Page 1

Operating instructions

Betriebsanleitung

Mode d‘emploi

Manual de instrucciones

OEM pressure sensor, model MH-3

OEM-Drucksensor, Typ MH-3

Capteur de pression OEM, type MH-3

Sensor de presión para OEM, modelo MH-3

EN

DE

FR

ES

Examples/Beispiele/Exemples/Ejemplos

Page 2

EN

Operating instructions model MH-3

Betriebsanleitung Typ MH-3

DE

Page 3 - 22

Seite 23 - 42

FR

Mode d‘emploi

ES

Manual de instrucciones modelo

© 08/2015 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. / Alle Rechte vorbehalten.

®

WIKA

is a registered trademark in various countries.

®

WIKA

ist eine geschützte Marke in verschiedenen Ländern.

Prior to starting any work, read the operating instructions!

Keep for later use!

type MH-3 Page 43 - 62

MH-3 Página 63 - 82

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d‘emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta!

2

WIKA operating instructions OEM pressure sensor, model MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 3

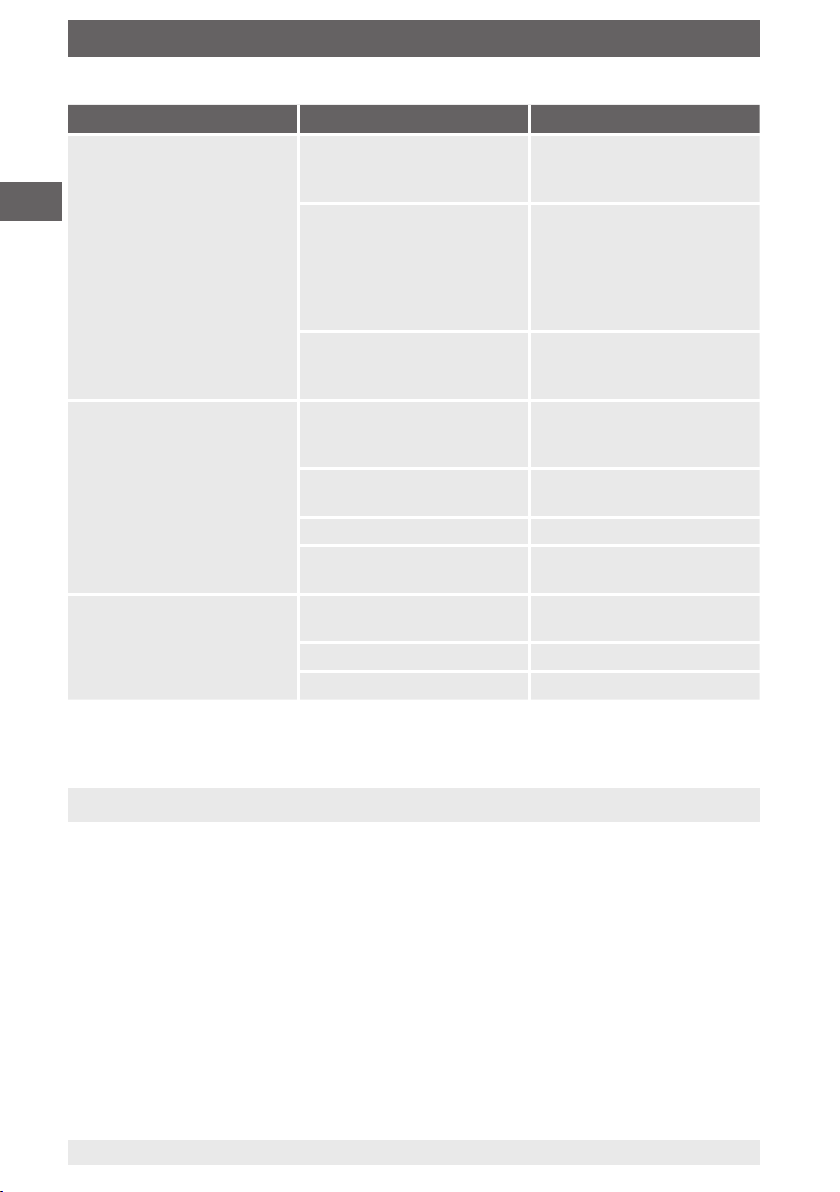

Contents

Contents

1. General information 4

2. Design and function 5

3. Safety 6

4. Transport, packaging and storage 8

5. Commissioning, operation 9

6. Faults 11

7. Maintenance and cleaning 12

8. Dismounting, return and disposal 13

9. Specifications 15

Declarations of conformity can be found online at www.wika.com

EN

14136172.03 11/2019 EN/DE/FR/ES

3WIKA operating instructions, OEM pressure sensor, model MH-3

Page 4

1. General information

1. General information

■

The instrument described in the operating instructions has been designed and

EN

manufactured using state-of-the-art technology. All components are subject to stringent quality and environmental criteria during production. Our management systems

are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all safety instructions and work instructions are

observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument's range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time. Pass

the operating instructions on to the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

■

Further information:

- Internet address: www.wika.de / www.wika.com

- Relevant data sheet: PE 81.59

- Application consultant:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

4

WIKA operating instructions, OEM pressure sensor, model MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 5

2. Design and function

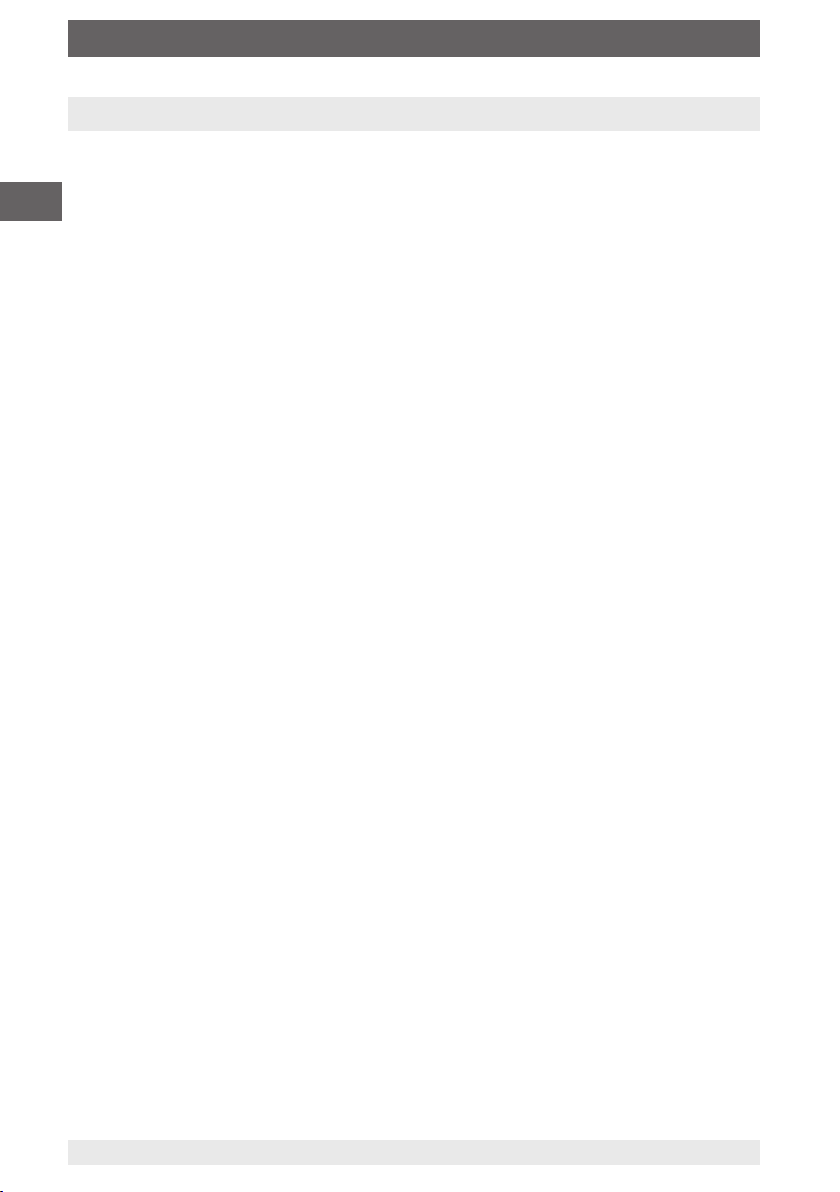

2. Design and function

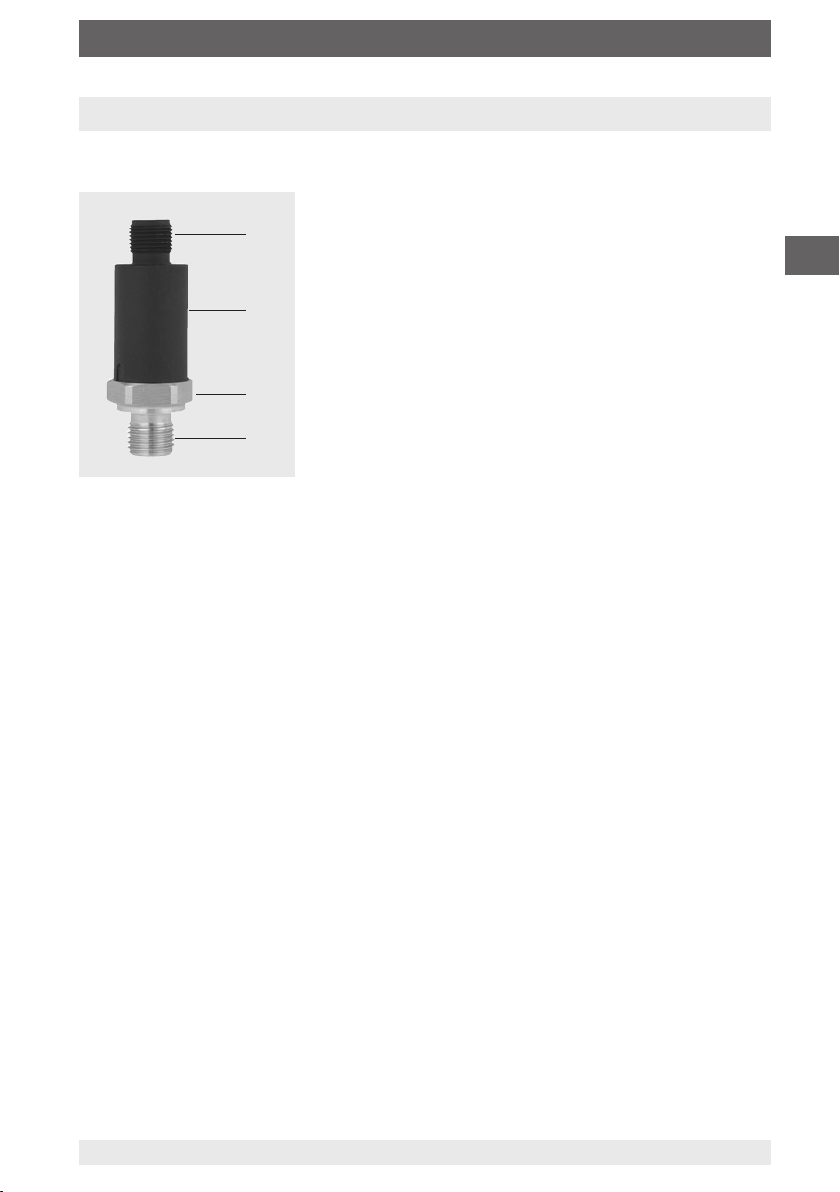

2.1 Overview

Electrical connection (depending on version)

Case

Process connection, spanner flats

Process connection, thread

2.2 Signal clamping (not for MH-3-HY)

The output signal of a pressure sensor can be above the nominal maximum signal

value, if no signal clamping has been set. Likewise, the output signal can also be below

the nominal minimum signal value. This undefined condition can cause an error in

the machine (software) of the customer. Signal clamping limits the output signal to a

minimum or maximum value which is to be defined by the customer.

EN

2.3 Diagnostic function

By means of the output signal, fault conditions can be detected and evaluated via

software. Thus it is possible to differentiate between permanent and temporary faults.

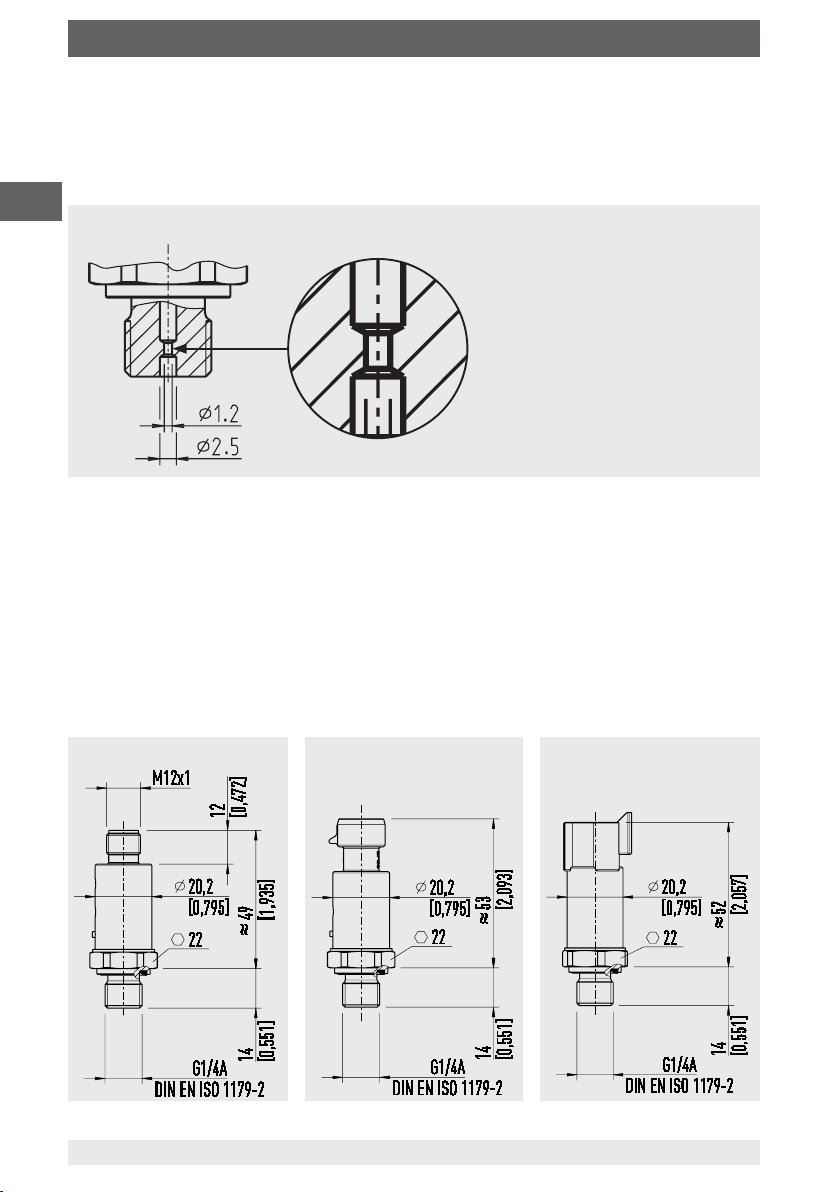

2.4 CDS system

All process connections are available with the CDS system. The diameter of the pressure port is reduced in order to counteract pressure spikes and cavitation.

2.5 Scope of delivery

■

Pressure sensor

■

Operating instructions (for model MH-3-HY)

Cross-check scope of delivery with delivery note.

14136172.03 11/2019 EN/DE/FR/ES

5WIKA operating instructions, OEM pressure sensor, model MH-3

Page 6

3. Safety

3. Safety

3.1 Explanation of symbols

EN

3.2 Intended use

The pressure sensor is used for measuring pressure. The measured pressure is output

as an electrical signal.

The pressure sensor model MH-3 is intended for use in mobile working machines.

The MH-3-HY pressure sensor for mobile hydrogen applications is typically used to

monitor tank pressure and the pressure after the reducing valve in hydrogen-powered

vehicles, especially industrial trucks, utility/municipal vehicles and buses. The exact

position of the sensor is therefore dependent upon the customer and application.

Only use the pressure sensor in applications that lie within its technical performance

limits (e.g. max. ambient temperature, material compatibility, ...).

→ For performance limits see chapter 9 “Specifications”.

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light

injuries or damage to property or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for efficient

and trouble-free operation.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

Technical restrictions

■

Any permanent operation in the overload range is not permitted. Above the operating

pressure, up to the overload limit, the pressure sensor is operating outside its specification. The overload limit is intended to prevent damage to the pressure sensor, as

part of a pressure vessel system, during the pressure containment test.

■

The overload limit must never be exceeded, even when failures occur in the end-use

application. Loads above the overload limit can cause irreversible damage, which can

lead, for example, to permanent measuring errors.

6

WIKA operating instructions, OEM pressure sensor, model MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 7

3. Safety

Specific notes based on the medium hydrogen (model MH-3-HY)

The sensor offered uses the wetted materials 2.4711 and 1.4404. These materials are

resistant to hydrogen embrittlement.

With a temperature of up to 30 °C, the stability under hydrogen influence is typically

1 %/year, maximum 3 %/year.

Due to hydrogen diffusion into the sensor structures, a signal drift can occur dependent

upon the time. The time until the occurrence of a relevant signal drift and the size of the

signal drift depends mainly on factors such as the temperature of the hydrogen, hydrogen content in the medium, and the diaphragm thickness of the pressure sensor used.

It is explicitly recommended for the user to test the selected product version for suitability in the intended application(s) with the specified ambient conditions.

3.3 Personnel qualification

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who,

based on their technical training, knowledge of measurement and control technology and on their experience and knowledge of country-specific regulations, current

standards and directives, are capable of carrying out the work described and independently recognising potential hazards.

3.4 Personal protective equipment

The personal protective equipment is designed to protect the skilled personnel from

hazards that could impair their safety or health during work. When carrying out the

various tasks on and with the instrument, the skilled personnel must wear personal

protective equipment.

EN

Follow the instructions displayed in the work area regarding personal protective

equipment!

The requisite personal protective equipment must be provided by the operating company.

14136172.03 11/2019 EN/DE/FR/ES

7WIKA operating instructions, OEM pressure sensor, model MH-3

Page 8

3. Safety/4. Transport, packaging and storage

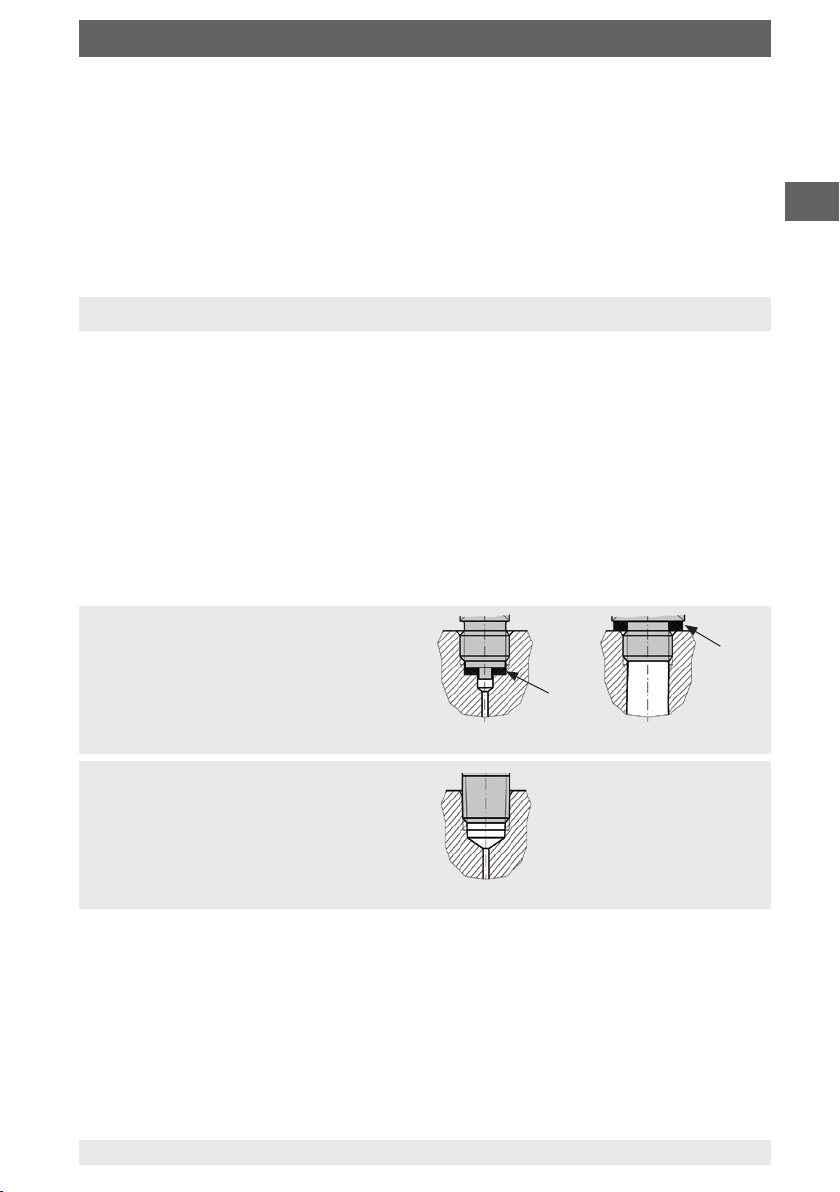

3.5 Labelling, safety marks

Product labels

EN

wika.com

1

2

MH-3

1 Product no. 3 Coded date of manufacture

2 Serial no. 4 Measuring range

1 Product no. 4 Specifications

2 Approvals 5 Coded date of manufacture

3 Nominal working pressure (NWP)

The nominal working pressure per 79/2009/EC corresponds to a nominal working pressure at 15 °C

4

4. Transport, packaging and storage

4.1 Transport

Check the pressure sensor for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

3

5

4.2 Packaging and storage

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, sending for repair).

Permissible conditions at the place of storage:

■

Storage temperature see chapter 9 “Specifications”

■

Humidity: 67 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

8

WIKA operating instructions, OEM pressure sensor, model MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 9

4.Transport, .../5. Commissioning, operation

Store the instrument in its original packaging in a location that fulfils the conditions

listed above. If the original packaging is not available, pack and store the instrument as

described below:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

5. Commissioning, operation

5.1 Mounting the instrument

Requirements for mounting point

The mounting point must meet the following conditions:

■

Sufficient space for a safe electrical installation.

■

Permissible ambient and medium temperatures remain within the performance limits.

Consider possible restrictions on the ambient temperature range caused by mating

connector used.

→ For performance limits see chapter 9 “Specifications”

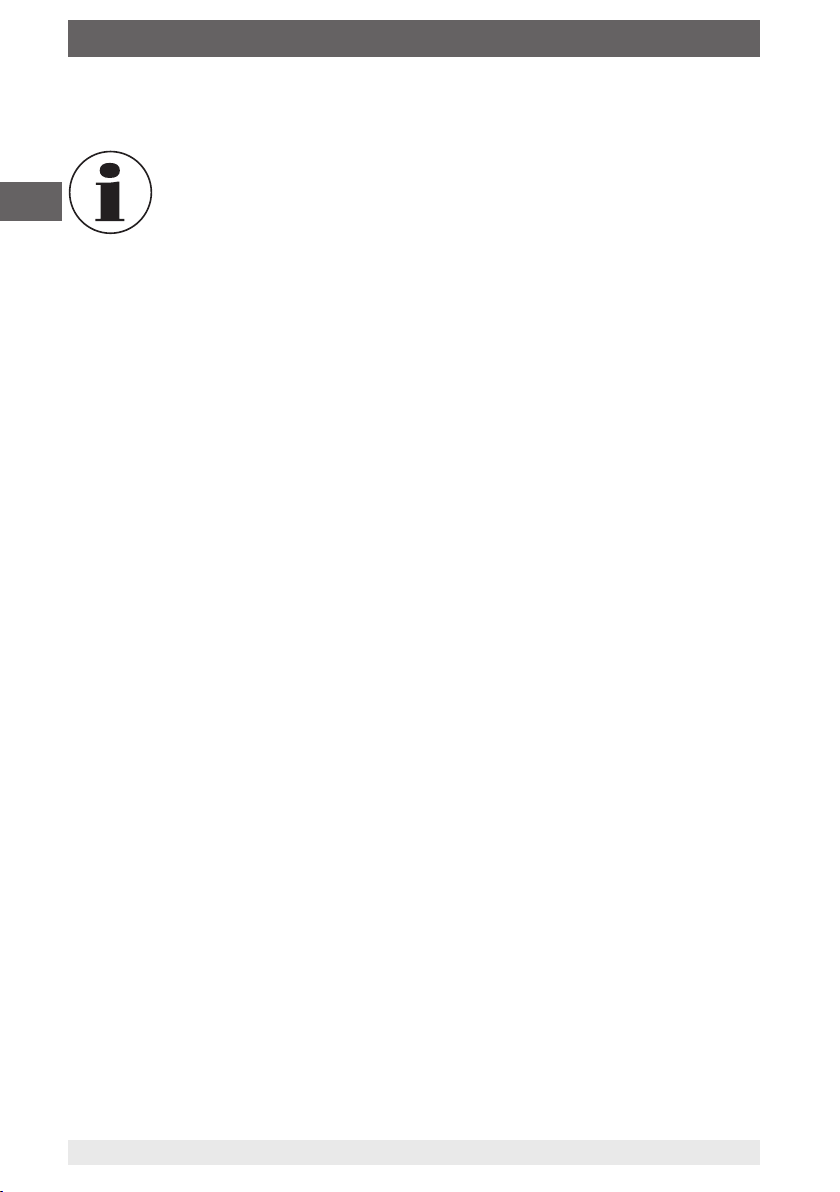

Sealing variants

EN

Parallel threads

Seal the sealing face with flat gasket, lens-type

sealing ring or WIKA profile sealing.

Tapered threads

Wrap threads with sealing material

(e.g. PTFE tape).

14136172.03 11/2019 EN/DE/FR/ES

per EN 837

NPT, R and PT

per ISO 1179-2

(formerly DIN 3852-E)

9WIKA operating instructions, OEM pressure sensor, model MH-3

Page 10

5. Commissioning, operation

Mounting the instrument

The max. torque depends on the mounting point (e.g. material and shape).

If you have any questions, please contact our application consultant.

EN

1. Seal the sealing face (→ see “Sealing variants”).

.

2

At the mounting point, screw the pressure sensor in hand-tight.

.

Tighten with a torque spanner using the spanner flats.

3

5.2 Connecting the instrument to the electric system

Requirements for voltage supply

Supply voltage see chapter 9 „Specifications“.

Requirements for electrical connection

■

Cable diameter matches the cable bushing of the mating connector.

■

Cable gland and seals of the mating connector are correctly seated.

■

With cable outlets, no humidity can ingress at the cable end.

Requirement for shielding and grounding

■

The pressure sensor must be grounded via the process connection (model MH-3).

■

The connection is made in the vehicle with a suitable power supply/control unit that

complies with regulation 10. (MH-3-HY).

■

The connection to vehicle ground is made via the process connection (MH-3-HY).

→ For contact details see chapter 1 “General information” or the back

page of the operating instructions.

In accordance with EN 61326-1, in case of outdoor installations, faults caused by surge

voltages must be considered. To protect the instrument, it must be connected using

a shielded cable. The shield of the cable must be connected on at least one side to

ground or a suitable reference potential. Optionally, a suitable external measure can be

taken to ensure protection against surge voltages.

Connecting the instrument

1. Assemble the mating connector or cable outlet.

→ See “Pin assignments”

.

2

Establish the plug connection.

Pin assignments

See chapter 9 “Specifications”.

10

WIKA operating instructions, OEM pressure sensor, model MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 11

6. Faults

6. Faults

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the

pressure sensor must be taken out of operation immediately.

▶

Ensure that pressure or signal is no longer present and protect against

accidental commissioning.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter 8.2

“Return”.

WARNING!

Physical injuries and damage to property and the environment

caused by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there is a

danger of physical injuries and damage to property and the environment.

▶

Should a failure occur, aggressive media with extremely high temperature and under high pressure or vacuum may be present at the

instrument.

▶

For these media, in addition to all standard regulations, the appropriate

existing codes or regulations must also be followed.

▶

Wear the requisite protective equipment (see chapter 3.4 “Personal

protective equipment”).

EN

For contact details see chapter 1 “General information” or the back page

of the operating instructions.

Faults Causes Measures

Plastic has faded UV irradiation No measures required

No output signal Cable break Check the continuity, and if

No/wrong supply voltage Rectify the supply voltage

No/wrong output signal

Constant output signal upon

change in pressure

14136172.03 11/2019 EN/DE/FR/ES

Wiring error Rectify the wiring

Mechanical overload caused

by overpressure

Discolouration is harmless

necessary exchange the cable

Replace instrument; if it

fails repeatedly, contact the

manufacturer.

11WIKA operating instructions, OEM pressure sensor, model MH-3

Page 12

6. Faults/7. Maintenance and cleaning

Faults Causes Measures

Signal span too small/drops Mechanical overload caused

by overpressure

EN

Signal span varies/inaccurate

Deviating zero point signal Operating temperature too

Diaphragm damaged, e.g. due

to impacts, abrasive/aggressive medium; corrosion at

diaphragm or process connection; transmission medium

missing

Sealing/sealing face damaged

or soiled, sealing does not

have a tight fit, threads jammed

EMC interference sources in

the environment; e.g. frequency

converter

Operating temperature too

high/low

Instrument not grounded Ground the instrument

Strongly fluctuating pressure of

the process medium

high/low

Other mounting position Adjust the zero point

Overpressure limit exceeded Reduce the pressure

If complaint is unjustified, we will charge you the complaint processing fees.

Replace instrument; if it

fails repeatedly, contact the

manufacturer.

Replace instrument; if it

fails repeatedly, contact the

manufacturer.

Clean the sealing/sealing face,

replace sealing if applicable

Shield instrument; cable shield;

remove source of interference

Lower/increase the temperature

Dampening; consulting by the

manufacturer

Lower/increase the temperature

7. Maintenance and cleaning

7.1 Maintenance

This pressure sensor is maintenance-free.

Repairs must only be carried out by the manufacturer.

Regular inspection of the sealing by the operator is necessary.

12

WIKA operating instructions, OEM pressure sensor, model MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 13

7. .../8. Dismounting, return and disposal

7.2 Cleaning

CAUTION!

Unsuitable cleaning agents

Cleaning with unsuitable cleaning agents may damage the instrument and

the product label.

▶

Do not use any aggressive cleaning agents.

▶

Do not use any hard or pointed objects.

▶

Do not use any abrasive cloths or sponges.

Suitable cleaning agents

■

Water

■

Conventional dishwashing detergent

Cleaning the instrument

▶

Wipe the instrument surface using a soft, damp cloth.

8. Dismounting, return and disposal

8.1 Dismounting

WARNING!

Physical injuries and damage to property and the environment

caused by hazardous media

Upon contact with hazardous media (e.g. oxygen, acetylene, flammable

or toxic substances), harmful media (e.g. corrosive, toxic, carcinogenic,

radioactive), and also with refrigeration plants and compressors, there

is a danger of physical injuries and damage to property and the environment.

▶

Should a failure occur, aggressive media with extremely high temperature and under high pressure or vacuum may be present at the

instrument.

▶

Wear the requisite protective equipment (see chapter 3.4 “Personal

protective equipment”).

EN

Dismounting the instrument

1. Disconnect the instrument from the mains.

.

2

Disconnect the electrical connection.

.

Unscrew the instrument with a spanner using the spanner flats.

3

14136172.03 11/2019 EN/DE/FR/ES

13WIKA operating instructions, OEM pressure sensor, model MH-3

Page 14

8. Dismounting, return and disposal

8.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.) and must therefore be cleaned before being returned.

EN

WARNING!

Physical injuries and damage to property and the environment

through residual media

Residual media in the dismounted instrument can result in a risk to

persons, the environment and equipment.

▶

With hazardous substances, include the material safety data sheet for

the corresponding medium.

▶

Clean the instrument, see chapter 7.2 “Cleaning”.

When returning the instrument, use the original packaging or a suitable transport

packaging.

Information on returns can be found under the heading “Service” on our

local website.

8.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

14

Do not dispose of with household waste. Ensure a proper disposal in

accordance with national regulations.

14136172.03 11/2019 EN/DE/FR/ES

WIKA operating instructions, OEM pressure sensor, model MH-3

Page 15

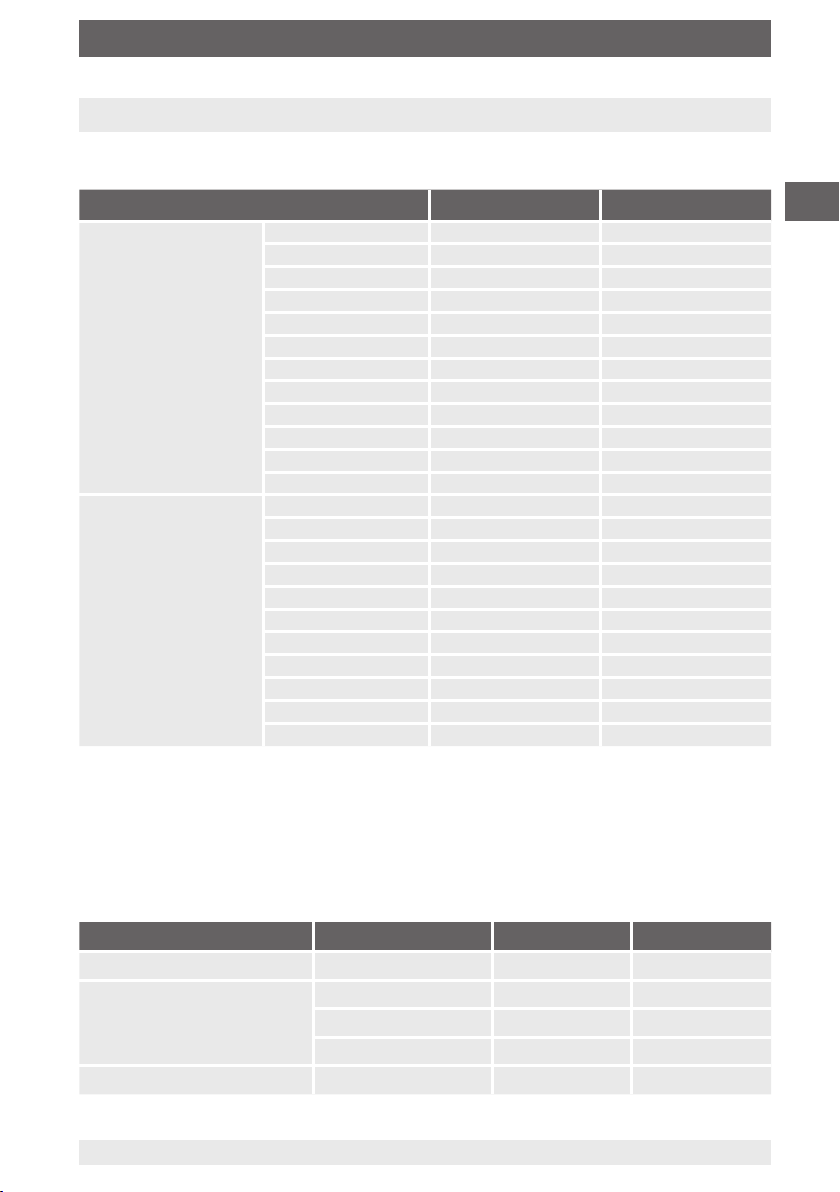

9. Specifications

9. Specifications

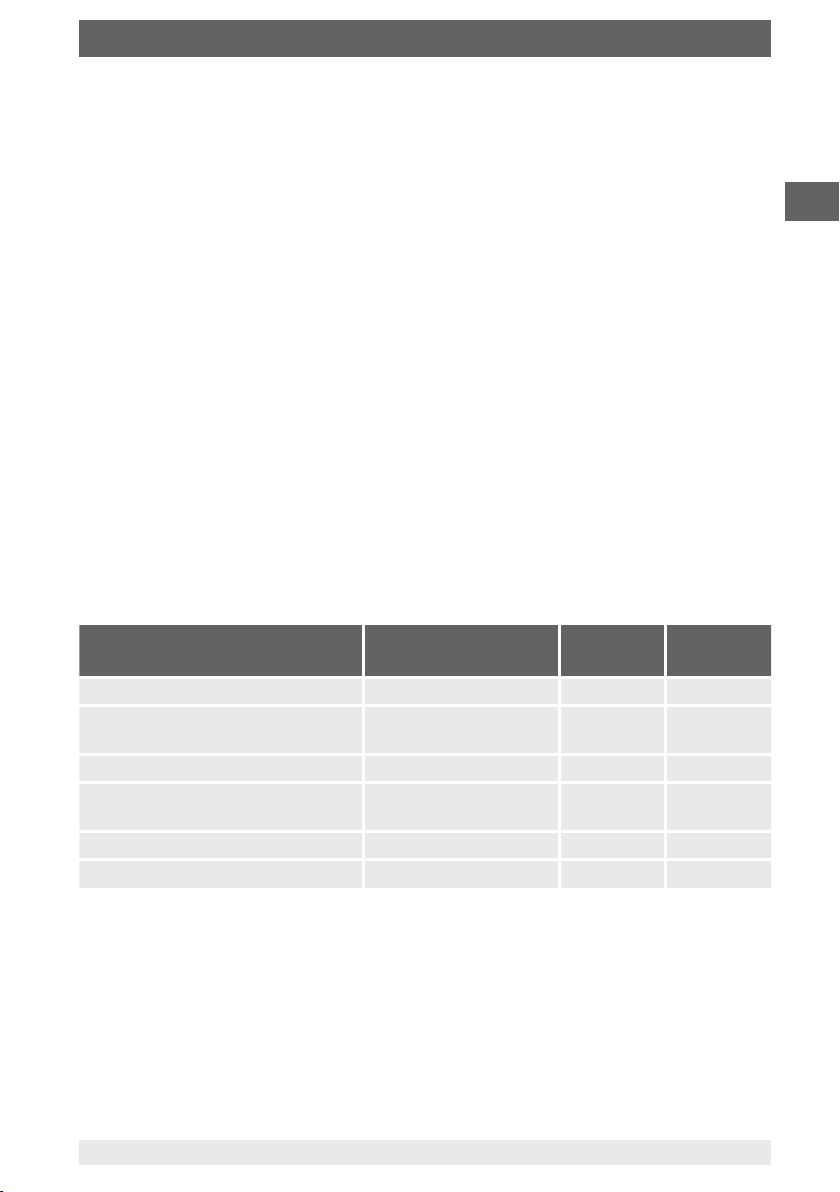

9.1 Measuring ranges

Gauge pressure MH-3 MH-3-HY

bar 0 ... 6 x -

0 ... 10 x 0 ... 16 x 0 ... 20 - x

0 ... 25 x x

0 ... 40 x x

0 ... 60 x x

0 ... 100 x x

0 ... 160 x x

0 ... 250 x x

0 ... 400 x x

0 ... 600 x x

psi 0 … 100 x -

0 … 160 x 0 … 200 x 0 ... 300 x x

0 ... 500 x x

0 ... 1,000 x x

0 ... 1,500 x x

0 ... 2,000 x x

0 ... 3,000 x x

0 ... 5,000 x x

0 ... 8,000 x x

MPa (1 bar = 0.1 MPa)

EN

Overload safety: 2 times (deviating for individual psi measuring ranges of model

MH-3-HY)

Vacuum tightness: Yes

9.2 Output signals

Signal type Signal MH-3 MH-3-HY

Current (2-wire) 4 ... 20 mA x x

Voltage (3-wire) DC 0 ... 10 V x -

DC 1 ... 5 V x DC 1 ... 6 V x -

Ratiometric DC 0.5 ... 4.5 V x x

14136172.03 11/2019 EN/DE/FR/ES

15WIKA operating instructions, OEM pressure sensor, model MH-3

Page 16

9. Specifications

Load

■

4 ... 20 mA: ≤ (power supply - 10 V)/0.02 A

■

DC 0 ... 10 V: > 5 kΩ

■

EN

DC 1 ... 5 V: > 2.5 kΩ

■

DC 1 ... 6 V: > 5 kΩ

■

DC 0.5 ... 4.5 V: > 4.5 kΩ

9.3 Voltage supply

Supply voltage

The power supply depends on the selected output signal.

■

4 ... 20 mA: DC 10 ... 36 V

■

DC 0 ... 10 V: DC 14 ... 36 V

■

DC 1 ... 5 V: DC 8 ... 36 V

■

DC 1 ... 6 V: DC 9 ... 36 V

■

DC 0.5 ... 4.5 V: DC 4.5 ... 5.5 V

Current supply

The current supply depends on the selected output signal.

■

4 ... 20 mA < 30 mA

■

DC 0 ... 10 V < 10 mA

■

DC 1 ... 5 V < 10 mA

■

DC 1 ... 6 V < 10 mA

■

DC 0.5 ... 4.5 V < 10 mA

9.4 Reference conditions (per IEC 61298-1)

Temperature: 15 ... 25 °C [59 ... 77 °F]

Atmospheric pressure: 860 ... 1,060 mbar [12.5 ... 15.4 psi]

Air humidity: 45 ... 75 % r. h.

Supply voltage: DC 24 V

Mounting position: Calibrated in vertical mounting position with pressure connection

facing downwards.

9.5 Accuracy specifications

Accuracy at reference conditions

≤ ±1 % of span for measuring ranges ≥ 40 bar [≥ 500 psi]

≤ ±2 % of span for measuring ranges < 40 bar [< 500 psi]

Including non-linearity, hysteresis, zero offset and end value deviation (corresponds to

measured error per IEC 61298-2).

Non-linearity (per IEC 61298-2)

≤ ±0.25 % of span for measuring ranges ≥ 40 bar [≥ 500 psi]

≤ ±0.40 % of span for measuring ranges < 40 bar [< 500 psi]

16

WIKA operating instructions, OEM pressure sensor, model MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 17

9. Specifications

Temperature error at -40 ... +100 °C [-40 ... +212 °F]

Mean temperature coefficient of zero point:

≤ ±0.15 % of span/10 K for measuring ranges ≥ 40 bar [≥ 500 psi]

For measuring ranges < 40 bar [< 500 psi]: On request

Mean temperature coefficient of span: ≤ ±0.08 % of span/10 K

Settling time

≤ 2 ms

Long-term stability

≤ ±0.2 % of span/year for measuring ranges ≥ 40 bar [≥ 500 psi]

≤ ±0.3 % of span/year for measuring ranges < 40 bar [< 500 psi]

For model MH-3-HY:

Medium temperature range -40 ... +30 °C [-40 ... +86 °F]:

typ. ≤ ±1 %/max. ≤ ±3 % of span/year

It is explicitly recommended for the user to test the selected product version for suitability in the intended application(s) with the specified ambient conditions.

9.6 Operating conditions

Ingress protection (per IEC 60529)

The ingress protection depends on the type of electrical connection.

EN

Electrical connection Ingress protection 1)MH-3 MH-3-HY

Deutsch DT04-3P (3-pin) IP67 x

Delphi connector Metri-Pack

series 150, 3-pin

Circular connector M12 x 1 (4-pin) IP67 x

AMP Superseal connector 1.5 series,

3-pin

Cable outlet (0.5/1/2.5 m), 2-pin IP6K9K x

Cable outlet (0.5/1/2.5 m), 3-pin IP6K9K x

1) The stated ingress protection only applies when plugged in using mating connectors that have the appropriate ingress protection.

IP67 x x

IP67 x x

Vibration resistance

20 g (per IEC 60068-2-6)

Shock resistance

500 g (per IEC 60068-2-27)

14136172.03 11/2019 EN/DE/FR/ES

17WIKA operating instructions, OEM pressure sensor, model MH-3

Page 18

9. Specifications

Permissible temperature ranges

MH-3 MH-3-HY

Ambient -40 ... +100 °C

EN

Medium -40 ... +125 °C

Storage -40 ... +100 °C

[-40 ... +212 °F]

[-40 ... +257 °F]

[-40 ... +212 °F]

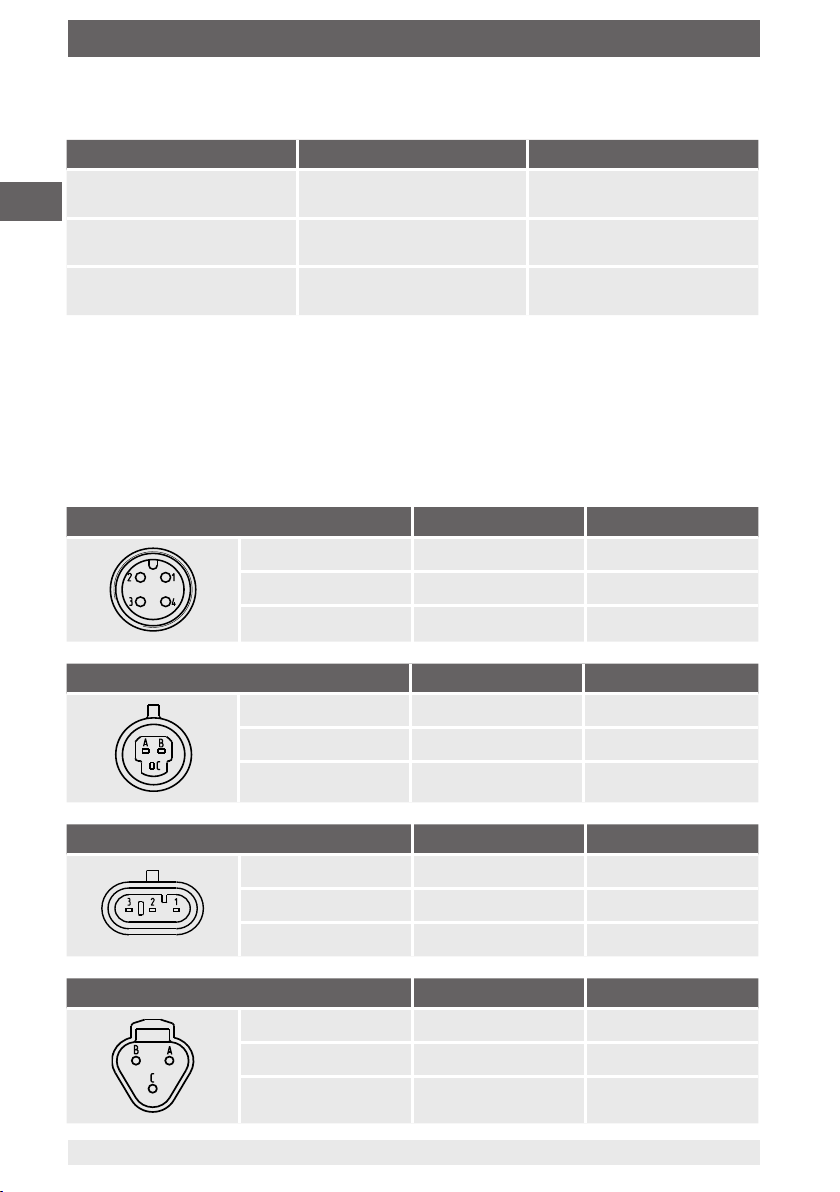

9.7 Electrical connections

Short-circuit resistance: S+ to U

-

Reverse polarity protection: U+ to U- (no reverse polarity protection with ratiometric

output signal)

Insulation voltage: DC 500 V

Connection diagrams

Circular connector M12 x 1 (4-pin) 2-wire 3-wire

U

+

U

-

S

+

1 1

3 3

- 4

-40 ... +85 °C

[-40 ... +185 °F]

-40 ... +85 °C

[-40 ... +185 °F]

-40 ... +85 °C

[-40 ... +185 °F]

Metri-Pack series 150 (3-pin) 2-wire 3-wire

U

+

U

-

S

+

B B

A A

- C

AMP Superseal 1.5 (3-pin) 2-wire 3-wire

U

+

U

-

S

+

3 3

1 1

- 2

Deutsch DT04-3P (3-pin) 2-wire 3-wire

18

U

+

U

-

S

+

WIKA operating instructions, OEM pressure sensor, model MH-3

A A

B B

- C

14136172.03 11/2019 EN/DE/FR/ES

Page 19

9. Specifications

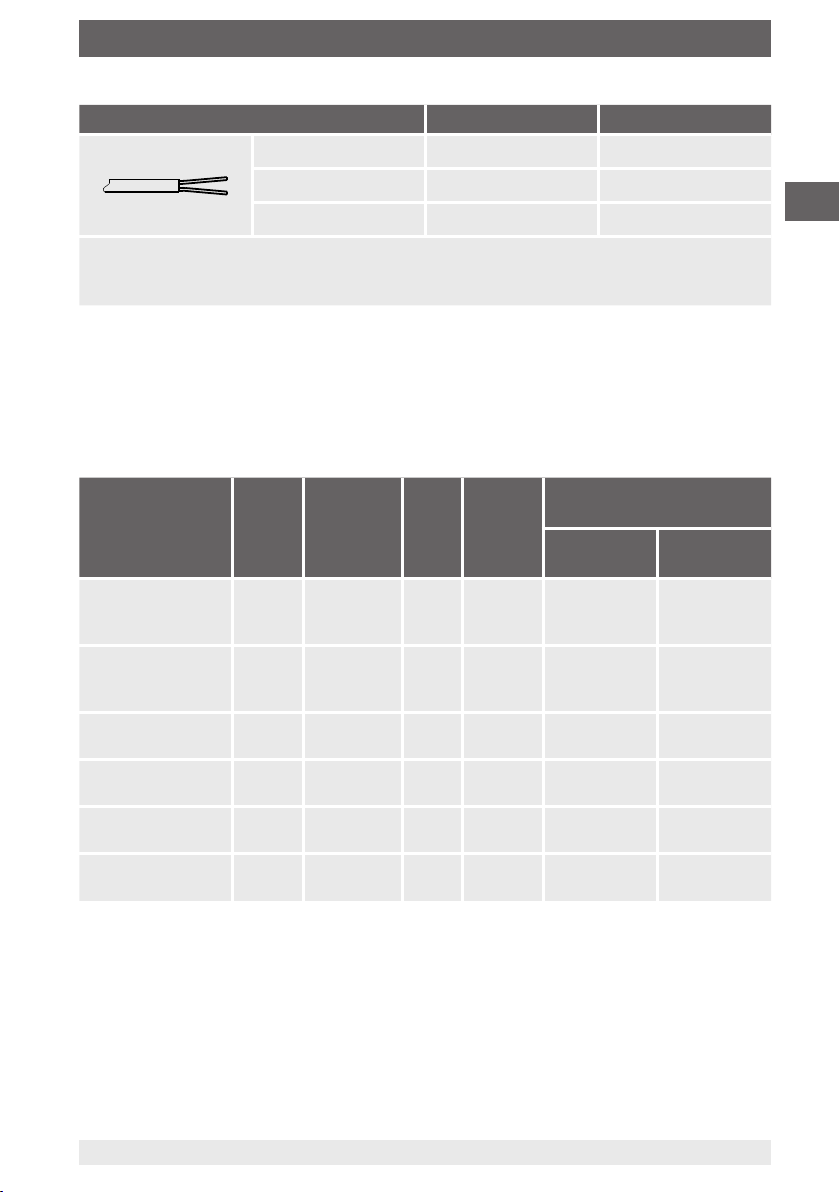

Cable outlet 2-wire 3-wire

U

+

U

-

S

+

Wire cross-section 0.75 mm

2

(with end splices)

Cable diameter 6.6 mm

Cable length 0.5 m or 2 m

Legend

U

Positive power supply terminal

+

U-Negative power supply terminal

Analogue output

S

+

9.8 Process connections

brown brown

green green

- white

EN

Standard Thread

size

Max.

nominal

pressure

MH-3 MH-3-HY Sealing and temperature

2)

1)

range

Standard

Option (MH-3)

(MH-3)

EN 837 G ¼ B 600 bar

[8,000 psi]

DIN EN ISO 1179-2

(formerly DIN 3852-E)

DIN EN ISO 9974-2

(formerly DIN 3852-E)

ISO 6149-2 M14 x 1.5 600 bar

SAE J514 Fig.34B 7/16-20

ANSI/ASME B1.20.1 ¼ NPT 600 bar

1) Details must be tested separately in the respective application. The specified values for the max. nominal

pressure serve only as a rough orientation. The values depend on the temperature, the seals used, the selected torque, the type and the material of the mating thread and the prevailing operating conditions.

2) Model MH-3-HY is delivered without sealing. Depending on the process connection and measuring range,

including overload safety, an appropriate sealing has to be selected.

G ¼ A 600 bar

[8,000 psi]

M14 x 1.5 600 bar

[8,000 psi]

[8,000 psi]

600 bar

UNF-2A

[8,000 psi]

[8,000 psi]

x x Copper

-40 ... +125 °C

[-40 ... +257 °F]

x - NBR

-40 ... +100 °C

[-40 ... +212 °F]

x - - -

x - - -

x x - -

x x - -

Stainless steel

-40 ... +125 °C

[-40 ... +257 °F]

FPM/FKM

-40 ... +125 °C

[-40 ... +257 °F]

The sealings listed under “Standard” are included in the delivery (only for model MH-3).

14136172.03 11/2019 EN/DE/FR/ES

19WIKA operating instructions, OEM pressure sensor, model MH-3

Page 20

9. Specifications

CDS system

All process connections are available with the CDS system.

The diameter of the pressure port is reduced in order to counteract pressure spikes and

cavitation (see fig.1).

EN

Illustration of the CDS system

9.9 Materials

Wetted parts

MH-3: Stainless steel

MH-3-HY: Stainless steel, 2.4711

Non-wetted parts

Highly resistant glass-fibre reinforced plastic (PBT)

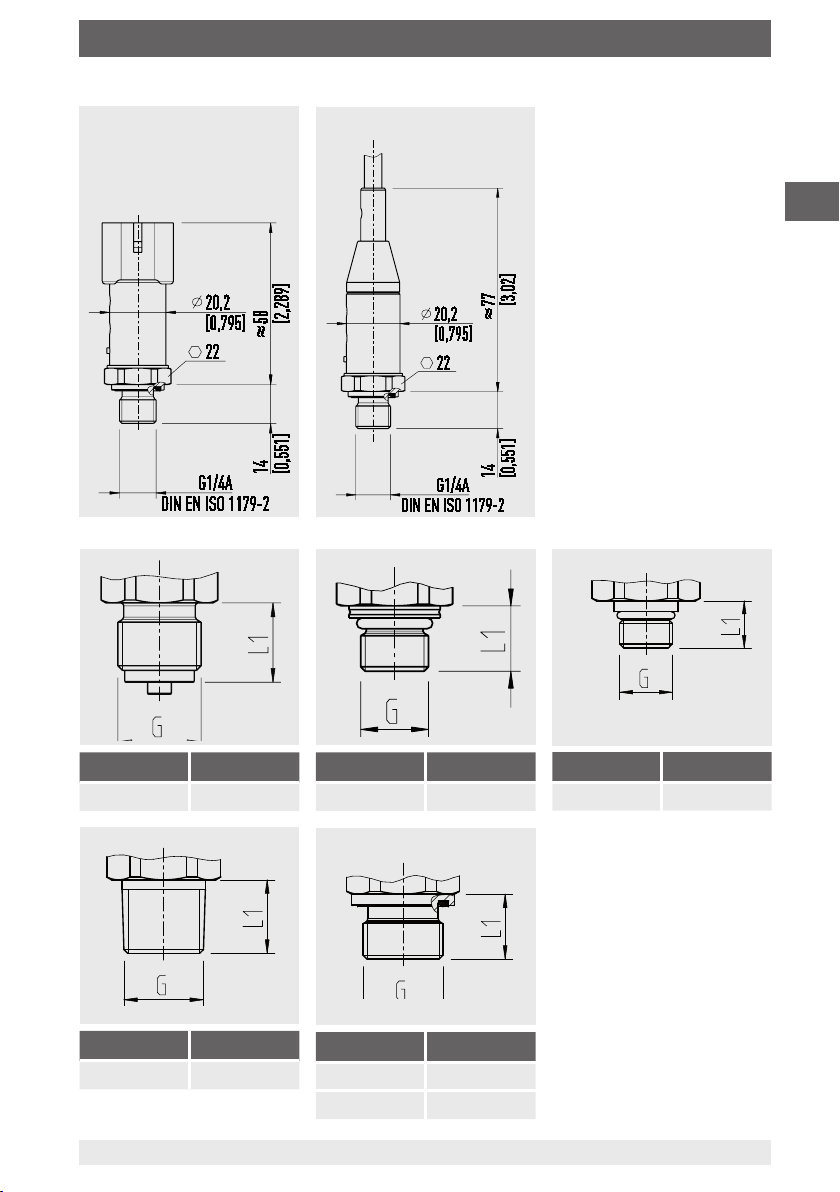

9.10 Dimensions in mm

with M12 x 1 circular connector with Metri-Pack series 150 with Deutsch DT04-3P

20

WIKA operating instructions, OEM pressure sensor, model MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 21

9. Specifications

with AMP Superseal 1.5

with cable outlet

EN

G L1

G ¼ B 13 [0.51]

G L1

¼ NPT 13 [0.51]

14136172.03 11/2019 EN/DE/FR/ES

G L1

M14 x 1.5 13.5 [0.53]

G L1

G ¼ A 14 [0.55]

M14 x 1.5 14 [0.55]

G L1

7/16-20 UNF 12 [0.47]

21WIKA operating instructions, OEM pressure sensor, model MH-3

Page 22

9. Specifications

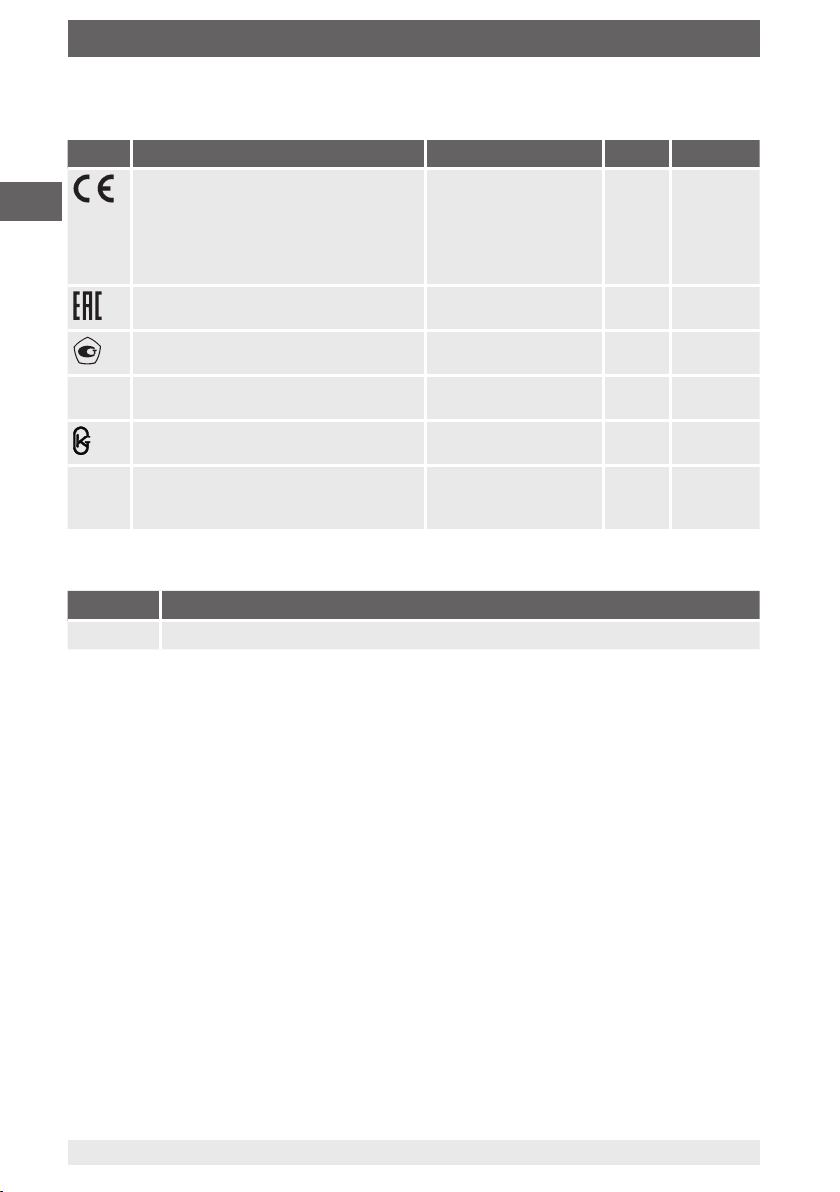

9.11 Approvals

Logo Description Country MH-3 MH-3-HY

EU declaration of conformity

■

EN

-

-

EMC directive, EN 61326 emission

(group 1, class B) and immunity (industrial application)

■

Pressure equipment directive

■

RoHS directive

EAC

EMC directive

GOST

Metrology, measurement technology

MTSCHS

Permission for commissioning

MazInMetr

Metrology, measurement technology

EC79/2009

Type approval for hydrogen-powered

vehicles

Manufacturer‘s information and certificates

Logo Description

- MTTF: > 100 years (only applies to model MH-3)

European Union x x

Eurasian Economic

Community

Russia x -

Kazakhstan x -

Kazakhstan x -

European Union - x

x -

Approvals and certificates, see website

For information on tapped holes and welding sockets, see technical information

IN 00.14 at www.wika.com.

For special models MH-30000 other technical specifications apply. Please note the

specifications stated on the order confirmation and the delivery note.

For further specifications see WIKA data sheet PE 81.59 and the order documentation.

22

WIKA operating instructions, OEM pressure sensor, model MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 23

Inhalt

Inhalt

1. Allgemeines 24

2. Aufbau und Funktion 25

3. Sicherheit 26

4. Transport, Verpackung und Lagerung 28

5. Inbetriebnahme, Betrieb 29

6. Störungen 31

7. Wartung und Reinigung 32

8. Demontage, Rücksendung und Entsorgung 33

9. Technische Daten 35

Konformitätserklärungen finden Sie online unter www.wika.de

DE

14136172.03 11/2019 EN/DE/FR/ES

23WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 24

1. Allgemeines

1. Allgemeines

■

Das in der Betriebsanleitung beschriebene Gerät wird nach dem aktuellen Stand der

Technik konstruiert und gefertigt. Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und Umweltkriterien. Unsere Managementsysteme sind

DE

nach ISO 9001 und ISO 14001 zertifiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden. Betriebsanleitung an nachfolgende Benutzer oder Besitzer des Gerätes weitergeben.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- Zugehöriges Datenblatt: PE 81.59

- Anwendungsberater:

Tel.: +49 9372 132-0

Fax: +49 9372 132-406

info@wika.com

24

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 25

2. Aufbau und Funktion

2. Aufbau und Funktion

2.1 Überblick

Elektrischer Anschluss (je nach Ausführung)

Gehäuse

Prozessanschluss, Schlüsselfläche

Prozessanschluss, Gewinde

2.2 Signalbegrenzung (nicht für MH-3-HY)

Das Ausgangssignal eines Drucksensors kann über dem nominellen maximalen Signalwert liegen, sofern keine Signalbegrenzung eingestellt ist. Ebenso kann das Ausgangssignal unter dem nominellen minimalen Signalwert liegen. Dieser undefinierte Zustand

kann einen Fehler in der Maschine (Software) des Kunden verursachen. Die Signalbegrenzung beschränkt das Ausgangssignal auf einen vom Kunden zu definierenden

Minimal- bzw. Maximalwert.

DE

2.3 Diagnosefunktion

Anhand des Ausgangssignales lassen sich Fehlerzustände erkennen und mittels

Software bewerten. Somit können permanente und temporäre Fehler unterschieden

werden.

2.4 CDS-System

Alle Prozessanschlüsse verfügen über das CDS-System. Der Durchmesser des Druckkanals ist verringert, um Druckspitzen und Kavitation entgegenzuwirken

2.5 Lieferumfang

■

Drucksensor

■

Betriebsanleitung (bei Typ MH-3-HY)

Lieferumfang mit dem Lieferschein abgleichen.

14136172.03 11/2019 EN/DE/FR/ES

25WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 26

3. Sicherheit

3. Sicherheit

3.1 Symbolerklärung

WARNUNG!

... weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

DE

3.2 Bestimmungsgemäße Verwendung

Der Drucksensor dient der Messung von Druck. Der gemessene Druck wird als elektrisches Signal ausgegeben.

Der Drucksensor Typ MH-3 ist für den Einsatz in mobilen Arbeitsmaschinen bestimmt.

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

... weist auf eine möglicherweise gefährliche Situation hin, die zu geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden

führen kann, wenn sie nicht gemieden wird.

Information

... hebt nützliche Tipps und Empfehlungen sowie Informationen für einen

effizienten und störungsfreien Betrieb hervor.

Der Drucksensor MH-3-HY für mobile Wasserstoffanwendungen dient üblicherweise zur

Überwachung des Tankdruckes und des Druckes nach dem Reduzierventil in wasserstoffbetriebenen Fahrzeugen, speziell Flurförderfahrzeugen, Nutz-/Kommunalfahrzeugen und Bussen. Die genaue Position des Sensors ist dabei Kunden- und Applikationsabhängig.

Den Drucksensor nur in Anwendungen verwenden, die innerhalb seiner technischen

Leistungsgrenzen liegen (z. B. max. Umgebungstemperatur, Materialverträglichkeit, ...).

→ Leistungsgrenzen siehe Kapitel 9 „Technische Daten“

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwendet werden.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

26

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 27

3. Sicherheit

Technische Einschränkungen

■

Ein dauerhafter Betrieb im Überlastbereich ist nicht zulässig. Oberhalb des Betriebsdruckes bis zur Überlastgrenze arbeitet der Drucksensor außerhalb seiner Spezifikation. Die Überlastgrenze ist dafür gedacht, dass der Drucksensor als Teil eines

Druckbehältersystems während der Druckfestigkeitsprüfung nicht beschädigt wird.

■

Die Überlastgrenze darf zu keinem Zeitpunkt überschritten werden, auch nicht beim

Auftreten von Fehlern in der Endanwendung. Belastungen oberhalb der Überlastgrenze können irreversible Schäden hervorrufen, die z. B. zu dauerhaften Messfehlern führen.

Besondere Hinweise aufgrund des Mediums Wasserstoff (Typ MH-3-HY)

Der angebotene Sensor verwendet die medienberührten Werkstoffe 2.4711 und 1.4404.

Diese Werkstoffe sind beständig gegen Wasserstoffversprödung.

Bei einer Temperatur von bis zu 30 °C beträgt die Stabilität unter Wasserstoffeinfluss

typisch 1 %/Jahr, maximal 3 %/Jahr.

Aufgrund von Wasserstoffdiffusion in die Sensorstrukturen kann es in Abhängigkeit der

Zeit zum Driften des Signals kommen. Die Zeitdauer bis zum Auftreten einer relevanten Signaldrift und die Größe der Signaldrift hängen hauptsächlich von Faktoren wie

der Temperatur des Wasserstoffs, dem Wasserstoffanteil im Messmedium sowie der

verwendeten Membranstärke des Drucksensors ab.

Es wird ausdrücklich empfohlen, dass der Anwender die ausgewählte Produktausführung in der/den vorgesehenen Applikation(en) mit den spezifizierten Umgebungsbedingungen auf Eignung testet.

DE

3.3 Personalqualifikation

Fachpersonal

Das vom Betreiber autorisierte Fachpersonal ist aufgrund seiner fachlichen Ausbildung,

seiner Kenntnisse der Mess- und Regelungstechnik und seiner Erfahrungen sowie

Kenntnis der landesspezifischen Vorschriften, geltenden Normen und Richtlinien in der

Lage, die beschriebenen Arbeiten auszuführen und mögliche Gefahren selbstständig zu

erkennen.

3.4 Persönliche Schutzausrüstung

Die persönliche Schutzausrüstung dient dazu, das Fachpersonal gegen Gefahren

zu schützen, die dessen Sicherheit oder Gesundheit bei der Arbeit beeinträchtigen

könnten. Beim Ausführen der verschiedenen Arbeiten an und mit dem Gerät muss das

Fachpersonal persönliche Schutzausrüstung tragen.

Im Arbeitsbereich angebrachte Hinweise zur persönlichen Schutzausrüstung

befolgen!

Die erforderliche persönliche Schutzausrüstung muss vom Betreiber zur Verfügung

gestellt werden.

14136172.03 11/2019 EN/DE/FR/ES

27WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 28

3. Sicherheit/ 4. Transport, Verpackung und Lagerung

5

3

2

3.5 Beschilderung, Sicherheitskennzeichnungen

Typenschilder

wika.com

DE

MH-3

1 Erzeugnis-Nr. 3 Kodiertes Herstelldatum

2 Serien-Nr. 4 Messbereich

1 Erzeugnis-Nr. 4 Technische Daten

2 Zulassungen 5 Kodiertes Herstelldatum

3 Nominal Working Pressure (NWP)

Nominal Working Pressure nach 79/2009/EG, entspricht Nennbetriebsdruck bei 15 °C

4. Transport, Verpackung und Lagerung

4.1 Transport

Drucksensor auf eventuell vorhandene Transportschäden untersuchen.

Offensichtliche Schäden unverzüglich mitteilen.

1

2

4

3

5

4.2 Verpackung und Lagerung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen optimalen

Schutz (z. B. wechselnder Einbauort, Reparatursendung).

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: siehe Kapitel 9 „Technische Daten“

■

Feuchtigkeit: 67 % relative Feuchte (keine Betauung)

Folgende Einflüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

28

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 29

4. Transport, .../5. Inbetriebnahme, Betrieb

Das Gerät in der Originalverpackung an einem Ort lagern, der die oben gelisteten

Bedingungen erfüllt. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät

wie folgt verpacken und lagern:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

5. Inbetriebnahme, Betrieb

5.1 Gerät montieren

Anforderungen an Montagestelle

Die Montagestelle muss folgende Bedingungen erfüllen:

■

Ausreichend Platz für eine sichere elektrische Installation.

■

Zulässige Umgebungs- und Messstofftemperaturen bleiben innerhalb der Leistungsgrenzen. Mögliche Einschränkungen des Umgebungstemperaturbereichs durch

verwendeten Gegenstecker berücksichtigen.

→ Leistungsgrenzen siehe Kapitel 9 „Technische Daten“

Abdichtungsvarianten

Zylindrische Gewinde

Dichtfläche mit Flachdichtung, Dichtlinse oder

WIKA-Profildichtung abdichten.

DE

Kegelige Gewinde

Gewinde mit Dichtwerkstoff umwickeln

(z. B. PTFE-Band).

Gerät montieren

Der max. Drehmoment ist abhängig von der Montagestelle (z. B.

Werkstoff und Form). Bei Fragen wenden Sie sich an unseren Anwendungsberater.

→ Kontaktdaten siehe Kapitel 1 „Allgemeines“ oder Rückseite der

Betriebsanleitung.

14136172.03 11/2019 EN/DE/FR/ES

nach EN 837

NPT, R und PT

nach ISO 1179-2

(ehemals DIN 3852-E)

29WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 30

5. Inbetriebnahme, Betrieb

1. Dichtfläche abdichten (→ siehe „Abdichtungsvarianten“).

.

Drucksensor handfest in Montagestelle einschrauben.

2

.

Mit Drehmomentschlüssel über Schlüsselfläche anziehen.

3

5.2 Gerät elektrisch anschließen

Anforderungen an Spannungsversorgung

DE

Hilfsenergie: siehe Kapitel 9 „Technische Daten“

Anforderungen an elektrische Verbindung

■

Kabeldurchmesser passt zur Kabeldurchführung des Gegensteckers.

■

Kabelverschraubung und Dichtungendes Gegensteckers sitzen korrekt.

■

Bei Kabelausgängen kann keine Feuchtigkeit am Kabelende eindringen.

Anforderung an Schirmung und Erdung

■

Den Drucksensor über den Prozessanschluss erden (Typ MH-3).

■

Der Anschluss erfolgt im Fahrzeug mit einer geeigneten, der Regelung 10 entsprechenden, Spannungsversorgung/Steuergerät (MH-3-HY).

■

Der Anschluss an Fahrzeug-Masse erfolgt über den Prozessanschluss (MH-3-HY).

Gemäß EN 61326-1 müssen bei Außeninstallationen Störungen durch Stoßspannungen berücksichtigt werden. Zum Schutz des Gerätes muss der Anschluss mit einem

geschirmten Kabel erfolgen. Der Schirm des Kabels muss auf mindestens einer Seite

mit Erde bzw. einem geeigneten Bezugspotential verbunden werden. Optional ist eine

geeignete externe Maßnahme zum Schutz vor Stoßspannungen vorzusehen.

Gerät anschließen

1. Gegenstecker oder Kabelausgang konfektionieren.

→ Siehe „Anschlussbelegungen“

.

2

Steckverbindung herstellen.

Anschlussbelegungen

Siehe Kapitel 9. „Technische Daten“.

30

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 31

6. Störungen

6. Störungen

VORSICHT!

Körperverletzungen, Sach- und Umweltschäden

Können Störungen mit Hilfe der aufgeführten Maßnahmen nicht beseitigt

werden, Drucksensor unverzüglich außer Betrieb setzen.

▶

Sicherstellen, dass kein Druck bzw. Signal mehr anliegt und gegen

versehentliche Inbetriebnahme schützen.

▶

Kontakt mit dem Hersteller aufnehmen.

▶

Bei notwendiger Rücksendung die Hinweise unter Kapitel 8.2

„Rücksendung“ beachten.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch gefährliche

Messstoffe

Bei Kontakt mit gefährlichen Messstoffen (z. B. Sauerstoff, Acetylen,

brennbaren oder giftigen Stoffen), gesundheitsgefährdenden Messstoffen (z. B. ätzend, giftig, krebserregend, radioaktiv) sowie bei Kälteanlagen, Kompressoren besteht die Gefahr von Körperverletzungen, Sachund Umweltschäden.

▶

Am Gerät können im Fehlerfall aggressive Messstoffe mit extremer

Temperatur und unter hohem Druck oder Vakuum anliegen.

▶

Bei diesen Messstoffen müssen über die gesamten allgemeinen

Regeln hinaus die einschlägigen Vorschriften beachtet werden.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 3.4 „Persönliche

Schutzausrüstung“).

DE

Kontaktdaten siehe Kapitel 1 „Allgemeines“ oder Rückseite der Betriebsanleitung.

Störungen Ursachen Maßnahmen

Kunststoff ist ausgeblichen UV-Einstrahlung Keine Maßnahmen notwendig

Kein Ausgangssignal Leitungsbruch Durchgang überprüfen, ggf.

Keine/Falsche Hilfsenergie Hilfsenergie korrigieren

Kein/Falsches Ausgangssignal

Gleichbleibendes Ausgangssi-

gnal bei Druckänderung

14136172.03 11/2019 EN/DE/FR/ES

Verdrahtungsfehler Verdrahtung korrigieren

Mechanische Überlastung

durch Überdruck

Verfärbung ist unbedenklich

Leitung austauschen

Gerät austauschen, bei

wiederholtem Ausfall Kontakt

mit dem Hersteller aufnehmen.

31WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 32

6. Störungen/7. Wartung und Reinigung

Störungen Ursachen Maßnahmen

Signalspanne zu klein/fällt ab Mechanische Überlastung

durch Überdruck

Membranbeschädigung, z. B.

durch Schläge, abrasives/

DE

Signalspanne schwankend/

ungenau

Abweichendes Nullpunktsignal Zu hohe/niedrige Einsatztem-

aggressives Medium; Korrosion an Membran oder Prozessanschluss; Übertragungsmedium fehlt

Dichtung/Dichtfläche beschädigt oder verschmutzt,

Dichtung sitzt nicht korrekt,

Gewindegänge verkantet

EMV-Störquellen in Umgebung,

z. B. Frequenzumrichter

Zu hohe/niedrige Einsatztemperaturen

Gerät nicht geerdet Gerät erden

Stark schwankender Druck des

Prozessmediums

peraturen

Abweichende Einbaulage Nullpunkt korrigieren

Überlast-Druckgrenze

überschritten

Im unberechtigten Reklamationsfall berechnen wir die Reklamationsbearbeitungskosten.

Gerät austauschen, bei wiederholtem Ausfall Kontakt mit dem

Hersteller aufnehmen.

Gerät austauschen, bei

wiederholtem Ausfall Kontakt

mit dem Hersteller aufnehmen.

Dichtung/Dichtfläche säubern,

ggf. Dichtung austauschen

Gerät abschirmen; Leitungsabschirmung; Störquelle entfernen

Temperatur senken/erhöhen

Dämpfung; Beratung durch

Hersteller

Temperatur senken/erhöhen

Druck reduzieren

7. Wartung und Reinigung

7.1 Wartung

Dieser Drucksensor ist wartungsfrei.

Reparaturen sind ausschließlich vom Hersteller durchzuführen.

Regelmäßige Kontrolle der Dichtung durch den Betreiber notwendig.

32

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 33

7. .../8. Demontage, Rücksendung und Entsorgung

7.2 Reinigung

VORSICHT!

Ungeeignete Reinigungsmittel

Eine Reinigung mit ungeeigneten Reinigungsmitteln kann Gerät und

Typenschild beschädigen.

▶

Keine aggressiven Reinigungsmittel verwenden.

▶

Keine harten oder spitzen Gegenstände verwenden.

▶

Keine scheuernden Tücher oder Schwämme verwenden.

Geeignete Reinigungsmittel

■

Wasser

■

Handelsüblicher Geschirrreiniger

Gerät reinigen

▶

Geräteoberfläche mit weichem, feuchten Tuch abwischen.

8. Demontage, Rücksendung und Entsorgung

8.1 Demontage

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch gefährliche

Messstoffe

Bei Kontakt mit gefährlichen Messstoffen (z. B. Sauerstoff, Acetylen,

brennbaren oder giftigen Stoffen), gesundheitsgefährdenden Messstoffen (z. B. ätzend, giftig, krebserregend, radioaktiv) sowie bei Kälteanlagen, Kompressoren besteht die Gefahr von Körperverletzungen, Sachund Umweltschäden.

▶

Am Gerät können im Fehlerfall aggressive Messstoffe mit extremer

Temperatur und unter hohem Druck oder Vakuum anliegen.

▶

Notwendige Schutzausrüstung tragen (siehe Kapitel 3.4 „Persönliche

Schutzausrüstung“).

DE

Gerät demontieren

1. Gerät stromlos schalten.

.

2

Elektrische Verbindung trennen.

.

Gerät mit Schraubenschlüssel über Schlüsselfläche ausschrauben.

3

14136172.03 11/2019 EN/DE/FR/ES

33WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 34

8. Demontage, Rücksendung und Entsorgung

8.2 Rücksendung

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoffen (Säuren, Laugen,

Lösungen, etc.) sein und sind daher vor der Rücksendung zu reinigen.

DE

Zur Rücksendung des Gerätes die Originalverpackung oder eine geeignete Transportverpackung verwenden.

8.3 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezifischen Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

WARNUNG!

Körperverletzungen, Sach- und Umweltschäden durch

Messstoffreste

Messstoffreste im ausgebauten Gerät können zur Gefährdung von Personen, Umwelt und Einrichtung führen.

▶

Bei Gefahrenstoffen das Sicherheitsdatenblatt für den entsprechenden Messstoff beilegen.

▶

Gerät reinigen, siehe Kapitel 7.2 „Reinigung“.

Hinweise zur Rücksendung befinden sich in der Rubrik „Service“ auf

unserer lokalen Internetseite.

Nicht mit dem Hausmüll entsorgen. Für eine geordnete Entsorgung

gemäß nationaler Vorgaben sorgen.

34

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 35

9. Technische Daten

9. Technische Daten

9.1 Messbereiche

Relativdruck MH-3 MH-3-HY

bar 0 ... 6 x -

0 ... 10 x 0 ... 16 x 0 ... 20 - x

0 ... 25 x x

0 ... 40 x x

0 ... 60 x x

0 ... 100 x x

0 ... 160 x x

0 ... 250 x x

0 ... 400 x x

0 ... 600 x x

psi 0 … 100 x -

0 … 160 x 0 … 200 x 0 ... 300 x x

0 ... 500 x x

0 ... 1.000 x x

0 ... 1.500 x x

0 ... 2.000 x x

0 ... 3.000 x x

0 ... 5.000 x x

0 ... 8.000 x x

MPa (1 bar = 0,1 MPa)

DE

Überlastsicherheit: 2-fach (für einzelne psi-Messbereiche bei Typ MH-3-HY abweichend)

Vakuumfestigkeit: Ja

9.2 Ausgangssignale

Signalart Signal MH-3 MH-3-HY

Strom (2-Leiter) 4 ... 20 mA x x

Spannung (3-Leiter) DC 0 ... 10 V x -

DC 1 ... 5 V x DC 1 ... 6 V x -

Ratiometrisch DC 0,5 ... 4,5 V x x

14136172.03 11/2019 EN/DE/FR/ES

35WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 36

9. Technische Daten

Bürde

■

4 ... 20 mA: ≤ (Hilfsenergie - 10 V)/0,02 A

■

DC 0 ... 10 V: > 5 kΩ

■

DC 1 ... 5 V: > 2,5 kΩ

■

DC 1 ... 6 V: > 5 kΩ

■

DC 0,5 ... 4,5 V: > 4,5 kΩ

DE

9.3 Spannungsversorgung

Hilfsenergie

Die Hilfsenergie ist abhängig vom gewählten Ausgangssignal.

■

4 ... 20 mA: DC 10 ... 36 V

■

DC 0 ... 10 V: DC 14 ... 36 V

■

DC 1 ... 5 V: DC 8 ... 36 V

■

DC 1 ... 6 V: DC 9 ... 36 V

■

DC 0,5 ... 4,5 V: DC 4,5 ... 5,5 V

Stromaufnahme

Die Stromaufnahme ist abhängig vom gewählten Ausgangssignal.

■

4 ... 20 mA < 30 mA

■

DC 0 ... 10 V < 10 mA

■

DC 1 ... 5 V < 10 mA

■

DC 1 ... 6 V < 10 mA

■

DC 0,5 ... 4,5 V < 10 mA

9.4 Referenzbedingungen (nach IEC 61298-1)

Temperatur: 15 ... 25 °C [59 ... 77 °F]

Luftdruck: 860 ... 1.060 mbar [12,5 ... 15,4 psi]

Luftfeuchte: 45 ... 75 % r. F.

Hilfsenergie: DC 24 V

Einbaulage: Kalibriert bei senkrechter Einbaulage mit dem Prozessanschluss nach

unten.

9.5 Genauigkeitsangaben

Genauigkeit bei Referenzbedingungen

≤ ±1 % der Spanne für Messbereiche ≥ 40 bar [≥ 500 psi]

≤ ±2 % der Spanne für Messbereiche < 40 bar [< 500 psi]

Einschließlich Nichtlinearität, Hysterese, Nullpunkt- und Endwertabweichung (entspricht

Messabweichung nach IEC 61298-2).

Nichtlinearität (nach IEC 61298-2)

≤ ±0,25 % der Spanne für Messbereiche ≥ 40 bar [≥ 500 psi]

≤ ±0,40 % der Spanne für Messbereiche < 40 bar [< 500 psi]

36

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 37

9. Technische Daten

Temperaturfehler bei -40 ... +100 °C [-40 ... +212 °F]

Mittlerer Temperaturkoeffizient Nullpunkt:

≤ ±0,15 % der Spanne/10 K für Messbereiche ≥ 40 bar [≥ 500 psi]

Für Messbereiche < 40 bar [< 500 psi]: Auf Anfrage

Mittlerer Temperaturkoeffizient Spanne: ≤ ±0,08 % der Spanne/10 K

Einschwingzeit

≤ 2 ms

Langzeitstabilität

≤ ±0,2 % der Spanne/Jahr für Messbereiche ≥ 40 bar [≥ 500 psi]

≤ ±0,3 % der Spanne/Jahr für Messbereiche < 40 bar

[< 500 psi]

Bei Typ MH-3-HY:

Messstofftemperaturbereich -40 ... +30 °C [-40 ... +86 °F]:

typ. ≤ ±1 %/max. ≤ ±3 % der Spanne/Jahr

Es wird ausdrücklich empfohlen, dass der Anwender die ausgewählte Produktausführung in der/den vorgesehenen Applikation(en) mit den spezifizierten Umgebungsbedingungen auf Eignung testet.

9.6 Einsatzbedingungen

Schutzarten (nach IEC 60529)

Die Schutzart ist abhängig vom Typ des elektrischen Anschlusses.

Elektrischer Anschluss Schutzart

Deutsch DT04-3P (3-polig) IP67 x

Delphi Stecker Metri-Pack Serie 150,

3-polig

Rundstecker M12 x 1 (4-polig) IP67 x

AMP Superseal Stecker 1.5, 3-polig IP67 x x

Kabelausgang (0,5/1/2,5 m), 2-polig IP6K9K x

Kabelausgang (0,5/1/2,5 m), 3-polig IP6K9K x

1) Die angegebenen Schutzarten gelten nur im gesteckten Zustand mit Gegensteckern entsprechender Schutzart.

IP67 x x

1)

MH-3 MH-3-HY

DE

Vibrationsbeständigkeit

20 g (nach IEC 60068-2-6)

Schockfestigkeit

500 g (nach IEC 60068-2-27)

Zulässige Temperaturbereiche

14136172.03 11/2019 EN/DE/FR/ES

37WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 38

9. Technische Daten

MH-3 MH-3-HY

Umgebung -40 ... +100 °C

[-40 ... +212 °F]

Messstoff -40 ... +125 °C

[-40 ... +257 °F]

Lagerung -40 ... +100 °C

DE

[-40 ... +212 °F]

9.7 Elektrische Anschlüsse

Kurzschlussfestigkeit: S+ gegen U

-

Verpolungssschutz: U+ gegen U- (kein Verpolschutz bei ratiometrischem Ausgangssignal)

Isolationsspannung: DC 500 V

Anschlussschemen

Rundstecker M12 x 1 (4-polig) 2-Leiter 3-Leiter

U

+

U

-

S

+

1 1

3 3

- 4

-40 ... + 85 °C

[-40 ... +185 °F]

-40 ... + 85 °C

[-40 ... +185 °F]

-40 ... + 85 °C

[-40 ... +185 °F]

Metri-Pack Serie 150 (3-polig) 2-Leiter 3-Leiter

U

+

U

-

S

+

B B

A A

- C

AMP Superseal 1,5 (3-polig) 2-Leiter 3-Leiter

U

+

U

-

S

+

3 3

1 1

- 2

Deutsch DT04-3P (3-polig) 2-Leiter 3-Leiter

38

U

+

U

-

S

+

A A

B B

- C

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 39

9. Technische Daten

Kabelausgang 2-Leiter 3-Leiter

U

+

U

-

S

+

Aderquerschnitt 0,75 mm

2

(mit Aderendhülsen)

Kabeldurchmesser 6,6 mm

Kabellänge 0,5 m oder 2 m

Legende

U

Positiver Versorgungsanschluss

+

U-Negativer Versorgungsanschluss

Analogausgang

S

+

9.8 Prozessanschlüsse

braun braun

grün grün

- weiß

DE

Norm Gewinde-

größe

EN 837 G ¼ B 600 bar

DIN EN ISO 1179-2

(ehemals DIN 3852-E)

DIN EN ISO 9974-2

(ehemals DIN 3852-E)

ISO 6149-2 M14 x 1,5 600 bar

SAE J514 Fig.34B 7/16-20

ANSI/ASME B1.20.1 ¼ NPT 600 bar

1) Details sind in der jeweiligen Anwendung separat zu prüfen. Die angegebenen Werte für den max. Nenndruck

dienen nur zur groben Orientierung. Die Werte hängen von der Temperatur, der verwendeten Dichtung, dem

gewählten Drehmoment, der Art und dem Material des Gegengewindes und den vorherrschenden Betriebsbedingungen ab.

2) Typ MH-3-HY wird ohne Dichtung geliefert. Je nach Prozessanschluss und Messbereich, inklusive der Überlastsicherheit, muss eine entsprechende Dichtung gewählt werden.

G ¼ A 600 bar

M14 x 1,5 600 bar

UNF-2A

Max. Nenn-

1)

druck

[8.000 psi]

[8.000 psi]

[8.000 psi]

[8.000 psi]

600 bar

[8.000 psi]

[8.000 psi]

MH-3 MH-3-HY Dichtung und Temperatur-

bereich

Standard

(MH-3)

x x Kupfer

-40 ... +125 °C

[-40 ... +257 °F]

x - NBR

-40 ... +100 °C

[-40 ... +212 °F]

x - - -

x - - -

x x - -

x x - -

2)

Option

(MH-3)

CrNi-Stahl

-40 ... +125 °C

[-40 ... +257 °F]

FPM/FKM

-40 ... +125 °C

[-40 ... 257 °F]

Die unter „Standard“ aufgelisten Dichtungen sind im Lieferumfang enthalten (nur für

Typ MH-3).

14136172.03 11/2019 EN/DE/FR/ES

39WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 40

9. Technische Daten

CDS-System

Alle Prozessanschlüsse verfügen über das CDS-System.

Der Durchmesser des Druckkanals ist verringert, um Druckspitzen und Kavitation

entgegenzuwirken (siehe Abb.1).

Darstellung des CDS-Systems

DE

9.9 Werkstoffe

Messstoffberührte Teile

MH-3: CrNi-Stahl

MH-3-HY: CrNi-Stahl, 2.4711

Nicht messstoffberührte Teile

Hochbeständiger, glasfaserverstärkter Kunststoff (PBT)

9.10 Abmessungen in mm

mit Rundstecker M12 x 1 mit Metri-Pack Serie 150 mit Deutsch DT04-3P

40

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 41

9. Technische Daten

mit AMP Superseal 1,5

mit Kabelausgang

DE

G L1

G ¼ B 13 [0,51]

G L1

¼ NPT 13 [0,51]

14136172.03 11/2019 EN/DE/FR/ES

G L1

M14 x 1,5 13,5 [0,53]

G L1

G ¼ A 14 [0,55]

M14 x 1,5 14 [0,55]

G L1

7/16-20 UNF 12 [0,47]

41WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

Page 42

9. Technische Daten

9.11 Zulassungen

Logo Beschreibung Land MH-3 MH-3-HY

EU-Konformitätserklärung

■

EMV-Richtlinie, EN 61326 Emission

(Gruppe 1, Klasse B) und Störfestigkeit

(industrieller Bereich)

■

DE

-

-

Druckgeräterichtlinie

■

RoHS-Richtlinie

EAC

EMV-Richtlinie

GOST

Metrologie, Messtechnik

MTSCHS

Genehmigung zur Inbetriebnahme

MazInMetr

Metrologie, Messtechnik

EC79/2009

Typgenehmigung für wasserstoffbetriebene

Kraftfahrzeuge

Herstellerinformationen und Bescheinigungen

Logo Beschreibung

- MTTF: > 100 Jahre (gilt nur für Typ MH-3)

Europäische Union x x

Eurasiche

Wirtschaftsgmeinschaft

Russland x -

Kasachstan x -

Kasachstan x -

Europäische Union - x

x -

Zulassungen und Zertifikate siehe Internetseite

Angaben zu Einschraublöchern und Einschweißstutzen siehe Technische Information

IN 00.14 unter www.wika.de.

Bei Sondertypen MH-30000 gelten abweichende technische Spezifikationen. Spezifikationen gemäß Auftragsbestätigung und Lieferschein beachten.

Weitere technische Daten siehe WIKA-Datenblatt PE 81.59 und Bestellunterlagen.

42

WIKA Betriebsanleitung OEM-Drucksensor, Typ MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 43

Sommaire

Sommaire

1. Généralités 44

2. Conception et fonction 45

3. Sécurité 46

4. Transport, emballage et stockage 48

5. Mise en service, utilisation 49

6. Dysfonctionnements 51

7. Entretien et nettoyage 53

8. Démontage, retour et mise au rebut 53

9. Spécifications 55

Déclarations de conformité disponibles en ligne sur www.wika.com

FR

14136172.03 11/2019 EN/DE/FR/ES

43Mode d'emploi WIKA, capteur de pression OEM, type MH-3

Page 44

1. Généralités

1. Généralités

■

L'instrument décrit dans le mode d'emploi est conçu et fabriqué selon les dernières

technologies en vigueur. Tous les composants sont soumis à des exigences environnementales et de qualité strictes durant la fabrication. Nos systèmes de gestion sont

certifiés selon ISO 9001 et ISO 14001.

■

FR

Ce mode d'emploi donne des indications importantes concernant l'utilisation de l'instrument. Il est possible de travailler en toute sécurité avec ce produit en respectant

toutes les consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d'application de

l'instrument.

■

Le mode d'emploi fait partie de l'instrument et doit être conservé à proximité

immédiate de l'instrument et accessible à tout moment pour le personnel qualifié.

Confier le mode d'emploi à l'utilisateur ou propriétaire ultérieur de l'instrument.

■

Le personnel qualifié doit, avant de commencer toute opération, avoir lu soigneusement et compris le mode d'emploi.

■

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

■

Sous réserve de modifications techniques.

■

Pour obtenir d'autres informations :

- Consulter notre site Internet : www.wika.fr

- Fiche technique correspondante : PE 81.59

- Conseiller applications :

Tél. : +33 1 787049-46

Fax : +33 1 343084-94

info@wika.fr

44

Mode d'emploi WIKA, capteur de pression OEM, type MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 45

2. Conception et fonction

2. Conception et fonction

2.1 Vue générale

Raccordement électrique (en fonction de la version)

Boîtier

Raccord process, six pans

Raccord process, filetage

2.2 Limitation de signal (pas pour MH-3-HY)

Le signal de sortie d'un capteur de pression peut se trouver au-dessus de la valeur

de signal maximum nominale si aucune limitation de signal n'a été réglée. De même,

le signal de sortie peut aussi se trouver en-dessous de la valeur de signal minimum

nominale. Cette condition indéfinie peut causer une erreur dans la machine (logiciel)

du client. La limitation de signal limite le signal de sortie à une valeur minimum ou

maximum qui peut être définie par le client.

2.3 Fonction de diagnostic

Au moyen du signal de sortie, des conditions défectueuses peuvent être détectées

et évaluées par un logiciel. Il est ainsi possible de faire la différence entre des défauts

permanents et des défauts temporaires.

2.4 Système CDS

Tous les raccords process sont disponibles avec le système CDS. Le diamètre du canal

de pression est réduit afin de contrer les pics de pression et la cavitation.

2.5 Détail de la livraison

■

Capteur de pression

■

Mode d'emploi (pour le type MH-3-HY)

FR

Comparer le détail de la livraison avec le bordereau de livraison.

14136172.03 11/2019 EN/DE/FR/ES

45Mode d'emploi WIKA, capteur de pression OEM, type MH-3

Page 46

3. Sécurité

3. Sécurité

3.1 Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la mort ou des blessures graves si elle n'est pas évitée.

ATTENTION !

FR

3.2 Utilisation conforme à l'usage prévu

Le capteur de pression est utilisé pour mesurer la pression. La pression mesurée est

émise sous forme de signal électrique.

… indique une situation potentiellement dangereuse et susceptible de

provoquer de légères blessures ou des dommages matériels et pour

l'environnement si elle n'est pas évitée.

Information

... met en exergue les conseils et recommandations utiles de même que

les informations permettant d'assurer un fonctionnement efficace et

normal.

Le capteur de pression type MH-3 est prévu pour être utilisé dans des engins mobiles.

Le capteur de pression MH-3-HY pour des applications d'hydrogène mobiles est

utilisé typiquement pour la surveillance de la pression de cuves et la pression après

la soupape de réduction dans des véhicules fonctionnant à l'hydrogène, en particulier

des camions industriels, des véhicules utilitaires ou municipaux et des bus. La position

exacte du capteur dépend donc du client et de l'application.

Utiliser l'instrument analytique uniquement dans des applications qui se trouvent

dans les limites de ses performances techniques (par exemple température ambiante

maximale, étendues de mesure, ...).

→ Pour limites de performance voir chapitre 9 “Spécifications”.

Ces instruments sont conçus et construits exclusivement pour une utilisation conforme

à l'usage prévu décrit ici, et ne doivent être utilisés qu'à cet effet.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage

prévu.

46

Mode d'emploi WIKA, capteur de pression OEM, type MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 47

3. Sécurité

Restrictions techniques

■

Toute opération permanente dans la plage de surpression est interdite. Au-dessus

de la pression de service, jusqu'à la limite de surpression, le capteur de pression

fonctionne en-dehors de sa spécification. La limite de surpression a pour but d'éviter

des dommages au capteur de pression, en tant que système sous pression, lors du

test de résistance à la pression.

■

Il ne faut jamais excéder la limite de surpression, même si des pannes se produisent

dans l'application finale. Les pressions supérieures à la limite de surpression peuvent

provoquer des dommages irréversibles pouvant conduire, par exemple, à des écarts

de mesure permanents.

Notes spécifiques basées sur le fluide hydrogène (type MH-3-HY)

Le capteur proposé utilise les matériaux en contact avec le fluide 2.4711 and 1.4404.

Ces matériaux sont résistants à la fragilisation due à l'hydrogène.

Avec une température allant jusqu'à 30 °C, la stabilité sous l'influence de l'hydrogène

est typiquement de 1 %/an, au maximum de 3 %/an.

En raison de la diffusion d'hydrogène dans les structures du capteur, une dérive de

signal peut se produire en fonction de la durée. La durée jusqu'à ce qu'une dérive de

signal importante se produise et la taille de la dérive de signal dépendent principalement de facteurs tels que la température de l'hydrogène, la teneur en hydrogène dans le

fluide et l'épaisseur de la membrane du capteur de pression utilisé.

Il est explicitement recommandé à l'utilisateur de tester la version de produit choisie

pour vérifier si elle convient à la ou les application(s) prévues dans les conditions

ambiantes spécifiées.

FR

3.3 Qualification du personnel

Personnel qualifié

Le personnel qualifié, autorisé par l'opérateur, est, en raison de sa formation spécialisée, de ses connaissances dans le domaine de l'instrumentation de mesure et de

régulation et de son expérience, de même que de sa connaissance des réglementations nationales et des normes en vigueur, en mesure d'effectuer les travaux décrits et

d'identifier de façon autonome les dangers potentiels.

3.4 Equipement de protection individuelle

L'équipement de protection individuelle sert à protéger le personnel qualifié contre

les dangers pouvant entraver la sécurité et la santé de ce dernier durant le travail. Le

personnel qualifié doit porter l'équipement de protection individuelle lors de l'exécution

des différents travaux sur et avec l'instrument.

Respecter les indications concernant l'équipement de protection individuelle

dans la zone de travail !

L'équipement de protection individuelle requis doit être mis à disposition par l'utilisateur.

14136172.03 11/2019 EN/DE/FR/ES

47Mode d'emploi WIKA, capteur de pression OEM, type MH-3

Page 48

3. Sécurité/4. Transport, emballage et stockage

3.5 Etiquetage, marquages de sécurité

Plaques signalétiques

wika.com

1

2

FR

1 N° Produit 3 Date de fabrication codée

2 Numéro de série 4 Etendue de mesure

1 N° Produit 4 Spécifications

2 Agréments 5 Date de fabrication codée

3 Pression de service nominale (NWP)

La pression de service nominale selon 79/2009/CE correspond à une pression de service nominale

à 15 °C

MH-3

4

4. Transport, emballage et stockage

4.1 Transport

Vérifier s'il existe des dégâts sur le capteur de pression qui pourraient être liés au transport.

Communiquer immédiatement les dégâts constatés.

3

5

4.2 Emballage et stockage

N'enlever l'emballage qu'avant le montage.

Conserver l'emballage, celui-ci offre, lors d'un transport, une protection optimale (par ex.

changement de lieu d'utilisation, renvoi pour réparation).

Conditions admissibles sur le lieu de stockage :

■

Température de stockage, voir chapitre 9 “Spécifications”

■

Humidité : 67 % d'humidité relative (sans condensation)

48

Mode d'emploi WIKA, capteur de pression OEM, type MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 49

4. Transport, .../5. Mise en service, exploitation

Eviter les influences suivantes :

■

Lumière solaire directe ou proximité d'objets chauds

■

Vibrations mécaniques, chocs mécaniques (mouvements brusques en le posant)

■

Suie, vapeur, poussière et gaz corrosifs

■

Environnements dangereux, atmosphères inflammables

Conserver l'instrument dans l'emballage original dans un endroit qui satisfait aux conditions susmentionnées. Si l'emballage d'origine n'est pas disponible, emballer et stocker

l'instrument comme suit :

1. Emballer l'instrument dans une feuille de plastique antistatique.

2. Placer l'instrument avec le matériau isolant dans l'emballage.

3. En cas de stockage prolongé (plus de 30 jours), mettre également un sachet absor-

beur d'humidité dans l'emballage.

5. Mise en service, utilisation

5.1 Montage de l'instrument

Exigences concernant le lieu d'installation

Le lieu d'installation doit remplir les conditions suivantes :

■

Un espace suffisant pour une installation électrique en toute sécurité.

■

Les températures ambiantes et du fluide admissibles restent dans les limites de

leurs performances. Considérer les restrictions possibles sur la plage de température

ambiante en fonction du contre-connecteur utilisé.

→ Pour les limites de performance voir chapitre 9 “Spécifications”

FR

Variantes de joint d'étanchéité

Filetage parallèle

Sceller la surface d'étanchéité avec un joint

d'étanchéité plat, une bague d'étanchéité de type

lentille ou un joint d'étanchéité profilé WIKA.

Filetages coniques

Envelopper les filetages avec du matériau

d'étanchéité (par exemple du ruban PTFE).

14136172.03 11/2019 EN/DE/FR/ES

selon EN 837

NPT, R et PT

selon ISO1179-2

(autrefois DIN 3852-E)

49Mode d'emploi WIKA, capteur de pression OEM, type MH-3

Page 50

5. Mise en service, utilisation

Montage de l'instrument

Le couple maximum dépend du point d'installation (par exemple matériau

et forme). Si vous avez des questions, veuillez contacter notre conseiller

applications.

→ Pour le détail des contacts voir le chapitre 1 “Généralités” ou au dos du

mode d'emploi.

1. Sceller la surface d'étanchéité (→ voir “Variantes de joints d'étanchéité”).

FR

.

2

A l'endroit d'installation, visser le capteur de pression en serrant à la main.

.

Serrer avec une clé dynamométrique en utilisant une clé plate

3

5.2 Connexion de l'instrument au système électrique

Exigences concernant la tension d'alimentation

Tension d'alimentation, voir chapitre 9 “Spécifications”.

Exigences concernant le raccordement électrique

■

Le diamètre du câble correspond au passe-câble du contre-connecteur.

■

Le presse-étoupe et les joints d'étanchéité du contre-connecteur sont posés correctement.

■

Avec les sorties câble, aucune humidité ne peut pénétrer à l'extrémité du câble.

Exigences concernant le blindage et la mise à la terre

■

Le capteur de pression doit être mis à la terre à l'aide du raccord process (type

MH-3).

■

Le raccordement est effectué dans le véhicule avec une alimentation électrique ou

une unité de commande conforme à la réglementation 10. (MH-3-HY).

■

Le raccordement à la masse du véhicule est effectué via le raccord process

(MH-3-HY).

En accord avec EN 61326-1, dans le cas d'installations situées à l'extérieur, des

défaillances causées par des surtensions doivent être prises en compte. Pour protéger

l'instrument, il faut le raccorder au moyen d'un câble blindé. Le blindage du câble doit

être connecté sur au moins un côté à la terre ou à un potentiel de référence adéquat. En

option, une mesure externe adéquate peut être prise pour assurer la protection contre

les surtensions.

Connexion de l'instrument

1. Assembler le contre-connecteur ou la sortie câble.

→ Voir “Configurations du raccordement”

.

2

Etablir la connexion.

Configurations du raccordement

Voir chapitre 9 “Spécifications”.

50

Mode d'emploi WIKA, capteur de pression OEM, type MH-3

14136172.03 11/2019 EN/DE/FR/ES

Page 51

6. Dysfonctionnements

6. Dysfonctionnements

ATTENTION !

Blessures physiques, dommages aux équipements et à l'environnement

Si des pannes ne peuvent être éliminées au moyen des mesures ici

énumérées, le capteur de pression doit être immédiatement mis hors

service

▶

S'assurer que la pression ou le signal n'est plus présent et protéger

contre une mise en service accidentelle.

▶

Contacter le fabricant.

▶

S'il est nécessaire de retourner l'instrument au fabricant, respecter les

indications mentionnées au chapitre 8.2 “Retour”.

AVERTISSEMENT !

Blessures physiques et dommages aux équipements et à l'environnement causés par un fluide dangereux

Lors du contact avec un fluide dangereux (par ex. oxygène, acétylène,

substances inflammables ou toxiques), un fluide nocif (par ex. corrosif,

toxique, cancérigène, radioactif), et également avec des installations

de réfrigération et des compresseurs, il y a un danger de blessures

physiques et de dommages aux équipements et à l'environnement.

▶

En cas d'erreur, des fluides agressifs peuvent être présents à une

température extrême et sous une pression élevée ou sous vide au

niveau de l'instrument.

▶

Pour ces fluides, les codes et directives appropriés existants doivent

être observés en plus des régulations standard.

▶

Porter les équipements de protection requis (voir chapitre 3.4 “Equipement de protection individuelle”).

FR

Pour le détail des contacts voir le chapitre 1 “Généralités” ou au dos du

mode d'emploi.

Dysfonctionnements Raisons Mesures

Le plastique se décolore Irradiation UV Pas de mesure requise

La décoloration n'a aucune

conséquence.

Pas de signal de sortie Câble sectionné Vérifier la continuité, et si

nécessaire changer le câble.