Page 1

Operating instructions

操作说明书

GB

CN

Hand-held multi-function calibrator, model CEP6000

CEP6000 型手持多功能校准仪

Hand-held multi-function calibrator, model CEP6000

CEP6000 型手持多功能校准仪

Page 2

GB

CN

2

MM/YYYY country code based on 10/2014 GB/CN

WIKA operating instructions, model CEP6000

Operating instructions model CEP6000 Page 3 - 50

CEP6000 型操作说明书 页码

51 - 100

© 2014 WIKA Alexander Wiegand SE & Co. KG

All rights reserved. 保留一切权利。/ Alle Rechte vorbehalten.

WIKA® is a registered trademark in various countries.

WIKA® 是在各个国家/地区的注册商标。

Prior to starting any work, read the operating instructions!

Keep for later use!

在开始任何工作之前,请阅读本操作说明书!

请妥善保存,以备将来使用!

Page 3

3

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

Contents

Contents

1. General information 5

2. Short overview 6

2.1 Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

2.2 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

2.3 Scope of delivery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

3. Safety 8

3.1 Explanation of symbols. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.2 Intended use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

3.3 Improper use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.4 Responsibility of the operator . . . . . . . . . . . . . . . . . . . . . . . . . . 9

3.5 Personnel qualification . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

3.6 Labelling, safety marks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .10

4. Design and function 11

4.1 Front foil . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

4.1.1 Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

4.1.2 Key function. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

4.2 Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

4.2.1 Selecting the batteries or rechargeable batteries . . . . . . . . . . . . 14

4.2.2 Using the power supply unit . . . . . . . . . . . . . . . . . . . . . . . .14

5. Transport, packaging and storage 15

5.1 Transport . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

5.2 Packaging and storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .15

6. Commissioning, operation 16

6.1 Main display . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

6.2 Menu bar . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2.1 Menu function “Measuring” . . . . . . . . . . . . . . . . . . . . . . . . 18

6.2.2 Menu function “Output” . . . . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.3 Menu function “Pulse output” . . . . . . . . . . . . . . . . . . . . . . . 19

6.2.4 Menu function “UPPER”, “LOWER” and “MORE” . . . . . . . . . . . . 19

6.2.5 Menu function “Automatic output function” . . . . . . . . . . . . . . . . 20

6.2.6 Menu function “Contrast” . . . . . . . . . . . . . . . . . . . . . . . . . 20

6.2.7 Menu function “Automatic switch-off” . . . . . . . . . . . . . . . . . . .20

6.2.8 Menu function “Frequency or pulse output” . . . . . . . . . . . . . . . 21

6.2.9 Menu function “Probe-specific coefficients” . . . . . . . . . . . . . . . 21

6.2.10 Menu function “ZERO” . . . . . . . . . . . . . . . . . . . . . . . . . . .21

6.2.11 Menu function “Parameter selection” . . . . . . . . . . . . . . . . . . . 22

Page 4

4

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

Contents

Declarations of conformity can be found online at www.wika.com.

6.3 Cursor control/set point control . . . . . . . . . . . . . . . . . . . . . . . . . 22

6.4 Using the measuring modes (lower display) . . . . . . . . . . . . . . . . . . 22

6.4.1 Measuring voltage and frequency. . . . . . . . . . . . . . . . . . . . .22

6.4.2 Measuring current (mA) . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4.3 Measuring temperature . . . . . . . . . . . . . . . . . . . . . . . . . . 23

6.4.4 Measuring pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

6.5 Using the output modes (lower display). . . . . . . . . . . . . . . . . . . . .27

6.5.1 Setting the output parameters 0 % and 100 %. . . . . . . . . . . . . .27

6.5.2 Using the automatic output functions . . . . . . . . . . . . . . . . . . .28

6.5.3 Current output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

6.5.4 Simulating a transmitter . . . . . . . . . . . . . . . . . . . . . . . . . .30

6.5.5 Voltage output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

6.5.6 Frequency output. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .31

6.5.7 Pulse output . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

6.5.8 Simulating thermocouples . . . . . . . . . . . . . . . . . . . . . . . . .31

6.5.9 Simulating resistance or resistance thermometers . . . . . . . . . . . 32

6.6 Using the isolated measuring modes (upper display) . . . . . . . . . . . . .34

6.6.1 Measuring voltage (V) or current (mA) . . . . . . . . . . . . . . . . . .34

6.6.2 Current measurement with DC 24 V voltage supply . . . . . . . . . . .34

6.7 Using the upper and lower displays for test and calibration . . . . . . . . . . 35

6.7.1 Calibrating a display instrument. . . . . . . . . . . . . . . . . . . . . .35

6.7.2 Calibrating an I/P instrument . . . . . . . . . . . . . . . . . . . . . . .36

6.7.3 Calibrating a transmitter . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6.7.4 Calibrating a pressure transmitter. . . . . . . . . . . . . . . . . . . . .37

7. Faults 38

8. Maintenance, cleaning and recalibration 40

8.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

8.2 Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

8.3 Recalibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9. Dismounting, return and disposal 41

9.1 Dismounting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

9.2 Return . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

9.3 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

10. Specifications 43

11. Accessories 49

Appendix: EC declaration of conformity 50

Page 5

5

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

1. General information

1. General information

■

The model CEP6000 hand-held multi-function calibrator described in these operating

instructions has been manufactured using state-of-the-art technology. All components

are subject to stringent quality and environmental criteria during production. Our

management systems are certified to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument.

Working safely requires that all safety instructions and work instructions are observed.

■

Observe the relevant local accident prevention regulations and general safety

regulations for the instrument’s range of use.

■

The operating instructions are part of the product and must be kept in the immediate

vicinity of the instrument and readily accessible to skilled personnel at any time. Pass

the operating instructions onto the next operator or owner of the instrument.

■

Skilled personnel must have carefully read and understood the operating instructions

prior to beginning any work.

■

The general terms and conditions contained in the sales documentation shall apply.

■

Subject to technical modifications.

■

Factory calibrations / DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address: www.wika.com.cn / www.wika.com

- Relevant data sheet: CT 83.01

- Application consultant:

Tel.: +49 9372 132-5049

Fax: +49 9372 132-8005049

CTServiceteam@wika.com

Page 6

6

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

1

2

3

Abbreviations, definitions

RTD Resistance thermometer

TC Thermocouple

2W 2-wire measurement

Two test cables are used for the voltage supply.

The measurement signal also provides the supply current.

3W 3-wire measurement

Two test cables are used for the voltage supply.

One test cable is used for the measurement signal.

4W 4-wire measurement

Two test cables are used for the voltage supply.

Two test cables are used for the measurement signal.

CJC Cold junction compensation

2. Short overview

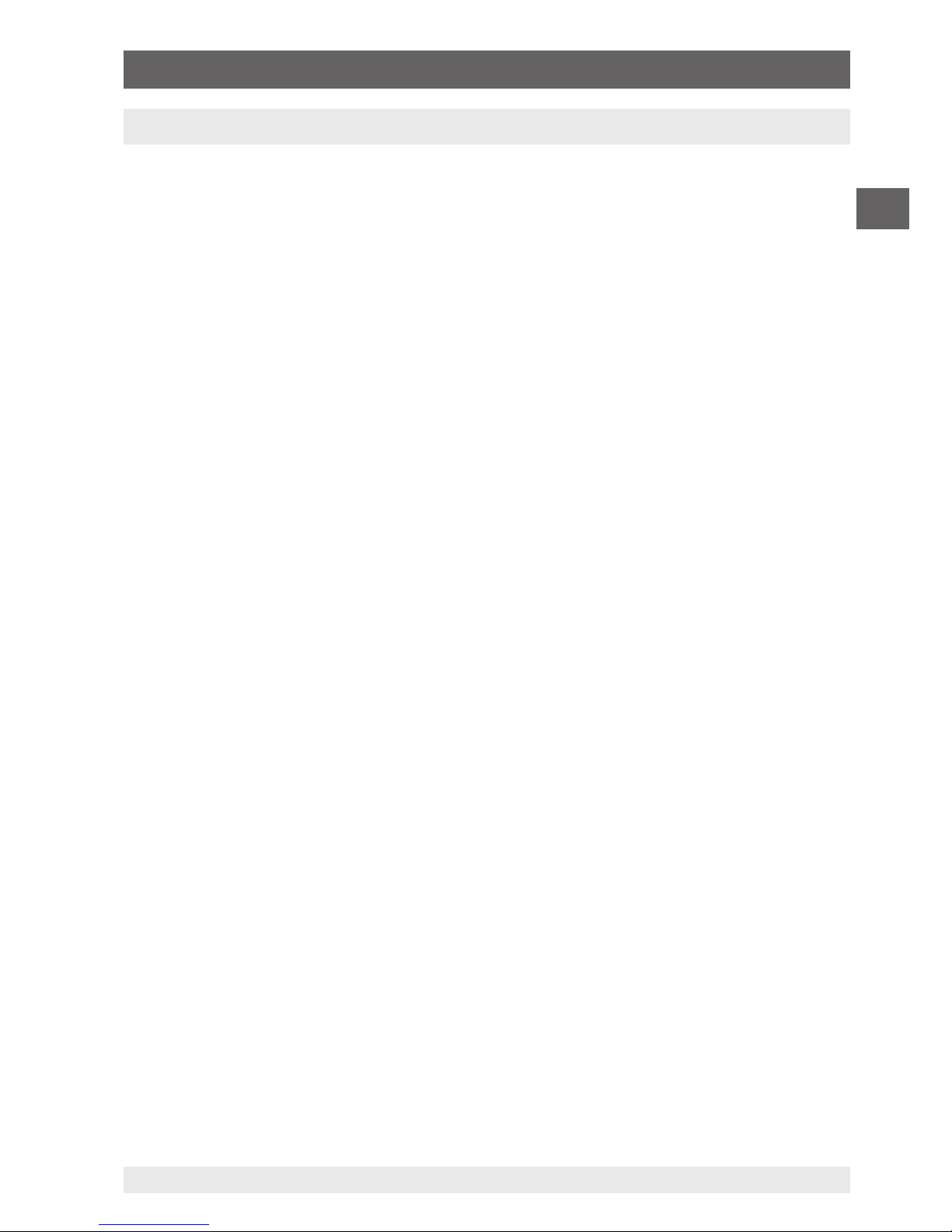

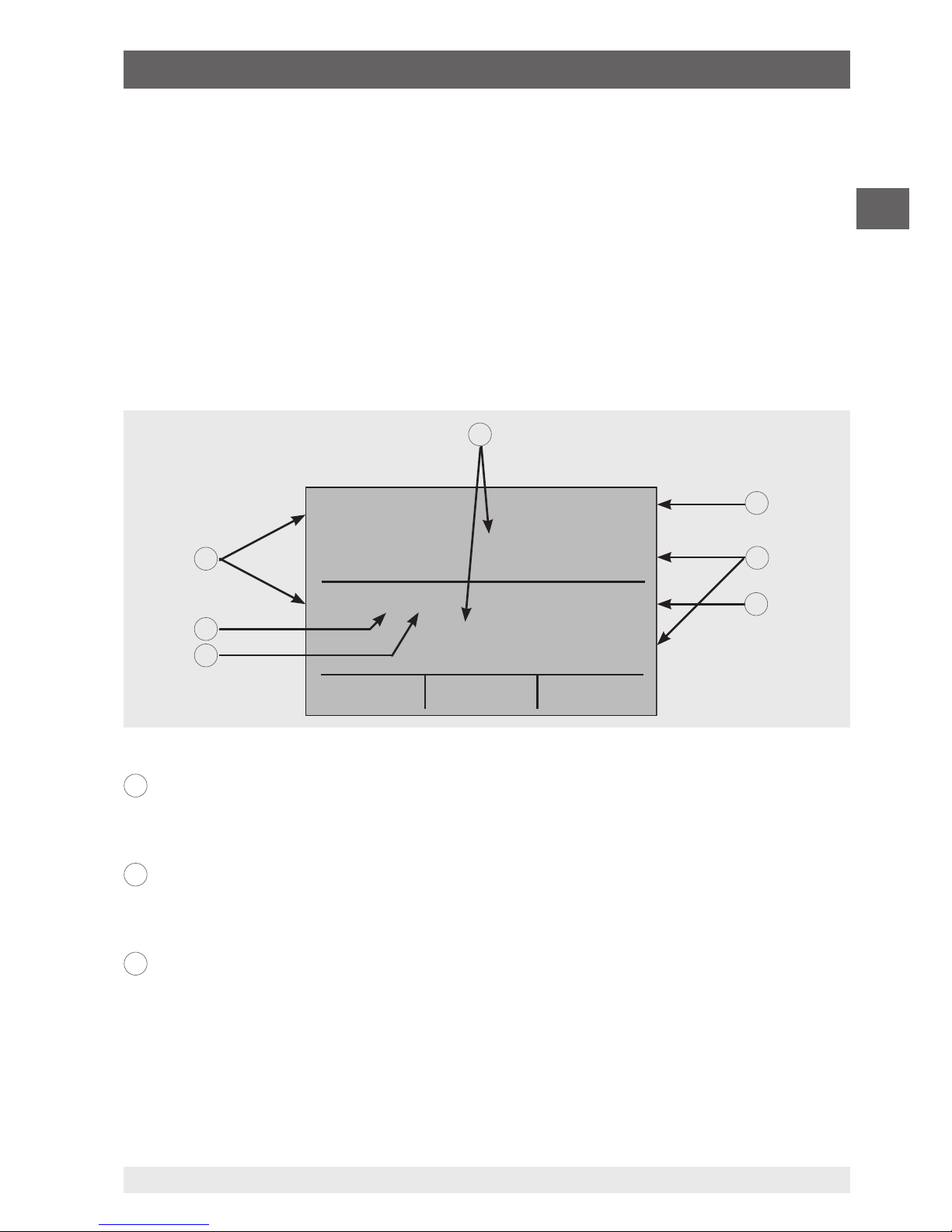

2.1 Overview

Display

Keypad

Connections

1

2

3

1. General information / 2. Short overview

Page 7

7

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

2.2 Description

The model CEP6000 hand-held multi-function calibrator is a battery-operated hand-held

instrument which can measure or simulate electrical parameters.

The model CEP6000 works with different thermocouples and resistance thermometers,

among others.

Very high accuracy and diverse special functions make the instrument to a user-friendly

and highly flexible calibration instrument.

2.3 Scope of delivery

■

Hand-held multi-function calibrator model CEP6000

■

Operating instructions

■

Test cables, three sets (red/black)

■

3.1 calibration certificate per DIN EN 10204

■

Four AA batteries

■

Protective rubber boot

■

Quick Start Guide

Cross-check scope of delivery with delivery note.

2. Short overview

Page 8

8

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

3. Safety

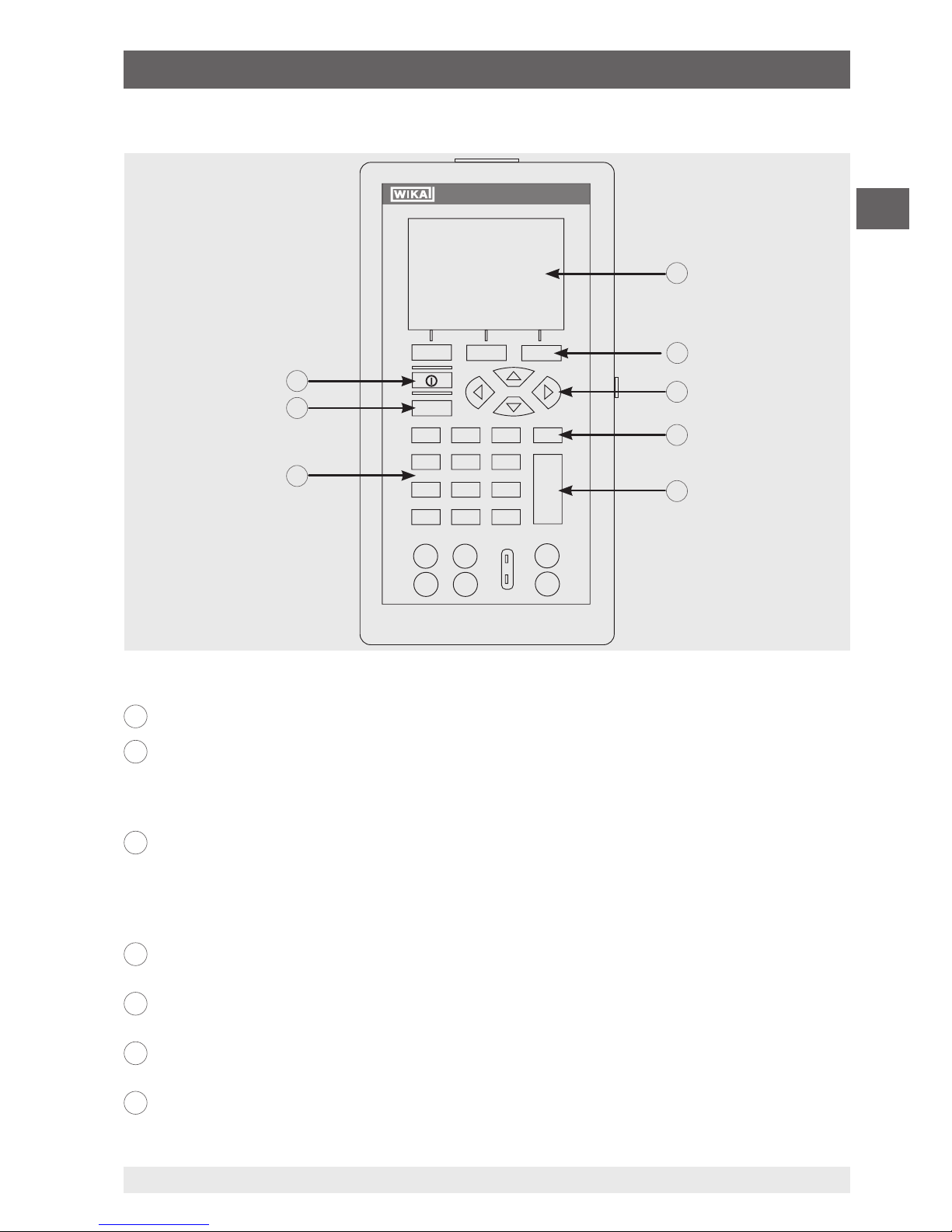

3.1 Explanation of symbols

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light injuries

or damage to equipment or the environment, if not avoided.

DANGER!

... identifies hazards caused by electrical power. Should the safety instructions not be observed, there is a risk of serious or fatal injury.

Information

... points out useful tips, recommendations and information for efficient

and trouble-free operation.

3.2 Intended use

The model CEP6000 hand-held multi-function calibrator is a battery-operated hand-held

instrument which can measure and output/simulate current, voltage, resistance, RTD’s,

TC’s, frequency and pulses.

In addition, external pressure sensors/pressure modules can be connected which enable

pressure to measure with this calibrator. The WIKA model CPT6600 pressure modules

and the Mensor model CPT6100/CPT6180 precision pressure sensors are compatible

here.

This instrument is not permitted to be used in hazardous areas!

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specifications contained in these operating instructions must be observed.

Improper handling or operation of the instrument outside of its technical specifications

3. Safety

Page 9

9

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

requires the instrument to be taken out of service immediately and inspected by an

authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic fields, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

The manufacturer shall not be liable for claims of any type based on operation contrary to

the intended use.

3.3 Improper use

WARNING!

Injuries through improper use

Improper use of the instrument can lead to hazardous situations and

injuries.

▶

Refrain from unauthorised modifications to the instrument.

▶

Do not use the instrument within hazardous areas.

▶

Only use accessories provided by WIKA.

Any use beyond or different to the intended use is considered as improper use.

Do not use this instrument in safety or emergency stop devices.

3.4 Responsibility of the operator

The instrument is used in the industrial sector. The operator is therefore responsible for

legal obligations regarding safety at work.

The safety instructions within these operating instructions, as well as the safety, accident

prevention and environmental protection regulations for the application area must be

maintained.

3. Safety

Page 10

10

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

3.5 Personnel qualification

WARNING!

Risk of injury should qualification be insufficient

Improper handling can result in considerable injury and damage to equipment.

▶

The activities described in these operating instructions may only be

carried out by skilled personnel who have the qualifications described

below.

Skilled personnel

Skilled personnel, authorised by the operator, are understood to be personnel who,

based on their technical training, knowledge of measurement and control technology and

on their experience and knowledge of country-specific regulations, current standards and

directives, are capable of carrying out the work described and independently recognising

potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

3.6 Labelling, safety marks

Product label

The product label is located on the side of the instrument beneath the protective rubber

boot.

Binary code

Serial no.

3. Safety

Page 11

11

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

Symbols

Before commissioning the instrument, ensure you read the operating

instructions!

Instruments bearing this mark comply with the relevant European directives.

This marking on the instruments indicates that they must not be disposed

of in domestic waste. The disposal is carried out by return to the manufacturer or by the corresponding municipal authorities (see EU directive

2002/96/EC).

4. Design and function

The model CEP6000 hand-held multi-function calibrator is a battery-operated hand-held

instrument which can measure and output/simulate current, voltage, resistance, RTD’s,

TC’s, frequency and pulses.

In addition, external pressure sensors/pressure modules can be connected which enable

pressure to measure with this calibrator. The WIKA model CPT6600 pressure modules

and the Mensor model CPT6100/CPT6180 precision pressure sensors are compatible

here.

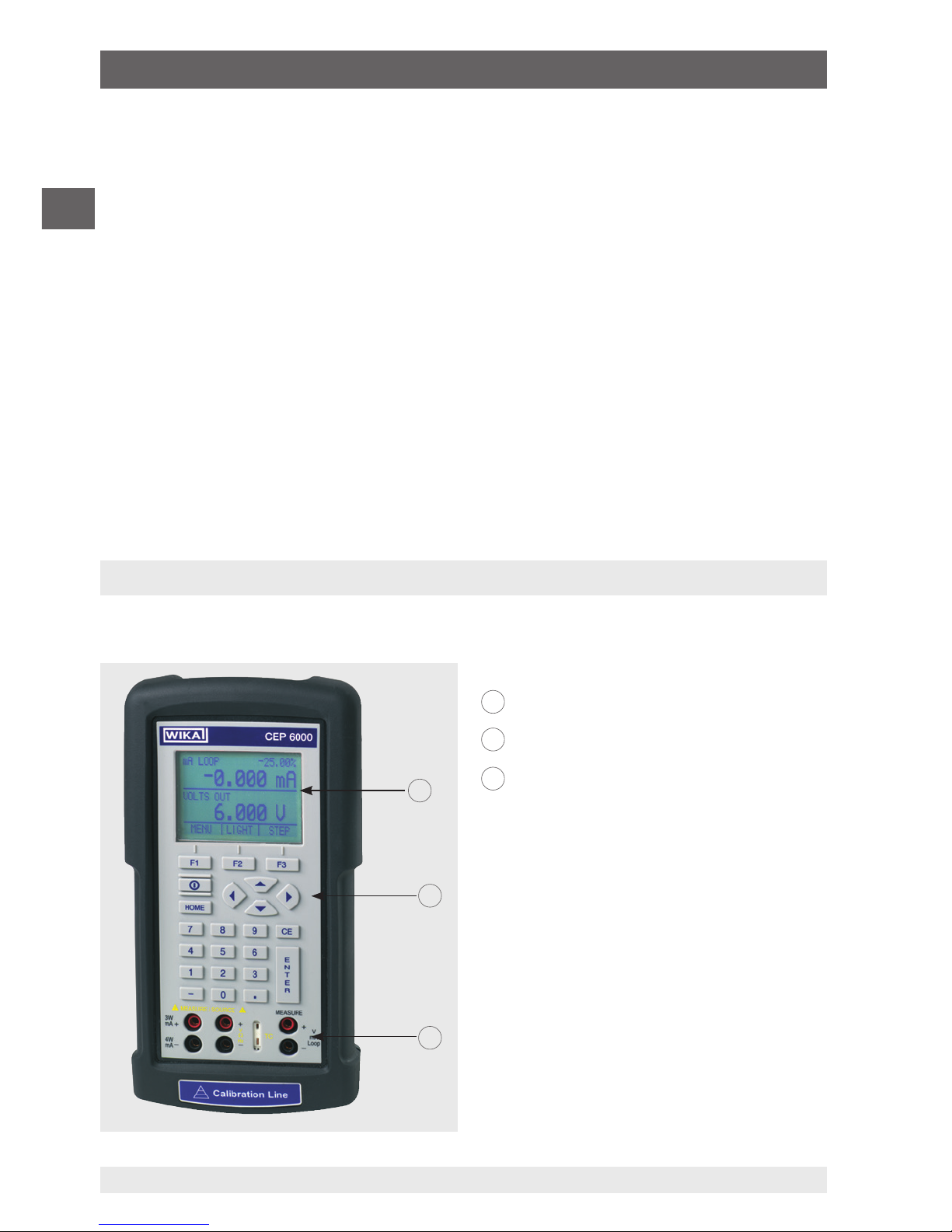

4.1 Front foil

The following figures show the location of the input and output terminals and also the

positions of the buttons on the calibrator.

3. Safety / 4. Design and function

Page 12

12

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

F1

HOME

7

F2 F3

89CE

E

N

T

E

R

4

1

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

–

5

2

0

6

3

.

4W

mA–

MEASURE

–

CEP6000

Ω

1

2

3

4

6

8

9

7 5

4.1.1 Connections

1

Connection for external pressure module

Connects the calibrator with a pressure module for pressure measurement.

2

Serial interface

Connects the calibrator with a PC for remote operation.

3

+

4

(Isolated) Current and voltage input as well as for output of DC 24 V voltage

supply

Terminals for the measurement of current, voltage and separate current loop supplies.

5

Thermocouple input/output

Terminal for the measurement or simulation of thermocouples. Suitable for polarised

miniature connectors for thermocouples.

6

+

7

Voltage, resistance thermometers (2-wire), frequency, pulse, input/output

Terminals for the simulation and measurement of voltage, frequency, pulse trains and

resistance thermometers (RTDs).

8

+

9

Current, resistance thermometers (3-wire, 4-wire), input/output

Terminals for the simulation and measurement of current and also for resistance thermometer measurements with 3- and 4-wire connection.

4. Design and function

Page 13

13

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

F1

HOME

7

F2 F3

89CE

E

N

T

E

R

4

1

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

–

5

2

0

6

3

.

4W

mA–

MEASURE

–

CEP6000

Ω

1

2

3

4

6

8

7

5

4.1.2 Key function

1

Display

2

Function keys, used to operate the menu bar at the bottom of the calibrator display

The [F1] key acts to select the options in the left-hand box, the [F2] key acts for the selection of

the functions in the middle box and the [F3] key for the selection of the functions in the righthand box.

3

Modification of individual digits of the output value; increase, decrease or ramp output

value

Use the left and right arrow buttons to select which digit in the output value should be changed.

With the up and down arrow keys, the output value can be increased, decreased or changed to

a ramp form.

4

Clear the input value

The last numerical value input will be deleted.

5

ENTER

Confirms the input of numerical values.

6

Numeric keys

Used for the input of numerical values.

7

HOME, returns to main menu

Reverts back to the start menu on the menu bar.

4. Design and function

Page 14

14

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

8

ON/OFF

Switches the calibrator on and off.

4.2 Batteries

4.2.1 Selecting the batteries or rechargeable batteries

The model CEP6000 works with four alkaline batteries (AA) or with four NiMH

rechargeable batteries (AA).

4.2.2 Using the power supply unit

CAUTION!

Physical injuries and damage to property and the environment

If alkaline batteries are used in the model CEP6000 hand-held multifunction calibrator, when the power supply unit is used at the same time,

overheating, severe damage and leakage can occur. Leakage of electrolyte from batteries presents a significant health risk.

▶

Only ever use the power supply unit without batteries or with NiMH

rechargeable batteries in the instrument.

▶

Only use undamaged and fault-free power supply units.

▶

Use WIKA accessories.

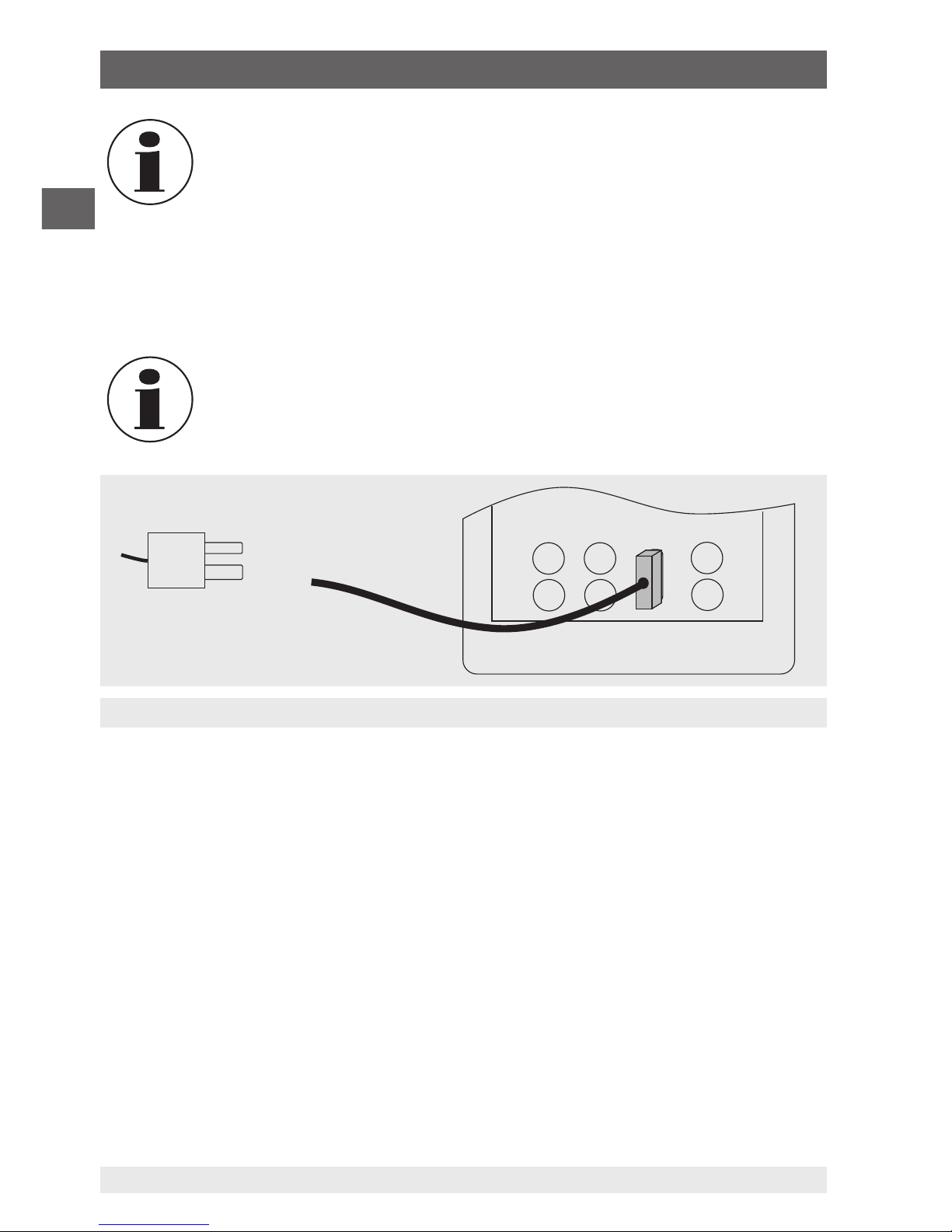

Using the power supply unit:

1. Remove alkaline batteries from the model CEP6000 hand-held multi-function

calibrator or insert rechargeable batteries in the calibrator’s compartment.

2. Connect the power supply unit to the calibrator.

3. Insert the power cord into the power connector.

Ensure that the correct power supply is present when doing this.

The NiMH rechargeable batteries in the instrument are recharged slowly.

Recharging takes between approx. 10 and 12 hours.

4. After use, disconnect the power cord from the mains and the calibrator.

4. Design and function

Page 15

15

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

5. Transport, packaging and storage

5.1 Transport

Check the model CEP6000 hand-held multi-function calibrator for any damage that may

have been caused by transport.

Obvious damage must be reported immediately.

CAUTION!

Damage through improper transport

With improper transport, a high level of damage to property can occur.

▶

When unloading packed goods upon delivery as well as during

internal transport, proceed carefully and observe the symbols on the

packaging.

▶

With internal transport, observe the instructions in chapter 5.2 “Packaging and storage”.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in instrument malfunction. Before putting it back into operation,

wait for the instrument temperature and the room temperature to equalise.

5.2 Packaging and storage

Do not remove packaging until just before use.

Keep the packaging as it will provide optimum protection during transport (e.g. change in

place of use, sending for repair).

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +70 °C

■

Humidity: 0 ... 90 % relative humidity (non-condensing)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Hazardous environments, flammable atmospheres

5. Transport, packaging and storage

Page 16

16

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

Store the model CEP6000 hand-held multi-function calibrator in its original packaging in

a location that fulfils the conditions listed above. If the original packaging is not available,

pack and store the instrument as described below:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag containing a

desiccant inside the packaging.

6. Commissioning, operation

ATTENTION!

Damage through electric shock

Higher voltages than the rated voltage can cause damage to the multifunction calibrator. With any damage to the case or the test cables, an

electric shock can result from any contact.

▶

Apply the correct rated voltage, see chapter 10 “Specifications”.

▶

Do not use the calibrator if it is damaged. Prior to use check the case of

the calibrator. Pay attention to missing plastic components and cracks,

in particular to the insulation around the connections.

▶

Do not use the calibrator in case of malfunction. The instrument

protection might be compromised. In case of doubt, have the calibrator

checked.

▶

The battery compartment must be closed and sealed.

▶

Change the batteries as soon as the battery symbol is displayed.

▶

Always use the correct connector sockets, functions and measuring

ranges for the measurement or simulation.

▶

Only open the battery compartment once all cable connections have

been disconnected from the calibrator.

▶

Check the test cables for damaged insulation or bare metal components. Test the continuity of the test cables. Replace any damaged test

cable before using the calibrator.

▶

Do not touch the metal parts at the test cables.

As soon as the model CEP6000 hand-held multi-function calibrator is turned on, by

pressing the ON/OFF key, it will go through a short self-test routine. During this routine,

the display shows the current firmware version and the auto-shutdown status. The

calibrator requires a maximum of 5 minutes warm-up to reach its specified accuracy.

Large changes in ambient temperature may make a longer warm-up period necessary.

5. Transport, packaging and storage / 6. Commissioning, ...

Page 17

17

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

mA IN

0.000 mA

-25.00%

RTD IN 4W P10-385

MENU

-OL °C

LIGHT

2

3

4

7

6

5

1

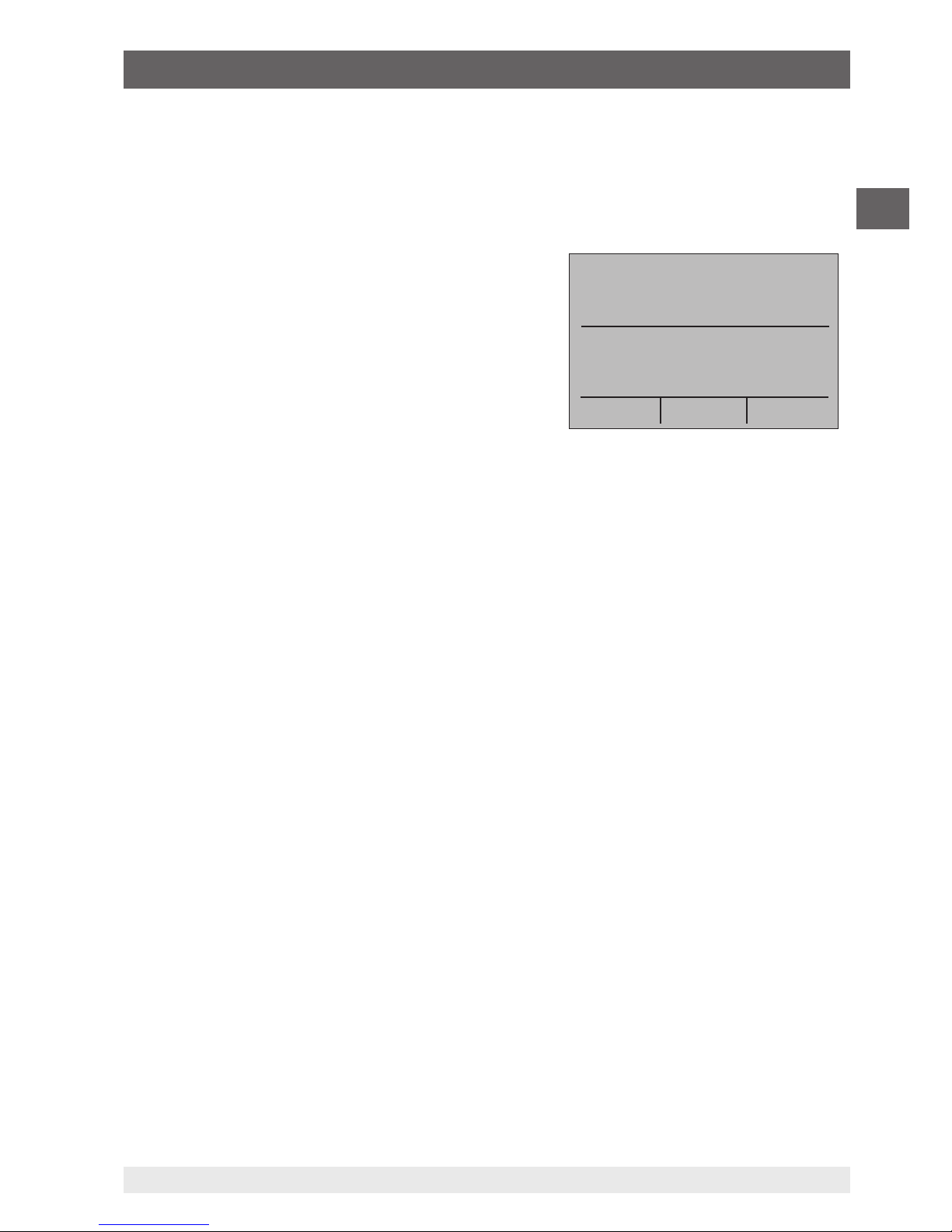

6.1 Main display

The display of the multi-function calibrator is subdivided into 3 main sections: the upper

display, the lower display and the menu bar.

■

The upper display is used for the measurement of direct current voltages, direct

current (with or without loop voltage) and for pressure measurement.

■

The lower display can be used both for measurement and for simulation.

■

The menu bar (at the bottom of the display) serves for configuration of the upper and

lower display (according to the desired function).

The following figure shows the location of the various display fields, which are described

in the table.

Numeric display

Displays the numeric value of the measured or simulated signals.

A measurement “OL” or “-OL” signals a value outside of the measuring range.

Display of the span

Only for the display “mA” and “mA LOOP”.

Displays the current measured value with respect to 4 mA = 0 % and 20 mA = 100 %.

Units

Displays the corresponding unit for measurement or output/simulation.

For “RTD” (resistance thermometer) and “TC” (thermocouple), °C or °F are offered; for

“FREQ” (frequency) and “PULSE” (pulse), CPM, Hz or kHz.

1

2

3

6. Commissioning, operation

Page 18

18

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

Sensor type

For measurements and simulation of various resistance thermometers (RTDs) and

thermocouples (TCs).

All possible sensor types are stated in the specifications (see chapter 10

“Specifications”). The options also show the amplitude of the pulse or frequency

simulation and the pressure unit.

Additional settings

Only available for the option “TC measurement” (thermocouple) and “RTD

measurement” (resistance thermometer).

With the option “TC”, this setting switches the cold junction compensation (CJC) on or

off.

With RTD measurements, this setting defines the number of wires for the

measurement (2W = 2-wire measurement, 3W = 3-wire measurement, 4W = 4-wire

measurement).

Input/output display

Switches the lower display between input mode (measuring) and output mode

(output/simulation).

Primary parameters

Defines which parameter will be measured or outputted/simulated.

The available options for the upper display are: “VOLTS IN” (input voltage),

“PRESSURE” (pressure), “mA IN” (input current in mA) and “mA LOOP” (mA with

DC 24 V voltage supply).

The available options for the lower display are: “VOLTS” (voltage), “TC”

(thermocouple), “RTD” (resistance thermometer), “FREQ” (frequency), “PULSE”

(pulse), “PRESSURE” (pressure) and “mA” (current) or “mA 2W SIM” (current

simulation).

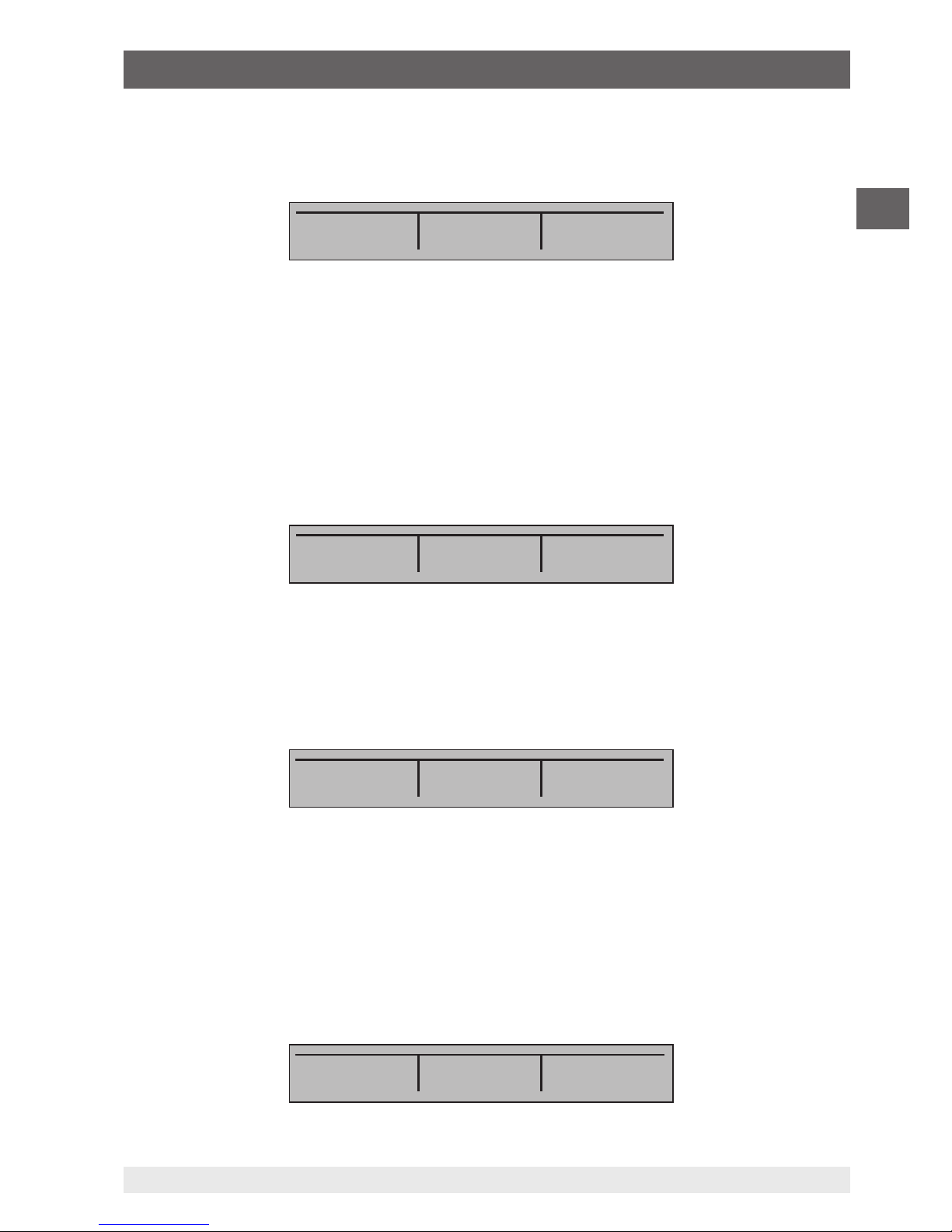

6.2 Menu bar

The display parameters are managed via the menu bar, which is found along the bottom

of the LCD display. The function keys [F1], [F2] and [F3] enable navigation through all

levels and options of the menu bar. The upper menu level is the start menu.

One can return to this at any time with the [HOME] key. There are three variants of the

start menu: the input start menu, the output start menu and the pulse start menu.

6.2.1 Menu function “Measuring”

In the start menu for the function “Measuring”, only the options “MENU” and “LIGHT” are

active. The option “MENU” calls the next menu level to the menu bar, i.e. to call the main

4

5

6

7

6. Commissioning, operation

Page 19

19

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

menu. Press the corresponding function key, [F1], to call the main menu.

The option “LIGHT” switches on the backlight for the LCD display. Press the corresponding function key [F2] to switch on the backlighting.

6.2.2 Menu function “Output”

In the start menu for the function “Output” there are three active options “MENU”, “LIGHT”

and “STEP” or “RAMP”.

The first two options work just like in the start menu. The third option can be selected

via the automatic output function menu option, and acts to switch on or off the selected

automatic function. For further information, see chapter 6.5.2 “Using the automatic output

functions”. The automatic output functions are stopped as soon as the menu is exited or

the [HOME] key is pressed.

6.2.3 Menu function “Pulse output”

The pulse start menu also has three active options, “MENU”, “TRIG” and “COUNTS”.

The options “TRIG” and “COUNTS” are used for pulse simulation. The function of these

options is explained in chapter 6.5.7 “Pulse output”.

6.2.4 Menu function “UPPER”, “LOWER” and “MORE”

The next level of the menu bar is the main menu itself. Which levels are available under

the main menu depends on the selected operating mode of the calibrator. The options are

“UPPER”, “LOWER” and “MORE”.

With “UPPER”, the selection menu for the parameters of the upper display will be called.

With “LOWER”, the selection menu for the parameters of the lower display will be called.

“MORE” switches to the next menu level.

MENU LIGHT

MENU LIGHT STEP

MENU TRIG

COUNTS

UPPER LOWER MORE

6. Commissioning, operation

Page 20

20

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

6.2.5 Menu function “Automatic output function”

The “Automatic output function” is a menu function in the “Output” mode and is called by

pressing “MORE”. The options are “AUTO FUNC”, “NEXT” and “DONE”.

With “AUTO FUNC” the parameters of the automatic output function can be set. “NEXT”

switches to the next menu function and “DONE” returns to the start menu. For further

information, see chapter 6.5.2 “Using the automatic output functions”.

6.2.6 Menu function “Contrast”

The next menu level is the contrast menu. The options are “CONTRAST”, “NEXT” and

“DONE”.

The option “CONTRAST” acts to set the contrast. “NEXT” switches to the next menu

function and DONE returns to the start menu. The contrast can be set with the arrow keys

[F1, F2], which are displayed after selecting the option “CONTRAST”.

In certain cases, large changes in contrast can make the display difficult to read under

normal conditions. If the display is too bright or too dark for the values to be read, the

following steps should be taken in order to reset the contrast setting to the default.

1. Turn the instrument on while holding the [HOME] key down.

2. Hold this button down for 10 seconds in order to reset the factory settings for the

contrast. If the display is so light that it is not possible to see whether the instrument is

switched on or off, use the button for the backlighting as an indication of this.

6.2.7 Menu function “Automatic switch-off”

The main menu for the automatic switch-off contains the options “AUTO OFF”, “NEXT”

and “DONE”.

The option “AUTO OFF” acts to switch on and off the automatic switch-off function and

specifies how long the instrument remains in standby before it switches off. “NEXT”

switches to the next menu function and “DONE” returns to the start menu.

AUTO FUNC

NEXT DONE

CONTRAST

NEXT DONE

AUTO OFF NEXT DONE

6. Commissioning, operation

Page 21

21

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

6.2.8 Menu function “Frequency or pulse output”

When the lower display is used for frequency or pulse outputs, in addition, the sub-menu

for frequency is displayed after the main menu. The options are “FREQ LEVEL”, “NEXT”

and “DONE”.

The option “FREQ LEVEL” enables the setting of the amplitude of the oscillation. “NEXT”

switches to the next menu function and “DONE” returns to the start menu.

6.2.9 Menu function “Probe-specific coefficients”

If the calibrator is working in the “RTD CUSTOM” mode, following the main menu,

the RTD menu for the user-defined configuration is displayed. The options are “SET

CUSTOM”, “NEXT” and “DONE”.

The option “SET CUSTOM” enables the input of the coefficients of a user-defined “PRT”

(platinum resistance thermometer) into the calibrator. “NEXT” switches to the next menu

function and “DONE” returns to the start menu.

6.2.10 Menu function “ZERO”

Resetting the pressure to the zero value is the final option on selecting “MORE” in the

main menu and is only shown if an external pressure sensor is connected. The options

are “ZERO”, “NEXT” and “DONE”.

The option “ZERO” acts to reset the pressure to zero. “NEXT” switches to the next menu

function and “DONE” returns to the start menu. For further information on resetting to 0,

see chapter 6.4.4 “Measuring pressure”.

FREQ LEVEL

NEXT DONE

SET CUSTOM

NEXT DONE

ZERO NEXT DONE

6. Commissioning, operation

Page 22

22

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

–

+

Ω

VOLTS IN

-0.000 V

VOLTS IN

MENU

5.000 V

LIGHT

Measuring voltage and frequency with the input and output terminals

6.2.11 Menu function “Parameter selection”

The menu for parameter selection is called via the main menu using “UPPER” or

“LOWER”. The options are “SELECT”, “NEXT” and “DONE”. When selected, one parameter flashes in the display.

Using the option “SELECT”, the parameter can be altered. With the option “NEXT”, one

can switch to another variable. “DONE” switches back to the start menu and accepts the

selection.

6.3 Cursor control/set point control

The output value can be changed using the four arrow keys on the keypad. If an arrow key

is pressed, a cursor appears under the last digit of the output value. Use the left and right

arrow buttons to select which digit in the output value should be changed. With the up

and down arrow keys, the output value can be increased or decreased. The menu bar will

change to the set point menu, as soon as one of the four arrow keys is pressed.

The three function keys are assigned the values “0 %”, “25 %” and “100 %”. The value for

0 and 100 % can be saved through the input of a value, when the corresponding function

key is held down at the same time. The key for “25 %” then switches to the value corresponding to 25 %.

6.4 Using the measuring modes (lower display)

6.4.1 Measuring voltage and frequency

To measure voltage or frequency, follow the steps below:

1. In the main menu, switch to the lower display “LOWER” and select “V” or “FREQ”.

2. The input/output setting must be set to “IN”.

3. Connect the test cables (see following figure).

SELECT NEXT DONE

0% 25% 100%

6. Commissioning, operation

Page 23

23

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

–

+

Ω

mA IN

0.000 mA

-25.00%

mA IN

MENU

5.000 mA

LIGHT

Measurement of the current in mA at the input and output

terminals

6.4.2 Measuring current (mA)

To measure current in mA, follow the steps below:

1. In the main menu, switch to the lower display “LOWER” and select “mA”.

2. The input/output setting must be set to “IN”.

3. Connect the test cables (see following figure).

6.4.3 Measuring temperature

6.4.3.1 Using thermocouples

The calibrator supports the following types of

thermocouples: B, C, E, J, K, L, N, R, S, T, U, BP and

XK. The typical characteristics of all of these types

are described in chapter 10 “Specifications”. The

calibrator also has a “CJC” (cold junction compensation) function. In normal operation, the function

will be activated, and it will measure the effective

temperature of the thermocouple. If the option “CJC”

is deactivated, the calibrator measures the difference between the thermocouple at the connection point and the input terminal of the

thermocouple.

The CJC option should only be deactivated when the calibration is being

made with an external ice bath.

To measure temperature with the thermocouple, follow the steps below:

1. Connect the wires of the thermocouple to the input/output of the calibrator using the

thermocouple mini-connector (see following figure).

mA IN

0.000 mA

-25.00%

TC IN CJC OFF B

MENU

OL °C

LIGHT

6. Commissioning, operation

Page 24

24

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

+

–

Ω

Measurement of the temperature at the thermocouple terminal

Thermocouple plug

The connecting cable for the thermocouple must match the type of the

thermocouple being calibrated.

2. In the main menu, switch to the lower display “LOWER” and select “TC”.

3. The input/output setting must be set to “IN”.

4. Select the corresponding thermocouple model in the menu.

5. Select temperature unit.

In the interests of optimum accuracy, wait 2 to 5 minutes so that the

temperature between the mini-connector and the calibrator stabilises.

After this, carry out the measurement.

The calibrator can measure the voltage of the thermocouple in mV, so that the temperature can be determined with the aid of a table if the corresponding thermocouple type is

not supported by the calibrator. For the case described above, proceed and select “mV”

as the type.

6.4.3.2 Using resistance thermometers (RTDs)

The supported resistance thermometers are detailed in the specifications in chapter

10 “Specifications”. The specific characteristic of RTDs is their temperature-dependent

resistance (R0). The calibrator can work with input signals with 2-, 3- or 4-wires, where

input measurements with 4-wire connection are the most accurate.

To measure temperature with resistance thermometers, follow the steps below:

1. In the main menu, switch to the lower display “LOWER” and select “RTD”.

2. The input/output setting must be set to “IN”.

3. Select 2-, 3- or 4-wire connection “2W, 3W, 4W”.

6. Commissioning, operation

Page 25

25

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

–

+

–

+

–

+

–

+

–

+

–

+

3W

4W

RTD

RT

D

RT

D

2W

Ω

mA IN

0.000 mA

-25.00%

RTD IN 4W P10-385

MENU

25.0 °C

LIGHT

Measuring the temperature with RTD probe connected

4. Select the corresponding RTD type in the menu.

5. Select temperature unit.

6. Connect the RTD wires (see following figure).

The resistance can also be measured with this function. For this, follow the steps as

described above, and as RTD type, select “OHMS”. With this option and a measurement table, an RTD probe that is not programmed into the calibrator can also be used for

measurement.

6.4.4 Measuring pressure

CAUTION!

Pressurisation

Damage within the pressure system due to open valves.

1. Close the valve.

2. Release the pressure slowly.

3. Connect the pressure module to the pressure line.

ATTENTION!

Damage to the threaded connections

The pressure module can be damaged by over-tightening the threaded

connection.

▶

Use suitable tools.

▶

Tighten the pressure connection with a maximum of 13.6 Nm (torque

spanner).

6. Commissioning, operation

Page 26

26

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

F1

HOME

7

F2 F3

89CE

E

N

T

E

R

4

1

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

–

5

2

0

6

3

.

4W

mA–

MEASURE

–

CEP6000

Ω

Connection for pressure measurement

Valve

Pressure

module

Pressure module

adapter

▶

Never exceed the permissible maximum pressure.

▶

Only use pressure modules with compatible media. See specification of

the pressure module.

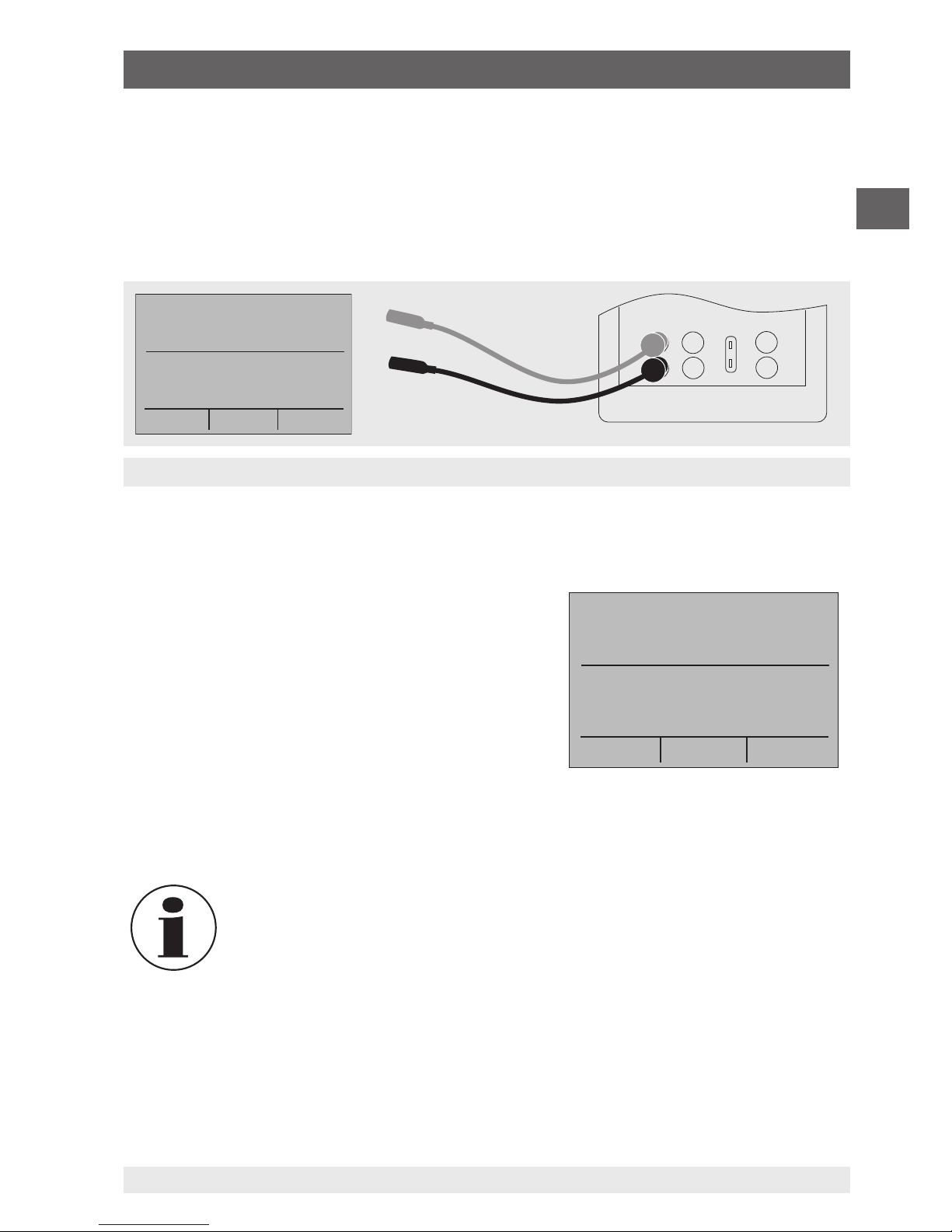

To measure pressure with external pressure modules, follow the steps below:

1. Connect the pressure module to the calibrator using the pressure module adapter (see

following figure).

For the connection of the pressure module to the calibrator, a WIKA

pressure module adapter must be used.

2. From the main menu, switch to the upper or lower display as required. The calibrator

measures pressure in the upper as well as the lower display. In this way, pressure can

be measured on two different units at the same time.

3. As the primary parameter, select “PRESSURE”.

4. Select the desired unit of measure.

■

With high-pressure modules, technical units of measure that are only

used for low pressure ranges, such as inH2O, cmH2O, etc., are not

valid selections. If one of these units is selected with a high-pressure

module connected, “----” is shown on the display.

5. Set the pressure module to zero (ZERO). The function to reset the calibrator is found

under the menu function “ZERO”.

6. Commissioning, operation

Page 27

27

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

6.4.4.1 Zeroing of absolute pressure modules

To reset the calibrator to zero, set it so that it measures a known pressure, for example the

barometric pressure.

To zero the calibrator, follow the steps below:

1. Call up the menu function “ZERO”.

2. Select “ZERO”. “SET REFERENCE ABOVE” will

be displayed.

3. Enter the reference pressure via the keypad.

The calibrator saves the barometric reference value

in permanent memory. The reference value will

always be saved for an absolute pressure module. If

a new absolute pressure module is connected, this

procedure must be repeated.

6.5 Using the output modes (lower display)

The calibrator can generate signals for testing and calibrating process instruments. It can

simulate voltage, current, resistance, frequency, pulses and the electrical output signal of a

resistance thermometer or a thermocouple.

6.5.1 Setting the output parameters 0 % and 100 %

To enter the 0 % and 100 % points, follow the steps below:

1. Select the lower display “LOWER” from the main menu and then select the required

function.

2. Select the output “OUT” at the input/output setting and enter the desired value.

(example: “VOLTS OUT”).

3. On the keypad, enter (for example) 5 V and press the enter key.

4. Press one of the arrow keys in order to select the set point setting from the menu.

5. Hold down the function key for “0 %” [F1]. The value 0 % will flash for a short time and

the set point (e.g. 5 V) will be saved.

6. Repeat these steps with (for example) 20 V and hold down the function key for “100 %”

[F3].

7. With the function key for “25 %”, it is now possible to move between 5 V and 20 V in

steps of 25 %.

PRESSURE

-------

psi

PRESSURE mbar

MENU

-------

LIGHT

6. Commissioning, operation

Page 28

28

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

mA LOOP

0.000 mA

-25.00 %

mA OUT

MENU

5.000 mA

LIGHT

–

+

UUT

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

Ω

Connection for use as a mA source

6.5.1.1 Increasing the output current in steps

To use the 25 % function with an output signal in the milliampere range, follow the

steps below:

1. Select the option “mA” for the lower display from the main menu.

2. With the key for “25 %”, it is possible to move between 4 mA and 20 mA in intervals of

25 %.

6.5.2 Using the automatic output functions

The step function and automatic ramp function are available as automatic output

functions. The selected function can be switched on and off via the start menu (“STEP” or

“RAMP”). The automatic output parameters can be set in the menu via “Automatic output

function”.

The parameters include:

■

Which automatic output function is available (step function or ramp function).

■

The time for the automatic output function defines the time between the individual

steps or, in the ramp function, the time between the first and second limit value in the

ramp.

■

The limit values for the ramp mode and step function are set to 0 % and 100 %. For

further information, see chapter 6.5.1 “Setting the output parameters 0 % and 100 %”.

The step increase is made in 25 % steps from 0 % to 100 %.

6.5.3 Current output

To output a current, follow the steps below:

1. In the main menu, switch to the lower display “LOWER” and select “mA”.

2. The input/output setting must be set to “OUT”.

3. Connect the test cables to the terminals for current output (see following figure).

4. Enter the desired current value via the keypad.

6. Commissioning, operation

Page 29

29

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

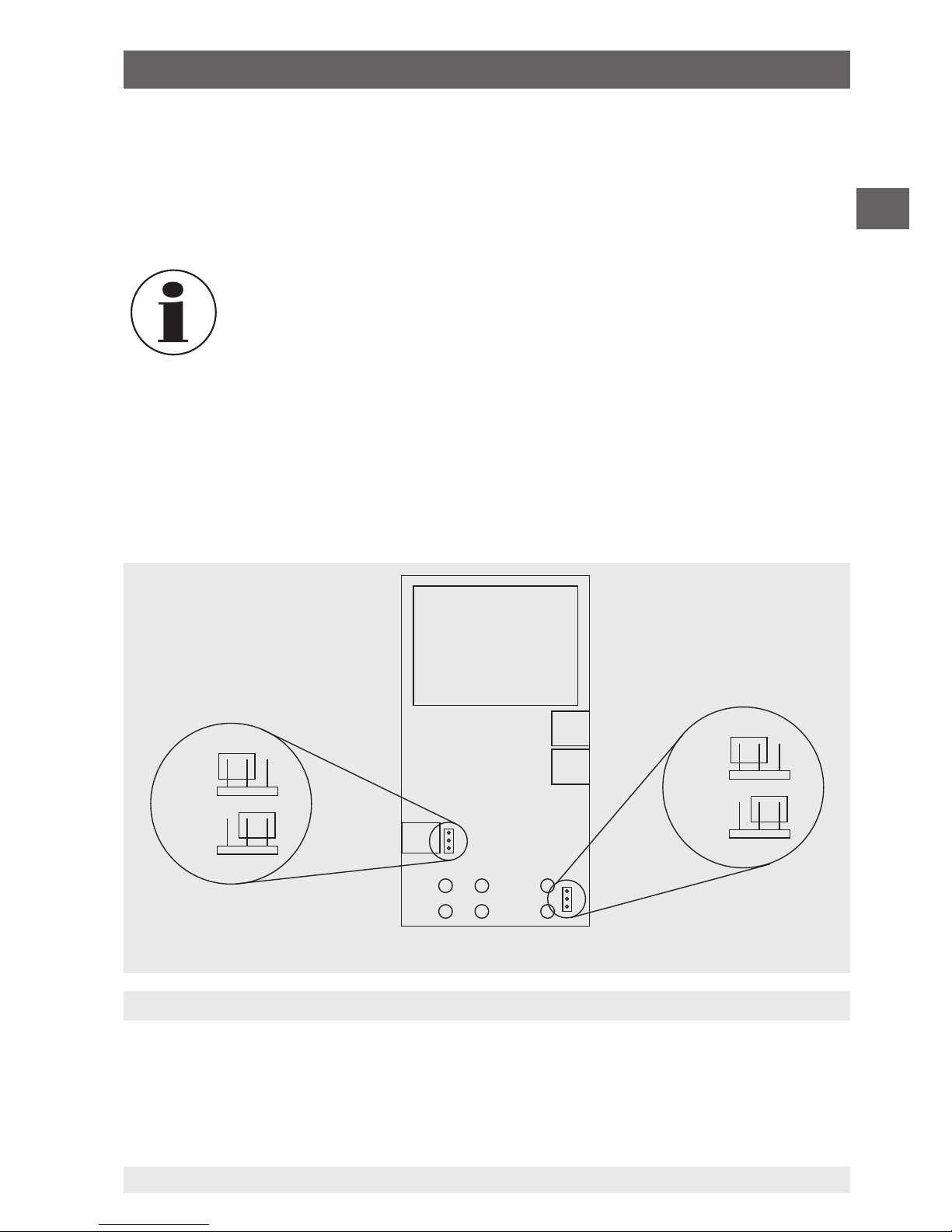

Position of the HART™ jumpers

HART™ resistor

Circuit board

6.5.3.1 HART™ resistor selection

The CEP6000 can be configured so that the 250 Ω resistor for HART™ compatible

instruments can be activated within the CEP6000. If the internal 250 Ω resistor within the

CEP6000 is used, a serial resistance for the calibration of HART™ modules must not be

activated.

When using the internal 250 Ω resistor, the maximum load resistance is

reduced from 1,000 Ω to 750 Ω, at a current of 20 mA.

6.5.3.2 HART™ resistor, activation/deactivation procedure

1. Remove the battery cover and loosen both of the screws on the upper part of the case.

2. Remove both of the screws on the lower part of the case.

3. Carefully remove the upper half of the case from the lower half.

The following picture indicates the position of the HART™ jumpers.

6. Commissioning, operation

OFF

OFF

ON

ON

Page 30

30

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

–

+

UUT

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

Ω

mA LOOP

0.000 mA

-25.00%

mA OUT

MENU

6.000 V

LIGHT

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

–

–

+

+

UUT

Ω

mA IN

0.000 mA

-25.00%

mA 2W SIM

MENU

4.000 mA

LIGHT

Connection for the transmitter simulation

Connections for voltage, frequency and pulse outputs

30 V max.

Voltage

supply

6.5.4 Simulating a transmitter

To use the calibrator to simulate a transmitter in a current loop, follow the steps

below:

1. In the main menu, switch to the lower display “LOWER” and select “mA 2W SIM”.

2. Enter the desired current with the keypad.

3. Connect the test cables to the terminals for current input (see following figure).

3. Connect the external DC 24 V voltage supply (see following figure).

6.5.5 Voltage output

To output a voltage, follow the steps below:

1. In the main menu, switch to the lower display “LOWER” and select “VOLTS”.

2. The input/output setting must be set to “OUT”.

3. Connect the test cables to the terminals for voltage output (see following figure).

4. Enter the desired voltage value via the keypad.

6. Commissioning, operation

Page 31

31

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

6.5.6 Frequency output

To output a frequency, follow the steps below:

1. In the main menu, switch to the lower display

“LOWER” and select “FREQ”.

2. The input/output setting must be set to “OUT”.

3. Set the corresponding frequency unit.

4. Connect the test cables to the terminals for

frequency output (see figure “Connections for

voltage, frequency and pulse outputs”).

5. Enter the desired frequency value via the keypad.

6. To change the amplitude, select the option

“FREQ LEVEL” in the menu function “Frequency or pulse output”.

7. Enter the desired amplitude value via the keypad.

6.5.7 Pulse output

The calibrator can generate a pulse train with an

adjustable number of pulses at a desired frequency.

As an example, if the frequency is set to 60 Hz and

the number of pulses set to 60, the calibrator will

generate 60 pulses in 1 second.

For operation as a pulse generator, the same

connections are used as for frequency “Output”.

To output a pulse, follow the steps below:

1. In the main menu, switch to the lower display “LOWER” and select “PULSE”.

2. Set the corresponding pulse unit.

3. Connect the test cables to the terminals for pulse output (see figure “Connections for

voltage, frequency and pulse outputs”).

4. With the function “COUNTS” in the start menu, the number of pulses is set. The signal

is started and stopped using the “TRIG” key.

5. To change the amplitude, select the option “FREQ LEVEL” in the menu function

“Frequency or pulse output”.

6.5.8 Simulating thermocouples

To simulate a thermocouple, follow the steps below:

1. Connect the wires of the thermocouple to the input/output of the calibrator using the

thermocouple mini-connector (see following figure).

2. In the main menu, switch to the lower display “LOWER” and select “TC”.

mA IN

0.000 mA

-25.00%

FREQ OUT

5.0 Vpp

MENU

4.0 kHz

LIGHT

mA LOOP

0.000 mA

-25.00%

PULSE

5.0 Vpp

MENU

5.0 kHz

TRIG COUNTS

6. Commissioning, operation

Page 32

32

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

mA LOOP

0.000 mA

-25.00%

RTD OUT P500-385

MENU

10.0 °C

LIGHT

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

Ω

mA IN

0.000 mA

-25.00%

TC OUT CJC OFF

E

MENU

100.0 °C

LIGHT

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

–

+

+

–

Ω

Simulating the temperature at the thermocouple terminal

Simulating resistance or resistance thermometers

Thermocouple plug

3. The input/output setting must be set to “OUT”.

4. Select the corresponding thermocouple model in the menu.

5. Select temperature unit.

6. Enter the temperature value or voltage value, respectively, via the keypad.

Used thermocouple wire must match the thermocouple type being

calibrated.

6.5.9 Simulating resistance or resistance thermometers

To simulate a resistance/resistance thermometer, follow the steps below:

1. Connect the wires of the RTD type to the input/output of the calibrator (see following

figure).

2. In the main menu, switch to the lower display “LOWER” and select “RTD”.

3. The input/output setting must be set to “OUT”.

4. Select the corresponding RTD type in the menu.

5. Select temperature unit.

6. Enter the temperature value or resistance value, respectively, via the keypad.

6. Commissioning, operation

Page 33

33

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

3W

4W

1

1

2

2

3

3

4

4

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

Ω Ω

3- or 4-wire connection for RTDs

Use stackable test

cables for common

terminals

The calibrator simulates an RTD probe with 2-wires. To connect a probe

with 3- or 4-wires, use the stackable test cables (see following figure).

6.5.9.1 Customer-specific resistance thermometer (RTD)

To achieve the highest possible accuracy, it is possible to load probe-specific resistance

thermometer coefficients into the calibrator.

To enter probe-specific coefficients, follow the steps below:

1. In the main menu, switch to the lower display “LOWER” and select “RTD”.

2. Select RTD type “CUSTOM”.

3. Select menu function “Probe-specific coefficients”.

4. Enter the values requested by the calibrator using the keypad.

▶

Minimum temperature

▶

Maximum temperature

▶

R

0

▶

Temperature coefficients

The custom function uses the Callendar–Van Dusen equation for output and measure-

ment of custom resistance thermometers. The coefficient C is used only for temperatures

6. Commissioning, operation

Page 34

34

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

–

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

+

Isolated input

below 0 °C. For the range above 0 °C, only the coefficients A and B are required, so

coefficient C is then set to 0. R0 is the resistance of the probe at 0 °C.

Coefficients for Pt385, Pt3926 and Pt3616

RTD Range R0 Coefficient A Coefficient B Coefficient C

Pt385 -260 ... 0 °C 100 3.9083 x 10

-3

-5.775 x 10

-7

-4.183 x 10

-12

Pt385 0 ... 630 °C 100 3.9083 x 10

-3

-5.775 x 10

-7

-

Pt3926 Under 0 °C 100 3.9848 x 10

-3

-5.87 x 10

-7

-4 x 10

-12

Pt3926 Above 0 °C 100 3.9848 x 10

-3

-5.87 x 10

-7

-

Pt3916 Under 0 °C 100 3.9692 x 10

-3

-5.8495 x 10

-7

-4.2325 x 10

-12

Pt3916 Above 0 °C 100 3.9692 x 10

-3

-5.8495 x 10

-7

-

6.6 Using the isolated measuring modes (upper display)

6.6.1 Measuring voltage (V) or current (mA)

To measure voltage or current on the isolated input channel, follow the steps

below:

1. In the main menu, switch to the upper display “UPPER” and select “V” or “mA”.

2. Connect the test cables to the calibrator’s isolated inputs (see following figure).

6.6.2 Current measurement with DC 24 V voltage supply

To test a 2-wire transmitter, which has an external power supply that is not connected,

use the function for separate voltage supply. This function activates a DC 24 V voltage

supply in series with the measuring current loop.

6. Commissioning, operation

Page 35

35

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

–

+

Ω

mA LOOP

0.000 mA

-25.00%

mA IN

MENU

-0.001 mA

LIGHT

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

Ω

Isolated input

Connection of a display instrument

Maximum current: 1 mA

To measure current with a DC 24 V voltage supply on the isolated input channel,

follow the steps below:

1. In the main menu, switch to the upper display “UPPER” and select “mA LOOP”.

2. Connect the test cables to the calibrator’s isolated inputs (see following figure).

6.7 Using the upper and lower displays for test and calibration

6.7.1 Calibrating a display instrument

To calibrate recording and display instruments using the output functions, follow

the steps below:

1. In the main menu, switch to the lower display “LOWER” and select the corresponding

parameter.

2. The input/output setting must be set to “OUT”.

3. Connect the test cables to the calibrator (see following figure).

6. Commissioning, operation

Page 36

36

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

F1

HOME

7

F2 F3

89CE

E

N

T

E

R

4

1

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

–

5

2

0

6

3

.

4W

mA–

MEASURE

–

CEP6000

Ω

–

+

Calibrating an I/P instrument

Pressure module

and pressure

module adapter

6.7.2 Calibrating an I/P instrument

To calibrate pressure-controlling instruments, follow the steps below:

1. In the main menu, switch to the upper display “UPPER” and select “PRESSURE”.

2. In the main menu, switch to the lower display “LOWER” and select “mA”.

3. The input/output setting must be set to “OUT”.

4. Connect the calibrator to the sensor using the mA output (see following figure).

5. Enter the current value via the keypad.

The calibrator simulates the transmitter current and measures the output

pressure with an external pressure module.

6.7.3 Calibrating a transmitter

To calibrate a transmitter, both displays (“UPPER” and “LOWER”) are used - the upper

display for measurement and the lower for output/simulation. In this example, a thermocouple transmitter is calibrated.

6. Commissioning, operation

Page 37

37

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

4W

mA–

MEASURE

–

Ω

Calibrating a TC temperature transmitter

To calibrate TC temperature transmitters, follow the steps below:

1. In the main menu, switch to the upper display “UPPER” and select “mA LOOP”.

2. In the main menu, switch to the lower display “LOWER” and select “TC”.

3. The input/output setting must be set to “OUT”.

4. Set the end values 0 % and 100 % with the keypad and the [0 %] and [100 %] keys

(also see chapter 6.5.1 “Setting the output parameters 0 % and 100 %”).

5. Connect the calibrator with the TC output to the TC input of the transmitter. In addition,

connect the calibrator, using its mA input, to the mA output of the transmitter (see

following figure).

6. Output a temperature value using the keypad or test 0-25-50-75-100 % using the 25 %

step function (25 % key).

To calibrate a different type transmitter, follow the steps above with the

exception of the selection of the lower display. Set the thermocouple with

the correct parameters for the transmitter.

6.7.4 Calibrating a pressure transmitter

To calibrate pressure transmitters, follow the steps below:

1. In the main menu, switch to the upper display “UPPER” and select “mA LOOP”.

2. In the main menu, switch to the lower display “LOWER” and select “PRESSURE”.

3. Connect the calibrator with the mA input to the mA output of the pressure transmitter.

In addition, connect the external pressure module with the pressure connection of the

6. Commissioning, operation

Page 38

38

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

–

+

F1

HOME

7

F2 F3

89CE

E

N

T

E

R

4

1

MEASURE / SOURCE

3W

mA+

TC

V

mA

Loop

+

V

Hz

–

+

–

5

2

0

6

3

.

4W

mA–

MEASURE

–

CEP6000

Ω

Calibrating a pressure transmitter

Pressure module

and pressure

module adapter

pressure transmitter (see following figure).

4. Zero the pressure module (see chapter 6.2.10 “Menu function “ZERO””).

5. Test the pressure transmitter at (for example) 0 % and 100 % of the measuring range.

7. Faults

Personnel: Skilled personnel

CAUTION!

Physical injuries and damage to property and the environment

If faults cannot be eliminated by means of the listed measures, the model

CEP6000 hand-held multi-function calibrator must be shut down immediately.

▶

Ensure that pressure or signal is no longer present and protect against

accidental commissioning.

▶

Contact the manufacturer.

▶

If a return is needed, please follow the instructions given in chapter 9.2

“Return”.

6. Commissioning, operation / 7. Faults

Page 39

39

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

For contact details, please see chapter 1 “General information” or the back

page of the operating instructions.

Faults Cause Measures

Low battery power, functioning

is only guaranteed for a short

period of time

Insert new alkaline batteries or

charged NiMH batteries

OL

-OL

Reading is significantly above

or

below the measuring range

Check: are the parameters

within the permissible

measuring range of the

calibrator

--> Match pressure or signal to

the permitted value

No display or

undefinable

characters,

instrument is not

responding to key

press

Battery empty Insert new alkaline batteries or

charged NiMH batteries

Mains operation without

battery: incorrect voltage/

polarity

Check/exchange power supply

unit

System error Switch off the instrument,

wait for a short period of time,

switch on again

Instrument faulty Send instrument in for repair

7. Faults

Page 40

40

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

8. Maintenance, cleaning and recalibration

Personnel: Skilled personnel

For contact details, please see chapter 1 “General information” or the back

page of the operating instructions.

8.1 Maintenance

This model CEP6000 multi-function calibrator is maintenance-free.

Repairs must only be carried out by the manufacturer.

This does not apply to the battery replacement.

Only use original parts (see chapter 11 “Accessories”).

Replacing the batteries

To eliminate measuring errors, change the batteries as soon as the battery symbol is

displayed. If the battery capacity is too low, the CEP6000 will automatically switch off in

order to prevent electrolyte escaping.

To replace the batteries or rechargeable batteries, follow the steps below:

1. Remove test cable and mains cable (for rechargeable battery power) from the

CEP6000.

2. Remove the screw from the battery compartment cover on the back and remove the

cover.

3. Remove batteries or rechargeable batteries, respectively.

4. Insert new batteries or charged rechargeable batteries.

Only alkaline batteries or size AA NiMH batteries, as an option, should be

used.

5. Replace the battery cover and screw in and tighten the screw.

8.2 Cleaning

1. Prior to cleaning, switch off and disconnect the instrument from the mains.

2. Clean the instrument with a moist cloth (moist cloth with water or water with soap

solution). Do not use any solvents.

8. Maintenance, cleaning and recalibration

Page 41

41

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

CAUTION!

Damage to property

Improper cleaning may lead to damage to the instrument!

▶

Do not use aggressive cleaning agents.

▶

Do not use any pointed and hard objects for cleaning.

▶

Electrical connections must not come into contact with moisture.

8.3 Recalibration

DKD/DAkkS certificate - official certificates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with

time intervals of approx. 12 months. The basic settings will be corrected if necessary.

9. Dismounting, return and disposal

Personnel: Skilled personnel

9.1 Dismounting

WARNING!

Physical injury

When dismounting the optional external pressure sensor, there is a

danger from aggressive media and high pressures.

▶

Observe the information in the material safety data sheet for the

corresponding medium.

▶

Disconnect the pressure sensor once the system has been

depressurised.

9.2 Return

Strictly observe the following when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazardous substances

(acids, bases, solutions, etc.) and must therefore be cleaned before being returned.

WARNING!

Physical injuries and damage to property and the environment

through residual media

Residual media on the model CEP6000 hand-held multi-function calibrator

can result in a risk to persons, the environment and equipment.

▶

With hazardous substances, include the material safety data sheet for

the corresponding medium.

▶

Clean the instrument, see chapter 8.2 “Cleaning”.

8. Maintenance, cleaning and recalibration / 9. Dismounting, ...

Page 42

42

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

When returning the instrument, use the original packaging or a suitable transport

packaging.

To avoid damage:

1. Wrap the instrument in an antistatic plastic film.

2. Place the instrument, along with the shock-absorbent material, in the packaging. Place

shock-absorbent material evenly on all sides of the transport packaging.

3. If possible, place a bag containing a desiccant inside the packaging.

4. Label the shipment as carriage of a highly sensitive measuring instrument.

Information on returns can be found under the heading “Service” on our

local website.

9.3 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specific waste disposal regulations.

This marking on the instruments indicates that they must not be

disposed of in domestic waste. The disposal is carried out by return to

the manufacturer or by the corresponding municipal authorities (see EU

directive 2002/96/EC).

9. Dismounting, return and disposal

Page 43

43

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

10. Specifications

Basic instrument

Indication

Display 2-part, each with 10 digits and 8 mm character size

Input and output

Number and type 6 banana plug inputs for electrical parameters, resistance

thermometers and thermocouples

Resistance thermometer

(RTD)

Pt100 (385, 3926, 3916), Pt200, Pt500, Pt1000, Ni120, Cu10,

Cu50, Cu100, YSI400, Pt10, Pt50

Thermocouples Type J, K, T, E, R, S, B, L, U, N, C, XK, BP

Voltage signal Input: DC 30 V

Output: DC 20 V

Current signal Input: DC 24 mA

Output: DC 24 mA

Resistor 0 ... 4,000 Ω

Frequency/Pulse 2 CPM ... 10 kHz

Pressure dependent on pressure module

Voltage supply DC 24 V

Special features

Resistance thermometers

frequency response

5 ms; works with all pulsed transmitters

Customer-specific resistance

thermometers

Entry of customer-specific resistance thermometer coefficients

Functions automatic step function

Resistor HART® resistor, 250 Ω (activatable)

Communication

Interface RS-232, USB with optional serial adapter

Voltage supply

Power supply 4 x 1.5 V AA batteries

Battery life 20 hours

Battery status indication Icon in display for low battery level

10. Specifications

Page 44

44

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

Basic instrument

Permissible ambient conditions

Operating temperature -10 ... +50 °C

Storage temperature -20 ... +70 °C

Relative humidity 0 ... 90 % r. h. (non-condensing)

Temperature coefficient 0.003 % FS/°C, outside of 23 °C ±5 °C

Case

Material Plastic (with robust protective rubber boot)

Ingress protection IP 52

Dimensions see technical drawing

Weight approx. 860 g

CE conformity and certificates

CE conformity

EMC directive 2004/108/EC, EN 61326 emission (group 1, class B) and

interference immunity (portable test and measuring equipment)

Certificate

Calibration Standard: 3.1 calibration certificate per DIN EN 10204

Option: DKD/DAkkS calibration certificate

Approvals and certificates, see website

10. Specifications

Page 45

45

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

Input and

output signals

Measuring range Accuracy

(of reading)

Current signal

Output DC 0.000 ... 24.000 mA 0.015 % ±2 µA

Input DC 0.000 ... 24.000 mA (isolated)

DC 0.000 ... 24.000 mA (non-isolated)

0.015 % ±2 µA

0.015 % ±2 µA

Voltage signal

Output DC 0.000 ... 20.000 V 0.015 % ±2 mV

Input DC 0.000 ... 30.000 V (isolated)

DC 0.000 ... 20.000 V (non-isolated)

0.015 % ±2 mV

0.015 % ±2 mV

Resistance Stimulus current

Output 5.0 ... 400.0 Ω

5.0 ... 400.0 Ω

401 ... 1,500 Ω

1,501 ... 4,000 Ω

0.025 % ±0.1 Ω

0.025 % ±0.05 Ω

0.025 % ±0.5 Ω

0.025 % ±0.5 Ω

0.1 ... 0.5 mA

0.5 ... 3.0 mA

0.05 ... 0.8 mA

0.05 ... 0.4 mA

Input 0.00 ... 400.00 Ω

400.1 ... 4,000.0 Ω

0.025 % ±0.05 Ω

0.025 % ±0.5 Ω

Frequency

1)

Output 2.0 ... 600.0 CPM

2)

1.0 ... 1,000.0 Hz

1.0 ... 10.0 kHz

0.05 %

0.05 %

0.25 %

Input 2.0 ... 600.0 CPM

2)

1.0 ... 1,000.0 Hz

1.00 ... 10.00 kHz

0.05 % ±0.1 CPM

2)

0.05 % ±0.1 Hz

0.05 % ±0.01 kHz

Pulse

1)

Output 1 ... 30,000 counts

2.0 CPM 2) ... 10.0 kHz

Pressure

Input dependent on pressure module

1) Selectable amplitude of 1 ... 20 V based on a square wave

2) Counts per minute

10. Specifications

Page 46

46

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

Input and output

signals

Measuring range Accuracy

(all errors incl.)

Thermocouple voltage

signals

-10.000 ... +75.000 mV 0.02 % of reading ± 10 µV

Thermocouples Without cold junction

compensation

With cold junction

compensation

3)

Type J -210.0 ... -150.0 °C

-149.9 ... +1,200.0 °C

0.4 °C

0.2 °C

0.6 °C

0.4 °C

Type K -200.0 ... -100.0 °C

-99.9 ... +600.0 °C

600.1 ... 1,000.0 °C

1,000.1 ... 1,372.0 °C

0.5 °C

0.2 °C

0.3 °C

0.4 °C

0.7 °C

0.4 °C

0.5 °C

0.6 °C

Type T -250.0 ... -200.0 °C

-199.9 ... 0.0 °C

0.1 ... 400.0 °C

1.5 °C

0.5 °C

0.2 °C

1.7 °C

0.7 °C

0.4 °C

Type E -250.0 ... -200.0 °C

-199.9 ... -100.0 °C

-99.9 ... +1,000.0 °C

1.0 °C

0.3 °C

0.2 °C

1.2 °C

0.5 °C

0.4 °C

Type R 0 ... 200 °C

201 ... 1,767 °C

1.7 °C

1.0 °C

1.9 °C

1.2 °C

Type S 0 ... 200 °C

201 ... 1,767 °C

1.7 °C

1.1 °C

1.9 °C

1.3 °C

Type B 600 ... 800 °C

801 ... 1,000 °C

1,001 ... 1,820 °C

1.5 °C

1.2 °C

1.0 °C

1.7 °C

1.4 °C

1.2 °C

Type C 0.0 ... 1,000.0 °C

1,000.1 ... 2,316.0 °C

0.5 °C

1.5 °C

0.7 °C

1.7 °C

Type XK -200.0 ... +800.0 °C 0.2 °C 0.4 °C

Type BP 0.0 ... 800.0 °C

800.1 ... 2,500.0 °C

1.9 °C

0.6 °C

2.1 °C

0.8 °C

Type L -200.0 ... +900.0 °C 0.2 °C 0.4 °C

Type U -200.0 ... 0.0 °C

0.1 ... 600.0 °C

0.4 °C

0.2 °C

0.6 °C

0.4 °C

Type N -200.0 ... -100.0 °C

-99.9 ... +1,300.0 °C

0.8 °C

0.3 °C

1.0 °C

0.5 °C

3) Error of cold junction compensation outside of 23 ± 5 °C is 0.05 °C/°C.

10. Specifications

Page 47

47

WIKA operating instructions, model CEP6000

MM/YYYY country code based on 10/2014 GB/CN

GB

Input and output

signals

Measuring range Accuracy

(all errors incl.)

Resistance thermometer

4)

Pt100 (385) -200.0 ... -80.0 °C

-79.9 ... +300.0 °C

300.1 ... 630.0 °C

630.1 ... 800.0 °C

0.1 °C