Page 1

Operating Instructions

Betriebsanleitung

Mode d'emploi

Manual de Instrucciones

Pressure gauges with integrated transmitter

Druckmessgeräte mit integriertem Ferngeber

Manomètre avec transmetteur de pression intégré

Manómetro con transmisor de presión integrado

Model PGT23.063

Model PGT23.100 Model PGT43.100

GB

D

F

E

Model APGT43.100

Model DPGT43HP.100

Model DPGT43.100

Page 2

Operating Instructions intelliGAUGE family Page 3 - 24

GB

Betriebsanleitung intelliGAUGE-Familie Seite 25 - 46

D

Mode d'emploi famille intelliGAUGE Page 47 - 65

F

Manual de Instrucciones intelliGAUGE familia Página 67 - 85

E

11297264 05/2009 GB/D/F/E

2

Page 3

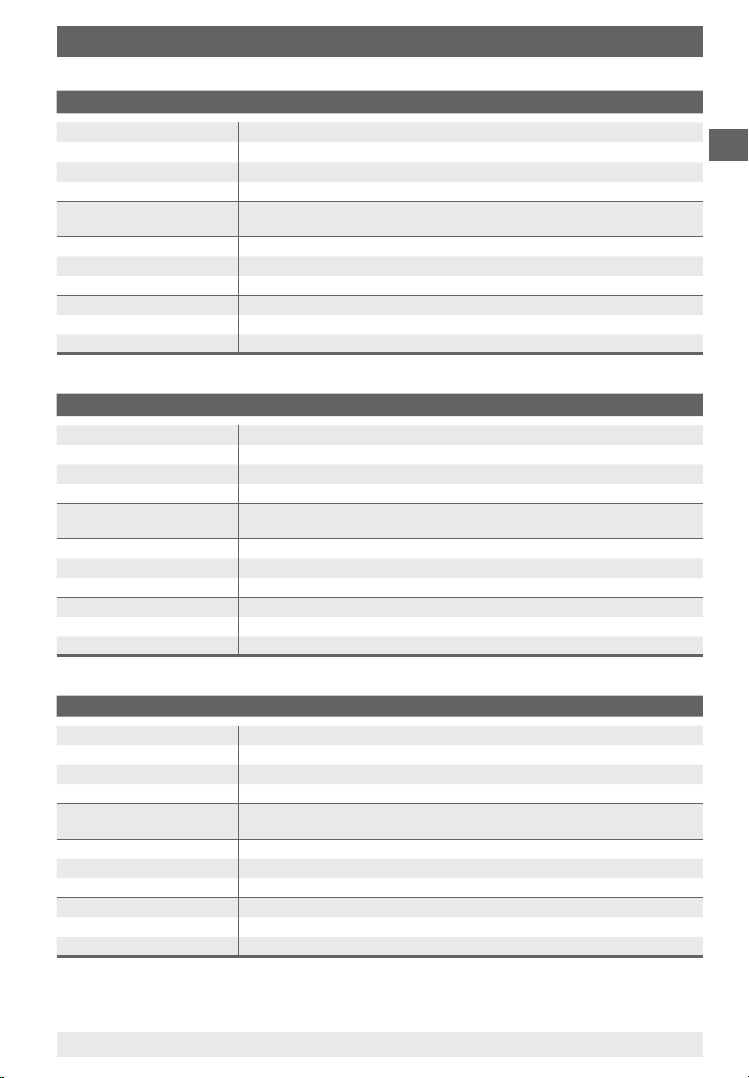

Contents

Contents

1. Safety instructions 4

2. Operating principle 4

3. Technical data 5

4. Installation instructions 10

5. Installation and commissioning 12

6. Measuring arrangements 13

7. Wiring details 14

8. Instruments with ATEX approval 15

9. Service and maintenance 17

10. Troubleshooting 19

11. Storage 20

12. Maintenance and servicing/cleaning 20

13. Repairs 21

14. Disposal 21

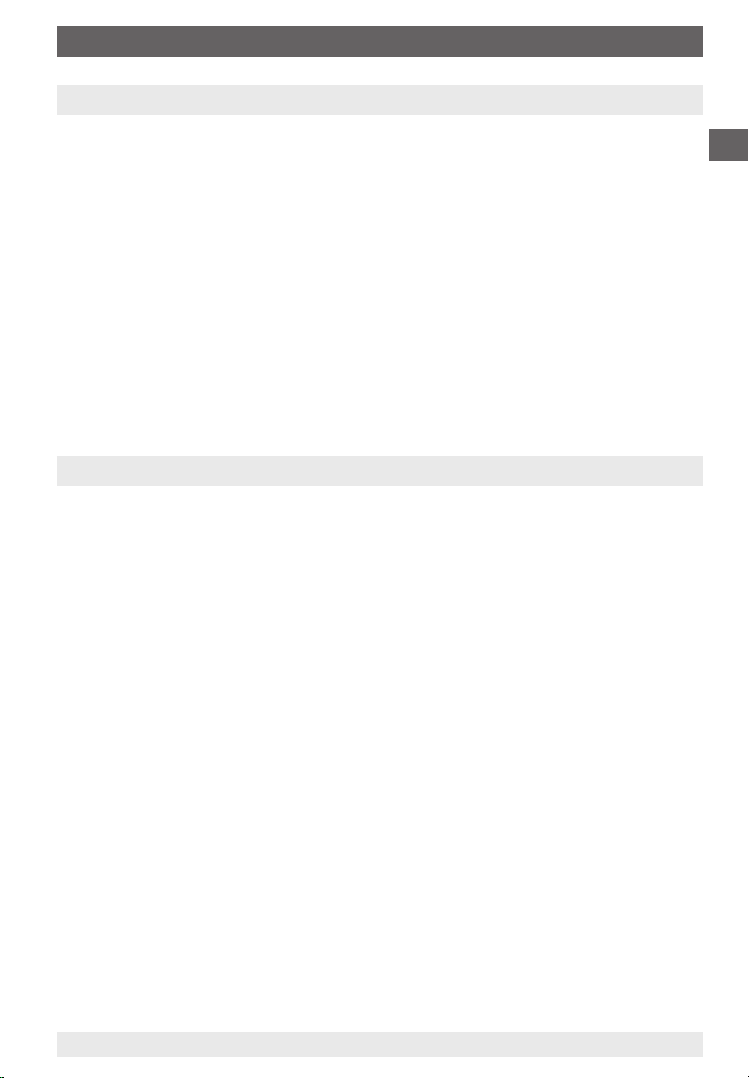

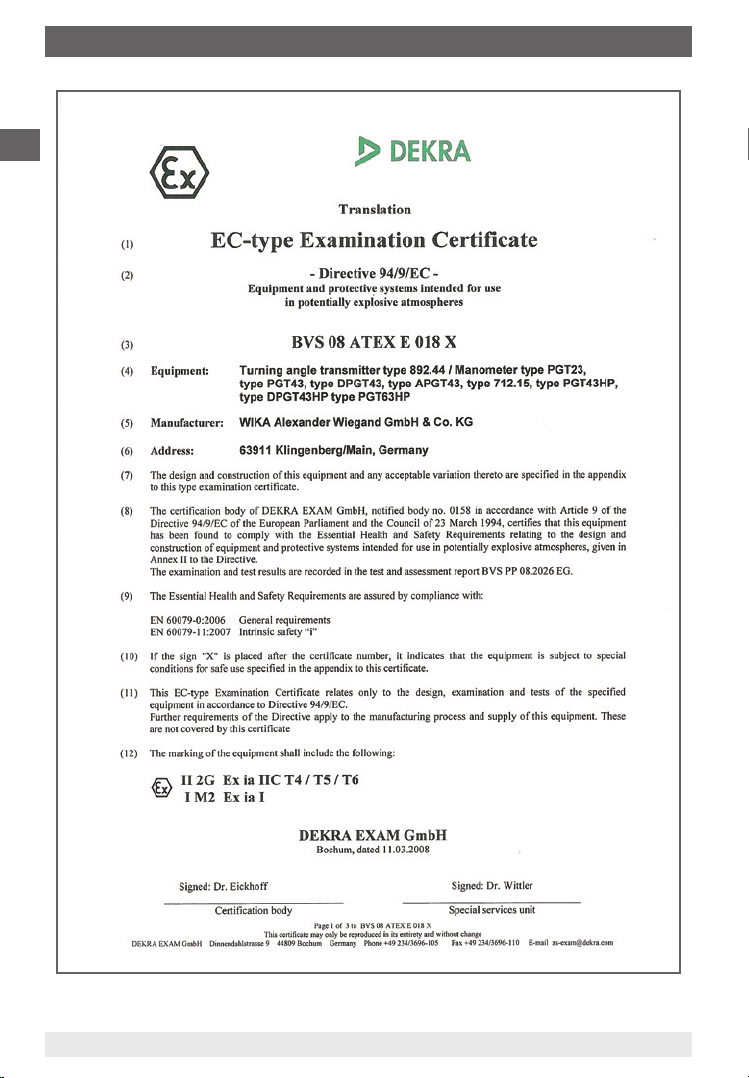

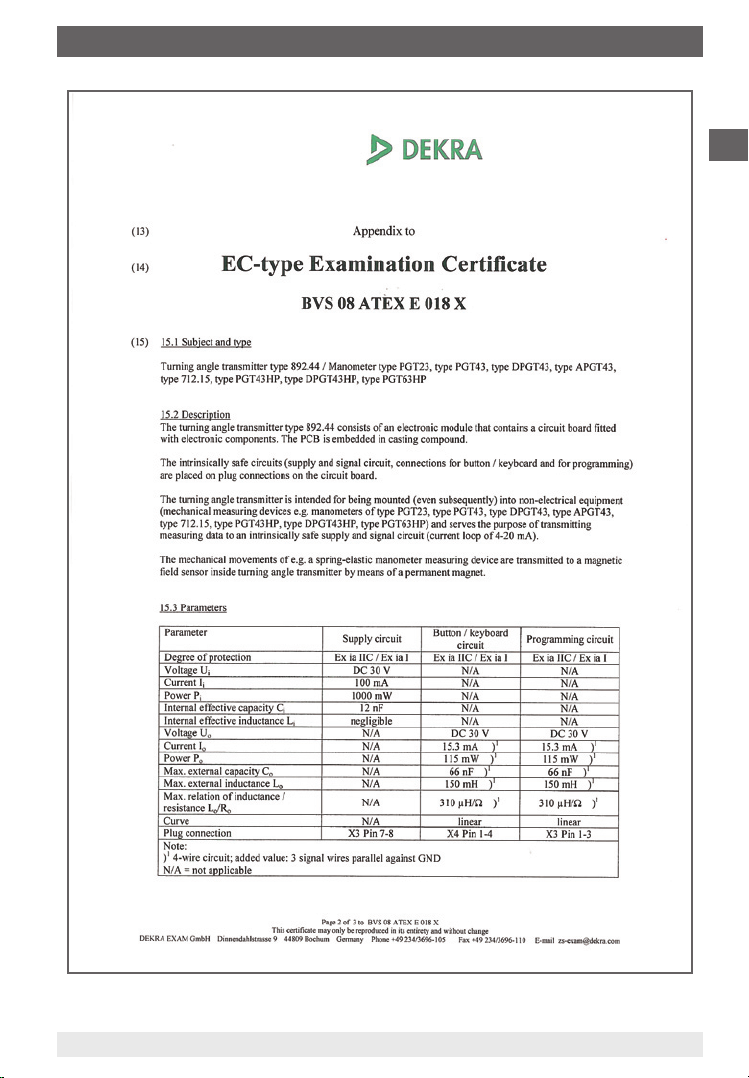

15. EC-type examination certificate 22 - 24

GB

Information

This symbol provides you with information, notes and tips.

Warning!

This symbol warns you against actions that can cause injury

to people or damage to the instrument.

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 3

Page 4

1. Safety instructions / 2. Operating principle

1. Safety instructions

GB

Serious injuries and/or damage can occur should the appropriate

regulations not be observed.

Only appropriately qualified personnel should work on these instru-

ments.

The appropriate national safety regulations (e.g. EN 837-2

"Selection and installation recommendations for pressure

gauges") must be observed when installing, commissioning

and operating these devices.

2. Operating principle

Bourdon tube, diaphragm and capsule measuring elements are widely used as

measuring elements for such transmitters thanks to their robustness and easeof-use within technical pressure measurement. Under the influence of pressure,

these measuring elements will be deformed within their elastic range.

This movement is converted into a rotary motion by means of a mechanical

movement (gear). A magnet, fixed to the pointer axle, turns with the instrument‘s pointer, in direct proportion to the process pressure. The connected

electronics detect the rotary motion of the magnet between 0 and 270 degrees.

A non-contact (and thus wear-reseistant), magnetic-field dependant sensor

(angular rotation sensor, 10 bit resolution) measures the change electrically.

An amplifier converts the rotary motion into an electrical output signal. The

electronics are factory set to a standard passive 4 ... 20 mA output signal,

(0 ... 20 mA, 0 ... 10 V and 4 ... 20 mA ATEX versions are available as options).

The electrical output signal range corresponds to the measuring range on the

dial.

With these three standard electrical output signals, this series of instruments

can be used in all areas of industry.

A pressure gauge with an intelliGAUGE series transmitter combines all the

advantages of an on-site mechanical display with the demands modern industry makes for electrical signal transmission for the acquisition of measured

values.

WIKA Operating Instructions intelliGAUGE family4

11297264 05/2009 GB/D/F/E

Page 5

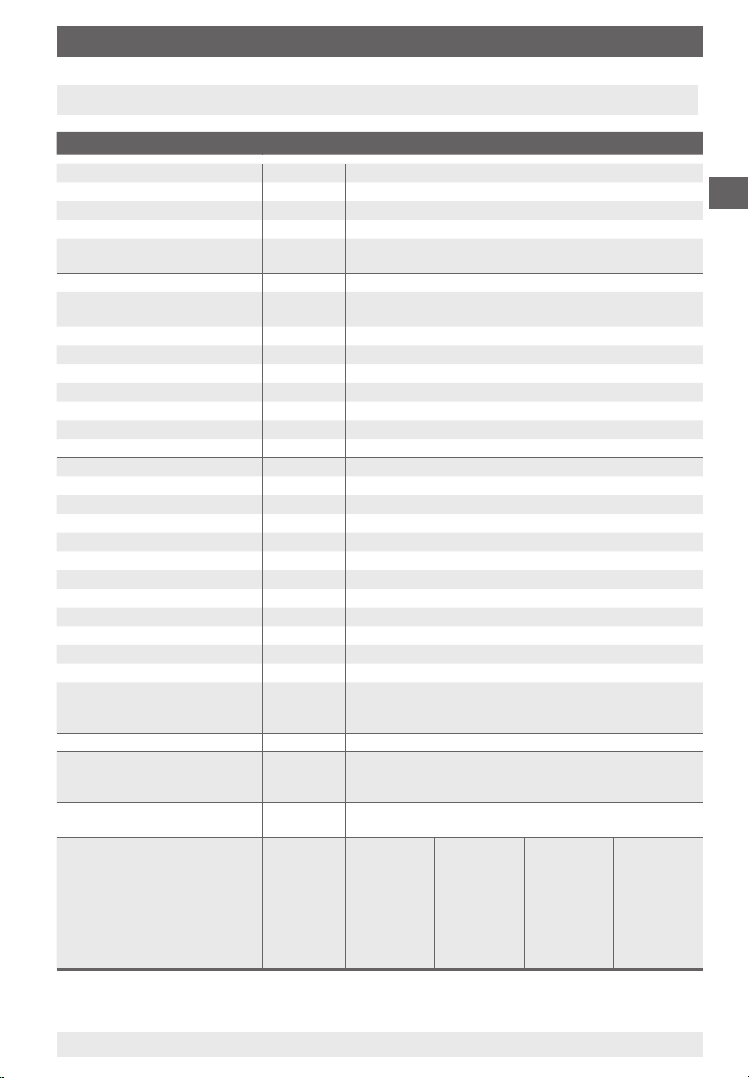

3. Technical data

3. Technical data

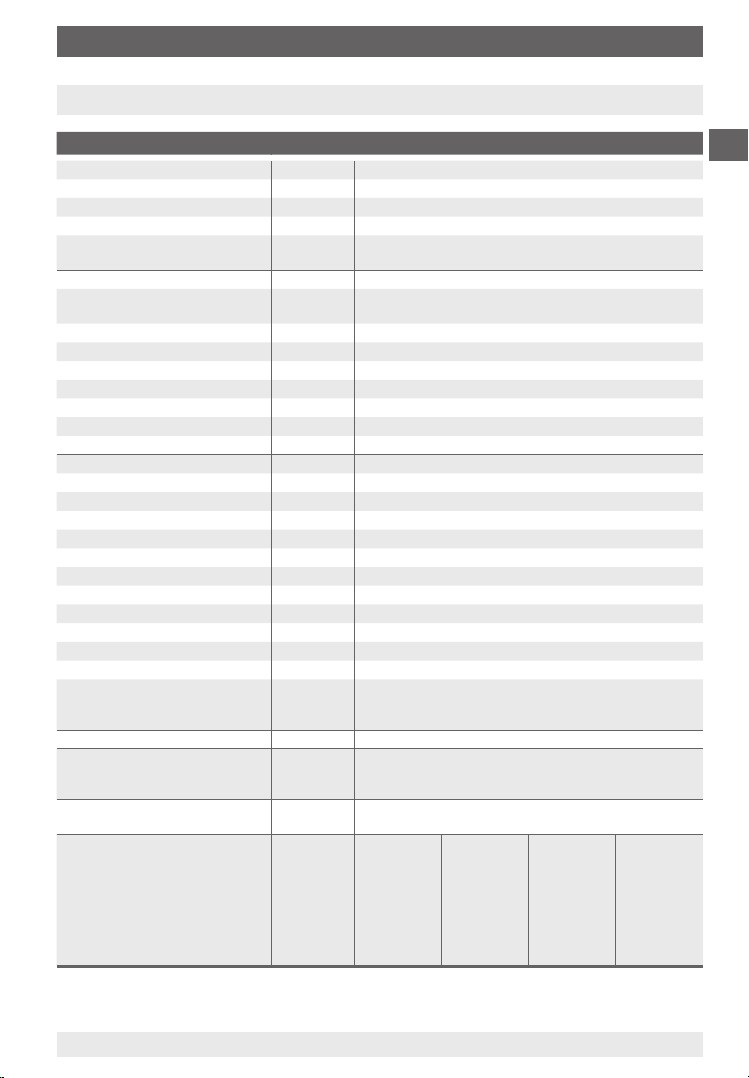

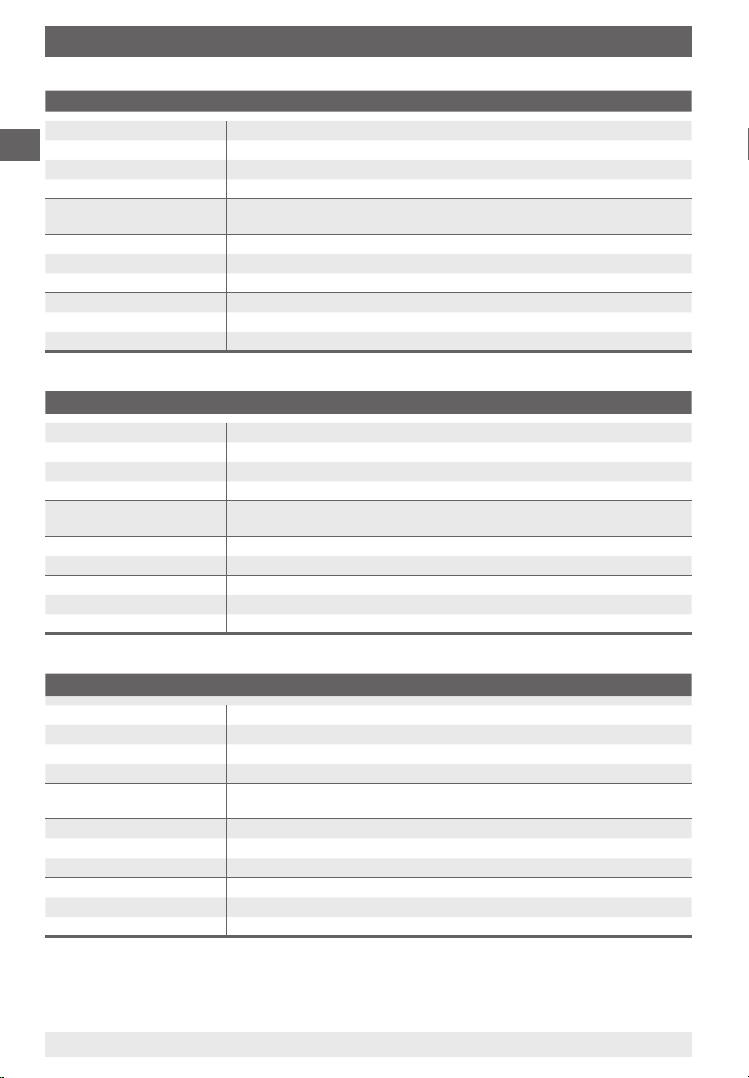

3.1 Transmitter

Power supply U

Supply voltage effect

Permissible residual ripple

1)

B

DC V

% of FS/10 V

% ss

12 ≤ UB ≤ 30≤

≤ 0.1

≤ 10

Output signal, variant I 4 … 20 mA, 2-wire, passive, per NAMUR NE43

Permissible max. load R

Effect of load

A

% FS

- 12 V)/0.02 A with R

RA ≤ (U

B

however max. 600 Ω

≤ 0.1

in Ohm and UB in Volt

A

Output signal, variant II 4 … 20 mA, 2-wire - Ex≤, per ATEX Ex II 2G Ex ia IIC T4/T5/

Output signal, variant III 0 ... 20 mA, 3-wire

T6 or Ex I M2 Ex ia I

2)

Output signal, variant IV 0 ... 10 V *

Impendance on the voltage output

Load-carrying ability voltage output

Sample rate sensor

Electrical zero point

Zero point adustable range

Linearity

Output signal accuracy

Resolution

Update rate (measuring rate)

Input signal rotational angle

Expanded special span

Long-term stability of electronics

Temperature error, electronics

Warming-up time

Permissible ambient temperature

Permissible storage temperature

Permissible medium temperature

Ω

kΩ

ms

)

< °

% of span

% FS

% FS

1/s

)

< °

< °

)

% FS/a

% FS/10K

min.

°C

°C

°C

0.5

2 … 100

600, with 3-wire optionally faster

Zeroing through short-term jumper across ternimals 5 and 6

45

≤ 1.0 (limit point calibration)

0.2 (only electronic)

0.15 (10 bit resolution at 360°)

> 1

0 … 270

< 330 (Option)

< 0.3

< 0.3 (over the complete temperature range)

≤ 5

-40 … +60

-40 … +70

-40 … +100

Special function Option: non-proportional angular output signal, via auxili-

ary points and interpolation of the intermediate values (to

specify with the order)

CE-conformity Interference emission and immunity per EN 61 326-1

Wiring L-plug connector, 180 °C rotatable, max. 1.5 mm², wire

protector, Cable gland M20 x 1.5, External cable diameter

7-13 mm, incl. strain relief

Wiring protection IP65 to EN 60 529 / IEC 529;

Protected against reverse polarity and overvoltage

Connection details,

depending on variant

Terminal

No

1

2

3

4

5

6

Variant I

4 ... 20mA

GND

I+

reserved

reserved

Zeroing

Zeroing

Ex-Variant II

4 ... 20mA

GND

I+

reserved

reserved

Zeroing

Zeroing

Variant III

0 ... 20 mA

GND

UB+

I

out

reserved

Zeroing

Zeroing

Variant IV

0 ... 10V

GND

UB+

U

out

reserved

Zeroing

Zeroing

GB

1) Not model PGT23.063

2) Not model DPGT43HP.100 / DPGT43HP.160

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 5

Page 6

3. Technical data

3.2 Transmitter with model PGT23.063

Power supply U

GB

Supply voltage effect % FS/10 V ≤ 0.1

Permissible residual ripple % ss ≤ 10

Output signal, variant I 4 … 20 mA, 2-wire

Permissible max. load R

Effect of load % FS ≤ 0.1

Linearity % of span ≤ 1.0 (limit point calibration)

Output signal accuracy % FS < 1.6 electronic

Input signal rotational angle < ° 0 … 270

Expanded special span < ° < 330 (option)

Long-term stability of electronics % FS/a < 0.5

Permissible ambient temperature °C -40 … +60

Permissible storage temperature °C -40 … +70

Permissible medium temperature °C -40 … +100

CE-conformity 2007/108/EC interference emission (Limit Class B) and

Wiring Free cable or as option miniature plug connector M8 x 1,

Wiring protection IP 54 per EN 60 529 / IEC 529, filled IP 65

Connection details see page 9

1) For technical reasons, up to the first scale marking, the measured value can lie outside of the class accuracy.

B

A

3.3 Model PGT23.063

Working pressure

- Steady 3/4 x full scale range

- Fluctuating 2/3 x full scale range

- Transient Full scale range

Temperature influence

IP protection class

- Housing IP 54 per EN 60 529 / IEC 60 529

- With liquid filling IP 65

Permissible temperatures

- Ambient filled/unfilled -40 ... +60 °C

- Medium Maximum +100 °C

Further technical data see data sheet PV 12.03

DC V 12 ≤ UB ≤ 30≤

- 12 V)/0.02 A with R

RA ≤ (U

B

max. 600 Ω

1)

)

)

immunity to EN 61 326-1

4-pin

in Ω and UB in Volt, but

A

1)

max. ± 0.4 % of full scale range/10 K (when the temperature of the

measuring system deviates from +20 °C reference temperature)

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family6

Page 7

3. Technical data

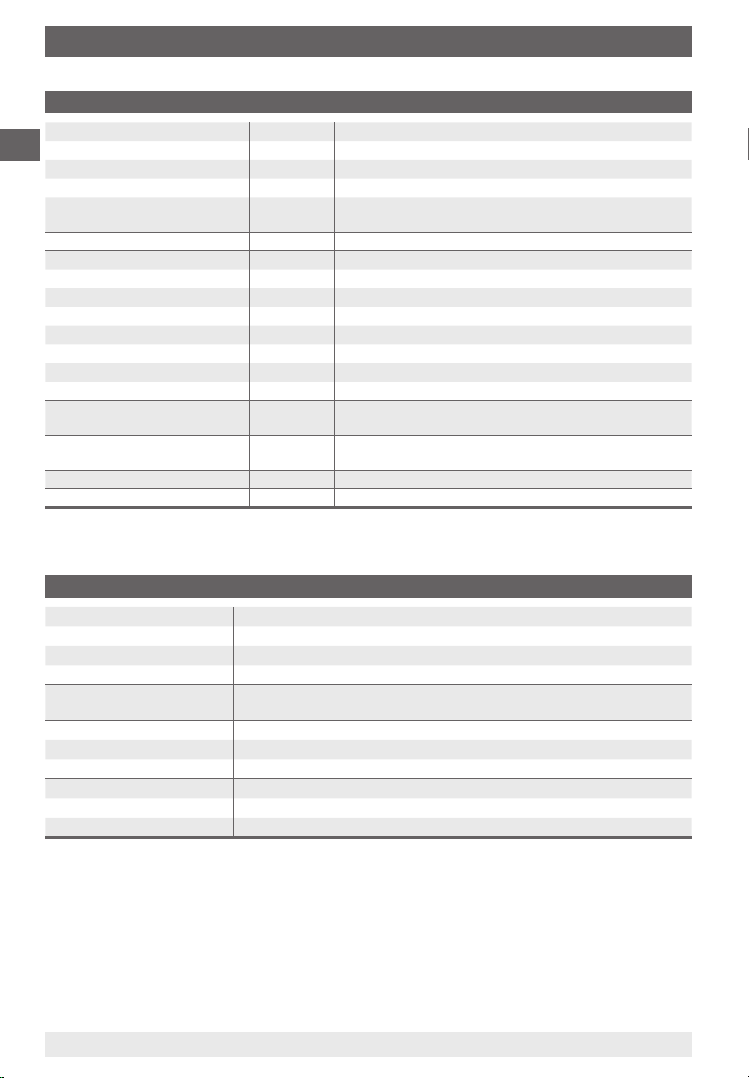

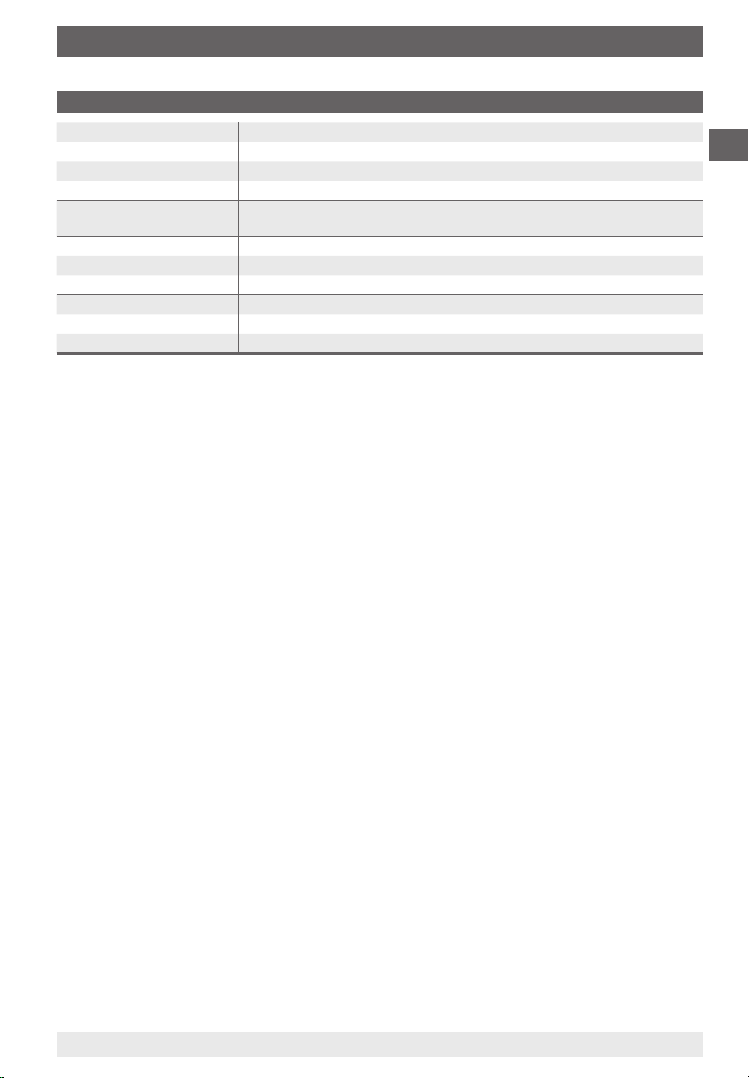

3.4 Model PGT23.100 / PGT23.160

Working pressure

- Steady Full scale range

- Fluctuating 0.9 x full scale range

- Transient 1.3 x full scale range

Temperature influence

IP protection class

- Housing IP 54 per EN 60 529 / IEC 60 529

- With liquid filling IP 65

Permissible temperatures

- Ambient filled/unfilled -40 ... +60 °C

- Medium maximum +100 °C

Further technical data see data sheet PV 12.04

3.5 Model PGT43.100 / PGT43.160

Working pressure

- Steady Full scale range

- Fluctuating 0.9 x full scale range

- Transient 5 x full scale range, however max. 40 bar

Temperature influence

IP protection class

- Housing IP 54 per EN 60 529 / IEC 60 529

- With liquid filling IP 65

Permissible temperatures

- Ambient filled/unfilled -20 ... +60 °C

- Medium maximum +100 °C

Further technical data see data sheet PV 14.03

max. ± 0.4 % of full scale range/10 K (when the temperature of the

measuring system deviates from +20 °C reference temperature)

max. ± 0.8 % of full scale range/10 K (when the temperature of the

measuring system deviates from +20 °C reference temperature)

GB

3.6 Model PGT43HP.100 / PGT43HP.160

Working pressure

- Steady Full scale range

- Fluctuating 0.9 x full scale range

- Overload capability 40, 100 and 400 bar

Temperature influence

IP protection class

- Housing IP 54 per EN 60 529 / IEC 60 529

- With liquid filling IP 65

Permissible temperatures

- Ambient filled/unfilled -20 ... +60 °C

- Medium maximum +100 °C

Further technical data see data sheet PV 14.07

11297264 05/2009 GB/D/F/E

max. ± 0.8 % of full scale range/10 K (when the temperature of the

measuring system deviates from +20 °C reference temperature)

WIKA Operating Instructions intelliGAUGE family 7

Page 8

3. Technical data

3.7 Model APGT43.100 / APGT43.160

Working pressure

GB

- Steady Full scale range

- Fluctuating 0.9 x full scale range

- Overload capability see data sheet PM 05.02

Temperature influence

IP protection class

- Housing IP 54 per EN 60 529 / IEC 60 529

- With liquid filling IP 65

Permissible temperatures

- Ambient filled/unfilled -20 ... +60 °C

- Medium maximum +100 °C

Further technical data see data sheet PV 15.02

3.8 Model PGT63HP.100 / PGT63HP.160

Working pressure

- Steady Full scale range

- Fluctuating 0.9 x full scale range

- Overload capability 50 x full scale range

Temperature influence

IP protection class

- Housing IP 54 per EN 60 529 / IEC 60 529

Permissible temperatures

- Ambient -20 ... +60 °C

- Medium maximum +100 °C

Further technical data see data sheet PV 16.06

max. ± 0.8 % of full scale range/10 K (when the temperature of the

measuring system deviates from +20 °C reference temperature)

max. ± 0.6 % of full scale range/10 K (when the temperature of the

measuring system deviates from +20 °C reference temperature)

3.9 Model DPGT43.100 / DPGT43.160

Working pressure

- Steady Full scale range

- Fluctuating 0.9 x full scale range

- Overload capability at least 10 x full scale value, max. 25 bar

Temperature influence

IP protection class

- Housing IP 54 per EN 60 529 / IEC 60 529

- With liquid filling IP 65

Permissible temperatures

- Ambient filled/unfilled -20 ... +60 °C

- Medium maximum +100 °C

Further technical data see data sheet PV 17.05

max. ± 0.5 % of full scale range/10 K (when the temperature of the

measuring system deviates from +20 °C reference temperature)

WIKA Operating Instructions intelliGAUGE family8

11297264 05/2009 GB/D/F/E

Page 9

3. Technical data

3.10 Model DPGT43HP.100 / DPGT43HP.160

Working pressure

- Steady Full scale range

- Fluctuating 0.9 x full scale range

- Overload capability 40, 100, 250 or 400 bar

Temperature influence

IP protection class

- Housing IP 54 per EN 60 529 / IEC 60 529

- With liquid filling IP 65

Permissible temperatures

- Ambient filled/unfilled -20 ... +60 °C

- Medium maximum +100 °C

Further technical data see data sheet PV 17.13

max. ± 0.5 % of full scale range/10 K (when the temperature of the

measuring system deviates from +20 °C reference temperature)

GB

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 9

Page 10

4. Installation instructions

4. Installation instructions

The pressure gauge must be installed in a shock-free way and positioned in

GB

order to be clearly visible. We recommend connecting an interlocking device

between the pressure tapping point and the pressure gauge, enabling the

measuring device to be changed and to allow the zero point to be checked with

the plant still running.

Installation

Nominal position in accordance with EN 837-3 / 9.6.6 fig 7: 90° (⊥)

Bottom entry pressure connection

There must be a free space of at least 25 mm behind the housing to allow

the pressure to be safely and reliably vented through the rear wall in the

event of a fault!

To avoid supplementary heating, the instruments must not be exposed to

direct sunlight during operation!

With filled variants, open the vent valve (with pressure ranges ≤ 10 bar) on

the top of the housing before commissioning!

Permissible vibration load at the mounting point

The instruments should always be installed in locations free from vibration.

If necessary, it is possible to isolate the instrument from the mounting point

by installing a flexible connection line between the measuring point and the

pressure gauge and mounting the instrument on a suitable bracket.

If this is not possible, the following limit values must not be exceeded:

Unfilled devices: Frequency range < 150 Hz

Acceleration < 0.7 g (7 m/s²)

Liquid filled devices: Frequency range < 150 Hz

Acceleration < 4 g (40 m/s²)

Check the liquid filling at regular intervals.

The liquid level must not drop below 75 % of the instrument‘s diameter.

Test connector

Local safety codes such as those for pressure or steam vessels may specify

isolating devices to enable on-site testing of the pressure instrument.

10

WIKA Operating Instructions intelliGAUGE family

11297264 05/2009 GB/D/F/E

Page 11

4. Installation instructions

Mounting provisions

If the line for the pressure gauge is not rigid enough for vibration-free installation, fasten the instrument using appropriate fastening elements for wall and/or

pipe mounting, and, if necessary, by means of a capillary line.

Measuring system damping

If it is not possible to avoid vibration by means of appropriate mounting, use

pressure gauges with liquid filling.

Effects of temperature

The operating temperature of the pressure instrument, resulting from the effects

of radiated heat, must not exceed the temperature range the pressure instrument is intended for. Suitably-shaped tailpipes or syphons with water filling may

be used to separate the pressure transmitter and its isolating device from hot

pressure media.

The effective maximum surface temperature is not dependant

upon the device, but mainly on the temperature of the respective pressure medium! In the case of gaseous substances, the

temperature may increase due to compression warming. In

these cases it may be necessary to throttle the rate of change

of pressure or reduce the permissible temperature of the

pressure medium.

GB

Diaphragm seal/separating foil

In the case of aggressive, hot, highly viscous, contaminated or crystallising

pressure media, which must not be allowed to enter the measuring element,

diaphragm seals must be used as a separating barrier. A neutral transmission fluid, used to transmit the pressure to the measuring element, should be

selected with consideration to the measuring range, the temperature and its

compatibility with the pressure media.

Under no circumstances must the connection between the pressure gauge and

the diaphragm seal be loosened.

Protection of the measuring element against overload

If the pressure media is subject to rapid pressure changes, or pressure impulses may be expected, these must not act directly on the measuring element. The

effect of the pressure impulses must be damped, e.g. by installing an integrated

restrictor screw (reduction of the cross-section in the pressure channel) or by

connecting an adjustable throttle device in series.

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 11

Page 12

4. Installation instructions / 5. Installation and commissioning

Pressure test connection

The pressure test connection, with a sufficiently large bore (≥ 6 mm diameter),

should be arranged, as far as possible, over a shut-off device, in a position

GB

where the accuracy of the reading will not be affected by the flow of the media

being measured.

The piping between the pressure test connection and the pressure instrument

should have an inner diameter large enough to avoid blockages or delays in

pressure transmission.

Also, it should not have any sharp bends. It is recom-

mended that it is mounted with a continuous incline of approx. 1:15.

Piping

The piping should be arranged and fitted so that it can withstand the stresses

caused by expansion, vibration and the influence of heat. When the media is

gaseous, a water drain point should be provided at the lowest point. For liquid

pressure media, an air bleed should be provided at the highest point.

5. Installation and commissioning

The correct sealing of pressure connections should be achieved by means of

suitable sealing rings, sealing washers or WIKA profile seals.

We recommend connection by means of a union nut or a LH-RH adjusting nut

in order to simplify correct orientation of the gauge. When mounting them or

removing them, the pressure gauges must not be tightened using the housing,

but only on the spanner flats on the stem!

Installation using

a spanner

If the pressure transmitter is positioned lower than the pressure test connection, the tailpipe should be thoroughly cleaned prior to fitting the transmitter.

For technical reasons, it is necessary to ventilate liquid-filled pressure gauges

after installation. See the relevant label on the pressure gauge.

WIKA Operating Instructions intelliGAUGE family12

11297264 05/2009 GB/D/F/E

Page 13

5. Installation and commissioning ... 6. Measuring arrangements

Once the pressure and electrical connections have been made, the transmitters

are ready for immediate use.

The A-VA-1 type or KFA6-STR-1.24.500 type feed units may be used to provide

the standard transmitter with DC voltage.

No attempt should be made to remove a pressurised instrument. If the transmitter cannot be otherwise isolated, the pressure system must be fully vented.

The clamping screws on the top and bottom flanges of diaphragm element

pressure gauges must not be unscrewed.

Any residual pressure medium contained in the pressure

element may be hazardous or toxic. This should be taken into

account when handling and storing pressure gauges which

have been removed.

Pressure connection

In accordance with the general technical regulations for pressure gauges (e.g.

EN 837-2 "Selection and installation recommendations for pressure gauges").

6. Measuring arrangements

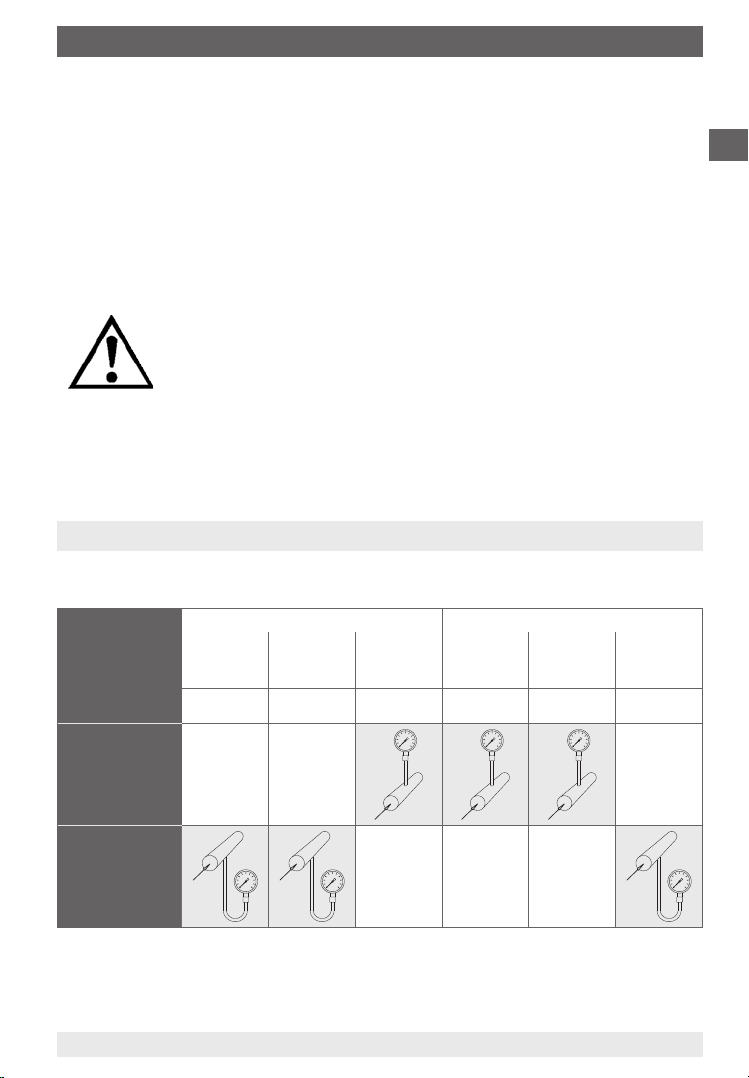

Proven measuring arrangements for various types of media.

Liquid media Gaseous media

Contents of

tailpipe

Typically

Pressure

instrument

higher than

tapping point

Liquid Liquid with

vapour

Condensate Boiling liquid Liquefied gas Dry air Moist air,

Vapour

only

Gas only Wet gas Liquid gas

Flue gas

condensate

Steam

GB

Pressure

instrument

lower than

tapping point

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 13

Page 14

7. Wiring details

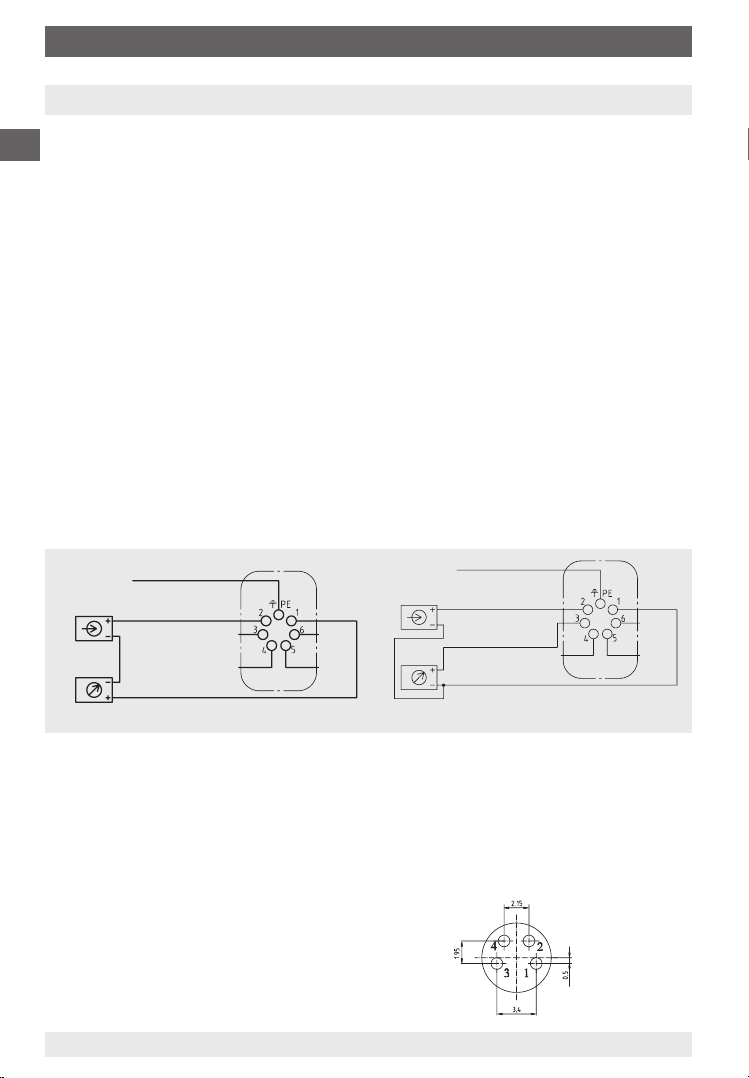

7. Wiring details

Electrical connection of this pressure transmitter is made via an L-plug connec-

GB

tor. Precise wiring diagrams can be found in the following drawings. In addition

to the wiring details, output signal and required power supply are given on the

rating plate.

Description of terminal designations used:

UB+ Plus terminal for supply voltage

0 V Minus terminal for supply voltage

Sig+ Plus terminal for output signal

Sig- Minus terminal for output signal

The instruments must be included within the plant’s equipotential bonding

Terminal assignment

Terminals 1 and 2 are the terminals for the signal output and for the power

supply. The terminal marked with PE (protective earth) is connected internally

to the housing. The connections 3 to 6 or 4 to 6 (for the 3-wire version), must

remain free and must not be used as connection points (also see Chapter 10

"Technical data").

2-wire design 3-wire design

i.e. 4 ... 20 mA i.e. 0 ... 20 mA / 0 ... 10 V

Power supply

Evaluation

(display/recorder)

ground, bonded/

connected to case

UB+/Sig+

+0V/Sig-

Connector housing

Terminals 3, 4, 5 and 6:

only for internal use

Power supply

Evaluation

(display/recorder)

ground, bonded/

connected to case

UB+/Sig+

I

out/Uout

+0V/Sig-

Terminals 4, 5 and 6:

only for internal use

An unstabilised DC voltage, with a residual ripple of max. 10 % peak-to-peak in

the range of the indicated supply voltage limits, is sufficient as a power supply.

Make sure that the supply voltage applied exceeds the maximum required

voltage by at least the value of the voltage drop across the external display

or evaluation devices; i.e. the transmitter can operate using a non-stabilised

supply voltage within the given limits, so long as the voltage available to the

transmitter does not fall below 12 V, or below 14 V for the Ex-version.

Connection details (only model PGT23.063)

Cable Plug connector Meaning

red Pin 1 U

black Pin 4 0 V/Sig -

+/Sig +

B

brown Pin 2 n.c.

- - - Pin 3 n.c

14

WIKA Operating Instructions intelliGAUGE family

11297264 05/2009 GB/D/F/E

Page 15

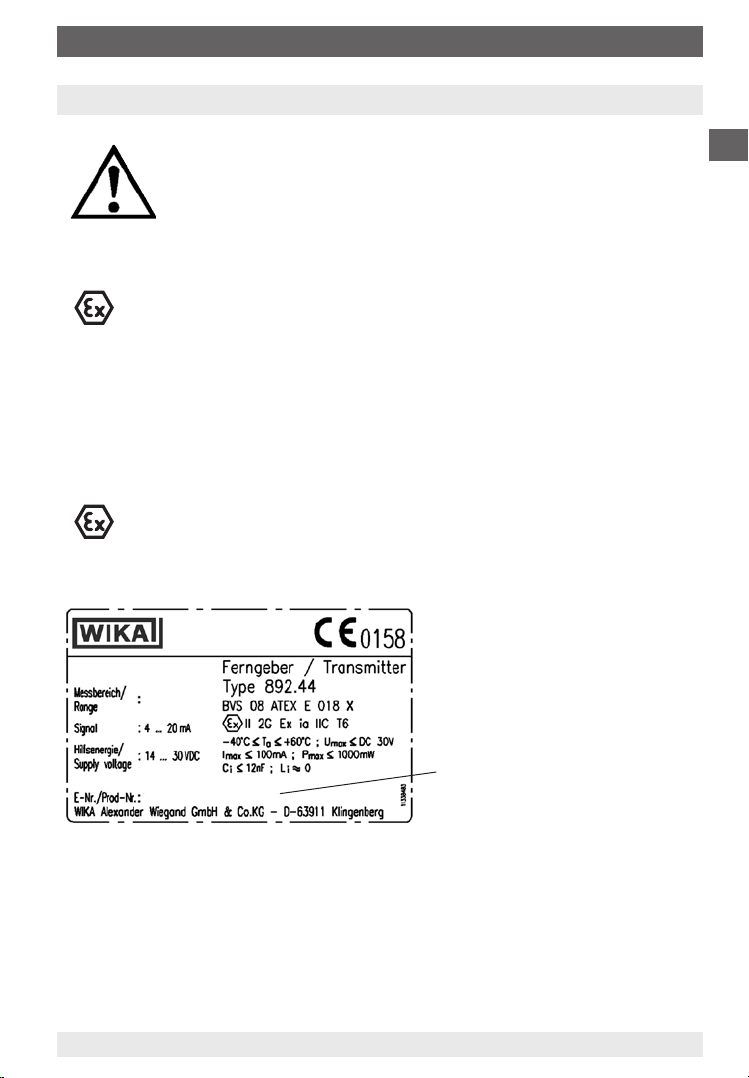

8. Instruments with ATEX approval

8. Instruments with ATEX approval

Read the operating conditions and the safety-related data

in the EC-type examination certificate (BVS 08 ATEX E018 X,

included in these operating instructions).

Key to symbols

ATEX

European directive for explosion protection (atmosphere=AT, explosive=EX)

The product corresponds to the requirements of the European Directive 94/9/

EC (ATEX) regarding explosion protection.

ATEX approval

Pressure gauges intended for the use in potentially explosive areas, see the

attached EC-type examination certificate BVS 08 ATEX E018 X

II 2G Ex ia IIc T4/T5/T6

I M2 Ex ia I

Product label (example)

Druckmessumformer

Pressure transmitter

PGT23.100

0 ... 10 bar

GB

≤ Coded date of manufacture

Month/year

(here April 2009)

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 15

12345678 0409

Page 16

8. Instruments with ATEX approval

Conformity specifications

For instruments with ATEX approval the following conformity specifications,

which differ slightly from the specifications indicated in the data sheet, are

GB

applicable:

Power supply: 14 … 30 DC V

Short circuit rating: Imax ≤ 100 mA

Power: Umax ≤ 1000 mW

Internal capacitance: Ci ≤ 12 nF

Internal inductance: negligible

Safety instructions for installation

Observe the installation and safety instructions included in

the operating instructions

≤Install the instruments in accordance with the instructions of

the manufacturer and the applicable standards and regulations

≤Seal the cable entries using approved cable glands so that

they are leak-tight

≤Only use cable glands which possess an ATEX Ex e appro

val and have an ingress protection of at least IP 65.

Fix the connection cable securely

≤If intrinsically safe equipment is installed in hazardous areas,

it must only be operated as part of a certified intrinsically

safe circuit.

Transmitter supply isolators

When using ATEX instruments, an Ex transmitter supply isolator is an absolute

requirement.

We recommend Model KFD2-STC4-Ex1 with a power supply of 20 ... 35 DC V,

installation on standard rail, our order number 2341268

16

WIKA Operating Instructions intelliGAUGE family

-

11297264 05/2009 GB/D/F/E

Page 17

9. Service and maintenance

9. Service and maintenance

Always open isolating devices gently, never abruptly, since this may generate

sudden pressure surges that may damage the gauge. The maximum working

pressure for pressure gauges with transmitters is indicated by the limit marks

on the dial.

With fluctuating pressure loads, lower values apply in accordance with EN 837.

The pressure gauges with transmitters require no maintenance and feature a

long service life if handled and operated properly. As a result of the mechanical

loading, and depending on the service conditions, it may become necessary to

check and readjust the zero point of the transmitter.

Zero point test

Normally the zero point is checked and adjusted in an unpressurised state. The

zero point of differential pressure gauges with transmitters should be checked

and adjusted by opening the pressure compensating valve under static load.

Mechanical zero point (pointer)

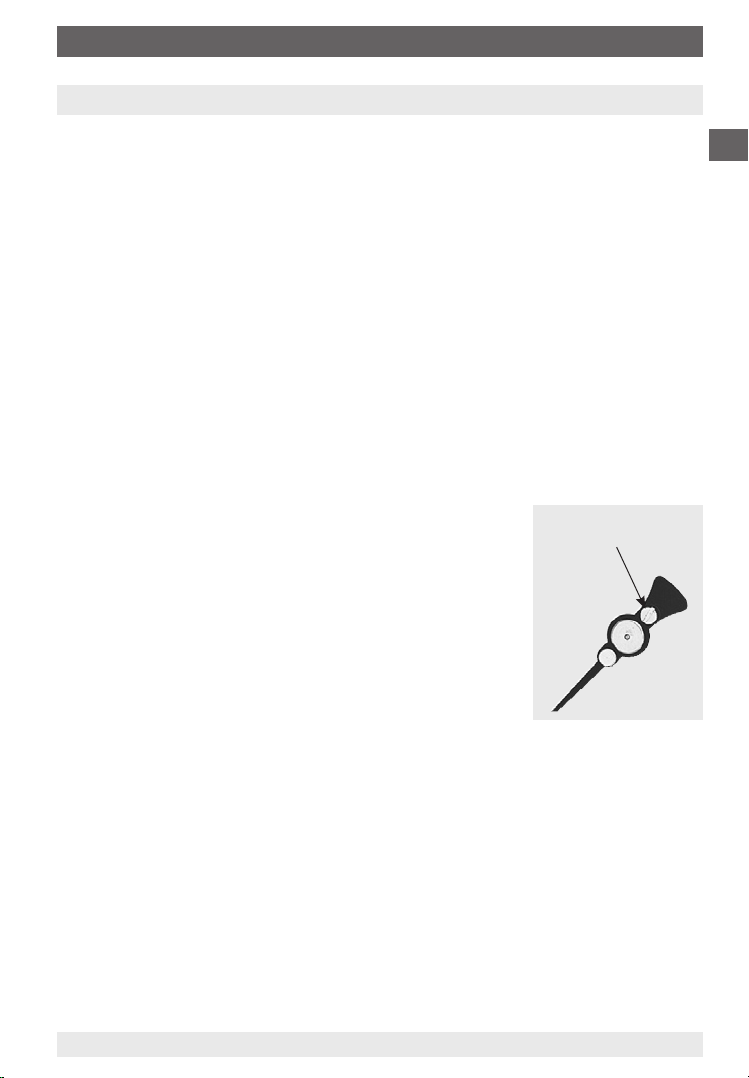

If the pointer deviates from the zero point (in the unpres-

1)

Slotted

screw

surised condition), the zero point may be corrected by

means of the integrated adjustable pointer. To do this,

remove the bayonet ring, including the window and seal,

from the housing. The zero point is altered by turning the

adjusting screw on the adjustable pointer.

After correcting the zero point, fasten the bayonet ring

and the window with its seal and then close the pressure

compensating valve or open the stop valve.

GB

Electrical zero point (4 mA)

1)

If the mechanical zero point is changed by means of the adjustable pointer, the

electrical zero point must be reset to the mechanical zero point.

First depressurise the pressure gauge.

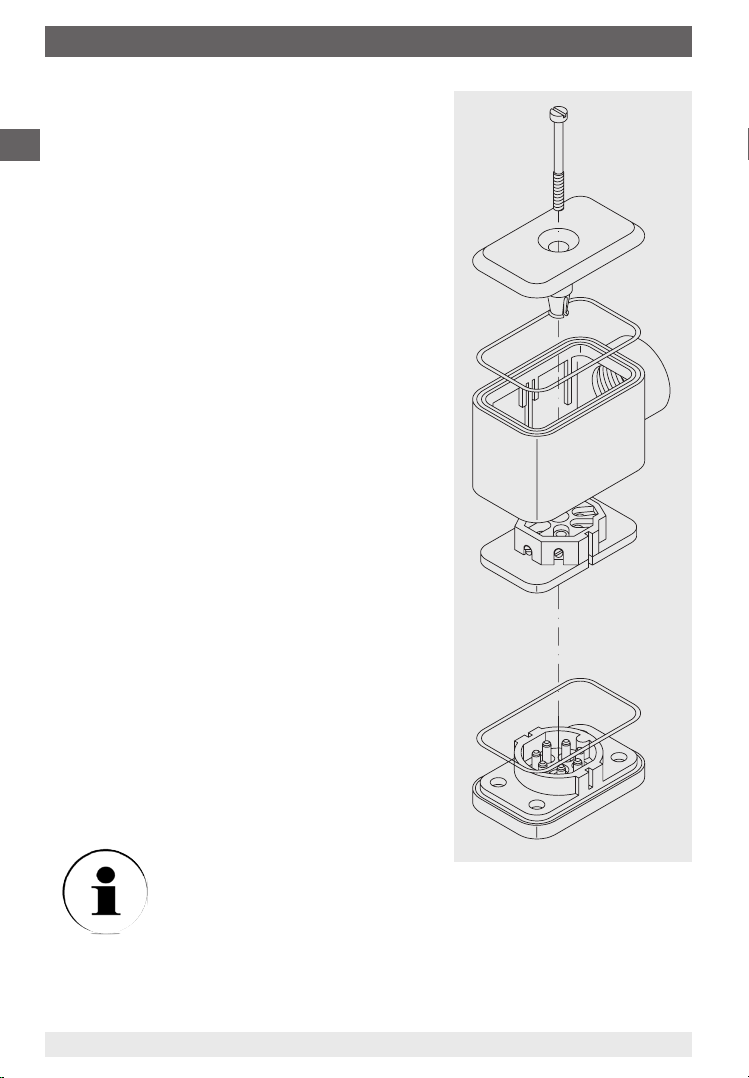

Loosen the complete cable hood on the right-hand side of the pressure gauge

by completely unscrewing the screw on the top of the cable hood cover

using an appropriate screwdriver (0.6 x 3.5 mm).

1) Not model PGT23.063

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 17

Page 18

9. Service and maintenance

Extract the screw. Remove the cable hood

with the socket insert from the cable socket

base and thus separate the pressure gauge

GB

from the power supply.

Remove the cable hood cover from the

cable hood and push the socket insert

out downwards through the entire cable hood

.

Use a short stranded wire with bare points at

both ends (max. permissible resistance 30 Ω)

to bridge contacts 5 and 6 on the socket

insert.

Reassemble the plug in reverse order. Place

the plug, with the attached piece of stranded

wire, onto the pin insert , and thus reestablish the power supply.

Within a max. 30 seconds the new zero point

will be stored within the electronics. During

this period, the current in the loop will increase

to 9.5 mA.

The new zero point also remains stored in the

case of a power failure.

Loosen the plug again in the same sequence

as described above and remove the piece of

stranded wire. After reassembling the plug,

the electrical output signal will once more

correspond to the indication of the mechanical

pointer.

18

Ensure the seals are properly

and securely reinstalled to

maintain the protection class.

WIKA Operating Instructions intelliGAUGE family

Screw

Cable hood cover

Cable hood

Socket insert

Cable socket base

Seals

11297264 05/2009 GB/D/F/E

Page 19

10. Troubleshooting

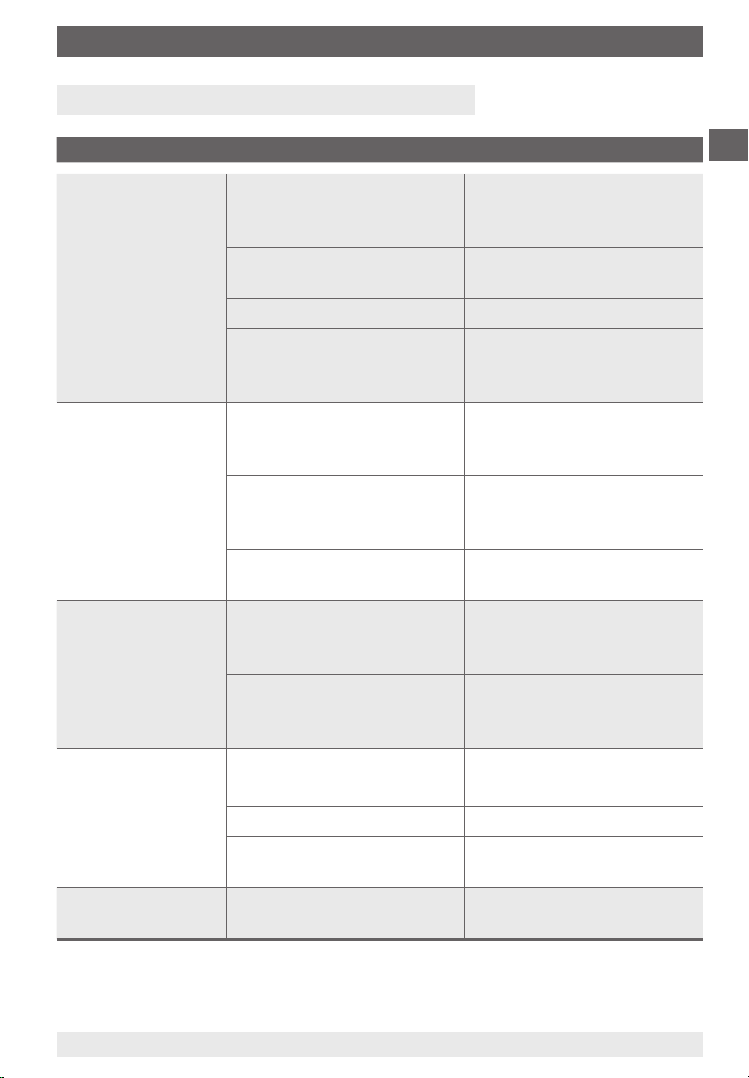

10. Troubleshooting

Defect Possible reason Remedy

No signal output Failure of power supply or

wiring interrupted

Transmitter miswired Check wiring; if necessary

No pressure (only 3-wire)

Electronic defect through incorrect supply voltage or external

voltage

Steady signal, despite

pressure changes

Steady and excessively high signal,

despite pressure

changes

Full span reading too

low

Pressure entry blocked Check tailpipes and pressure

Supply voltage connected the

wrong way round

(I = approx. 4.5 mA)

Transmitter failure Return instrument to manufac-

Bridge between terminals 5

and 6 (I = approx. 9.5 mA) was

not removed

Electronic defect through incorrect supply voltage or external

voltage

Supply voltage too low Adjust supply voltage

Check power supply and

wiring; replace defective

components

rectify it

Check tailpipes

Return instrument to manufacturer for repair

entry bore, if necessary clean it

carefully

Check the clamping and, if

necessary, change terminals 1

and 2 around

turer for repair

Open the cable hood and

remove the bridge between the

terminals 5 and 6

Return instrument to manufacturer for repair

GB

Load impedance too high Consider permissible max. load

Zero point shifted Readjust the zero point (see

chapter 9)

Zero signal too low/

too high

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 19

Zero point shifted Readjust the zero point (see

chapter 9)

Page 20

11. Storage / 12. Maintenance and servicing/cleaning

11. Storage

GB

Before installation, in order to prevent damage to the pressure instruments, the following points should be observed:

The pressure transmitter should be left in its original packing until installation.

After taking the transmitter out (e.g. for tests), reuse the original packaging

material.

The storage temperature should not be less than -40 °C or more than +70 °C.

Avoid the following influences:

Direct sunlight or vicinity to hot objects

Mechanical vibration

Soot, steam, dust, humidity and corrosive gasses

Potentially explosive environment, inflammable atmosphere

Before the system is stored, all traces of any medium residue

must be removed. This is particularly important if the medium

is a health hazard such as corrosive, toxic, carcinogenic,

radioactive, etc.

12. Maintenance and servicing/cleaning

The instruments require no maintenance or servicing and will give very long

service when handled and operated properly.

The indicator and switching function should be checked once or twice every 12

months. The instrument must be disconnected from the process before being

checked using pressure testing equipment.

The instruments should be cleaned with a damp cloth, moistened with soap

solution. Clean the instrument with a damp cloth. Particularly with regards to

ATEX model do not use a dry cloth for cleaning (electrostatic charging!)

Ensure that all parts are dry before the power is switched on again.

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family20

Page 21

13. Repairs / 14. Disposal

13. Repairs

Repairs should only be carried out by the manufacturer or appropriately trained

personnel.

For more technical data see the data sheet of the respective instrument:

Model PGT23.063 Data sheet PV 12.03

Model PGT23.100 / PGT23.160 Data sheet PV 12.04

Model PGT43.100 / PGT43.160 Data sheet PV 14.03

Model PGT43HP.100 / PGT43HP.160 Data sheet PV 14.07

Model APGT43.100 / APGT43.160 Data sheet PV 15.02

Model PGT63HP.100 / PGT63HP.160 Data sheet PV 16.06

Model DPGT43.100 / DPGT43.160 Data sheet PV 17.05

Model DPGT43HP.100 / DPGT43HP.160 Data sheet PV 17.13

14. Disposal

Dispose of instrument components and packaging materials in accordance

with the respective waste treatment and disposal regulations of the region or

country to which the instrument is supplied.

GB

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 21

Page 22

15. EC-type Examination Certificate

GB

22

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family

Page 23

15. EC-type Examination Certificate

GB

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family 23

Page 24

15. EC-type Examination Certificate

GB

11297264 05/2009 GB/D/F/E

WIKA Operating Instructions intelliGAUGE family24

Page 25

Inhalt

Inhalt

1. Sicherheitshinweise 26

2. Funktionsprinzip 26

3. Technische Daten 27

4. Montagehinweise 32

5. Montage und Inbetriebnahme 34

6. Messanordnung 35

7. Elektrischer Anschluss 36

8. Geräte mit ATEX-Zulassung 37

9. Bedienung und Wartung 39

10. Maßnahmen bei Störungen 41

11. Lagerung 42

12. Wartung und Reinigung 42

13. Reparaturen 43

14. Entsorgung 43

15. EG-Baumusterprüfbescheinigung 44 - 46

D

Information

Dieses Zeichen gibt Ihnen Informationen, Hinweise oder

Tipps.

Warnung!

Dieses Symbol warnt Sie vor Handlungen, die Schäden an

Personen oder am Gerät verursachen können.

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 25

Page 26

1. Sicherheitshinweise / 2. Funktionsprinzip

1. Sicherheitshinweise

Beachten Sie unbedingt bei Montage, Inbetriebnahme und

Betrieb dieser Geräte die entsprechenden nationalen Sicher-

D

Bei Nichtbeachten der entsprechenden Vorschriften können schwere

Körperverletzungen und/oder Sachschäden auftreten.

Nur entsprechend qualifiziertes Personal darf an diesen Geräten arbei-

ten.

heitsvorschriften (z. B. EN 837-2 Auswahl- und Einbauempfehlungen für Druckmessgeräte).

2. Funktionsprinzip

Als Messelement für diesen Ferngeber werden die in der technischen Druckmesstechnik wegen ihrer Robustheit und einfachen Handhabung weit verbreiteten Rohr-, Platten-, Kapselfeder- und Wellrohrfedermessglieder verwendet.

Unter dem Einfluss eines Druckes verformen sich die Messglieder im

elastischen Bereich.

Diese Bewegung wird über ein mechanisches Messwerk (Zahnräder) in eine

Drehbewegung umgesetzt. Ein auf der Zeigerachse aufgesetzter Magnet dreht

sich proportional mit dem Instrumentenzeiger in direkter linearer Abhängigkeit

zum Prozessdruck. Die nachgeschaltete Elektronik erfasst die Drehbewegung

des Magneten im Bereich von 0 bis 270 Winkelgrade.

Ein magnetfeldabhängiger Sensor (Drehwinkelsensor, 10 bit Auflösung) greift

auf der elektrischen Seite diese Veränderung berührungslos ab und arbeitet

somit verschleißfrei.

Über einen Verstärker wird die Drehbewegung in ein elektrisches Ausgangssignal umgesetzt. Werkseitig ist die Elektronik auf das normierte Ausgangssignal

4 ... 20 mA passiv, eingestellt (0 ... 20 mA, 0 ... 10 V und 4 ... 20 mA ATEX-Version als Option verfügbar; nicht bei Typ PGT23.063). Die Spanne des elektrischen

Ausgangssignals entspricht der Messspanne auf dem Zifferblatt.

Durch die drei normierten elektrischen Ausgangssignale ist diese Gerätereihe in

allen Bereichen der Industrie einsetzbar.

Ein Druckmessgerät mit Ferngeber aus der intelliGAUGE-Reihe verbindet alle

Vorteile einer mechanischen Anzeige vor Ort mit der Forderung nach einer

elektrischen Signalübertragung für eine moderne Messwerterfassung in der

Industrie.

WIKA Betriebsanleitung intelliGAUGE-Familie26

11297264 05/2009 GB/D/F/E

Page 27

3. Technische Daten

3. Technische Daten

3.1 Transmitter

Hilfsenergie U

Einfluss der Hilfsenergie

Zulässige Restwelligkeit

1)

B

DC V

% v. EW/10 V

% ss

12 ≤ UB ≤ 30≤

≤ 0,1

≤ 10

Ausgangssignal, Variante I 4 … 20 mA, 2 Leiter, passiv, nach NAMUR NE43

Zulässige max. Bürde R

Bürdeneinfluss

A

% vom EW

- 12 V)/0,02 A mit R

RA ≤ (U

B

jedoch max. 600 Ω

≤ 0,1

in Ohm und UB in Volt

A

Ausgangssignal, Variante II 4 … 20 mA, 2-Leiter - Ex, nach ATEX Ex II 2G Ex ia IIC

Ausgangssignal, Variante III 0 ... 20 mA, 3-Leiter

T4/T5/T6 bzw. Ex I M2 Ex ia I

2)

Ausgangssignal, Variante IV 0 ... 10 V *

Impedanz am Spannungsausgang

Belastbarkeit Spannungsausgang

Abtastrate Sensor

Elektrischer Nullpunkt

Einstellbarkeit Nullpunkt

Kennlinienabweichung

Genauigkeit Ausgangssignal

Auflösung

Aktualisierungsrate (Messrate)

Eingangssignal Drehwinkel

Erweiterte Sonderspanne

Langzeitstabilität Elektronik

Temperaturfehler Elektronik

Aufwärmzeit

Zulässige Umgebungstemperatur

Zulässige Lagertemperatur

Zulässige Messstofftemperatur

Ω

kΩ

ms

< °

)

% d. Spanne

% vom EW

% vom EW

1/s

)

< °

< °

)

% vom EW/a

% v. EW/10K

min.

°C

°C

°C

0,5

2 … 100

600, bei 3-Leiter optional schneller

Nullung durch kurzzeitiges überbrücken der Klemmen 5 und 6

45

≤ 1,0 (Grenzpunkteinstellung)

0,2 (nur Elektronik)

0,15 (10 bit Auflösung bei 360°)

> 1

0 … 270

< 330 (Option)

< 0,3

< 0,3 (im gesamten Temperaturbereich)

≤ 5

-40 … +60

-40 … +70

-40 … +100

Sonderfunktion Option: beliebiges, nicht winkelproportionales Ausgangssi-

gnal über Stützstellen und Interpolation der Zwischenwerte

(bei Bestellung anzugeben)

CE-Kennzeichen Störemission und Störfestigkeit nach EN 61 326-1

Elektrischer Anschluss Über Winkelsteckverbinder, 180° verdrehbar, max. 1,5 mm²,

Drahtschutz, Kabelverschraubung M20 x 1,5,

Kabelaußendurchmesser 7-13 mm, inkl. Zugentlastung

Schutzart IP 65 nach EN 60 529 / IEC 529;

Verpolungs- und Überspannungsschutz

Belegung der Anschlussklemmen

je nach Variante des Ausgangssignals

Klemme

Art

1

2

3

4

5

6

Variante I

4 ... 20 mA

GND

I+

reserviert

reserviert

Nullung

Nullung

Ex-Variante II

4 ... 20 mA

GND

I+

reserviert

reserviert

Nullung

Nullung

Variante III

0 ... 20 mA

GND

UB+

I

out

reserviert

Nullung

Nullung

Variante IV

0 ... 10 V

GND

UB+

U

out

reserviert

Nullung

Nullung

D

1) Nicht bei Typ PGT23.063

2) Nicht bei Typ DPGT43HP.100 / DPGT43HP.160

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 27

Page 28

3. Technische Daten

3.2 Transmitter bei Typ PGT23.063

Hilfsenergie U

Einfluss der Hilfsenergie

Zulässige Restwelligkeit

Ausgangssignal, Variante I 4 … 20 mA, 2 Leiter

D

Zulässige max. Bürde R

Bürdeneinfluss

Kennlinienabweichung

Genauigkeit Ausgangssignal

Eingangssignal Drehwinkel

Erweiterte Sonderspanne

Langzeitstabilität Elektronik

Zulässige Umgebungstemperatur

Zulässige Lagertemperatur

Zulässige Messstofftemperatur

EMV-Richtlinie 2007/108/EG Störaussendung (Grenzwertklasse B) und

Elektrischer Anschluss Freies Kabel oder optional Miniatursteckverbinder M8 x 1,

Schutzart IP 54 nach EN 60 529 / IEC 529, gefüllt IP 65

Kabelbelegung siehe Seite 29

1) Aus technischen Gründen kann der Messwert bis zum ersten Teilstrich der Skala außerhalb der Klassengenauigkeit liegen

B

A

3.3 Typ PGT23.063

Druckbelastbarkeit

- Ruhebelastung 3/4 x Skalenendwert

- Wechselbelastung 2/3 x Skalenendwert

- Kurzzeitig Skalenendwert

Temperatureinfluss

Schutzart

- Umhüllendes Gehäuse IP 54 nach EN 60 529 / IEC 60 529

- Mit Flüssigkeitsfüllung IP 65

Zulässige Temperatur

- Umgebung Gefüllt/ungefüllt -40 ... +60 °C

- Messstoff Maximal +100 °C

Weitere technische Daten siehe Datenblatt PV 12.03

DC V

% v. EW/10 V

% ss

% vom EW

% d. Spanne

% vom EW

< °

)

)

< °

% vom EW/a

°C

°C

°C

12 ≤ UB ≤ 30≤

≤ 0,1

≤ 10

- 12 V)/0,02 A mit R

RA ≤ (U

B

max. 600 Ω

≤ 0,1

≤ 1,0 (Grenzpunkteinstellung)

< 1,6 Elektronik

0 … 270

< 330 (Option)

< 0,5

-40 … +60

-40 … +70

-40 … +100

Störfestigkeit nach EN 61 326-1

4-polig

1)

in Ohm und UB in Volt jedoch

A

1)

Bei Abweichung von der Referenztemperatur am Messsystem (+20 °C):

max. ± 0,4 %/10 K vom jeweiligen Skalenendwert

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie28

Page 29

3. Technische Daten

3.4 Typ PGT23.100 / PGT23.160

Druckbelastbarkeit

- Ruhebelastung Skalenendwert

- Wechselbelastung 0,9 x Skalenendwert

- Kurzzeitig 1,3 x Skalenendwert

Temperatureinfluss

Schutzart

- Umhüllendes Gehäuse IP 54 nach EN 60 529 / IEC 60 529

- Mit Flüssigkeitsfüllung IP 65

Zulässige Temperatur

- Umgebung Gefüllt/ungefüllt -40 ... +60 °C

- Messstoff Maximal +100 °C

Weitere technische Daten siehe Datenblatt PV 12.04

3.5 Typ PGT43.100 / PGT43.160

Druckbelastbarkeit

- Ruhebelastung Skalenendwert

- Wechselbelastung 0,9 x Skalenendwert

- Kurzzeitig 5 x Skalenendwert, jedoch max. 40 bar

Temperatureinfluss

Schutzart

- Umhüllendes Gehäuse IP 54 nach EN 60 529 / IEC 60 529

- Mit Flüssigkeitsfüllung IP 65

Zulässige Temperatur

- Umgebung Gefüllt/ungefüllt -20 ... +60 °C

- Messstoff Maximal +100 °C

Weitere technische Daten siehe Datenblatt PV 14.03

Bei Abweichung von der Referenztemperatur am Messsystem (+20 °C):

max. ± 0,4 %/10 K vom jeweiligen Skalenendwert

Bei Abweichung von der Referenztemperatur am Messsystem (+20 °C):

max. ± 0,8 %/10 K vom jeweiligen Skalenendwert

D

3.6 Typ PGT43HP.100 / PGT43HP.160

Druckbelastbarkeit

- Ruhebelastung Skalenendwert

- Wechselbelastung 0,9 x Skalenendwert

- Überlastbarkeit 40, 100 und 400 bar

Temperatureinfluss

Schutzart

- Umhüllendes Gehäuse IP 54 nach EN 60 529 / IEC 60 529

- Mit Flüssigkeitsfüllung IP 65

Zulässige Temperatur

- Umgebung Gefüllt/ungefüllt -20 ... +60 °C

- Messstoff Maximal +100 °C

Weitere technische Daten siehe Datenblatt PV 14.07

11297264 05/2009 GB/D/F/E

Bei Abweichung von der Referenztemperatur am Messsystem (+20 °C):

max. ± 0,8 %/10 K vom jeweiligen Skalenendwert

WIKA Betriebsanleitung intelliGAUGE-Familie 29

Page 30

3. Technische Daten

3.7 Typ APGT43.100 / APGT43.160

Druckbelastbarkeit

- Ruhebelastung Skalenendwert

- Wechselbelastung 0,9 x Skalenendwert

- Überlastbarkeit siehe Datenblatt PM 05.02

D

Temperatureinfluss

Schutzart

- Umhüllendes Gehäuse IP 54 nach EN 60 529 / IEC 60 529

- Mit Flüssigkeitsfüllung IP 65

Zulässige Temperatur

- Umgebung Gefüllt/ungefüllt -20 ... +60 °C

- Messstoff Maximal +100 °C

Weitere technische Daten siehe Datenblatt PV 15.02

3.8 Typ PGT63HP.100 / PGT63HP.160

Druckbelastbarkeit

- Ruhebelastung Skalenendwert

- Wechselbelastung 0,9 x Skalenendwert

- Überlastbarkeit 50 x Skalenendwert

Temperatureinfluss

Schutzart

- Umhüllendes Gehäuse IP 54 nach EN 60 529 / IEC 60 529

Zulässige Temperatur

- Umgebung -20 ... +60 °C

- Messstoff Maximal +100 °C

Weitere technische Daten siehe Datenblatt PV 16.06

Bei Abweichung von der Referenztemperatur am Messsystem (+20 °C):

max. ± 0,8 %/10 K vom jeweiligen Skalenendwert

Bei Abweichung von der Referenztemperatur am Messsystem (+20 °C):

max. ± 0,6 %/10 K vom jeweiligen Skalenendwert

3.9 Typ DPGT43.100 / DPGT43.160

Druckbelastbarkeit

- Ruhebelastung Skalenendwert

- Wechselbelastung 0,9 x Skalenendwert

- Überlastbarkeit mindestens 10 x Skalenendwert, max. 25 bar

Temperatureinfluss

Schutzart

- Umhüllendes Gehäuse IP 54 nach EN 60 529 / IEC 60 529

- Mit Flüssigkeitsfüllung IP 65

Zulässige Temperatur

- Umgebung Gefüllt/ungefüllt -20 ... +60 °C

- Messstoff Maximal +100 °C

Weitere technische Daten siehe Datenblatt PV 17.05

Bei Abweichung von der Referenztemperatur am Messsystem (+20 °C):

max. ± 0,5 %/10 K vom jeweiligen Skalenendwert

WIKA Betriebsanleitung intelliGAUGE-Familie30

11297264 05/2009 GB/D/F/E

Page 31

3. Technische Daten

3.10 Typ DPGT43HP.100 / DPGT43HP.160

Druckbelastbarkeit

- Ruhebelastung Skalenendwert

- Wechselbelastung 0,9 x Skalenendwert

- Überlastbarkeit 40, 100, 250 oder 400 bar

Temperatureinfluss

Schutzart

- Umhüllendes Gehäuse IP 54 nach EN 60 529 / IEC 60 529

- Mit Flüssigkeitsfüllung IP 65

Zulässige Temperatur

- Umgebung Gefüllt/ungefüllt -20 ... +60 °C

- Messstoff Maximal +100 °C

Weitere technische Daten siehe Datenblatt PV 17.13

Bei Abweichung von der Referenztemperatur am Messsystem (+20 °C):

max. ± 0,5 %/10 K vom jeweiligen Skalenendwert

D

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 31

Page 32

4. Montagehinweise

4. Montagehinweise

Das Druckmessgerät muss erschütterungsfrei befestigt werden und soll gut

ablesbar angeordnet sein. Es empfiehlt sich, zwischen Druckentnahmestelle

und Druckmessgerät eine Absperrvorrichtung zwischenzuschalten, die einen

D

Austausch des Messgerätes und eine Nullpunktkontrolle bei laufender Anlage

ermöglicht.

Installation

Nennlage nach EN 837-3 / 9.6.6 Bild 7: 90° (

Druckanschluss unten

Damit im Fehlerfall die sichere Druckentlastung durch die Rückwand erfol-

gen kann, müssen hinter dem Gehäuse mindestens 25 mm frei bleiben!

Um zusätzliche Aufheizung zu vermeiden, dürfen die Geräte im Betrieb

keiner direkten Sonneneinstrahlung ausgesetzt werden!

Bei gefüllten Ausführungen muss vor Inbetriebnahme das Entlüftungsventil

(bei Druckbereichen ≤ 10 bar) an der Oberseite des Gehäuses geöffnet

werden!

Zulässige Schwingungsbelastung am Einbauort

Die Geräte sollten grundsätzlich nur an Stellen ohne Schwingungsbelastung

eingebaut werden

Gegebenenfalls kann z. B. durch eine flexible Verbindungsleitung von der

Messstelle zum Druckmessgerät und die Befestigung über eine Messgerätehalterung eine Entkopplung vom Einbauort erreicht werden.

Falls dies nicht möglich ist, dürfen folgende Grenzwerte nicht überschritten

werden:

⊥)

Ungefüllte Geräte: Frequenzbereich < 150 Hz

Beschleunigung < 0,7 g (7 m/s²)

Flüssigkeitsgefüllte Geräte: Frequenzbereich < 150 Hz

Beschleunigung < 4 g (40 m/s²)

Die Flüssigkeitsfüllung ist regelmäßig zu überprüfen.

Der Flüssigkeitsspiegel darf nicht unter 75 % des Gerätedurchmessers fallen.

Prüfanschluss

In bestimmten Anwendungsfällen (z. B. Dampfkessel) müssen die Absperrarmaturen einen Prüfanschluss besitzen, damit das Druckmessgerät ohne Ausbau

überprüft werden kann.

32

WIKA Betriebsanleitung intelliGAUGE-Familie

11297264 05/2009 GB/D/F/E

Page 33

4. Montagehinweise

Messgerätebefestigung

Ist die Leitung zum Druckmessgerät für eine erschütterungsfreie Anbringung

nicht stabil genug, so ist die Befestigung über entsprechende Befestigungselemente für Wand- und/oder Rohrmontage, gegebenenfalls über eine Kapillarleitung vorzunehmen.

Messsystemdämpfung

Können Erschütterungen nicht durch geeignete Installationen vermieden

werden, dann sollten Druckmessgeräte mit Flüssigkeitsfüllung eingesetzt

werden.

Temperaturbelastung

Die Anbringung des Druckmessgerätes ist so auszuführen, dass die zulässige

Betriebstemperatur, auch unter Berücksichtigung des Einflusses von Konvektion und Wärmestrahlung, weder unter noch überschritten wird. Dazu sind

Druckmessgerät und Absperrarmatur durch ausreichend lange Messleitungen

oder Wassersackrohre zu schützen.

Der Temperatureinfluss auf die Anzeige- bzw. Messgenauigkeit ist zu beachten.

Die tatsächliche maximale Oberflächentemperatur ist nicht

von diesen Geräten selbst abhängig, sondern hauptsächlich

von der jeweiligen Messstofftemperatur! Bei gasförmigen

Stoffen kann sich die Temperatur durch Kompressionswärme

erhöhen. In solchen Fällen muss ggf. die Druckänderungsgeschwindigkeit gedrosselt bzw. die zulässige Messstofftemperatur reduziert werden.

D

Druckmittler / Schutzvorlagen

Bei aggressiven, heißen, hochviskosen, verunreinigten oder kristallisierenden

Messstoffen, die nicht in das Messglied eindringen dürfen, sind Druckmittler als

Trennvorlagen vorzusehen. Zur Druckübertragung auf das Messglied dient eine

neutrale Mittlerflüssigkeit, die entsprechend dem Messbereich, der Temperatur

und der Verträglichkeit mit dem Messstoff auszuwählen ist.

Die Verbindung zwischen Druckmessgerät und Druckmittler darf auf keinen Fall

gelöst werden.

Schutz der Messglieder vor Überlastung

Unterliegt der Messstoff schnellen Druckänderungen oder ist mit Druckstößen

zu rechnen, dürfen diese nicht direkt auf das Messglied einwirken. Die Druckstöße müssen in ihrer Wirkung gedämpft werden, z. B. durch Einbau einer

Drosselstrecke (Verringerung des Querschnittes im Druckkanal) oder durch

Vorschaltung einer einstellbaren Drosselvorrichtung.

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 33

Page 34

4. Montagehinweise / 5. Montage und Inbetriebnahme

Druckentnahmestutzen

Der Druckentnahmestutzen soll mit einer genügend großen Bohrung (≥ 6 mm)

möglichst über ein Absperrorgan so angeordnet werden, dass die Druckentnahme nicht durch eine Strömung des Messstoffes verfälscht wird. Die Messleitung

zwischen Druckentnahmestutzen und Druckmessgerät soll zur Vermeidung von

D

Verstopfung und Verzögerungen bei der Druckübertragung einen genügend

großen Innendurchmesser besitzen. Sie soll auch ohne scharfe Krümmung sein.

Ihre Verlegung mit einer stetigen Neigung von ca. 1:15 ist zu empfehlen.

Messleitung

Die Messleitung ist so auszuführen und zu montieren, dass sie die auftretenden

Belastungen durch Dehnung, Schwingung und Wärmeeinwirkung aufnehmen

kann. Bei Gasen als Messstoff ist an der tiefsten Stelle eine Entwässerung, bei

flüssigen Messstoffen an der höchsten Stelle eine Entlüftung vorzusehen.

5. Montage und Inbetriebnahme

Zur Abdichtung der Anschlüsse sind Flachdichtungen, Dichtlinsen oder

WIKA-Profildichtungen einzusetzen. Um das Druckmessgerät in die Stellung

zu bringen, in der sich die örtliche Anzeige am besten ablesen lässt, ist ein

Anschluss mit Spannmuffe oder Überwurfmutter zu empfehlen. Beim Ein- und

Ausschrauben dürfen die Druckmessgeräte nicht am Gehäuse angezogen

werden, sondern nur an den Schlüsselflächen des Anschlussstutzens!

Montage mit

Gabelschlüssel

Ist das Druckmessgerät tiefer als der Druckentnahmestutzen angeordnet, muss

die Messleitung vor dem Anschließen gut durchgespült werden um Fremdkörper zu beseitigen. Nach der Montage sind die Druckmessgeräte, deren Gehäuse flüssigkeitsgefüllt sind, aus technischen Gründen zu belüften. Siehe dazu

den entsprechenden Aufkleber auf dem Druckmessgerät.

WIKA Betriebsanleitung intelliGAUGE-Familie34

11297264 05/2009 GB/D/F/E

Page 35

5. Montage und Inbetriebnahme / 6. Messanordnungen

Nach Herstellen der Druckverbindung und der elektrischen Anschlüsse sind die

Druckmessgeräte sofort betriebsbereit.

Zur Gleichspannungsversorgung des Ferngebers in Standardausführung

können die Speisegeräte Typ A-VA-1 oder Typ KFA6-STR-1.24.500 verwendet

werden.

Vor dem Ausbau des Druckmessgerätes ist das Messglied drucklos zu machen.

Gegebenenfalls muss die Messleitung entspannt werden. Bei Druckmessgeräten mit Plattenfedermessglied dürfen die Spannschrauben des Ober- und

Unterflansches nicht gelöst werden.

Messstoffreste in ausgebauten Druckmessgeräten können

zur Gefährdung von Menschen, Umwelt und Einrichtung

führen. Ausreichende Vorsichtsmaßnahmen sind zu ergreifen.

Druckanschluss

Entsprechend den allgemeinen technischen Regeln für Druckmessgeräte (z. B.

EN 837-2 „Auswahl- und Einbauempfehlungen für Druckmessgeräte“).

6. Messanordnungen

Bewährte Messanordnungen für verschiedene Messstoffarten.

D

flüssige Messstoffe gasförmige Messstoffe

Füllung der

Messleitung

Beispiele

Druckmessgerät

oberhalb des

Entnahmestutzens

Druckmessgerät

unterhalb des

Entnahmestutzens

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 35

flüssig zum Teil

Kondensat siedende

ausgasend

Flüssigkeiten

vollständig

verdampft

„Flüssiggase“ trockene Luft feuchte Luft,

gasförmig z. T. kon-

densiert

(feucht)

Rauchgase

vollständig

kondensiert

Wasserdampf

Page 36

7. Elektrischer Anschluss

7. Elektrischer Anschluss

Der elektrische Anschluss des Ferngebers wird über einen Winkelsteckverbinder hergestellt (nicht bei Typ PGT23.063). Die genauen Anschlussbelegungen

können den nachfolgenden Zeichnungen entnommen werden. Zusätzlich sind

D

Anschlussbelegung, Ausgangssignal und erforderliche Hilfsenergie auf dem

Typenschild vermerkt.

Bedeutung der verwendeten Klemmenbezeichnungen:

UB+ Plusklemme der Versorgungsspannung

0 V Minusklemme der Versorgungsspannung

Sig+ Plusklemme des Ausgangssignals

Sig- Minusklemme des Ausgangssignals

Die Geräte sind in den Potenzialausgleich der Anlage mit einzubeziehen.

Belegung der Anschlussklemmen

Die Klemmen 1 und 2 sind die Anschlussklemmen für den Signalausgang bzw. für die

Spannungsversorgung. Die mit PE (protective earth, Schutzleiter) gekennzeichnete

Klemme ist intern mit dem Gehäuse verbunden. Die Anschlüsse 3 bis 6, bzw. 4 bis 6

bei den 3 Leiter-Varianten sind frei zu lassen und dürfen auch nicht als Stützpunkte

verwendet werden (siehe auch Kapitel 10 „Technische Daten“).

2-Leiter-Ausführung 3-Leiter-Ausführung

z. B. 4 ... 20 mA z. B. 0 ... 20 mA / 0 ... 10 V

Hilfsenergie

Auswertung

(Anzeige)

Erde, verbunden

mit Gehäuse

UB+/Sig+

+0V/Sig-

Kabeldose

Klemmen 3, 4, 5 und 6:

nur für internen Gebrauch

Hilfsenergie

Auswertung

(Anzeige)

Erde, verbunden

mit Gehäuse

UB+/Sig+

I

out/Uout

+0V/Sig-

Klemmen 4, 5 und 6:

nur für internen Gebrauch

Als Hilfsenergie genügt eine unstabilisierte Gleichspannung mit einer Restwelligkeit

von max. 10 % ss im Bereich der angegebenen Versorgungsspannungsgrenzen.

Es ist darauf zu achten, dass die angelegte Versorgungsspannung um mindestens

den Betrag höher ist als die maximal erforderliche Spannung, die an den externen

Anzeige- und Auswertegeräten abfällt; d. h. die am Ferngeber anliegende Spannung

darf nicht unter 12 V und bei der Ex-Ausführung nicht unter 14 V fallen.

Kabelbelegung (nur bei Typ PGT23.063)

Kabel Steckverbinder Bedeutung

rot Pin 1 U

schwarz Pin 4 0 V/Sig -

+/Sig +

B

braun Pin 2 n.c.

- - - Pin 3 n.c

WIKA Betriebsanleitung intelliGAUGE-Familie36

11297264 05/2009 GB/D/F/E

Page 37

8. Geräte mit ATEX-Zulassung

8. Geräte mit ATEX-Zulassung

Lesen Sie unbedingt die Einsatzbedingungen und Sicherheitstechnischen Daten in der EG Baumusterprüfbescheinigung nach (BVS 08 ATEX E018 X, in dieser Betriebsanleitung enthalten).

Zeichenerklärung

ATEX

Europäische Explosionsschutz-Richtlinie (Atmosphäre=AT, Explosion=EX)

Das Produkt stimmt überein mit den Anforderungen der europäischen Richtlinie

94/9/EG (ATEX) zum Explosionsschutz.

Zulassung ATEX

Druckmessgeräte zur bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen, siehe beiliegende EG-Baumusterprüfbescheinigung

BVS 08 ATEX E018 X

II 2G Ex ia IIc T4/T5/T6

I M2 Ex ia I

Typenschild (Beispiel)

Druckmessumformer

Pressure transmitter

PGT23.100

0 ... 10 bar

D

≤ Codiertes Herstellungsdatum

Monat/Jahr

(hier April 2009)

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 37

12345678 0409

Page 38

8. Geräte mit ATEX-Zulassung

Sicherheitstechnische Höchstwerte

Bei Geräten mit ATEX Zulassung gelten folgende, teilweise von dem Datenblatt

abweichende, sicherheitstechnische Höchstwerte:

Hilfsenergie: 14 … 30 DC V

D

Kurzschlussstrom: Imax ≤ 100 mA

Leistung: Umax ≤ 1000 mW

Innere Kapazität: Ci ≤ 12 nF

Innere Induktivität: vernachlässigbar

Sicherheitshinweise bei Installation

Die Installations- und Sicherheitshinweise der Betriebsanlei-

tung beachten

Geräte gemäß Herstellerangaben und den gültigen Normen

und Regeln installieren

Kabeleinführung mit entsprechend zugelassenen Kabelver-

schraubungen dicht verschließen

Nur Kabelverschraubungen mit ATEX-Ex e-Zulassung und

mindestens Schutzart IP 65 verwenden. Anschlusskabel

fest verlegen

Eigensichere Betriebsmittel dürfen in explosionsgefährdeten

Bereichen nur in eigensicher bescheinigten Stromkreisen

betrieben werden

Speisetrenner

Für die Anwendung von ATEX Geräten ist ein Ex-Speisetrenner zwingend erforderlich.

Wir empfehlen den Typ KFD2-STC4-Ex1 mit 20 ... 35 DC V Hilfsenergie,

Montage auf Normschiene, unsere Bestellnummer: 2341268

WIKA Betriebsanleitung intelliGAUGE-Familie38

11297264 05/2009 GB/D/F/E

Page 39

9. Bedienung und Wartung

9. Bedienung und Wartung

Absperreinrichtungen dürfen zur Vermeidung von Druckstößen nur langsam

geöffnet werden. Der Verwendungszweck für ruhende Belastung ist bei Druck-

messgeräten mit Ferngebern am Zifferblatt durch die Begrenzungsmarke ≤ auf

dem Zifferblatt gekennzeichnet.

Bei wechselnder Belastung gelten entsprechend EN 837 niedrigere Werte.

Die Druckmessgeräte mit Ferngeber sind wartungsfrei und zeichnen sich

bei sachgemäßer Behandlung und Bedienung durch eine hohe Lebensdauer

aus. Durch mechanische Belastung und je nach Einsatzbedingungen kann

es notwendig werden, dass der Nullpunkt des Ferngebers überprüft und ggf.

nachjustiert werden muss.

Nullpunktprüfung

Im Allgemeinen erfolgt die Überprüfung und Einstellung des Nullpunktes im

drucklosen Zustand. Bei Differenzdruckmessgeräten mit Ferngeber sollte die

Überprüfung und Einstellung des Nullpunktes durch Öffnen des Druckausgleichventils unter statischer Last erfolgen.

D

Mechanischer Nullpunkt (Zeiger)

Bei Abweichung des Zeigers von dem Nullpunkt (im

drucklosen Zustand), kann eine Nullpunktkorrektur über

1)

Schlitzschraube

den eingebauten Verstellzeiger erfolgen. Hierzu den

Bajonettring inklusive der Sichtscheibe und der Dichtung

vom Gehäuse entfernen. Die Nullpunkt-Verstellung wird

durch Verdrehen der Einstellschraube am Verstellzeiger

erreicht.

Nach erfolgter Nullpunktkorrektur den Bajonettring und

die Sichtscheibe mit der Dichtung wieder befestigen und

das Druckausgleichsventil schließen oder das Absperrventil öffnen.

Elektrischer Nullpunkt (4 mA)

1)

Wird der mechanische Nullpunkt über den Verstellzeiger verändert, sollte der

elektrische Nullpunkt wieder dem mechanischen angepasst werden.

Bringen Sie hierzu das Manometer zuerst in den drucklosen Zustand.

Lösen Sie die ganze Kabelhaube an der rechten Manometerseite in dem Sie mit

einem Schlitzschraubendreher (0,6 x 3,5 mm) die Schraube

an der Obersei-

te des Kabelhaubendeckels vollständig lösen. Nehmen Sie die Schraube

1) Nicht bei Typ PGT23.063

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 39

Page 40

9. Bedienung und Wartung

heraus. Ziehen Sie die Kabelhaube samt

Buchseneinsatz vom Kabeldosenunterteil

ab und trennen somit das Manometer von

der Spannungsversorgung.

D

Entfernen Sie den Kabelhaubendeckel

von der Kabelhaube und drücken Sie den

Buchseneinsatz ganz durch die Kabelhaube

nach unten heraus.

Überbrücken Sie die Kontakte 5 und 6 an dem

Buchseneinsatz mit einem kurzen, an beiden

Enden abisolierten Stück Litze (maximal zulässiger Widerstand 30 Ω).

Montieren Sie den Stecker wieder in

umgekehrter Reihenfolge. Stecken Sie den

Stecker mit montiertem Stück Litzendraht

auf den Stifteinsatz und stellen somit die

Versorgungsspannung wieder her.

Innerhalb von max. 30 Sekunden wird der neue

Nullpunkt in der Elektronik gespeichert. Während

dieser Zeit steigt der Strom in der Schleife auf

9,5 mA.

Der neue Nullpunkt bleibt auch bei

Spannungsausfall auf Dauer gespeichert.

Lösen Sie wieder den Stecker in der oben

beschriebenen Reihenfolge und entfernen das

Stück Litzendraht. Nach erneutem Montieren

des Steckers ist das elektrische Ausgangssignal wieder deckungsgleich mit der Anzeige

des mechanischen Zeigers.

Damit die Schutzart erhalten

bleibt, unbedingt die

Dichtungen wieder

montieren.

WIKA Betriebsanleitung intelliGAUGE-Familie40

Schraube

Kabelhaubendeckel

Kabelhaube

Buchseneinsatz

Kabeldosenunterteil

Dichtungen

11297264 05/2009 GB/D/F/E

Page 41

10. Maßnahmen bei Störungen

10. Maßnahmen bei Störungen

Störung mögliche Ursache Maßnahme

Kein Ausgangssignal keine Versorgungsspannung

oder Leitungsbruch

Ferngeber falsch angeschlossen

Kein

Eingangsdruck (nur 3 Leiter)

Elektronik defekt durch zu hohe

Versorgungsspannung oder

durch Fremdspannung

gleichbleibendes

Ausgangssignal bei

Druckänderung

zu hohes, bei Druckänderung gleichbleibendes Ausgangssignal

Signalspanne zu klein Versorgungsspannung zu

Nullpunktsignal zu

klein/zu groß

Eingangskanal verstopft Eingangskanal bzw. Drossel-

Versorgungsspannung verpolt

angeschlossen

(I = ca. 4,5 mA)

Ferngeber defekt Messgerät zur Instandsetzung

Brücke zwischen Klemmen 5

und 6 nicht entfernt

(I = ca. 9,5 mA)

Elektronik defekt durch zu hohe

Versorgungsspannung oder

durch Fremdspannung

niedrig

Bürde zu hoch max. zulässige Bürde beachten

Nullpunkt verstellt Nullpunkt neu setzen (siehe

Nullpunkt verstellt Nullpunkt neu setzen (siehe

Spannungsversorgung und

Leitungen überprüfen. Ggf.

defekte Teile austauschen

Anschlüsse überprüfen;

Anschlüsse ggf. korrigieren

Druckzuführung überprüfen

Messgerät zur Instandsetzung

an Hersteller zurück

schraube reinigen

Verklemmung prüfen und ggf.

Klemme 1 und 2 vertauschen

an Hersteller zurück

Kabelhaube öffnen und Brücke

zwischen Klemmen 5 und 6

entfernen

Messgerät zur Instandsetzung

an Hersteller zurück

Versorgungsspannung korrigieren

Kapitel 9)

Kapitel 9)

D

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 41

Page 42

11. Lagerung / 12. Wartung und Reinigung

11. Lagerung

Vor der Einlagerung des Gerätes müssen alle ggf. anhaftenden Mediumsreste entfernt werden. Dies ist besonders

D

Um Schäden zu vermeiden, sind für die Lagerung der Druckmessgeräte

folgende Punkte zu beachten:

Druckmessgeräte in der Originalverpackung belassen

Nach einer eventuellen Entnahme der Messgeräte für z.B. Prüfungen, sollte

das Gerät wieder in der Originalverpackung eingelagert werden

Lagertemperaturbereich -40 °C ... +70 °C

Vermeiden Sie folgende Einflüsse:

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

Ruß, Dampf, Staub, Feuchtigkeit und korrosive Gase

Explosionsgefährdete Umgebung, entzündliche Atmosphären

wichtig, wenn das Medium gesundheitsgefährdend ist, wie

z. B. ätzend, giftig, krebserregend, radioaktiv, usw.

12. Wartung und Reinigung

Die Geräte sind wartungsfrei und zeichnen sich bei sachgemäßer Behandlung

und Bedienung durch eine hohe Lebensdauer aus.

Eine Überprüfung der Anzeige und der Schaltfunktion sollte etwa 1 bis 2 mal

pro Jahr erfolgen. Dazu ist das Gerät vom Prozess zu trennen und mit einer

Druckprüfvorrichtung zu kontrollieren.

Reinigen der Geräte mit einem (in Seifenlauge) angefeuchteten Tuch.

Verwenden Sie insbesondere bei der ATEX-Ausführung KEIN trockenes Tuch

zum Abwischen des Gerätes (statische Aufladung!)

Vor Wiedereinschalten des Stromes ist sicherzustellen, dass alle Teile

abgetrocknet sind.

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie42

Page 43

13. Reparaturen / 14. Entsorgung

13. Reparaturen

Reparaturen sind ausschließlich vom Hersteller oder entsprechend geschultem

Personal durchzuführen.

Weitere technische Daten entnehmen Sie bitte dem Datenblatt des jeweiligen

Gerätes:

Typ PGT23.063 Datenblatt PV 12.03

Typ PGT23.100 / PGT23.160 Datenblatt PV 12.04

Typ PGT43.100 / PGT43.160 Datenblatt PV 14.03

Typ PGT43HP.100 / PGT43HP.160 Datenblatt PV 14.07

Typ APGT43.100 / APGT43.160 Datenblatt PV 15.02

Typ PGT63HP.100 / PGT63HP.160 Datenblatt PV 16.06

Typ DPGT43.100 / DPGT43.160 Datenblatt PV 17.05

Typ DPGT43HP.100 / DPGT43HP.160 Datenblatt PV 17.13

14. Entsorgung

Entsorgen Sie Gerätekomponenten und Verpackungsmaterialien entsprechend

den einschlägigen landesspezifischen Abfallbehandlungs- und Entsorgungsvorschriften des Anliefergebietes.

D

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 43

Page 44

15. EG-Baumusterprüfbescheinigung

D

44

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie

Page 45

15. EG-Baumusterprüfbescheinigung

D

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie 45

Page 46

15. EG-Baumusterprüfbescheinigung

D

46

11297264 05/2009 GB/D/F/E

WIKA Betriebsanleitung intelliGAUGE-Familie

Page 47

Sommaire

Sommaire

1. Consignes de sécurité 48

2. Principe de fonctionnement 48

3. Données techniques 49

4. Instructions de montage 54

5. Installation et mise en service 56

6. Installation sur le point de mesure 57

7. Branchement électrique 58

8. Appareils avec l‘agrément ATEX 59

9. Commande et maintenance 61

10. Mesures à prendre en cas de pannes 63

11. Stockage 64

12. Entretien et nettoyage 64

13. Réparations 65

14. Mise au rebus 65

15.

Attenstation d'examen CE anglais

allemand

22 - 24

44 - 46

F

Informations

Ce signe vous donne des informations, des remarques ou

des conseils.

Avertissement !

Ce symbole vous avertit d'actions qui sont susceptibles

d'entraîner des dommages physiques ou matériels.

11297264 05/2009 GB/D/F/E

WIKA Mode d'emploi famille intelliGAUGE 47

Page 48

1. Consignes de sécurité / 2. Principe de fonctionnement

1. Consignes de sécurité

Respectez impérativement les directives de sécurité nationales correspondantes lors du montage, de la mise en service

et de l'exploitation de ces appareils (p. ex. EN 837-2 Choix et

recommandations relatives à l'installation de manomètres).

F

Le non-respect des instructions correspondantes est susceptible

d‘entraîner des risques de blessure et/ou des dégâts matériels.

Seul le personnel habilité et qualifié est autorisé à manipuler les instru-

ments.

2. Principe de fonctionnement

Ces transmetteurs utilisent comme éléments de mesure des systèmes à tube

manométrique, à membrane ou à capsule, qui constituent des systèmes de

mesure éprouvés, fiables et souples d’utilisation dans le domaine de la technique de mesure de pression.

Sous l'influence d'une pression, ces éléments de mesure se déforment dans

leur zone d'élasticité.

Ce mouvement est transformé en mouvement rotatif au moyen d'un dispositif

de mesure mécanique (roues dentées). Un aimant fixé sur l'axe de l'aiguille

tourne proportionnellement à la rotation de l'aiguille de l‘instrument en fonction

de la pression process. L'électronique en aval saisit le mouvement de rotation

de l'aimant sur une plage de 0 à 270 degrés d'angle.

Un capteur indépendant du champ magnétique (capteur d'angle de rotation,

résolution 10 bits) mesure du côté électrique cette modification sans le moindre

contact et travaille donc sans usure.

Au moyen d'un amplificateur, le mouvement de rotation est transformé en

signal de sortie électrique. En usine, l'électronique est réglée en standard sur

le signal de sortie 4 ... 20 mA (version 0 ... 20 mA, 0 ... 10 V et 4 ... 20 mA ATEX

disponible en option). La plage du signal de sortie électrique correspond à la

plage de mesure sur le cadran.

Ces appareils peuvent être utilisés dans tous les domaines de l'industrie grâce

à ces trois signaux de sortie électriques.

Un manomètre avec fonction transmetteur de la série intelliGAUGE allie tous les

avantages d'un affichage mécanique local et l'exigence de transmission d’un

signal électrique permettant l’acquisition des valeurs de mesure.

48

WIKA Mode d'emploi famille intelliGAUGE

11297264 05/2009 GB/D/F/E

Page 49

3. Données techniques

3. Données techniques

3.1 Transmetteur

Alimentation U

Influence de l'alimentation % de la pleine

Ondulation résiduelle admissible % ss ≤ 10

Signal de sortie, variante I 4 … 20 mA, 2 fils, passifs, selon NAMUR NE43

Charge max. admissible R

Influence de la charge % de la pleine

Signal de sortie, variante II

Signal de sortie, variante III 0 ... 20 mA, 3 fils

Signal de sortie, variante IV

Impédance sur la sortie de tension

Tolérance de charge sortie de tension k≤ 2 … 100

Fréquence de balayage du capteur ms 600, avec 3 fils en option plus rapide

Point zéro Mise à zéro en court-circuitant les bornes 5 et 6 pour une courte durée

Possibilité de réglage point zéro < ° 45

Linéarité % de l’échelle ≤ 1,0 (étalonnage points limites)

Précision du signal de sortie % de la pleine

Résolution % de la pleine

Taux d'actualisation (vitesse de lecture)

Angle de rotation signal d'entrée < ° 0 … 270

Echelle spéciale étendue < ° < 330 (option)

Stabilité à long terme de l‘électronique % de la pleine

Erreur de température de

l'électronique

Temps d'échauffement min. ≤ 5

Température ambiante admissible °C -40 … +60

Température de stockage admissible °C -40 … +70

Température du fluide de mesure

admissible

Fonction spéciale En option : signal de sortie arbitraire non proportionnel à l'angle via

Marquage CE Emission de perturbations et résistance aux perturbations selon

Branchement électrique Par connecteur coudé, tournable à 180°, max. 1,5 mm²,

Indice de protection IP65 selon EN 60 529 / IEC 529 ; Irréversibilité et protection contre les

Affectation des bornes de raccordement en fonction de la variante du

signal de sortie

1) Sauf type PGT23.063

2)

Sauf type DPGT43HP.100 / DPGT43HP.160

11297264 05/2009 GB/D/F/E

B

WIKA Mode d'emploi famille intelliGAUGE 49

1)

C.C. V 12 ≤ UB ≤ 30≤

échelle/10K

A

échelle

Ω

kΩ

)

échelle

échelle

1/s > 1

)

)

échelle/a

% de la pleine

échelle/10K

°C -40 … +100

Borne

Type

1

2

3

4

5

6

≤ 0,1

RA ≤ (UB - 12 V)/0,02 A avec RA en ohm et UB en volt cependant 600 Ω

au maximum

≤ 0,1

4 … 20 mA, 2 fils - Ex, selon

Ex I M2 Ex ia I

0 ... 10 V *

0,5

0,2 (uniquement le système électronique)

0,15 (10 bit résolution à 360°)

< 0,3

< 0,3 (sur toute la plage de température)

points de reprise et interpolation des valeurs intermédiaires (à indiquer

lors de la commande)

EN 61 326-1

Protection de câble, passe-câble à vis M20 x 1,5,

Diamètre extérieur du câble 7-13 mm, délestage de traction inclus

surtensions

Variante I

4 ... 20 mA

GND

I+

Réservé

Réservé

Mise à zéro

Mise à zéro

ATEX Ex II 2G Ex ia IIC T4/T5/T6 ou

2)

Variante Ex II

4 ... 20 mA

GND

I+

Réservé

Réservé

Mise à zéro

Mise à zéro

Variante III

0 ... 20 mA

GND

UB+

Iout

Réservé

Mise à zéro

Mise à zéro

Variante IV

0 ... 10 V

GND

UB+

Uout

Réservé

Mise à zéro

Mise à zéro

F

Page 50

3. Données techniques

3.2 Transmetteur pour type PGT23.063

A

DC V

% de la pleine

échelle

% ss

% de E.M.

% de l’échelle

% de la pleine

échelle

< °

)

)

< °

% de la pleine

échelle/a

°C

°C

°C

12 ≤ UB ≤ 30≤

≤ 0,1

≤ 10

- 12 V)/0,02 A avec R

RA ≤ (U

B

cependant 600 Ω au maximum

≤ 0,1

≤ 1,0 (Réglage sur point limites)

< 1,6 électronique

0 … 270

< 330 (option)

< 0,5

-40 … +60

-40 … +70

-40 … +100

résistance aux perturbations selon EN 61 326-1

1)

en Ohm et UB en Volt

A

1)

Alimentation U

Influence de l'alimentation

Ondulation résiduelle admissible

Signal de sortie, variante I 4 … 20 mA, 2-fils

Charge max. admissible R

F

Influence de la charge

Linéarité

Précision du signal de sortie

Angle de rotation signal d'entrée

Echelle spéciale étendue

Stabilité à long terme de