsgrad 2 eingesetzt werden.

■

Die Stromkreise dürfen maximal die Überspannungskategorie II nach ANSI/ISA 61010-1

bzw. IEC 60664-1 besitzen.

Page 57

DE

7. Konfigurationssoftware WIKAsoft-TT

WIKA Betriebsanleitung Typ T16

57

14147933.02 10/2018 EN/DE

7. Konfigurationssoftware WIKAsoft-TT

Zur Installation den Anweisungen der Installationsroutine folgen.

7.1 Starten der Software

Die Konfigurationssoftware mit einem Doppelklick auf das WIKAsoft-TT Icon starten.

Nach dem Starten der Software kann die

Sprache über Auswahl der entsprechenden

Länderflagge geändert werden.

Die Auswahl des COM-Ports erfolgt

automatisch.

Nach dem Anschluss eines Transmitters (mit

PU-548) kann durch Aktivieren des StartButtons die Konfigurationsoberfläche geladen

werden.

Die Konfigurationsoberfläche kann nur mit einem angeschlossenen Gerät

geladen werden.

Page 58

DE

7. Konfigurationssoftware WIKAsoft-TT

WIKA Betriebsanleitung Typ T16

58

14147933.02 10/2018 EN/DE

7.2 Ablauf Konfiguration

Die Schritte 1 und 2 erfolgen beim Start der Software automatisch.

1. „Gerätedaten laden“

2. „Konfiguration laden“

3. [optional] Schreibschutz aufheben (Schlosssymbol unten rechts)

4. Ändern der gewünschten Parameter

→ Sensor/Messbereich/Fehlersignalisierung etc.

5. „In das Gerät speichern“

6. [optional] Schreibschutz aktivieren

7. [optional] Konfigurationsprotokoll ausdrucken

8. [optional] Test: „Konfiguration laden“ → Konfiguration überprüfen

7.3 Fehlerdiagnose

Hier wird im Fall eines „vom Transmitter detektierten Fehlers“ die Fehlermeldung angezeigt.