Page 1

Operating Instructions

Betriebsanleitung

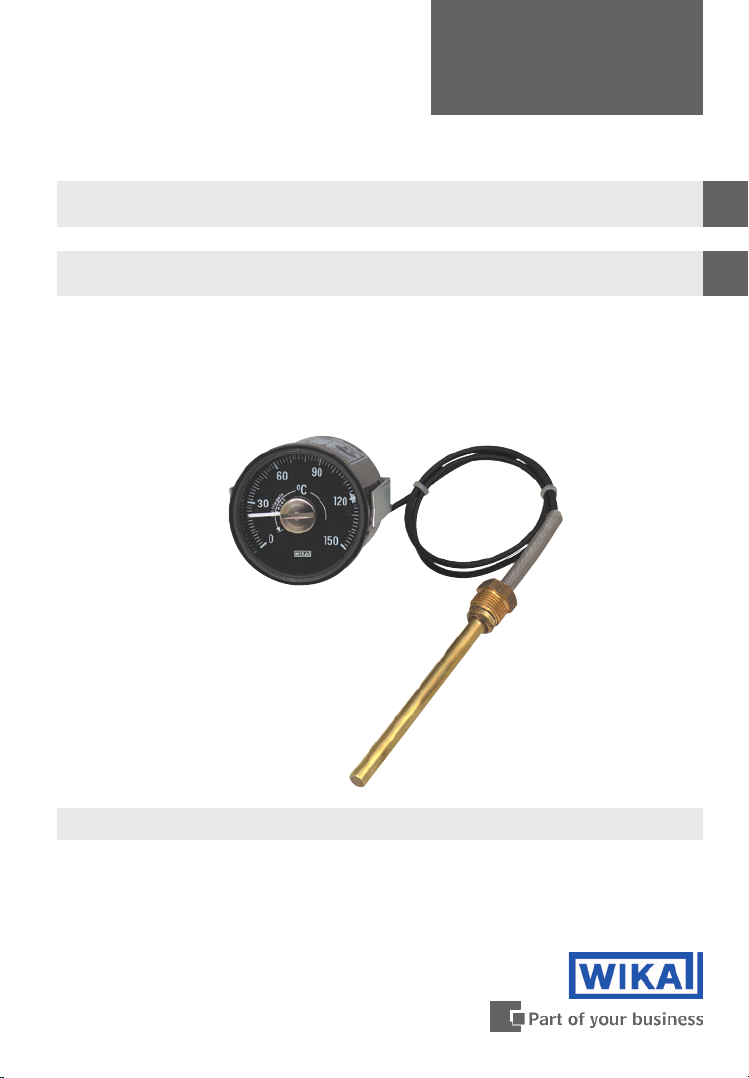

Safety Temperature Limiter Model SB15

Sicherheitstemperaturbegrenzer Typ SB15

GB

D

Safety Temperature Limiter Model SB15

Page 2

Operating Instructions

GB

Safety Temperature Limiter Model SB15 Page 3 - 8

Betriebsanleitung

D

Sicherheitstemperaturbegrenzer Typ SB15 Seite 9 - 17

11433094 03/2009 GB/D

WIKA Operating Instructions Safety Temperature Limiter Model SB152

Page 3

Contents

Contents

1. Safety instructions

GB

4

2. Application

3. Design and operating principle

4. Technical data

5. Installation, commissioning and operation

6. Maintenance

Enclosure 1: TÜV CERT EC type examination certificate

per directive 97/23/EG (german)

Enclosure 2: DIN CERTO DIN EN 14 597 (german)

Information

This symbol provides you with information, notes and tips.

4

4

5

6

7

14 - 15

16 - 17

Warning!

This Symbol warns you against actions that can cause injury to

people or damage to the instrument.

11433094 03/2009 GB/D

WIKA Operating Instructions Safety Temperature Limiter Model SB15 3

Page 4

1. Safety instructions / 2. Application / 3. Design, operating principle

1. Safety instructions

The appropriate national safety regulations (e.g. VDE 0100) must

be observed when installing, commissioning and operating

GB

Serious injuries and/or damage can occur should the appropriate

regulations not be observed.

Only appropriately qualified personnel should carry out the connection

work.

Any connection work may only be carried out once the equipment has

been isolated.

2. Application

Universally applicable safety temperature limiter for water, oil and gas.

3. Design and operating principle

The fluid-filled, closed measuring system consists of a temperature sensor, a

measuring capillary and a bourdon tube. Heating the temperature sensor leads

to a volume change in the closed system and thus a change in the pressure.

This is transferred through a measuring capillary to the bourdon tube and,

through the angular motion of the pointer shaft, to the dial on the display.

When the switch point is passed, the switch disc (cam disc), fitted to the

pointer shaft, triggers the micro switch action of the micro switch and latches

the current switch status.

these devices.

When reaching the switch point and in case of capillary-break a switch disc

(cam disc) on the pointer shaft releases the switching operation at microswitch

and unlatch the active switching status. With fixed switching points, the

switching point is indicated by an additional pointer and is written on the

instrument label.

Unlatching and resetting the working status:

The temperature limiter is unlatched by removing the plug on the window using

a screwdriver and turning the pointer shaft in an anti-clockwise direction.

(Only possible if there is no available capillary-break.)

WIKA Operating Instructions Safety Temperature Limiter Model SB154

11433094 03/2009 GB/D

Page 5

4. Technical Data

4. Technical Data

Ingress protection

Case IP 53, terminals IP 00 (DIN EN 60 529 / IEC 529)

Display accuracy

Max. +4 % of the measuring range at the reference temperature of 23 °C at the

case and capillary.

Scale ranges

0 °C ... 400 °C

Permissible temperatures

Case: +60 °C

Capillary:

plastic sheathed -40 °C ... +100 °C

copper braided -40 °C ... +350 °C

Scale limits

Max. 270 °

Measuring principle

Bourdon tube system

Capillary

Plastic sheathed or copper braided,

capillary of copper or stainless steel 1.4571 depending on scale range

Capillary length

Max. 5 m

Capillary outlet

Lower back

p

GB

Contact

1 Micro switch (fixed setting)

Load data

5 A, 250 V AC

There is no overcurrent protection fitted to these instruments. In order to

prevent the switches being welded through overload, a suitable protection

device should be fitted by the user.

11433094 03/2009 GB/D

WIKA Operating Instructions Safety Temperature Limiter Model SB15 5

Page 6

4. Technical data / 5. Installation, commissioning and operation

Adjustable range:

Fixed, factory pre-set to customer requirements

Standard switch differential

Unlatching after lowering (reducing) the temperature by about 3 % of scale

range possible

GB

Electrical connection

0.8 x 0.63 mm terminal block or AMP plug connection

Case

Plastic (ABS), black or steel

Type of mounting

Panel mounting with clamp

Option

Panel mounting flange

5. Installation, commissioning and operation

When fitting and using the instruments, the following

fundamental requirements must be followed:

The display range of the safety temperature alerter should be chosen

so that the maximum temperature at the sensor does not exceed the

display range. Also, after the switchpoint has been exceeded, a

resultant reheating process has to be taken into account.

In operation the equipment should not be subjected to strong vibration

or impact loads.

Contamination and high ambient temperature fluctuations should be

avoided.

Any break in the capillary will destroy the instrument and result in it

switching off.

Electrical connection

The connection diagram is shown on the instrument label on the

outer rim of the case.

WIKA Operating Instructions Safety Temperature Limiter Model SB156

11433094 03/2009 GB/D

Page 7

5. Installation, commissioning and operation / 6. Maintenance

Temperature sensors for heating generation plants

Temperature sensor Sheath Operating medium

Ø

Model

SF 91 6 Brass - - x

SF 91 6 Brass SH16 Brass x

SF 91 6 Brass SH16 1.4571 x x x

SF 91 8 Brass - - x x x

SF 91 8 Brass SH16 Brass x x x

SF 91 8 Brass SH16 1.4571 x x x x x

SF 91 10 Brass - - x x x

SF 91 6 1.4571 - - x x x x x x

SF 91 6 1.4571 SH16 1.4571 x x x x x x

SF 91 8 1.4571 - - x x x x x x

SF 91 8 1.4571 SH16 1.4571 x x x x x x

SF 91 10 1.4571 - - x x x x x x

SF 91 = Design of connection 2 (WIKA data sheet TV 28.03)

6. Maintenance

The instruments require no maintenance!

We recommend that their function should be checked annually.

in mm

Material

Model

Material

Water Oil Air

p = 16 bar

p = 32 bar

T = 350 °C

p = 16 bar

T = 200 °C

T = 150 °C

p = 32 bar

T = 350 °C

unpressured

T = 350 °C

unpressured

T = 400 °C

GB

11433094 03/2009 GB/D

WIKA Operating Instructions Safety Temperature Limiter Model SB15 7

Page 8

GB

11433094 03/2009 GB/D

WIKA Operating Instructions Safety Temperature Limiter Model SB158

Page 9

Inhalt

Inhalt

1. Sicherheitshinweise

2. Anwendung

3. Aufbau und Wirkungsweise

4. Technische Daten

5. Montage, Inbetriebnahme und Betrieb

6. Wartung

Anhang 1: TÜV CERT EG-Baumusterprüfung nach

Richtlinie 97/23/EG

Anhang 2: DIN CERTO DIN EN 14 597

Information

Dieses Zeichen gibt Ihnen Informationen, Hinweise oder Tipps.

10

10

D

10

11

12

13

14 - 15

16 - 17

Warnung!

Dieses Symbol warnt Sie vor Handlungen, die Schäden an

Personen oder am Gerät verursachen können.

11433094 03/2009 GB/D

WIKA Betriebsanleitung Sicherheitstemperaturbegrenzer Typ SB15 9

Page 10

1. Sicherheitshinweise / 2. Anwendung / 3. Aufbau, Wirkungsweise

1. Sicherheitshinweise

Beachten Sie unbedingt bei Montage, Inbetriebnahme und

Betrieb dieser Geräte die entsprechenden nationalen Sicherheitsvorschriften (z. B. VDE 0100).

Bei Nichtbeachten der entsprechenden Vorschriften können schwere

Körperverletzungen und/oder Sachschäden auftreten.

D

Nur entsprechend qualifiziertes Personal darf die Anschlussarbeiten

durchführen.

Alle Anschlussarbeiten dürfen nur im spannungslosen Zustand durch-

geführt werden.

2. Anwendung

Universell einsetzbarer Sicherheitstemperaturbegrenzer für Wasser, Öl und Gas.

3. Aufbau und Wirkungsweise

Das flüssigkeitsgefüllte, geschlossene Messsystem besteht aus einem

Temperaturfühler, Messleitung und Bourdonfeder. Die durch die Wärmebeaufschlagung am Temperaturfühler erzeugte Volumenänderung und somit auch

die Druckänderung im geschlossenen System wird durch die Messleitung zur

Bourdonfeder übertragen und über den Winkelausschlag der Zeigerwelle auf

dem Zifferblatt zur Anzeige gebracht.

Die auf der Zeigerwelle angeordnete Schaltscheibe (Kurvenscheibe) löst

bei Erreichen des Schaltpunktes und bei Messleitungsbruch den Schaltvorgang am Mikroschalter aus und verriegelt den aktuellen Schaltzustand. Der

festeingestellte Schaltpunkt ist auf dem Zifferblatt im Anzeigeblatt mittels

eines Dreieckes oder mittels einer Hilfsskala bei 6 Uhr zwischen Anfangs- und

Endwert angezeigt und zusätzlich auf dem Typenschild vermerkt.

Entriegeln und Wiederherstellen des Betriebszustandes:

Die Temperaturbegrenzer sind durch Entfernen der Verschlussschraube auf

der Sichtscheibe mittels eines Schraubendrehers und Drehen der Zeigerwelle

gegen den Uhrzeigersinn entriegelt.

(Nur möglich wenn kein Messleitungsbruch vorliegt.)

10

WIKA Betriebsanleitung Sicherheitstemperaturbegrenzer Typ SB15

11433094 03/2009 GB/D

Page 11

4. Technische Daten

4. Technische Daten

Schutzart

Gehäuse IP 53, Klemmen IP 00 (DIN EN 60 529 / IEC 529)

Anzeigeabweichung

Max. +4 % des Messbereiches bei Referenztemperatur von 23 °C auf Gehäuse

und Messleitung

Anzeigebereich

0 °C ... 400 °C

Zulässige Temperaturen

Gehäuse: +60 °C

Messleitung:

kunststoffummantelt -40 °C ... +100 °C

kupferumsponnen -40 °C ... +350 °C

Skalenlänge

Max. 270 °

Messprinzip

Bourdonfedersystem

p

D

Messleitung

Kunststoffummantelt oder kupferumsponnen,

Kapillare aus Kupfer oder CrNi-Stahl 1.4571 je nach Anzeigebereich

Messleitungslänge

Max. 5 m

Messleitungsaustritt

Rückseitig exzentrisch

Kontakt

1 Mikroschalter (einpoliger Umschalter)

Lastdaten

5 A, 250 V AC

In den Geräten sind keine Überstrom-Schutzeinrichtungen eingebaut. Um

ein Verschweißen der Schalter durch Überlast zu verhindern sind geeignete

Schutzeinrichtungen vom Anwender vorzusehen.

11433094 03/2009 GB/D

WIKA Betriebsanleitung Sicherheitstemperaturbegrenzer Typ SB15 11

Page 12

4. Technische Daten / 5. Montage, Inbetriebnahme und Betrieb

Einstellbereich

Werkseitig nach Kundenvorgabe fest eingestellt

Standardschaltdifferenz

Entriegelung nach Temperaturabsenkung um etwa 3 % des Anzeigebereiches

möglich

Elektrischer Anschluss

Flachstecker 0,8 x 0,63 mm oder Klemmanschluss

D

Gehäuse

Kunststoff (ABS), schwarz oder Stahl

Befestigungsart

Tafeleinbau mit Befestigungsbügel

Option

Befestigungsrand vorne

5. Montage, Inbetriebnahme und Betrieb

Für die Montage und den Betrieb der Geräte sind folgende,

grundsätzliche Anforderungen zu beachten:

Der Anzeigebereich des Temperaturwächters sollte so gewählt werden,

dass die maximal am Fühler anliegende Temperatur den Anzeigebereich

nicht überschreitet. Dabei sind auch nach überschreiten des Schaltpunktes auftretende Nachheizvorgänge zu beachten.

In Betrieb sollte das Gerät keinen starken Schwingungen und Stoß-

belastungen ausgesetzt sein.

Verschmutzungen und hohe Umgebungstemperaturschwankungen sind

zu vermeiden.

Ein Durchtrennen der Messleitung führt zur Zerstörung des Gerätes und

zur Abschaltung.

Elektrischer Anschluss

Die Klemmenbelegung ist auf dem Typenschild am Gehäuseumfang

angegeben.

WIKA Betriebsanleitung Sicherheitstemperaturbegrenzer Typ SB1512

11433094 03/2009 GB/D

Page 13

5. Montage, Inbetriebnahme und Betrieb / 6. Wartung

Wärmefühler für Wärmeerzeugungsanlagen

Wärmefühler Tauchhülse Betriebsmedien

Ø

Typ

SF 91 6 Messing - - x

SF 91 6 Messing SH16 Messing x

SF 91 6 Messing SH16 1.4571 x x x

SF 91 8 Messing - - x x x

SF 91 8 Messing SH16 Messing x x x

SF 91 8 Messing SH16 1.4571 x x x x x

SF 91 10 Messing - - x x x

SF 91 6 1.4571 - - x x x x x x

SF 91 6 1.4571 SH16 1.4571 x x x x x x

SF 91 8 1.4571 - - x x x x x x

SF 91 8 1.4571 SH16 1.4571 x x x x x x

SF 91 10 1.4571 - - x x x x x x

SF 91 = Anschlussbauform 2 (WIKA Datenblatt TV 28.03)

6. Wartung

Die Geräte sind wartungsfrei!

Wir empfehlen eine jährliche Funktionskontrolle.

in mm

Werkstoff

Typ

Werkstoff

Wasser Öl Luft

p = 16 bar

T = 150 °C

p = 32 bar

T = 350 °C

p = 16 bar

T = 200 °C

p = 32 bar

T = 350 °C

drucklos

T = 350 °C

drucklos

T = 400 °C

D

11433094 03/2009 GB/D

WIKA Betriebsanleitung Sicherheitstemperaturbegrenzer Typ SB15 13

Page 14

D

Anhang 1

14

11433094 03/2009 GB/D

WIKA Betriebsanleitung Sicherheitstemperaturbegrenzer Typ SB15

Page 15

Anhang 1

D

11433094 03/2009 GB/D

WIKA Betriebsanleitung Sicherheitstemperaturbegrenzer Typ SB15 15

Page 16

D

Anhang 2

16

11433094 03/2009 GB/D

WIKA Betriebsanleitung Sicherheitstemperaturbegrenzer Typ SB15

Page 17

Anhang 2

D

11433094 03/2009 GB/D

WIKA Betriebsanleitung Sicherheitstemperaturbegrenzer Typ SB15 17

Page 18

WIKA Global

Europe

Austria

WIKA Messgerätevertrieb

Ursula Wiegand

GmbH & Co. KG

1230 Vienna

Phone: (+43) 1-86 91 631

Fax: (+43) 1-86 91 634

E-mail: info@wika.at

www.wika.at

Benelux

WIKA Benelux

6101 WX Echt

Phone: (+31) 475-535 500

Fax: (+31) 475-535 446

E-mail: info@wika.nl

www.wika.nl

Bulgaria

WIKA Bulgaria EOOD

1309 Sofia

Phone: (+359) 2 82138-10

Fax: (+359) 2 82138-13

E-mail: t.antonov@wika.bg

Croatia

WIKA Croatia d.o.o.

Hrastovička 19

10250 Zagreb-Lučko

Phone: (+385) 1 6531034

Fax: (+385) 1 6531357

E-mail: info@wika.hr

Finland

WIKA Finland Oy

00210 Helsinki

Phone: (+358) 9-682 49 20

Fax: (+358) 9-682 49 270

E-mail: info@wika.fi

www.wika.fi

France

WIKA Instruments s.a.r.l.

95610 Eragny-sur-Oise

Phone: (+33) 1-34 30 84 84

Fax: (+33) 1-34 30 84 94

E-mail: info@wika.fr

www.wika.fr

18

Germany

WIKA Alexander Wiegand

GmbH & Co. KG

63911 Klingenberg

Phone: (+49) 93 72-13 20

Fax: (+49) 93 72-13 24 06

E-mail: info@wika.de

www.wika.de

Italy

WIKA Italiana SRL

20020 Arese (Milano)

Phone: (+39) 02-93 86 11

Fax: (+39) 02-93 86 174

E-mail: info@wika.it

www.wika.it

Poland

WIKA Polska S.A.

87-800 Wloclawek

Phone: (+48) 542 30 11 00

Fax: (+48) 542 30 11 01

E-mail: info@wikapolska.pl

www.wikapolska.pl

Romania

WIKA Instruments Romania

S.R.L.

Bucuresti, Sector 5

Calea Rahovei Nr. 266-268

Corp 61, Etaj 1

Phone: (+40) 21 4563138

Fax: (+40) 21 4563137

E-mail: m.anghel@wika.ro

Russia

ZAO „WIKA Mera“

127015 Moscow

Phone: (+7) 495-648 01 80

Fax: (+7) 495-648 01 81

E-mail: info@wika.ru

www.wika.ru

Serbia

WIKA Merna Tehnika d.o.o.

Sime Solaje 15

11060 Belgrade

Phone: (+381) 11 27 63 722

Fax: (+381) 11 75 36 74

E-mail: info@wika.co.yu

www.wika.co.yu

Spain

Instrumentos WIKA, S.A.

C/Josep Carner, 11-17

08205 Sabadell (Barcelona)

Phone: (+34) 902 902 577

Fax: (+34) 933 938 666

E-mail: info@wika.es

www.wika.es

Switzerland

Manometer AG

6285 Hitzkirch

Phone: (+41) 41-919 72 72

Fax: (+41) 41-919 72 73

E-mail: info@manometer.ch

www.manometer.ch

Turkey

WIKA Alexander Wiegand

GmbH & Co. KG

Türkiye (Istanbul) irtibat

bürosu

Zümrütevler Mah.

Hanimeli Cad. No. 4 Kat: 4

Maltepe - Istanbul

Phone: (+90) 216/305 46 24

Fax: (+90) 216/305 36 19

E-mail: info@wika.com.tr

www.wika.com.tr

Ukraine

WIKA Pribor GmbH

83016 Donetsk

Phone: (+38) 062 345 34 16

Fax: (+38) 062 345 34 17

E-mail: info@wika.ua

www.wika.ua

United Kingdom

WIKA Instruments Ltd

Merstham, Redhill RH13LG

Phone: (+44) (0) 1737 644 008

Fax: (+44) (0) 1737 644 403

E-mail: info@wika.co.uk

www.wika.co.uk

North America

Canada

WIKA Instruments Ltd.

Head Office

Edmonton, Alberta, T6N 1C8

Phone: (+1) 780-463 70 35

Fax: (+1) 780-462 00 17

E-mail: info@wika.ca

www.wika.ca

11433094 03/2009 GB/D

Page 19

WIKA Global

Mexico

Instrumentos WIKA Mexico

S.A. de C.V.

01210 Mexico D.F.

Phone: (+52) 555 020 53 00

Fax: (+52) 555 020 53 01

E-mail: ventas@wika.com

www.wika.com.mx

USA

WIKA Instrument Corporation

Lawrenceville, GA 30043

Phone: (+1) 770-513 82 00

Fax: (+1) 770-338 51 18

E-mail: info@wika.com

www.wika.com

South America

Argentina

WIKA Argentina S.A.

Buenos Aires

Phone: (+54) 11-4730 18 00

Fax: (+54) 11-4761 00 50

E-mail: info@wika.com.ar

www.wika.com.ar

Brazil

WIKA do Brasil Ind. e Com.

Ltda.

CEP 18560-000 Iperó - SP

Phone: (+55) 15-3459 97 00

Fax: (+55) 15-3266 16 50

E-mail: marketing@wika.

com.br

www.wika.com.br

Africa / Middle East

Egypt

WIKA Alexander Wiegand

GmbH & Co. KG

El-Serag City Towers

Tower #2, Office#67

Nasr City, Cairo

Phone: (+20) 2 2287 6219

Fax: (+20) 2 2273 3140

E-mail: ahmed.azab@wika.de

11433094 03/2009 GB/D

South Africa

WIKA Instruments (Pty.) Ltd.

Gardenview, Johannesburg

2047

Phone: (+27) 11-621 00 00

Fax: (+27) 11-621 00 59

E-mail: sales@wika.co.za

www.wika.co.za

United Arab Emirates

WIKA Middle East FZE

Jebel Ali, Dubai

Phone: (+971) 4 - 883 90 90

Fax: (+971) 4 - 883 91 98

E-mail: wikame@emirates.

net.ae

Asia

China

WIKA International Trading

(Shanghai) Co., Ltd.

200001 Shanghai

Phone: (+86) 21 - 53 85 25 72

Fax: (+86) 21 - 53 85 25 75

E-mail: info@wika.com.cn

India

WIKA Instruments India Pvt. Ltd.

Village Kesnand, Wagholi

Pune - 412 207

Phone: (+91) 20 - 66 29 32 00

Fax: (+91) 20 - 66 29 33 25

E-mail: sales@wika.co.in

www.wika.co.in

Japan

WIKA Japan K. K.

Tokyo 105-0023

Phone: (+81) 3-54 39 66 73

Fax: (+81) 3-54 39 66 74

E-mail: t-shimane@wika.co.jp

Kazakhstan

TOO WIKA Kazakhstan

050050 Almaty

Phone: (+7) 32 72 33 08 48

Fax: (+7) 32 72 78 99 05

E-mail: info@wika.kz

Korea

WIKA Korea Ltd.

Seoul 153-023

Phone: (+82) 2 - 8 69 05 05

Fax: (+82) 2 - 8 69 05 25

E-mail: info@wika.co.kr

Malaysia

WIKA Instrumentation (M)

Sdn. Bhd.

47100 Puchong, Selangor

Phone: (+03) 80 63 10 80

Fax: (+03) 80 63 10 70

E-mail: info@wika.com.my

www.wika.com.my

Singapore

WIKA Instrumentation Pte. Ltd.

569625 Singapore

Phone: (+65) 68 44 55 06

Fax: (+65) 68 44 55 07

E-mail: info@wika.com.sg

www.wika.com.sg

Taiwan

WIKA Instrumentation Taiwan

Ltd.

Pinjen, Taoyuan

Phone: (+886) 3 420 6052

Fax: (+886) 3 490 0080

E-mail: info@wika.com.tw

www.wika.com.tw

Australia

Australia

WIKA Australia Pty. Ltd.

Rydalmere, NSW 2116

Phone: (+61) 2 - 88 45 52 22

Fax: (+61) 2 - 96 84 47 67

E-mail: sales@wika.com.au

www.wika.com.au

New Zealand

Process Instruments Limited

Unit 7 / 49 Sainsbury Road

St Lukes - Auckland 1025

Phone: (+64) 9 - 847 90 20

Fax: (+64) 9 - 846 59 64

E-mail: info@wika.co.nz

www.wika.co.nz

19

Page 20

Technical alteration rights reserved.

Technische Änderungen vorbehalten.

20

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Strasse 30

63911 Klingenberg • Germany

Tel (+49) 9372/132-0

Fax (+49) 9372/132-406

E-Mail info@wika.de

www.wika.de

11433094.01 03/2009 GB/D

Loading...

Loading...