Operating instructions

Betriebsanleitung

Mode d'emploi

Manual de instrucciones

OEM pressure switch with display, model PSD-4-ECO

OEM-Druckschalter mit Anzeige, Typ PSD-4-ECO

Pressostat OEM avec afficheur, type PSD-4-ECO

Presostato con display OEM, modelo PSD-4-ECO

OEM pressure switch with display, model PSD-4-ECO

EN

DE

FR

ES

EN

Operating instructions model PSD-4-ECO Page 3 - 36

DE

Betriebsanleitung Typ PSD-4-ECO Seite 37 - 70

FR

Mode d‘emploi type PSD-4-ECO Page 71 - 104

ES

Manual de instrucciones modelo PSD-4-ECO Página 105 - 139

© 07/2019 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

Contents

Contents

1. General information 4

2. Design and function 5

3. Safety 7

4. Transport, packaging and storage 11

5. Commissioning, operation 11

6. Faults 22

7. Maintenance and cleaning 25

8. Dismounting, return and disposal 26

9. Specications 28

Declarations of conformity can be found online at www.wika.com

EN

14247391.01 07/2019 EN/DE/FR/ES

3WIKA operating instructions, model PSD-4-ECO

1. General information

1. General information

■

The instrument described in the operating instructions has been designed and manufactured using state-of-theart technology. All components are subject to stringent quality and environmental criteria during production. Our

EN

management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that

all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument’s range

of use.

■

The operating instructions are part of the product and must be kept in the immediate vicinity of the instrument and

readily accessible to skilled personnel at any time. Pass the operating instructions on to the next operator or owner

of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PE 81.69

- Application consultant: Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

4 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

2. Design and function

2. Design and function

2.1 Scope of delivery

■

Pressure switch

■

Operating instructions

Cross-check scope of delivery with delivery note.

2.2 Overview

EN

Down button [▼]

Digital display

Status display, switching outputs

Electrical connection

Up button [▲]

Confirmation button [◊]

Stop mark, rotation limitation

Process connection, spanner flats

Process connection, thread

14247391.01 07/2019 EN/DE/FR/ES

5WIKA operating instructions, model PSD-4-ECO

2. Design and function

2.3 Display and operating unit

Status of switching output 1

4-digit LED display

■

EN

Display of pressure value

■

Display of menu item

■

Display of parameter

Display mode

▶

Short press

Display of unit

▶

Long press

Display of the set parameters,

see chapter 5.7 “Parameters”

Programming mode

▶

Short press

Menu down

Parameter value down

(step-wise)

▶

Long press

Menu down (fast)

Parameter value down (fast)

Display mode

▶

Short press

Display of unit

Programming mode

▶

Short press

Selection of menu item

Conrmation of input

Status of switching output 2

(optional)

Display mode

▶

Short press

Display of unit

▶

Long press

Jumping into the programming

mode

Programming mode

▶

Short press

Menu up

Parameter value up (step-wise)

▶

Long press

Menu up (fast)

Parameter value up (fast)

6 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

3. Safety

3. Safety

3.1 Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries or damage to property or the

environment, if not avoided.

WARNING!

... indicates a potentially dangerous situation that can result in burns, caused by hot surfaces or liquids,

if not avoided.

Information

... points out useful tips, recommendations and information for ecient and trouble-free operation.

3.2 Intended use

The instrument has been designed and built solely for the intended use described here, and may only be used

accordingly.

The manufacturer shall not be liable for claims of any type based on operation contrary to the intended use.

Intended use

The model PSD-4-ECO pressure switch is used for the switching of circuits as a function of the measured pressure

via a PNP or NPN output signal. In addition, the pressure value can be output to appropriate read-out units as a

standardised analogue signal (4 ... 20 mA or DC 0 ... 10 V) or digital signal (IO-Link 1.1). The switching conditions can

be programmed directly at the pressure switch or by means of IO-Link 1.1 (switch and reset points, normally closed/

normally open, ...). Via the dierent display elements of the pressure switch, switching states and pressure values can

be read on site.

EN

14247391.01 07/2019 EN/DE/FR/ES

7WIKA operating instructions, model PSD-4-ECO

3. Safety

The model PSD-4-ECO has been developed for the pressure measurement of non-hazardous uids, liquids and gases

(classication in accordance with Directive 2014/68/EU Article 13, Regulation (EC) No. 1272/2008, or GHS

are mainly used for cooling, lubrication, cleaning or power transmission in industrial machines.

WARNING!

Physical injuries and damage to property and the environment through exceeding the perfor-

EN

Special versions for oil and grease-free applications, as well as for use with oxygen (dangerous uid according to

Directive 2014/68/EU Article 13, Regulation (EC) No. 1272/2008, or GHS

1) Globally Harmonized System of Classication, Labelling and Packaging of Chemicals

The (dis-)mounting, installation, parameterisation and maintenance of the model PSD-4 ECO in industrial

environments absolutely requires suitably skilled personnel in accordance with chapter 3.3. “Personnel qualication”.

mance limits

Exceeding the performance limits can destroy the instrument and lead to danger in the end-use

application.

▶

Only use the instrument in applications that lie within its technical performance limits. → For

performance limits, such as derating (maximum current consumption at a corresponding medium

temperature), see chapter 9 “Specifications”

▶

Any permanent operation in the overload range is not permitted. Above the highest operating

pressure permitted, up to the overload limit, the pressure sensor is operating outside its specification. The overload range is intended to prevent damage to the pressure sensor, as part of a pressure

vessel system, during the pressure containment test.

▶

The overload limit must never be exceeded, even when failures occur in the end-use application.

Loads above the overload limit can cause irreversible damage, which can lead, for example, to

permanent measuring errors.

▶

The manufacturer or operator of the machine or plant in which the product is used must ensure the

compatibility of the materials of the wetted parts with the medium used.

▶

The pressure switch should not be used with abrasive or unstable fluids, in particular not with

hydrogen.

1)

), are available on request.

1)

) which

8 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

3. Safety

■

Pressure surges below the nominal pressure and shorter than 1 ms can cause measuring errors.

■

For applications where pressure spikes can occur, the use of a restrictor is recommended. The

restrictor narrows the pressure port to 0.6 mm and thus increases the resistance against pressure

spikes.

■

With media that could block the pressure port (e.g. through particles), it is recommended to use a

wider pressure port of 6 or 12 mm.

■

There must be no build-up of atomic hydrogen in the pressure port of the pressure switch.

3.3 Personnelqualication

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of country-specic regulations, current standards and directives, are capable of carrying out the work described and independently recognising

potential hazards.

3.4 Use of accessories and spare parts

It is recommended to use original accessories and original spare parts from WIKA. Using accessories and spare parts

from third parties can lead to damage to the instrument or accidents, due to quality defects or other reasons.

WIKA assumes no liability for damage or accidents caused by a malfunction or unsuitability of accessories and spare

parts which do not originate from WIKA (e.g. non-compliance with the IP ingress protection of connectors). No warranty

claims can be made which arise due to a malfunction or unsuitability of any accessory or spare part from a third party.

EN

14247391.01 07/2019 EN/DE/FR/ES

9WIKA operating instructions, model PSD-4-ECO

3. Safety

3.5 Labelling, safety marks

Product label

If the serial number becomes illegible (e.g. due to mechanical damage or overpainting), traceability will no longer be

possible.

EN

PSD-4-ECO

IO-Link version (option)

P# Product no.

S# Serial no.

Measuring range

Symbols

10 WIKA operating instructions, model PSD-4-ECO

www.wika.com Made in Germany

Coded date of manufacture

Pin assignment and specications

Approvals

Before mounting and commissioning the instrument, ensure you read the operating instructions!

14247391.01 07/2019 EN/DE/FR/ES

4. Transport, packaging and storage / 5. Commissioning, operation

4. Transport, packaging and storage

4.1 Transport

Check the pressure switch for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change in installation site, sending for

repair).

Permissible conditions at the place of storage:

■

Storage temperature: -40 ... +70 °C

■

Humidity: 45 ... 75 % relative humidity (no condensation)

5. Commissioning, operation

5.1 Check the instrument

Prior to commissioning, the pressure switch must be subjected to a visual inspection.

■

Leaking uid is indicative of damage.

■

Only use the pressure switch if it is in perfect condition with respect to safety.

5.2 Requirements for mounting point

The mounting point must meet the following conditions:

■

Protected from weather inuences.

■

Permanent exposure to UV light/sunlight can lead to a change in the colour of the plastic parts and a clouding/

yellowing of the status displays. Therefore, a possible limitation of the visibility of the status displays cannot be

excluded. However, this has no eect on the functionality of the instrument.

■

Under corrosive environmental conditions (such as salty, humid air), reductions in the gloss level of the metallic

surfaces, or even corrosion on the instrument, may occur, which make readability of the product label more dicult.

However, this has no eect on the functionality of the instrument.

■

Sealing faces are clean and undamaged.

■

Sucient space for a safe electrical installation.

EN

14247391.01 07/2019 EN/DE/FR/ES

11WIKA operating instructions, model PSD-4-ECO

5. Commissioning, operation

■

The instrument is vented to the atmosphere. Therefore, no coating or other covering may be applied which might

restrict the venting.

■

For information on tapped holes and welding sockets, see Technical information IN 00.14 at www.wika.com.

WARNING!

Physical injuries and damage to property and the environment through running above or

EN

5.3 Mechanical mounting

1. Seal the sealing face (→ see “Sealing variants”).

.

At the mounting point, screw the pressure switch in hand-tight.

2

.

Tighten with a torque spanner using the spanner ats.

3

below the temperature limits

Running above or below the temperature limits can destroy the instrument and lead to danger in the

end-use application.

▶

Permissible ambient and medium temperatures remain within the performance limits. Consider

possible restrictions on the ambient temperature range caused by mating connector used.

For performance limits, such as derating (maximum current consumption at a corresponding

medium temperature), see chapter 9 “Specifications”

The max. torque depends on the mounting point (e.g. material and shape). If you have any questions,

please contact our application consultant.

→ For contact details see chapter 1 “General information” or the back page of the operating instructions.

12 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

5. Commissioning, operation

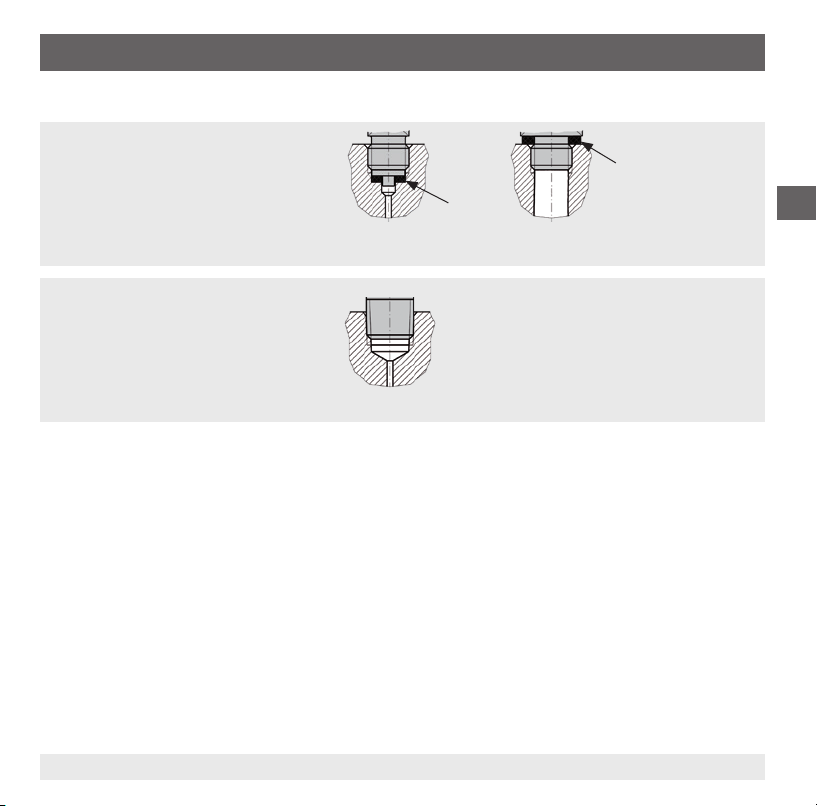

Sealing variants

Parallel threads

Seal the sealing face with flat gasket,

lens-type sealing ring or WIKA profile

sealing.

per EN 837

Tapered threads

Wrap threads with sealing material

(e.g. PTFE tape).

NPT, R and PT

5.4 Electrical mounting

5.4.1 Requirements for voltage supply

→ For power supply see product label

The power supply for the pressure switch must be made via an energy-limited electric circuit in accordance with

section 9.4 of UL/EN/IEC 61010-1, or an LPS per UL/EN/IEC 60950-1 / CSA C22.2 no. 60950-1, or class 2 in

accordance with UL1310/UL1585 (NEC or CEC). The voltage supply must be suitable for operation above 2,000 m

should the pressure switch be used at this altitude.

5.4.2 Requirements for electrical connection

■

Ingress protection of the mating connector corresponds to the ingress protection of the pressure switch.

■

Cable diameter matches the cable bushing of the mating connector.

■

Cable gland and seals of the mating connector are correctly seated.

■

No humidity can ingress at the cable end.

per DIN EN ISO 1179-2

(formerly DIN 3852-E)

EN

14247391.01 07/2019 EN/DE/FR/ES

13WIKA operating instructions, model PSD-4-ECO

5. Commissioning, operation

5.4.3 Requirement for shielding and grounding

The pressure switch must be grounded via the process connection.

When working during a running process operation, measures to prevent electrostatic discharge on the connection

terminals should be taken, as a discharge could lead to temporary corruption of the measured value.

5.4.4 Connecting the instrument

EN

1. Assemble the mating connector or cable outlet.

→Pin assignment, see product label

.

Establish the plug connection.

2

5.5 Zero point setting

Check the indicated zero point on the digital display during commissioning. Should a zero point oset be displayed as

a result of installation, this can be reset in programming mode or via IO-Link with the 0SET parameter

Only carry out zero point setting for gauge and vacuum pressure measuring ranges at the start of the measuring range.

Carry out zero point setting of absolute pressure measuring ranges at 0 bar absolute (vacuum). Since

appropriate references are required for this, we recommend that this is only carried out by the manufacturer.

14 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

5. Commissioning, operation

5.6 Operating modes

Mode Description

System start Digital display is fully activated for 1 sec.

Programming mode

(setting the parameters)

Display mode

(normal operation, display of

pressure value)

5.7 Overview of parameters

Menu

Description Parameter Factory setting

item

SP1/SP2 Hysteresis function:

FH1/FH2 Window function:

RP1/RP2 Hysteresis function: Reset point, switching

FL1/FL2 Window function: Window low switch output

EF Extended programming functions

RES Return the set parameters to the factory

DS1/DS2 Switching delay time, in which the switching

Switch point (switching output 1 / 2)

Window high (switching output 1 / 2)

output (1 or 2)

(1 or 2)

settings

value must be continuously present until

an electrical signal change occurs (SP1

or SP2)

When the pressure switch is powered up within the range of the hysteresis, the output switch is set to

“not active” by default.

Activating the programming mode

Keep the up button [▲] pressed for approx. 5 sec. If the password is set to ≠ 0000, a password will be

requested. If authentication is successful, then it enters the programming mode, otherwise it reverts to

display mode.

Timeout

If, during the setting of a parameter, no button is pressed for 60 s, the instrument returns to the display

mode with the value unchanged.

Returning to the display mode

Simultaneous pressing of the up and down buttons [▼] + [▲]

0.25 ... 100 % of measuring range Nominal pressure

0.25 ... 100 % of measuring range Nominal pressure

0 ... (switch point - 0.25 % of measuring range)

0 ... (window high - 0.25 % of measuring range)

Yes / No

0.00 ... 65.00 s 0.00 s

Nominal pressure

- 10 %

Nominal pressure

- 10 %

EN

14247391.01 07/2019 EN/DE/FR/ES

15WIKA operating instructions, model PSD-4-ECO

5. Commissioning, operation

Menu

Description Parameter Factory setting

item

DR1/DR2 Reset delay time, at which the reset value

OU1 / OU2 Switching function (switching output 1 / 2) HNO = hysteresis function, normally open HNO

EN

AVGD Damping (digital display) 0.00 ... 65.00 s 0.20 s

AVG1/AVG2 Damping (switching output 1 / 2) 0.00 ... 65.00 s 0.00 s

AVG3 Damping (analogue signal) 0.00 ... 65.00 s 0.00 s

UNIT Unit switching BAR, mBAR, MPA, KPA, PSI, KGcm (kg/cm²), % Order-related

0SET Zero point setting / Executing “Autozero”

DISM Display value in display mode ACT = current system pressure ACT

DISU Refresh rate (digital display) 1, 2, 5, 10 updates/second 5

DISR Rotate the indication by 180° (digital

DRES Resolution (digital display) OPT = optimised (Stabilises the display of the

must be continuously present until an

electrical signal change occurs (RP1 or

RP2)

(max. 3 % of span)

display)

0.00 ... 65.00 s 0.00 s

HNC = hysteresis function, normally closed

FNO = window function, normally open

FNC = window function, normally closed

Yes / No

LOW, HIGH = min/max system pressure

OFF = display o

SP1/FH1 = set switching value

RP1/FL1 = set reset value

SP2/FH2 = set switching value

RP2/FL2 = set reset value

Yes / No

measured values, with rounding factors for the last

digit, optimised for the measuring range)

FULL = maximum (nest resolution, if required, for a

stable display of measured values a damping must

be set for the digital display)

OPT

16 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

5. Commissioning, operation

Menu

Description Parameter Factory setting

item

COLR Colour settings (digital display) rEd (0) = display always red rEd (0)

CLRH Upper limit value of the COLR function

CLRL Lower limit value of the COLR function

RHL Clear memory (min/max system pressure) Yes / No

PAS Password entry 0000 = no password

TAG Measuring instrument name (TAG) 32 selectable characters (A-Z ‚0 ... 9; - ‚SPACE)

Only active if COLR = rEd1, rEd2, Grn1

or Grn2

Only active if COLR = Grn1 or Grn2

Grn (1) = display always green

rEd1 (2) = Red display, when the pressure value

is greater than/equal to the set value from CLRH

(otherwise green)

Grn1 (3) = Green display, when the pressure value

is greater than/equal to the set value from CLRH

(otherwise red)

rEd2 (4) = Red display, when the pressure value is

in the range of the set values of CLRL and CLRH

(otherwise green)

Grn2 (5) = Green display, when the pressure value

is in the range of the set values of CLRL and CLRH

(otherwise red)

Pressure value 0.25 ... 100 % of measuring range Nominal pressure

0 ... (CLRH - 0.25 % of measuring range) Nominal pressure

Password input digit by digit

(2 spaces in sequence terminate the input and lead

to the deletion of this and the underlying characters)

- 10 %

0000

without

EN

14247391.01 07/2019 EN/DE/FR/ES

17WIKA operating instructions, model PSD-4-ECO

5. Commissioning, operation

5.8 Menu tree

Certain menu items (light grey) are only displayed if the pressure switch features the respective option.

Display mode

EN

18 WIKA operating instructions, model PSD-4-ECO

SP1 / FH1 Value Switch point/window high (switching output 1)

RP1 / FL1 Value Reset point/window low (switching output 1)

SP2 / FH2 Value Switch point/window high (switching output 2)

RP2 / FL2 Value Reset point/window low (switching output 2)

EF RES Yes / No Reset to factory settings

END DS1 Value Switching delay (switching output 1)

DR1 Value Reset delay (switching output 1)

DS2 Value Switching delay (switching output 2)

DR2 Value Reset delay (switching output 2)

OU1 PARA Switching function (switching output 1)

OU2 PARA Switching function (switching output 2)

AVGD Value Damping (digital display)

AVG1 Value Damping (switching output 1)

AVG2 Value Damping (switching output 2)

AVG3 Value Damping (analogue output)

UNIT Unit Unit switching

0SET Yes / No Zero point setting

DISM PARA Display value in display mode

DISU Value Refresh rate (digital display)

DISR Yes / No Rotate the indication by 180° (digital display)

14247391.01 07/2019 EN/DE/FR/ES

5. Commissioning, operation

DRES PARA Resolution (digital display)

COLR PARA Colour settings (digital display)

CLRH Value Upper limit value of the COLR function

CLRL Value Lower limit value of the COLR function

RHL Yes / No Clear Min/Max memory

PAS Value Password entry

TAG Value Measuring instrument name (TAG)

END

EN

14247391.01 07/2019 EN/DE/FR/ES

19WIKA operating instructions, model PSD-4-ECO

5. Commissioning, operation

5.9 Switching functions

Hysteresis function

If the system pressure uctuates around the set point, the hysteresis keeps the

switching status of the outputs stable. With increasing system pressure, the

output switches when reaching the switch point (SP).

EN

■

Normally open contact (HNO): Active

■

Contact normally closed (HNC): Inactive

With system pressure falling again, the output will not switch back before the reset

point (RP) is reached.

■

Normally open contact (HNO): Inactive

■

Contact normally closed (HNC): Active

Window function

The window function allows for the control of a dened range.

When the system pressure is between window high (FH) and window low (FL),

the output switches on.

■

Normally open contact (FNO): Active

■

Contact normally closed (FNC): Inactive

When the system pressure is outside window high (FH) and window low (FL), the

output does not switch on.

■

Normally open contact (FNO): Inactive

■

Contact normally closed (FNC): Active

Fig.: Hysteresis function

Fig.: Window function

20 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

5. Commissioning, operation

Delay times (0 ... 65 s)

This makes it possible to lter out unwanted pressure peaks of a short duration or

a high frequency.

The pressure must be present for at least a certain pre-set time for the output to

switch on. The output does not immediately change its status when it reaches the

switching event (SP), but rather only after the pre-set delay time (DS).

If the switching event is no longer present after the delay time, the switch output

does not change.

The output only switches back when the system pressure has fallen down to the

reset point (PR) and stays at or below the reset point (RP) for at least the pre-set

delay time (DR).

If the switching event is no longer present after the delay time, the switch output

does not change.

EN

Fig.: Delay times

5.10 Damping function

The time constant “x” species the time duration which the digital display, the

100 %

switching output or the analogue signal requires to approach the end value with

a deviation of ± 1 % following a change in measured value. After a duration of 2

times “x”, the output value has reached 100 % with a deviation of ± 0.01 % of the

prevailing pressure.

0

Time

Zeit

5.11 Description of the IO-Link functionality (optional)

IO-Link is a point-to-point connection for the communication of the PSD-4-ECO with an IO-Link master.

IO-Link specication: Version 1.1

A detailed description of the IO-Link functionality and the device description le (IODD) can be found online on the

product details page of the pressure switch at www.wika.com.

14247391.01 07/2019 EN/DE/FR/ES

x

21WIKA operating instructions, model PSD-4-ECO

6. Faults

6. Faults

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the pressure switch must be taken out of

EN

In the event of any faults, rst check whether the pressure switch is mounted correctly, mechanically and electrically.

If complaint is unjustied, the handling costs will be charged.

operation immediately.

▶

Ensure that pressure or signal is no longer present and protect against accidental commissioning.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter 8.2 “Return”.

WARNING!

Physical injuries and damage to property and the environment caused by hazardous media

Upon contact with hazardous media (e.g. oxygen), and also with refrigeration plants and compressors,

there is a danger of physical injuries and damage to property and the environment.

▶

Should a failure occur, media with extremely high temperature and under high pressure or vacuum

may be present at the instrument.

▶

For these media, in addition to all standard regulations, the appropriate existing codes or regulations

must also be followed.

▶

Wear the requisite protective equipment.

For contact details see chapter 1 “General information” or the back page of the operating instructions.

22 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

6. Faults

Fault Possible cause Measure

No output signal Cable break Check the continuity

No output signal No/wrong power supply Rectify the power supply

No/wrong output signal Wiring error or switching of switching logic/

Constant output signal upon change in

pressure

Deviating zero point signal Overpressure limit exceeded Observe the permissible overpressure limit

Signal span too small Mechanical overload caused by overpres-

Signal span too small Power supply too high/low Rectify the power supply

Signal span drops Moisture has entered Fit the cable correctly

analogue signal

Mechanical overload caused by overpressure

sure

Warnings and errors

Via the digital display, the instrument's internal warnings and errors are output. The instrument continues to measure,

even when a warning exists. The output signal and the switching outputs are still output.

The following table shows the codes and their meaning.

WARNING Description

ATT1 On changing the switch point (SP1 / SP2) and the upper display limit value CLRH, the reset point / lower display

ATT2 Zero point oset, current pressure is outside the limits

ATT3 Password entered for menu access is incorrect

ATT4 Unit cannot be displayed on digital display, previous unit is used

ILOC Menu locked over IO-Link

OL Overpressure, measuring range exceeded > approx. 3.125 % (digital display ashing)

PAS Prompt for password input

UL Underpressure, below measuring range < approx. 3.125 % (digital display ashing)

14247391.01 07/2019 EN/DE/FR/ES

limit value (CLRL)) of the instrument is automatically reduced by the smallest hysteresis of 0.25 %.

Observe the pin assignment

Check the output conguration

Replace instrument; if it fails repeatedly,

contact the manufacturer

Replace instrument; if it fails repeatedly,

contact the manufacturer

EN

23WIKA operating instructions, model PSD-4-ECO

6. Faults

Error Description

ERR Internal error (restarting the instrument or resetting to factory settings can provide a solution)

The analogue output controls the alarm signal ≤ 3.6 mA (4 ... 20 mA output signal) or ≥ 11 V

(0 ... 10 V output signal) in accordance with NAMUR43

EN

ERR1 Instrument temperature exceeded/too low or power supply too low

ERR2 Sensor defect detected, check whether high overload pressure is present (can be detected as sensor defect), if

SC Short-circuit detected at switching output 1 or 2

Acknowledge warnings and errors with conrmation button.

The switching outputs keep the current switching state (output open or closed)

The analogue output is output. There are limitations with respect to accuracy (temperature inuence) and

maximum analogue value (power supply too low)

The switching outputs keep the current switching state (output open or closed)

necessary, restart instrument or exchange of instrument is needed

The analogue output controls the alarm signal ≤ 3.6 mA (4 ... 20 mA output signal) or ≥ 11 V

(0 ... 10 V output signal) in accordance with NAMUR43

The switching outputs keep the current switching state (output open or closed)

The switching output aected is inactive so long as the short-circuit is present

The user must ensure a regular change in pressure and thus a proportional output signal change. The

pressure transmitter does not have any diagnostic function for detecting a static signal as a result of an

instrument error.

24 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

7. Maintenance and cleaning

7. Maintenance and cleaning

7.1 Maintenance

This pressure switch is maintenance-free.

Repairs must only be carried out by the manufacturer.

Regular inspection of the sealing by the operator is necessary.

7.2 Cleaning

CAUTION!

Unsuitable cleaning agents

Cleaning with unsuitable cleaning agents may damage the instrument and the product label.

▶

Do not use any aggressive cleaning agents.

▶

Do not use any hard or pointed objects.

▶

Do not use any abrasive cloths or sponges.

Suitable cleaning agents

■

Water

■

Conventional dishwashing detergent

Cleaning the instrument

Wipe the instrument surface using a soft, damp cloth.

EN

14247391.01 07/2019 EN/DE/FR/ES

25WIKA operating instructions, model PSD-4-ECO

8. Dismounting, return and disposal

8. Dismounting, return and disposal

8.1 Dismounting

WARNING!

EN

Dismounting the instrument

1. Depressurise and de-energise the pressure switch.

.

2

Disconnect the electrical connection.

.

Unscrew the pressure switch with a spanner using the spanner ats.

3

Physical injuries and damage to property and the environment caused by hazardous media

Upon contact with hazardous media (e.g. oxygen), and also with refrigeration plants and compressors,

there is a danger of physical injuries and damage to property and the environment.

▶

Should a failure occur, media with extremely high temperature and under high pressure or vacuum

may be present at the instrument.

▶

For these media, in addition to all standard regulations, the appropriate existing codes or regulations

must also be followed.

▶

Wear the requisite protective equipment.

WARNING!

Risk of burns

During dismounting there is a risk of dangerously hot media escaping.

The pressure switch may have heated up severely due to hot media.

▶

Let the instrument cool down sufficiently before dismounting it.

▶

Wear the requisite protective equipment.

26 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

8. Dismounting, return

8.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances (acids, bases, solutions, etc.)

and must therefore be cleaned before being returned.

WARNING!

Physical injuries and damage to property and the environment through residual media

Residual media in the dismounted instrument can result in a risk to persons, the environment and

equipment.

▶

With hazardous substances, include the material safety data sheet for the corresponding medium.

▶

Clean the instrument, see chapter 7.2 “Cleaning”.

When returning the instrument, use the original packaging or a suitable transport packaging.

Information on returns can be found under the heading “Service” on our local website.

8.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally compatible way and in accordance

with the country-specic waste disposal regulations.

Do not dispose of with household waste. Ensure a proper disposal in accordance with national regulations.

14247391.01 07/2019 EN/DE/FR/ES

EN

27WIKA operating instructions, model PSD-4-ECO

9.Specications

9. Specications

Specications

Measuring range

Measuring range see product label

EN

Overload safety The overload safety is based on the sensor element used. Depending on the selected process

Increased overload safety

(option)

Vacuum-tight Ye s

Digital display

Model 7-segment LED, 2-coloured red/green, 4-digit, 8.9 [0.35 in] character size

Output signal

Output signal see product label

Load 4 ... 20 mA ≤ 500 Ω

IO-Link (option)

Revision 1.1

Rate 38.4 kBaud (COM2)

Min. cycle time 2.3 ms

Master port class A

Zero point setting max. 3 % of span

Damping of analogue output/

switching outputs

connection and sealing, restrictions in overload safety can result.

Measuring ranges ≤ 600 bar (< 8,000 psi): 2-fold

Measuring ranges to 1.000 bar (≥ 8,000 psi): 1.5-fold

Deviating temperature errors and long-term stability with respect to the selected measuring

range apply here.

Display can be turned electronically by 180°

Colour ranges through green/red switching can be parameterised

Display can be rotated mechanically through 335°

DC 0 ... 10 V > max. output voltage / 1 mA

congurable from 0 ms ... 65 s

28 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

9.Specications

Specications

Switch-on time 1 s

Switching thresholds Switch point 1 and switch point 2 are individually adjustable

Switching functions Normally open, normally closed, window, hysteresis (adjustable)

Switching voltage Power supply - 1 V

Switching current max. 250 mA to 85 °C [176 °F]

Settling time/response time Analogue signal: ≤ 5 ms

Service life 100 million switching cycles

Voltage supply

Power supply DC 15 ... 32 V

Current consumption ≤ 45 mA for versions without output signal

Total current consumption max. 600 mA including switching current

Accuracyspecications

Accuracy, analogue signal ≤ ±1.0 % of span

Non-repeatability, analogue

signal

Long-term drift, analogue signal ≤ ±0.1 % of span (IEC 61298-2)

max. 250 mA to 70 °C [176 °F] with UL approval

For details, see the derating curves on page 33

Switching output: ≤ 5 ms

With a current output and a medium temperature of 125 °C [257 °F], only a max. power supply

of DC 28 V is permissible.

The power supply for the pressure sensor must be made via an energy-limited electric circuit in

accordance with section 9.3 of UL/EN/IEC 61010-1 or an LPS to UL/EN/IEC 60950-1 or class

2 in accordance with UL1310/UL1585 (NEC or CEC). The voltage supply must be suitable for

operation above 2,000 m should the pressure sensor be used at this altitude.

≤ 70 mA for versions with output signal

Including non-linearity, hysteresis, zero oset and end value deviation (corresponds to

measured error per IEC 61298-2).

≤ 0.1 % of span (IEC 61298-2)

≤ ±0.2 % of span (IEC 61298-2) for measuring ranges ≤ 0.6 bar [10 psi] and for increased

overload safety

EN

14247391.01 07/2019 EN/DE/FR/ES

29WIKA operating instructions, model PSD-4-ECO

9.Specications

Specications

Accuracy, switching output ≤ ±1.0 % of span

Temperature error in nominal

temperature range

Temperaturecoecientsin

EN

nominal temperature range

Mean TC zero point ≤ ±0.16 % of span/10 K

Mean TC span ≤ ±0.16 % of span/10 K

Reference conditions (per IEC 61298-1)

Ambient temperature 15 ... 25 °C [59 ... 77 °F]

Atmospheric pressure 860 ... 1,060 mbar [12.5 ... 15.4 psi]

Air humidity 45 ... 75 % r. h.

Power supply DC 24 V

Mounting position Process connection lower mount

Operating conditions

Permissible temperature ranges

Medium -25 ... +85 °C [-13 ... +185 °F]

Ambient -20 ... +85 °C [-22 ... +185 °F]

Storage -40 ... +70 °C [-40 ... +158 °F]

Nominal temperature -20 ... +80 °C [-4 ... +176 °F]

Air humidity 45 ... 75 % r. h.

Vibration resistance 20 g, 10 ... 2,000 Hz (IEC 60068-2-6, under resonance)

Shock resistance 50 g, 6 ms (IEC 60068-2-27, mechanical)

maximum: ≤ ±1.5 % of span

maximum: ≤ ±2.5 % of span for increased overload safety

Option: -40 ... +125 °C [-40 ... +257 °F]

1) Medium temperature restricted to -30 ... +85 °C [-22 ... +185 °F] with UL approval

With ambient temperatures less than -20 °C, the turning of the display head and button operation is not permitted.

1)

30 WIKA operating instructions, model PSD-4-ECO

14247391.01 07/2019 EN/DE/FR/ES

Loading...

Loading...