Page 1

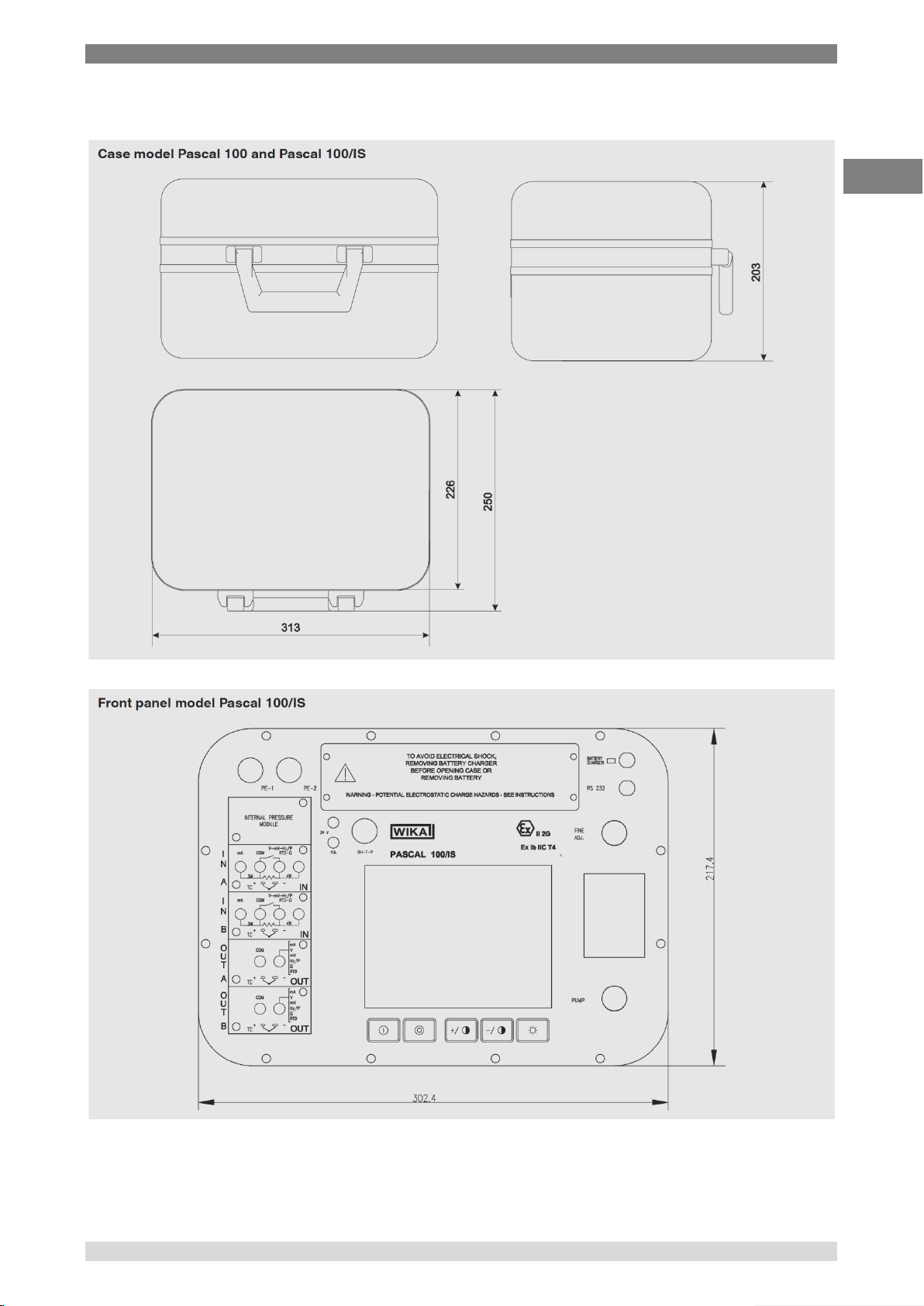

Multichannel Calibrator PASCAL 100 and PASCAL 100/IS

GB

Documenting Multivariable Multichannel Calibrator PASCAL100 / PASCAL100/IS

Operating instructions

Page 2

GB

Operating instructions PASCAL 100

Page

1 - 87

© 2012 WIKA Alexander Wiegand SE & Co. KG

All rights reserved.

WIKA® is a registered trademark in various countries.

Prior to starting any work, read the operating instructions!

Keep for later use!

2 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 3

Contents

GB

1 General Information ............................................................................................................. 5

2 Safety .................................................................................................................................. 6

2.1 Intended use ........................................................................................................................ 7

2.2 Personnel qualification ......................................................................................................... 7

2.3 Additional safety instructions for instruments with ATEX approval only Pascal 100/IS ........ 8

2.4 Special hazards ................................................................................................................... 9

2.5 Labelling / safety marks ..................................................................................................... 10

3 Specifications ................................................................ .................................................... 11

4 Design and Function .......................................................................................................... 14

4.1 Description ........................................................................................................................ 14

4.2 Scope of delivery ............................................................................................................... 15

4.3 Power supply ..................................................................................................................... 15

5 Transport, packaging and storage ..................................................................................... 16

5.1 Transport ........................................................................................................................... 16

5.2 Packaging .......................................................................................................................... 16

5.3 Storage ................................................................................................ .............................. 16

6 Commissioning, operation ................................................................................................. 17

6.1 Commissioning .................................................................................................................. 17

6.1.1 Instrument Overview .......................................................................................................... 17

6.1.2 Functional Modules ........................................................................................................... 17

6.1.2.1 Input module for electrical/temperature signals ................................................. 18

6.1.2.2 Output module for electrical/temperature signals .............................................. 18

6.1.2.3 Pressure module............................................................................................... 19

6.1.2.4 HART module ................................................................ ................................... 20

6.1.2.5 Environmental parameters module (optional) .................................................... 22

6.2 Pressure ............................................................................................................................ 23

6.2.1 Pneumatic circuit ............................................................................................................... 23

6.3 Electrical ............................................................................................................................ 25

6.3.1 Electrical measurements ................................................................................................... 25

6.3.2 Thermocouple measurements ........................................................................................... 26

6.3.3 Thermoresistance measurements...................................................................................... 27

6.3.4 Generation of electrical parameters ................................................................................... 28

6.3.5 Thermocouple simulation ................................................................................................... 28

6.3.6 Thermoresistance simulation ............................................................................................. 29

6.4 User Interface .................................................................................................................... 30

6.4.1 Channel configuration ........................................................................................................ 31

6.4.2 Other assignments ............................................................................................................ 37

6.4.2.1 Pressure measurement..................................................................................... 37

6.4.2.2 Thermocouple signal measurement .................................................................. 41

6.4.2.3 Electrical parameter measurement ................................................................... 46

6.4.2.4 Temperature Simulation .................................................................................... 50

6.4.2.5 Electrical parameter generation ........................................................................ 50

6.4.2.6 Channel 4 – mathematic functions .................................................................... 51

6.4.2.7 HART channel assignment ............................................................................... 55

6.4.2.8 HART trimmer calibration .................................................................................. 58

6.4.2.9 HART scale adjust ............................................................................................ 60

6.5 Menu ................................................................................................................................. 61

6.5.1 Channel Menu ................................................................................................................... 62

6.5.2 Instrument Menu ................................................................................................................ 63

6.5.3 Report Menu ...................................................................................................................... 65

6.5.4 Engineering unit Menu ....................................................................................................... 65

6.5.5 Logger Menu ..................................................................................................................... 65

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 3

Page 4

Contents

GB

6.5.6 Calibration Menu ............................................................................................................... 65

6.5.7 Graph Menu ...................................................................................................................... 66

6.5.8 Ramp Menu ....................................................................................................................... 67

6.5.9 Disk Menu ......................................................................................................................... 69

6.6 Measurement Channel ...................................................................................................... 69

6.6.1 Status ................................................................................................................................ 70

6.6.2 Res. MxMn ........................................................................................................................ 70

6.6.3 Scaling .............................................................................................................................. 70

6.6.4 Filter .................................................................................................................................. 71

6.6.5 Hold On – Hold Off ............................................................................................................ 71

6.6.6 Offset On – Offset Off ........................................................................................................ 72

6.6.7 Inc. Dec – Dec. Dec ........................................................................................................... 72

6.6.8 Chg. Out ............................................................................................................................ 72

6.7 Report ............................................................................................................................... 74

6.8 Data Logger ....................................................................................................................... 79

6.9 Communication.................................................................................................................. 81

6.10 Calibration Examples ......................................................................................................... 82

6.10.1 Example 1 – Calibration of two wires pressure transmitters ............................................... 82

6.10.2 Example 2 – Calibration of PTZ gas volume converters ..................................................... 83

6.10.3 Example 3 – Calibration of four wires RTD’s ...................................................................... 84

6.10.4 Example 4 – Calibration of Thermocouples ....................................................................... 85

7 Maintenance, cleaning and servicing ................................................................................. 86

7.1 Maintenance ...................................................................................................................... 86

7.2 Cleaning ............................................................................................................................ 86

7.3 Recalibration ..................................................................................................................... 86

8 Dismounting, return and disposal ...................................................................................... 87

8.1 Dismounting ...................................................................................................................... 87

8.2 Return ............................................................................................................................... 87

8.3 Disposal ............................................................................................................................ 87

Appendix 1: ATEX Approval of Pascal 100/IS ............................................................................... 88

Declarations of conformity can be found online at www.wika.com.

4 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 5

1 General Information

GB

1 General Information

■ The Multichannel Calibrator model Pascal 100 or Pascal 100/IS described in the operating

instructions has been manufactured using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during production. Our

management systems are certified to ISO 9001 and ISO 14001.

■ These operating instructions contain important information on handling the Multichannel

Calibrator model Pascal 100 or Pascal 100/IS. Working safely requires that all safety instructions

and work instructions are observed.

■ Observe the relevant local accident prevention regulations and general safety regulations for the

range of use of the Multichannel Calibrator model Pascal 100 or Pascal 100/IS.

■ The operating instructions are part of the instrument and must be kept in the immediate vicinity

of the Multichannel Calibrator model Pascal 100 or Pascal 100/IS and readily accessible to

skilled personnel at any time.

■ Skilled personnel must have carefully read and understood the operating instructions, prior to

beginning any work.

■ The manufacturer's liability is void in the case of any damage caused by using the product

contrary to its intended use, non-compliance with these operating instructions, assignment of

insufficiently qualified skilled personnel or unauthorised modifications to the Pascal 100 or

Pascal 100/IS.

■ The general terms and conditions, contained in the sales documentation, shall apply.

■ Subject to technical modifications.

■ Factory calibrations/DKD/DAkks calibrations are carried out in accordance with international

standards.

■ Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant Data Sheet: CT 18.01

- Application consultant: Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-8767

E-Mail: testequip@wika.de

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 5

Page 6

1 General Information / 2 Safety

GB

Explanation of symbols

WARNING!

... indicates a potentially dangerous situation, which can result in serious

injury or death, if not avoided.

Information

... points out useful tips, recommendations and information for efficient and

trouble -free operation.

WARNING!

... indicates a potentially dangerous situation in a potentially explosive

atmosphere, resulting in serious injury or death, if not avoided.

2 Safety

WARNING!

Before installation, commissioning and operation, ensure that the appropriate

reference pressure sensor has been selected in terms of measuring range, design and

specific measuring conditions. Serious injuries and/or damage can occur should these

not be observed.

Further important safety instructions can be found in the individual chapters of these

operating instructions.

6 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 7

2 Safety

GB

2.1 Intended use

The Multichannel Calibrator model Pascal 100 or Pascal 100 IS gauge can be used as a

calibration instrument and also for any application which requires accuracy pressure measurement.

The Multichannel Calibrator model Pascal 100 or Pascal 100/IS has been designed and built solely

for the intended use described here, and may only be used accordingly.

The technical specifications contained in these operating instructions must be observed.

Improper handling or operation of the Multichannel Calibrator model Pascal 100 or Pascal 100/IS

outside of its technical specifications requires the instrument to be shut down immediately and

inspected by an authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from strong

magnetic fields, static electricity and extreme temperatures, do not insert any objects into the

instrument or its openings). Plugs and sockets must be protected from contamination.

If the Multichannel Calibrator model Pascal 100 or Pascal 100/IS is transported from a cold into a

warm environment, the formation of condensation may result in the instrument malfunctioning.

Before putting it back into operation, wait for the instrument temperature and the room temperature

to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary to the

intended use.

2.2 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient!

Improper handling can result in considerable injury and damage to equipment.

■The activities described in these operating instructions may only be carried out by

skilled personnel who have the qualifications described below.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowledge of

country-specific regulations, current standards and directives, are capable of carrying out the work

described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive media.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 7

Page 8

2 Safety

GB

II 2G

Ex ib IIC T4 Gb - Tamb: -10°C / 50°C

2.3 Additional safety instructions for instruments with ATEX approval

only Pascal 100/IS

WARNING!

Non-observance of these instructions and their contents may result in the loss of

explosion protection.

■ Battery operation:

Use only the rechargeable battery which is supplied by WIKA! Only charge the

battery outside of the hazardous area!

■ Operation of the serial interface in the hazardous area is prohibited.

Further hazardous area safety instructions!

Observe the operating information and the relevant country-specific regulations

concerning use in hazardous areas (e.g. EN IEC 60079-14).

The Pascal 100/IS intrinsically safe multichannel calibrator has been designed for

use in Ex Hazardous Areas. These are areas where potentially flammable or

explosive vapors may occur. These areas are referred to as hazardous (classified)

locations in the United States, as Hazardous Locations in Canada, as Potentially

Explosive Atmospheres in Europe and as Explosive Gas Atmospheres by most of

the rest of the world. The Pascal 100/IS intrinsically safe multichannel calibrator is

designed as intrinsically safe. This means that connecting the Pascal 100/IS

intrinsically safe multichannel calibrator to equipment that is used within intrinsically

safe circuits will not cause an ignition capable arc as long as the entity parameters

are suitably matched.

Information/Approval for hazardous locations:

WARNING!

■ Ex Hazardous Areas

An Ex-hazardous area as used in this manual refers to an area made hazardous

by the potential presence of flammable or explosive vapors. These areas are also

referred to as hazardous locations.

WARNING!

Only gauges powered by batteries are approved for use in hazardous locations.

Use only the rechargeable battery which is supplied by WIKA! Only charge the

battery outside of the hazardous area!

8 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 9

2 Safety

GB

2.4 Special hazards

WARNING!

■ When measuring pressure, make sure that the process pressure line is shut off

and depressurised before it is connected to or disconnected from the pressure

module.

■Disconnect test leads before changing to another measurement or generation

function.

■ Observe the working conditions in accordance with chapter "3. Specifications".

■ Always operate the device within its overload limits.

■ To ensure problem-free operation, only operate the Multichannel Calibrator

model Pascal 100 or Pascal 100/IS on battery power. Only use the mains

connection for charging the Hand-held pressure calibrators batteries.

■ Do not apply a voltage greater than the specified voltage to the instrument.

See chapter "3. Specifications".

■ Make sure that the test probes never contact a voltage source while the test

leads are connected to the current terminals.

■ Do not use the calibrator if it is damaged. Before using the multichannel

calibrator, check that there are no cracks or missing plastic parts on the case.

Pay particular attention to the insulation of the connectors.

■ Select the proper function and correct measuring range for the measurement.

■ Inspect the test leads for damaged insulation or exposed metal. Check the

continuity of the test leads. Damaged test leads should be replaced before using

the multichannel calibrator.

■ When using test probes keep fingers away from the test probe contacts. Keep

your fingers behind the test probes' finger guards.

■ First connect the common lead, and then the live lead. When disconnecting,

remove the live test lead first.

■ Do not use the multichannel calibrator if it is not working properly. The

instrument protection might be compromised. If in doubt, have the instrument

checked.

■ Do not operate the calibrator in areas with explosive gases, vapours or dust.

■ To avoid false readings, which could lead to possible electric shock or personal

injury, charge the rechargeable battery as soon as the battery indicator appears.

■ In order to avoid any possible damage to the multichannel calibrator or the test

equipment, use the correct leads, the correct function and the correct range for

the measuring application.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 9

Page 10

2 Safety

GB

2.5 Labelling / safety marks

Explanation of symbols

Pascal 100 and Pascal 100/IS

Before mounting and commissioning the Multichannel Calibrator model

Pascal 100 or Pascal 100/IS, ensure you read the operating instructions!

CE, Communauté Européenne

Instruments bearing this mark comply with the relevant European directives.

This marking on the instruments indicates that they must not be disposed of in

domestic waste. The disposal is carried out by return to the manufacturer or by

the corresponding municipal authorities. See Directive 2002/96/EC.

Only Pascal 100/IS

ATEX European Explosion Protection Directive

(Atmosphère = AT, explosible = Ex)

Instruments bearing this mark comply with the requirements of the European

Directive 94/9/CE (ATEX) on explosion protection.

10 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 11

3 Specifications

GB

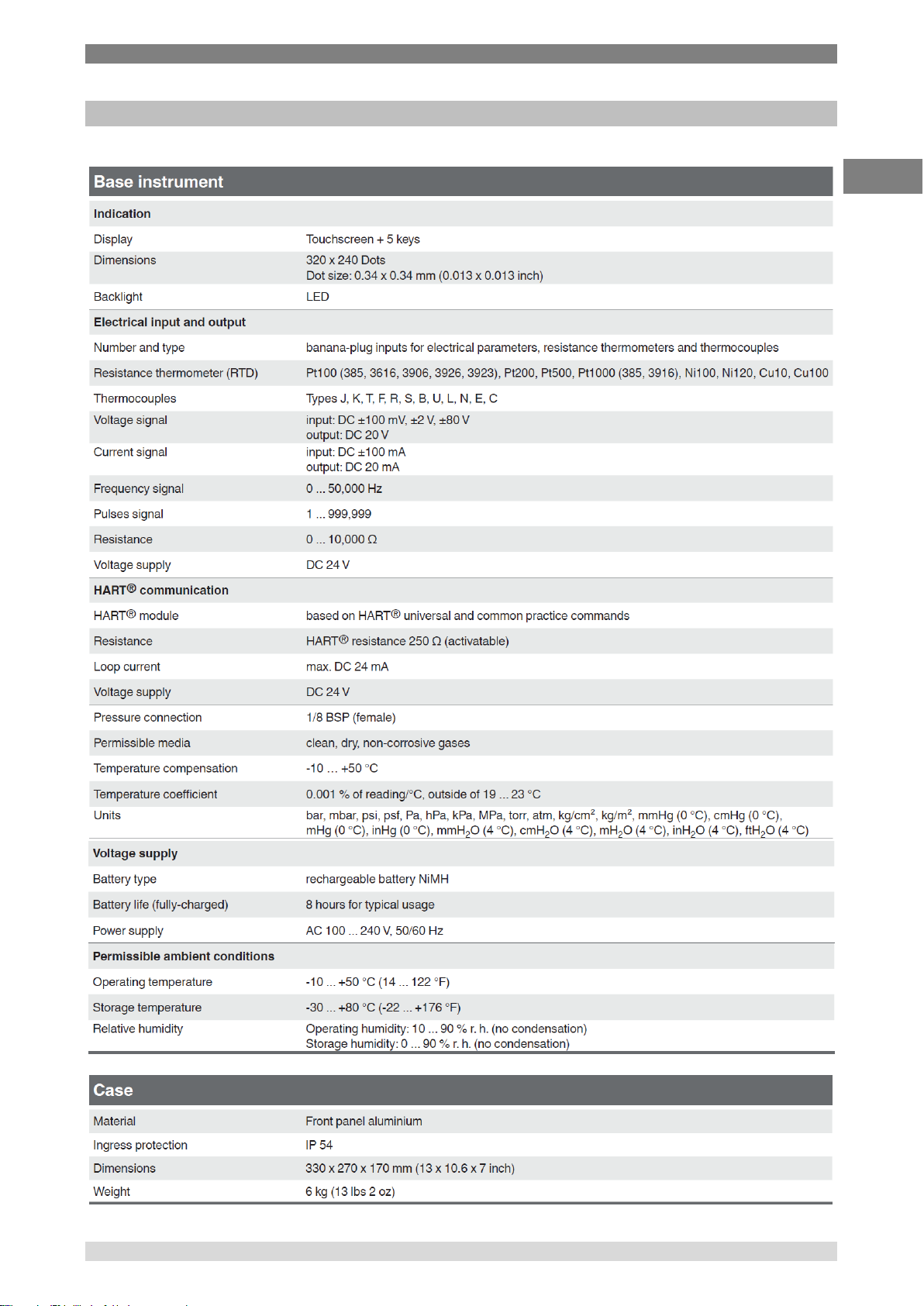

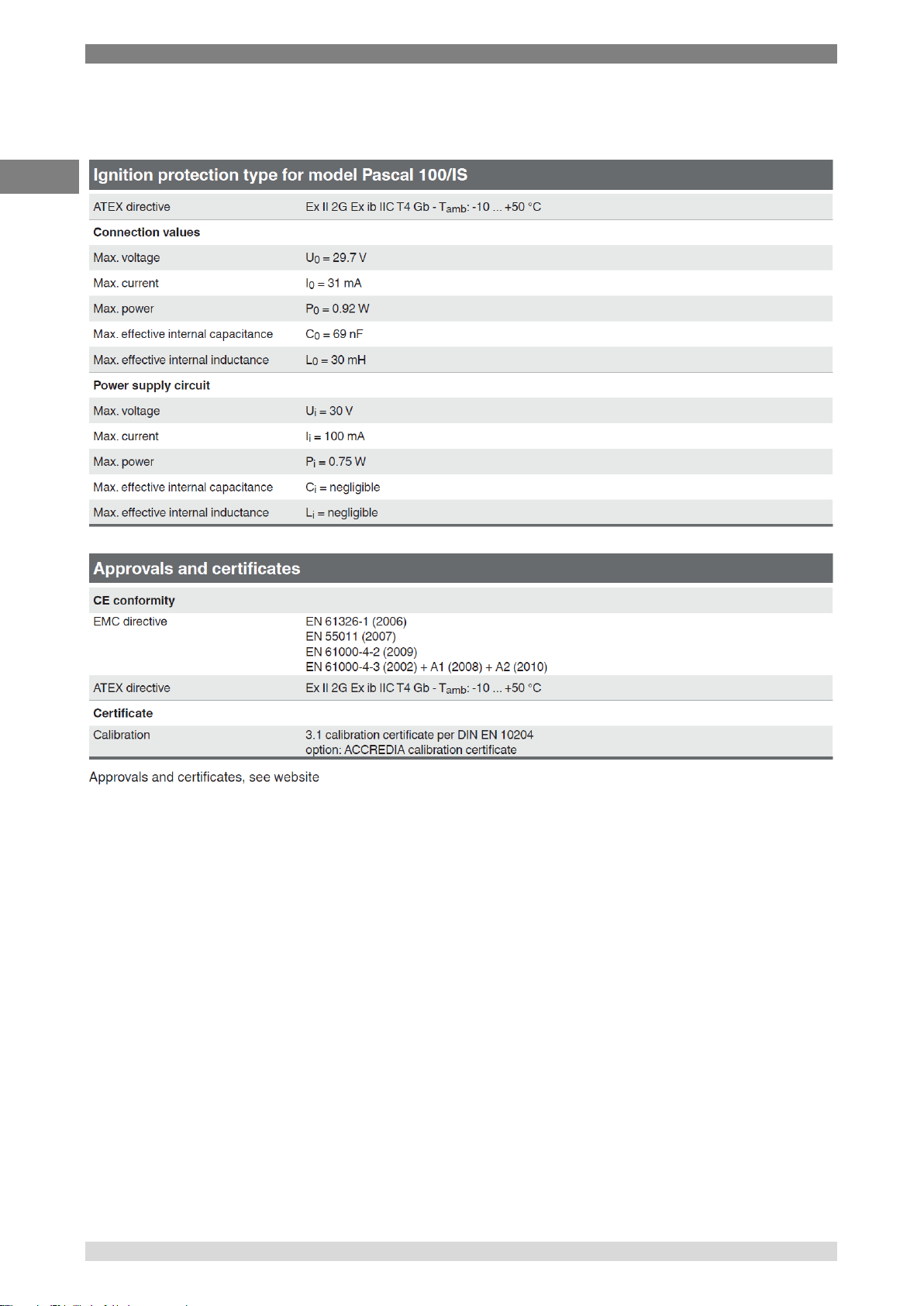

1)

3 Specifications

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 11

Page 12

3 Specifications

GB

12 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 13

3 Specifications

GB

For further specifications see WIKA data sheet CT 18.01 and the order documentation.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 13

Page 14

4 Design and Function

GB

4 Design and Function

4.1 Description

Pascal 100 or Pascal 100/IS is the Professional Advanced Scandura Calibrator of latest

generation.

User friendly interface by a wide display with an industrial touch screen through which it is possible

to manage the instrument completely.

The operations are simplified thanks to the touch screen: the display changes in a dynamic way

according to the user selections, following test by step the operator during the calibration process,

decreasing the learning time and the human errors.

The touch screen can be operated by nude or gloved hands: dirty parts can be easily removed with

a cloth or a sponge. The touch screen can be locked during the measurement process to avoid

unintentional pressing of keys

The backlight illumination with LED guarantees a perfect view in case of low environmental

visibility.

Five keys are present below the touch screen : turn on/off of the instrument, contrast settings and

backlight.

Pascal 100 or Pascal 100/IS consists of two parts: pressure part and electrical one.

The pressure part consists of:

■ 1 a pneumatic distribution block

■ 2 internal manual vacuum/pressure generator with fine adjustment

■ 3 up to four internal pressure sensors with overpressure valves.

The electrical part consists of up to four electrical module (2 input (IN) and 2 output (OUT) for the

measurement and generation of mA, mV, V, Hz, Ohm, Pulse, TC/RTD.

On the front panel of the instrument there are several connectors for:

■ recharging the battery

■ RS232 port

■ Connection to the external pressure transducers

■ Connection for the environment parameters

(temperature, humidity and atmospheric pressure)

Moreover there are the connections to provide 24 V d.c. power supply to the device under test.

The Pascal 100 or Pascal 100/IS is powered with an internal battery pack. The battery allows 8

hours of standard operation before recharging.

Operating Pascal 100 or Pascal 100/IS user is able to calibrate the whole industrial instrumentation

like for example:

■ Electronic and pneumatic pressure/vacuum transmitter

■ Electronic and pneumatic differential pressure transmitter

■ Electronic and pneumatic temperature transmitter (thermocouple and RTD)

■ Signal converter V, mV, mA, Hz, Pulse, ohm

■ Signal converter I/P and P/I

■ Signal isolator mA, mV

■ Mathematical Device (adder, subtractor, multiplier, divider)

■ Manometer, Pressure switch

■ Temperature monitor switch

■ Thermocouple and thermoresistance

■ Compensation device (up to 4 in-out signals)

■ Electronic and pneumatic receiver

■ Electronic and pneumatic controller

■ Electronic and pneumatic recorder

■ Miscellaneous instrument

14 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 15

4 Design and Function

GB

Pascal 100 or Pascal 100/IS includes different modules and can be ordered with different hardware

configurations.

The hardware configuration depends on the installation of different functional modules:

■ Two electrical/temperature IN modules (IN A & IN B)

■ Two electrical/temperature OUT modules (OUT A & OUT B)

■ Two pressure modules

(each one can support two internal and one external transducer. Total 6 sensors)

■ One environment parameters module

(atmospheric pressure, ambient temperature and relative humidity)

■ One power supply 24 V d.c.

■ One RS-232 communication port

■ One connection for recharging the battery

■ One hand pump for pressure or vacuum generation

■ One fine adjustment for a good regulation of pressure or vacuum

■ One set of valves for sensor protection against overpressure

Battery Life

In order to preserve battery life is recommended to keep the battery charger

connected for no more than 36 hours

Functional module

A functional module is a hardware component that allows the Pascal 100 or

Pascal 100/IS to perform some operations like for example measurement and

generation of electrical signals and pressure.

4.2 Scope of delivery

■ Portable multifunction calibrator model Pascal 100 or Pascal 100/IS

■ Operating instructions

■ AC adapter

■ Pascal report software

■ RS-232 interface cable

■ RS-232 to USB adapter

■ Electrical kit order no. 241076

■ Pneumatic pressure kit order no. 241028 and 241029

(Depending on pressure range)

■ 3.1 calibration certificate per DIN EN 10204

Cross-check scope of delivery with delivery note.

4.3 Power supply

Charging

To avoid false measurements, charge the rechargeable batteries as soon as the battery indicator

appears. If the batteries run too low the Pascal 100 or Pascal 100/IS will automatically shut down.

Use only the original AC/DC converter which is supplied by WIKA

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 15

Page 16

5 Transport, packaging and storage

GB

5 Transport, packaging and storage

5.1 Transport

Check the Multichannel Calibrator model Pascal 100 or Pascal 100/IS for any damage that may

have been caused by transport. Obvious damage must be reported immediately.

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. sending for

calibration).

5.3 Storage

Permissible conditions at the place of storage:

■ Storage temperature: -30 ... +80 °C

■ Relative Humidity: 10 ... 90 % r. H. (non-condensing)

Avoid exposure to the following factors:

■ Direct sunlight or proximity to hot objects

■ Mechanical vibration, mechanical shock (putting it down hard)

■ Soot, vapour, dust and corrosive gases

■ Potentially explosive environments, flammable atmospheres

Store the instrument in its original packaging in a location that fulfills the conditions listed above. If

the original packaging is not available, pack and store the instrument as described below:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag, containing a

desiccant, inside the packaging.

16 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 17

6 Commissioning, operation

GB

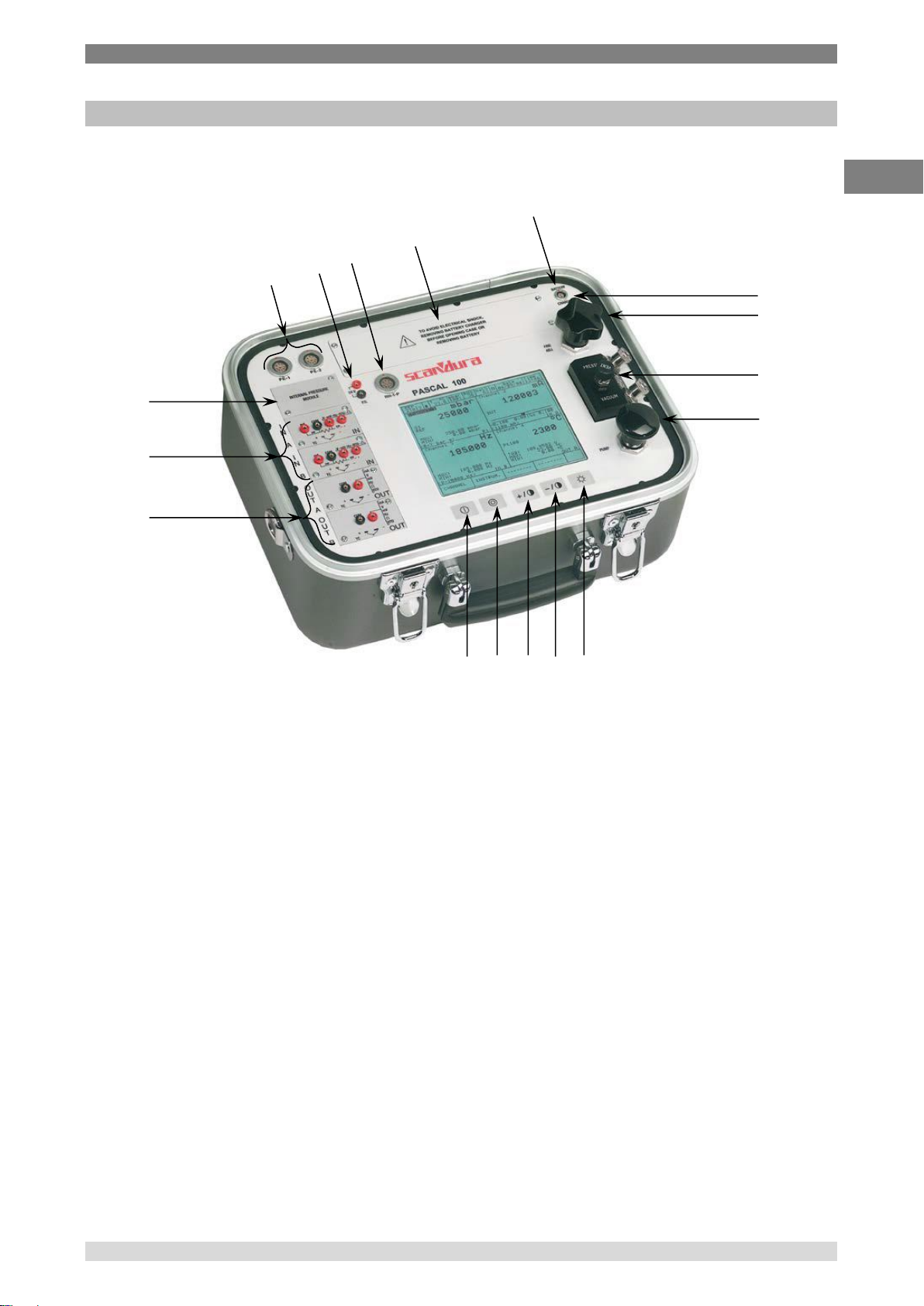

3

4

5

6

7

8

12

10

11

1

2 9 13

14

15

16

17

6 Commissioning, operation

6.1 Commissioning

6.1.1 Instrument Overview

1 Connectors for external P transducer 10 Hand pump (vacuum/21 bar)

2 Pressure modules 11 Pneumatic distribution

3 IN electrical/temperature modules 12 Fine adjustment

4 OUT electrical/temperature modules 13 Connector RS-232

5 Power ON 14 Connector for battery charger

6 Power OFF 15 Battery

7 Contrast + 16 Environmental Parameter Connector

8 Contrast – 17 Loop power supply – 24 V d.c.

9 Back light OFF (Lamp)

6.1.2 Functional Modules

The functional modules can be classified according to their assignments:

■ Electrical and temperature signals measurement

■ Pressure measurement, (2 different modules, up to 4 internal pressure sensors and 2

connectors for external pressure sensor)

■ Electrical and temperature signals generation/simulation

■ Pressure generation and regulation

■ Environmental parameters measurement

Many different configurations are available according to the specific requirements of the user.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 17

Page 18

6 Commissioning, operation

GB

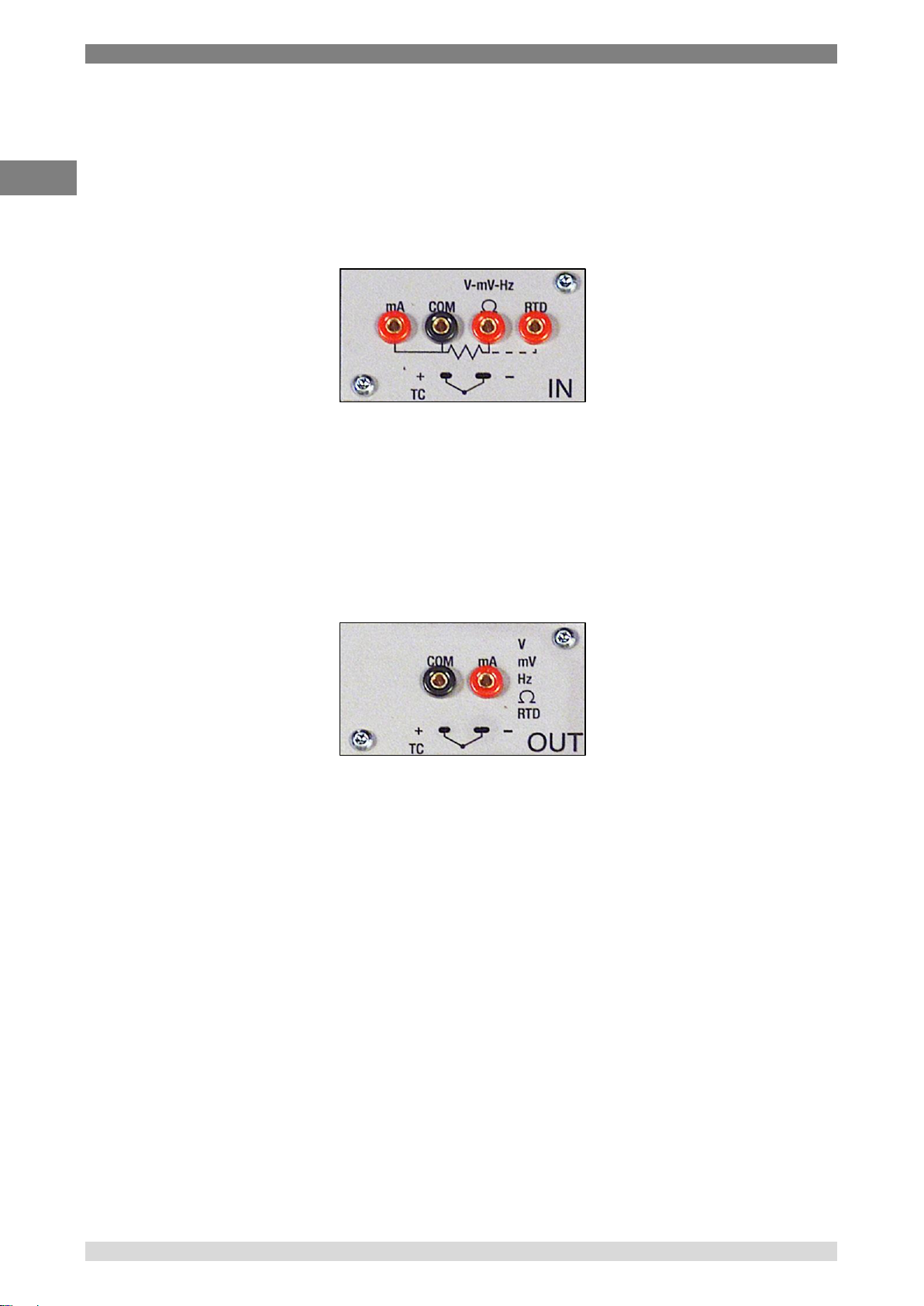

6.1.2.1 Input module for electrical/temperature signals

The input module for electrical/temperature parameters measurement is one of those modules

inserted from the instrument’s front panel; two slides drive the module into its position. It is possible

to have up to two input modules in the same instrument: IN A and IN B. This terminology is used

also by the software to carry out the connection between physical input IN and software channel.

For example: if you connect a thermoresistance Pt100 to module IN A, the temperature measured

by this thermoresistance can be displayed in any of the four software channels available. The

following figure shows the pins connection in electrical/temperature IN module.

Figure 1 – Input panel module

6.1.2.2 Output module for electrical/temperature signals

The output module for electrical/temperature parameters generation or simulation is one of those

inserted from the instrument’s front panel; two slides drive the module into its position. It is possible

to have up to two output modules in the same instrument: OUT A and OUT B. This terminology is

used also by the software to carry out the connection between physical output OUT and software

channel. For example: if you connect a signal-receiver to module output OUT A, the current 4…20

mA generated can be displayed in any of the four software channels available.

The following figure shows the output module for electrical/temperature parameters.

Figure 2 – Output panel module

The 2 INPUT cards and 2 OUTPUT cards are plug and play modules and can be installed by the

user himself.

18 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 19

6 Commissioning, operation

GB

Range

Precision (% FS)

Accuracy (% FS)

Typical Resolution

Gauge

-60…+60 mbar

0,08

0,1

0,01 mbar

-500…+500 mbar

0,015

0,025

0,01 mbar

-900…+1500 bar

0,015

0,025

0;01 mbar

0…7 bar

0,015

0,025

0,1 mbar

0…21 bar

0,015

0,025

0;1 mbar

0…50 bar

0,015

0,025

1 mbar

0…100 bar

0,015

0,025

1 mbar

Absolute

600…1300 mbar abs.

0,015

0,025

0,01 mbar

0…1500 mbar abs.

0,015

0,025

0,01 mbar

0…2500 mbar abs

0,015

0,025

0,01 mbar

0…2500 mbar abs

0,010

0,015

0,01 mbar

0…5 bar abs.

0,015

0,025

0,1 mbar

0…7 bar abs.

0,015

0,025

0,1 mbar

0…21 bar abs.

0,015

0,025

0,1 mbar

0…81 bar abs.

0,015

0,025

1 mbar

0…100 bar abs.

0,015

0,025

1 mbar

Range

Precision (% FS)

Accuracy (% FS)

Typical Resolution

Gauge

-60…+60 mbar

0,1

0,15

0,01 mbar

-500…+500 mbar

0,015

0,025

0,01 mbar

-900…+1500 bar

0,015

0,025

0;01 mbar

0…7 bar

0,015

0,025

0,1 mbar

0…21 bar

0,015

0,025

0;1 mbar

0…50 bar

0,015

0,025

1 mbar

0…100 bar

0,015

0,025

1 mbar

0…200 bar

0,015

0,025

10 mbar

0…400 bar

0,015

0,025

100 mbar

0…700 bar

0,025

0,05

100 mbar

0…1000 bar

0,025

0,05

100 mbar

Absolute

0…1500 mbar abs.

0,015

0,025

0,01 mbar

0…2500 mbar abs

0,015

0,025

0,01 mbar

0…5 bar abs.

0,015

0,025

0,1 mbar

0…7 bar abs.

0,015

0,025

0,1 mbar

0…21 bar abs.

0,015

0,025

0,1 mbar

0…81 bar abs.

0,015

0,025

1 mbar

0…100 bar abs.

0,015

0,025

1 mbar

6.1.2.3 Pressure module

The pressure module is installed only at factory location in accordance with the Pascal 100 or

Pascal 100/IS configuration required. It is possible to install two pressure modules, each one can

support up to two internal and one external transducers. In total Pascal 100 can accommodate four

internal and two external transducers. Transducer’s selection with range and their resolutions are

in the following table. If requested, one of the standard pressure modules can be changed with one

high accuracy pressure module (with one high accuracy transducer).

Internal transducers *

External transducers *

* Other ranges available on request

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 19

Page 20

6 Commissioning, operation

GB

Transmitter

HART slave

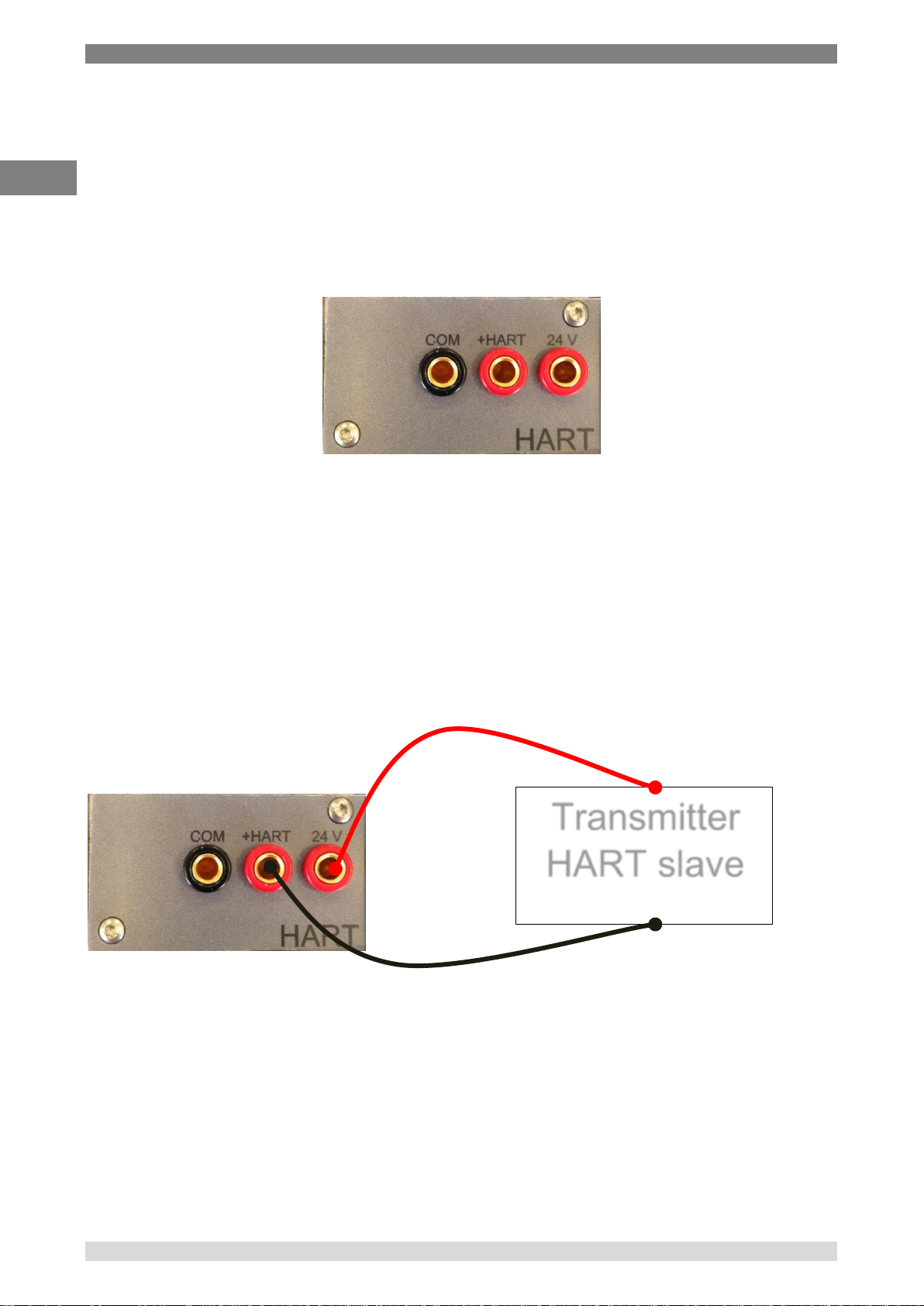

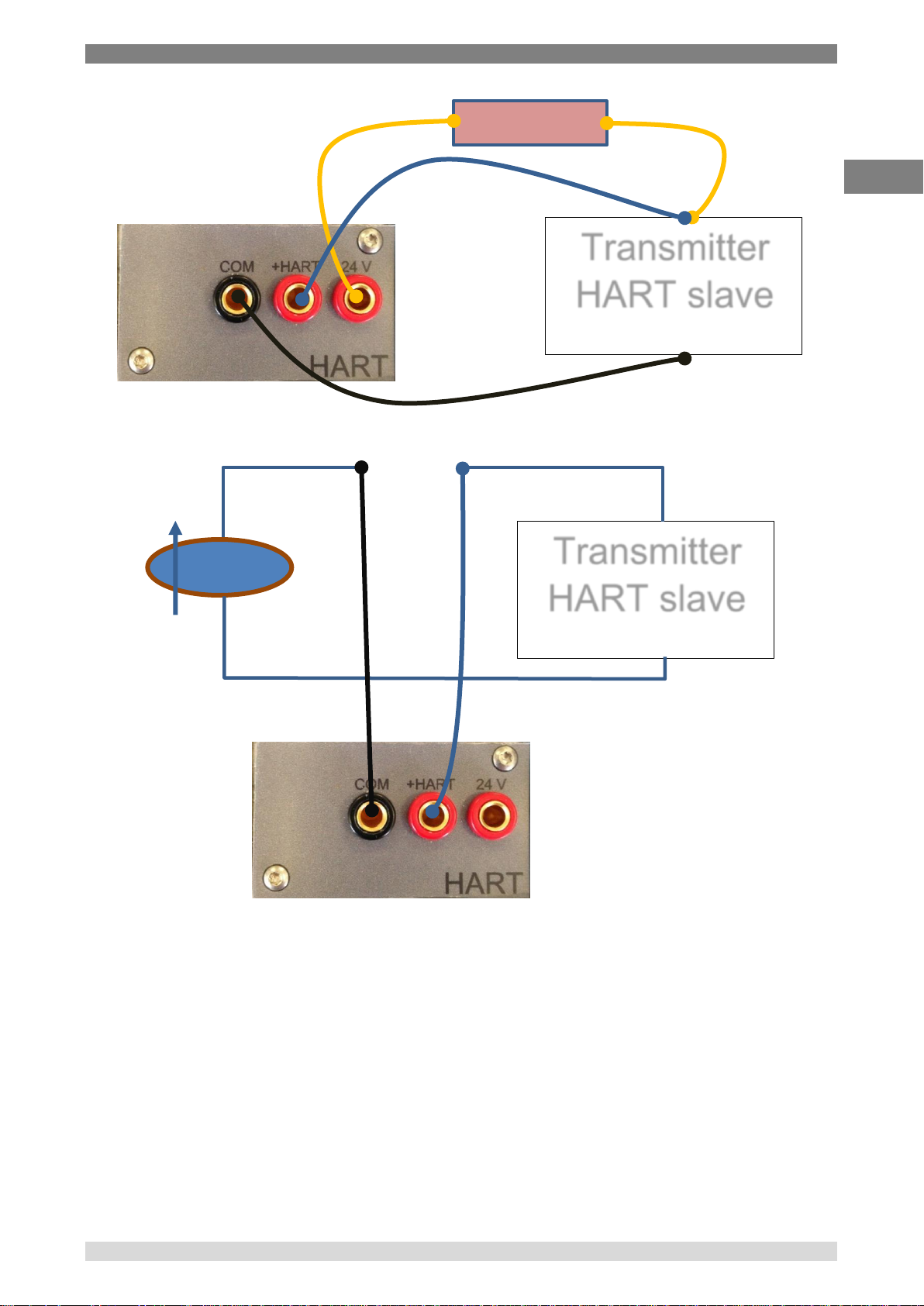

6.1.2.4 HART module

The HART module allows communication with HART instruments (usually transmitters) permitting

to acquire digital measurements, instrument data and modifying settings. It can be inserted in the

front panel in place of OUT A or OUT B module.

It is a fully galvanically isolated board (like IN and OUT modules) from internal electronics of the

Pascal.

The module allow the 24V to supply directly the output loop for the transmitter.

Further, it can supply a 250Ω load resistance electronically switchable necessary to HART

communication, permitting to avoid the use of an external one.

The following figure shows the pin connections in HART module:

Figure 3 – HART module

6.1.2.4.1 HART wiring

Depending by several factors and combination that the user can found in a plant, there are many

wiring possibility depending by:

Using module internal or external Power Supply.

Using internal or external load resistance.

Simultaneous analog connection of AO TRX to one Input module for mA reading

Please consider, if the user enable the internal load resistance, this will be connected between the

+HART and COM terminals.

Here same examples:

20 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Figure 4 - Case 1: 24V from module, 250Ω from module

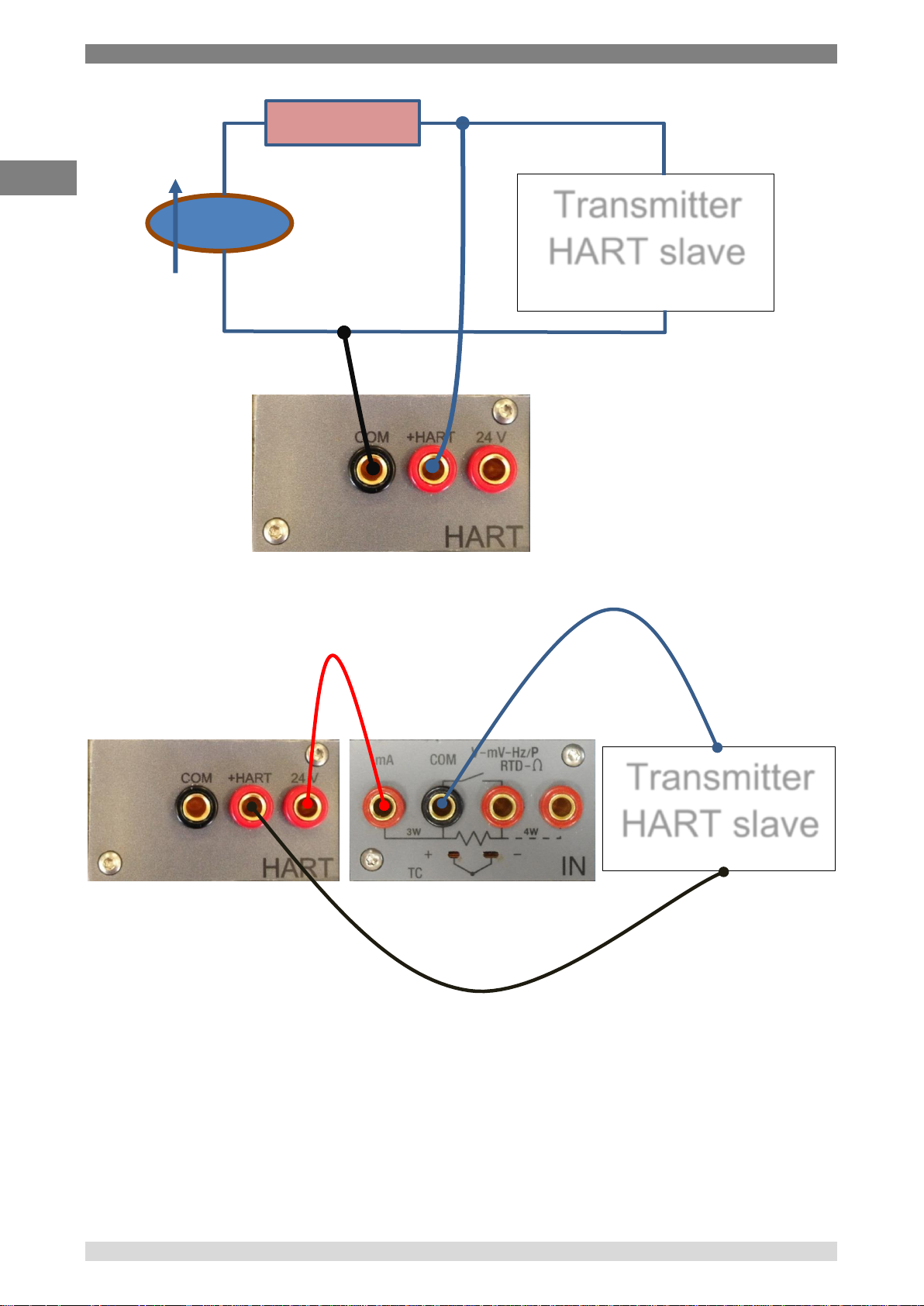

Page 21

6 Commissioning, operation

GB

Transmitter

HART slave

250 Ω

Transmitter

HART slave

24V ext.

Figure 5 - Case 2: 24V from module, 250Ω external

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 21

Figure 6 - Case 3: 24V external, 250Ω from module

Page 22

6 Commissioning, operation

GB

Transmitter

HART slave

24V ext.

250 Ω

Transmitter

HART slave

Figure 7 - Case 4: 24V external, 250Ω external

Figure 8 - Case 5: 24V from module, 250Ω from module, mA reading by IN module

6.1.2.5 Environmental parameters module (optional)

This module allows to measure: temperature, relative humidity and atmospheric pressure. These

parameters represent the most important factors that affect the calibration results. This module is

connected to Pascal 100 or Pascal 100/IS with a multiple pin connector present in

Pascal 100 or Pascal 100/IS front panel. This module is plug & play and the relevant information

about the environmental parameters are displayed on the status bar at the top of the screen.

This information is automatically reported on the calibration report.

22 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 23

6 Commissioning, operation

GB

Direct transducer

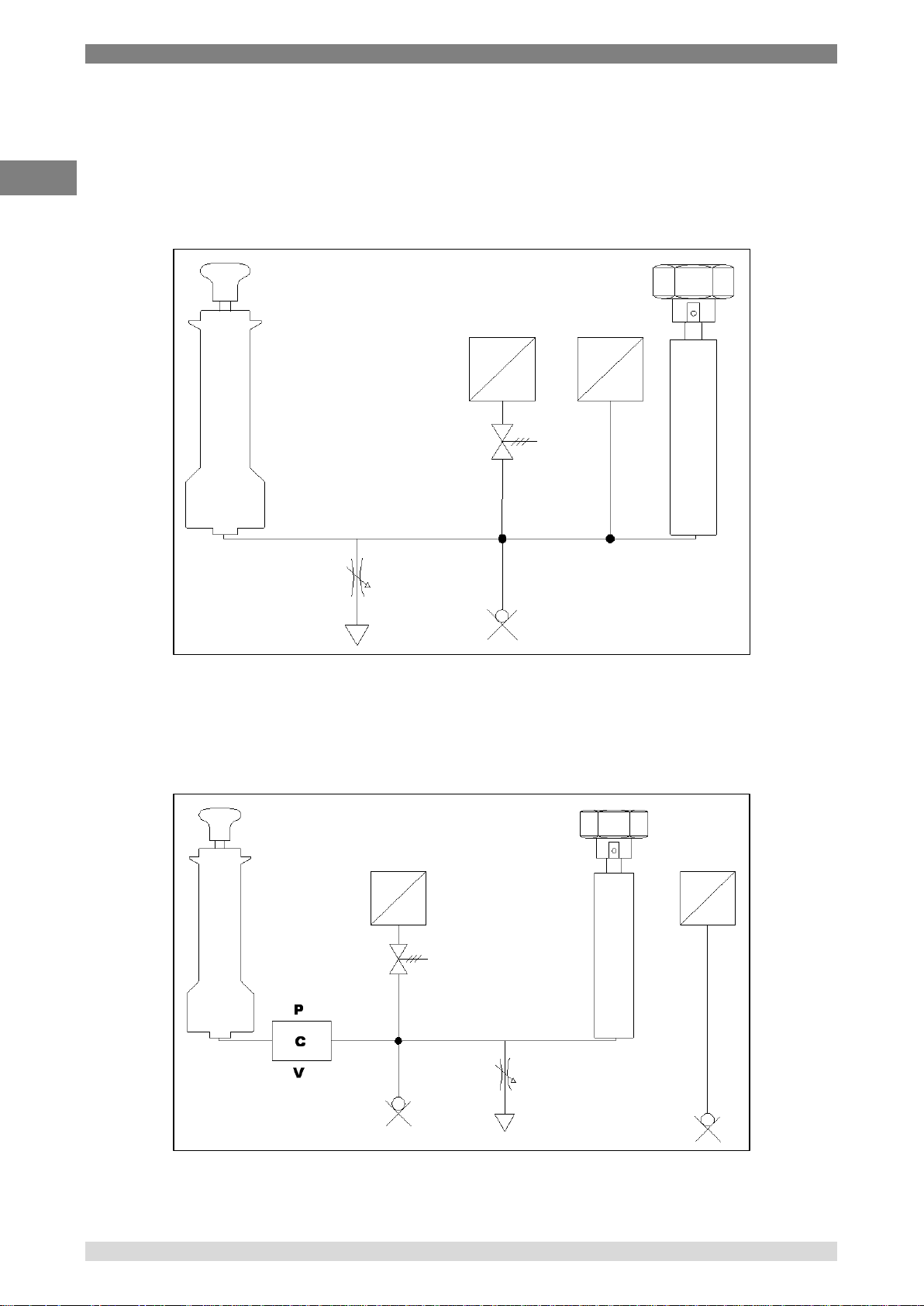

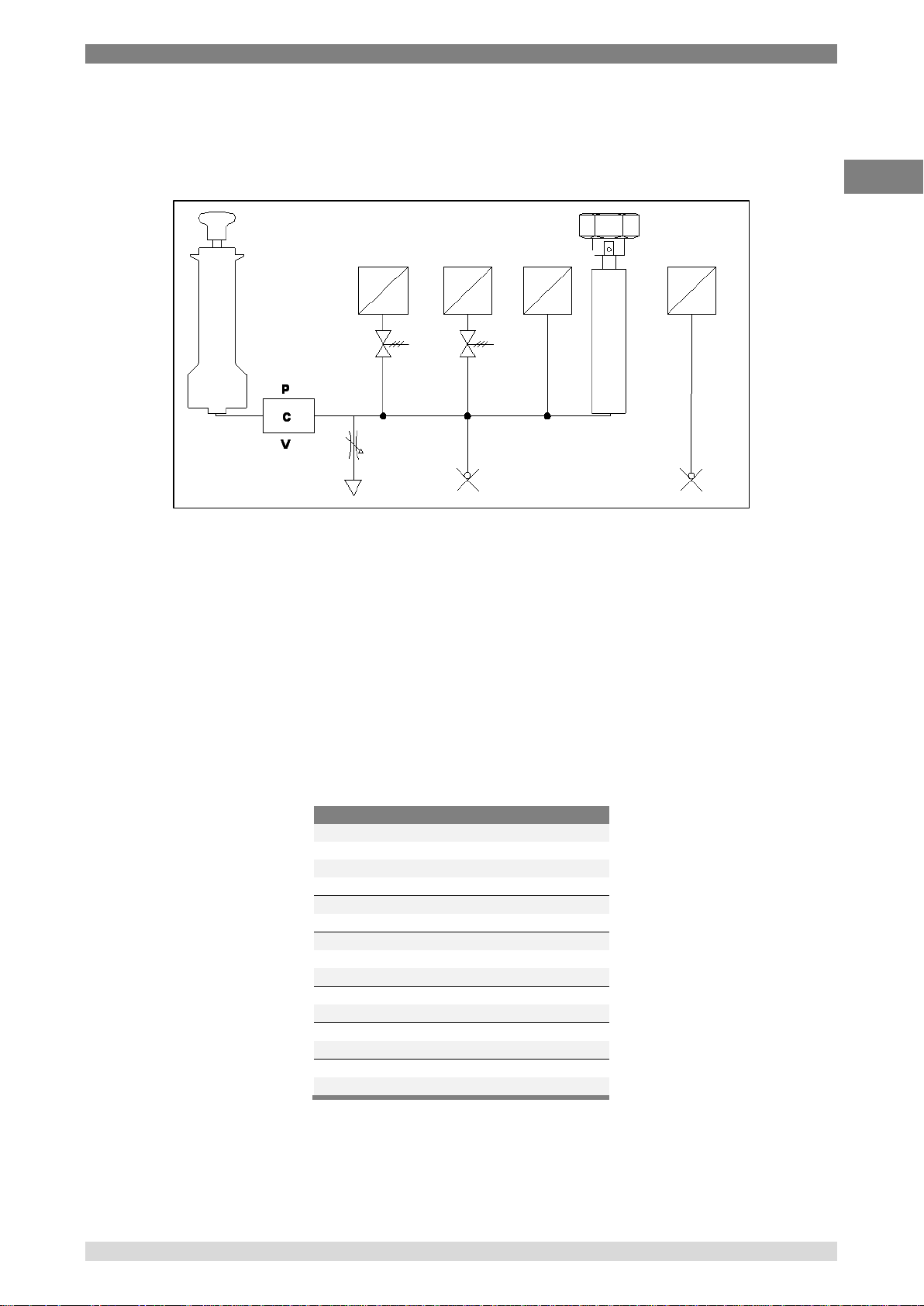

6.2 Pressure

6.2.1 Pneumatic circuit

Pascal 100 or Pascal 100/IS can be equipped with four internal and two external pressure sensors.

The internal sensors work only with clean dry gas (like dry air) whereas the external sensors can

work with gas or liquid. Gas is related to pneumatic circuit and liquid to hydraulic circuits.

Pascal 100 or Pascal 100/IS has a pneumatic circuit that gives possibility to execute a large

number of calibration in an easy way for connecting the device under test. An integrated pump and

a fine adjustment allow to generate the required pressure. The generated pressure, according to

the model, can be distributed in parallel to all sensors. The sensors whose ranges are much lower

than the maximum pressure generated in the pneumatic circuit are protected from overpressure by

a mechanical valve that closes the circuit when the pressure gets over its range.

Switching the pressure-vacuum selector in the vacuum position is possible to generate vacuum

(pressure under the barometric)

For example, if we want to measure a signal from pneumatic instrument 3 - 15 PSI or to measure

high gas pressure over 21 bar and we use an internal sensor directly connected to the process, we

must pay attention not to damage it by applying pressure over its range.

Figure 9 – Direct transducer

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 23

Page 24

6 Commissioning, operation

GB

Transducer 1

Transducer 2

Overpressurevalve

Transducer 1

Pressure- Vacuum

variator

There are three different pneumatic schemes available in a standard Pascal 100 or

Pascal 100/IS configuration:

■ This is an example of pneumatic circuit with two sensors in parallel to the pump. One of

them is protected by an overpressure valve, the other one is not protected because it has a

full-scale equal to the maximum pressure generated by the pump. See following:

Figure 10 – Circuit with two sensors in parallel

■ This is an example of pneumatic circuit with two sensors: one sensor connected in parallel

to the pump with over pressure protection, and one sensor directly connected for

measuring the external pressure signals without overpressure protection. See following:

24 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Figure 11 - Circuit with transducer connected to process

Page 25

6 Commissioning, operation

GB

Range

Max resolution

Voltage

(-100…100) mV

0,0001 mV

(-2…2) V

0,000001 V

(-80…80) V

0,00001 V

Current

(-100…100) mA

0,0001 mA

Resistance

(0…400) Ω

0,001 Ω

(0…10000) Ω

0,01 Ω

Frequency

(0,4…50000) Hz

0,001 Hz

Pulse

0,4…20 Hz

-

Contact

Open - Closed

-

Pressure-

Vacuum variator

Transducer 1

Transducer 2

Transducer 3

Transducer 4

■ This is an example of pneumatic circuit with four sensors: three of them are connected in

parallel to the pumps and one straight to external. Two of them are protected by

overpressure valves, the other one is not protected because it has its full-scale equal to the

maximum pressure generated by pump. See following:

Figure 12 - Circuit with four transducers

6.3 Electrical

The Pascal 100 or Pascal 100/IS is a multifunction calibrator.

The electrical modules can be maximum four, two of them are input modules (IN A – IN B), and the

other two are output modules (OUT A – OUT B).

6.3.1 Electrical measurements

The instrument is able to measure voltage, current, resistance and frequency. To optimise the

resolution and get better measurement results, there are three ranges for voltage measurement,

two for resistance measurements, one range for current and three ranges for frequency.

Ranges of measurement and resolutions are specified in following table:

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 25

Table 1 - Range of input signals

Page 26

6 Commissioning, operation

GB

Type

Range/°C

Resolution/°C

Max

J

-210…1200

0,1

-190…1200

0,01

K

-270…1370

0,1

-160…1260

0,01

T

-270…400

0,1

-130…400

0,01

F

0…1400

0,1

0…1400

0,01

R

-50…1760

0,1

150…1760

0,01

S

-50…1760

0,1

170…1760

0,01

B

50…1820

0,1

920...1820

0,01

U

-200…400

0,1

-160…400

0,01

L

-200…760

0,1

-200…760

0,01

N

-270…1300

0,1

0…1300

0,01

E

-270…1000

0,1

-200…1000

0,01

C

0…2300

0,1

0…2000

0,01

M

-50…1410

0,1

-50…1410

0,01

6.3.2 Thermocouple measurements

The electrical module measures signals from the thermocouple and shows it in different

engineering units (°C, °F, K).

Thermocouple types, measuring range, linearity error and related resolutions are given in the

following table:

Table 2 – Thermocouple measurements table

It is possible to perform the measurement in two different ways: with internal reference (cold

junction), with external reference cold junction by entering the reference value through the

keyboard. When internal reference cold junction is selected, the ambient temperature is measured

through the thermocouple pins using a special thermo resistance. This temperature value is used

for compensation. The Standard connector Mignon for thermocouple is shown in Figure 1. The

thermoresistance for compensation of the reference cold junction is integrated in the same

connector.

26 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 27

6 Commissioning, operation

GB

Type

Range/°C

Resolution/°C

Max

Pt100 (385)

-200…850

0,1

-200…850

0,01

Pt100 (3916)

-200…850

0,1

-200…850

0,01

Pt100 (3926)

-200…850

0,1

-200…850

0,01

Pt100 (3902)

-200…650

0,1

-200…650

0,01

Pt100 (3923)

-200…600

0,1

-200…600

0,01

Pt100 JIS (3916)

-200…600

0,1

-200…600

0,01

Pt200 (385)

-200…850

0,1

-200…850

0,01

Pt500 (385)

-200…850

0,1

-200…530

0,01

Pt1000 (385)

-200…850

0,1

-200…850

0,01

Pt1000 (3916)

-200…850

0,1

-200…850

0,01

Ni100 (617)

-60…180

0,1

-60…180

0,01

Ni120 (672)

0…150

0,1

0…150

0,01

Cu10 (42)

-70…150

0,1

-70…150

0,01

Cu100

-180…150

0,1

-180…150

0,01

6.3.3 Thermoresistance measurements

The electrical module measures signals from thermoresistance and shows it in different

engineering units (°C, °F, K).

Thermoresistance types, measuring range and related resolutions are given in the following table:

Table 3 - Thermoresistance measurements table

It is possible to connect the thermoresistance according to the type of measurement: 2 wires, 3

wires and 4 wires. The two wires measurement is performed without any compensation of the

connecting cables resistances; in this case the connection is among the two central (COM - Ω)

pins. In the case of three wires connection the pin identified with the writing 3W must also be used.

While for the four wires measurement, the most accurate of the above, is performed by using all

four pins.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 27

Page 28

6 Commissioning, operation

GB

Range

Max resolution

Voltage

(0…100) mV

0,0001 mV

(0…2) V

0,000001 V

(0…20) V

0,00001 V

Current

(0…20) mA

0,0001 mA

Resistance

(0…400) Ω

0,001 Ω

(0…10000) Ω

0,01 Ω

Frequency

(0,5…20000) Hz

0,001 Hz

Pulse

(0,5…200) Hz / 9999999 impulse

Type

Range/°C

Resolution/°C

Max

J

-210…1200

0,1

-190…1200

0,01

K

-270…1370

0,1

-160…1260

0,01

T

-270…400

0,1

-130…400

0,01

F

0…1400

0,1

0…1400

0,01

R

-50…1760

0,1

150…1760

0,01

S

-50…1760

0,1

170…1760

0,01

B

50…1820

0,1

920…1820

0,01

U

-200…400

0,1

-160…400

0,01

L

-200…760

0,1

-200…760

0,01

N

-270…1300

0,1

0…1300

0,01

E

-270…1000

0,1

-200…1000

0,01

C

0…2300

0,1

0…2000

0,01

M

-50…1410

0,1

-50…1410

0,01

6.3.4 Generation of electrical parameters

The output module (OUT) allows to generate voltage, current, resistance and frequency.

For the voltage there are three different ranges with different resolutions. Resistance has two

ranges while current and frequency have only one range. Ranges and resolutions are given in the

following table:

Table 4 – Range of output signals

6.3.5 Thermocouple simulation

Through the output module it is possible to simulate thermocouples. This function can be used to

test and calibrate: thermocouple transmitters, analog or digital indicator. A thermoresistance Pt100,

inserted in isothermal contact with the connectors, measures the ambient temperature for the cold

junction compensation. It is possible to disable the automatic cold junction compensation and set

out the reference temperature by the keyboard.

The instrument can simulate thermocouple types indicated in the following table:

28 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Table 5 – Thermocouple simulation table

Page 29

6 Commissioning, operation

GB

Type

Range/°C

Resolution/°C

Max

Pt100 (385)

-200…850

0,1 -200…850

0,01

Pt100 (3916)

-200…850

0,1

-200…850

0,01

Pt100 (3926)

-200…850

0,1

-200…850

0,01

Pt100 (3902)

-200…650

0,1 -200…650

0,01

Pt100 (3923)

-200…600

0,1 -200…600

0,01

Pt100 JIS (3916)

-200…600

0,1 -200…600

0,01

Pt200 (385)

-200…850

0,1 -200…850

0,01

Pt500 (385)

-200…850

0,1

-200…530

0,01

Pt1000 (385)

-200…850

0,1

-200…850

0,01

Pt1000 (3916)

-200…850

0,1 -200…850

0,01

Ni100 (617)

-60…180

0,1 -60…180

0,01

Ni120 (672)

0…150

0,1 0…150

0,01

Cu10 (42)

-70…150

0,1

-70…150

0,01

Cu100

-180…150

0,1

-180…150

0,01

6.3.6 Thermoresistance simulation

Through the output module (OUT) it is possible to simulate thermoresistance. This function can be

used to check and calibrate: temperature transmitters – analogue or digital indicators.

The instrument can simulate thermoresistance types indicated in the following table:

Fast programming of the value to be simulated

In generation or simulation on any particular channel the simulated value can be

rapidly changed by pressing immediately to the right of the simulated value where

there is a sensitive square that pressed allows user to enter the value to simulate by a

numerical keyboard.

Table 6 – Thermoresistance simulation table

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 29

Page 30

6 Commissioning, operation

GB

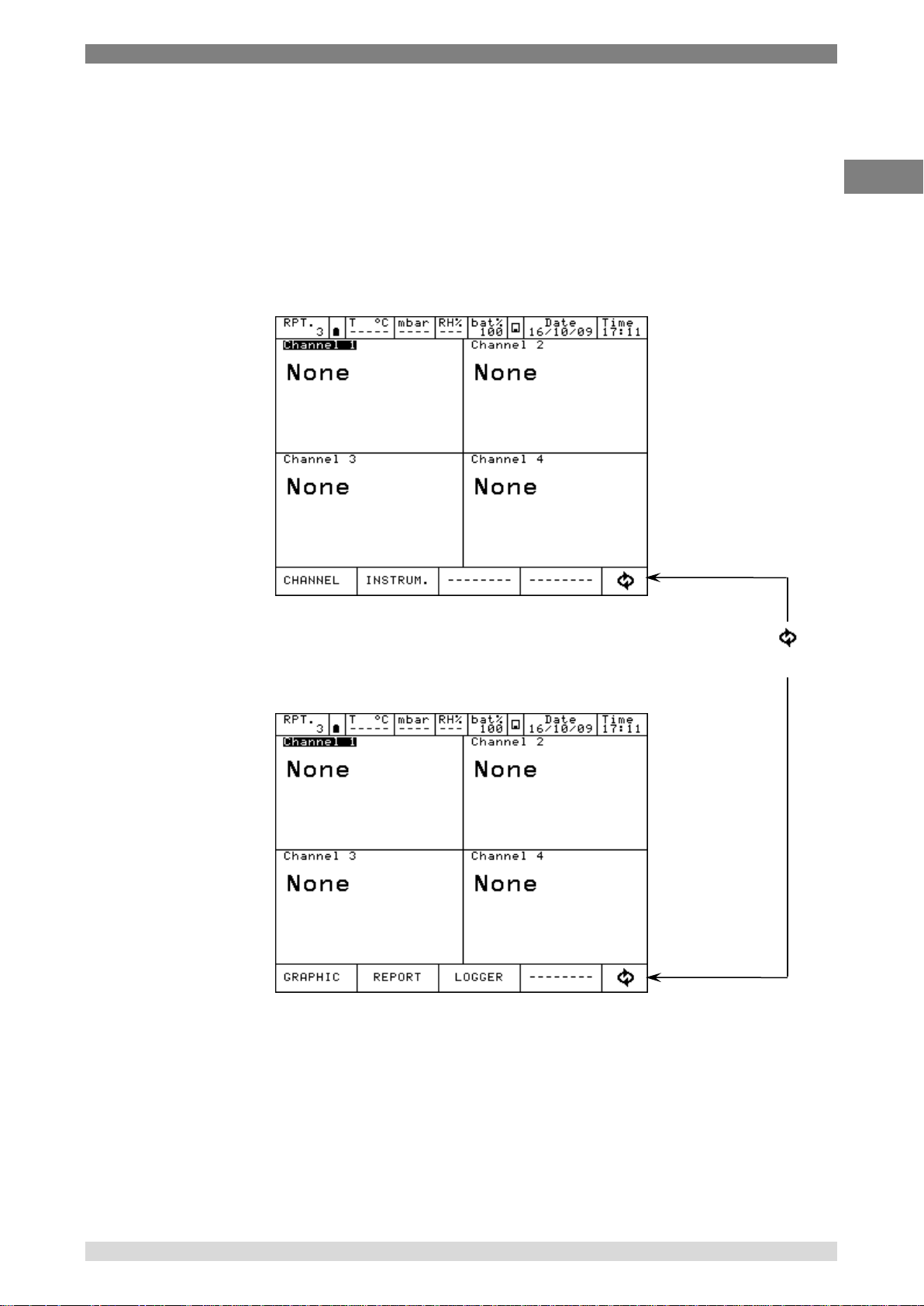

6.4 User Interface

The Pascal 100 or Pascal 100/IS calibrator has a wide display with touch screen through which it is

possible to set up the instrument.

The following picture is a typical display of the Pascal 100 or Pascal 100/IS.

The top portion represents a status bar where are indicated:

■ Number of calibration report saved in memory

■ Power supply

■ Ambient temperature

■ Barometric pressure

■ Relative humidity

■ Battery charge status

■ Data Logger status

■ Date

■ Time

Figure 13 – Typical display of Pascal 100 or Pascal 100/IS

In the central part four software channels are available for selection and configuration according to

the user requirement.

In the above screen, the instrument is set up for generating the current and to display it in the

software channel 2. The other software channels are not assigned.

At the bottom part a dynamic menu is available, that changes according to the context.

30 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 31

6 Commissioning, operation

GB

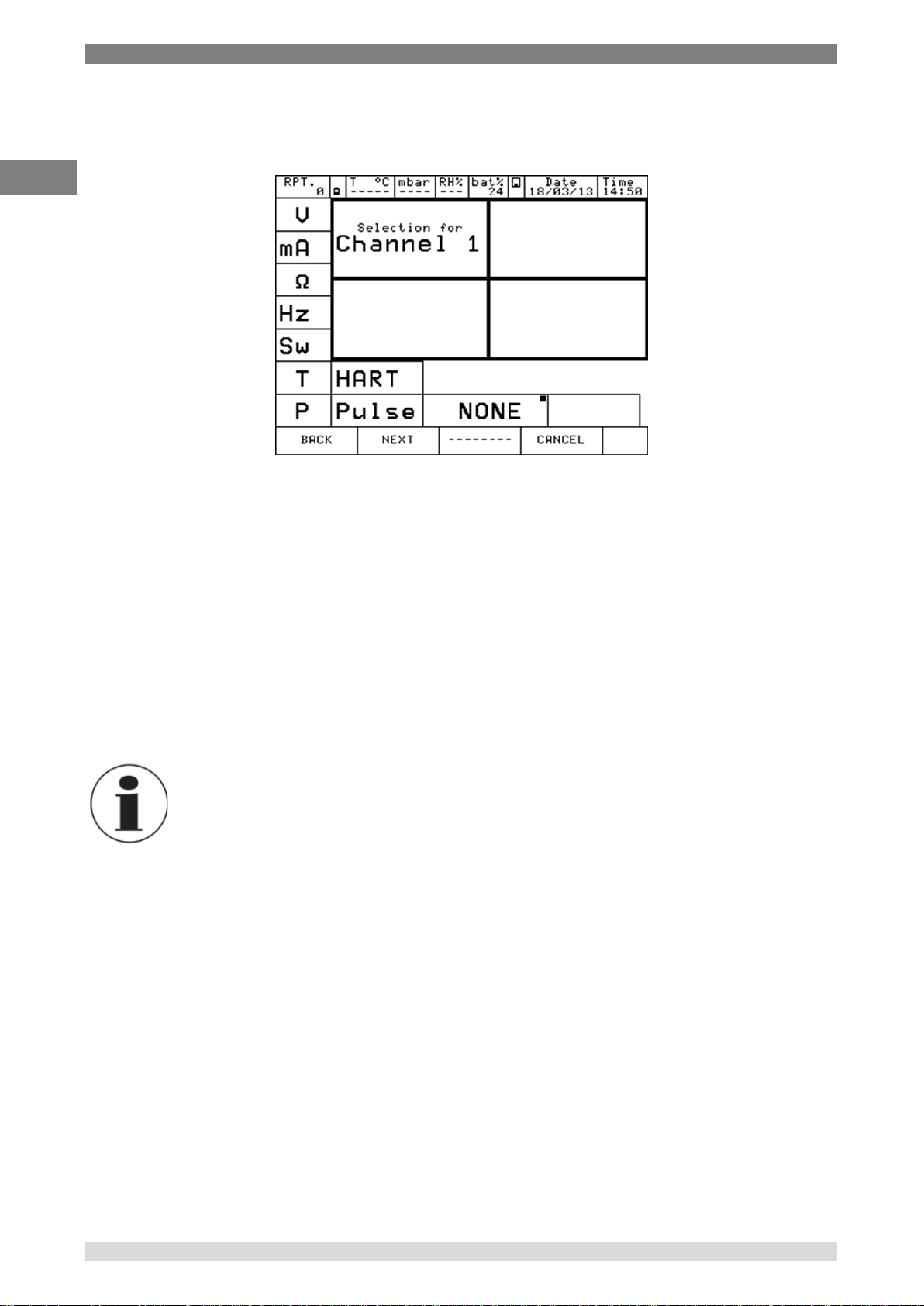

6.4.1 Channel configuration

The assignment of a function to a software channel is a simple procedure that guides the operator

step by step.

The channel assignments are very similar, therefore only one assignment will be shown as

example. The following procedure shows how to set up the Pascal 100 or Pascal 100/IS for

temperature measurement through a Pt100 thermo resistance connected to the input pins of the IN

A module (using 4 wires measurement).

The selection of one of the four available software channels is made by pressing one of the four

big channel displays, as shown in the figure below.

Channel selection

To verify if the channel has been correctly selected it is possible to check if the word

“Channel”, in the respective channel block, is in a negative form (white on black

background) or not. See figure below.

Figure 14 – Channel 1 selected

To continue the assignment procedure select CHANNEL menu and press ASSIGN.

Figure 15 - Menu ASSIGN selected.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 31

Page 32

6 Commissioning, operation

GB

Automatically the program shows the following screen and remains in this position till the operator

select what type of parameter to associate to Channel 1.

Figure 16 – Parameter selection

The possible choices are:

■ V (Voltage)

■ mA (Current)

■ (Resistance)

■ Hz (Frequency)

■ Sw (Switch (Open/Closed))

■ T (Temperature)

■ P (Pressure)

■ HART (Hart communication) [Only when the module is fitted]

■ PULSE (Pulse)

■ NONE (No selection)

Previous set-up

A small black square in the top right side of the selection of the

Figure 16 – Parameter selection, NONE, shows the last configuration of the selected

channel. To maintain the same setting press NEXT.

32 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 33

6 Commissioning, operation

GB

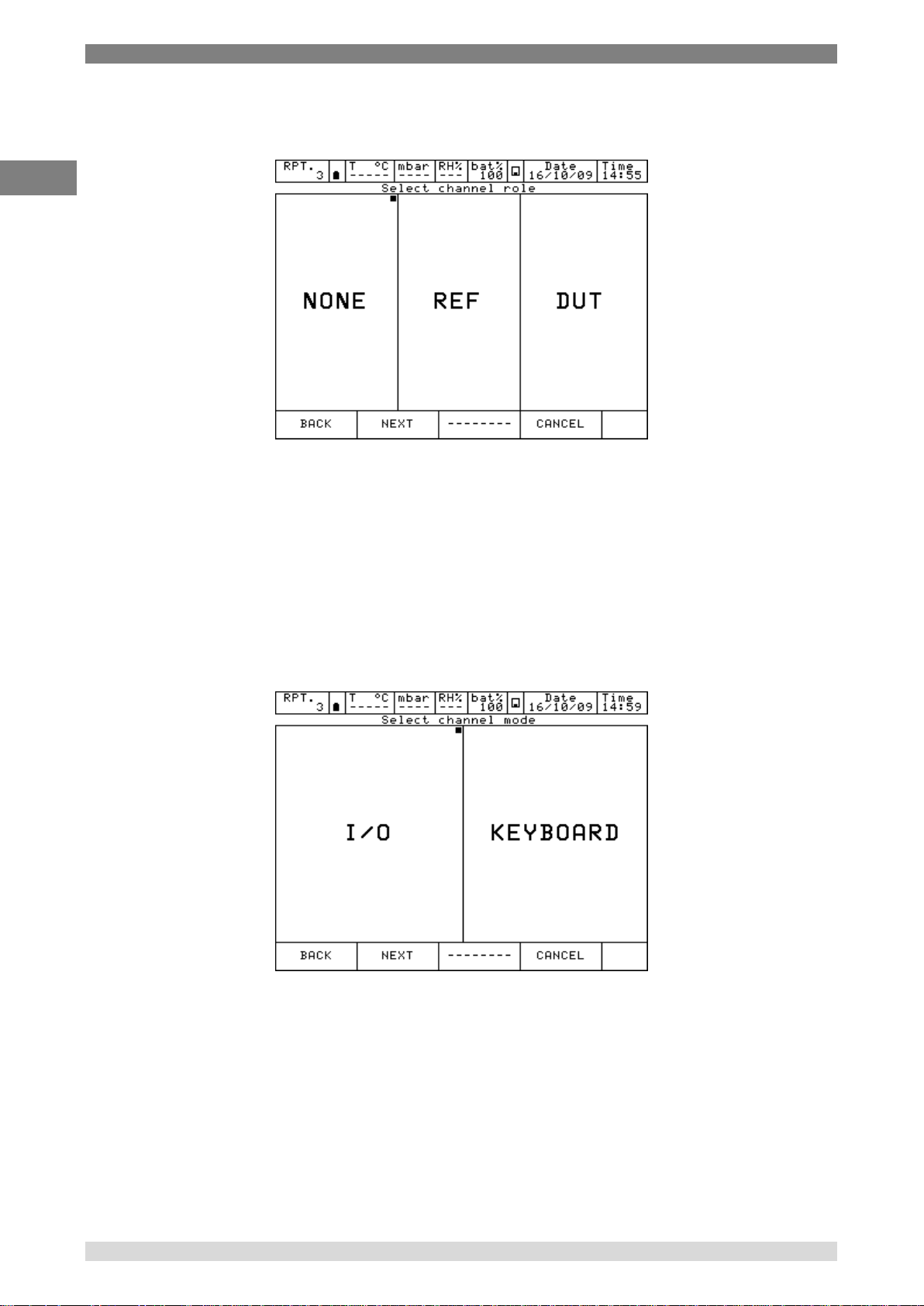

Once a particular parameter is selected, for example pressing “T” for temperature, the instrument

asks for the channel role:

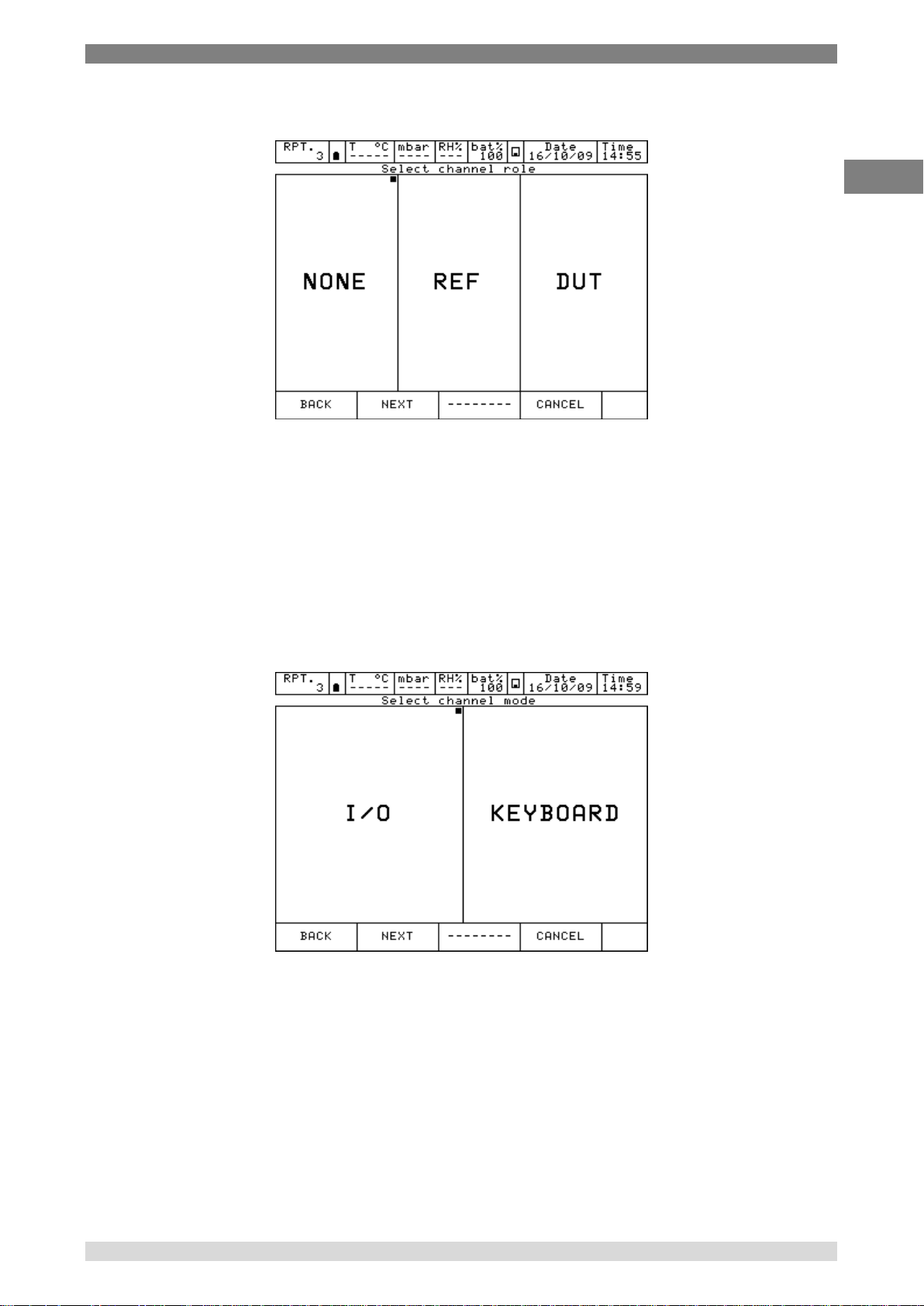

Figure 17 – Channel role selection

NONE to use the channel for simple measurement

REF to use the channel as reference in a comparison calibration

DUT to use the channel as measurement of a Device Under Test in a comparison

calibration

Press one of the above button (NONE, REF, DUT) to define the channel role.

Pressing REF or DUT the procedure continues as shown below:

I/O to assign a particular I/O module to the software channel.

KEYBOARD to setup by keyboard a particular value read from an external instrument

(i.e. analogue gauge).

Figure 18 – Channel mode selection

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 33

Page 34

6 Commissioning, operation

GB

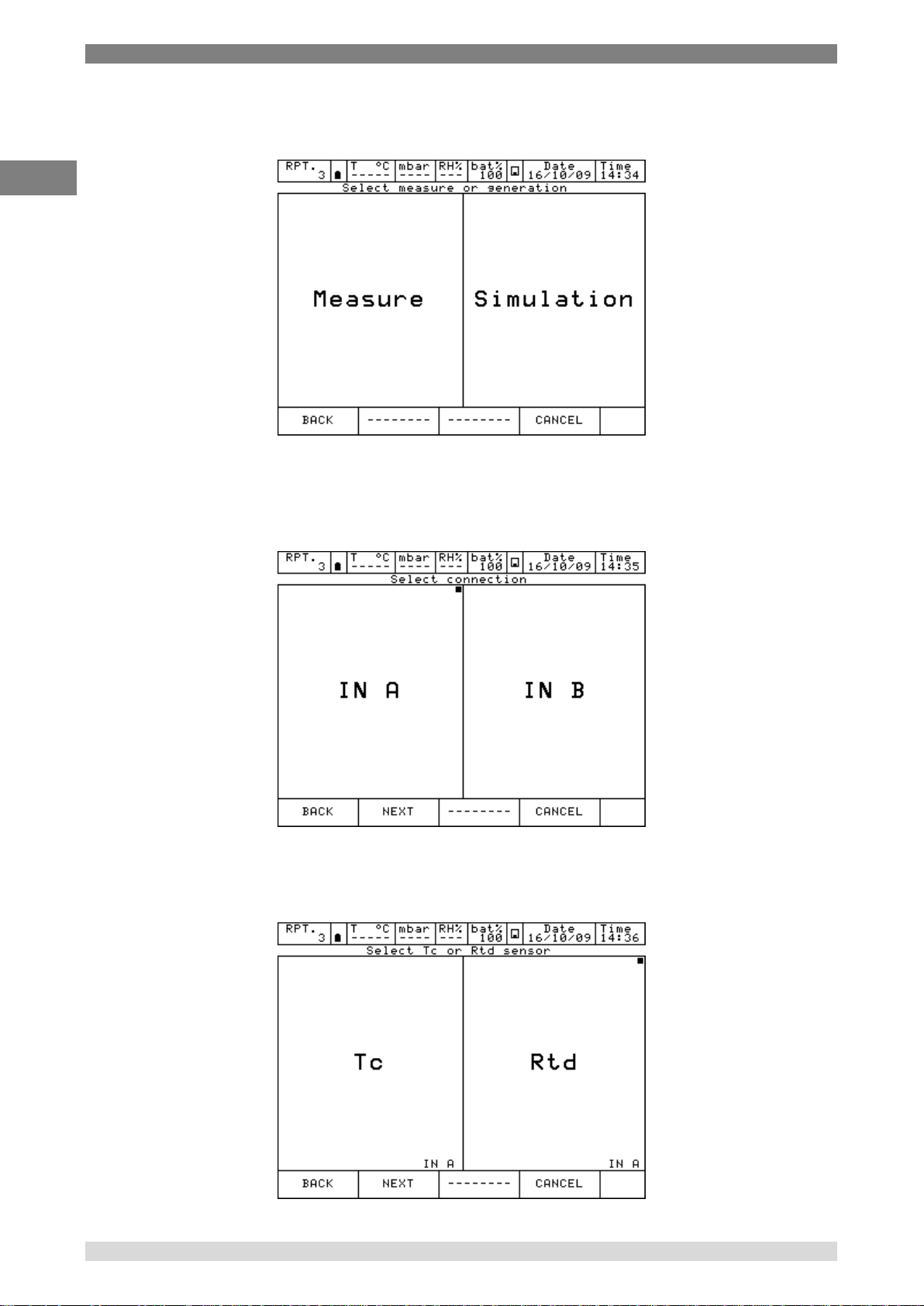

By selecting I/O the instrument requires now to specify whether to measure a signal or to perform a

simulation: for example Measure.

Figure 19 – Measure or Simulation selection

At this point the operator needs to select on which physical channel the thermoresistance has to be

connected, example IN A.

Figure 20 – Input module selection

It is necessary now to select a thermocouple (Tc) or a thermoresistance (Rtd):

Figure 21 – Tc / Rtd selection

34 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 35

6 Commissioning, operation

GB

Selecting RTD the page for the thermoresistance set up is shown. Fourteen RTD’s types are

available, plus one RTD User (with coefficient defined by the user).

Figure 22 – Rtd type selection

Once the type of thermoresistance connected to the input IN A is identified, the operator must

indicate the measurement mode: 2 wires, 3 wires or 4 wires measurement; the engineering unit

(°C, °F, K) and related number of decimal.

Measurements of RTD - 4 wires

If possible it is recommended to perform RTD measurement with four wires to

eliminate parasite resistances of the connecting cables. All specifications for

thermoresistance aim for four wires measurement.

RTD USER must be selected when the operator needs to measure a non-standard RTD in

agreement with the following formula:

If T≥ 0 °C R(t)= Ro * (1 + A * t + B * T²)

If T< 0 °C R(t)= Ro * (1 + A * t + B * T² + C (t – 100) * t³)

Figure 23 – RTD parameters setup

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 35

Page 36

6 Commissioning, operation

GB

Once RTD USER is selected, it is possible to set the parameter of the RTD used.

A = X * 10-3 °C-1

B = X * 10ˉ7 °C-2

C = X * 10

-12

°C-3

Ro = Resistance @ t = 0,01 °C

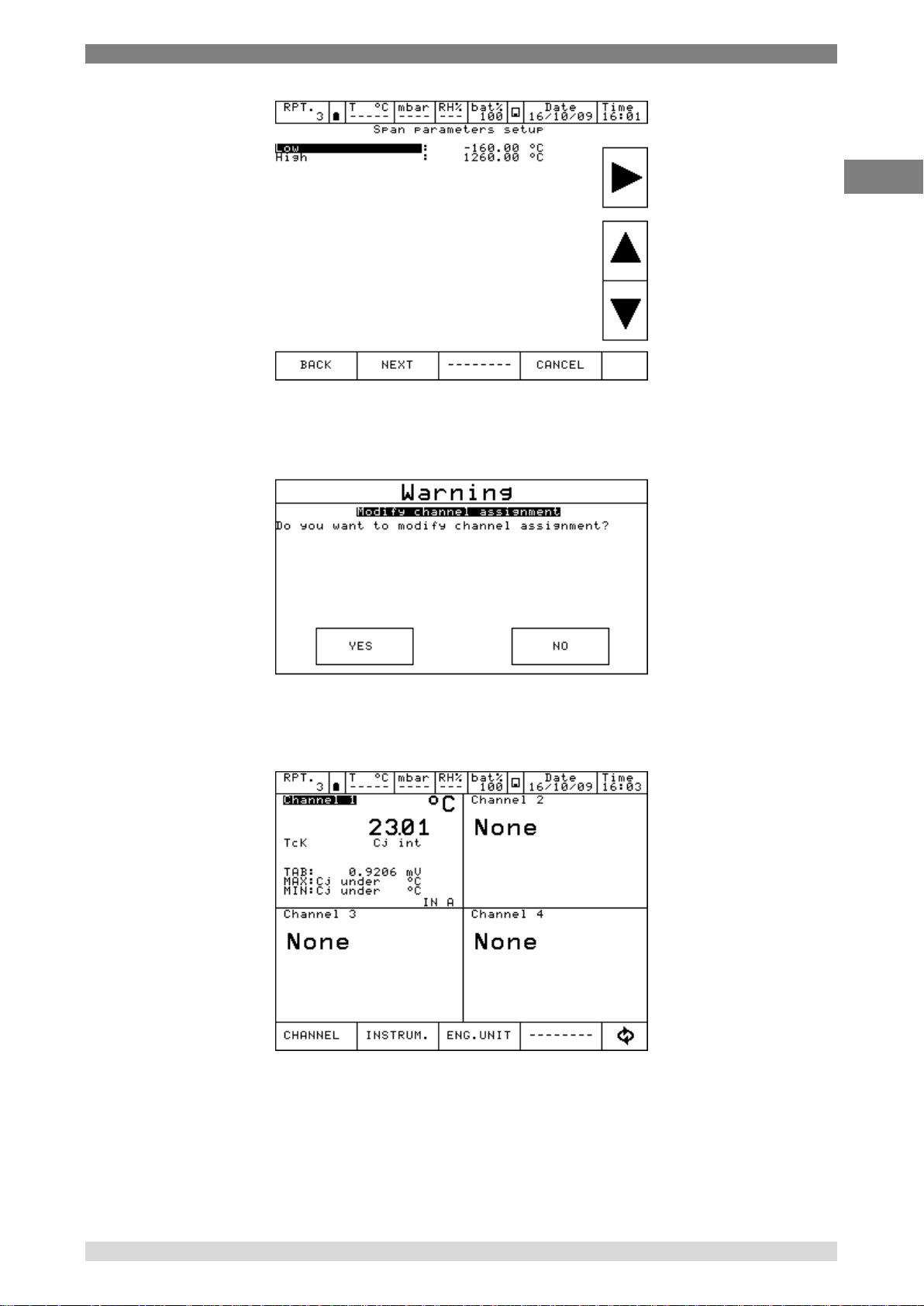

X = Value

Next step is to define the measurement range. The range selection is necessary during the

calibration procedure to define the relationship between the REF and DUT channels.

Figure 24 – Range setup

Now it is possible to conclude the procedure by pressing the YES button or come back to the

previous step pressing NO.

Figure 25 – Channel setup confirmation

Once the YES key is pressed, the calibrator returns to the initial page where the user can proceed

with the measurement/simulation, or assign another function to a different software channel

following the same procedure.

36 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 37

6 Commissioning, operation

GB

6.4.2 Other assignments

6.4.2.1 Pressure measurement

The following procedure illustrates the setting of Pascal 100 or Pascal 100/IS for pressure

measurement. The particular channel is selected by pressing one of the four big displays and then

pressing CHANNEL and ASSIGN from the menu, as shown below:

Figure 26 – Channel assign selection

Automatically the program shows the following screen and it remains in this position until the

operator points out what type of parameter he desires to associate to a selected channel, for

example to the Channel 1. In this case press P for pressure.

Figure 27 – Pressure parameter selection

The Pascal 100 or Pascal 100/IS can be equipped with up to two pressure modules and each of

them can handle up to three pressure sensors, two internals and one external with standard

accuracy.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 37

Page 38

6 Commissioning, operation

GB

The instrument requires the channel role:

Figure 28 – Channel role selection

NONE to use the channel for simple measurement

REF to use the channel as reference in a comparison calibration

DUT to use the channel as measurement of a Device Under Test in a comparison

calibration

Press one of the above button (NONE, REF, DUT) to define the channel role.

Pressing REF or DUT the procedure continues as shown below:

I/O to assign a particular I/O module to the software channel.

KEYBOARD to setup by keyboard a particular value read from an external instrument

(i.e. analogue gauge).

Figure 29 – Channel mode selection

38 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 39

6 Commissioning, operation

GB

Measure unit

bar

mbar

ftH2O@4°C

inH2O@4°C

inHg@0°C

psf

psi

atm

torr

mH2O@4°C

cmH2O@4°C

mmH2O@4°C

mHg@0°C

cmHg@0°C

mmHg@0°C

kg/m2@g_std

kg/cm2@g_std

MPa

kPa

hPa

Pa

By selecting I/O the procedure requires to select the type and the range of the sensor to be used.

The sensor is identified by the measurement range and the measurement mode (g = gauge

pressure or a = absolute pressure). This information is displayed under the writing PE-1 (first

external sensor) or PE-2 (second external sensor). See the the figure below as example:

Figure 30 – Pressure sensor selection

When the sensor has been selected, the next page helps to set the engineering unit and related

number of decimals.

Figure 31 – Pressure sensor parameters selection

The pressure engineering units available are:

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 39

Page 40

6 Commissioning, operation

GB

The next screen shows the Span parameter (measuring range). For default the sensor has its

maximum range equal to the measuring range (Span). If the Span has to be redefined, or to be

reduced, the same can be changed by using a numeric keyboard. The redefinition of the Span is

used during a calibration for comparison where a relationship between a REF and a DUT channel

has to be done.

Figure 32 – Sensor range setup

Now it is possible to finalize the procedure by pressing the YES button or come back to the

previous step pressing NO.

Figure 33 - Channel setup confirmation

Pressing the key YES, the channel is set up with the selected parameters and the screen with four

channels is displayed again.

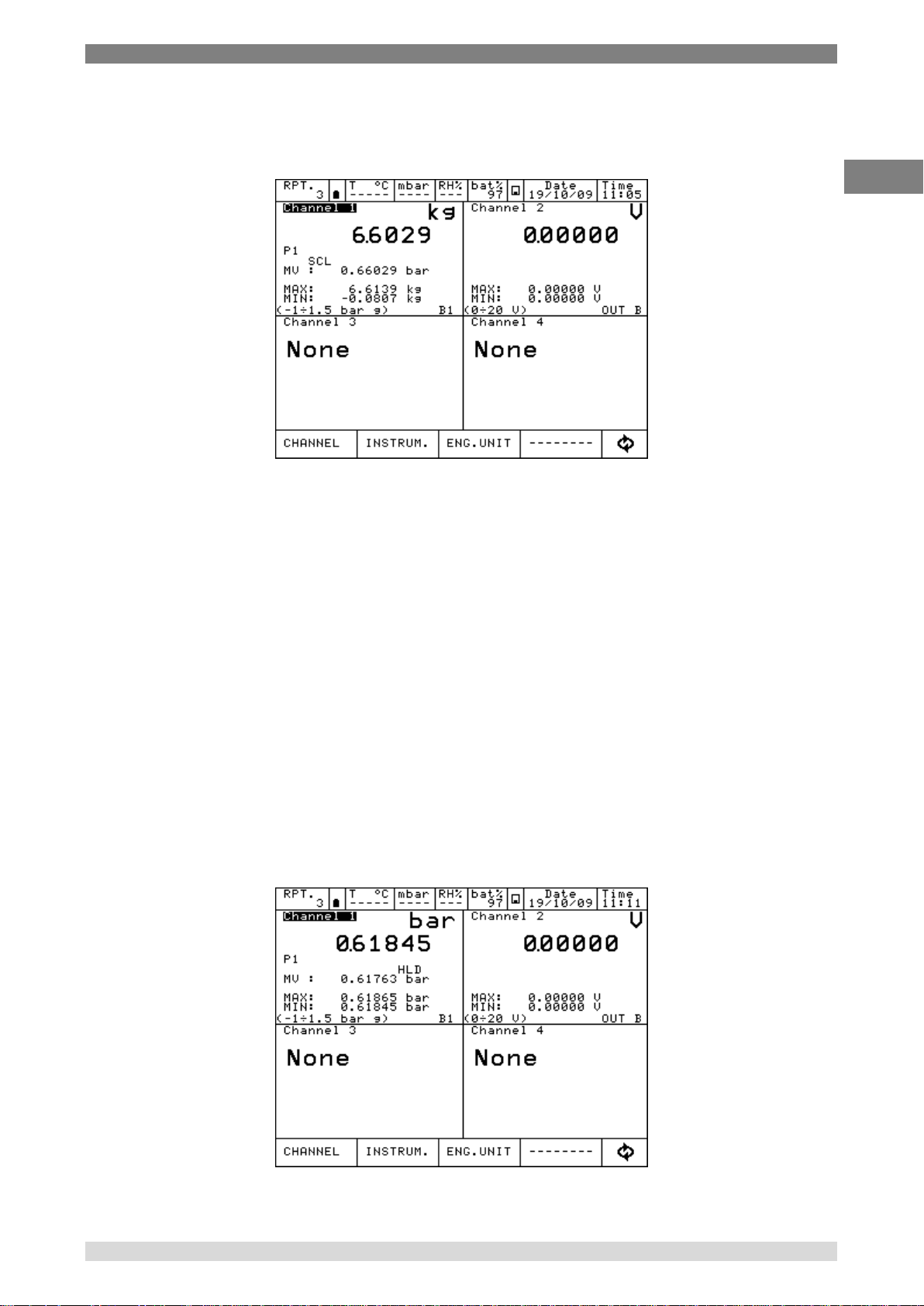

Figure 34 – Main display with pressure measurement

40 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 41

6 Commissioning, operation

GB

6.4.2.2 Thermocouple signal measurement

The following procedure shows the setup of Pascal 100 or Pascal 100/IS for temperature signal

measurement, for example, through a thermocouple connected to the input module. The channel

for measurement is selected by pressing one of the four large displays, once the menu CHANNEL

is selected, press ASSIGN as shown in the below figure.

Figure 35 – Channel assign selection

Automatically the program shows the following screen and it remains in this position until the

operator selects the type of parameter he desires to associate to the Channel 1.

Figure 36 – Temperature parameter selection

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 41

Page 42

6 Commissioning, operation

GB

Press T for Temperature.

The instrument requires the channel role:

Figure 37 – Channel role selection

NONE to use the channel for simple measurement

REF to use the channel as reference in a comparison calibration

DUT to use the channel as measurement of a Device Under Test in a comparison

calibration

Press one of the above button (NONE, REF, DUT) to define the channel role.

Pressing REF or DUT the procedure continues as shown below:

I/O to assign a particular I/O module to the software channel.

KEYBOARD to setup by keyboard a particular value read from an external instrument.

Figure 38 – Channel mode selection

42 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 43

6 Commissioning, operation

GB

By selecting I/O the instrument requires now to specify whether to measure a signal or to perform a

simulation: for example Measure.

Figure 39 - Measure or Simulation selection

At this point the operator needs to select on which physical channel the thermocouple has to be

connected, example IN A.

Figure 40 - Input module selection

It is necessary now to select a thermocouple (Tc) or a thermoresistance (Rtd), for example Tc.

Figure 41 - Tc / Rtd selection

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 43

Page 44

6 Commissioning, operation

GB

Selecting Tc the page for thermocouple set up is shown as follow:

Figure 42 – Tc type selection

Next page helps the operator to select: the engineering unit (°C - °F - K) and the type of reference

cold junction (internal or external). Selecting “internal cold junction”, a Pt100 is directly connected

to the TC input pins, measures the environmental temperature; whereas by selecting “external cold

junction”, the temperature value must be inserted by using the keyboard.

Figure 43 – Tc parameters selection

The next screen shows the Span parameter (measuring range). In the default settings, the sensor

has its maximum range equal to the measuring range (Span). If the Span has to be redefined, or to

be reduced, same can be changed by using a numeric keyboard. The redefinition of the Span is

used during a calibration for comparison where a relationship between a REF and a DUT channel

has to be done.

44 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 45

6 Commissioning, operation

GB

Figure 44 – Tc range selection

Now it is possible to finalize the procedure by pressing the YES button or come back to the

previous step pressing NO.

Figure 45 - Channel setup confirmation

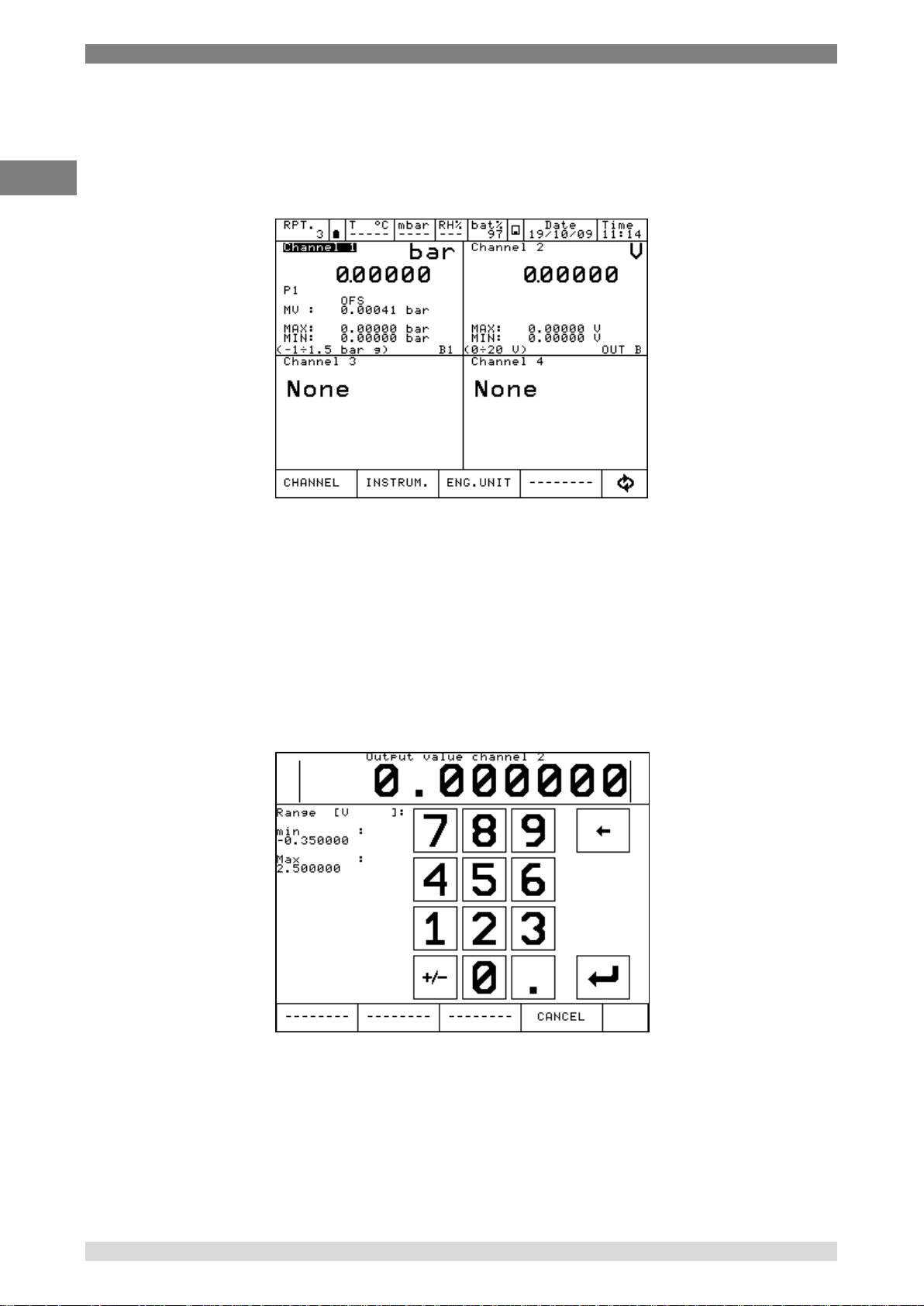

Pressing the key YES, the channel is set up with selected parameters and the screen with four

channels is displayed again.

Figure 46 - Main display with temperature measurement

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 45

Page 46

6 Commissioning, operation

GB

6.4.2.3 Electrical parameter measurement

The following procedure shows the settings of Pascal 100 or Pascal 100/IS for the electrical

parameters measurement through the input module. To select the channel press on one of the four

large displays, then press CHANNEL: once menu is displayed press ASSIGN. Procedure is shown

below:

Figure 47 - Channel assign selection

Automatically the program shows the following configuration and it remains in this position till the

operator selects the parameter to be associated to the Channel 1.

For example, press mA for current measurement.

Figure 48 – mA parameter selection

46 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 47

6 Commissioning, operation

GB

The instrument requires the selection of the role:

Figure 49 - Channel role selection

NONE to use the channel for simple measurement

REF to use the channel as reference in a comparison calibration

DUT to use the channel as measurement of a Device Under Test in a comparison

calibration

Press one of the above button (NONE, REF, DUT) to define the channel role.

Pressing REF or DUT the procedure continues as shown below:

I/O to assign a particular I/O module to the software channel.

KEYBOARD to setup by keyboard a particular value read from an external device.

Figure 50 - Channel mode selection

Then press I/O to assign a particular I/O module to the software channel, or press keyboard to

setup a particular value read from an external device.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 47

Page 48

6 Commissioning, operation

GB

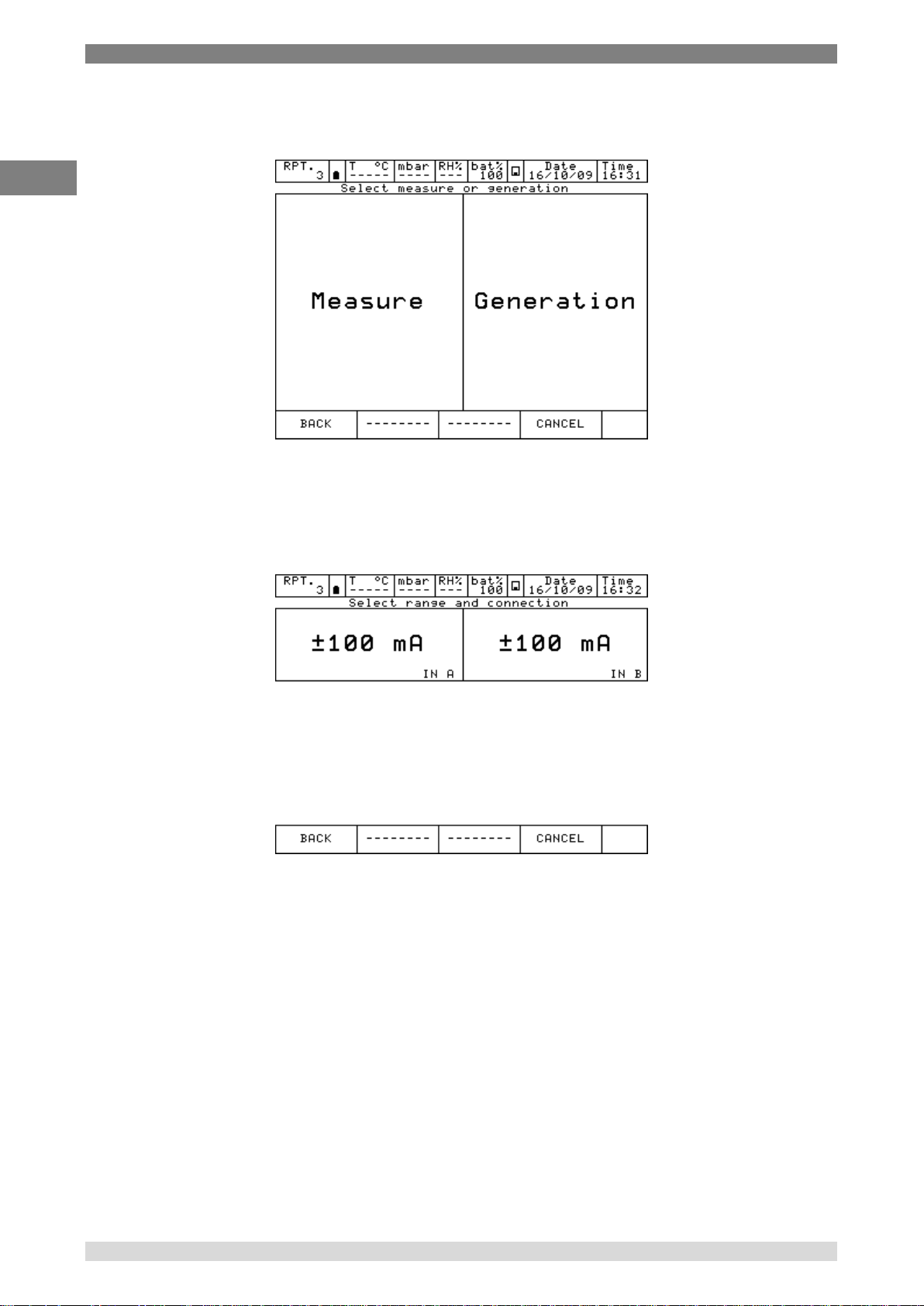

By selecting the input/output (I/O) the procedure requires to select MEASURE (to measure a

signal) or GENERATION (to generate a signal)

Figure 51 – Measure or generation selection

By pressing MEASURE, automatically the Pascal 100 or Pascal 100/IS requires to select input

module (IN A- IN B) to be used. Double input will be displayed when the calibrator has a double

input configuration and both modules are not assigned yet. Otherwise only one input will be

displayed

Figure 52 – mA selection from IN A or IN B

48 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 49

6 Commissioning, operation

GB

The next step shows the span parameter (measuring range). In the default settings, the maximum

range is equal to the measuring range (span). If the span has to be redefined or reduced, it can be

changed by using a numeric keyboard. To access to the keyboard use the arrows displayed on the

right side of the screen. Change of the span is used during a calibration for comparison where a

relationship between a REF and a DUT channel has to be assigned.

Figure 53 – mA range setup

Now it is possible to finalize the procedure pressing YES or come back to the previous step

pressing NO.

Figure 54 - Channel setup confirmation

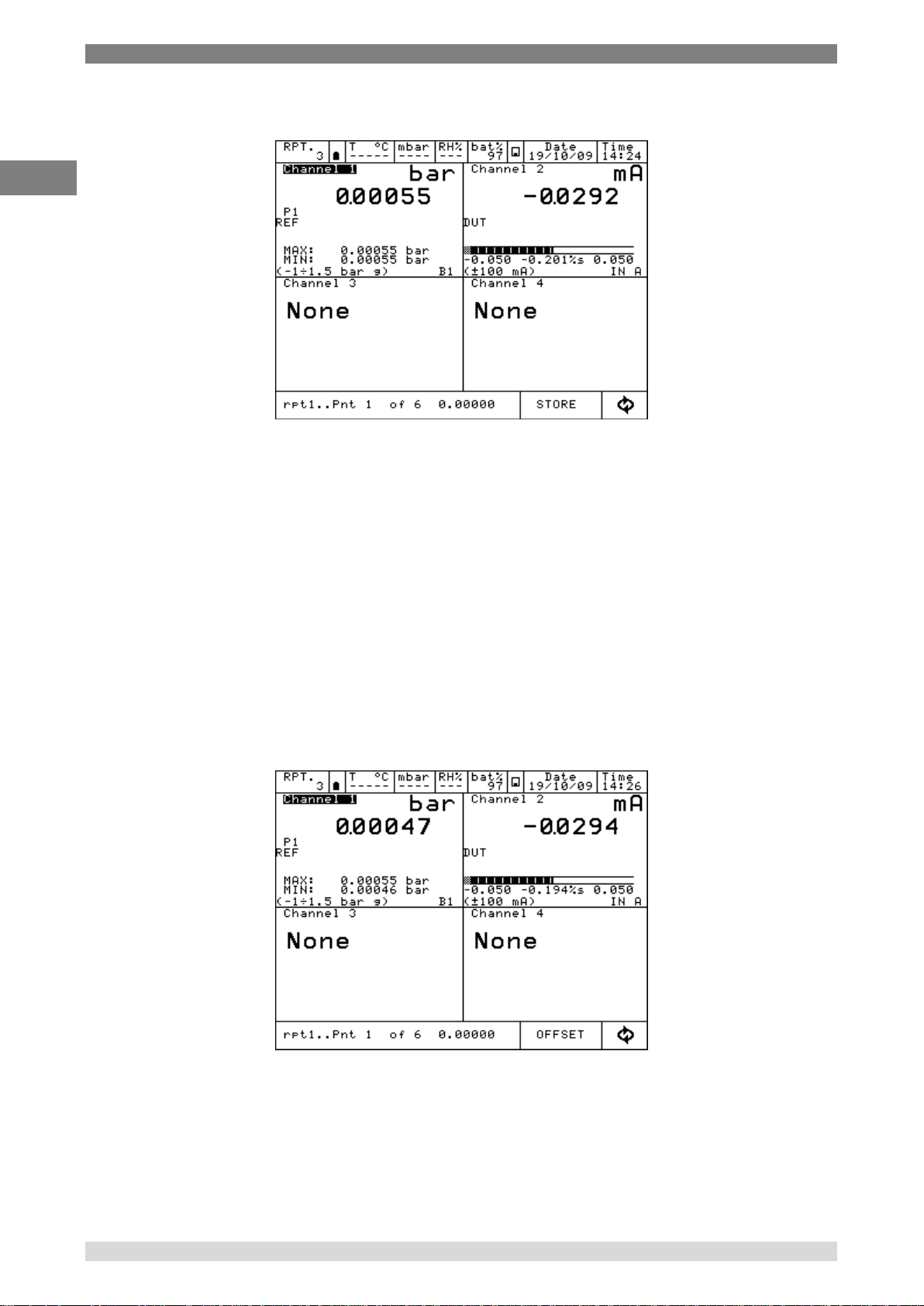

Pressing YES, the channel is assigned to the selected parameter and the screen with four

channels is displayed again.

Figure 55 – Main display with mA measurement

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 49

Page 50

6 Commissioning, operation

GB

6.4.2.4 Temperature Simulation

The procedure for the temperature simulation assignment is similar to the measurement one as

described previously, except for the step “Select measure or simulation” where the operator needs

to press SIMULATION instead of MEASURE. In the following step the user needs to select one of

the output OUT A or OUT B available.

Figure 56 – Generation module selection

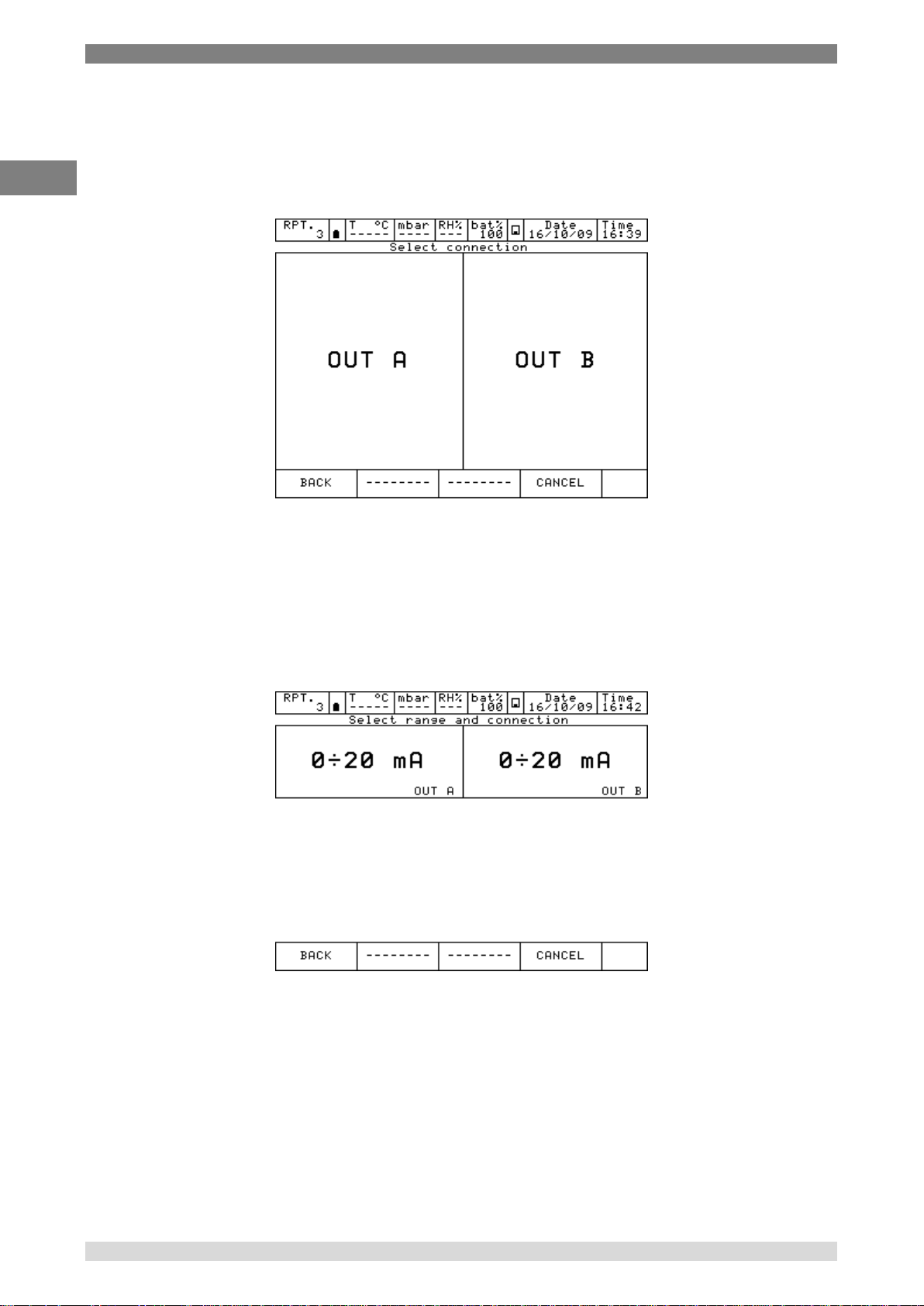

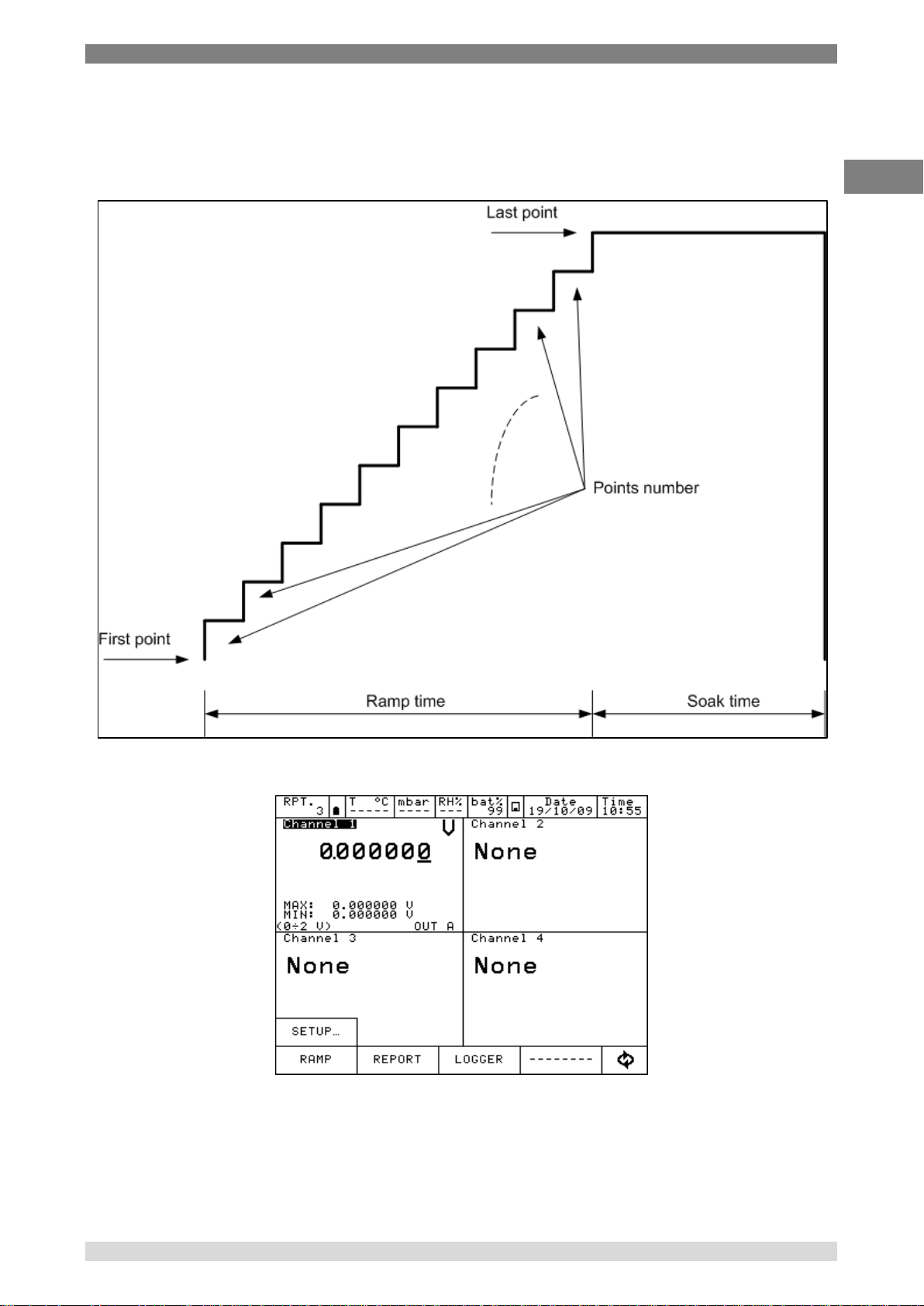

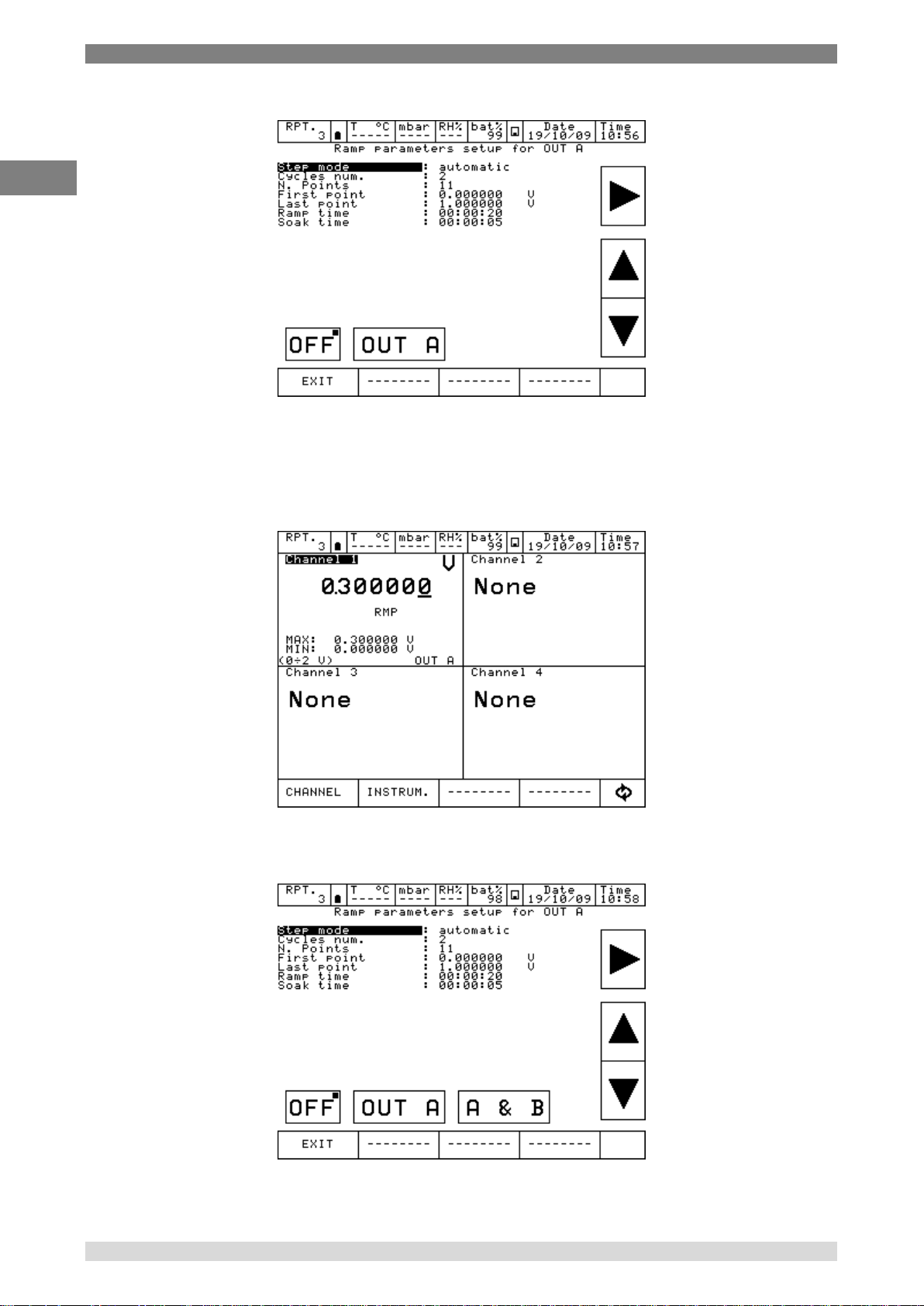

6.4.2.5 Electrical parameter generation

The procedure for the assignment of the generation of an electric parameter (for example mA) is

similar to the electrical signal measurement one as described previously, except for the step

"Select measure or generation” where the operator needs to select GENERATION instead of

MEASURE.

Then the user needs to select OUT A or OUT B (if available).

Figure 57 – mA generation module selection

50 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 51

6 Commissioning, operation

GB

The next selection ask if a passive or active loop is required (with 24 V supply for the loop).

Figure 58 – mA loop generation setup

6.4.2.6 Channel 4 – mathematic functions

Channel four has an additional setting named CALC. This function enables to display on channel

n. 4 a value, result of the combination of the values displayed in channel 1 and 2. To access, press

on the display of channel 4, then Channel on the bottom bar and then assign.

Figure 59 – Channel 4 assignment

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 51

Page 52

6 Commissioning, operation

GB

Pressing CALC the followings are displayed:

Figure 60 – Calculation types

CH1 + CH2 channel 4 displays the total value of the values displayed on channel 1 and 2

CH1 - CH2 channel 4 displays the difference value of the values displayed on channel 1 and 2

Cell Load channel 4 displays the ratio mV/V of the load cells

CH1+CH2 and CH1-CH2 functions can be used only if channel 1 and 2 are set with the same

values: same engineering unit, same number of digits, no channel assigned with error indication.

In this case, below what will be displayed:

Figure 61 - Calculation on Channel 4

52 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 53

6 Commissioning, operation

GB

Otherwise the channel 4 will be displayed as:

Figure 62 – Calculation not possible on Channel 4

For the Cell Load, the channel 4 can calculate the result coming from a load cell connected as per

the below scheme:

Figure 63 – Cell Load connection

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 53

Page 54

6 Commissioning, operation

GB

Calculation is possible only when channel 1 is assigned for mV measurement (bridge signal) and

channel 2 is assigned for V generation, range 0÷20 V (bridge supply). Moreover channel 1 should

not be set in error mode.

In this case, below what will be displayed:

Figure 64 – Cell Load calculation

Pascal 100 or Pascal 100/IS allows to manage the sensitivity of the load cell from 0 mV/V up to

9.99999 mV/V.

Moreover, on channel 4, the SCALING function can be assigned through the menu CHANNEL in

order to display an engineering unit more appropriate (for example Kg or a pressure unit).

Figure 65 – Cell Load calculation with Scaling function active

54 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 55

6 Commissioning, operation

GB

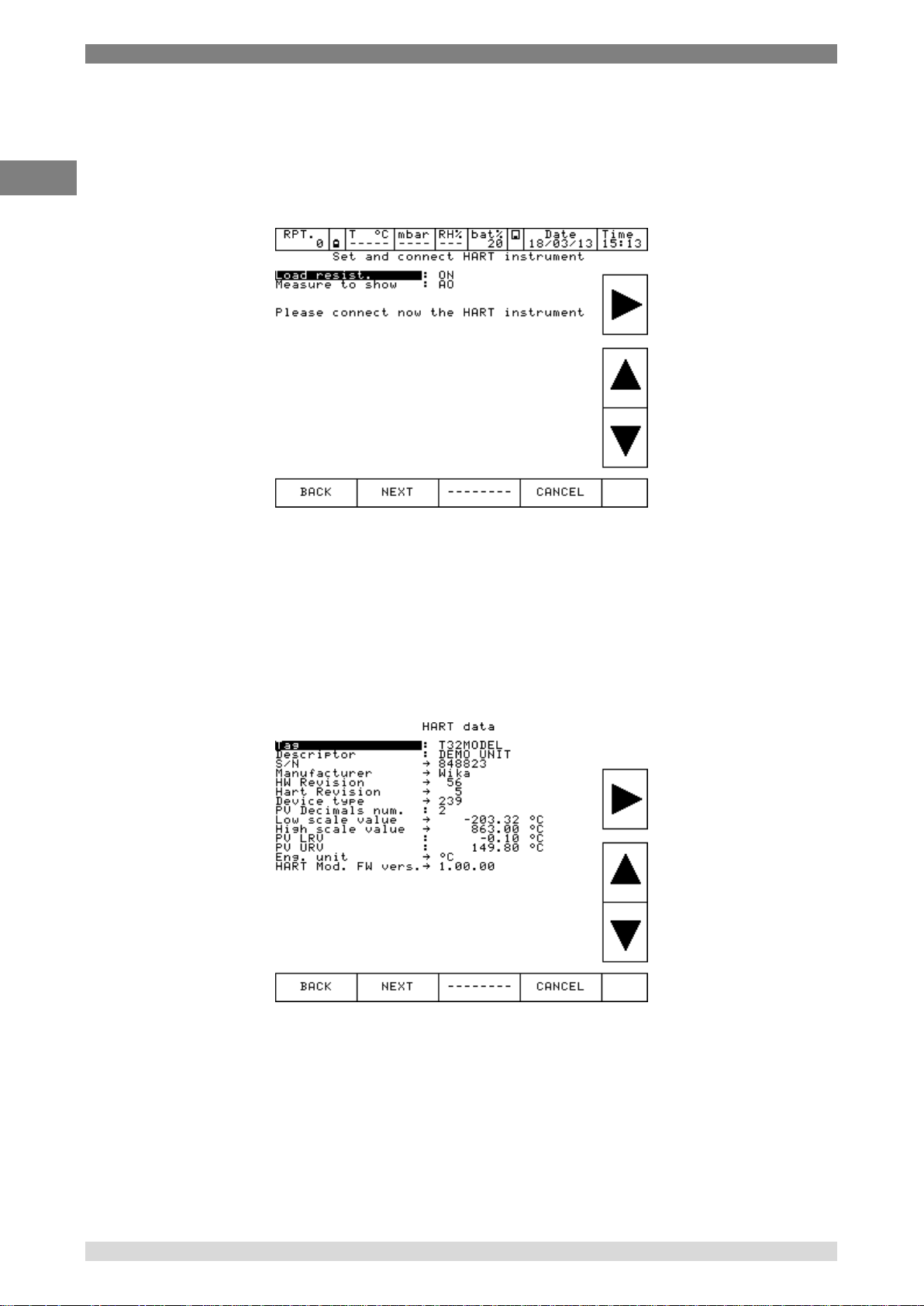

6.4.2.7 HART channel assignment

To select the channel press on one of the four large displays, then press CHANNEL. Once menu is

displayed press ASSIGN. Procedure is shown below:

Automatically the program shows the following configuration and it remains in this position till the

operator selects the parameter to be associated to the Channel 1.

For example, press HART for HART measurement.

The instrument requires the selection of the role:

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 55

Page 56

6 Commissioning, operation

GB

NONE to use the channel for simple measurement

REF to use the channel as reference in a comparison calibration

DUT to use the channel as measurement of a Device Under Test in a comparison calibration

Press one of the above button (NONE, REF, DUT) to define the channel role.

Pressing REF or NONE the procedure continues as shown below:

Here the user can choose if enable the internal module 250Ω resistor (ON or OFF), and choose

what digital measure wants to show as the big value displayed on the channel window: PV or AO.

The other type of measure however is displayed on the channel in a smaller font.

Before pressing NEXT be sure to already make the proper connections to the HART instrument as

show in previous chapter

Press NEXT and, after few seconds, if no error is shown the following appear (depending on HART

transmitter type connected):

Here the user has the possibility to change some parameter (they showed with ‘:’ moving the black

line with arrows.

They can be: TAG, DESCRIPTOR, PV decimals units, PV LRV and PV URV.

56 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 57

6 Commissioning, operation

GB

After positioned to the parameter needed to modify press right arrow key, for example on the TAG

parameter:

If desired delete all the characters with backspace and insert the desired. After press ENTER to

store the parameter inside the HART transmitter; the Pascal will return to the previous display.

IMPORTANT NOTE: HART requires that all the characters must be in upper case in order to

be properly stored.

Press NEXT to continue.

The next step shows the span parameter (measuring range). In the default settings, the maximum

range is equal to the measuring range (span). If the span has to be redefined or reduced, it can be

changed by using a numeric keyboard. To access to the keyboard use the arrows displayed on the

right side of the screen. Change of the span is used during a calibration for comparison where a

relationship between a REF and a DUT channel has to be assigned.

Now it is possible to finalize the procedure pressing YES or come back to the previous step

pressing NO.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 57

Page 58

6 Commissioning, operation

GB

Pressing YES, the channel is assigned to the selected parameter and the screen with four

channels is displayed again.

6.4.2.8 HART trimmer calibration

When the HART transmitter needs to be recalibrated or adjusted the HART menu can achieve

these two types of possibilities:

- ADJ.SCL

- CAL.TRIM

CAL.TRIM permits to correct the analog mA generation, of the HART transmitter, referred to the

digital AO value displayed if the output DAC goes out of tolerance.

Zero and Span needs to be corrected.

If the user wants to recalibrate the Trim. an INPUT mA measurement channel has to configured as

REF channel. In addition, the loop wiring needs to flow to the IN mA terminals.

If no REF mA Input channel is configured first an error will be shown.

58 WIKA Operating Instruction, Pascal 100 and Pascal 100/IS

Page 59

6 Commissioning, operation

GB

The instrument shows:

Press “Zero Trim” or “Span Trim”, and the display shows (in this case Span Trim is selected):

The HART instrument is put in fixed mode generation (4 or 20 mA) and the REF channel is

measuring the true analog mA generation. To re-align to the correct 20 mA (or 4 mA) generation

press “Calibrate” button.

If needed follow the same procedure for “Zero Trim”.

WIKA Operating Instruction, Model Pascal 100 and Pascal 100/IS 59

Page 60

6 Commissioning, operation

GB

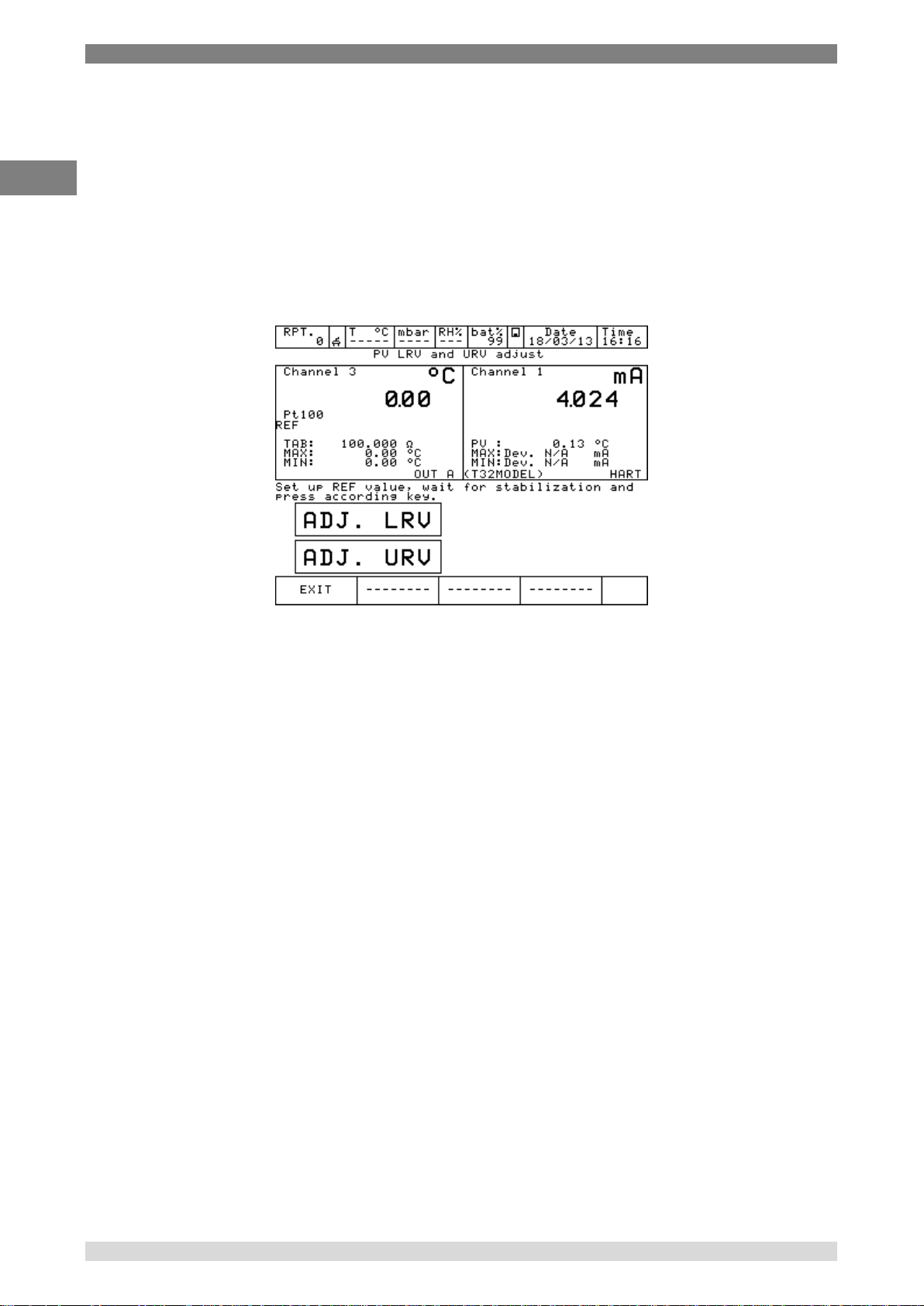

6.4.2.9 HART scale adjust

ADJ.SCL permits to align the range of PV to the Lower and Upper mA generation values.

The Lower value of PV is the value at which the transmitter will generate the 4 mA nominal value,

and the Upper value is the value at which the transmitter will generate the 20 mA nominal value.

Here is described the “automated” procedure that permits to align in “real-time” these values. The

user can also change them manually in the “HART data” page as seen before.

If the user wants to adjust the scale a channel of the same input type of the transmitter has to be

configured as REF channel. If no REF channel is configured first an error will be shown.

Press ADJ.SCL menu and the following is shown (assuming that we are using a Pt100 transmitter,

e REF simulation Pt100 channel is configured as Channel 3):

Set the REF Channel to the desired value that permits to output by the transmitter the 4mA value