Page 1

Electronic

Pressure Measurement

Model S-20

High Performance Pressure Transmitter

for General Industrial Applications

WIKA Datasheet S-20

Applications

■

General industrial applications

■

Demanding research and development applications

■

Harsh industrial environments

Special Features

■

Measuring ranges from 0…10 to 0…20,000 psi (0 ... 0.4

to 0 ... 1,600 bar)

■

Non-linearity of up to 0.125 % B.F.S.L.

■

Available output signals include 4 ... 20 mA, 0 ... 10 VDC,

1 ... 5 VDC and many others

■

Industry standard electrical connections including

DIN 175301-803A L- connector, cables, housings and

many others

■

Common USA and international process connections

available

Model S-20 Pressure Transmitter

Description

The model S-20 pressure transmitter is the ideal solution for

customers with demanding performance requirements in

many industrial applications.

It features high accuracy, a robust design and is available with

an exceptional number of options that make it suitable for an

extremely broad range of pressure measurement applications.

.

High versatility

The model S-20 oers continuous measuring ranges between

0…10 psi and 0…20,000 psi (0 ... 0.4 and 0 ... 1,600 bar) in

all common engineering units. Vacuum and compound ranges

are also available.

These measuring ranges can be combined with virtually any

standard industry output signal, common international process

connections and a wide variety of electrical connections.

A large number of options are available including dierent

accuracy classes, extended temperature ranges and

customer specic pin assignments to provide compatibility

with most industrial applications.

Data sheets showing similar products:

Pressure transmitter for general industrial applications; model A-10; see data sheet PE 81.60

High quality

The rugged design makes the model S-20 a highly reliable

transmitter that is not aected by most adverse environmental

conditions. This transmitter meets most application

performance requirements when exposed to very low outdoor

temperatures, extreme shock and vibration and aggressive

media.

Availability

Variations of the S-20 described in this data sheet are usually

available with short lead times. Inventory of popular designs

are usually available for particularly urgent requirements.

Page 1 of 15WIKA Datasheet S-20 · 4/2013

R

Page 2

Measuring ranges

Relative pressure ranges

psi 0 … 10 0 … 15 0 … 25 0 … 30 0 … 50 0 … 60 0 … 100

0 … 150 0 … 160 0 … 200 0 … 250 0 … 300 0 … 400 0 … 500

0 … 600 0 … 750 0 … 1,000 0 … 1,500 0 … 2,000 0 … 3,000 0 … 4,000

0 … 5,000 0 … 6,000 0 … 7,500 0 … 10,000 0 … 15,000 0 … 20,000

bar 0 ... 0.4 0 ... 0.6 0 … 1 0 … 1.6 0 … 2.5 0 … 4 0 … 6

0 … 10 0 … 16 0 … 25 0 … 40 0 … 60 0 … 100 0 … 160

0 … 250 0 …. 400 0 … 600 0 … 1,000 0 … 1,600

Absolute pressure ranges

psi 0 … 10 0 … 15 0 … 25 0 … 30 0 … 50 0 … 60 0 … 100

0 … 150 0 … 160 0 … 200 0 … 250 0 … 300 0 … 400 0 … 500

bar 0 … 0.4 0 … 0.6 0 … 1 0 … 1.6 0 … 2.5 0 … 4 0 … 6

0 … 10 0 … 16 0 … 25 0 … 40

Vacuum and compound ranges

psi -30 inHg ... 0 -30 inHg ... +15 -30 inHg ... +30 -30 inHg ... +45 -30 inHg ... +60

-30 inHg ... +100 -30 inHg ... +160 -30 inHg ... +200 -30 inHg ... +300 -30 inHg ... +500

bar -0.4 … 0 -0.6 … 0 -1 … 0 -1 … +0.6 -1 … +1.5

-1 … +3 -1 … +5 -1 … +9 -1 … +15 -1 … +24

-1 … +39 -1 … +59

The listed pressure ranges are also available in kg/cm2, kPa and MPa.

Special measuring ranges between 0 ... 10 and 0 ... 20,000 psi ( 0.4…1600 bar) are available on request.

Special pressure ranges may have reduced long-term stability and increased temperature errors.

Overpressure limit

The overpressure limit depends on the specic sensor element used for the selected pressure range. A reduction in the

overpressure safety rating may occur depending on the specic process connection and seal selected. A higher overpressure

limit may provide a greater temperature error.

Measuring range < 150 psi/10 bar ≥ 150 psi/10 bar

3 times (standard) 2 times

5 times 3 times

1) Restriction: max. 60 bar/870 psi with absolute pressure

2) Only possible for relative pressure measuring ranges ≤ 400 bar or 5,800 psi

3) Only possible for absolute pressure measuring ranges < 16 bar or 220 psi

1)

(standard)

2) 3)

Vacuum resistance

Ye s

(No damage to sensor when vacuum is applied)

Page 2 of 15 WIKA Datasheet S-20 · 4/2013

Page 3

Output signal

Signal type Signal

Current (2-wire) 4 ... 20 mA

20 ... 4 mA

Voltage (3-wire) DC 0 ... 10 V

DC 0 ... 5 V

DC 1 ... 5 V

DC 0.5 ... 4.5 V

DC 1 ... 6 V

DC 10 ... 0 V

Ratiometric (3-wire) DC 0.5 ... 4.5 V

Other output signals on request.

Permissible load in Ω

■

Current output (2-wire): ≤ (power supply - 7.5 V) / 0.023 A

≤ (power supply - 11.5 V) / 0.023 A (with optional settling time of 1 ms)

■

Voltage output (3-wire): > maximum output voltage / 1 mA

■

Ratiometric output (3-wire): > 4.5k

Optional output signal limits

■

4 ... 20 mA signal: Minimum zero point setting: 3.6 mA 1), 3.8 mA, 4.0 mA

Maximum full scale setting: 20 mA, 21.5 mA, 23 mA

■

DC 0 ... 10 V signal: Full scale: 10 VDC or 11.5 VDC

1) Not available with the zero point adjustment option

Voltage supply

Power supply

Maximum allowable power supply rating for cULus approval: 35 VDC (32 VDC with heavy-duty connector)

■

Current output (2-wire)

4 ... 20 mA: 8 ... 36 VDC (12 ... 36 VDC with optional 1 ms settling time)

20 ... 4 mA (reverse output): 8 ... 36 VDC

■

Voltage output (3-wire)

0 ... 10 VDC: 12 ... 36 VDC

0 ... 5 VDC: 8 ... 36 VDC

1 ... 5 VDC: 8 ... 36 VDC

0.5 ... 4.5 VDC: 8 ... 36 VDC

1 ... 6 VDC: 9 ... 36 VDC

10 ... 0 VDC: 12 ... 36 VDC

■

3-wire ratiometric output:

0.5 ... 4.5 VDC: 5 VDC ±10 %

Power dissipation (loss)

■

Current output (2-wire): 828 mW (22 mW/K derating of the power dissipation when ambient temperatures

are ≥ 212 ° F/100 °C)

■

Voltage output (3-wire): 432 mW

Maximum current consumption

■

Current output (2-wire): Current signal, max. 25 mA

■

Voltage output (3-wire): max. 12 mA

Page 3 of 15WIKA Datasheet S-20 · 4/2013

Page 4

Reference conditions (per IEC 61298-1)

Temperature

59…77ºF (15…25ºC)

Barometric pressure

860 ... 1,060 mbar

Humidity

45 ... 75 % relative

Power supply

■

24 VDC

■

5 VDC for ratiometric output

Mounting position

Calibrated in vertical position with pressure connection facing down

Response time

Signal type Settling time per IEC 62594 Signal damping

Standard

Current (2-wire) 3 ms 1 ms 10, 50, 100, 500, 1,000, 5,000 ms

Voltage (3-wire) 2 ms 1 ms 10, 50, 100, 500, 1,000, 5,000 ms

Ratiometric (3-wire) 2 ms 1 ms 10, 50, 100, 500, 1,000, 5,000 ms

1) 3 dB limit frequency: 500 Hz

2) 3 dB limit frequency: 1,000 Hz

3) Alternative specications for 4 ... 20 mA output signal:

Load: ≤ (power supply - 11.5 V) / 0.023 A

Power supply: DC 12 ... 36 V

1)

Option 1

2) 3)

Option 2

Switch-on time (from power up to output signal)

150 ms

Switch-on drift time

5 s to reach stated accuracy (60 s with optional 0.1 % zero point adjustment)

Page 4 of 15 WIKA Datasheet S-20 · 4/2013

Page 5

Accuracy data

Non-linearity (per IEC 61298-2)

Accuracy at calibration temperature

BFSL Terminal method

≤ ±0.5 % of span (standard) ≤ ±1.0 % of span ≤ ±1.0 % of span

≤ ±0.25 % of span ≤ ±0.5 % of span ≤ ±0.5 % of span

≤ ±0.125 % of span

1) Restrictions for the non-linearity of 0.125 % BFSL or 0.25 % with terminal method:

Available output signals: 4 ...20 mA and DC 0 ... 10 V

Available measuring ranges: All measuring ranges specied in the data sheet

For further output signals or measuring ranges, please ask the manufacturer

1)

≤ ±0.25 % of span

1)

≤ ±0.25 % of span

Calibration temperature

15 ... 25 °C (standard)

4 °C ±5 °C

40 °C ±5 °C

60 °C ±5 °C

80 °C ±5 °C

Zero point adjustment

≤ ±0.2 % of span, factory setting (standard)

≤ ±0.1 % of span, factory setting

±10 % of span, in 0.05 % increments, customer setting

1) Restrictions for the optional factory set 0.1 % zero point adjustment:

Only available with 4 ...20 mA and 0 ... 10 VDC output signals

Available measurement ranges: All relative pressure ranges specied in the

data sheet. Not available in combination with the optional calibration temperature.

2) The “optional zero point adjustment access” is not available with every electrical

connection, see “Electrical connections” for details.

1)

2)

1)

Eect of mounting position on zero oset

For measuring ranges < 15 psi ( 1 bar), an additional zero oset of up to 0.15 % applies

Non-repeatability

≤ ±0.1 % of span

Temperature hysteresis

0.1 % of span at > 176 °F (80 °C)

Long-term drift (per IEC 61298-2)

■

≤ ±0.1 % of span

■

≤ ±0.2 % of span (with special measuring ranges)

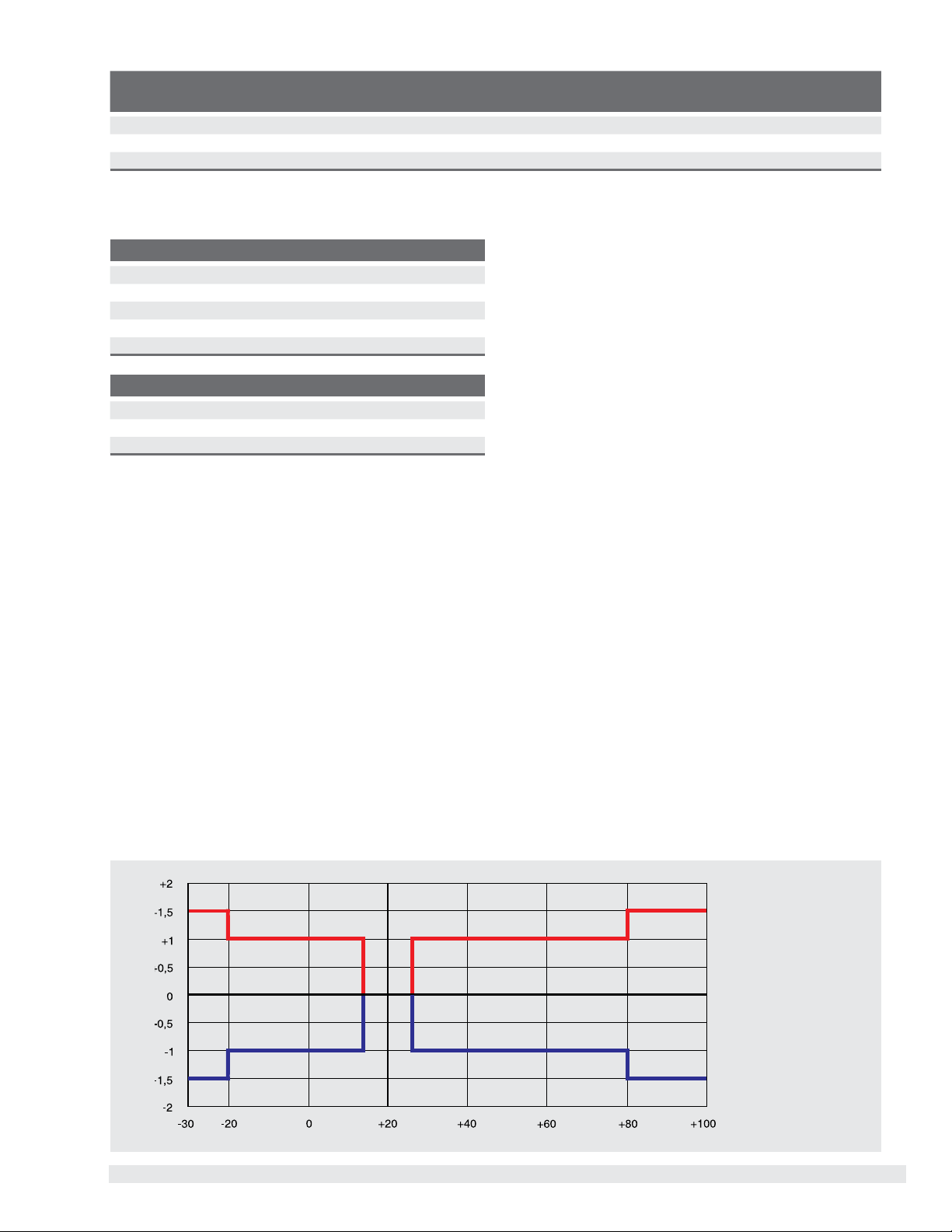

Temperature error (for calibration temperature of 59…77 °F (15 ... 25 °C))

For measuring ranges < 15 psi (1 bar), special measuring ranges and instruments with an increased overpressure limit the

temperature error increases by 0.5 % of span

Temperature error [%]

Medium temperature [°C]

Page 5 of 15WIKA Datasheet S-20 · 4/2013

Page 6

Operating conditions

Permissible temperature ranges

Medium Ambient Design maximum permissible pressure

-30 ... +100 °C (standard) -30 ... +100 °C - -

-40 ... +125 °C -40 ... +125 °C - -

-40 ... +150 °C -40 ... +125 °C

-40 ... +200 °C -40 ... +125 °C

-20 ... +60 °C -20 ... +60 °C Oxygen applications -

1) Derating curve and formula (see following diagram)

There may be other media and ambient temperature limitations depending upon the sealing material used with the process

connection and the specic electrical connection selected.

For restrictions see "Process connections, sealings" and "Electrical connections".

1)

1)

with integrated cooling element 5800 psi (400 bar)

with integrated cooling element 5800 psi (400 bar)

Ambient temperature [°C]

Medium temperature [°C]

Maximum permissible ambient temperature

T

(T

amb

T

amb

T

= ambient temperature [°C]

amb

= medium temperature [°C]

T

med

< 125 °C) = 125 °C

med

(T

≥ 125 °C) = -0.62 x T

med

med

+ 202 °C

Maximum permissible medium temperature

T

(T

< 80 °C) = 200 °C

amb

(T

≥ 80 °C) = -1.61 x T

amb

amb

+ 326 °C

T

med

med

Storage and transport conditions

■

Permissible temperature range: -40…158° F (-40 ... +70 °C)

■

Maximum humidity (per IEC 68-2-78): 67 % r.h. at 104 F (40 °C) (in accordance with 4K4H per EN 60721-3-4)

Vibration resistance (per IEC 68-2-6)

20 g, 10 ... 2,000 Hz, (40 g, 10 ... 2,000 Hz for heavy-duty connector)

For instruments with cooling elements a limited vibration resistance of 10 g applies (10 ... 2,000 Hz)

Continuous vibration resistance (per IEC 68-2-6)

10 g

Shock resistance (per IEC 68-2-27)

100 g, 6 ms (500 g, 1 ms for heavy-duty connector)

Service life

100 million load cycles (10 million load cycles for measuring ranges > 7,500 psi /600 bar)

Free-fall test (following IEC 60721-3-2)

■

Individual packaging: 5 ft (1.5 m)

■

Multiple packaging: 1.6 ft (0.5 m)

■

PE bag: 1.6 ft (0.5 m)

Page 6 of 15 WIKA Datasheet S-20 · 4/2013

Page 7

Process connections

Available connections

Process connection per Thread size Maximum overpressure limit

EN 837 G ⅛ B 11,600 psi (800 bar)

G ¼ B 20,300 psi (1,400 bar)

G ¼ B female 20,300 psi (1,400 bar)

G ½ B 26,100 psi (1,800 bar) (1.4404)

46,400 psi (3,200 bar) (1.4542)

G ⅜ B 20,300 psi (1,400 bar)

DIN 3852-E G ¼ A 8700 psi (600 bar)

G ½ A 8700 psi (600 bar)

M14 x 1.5 8700 psi (600 bar)

ISO 228 M20 x 1.5 26,100 psi (1,800 bar) (1.4404)

47,800 psi (3,300 bar) (1.4542)

M12 x 1.5 8700 psi (600 bar)

SAE J514 E 7/16-20 UNF BOSS 8700 psi (600 bar)

7/16-20 UNF J514 sealing cone 74° 15,900 psi (1,100 bar)

9/16-18 UNF BOSS 8700 psi (600 bar)

ANSI/ASME B1.20.1 ⅛ NPT 15,900 psi (1,100 bar)

¼ NPT 21,700 psi (1,500 bar)

¼ NPT female 21,700 psi (1,500 bar)

½ NPT 21,700 psi (1,500 bar) (1.4404)

40,600 psi (2,800 bar) (1.4542)

KS PT ¼ 23,200 psi (1,600 bar)

PT ½ 21,700 psi (1,500 bar)

PT ⅜ 20,300 psi (1,400 bar)

ISO 7 R ¼ 23,200 psi (1,600 bar)

R ⅜ 21,700 psi (1,500 bar)

R ½ 20,300 psi (1,400 bar) (1.4404)

41,200 psi (2,840 bar) (1.4542)

Other process connections available on request.

Pressure port diameter

Pressure port diameter Available for thread sizes

2.5 mm (standard) all thread sizes

0.3 mm G ¼ A, G ½ A, ¼ NPT, ½ NPT, R ¼, 7/16-20 UNF BOSS

0.6 mm G ¼ A, G ½ A, ¼ NPT, ½ NPT, R ¼, 7/16-20 UNF BOSS

6 mm* G ¼ A, ¼ NPT, R ¼, 7/16-20 UNF BOSS

12 mm* G ½ A, ½ NPT

*6 or 12 mm enlarged pressure port is only available for measuring ranges up to and including 0 ... 500 psi (0 ... 40 bar).

Sealing rings

Process connection per Copper Stainless steel NBR FKM

-40 ... +125 °C -40 ... +125 °C -20 ... +100 °C -15 ... +125 °C

EN 837 Standard Option - DIN 3852-E - - Standard Option

ISO 228 Standard Option - SAE J514 E

-

- Standard Option

Page 7 of 15WIKA Datasheet S-20 · 4/2013

Page 8

Electrical connections

Available connections

Electrical connection Ingress

protection

Wire

cross-sec-

Cable ∅ Cable

material

maximum permissible

temperature

tion

L-connector DIN 175301-803 A

L-connector DIN 175301-803 C

Circular connector M12 x 1 (4-pin)

Circular connector M12 x 1 (4-pin, metallic) IP 67 - - - -40 ... +125 °C (cULus: +85 °C)

Bayonet connector (6-pin) IP 67 - - - -40 ... +125 °C

Field case IP 6K9K - - - -25 ... +100 °C

Heavy-duty connector

Cable outlet IP 67

2)

1)

Cable outlet ½ NPT conduit IP 67 6 x 0.35 mm

Cable outlet IP 68 IP 68 6 x 0.35 mm

Cable outlet IP 68, FEP IP 68 6 x 0.39 mm

Cable outlet IP 6K9K IP 6K9K 6 x 0.35 mm

1) Customer zero point adjustment available as an option.

2) max. DC 32 V with cULus approval

1)

1)

1)

IP 65 - - - -30 ... +100 °C

IP 65 - - - -30 ... +100 °C

IP 67 - - - -30 ... +100 °C

IP 68 - - - -40 ... +125 °C

IP 67 3 x 0.34 mm25.5 mm PUR -30 ... +100 °C

2

6.1 mm PUR -30 ... +100 °C (cULus: +90 °C)

2

6.1 mm PUR -30 ... +125 °C (cULus: +90 °C)

2

5.8 mm FEP -40 ... +125 °C (cULus: +105 °C)

2

6.1 mm PUR -30 ... +125 °C (cULus: +90 °C)

Other connections on request.

Assembly congurations of the mating connectors

Mating connector for electrical

connection

L-connector DIN 175301-803 A

■

Mating connector IP 65 max. 1.5 mm26 ... 8 mm - -40 ... +125 °C -

■

Mating connector (conduit) IP 65 max. 1.5 mm2- - -40 ... +125 °C -

■

Mating connector with molded

cable

■

Mating connector with molded

cable, shielded

L-connector DIN 175301-803 C

■

Mating connector IP 65 max. 0.75 mm24.5 ... 6 mm - -40 ... +125 °C -

■

Mating connector with molded

cable

Circular connector M12 x 1 (4-pin)

■

Mating connector, straight, with

molded cable

■

Straight mating connector, with

molded cable, shielded

■

Mating connector, angled, with

molded cable

Heavy-duty connector

■

Mating connector with cable IP 68 6 x 0.14 mm26.5 mm PUR -40 ... +125 °C

Ingress

protection

IP 65 3 x 0.75 mm26 mm PUR -40 ... +125 °C

Wire

cross-section

Cable ∅ Cable

material

max. permissible

temperature

Cable ends

no nishing

(cULus: -25 ... +85°C)

IP 65 6 x 0.5 mm

2

6.8 mm PUR -25 ... +85 °C End splices

IP 65 4 x 0.75 mm25.9 mm PUR -25 ... +85 °C no nishing

IP 67 3 x 0.34 mm24.3 mm PUR -25 ... +80 °C no nishing

IP 67 3 x 0.34 mm24.3 mm PUR -25 ... +80 °C no nishing

IP 67 3 x 0.34 mm25.5 mm PUR -25 ... +80 °C no nishing

no nishing

(cULus: -30 ... +90°C)

Assembly congurations of the cable outlets

Electrical connection Unnished wire ends Tinned wire ends with end splices

Cable outlet IP 67 Standard Option Option

Cable outlet ½ NPT conduit - Option Standard

Cable outlet IP 68 - Option Standard

Cable outlet IP 68, FEP - Option Standard

Cable outlet IP 6K9K - Option Standard

Cable lengths of 6 ft, 15 ft, 2 m or 5 m are available, other cable lengths on request.

Page 8 of 15 WIKA Datasheet S-20 · 4/2013

Page 9

Connection diagrams

L-connector DIN 175301-803 A

U

+

U

-

S

+

Shield (option) 4 4

L-connector DIN 175301-803 C

U

+

U

-

S

+

Shield (option) 4 4

Bayonet connector (6-pin)

U

+

U

-

S

+

Shield Case Case

2-wire 3-wire

1 1

2 2

- 3

2-wire 3-wire

1 1

2 2

- 3

2-wire 3-wire

A A

B B

- C

Heavy-duty connector

U

+

U

-

S

+

Shield Case Case

Circular connector M12 x 1 (4-pin)

U

+

U

-

S

+

Shield (option) Case Case

Field case

U

+

U

-

S

+

Shield 5 5

2-wire 3-wire

1 1

2 2

- 3

2-wire 3-wire

1 1

3 3

- 4

2-wire 3-wire

1 1

2 2

- 3

Cable outlet

incl. mating connector with molded cable

2-wire 3-wire

U

+

U

-

S

+

Shield grey (GY) grey (GY)

brown (BN) brown (BN)

blue (BU) blue (BU)

- black (BK)

Cable outlet

(US code)

Other pin assignments on request.

Electrical protection

The electrical protection measures below do not apply to ratiometric output signals.

■

Short-circuit protection: S+ vs. U

■

Reverse polarity protection: U+ vs. U

■

Overvoltage protection: 40 VDC

■

Insulation voltage: 750 VDC

-

-

2-wire 3-wire

U

+

U

-

S

+

Shield grey (GY) grey (GY)

red (RD) red (RD)

black (BK)

- white (WH)

black (BK)

Page 9 of 15WIKA Datasheet S-20 · 4/2013

Page 10

Materials

Wetted parts

■

Relative measuring ranges:

- Measuring ranges ≤ 150 psi / 10 bar: 316L

- Measuring ranges > 150 psi / 10 bar: 316L + 13-8 PH

■

Absolute pressure measuring ranges:

- Measuring ranges ≤ 10,000 psi / 1,000 bar: ASTM 630 and 13-8 PH

- Measuring ranges > 10,000 psi / 1,000 bar: 316L + 13-8 PH

■

Sealing materials: see "Process connections"

Non-wetted parts

■

Case: 316 Ti

■

Zero point adjustment ring: PBT/PET GF30

■

Electrical connections:

L-connector DIN 175301-803 A: PBT/PET GF30

L-connector DIN 175301-803 C: PBT/PET GF30

Circular connector M12 x 1 (4-pin): PBT/PET GF30

Circular connector M12 x 1 (4-pin, metallic): 316L

Bayonet connector (6-pin) 316L + Al

Field case: 316L, 316Ti

Heavy-duty connector: 316L

Cable outlet IP 67: PA66

Cable outlet ½ NPT conduit: 316L

Cable outlet IP 68: 316L

Cable outlet IP 68, FEP: 316L

Cable outlet IP 6K9K: 316L

Pressure transmission uid

Synthetic oil (for measuring ranges < 150 psi / 10 bar relative and absolute pressure)

Options for specic media

Medium Option

Food Food-compatible transmission uid

Oil and grease free Residual hydrocarbon: < 1,000 mg/m

Packaging: Protection cap on the process connection

Oxygen, oil and grease free Residual hydrocarbon (measuring range < 30 bar): < 500 mg/m

Residual hydrocarbon (measuring range > 30 bar): < 200 mg/m

Packaging:

Maximum permissible temperature -20 ... +60 °C

Elastomer sealing: oly FKM possible, max. -15 ... +60 °C and max. 30 bar measuring range.

Not possible with process connections with female thread

Hydrogen On request

Measuring ranges: from 25 bar relative

Wetted parts: 316L and Elgiloy

Maximum permissible temperature: -30 ... +30 °C

Protection cap on the process connection, instrument sealed in a PE bag

2

(2.4711)

2

2

Page 10 of 15 WIKA Datasheet S-20 · 4/2013

Page 11

CE conformity

Pressure equipment directive

97/23/EC

EMC directive

2004/108/EC, EN 61326 emission (group 1, class B) and interference immunity (industrial application)

EM eld

30 V/m (80 ... 1,000 MHz)

RoHS conformity

Directive 2002/95/EC

Performance level (per EN ISO 13849-1:2008)

■

Performance level: PL = C

■

Category: Cat. = 1

■

Diagnostic coverage: DC = none

■

MTTF: > 100 years

Certicates (optional)

Available certicates

2.2 test report State-of-the-art manufacturing

Wetted metallic parts

Conrmation of the class and indication accuracy

3.1 inspection certicate Wetted metallic parts

Wetted metallic parts with suppliers' certicate

Conrmation of the class and indication accuracy

List of single measured values

DKD/DAkkS calibration certicate

Approvals and certicates, see website

Scope of delivery

Test report

■

Non-linearity 0.5 % (B.F.S.L.)

■

Non-linearity 0.25 % (B.F.S.L.)

■

Non-linearity 0.125 % (B.F.S.L.)

Packaging

Individual packaging (standard)

Multiple packaging (up to 20 pieces)

Instrument labeling

WIKA laser-etched label (standard)

Customer-specic label on request

3 points

5 points

5 points

Page 11 of 15WIKA Datasheet S-20 · 4/2013

Page 12

Dimensions in mm

Pressure transmitter model S-20

with L-connector DIN 175301-803 A

Weight: approx. 150 g

with circular connector M12 x 1 (4-pin)

with L-connector DIN 175301-803 C

Weight: approx. 150 g

with circular connector M12 x 1

(4-pin, metallic)

with bayonet connector (6-pin)

Weight: approx. 150 g

with heavy-duty connector

Weight: approx. 150 g

with eld case

Weight: approx. 290 g

Page 12 of 15 WIKA Datasheet S-20 · 4/2013

Weight: approx. 150 g

with cable outlet IP 68, FEP, IP 6K9K

Weight: approx. 220 g

Weight: approx. 150 g

with cable outlet ½ NPT conduit

Weight: approx. 220 g

Page 13

with L-connector DIN 175301-803 A and

cooling element

Weight: approx. 360 g Weight: approx. 150 gWeight: approx. 150 g

with cable outlet IP 67

with L-connector DIN 175301-803 A and

zero point adjustment

Page 13 of 15WIKA Datasheet S-20 · 4/2013

Page 14

Process connections

G L1

G ¼ A 14

G ½ A 17

M14 x 1.5 14

G L1

7/16-20 UNF J514 sealing cone 74° 15

G L1

G ⅛ B 10

G D1 L1 L2 L3

G ¼ B female 25 20 13 10

G L1

7/16-20 UNF BOSS 12.06

9/16-18 UNF BOSS 12.85

G D1 L1 L2

¼ NPT female 25 20 14

G L1

⅛ NPT 10

¼ NPT 13

½ NPT 19

PT ¼ 13

PT ½ 19

PT ⅜ 15

R ¼ 13

R ½ 19

R ⅜ 15

G L1

G ¼ B 13

G ½ B 20

G ⅜ B 16

M12 x 1.5 15

M20 x 1.5 20

For information on tapped holes and welding sockets, see Technical information IN 00.14 at www.wika.com.

Page 14 of 15 WIKA Datasheet S-20 · 4/2013

Page 15

Accessories and spare parts

Mating connector

Designation Order number

without cable with 2 m cable with 5 m cable with 2 m cable, shielded

L-connector DIN 175301-803 A

■

with gland, metric 11427567 11225793 11250186 2242656

■

with gland, conduit 11022485 - - -

L-connector DIN 175301-803 C 1439081 11225823 11250194 -

Circular connector M12 x 1 (4-pin)

■

straight - 11250780 11250259 14056584

■

angled - 11250798 11250232 -

Sealings for mating connectors

Mating connector Order number

Blue (WIKA) Brown (neutral)

L-connector DIN 175301-803 A 1576240 11437902

L-connector DIN 175301-803 C 11169479 11437881

Sealings for process connection

Thread size Order number

Copper Stainless steel NBR FKM

G ⅛ B 11251051 - - G ¼ B 11250810 11250844 - G ½ B 11250861 11251042 - G ⅜ B 14065101 - - M12 x 1.5 11250810 11250844 - M20 x 1.5 11250861 11251042 - G ¼ A - - 1537857 1576534

G ½ A - - 1039067 1039075

M14 x 1.5 - - 1537857 1576534

7/16-20 UNF BOSS - - 14057554 11472022

9/16-18 UNF BOSS - - 14057555 2063240

Ordering information

Model / Measuring range / Overpressure limit / Output signal / Non-linearity / Calibration temperature / Zero point adjustment

/ Process connection / Pressure channel / Sealing / Electrical connection / Assembly / Cable length / Shielding / Certicates /

Packaging / Instrument labeling / Accessories and spare parts

© 2013 WIKA Alexander Wiegand SE & Co. KG, all rights reserved.

The specications given in this document represent the state of engineering at the time of publishing.

We reserve the right to make modications to the specications and materials.

WIKA Datasheet S-20 · 4/2013Page 15 of 15

© Copyright 2013 WIKA Instrument, LP. All Rights Reserved.

WIKA Instrument, LP

1000 Wiegand Boulevard

Lawrenceville, GA 30043-5868

Tel: 888-WIKA-USA • 770-513-8200

Fax: 770-338-5118

E-Mail: info@wika.com

www.wika.com

R

Loading...

Loading...