Page 1

Hazardous Area Non-incendive Transmitters

Model N-10, N-11

Applications

■

Natural gas compressors

■

Wellhead monitoring

■

Pipeline pressure

■

General industrial applications

Special Features

Electronic

Pressure Measurement

Datasheet N-10, N-11

■

FM /CSA approved Non-incedive for Class I Division 2,

Dust-ignitionproof for Class II, Division 1

■

Engineered to meet the harsh demands of

gas compressor applications

■

Does not require the use of intrinsically safe barriers

■

NACE MR-01-75 compliant wetted parts

■

4-20 mA or low power 1-5 volt output signals available

Description

Type N-10 pressure transmitters are specically designed

to meet the durability and performance requirements of gas

compressor systems. These pressure transmitters feature an

industry standard 4-20 mA 2 wire signal output, NEMA 4X (IP

67) weather protection and are extremely resistant to pressure

spikes, vibration and moisture intrusion. NACE MR-01-75

compliance provides extra resistance against sulde stress

cracking when exposed to gases containing sulphur.

Type N-11 pressure transmitters feature a at, non-clogging

diaphragm. This is designed for use with viscous uids or

media containing particulates that could clog the pressure port

of the standard NPT version.

Left: N-10 pressure transmitter with NPT connection

Right: N-11 ush diaphragm pressure transmitter

The transmitters are engineered to meet Class I Division 2

non-incendive protection requirements, as well as Class II

Division 1 dust-ignition protection requirements in hazardous environments. Each undergoes extensive quality

control testing and calibration to achieve a linearity of <

0.25% full scale. In addition, each pressure transmitter is

temperature compensated to assure accuracy and long

term stability when exposed to severe ambient temperature

variations.

Datasheet N-10, N-11 · 11/2016

Page 1 of 4

R

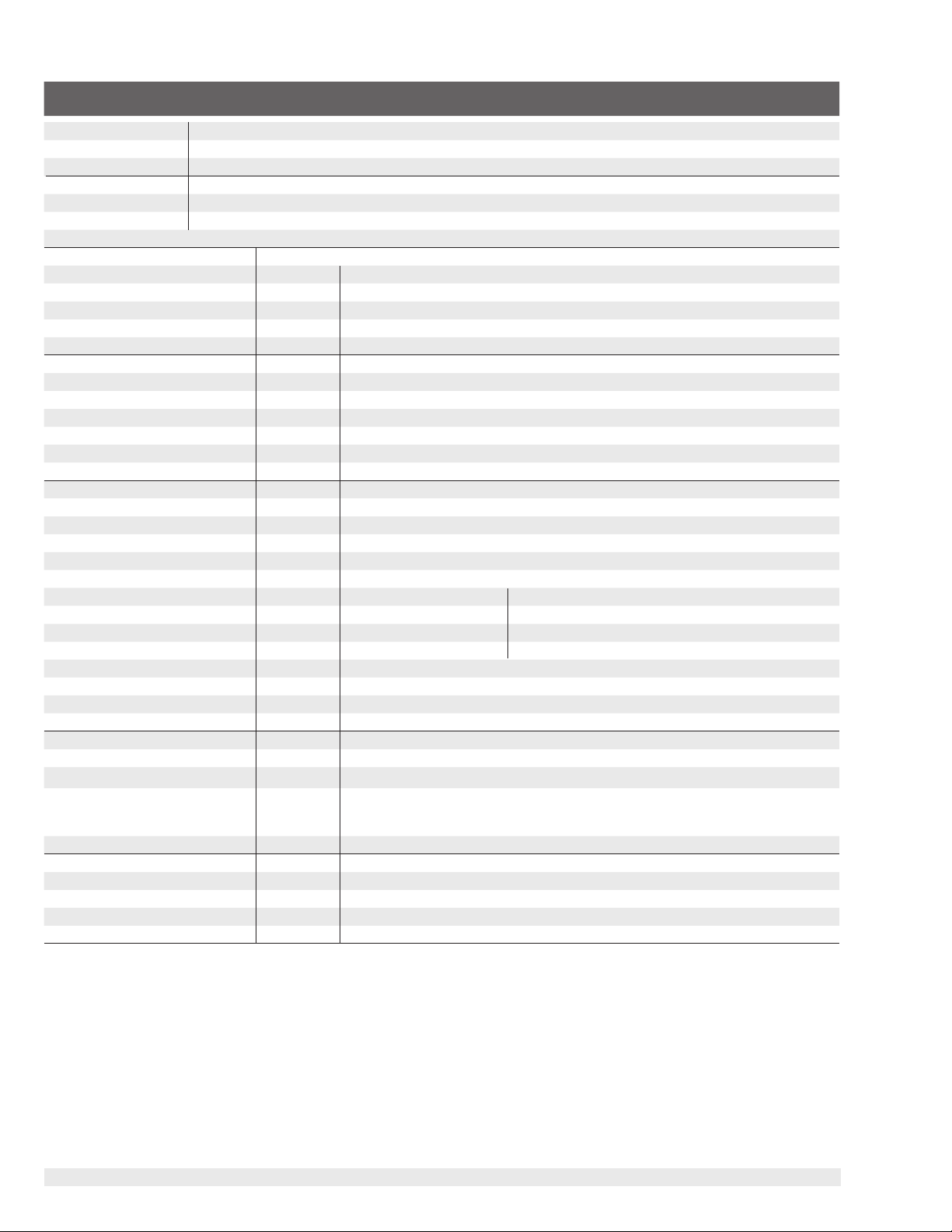

Page 2

Specications Type N-10 / N-11

Pressure range 5 psi 10 psi 15 psi 25 psi 30 psi 60 psi 100 psi 200 psi 300 psi

Maximum pressure* 29 psi 58 psi 72 psi 145 psi 145 psi 240 psi 500 psi 1,160 psi 1,160 psi

Burst pressure** 35 psi 69 psi 87 psi 170 psi 170 psi 290 psi 600 psi 1,390 psi 1,390 psi

Pressure range 500 psi 1,000 psi 1,500 psi 2,000 psi 3,000 psi 5,000 psi 8,000 psi110,000 psi115,000 psi

Maximum pressure* 1,160 psi 1,740 psi 2,900 psi 4,600 psi 7,200 psi 11,600 psi 17,400 psi 17,400 psi 21,750 psi

Burst pressure** 5,800 psi 7,970 psi 11,600 psi 14,500 psi 17,400 psi 24,650 psi234,800 psi 34,800 psi 43,500 psi

{vacuum, gauge pressure, compound ranges, and absolute pressure references are available}

Materials

Wetted parts

N-10

N-11

Case

Nace compliant

Stainless steel (> 1,000 psi stainless steel and Elgiloy)

Stainless steel; O-ring: NBR {Viton or EPDM}

Stainless steel

Internal transmission uid Synthetic oil (only for pressure ranges up to 300 psi or ush diaphragm units)

Power supply U

B

DC V 10 < UB ≤ 30 for 4 ... 20 mA, 2-wire

6 < U

< 30 for 1 ... 5 V, 3-wire low power version

B

Signal output and 4…20 mA: RA ≤ (UB - 10 V) / 0,02 A with R

maximum load R

A

1 ... 5 V, 3-wire: RA > 10 kOhm

Response time (10 ... 90 %) ms ≤ 1 (≤ 10 ms when media temperatures are below –22 ° F ( -30 °C) for pressure

ranges up to 300 psi or with ush diaphragm)

Isolation voltage

Accuracy

3)

V

% of span

500

≤ 0.25 (BFSL)

% of span ≤ 0.5 (limit point calibration)

Non-repeatability % of span ≤ 0.05

Hysteresis % of span ≤ 0.1

1-year stability % of span ≤ 0.2 (at reference conditions)

Permissible temperature of

Medium

Ambient

Storage

-22 ... +176 °F -30 ... +80 °C (-40 °C only with NPT threads)

-22 ... +176 °F -30 ... +80 °C

-22 ... +221 °F -30 ... +105 °C

Compensated temp. range 32 ... +176 °F 0 ... +80 °C

Temperature coecients in

compensated temp range:

Mean TC of zero

Mean TC of range

Approval authority

% of span ≤ 0.2 / 10 K (< 0,4 for pressure range < 100 InWC)

% of span ≤ 0.2 / 10 K

Factory Mutual (FM) non-incendive with entity approval for:

Class 1, Division 2, Groups A, B, C, D

Dust ignition-proof for Class II, Division 1, Groups E,F and G

Vmax=30V, Imax=30mA, Pi=1W

Maximum electrical ratings

For 2wire system: Ci=22nF (ying leads: +0.2 nF/m) , Li=0mH (ying leads: +2µH/m)

For 3wire systems: Ci=140nF (ying leads: +0.2 nF/m) , Li=0mH (ying leads: +2µH/m)

FM Standards according to FMRC 3600, 3611, 3810

Ingress protection NEMA 4X (IP 67)

Shock resistance g 1,000 according to IEC 60068-2-27 (mechanical shock)

Vibration resistance g 20 according to IEC 60068-2-27 (vibration under resonant conditions)

Wiring protection Protected against reverse polarity, overvoltage, and short circuiting

Weight

* Pressure applied up to the maximum rating will cause no permanent change in specications but may lead to zero and span shifts

**Exceeding the burst pressure may result in destruction of the transmitter

1) Only Type N-10.

2) For Type N-11: the burst pressure is limited to 21,000 psi unless the pressure seal is accomplished by using the sealing ring underneath the hex.

3) Includes non-linearity, hysteresis and repeatability. Limit point calibration performed in vertical mounting position with pressure connection facing down.

4) Transmitters will function when exposed to these extended temperature ranges. The media, when exposed to temperature extremes, may change

characteristics that eect transmitter performance.

5) Wetted parts comply with recommendations per NACE MR0175. Environmental limits apply to certain materials. Consult latest standard for details.

{ } Items in curved brackets are options available at additional cost.

lb 0.4

5

in Ohm and UB in Volt

A

1

Datasheet N-10, N-11 · 11/2016Page 2 of 4

Page 3

Dimensions in inches (mm)

Electrical connection

6 foot cable with free ends

NEMA 4 / IP 67

Order code: 2X

1.06“ (27mm)

Case

N-10 pressure connections

1/4 NPT male

Order code: NB

.85” (21.5mm)

.51” (13mm)

1/ 2 NPT male

Order code: ND

.75”(19mm)

1.08”(27.5mm)

1.06“ (27mm)

2.28“ (58mm)

G 1/2

EN 837

Order code: GD

.79”(20mm)

1.12”(28.5mm)

.12”(3mm)

.32”(8mm)

O .24”

(6mm)

O .69”

(17.5mm)

G 1/4

EN 837

Order code: GB

.85”(21.5mm)

.51”(13mm)

.08”(2mm)

.08”(2mm)

O .20”

(5mm)

O .37”

(9.5mm)

N-11 ush diaphragm pressure connections

N-11 G 1

50 InWC to 25 psi

Order code: 85

Sealing ring

29.7x35.7x2.0

1.26”(31.9mm)

.81”(20.5mm)

.39”(10mm)

O-ring 26x2

N-11 G 1/2

30 psi to 5,000 psi

Order code: 86

1.22”(31mm)

.81”(20.5mm)

.39”(10mm)

Sealing ring

18.5x23.9x1.5

O-ring 15x2

Page 3 of 4Datasheet N-10, N-11 · 11/2016

Page 4

Matching P-1 weld insert adapters for N-11 ush diaphragm transmitters

weld

P-1 G1 weld insert adapter

Part # 1206974

for pressure ranges < 25 psi

Wiring details

6 foot cable with free

ends

Legend:

2-wire system

shield / case

P-1 G1/2 weld insert adapter

Part # 1097008

for pressure ranges > 30 psi

brown

green

Cross section view of P-1

adapter installed in pipe.

3-wire system

brown

white

green

shield / case

Sig+ output signal positive

UB+ power supply positive

0V power supply negative

Sig - output signal negative

Page 4 of 4

Specications and dimensions given in this data sheet represent the state of engineering at the time of printing.

Modications may take place and materials specied may be replaced by others without prior notice.

Datasheet N-10, N-11 · 11/2016

R

WIKA Instrument, LP

1000 Wiegand Boulevard

Lawrenceville, GA 30043

1-888-WIKA-USA /770-513-8200 (in GA)

Fax 770-338-5118

info@wika.com www.wika.com

Loading...

Loading...