Page 1

Operating

Instructions GB

SF6 Gas Density Monitors

with magnetic snap-action contacts

(Models 233.52.100, with gas or

liquid filling as well as Model 212.22.100)

Examples:

3. Description, application

The built-in electric alarm contacts (magnetic

snap-action) are auxiliary current switches

which open and close the connected electrical

circuits at the set points via the contact arm,

which is driven by the main instrument

pointer.

4. Mechanical connection

According to the general technical regulations

for pressure gauges, respectively (i.e. EN 837-2).

When screw-fitting the gauges the force

required for this must not be applied through the

case or terminal box but just through the

spanner flats (with suitable tool) provided for

this purpose.

Model 233.52.100,

with external

temperature sensor

Model 233.52.100

Contents

1. Safety instructions

2. General information

3. Description, application

4. Mechanical connection

5. Wiring details

6. To set desired value indicator

7. Ingress protection IP

8. Admissible ambient temperatures

9. Maintenance and servicing / cleaning

10. Power ratings

11. Overcurrent protection devices

12. Repairs / Complaints

1. Safety instructions

The appropriate national safety

regulations (i.e. VDE 0100) must be

observed when installing, putting into

operation and running these

while under voltage.

Serious injuries and/or damage can occur

should the appropriate regulations not be

observed.

Only appropriately qualified persons should

work on these instruments.

2. General information

Gas density monitors are modified pressure

measuring instruments with electrical

accessories. Gas density monitors combine

both measuring and switching functions in one

single instrument. Temperature influences that

have an effect on the confined SF6 gas are compensated by means of a compensation system.

Each density monitor is specially adapted to the

specific application conditions of the switchgear

it is intended for (pure SF6 gas, gas compounds,

calibration pressure, switching points ...).

During transportation or storage gas density

monitors might warm up or cool down.

Temperatures that are different from the

reference temperature (20 °C) lead to pointer

deflections. This is absolutely normal, because

the compensation system is working.

In order to ensure that the instruments have

sufficiently adjusted to the ambient temperature,

they have to be exposed to a temperature of 20

±2 °C for at least 2 hours. Subsequently in an

unpressurised condition the pointer will be

within the tolerance bar.

instruments. Do not work on gauge

Installation with

open-end wrench

5. Wiring details

The electrical connections should be made by

qualified electricians. Connection details and

switch functions are given on the instrument

type plate.

Connection terminals and ground terminal are

appropriately marked. The main connection line

to be provided must be dimensioned for

maximum instrument power consumption and

comply with IEC 227 or IEC 245.

Power ratings and overcurrent protection

devices see overleaf!

6. To set desired value indicator

As a standard the alarm contacts of SF6 gas

density monitors are non-adjustable, i.e. they

cannot be re-adjusted later on. Therefore the

risk of unintentionally mis-adjusting the alarm

contacts is eliminated.

Desired value

indicators

(red set pointer)

If on express request by the customer the

contacts have to be adjustable, re-adjustments

can be carried out as follows:

The desired value can be set via the adjustment

lock in the window by means of the readjustment key provided (at the terminal box

of standard instruments).

7. Ingress protection IP

The type of enclosure to EN 60 529 for

protection against external influences depends

on the basic instrument and is found in the

respective data sheet.

8. Admissible ambient temperatures

The permissible ambient temperatures for alarm

contacts is -20 to +70 °C. Where this span

exceeds the permissible temperature limits for

the instrument to which the contacts are fitted,

the limits for the instrument apply (see data sheet).

9. Maintenance and servicing / cleaning

The instruments require no maintenance or

servicing. The instruments should be cleaned

with a damp cloth moistened with soap solution.

For cleaning inside the instrument the mains

power supply should be disconnected by

means of the plug box or plug connection.

It must be ensured that all the parts are dry

before the power is switched on again.

Page 2

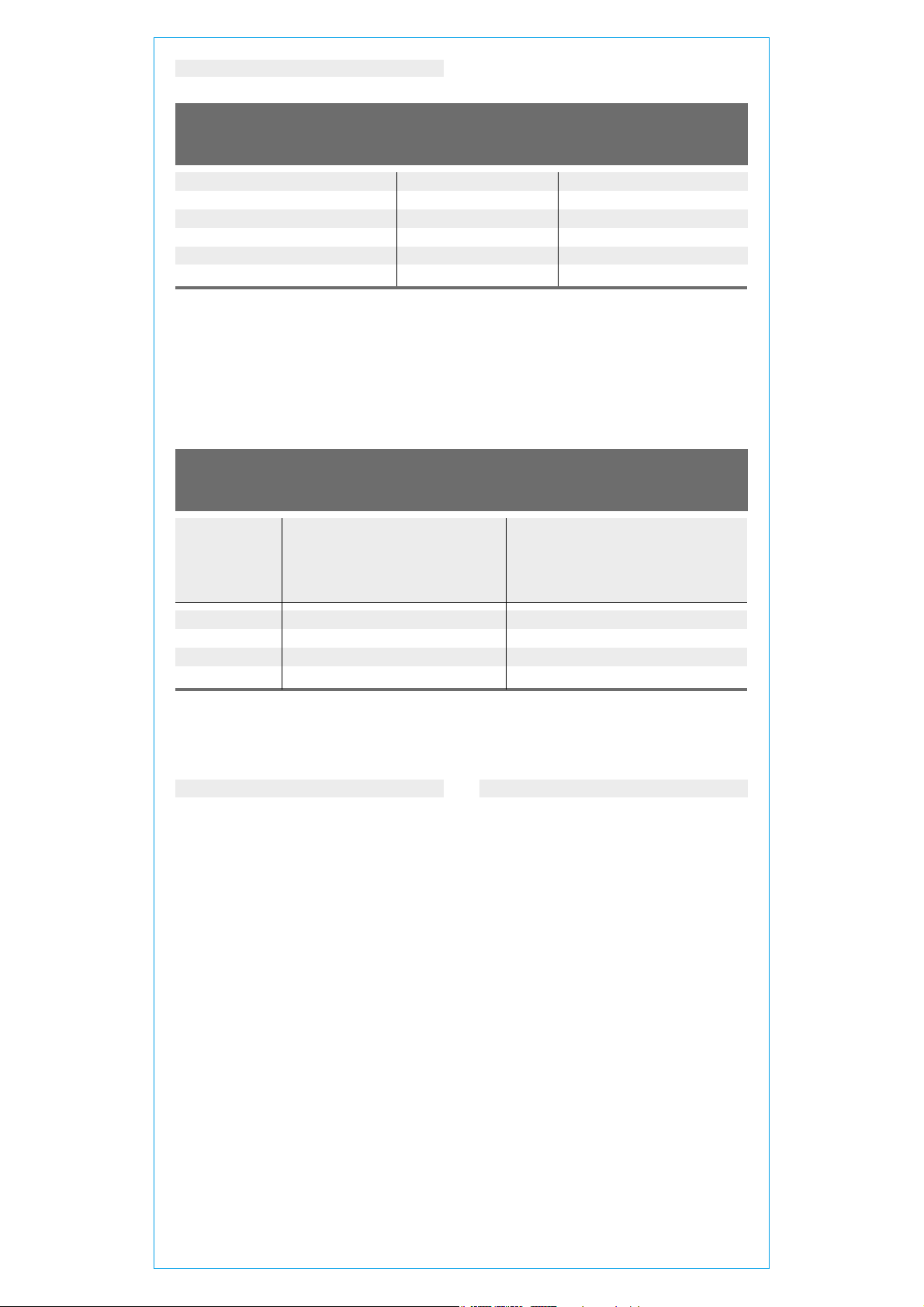

10. Power ratings

Table 1: Maximum contact rating

Maximum contact rating Magnetic snap-action contact model 821

with non-inductive

Gas filled gauges Liquid filled gauges

(ohmic) load

Maximum voltage (MSR) U

eff

Current ratings:

Make rating 1.0 A 1.0 A

Break rating 1.0 A 1.0 A

Continous load 0.6 A 0.6 A

Maximum load 30 W 50 VA 20 W 20 VA

Note: None of the limit values for voltage,

current and capacity are to be exceeded!

We recommend the following load values to

ensure safe, continuous operation:

Table 2: Recommended contact ratings with

different nominal voltages and instrument

versions

250 V 250 V

Voltage Magnetic snap-action contact model 821

(DIN IEC 38) Gas filled gauges Liquid filled gauges

DC / AC

ohmic load inductive ohmic load inductive

load load

DC AC cos ϕ >0.7 DC AC cos ϕ >0.7

VmAmAmAmAmAmA

230 100 120 65 65 90 40

110 200 240 130 130 180 85

48 300 450 200 190 330 130

24 400 600 250 250 450 150

The switching current must not be less than 20 mA

with low voltages for switching reliability reasons.

For higher loads, and instruments with liquid-filled

cases, we recommend the use of a separate relay,

WIKA Models 905.1X.

11. Overcurrent protection devices

No overcurrent protection devices are installed

in the instruments.

Should overcurrent protection devices be

required we recommend the following values in

12. Repairs / Complaints

Repairs are to be carried out by the

manufacturer only. The instruments must not be

opened, as this would result in indication and

switching point errors.

accordance with EN 60 947-5-1.

In the case of complaints the manufacturing and

Voltage 24 V: 2 A

Voltage 250 V: 1 A

product identification numbers have to be

stated. The manufacturing number is indicated

on the dial, the product identification number on

Data refers to miniature fuses M and

a maximum short circuit current 100 A.

the type plate. When measuring, the

atmospheric pressure, the temperature during

measurement and the data of the reference

standard (model, class) always have to be

indicated.

The density monitors have to be exposed to a

specific temperature long enough (at least 2

hours) to ensure temperature equalisation.

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg • Germany

Phone (+49) 93 72/132-0

Fax (+49) 93 72/132-406

E-Mail SF6@wika.de

info@wika.de

www.wika.de

Technical alteration rights reserved.

9078061 01/2003 GB/D/F

Loading...

Loading...