Page 1

Current terms and conditions apply.

Details are available on ...

Es gelten unsere aktuellen Verkaufsund Lieferbedingungen siehe unter ...

Toute commande est assujettie à nos

conditions de ventes et de fournitures

dans leur dernière version en vigueur, voir

sous ...

Se aplican nuestras condiciones actuales

de venta y de suministro, que se pueden

consultar en ...

www.wika.de

Operating instructions

Betriebsanleitung

Mode d’emploi

Manual de instrucciones

N-10,

N-11

Pressure transmitter /

Druckmessumformer /

Transmetteur de pression /

Transmisor de presión

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Phone (+49) 93 72/132-295

Fax (+49) 93 72/132-706

E-Mail support-tronic@wika.de

www.wika.de

2147614.07 GB/D/F/E 04/2009

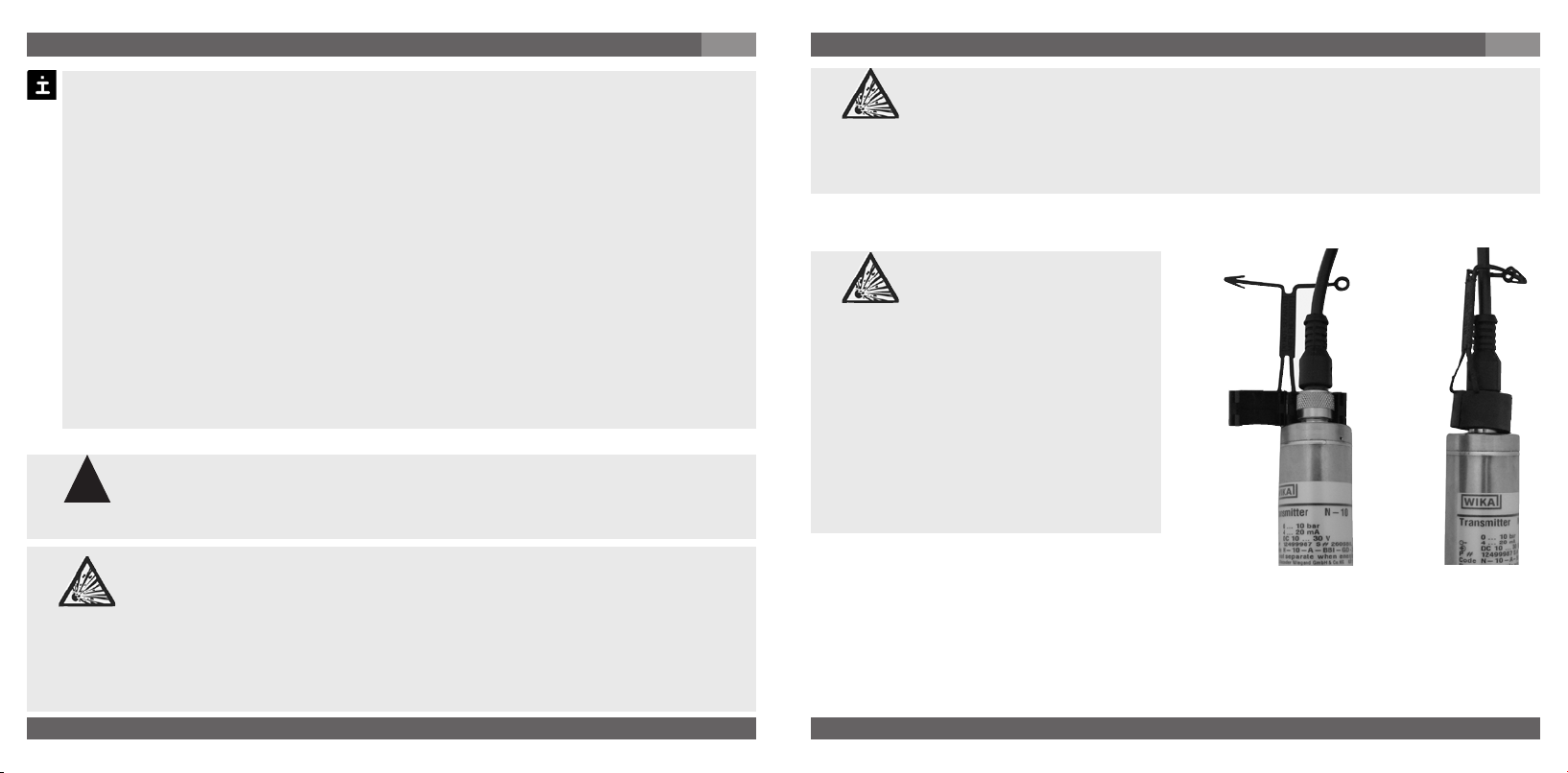

N-10

N-11

Page 2

2147614.07 GB/D/F/E 04/2009

2

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

3

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

Contents / Inhalt / Contenu / Contenido

Contents Page 3-18 GB

1. Important details for your information

2. A quick overview for you

3. Signs, symbols and abbreviations

4. Function

5. For your safety

6. Packaging

7. Starting, operation

8. Maintenance, accessories

9. Trouble shooting

10. Storage, disposal

11. EC declaration of conformity

WIKA Global Page 68

Inhalt Seite 19-34 D

1. Wichtiges zu Ihrer Information

2. Der schnelle Überblick für Sie

3. Zeichenerklärungen, Abkürzungen

4. Funktion

5. Zu Ihrer Sicherheit

6. Verpackung

7. Inbetriebnahme, Betrieb

8. Wartung, Zubehör

9. Störbeseitigung

10. Lagerung, Entsorgung

11. EG-Konformitätserklärung

WIKA Global Seite 68

Contenu Page 35-50 F

1. Informations inportantes

2. Aperçu rapide

3. Explication des symboles,abréviations

4. Fonction

5. Pour votre sécurité

6. Emballage

7. Mise en service, exploitation

8. Entretien, accessoires

9. Elimination de perturbations

10. Stockage, mise au rebut

11. Déclaration de confeamité CE

WIKA Global Page 68

Contenido Paginás 51-66 E

1. Detalles importantes para su información

2. Resumen rápido para usted

3. Signos, símbolos y abreviaciones

4. Función

5. Para su seguridad

6. Embalaje

7. Puesta en servicio, funcionamiento

8. Mantenimiento, accesorios

9. Eliminación de perturbaciones

10. Almacenaje, eliminación de desechos

11. Declaración de conformidad CE

WIKA Global Paginá 68

GB D

F

E

1. Important details for your information

1. Important details for your information

Read these operating instructions before installing and starting the pressure transmitter. Keep

the operating instructions in a place that is accessible to all users at any time.

The following installation and operating instructions have been compiled by us with great care

but it is not feasible to take all possible applications into consideration. These installation and

operation instructions should meet the needs of most pressure measurement applications. If

questions remain regarding a specific application, you can obtain further information:

If the serial number on the product label and/or the 2D code on the hexagon gets illegible (e.g.

by mechanical damage or repainting), the retraceability of the instrument is not possible any

more.

WIKA pressure transmitters are carefully designed and manufactured using state-of-the-art

technology. Every component undergoes strict quality and environmental inspection before

assembly and each instrument is fully tested prior to shipment. Our environmental management system is certified to DIN EN ISO 14001.

Use of the product in accordance with the intended use N-10, N-11:

Use the non-incendive pressure transmitter to transform the pressure into an electrical signal

in hazardous areas, where category 3G resp. 3D equipment is required.

Certificate ATEX:

Pressure transmitter for operation in hazardous areas

II 3G EEx nA II T6 and II 3D IP65 T80°C

Knowledge required: Install and start the pressure transmitter only if you are familiar with the

relevant regulations and directives of your country and if you have the qualification required.

You have to be acquainted with the rules and regulations on hazardous areas, measurement

and control technology and electric circuits, since this pressure transmitter is „electrical

equipment“ as defined by EN 50178. Depending on the operating conditions of your application you have to have the corresponding knowledge, e.g. of aggressive media.

GB

Via our Internet address www.wika.de / www.wika.com

The product data sheet is designated as PE 81.26

Contact WIKA for additional technical support (+49) 9372 / 132-295

Page 3

2147614.07 GB/D/F/E 04/2009

4

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

5

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2. A quick overview / 3. Signs, symbols and abbreviations

2. A quick overview for you

If you want to get a quick overview, read Chapters 3, 5, 7 and 10. There you will get some

short safety instructions and important information on your product and its starting. Read

these chapters in any case.

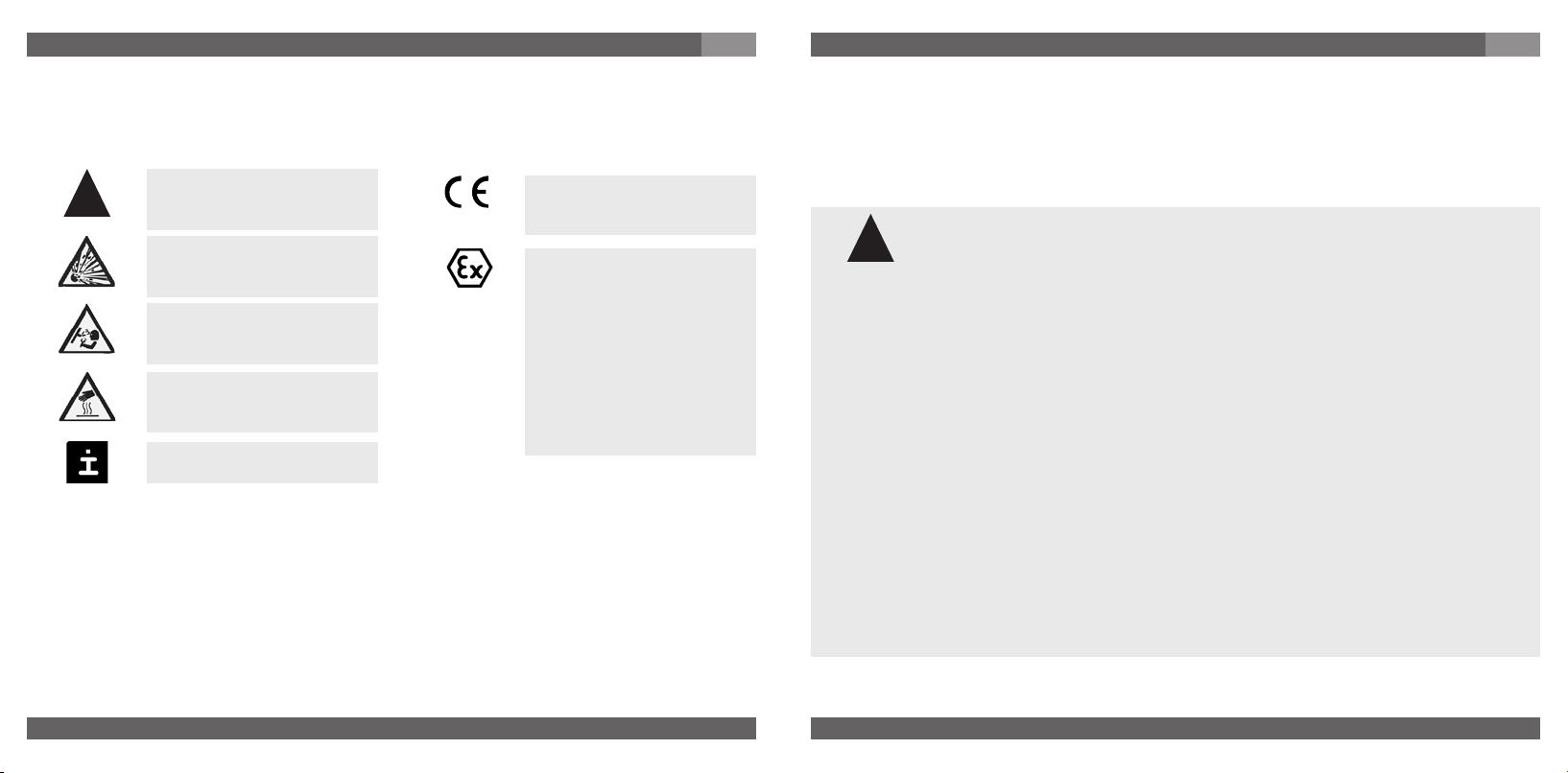

3. Signs, symbols and abbreviations

Potential danger of life or of

!

Warning

Warning

Warning

Caution

2-wire Two connection lines are intended for the voltage supply.

The supply current is the measurement signal.

3-wire Two connection lines are intended for the voltage supply.

One connection line is intended for the measurement signal.

U+ Positive supply connection

U- Negative supply connection

S+ Positive measurement connection

severe injuries.

Instructions for hazardous

areas: Potential danger of

life or of severe injuries.

Potential danger of life or

of severe injuries due to

catapulting parts.

Potential danger of burns

due to hot surfaces.

Notice, important information, malfunction.

The product complies with

the applicable European

directives.

ATEX

European guideline

for explosion protection (Atmosphäre=AT,

Explosion=EX)

The product complies with

the requirements of the

European directive 94/9/EC

(ATEX) on explosion protection.

4. Function

N-10: Pressure connection (non-incendive) with internal diaphragm (standard version).

N-11: Pressure connection with flush diaphragm (non-incendive) for highly viscous or

solids entrained media which might clog the pressure port.

GB

Function

The pressure prevailing within the application is transformed into a standardised electrical

signal through the deflection of the diaphragm, which acts on the sensor element with the

power supply fed to the transmitter. This electric signal changes in proportion to the pressure

and can be evaluated correspondingly.

5. For your safety

Information about material consistency against corrosion and diffusion can be found in our

WIKA-Handbook, 'Pressure and Temperature Measurement'.

4. Function / 5. For your safety

Select the appropriate pressure transmitter with regard to scale range,

!

Warning

dangerous media such as acetylene, flammable gases or liquids and toxic gases or liquids

and with refrigeration plants or compressors). If you do not observe the appropriate

regulations, serious injuries and/or damage can occur!

Open pressure connections only after the system is without pressure!

Please make sure that the pressure transmitter is only used within the overload threshold

limit all the time!

Observe the ambient and working conditions outlined in section 7 „Technical data”.

Ensure that the pressure transmitter is only operated in accordance with the provisions i.e.

as described in the following instructions.

Do not interfere with or change the pressure transmitter in any other way than described in

these operating instructions.

Remove the pressure transmitter from service and mark it to prevent it from being used

again accidentally, if it becomes damaged or unsafe for operation

Take precautions with regard to remaining media in removed pressure transmitter.

Remaining media in the pressure port may be hazardous or toxic!

Have repairs performed by the manufacturer only.

performance and specific measurement conditions prior to installing and

starting the instrument.

Observe the relevant national regulations (e.g.: EN 50178) and observe the

applicable standards and directives for special applications (e.g. with

GB

Page 4

2147614.07 GB/D/F/E 04/2009

6

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

7

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

5. For your safety / 6. Packaging / 7. Starting, operation

GB

Consider the respective country specific regulations for installation and

operation in hazardous areas (e.g.: IEC 60079-14). If you do not observe

Warning

these stipulations, serious injuries and/or damage can occur.

6. Packaging

Has everything been supplied?

Check the scope of supply:

Completely assembled pressure transmitters; with flush version N-11 including pre-

assembled sealings and protection cap.

Inspect the pressure transmitter for possible damage during transportation. Should

there be any obvious damage, inform the transport company and WIKA without delay.

Keep the packaging, as it offers optimal protection during transportation (e.g. chan-

ging installation location, shipment for repair).

Ensure that the pressure connection thread and the connection contacts will not be

damaged.

In order to protect the diaphragm, the pressure connection of the instrument N-11 is provided

with a special protection cap.

Remove this protection cap by hand only just before installing the pressure transmitter

in order to prevent any damage to the diaphragm or the thread.

Keep the protection cap of the pressure connection thread and the diaphragm for

later storage or transport.

Mount the protection cap when removing and transporting the instrument.

7. Starting, operation

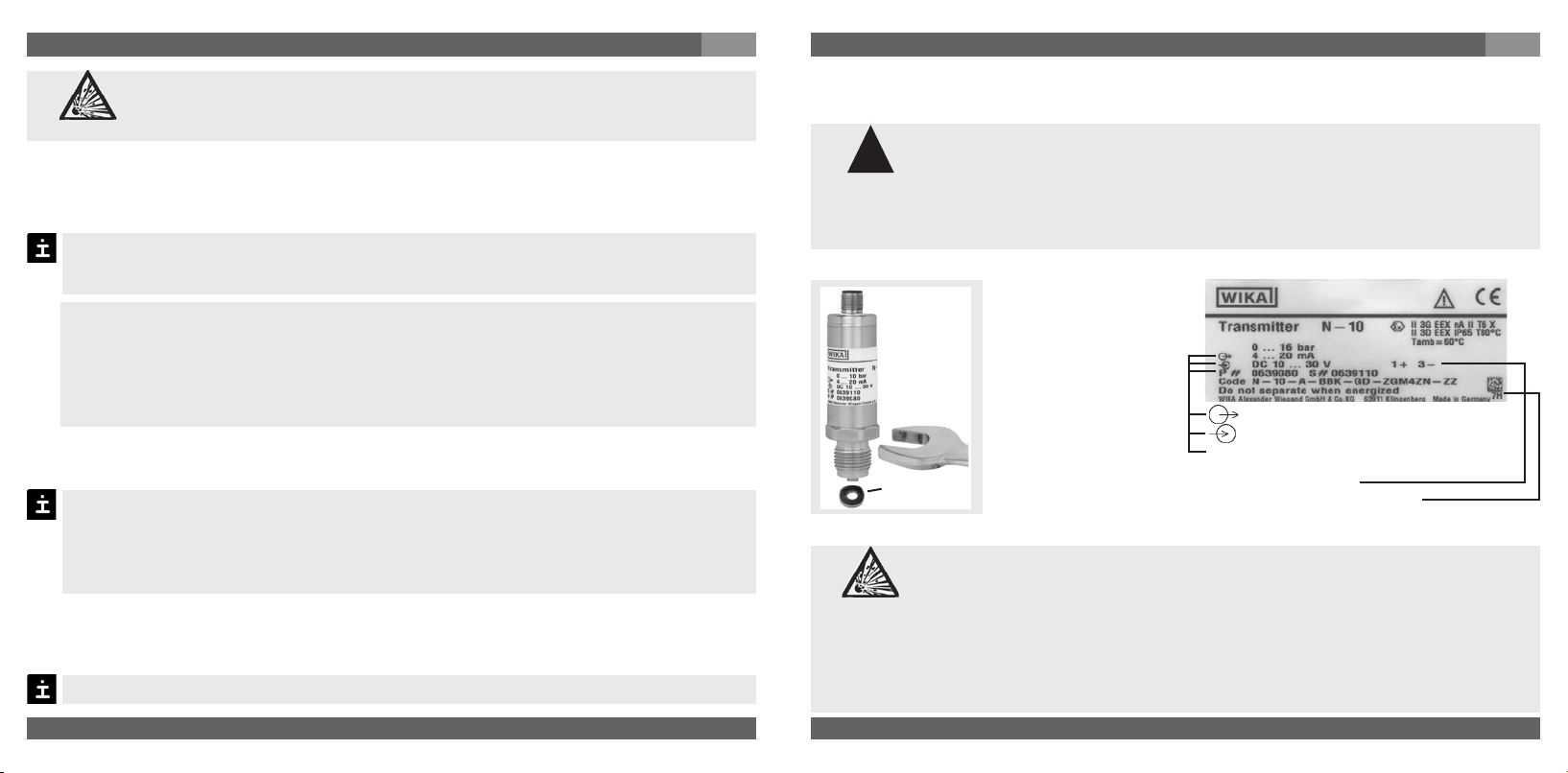

Required tools: wrench (flats 27), screw driver

7. Starting, operation

Diaphragm test for your safety

It is necessary that before starting the pressure transmitter you test the diaphragm visually, as

this is a safety-relevant component.

Warning

Mechanical connection Product label (example)

Warning

!

max.

50 Nm

Sealing

Pay attention to any liquid leaking out, for this points to a diaphragm

damage.

Check the diaphragm visually for any damage (N-11).

Use the pressure transmitter only if the diaphragm is undamaged.

Use the pressure transmitter only if it is in a faultless condition as far as the

safety-relevant features are concerned.

Generally the

serial number on

the product label

applies. If there is

no serial number on

the product label,

the number on the

hexagon will apply.

Protect the diaphragm against any contact with abrasive substances and

Signal

Power Supply

Product No.

P #

Serial No.

S #

PIN assignment

Coded manufacture date

pressure peaks and do not touch it with tools. If you damage the diaphragm,

no intrinsic safety can be guaranteed (ATEX)!

Ensure that under hazardous ennvironment the pressure transmitter is

mounted in a shielded section and protect it against shocks.

Observe the technical data for the use of the pressure transmitter in connec-

tion with aggressive / corrosive media and for the avoidance of mechanical

hazards.

GB

Page 5

2147614.07 GB/D/F/E 04/2009

8

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

9

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

7. Starting, operation

Remove the protection cap by hand only just before installation and absolutely avoid

any damage to the diaphragm during installation as well (N-11).

For Model N-10 you have to provide for a sealing element; exceptions are instruments

with self-sealing threads (e.g. NPT thread).

For Model N-11 the sealing ring is included in delivery.

Please refer to our data sheet “Pressure gauge sealing washers AC 09.08” in WIKA’s

product catalog Pressure and Temperature Measurement or our website

www.wika.de for details about sealing washers.

When mounting the instrument, ensure that the sealing faces of the instrument and

the measuring point are clean and undamaged.

Screw in or unscrew the instrument only via the flats using a suitable tool and the

prescribed torque. The appropriate torque depends on the dimension of the pressure

connection and on the sealing element used (form/material). Do not use the case as

working surface for screwing in or unscrewing the instrument.

When screwing the transmitter in, ensure that the threads are not jammed.

For tapped holes and welding sockets please see Technical Information IN 00.14 for

download at www.wika.de -Service

Electrical connection

!

Warning

Warning

Do not disconnect the electrical connection while under voltage!

Use a supply voltage with power limitation P ≤ W.

Ensure that the power supply is limited to U < 42 VDC even in the case of

malfunction.

Switch on the operating voltage only after establishing the electrical connec-

tion in order to avoid any spark formation.

Ground the cable screen at one end, preferably in the safe, thus non-

Ex, area (EN 60079-14). For transmitters with flying leads, the screen is

connected to the housing. The simultaneous connection of housing and

cable screen to ground is only permitted if ground loop problems between

the screen connection (e.g. at the power supply) and housing can be

excluded (see EN 60079-14).

GB

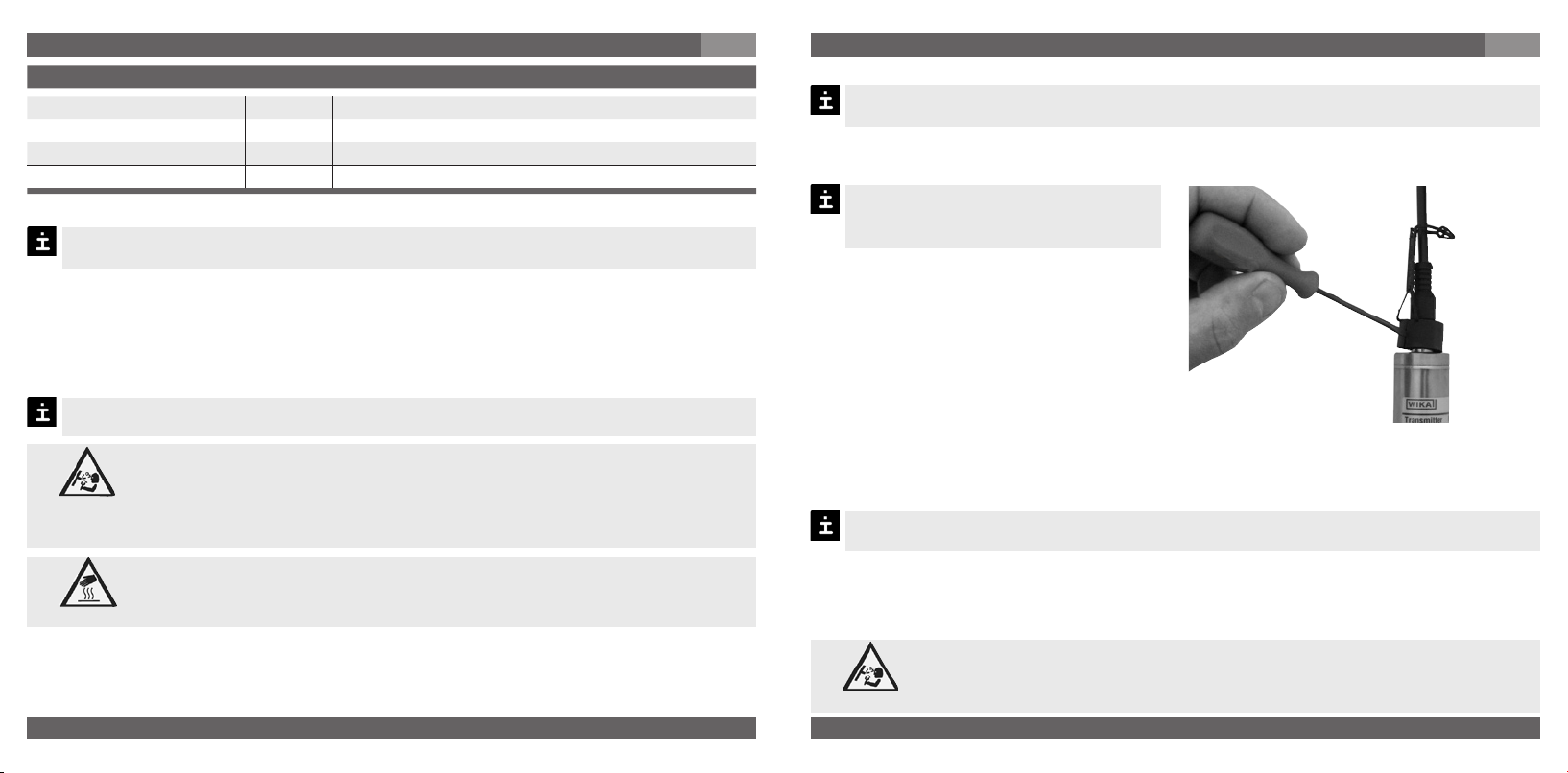

For Transmitters with connector M12x1 and installation/use in Zone 22:

7. Starting, operation

Supply the pressure transmitter from a galvanically isolating power supply

unit.

Consider both the internal capacitance and inductance.

Warning

Consider that cables for use in zones 20 and 22 must be checked with a test voltage

between conductor/earth, conductor/screen, screen/earth of more than 500V (AC).

Warning

Cover flying leads with fine wires by an end splice (cable preparation).

An additional interlock,

to prevent the M12x1

connector from being

opened unintentionally, is

required. Use the attached

clip (WIKA part number

2073164). Put both parts

of the sleeve over the

connector shroud and

press them together to

secure it. Attach the flag to

the cable by inserting the

“arrow” into the hole.

GB

Page 6

2147614.07 GB/D/F/E 04/2009

10

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

11

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

7. Starting, operation

Earth the housing, through the process connection, against electromagnetic fields and

electrostatic discharge.

Operate the pressure transmitter with a shielded cable and earth the shield at least on

one side of the cable, if the cable is longer than 30m (2-wire) or 3m (3-wire), or if it is

run outside of the building.

Ingress protection per IEC 60529 (The ingress protection classes specified only apply

while the pressure transmitter is connected with female connectors that provide the

corresponding ingress protection).

Please observe the following when selecting

the connector:

Temperature range T > T transmitter + 20 K

Ingress protection

Conductor cross-section

≥ IP 54 (explosion protection)

≥ A 0.25 mm2

the cable:

when selecting the cable length, ensure that it is 3x longer than the cable length

required, so that the cable can be pulled to different locations.

Ensure that the cable diameter you select fits to the cable gland of the connector

Ensure that the cable gland of the mounted connector is positioned correctly and

that the sealings are available and undamaged. Tighten the threaded connection and

check the correct position of the sealings in order to ensure the ingress protection.

Please make sure that the ends of cables with flying leads do not allow any ingress of

moisture.

GB

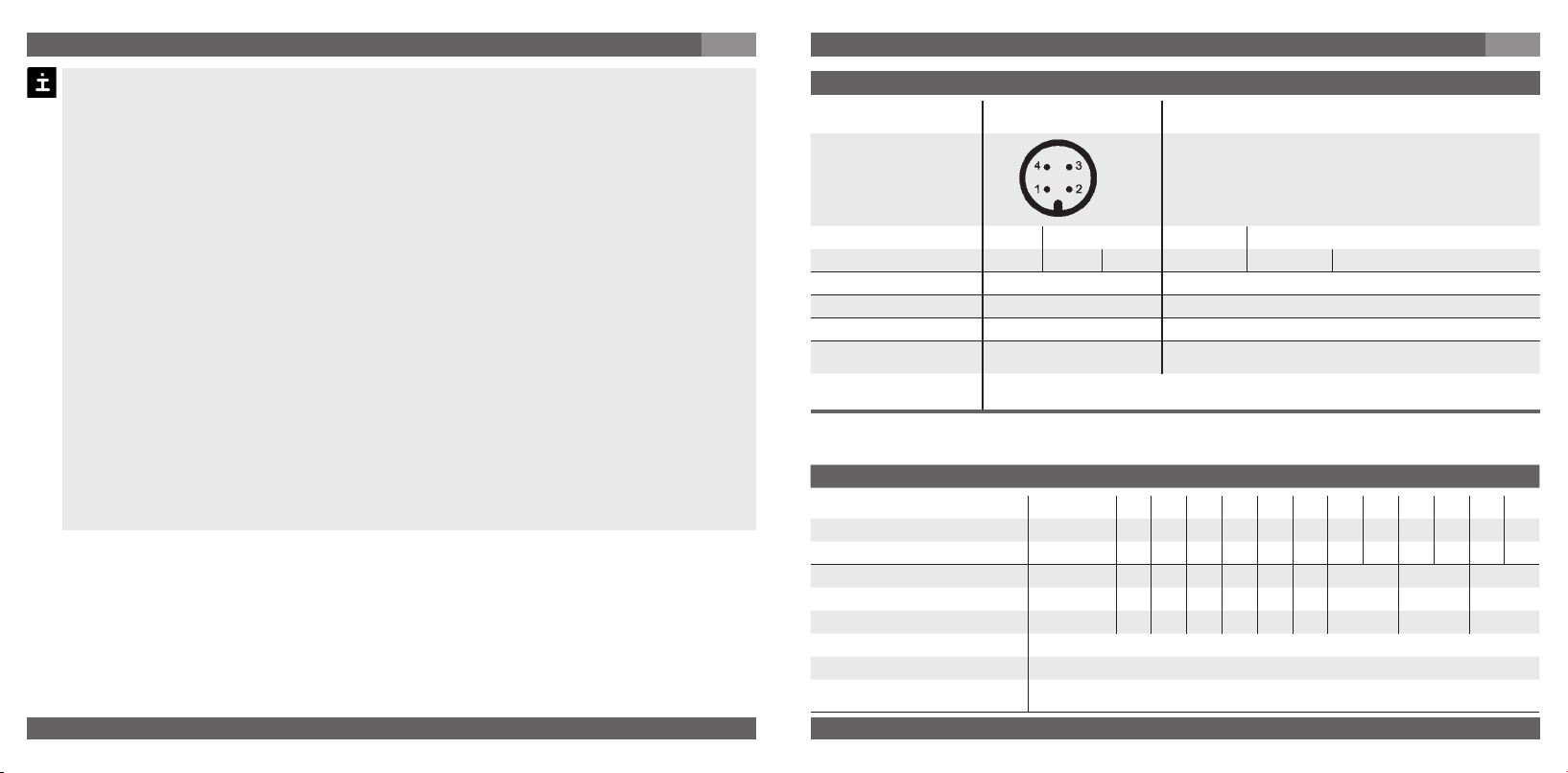

Electrical connections

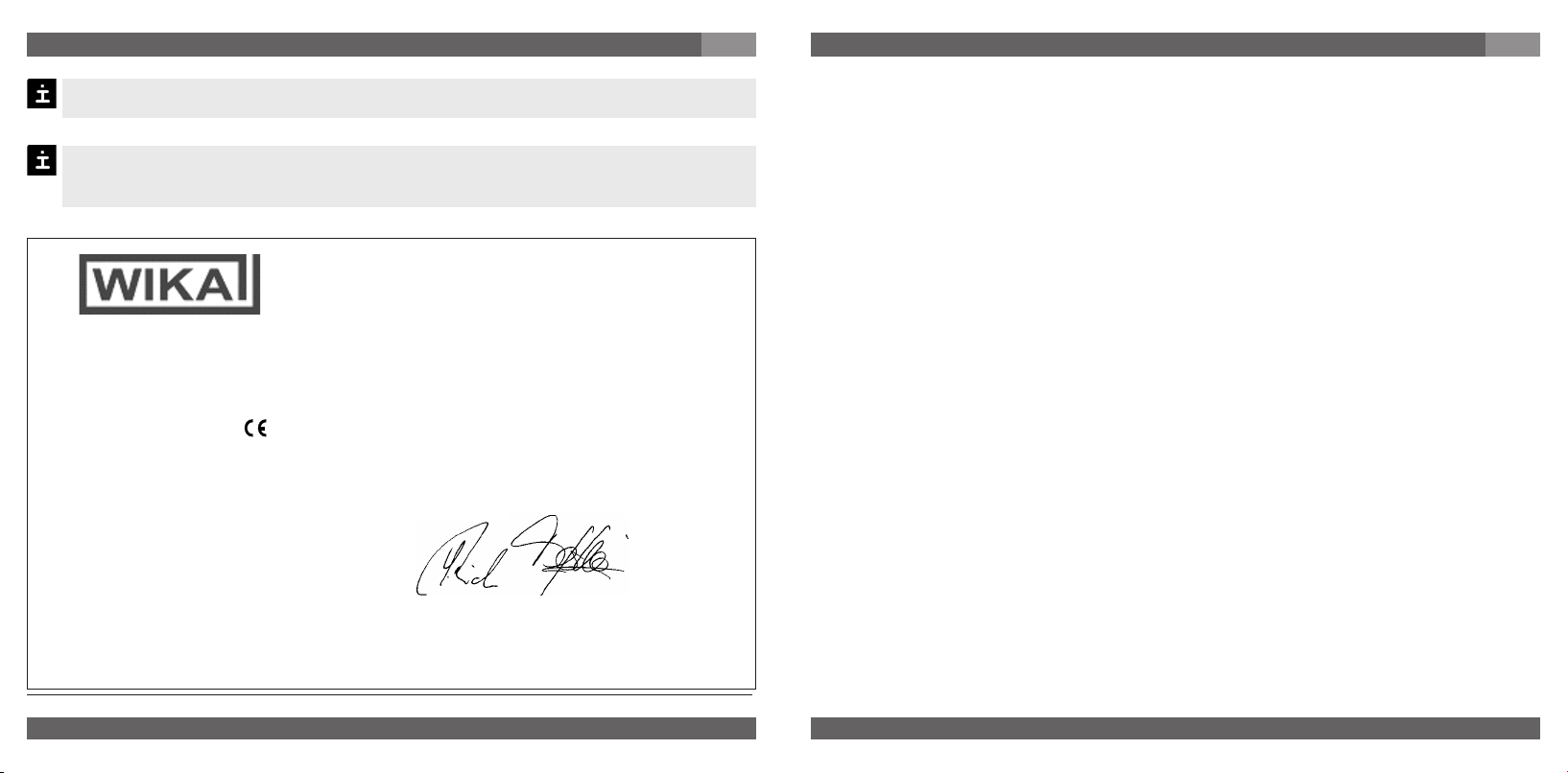

Specifications Model N-10 / N-11

7. Starting, operation

Circular connector M12x1 Flying leads with 1.6 m (6 foot) length

2-wire U+ = 1 U- = 3 U+ = brown U- = green

3-wire U+ = 1 U- = 3 S+ = 4 U+ = brown U- = green S+ = white

Cable screen - grey

Wire gauge - 0.5 mm2 (AWG 20)

Diameter of cable - 6.8 mm

Ingress protection per

IEC 60 529

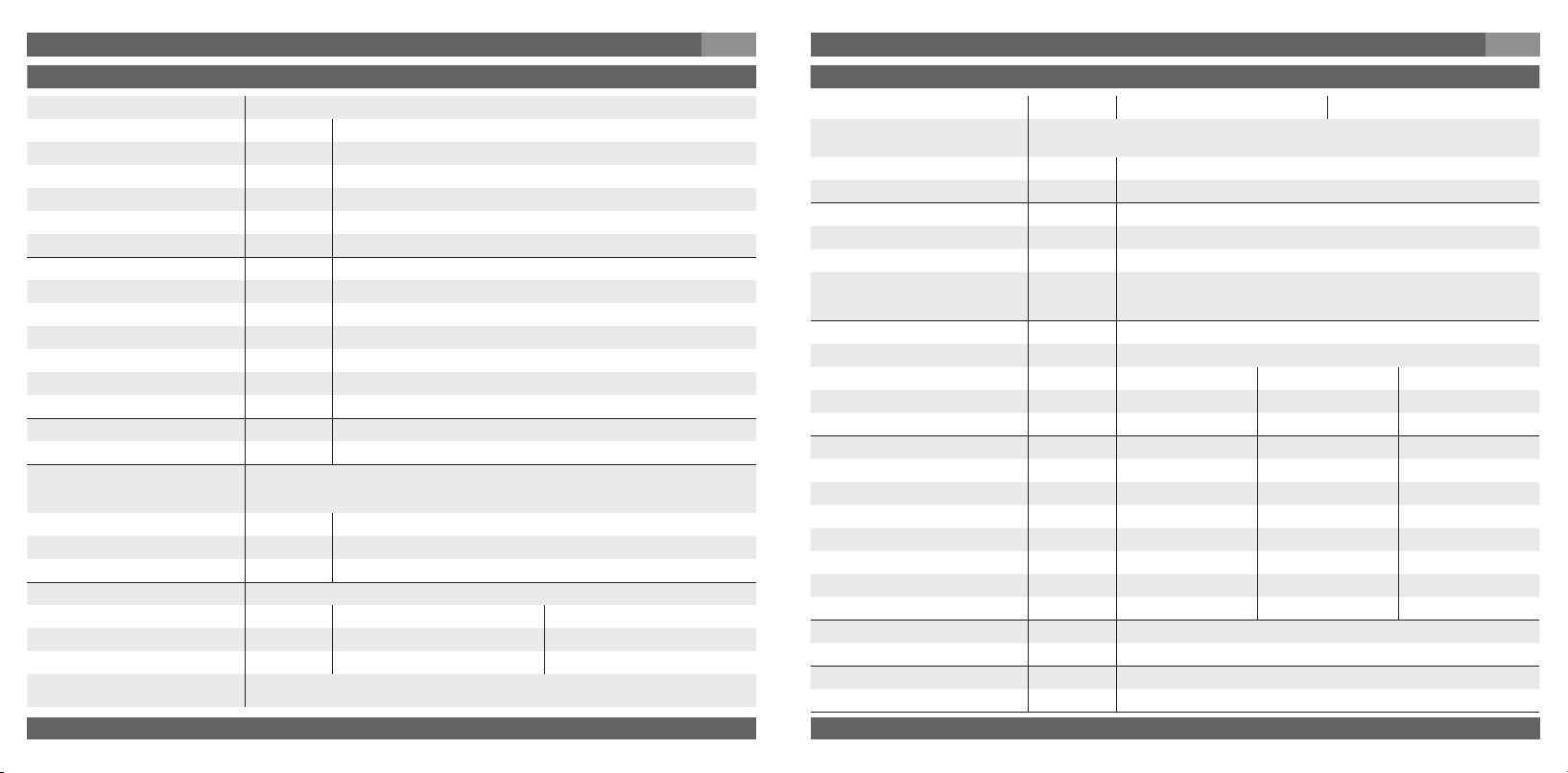

Pressure ranges bar 0.1 0.16 0.25 0.4 0.6 1 1.6 2.5 4 6 10 16

Over pressure safety bar 1 1.5 2 2 4 5 10 10 17 35 35 80

Burst pressure bar 2 2 2.4 2.4 4.8 6 12 12 20.5 42 42 96

Pressure ranges bar 25 40 60 100 160 250 400 600 1000

Over pressure safety bar 50 80 120 200 320 500 800 1200 1500

Burst pressure bar 96 400 550 800 1000 1200 1700 2)2400 2)3000

IP 67 IP 68

The ingress protection classes specified only apply while the pressure transmitter is

connected with female connectors that provide the corresponding ingress protection.

{Vacuum, gauge pressure, compound range, absolute pressure are available}

1)

Only Model N-10 gültig.

2)

For model N-11: the value specified in the table applies only when sealing is

realised with the sealing ring underneath the hex. Otherwise max. 1500 bar applies.

GB

1)

Page 7

2147614.07 GB/D/F/E 04/2009

12

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

13

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

7. Starting, operation

Specifications Model N-10 / N-11

Materials

Wetted parts (Other materials see WIKA diaphragm seal program)

Model N-10 » Stainless steel (> 25 bar stainless steel and Elgiloy®)

Model N-11» Stainless steel

O-ring: NBR {FPM/FKM or EPDM}

Case Stainless steel

Internal transmission fluid Synthetic oil (not for N-10 with pressure ranges > 25 bar)

Power supply UB UB in VDC

Signal output and 4 ... 20 mA, 2-wire RA ≤ (UB – 10 V) / 0.02 A

maximum ohmic load RA RA in Ohm 1 ... 5 V, 3-wire RA > 10 k

Response time (10 ... 90 %) ms

Dielectric strength VDC 500

Accuracy % of span

3)

Including non-linearity, hysteresis, zero point and full scale error (corresponds to

error of measurement per IEC 61298-2).

Adjusted in vertical mounting position with lower pressure connection.

Non-linearity % of span

Non-repeatability % of span

1-year stability % of span

Permissible temperature of

4)

Medium

Ambience

Storage

4)

4)

4)

Also complies with EN 50178, Tab. 7, Operation (C) 4K4H, Storage (D) 1K4,

Transport (E) 2K3

10 < UB ≤ 30 with signal output 4 … 20 mA, 2-wire

10 < UB ≤ 30 with signal output 1 … 5 V, 3-wire

{low power 6 < UB ≤ 30}

≤ 1

≤ 0.25 (BFSL)

3)

≤ 0.5

≤ 0.2 (BFSL) according to IEC 61298-2

≤ 0.1

≤ 0.2 (at reference conditions)

-30 ... +105 °C -22 ... +221 °F

-30 ... +80 °C -22 ... +176 °F

-30 ... +105 °C -22 ... +221 °F

GB

Specifications Model N-10 / N-11

7. Starting, operation

Compensated temp range 0 ... +80 °C 32 ... +176 °F

Temperature coefficients within

compensated temp range

Mean TC of zero % of span

Mean TC of range % of span

CE- conformitiy

Pressure equipment directive 97/23/EC

EMC directive 89/336/EEC emission (class B) and immunity according to EN 61 326

Directive ATEX of equipment

intended for use in potentially

explosive atmospheres

Ex-protection ATEX II 3G EEx nA II

Ignition protection type EEx nA II 4 EEx nA II T5 EEx nA II T6

Conformity specifications

Power supply UB VDC 30 30 30

Medium -30 ... +105 °C -30 ... +80 °C -30 ... +60 °C

Ambient » M12x1 -25 ... +90 °C -25 ... +80 °C -25 ... +60 °C

» Flying leads -30 ... +80 °C -30 ... +80 °C -30 ... +60 °C

Storage -30 ... +105 °C -30 ... +105 °C -30 ... +105 °C

RF-immunity V/m 10

Burst KV 4

Shock resistance g 1000 according to IEC 60068-2-27 (mechanical shock)

Vibration resistance g 20 according to IEC 60068-2-6 (vibration under resonance)

≤ 0.2 / 10 K (< 0.4 for pressure range ≤ 0,25 bar)

≤ 0.2 / 10 K

94/9/EC

II 3D IP65 T80°C

-22 ... +221 °F -22 ... +176 °F -22 ... +140 °F

-13 ... +194 °F -13 ... +176 °F -13 ... +140 °F

-22 ... +176 °F -22 ... +176 °F -22 ... +140 °F

-22 ... +221 °F -22 ... +221 °F -22 ... +221 °F

GB

Page 8

2147614.07 GB/D/F/E 04/2009

14

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

15

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

7. Starting, operation

Specifications Model N-10 / N-11

Wiring protection

Short-circuit proofness S+ towards U-

Reverse polarity protection U+ towards U-

Weight kg Approx. 0.2

{ } Items in curved brackets are optional extras for additional price.

When designing your plant, take into account that the stated values (e.g.burst pressure,

over pressure safety) apply depending on the material, thread and sealing element used.

Functional test

The output signal must be proportional to the pressure. If not, this might point to a

damage of the diaphragm. In that case refer to chapter 9 „Troubleshooting“.

Open pressure connections only after the system is without pressure!

Observe the ambient and working conditions outlined in section 7

Warning

„Technical data.

Please make sure that the pressure transmitter is only used within the over

load threshold limit at all times!

When touching the pressure transmitter, keep in mind that the surfaces of

the instrument components might get hot during operation.

Caution

GB

7. Starting, operation / 8. Maintenance, accessories / 9. Trouble shooting

Shutdown

1) Switch on the operating voltage.

2) Pull the connector or disconnect the cable.

For Transmitters with connector M12x1 and installation/use in Zone 22:

To open the interlock, insert a small

screw driver into the slot of the sleeve

and turn it.

8. Maintenance, accessories

WIKA pressure transmitters require no maintenance.

Have repairs performed by the manufacturer only.

Accessories: For details about the accessories (e. g. connectors), please refer to WIKA‘s

price list, WIKA‘s product catalog on CD or or contact our sales department.

9. Trouble shooting

Open pressure connections only after the system is without pressure!

GB

Warning

Page 9

2147614.07 GB/D/F/E 04/2009

16

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

17

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

9. Trouble shooting

Take precautions with regard to remaining media in removed pressure trans-

!

Warning

mitters. Remaining media in the pressure port may be hazardous or

toxic!

Remove the pressure transmitter from service and mark it to prevent it from

being used again accidentally, if it becomes damaged or unsafe for operation.

Have repairs performed by the manufacturer only.

Do not insert any pointed or hard objects into the pressure port for cleaning to prevent

damage to the diaphragm of the pressure connection.

Please verify in advance if pressure is being applied (valves/ball valve etc. open) and if the

right voltage supply and the right type of wiring (2-wire/3-wire) has been chosen?

Failure Possible cause Procedure

No output signal

No/False output signal

Output signal unchanged after change

in pressure

Signal span dropping off/too small

Signal span too small Power supply too high/too low

Signal span drops off Moisture present (e.g. at the cable tail) Install the cable correctly

No/incorrect voltage supply or current

spike

Cable break Check connections and cable

Incorrectly wired (e.g. Connected as

2-wire instead of 3-wire system)

Mechanical overload through over-

pressure

Wrong supply voltage or current spike Replace instrument

Diaphragm is damaged, e.g. through

impact, abrasive/agressive media;

corrosion of diaphragm/pressure

connector; transmission fluid missing.

Mechanical overload through overpressure

Adjust the voltage supply to correspond

with the Operating Instructions *)

Follow pin assignment (see Instrument

Label / Operating Instructions)

Replace instrument; if failure reoccurs,

consult the manufacturer *)

Contact the manufacturer and replace

the instrument

Correct the power supply in line with

the Operating Instructions

Re-calibrate the instrument *)

GB

Failure Possible cause Procedure

In case of unjustified reclamation we charge the reclamation handling expenses.

*) Make sure that after the setting the unit is working properly. In case the error continues to exist send in the instrument for reparation (or

replace the unit).

If the problem persists, contact our sales department.

USA, Canada

If the problem continues, contact WIKA or an authorized agent for assistance. If the pressure transmitter must be returned obtain an RMA (return material authorization) number and

shipping instructions from the place of purchase. Be sure to include detailed information about

the problem. Pressure transmitters received by WIKA without a valid RMA number will not be

accepted.

Process material certificate (Contamination declaration for returned goods)

Purge / clean dismounted instruments before returning them in order to protect our employees

and the environment from any hazard caused by adherent remaining media.

Service of instruments can only take place safely when a Product Return Form has been

submitted and fully filled-in. This Return Form contains information on all materials with which

the instrument has come into contact, either through installation, test purposes, or cleaning.

You can find the Product Return Form on our internet site (www.wika.de / www.wika.com).

10. Storage, disposal

9. Trouble shooting / 10. Storage, disposal

Signal span erratic

Electromagnetic interference source in

the vicinity, e.g. inverter drive

Instrument not grounded Ground instrument

Strong fluctuations in the power supply

Violent fluctuations in the process

media pressure

When storing or disposing of the pressure transmitter, take precautions with

!

Warning

regard to remaining media in removed pressure transmitters. We recommend cleaning the transmitter properly and carefully. Remaining media in

the pressure port may be hazardous or toxic!

GB

Shield the device; shield the cables;

remove the interference source.

Stabilise the power supply; smooth it

(i.e.; remove interferences)

Damping; consult with manufacturer

Page 10

2147614.07 GB/D/F/E 04/2009

18

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

19

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

responsibility, that the

marked

products

Nous déclarons sous notre seule

responsabilité que les appareils

marqués

Non incendive

Transmetteur de pression,

type de protection n

the directive(s)

sont conformes aux exigences

essentielles de la (les) directive(s)

- 89/336/EEC (EMC)

- 94/9/EC (ATEX)

- 89/336/CEE (CEM)

- 94/9/CE (ATEX)

responsibility, that the

marked

products

Nous déclarons sous notre seule

responsabilité que les appareils

marqués

Non incendive

Transmetteur de pression,

type de protection n

the directive(s)

sont conformes aux exigences

essentielles de la (les) directive(s)

- 89/336/EEC (EMC)

- 94/9/EC (ATEX)

- 89/336/CEE (CEM)

- 94/9/CE (ATEX)

according to the norm:

Les appareils ont été vérifiés suivant

les normes:

WIKA Alexander Wiegand GmbH &

Co. KG

WIKA Alexander Wiegand GmbH &

Co. KG

10. Storage, disposal / 11. EC declaration of conformity

Storage

Mount the protection cap when storing the pressure transmitter in order to prevent any

damage to the diaphragm (N-11).

Disposal

Dispose of instrument components and packaging materials in accordance with the

respective waste treatment and disposal regulations of the region or country to which

the instrument is supplied.

11. EC declaration of conformity

WIKA reserves the right to alter these technical specifications.

GB

1. Wichtiges zu Ihrer Information

Lesen Sie diese Betriebsanleitung vor Montage und Inbetriebnahme des Druckmessgerätes.

Bewahren Sie die Betriebsanleitung an einem für alle Benutzer jederzeit zugänglichen Ort auf.

Die nachfolgenden Einbau- und Betriebshinweise haben wir mit Sorgfalt zusammengestellt.

Es ist jedoch nicht möglich, alle erdenklichen Anwendungsfälle zu berücksichtigen. Sollten Sie

Hinweise für Ihre spezielle Aufgabenstellung vermissen, können Sie hier weitere Informationen

finden:

Wird die Seriennummer auf dem Typenschild und/oder der 2D-Code auf dem Sechskant unleserlich (z. B. durch mechanische Beschädigung oder Übermalen), ist eine Rückverfolgbarkeit

nicht mehr möglich.

Die in der Betriebsanleitung beschriebenen WIKA-Druckmessgeräte werden nach den

neuesten Erkenntnissen konstruiert und gefertigt. Alle Komponenten unterliegen während der

Fertigung strengen Qualitäts- und Umweltkriterien. Unser Umweltmanagementsystem ist nach

DIN EN ISO 14001 zertifiziert.

Bestimmungsgemäße Produktverwendung N-10, N-11:

Verwenden Sie den nicht funkenden Druckmessumformer, um in explosionsgefährdeten

Bereichen, die Geräte der Kategorie 3G bzw. 3D erfordern, Druck in ein elektrisches Signal zu

wandeln.

Zulassung ATEX:

Druckmessgerät zur bestimmungsgemäßen Verwendung in explosionsgefährdeten Bereichen

II 3G EEx nA II T6 und II 3D IP65 T80°C

Ihre erforderlichen Kenntnisse

Montieren und nehmen Sie das Druckmessgerät nur in Betrieb, wenn Sie mit den zutreffenden

landesspezifischen Richtlinien vertraut sind und die entsprechende Qualifikation besitzen.

Sie müssen mit den Vorschriften und Kenntnissen für explosionsgefährdete Bereiche, Messund Regeltechnik sowie elektrische Stromkreise vertraut sein, da das Druckmessgerät ein

„elektrisches Betriebsmittel“ nach EN 50178 ist. Je nach Einsatzbedingung müssen Sie über

entsprechendes Wissen verfügen, z. B. über agressive Medien.

1. Wichiges zu Ihrer Information

Über unsere Internet-Adresse www.wika.de / www.wika.com

Die Bezeichnung des zugehörigen Datenblattes ist PE 81.26

Anwendungsberater: (+49) 9372/132-295

D

Page 11

2147614.07 GB/D/F/E 04/2009

20

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

21

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2. Schneller Überblick / 3. Zeichenerklärungen, Abkürzungen / 4. Funktion

2. Der schnelle Überblick für Sie

Wollen Sie sich einen schnellen Überblick verschaffen, lesen Sie Kapitel 3, 5, 7 und 10. Dort

erhalten Sie kurze Hinweise zu Ihrer Sicherheit und wichtige Informationen über Ihr Produkt

und zur Inbetriebnahme. Lesen Sie diese unbedingt.

3. Zeichenerklärungen, Abkürzungen

Mögliche Gefahr für Ihr

!

Warnung

Warnung

Warnung

Vorsicht

2-Leiter Zwei Anschlussleitungen dienen zur Spannungsversorgung.

Der Speisestrom ist das Mess-Signal.

3-Leiter Zwei Anschlussleitungen dienen zur Spannungsversorgung.

Eine Anschlussleitung dient für das Mess-Signal.

U+ Positiver Versorgungsanschluss

U- Negativer Versorgungsanschluss

S+ Positiver Messanschluss

Leben oder schwerer

Verletzungen.

Ex-Hinweise:

Mögliche Gefahr für Ihr

Leben oder schwerer Verletzungen.

Mögliche Gefahr für Ihr

Leben oder schwerer Verletzungen durch wegschleudernde Teile.

Mögliche Gefahr von

Verbrennungen durch

heisse Oberflächen.

Hinweis, wichtige Information, Funktionsstörung.

Das Produkt stimmt mit den

zutreffenden europäischen

Richtlinien überein.

ATEX

Europäische Explosionsschutz-Richtlinie (Atmosphäre=AT,

Explosion=EX)

Das Produkt stimmt überein

mit den Anforderungen der

europäischen Richtlinie

94/9/EG (ATEX) zum Explosionsschutz.

4. Funktion

N-10: Druckanschluss (nicht funkend) mit innenliegender Membran (Standardausführung)

N-11: Druckanschluss (nicht funkend) mit frontbündiger Membrane für hochviskose oder

kristallisierende Medien, die die Bohrung des Druckanschlusses zusetzen können.

D

4. Funktion / 5. Zu Ihrer Sicherheit

Funktion

Mittels Sensorelement und unter Zuführung von Hilfsenergie wird über die Verformung einer

Membran der anstehende Druck in Ihrer Anwendung in ein verstärktes standardisiertes elektrisches Signal umgewandelt. Dieses elektrische Signal verändert sich proportional zum Druck

und kann entsprechend ausgewertet werden.

5. Zu Ihrer Sicherheit

Normen und Richtlinien (z. B. bei gefährlichen Messstoffen wie Acetylen, brennbaren

oder giftigen Stoffen sowie bei Kälteanlagen und Kompressoren). Wenn Sie die entspre

chenden Vorschriften nicht beachten, können schwere Körperverletzungen und

Sachschäden entstehen!

Angaben zu Korrosions- bzw. Diffusionsbeständigkeit der Gerätewerkstoffe entnehmen Sie

bitte unserem WIKA-Handbuch zur Druck- und Temperaturmesstechnik.

D

Wählen Sie das richtige Druckmessgerät hinsichtlich Messbereich, Ausfüh-

!

Warnung

Öffnen Sie Anschlüsse nur im drucklosen Zustand!

Betreiben Sie das Druckmessgerät immer innerhalb des Überlastgrenzbereiches!

Beachten Sie die Betriebsparameter gemäß Punkt 7 „Technische Daten“.

Stellen Sie sicher, dass das Druckmessgerät nur bestimmungsgemäß -also wie in der

folgenden Anleitung beschrieben- betrieben wird.

Unterlassen Sie unzulässige Eingriffe und Änderungen am Druckmessgerät, welche nicht

in dieser Betriebsanleitung beschrieben sind.

Setzen Sie das Druckmessgerät außer Betrieb und schützen Sie es gegen versehentliche

Inbetriebnahme, wenn Sie Störungen nicht beseitigen können.

Ergreifen Sie Vorsichtsmaßnahmen für Messstoffreste in ausgebauten Druckmessgeräten. Messstoffreste können zur Gefährdung von Menschen, Umwelt und Einrichtung führen!

Lassen Sie Reparaturen nur vom Hersteller durchführen.

rung und spezifischen Messbedingungen vor Montage oder Inbetriebnahme.

Halten Sie die entsprechenden landesspezifischen Vorschriften ein (z. B.:

EN 50178) und beachten Sie bei speziellen Anwendungen die geltenden

Page 12

2147614.07 GB/D/F/E 04/2009

22

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

23

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

5. Zu Ihrer Sicherheit / 6. Verpackung

Beachten Sie die jeweiligen landesspezifischen Vorschriften zur Installation

und Einsatz in explosionsgefährdeten Bereichen (z.B.: IEC 60079-14). Wenn

Warnung

Sie diese nicht beachten, können schwere Körperverletzungen und Sachschäden entstehen.

6. Verpackung

Wurde alles geliefert?

Überprüfen Sie den Lieferumfang:

Komplett montierte Druckmessgeräte; bei frontbündiger Ausführung N-11 mit

vormontierten Dichtungen und Schutzkappe.

Untersuchen Sie das Druckmessgerät auf eventuell entstandene Transportschäden.

Sind offensichtlich Schäden vorhanden, teilen Sie dies dem Transportunternehmen

und WIKA unverzüglich mit.

Bewahren Sie die Verpackung auf, denn diese bietet bei einem Transport einen opti-

malen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

Achten sie darauf, dass das Druckanschluss-Gewinde und die Anschlusskontakte

nicht beschädigt werden.

Zum Schutz der Membran ist der Druckanschluss des Gerätes N-11 mit einer speziellen

Schutzkappe versehen.

Entfernen Sie diese Schutzkappe von Hand erst kurz vor dem Einbau, damit die

Membran bzw. das Druckanschluss-Gewinde nicht beschädigt wird.

Bewahren Sie die Schutzkappe des Druckanschluss-Gewindes und der Membran zur

späteren Lagerung oder Transport auf.

Montieren Sie die Schutzkappe bei Ausbau und Transport des Gerätes.

D

7. Inbetriebnahme, Betrieb

D

7. Inbetriebnahme, Betrieb

Membran-Prüfung zu Ihrer Sicherheit

Benötigtes Werkzeug: Maulschlüssel SW 27, Schraubendreher

Es ist erforderlich, dass Sie vor Inbetriebnahme des Druckmessgerätes die Membran optisch

prüfen, denn sie ist ein sicherheitsrelevantes Teil.

Achten Sie auf auslaufende Flüssigkeit, denn sie ist ein Hinweis auf eine

!

Warnung

Montage mechanischer Anschluss

max.

50 Nm

Dichtung

Befindet sich keine Seriennummer auf dem Typenschild, so gilt die Nummer auf dem Sechskant.

Membranbeschädigung.

Prüfen Sie die Membran optisch auf Beschädigung (N-11).

Setzen Sie das Druckmessgerät nur ein, wenn die Membran unbeschädigt

ist.

Setzen Sie das Druckmessgerät nur in sicherheitstechnisch einwandfreiem

Zustand ein.

Typenschild (Beispiel)

Signal

Spannungsversorgung

Erzeugnis-Nr.

P #

Serien-Nr.

S #

Anschlussbelegung

Codiertes Herstelldatum

Page 13

2147614.07 GB/D/F/E 04/2009

24

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

25

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

7. Inbetriebnahme, Betrieb

Schützen Sie die Membran vor Kontakt mit abrasiven Medien und gegen

Schläge. Wenn Sie die Membran beschädigen, ist kein Explosionsschutz

Warnung

Beachten Sie die Technischen Daten zur Verwendung des Druckmessgerätes in Verbin-

dung mit agressiven/korrosiven Medien und zur Vermeidung von mechanischen Gefährdungen.

Entfernen Sie die Schutzkappe von Hand erst kurz vor dem Einbau und achten Sie

unbedingt darauf, dass die Membran auch während des Einbaus nicht beschädigt

wird (N-11).

Bei Typ N-10 müssen Sie eine Dichtung vorsehen; Ausnahme sind Geräte mit selbst

dichtendem Gewinde (z. B. NPT-Gewinde).

Bei Typ N-11 ist der Dichtring im Lieferumfang enthalten.

Hinweise zu Dichtungen entnehmen Sie bitte unserer Information “Zubehör Dich-

tungen AC 09.08” im Gesamtkatalog Druck- und Temperaturmesstechnik oder

unserer Internet-Seite unter www.wika.de.

Achten Sie bei der Montage auf saubere und unbeschädigte Dichtflächen am Gerät

und Messstelle.

Schrauben Sie das Gerät nur über die Schlüsselflächen mit einem geeigneten Werk-

zeug und dem vorgeschriebenen Drehmoment ein bzw. aus. Das richtige Drehmoment ist abhängig von der Dimension des Druckanschlusses sowie der verwendeten

Dichtung (Form/Werkstoff). Verwenden Sie zum Ein- bzw. Ausschrauben nicht das

Gehäuse als Angriffsfläche.

Beachten Sie beim Einschrauben, dass die Gewindegänge nicht verkantet werden.

Angaben zu Einschraublöchern und Einschweißstutzen entnehmen Sie bitte unserer

Montage elektrischer Anschluss

Technischen Information IN 00.14 unter www.wika.de -Service

!

Warnung

gewährleistet (ATEX).

Sorgen Sie für eine geschützte Anordnung des Druckmessgerätes und

schützen Sie es vor Schlägen.

Trennen Sie den elektrischen Anschluss nicht unter Spannung!

Verwenden Sie eine Versorgungsspannung mit Leistungsbegrenzung P<1W.

Begrenzen Sie die Versorgungsspannung auch im Störfall sicher auf

U < 42 VDC.

D

7. Inbetriebnahme, Betrieb

Bei Geräten mit Rundsteckverbinder M12x1 und Installation/Verwendung in Zone 22:

Schalten Sie die Betriebsspannung erst ein, nachdem Sie den elektrischen

Anschluss hergestellt haben, um Funkenbildung zu vermeiden.

Erden Sie den Kabelschirm einseitig und bevorzugt im sicheren, also Nicht-

Warnung

Versorgen Sie den Druckmessumformer aus einem galvanisch trennenden Netzteil.

Beachten Sie die innere wirksame Kapazität und Induktivität.

Versehen Sie feindrahtige Leiterenden mit Aderendhülsen (Kabelkonfektionierung).

Beachten Sie, dass bei Kabeln für den Einsatz in Zone 2 und 22 die Prüfspannung

Leiter/Erde, Leiter/Schirm, Schirm/Erde > 500V Wechselspannung betragen muss.

Warnung

Ex-Bereich (EN 60079-14). Bei Geräten mit Kabelausgang ist der Schirm

mit dem Gehäuse verbunden. Der gleichzeitige Anschluss von Gehäuse

und Kabelschirm an Erde ist nur dann zulässig, wenn eine Potentialverschleppung zwischen Schirmanschluss (z.B. am Speisegerät) und Gehäuse

ausgeschlossen werden kann (siehe EN 60079-14).

Den Rundsteckverbinder

M12x1 mittels einer zusätzlichen Verriegelung gegen

unbeabsichtigtes Öffnen

sichern. Verwenden Sie den

beiliegenden Clip (WIKA

Sachnummer 2073164). Legen

Sie die beiden Hälften der

Manschette über den Griffring des Steckverbinders und

verriegeln diese durch Zusammendrücken. Das Fähnchen

befestigen Sie am Kabel,

indem Sie den „Pfeil“ um das

Kabel legen und durch die

Öse stecken.

D

Page 14

2147614.07 GB/D/F/E 04/2009

26

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

27

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

Erden Sie das Gehäuse über den Prozessanschluss gegen elektromagnetische Felder

und elektrostatische Aufladungen.

Betreiben Sie den Druckmessumformer mit geschirmter Leitung und erden Sie den

Schirm auf mindestens einer Leitungsseite, wenn die Leitungen länger als 30m

(2-Leiter) bzw. 3m (3-Leiter) sind oder das Gebäude verlassen.

Schutzart IP nach IEC 60 529 (Die angegebenen Schutzarten gelten nur im gesteckten

Zustand mit Leitungsteckern (Buchsen) entsprechender Schutzart).

Beachten Sie bei der Auswahl

des Steckers:

Temperaturbereich T > T Druckmessumformer + 20 K

Schutzart

Leitungsquerschnitt A

≥ IP 54 (Ex-Schutz)

≥ 0,25 mm

2

des Kabels:

Wählen Sie die Kabellänge so, dass das Kabelende mindestens 3-mal nachgesetzt

werden könnte.

Wählen Sie den Kabeldurchmesser passend zur Kabeldurchführung des Steckers.

Achten Sie darauf, dass die Kabelverschraubung des montierten Steckers korrekt

sitzt und dass die Dichtungen vorhanden und nicht beschädigt sind. Ziehen Sie die

Verschraubung fest und überprüfen Sie den korrekten Sitz der Dichtungen, um die

Schutzart zu gewährleisten.

Stellen Sie bei Kabelausgängen sicher, dass am Ende des Kabels keine Feuchtigkeit

eintritt.

7. Inbetriebnahme, Betrieb

Elektrische Anschlüsse

Rundsteckverbinder M12x1 Kabelausgang mit 1,6 m Länge

2-Leiter U+ = 1 U- = 3 U+ = braun U- = grün

3-Leiter U+ = 1 U- = 3 S+ = 4 U+ = braun U- = grün S+ = weiß

Kabelschirm - grau

Aderquerschnitt - 0,5 mm2 (AWG 20)

Kabeldurchmesser - 6,8 mm

Schutzart nach IEC 60 529 IP 67 IP 68

Die angegebenen Schutzarten gelten nur im gesteckten Zustand mit Leitungssteckern

entsprechender Schutzart.

Technische Daten Typ N-10 / N-11

Messbereich bar 0,1 0,16 0,25 0,4 0,6 1 1,6 2,5 4 6 10 16

Überlastgrenze bar 1 1,5 2 2 4 5 10 10 17 35 35 80

Berstdruck bar 2 2 2,4 2,4 4,8 6 12 12 20,5 42 42 96

Messbereich bar 25 40 60 100 160 250 400 600 1000

Überlastgrenze bar 50 80 120 200 320 500 800 1200 1500

Berstdruck bar 96 400 550 800 1000 1200 1700 2)2400 2)3000

{Unterdruck, Überdruck, +/- , sowie Absolutdruck erhältlich}

1)

Nur für Typ N-10 gültig.

2)

Bei Typ N-11: Der Tabellenwert gilt ausschließlich bei Abdichtung mittels Dichtring

unterhalb vom Sechskant. Andernfalls gilt max. 1500 bar.

D

1)

Page 15

2147614.07 GB/D/F/E 04/2009

28

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

29

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

7. Inbetriebnahme, Betrieb

Technische Daten Typ N-10 / N-11

Werkstoff

Messstoffberührte Teile (Andere Werkstoffe siehe WIKA Druckmittler-Programm)

Typ N-10» CrNi-Stahl (> 25 bar CrNi-Stahl und Elgiloy®)

Typ N-11» CrNi-Stahl

O-Ring: NBR {FPM/FKM oder EPDM}

Gehäuse CrNi-Stahl

Interne Übertragungsflüssigkeit Synthetisches Öl (nicht für Typ N-10 für Messbereiche > 25 bar

Hilfsenergie UB UB in VDC 10 < UB ≤ 30 mit Ausgang 4 ... 20 mA, 2-Leiter

10 < UB ≤ 30 mit Ausgang 1 ... 5 V, 3-Leiter {low power 6 < UB ≤ 30}

Ausgangssignal und zulässige 4 ... 20 mA, 2-Leiter RA ≤ (UB - 10 V) / 0,02 A

max. ohmsche Bürde RA RA in Ohm 1 ... 5 V, 3-Leiter RA > 10 kOhm

Einstellzeit (10 … 90 %) ms

Spannungsfestigkeit VDC 500

Genauigkeit % d. Spanne

3)

Einschließlich Nichtlinearität, Hysterese, Nullpunkt- und Endwertabweichung

(entspricht Messabweichung nach IEC 61298-2).

Kalibriert bei senkrechter Einbaulage Druckanschluss nach unten.

Nichtlinearität % d. Spanne

Nichtwiederholbarkeit % d. Spanne

Stabilität pro Jahr % d. Spanne

Zulässige Temperaturbereiche

Messstoff

Umgebung

Lagerung

Kompensierter Temperaturbereich °C 0 ... +80

4)

4)

4)

°C -30 ... +105

°C -30 ... +80

°C -30 ... +105

4)

Erfüllt auch EN 50178, Tab. 7, Betrieb (C) 4K4H, Lagerung (D) 1K4,

Transport (E) 2K3

≤ 1

≤ 0,25 (BFSL)

≤ 0,5 3)

≤ 0,2 (BFSL) nach IEC 61298-2

≤ 0,1

≤ 0,2 (bei Referenzbedingungen)

D

7. Inbetriebnahme, Betrieb

Technische Daten Typ N-10 / N-11

Temperaturkoeffizienten im

kompensierten Temperaturbereich

CE- Konformität

Ex -Schutz ATEX II 3G EEx nA II

Zündschutzart EEx nA II T4 EEx nA II T5 EEx nA II T6

Sicherheitstechnische Höchstwerte

HF-Immunität V/m 10

Burst KV 4

Schockbelastbarkeit g 1000 nach IEC 60068-2-27 (Schock mechanisch)

Vibrationsbelastbarkeit g 20 nach IEC 60068-2-6 (Vibration bei Resonanz)

Elektrische Schutzarten

Gewicht kg Ca. 0,2

Mittlerer TK des Nullpunktes % d. Spanne

Mittlerer TK der Spanne % d. Spanne

Druckgeräterichtlinie 97/23/EG

EMV-Richtlinie

ATEX-Richtlinie für Geräte zur 94/9/EG

Hilfsenergie VDC 30 30 30

Messstofftemperatur °C -30 ... +105 -30 ... +80 -30 ... +60

Umgebungstemperatur

M12x1» °C -25 ... +90 -25 ... +80 -25 ... +60

Kabel» °C -30 ... +80 -30 ... +80 -30 ... +60

Lagertemperatur °C -30 ... +105 -30 ... +105 -30 ... +105

Kurzschlussfestigkeit S+ gegen U-

Verpolschutz U+ gegen U-

≤ 0,2 / 10 K (< 0,4 für Messbereiche ≤ 0,25 bar)

≤ 0,2 / 10 K

89/336/EWG Störemission (Grenzwertklasse B) und Störfestigkeit

nach EN 61 326

II 3D IP65 T80°C

D

Page 16

2147614.07 GB/D/F/E 04/2009

30

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

31

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

7. Inbetriebnahme, Betrieb

{ } Angaben in geschweiften Klammern beschreiben gegen Mehrpreis lieferbare Sonderheiten.

Beachten Sie bei der Auslegung Ihrer Anlage, dass die angegebenen Werte (z. B.

Berstdruck, Überlastgrenze) in Abhängigkeit vom verwendeten Material, Gewinde und

Dichtung gelten.

Funktionsprüfung

Das Ausgangssignal muss sich dem anstehenden Druck proportional verhalten. Wenn

dies nicht so ist, kann das ein Hinweis auf eine Beschädigung der Membran sein. Lesen

Sie in diesem Fall in Kapitel 9 „Störbeseitigung“ nach.

Öffnen Sie Anschlüsse nur im drucklosen Zustand!

Beachten Sie die Betriebsparameter gemäß Punkt 7„Technische Daten“.

Betreiben Sie das Druckmessgerät immer innerhalb des Überlastgrenzbe-

Warnung

reichs!

Beachten Sie beim Berühren des Druckmessgerätes, dass die Oberflächen

der Gerätekomponenten während des Betriebes heiß werden können.

Vorsicht

D

7. Inbetriebnahme, Betrieb / 8. Wartung, Zubehör

D

Ausserbetriebnahme

1) Schalten Sie die Betriebsspannung ab.

2) Ziehen Sie den Stecker bzw. klemmen Sie das Kabel ab.

Bei Geräten mit Rundsteckverbinder M12x1 und Installation/Verwendung in Zone 22:

Verwenden Sie zum Öffnen der Verriegelung einen kleinen Schraubendreher,

den Sie in den Schlitz der Manschette

stecken und drehen (bzw. aufhebeln).

8. Wartung, Zubehör

WIKA Druckmessgeräte sind wartungsfrei.

Lassen Sie Reparaturen nur vom Hersteller durchführen.

Zubehör

Entnehmen Sie bitte Zubehörangaben (z. B. Stecker) unserer aktuellen Standardpreisliste, dem

CD-Katalog oder setzen Sie sich mit unserem Vertriebsmitarbeiter in Verbindung.

Page 17

2147614.07 GB/D/F/E 04/2009

32

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

33

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

9. Störbeseitigung

D

9. Störbeseitigung

Öffnen Sie Anschlüsse nur im drucklosen Zustand!

Warnung

Ergreifen Sie Vorsichtsmaßnahmen für Messstoffreste in ausgebauten

!

Warnung

Verwenden Sie keine spitzen bzw. harten Gegenstände zur Reinigung, denn die

Membran des Druckanschlusses darf nicht beschädigt werden.

Prüfen Sie bitte vorab, ob Druck ansteht (Ventile/Kugelhahn usw. offen) und ob Sie die richtige

Spannungsversorgung und die richtige Verdrahtungsart (2-Leiter/3-Leiter) gewählt haben.

Störung Mögliche Ursache Maßnahme

Kein Ausgangssignal

Kein/Falsches Ausgangssignal

Gleichbleibendes Ausgangssignal bei

Druckänderung

Signalspanne fällt/ab/zu klein

Druckmessgeräten. Messstoffreste können zur Gefährdung von Menschen,

Umwelt und Einrichtung führen!

Setzen Sie das Druckmessgerät außer Betrieb und schützen Sie es gegen

versehentliche Inbetriebnahme, wenn Sie Störungen nicht beseitigen

können.

Lassen Sie Reparaturen nur vom Hersteller durchführen.

Keine/Falsche Versorgungsspannung

oder Stromstoß

Leitungsbruch Durchgang überprüfen

Verdrahtungsfehler (z. B. 2-Leiter als

3-Leiter verdrahtet)

Mechanische Überlastung durch

Überdruck

Falsche Versorgungsspannung oder

Stromstoß

Membranbeschädigung, z. B. durch

Schläge, abrasives/agressives Medium;

Korrosion an Membran/Druckanschluss; Übertragungsmedium fehlt

Versorgungsspannung gemäß Betriebsanleitung korrigieren *)

Anschlussbelegung beachten (siehe

Typenschild / Betriebsanleitung)

Gerät austauschen; bei wiederholtem

Ausfall Rücksprache mit Hersteller *)

Gerät austauschen

Hersteller kontaktieren und Gerät

austauschen

9. Störbeseitigung / 10. Lagerung, Entsorgung

Störung Mögliche Ursache Maßnahme

Signalspanne zu klein Versorgungsspannung zu hoch/niedrig

Signalspanne fällt ab

Signalspanne schwankend

Im unberechtigtem Reklamationsfall berechnen wir die Reklamationsbearbeitungs-Kosten.

*) Überprüfen Sie nach dem Justieren die korrekte Arbeitsweise des Systems. Besteht der Fehler weiterhin, senden Sie das Gerät zur

Reparatur ein (oder tauschen Sie das Gerät aus).

Wenn das Problem bestehen bleibt, setzen Sie sich mit unserem Vertriebsmitarbeiter in

Verbindung.

Prozess Material Zertifikat (Kontaminationserklärung im Servicefall)

Spülen bzw. säubern Sie ausgebaute Geräte vor der Rücksendung, um unsere Mitarbeiter und

die Umwelt vor Gefährdung durch anhaftende Messstoffreste zu schützen.

Eine Überprüfung ausgefallener Geräte kann nur sicher erfolgen, wenn das vollständig ausgefüllte Rücksendeformular vorliegt. Eine solche Erklärung beinhaltet alle Materialien, welche

mit dem Gerät in Berührung kamen, auch solche, die zu Testzwecken, zum Betrieb oder zur

Reinigung eingesetzt wurden. Das Rücksendeformular ist über unsere Internet-Adresse (www.

wika.de / www.wika.com) verfügbar.

10. Lagerung, Entsorgung

Warnung

D

Versorgungsspannung gemäß Betriebsanleitung korrigieren

Feuchtigkeit eingetreten (z. B. am

Kabelende)

EMV-Störquellen in Umgebung, z. B.

Frequenzumrichter

Gerät nicht geerdet Gerät erden

Stark schwankende Versorgungsspan-

nung

Ergreifen Sie bei Lagerung und Entsorgung Vorsichtsmaßnahmen für Mess-

!

stoffreste in ausgebauten Druckmessgeräten. Wir empfehlen eine geeignete

und sorgfältige Reinigung. Messstoffreste können zur Gefährdung von

Menschen, Umwelt und Einrichtung führen!

Kabel korrekt montieren

Gerät abschirmen; Leitungsabschirmung; Störquelle entfernen

Versorgungsspannung stabilisieren;

entstören

Page 18

2147614.07 GB/D/F/E 04/2009

34

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

35

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

EG-Konformitätserklärung

EC Declaration of Conformity Déclaration de Conformité CE

Dokument Nr.: Document No.: Document Nr.:

6005701 6005701 6005701

Wir erklären in alleiniger Verantwortung,

dass die mit

gekennzeichneten

Produkte

We declare under our sole

responsibility, that the

marked

products

Nous déclarons sous notre seule

responsabilité que les appareils

marqués

Typen: Models: Type:

N-10, N-11 N-10, N-11 N-10, N-11

Beschreibung: Description: Description:

Druckmessumformer

nicht funkend

Pressure Transmitter,

Non incendive

Transmetteur de pression,

type de protection n

gemäß gültigem Datenblatt: according to the valid datasheet: selon fiche technique en vigueur:

PE 81.26 PE 81.26 PE 81.26

die grundlegenden Anforderungen der

folgenden Richtlinie(n) erfüllen:

fulfills the essential requirements of

the directive(s)

sont conformes aux exigences

essentielles de la (les) directive(s)

- 89/336/EWG (EMV)

- 94/9/EG (ATEX)

- 89/336/EEC (EMC)

- 94/9/EC (ATEX)

- 89/336/CEE (CEM)

- 94/9/CE (ATEX)

EG-Konformitäts-

erklärung

EC Declaration of Conformity Déclaration de Conformité CE

Dokument Nr.: Document No.: Document Nr.:

6005701 6005701 6005701

Wir erklären in alleiniger Verantwortung,

dass die mit

gekennzeichneten

Produkte

We declare under our sole

responsibility, that the

marked

products

Nous déclarons sous notre seule

responsabilité que les appareils

marqués

Typen: Models: Type:

N-10, N-11 N-10, N-11 N-10, N-11

Beschreibung: Description: Description:

Druckmessumformer

nicht funkend

Pressure Transmitter,

Non incendive

Transmetteur de pression,

type de protection n

gemäß gültigem Datenblatt: according to the valid datasheet: selon fiche technique en vigueur:

PE 81.26 PE 81.26 PE 81.26

die grundlegenden Anforderungen der

folgenden Richtlinie(n) erfüllen:

fulfills the essential requirements of

the directive(s)

sont conformes aux exigences

essentielles de la (les) directive(s)

- 89/336/EWG (EMV)

- 94/9/EG (ATEX)

- 89/336/EEC (EMC)

- 94/9/EC (ATEX)

- 89/336/CEE (CEM)

- 94/9/CE (ATEX)

Die Prüfung der Geräte wurde

entsprechend den Normen

The devices have been tested

according to the norm:

Les appareils ont été vérifiés suivant

les normes:

EMV: EN 61326:2002 EMC: EN 61326:2002 CEM: EN 61326:2002

ATEX: EN 50014:1997+A1+A2 ATEX: EN 50014:1997+A1+A2 ATEX: EN 50014:1997+A1+A2

ATEX: EN 50021: 1998 ATEX: EN 50021: 1998 ATEX: EN 50021: 1998

ATEX: prEN 60079-0: 2002 ATEX: prEN 60079-0: 2002 ATEX: prEN 60079-0: 2002

ATEX: EN 60079-15: 2003 ATEX: EN 60079-15: 2003 ATEX: EN 60079-15: 2003

ATEX: EN 50281-1-1:1998+A1 ATEX: EN 50281-1-1:1998+A1 ATEX: EN 50281-1-1:1998+A1

durchgeführt

WIKA Alexander Wiegand GmbH & Co.

KG

WIKA Alexander Wiegand GmbH &

Co. KG

WIKA Alexander Wiegand GmbH &

Co. KG

Klingenberg, 19.10.2004 Klingenberg, 19.10.2004 Klingenberg, 19.10.2004

Geschäftsbereich TRONIC Company division TRONIC Company division TRONIC

i. V. Stefan Richter i. V. Stefan Richter i. V. Stefan Richter

Qualitätsmanagement TRONIC Quality management TRONIC Quality management TRONIC

i. A. Thomas Gerling i. A. Thomas Gerling i. A. Thomas Gerling

10. Lagerung, Entsorgung / 11. EG-Konformitätserklärung

Lagerung

Montieren Sie die Schutzkappe bei Lagerung des Druckmessgerätes, damit die

Membran nicht beschädigt wird (N-11).

Entsorgung

Entsorgen Sie Gerätekomponenten und Verpackungsmaterialien entsprechend den

einschlägigen landesspezifischen Abfallbehandlungs- und Entsorgungsvorschriften des

Anliefergebietes.

11. EG-Konformitätserklärung

D

Technische Änderungen vorbehalten.

1. Informations importantes

1. Informations importantes

Veuillez lire ce mode d’emploi avant le montage et la mise en service de transmetteur de pression. Conservez ce mode d’emploi dans un endroit accessible en tout temps pour tous les

utilisateurs. Les instructions de montage et de service présentées ci-après ont été établi avec

grand soin. Il reste toutefois impossible d’envisager tous les cas d’applications possibles.

Dans le cas où vous constateriez des lacunes dans ces instructions pour les tâches spéciales

qu’il vous faut exécuter, vous avez la possibilité de recevoir des compléments d’informations:

Sous notre adresse internet www.wika.de / www.wika.com

La fiche technique de ce produit a la désignation PE 81.26

Par contact direct avec notre conseiller applications (+49) 9372/132-295

Si le numéro de série sur la plaque de fabrication et/ou la codification 2D sur l’hexagone du

raccord n’est (ne sont) plus lisible (s) (par exemple par endommagement mécanique ou si le

numéro est recouvert de peinture), la traçabilité n’est plus assurée.

La conception et la fabrication des transmetteurs de mesure WIKA, tels que décrits dans les

instructions de service, satisfont aux toutes dernières règles de l’art. Tous les composants

sont soumis à un contrôle strict des critères de qualité et d’environnement en cours de fabrication. Notre système de gestion de l’environnement est certifié selon DIN EN ISO 14001.

Définition conforme d’utilisation du produit N-10, N-11:

Utilisez le transmetteur sans danger d'inflammation afin de transformer le signal de pression

en signal électrique dans les zones sous danger d’explosion, demandant des appareils de la

catégorie 3G ou 3D).

Homologation ATEX: Ces transmetteurs de pression sont certifiés pour utilisation dans un

environnement explosible. ATEX homologation: II 3G EEx nA II T6 and II 3D IP65 T80°C

Vos connaissances nécessaires

N’installez et ne mettez en service le transmetteur de pression que si vous avez les connaissances exactes des directives spécifiques nationales et si vous êtes en possession de la

qualification en rapport. Vous devez posséder des connaissances des prescriptions pour

les zones sous danger d’explosion ainsi que de la technique de mesure et régulation et des

circuits électriques étant donné que le transmetteur de pression est un équipement électrique

selon EN 50178. Suivant les conditions d’utilisation vous devez disposer de connaissances

parti-culières, par exemple sur les fluides agressifs.

F

Page 19

2147614.07 GB/D/F/E 04/2009

36

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

37

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2. Aperçu rapide / 3. Explication des symboles, abréviations / 4. Fonction

F

2. Aperçu rapide

Si vous voulez vous procurer un résumé rapide, veuillez lire les chapitres 3, 5, 7 et 10. Là

vous trouverez des indications concernant votre sécurité et des informations importantes sur

votre produit et sa mise en service. Veuillez absolument en prendre connaissance.

3. Explication des symboles, abréviations

Risque de danger de mort

!

Avertissement

Avertissement

2-fils Deux conducteurs servent à l’alimentation.

Le courant de l’alimentation est le signal de mesure.

3-fils Deux conducteurs servent à l’alimentation.

Un conducteur servent au signal de mesure.

U+ Alimentation positive raccord

U- Alimentation négative raccord

S+ Positive raccord mesure

ou de blessures graves.

Consignes spéciales pour la

sécurité intrinsèque:

Risque de danger de mort

ou de blessures graves.

Remarques, informations

importantes, dérangement

de fonction.

Ce produit est conforme

aux directives européennes

correspondantes.

Avertissement

Attention

Risque de danger de mort

ou de blessures graves par

des pièces éjectées.

Possibilité de danger de

brûlures par surfaces

brûlantes.

ATEX

Directive européen pour

atmosphères explosibles

(Atmosphäre=AT,

Explosion=EX)

Ce produit est conforme aux

exigences selon la directive

94/9/CE (ATEX) protection

contre les explosions.

4. Fonction

N-10: Raccord pression (sans danger d'inflammation) avec membrane intérieure (exécution

standard).

N-11: Raccord de pression avec membrane affleurante (sans danger d'inflammation)

pour fluides hautement visqueux ou cristallisants pouvant obstruer le trou du raccord

de pression standard.

4. Fonction / 5. Pour votre sécurité

Fonction

A l'aide d'un capteur et sous alimentation électrique, on obtient la transformation en un signal

amplifié, normalisé et électrique de la pression appliquée, par la déformation d'une membrane. Ce signal électrique varie proportionnellement par rapport à la pression et peut être

exploité en rapport.

5. Pour votre sécurité

Avertissement

N’ouvrez les raccords que hors pression!

N'utilisez le transmetteur de pression qu'à l'intérieur de la zone limite!

Prenez en considération les paramètres de service selon le chapitre 7 „Caractéristiques

techniques”.

Assurez-vous que le transmetteur de pression ne soit utilisé qu’en accord avec le règle-

ment, c’est-à-dire comme décrit dans la directive suivante.

Abstenez-vous d’effectuer des empiétements et changements inadmissibles sur le trans-

metteur de pression n’étant pas décrits dans le mode d’emploi.

Si vous ne pouvez pas éliminer des dérangements sur le transmetteur de pression, mettez

celui-ci hors service et protégez le contre une remise en service par inadvertance.

Prenez des mesures de sécurité pour les restes de fluides se trouvant dans les trans-

metteurs de pression démontés. Ces restes de fluides peuvent mettrent en danger

les personnes, l’environnement ainsi que l’installation!

Ne faites effectuer les réparations que par le fabricant.

F

Choisissez le transmetteur de pression adéquat, avant le montage et la mise

!

en service, en rapport à l’étendue de mesure, l’exécution et les conditions

de mesure spécifiques.

Respectez les prescriptions de sécurité nationales (comme par exemple:

EN 50178) et observez lors d’applications spéciales les normes et règlements en rigueur (par exemple pour fluides dangereux tels que : acétylène,

fluides combustibles ou toxiques ainsi que les installations frigorifiques et

compresseurs). Si vous ne respectez pas les prescriptions correspon-

dantes, de graves lésions corporelles et dégâts matériels peuvent en

résulter!

Page 20

2147614.07 GB/D/F/E 04/2009

38

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

39

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

5. Pour votre sécurité / 6. Emballage / 7. Mise en service, exploitation

F

Les données relatives à la résistance à la corrosion et diffusion des instruments se trouvent

dans le manuel WIKA sur la mesure des pressions et des températures.

Prenez en considération les prescriptions nationales respectives concernant

l’utilisation en zone sous danger d’explosion (par exemple: IEC 60079-14).

Avertissement

Si vous ne respectez pas celles-ci, de graves lésions corporelles et des

dégâts matériels peuvent en résulter.

6. Emballage

Est-ce que la livraison est complète?

Contrôlez le volume de la livraison:

Transmetteurs de pression complets; pour l’exécution à membrane affleurante N-11

avec le joint prémonté et le capuchon de protection.

Examinez le transmetteur de pression en vue de dommages éventuels résultant

du transport. Si des dommages sont évidents, veuillez en informer immédiatement

i’entreprise de transport et WIKA.

Conservez l’emballage, celui-ci offre lors d’un transport une protection optimale (par

exemple changement du lieu d’utilisation, renvoi pour réparation).

Veillez à ce que le filetage du raccord pression ainsi que les contacts de branchement

ne soient pas détériorés.

Afin de protéger la membrane, le raccord pression de l’appareil N-11 est muni d’un capuchon

de protection.

N’enlevez ce capuchon à la main que juste avant le montage afin que la membrane ne

soit pas endommagée.

Conservez le capuchon de protection du filetage du raccord pression et la membrane

pour un stockage ou pour un transport futur.

Remontez le capuchon de protection lors du démontage ou transport de transmetteur

de pression.

7. Mise en service, exploitation

Outillage nécessaire: clé à fourche de 27, tournevis

7. Mise en service, exploitation

Pour votre sécurité contrôler la membrane

Il est nécessaire que, avant la mise en service de transmetteur de pression, vous contrôlez

visuellement la membrane, car celle-ci est une pièce élémentaire de sécurité.

Avertissement

Montage du raccord Plaque de fabrication (exemple)

Fondamentalement est valable le numéro de série sur la plaque de fabrication. S‘il n‘y a pas de numéro de

série sur la plaque de fabrication, le numéro sur l‘hexagone est valable.

Avertissement

!

max.

50 Nm

Joint

d’etanchéité

Surveillez les fuites de liquide, celles-ci pouvant indiquer une membrane

endommagée.

Contrôlez visuellement si la membrane est endommagée (N-11).

N’utilisez le transmetteur de pression que si la membrane est intacte.

Utilisez le transmetteur de pression uniquement s’il est dans un état parfait

quant à la sécurité technique.

Signal de sortie

Alimentation

P #

Code Article S# No. Série

Position des connections

Date de fabrication (Code)

Protégez la membrane du contact avec des fluides abrasifs et contre les

coups. Si vous endommagez la membrane, la protection contre les risques

d’explosion n’est plus garantie (ATEX)!

Dans les environnements explosibles en raison de la présence de pous

sières, veillez à ce que la disposition de transmetteur de pression soit

protégée également contre les coups.

F

Page 21

2147614.07 GB/D/F/E 04/2009

40

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

41

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

7. Mise en service, exploitation

Prenez en considération les données techniques pour l’utilisation de trans-

metteur de pression liaison avec des fluides agressifs / corrosifs et pour

Avertissement

N’enlevez le capuchon à la main de protection que juste avant le montage et faites

absolument attention à ne pas endommager la membrane lors du montage (N-11).

Pour le type N-10 veuillez prévoir un joint; à l’exception des appareils avec filetage

autoétanchéifiant (par exemple filetage NPT).

Pour le type N-11 le joint fait partie de la livraison.

Les renseignements concernant les joints figurent dans notre information ”acces-

soires joints AC 09.08” dans le Catalogue Général Mesure de Pression et Température

ou sur notre site internet www.wika.de

Veuillez faire attention lors du montage à ce que les surfaces d’étanchéité de

l’appareil et du point de mesure ne soient pas détériorées ou malpropres.

Serrez ou desserrez l’appareil uniquement par l’intermédiaire des surfaces pour clés

à l’aide d’un outil approprié en respectant le couple de serrage. Le couple de serrage

correct dépend de la dimension du raccord de pression ainsi que du joint utilisé

(forme / matière). Pour visser ou dévisser l’appareil, n’utilisez pas le boîtier en tant que

surface d’attaque.

Prenez garde lors du vissage de l’appareil, que le pas de vis ne se coince pas.

Pour les taraudages et les embases à souder voir Information Technique IN 00.14

sous www.wika.de -Service

Montage branchement électrique

!

Avertissement

éviter des mises en danger mécaniques.

Ne pas interrompre le branchement électrique sous tension!

Utilisez une alimentation de tension avec une limitation de puissance P<1W.

Limitez de façon sûre la tension d’alimentation, même en cas de dérange-

ment, à une tension U> 42 VDC.

F

7. Mise en service, exploitation

Mettez le blindage à la terre d‘un seul côté et de préférence en zone de

sécurité, donc en zone sans danger d‘explosion (EN 60079-14). Dans les

Avertissement

Alimentez le transducteur de pression avec une alimentation secteur à séparation galva-

nique.

Observez la capacité et inductivité efficace interne.

Veuillez munir les embouts avec brins de câble ténus de cosses tubulaires (confection de

câbles).

Considérez que pour l’utilisation avec câble en zone 2 et 22 la tension de test entre

conducteur / terre, conducteur / blindage et blindage / terre doit être de > 500V.

Pour les appareils équipés de connecteurs ronds M12x1 et installation/utilisation en

zone 22 :

Avertissement

instruments avec sortie de câble, le blindage est relié au boîtier. Le raccord

simultané du boîtier et du blindage à la terre n‘est admissible que si une

transmission de potentiel peut être exclue entre le raccord de blindage (par

ex. à l‘alimentation) et le boîtier (voir EN 60079-14).

Protéger le connecteur à

fiches rond M12x1 au moyen

d‘un verrouillage supplémentaire afin d‘éviter toute

ouverture involontaire. Utilisez

le clip livré (numéro de produit

Wika 2073164). Placez les

deux moitiés de la manchette

à l‘aide de l‘anneau moleté

du connecteur à fiches et

verrouillez les en les pressant.

Fixez le petit drapeau au câble

en plaçant la « flèche » autour

du câble et l‘introduire par

l‘œillet.

F

Page 22

2147614.07 GB/D/F/E 04/2009

42

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

2147614.07 GB/D/F/E 04/2009

43

WIKA Operating instructions/Betriebsanleitung/Mode d'emploi/Instrucciones de servicio N-10, N-11

7. Mise en service, exploitation

Mettez le boîtier à la terre contre des champs électromagnétiques et des charges

électrostatiques par le raccord au processus.

Utilisez le transducteur de pression avec un câble blindé et mettez-le à la terre

au moins d’un côté si la longueur du câble dépasse 30 m (système à deux fils) ou

dépasse 3 m (système á 3 fils) ou si vous sortez le câble d’un bâtiment.

Protection IP selon IEC 60 529 (les degrés de protection indiqués ne sont valables

que pour les connecteurs enfichés avec connecteurs femelles possédant l’indice de

protection correspondant).

Veuillez prendre en considération lors du choix

du connecteur:

Plage de température T >T transmetteur + 20K

Indice de protection

Section des conducteurs A

> IP 54 (protection Ex)

> 0.25mm2

du câble:

Choisissez la longueur du câble de façon à ce qu’elle soit au moins 3x plus longue

que la longueur nécessaire et qu’il soit possible de reprendre la pose du câble.

Choisissez le diamètre du câble en rapport au presse étoupe du connecteur. Faites

attention à ce que le serre-câble du connecteur assemblé soit bien positionné et que

les joints soient tous présents et non endommagés. Serrez les raccords à fond et

contrôlez la position correcte des joints afin d’assurer l’indice de protection.

En cas d’utilisation de sorties par câble, veuillez vous assurer qu’aucune humidité ne

puisse entrer à la sortie du câble.

F

7. Mise en service, exploitation

Branchement electrique

2-fils U+ = 1 U- = 3 U+ = brun U- = vert

3-fils U+ = 1 U- = 3 S+ = 4 U+ = brun U- = vert S+ = blanc

Gaine de câble - gris

Section de conducteur - 0,5 mm2 (AWG 20)

Diamètre extérieur du

conducteur

Protection selon IEC 60 529 IP 67 IP 68

Données techniques Type N-10 / N-11

Etendue de mesure

Limites de surcharge bar 1 1,5 2 2 4 5 10 10 17 35 35 80

Pression de destruction bar 2 2 2,4 2,4 4,8 6 12 12 20,5 42 42 96

Etendue de mesure

Limites de surcharge bar 50 80 120 200 320 500 800 1200 1500

Pression de destruction bar 96 400 550 800 1000 1200 1700 2)2400 2)3000

Connecteur M12x1 Sortie câble avec 1,6 m longleur

- 6,8 mm