Page 1

Temperature Indicating Controller, Model CF2S

Operating Instructions

WIKA Operating Instructions CF2S V1.2 • 08/2004

WIKA Alexander Wiegand GmbH & Co. KG

Alexander-Wiegand-Straße 30

63911 Klingenberg/Germany

Phone (+49) 93 72/132-0

Fax (+49) 93 72/132-406

E-Mail

www.wika.de

info@wika.de

Page 2

Operating Instructions Temperature Indicating Controller CF2S

Thank you for your purchase of our Microcomputer based Temperature Indicating Controller CF2S.

This manual contains instructions for the mounting, functions, operations and notes when operating the CF2S.

For model confirmation and unit specifications, please read this instruction manual carefully

before starting operation.

To prevent accidents arising from the use of this controller, please ensure

the operator using it receives this manual.

***** Note to users *****

Before operating this controller, make sure you have understood the following.

Warning

Turn the power supply to the instrument OFF before wiring or checking.

Working or touching the terminal with the power switched ON may

result in an Electric Shock which could cause severe injury or death.

Moreover, the instrument must be grounded before the power supply

to the instrument is turned on.

Caution

• Do not apply a commercial power source to the sensor connected to the input terminal

nor allow the power source to come into contact with the sensor, as the input circuit

may be burnt out.

• This instrument should be used according to the specifications described in the manual.

If it is used outside the specifications, it may malfunction or cause fire.

• Be sure to follow the warnings, cautions and notices. If not, it could cause serious injury

or malfunction.

• Specifications of the CF2S and the contents of this instruction manual are subject to

change without notice.

• Care has been taken to assure that the contents of this instruction manual are correct,

but if there are any doubts, mistakes or questions, please inform our sales department.

• Be sure to turn the power supplied to the instrunment OFF when cleaning.

• Wipe the instrument using dry soft cloth.

(If the paint thinner is used for wiping, the instrument may be deformed or discolored.)

• The display parts are more easily damaged. Do not strike them with hard objects

or press hard on them.

• Any unauthorized transfer or copying of this document, in part or in whole, is prohibited.

• WIKA is not responsible for any damages or secondary damages incurred

as a result of using this product, including any indirect damages.

• Setup by the DIP switch and the rotary switch inside of the controller is required

before the power is turned on.

• It is recommended that the PID auto-tuning be performed on the trial run.

• It is advised to provide the protective device against such environmental conditions

which may cause damage to the device or contribute to the deterioration of its parts.

V1.2 • 08/2004 - 2 -

Page 3

Operating Instructions Temperature Indicating Controller CF2S

--- CONTENTS ---

1. Model names -------------------------------------------------------------------------------- 5

2. Name and functions of the sections -------------------------------------------- 6

3. Setup

3.1 Taking the internal assembly out ----------------------------------------------------- 7

3.2 Switch setting (multi-function) --------------------------------------------------------- 7

3.3 Insertion of the internal assembly ---------------------------------------------------- 10

4. Operations

4.1 Operating flow chart -------------------------------------------------------------------- 11

4.2 Operations

(1) PV/SV display mode ------------------------------------------------------------------ 13

(2) Main setting mode --------------------------------------------------------------------- 14

(3) Sub setting mode

Setting value memory number selection ----------------------------------------- 14

Auto-tuning Perform/Cancel --------------------------------------------------------- 14

Proportional band setting ------------------------------------------------------------- 15

Integral time setting -------------------------------------------------------------------- 15

Derivative time setting ----------------------------------------------------------------- 15

Proportional cycle setting ------------------------------------------------------------- 15

Manual reset setting ------------------------------------------------------------------- 15

Alarm 1, 2 (A1, A2) settings ---------------------------------------------------------- 16

Loop break alarm time setting ------------------------------------------------------- 16

Loop break alarm span setting ------------------------------------------------------ 16

(4) Auxiliary function setting mode 1

Setting value lock designation ------------------------------------------------------ 17

Main setting value high limit setting ------------------------------------------------ 18

Main setting value low limit setting ------------------------------------------------- 18

Sensor correction setting ------------------------------------------------------------- 18

Instrument number setting ----------------------------------------------------------- 18

Transfer rate selection ---------------------------------------------------------------- 18

Communication protocol selection ------------------------------------------------- 18

(5) Auxiliary function setting mode 2

Scaling high limit value setting ------------------------------------------------------ 19

Scaling low limit value setting ------------------------------------------------------- 19

PV filter time constant setting ------------------------------------------------------- 19

Main output high limit setting -------------------------------------------------------- 19

Main output low limit setting --------------------------------------------------------- 19

Main output ON/OFF action hysteresis setting --------------------------------- 20

Alarm 1, 2 (A1, A2) action Energized/Deenergized selections ------------- 20

Alarm 1, 2 (A1, A2) hysteresis settings ------------------------------------------- 20

Alarm 1, 2 (A1, A2) action delayed timer settings ------------------------------ 21

Display selection when control output is off ------------------------------------- 21

Main setting value rising rate setting ---------------------------------------------- 21

Main setting value falling rate setting --------------------------------------------- 21

V1.2 • 08/2004 - 3 -

Page 4

Operating Instructions Temperature Indicating Controller CF2S

(6) Program mode

Program control change -------------------------------------------------------------- 22

Step 1 to 7 time setting --------------------------------------------------------------- 23

(7) Control output OFF function -------------------------------------------------------- 24

(8) Output manipulating value and Step rest time indication mode ----------- 25

5. Setting value memory number external selection ----------------------- 25

6. Running

6.1 When using the CF2S as a Temperature controller ------------------------------ 26

6.2 When using the CF2S as a Simplified program controller ---------------------- 26

7. Action explanations

7.1 Standard action drawings --------------------------------------------------------------- 27

7.2 ON/OFF action drawings ---------------------------------------------------------------- 28

7.3 Pattern end action drawing ------------------------------------------------------------- 28

7.4 Alarm 1, 2 (A1, A2) action drawings -------------------------------------------------- 29

8. Control actions

8.1 Fuzzy self-tuning -------------------------------------------------------------------------- 31

8.2 Explanations of PID ---------------------------------------------------------------------- 31

8.3 PID auto-tuning of this controller ----------------------------------------------------- 32

9. Other functions ---------------------------------------------------------------------------- 33

10. Mounting to control panel

10.1 Site selection ------------------------------------------------------------------------------- 34

10.2 External dimension drawing ------------------------------------------------------------ 34

10.3 Panel cutout drawing --------------------------------------------------------------------- 34

10.4 Mounting ------------------------------------------------------------------------------------- 35

11. Wiring connection

11.1 Terminal arrangement -------------------------------------------------------------------- 36

11.2 Wiring connection examples ------------------------------------------------------------ 38

12. Specifications

12.1 Standard specifications ------------------------------------------------------------------ 39

12.2 Optional specifications ------------------------------------------------------------------- 42

13. Troubleshooting --------------------------------------------------------------------------- 44

14. Character table ----------------------------------------------------------------------------- 46

V1.2 • 08/2004 - 4 -

Page 5

Operating Instructions Temperature Indicating Controller CF2S

1. Model names

CF2S -3 A- / M - - - - ..... Series name CF2S

3 Control action PID

(1)

Alarm A Alarm action, output relais

Output

R Relais contact output

S Non contact voltage output (0/12 VDC)

A Current output 4 ... 20 mA

Input M Multi-range input

Power supply

Mounting provision

H

L

AC 100 ... 240 V, 50 ... 60 Hz

AC/DC 24 V

FT One-touch mounting bracket (for mounting

panel thickness 1 to 3 mm)

FS Screw bracket (for mounting panel thickness

1 to 15 mm)

Instrument configuration

B Factory adjustment, device will be configured

by the operator

?/# To customers specification

Options

2AS

2AR

2AL

CR2

CR5

IP4

(3)

Alarm 2 output

(3)

Loop break alarm output

(3)

Alarm 2 output and loop break alarm output

with common terminals

(4)

Serial communication RS 232C

(4)

Serial communication RS 485

(5)

IP 54 front protection

KAB Terminal cover

(2)

(1) Fuzzy self-tuning PID, PID, PD and ON/OFF action are selectable by internal DIP switch.

(2) 12 types of alarm action and no alarm action are selectable by internal rotary switch and DIP switch.

(3)(4) Please note that only one option from every group can be selected.

(5) Condition for this option is the screw type mounting bracket (FS).

V1.2 • 08/2004 - 5 -

Page 6

Operating Instructions Temperature Indicating Controller CF2S

2. Name and functions of the sections

(1)

(3)

(2)

[Fig. 2-1]

(1) PV display

Indicates the Process variable (PV) with the red LED.

(2) SV display

Indicates the Setting value (SV), Manipulating value (MV) or Time (TIME) with the green LED.

(3) Control output indicator (OUT)

The green LED is lit when the Control output is on.

(For the current output type, it blinks corresponding to the manipulating value at 0.125

seconds of period.)

(4) Alarm 1 (A1) output action or Pattern end 1 output indicator (A1)

The red LED is lit when the Alarm 1 (A1) output or Pattern end 1 output is on.

(5) Alarm 2 (A2) output action or Pattern end 2 output indicator (A2) [Option]

The red LED is lit when the Alarm 2 (A2) output or Pattern end 2 output is on.

(6) Auto-tuning action indicator (AT)

The yellow LED blinks during auto-tuning.

(4)

(5)

(6)

Increase key : Increases the numeric value on the SV display during setting mode.

Decrease key : Decreases the numeric value on the SV display during setting mode.

Mode key : Selects the setting mode.

OUT/OFF key : Performs the control output ON or OFF, or program control Start or Stop.

In any mode, if the

When the function is working, the function cannot be released. Even if the insrument power is turned

off and on again, and the function is not released.

To release the function, press the

The setting value is registered by pressing the

In any setting item, if the key is pressed for approx. 3 seconds, the mode returns to the PV/SV display.

key is pressed for approx. 1 second, the Control output OFF function will work.

key for 1 second.

key.

V1.2 • 08/2004 - 6 -

Page 7

Operating Instructions Temperature Indicating Controller CF2S

A

A

3. Setup

3.1 Taking the internal assembly out

Warning

Do not take the inner assembly out nor touch the terminal with

the power supply on.

Touching the terminal with the power switched ON may result in

an Electric Shock which could cause severe injury or death.

Before the power supply to this instrument is on, take the internal assembly out from the case by pushing

the hook (bottom of the instrument) in the direction indicated by the arrow and holding the notches.

[Fig. 3.1-1]

3.2 Switch setting (multi-function)

Using a small slotted screwdriver and tweezers, set the Sensor input, Alarm 1 action, Alarm 2 action,

Control action, Heating (reverse)/Cooling (direct) action, Alarm 1 and 2 standby functions, Unit °C/°F and

Program starting form Auto/Manual change by rotary switch and DIP switch by the following procedure.

The rotary switch A2 (SW301) is equipped only when the option A2 is applied.

Control action designation Alarm 2 action type designation

Heating/Cooling action designation Alarm 1 action type designation

larm 1 standby action designation Sensor input designation

larm 2 standby action designation

°C/°F designation

Sensor input designation

Program start Auto/Manual

designation

Rotary switch

DIP switch

[Fig. 3.2-1]

V1.2 • 08/2004 - 7 -

Page 8

Operating Instructions Temperature Indicating Controller CF2S

The following items can be designated by the DIP switch (SW304).

Factory adjusted as all switches OFF [

].

[Table 3.2-1]

Item

Control action

action

Sw. No.

1

and

2

3

Fuzzy self-tuning PID action No.1: OFF No.2: OFF

PID action No.1: ON No.2: OFF

PD action No.1: OFF No.2: ON

ON/OFF action No.1: ON No.2: ON

Heating (reverse) action No.3: OFFHeating/Cooling

Cooling (direct) action No.3: ON

Designation Switch status

No standby action No.4: OFFAlarm 1 (A1)

standby action

4

Standby action No.4: ON

No standby action No.5: OFFAlarm 2 (A2)

standby action

5

Standby action No.5: ON

(*1)

°C/°F 6

Sensor input

(*2)

°C No.6: OFF

°F No.6: ON

K, J, R, B, N, PL- ,

Pt100, JPt100

7

S, E, T, C,

(With decimal point)

No.7: OFF

No.7: ON

Pt100 (Without decimal point)

Manual start No.8: OFFProgram start

Auto/Manual

8

Automatic start No.8: ON

*1: The standby function will not work if the option A2 is not applied.

*2: The sensor input can be designated by the combination of this item and the rotary

switch sensor input (SW303). (See page 11.)

Program start: This item is available for the program control.

Manual start : Program starts by pressing the

key.

Automatic start : Set program is automatically started from step 1 by turning the power

supply to the instrument on (after 2 seconds of warm-up status).

V1.2 • 08/2004 - 8 -

Page 9

Operating Instructions Temperature Indicating Controller CF2S

Select the sensor type by rotary switch sensor input (SW303).

Factory adjusted as K, [

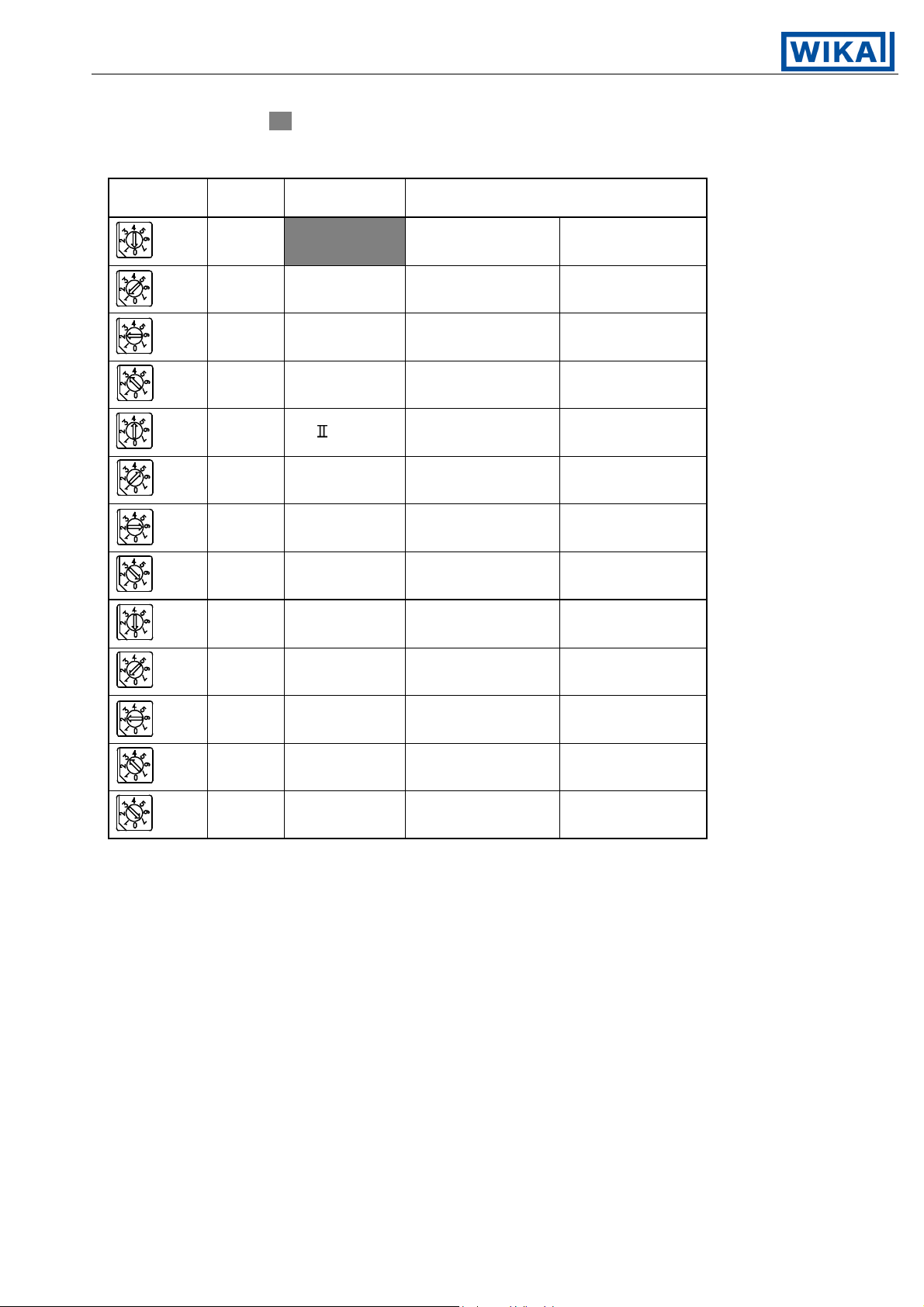

[Table 3.2-2]

].

Rotary Sw.

No.

0OFFK -200 to 1370 °C -320 to 2500 °F

1 OFF J -200 to 1000 °C -320 to 1800 °F

2 OFF R 0 to 1760 °C 0 to 3200 °F

3 OFF B 0 to 1820 °C 0 to 3300 °F

4OFF PL- 0 to 1390 °C 0 to 2500 °F

5 OFF N 0 to 1300 °C 0 to 2300 °F

6 OFF Pt100 -199.9 to 850.0 °C -199.9 to 999.9 °F

7 OFF JPt100 -199.9 to 500.0 °C -199.9 to 900.0 °F

0 ON S 0 to 1760 °C 0 to 3200 °F

DIP Sw.

No. 7

Type of

sensor

Scale range

1 ON E 0 to 1000 °C 0 to 1800 °F

2 ON T -199.9 to 400.0 °C -199.9 to 750.0 °F

3 ON C (W/Re5-26) 0 to 2315 °C 0 to 4200 °F

7 ON Pt100 -200 to 850 °C -320 to 1560 °F

V1.2 • 08/2004 - 9 -

Page 10

Operating Instructions Temperature Indicating Controller CF2S

The alarm action type and the pattern end output when program control can be

designated by the rotary switch A1 (SW302) and A2 (SW301).

The rotary switch A2 (SW301) is equipped only when the option A2 is applied.

Rotary switch A1 (SW302): Alarm 1 (A1) action or Pattern end 1 output.

Rotary switch A2 (SW301): Alarm 2 (A2) action or Pattern end 2 output.

Factory adjusted as No alarm action, [

[Table 3.2-3]

Alarm 1 action

No alarm action 0 No alarm action 0

High limit alarm 1 High limit alarm 1

Low limit alarm 2 Low limit alarm 2

High/Low limits alarm 3 High/Low limits alarm 3

Hi/Lo limit range alarm 4 Hi/Lo limit range alarm 4

Process high alarm 5 Process high alarm 5

Process low alarm 6 Process low alarm 6

A1 Rotary Sw.

(Sw302) No.

].

Alarm 2 action

A2 Rotary Sw.

(Sw301) No.

Pattern end 1 output 7 Pattern end 2 output 7

3.3 Insertion of the internal assembly

When the setup is completed, insert the internal assembly into the case.

Firmly insert the assembly until it is locked by the hook at the bottom of the instrument.

(There will be a clicking sound.)

Caution

Do not confuse the top and bottom of the internal assembly.

If inserting the assembly into the case by force in the wrong direction, the PCB

may be damaged.

V1.2 • 08/2004 - 10 -

Page 11

Operating Instructions Temperature Indicating Controller CF2S

4. Operations

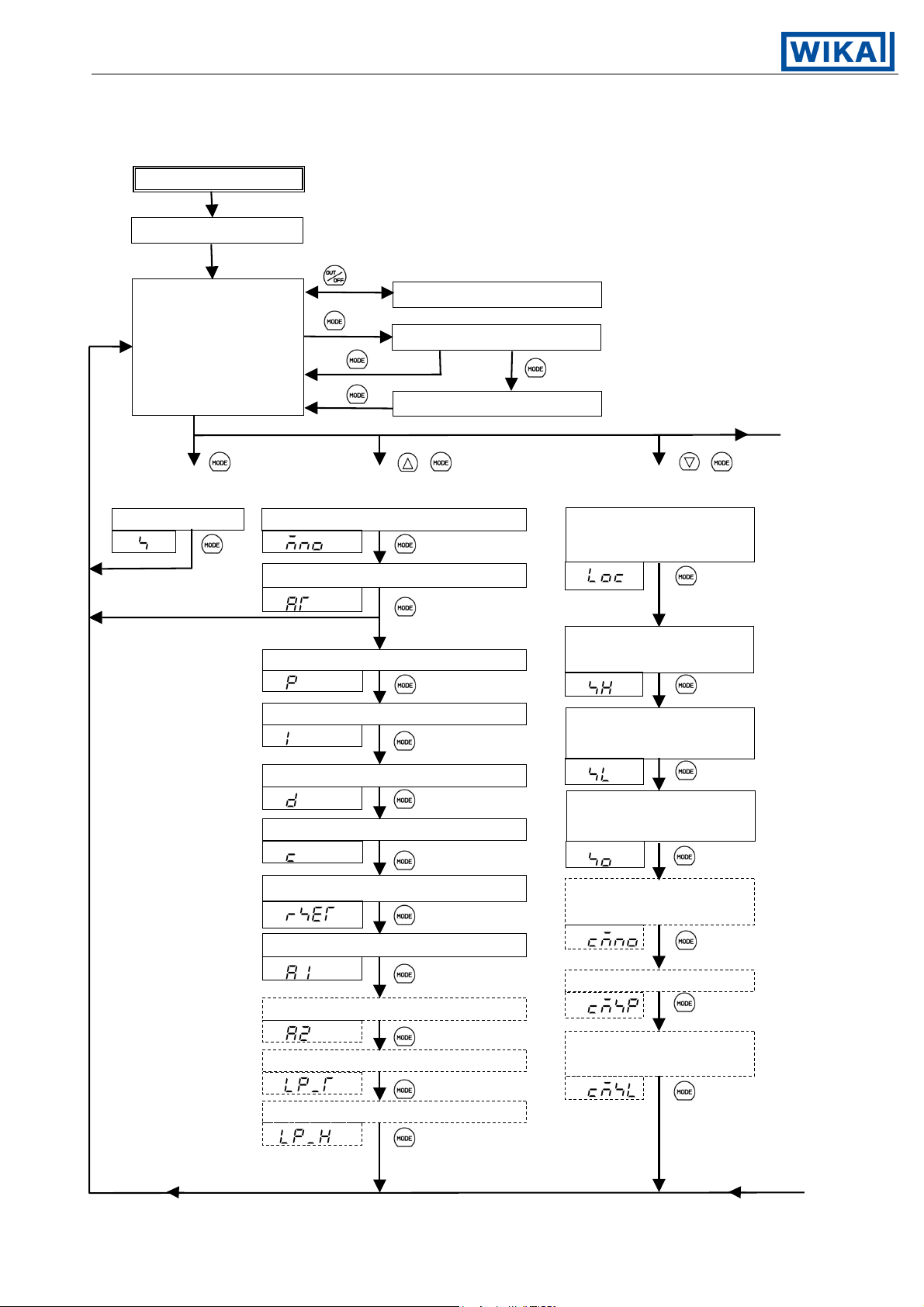

4.1 Operating flow chart

Instrument power ON

Warm-up status (For approx. 2s, displays as shown on page 15.)

1s

PV/SV display mode

+ + 3s

[Main setting mode] [Sub setting mode] [Auxiliary function setting mode 1]

Control output OFF function

3s

Output manipulating value

Step rest time *1

Main setting Setting value memory No. selection Setting value lock

PV

PV

Auto-tuning Perform/Cancel

PV

*2

designation

PV

Main setting value

Proportional band setting high limit setting

PV

Integral time setting

PV

Derivative time setting

PV

Proportional cycle setting

PV

Manual reset setting

PV

Alarm 1 (A1) setting

PV

Transfer rate selection

Alarm 2 (A2) setting

PV

setting

PV

PV

Main setting value

low limit setting

PV

Sensor correcting

value setting

PV

Instrument number

PV

Communication protocol

Loop break alarm time setting selection

PV

Loop break alarm span setting

PV

PV

V1.2 • 08/2004 - 11 -

Page 12

Operating Instructions Temperature Indicating Controller CF2S

: Options

+ : Press the key while the key is being pressed.

+ 3s: Press the key for approx. 3 seconds while the key is being pressed.

+ + 3s: Press the key for approx. 3 seconds

while the

and keys are being pressed.

+ 3s : Pressing the key, press the key for approx. 3 seconds.

*1: Step rest time is indicated only during program control.

*2: If the Auto-tuning is performed, the mode reverts to the PV/SV display.

If the Auto-tuning is released, the mode will move to “Proportional band setting”.

*3: In the mode Program control change, if is selected and the key is

pressed, the display reverts to the PV/SV display mode.

Set the temperature setting of program in the Sub setting mode, Auxiliary fuction

setting mode 1 and 2.

+ + 3s + 3s

[Auxiliary function setting mode 2] [Program mode]

Scaling high limit Alarm 1 (A1) hysteresis Program control change

setting setting

PV

PV

PV

Scaling low limit Alarm 2 (A2) hysteresis Step 1 time setting

setting setting

PV

PV

PV

PV filter time constant Alarm 1 (A1) action Step 2 time setting

setting delayed timer setting

PV PV

PV

Main output high limit Alarm 2 (A2) action Step 3 time setting

setting delayed timer setting

PV PV

PV

Main output low limit Display selection when Step 4 time setting

setting control output off

PV PV

PV

Main output ON/OFF Main setting value Step 5 time setting

action hysteresis setting rising rate setting

PV PV

PV

*3

Alarm 1 (A1) action Main setting value Step 6 time setting

Energized/Deenergized falling rate setting

PV

PV

PV

Alarm 2 (A2) action Step 7 time setting

Energized/Deenergized

PV PV

V1.2 • 08/2004 - 12 -

Page 13

Operating Instructions Temperature Indicating Controller CF2S

4.2 Operations

The PV display indicates the sensor type and the SV display indicates the rated value

selected by Sensor input designation (page 10, 11) for approx. 2 seconds after the power

is turned on. See [table 4.2-1].

During this time, all outputs and LED indicators are in their off status.

After that, the actual temperature is displayed on the PV display, main setting value on the SV

display and starts control.

(1) PV/SV display mode

Instrument power ON

Warm-up status (for 2s)

[Table 4.2-1] Rated value

[Table 4.2-1]

Input

PV display SV display PV display SV display

°C °F

K

J

R

B

PL-ll

N

S

E

T

C

Pt100

JPt100

Pt100

PV/SV display mode Mode during control.

Actual Main The contents of setting items nor setting values

Temperature setting value cannot be changed.

V1.2 • 08/2004 - 13 -

Page 14

Operating Instructions Temperature Indicating Controller CF2S

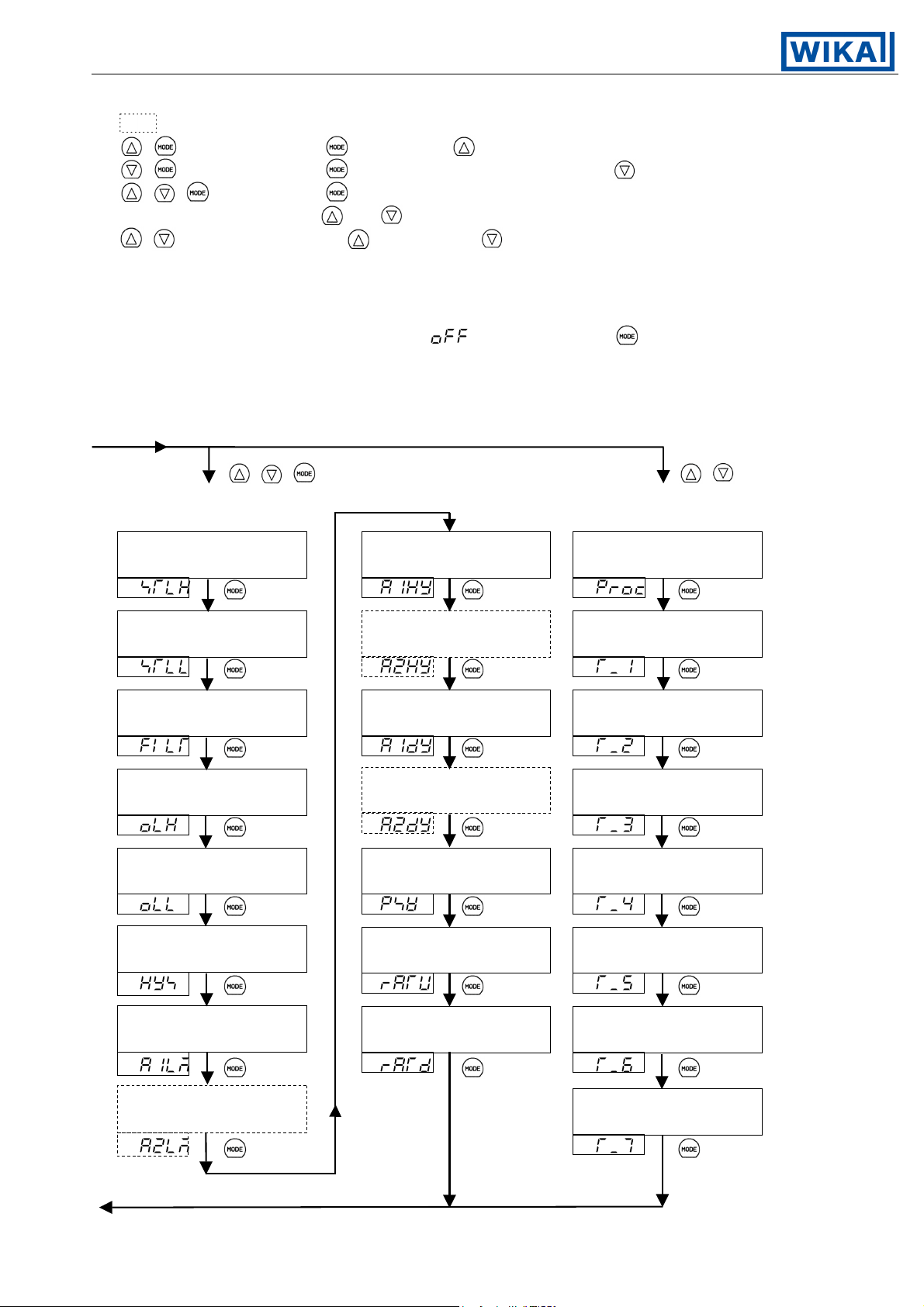

(2) Main setting mode

In the PV/SV display mode, if the

key is pressed, the Main setting mode will be selected.

The setting value can be increased or decreased by pressing the and keys.

If the

key is pressed, the setting value will be registered and the controller will

revert to the PV/SV display.

PV/SV display mode

Actual Main setting

Temperature value

Main setting

Setting Mode to set the setting value of the main control.

value

Setting range: From Main setting value low limit

to Main setting value high limit

[Factory adjusted as 0°C]

(3) Sub setting mode

In the PV/SV display mode, if the

key is pressed while the key is being pressed,

Sub setting mode will be selected.

The setting value can be increased or decreased by pressing the

If the

key is pressed, the setting value is registered and the next setting item will be selected.

PV/SV display mode

and keys.

Actual Main setting

temperature value

+

Setting value memory Mode to select the memory number (file)

number selection to be set or to be called.

Selected Selecting items: 1 to 7

value [Factory adjusted as Memory number 1.]

Auto-tuning Mode to designate the auto-tuning Perform or Cancel.

Perform/Cancel If Auto-tuning Perform is designated, and the

Designation key is pressed, the controller reverts to PV/SV display mode.

(When Perform) To set the other values, cancel the Auto-tuning.

When the ON/OFF action or PD action is selected in the

Control action designation (page 10), this display is not available.

V1.2 • 08/2004 - 14 -

Page 15

Operating Instructions Temperature Indicating Controller CF2S

SV

(Auto-tuning Cancel)

SV

If the Auto-tuning is released during the process,

Proportional band setting Mode to set the proportional band.

Setting value Setting range: 0.1 to 999.9%

Integral time setting Mode to set the integral time.

Setting value Setting range: 0 to 3600s

[Factory adjusted as 200s]

Derivative time setting Mode to set the derivative time.

Setting value Setting range: 0 to 3600s

[Factory adjusted as 50s]

(Auto-tuning Perform)

[Factory adjusted as Auto-tuning Cancel]

the PID value reverts to the former value.

[Factory adjusted as 2.5%]

This display is not available when the ON/OFF action is

selected in Control action designation (page 10).

Setting the value to 0 disables the function.

This display is not available when the ON/OFF action or

PD action is selected in Control action designation (page 10).

Setting the value to 0 disables the function.

This display is not available when the ON/OFF action is

selected in Control action designation (page 10).

Proportional cycle setting Mode to set the proportional cycle

Setting value Setting range: 1 to 120s

[Factory adjusted as 30s to Relay contact output type

and 3s to Non-contact voltage output type]

This display is not available when the ON/OFF action is

selected in Control action designation (page 10).

This setting item is not available to Current output type.

With the Relay contact output type, if the proportional cycle time

is decreased, the frequency of the relay action increases, and

the life of the relay contact is shortened.

Manual reset setting Mode to set the reset value to correct the offset

Setting value (Deviation between SV and PV when equilibrium status).

Setting range: proportional band converted value

[However, in the range, –199.9 to 999.9°C (°F)]

[Factory adjusted as 0.0°C]

This display is indicated only when PD action is designated in

the Control action designation (page 10).

Manual reset setting method:

When SV>PV, set the positive + value (SV–PV).

When SV<PV, set the negative – value (SV–PV).

V1.2 • 08/2004 - 15 -

Page 16

Operating Instructions Temperature Indicating Controller CF2S

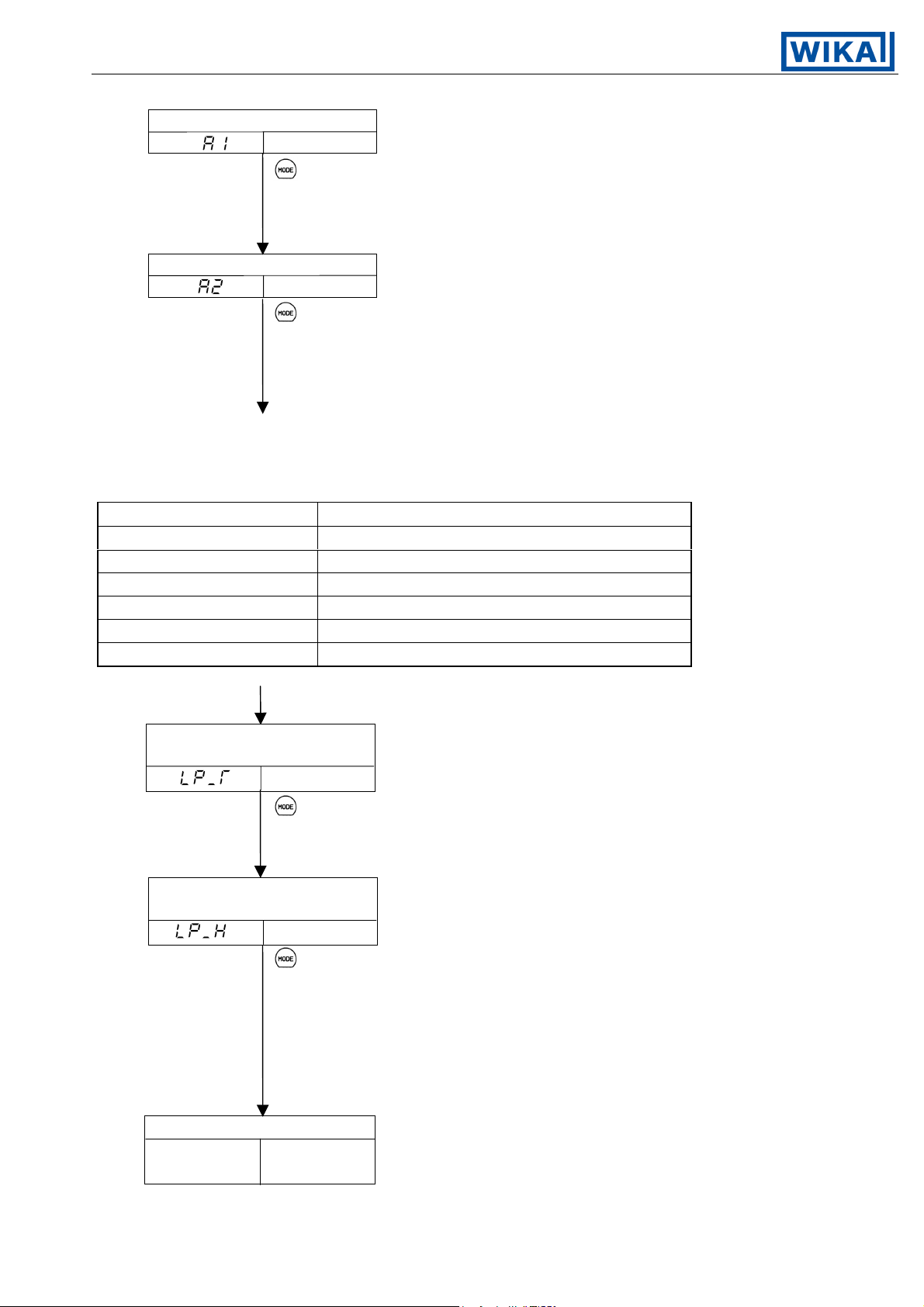

Alarm 1 (A1) setting Mode to set the action point of the Alarm 1 (A1) output.

[Factory adjusted as 0°C]

[Factory adjusted as 0°C]

Setting range of Alarm 1 and 2

(The setting range is the same when the standby function is added.)

[Table 4.2-2]

Alarm type Setting range

High limit alarm –Input span to Input span

Low limit alarm –Input span to Input span

High/Low limits alarm 1 to Input span

High/Low limit range alarm 1 to Input span

Process high alarm Input range minimum to Input range maximum

Process low alarm Input range minimum to Input range maximum

For RTD input, the minimum value of the negative side is –199.9.

Setting value

This item is not displayed if setting the rotary switch

to No. 0 or No. 7 (See page 12.)

Setting range: see [table 4.2-2].

Alarm 2 (A2) setting Mode to set the action point of the Alarm 2 (A2) output.

Setting value

This item is not displayed if the option [A2] is not

applied or even if it is applied, when setting the

rotary switch to No. 0 or No. 7 (See page 12.)

Setting range: see [table 4.2-2].

Loop break alarm Mode to set the time for Loop break alarm

time setting activation assessment.

Loop break alarm Mode to set the span for Loop Break Alarm

Actual Main setting

Temperature value

Setting value Setting range: 0 to 200 minutes

[Factory adjusted as 0 minutes.]

This display is indicated only when the option [AR] or

[AL] is applied.

span setting activation assessment.

Setting value Setting range:

0 to 150°C (Thermocouple, except T and RTD

without a decimal point)

0.0 to 150.0°C (Thermocouple T and RTD

with a decimal point)

[Factory adjusted as 0°C]

This display is indicated only when the option [AR] or

[AL] is applied.

PV/SV display mode

V1.2 • 08/2004 - 16 -

Page 17

Operating Instructions Temperature Indicating Controller CF2S

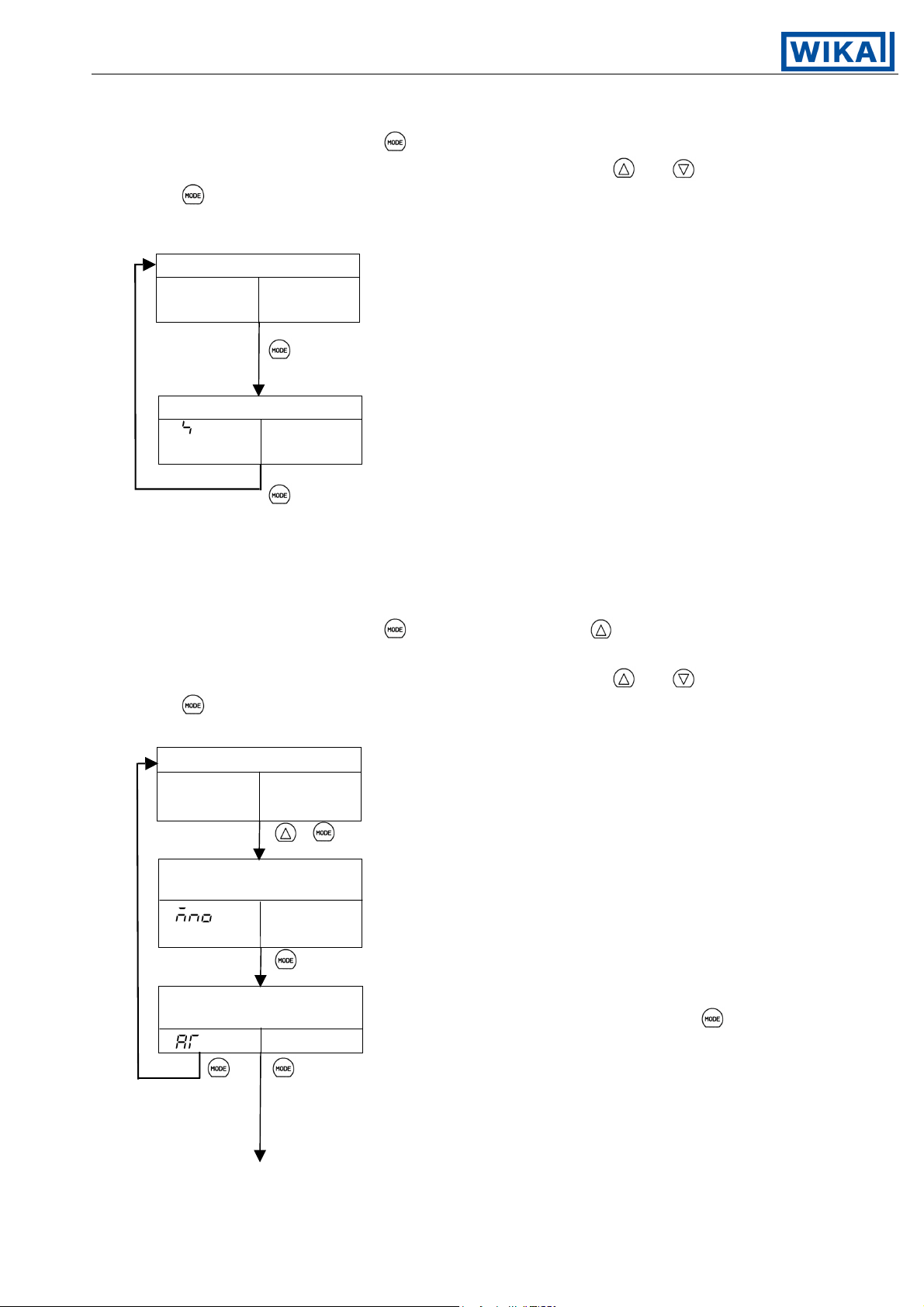

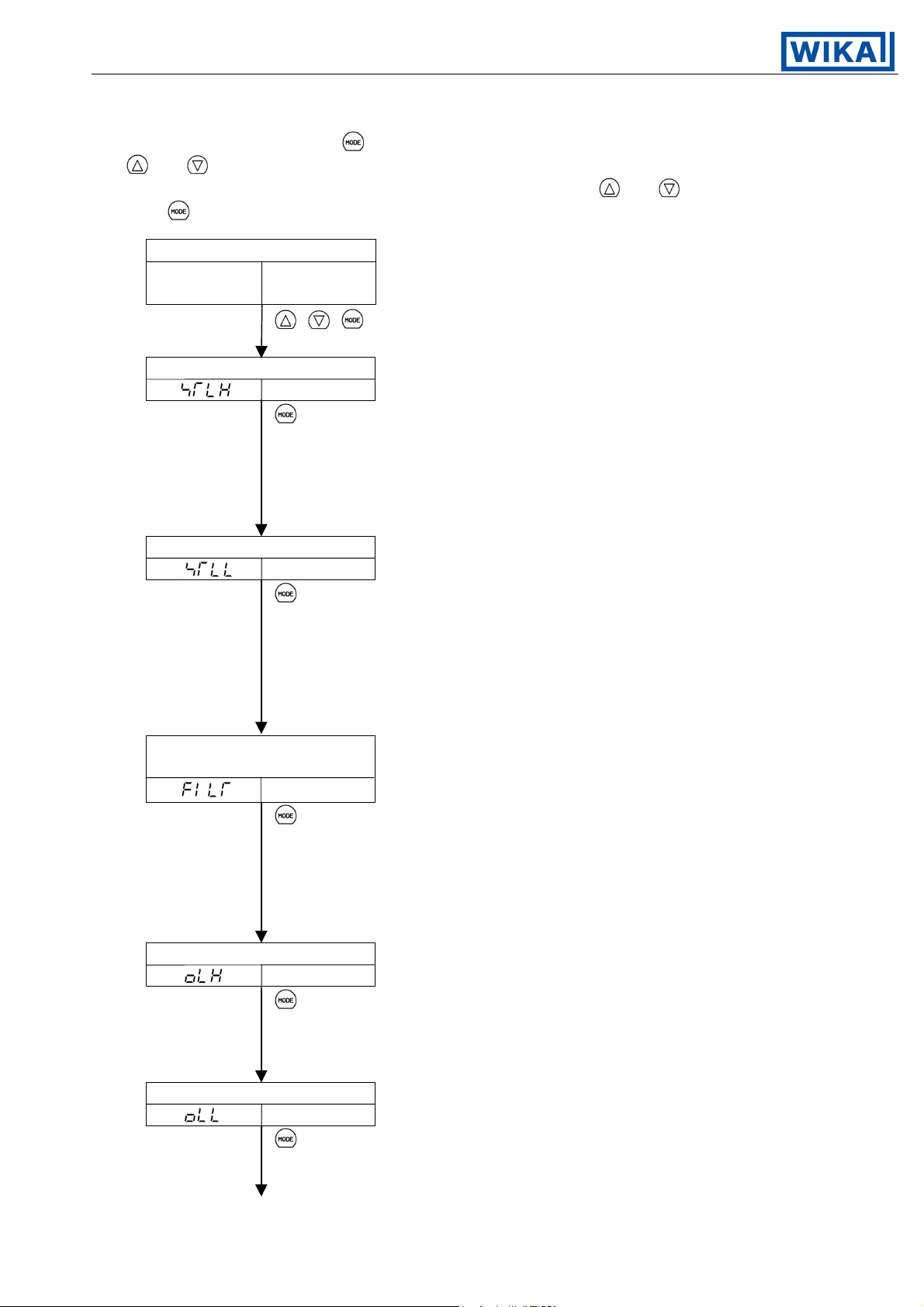

(4) Auxiliary function setting mode 1

In PV/SV display mode, if the

is being pressed, Auxiliary function setting mode 1 can be selected.

The setting value can be increased or decreased by pressing the

If the key is pressed, the setting value is registered and the next setting item is selected.

PV/SV display mode

Actual Main setting

Temperature value

+ for approx. 3s

Setting value lock Mode to lock the setting value to prevent error.

designation

Designation designation.

[Factory adjusted as Unlock status.]

key is pressed for approx. 3 seconds while the key

and keys.

The setting item to be locked depends on the

Unlock status. All setting values are changeable.

None of the setting items can be changed.

Only main setting value is changeable.

All setting items can be changed, however, the value returns

to the former value after the power off because the

value is not written on the non-volatile memory.

This mode is used when changing the value temporarily.

Fuzzy self-tuning or Auto-tuning PID action will not

function if [

When designating Lock, designate Lock 1, 2 or 3 after

setting the necessary items in the status Unlock.

As to the Lock mode 3

When using the CF2S as a Fixed value controller.

The setting values can temporarily be changed by the selected

setting value memory number, however, when the number is

changed, the setting values changed by the previous number are

canceled and returns to the former values.

When using the CF2S as a Program controller.

The setting values can temporarily be changed by the step

number performing, however, when the step number is changed,

the setting values are canceled and returns to the former values.

Setting value change is null when the controller is waiting for

running. The running starts by the values memorized.

] or [ ] is designated.

V1.2 • 08/2004 - 17 -

Page 18

Operating Instructions Temperature Indicating Controller CF2S

Main setting value Mode to set the high limit of main setting value.

high limit setting (If scaling high limit value is changed,

Setting value this setting value will be changed as well.)

Setting range: Main setting value low limit to scaling high limit value

[Factory adjusted as 400°C]

Main setting value Mode to set the low limit of main setting value.

low limit setting (If scaling low limit value is changed,

Setting value this setting value will be changed as well.)

Setting range: Scaling low limit value to main setting value high limit

[Factory adjusted as 0°C]

Sensor correction setting Mode to set the correct value of the sensor.

Setting value Setting range: –100.0 to 100.0°C

Instrument number setting Mode to set the Instrument number individually

Setting value to each instrument when communicating by

[Factory adjusted as 0.0°C]

connecting multiple instruments in serial communication.

Setting range: 0 to 95 [Factory adjusted as 0]

This display is available only when the option

[CR2] or [CR5] is applied.

Transfer rate selection Mode to select a communication transfer rate

4800bps

Selection to meet the rate of the host computer.

[Factory adjusted as 9600bps]

2400bps

9600bps

19200bps

This display is available only when the option [CR2] or [CR5] is applied.

Communication protocol Mode to select a communication protocol

selection between the CF2S and the host computer.

Selection [Factory adjusted as ]

Based on Modbus, ASCII mode

PV/SV display mode

Actual Main setting

Temperature value

V1.2 • 08/2004 - 18 -

This display is available only when the option [CR2] or [CR5] is applied.

WIKA standard protocol

Page 19

Operating Instructions Temperature Indicating Controller CF2S

(5) Auxiliary function setting mode 2

In PV/SV display mode, if the

and keys are being pressed, Auxiliary function setting mode 2 can be selected.

The setting value can be increased or decreased by pressing the

If the

PV/SV display mode

Actual Main setting

temperature value

Scaling high limit setting Mode to set the high limit value of the scaling.

key is pressed, the setting value is registered and the next setting item is selected.

+ + for approx. 3s

Setting value If scaling high limit value is changed, main setting

high limit value will be changed to the scaling

key is pressed for approx. 3 seconds while the

and keys.

high limit value as well.

Setting range: Scaling low limit value to

input range maximum value

[Factory adjusted as 1370°C]

Scaling low limit setting Mode to set the low limit value of the scaling.

PV filter time constant Mode to suppress the PV fluctuation caused by

setting such as disturbance.

[Factory adjusted as 0.0s]

Main output high limit setting Mode to set the high limit value of the main output.

Setting value If scaling low limit value is changed, main setting

low limit value will be changed to the scaling

low limit value as well.

Setting range: Input range minimum value to

scaling high limit value

[Factory adjusted as –200°C]

Setting value Set the value larger by degrees, and find the setting

value at which the value does not fluctuate.

If the value is set too large, it affects control result

due to the delay of response.

Setting range: 0.0 to 10.0s

Setting value Setting range: Main output low limit value to 105%

Setting greater than 100% is effective to the type

Current output. [Factory adjusted as 100%]

This display is not available for the ON/OFF action.

Main output low limit setting Mode to set the low limit value of the main output.

V1.2 • 08/2004 - 19 -

Setting value Setting range: –5% to Main output high limit value

Setting less than 0% is effective to the type

Current output. [Factory adjusted as 0%]

This display is not available for the ON/OFF action.

Page 20

Operating Instructions Temperature Indicating Controller CF2S

Main output ON/OFF Mode to set the ON/OFF action hysteresis of the

action hysteresis setting main control output.

Alarm 1 (A1) action Mode to select the action Energized or Deenergized

Energized/Deenergized for Alarm 1.

Setting value Setting range: 0.1 to 100.0°C

[Factory adjusted as 1.0°C]

This display is indicated only when the ON/OFF action

is designated in Control action designation (page10).

Selection [Factory adjusted as Energized]

This display is not indicated when the rotary switch is set to No. 0

or No. 7 in Alarm 1 action designation (page 12).

Energized

Deenergized

Alarm 2 (A2) action Mode to select the action Energized or Deenergized

Energized/Deenergized for Alarm 2.

Alarm 1 hysteresis setting Mode to set the hysteresis value for Alarm 1.

Selection [Factory adjusted as Energized]

This display is not indicated when the rotary switch is set to

No. 0 or No. 7 in Alarm 2 action designation (page 14), or

the option [2AS] or [2AL] is not applied.

Selection items: The same as those of the alarm 1 (A1) action

Energized/Deenergized selection.

Setting value Setting range: 0.1 to 100.0°C

[Factory adjusted as 1.0°C]

This display is not indicated when the rotary switch is set to

No. 0 or No. 7 in Alarm 1 action designation (page 12).

Alarm 2 hysteresis setting Mode to set the hysteresis value for Alarm 2.

V1.2 • 08/2004 - 20 -

Setting value Setting range: 0.1 to 100.0°C

[Factory adjusted as 1.0°C]

This display is not indicated when the option [2AS] or [2AL]

is not applied and when the rotary switch is set to No. 0

or No. 7 in Alarm 2 action designation (page 12) even

if the option [2AS] or [2AL] is applied.

Page 21

Operating Instructions Temperature Indicating Controller CF2S

Alarm 1 (A1) action Mode to set the action delayed timer for Alarm 1.

delayed timer setting Setting range: 0 to 9999s

Alarm 2 (A2) action Mode to set the action delayed timer for Alarm 2.

delayed timer setting Setting range: 0 to 9999s

Setting value [Factory adjusted as 0s]

Alarm output is turned on when the setting time has passed

after the input gets into the alarm output range.

This display is not indicated if the rotary switch is set to

No. 0 or No. 7 in Alarm 1 action designation (page 12).

Setting value [Factory adjusted as 0s]

Alarm output is turned on when the setting time has passed

after the input gets into the alarm output range.

This display is not indicated when the option [2AS] or [2AL] is

not applied and when the rotary switch is set to No. 0 or

No. 7 in Alarm 2 action designation even if the option [2AS]

or [2AL] is applied (P.12).

Display selection when Mode to select the display when the control output

control output is off is off.

OFF is indicated on the PV display.

Selection [Factory adjusted as indicating OFF on the PV display]

No indication (all unlit).

Only PV is indicated.

Main setting value Mode to set the rising rate of the main setting

rising rate setting value. (Rising value per minute)

Main setting value Mode to set the falling rate of the main setting

falling rate setting value. (Falling value per minute)

Setting value Setting the value to 0 or 0.0 disables the function.

Setting range:

0 to 9999°C /min. Thermocouple, except T and RTD without a decimal point

0.0 to 999.9°C /min. Thermocouple T and RTD with a decimal point

[Factory adjusted as 0°C /min.]

Setting value Setting the value to 0 or 0.0 disables the function.

Setting range:

0 to 9999°C /min. Thermocouple, except T and RTD without a decimal point

0.0 to 999.9°C /min. Thermocouple T and RTD with a decimal point

[Factory adjusted as 0°C /min.]

PV/SV display mode

Actual Main setting

temperature value

V1.2 • 08/2004 - 21 -

Page 22

Operating Instructions Temperature Indicating Controller CF2S

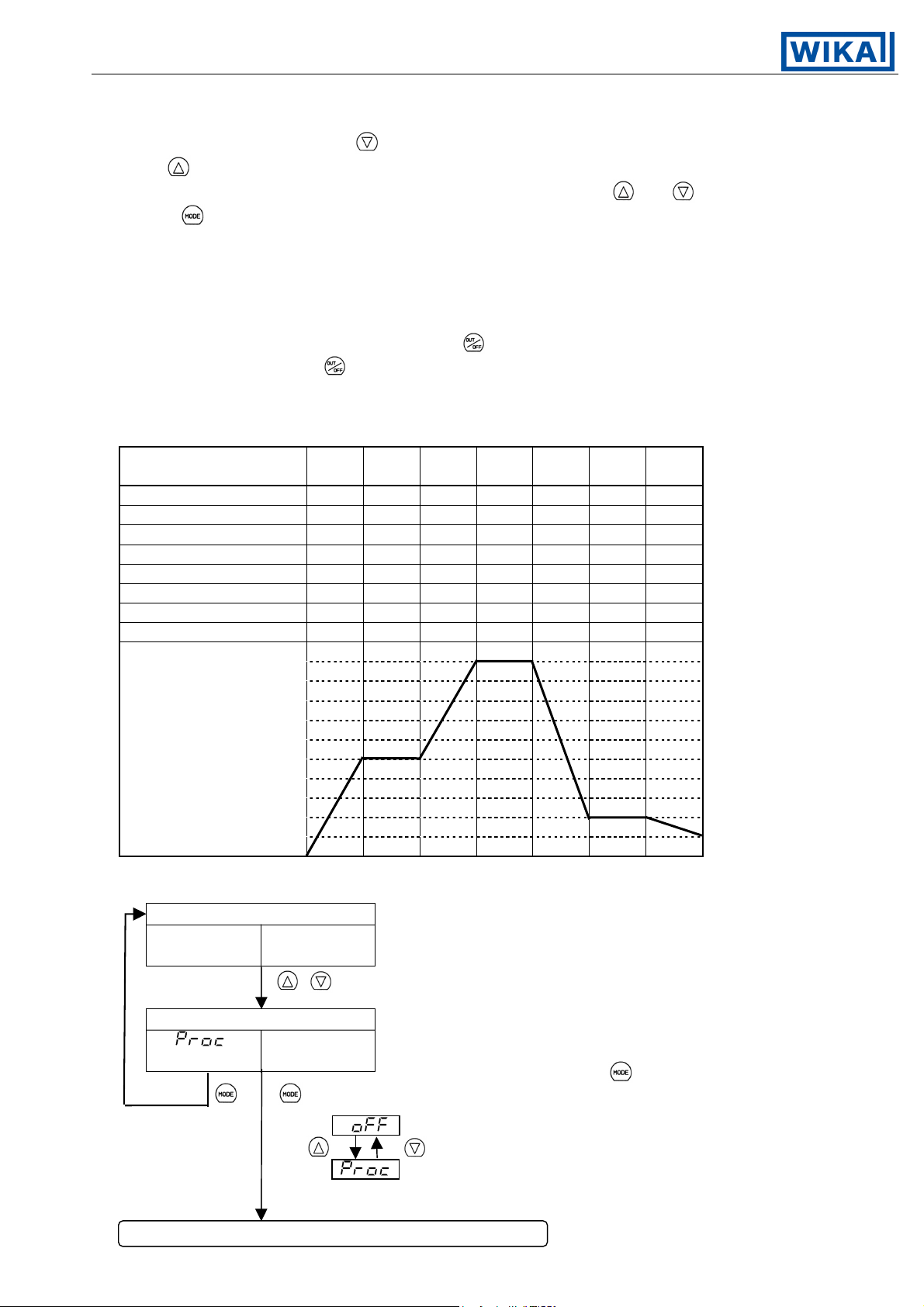

(6) Program mode

In PV/SV display mode, if the

the

key is being pressed, the Program mode can be selected.

key is pressed for approximately 3 seconds while

The setting value can be increased or decreased by pressing the and keys.

If the

key is pressed, the setting value is registered and the next setting item is selected.

As to the setting values of the step 1 to 7, each setting value for setting value memory

number 1 to 7 set during the Fixed value control is assigned respectively. For example,

values in memory number 1 are assigned to the values for step 1, and number 2 for step 2.

If the Pattern end output is designated and the program control is performed,

the Pattern end output is turned on when the program is completed.

When the Pattern end output is on and if the

output is turned off. If the

key is pressed again, the program will be performed.

key is pressed, the Pattern end

If some steps are unnecesary, set the times 00.00 for the step numbers not used.

Program Example

Step number (Setting

value memory number)

1234567

Main setting value 500 500 1000 1000 200 200 100

Proportional band 2.0 1.8 2.0 1.8 2.5 1.8 2.0

Integral time 180 80 180 80 200 80 200

Derivative time 30 20 30 20 50 20 50

Proportional cycle 30 30 30 30 30 30 30

Alarm 1 2 5 2 5 10 0 5

Alarm 2 2 5 2 5 10 0 5

Step time 00:30 01:00 00:40 01:00 02:00 00:30 01:00

1000

500

0

PV/SV display mode

Actual Main setting

temperature value

+ for approx. 3s

Program control change Control form is changed between Fixed value and Program.

Setting value of

fixed value control

In Fixed value control, if the key is pressed,

(Fixed value control)

the mode will revert to the PV/SV display.

Fixed value control

Program control

[Factory adjusted as Fixed value control]

Following display is available only when Program control.

V1.2 • 08/2004 - 22 -

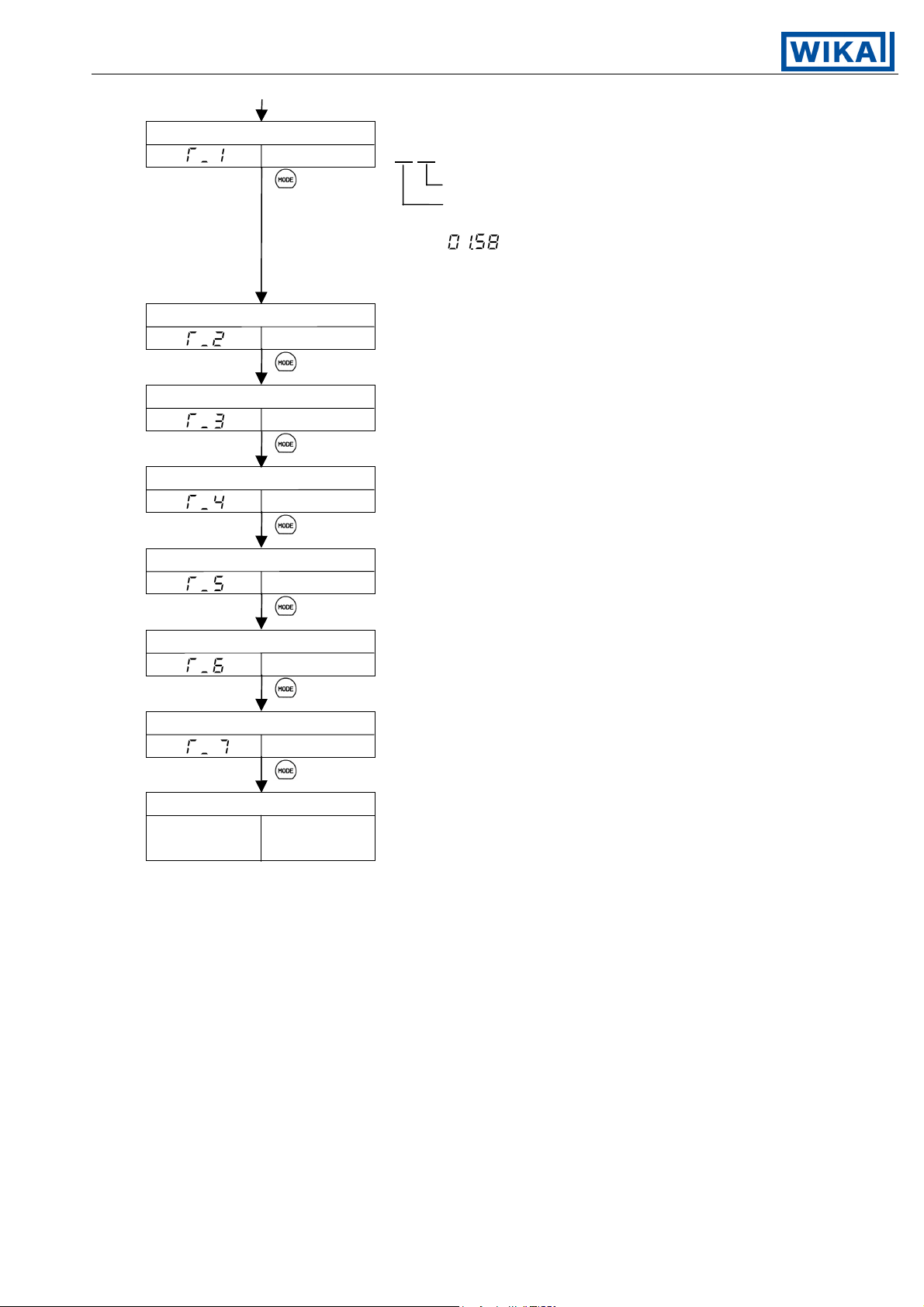

Page 23

Operating Instructions Temperature Indicating Controller CF2S

Step 1 Time setting Mode to set the Time for step 1.

Setting value 00.00

Minute indication

Hour indication

For example, when setting 1 hour 58 minutes,

set as [

Setting range: 00.00 to 99.59

[Factory adjusted as 00.00]

Step 2 Time setting Mode to set the Time for step 2.

Setting value [The setting range and the factory adjusted value

are the same as Step 1.]

Step 3 Time setting Mode to set the Time for step 3.

Setting value [The setting range and the factory adjusted value

are the same as Step 1.]

Step 4 Time setting Mode to set the Time for step 4.

Setting value [The setting range and the factory adjusted value

are the same as Step 1.]

].

Step 5 Time setting Mode to set the Time for step 5.

Setting value [The setting range and the factory adjusted value

are the same as Step 1.]

Step 6 Time setting Mode to set the Time for step 6.

Setting value [The setting range and the factory adjusted value

are the same as Step 1.]

Step 7 Time setting Mode to set the Time for step 7.

Setting value [The setting range and the factory adjusted value

are the same as Step 1.]

PV/SV display mode

Actual Main setting

temperature value

V1.2 • 08/2004 - 23 -

Page 24

Operating Instructions Temperature Indicating Controller CF2S

(7) Control output OFF function

A function to turn the control output OFF even if the power to the instrument is supplied.

The function is used when required to halt the control action or when the CF2S is not

being used in multiple controllers.

Control output OFF function can be selected from any mode by pressing the

for approx. 1 second.

The display is the same as when [Display selection when control output is off] is selected.

(See page 26.)

PV/SV display mode

Actual Main setting

temperature value

key

Control output OFF function

(*) [Unlit]

for approx. 1s [From any mode, as an example]

1s Manual reset setting

for approx. 1s

(*): PV display indicates [OFF indication], [No indication] or [Only PV]

selected in Display selection when control output is off (page 26).

Notice

Once the Control output OFF function is enabled, the function cannot be released

even if the power to the instrument is turned OFF and turned ON again.

To cancel the function, press the

In the program control, the Control output OFF function cannot be used because

the

key functions as Program Start/Stop key.

key again for approx. 1 second.

Setting value

V1.2 • 08/2004 - 24 -

Page 25

Operating Instructions Temperature Indicating Controller CF2S

(8) Output manipulating value and Step rest time indication mode

In the PV/SV display mode, press the

key for approx. 3 seconds.

The display will be changed to main setting mode in the process, however, keep

pressing it until the Output manipulating value is displayed.

If the

During program control, if the

key is pressed again, the mode reverts to the PV/SV display.

key is pressed in Output manipulating value

indication, the Step rest time indication will be selected.

If the

key is pressed again, the mode reverts to the PV/SV display.

PV/SV display mode

Actual Main setting

temperature value

for approx. 3s

Output manipulating

value indication mode

Actual manipulating Manipulating value is indicated on the SV display

temperature value by the blinking of the decimal point.

(Fixed value control) (Program control)

Step rest time indication

Actual Step Step rest time is indicated on the SV display.

temperature rest time

5. Setting value memory number external selection [Option code: SM2]

If the option [SM2] is applied, setting value memory number 2 can be selected by external operation.

The option [SM2] cannot be applied in combination with option [2AS], [2AR], [2AL], [CR2] or [CR5].

● Wiring connection of setting value memory number external selection

1

3( )

2 7

3

4

2(NC)

1( )

6

(Color of wire: Red)

NC

8

9

(Color of wire: Blue) 1

3

2

5

10

The Setting value memory number 2 can be selected by shorting between 1 and 3.

If Setting value memory number 2 is selected by the Open collector, connect the

pin No.1 to the collector and the pin No. 3 to the emitter.

When the Setting value memory number 2 is selected by external operation,

the number cannot be selected by front key operation.

Memory number cannot be changed during setting mode or PID auto-tuning.

V1.2 • 08/2004 - 25 -

Page 26

Operating Instructions Temperature Indicating Controller CF2S

6. Running

After the controller has been mounted to the control panel and wiring is

completed, it can be started in the following manner.

6.1 When using the CF2S as a Temperature controller

(1) Turn the power supply to the CF2S ON.

For approx. 2s after the power is switched ON, the type of sensor and the unit designated

in Sensor input designation (page 11) will be indicated on the PV display, and the rated

maximum value will be indicated on the SV display. See [table 6.1-1].

During this time, all outputs and LED indicators are in their OFF status.

After that, the display turns to the PV/SV display.

When the Control output OFF function is working, the item selected in the

[Display selection when control output is off] is displayed on the PV display.

(See page 26.)

[Table 6.1-1]

Input

K

J

R

B

PL-ll

N

S

E

T

C

Pt100

JPt100

Pt100

PV display SV display PV display SV display

°C °F

(2) Input the setting value, referring to Chapter 4. Operations (page 13ff).

When controlling by Fuzzy self-tuning PID action, designate [Perform] in the

Auto-tuning Perform/Cancel function to start the control in optimum conditions.

(3) Turn the load circuit power ON.

Starts the control action so as to keep the controlled object at the main setting value.

6.2 When using the CF2S as a Simplified program controller

(1) Turn the power supply to the CF2S ON.

For approx. 2s after the power is turned ON, the type of sensor and the unit designated in

Sensor input designation (page 11) are indicated on the PV display, and the rated maximum

value is indicated on the SV display. See [table 6.1-1].

During this time, all outputs and LED indicators are in their OFF status.

After that, the display reverts to the PV/SV display.

When the Control output OFF function is working, the item selected in Display

selection when control output is off is displayed on the PV display. (See page 26.)

(2) Input each setting value and each step time referring to Chapter 4. Operations (page 13ff).

Then the PV display will indicate the actual temperature and the status turns standby.

V1.2 • 08/2004 - 26 -

Page 27

Operating Instructions Temperature Indicating Controller CF2S

(3) Turn the load circuit power ON.

(4) Program control start

If Automatic start is designated in the Program start Auto/Manual designation (page 10), it will

switch to warm-up status for approx. 2 seconds after the power is turned on, and then will

automatically start the program control from step 1.

If Manual start is designated in Program start Auto/Manual designation (page 10), it will switch

to warm-up status for approx. 2 seconds after the power is turned on, and then it reverts to

standby status. In this status, if the

key is pressed, it starts the program control from the step 1.

While the program control is being performed, the change of Step number (Setting value

memory number) is ineffective.

To end the program control during the process.

The program control is ended if the key is pressed for approx. 1 second or longer.

To change the displays.

In the PV/SV display, if the key is pressed for approximately 3 seconds, the Output

manipulating value display mode is activated, and if the

key is pressed again, the

Step rest time display will be indicated (see page 29.).

Instrument status when power failure is restored.

When power is restored after a power failure occurs during program control,

the CF2S performs the program continuously.

The PV display blinks until the step at which the power failure occurs is finished.

7. Action explanations

7.1 Standard action

Action Heating (reverse) action

Control

action

Output

ON

OFF

6

7

Relay contact

6

12Vdc

Non-contact

7

voltage

+

Cooling (direct) action

Proportional band

Setting

6

7

(*1) (*1)

+

6

12/0Vdc

7

(*1)

6

7

6

0Vdc

7

+

6

7

6

0Vdc

7

+

Proportional band

Setting

6

7

+

6

0/12Vdc

7

(*1)

6

7

6

12Vdc

7

ON

OFF

+

Indicator

[OUT] Green

20mAdc

Current

6

7

Lit

+

+

6

20 to 4mAdc

7

(*2)

6

4mAdc

7

Unlit

+

(*1) Cycle action is performed according to deviation.

(*2) Changes continuously according to deviation.

V1.2 • 08/2004 - 27 -

6

4mAdc

7

+

+

6

4 to 20mAdc

7

(*2)

+

6

20mAdc

7

LitUnlit

Page 28

Operating Instructions Temperature Indicating Controller CF2S

7.2 ON/OFF action

Action Heating (reverse) action

Hysteresis

Control

action

Output

ON

OFF

6

7

Relay contact

6

12Vdc

7

Non-contact

voltage

6

20mAdc

Current

7

Main setting

+

+

6

7

6

0Vdc

7

6

4mAdc

7

Cooling (direct) action

Hysteresis

ON

OFF

Main setting

6

7

+

+

+

6

0Vdc

7

+

6

4mAdc

7

6

7

+

6

12Vdc

7

+

6

20mAdc

7

Indicator

[OUT] Green

Lit

Unlit

: Either ON or OFF

7.3 Pattern end action

Program control end

ON

OFF

[Time]

Pattern end output is

released by pressing

the key.

3

4

Unlit

Pattern end output is turned ON when the program control is ended, and it is

not released until the key is pressed.

LitUnlit

3

4

Lit

3

4

Unlit

V1.2 • 08/2004 - 28 -

Page 29

Operating Instructions Temperature Indicating Controller CF2S

7.4 Alarm 1 (A1) and 2 (A2) actions

High limit alarm

Hysteresis

Low limit alarm

Hysteresis

Temperature

alarm action

Output

Indication

Temperature

alarm action

Output

Indication

Temperature

alarm action

ON

OFF

Main

setting

3

4

Unlit

High limit alarm with standby

ON

OFF

Main

setting

3

4

Unlit

High/Low limits alarm

ON

OFF

Alarm

setting

Alarm

setting

Hysteresis

Alarm

setting

Hysteresis

Main

setting

3

4

Lit

3

4

Lit

Alarm

setting

ON

OFF

Alarm

setting

3

4

Lit

Low limit alarm with standby

Hysteresis

ON

OFF

Alarm

setting

3

4

Lit

High/Low limit range alarm

ON

OFF

Alarm

setting

Main

setting

3

4

Unlit

Main

setting

3

4

Unlit

Hysteresis

Main

setting

Alarm

setting

3

Output

4

Indication

Lit

3

4

Unlit

3

4

Lit

Standby function works at part.

and shows the action point of the alarm output.

Output terminals for Alarm 2: 3 – 5

V1.2 • 08/2004 - 29 -

3

4

Unlit

3

4

Lit

3

4

Unlit

Page 30

Operating Instructions Temperature Indicating Controller CF2S

Temperature

alarm action

Output

Indication

Temperature

alarm action

Output

High/Low limits alarm with standby

Hysteresis

ON

OFF

Alarm

setting

3

4

Lit

Process high alarm

ON

OFF

3

Main

setting

3

4

Unlit

Hysteresis

Alarm

setting

Alarm

setting

3

4

3

High/Low limit range alarm with standby

Hysteresis

ON

OFF

Lit

Alarm

setting

3

4

Unlit

Process low alarm

3

Main

setting

3

4

Lit

Hysteresis

Alarm

setting

Alarm

setting

3

4

Unlit

ON

OFF

3

Indication

Temperature

alarm action

Output

Indication

4

Unlit

Process high alarm with standby

Hysteresis

ON

OFF

3

4

Unlit

4

Lit

Alarm

setting

3

4

Lit

Standby function works at part.

and shows the action point of the alarm output.

Output terminals for Alarm 2: 3 – 5

4

Lit

Process low alarm with standby

Hysteresis

Alarm

setting

3

4

Lit

4

Unlit

ON

OFF

3

4

Unlit

V1.2 • 08/2004 - 30 -

Page 31

Operating Instructions Temperature Indicating Controller CF2S

8. Control actions

8.1 Fuzzy self-tuning

Fuzzy self-tuning is a function to perform a fine adjustment of PID values automatically.

The stable control can be carried out even if the conditions of the process are changed

due to things like change in types and rates of production.

(1) When the control is rising, the controller performs the control by the PID values

turned in advance.

(2) When the control result is disordered by the disturbance or a change in the process,

the controller checks the converging status, and performs a fine adjustment of PID values

if necessary.

(a) If the convergence is performed smoothly, the PID values are not changed.

(b) If the convergent speed is slow, the controller corrects the PID values

to accelerate the convergence.

(c) When overshoot is generated during the convergence, the controller corrects

the PID values so as not to generate the overshoot.

(d) When hunting is generated, the controller checks the waveform and performs

fine adjustment of PID values.

(3) The controller can be used without Fuzzy self-tuning by designating the internal switch.

(4) When using the controller for the first time, perform the PID auto-tuning or set the

proper PID values by key operation.

The instrument is always in self-tuning status itself, and when deviation is created, it starts

the tuning. Even if in Fuzzy self-tuning status, when very large hunting is caused and the

control is not stabilized, it starts auto-tuning automatically.

When the auto-tuning performance is designated by the key operation, tuning is initiated

and when the control is stabilized, the auto-tuning is released and returns to self-tuning status.

When lock mode [

or Auto-tuning PID action cannot work.

With the control system in which load fluctuation periodically occurs,

the Fuzzy self-tuning may fall into malfunction.

In such a case, use the controller with the PID auto-tuning mode.

8.2 Explanations of PID

(1) Proportional band (P)

Proportional action is the action which the control output varies in proportion to the deviation

between the setting value and the processing temperature.

If the proportional band is narrowed, even if the output changes by a slight variation of the

processing temperature, better control results can be obtained as the offset decreases.

However, if the proportional band is narrowed too much, even slight disturbances may cause

variation in the processing temperature, and control action changes to ON/OFF action and

the so called hunting phenomenon occurs.

Therefore, when the processing temperature comes to the balanced position near the setting

value and a constant temperature is maintained, the most suitable value is selected by

gradually narrowing the proportional band while observing the control results.

] or [ ] is designated, Fuzzy self-tuning

(2) Integral time (I)

Integral action is used to eliminate offset. When the integral time is shortened, the returning

speed to the setting point is quickened. However, the cycle of oscillation is also quickened

and the control becomes unstable.

(3) Derivative time (D)

Derivative action is used to restore the change in the processing temperature according to the

rate of change. It reduces the amplitude of overshoot and undershoot width.

If the derivative time is shortened, restoring value becomes small, and if the derivative time

is made longer, an excessive returning phenomenon may occur and the control system

may be oscillated.

V1.2 • 08/2004 - 31 -

Page 32

Operating Instructions Temperature Indicating Controller CF2S

8.3 PID auto-tuning of this controller

In order to decide each value of P, I, D and ARW automatically, this system makes the

controlled object’s temperature fluctuate.

(1) When the difference between setting value and processing temperature

is large when the temperature rises.

Fluctuation is applied at the temperature 1.5% of scaling span less than the setting value.

1.5% of scaling span

Setting value

Temperature

Time

Controlling action is performed

with the values set by PID

auto-tuning.

[Figure 8.3-1]

(2) When the control is stable or when control temperature is within ±1.5%

of scaling span.

Fluctuation is applied at the setting value.

Starting point of auto-tuning

Setting value

Controlling action is performed

Temperature

Time

with the values set by PID

auto-tuning.

[Figure 8.3-2]

(3) When the control temperature is 1.5% or greater of scaling span higher

than the setting value.

Fluctuation is applied at the temperature 1.5% of scaling span higher than the setting value.

1.5% of scaling span

Setting value

Temperature

Time

V1.2 • 08/2004 - 32 -

Controlling action is performed

with the values set by PID

auto-tuning.

[Figure 8.3-3]

Page 33

Operating Instructions Temperature Indicating Controller CF2S

9. Other functions

(1) Burnout alarm

(Upscale)

When the thermocouple or RTD is burnt out or the input value exceeds [Rated scale

maximum value +1% of rated scale span], the control output is turned OFF (main output

low limit value for the current output type) and the PV display blinks [

With the input RTD Pt100 (°F), if the input value is greater than 999.9, the PV display

blinks [

rated scale span].

(Downscale)

When the input value falls to [Rated scale minimum value –1% of rated scale span] or less,

the control output is turned OFF (main output low limit value for the current output type)

and the PV display blinks [

For the Thermocouple T or RTD input, if the input falls to less than –199.9, the PV display

blinks [

rated scale span].

(2) Self-diagnostic function

The CPU is monitored by a watchdog timer, and when any abnormal status is

found on the CPU, the controller is switched to warm-up status.

], however, the control is performed to [rated scale maximum value +1% of

].

], however, the control is performed to [rated scale minimum value –1% of

].

(3) Automatic cold junction temperature compensation (

This detects the temperature at the connecting terminal between thermocouple

and the instrument, and always keeps it at the same status as when the

reference junction is located at 0°C [32°F].

(4) Warm-up indication

For approximately 2 seconds after the power supply to the instrument is turned on,

the type of input and the temperature unit are indicated on the PV display, and the

maximum input rated value on the SV display.

(5) Setting value ramp function

When the main setting value is adjusted, it approaches the new setting value by the set rate

of change.

When the power is turned on, the control starts from the PV (process variable)

and approaches the main setting value by the rate of change.

Thermocouple input type)

V1.2 • 08/2004 - 33 -

Page 34

Operating Instructions Temperature Indicating Controller CF2S

10. Mounting to control panel

10.1 Site selection

This instrument is intended to be used under the following environmental

conditions (IEC61010-1): Overvoltage category

Mount the controller in a place with:

(1) A minimum of dust, and an absence of corrosive gases

(2) No flammable, explosive gases

(3) No mechanical vibrations or shocks

(4) No exposure to direct sunlight, an ambient temperature of 0 to 50°C (32 to122°F)

that does not change suddenly

(5) An ambient non-condensing humidity of 35 to 85%RH

(6) The controller away from large capacity electromagnetic switches or cables

through which large current is flowing

(7) No water, oil or chemicals or where the vapors of these substances can

come into direct contact with the unit

10.2 External dimension drawing

One-touch type mounting bracket

, Pollution degree 2

48

Screw type mounting bracket

48

10010

[Fig. 10.2-1]

10010

[Fig. 10.2-2]

44.5

44.5

59.7

10.3 Panel cutout drawing

75

0

+0.5

n x 48-3

+0.5

0

45

+0.5

45

Lateral close mounting

[Fig. 10.3-1] n: Number of units mounted

V1.2 • 08/2004 - 34 -

0

0

+0.5

45

Page 35

Operating Instructions Temperature Indicating Controller CF2S

10.4 Mounting

• When using the One-touch type mounting bracket [code: FT]

Mounting panel thickness is 1 to 3mm.

Mount one-touch mounting bracket 1

to the body in advance, and then insert

the CF2S 2 from the front of the panel.

If Soft front cover is used the mounting panel

thickness will be 1 to 2.5mm.

2

1

[Fig. 10.4-1]

• When using the Screw type mounting bracket [code: FS]

Mounting panel thickness is 1 to 15mm.

Insert the CF2S from the front of the panel.

Slot the mounting bracket to the holes at the top and bottom of the case, and screw in place.

1

Notice

As the case is made of resin, do not use excessive force while

screwing in the mounting bracket.

The torque is approximately 0.12N•m.

[Fig. 10.4-2]

V1.2 • 08/2004 - 35 -

Page 36

Operating Instructions Temperature Indicating Controller CF2S

11. Wiring connection

Warning

Turn the power supply to the instrument off before wiring or checking.

Working or touching the terminal with the power switched on may result

in an Electric Shock which could cause severe injury or death.

Moreover, the instrument must be grounded before the power supply to the

instrument is turned on.

11.1 Terminal arrangement

[Control output]

1

24Vdc

2

6

Non-contact

voltage output or

7

current output

[Control output]

6

Relay contact

output

7

A

B

9

10

RTD

B

8

TC

10

100 to 240Vac

or 24Vac

A1/P.end 1

A2/P.end 2/LA

1

2

3 8

4

5

TX (color of wire: Yellow)

RX (color of wire: Blue)

COM (color of wire: Black)

SM2

SM

C, C5

RS-485RS-232

YA ( ) (color of wire: Yellow)

YB ( ) (color of wire: Blue)

COM (color of wire: Black)

YA ( ) (color of wire: Yellow)

YB ( ) (color of wire: Blue)

COM (color of wire: Black)

[Fig. 11.1-1]

A1: Alarm 1 P. end 1: Pattern end 1

A2: Alarm 2 [2AS] P. end 2: Pattern end 2

[2AR]: Loop break alarm [2AL]: Alarm 2 and loop break alarm with common terminals

[CR2], [CR5]: Serial communication [SM2]: Setting value memory number external selection

• The terminal block of this instrument is designed to be wired from the left side.

The lead wire must be inserted from the left side of the terminal, and fastened with the terminal screw.

• Dotted lines show options, no terminal is equipped if it is not specified.

• If the Alarm 2 (pattern end 2 output) is applied with a combination of the Loop break

alarm output, the output terminal is common.

• Serial communication [CR2, CR5] cannot be applied in combination with the options

[2AS], [2AR], [2AL] and [SM2].

Alarm 2 (A2) is applied, however, it does not involve the alarm output but

provides the functions for indication and communication.

V1.2 • 08/2004 - 36 -

Page 37

Operating Instructions Temperature Indicating Controller CF2S

Notice

• Use a thermocouple and compensating lead wire according to the input

specifications of this controller.

• Use a 3-wire RTD system according to the input specifications of this controller.

• This controller has neither built-in power switch nor fuse. Therefore, it is

necessary to install them in the circuit near the external controller.

(Recommended fuse: Time-lag fuse, rated voltage 250V, rated current 2A)

• In the case of 24Vdc for power source, do not confuse the polarity.

• For the relay contact output type, use an external auxiliary electromagnetic

switch to protect the built-in relay contact.

• When wiring, keep the input wire (Thermocouple, RTD, etc.) away from AC

source and the load wire to avoid external interference.

• Use a thick wire (1.25 to 2.0mm²) for the earth ground.

n Solderless terminal

Use a solderless terminal with an insulation sleeve that fits to an M3 screw as shown

below.

3.2mm

3.2mm

5.8mm or less

5.8mm or less

V1.2 • 08/2004 - 37 -

Page 38

Operating Instructions Temperature Indicating Controller CF2S

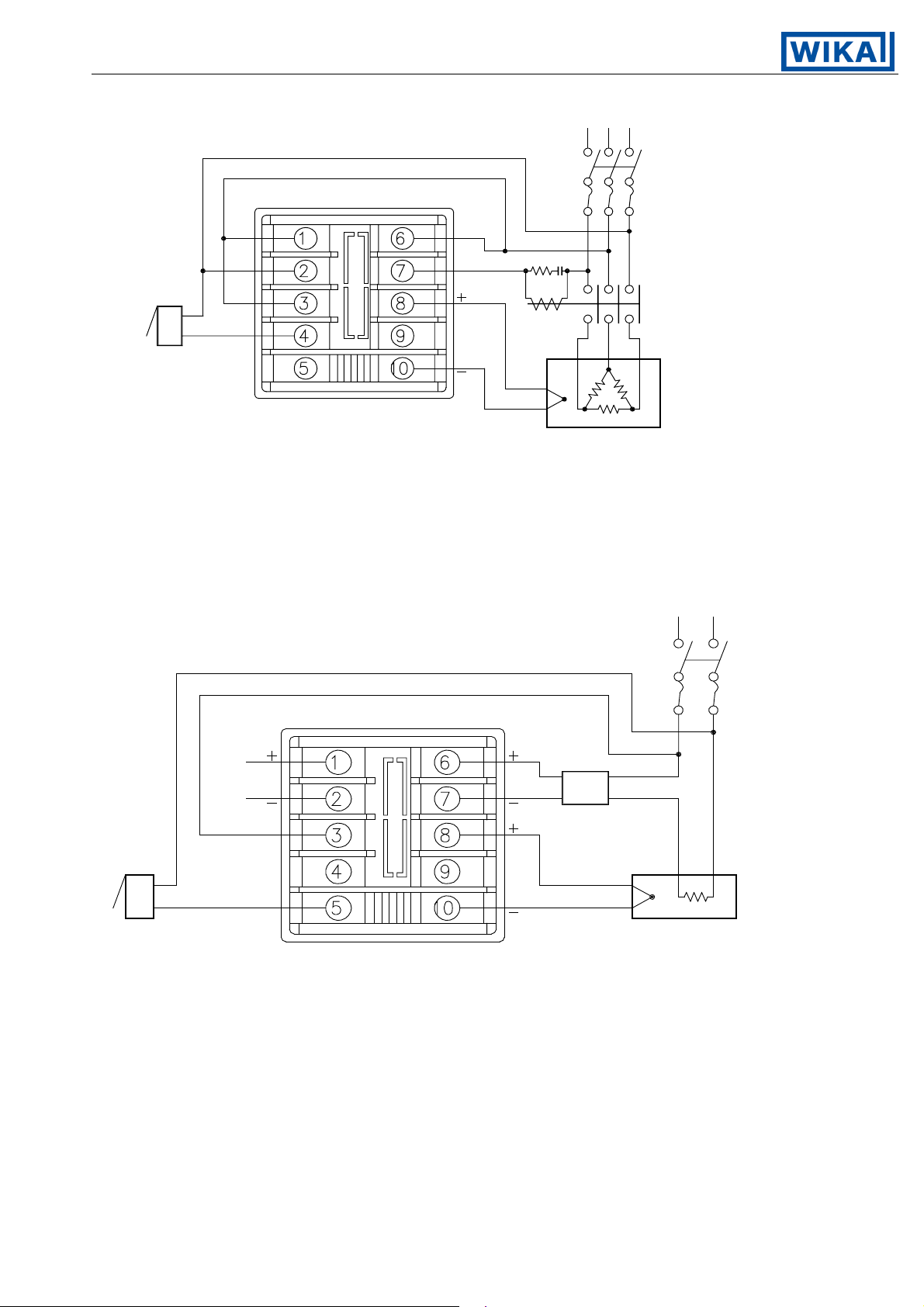

11.2 Wiring connection examples

Alarm unit (for

temperature alarm)

Thermocouple

Electric furnace

[Fig. 11.2-1]

3-phase

Heater

• To prevent the unit from harmful effects of unexpected level noise, it is recommended that

a surge absorber be installed between the electromagnetic switch coils.

Single phase

Alarm unit (for Electric furnace

temperature alarm) [Fig. 11.2-2]

• AC or DC is available to supply voltage 24V, however, do not confuse the polarity when DC is applied.

V1.2 • 08/2004 - 38 -

Page 39

Operating Instructions Temperature Indicating Controller CF2S

12. Specifications

12.1 Standard specifications

Mounting method : Flush

Setting : Input system using membrane sheet key

Display

PV display : Red LED display 4 digits, size: 8(H) x 4(W)mm

SV/MV/TIME display : Green LED display 4 digits, size: 8(H) x 4(W)mm

Indicating accuracy

Thermocouple input : Within ±0.3% of input range full scale ±1digit

however, for R or S input, the range 0 to 200°C (400°F), within ±6°C (12°F)

When B input, the range 0 to 300°C (600°F), accuracy is not guaranteed.

When K, J, T input, the range less than 0°C (32°F),

within ±0.5% of full scale ±1digit

(Cold junction compensating accuracy, ±1°C, at 0 to 50°C)

RTD input : Within ±0.3% of input range full scale ±1digit

Setting accuracy : The same as indicating accuracy

Input sampling period : 0.125 seconds

Input

Thermocouple : K, J, R, S, B, E, T [JIS, IEC], C (W/Re5-26) [ASTM],

N (IEC) and PL-ll (NBS)

External resistance, 100Ω or less

In the case of input burnout, Upscale

RTD : Pt100 (JIS, IEC), JPt100, 3-wire system

Allowable input lead wire resistance 10Ω or less per wire

In the case of input burnout, Upscale

Control output

Relay contact : 1a

Control capacity, 250Vac 3A (resistive load)

250Vac 1A (inductive load cosø=0.4)

Non-contact voltage : For SSR drive

Current : 4 to 20mA DC (Isolated type)

Load resistance, maximum 550Ω

+2

12 VDC maximum 40mA DC (short circuit protected)

0

V1.2 • 08/2004 - 39 -

Page 40

Operating Instructions Temperature Indicating Controller CF2S

Alarm 1 (A1) output

The alarm action point is set by ±deviation to main setting (except Process value alarm).

[When the alarm action is set as energized]

When the input exceeds the range, the output turns ON or OFF

(in the case of High/Low limit range alarm).

[When the alarm action is set as deenergized]

The output acts conversely.

One of the alarms can be selected by rotary switch and DIP switch from 14 types of alarm,

High limit alarm, Low limit alarm, High/Low limits alarm, High/Low limit range alarm,

Process high alarm and Process low alarm, and the standby function is applied to them

respectively, as well as No alarm and Pattern end output.

Setting accuracy : Within ±0.3% of input range full scale ±1digit

Action : ON/OFF action, Hysteresis setting range, 0.1 to 100.0°C (°F)

Output : Relay contact 1a

Control capacity 250Vac 3A (resistive load)

250Vac 1A (inductive load cosø =0.4)

(However, A1, A2 common terminal, Max. 3A)

Controlling action

The fuzzy self-tuning PID, PID, PD or ON/OFF action is selectable by DIP switch.

Fuzzy self-tuning PID action

Proportional band (P) : Automatic

Integral time (I) : Automatic

Derivative time (D) : Automatic

Anti-reset windup (ARW) : Automatic

Proportional cycle : 1 to 120s

Output limiter : 0 to 100% (In the case of Current output, –5 to 105%)

PID action (with auto-tuning function)

Proportional band (P) : 0.1 to 999.9%

Integral time (I) : 0 to 3600s (off when set to 0)

Derivative time (D) : 0 to 3600s (off when set to 0)

Anti-reset windup (ARW) : Automatic

Proportional cycle : 1 to 120s

Output limiter : 0 to 100% (In the case of Current output, –5 to 105%)

PD action

Proportional band (P) : 0.1 to 999.9%

Derivative time (D) : 0 to 3600s (Off when set to 0)

Proportional cycle : 1 to 120s

Reset : ± Proportional band converted value

Output limiter : 0 to 100% (In the case of Current output, –5 to 105%)

ON/OFF action

Hysteresis setting range : 0.1 to 100.0°C (°F)

V1.2 • 08/2004 - 40 -

Page 41

Operating Instructions Temperature Indicating Controller CF2S

Supply voltage : 100 to 240V AC 50/60Hz, 24V AC/DC 50/60Hz

Allowable voltage fluctuation : 100 to 240V AC : 85 to 264V AC

24V AC/DC : 20 to 28V AC/DC

Ambient temperature : 0 to 50°C (32 to 122°F)

Ambient humidity : 35 to 85%RH (non-condensing)

Power consumption : Approx. 8VA

Circuit insulation configuration

1

Power source

2

3

Alarm 1 (A1) output

4

Alarm 2 (A2) output

5

Option SM2 Option CR2, CR5

Isolated

CPU

Control output

(OUT)

Input

When control output is Current output type or Non-contact voltage output

type (the SSR drive), between Input and Output is non-isolated.

Insulation resistance

10MΩ or greater at 500V DC

Dielectric strength

Between input terminal and ground terminal, 1.5kV AC for 1 minute

Between input terminal and power terminal, 1.5kV AC for 1 minute

Between power terminal and ground terminal, 1.5kV AC for 1 minute

Between output terminal and ground terminal, 1.5kV AC for 1 minute

Between output terminal and power terminal, 1.5kV AC for 1 minute

Weight : Approx. 140g

External dimension : 48 x 48 x 100mm (W x H x D)

Material : Base and Case, Flame resisting resin

Color : Base and Case, black

6

7

8

9

10

Attached functions : Power failure countermeasure

Self-diagnostic function

Automatic cold junction temperature compensating function

Sensor burnout function [upscale, downscale]

Accessories : Mounting bracket 1 set

Instruction manual 1 copy

Unit nameplate 1 sheet

Wire harness CO 1 piece [When the option CR2 is applied.]

Wire harness CO

1 piece [When the option CR5 is applied.]

Wire harness C5

Terminal cover 1 piece [When the option KAB is applied.]

V1.2 • 08/2004 - 41 -

Page 42

Operating Instructions Temperature Indicating Controller CF2S

12.2 Optional specifications

Alarm 2 output [2AS]

The alarm action point is set by ±deviation to main setting (except Process value alarm).

[When the alarm action is set as energized]

When the input exceeds the range, the output turns ON or OFF

(in the case of High/Low limit range alarm).

[When the alarm action is set as deenergized]

The output acts conversely.

One of the alarms can be selected by rotary switch and DIP switch from 14 types

of alarm: High limit alarm, Low limit alarm, High/Low limits alarm, High/Low limit

range alarm, Process high alarm and Process low alarm and the standby function

is applied to them respectively, as well as No alarm and Pattern end output.

Setting accuracy : Within ±0.3% of input range full scale ±1digit

Action : ON/OFF action

Hysteresis setting range, 0.1 to 100.0°C (°F)

Output : Relay contact 1a

Control capacity, 250Vac 3A (resistive load)

250Vac 1A (inductive load cosø=0.4)

(However, A1 and A2 common terminal, Max. 3A)

Loop break alarm output [2AR]

Detects the breaking status on the loop such as heater burnout, sensor burnout or

the operation end trouble.

Output Relay contact 1a

Control capacity, 250Vac 3A (resistive load)

250Vac 1A (inductive load, cosø=0.4)

Alarm 2 output and Loop break alarm output [2AL]

When option [2AL] Alarm 2 output and Loop break alarm output is selected,

the output terminal is common.

Output Relay contact 1a

Control capacity, 250Vac 3A (resistive load)

250Vac 1A (inductive load, cosø=0.4)

Serial communication [CR2 or CR5]

The options [Code; 2AS, 2AR, 2AL and SM2] cannot be applied in combination with this option.

Alarm 2 (A2) is applied, however, it does not involve the alarm output but

provides the functions for indication and communication.