Page 1

NI-221E

INSTRUCTION MANUAL

Rev. 1 11/02

DIAPHRAGM PRESSURE SWITCHES

WEATHERPROOF:SERIES MW EXPLOSIONPROOF: SERIES MA

Models: MW-MWH Models: MA-MAH-MAG

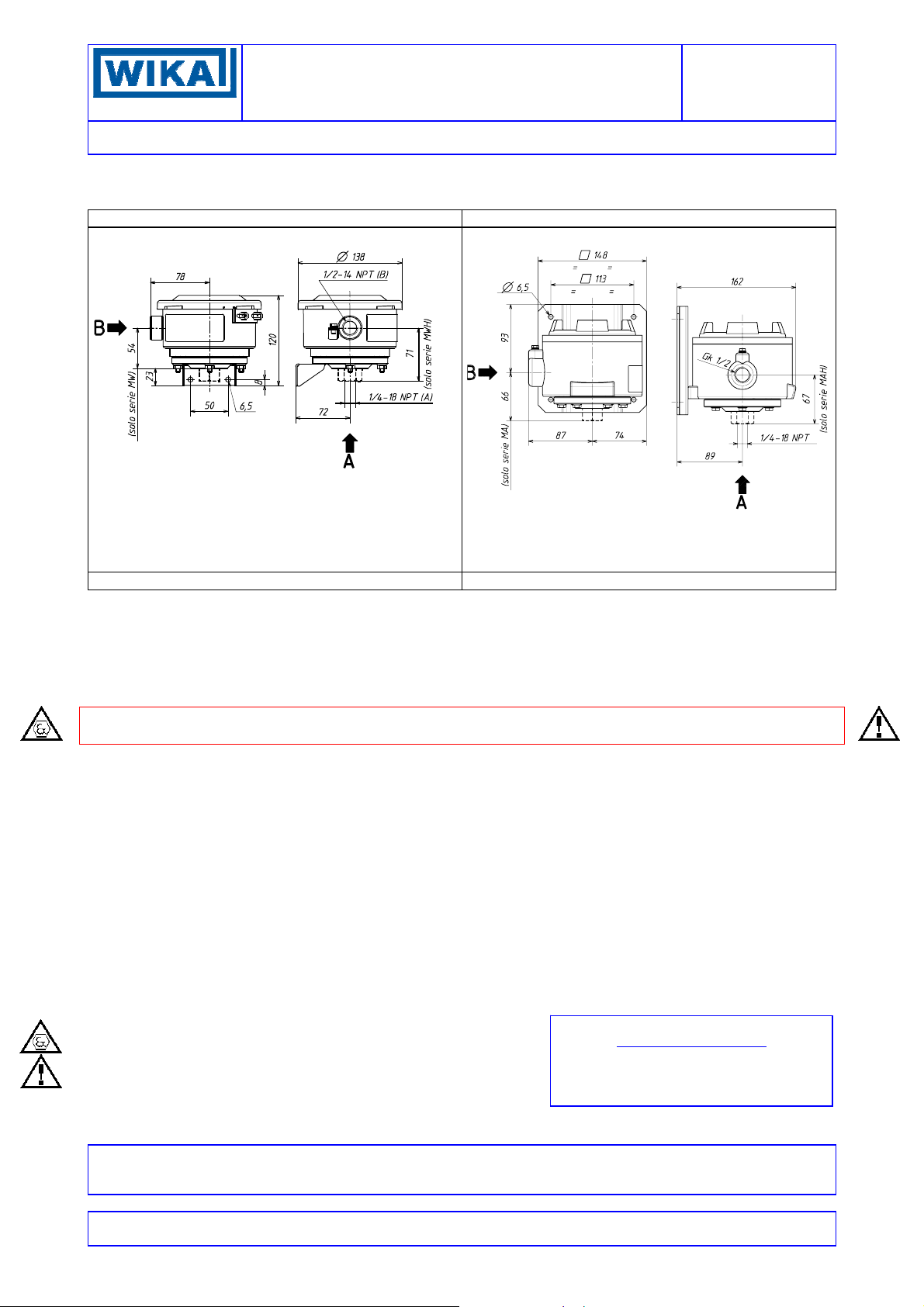

A = pressure attachment

B = cable entry

WEIGHT 1,8 kg dimensions in mm WEIGHT 3,2 kg dimensions in mm

NOTE: dimensions and weights are not binding unless released on certified drawings.

CAUTION

• Before installing, using or carrying out maintenance on the instrument it is necessary to read and understand the

indications given in the attached Instruction Manual.

• The instrument must only be installed and maintained by qualified personnel.

• INSTALLATION IS TO BE CARRIED OUT ONLY AFTER CHECKING THAT INSTRUMENT CHARACTERISTICS

ARE CONSISTENT WITH PROCESS AND PLANT REQUIREMENTS.

• The functional features of the instrument and its degree of protection are shown on the identification plate fixed to the

case.

CONTENTS:

1

GENERAL NOTES

2 OPERATING PRINCIPLE

3 IDENTIFICATION PLATE AND MARKINGS

4 SET POINT REGULATION

5 SET POINT CALIBRATION

6 MOUNTING AND CONNECTIONS

7 INSTRUMENT PLUMBING

8 PUTTING INTO OPERATION

9 FUNCTIONAL VERIFICATION

10 TROUBLESHOOTING

11 STOPPING AND DISMOUNTING

12 DEMOLITION

SAFETY INSTRUCTIONS FOR USE IN HAZARDOUS ATMOSPHERES.

RECOMMENDATIONS FOR PRESSURE SWITCH SAFE USE.

A = pressure attachment

B = cable entry

RELATED DOCUMENT

To authentified document with certificate

N° CESI 02 ATEX 144

All data, statements and recommendations supplied with this manual are based on information believed by us to be

reliable. As the conditions of effective use are beyond our control, our products are sold under the condition that the

user himself evaluates such conditions before following our recommendations for the purpose or use foreseen by him.

The present document is the property of ETTORE CELLA SPA and may not be reproduced in any form, nor used for

any purpose other than that for which it is supplied.

Page 2

INSTRUCTION MANUAL

1 GENERAL NOTES

1.1 FOREWORD

The wrong choice of a series or a model, as well as the

incorrect installation, lead to malfunction and reduce instrument life. Failure to abide by the indications given in

this manual can cause damage to the instrument, the

environment and persons.

1.2 ALLOWED OVERRANGE

Pressure exceeding the working range can be occasionally tolerated provided they remain within the limits stated

in the instrument features (vacuum or proof pressure).

Continuous pressures exceeding the working range can

be applied to the instrument provided they are clearly

stated in the instrument features. The current and voltage

values stated in the technical specifications and ratings

must not be exceeded. Transitory overages can have a

destructive effect on the switch.

1.3 MECHANICAL VIBRATION

Can generally lead to the wearing of some parts of the

instrument or cause false actuation. It is therefore recommended that the instrument be installed in a place where

there are no vibrations. In cases where this is impossible it

is a good idea to take measures to lessen the effects

(elastic supports, installation with the peg of the microswitch positioned at right angles to the vibration plane).

1.4 TEMPERATURE

Due to the temperature of both the environment and the

process fluid, the temperature of the instrument could

exceed the allowed limits (normally from -20° to +70°C).

Therefore, in case it does, suitable measures (protection

against heat radiation, fluid separators, cooling coils,

heated lockers) must be taken.

2 OPERATING PRINCIPLE

• The pressure, acting on the sensitive element (dia-

phragm), determines its elastic deformation which is used

to activate one or two electric microswitches regulated at

set point values. The microswitches are of the rapid release type with automatic rearm. When the pressure

moves away from the set values, returning towards the

normal values, the switch is rearmed. The differential gap

(difference between the set point value and the reset

value) can be set or adjustable (letter R in the contact

codes).

• Piston activated diaphragm instruments (MWH - MAH)

differ from the former as the pressure, acting on the piston

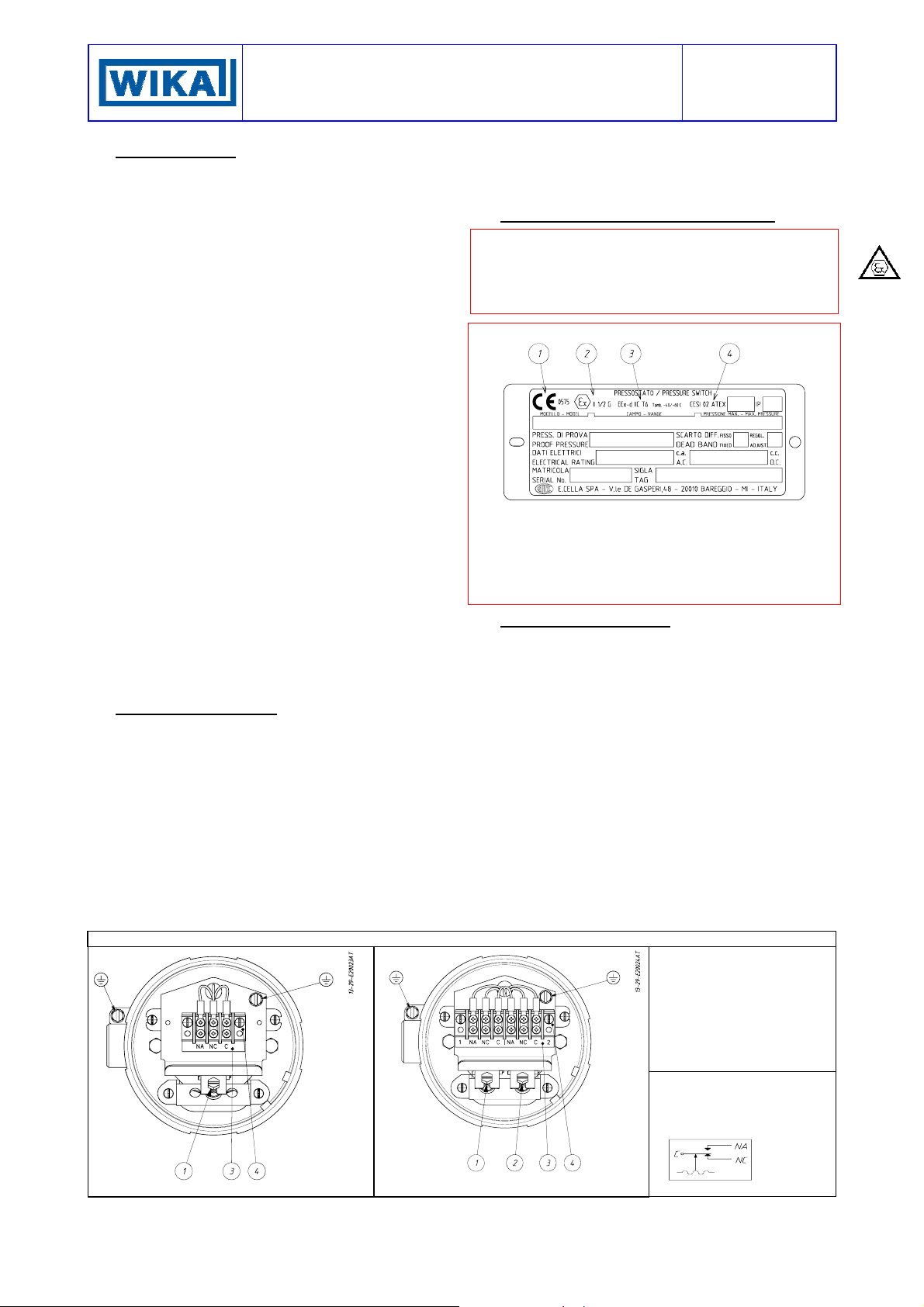

Fig. 2 - Electrical connections and adjustment screws

NI-221E

Rev. 1 11/02

element, generates a force which, applied to the diaphragm, causes an elastic deformation. This deformation

is then used as in the previous case, to activate one or two

microswitches.

3 IDENTIFICATION PLATE AND MARKINGS

The instrument is fitted with a metal plate bearing all its

functional characteristics and – in case of explosionproof

execution (Series MA) – also the markings prescribed by

standard CEI EN 50014. Fig.1 shows the plate mounted

on explosionproof instruments.

Fig. 1 - Explosionproof instruments plate

1 CE marking and identification number of the notified body

responsible for production surveillance.

2 Apparatus classification according to ATEX 949 CE directive.

3 Type of protection and ambient temperature limits of opera-

tion.

4 Notified body that issued the type certificate and number of

said certificate.

4 SET POINT REGULATION

Each microswitch is independent and can be regulated by

means of a screw (for adjustment) in such a way that it is

released when the pressure reaches (increasing or decreasing) the desired value (set point). The instrument is

usually supplied with the switches set at the setting range

value nearest to zero (factory calibration). The instrument is supplied with an adhesive rating plate showing the

set point calibration value. With factory calibration the

values are not indicated on the ratings, as these are temporary and will be modified with the definitive values. Prior

to installation the instrument must be calibrated and the

definitive calibration values written on the adhesive rating

plate using a suitable indelible ink pen.

1- Microswitch 1 set point

calibration screw

2- Microswitch 2 set point

calibration screw

3- Electrical connection identifi-

cation plate

4- Terminal block

Designation of the contacts:

C - Common

NA - Normally open

NC - Normally closed

Page 3

INSTRUCTION MANUAL

If the instrument has been ordered with a specific cali-

bration, it is a good rule to check the calibration values

marked on the relevant adhesive label, prior to installation.

The position of the adjustment screw is given in figure 2.

The effect that the direction of rotation of the adjustment

screw has is described on the adhesive plate.

5 SET POIT CALIBRATION

In order to proceed with the calibration and the periodical

functional verification of the instrument a suitable calibra-

tion circuit (fig. 4) and an adequate pressure source is

required.

5.1 PRELIMINARY OPERATIONS

5.1.1 Weatherproof pressure switches (Series MW)

Remove the blocking device fixed to the side of the instrument case (Fig. 3).

Remove the cover by rotating it in an anticlockwise direction.

Fig. 3 - Weatherproof pressure switch blocking device

NI-221E

Rev. 1 11/02

• If the circuit is open at the working pressure, the switch

closes the circuit as the pressure increases when the

desired value is reached.

• If the circuit is closed at the working pressure, the switch

opens the circuit as the pressure decreases when the

desired value is reached.

Connection of C and NC terminals

• If the circuit is closed at the working pressure, the switch

opens the circuit as the pressure increases when the

desired value is reached.

• If the circuit is open at the working pressure, the switch

closes the circuit as the pressure decreases when the

desired value is reached.

The test instrument should have a measurement range

approximately equal to or slightly wider than the pressure

switch range and should have an accuracy consistent with

the precision required to calibrate the set point.

The pressure switch must be mounted in the normal installation position, i.e. with the pressure connection pointing downwards.

Fig. 5 - Calibration circuit

a - Plumbing wire

b - Plumbing

5.1.2 Explosionproof pressure switches (Series MA)

CAUTION: do not open the cover of explosionproof pres-

sure switches (Series MA) when energized, in explosive

atmospheres.

Loosen the locking headless screw situated on the cover

using a 1,5 hexagonal key then unscrew the cover. (Fig.

4).

Fig. 4 - Explosionproof pressure switch blocking device

c - Nut

d - Blocking bracket

5.2 CALIBRATION CIRCUIT AND OPERATIONS

Prepare the control circuit as indicated in Fig.5.

The warning lamps should be connected to contact 1 or 2

in the NO or NC position according to the required contact

action.

Connection of C and NO terminals

PS - Pressure switch

CA - Test pressure gauge

V1 - Inlet valve

V2 - Discharge valve

P - Pressure source

Avoid forcing the elastic support of the microswitch by

hand or with tools. This could affect the instrument functioning.

CAUTION: if the switch is of the kind with adjustable dead

band (letter R in the contact codes) before proceeding

with the following operations it is necessary to proceed

with the adjustment of the dead band (see attachment NI-

706).

Increase the pressure in the circuit up to the desired set

point value for the first microswitch. Use a wide bladed

screwdriver, as indicated on the adhesive plate, until the

relative lamp turns on (or turns off).

- If the instrument is equipped with only one contact the

calibration is complete.

- If it is equipped with two contacts continue in the following manner.

Vary the pressure until the desired set point value for the

second microswitch is reached. Act on the adjustment

screw of the second contact.

Repeat calibrating operations on the first contact, then on

the second contact, until the required set point precision is

obtained. This is necessary due to the reciprocal influence

which the microswitches have on the sensitive element of

the instrument.

Check the calibration values (varying the pressure in the

circuit accordingly) and record them on the adhesive plate

using a pen with indelible ink.

5.3 FINAL OPERATIONS

Disconnect the instrument from the calibration circuit.

Test fluid:

air for P ≤ 10 bar

water for P > 10 bar

Page 4

INSTRUCTION MANUAL

5.3.1 Weatherproof pressure switches (Series MW)

Take the cover, ensure that the sealing gasket is correctly

fitted into its seat, and insert the cover onto the case, with

the blocking gap positioned in correspondence to the

blocking bracket.

Turn the cover clockwise closing it tightly.

Mount the blocking device as in Fig. 3.

5.3.2 Explosionproof pressure switches (Series MA).

Screw on the cover and block it using the headless screw

with which it is equipped (Fig. 4)

Mount on pressure connection and cable entry the protection caps supplied with the instrument. The protection

caps should only be definitively removed during the connection steps (see § 6).

6 MOUNTING AND CONNECTIONS

6.1 MOUNTING

Surface mount the instrument by means of the holes

provided, or pipe mount using the appropriate bracket

(see Fig. 9).

The chosen position must be such that vibrations, the

possibility of shocks or temperature changes are within

tolerable limits. The above also applies to direct mounting.

With gas or vapour process fluid, the instrument must be

positioned higher than the pipe inlet (see Fig. 8). With a

liquid process fluid, the instrument can be positioned

higher or lower, indifferently (see Fig. 7 e 8). ). In this

case, during set point calibration the negative or positive

head must be taken into account (distance h in Fig.7 e 8).

6.2 PRESSURE CONNECTIONS

For a correct installation it is necessary to:

Mount a shut-off valve with drain (root valve) on the process tube to allow the instrument to be excluded and the

connection tubing to be drained. It is recommended that

said valve has a capstan-blocking device aimed at preventing it being activated casually and without authorisation. Mount a service valve near the instrument to permit

possible functional verification on site. It is recommended

that the service valve is closed with a plug to prevent the

outlet of the process fluid caused by the incorrect use of

said valve. Mount a three-piece joint onto the threaded

attachment of the instrument to permit the easy mounting

or removal of the instrument itself. Carry out the connection using a flexible tube in such a way that variations in

the temperature of the tube itself do not force the instrument attachment. Ensure that all the pressure connections

are airtight. It is important that there are no leakages in

the circuit. Close the root valve and the relative drain

device. Close the service valve using a safety plug.

6.3 ELECTRICAL CONNECTIONS

It is recommended to carry out the electrical connections

according to the applicable standards. In case of explosionproof instruments (Series MA) see also the Standard

EN-60079-14. If the electrical connection is carried out in

a protected tube, it shall be made so that condensate is

prevented from entering instrument enclosure.

The arrangement shown in Fig. 7 or 8 is therefore recommended..

CAUTION: fittings used for the electrical connection of

the pressure switch Series MA (explosionproof) shall be

certified to Standards EN 50014 and 50018, and shall

guarantee instrument degree of protection (IP65).

Check that there is no power in the lines.

Remove the cover and carry out the cabling and connections to the terminal block (see Fig. 2).

Flexible cables with a maximum section of 1.2 mm

(16AWG) are recommended using the pre-insulated fork

2

NI-221E

Rev. 1 11/02

thimbles. Do not touch the adjustment screws and do

not bend the elastic microswitch supports in order to

prevent the instrument calibration being altered.

Ensure that no deposits or wire ends remain inside the

case.

As soon as connection steps are completed, mount the

cover on and make sure it is tight and blocked See Fig. 3

and 4.

6.4 SPECIAL NOTE FOR INSTALLATION OF

CATEGORY 1 / 2 G PRESSURE SWITCHES

Explosionproof pressure switches (Series MA) can be

installed on processes requiring apparatus of group II

category 1 in an ambient requiring apparatus of group II

category 2 (see Fig. 6).

Fig. 6 - Installation of Group II Cat. 1 / 2 G instruments

7 INSTRUMENT PLUMBING

7.1 Weatherproof p ressure switches (Series MW)

The plumbing, aimed as a guarantee against possible

tampering of the calibration and electrical connections,

can be carried out using a flexible steel wire (c) inserted

into the holes in the screw (a) and the bracket (e) provided

for this purpose (see Fig. 3).

7.2 Explosionproof pressure switches (Series MA )

Plumbing is not necessary as the cover is blocked with a

headless screw and the instrument does not have to be

opened when installed (see Fig. 4).

8 PUTTING INTO OPERATION

As the signal transmitted by the instrument is used in a

complex system, it is necessary that the means of putting

it into operation are established by those in charge of the

plant.

The instrument comes into operation as soon as the root

valve is opened. Any possible drainage of the connection

tubing can be carried out by removing the safety plug and

opening the service valve with the necessary caution.

In case of explosionproof instruments (Series MA), initial

inspections are to be carried out according to customer

procedures and at least in accordance with Standard EN60079-17.

Page 5

NI-221E

INSTRUCTION MANUAL

9 FUNCTIONAL VERIFICATION

This will be carried out according to the Client’s control

procedures. Series MW and MWH instruments can be

verified on the plant if installed as illustrated in Fig. 7 e 8.

The instruments Series MA may be checked on site only if

apparatus suitable for explosive atmospheres are used

and provided that the electric line is not energized.

If this is not the case it is necessary to stop operation,

dismount by means of the three-piece joints and carry out

the verification in a test room.

10 TROUBLESHOOTING

IMPORTANT NOTE: operations involving replacement of essential components must be carried out at our workshop, especially for instruments with explosionproof certificate; this is to guarantee the user the total and correct restoration of the product original characteristics.

MALFUNCTION PROBABLE CAUSE REMEDY

Set point shift

Poor repeatability

Slow response

No actuation or

undue actuation

Undue actuation

11 STOPPING AND DISMOUNTING

Before proceeding with these operations ensure that the

plant or machines have been put into the conditions

foreseen to allow these operations.

With reference to Figures 7 e 8

Remove the power supply (signal) from the electrical line.

Close the root valve (6) and open the drain. Remove the

plug (2), open the valve (3) and wait until the process fluid

has drained from the tubing through the drain.

Do not dispose of the process fluid into the environment, if

this can cause pollution or damage to people.

Unscrew the three-piece joint (8).

CAUTION: do not open the cover of explosionproof pressure switches (Series MA) when energized, in explosive

atmospheres.

Unscrew the three-piece joint (10) (electrical cable tubing).

Permanent deformation of the sensitive ele-

ment due to fatigue or non-tolerated overages.

Variation of the elastic features of the sensitive

element due to its chemical corrosion.

O-ring wear (only MWH and MAH)

O-ring wear (only MWH and MAH)

Air bubbles or condensation (only for types

with pressure <1 bar).

Clogged or obstructed connection line.

Root valve partially closed.

Too viscous fluid.

Root valve closed.

Microswitch contacts damaged.

Loosened electrical joints.

Interrupted or short-circuited electrical line.

Accidental shocks or excessive mechanical

vibrations.

CAUTION: do not open the cover of explosionproof pres-

sure switches (Series MA) when energized, in explosive

atmospheres.

Verification consists in checking the calibration values

and possibly regulating the adjustment screw (see §4 )

Verification consists in checking the calibration value

and possibly regulating the adjustment bush (see §5).

In case of explosionproof instruments (Series MA), inspections of the electrical installation are to be carried out

also according to customer procedures and at least in

accordance with Standard EN-60079-17.

Recalibrate or replace the sensitive element.

Recalibrate or replace the sensitive element

with another made of a suitable material. If

necessary apply a fluid separator.

Replace the piston subgroup and recalibrate.

Replace the piston subgroup and recalibrate.

Drain the process connection line and if

necessary modify it.

Check and clean line.

Open valve.

Provide instrument with suitable fluid separa-

tor.

Open the valve.

Replace the Microswitch.

Check all electrical joints.

Check the conditions of the electrical line.

Modify the mounting.

Remove the instrument cover and disconnect the electrical

cables from the terminal block and earth screws.

Remove the screws fixing the case to the panel (or pipe)

and remove the instrument, taking care to slide the electrical conductors out from the case. Mount instrument cover.

Insulate and protect cables around, if any. Temporarily

plug pipes not connected to the instrument.

In case of explosionproof instruments (Series MA) it is

recommended to follow - at least – the standard EN60079-17 for the withdrawal from service of electrical

apparatus.

12 DEMOLITION

The instruments are mainly made of stainless steel and

aluminium and therefore, once the electrical parts have

been dismounted and the parts coming into contact with

fluids which could be harmful to people or the environment

have been properly dealt with, they can be scrapped.

Rev. 1 11/02

Page 6

NI-221E

INSTRUCTION MANUAL

WEATHERPROOF EXPLOSIONPROOF

Fig. 7 - Example of connections Fig. 8 - Example of cpnnections

Rev. 1 11/02

Fig. 9 - Example of mounting

Surface mounting

Montaggio a parete

2” pipe mounting

Montaggio su staffa da 2”

NOTE With gas or vapour process fluid, the instrument

must be positioned higher than the pipe inlet (see Fig.

8). With a liquid process fluid, the instrument can be

positioned higher or lower, indifferently (see Fig. 7 e 8).

In this case, during set point calibration the negative or

positive head must be taken into account. (distance h

in Fig.7 and 8).

LEGEND

1 - Fitting

2 - Drain plug

3 - Service valve

4 - Piping

5 - Three piece fitting

6 - Root valve with drain

7 - Process piping

8 - Three piece fitting

9 - “T” fitting

10 - Three piece fitting

11 - Curve

12 - Blocking joint

13 - M6 screws (No4)

14 - Bracket for 2” pipe

15 - Horizontal pipe

16 - Vertical pipe

ETTORE CELLA SPA Viale de Gasperi, 48 - Casella Postale (P.O. Box) 96 - I 20010 Bareggio (MILANO) ITALY

Telefoni +39 029036.1146/1147/1237/1241 - FAX +39 029036.1331 E-mail: cella@ecellaspa.com

Loading...

Loading...