Page 1

Operating instructions

Betriebsanleitung

Mode d‘emploi

Manual de instrucciones

OEM oat switch, miniature design

Models RLS-7000, RLS-8000

OEM-Schwimmerschalter, Miniaturausführung

Typen RLS-7000, RLS-8000

Détecteur de niveau à otteur OEM, version miniature

Types RLS-7000, RLS-8000

Interruptor de otador OEM, versión en miniatura

Modelos RLS-7000, RLS-8000

Model RLS-7000 Model RLS-8000

EN

DE

FR

ES

Page 2

Operating instructions

EN

models RLS-7000, RLS-8000 Page 3 - 20

Betriebsanleitung

DE

Typen RLS-7000, RLS-8000 Seite 21 - 38

Mode d‘emploi

FR

types RLS-7000, RLS-8000 Page 39 - 56

Manual de instrucciones

ES

modelos RLS-7000, RLS-8000 Página 57 - 74

© 03/2019 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 3

Contents

Contents

1. General information 4

2. Design and function 5

3. Safety 6

4. Transport, packaging and storage 11

5. Commissioning, operation 11

6. Faults 16

7. Maintenance and cleaning 18

8. Dismounting, return and disposal 19

9. Specications 20

Declarations of conformity can be found online at www.wika.com.

EN

14317448.02 12/2019 EN/DE/FR/ES

WIKA operating instructions models RLS-7000, RLS-8000

3

Page 4

1. General information

1. General information

■

The oat switches described in the operating instructions have

EN

been designed and manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental

criteria during production. Our management systems are certied to

ISO 9001 and ISO 14001.

■

These operating instructions contain important information on

handling the instrument. Working safely requires that all safety

instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and

general safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept

in the immediate vicinity of the instrument and readily accessible to

skilled personnel at any time. Pass the operating instructions on to

the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the

operating instructions prior to beginning any work.

■

The general terms and conditions contained in the sales

documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: LM 50.11 (model RLS-7000)

- Application consultant: Tel.: +49 9372 132-0

LM 50.12 (model RLS-8000)

Fax: +49 9372 132-406

info@wika.de

4 WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 5

2. Design and function

2. Design and function

2.1 Functional description

The model RLS-7000 works according to the oat principle with

magnetic transmission and is suitable for vertical installation. A reed

contact integrated in the guide tube is actuated through the magnetic

eld of a permanent magnet, when a preset switch point is reached. The

permanent magnet is located within a oat, which changes its position

with the level of the medium it is monitoring. The switching status of the

reed contact can be evaluated and processed by a connected control

device. The switching function can be changed between normally closed

and normally open by turning the oat through 180°.

180°

The RLS-8000 is suitable for horizontal installation. The normally open

and normally closed switching function, as it is marked at the process

connection, can be set through a half turn on the mounting thread of the

switch.

EN

14317448.02 12/2019 EN/DE/FR/ES

WIKA operating instructions models RLS-7000, RLS-8000

180°

5

Page 6

2. Design and function / 3. Safety

2.2 Scope of delivery

■

Float switch

■

Operating instructions

Cross-check scope of delivery with delivery note.

EN

3. Safety

3.1 Explanation of symbols

DANGER!

... indicates a directly dangerous situation resulting in serious

injury or death, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result

in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result

in light injuries or damage to property or the environment, if

not avoided.

Information

... points out useful tips, recommendations and information

for ecient and trouble-free operation.

3.2 Intended use

Float switches are used exclusively for monitoring the levels of liquid

media. The scope of application is dened by the technical performance

limits and materials.

6 WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 7

3. Safety

■

The liquids must not have any large contamination or coarse particles

and must not have a tendency to crystallise. Ensure that the wetted

materials of the oat switch are suciently resistant to the medium

being monitored. Not suitable for dispersions, abrasive liquids, highly

viscous media and colours.

■

This instrument is not permitted to be used in hazardous areas!

■

The operating conditions specied in the operating instructions must

be observed.

■

Do not operate the instrument in the immediate vicinity of a magnetic

eld source (distance min. 100 mm).

■

Do not operate the instrument outdoors.

■

Do not operate the instrument in the immediate vicinity of strong

electromagnetic elds or in the immediate vicinity of equipment that

can be aected by magnetic elds (min. clearance 1 m).

■

Do not operate the instrument at an altitude above 2,000 m.

■

The oat switches must not be exposed to heavy mechanical strain

(impact, bending, vibration). In case of danger of mechanical loads,

the oat switch must be protected by a protective device (e.g. case).

■

The technical specications contained in these operating instructions

must be observed. Improper handling or operation of the instrument

outside of its technical specications requires the instrument to be

taken out of service immediately and inspected by an authorised

WIKA service engineer.

The instrument has been designed and built solely for the intended use

described here, and may only be used accordingly.

EN

The manufacturer shall not be liable for claims of any type based on

operation contrary to the intended use.

14317448.02 12/2019 EN/DE/FR/ES

WIKA operating instructions models RLS-7000, RLS-8000

7

Page 8

3. Safety

The instrument must be protected by an external fuse.

DANGER!

EN

3.3 Improper use

Improper use is dened as any application that exceeds the technical

performance limits or is not compatible with the materials.

Any use beyond or dierent to the intended use is considered as

improper use.

Do not use this instrument in safety or emergency stop devices.

3.4 Responsibility of the operator

The instrument is used in the industrial sector. The operator is therefore

responsible for legal obligations regarding safety at work.

Physical injuries

Work on containers involves the danger of intoxication and

suocation.

▶

No work is allowed to be carried out unless by taking

suitable personal protective measures (e.g. respiratory

protection apparatus, protective clothing etc.).

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous

situations and injuries.

▶

Refrain from unauthorised modifications to the instrument.

▶

Do not use the instrument within hazardous areas.

The safety instructions within these operating instructions, as well as the

safety, accident prevention and environmental protection regulations for

the application area must be maintained.

8 WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 9

3. Safety

To ensure safe working on the instrument, the operating company must

ensure

■

that the operating personnel are regularly instructed in all topics

regarding work safety, rst aid and environmental protection

and know the operating instructions and in particular, the safety

instructions contained therein.

■

that the instrument is suitable for the particular application in

accordance with its intended use.

■

that following testing, improper use of the instrument is excluded.

3.5 Personnel qualication

WARNING!

Risk of injury should qualication be insucient

Improper handling can result in considerable injury and

damage to equipment.

▶

The activities described in these operating instructions

may only be carried out by skilled personnel who have the

qualifications described below.

Skilled personnel

Skilled personnel, authorised by the operator, are understood to

be personnel who, based on their technical training, knowledge

of measurement and control technology and on their experience

and knowledge of country-specic regulations, current standards

and directives, are capable of carrying out the work described and

independently recognising potential hazards.

EN

14317448.02 12/2019 EN/DE/FR/ES

WIKA operating instructions models RLS-7000, RLS-8000

9

Page 10

3. Safety / 4. Transport, packaging and storage

3.6 Labelling, safety marks

Product label (example)

EN

Model

P# product number

S# serial number

Electrical connection

Before mounting and commissioning the instrument, ensure

you read the operating instructions!

4. Transport, packaging and storage

4.1 Transport

Check the oat switch for any damage that may have been caused by

transport. Obvious damage must be reported immediately.

CAUTION!

Physical injuries and damage to equipment

With improper transport, a high level of damage to property

can occur.

▶

Observe the symbols on the packaging.

▶

Handle packed goods with care.

10 WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 11

4. Transport ... / 5. Commissioning, operation

4.2 Packaging and storage

Do not remove packaging until just before commissioning.

Permissible conditions at the place of storage:

Storage temperature: -25 … +80 °C (-13 … +176 °F)

5. Commissioning, operation

■

Observe all instructions given on the shipment packaging for

removing the transportation safety devices.

■

Remove the oat switch carefully from the packaging!

■

When unpacking, check all components for any external damage.

5.1 Mounting preparation

Functional check

Before mounting, the oat switch can be connected as

described in chapter 5.3 and the switch points can be

operated manually.

WARNING!

Physical injuries and damage to equipment

A fault with the electrical functional check can lead to a

malfunction in the plant and thus lead to injury to personnel

or damage to equipment.

▶

Ensure that the functional check does not start any

unintended processes.

▶

Do not carry out a functional check during operation or

when actively controlling.

Ensure that the sealing faces of the vessel or oat switch are clean and

do not show any mechanical damage.

EN

14317448.02 12/2019 EN/DE/FR/ES

WIKA operating instructions models RLS-7000, RLS-8000

11

Page 12

5. Commissioning, operation

5.2 Mounting

■

Observe the torque values of screws specied in pipetting work.

■

In the selection of the mounting material (sealings, screws, washers

and nuts), take the process conditions into account. The suitability

EN

of the sealing must be specied with regard to the medium and its

vapours.

■

Install the oat switch using the mounting thread.

■

The model RLS-7000 is only suitable for

vertical installation, the model RLS-8000 only

for horizontal installation.

■

With the RLS-8000, ensure the correct

installation through the arrow direction on the

switch.

Model RLS-8000

horizontal installation

5.3 Electrical connection

■

The electrical connection must only be made by qualied skilled

personnel.

■

Connection details and switching functions are given on the

connection diagram.

■

The mains connection lines to be provided must be dimensioned

for maximum instrument current supply and comply with IEC 227 or

IEC 245.

■

Protect the instrument via an external fuse for mains connection

(AC 230 V).

Model RLS-7000

vertical installation

12 WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 13

5. Commissioning, operation

WARNING!

Physical injuries and damage to equipment

Electrical connection errors of the oat switches can destroy

the reed contacts. This can lead to a malfunction in the plant

and thus lead to injury to personnel or damage to equipment.

▶

No direct operation in circuits with inductive loads.

▶

No direct operation in circuits with capacitive loads, e.g.

PLC, PCS or cable lengths > 50 m.

▶

Do not exceed the permissible switching power.

DANGER!

Physical injuries

With oat switches with connection cable without protective

conductor connection, it is possible for the switch to become

live in the event of a malfunction. Any contact can result in

physical or even fatal injury.

▶

Only operate these switches at safety extra-low voltage

in accordance with IEC 60364 (VDE0100) or fit them

so that the float switch is electrically connected to the

equipotential bonding.

Electrical protection class

Depending on the electrical connection, the instruments are designed

in protection class II. The appropriate protection class of the electrical

connection is given in the respective data sheet.

Protection class II:

Protective insulation, no protective conductor connection

EN

14317448.02 12/2019 EN/DE/FR/ES

WIKA operating instructions models RLS-7000, RLS-8000

13

Page 14

5. Commissioning, operation

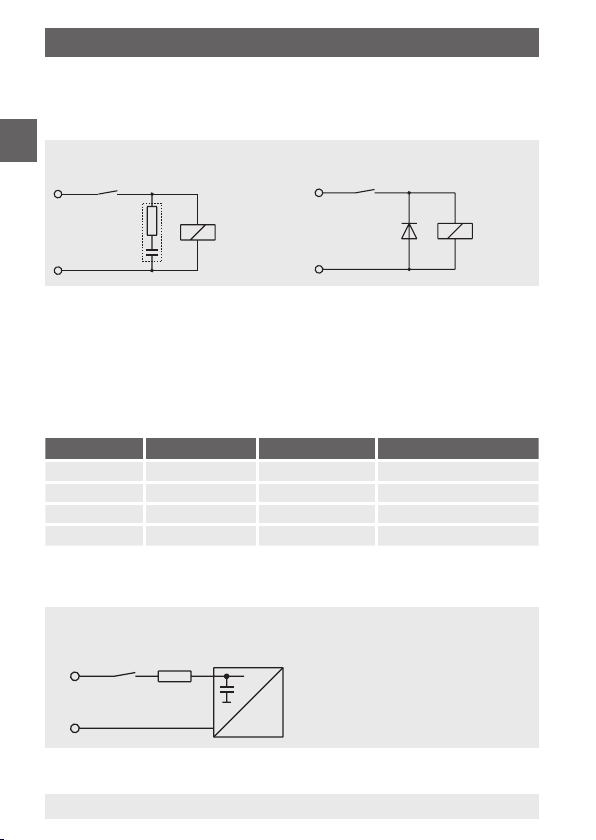

Connection with inductive load

With inductive loads, the oat switches should be protected by

connection to an RC element or a free-wheeling diode.

EN

AC voltage DC voltage

S1

AC 24 ... 230 V

R

C

RC

element,

see table

Protective RC elements

Depending on the operating voltage, use RC elements exclusively in

accordance with the table below. RC elements other than those specied

here will lead to the destruction of the reed switch.

RC elements for reed contacts 10 VA

Voltage Resistance Capacitance Type of RC element

AC 24 V 100 Ω 0.33 μF A 3/24

AC 48 V 220 Ω 0.33 μF A 3/48

AC 115 V 470 Ω 0.33 μF A 3/115

AC 230 V 1,500 Ω 0.33 μF A 3/230

Connection with capacitive load

AC voltage current limitation

e.g. for electronic time relay

S1 R

+

AC 230 V

–

S

C

1

Relay

S1

+

DC 24 ... 230 V

–

RS = 220 Ω (for AC 230 V)

C₁ = internal capacitance

Freewheeling

diode, e.g.

1N4007

14 WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 15

5. Commissioning, operation

To increase the service life of the contacts, we recommend

operation with a contact protection relay.

Connection diagrams, see product label

5.4 Commissioning

Switch on the voltage supply of the connected control device. Fill the

vessel and the check the switch points of the oat switch for function.

WARNING!

Physical injuries and damage to equipment

A fault with the electrical functional check can lead to a

malfunction in the plant and thus lead to injury to personnel

or damage to equipment.

▶

Ensure that the functional check does not start any

unintended processes.

▶

Do not carry out a functional check during operation or

when actively controlling.

Always observe the mounting and operating instructions of accessories

when commissioning them.

EN

14317448.02 12/2019 EN/DE/FR/ES

WIKA operating instructions models RLS-7000, RLS-8000

15

Page 16

6. Faults

6. Faults

EN

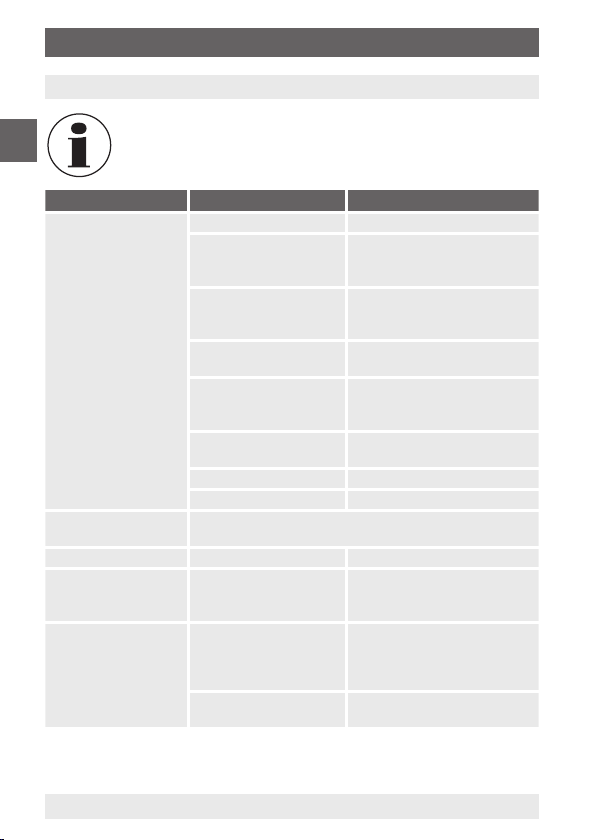

The following table contains the most frequent causes of

faults and the necessary countermeasures.

Faults Causes Measures

No signal / incorrect

switching function

Incorrect NO/NC

switching function

Model RLS-7000 Incorrectly mounted oat Turn the oat through 180°

Model RLS-8000 Incorrect direction of the

Float switch cannot

be mounted at the

planned place on

the vessel

Vessel wall too thick Check the mounting situation

Float jammed Check the suitability of

Float is not oating Density of the medium is

Switch is switching

without the oat moving

Electrical connection

incorrect

Moisture in the

electronics

Cable damaged Instrument replacement

Reed contact defective Instrument replacement

oat switch

Process connection of

the oat switch does

not match the process

connection of the vessel.

Process connection at

the vessel defective

the medium, clean the

contamination o the switch

too low, check material and

product selection

Shield from external magnetic

eld

see 5.3 “Electrical connection”

Check assignment with the

aid of the connection diagram

Check the resistance of the

material

Turn the instrument half way

around (180°), as per the

marking on the switch

Modication of the vessel;

Rework the thread or replace

the screwed coupling

Rework the thread or replace

the screwed coupling

16 WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 17

6. Faults

CAUTION!

Physical injuries and damage to property and the

environment

If faults cannot be eliminated by means of the listed

measures, the instrument must be taken out of operation

immediately.

▶

Ensure that there is no longer any pressure present and

protect against being put into operation accidentally.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given

in chapter 8.2 “Return”.

EN

14317448.02 12/2019 EN/DE/FR/ES

WIKA operating instructions models RLS-7000, RLS-8000

17

Page 18

7. Maintenance and cleaning

7. Maintenance and cleaning

7.1 Maintenance

EN

When used properly, the oat switches work maintenance-free. They

must be subjected to visual inspection within the context of regular

maintenance, however, and included in the vessel pressure test.

DANGER!

Physical injuries

Work on containers involves the danger of intoxication and

suocation.

▶

No work is allowed to be carried out unless by taking

suitable personal protective measures (e.g. respiratory

protection apparatus, protective clothing etc.).

Repairs must only be carried out by the manufacturer.

7.2 Cleaning

CAUTION!

Physical injuries and damage to property and the

environment

Improper cleaning may lead to physical injuries, damage

to property and the environment and to damage to the

instrument. Residual media in the dismounted instrument can

result in a risk to persons, the environment and equipment.

▶

Rinse or clean the dismounted instrument.

▶

Sufficient precautionary measures must be taken.

▶

Do not use any aggressive cleaning agents.

▶

Do not use any hard or pointed objects for cleaning.

1. Prior to cleaning, properly disconnect the instrument from the process

and the power supply.

2. Clean the instrument carefully with a moist cloth.

3. Electrical connections must not come into contact with moisture!

18 WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 19

8. Dismounting, return and disposal

8. Dismounting, return and disposal

WARNING!

Physical injuries and damage to property and the

environment through residual media

Residual media in the dismounted instrument can result in a

risk to persons, the environment and equipment.

▶

Wash or clean the dismounted instrument, in order to

protect persons and the environment from exposure to

residual media.

8.1 Dismounting

Only disconnect the measuring instrument once the system has been

depressurised and the power disconnected!

8.2 Return

Wash or clean the dismounted oat switch before returning it, in order to

protect personnel and the environment from exposure to residual media.

Information on returns can be found under the heading

“Service” on our local website.

8.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an

environmentally compatible way and in accordance with the country-

specic waste disposal regulations.

Do not dispose of with household waste. Ensure a proper

disposal in accordance with national regulations.

EN

14317448.02 12/2019 EN/DE/FR/ES

WIKA operating instructions models RLS-7000, RLS-8000

19

Page 20

9. Specications

9. Specications

Specications

EN

Switching

power

Accuracy ≤ 3 mm switch point accuracy incl. hysteresis, non-repeatability

Permissible

temperatures

■

Medium

■

Ambient

■

Storage

Operating

pressure

Density Polypropylene (PP):

Overvoltage

category

Pollution

degree

For further specications see WIKA data sheets LM 50.11, LM 50.12 and

the order documentation.

AC 230 V / 10 VA / 0.5 A / 50 ... 60 Hz

DC 230 V / 10 W / 0.5 A

Polypropylene (PP):

-25 … +80 °C [-13 … +176 °F]

-25 … +80 °C [-13 … +176 °F]

-25 … +80 °C [-13 … +176 °F]

≤ 4 bar [≤ 58.0 psi]

≥ 700 kg/m³ [43.7 lbs/ft³]

II

2

Polyamide PA6.6:

-25 … +100 °C [-13 … +212 °F]

-25 … +100 °C [-13 … +212 °F]

-25 … +80 °C [-13 … +176 °F]

Polyamide PA6.6:

≥ 750 kg/m³ [46.8 lbs/ft³]

20 WIKA operating instructions models RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 21

Inhalt

Inhalt

1. Allgemeines 22

2. Aufbau und Funktion 23

3. Sicherheit 24

4. Transport, Verpackung und Lagerung 29

5. Inbetriebnahme, Betrieb 29

6. Störungen 34

7. Wartung und Reinigung 36

8. Demontage, Rücksendung und Entsorgung 37

9. Technische Daten 38

Konformitätserklärungen nden Sie online unter www.wika.de.

DE

14317448.02 12/2019 EN/DE/FR/ES

WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

21

Page 22

1. Allgemeines

1. Allgemeines

■

Die in der Betriebsanleitung beschriebenen Schwimmerschalter

werden nach dem aktuellen Stand der Technik konstruiert und gefertigt. Alle Komponenten unterliegen während der Fertigung strengen

Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind

DE

nach ISO 9001 und ISO 14001 zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem

Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller

angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen

einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des Gerätes für das Fachpersonal jederzeit zugänglich

aufbewahrt werden. Betriebsanleitung an nachfolgende Benutzer

oder Besitzer des Gerätes weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig durchgelesen und verstanden haben.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Zugehöriges Datenblatt: LM 50.11 (Typ RLS-7000)

- Anwendungsberater: Tel.: +49 9372 132-0

LM 50.12 (Typ RLS-8000)

Fax: +49 9372 132-406

info@wika.de

22 WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 23

2. Aufbau und Funktion

2. Aufbau und Funktion

2.1 Funktionsbeschreibung

Der Typ RLS-7000 arbeitet nach dem Schwimmerprinzip mit magnetischer Übertragung und ist für den vertikalen Einbau geeignet. Ein im

Gleitrohr eingebauter Reed-Kontakt wird durch das Magnetfeld eines

Permanentmagneten bei Erreichen eines vorgegebenen Schaltpunktes

betätigt. Der Permanentmagnet bendet sich in einem Schwimmer, der

seine Höhenlage mit dem Flüssigkeitspegel des zu überwachenden

Messstoes verändert. Der Schaltzustand des Reed-Kontaktes kann

durch eine nachgeschaltete Steuereinrichtung ausgewertet und

weiterverarbeitet werden. Die Schaltfunktion kann durch Drehen des

Schwimmers um 180° in Öner oder Schließer umgekehrt werden.

180°

Der RLS-8000 ist für den horizontalen Einbau geeignet. Die Schaltfunkti-

on Schließer oder Öner, wie am Prozessanschluss gekennzeichnet,

kann durch eine halbe Umdrehung des Einschraubgewindes des

Schalters bestimmt werden.

DE

14317448.02 12/2019 EN/DE/FR/ES

WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

180°

23

Page 24

2. Aufbau und Funktion / 3. Sicherheit

2.2 Lieferumfang

■

Schwimmerschalter

■

Betriebsanleitung

Lieferumfang mit dem Lieferschein abgleichen.

DE

3. Sicherheit

3.1 Symbolerklärung

GEFAHR!

... weist auf eine unmittelbar gefährliche Situation hin, die

zum Tod oder zu schweren Verletzungen führt, wenn sie nicht

gemieden wird.

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin,

die zum Tod oder zu schweren Verletzungen führen kann,

wenn sie nicht gemieden wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin,

die zu geringfügigen oder leichten Verletzungen bzw. Sachund Umweltschäden führen kann, wenn sie nicht gemieden

wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informatio-

nen für einen ezienten und störungsfreien Betrieb hervor.

3.2 Bestimmungsgemäße Verwendung

Schwimmerschalter dienen ausschließlich der Füllstandsüberwachung

von üssigen Messstoen. Der Einsatzbereich ergibt sich aus den

technischen Leistungsgrenzen und Werkstoen.

24 WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 25

3. Sicherheit

■

Die Flüssigkeiten dürfen keine starken Verschmutzungen oder

Grobteile aufweisen und nicht zum Auskristallisieren neigen. Es

ist sicherzustellen, dass die messstoberührten Werkstoe des

Schwimmerschalters gegen den zu überwachenden Messsto

ausreichend beständig sind. Nicht geeignet für Dispersionen, abrasive Flüssigkeiten, hochviskose Medien und Farben.

■

Dieses Gerät ist nicht für den Einsatz in explosionsgefährdeten

Bereichen zugelassen!

■

Die in der Betriebsanleitung angegebenen Einsatzbedingungen sind

einzuhalten.

■

Gerät nicht in unmittelbarer Nähe einer Quelle eines Magnetfeldes

(Abstand min. 100 mm) betreiben.

■

Gerät nicht im Freien betreiben.

■

Gerät nicht in unmittelbarer Nähe von starken elektromagnetischen

Feldern oder in unmittelbarer Nähe von Einrichtungen betreiben, die

durch Magnetfelder beeinusst werden können (Abstand min. 1 m).

■

Gerät nicht in einer Höhe über 2.000 m betreiben.

■

Die Schwimmerschalter dürfen keinen starken mechanischen Belas-

tungen (Stoß, Verbiegen, Vibrationen) ausgesetzt werden. Bei Gefahr

mechanischer Belastungen muss der Schwimmerschalter durch eine

Schutzvorrichtung (z. B. Gehäuse) geschützt werden.

■

Die technischen Spezikationen in dieser Betriebsanleitung sind

einzuhalten. Eine unsachgemäße Handhabung oder ein Betreiben

des Gerätes außerhalb der technischen Spezikationen macht die

sofortige Stilllegung und Überprüfung durch einen autorisierten

WIKA-Servicemitarbeiter erforderlich.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen Verwendungszweck konzipiert und konstruiert und darf nur

dementsprechend verwendet werden.

DE

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer

Verwendung sind ausgeschlossen.

14317448.02 12/2019 EN/DE/FR/ES

WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

25

Page 26

3. Sicherheit

Das Gerät muss durch eine externe Sicherung abgesichert werden.

GEFAHR!

Körperverletzungen

Beim Arbeiten an Behältern besteht Vergiftungs- oder

DE

3.3 Fehlgebrauch

Als Fehlgebrauch gilt jede Verwendung, die die technischen Leistungs-

grenzen überschreitet oder mit den Werkstoen unverträglich ist.

Jede über die bestimmungsgemäße Verwendung hinausgehende oder

andersartige Benutzung gilt als Fehlgebrauch.

Dieses Gerät nicht in Sicherheits- oder in Not-Aus-Einrichtungen benutzen.

3.4 Verantwortung des Betreibers

Das Gerät wird im gewerblichen Bereich eingesetzt. Der Betreiber unter-

liegt daher den gesetzlichen Pichten zur Arbeitssicherheit.

Erstickungsgefahr.

▶

Arbeiten dürfen nur unter Anwendung geeigneter Personenschutzmaßnahmen (z. B. Atemschutzgerät, Schutzkleidung o. Ä.) durchgeführt werden.

WARNUNG!

Verletzungen durch Fehlgebrauch

Fehlgebrauch des Gerätes kann zu gefährlichen Situationen

und Verletzungen führen.

▶

Eigenmächtige Umbauten am Gerät unterlassen.

▶

Gerät nicht in explosionsgefährdeten Bereichen einsetzen.

Die Sicherheitshinweise dieser Betriebsanleitung, sowie die für den

Einsatzbereich des Gerätes gültigen Sicherheits-, Unfallverhütungs- und

Umweltschutzvorschriften einhalten.

26 WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 27

3. Sicherheit

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

■

dass das Bedienpersonal regelmäßig in allen zutreenden Fragen

von Arbeitssicherheit, Erste Hilfe und Umweltschutz unterwiesen

wird, sowie die Betriebsanleitung und insbesondere die darin enthaltenen Sicherheitshinweise kennt.

■

dass das Gerät gemäß der bestimmungsgemäßen Verwendung für

den Anwendungsfall geeignet ist.

■

dass nach Prüfung ein Fehlgebrauch des Gerätes ausgeschlossen

ist.

3.5 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation

Unsachgemäßer Umgang kann zu erheblichen Personen-

und Sachschäden führen.

▶

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur durch Fachpersonal nachfolgend beschriebener

Qualifikation durchführen lassen.

Fachpersonal

Das vom Betreiber autorisierte Fachpersonal ist aufgrund seiner

fachlichen Ausbildung, seiner Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezischen Vorschriften, geltenden Normen und Richtlinien in der Lage, die

beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu erkennen.

DE

14317448.02 12/2019 EN/DE/FR/ES

WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

27

Page 28

3. Sicherheit / 4. Transport, Verpackung, Lagerung

3.6 Beschilderung, Sicherheitskennzeichnungen

Typenschild (Beispiel)

DE

Typ

P# Erzeugnisnummer

S# Seriennummer

Elektrischer Anschluss

Vor Montage und Inbetriebnahme des Gerätes unbedingt die

Betriebsanleitung lesen!

4. Transport, Verpackung und Lagerung

4.1 Transport

Schwimmerschalter auf eventuell vorhandene Transportschäden unter-

suchen. Oensichtliche Schäden unverzüglich mitteilen.

VORSICHT!

Körperverletzungen und Sachschäden

Bei unsachgemäßem Transport können Sachschäden in

erheblicher Höhe entstehen.

▶

Symbole auf der Verpackung beachten.

▶

Packstücke vorsichtig behandeln.

28 WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 29

4. Transport ... / 5. Inbetriebnahme, Betrieb

4.2 Verpackung und Lagerung

Verpackung erst unmittelbar vor der Inbetriebnahme entfernen.

Zulässige Bedingungen am Lagerort:

Lagertemperatur: -25 … +80 °C (-13 … +176 °F)

5. Inbetriebnahme, Betrieb

■

Alle auf der Versandverpackung angegebenen Hinweise zum

Entfernen der Transportsicherungen beachten.

■

Den Schwimmerschalter vorsichtig aus der Verpackung entnehmen!

■

Beim Auspacken alle Teile auf äußerliche Beschädigungen überprüfen.

5.1 Montagevorbereitung

Funktionsprüfung

Vor der Montage kann der Schwimmerschalter wie unter

Kapitel 5.3 beschrieben angeschlossen und die Schaltpunkte manuell betätigt werden.

WARNUNG!

Körperverletzungen und Sachschäden

Ein Fehler bei der elektrischen Funktionsprüfung kann zu

einer Fehlfunktion der Anlage und dadurch zu Personenoder Sachschäden führen.

▶

Sicherstellen, dass die Funktionsprüfung keine unbeabsichtigten Prozesse startet.

▶

Funktionsprüfung nicht im laufenden Betrieb oder bei

aktiver Steuerung durchführen.

DE

Sicherstellen, dass die Dichtächen des Behälters bzw. des Schwimmerschalters sauber sind und keine mechanische Beschädigung aufweisen.

14317448.02 12/2019 EN/DE/FR/ES

WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

29

Page 30

5. Inbetriebnahme, Betrieb

5.2 Montage

■

Die im Rohrleitungsbau vorgeschriebenen Drehmomentwerte der

Schrauben einhalten.

■

Bei der Auswahl des Montagematerials (Dichtungen, Schrauben,

Unterlegscheiben und Muttern) die Prozessbedingungen beachten.

Die Eignung der Dichtung muss hinsichtlich Messsto und dessen

DE

Dämpfen gegeben sein.

■

Schwimmerschalter über Einschraubgewinde

einbauen.

■

Typ RLS-7000 ist nur für den vertikalen

Einbau, Typ RLS-8000 nur für den horizontalen Einbau geeignet.

■

Beim RLS-8000 den richtigen Einbau durch

die Pfeilrichtung am Schalter sicherstellen.

Typ RLS-8000

horizontaler Einbau

5.3 Elektrischer Anschluss

■

Der elektrische Anschluss darf nur durch qualiziertes Fachpersonal

erfolgen.

■

Die Belegung der Anschlüsse und die Schaltfunktionen sind auf dem

Anschlussschema am Gerät angegeben.

■

Die vorgesehenen Netzanschlussleitungen müssen für die größte

Stromaufnahme des Gerätes bemessen sein und IEC 227 oder

IEC 245 entsprechen.

■

Das Gerät über eine externe Sicherung für Netzanschluss (AC 230 V)

absichern.

Typ RLS-7000

vertikaler Einbau

30 WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 31

5. Inbetriebnahme, Betrieb

WARNUNG!

Körperverletzungen und Sachschäden

Fehler beim elektrischen Anschluss von Schwimmerschaltern können die Reed-Kontakte zerstören. Dies kann zu einer

Fehlfunktion der Anlage und dadurch zu Personen- oder

Sachschäden führen.

▶

Kein direkter Betrieb an Schaltungen mit induktiver Last.

▶

Kein direkter Betrieb an Schaltungen mit kapazitiver Last,

z. B. SPS, PLS oder Leitungslängen > 50 m.

▶

Kein Überschreiten der zulässigen Schaltleistung.

GEFAHR!

Körperverletzungen

Bei Schwimmerschaltern mit Anschlusskabel ohne Schutzleiteranschluss kann der Schalter im Fehlerfall spannungsführend sein. Bei Berührung können schwere Körperschäden

oder tödliche Verletzungen auftreten.

▶

Diese Schalter nur an Schutzkleinspannung nach

IEC 60364 (VDE0100) betreiben oder so montieren,

dass der Schwimmerschalter mit dem Potentialausgleich

elektrisch verbunden ist.

Elektrische Schutzklasse

Die Geräte werden je nach elektrischem Anschluss in Schutzklasse II

ausgeführt. Die zutreende Schutzklasse des elektrischen Anschlusses

bitte dem jeweiligen Datenblatt entnehmen.

Schutzklasse II:

Schutzisolierung, kein Schutzleiteranschluss

DE

14317448.02 12/2019 EN/DE/FR/ES

WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

31

Page 32

5. Inbetriebnahme, Betrieb

Anschluss bei induktiver Last

Bei induktiver Belastung sind die Schwimmerschalter durch Beschaltung

mit einem RC-Glied oder einer Freilaufdiode zu schützen.

Wechselspannung Gleichspannung

DE

S1

AC 24 ... 230 V

R

C

RC-Glied

siehe

Tabelle

RC-Glieder zur Schutzbeschaltung

RC-Glieder, je nach Betriebsspannung, ausschließlich entsprechend

untenstehender Tabelle verwenden. Andere als die hier aufgeführten

RC-Glieder führen zur Zerstörung des Reed-Schalters.

RC-Glieder für Reed-Kontakte 10 VA

Spannung Widerstand Kapazität RC-Glied-Typ

AC 24 V 100 Ω 0,33 μF A 3/24

AC 48 V 220 Ω 0,33 μF A 3/48

AC 115 V 470 Ω 0,33 μF A 3/115

AC 230 V 1.500 Ω 0,33 μF A 3/230

Anschluss bei kapazitiver Last

Strombegrenzung Wechselspannung

z. B. für elektronisches Zeitrelais

S1 R

+

AC 230 V

–

S

C

1

Relais

S1

+

DC 24 ... 230 V

–

RS = 220 Ω (für AC 230 V)

C₁ = innere Kapazität

Freilaufdiode, z. B.

1N4007

32 WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 33

5. Inbetriebnahme, Betrieb

Zur Erhöhung der Lebensdauer der Kontakte wird der

Betrieb an einem Kontaktschutzrelais empfohlen.

Anschlussbilder siehe Typenschild

5.4 Inbetriebnahme

Spannungsversorgung der angeschlossenen Steuerungseinrichtung

einschalten. Behälter füllen und die Schaltpunkte des Schwimmerschalters auf Funktion prüfen.

WARNUNG!

Körperverletzungen und Sachschäden

Ein Fehler bei der elektrischen Funktionsprüfung kann zu

einer Fehlfunktion der Anlage und dadurch zu Personenoder Sachschäden führen.

▶

Sicherstellen, dass die Funktionsprüfung keine unbeabsichtigten Prozesse startet.

▶

Funktionsprüfung nicht im laufenden Betrieb oder bei

aktiver Steuerung durchführen.

Zur Inbetriebnahme von Zubehör unbedingt die jeweilige Montage- und

Betriebsanleitung beachten.

DE

14317448.02 12/2019 EN/DE/FR/ES

WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

33

Page 34

6. Störungen

6. Störungen

In der folgenden Tabelle sind die häugsten Fehlerursachen

und erforderliche Gegenmaßnahmen aufgeführt.

DE

Störungen Ursachen Maßnahmen

Kein Signal /

falsche Schaltfunktion

Falsche Schaltfunktion NO/NC

Typ RLS-7000 Schwimmer falsch montiert Drehen des Schwimmers

Typ RLS-8000 Ausrichtung Schwimmer-

Schwimmerschalter lässt

sich nicht an der

vorgesehenen

Stelle am Behälter anbauen

34 WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

Behälterwandstärke zu dick Montagesituation prüfen

Schwimmer verklemmt Medieneignung prüfen,

Schwimmer schwimmt

nicht auf

Schalter schaltet ohne

Bewegung des Schwimmers

Elektrischer Anschluss

falsch

Feuchtigkeit in der

Elektronik

Kabel beschädigt Geräteaustausch

Reed-Kontakt defekt Geräteaustausch

schalter falsch

Prozessanschluss des

Schwimmerschalters passt

nicht zu dem Prozessanschluss des Behälters

Prozessanschluss am

Behälter defekt

Verunreinigungen am Schalter

reinigen

Dichte des Mediums zu

gering, Material- und Produktwahl prüfen

Fremdmagnetfeld abschirmen

siehe 5.3 „Elektrischer

Anschluss“

Belegung mit Hilfe des Anschlussbildes prüfen

Beständigkeit des Materials

prüfen

um 180°

Drehung des Gerätes um

½ Umdrehung (180°), gemäß

Kennzeichnung am Schalter

Umbau des Behälters;

Nacharbeiten des Gewindes

oder Austauschen der Befesti-

gungsmue

Nacharbeiten des Gewindes

oder Austauschen der Befesti-

gungsmue

14317448.02 12/2019 EN/DE/FR/ES

Page 35

6. Störungen

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Können Störungen mit Hilfe der aufgeführten Maßnahmen

nicht beseitigt werden, Gerät unverzüglich außer Betrieb

setzen.

▶

Sicherstellen, dass kein Druck mehr anliegt und gegen

versehentliche Inbetriebnahme schützen.

▶

Kontakt mit dem Hersteller aufnehmen.

▶

Bei notwendiger Rücksendung die Hinweise unter Kapitel

8.2 „Rücksendung“ beachten.

DE

14317448.02 12/2019 EN/DE/FR/ES

WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

35

Page 36

7. Wartung und Reinigung

7. Wartung und Reinigung

7.1 Wartung

Die Schwimmerschalter arbeiten bei bestimmungsgemäßem Gebrauch

wartungsfrei. Sie sind jedoch im Rahmen der regelmäßigen Wartung

einer Sichtkontrolle zu unterziehen und in die Druckprüfung des Behäl-

DE

ters mit einzubeziehen.

GEFAHR!

Körperverletzungen

Beim Arbeiten an Behältern besteht Vergiftungs- oder Erstickungsgefahr.

▶

Arbeiten dürfen nur unter Anwendung geeigneter Personenschutzmaßnahmen (z. B. Atemschutzgerät, Schutzkleidung o. Ä.) durchgeführt werden.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

7.2 Reinigung

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Eine unsachgemäße Reinigung führt zu Körperverletzungen, Sach- und Umweltschäden und zur Beschädigung des

Gerätes. Messstoreste im ausgebauten Gerät können zur

Gefährdung von Personen, Umwelt und Einrichtung führen.

▶

Ausgebautes Gerät spülen bzw. säubern.

▶

Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

▶

Keine aggressiven Reinigungmittel verwenden.

▶

Keine harten und spitzen Gegenstände zur Reinigung

verwenden.

1. Vor der Reinigung das Gerät ordnungsgemäß vom Prozess und der

Stromversorgung trennen.

2. Das Gerät vorsichtig mit einem feuchten Tuch reinigen.

3. Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen!

36 WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 37

8. Demontage, Rücksendung und Entsorgung

8. Demontage, Rücksendung und Entsorgung

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch

Messstoreste

Messstoreste im ausgebauten Gerät können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

▶

Ausgebautes Gerät spülen bzw. säubern, um Personen

und Umwelt vor Gefährdung durch anhaftende Messstoffreste zu schützen.

8.1 Demontage

Messgerät nur im drucklosen und spannungsfreiem Zustand demontieren!

8.2 Rücksendung

Ausgebauten Schwimmerschalter vor der Rücksendung spülen bzw.

säubern, um Mitarbeiter und Umwelt vor Gefährdung durch anhaftende

Messstoreste zu schützen.

Hinweise zur Rücksendung benden sich in der Rubrik

„Service“ auf unserer lokalen Internetseite.

8.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den

landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften

umweltgerecht entsorgen.

DE

Nicht mit dem Hausmüll entsorgen. Für eine geordnete

Entsorgung gemäß nationaler Vorgaben sorgen.

14317448.02 12/2019 EN/DE/FR/ES

WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

37

Page 38

9. Technische Daten

9. Technische Daten

Technische Daten

Schaltleistung AC 230 V / 10 VA / 0,5 A / 50 ... 60 Hz

DE

Genauigkeit ≤ 3 mm Schaltpunktgenauigkeit inkl. Hysterese, Nichtwieder-

Zulässige Temperaturen

■

Messsto

■

Umgebung

■

Lagerung

Betriebsdruck ≤ 4 bar [≤ 58,0 psi]

Dichte Polypropylen (PP):

Überspannungskategorie

Verschmutzungsgrad

Weitere technische Daten siehe WIKA-Datenblätter LM 50.11, LM 50.12

und Bestellunterlagen.

DC 230 V / 10 W / 0,5 A

holbarkeit

Polypropylen (PP):

-25 … +80 °C [-13 … +176 °F]

-25 … +80 °C [-13 … +176 °F]

-25 … +80 °C [-13 … +176 °F]

≥ 700 kg/m³ [43,7 lbs/ft³]

II

2

Polyamid PA6.6:

-25 … +100 °C [-13 … +212 °F]

-25 … +100 °C [-13 … +212 °F]

-25 … +80 °C [-13 … +176 °F]

Polyamid PA6.6:

≥ 750 kg/m³ [46,8 lbs/ft³]

38 WIKA Betriebsanleitung Typen RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 39

Sommaire

Sommaire

1. Généralités 40

2. Conception et fonction 41

3. Sécurité 42

4. Transport, emballage et stockage 47

5. Mise en service, utilisation 47

6. Dysfonctionnements 52

7. Entretien et nettoyage 54

8. Démontage, retour et mise au rebut 55

9. Spécications 56

Déclarations de conformité disponibles sur www.wika.fr.

14317448.02 12/2019 EN/DE/FR/ES

WIKA mode d‘emploi types RLS-7000, RLS-8000

FR

39

Page 40

1. Généralités

1. Généralités

■

Les contacts à otteur décrits dans ce mode d'emploi sont conçus

et fabriqués selon les dernières technologies en vigueur. Tous les

composants sont soumis à des exigences environnementales et de

qualité strictes durant la fabrication. Nos systèmes de gestion sont

certiés selon ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant

FR

l'utilisation de l'instrument. Il est possible de travailler en toute

sécurité avec ce produit en respectant toutes les consignes de

sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les

accidents et les prescriptions générales de sécurité en vigueur pour

le domaine d'application de l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à

proximité immédiate de l'instrument et accessible à tout moment

pour le personnel qualié. Coner le mode d'emploi à l'utilisateur ou

propriétaire ultérieur de l'instrument.

■

Le personnel qualié doit, avant de commencer toute opération, avoir

lu soigneusement et compris le mode d'emploi.

■

Les conditions générales de vente mentionnées dans les documents

de vente s'appliquent.

■

Sous réserve de modications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiche technique correspondante : LM 50.11 (type RLS-7000)

- Conseiller applications : Tel. : 0 820 951010

LM 50.12 (type RLS-8000)

+33 1 787049-46

Fax : 0 891 035891

info@wika.fr

(0,15 €/min)

(0,35 €/min)

40 WIKA mode d‘emploi types RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 41

2. Conception et fonction

2. Conception et fonction

2.1 Description fonctionnelle

Le type RLS-7000 fonctionne d'après le principe du otteur avec

transmission magnétique et convient pour une installation verticale. Un

contact reed intégré dans le tube de guidage est actionné par le champ

magnétique d'un aimant permanent lorsqu'un niveau de commutation

prédéni est atteint. L'aimant permanent est situé dans un otteur qui

change de position avec le niveau du uide qu'il surveille. Le statut de

commutation du contact reed peut être évalué et traité par un dispositif

de contrôle connecté. La fonction de commutation peut être changée

entre normalement fermé et normalement ouvert en pivotant le otteur

de 180°.

180°

Le RLS-8000 convient pour un montage horizontal. La fonction de

commutation normalement ouvert et normalement fermé, comme

indiqué sur le raccord process, peut être réglée par un demi-tour sur le

raccord leté du contact.

FR

14317448.02 12/2019 EN/DE/FR/ES

WIKA mode d‘emploi types RLS-7000, RLS-8000

180°

41

Page 42

2. Conception et fonction / 3. Sécurité

2.2 Détail de la livraison

■

Contact à otteur

■

Mode d'emploi

Comparer le détail de la livraison avec le bordereau de livraison.

3. Sécurité

FR

3.1 Explication des symboles

DANGER !

... indique une situation dangereuse pouvant entraîner la

mort ou des blessures graves si elle n'est pas évitée.

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles

de provoquer la mort ou des blessures graves si elle n'est

pas évitée.

ATTENTION !

… indique une situation potentiellement dangereuse et

susceptible de provoquer de légères blessures ou des

dommages pour le matériel et pour l'environnement si elle

n'est pas évitée.

Information

... met en exergue les conseils et recommandations utiles

de même que les informations permettant d'assurer un

fonctionnement ecace et normal.

3.2 Utilisation conforme à l'usage prévu

Les contacts à otteur sont utilisés exclusivement pour surveiller les

niveaux de liquides dans des cuves. Le domaine d'application est déni

par les limites techniques de performance et les matériaux.

42 WIKA mode d‘emploi types RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 43

3. Sécurité

■

Les liquides doivent être exempts de toute contamination importante

ou de particules en suspension grossières et ne doivent pas avoir

tendance à cristalliser. Assurez-vous que les matériaux en contact

avec le uide du contact à otteur soient susamment résistants

au uide qui est contrôlé. Ne convient pas aux milieux dispersés,

liquides abrasifs, uides hautement visqueux.

■

Cet instrument n'est pas certié pour être utilisé en zones explosives !

■

Les conditions de fonctionnement contenues dans le mode d'emploi

doivent être respectées.

■

Ne pas utiliser l‘instrument à proximité directe d‘une source de

champ magnétique (distance min. 100 mm).

■

Ne pas utiliser l‘instrument à l‘extérieur.

■

Ne pas utiliser l'instrument à proximité immédiate de champs

électromagnétiques puissants ou d'appareils pouvant être perturbés

par des champs magnétiques (distance min. 1 m).

■

Ne pas utiliser l‘instrument à une altitude supérieure à 2.000 m.

■

Les contacts à otteur ne doivent pas être exposés à de fortes

contraintes mécaniques (impacts, exions, vibrations). En cas de

danger dû à des contraintes mécaniques, le contact à otteur doit

être protégé par un dispositif de protection (un boîtier par exemple).

■

Les spécications techniques mentionnées dans ce mode d'emploi

doivent être respectées. En cas d'utilisation non conforme ou

de fonctionnement de l'instrument en dehors des spécications

techniques, un arrêt et contrôle doivent être immédiatement eectués

par un collaborateur autorisé du service de WIKA.

Ces instruments sont conçus et construits exclusivement pour une

utilisation conforme à l'usage prévu décrit ici, et ne doivent être utilisés

qu'à cet eet.

FR

Aucune réclamation ne peut être recevable en cas d'utilisation non

conforme à l'usage prévu.

14317448.02 12/2019 EN/DE/FR/ES

WIKA mode d‘emploi types RLS-7000, RLS-8000

43

Page 44

3. Sécurité

L‘instrument doit être protégé par un fusible externe.

DANGER !

Blessures physiques

Le travail sur les conteneurs implique un danger

d'intoxication et de suocation.

▶

Aucun travail ne peut être effectué, sauf en prenant des

mesures de protection personnelle appropriées (par

FR

3.3 Utilisation inappropriée

On dénit un usage impropre comme étant toute application qui excède

les limites techniques de performance ou étant incompatible avec les

matériaux.

Toute utilisation diérente ou au-delà de l'utilisation prévue est

considérée comme inappropriée.

Ne pas utiliser cet instrument dans des dispositifs de sécurité ou d'arrêt

d'urgence.

3.4 Responsabilité de l'opérateur

L'instrument est prévu pour un usage dans le domaine industriel.

L'opérateur est de ce fait responsable des obligations légales en matière

de sécurité du travail.

Les instructions de sécurité de ce mode d'emploi comme les

réglementations liées à la sécurité, à la prévention des accidents et à la

protection de l'environnement pour le domaine d'application doivent être

respectées.

44 WIKA mode d‘emploi types RLS-7000, RLS-8000

exemple appareil de protection respiratoire, vêtements de

protection etc.).

AVERTISSEMENT !

Blessures causées par une utilisation inappropriée

Une utilisation inappropriée peut conduire à des situations

dangereuses et à des blessures.

▶

S'abstenir de modifications non autorisées sur l'instrument

▶

Ne pas utiliser l'instrument en zone explosive.

14317448.02 12/2019 EN/DE/FR/ES

Page 45

3. Sécurité

An de travailler en toute sécurité sur l'instrument, la société exploitante

doit s'assurer

■

que le personnel de service soit formé à intervalles réguliers sur tous

les sujets concernant la sécurité du travail, les premiers secours et

la protection de l'environnement et qu'il connaît le mode d'emploi et

particulièrement les consignes de sécurité contenues dans celui-ci.

■

que l'instrument est adapté à l'application en respect de l'usage

prévu de l'instrument.

■

qu'à la suite des essais, une utilisation impropre de l'instrument est

exclue.

3.5 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante

Une utilisation non conforme peut entraîner d'importants

dommages corporels et matériels.

▶

Les opérations décrites dans ce mode d'emploi ne

doivent être effectuées que par un personnel ayant la

qualification décrite ci-après.

Personnel qualié

Le personnel qualié, autorisé par l'opérateur, est, en raison de sa

formation spécialisée, de ses connaissances dans le domaine de

l'instrumentation de mesure et de régulation et de son expérience,

de même que de sa connaissance des réglementations nationales et

des normes en vigueur, en mesure d'eectuer les travaux décrits et

d'identier de façon autonome les dangers potentiels.

FR

14317448.02 12/2019 EN/DE/FR/ES

WIKA mode d‘emploi types RLS-7000, RLS-8000

45

Page 46

3. Sécurité / 4. Transport, emballage et stockage

3.6 Etiquetage, marquages de sécurité

Plaque signalétique (exemple)

FR

Type

P# numéro produit

S# numéro de série

Raccordement électrique

Lire impérativement le mode d'emploi avant le montage et la

mise en service de l'instrument !

4. Transport, emballage et stockage

4.1 Transport

Vérier s'il y a des dégâts sur le contact à otteur liés au transport.

Communiquer immédiatement les dégâts constatés.

ATTENTION !

Blessures physiques et dommages matériels

Un transport inapproprié peut donner lieu à des dommages

importants.

▶

Observer les symboles présents sur l'emballage.

▶

Manipuler avec soin les marchandises emballées.

46 WIKA mode d‘emploi types RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 47

4. Transport, ... / 5. Mise en service, utilisation

4.2 Emballage et stockage

N'enlever l'emballage qu'avant la mise en service.

Conditions admissibles sur le lieu de stockage :

Température de stockage : -25 … +80 °C (-13 … +176 °F)

5. Mise en service, utilisation

■

Observez toutes les instructions données sur l'emballage de livraison

concernant le retrait des dispositifs de sécurité pour le transport.

■

Sortir avec précaution le contact à otteur de l'emballage !

■

Lors du déballage, vérier si les composants ne présentent aucune

détérioration externe visible.

5.1 Préparation de l'installation

Contrôle de fonctionnement

Avant l'installation, le contact à otteur peut être branché

comme décrit au chapitre 5.3 et les points de commutation

peuvent être testés à la main.

AVERTISSEMENT !

Blessures physiques et dommages matériels

Une erreur de vérication de fonctionnement électrique peut

conduire à un dysfonctionnement sur l'installation et conduire

ainsi à des blessures du personnel ou des dommages

matériels.

▶

Assurez-vous que la vérification de fonctionnement ne

lance pas des processus inopinément.

▶

Ne pas effectuer un test de fonctionnement pendant que

l'installation tourne et n'est pas consignée.

FR

S'assurer que les surfaces d'étanchéité de la cuve ou du contact à

otteur sont propres et ne présentent aucun dommage mécanique.

14317448.02 12/2019 EN/DE/FR/ES

WIKA mode d‘emploi types RLS-7000, RLS-8000

47

Page 48

5. Mise en service, utilisation

5.2 Installation

■

Observer les valeurs de couple des vis spéciées dans les normes

de tuyauterie.

■

Concernant le choix du matériel d'installation (joints d'étanchéité, vis,

rondelles et écrous), tenez compte des conditions de process. Il faut

considérer l'adéquation du joint d'étanchéité par rapport au uide et

à ses vapeurs.

■

Installer le contact à otteur au moyen du raccord leté.

■

Le type RLS-7000 convient seulement pour

FR

un montage vertical, et le type RLS-8000

seulement pour un montage horizontal.

■

Avec le RLS-8000, assurer l'installation

correcte indiquée par la direction de la èche

sur le contact.

Type RLS-8000

montage horizontal

5.3 Raccordement électrique

■

Les travaux de raccordement électrique ne doivent être eectués que

par des personnels qualiés.

■

Les détails de connexion et les fonctions de commutation sont

indiqués sur le diagramme de connexion.

■

Les câbles de raccordement au réseau prévus doivent être

dimensionnés pour la plus grande alimentation de courant de

l'instrument et correspondre à CEI 227 ou CEI 245.

■

Protéger l‘instrument au moyen d‘un fusible externe pour le

raccordement secteur (230 VAC).

Type RLS-7000

montage vertical

48 WIKA mode d‘emploi types RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 49

5. Mise en service, utilisation

AVERTISSEMENT !

Blessures physiques et dommages matériels

Des erreurs de raccordement électrique des contacts

à otteur peuvent détruire les contacts reed. Ceci peut

conduire à un dysfonctionnement sur l'installation et conduire

ainsi à des blessures du personnel ou des dommages

matériels.

▶

Pas de fonctionnement direct dans des circuits avec des

charges inductives.

▶

Pas de fonctionnement direct dans des circuits avec

des charges capacitives, par exemple PLC, PCS ou des

longueurs de câble > 50 m.

▶

Ne pas dépasser le pouvoir de coupure admissible.

DANGER !

Blessures physiques

Avec des contacts à otteur avec câble de connexion sans

conducteur de protection, il est possible que le détecteur soit

sous tension en cas de dysfonctionnement. Tout contact peut

provoquer des blessures physiques pouvant être mortelles.

▶

Ces contacts ne peuvent être manipulés que sous

tension extra-basse de sécurité en conformité avec

CEI 60364 (VDE0100) ou doivent être montés de sorte

que le contact à flotteur soit raccordé électriquement à la

liaison équipotentielle.

Classe de protection électrique

En fonction du raccordement électrique, les instruments sont conçus

en classe de protection II. La classe de protection appropriée du

raccordement électrique est donnée dans chaque che technique.

Classe de protection II :

Isolation protectrice, pas de conducteur de protection

FR

14317448.02 12/2019 EN/DE/FR/ES

WIKA mode d‘emploi types RLS-7000, RLS-8000

49

Page 50

5. Mise en service, utilisation

Connexion avec charge inductive

Avec des charges inductives, les contacts à otteur doivent être

protégés par un élément RC ou une diode de roue libre.

Tension AC Tension DC

S1

Elément

RC, voir

tableau

FR

AC 24 ... 230 V

R

C

Eléments de protection RC

En fonction de la tension de travail, utiliser des éléments RC

exclusivement en conformité avec le tableau ci-dessous. Les éléments

RC autres que ceux spéciés ici conduiraient à la destruction du contact

reed.

Eléments RC pour contacts reed 10 VA

Tension Résistance Capacité Type d'élément RC

24 VAC 100 Ω 0,33 μF A 3/24

48 VAC 220 Ω 0,33 μF A 3/48

115 VAC 470 Ω 0,33 μF A 3/115

230 VAC 1.500 Ω 0,33 μF A 3/230

Connexion avec charge capacitive

Limitation de courant de tension AC

par exemple pour un relais temporisé électronique

S1 R

+

AC 230 V

–

S

C

1

Relais

S1

+

DC 24 ... 230 V

–

RS = 220 Ω (pour 230 VAC)

C₁ = capacité interne

Diode

de roue

libre, par

exemple

1N4007

50 WIKA mode d‘emploi types RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 51

5. Mise en service, utilisation

Pour augmenter la durée de fonctionnement des contacts,

nous recommandons un fonctionnement avec un relais de

protection de contact.

Schémas de raccordement, voir plaque signalétique

5.4 Mise en service

Allumer la tension d'alimentation du dispositif de contrôle connecté.

Remplir la cuve et vérier les points de commutation du contact à otteur

pour voir s'ils fonctionnent.

AVERTISSEMENT !

Blessures physiques et dommages matériels

Une erreur de vérication de fonctionnement électrique peut

conduire à un dysfonctionnement sur l'installation et conduire

ainsi à des blessures du personnel ou des dommages

matériels.

▶

Assurez-vous que la vérification de fonctionnement ne

lance pas des processus inopinément.

▶

Ne pas effectuer un test de fonctionnement pendant que

l'installation tourne et n'est pas consignée.

Toujours respecter le manuel d'installation et le mode d'emploi des

accessoires avant de les mettre en service.

FR

14317448.02 12/2019 EN/DE/FR/ES

WIKA mode d‘emploi types RLS-7000, RLS-8000

51

Page 52

6. Dysfonctionnements

6. Dysfonctionnements

Le tableau suivant contient les causes de

dysfonctionnements les plus fréquentes et les contremesures nécessaires.

Dysfonctionnements

FR

Pas de signal /

fonction de

commutation

incorrecte

Fonction de

commutation NO/NF

incorrecte

Type RLS-7000 Flotteur mal installé Tourner le otteur de 180°

Type RLS-8000 Direction incorrecte du

Raisons Mesures

Paroi de la cuve trop

épaisse

Flotteur bloqué Vérier si le uide convient,

Le otteur ne otte pas La densité du uide est trop

Le contact commute sans

que le otteur ne bouge

Raccordement électrique

incorrect

Humidité dans

l'électronique

Câble endommagé Remplacement de l'appareil

Contact reed défectueux Remplacement de l'appareil

contact à otteur

Vérier le montage

nettoyer pour éliminer la

contamination présente sur

le contact

basse, vérier le choix du

matériau et du produit

Isoler d'un champ

magnétique extérieur

voir 5.3 “Raccordement

électrique”

Vérier l'aectation à l'aide

du schéma de raccordement

Vérier la résistance

chimique du matériau

Tourner l'instrument d'un

demi-tour (180°) comme sur

le marquage du contact

52 WIKA mode d‘emploi types RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 53

6. Dysfonctionnements

Dysfonctionnements

Le contact à otteur

ne peut pas être

installé à l'endroit

prévu sur la cuve

ATTENTION !

Blessures physiques, dommages aux équipements et à

l'environnement

Si les défauts ne peuvent pas être éliminés au moyen des

mesures listées, l'instrument doit être mis hors service

immédiatement.

▶

Assurez-vous qu'il n'y a plus aucune pression présente et

empêchez toute remise en marche accidentelle.

▶

Contacter le fabricant.

▶

S'il est nécessaire de retourner l'instrument au fabricant,

prière de respecter les indications mentionnées au

chapitre 8.2 “Retour”.

Raisons Mesures

Le raccord process du

contact à otteur ne

correspond pas au raccord

process de la cuve.

Raccord process

défectueux sur la cuve

Modication de la cuve ;

Refaire le letage ou

remplacer la connexion

vissée

Refaire le letage ou

remplacer la connexion

vissée

FR

14317448.02 12/2019 EN/DE/FR/ES

WIKA mode d‘emploi types RLS-7000, RLS-8000

53

Page 54

7. Entretien et nettoyage

7. Entretien et nettoyage

7.1 Entretien

Les contacts à otteur fonctionnent sans entretien lorsqu'ils sont utilisés

correctement. Ils doivent pourtant être soumis à une inspection visuelle

dans le cadre d'un entretien régulier et être inclus dans le test de

pression de cuve.

FR

Les réparations ne doivent être eectuées que par le fabricant.

7.2 Nettoyage

DANGER !

Blessures physiques

Le travail sur les conteneurs implique un danger

d'intoxication et de suocation.

▶

Aucun travail ne peut être effectué, sans prendre des

mesures de protection personnelle appropriées (par

exemple appareil de protection respiratoire, vêtements de

protection etc.).

ATTENTION !

Blessures physiques, dommages aux équipements et à

l'environnement

Un nettoyage inapproprié peut conduire à des blessures

physiques, à des dommages aux équipements ou à

l'environnement et à des dommages sur l'instrument. Les

restes de uides se trouvant dans les instruments démontés

peuvent mettre en danger les personnes, l'environnement

ainsi que l'installation.

▶

Rincer ou nettoyer avec des moyens appropriés

l'instrument qui a été démonté.

▶

Des mesures de sécurité suffisantes doivent être prises.

▶

Ne pas utiliser de détergents agressifs.

▶

Ne pas utiliser d'objets pointus ou durs pour le nettoyage.

1. Avant le nettoyage, débrancher correctement l'instrument du

processus et de l'alimentation.

2. Nettoyer l'instrument soigneusement avec un chion humide.

3. Eviter tout contact des raccords électriques avec l'humidité !

54 WIKA mode d‘emploi types RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 55

8. Démontage, retour et mise au rebut

8. Démontage, retour et mise au rebut

AVERTISSEMENT !

Blessures physiques et dommages aux équipements et

à l'environnement liés aux résidus de uides

Les restes de uides se trouvant dans les instruments

démontés peuvent mettre en danger les personnes,

l'environnement ainsi que l'installation.

▶

Laver et décontaminer l'instrument démonté afin de

protéger les personnes et l'environnement contre le

danger lié aux résidus de fluides.

8.1 Démontage

Déconnecter l'instrument de mesure seulement si le système a été mis

hors pression et l'alimentation électrique a été coupée !

8.2 Retour

Lavez ou nettoyez le contact à otteur démonté avant de le retourner

an de protéger le personnel et l‘environnement contre le danger lié aux

résidus de uides adhérents.

Des informations relatives à la procédure de retour sont

disponibles sur notre site Internet à la rubrique “Services”.

8.3 Mise au rebut

Une mise au rebut inadéquate peut entraîner des dangers pour

l'environnement.

Eliminer les composants des instruments et les matériaux d'emballage

conformément aux prescriptions nationales pour le traitement et l'élimination

des déchets et aux lois de protection de l'environnement en vigueur.

FR

Ne pas mettre au rebut avec les ordures ménagères.

Assurer une mise au rebut correcte en conformité avec les

régulations nationales.

14317448.02 12/2019 EN/DE/FR/ES

WIKA mode d‘emploi types RLS-7000, RLS-8000

55

Page 56

9. Spécications

9. Spécications

Spécications

Pouvoir de

coupure

Précision Incertitude de point de seuil ≤ 3 mm y compris hystérésis,

Températures

FR

admissibles

■

Fluide

■

Ambiante

■

Stockage

Pression de

service

Densité Polypropylène (PP) :

Catégorie de

surtension

Niveau de

colmatage

Pour de plus amples spécications, voir la che technique WIKA

LM 50.11, LM 50.12 et la documentation de commande.

AC 230 V / 10 VA / 0,5 A / 50 ... 60 Hz

DC 230 V / 10 W / 0,5 A

non-répétabilité

Polypropylène (PP) :

-25 … +80 °C [-13 … +176 °F]

-25 … +80 °C [-13 … +176 °F]

-25 … +80 °C [-13 … +176 °F]

≤ 4 bar [≤ 58,0 psi]

≥ 700 kg/m³ [43,7 lbs/ft³]

II

2

Polyamide PA6.6 :

-25 … +100 °C [-13 … +212 °F]

-25 … +100 °C [-13 … +212 °F]

-25 … +80 °C [-13 … +176 °F]

Polyamide PA6.6 :

≥ 750 kg/m³ [46,8 lbs/ft³]

56 WIKA mode d‘emploi types RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 57

Contenido

Contenido

1. Información general 58

2. Diseño y función 59

3. Seguridad 60

4. Transporte, embalaje y almacenamiento 65

5. Puesta en servicio, funcionamiento 65

6. Errores 70

7. Mantenimiento y limpieza 72

8. Desmontaje, devolución y eliminación de

residuos 73

9. Datos técnicos 74

Declaraciones de conformidad puede encontrar en www.wika.es.

ES

14317448.02 12/2019 EN/DE/FR/ES

Manual de instrucciones WIKA modelos RLS-7000, RLS-8000

57

Page 58

1. Información general

1. Información general

■

Los interruptores de otador descritos en el manual de instrucciones

están diseñados y fabricados conforme al estado actual de la

técnica. Todos los componentes están sujetos a rigurosos criterios de

calidad y medio ambiente durante la producción. Nuestros sistemas

de gestión están certicados según ISO 9001 e ISO 14001.

■

Este manual de instrucciones proporciona indicaciones importantes

acerca del manejo del instrumento. Para un trabajo seguro, es

imprescindible cumplir con todas las instrucciones de seguridad y

manejo indicadas.

ES

■

Cumplir siempre las normativas sobre la prevención de accidentes

y las normas de seguridad en vigor en el lugar de utilización del

instrumento.

■

El manual de instrucciones es una parte integrante del instrumento

y debe guardarse en la proximidad del mismo para que el personal

especializado pueda consultarlo en cualquier momento. Entregar

el manual de instrucciones al usuario o propietario siguiente del

instrumento.

■

El personal especializado debe haber leído y entendido el manual de

instrucciones antes de comenzar cualquier trabajo.

■

Se aplican las condiciones generales de venta incluidas en la

documentación de venta.

■

Modicaciones técnicas reservadas.

■

Para obtener más informaciones consultar:

- Página web: www.wika.es

- Hoja técnica correspondiente: LM 50.11 (modelo RLS-7000)

- Servicio técnico: Tel.: +34 933 938 630

LM 50.12 (modelo RLS-8000)

Fax: +34 933 9386-66

info@wika.es

58 Manual de instrucciones WIKA modelos RLS-7000, RLS-8000

14317448.02 12/2019 EN/DE/FR/ES

Page 59

2. Diseño y función

2. Diseño y función

2.1 Descripción del funcionamiento

El modelo RLS-7000 funciona según el principio de otador con

transmisión magnética y es adecuado para la instalación vertical. Un

contacto Reed montado en el tubo guía se acciona por el campo

magnético de un imán permanente al alcanzar un punto de conmutación

predeterminado. El imán permanente se encuentra en un otador que

cambia su posición en altura en función del nivel del medio a supervisar.

Un dispositivo de control permite la evaluación y el procesamiento

posterior del estado de conmutación del contacto Reed. La función de

conmutación puede invertirse a normalmente cerrada o normalmente

abierta girando el otador 180°.

180°

El RLS-8000 es adecuado para la instalación horizontal. La función de

conmutación normalmente abierta o normalmente cerrada, como se

indica en la conexión de proceso, puede determinarse girando media

vuelta la rosca del interruptor.

ES

14317448.02 12/2019 EN/DE/FR/ES

Manual de instrucciones WIKA modelos RLS-7000, RLS-8000

180°

59

Page 60

3. Seguridad

2.2 Alcance del suministro

■

Interruptor de otador

■

Manual de instrucciones

Comparar mediante el albarán si se han entregado todas las piezas.

3. Seguridad

3.1 Explicación de símbolos

¡PELIGRO!

ES

... señala una situación inmediatamente peligrosa que causa

la muerte o lesiones graves si no se evita.

¡ADVERTENCIA!

... indica una situación probablemente peligrosa que puede

causar la muerte o lesiones graves si no se la evita.

¡CUIDADO!

... indica una situación probablemente peligrosa que puede

causar lesiones leves o medianas, o daños materiales y

medioambientales, si no se la evita.

Información

... destaca consejos y recomendaciones útiles así como