Page 1

Operating instructions

Betriebsanleitung

Mode d‘emploi

Manual de instrucciones

Manuale d‘uso

Precision loop calibrator, model CEP1000

Präziser Stromschleifenkalibrator, Typ CEP1000

Calibrateur de boucle de précision, type CEP1000

Calibrador preciso de bucles de corriente, modelo CEP1000

Calibratore di loop di precisione, modello CEP1000

GB

D

F

E

I

Precision loop calibrator, model CEP1000

Page 2

GB

Operating instructions model CEP1000 Page 3 - 24

D

Betriebsanleitung Typ CEP1000 Seite 25 - 46

F

Mode d'emploi type CEP1000 Page 47 - 68

E

Manual de instrucciones modelo CEP1000

Manuale d'uso modello CEP1000 Pagina 91 - 112

I

© WIKA Alexander Wiegand SE & Co. KG 2010

Prior to starting any work, read the operating instructions!

Keep for later use!

Página 69 - 90

Vor Beginn aller Arbeiten Betriebsanleitung lesen!

Zum späteren Gebrauch aufbewahren!

Lire le mode d'emploi avant de commencer toute opération !

A conserver pour une utilisation ultérieure !

¡Leer el manual de instrucciones antes de comenzar cualquier trabajo!

¡Guardar el manual para una eventual consulta posterior!

Prima di iniziare ad utilizzare lo strumento, leggere il manuale d‘uso!

Conservare per future consultazioni!

2

WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 3

Contents

Contents

1. General information 4

2. Safety 5

2.1 Intended use 6

2.2 Personnel qualication 6

2.3 Special hazards 7

3. Specications 8

4. Design and function 9

4.1 Short description / Description 9

4.2 Scope of delivery 10

4.3 Front foil of the CEP1000 10

4.4 Battery selection 11

4.5 Input protection 11

5. Transport, packaging and storage 11

5.1 Transport 11

5.2 Packaging 11

5.3 Storage 11

6. Commissioning, operation 12

6.1 First steps 13

6.1.1 Battery saving function 13

6.1.2 HART™ resistance conguration 14

6.2 Basic operating modes 15

6.2.1 Milliampere source 15

6.2.2 Milliampere simulation 16

6.2.3 Milliampere measurement 17

6.2.4 Milliampere measurement with 24 V power supply 17

6.2.5 Voltage measurement 18

6.3 Advanced operating modes 19

6.3.1 Automatic step function/automatic ramp mode 19

6.3.2 Fault percentage function 19

6.3.3 Data acquisition for minimum and maximum 20

7. Maintenance, cleaning and service (recalibration) 21

7.1 Maintenance 21

7.2 Cleaning 21

7.3 Recalibration 21

8. Faults 22

9. Return and disposal 22

9.1 Return 22

9.2 Disposal 23

10. Accessories 23

GB

11570351.02 10/2010 GB/D/F/E/I

3WIKA operating instructions, model CEP1000

Page 4

1. General information

1. General information

■

GB

The loop calibrator described in the operating instructions has been manufactured

using state-of-the-art technology.

All components are subject to stringent quality and environmental criteria during

production. Our management systems are certied to ISO 9001 and ISO 14001.

■

These operating instructions contain important information on handling the instrument. Working safely requires that all safety instructions and work instructions are

observed.

■

Observe the relevant local accident prevention regulations and general safety regulations for the instrument's range of use.

■

The operating instructions are part of the instrument and must be kept in the immediate vicinity of the instrument and readily accessible to skilled personnel at any time.

■

Skilled personnel must have carefully read and understood the operating instructions, prior to beginning any work.

■

The manufacturer's liability is void in the case of any damage caused by using the

product contrary to its intended use, non-compliance with these operating instructions, assignment of insuciently qualied skilled personnel or unauthorised modications to the instrument.

■

The general terms and conditions, contained in the sales documentation, shall apply.

■

Subject to technical modications.

■

Factory calibrations/DKD/DAkkS calibrations are carried out in accordance with

international standards.

■

Further information:

- Internet address:

- Relevant data sheet:

- Application consultant: Tel.: (+49) 9372/132-9986

www.wika.de / www.wika.com

CT 81.01

Fax: (+49) 9372/132-217

E-Mail: testequip@wika.de

4 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 5

1. General information / 2. Safety

Explanation of symbols

2. Safety

WARNING!

... indicates a potentially dangerous situation that can result in serious

injury or death, if not avoided.

CAUTION!

... indicates a potentially dangerous situation that can result in light

injuries or damage to equipment or the environment, if not avoided.

Information

... points out useful tips, recommendations and information for ecient

and trouble-free operation.

DANGER!

...identies hazards caused by electric power. Should the safety instructions not be observed, there is a risk of serious or fatal injury.

GB

WARNING!

Before installation, commissioning and operation, ensure that the

appropriate loop calibrator been selected in terms of measuring range,

design and specic measuring conditions.

Non-observance can result in serious injury and/or damage to equipment.

Further important safety instructions can be found in the individual

chapters of these operating instructions.

11570351.02 10/2010 GB/D/F/E/I

5WIKA operating instructions, model CEP1000

Page 6

2. Safety

2.1 Intended use

The precision loop calibrator CEP1000 is designed for high-accuracy measuring and

simulation of current and voltage.

GB

The instrument has been designed and built solely for the intended use described here,

and may only be used accordingly.

The technical specications contained in these operating instructions must be

observed. Should the instrument be improperly handled or operated outside of its

technical specications, it has to be taken out of service immediately and inspected by

an authorised WIKA service engineer.

Handle electronic precision measuring instruments with the required care (protect from

humidity, impacts, strong magnetic elds, static electricity and extreme temperatures,

do not insert any objects into the instrument or its openings). Plugs and sockets must be

protected from contamination.

If the instrument is transported from a cold into a warm environment, the formation of

condensation may result in the instrument malfunctioning. Before putting it back into

operation, wait for the instrument temperature and the room temperature to equalise.

The manufacturer shall not be liable for claims of any type based on operation contrary

to the intended use.

2.2 Personnel qualication

WARNING!

Risk of injury should qualication be insucient!

Improper handling can result in considerable injury and damage to

equipment.

■

The activities described in these operating instructions may only

be carried out by skilled personnel who have the qualications

described below.

■

Keep unqualied personnel away from hazardous areas.

Skilled personnel

Skilled personnel are understood to be personnel who, based on their technical training,

knowledge of measurement and control technology and on their experience and knowl-

edge of country-specic regulations, current standards and directives, are capable of

carrying out the work described and independently recognising potential hazards.

Special operating conditions require further appropriate knowledge, e.g. of aggressive

media.

6 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 7

2. Safety

2.3 Special hazards

WARNING!

For hazardous media such as oxygen, acetylene, ammable or toxic

gases or liquids, and refrigeration plants, compressors, etc., in addition

to all standard regulations, the appropriate existing codes or regulations must also be followed.

WARNING!

Protection from electrostatic discharge (ESD) required.

The proper use of grounded work surfaces and personal wrist straps is

required when working with exposed circuitry (printed circuit boards),

in order to prevent static discharge from damaging sensitive electronic

components.

To ensure safe working on the instrument, the operating company must

ensure that the operating personnel are regularly instructed in all topics

regarding work safety, rst aid and environmental protection and knows

the operating instructions and, in particular, the safety instructions

contained therein.

DANGER!

Danger of death caused by electric current!

Operation using a defective power supply unit (e.g. short circuit from

the mains voltage to the output voltage) can result in life-threatening

voltages at the instrument!

GB

11570351.02 10/2010 GB/D/F/E/I

7WIKA operating instructions, model CEP1000

Page 8

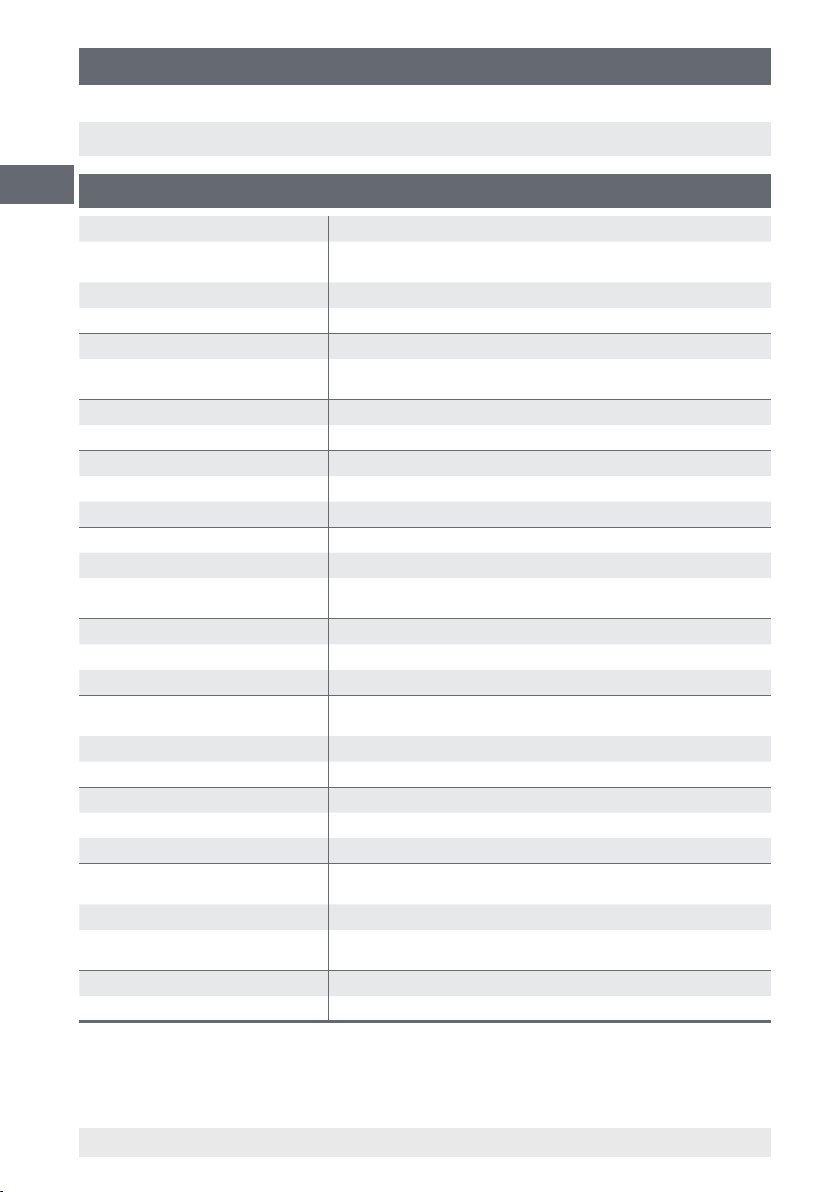

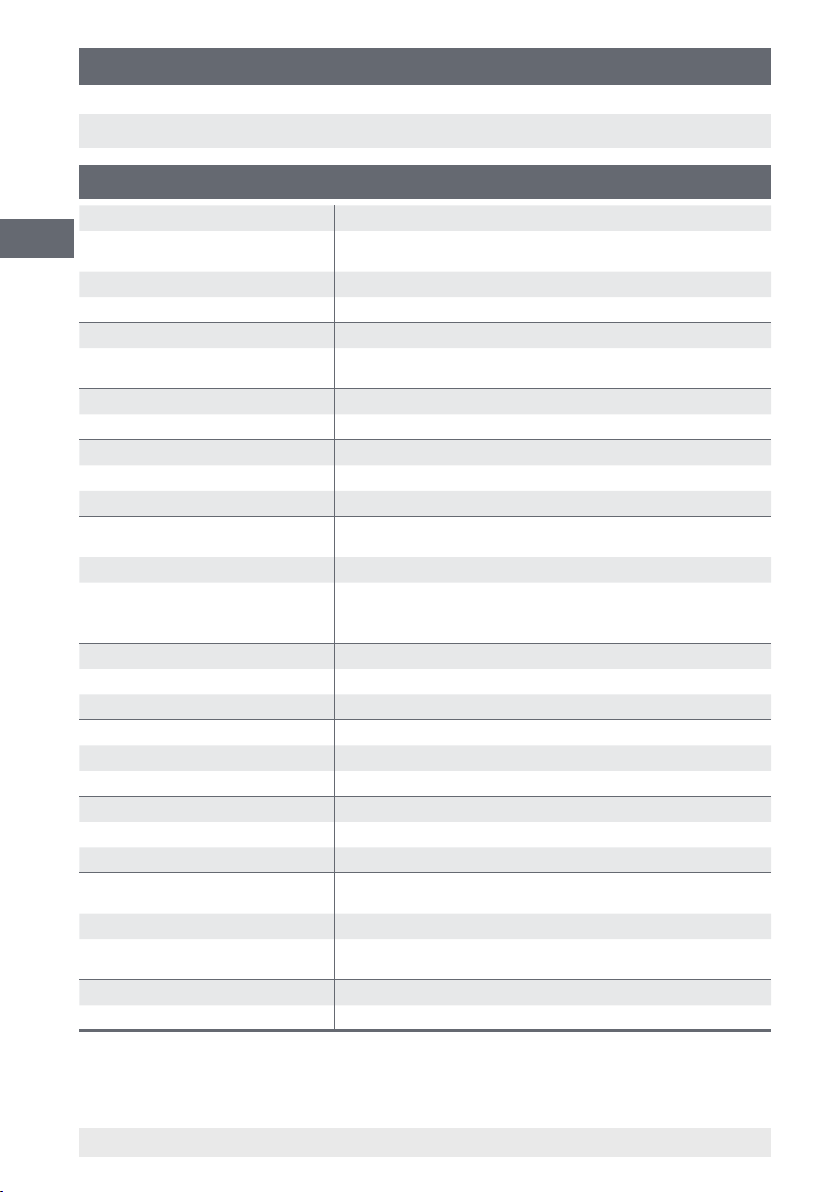

3. Specications

3. Specications

GB

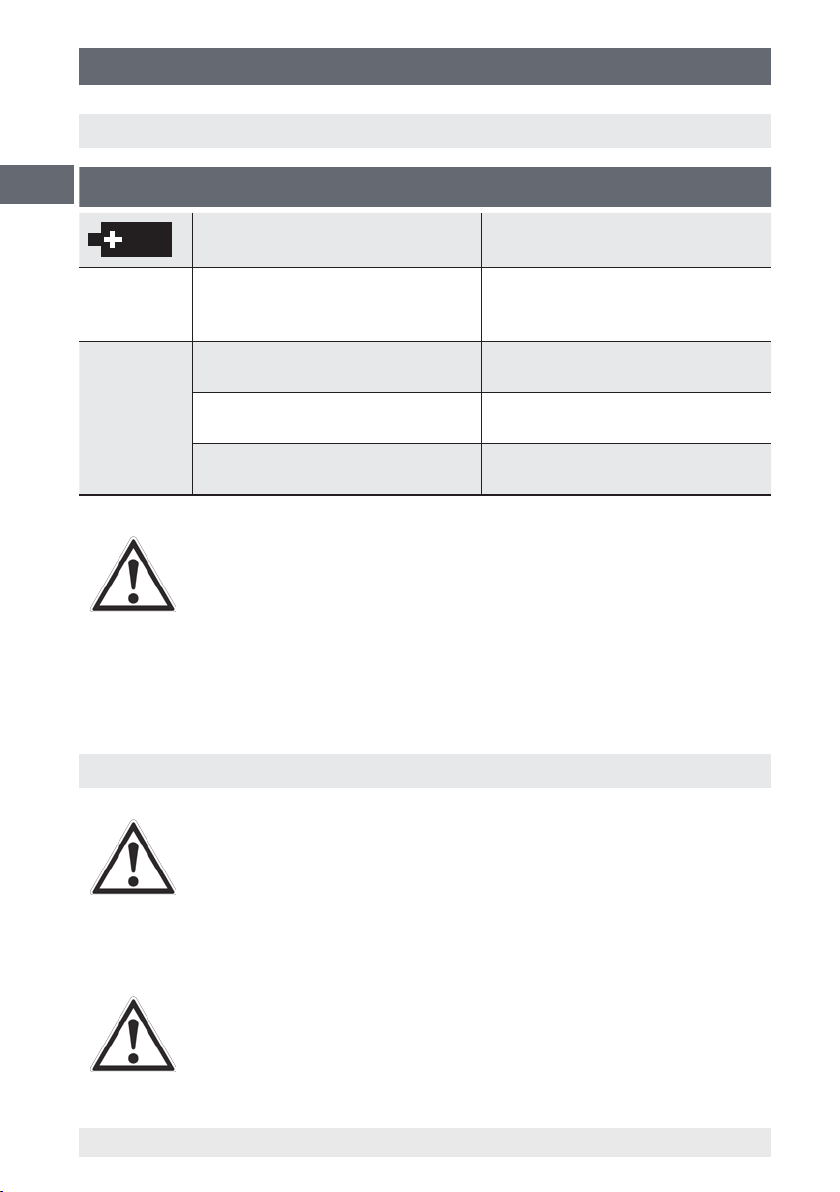

Specications

Input

Current range 0.000 … 24.000 mA

Voltage range DC 0.000 … 28.000 V

Input protection Fuseless, up to AC 250 V

Output

Current range 0.000 … 24.000 mA

Uncertainty ± 0.015 % of reading ± 2 µA

Resolution 1 µA, 1 mV

Drive capability

■

Without HART™-resistor 1200 Ω

■

With HART™-resistor 950 Ω

Loop supply voltage DC 24 V

Range select Decade; incremental to 0.001 mA steps

Special features Auto step/ramp, Auto “%-Error” function, built-in resistor

Permissible

■

Operating temperature -10 … +55 °C

■

Storage temperature -20 … +70 °C

Display 5 1/2-digit with character size 9 mm and %-announce-

Range mA, V, %

Recording options MIN-/MAX-storage

Power supply DC 9 V battery

■

Battery life 12 hours (12 mA into 250 Ω continuous)

■

Low battery indicator displayed icon near the end of battery life

EMC / CE conformity 2004/108/EC, EN 61326 Emission (Group 1, Class B) and

Ingress protection IP 52

Calibration 3.1 calibration certicate per DIN EN 10204 (option: DKD/

Dimensions 144.7 x 80.0 x 36.3 mm

Weight approx. 340 g

-25.00 … +125.00 %

-25.00 … +125.00 %

for HART™ communications

ment

Immunity (portable equipment)

DAkkS-calibration certicate)

For further specications see WIKA data sheet CT 81.01 and the order documentation.

8 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 9

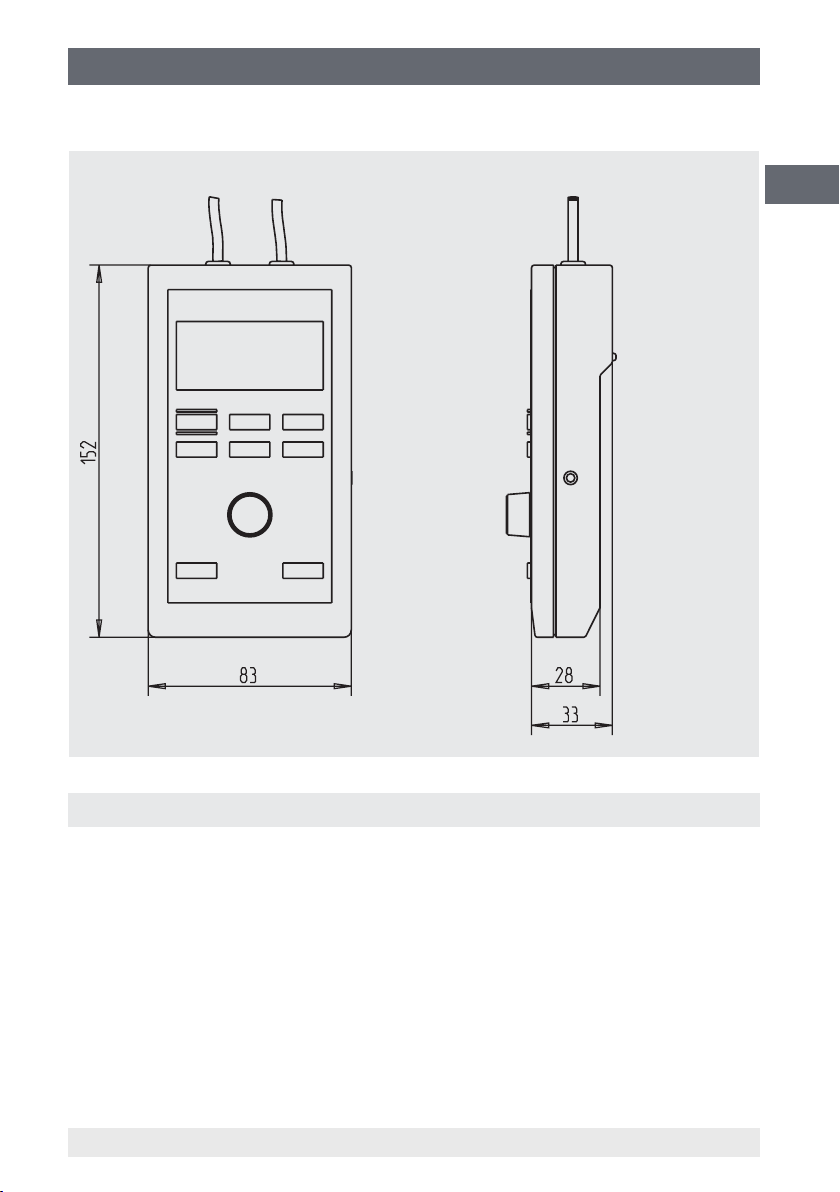

3. Specications / 4. Design and function

Dimensions in mm

Side viewFront view

GB

4. Design and function

4.1 Short description / Description

The CEP1000 is a loop calibrator operating in the range of 4 ... 20 mA designed for

both troubleshooting and calibration of circuits without separate power supply. Very

high accuracy and diverse special functions make the instrument to a user-friendly and

highly exible calibration instrument.

The CEP1000 can be used as current reference standard for up to 24 mA, it can also be

used to simulate a 2-wire connection or to perform measurements in circuits with up to

24 mA without separate power supply.

By means of the calibrator it is possible to measure process signal voltages of up to 28 V

direct current with an accuracy of 0.015 % of the measurement value.

11570351.02 10/2010 GB/D/F/E/I

9WIKA operating instructions, model CEP1000

Page 10

4. Design and function

Using the digital knob user interface as well as the decade output control the user

can set both large and incremental changes of the output signal conveniently. Multiple

unique functions such as the automatic step/ramp function allow easy application of the

GB

CEP1000.

Besides the CEP1000 can supply a 2-wire transmitters with voltage and at the same

time measure the emerging current. All measurements are displayed in mA as well as in

percent of the measuring range.

4.2 Scope of delivery

■

Precision loop calibrator model CEP1000

■

Operating instructions

■

Neoprene case

■

Calibration certicate 3.1 per to DIN EN 10204

■

9 V battery

Cross-check scope of delivery with delivery note.

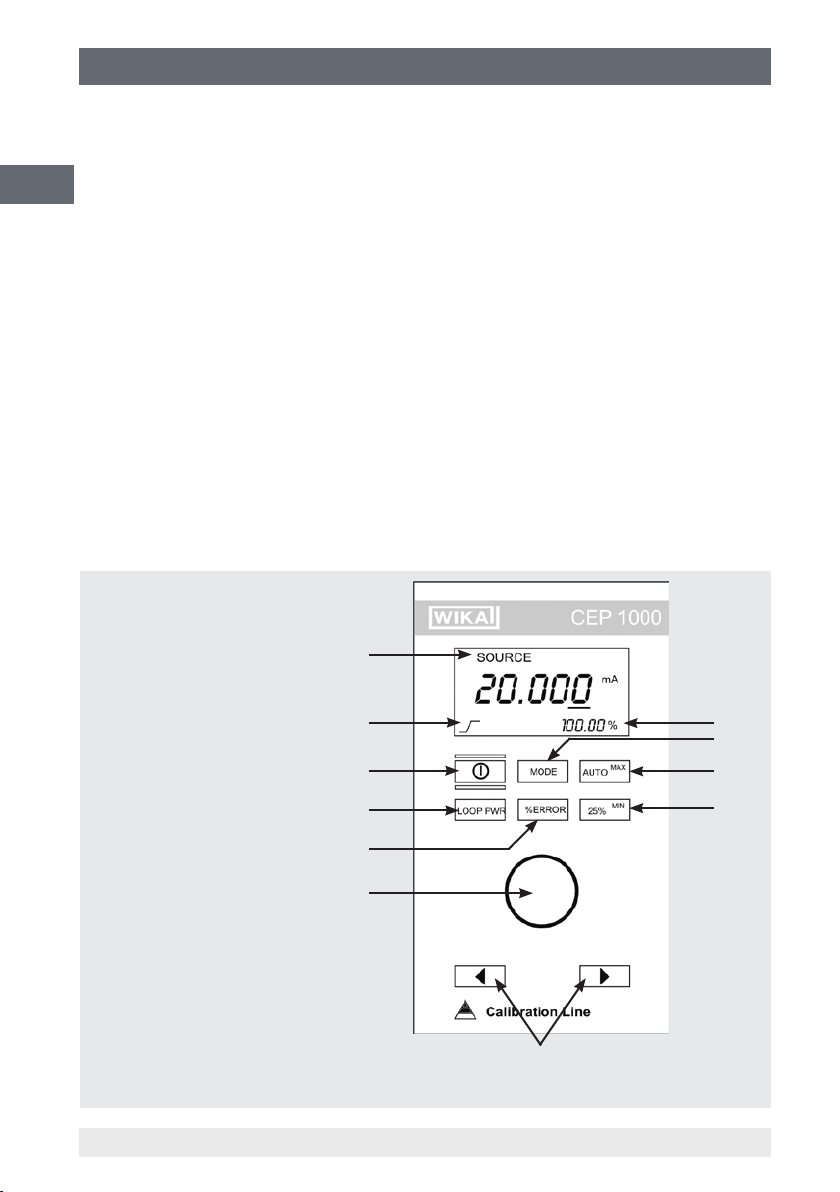

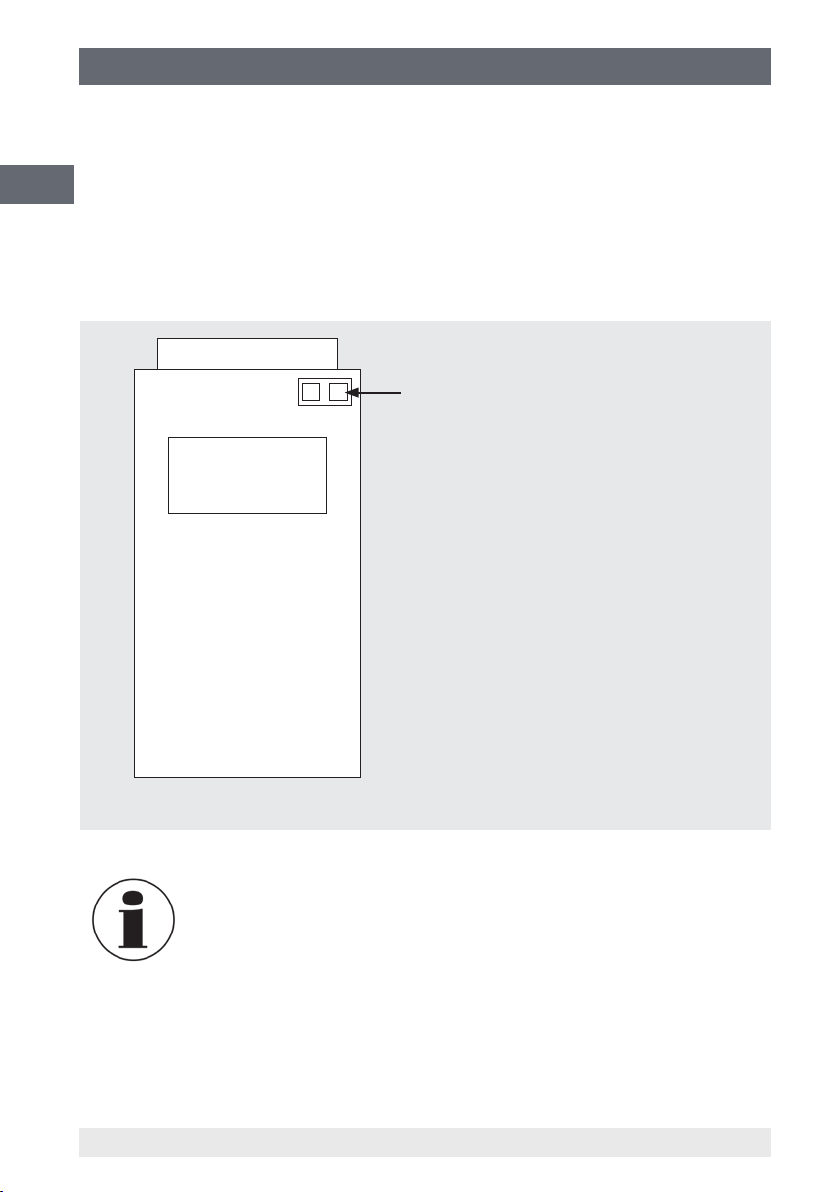

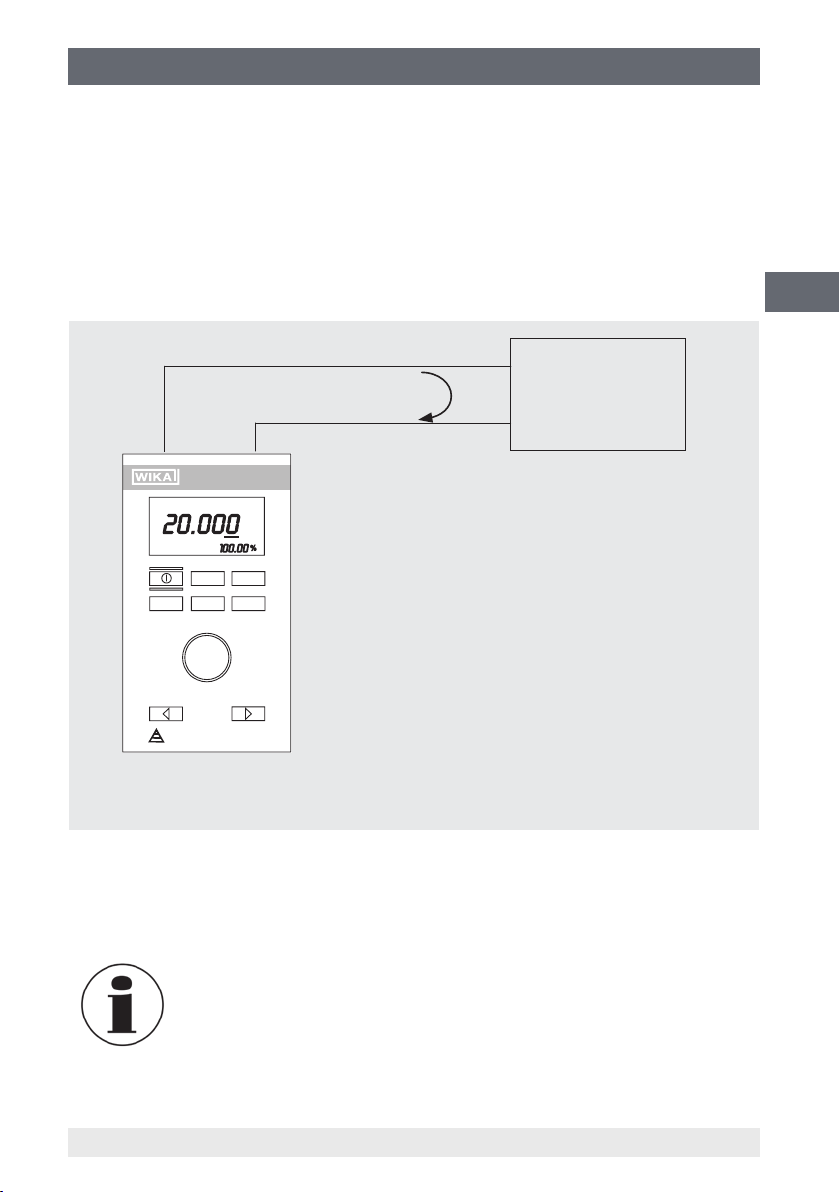

4.3 Front foil of the CEP1000

1) Mode indication

2) Step / ramp indication

3) On/O

4) Current loop key: Activation of

the 24 V power supply in the mA

measuring mode

5) %Error key: indicates the actual

vs. ideal error in %

6) Digital „knob“: output control

7) Simultaneous % display: 4 mA =

0.00 %, 20 mA = 100.00 %

8) Mode key

9) Auto key: Switching between

automatic step and ramp function

(slow or fast)

10) 25 %-key: manual activation of the

step function 4, 8, 12, 16, 20 mA

11) Cursor keys: arrow keys to select

the required decades

1

2

3

4

5

6

7

8

9

10

11

Figure 1

10 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 11

4. Design and function / 5. Transport, packaging and storage

4.4 Battery selection

The CEP1000 is operated with a normal 9 V alkaline battery or optionally with a

rechargeable 9 V Ni-Cd battery. For the most application cases the alkaline battery with

9 V is sucient. However, for the intensive use the 9 V Ni-Cd battery is the better choice.

The Ni-Cd battery for 9 V available optionally with an output current of 12 mA and full

battery enables continuous operation for approx. 3 hours (the alkaline battery lasts

approximately 12 hours). The optionally available charging device charges the battery

over night (10 to 12 hours long) and powers the instrument in the stationary mode. At

the same time the conservation charging of the Ni-Cd battery is carried out.

WARNING!

Never connect the power supply unit/charging device if a 9 V alkaline

cell is inserted.

4.5 Input protection

The device has an input protection without a fuse for up to 250 V of direct or alternating

current for the period of time of up to 30 seconds.

5. Transport, packaging and storage

5.1 Transport

Check loop calibrator for any damage that may have been caused by transport.

Obvious damage must be reported immediately.

GB

5.2 Packaging

Do not remove packaging until just before mounting.

Keep the packaging as it will provide optimum protection during transport (e.g. change

in installation site, sending for repair).

5.3 Storage

Permissible conditions at the place of storage:

■

Storage temperature: -20 ... +70 °C

■

Humidity: 0 ... 90 % relative humidity (no condensation)

Avoid exposure to the following factors:

■

Direct sunlight or proximity to hot objects

■

Mechanical vibration, mechanical shock (putting it down hard)

■

Soot, vapour, dust and corrosive gases

■

Potentially explosive environments, ammable atmospheres

11570351.02 10/2010 GB/D/F/E/I

11WIKA operating instructions, model CEP1000

Page 12

5. Transport, packaging and storage / 6. Commissioning ...

Store the instrument in its original packaging in a location that fulls the conditions

listed above. If the original packaging is not available, pack and store the instrument as

described below:

GB

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with shock-absorbent material, in the packaging.

3. If stored for a prolonged period of time (more than 30 days), place a bag, containing

a desiccant, inside the packaging.

WARNING!

Before storing the instrument (following operation), remove any residual

media. This is of particular importance if the medium is hazardous to

health, e.g. caustic, toxic, carcinogenic, radioactive, etc.

6. Commissioning, operation

DANGER!

To avoid electric shock and injuries:

■

Do not connect voltage higher than the nominal voltage. For the

supported voltage ranges refer to "3. Specications."

■

Observe all safety measures for the instruments.

■

Do not use the calibrator if it is damaged. Prior to use check the

housing of the calibrator. Check carefully if plastic parts are missing

and if there are any cracks. Pay special attention to insulation

around connections.

■

Select the proper function and correct measuring range.

■

The battery case must be closed and locked before the calibrator is

put into operation.

■

Disconnect the test leads from the calibrator prior to opening the

battery case.

■

Check the test leads for signs of damaged insulation or metal parts

with natural nish.

■

When using the probe keep the ngers away from the probe

contacts. Hold the probes behind the nger protection at the test

leads. Do not use the calibrator in case of malfunction. The instrument protection can be impaired. In case of doubt the instrument

must be repaired.

■

Do not operate the instrument in the environment with explosive

gases, vapours or dusts.

■

Disconnect the capillary prior to switching to another measurement

or before using as a simulator.

■

Use only the specied spare parts for repairs of the calibrator.

12 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 13

6. Commissioning, operation

■

To avoid faulty measurements that can lead to electric shock or

injuries, replace the battery immediately as soon as a dead battery

is indicated.

WARNING!

To avoid damages of the calibrator or devices during testing, use the

correct terminals, functions and measuring ranges for measurement or

simulation.

6.1. First steps

6.1.1 Battery saving function

To avoid discharge of the battery in case of unintended switching on of the CEP1000,

the battery saving function is activated ex works and set to 30 minutes. The battery

saving function turns o the CEP1000 automatically if no key is pressed within 30

minutes.

To change the turn-o time or deactivate it, the following steps must be carried out when

turning on:

1) Turn o the instrument.

2) Press the "AUTO" key.

3) Turn on the instrument again.

4) After turning on wait for 1 second and then release the "AUTO" key.

5) The set period of time appears on the display for the battery saving function

(between "O" and 30 minutes).

6) Set the required time using the knob (between "O" and 30 minutes).

7) Press the "AUTO" key again to save the value and switch the instrument back to

normal operation. The saved value is stored in the memory until it is changed by the

operator.

GB

11570351.02 10/2010 GB/D/F/E/I

13WIKA operating instructions, model CEP1000

Page 14

6. Commissioning, operation

6.1.2 HART™ resistance conguration

Due to internal 250

Communicator during calibration or installation of a HART™ transmitter. The internal

GB

resistance replaces the resistance of 250

model 275. To activate this function if necessary, the internal jumper must be removed.

The instrument is supplied with an inserted jumper (see gure 2). To activate the resistance, remove the jumper. The jumper can be either stored outside of the instrument or

just plugged onto a contact pin in the instrument, thus, the circuit is interrupted.

Ω resistance of the CEP1000 it is possible to use Rosemount 275

Ω required normally for the communicator

-J8 (HART™ JUMPER)

Remove the jumper to activate the HART™

resistance (250 Ω).

LCD

CEP1000

Figure 2

If the 250

maximum load of 950

Ω resistance is activated, it is possible to energise a

Ω instead of 1200 Ω. In most cases this would not

cause any problems for the calibration of products incompatible with

HART™.

14 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 15

6. Commissioning, operation

6.2 Basic operating modes

The CEP1000 has 4 operating modes for the mA range and one operating mode for

voltage measurement. The following text and gures explain dierent operating modes.

6.2.1 Milliampere source

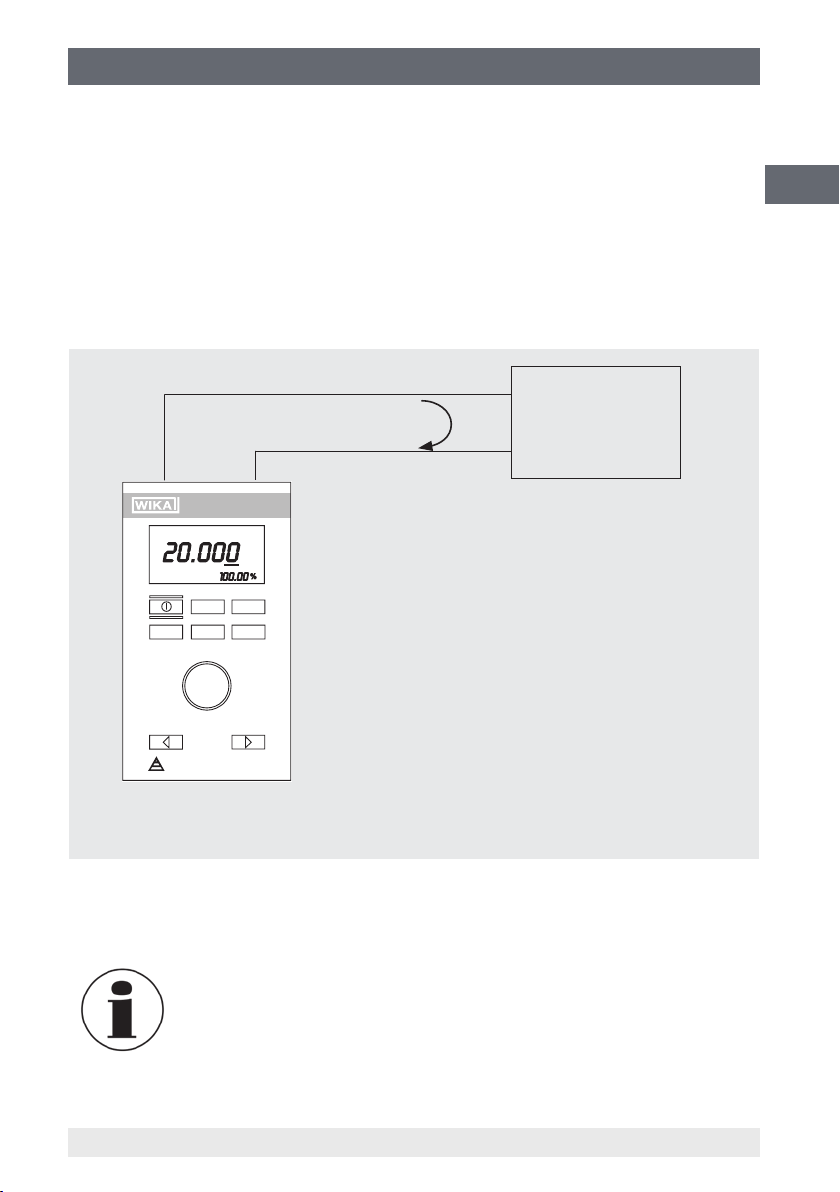

Figure 3 shows a typical application, for which the CEP1000 is used as a source of

current for the range from 4 ... 20 mA for the instrument to be tested.

( + )

GB

Instrument with an input

( - )

of 4 ... 20 mA

SOURCE

4 ... 20 mA

CEP 1000

mA

Max. load: 1200 Ω without HART™

950 Ω with HART™

MAX

MODE

AUTO

MIN

%ERROR

LOOPPWR

Calibration Line

25%

Figure 3 - Current source for 4 ... 20 mA

1) Turn on the instrument. As a standard the operating mode source of current in the

mA range is set.

2) Connect the instrument to be calibrated.

For the instrument to function as a source of current, the circuit must be

closed. In case of an interrupted circuit the LCD display "OL" is blinking

and indicating an overload or an interruption of the circuit.

11570351.02 10/2010 GB/D/F/E/I

15WIKA operating instructions, model CEP1000

Page 16

6. Commissioning, operation

3) The output signal can be adjusted to the set point by means of the knob. For this

purpose select the decade to be set using the arrow keys.

4) The output signal can also be increased incrementally in steps of 4 mA (25 %) using

GB

the "25%" key.

5) The automatic step function and automatic ramp function allow automatic change of

the output signal.

For further information refer to the section "6.3.1 Automatic operation modes" of the

instruction.

6.2.2 Milliampere simulation

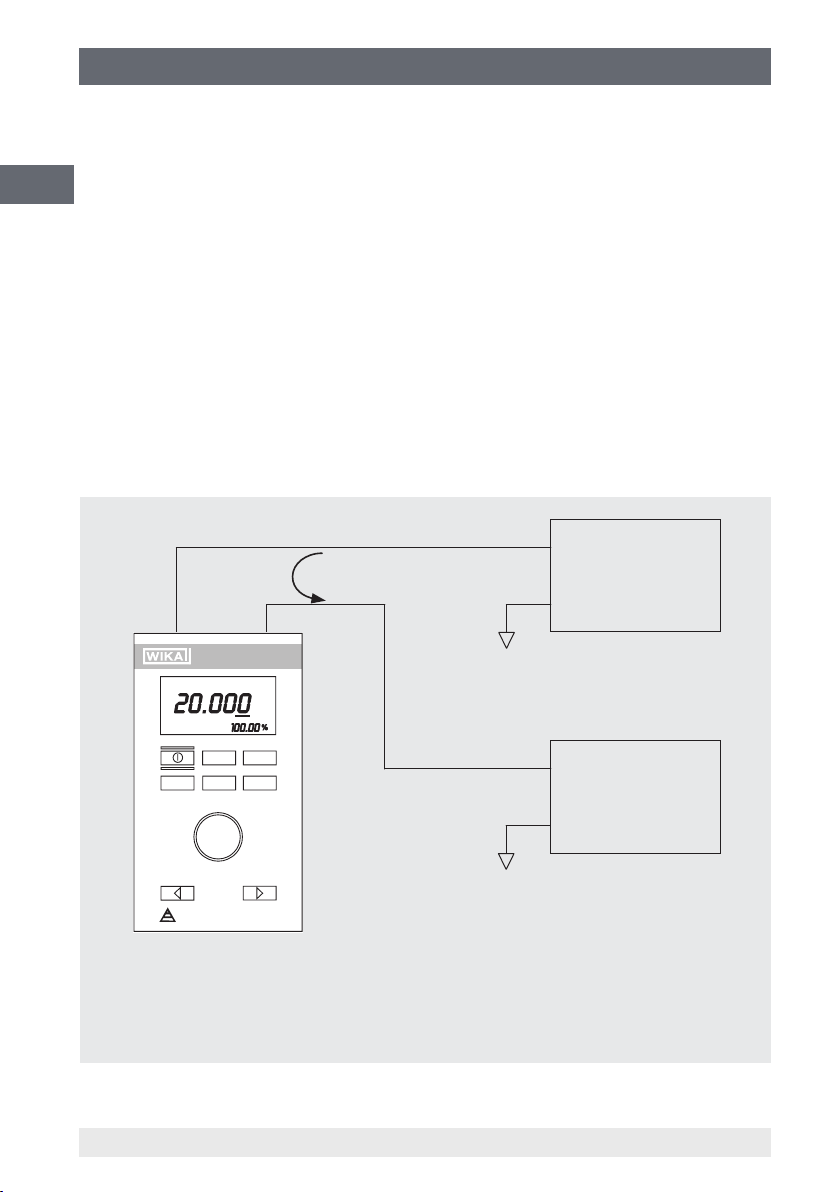

Figure 4 shows the way the CEP1000 is connected if it is supposed to function as a

2-wire transmitter with an external power supply. In this case the circuit is powered via

an external voltage source and the instrument just regulates the current in the circuit.

The regulating procedure of the output signal is the same as for the application as the

source of current in the milliampere range.

( + )

Power supply DC 30 V

( - )

( + )

Instrument with an input

( - )

of 4 ... 20 mA

max.

SIM

LOOPPWR

Calibration Line

MODE

%ERROR

CEP 1000

mA

MAX

AUTO

MIN

25%

4 ... 20 mA

The instrument is operated in the simulation mode as a

two-wire sensor.

Figure 4: Simulation of a sensor with a current output for 4 ... 20 mA

16 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 17

6. Commissioning, operation

6.2.3 Milliampere measurement

Figure 5 shows the way the CEP1000 must be connected to carry out a measurement in

a circuit for 4 ... 20 mA. During this application the instrument just measures the current

in the circuit and displays it on the main display in

indicates the percentage of current for the measuring range 4 ... 20 mA.

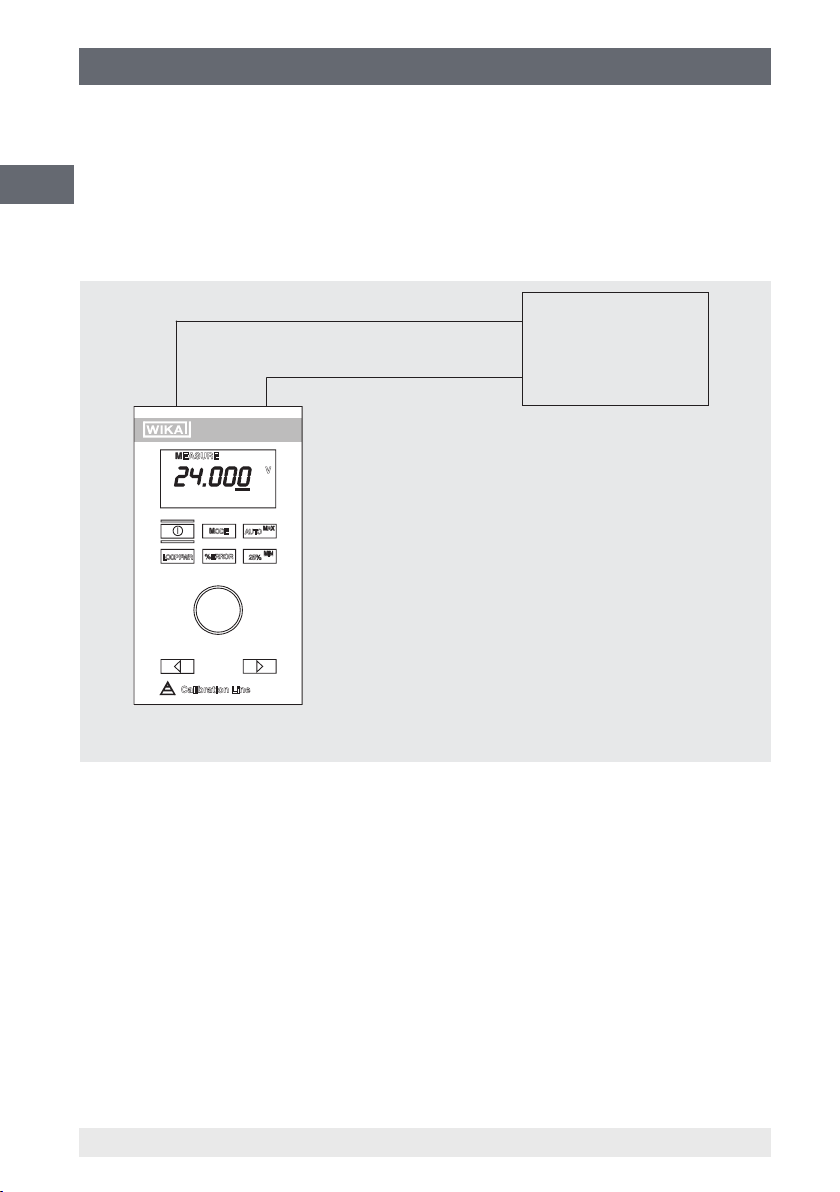

6.2.4 Milliampere measurement with 24 V power supply

For this case gure 5 also shows the correct connection. However, in this case a 2-wire

transmitter is tested, it requires an external power supply for the output current. For this

application the instrument supplies the circuit with an operating voltage of 24 V and at

the same time measures the emerging current. To enable the function with separate

power supply, press the "LOOP PWR" key if the option milliampere measurement is

selected.

mA

. The lower (smaller) scale range

( + )

GB

Instrument with an

output for 4 ... 20 mA

MEASURE

CEP 1000

mA

4 ... 20 mA

( - )

Maximum input signal: 24 mA

LOOPPWR

Calibration Line

MODE

%ERROR

AUTO

MAX

MIN

25%

To measure the output signal of a two-wire sensor use

the option measurement with separate power supply.

Figure 5: Measurement in the range of 4 ... 20 mA

The measuring mode with separate power supply can be activated for

the option measuring in the milliampere range.

11570351.02 10/2010 GB/D/F/E/I

17WIKA operating instructions, model CEP1000

Page 18

6. Commissioning, operation

6.2.5 Voltage measurement

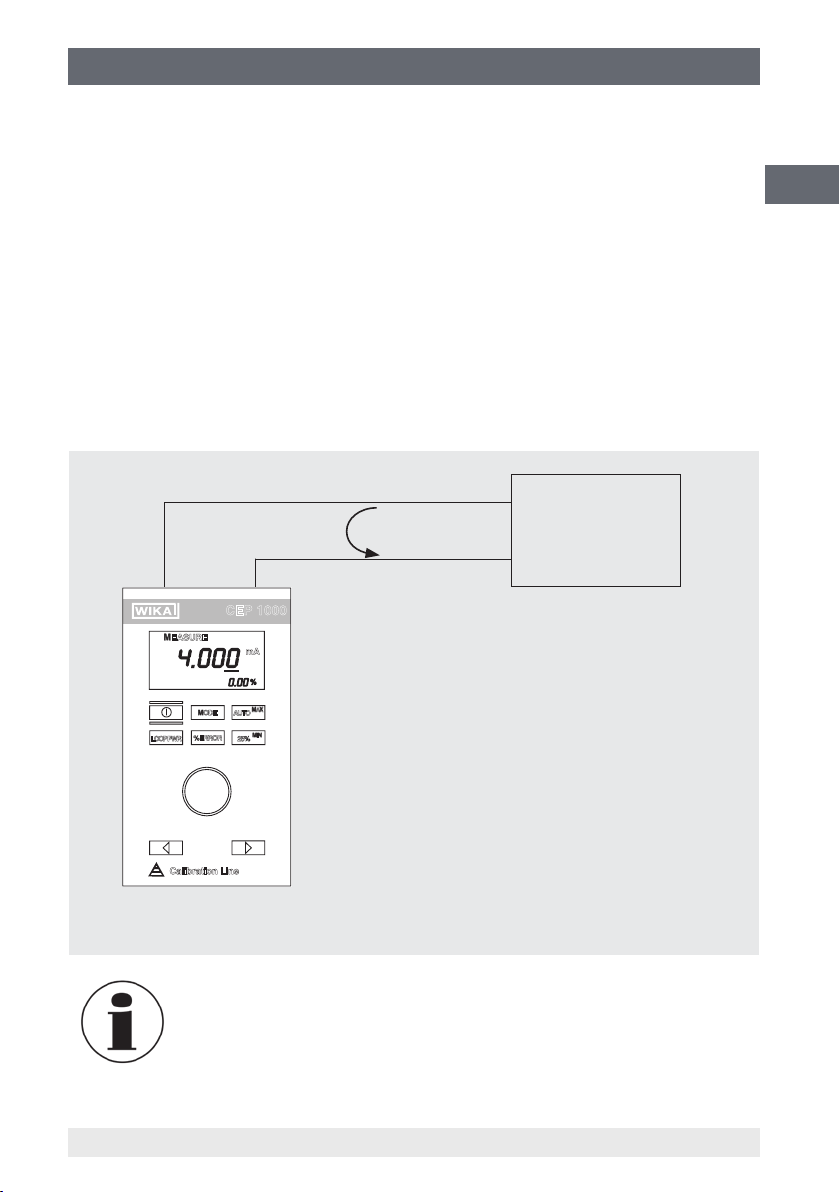

Figure 6 shows the connection of CEP1000 required to measure direct voltage of up

to 28 V. To activate the voltage measurement, just press the "MODE" key to search the

GB

individual functions until the voltage measurement is displayed.

The input impedance of the CEP1000 is higher than 1 MΩ in this mode.

( + )

instrument with an output

for 0 ... 28 V

MEASURE

LOOPPWR

MODE

%ERROR

CEP 1000

V

MAX

AUTO

MIN

25%

( - )

Maximum input signal: DC 28 V

Calibration Line

Figure 6: Measurement in the range of DC 0 ... 28 V

18 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 19

6. Commissioning, operation

6.3 Advanced operating modes

6.3.1 Automatic step function/automatic ramp mode

The CEP1000 is capable of increasing the output current in the mA range in steps of

25 % automatically with intervals of 5 seconds. The output current in the mA range

can be increased linearly in form of the ramp function from 4 mA up to 20 mA and then

reduced again automatically to 4 mA.

To activate the automatic step/ramp function proceed as follows:

1) The automatic step/ramp function can be used for the application as milliampere

source as well as for the milliampere simulation. Switch the instrument into the corresponding operating mode.

2) Connect the CEP1000 to the instrument to be tested.

3) For the automatic step function press the "AUTO" key once, for a slow ramp function

twice and for the quick ramp function three times. After every key stroke a small

conrmation window appears in the lower left corner of the LCD display, it indicates

which step function or ramp function has been selected.

4) As soon as the step function/ramp function has been activated, it is functioning

constantly until another key is pressed.

6.3.2 Fault percentage function

This unique function calculates the fault percentage of the measuring range (a measur-

ing range of 4 ... 20 mA gives a span of 16 mA). Using the function for calculation of fault

percentage the user can "Zero Out" the milliampere indication, thus, enabling indication

of deviation from the ideal value on the display as a fault percentage.

Procedure:

1) Connect the CEP1000 to the instrument to be tested.

2) Set a mode with milliampere output for the instrument (source or simulation).

3) Set the required output value.

4) If the instrument to be tested does not measure the exact value, press and hold

the "%ERROR" key and adjust the knob so that the instrument displays the correct

value. Press and keep holding the “%ERROR” key further on.

5) The indication in the percentage eld corresponds to the fault or deviation as a

percentage of the span.

6) After the "%ERROR" key has been released, the indication switches back to normal

operation.

GB

11570351.02 10/2010 GB/D/F/E/I

19WIKA operating instructions, model CEP1000

Page 20

6. Commissioning, operation

6.3.3 Data acquisition for minimum and maximum

If the CEP1000 is operated in a measuring mode (milliampere, milliampere with power

supply or voltage), the minimum and maximum values for the corresponding input mode

GB

are monitored and stored permanently. To activate the data acquisition proceed as

follows:

1) Switch the CEP1000 to a measuring mode.

2) Connect the instrument to the instrument to be tested.

3) Press both keys (“MIN” and “MAX”) to clear the memory for the minimum and

maximum values. The “CLR” message is displayed on the LCD display, if the

memory has been deleted.

4) Acquire the minimum value and the maximum value using the instrument as long as

required.

If necessary, deactivate the battery saving function prior to calling the

data acquisition function to avoid premature switching o of the calibrator.

5) The saved value can be accessed any time by pressing the "MIN" or "MAX" key.

6) When switching o the instrument or switching to another operating mode the

memory will be cleared. Back up the data before switching o.

20 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 21

7. Maintenance, cleaning and service (recalibration)

7. Maintenance, cleaning and service (recalibration)

7.1 Maintenance

The precision loop calibrator CEP1000 is maintenance-free.

Repairs must only be carried out by the manufacturer. This does not apply to the battery

replacement.

7.2 Cleaning

CAUTION!

■

Clean the instrument with a moist cloth.

■

Electrical connections must not come into contact with moisture.

For information on returning the instrument see chapter "9.1 Return".

7.3 Recalibration

DKD/DAkkS certicate - Certicates:

We recommend that the instrument is regularly recalibrated by the manufacturer, with

time intervals of approx. 12 months. Every factory recalibration includes, additionally, an

extensive free-of-charge check of all system parameters with respect to their compli-

ance with the specication. The basic settings will be corrected if necessary.

GB

11570351.02 10/2010 GB/D/F/E/I

21WIKA operating instructions, model CEP1000

Page 22

8. Faults / 9. Return and disposal

8. Faults

GB

Indication Type of fault Measures

Battery is low, functioning is only

guaranteed for a short period of time

OL

-OL

No display or

undenable

characters, the

instrument does

not respond to

key press

Reading is signicantly above or

below the measuring range

Battery is dead. Insert new batteries

System error Turn o the CEP1000, wait for a

The CEP1000 is defective Send in for repair

CAUTION!

If faults cannot be eliminated by means of the measures listed above,

the instrument must be shut down immediately, and it must be ensured

that pressure and/or signal are no longer present, and it must be

prevented from being inadvertently put back into service.

In this case, contact the manufacturer.

If a return is needed, please follow the instructions given in chapter

"9.1 Return".

9. Return and disposal

Insert new batteries

Test: if the measurement parameter

is within the approved measuring

range of the instrument?

short period of time, switch on again

WARNING!

Residual media in dismounted loop calibrator can result in a risk to

persons, the environment and equipment. Take sucient precautionary

measures.

9.1 Return

WARNING!

Strictly observe when shipping the instrument:

All instruments delivered to WIKA must be free from any kind of hazard-

ous substances (acids, bases, solutions, etc.).

22 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 23

9. Return and disposal / 10. Accessories

When returning the loop calibrator, use the original packaging or a suitable transport

package.

To avoid damage:

1. Wrap the instrument in an antistatic plastic lm.

2. Place the instrument, along with the shock-absorbent material, in the packaging.

Place shock-absorbent material evenly on all sides of the transport packaging.

3. If possible, place a bag, containing a desiccant, inside the packaging.

4. Label the shipment as transport of a highly sensitive measuring instrument.

Enclose the completed return form with the instrument.

The return form is available on the internet:

www.wika.de / Service / Return

9.2 Disposal

Incorrect disposal can put the environment at risk.

Dispose of instrument components and packaging materials in an environmentally

compatible way and in accordance with the country-specic waste disposal regulations.

This marking on the instruments indicates that they must not be

disposed of in domestic waste. The disposal is carried out by return to

the manufacturer or by the corresponding municipal authorities. See EU

regulation 2002/96/EC.

GB

10. Accessories

For accessories such as 9 V Ni-Cd battery (rechargeable), AC power supply unit/charging device for Europe, Japan, the UK or USA etc. refer to the current WIKA price list:

Testing and calibration technology.

11570351.02 10/2010 GB/D/F/E/I

23WIKA operating instructions, model CEP1000

Page 24

GB

24 WIKA operating instructions, model CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 25

Inhalt

Inhalt

1. Allgemeines 26

2. Sicherheit 27

2.1 Bestimmungsgemäße Verwendung 28

2.2 Personalqualikation 28

2.3 Besondere Gefahren 29

3. Technische Daten 30

4. Aufbau und Funktion 31

4.1 Kurzbeschreibung / Beschreibung 31

4.2 Lieferumfang 32

4.3 Frontfolie des CEP1000 32

4.4 Batterieauswahl 33

4.5 Eingangsschutz 33

5. Transport, Verpackung und Lagerung 33

5.1 Transport 33

5.2 Verpackung 33

5.3 Lagerung 33

6. Inbetriebnahme, Betrieb 34

6.1 Erste Schritte 35

6.1.1 Batteriesparfunktion 35

6.1.2 HART™ Widerstandskonguration 36

6.2 Grundlegende Betriebsarten 37

6.2.1 Milliampere-Quelle 37

6.2.2 Milliampere-Simulation 38

6.2.3 Milliampere-Messung 39

6.2.4 Milliampere-Messung mit 24 V Spannungsversorgung 39

6.2.5 Spannungsmessung 40

6.3 Erweiterte Betriebsarten 41

6.3.1 Automatische Schrittfunktion/automatischer Rampenmodus 41

6.3.2 Prozent-Fehler-Funktion 41

6.3.3 Datenerfassung für Minimum und Maximum 42

7. Wartung, Reinigung und Service (Rekalibrierung) 43

7.1 Wartung 43

7.2 Reinigung 43

7.3 Rekalibrierung 43

8. Störungen 44

9. Rücksendung und Entsorgung 44

9.2 Rücksendung 44

9.3 Entsorgung 45

10. Zubehör 45

D

11570351.02 10/2010 GB/D/F/E/I

25WIKA Betriebsanleitung, Typ CEP1000

Page 26

1. Allgemeines

1. Allgemeines

■

Der in der Betriebsanleitung beschriebene Stromschleifenkalibrator wird nach den

neuesten Erkenntnissen gefertigt.

Alle Komponenten unterliegen während der Fertigung strengen Qualitäts- und

D

Umweltkriterien. Unsere Managementsysteme sind nach ISO 9001 und ISO 14001

zertiziert.

■

Diese Betriebsanleitung gibt wichtige Hinweise zum Umgang mit dem Gerät. Voraussetzung für sicheres Arbeiten ist die Einhaltung aller angegebenen Sicherheitshinweise und Handlungsanweisungen.

■

Die für den Einsatzbereich des Gerätes geltenden örtlichen Unfallverhütungsvorschriften und allgemeinen Sicherheitsbestimmungen einhalten.

■

Die Betriebsanleitung ist Produktbestandteil und muss in unmittelbarer Nähe des

Gerätes für das Fachpersonal jederzeit zugänglich aufbewahrt werden.

■

Das Fachpersonal muss die Betriebsanleitung vor Beginn aller Arbeiten sorgfältig

durchgelesen und verstanden haben.

■

Die Haftung des Herstellers erlischt bei Schäden durch bestimmungswidrige Verwen-

dung, Nichtbeachten dieser Betriebsanleitung, Einsatz ungenügend qualizierten

Fachpersonals sowie eigenmächtiger Veränderung am Gerät.

■

Es gelten die allgemeinen Geschäftsbedingungen in den Verkaufsunterlagen.

■

Technische Änderungen vorbehalten.

■

Werkskalibrierungen/DKD/DAkkS-Kalibrierungen erfolgen nach internationalen

Normen.

■

Weitere Informationen:

- Internet-Adresse: www.wika.de / www.wika.com

- zugehöriges Datenblatt:

- Anwendungsberater:

CT 81.01

Tel.: (+49) 9372/132-9986

Fax: (+49) 9372/132-217

E-Mail:

testequip@wika.de

26 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 27

1. Allgemeines / 2. Sicherheit

Symbolerklärung

WARNUNG!

… weist auf eine möglicherweise gefährliche Situation hin, die zum Tod

oder zu schweren Verletzungen führen kann, wenn sie nicht gemieden

wird.

VORSICHT!

… weist auf eine möglicherweise gefährliche Situation hin, die zu

geringfügigen oder leichten Verletzungen bzw. Sach- und Umweltschäden führen kann, wenn sie nicht gemieden wird.

Information

… hebt nützliche Tipps und Empfehlungen sowie Informationen für

einen ezienten und störungsfreien Betrieb hervor.

GEFAHR!

…kennzeichnet Gefährdungen durch elektrischen Strom. Bei Nichtbeachtung der Sicherheitshinweise besteht die Gefahr schwerer oder

tödlicher Verletzungen.

D

2. Sicherheit

WARNUNG!

Vor Montage, Inbetriebnahme und Betrieb sicherstellen, dass der richtige Stromschleifenkalibrator hinsichtlich Messbereich, Ausführung und

spezischen Messbedingungen ausgewählt wurde.

Bei Nichtbeachten können schwere Körperverletzungen und/oder

Sachschäden auftreten.

Weitere wichtige Sicherheitshinweise benden sich in den einzelnen

Kapiteln dieser Betriebsanleitung.

11570351.02 10/2010 GB/D/F/E/I

27WIKA Betriebsanleitung, Typ CEP1000

Page 28

2. Sicherheit

2.1 Bestimmungsgemäße Verwendung

Dieser Präzise Stromschleifenkalibrator CEP1000 dient zum genauen messen und

simulieren von Strom und Spannung.

Das Gerät ist ausschließlich für den hier beschriebenen bestimmungsgemäßen

Verwendungszweck konzipiert und konstruiert und darf nur dementsprechend verwen-

D

det werden.

Die technischen Spezikationen in dieser Betriebsanleitung sind einzuhalten. Eine

unsachgemäße Handhabung oder ein Betreiben des Gerätes außerhalb der techni-

schen Spezikationen macht die sofortige Stilllegung und Überprüfung durch einen

autorisierten WIKA-Servicemitarbeiter erforderlich.

Elektronische Präzisionsmessgeräte mit erforderlicher Sorgfalt behandeln (vor Nässe,

Stößen, starken Magnetfeldern, statische Elektrizität und extremen Temperaturen schüt-

zen, keine Gegenstände in das Gerät bzw. Önungen einführen). Stecker und Buchsen

vor Verschmutzung schützen.

Wird das Gerät von einer kalten in eine warme Umgebung transportiert, so kann durch

Kondensatbildung eine Störung der Gerätefunktion eintreten. Vor einer erneuten

Inbetriebnahme die Angleichung der Gerätetemperatur an die Raumtemperatur abwarten.

Ansprüche jeglicher Art aufgrund von nicht bestimmungsgemäßer Verwendung sind

ausgeschlossen.

2.2 Personalqualikation

WARNUNG!

Verletzungsgefahr bei unzureichender Qualikation!

Unsachgemäßer Umgang kann zu erheblichen Personen- und

Sachschäden führen.

■

Die in dieser Betriebsanleitung beschriebenen Tätigkeiten nur

durch Fachpersonal nachfolgend beschriebener Qualikation

durchführen lassen.

■

Unqualiziertes Personal von den Gefahrenbereichen fernhalten.

Fachpersonal

Das Fachpersonal ist aufgrund seiner fachlichen Ausbildung, seiner Kenntnisse der

Mess- und Regelungstechnik und seiner Erfahrungen sowie Kenntnis der landesspezi-

schen Vorschriften, geltenden Normen und Richtlinien in der Lage, die beschriebenen

Arbeiten auszuführen und mögliche Gefahren selbstständig zu erkennen.

28 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 29

2. Sicherheit

Spezielle Einsatzbedingungen verlangen weiteres entsprechendes Wissen, z. B. über

aggressive Medien.

2.3 Besondere Gefahren

WARNUNG!

Bei gefährlichen Messstoen wie z. B. Sauersto, Acetylen, brennbaren oder giftigen Stoen, sowie bei Kälteanlagen, Kompressoren etc.

müssen über die gesamten allgemeinen Regeln hinaus die einschlägigen Vorschriften beachtet werden.

WARNUNG!

Schutz vor elektrostatischer Entladung (ESD) erforderlich!

Die ordnungsgemäße Verwendung geerdeter Arbeitsächen und

persönlicher Armbänder ist bei Arbeiten mit oenen Schaltkreisen

(Leiterplatten) erforderlich, um die Beschädigung empndlicher elektro-

nischer Bauteile durch elektrostatische Entladung zu vermeiden.

Für ein sicheres Arbeiten am Gerät muss der Betreiber sicherstellen,

dass das Bedienpersonal regelmäßig in allen zutreenden Fragen

von Arbeitssicherheit, Erste-Hilfe und Umweltschutz unterwiesen wird,

sowie die Betriebsanleitung und insbesondere die darin enthaltenen

Sicherheitshinweise kennt.

D

GEFAHR!

Lebensgefahr durch elektrischen Strom!

Bei Betrieb mit einem defekten Netzgerät (z. B. Kurzschluss von

Netzspannung zur Ausgangsspannung) können am Gerät lebens-

gefährliche Spannungen auftreten!

11570351.02 10/2010 GB/D/F/E/I

29WIKA Betriebsanleitung, Typ CEP1000

Page 30

3. Technische Daten

3. Technische Daten

Technische Daten

Eingang

D

Strombereich 0,000 … 24,000 mA

Spannungsbereich DC 0,000 … 28,000 V

Eingangsschutz Sicherungslos bis AC 250 V

Ausgang

Strombereich 0,000 … 24,000 mA

Messunsicherheit ± 0,015 % des Messwerts ± 2 µA

Auösung 1 µA, 1 mV

Maximale Last

■

Ohne HART™-Widerstand

■

Mit HART™-Widerstand

Versorgungs-Spannungsausgang

Bereichsauswahl Zehnerstellen; Schrittweise in 0,001 mA Schritten

Besonderheiten Stufen- und Rampenfunktion, Automatische „%-Fehler“-

Zulässige

■

Betriebstemperatur

■

Lagertemperatur

Display 5 1/2-stellig mit 9 mm Ziernhöhe und %-Anzeige

Anzeige mA, V, %

Aufzeichnungsoptionen MIN-/MAX-Speicher

Hilfsenergie DC 9 V Batterie

■

Batterielebensdauer

■

Batteriestandsanzeige

EMV/CE-Zulassung 2004/108/EC, EN 61326 Emission (Gruppe 1, Klasse B)

Schutzart IP 52

Kalibrierung Werkskalibrierschein 3.1 nach DIN EN 10204 (optional:

Abmessungen 144,7 x 80,0 x 36,3 mm

Gewicht ca. 340 g

-25,00 … +125,00 %

-25,00 … +125,00 %

1200 Ω

950 Ω

DC 24 V

Funktion, eingebauter Widerstand für HART™ Kommunikation

-10 … +55 °C

-20 … +70 °C

12 Stunden (12 mA / 250 Ω Dauerbelastung)

Symbolanzeige bei schwacher Batterie

Störfestigkeit (tragbares Gerät)

DKD/DAkkS Kalibrierschein)

Weitere technische Daten siehe WIKA Datenblatt CT 81.01 und Bestellunterlagen.

30 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 31

3. Technische Daten / 4. Aufbau und Funktion

Abmessungen in mm

SeitenansichtFrontansicht

D

4. Aufbau und Funktion

4.1 Kurzbeschreibung / Beschreibung

Der CEP1000 ist ein Stromschleifenkalibrator im Bereich 4 ... 20 mA sowohl zur Fehlerbehebung als auch zur Kalibrierung von Stromkreisen ohne separate Stromversorgung.

Die sehr hohe Genauigkeit sowie verschiedene Sonderfunktionen machen den Kalibra-

tor zu einem benutzerfreundlichen und hoch exiblen Kalibrierwerkzeug.

Der CEP1000 kann als Stromvergleichsnormal für bis zu 24 mA dienen, eine 2-LeiterSchaltung simulieren sowie Messungen in Stromkreisen bis 24 mA ohne separate

Stromversorgung durchführen. Mit dem Kalibrator lassen sich außerdem Prozesssignalspannungen bis 28 V Gleichspannung mit einer Genauigkeit von 0,015 % des Messwertes messen.

11570351.02 10/2010 GB/D/F/E/I

31WIKA Betriebsanleitung, Typ CEP1000

Page 32

4. Aufbau und Funktion

Über die digitale Drehknopf-Bedienoberäche sowie die Zehnerstellen-Ausgangssteuerung kann der Benutzer bequem sowohl große als auch kleine Änderungen des

Ausgangssignals einstellen. Mehrere einzigartige Funktionen wie die automatische

Schritt-/Rampenfunktion erleichtern den Einsatz des CEP1000.

Der CEP1000 kann außerdem 2-Leiter-Transmitter mit Spannung versorgen und gleich-

D

zeitig den entstehenden Strom messen. Alle Messungen werden in mA sowie in Prozent

des Messbereichs angezeigt.

4.2 Lieferumfang

■

Präziser Stromschleifenkalibrator Typ CEP1000

■

Betriebsanleitung

■

Neoprentasche

■

Kalibrierzertikat 3.1 nach DIN EN 10204

■

9 V Batterie

Lieferumfang mit dem Lieferschein abgleichen.

4.3 Frontfolie des CEP1000

1) Modus Anzeige

2) Stufen-/Rampen-Anzeige

3) An/Aus

4) Stromschleifen-Taste: Aktivierung

der 24 V Spannungsversorgung

im mA-Messmodus

5) %Error-Taste: Zeigt den aktuellen

Fehler zwischen Ist- und Sollwert

in % an

6) Digitaler „Drehknopf“: Ausgabesteuerung

7) Simultananzeige in %: 4 mA =

0.00 %, 20 mA = 100.00 %

8) Mode-Taste

9) Auto-Taste: Umschalten zwi-

schen automatischer Stufen- und

Rampen-Funktion (langsam oder

schnell)

10) 25 %-Taste: manuelle Aktivierung

der Stufen-Funktion 4, 8, 12, 16,

20 mA

11) Cursor-Tasten: Bedienpfeile zur

Auswahl der gewünschten Zehnerstellen

1

2

3

4

5

6

7

8

9

10

11

Abbildung 1

32 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 33

4. Aufbau und Funktion / 5. Transport, Verpackung und ...

4.4 Batterieauswahl

Der CEP1000 arbeitet mit einer normalen 9 V Alkalibatterie oder optional mit einem

wiederauadbaren 9 V Ni-Cd-Akku. Für die meisten Anwendungsfälle genügt eine

Alkalibatterie von 9 V. Bei intensiver Nutzung ist der Ni-Cd-Akku für 9 V jedoch die

bessere Wahl. Der optional erhältliche Ni-Cd-Akku für 9 V erlaubt bei einem Ausgangs-

strom von 12 mA und vollem Akku einen Dauerbetrieb von etwa 3 Stunden (die Alkali-

batterie hält etwa 12 Stunden). Das optional erhältliche Ladegerät lädt den Akku über

Nacht (10 bis 12 Stunden lang) auf und versorgt das Gerät im stationären Betrieb. Dabei

wird zugleich eine Erhaltungsladung des Ni-Cd-Akkus durchgeführt.

WARNUNG!

Das Netzteil/Ladegerät niemals anschließen, wenn eine 9 V Alkalibatterie eingesetzt ist.

4.5 Eingangsschutz

Das Gerät besitzt einen sicherungslosen Eingangsschutz bis zu einer Gleich- oder

Wechselspannung von 250 V für eine Zeitdauer bis zu 30 Sekunden.

5. Transport, Verpackung und Lagerung

D

5.1 Transport

Den Stromschleifenkalibrator auf eventuell vorhandene Transportschäden untersuchen.

Oensichtliche Schäden unverzüglich mitteilen.

5.2 Verpackung

Verpackung erst unmittelbar vor der Montage entfernen.

Die Verpackung aufbewahren, denn diese bietet bei einem Transport einen

optimalen Schutz (z. B. wechselnder Einbauort, Reparatursendung).

5.3 Lagerung

Zulässige Bedingungen am Lagerort:

■

Lagertemperatur: -20 ... +70 °C

■

Feuchtigkeit: 0 ... 90 % relative Feuchte (keine Betauung)

Folgende Einüsse vermeiden:

■

Direktes Sonnenlicht oder Nähe zu heißen Gegenständen

■

Mechanische Vibration, mechanischer Schock (hartes Aufstellen)

11570351.02 10/2010 GB/D/F/E/I

33WIKA Betriebsanleitung, Typ CEP1000

Page 34

5. Transport, Verpackung und Lagerung / 6. Inbetriebnahme ...

■

Ruß, Dampf, Staub und korrosive Gase

■

Explosionsgefährdete Umgebung, entzündliche Atmosphären

Das Gerät in der Originalverpackung an einem Ort, der die oben gelisteten Bedingungen erfüllt, lagern. Wenn die Originalverpackung nicht vorhanden ist, dann das Gerät

wie folgt verpacken und lagern:

D

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

3. Bei längerer Einlagerung (mehr als 30 Tage) einen Beutel mit Trocknungsmittel der

Verpackung beilegen.

WARNUNG!

Vor der Einlagerung des Gerätes (nach Betrieb) alle anhaftenden

Messstoreste entfernen. Dies ist besonders wichtig, wenn der

Messsto gesundheitsgefährdend ist, wie z. B. ätzend, giftig, krebser-

regend, radioaktiv, usw.

6. Inbetriebnahme, Betrieb

GEFAHR!

Zur Vermeidung eines elektrischen Schlages sowie von Verletzungen:

■

Keine höheren Spannungen als die Nennspannung anlegen.

Die unterstützten Spannungsbereiche sind in „3. Technischen

Daten“ zu nden.

■

Alle Sicherheitsmaßnahmen für Geräte einhalten.

■

Den Kalibrator nicht in beschädigtem Zustand verwenden. Vor

Verwendung des Kalibrators das Gehäuse kontrollieren. Auf fehlende Kunststoteile und Risse achten. Insbesondere auf die Isolierung um die Anschlüsse.

■

Die richtige Funktion und den richtigen Messbereich auswählen.

■

Das Batteriefach muss geschlossen und verriegelt sein, bevor der

Kalibrator in Betrieb genommen wird.

■

Die Messleitungen vom Kalibrator abklemmen, bevor das Batterie-

fach geönet wird.

■

Die Messleitungen auf beschädigte Isolierung oder blanke Metallteile prüfen.

■

Bei Verwendung von Prüfspitzen die Finger von den Prüfspitzenkontakten fern halten. Die Prüfspitzen hinter dem Fingerschutz auf

den Messleitungen anfassen. Den Kalibrator bei Fehlfunktion nicht

verwenden. Der Geräteschutz kann beeinträchtigt sein. Im Zweifelsfall den Kalibrator reparieren lassen.

34 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 35

6. Inbetriebnahme, Betrieb

■

Den Kalibrator nicht in Umgebungen mit explosiven Gasen,

Dämpfen oder Stäuben betreiben.

■

Die Messleitungen vor der Umschaltung auf eine andere Messung

oder vor der Verwendung als Simulator abklemmen.

■

Bei Reparaturen des Kalibrators nur die angegebenen Ersatzteile

verwenden.

■

Zur Vermeidung von Fehlmessungen, die zu einem elektrischen

Schlag oder Verletzungen führen könnten, die Batterie umgehend

austauschen, sobald eine verbrauchte Batterie angezeigt wird.

WARNUNG!

Zur Vermeidung von Schäden des Kalibrators oder der Geräte bei der

Prüfung die korrekten Anschlussklemmen, Funktionen und Messbereiche für die Messung bzw. die Simulation benutzen.

6.1. Erste Schritte

6.1.1 Batteriesparfunktion

Um eine Entladung der Batterie bei versehentlichem Einschalten des CEP1000 zu

verhindern, ist die Batteriesparfunktion werksseitig aktiviert und auf 30 Minuten eingestellt. Die Batteriesparfunktion schaltet den CEP1000 automatisch aus, wenn 30

Minuten lang keine Taste betätigt wird.

Um die Abschaltzeit zu ändern oder zu deaktivieren sind beim Einschalten folgende

Schritte auszuführen:

D

1) Das Gerät ausschalten.

2) Die „AUTO“-Taste drücken.

3) Das Gerät wieder einschalten.

4) Nach dem Einschalten 1 Sekunde warten und dann die „AUTO“-Taste freigeben.

5) Auf der Anzeige erscheint die eingestellte Zeitdauer für die Batteriesparfunktion

(zwischen Aus und 30 Minuten).

6) Mit dem Drehknopf die gewünschte Zeit (zwischen Aus und 30 Minuten) einstellen.

7) Die „AUTO“-Taste erneut drücken, um den Wert zu speichern und das Gerät wieder

auf Normalbetrieb zu schalten. Der gespeicherte Wert bleibt im Speicher,

11570351.02 10/2010 GB/D/F/E/I

35WIKA Betriebsanleitung, Typ CEP1000

Page 36

6. Inbetriebnahme, Betrieb

6.1.2 HART™ Widerstandskonguration

Durch den internen 250 Ω Widerstand des CEP1000 kann während der Kalibrierung

oder Installation eines HART™-Transmitters ein Rosemount 275 Communicator

verwendet werden. Der interne Widerstand ersetzt den normalerweise erforderlichen

Widerstand von 250 Ω, der bei dem Kommunikator-Modell 275 benötigt wird. Um diese

Funktion bei Bedarf zu aktivieren, muss eine interne Drahtbrücke entfernt werden. Das

D

Gerät wird mit eingesetzter Drahtbrücke ausgeliefert (siehe Abbildung 2). Zur Aktivierung des Widerstands die Drahtbrücke abziehen. Die Drahtbrücke kann entweder

außerhalb des Geräts aufbewahrt oder nur auf einen Kontaktstift im Gerät gesteckt

werden, so dass der Stromkreis unterbrochen wird.

-J8 (HART™ JUMPER)

Drahtbrücke entfernen, um den HART™

Widerstand (250 Ω) zu aktivieren.

LCD

CEP1000

Abbildung 2

Ist der 250 Ω Widerstand aktiviert, kann maximal eine Last von 950 Ω

statt 1200 Ω angesteuert werden. In den meisten Fällen dürfte dies kein

Problem für die Kalibrierung von Produkten darstellen, die nicht mit

HART™ kompatibel sind.

36 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 37

6. Inbetriebnahme, Betrieb

6.2 Grundlegende Betriebsarten

Der CEP1000 besitzt 4 Betriebsarten für den mA-Bereich und einen Betriebsmodus für

die Spannungsmessung. Die folgenden Texte und Abbildungen erläutern die verschiedenen Betriebsmodi.

6.2.1 Milliampere-Quelle

Abbildung 3 zeigt eine typische Anwendung, bei der der CEP1000 als Stromquelle

zwischen 4 ... 20 mA für ein zu prüfendes Gerät verwendet wird.

( + )

D

Gerät mit einem Eingang

( - )

für 4 ... 20 mA

SOURCE

4 ... 20 mA

CEP 1000

mA

Max. Last: 1200 Ω ohne HART™

950 Ω mit HART™

MAX

MODE

AUTO

MIN

%ERROR

LOOPPWR

Calibration Line

25%

Abbildung 3: Stromquelle für 4 ... 20 mA

1) Das Gerät einschalten. Es wird standardmäßig der Betriebsmodus Stromquelle im

mA-Bereich eingestellt.

2) Das zu kalibrierende Gerät anschließen.

Damit das Gerät als Stromquelle arbeitet, muss der Stromkreis

geschlossen sein. Bei einem unterbrochenen Stromkreis blinkt auf der

LCD-Anzeige „OL“ und weist auf eine Überlastung bzw. eine Unterbrechung des Stromkreises hin.

11570351.02 10/2010 GB/D/F/E/I

37WIKA Betriebsanleitung, Typ CEP1000

Page 38

6. Inbetriebnahme, Betrieb

3) Das Ausgangssignal kann mit dem Drehknopf auf den Sollwert abgeglichen werden.

Dazu die einzustellende Dekade mit den Pfeiltasten auswählen.

4) Das Ausgangssignal kann auch schrittweise in Schritten von jeweils 4 mA (25 %) mit

der „25%“-Taste erhöht werden.

5) Die automatische Schrittfunktion und automatische Rampenfunktion gestatten eine

automatische Änderung des Ausgangssignals.

D

Weitere Informationen nden Sie im Abschnitt „6.3.1 Automatische Betriebsmodi“

der Anleitung.

6.2.2 Milliampere-Simulation

Abbildung 4 zeigt, wie der CEP1000 angeschlossen wird, wenn er als 2-Leiter-Transmitter mit einer externen Stromversorgung arbeiten soll. In diesem Fall wird der Stromkreis

über eine externe Spannungsquelle versorgt, und das Gerät regelt lediglich den Strom

im Stromkreis. Die Vorgehensweise zur Regelung des Ausgangssignals ist dieselbe wie

bei der Verwendung als Stromquelle im mA-Bereich.

( + )

Versorgungsspannung

( - )

DC 30 V max

( + )

Gerät mit einem Eingang

( - )

für 4 ... 20 mA

SIM

LOOPPWR

Calibration Line

MODE

%ERROR

CEP 1000

mA

MAX

AUTO

MIN

25%

4 ... 20 mA

Das Gerät arbeitet im Simulationsmodus wie ein zweiadriger Sensor

Abbildung 4: Simulation eines Sensors mit einem Stromausgang für 4 ... 20 mA

38 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 39

6. Inbetriebnahme, Betrieb

6.2.3 Milliampere-Messung

Abbildung 5 zeigt, wie der CEP1000 zur Messung in einem Stromkreis für 4 ... 20 mA

angeschlossen werden muss. Bei dieser Anwendung misst das Gerät lediglich den

Strom im Stromkreis und zeigt diesen auf der Hauptanzeige in mA an. Der untere

(kleinere) Anzeigebereich zeigt den prozentualen Anteil des Stroms für den Messbereich 4 ... 20 mA an.

6.2.4 Milliampere-Messung mit 24 V Spannungsversorgung

Auch hierfür zeigt Abbildung 5 den richtigen Anschluss. In diesem Fall wird jedoch

ein 2-Leiter-Transmitter geprüft, der eine externe Versorgungsspannung für einen

Ausgangsstrom benötigt. Bei dieser Anwendung liefert das Gerät eine Betriebsspannung von 24 V für den Stromkreis und misst zugleich den entstehenden Strom. Zum

Einschalten der Funktion mit separater Versorgungsspannung die „LOOP PWR“-Taste

drücken, wenn die Option mA-Messung ausgewählt ist.

( + )

D

Gerät mit einem Aus-

( - )

gang für 4 ... 20 mA

MEASURE

4 ... 20 mA

CEP 1000

mA

Maximales Eingangssignal: 24 mA

LOOPPWR

Calibration Line

MODE

%ERROR

AUTO

MAX

MIN

25%

Zur Messung des Ausgangssignals eines zweiadrigen

Sensors die Option Messung mit separater Versorgungsspannung verwenden.

Abbildung 5: Messung im Bereich 4 ... 20 mA

Der Messmodus mit separater Versorgungsspannung kann nur für die

Option Messung im mA-Bereich aktiviert werden.

11570351.02 10/2010 GB/D/F/E/I

39WIKA Betriebsanleitung, Typ CEP1000

Page 40

6. Inbetriebnahme, Betrieb

6.2.5 Spannungsmessung

Abbildung 6 zeigt den Anschluss des CEP1000 zur Messung von Gleichspannung bis

28 V. Zur Aktivierung der Spannungsmessung einfach die „MODE“-Taste drücken, um

die einzelnen Funktion zu durchsuchen, bis die Spannungsmessung angezeigt wird.

Die Eingangsimpedanz des CEP1000 beträgt in diesem Modus über 1 MΩ.

D

( + )

Gerät mit einem Ausgang

für 0 ... 28 V

MEASURE

LOOPPWR

MODE

%ERROR

CEP 1000

V

MAX

AUTO

MIN

25%

( - )

Maximales Eingangssignal: DC 28 V

Calibration Line

Abbildung 6: Messung von DC 0 ... 28 V

40 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 41

6. Inbetriebnahme, Betrieb

6.3 Erweiterte Betriebsarten

6.3.1 Automatische Schrittfunktion/automatischer Rampenmodus

Der CEP1000 ist in der Lage, den Ausgangsstrom im mA-Bereich in Schritten von

25 % automatisch in Intervallen von 5 Sekunden zu erhöhen. Der Ausgangsstrom im

mA-Bereich kann linear in Form der Rampenfunktion auch von 4 mA bis auf 20 mA

erhöht und automatisch wieder auf 4 mA reduziert werden.

Zur Aktivierung der automatischen Schritt-/Rampenfunktion wie folgt vorgehen:

1) Die Funktion automatische Schritt-/Rampenfunktion kann sowohl beim Einsatz als

Milliampere-Quelle als auch bei der Milliampere-Simulation verwendet werden. Das

Gerät in den betreenden Betriebsmodus schalten.

2) Den CEP1000 an das zu prüfende Gerät anschließen.

3) Für die automatische Schrittfunktion „AUTO“-Taste einmal drücken, für eine langsa-

me Rampenfunktion zweimal und für die schnelle Rampenfunktion dreimal drücken.

Bei jedem Tastendruck erscheint in der unteren linken Ecke der LCD-Anzeige eine

kleine Bestätigung, welche Schrittfunktion bzw. welche Rampenfunktion ausgewählt

wurde.

4) Sobald die Schrittfunktion/Rampenfunktion aktiviert ist, läuft diese ständig durch, bis

eine andere Taste gedrückt wird.

6.3.2 Prozent-Fehler-Funktion

Diese einzigartige Funktion berechnet den prozentualen Fehler des Messbereiches

(ein Messbereich von 4 ... 20 mA ergibt eine Spanne von 16 mA). Mit der Funktion zur

prozentualen Fehlerberechnung kann der Benutzer die Milliampereanzeige abgleichen

stellen, so dass die Abweichung vom Idealwert auf der Anzeige als prozentualen Fehler

erscheint.

D

Vorgehensweise:

1) Den CEP1000 mit dem zu prüfenden Gerät verbinden.

2) Für das Gerät einen Modus mit Milliampereausgang einstellen (Quelle oder Simulation).

3) Den gewünschten Ausgabewert einstellen.

4) Wenn das zu prüfende Gerät nicht den exakten Wert misst, die „%ERROR“-Taste

gedrückt halten und den Drehknopf einstellen, bis das zu prüfende Gerät den

korrekten Wert anzeigt. Die „%ERROR“-Taste weiter gedrückt halten.

5) Die Anzeige im Prozentfeld entspricht dem Fehler bzw. der Abweichung als Prozent

der Spanne.

6) Nach Freigabe der „%ERROR“-Taste schaltet die Anzeige zurück auf Normalbe-

trieb.

11570351.02 10/2010 GB/D/F/E/I

41WIKA Betriebsanleitung, Typ CEP1000

Page 42

6. Inbetriebnahme, Betrieb

6.3.3 Datenerfassung für Minimum und Maximum

Arbeitet das CEP1000 in einem Messmodus (Milliampere, Milliampere mit Spannungs-

versorgung oder Spannung), werden der Minimalwert und der Maximalwert für den

betreenden Eingangsmodus permanent überwacht und gespeichert. Zur Aktivierung

der Datenprotokollierung wie folgt vorgehen:

D

1) Das CEP1000 in einen Messmodus schalten.

2) Das Gerät mit dem zu prüfenden Gerät verbinden.

3) Den Speicher für den Minimal- und Maximalwert durch gleichzeitiges Drücken der

beiden Tasten (“MIN“ und “MAX“) löschen. Auf der LCD-Anzeige erscheint die

Meldung “CLR“, wenn der Speicher gelöscht wurde.

4) Mit dem Gerät den Minimalwert und Maximalwert so lang wie erforderlich protokollieren.

Eventuell die Batteriesparfunktion vor dem Aufruf der Datenprotokollierung deaktivieren, damit der Kalibrator nicht vorzeitig abschaltet.

5) Der gespeicherte Wert kann zu beliebiger Zeit durch Betätigung der Taste “MIN“

oder “MAX“ aufgerufen werden.

6) Beim Ausschalten des Geräts bzw. beim Wechsel des Betriebsmodus wird der

Speicher gelöscht. Die Daten vor dem Ausschalten des Geräts sichern.

42 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 43

7. Wartung, Reinigung und Service (Rekalibrierung)

7. Wartung, Reinigung und Service (Rekalibrierung)

7.1 Wartung

Der Präzise Stromschleifenkalibrator CEP1000 ist wartungsfrei.

Reparaturen sind ausschließlich vom Hersteller durchzuführen. Ausgenommen ist der

Austausch der Batterie.

7.2 Reinigung

VORSICHT!

■

Das Gerät mit einem feuchten Tuch reinigen.

■

Elektrische Anschlüsse nicht mit Feuchtigkeit in Berührung bringen.

Hinweise zur Rücksendung des Gerätes siehe Kapitel „9.1 Rücksendung“.

7.3 Rekalibrierung

DKD/DAkkS-Schein - amtliche Bescheinigungen:

Es wird empfohlen, das Präzisions-Digitalmanometer in regelmäßigen Zeitabständen

von ca. 12 Monaten durch den Hersteller rekalibrieren zu lassen. Jede werksseitige

Rekalibrierung beinhaltet außerdem eine umfangreiche und kostenfreie Überprüfung

aller Systemparameter auf Einhaltung der Spezikationen. Die Grundeinstellungen

werden wenn notwendig korrigiert.

D

11570351.02 10/2010 GB/D/F/E/I

43WIKA Betriebsanleitung, Typ CEP1000

Page 44

8. Störungen / 9. Rücksendung und Entsorgung

8. Störungen

Anzeige Fehlerart Maßnahmen

D

OL

-OL

Keine Anzeige

bzw. wirre

Zeichen, Gerät

reagiert nicht

auf Tastendruck

Batteriespannung schwach, Funktion ist nur noch kurze Zeit gewährleistet

Messbereich weit über- oder unterschritten

Batterie ist leer Neue Batterie einsetzen

Systemfehler Gerät ausschalten, kurz warten,

Gerät defekt Zur Reparatur einschicken

VORSICHT!

Können Störungen mit Hilfe der oben aufgeführten Maßnahmen nicht

beseitigt werden, ist das Gerät unverzüglich außer Betrieb zu setzen,

sicherzustellen, dass kein Druck bzw. Signal mehr anliegt und gegen

versehentliche Inbetriebnahme zu schützen.

In diesem Falle Kontakt mit dem Hersteller aufnehmen.

Bei notwendiger Rücksendung die Hinweise unter Kapitel

„9.1 Rücksendung“ beachten.

9. Rücksendung und Entsorgung

Neue Batterie einsetzten

Prüfen: liegt die Messgröße im

zulässigen Messbereich des

Gerätes?

wieder einschalten

WARNUNG!

Messstoreste am Stromschleifenkalibrator können zur Gefährdung von

Personen, Umwelt und Einrichtung führen.

Ausreichende Vorsichtsmaßnahmen ergreifen.

9.1 Rücksendung

WARNUNG!

Beim Versand des Gerätes unbedingt beachten:

Alle an WIKA gelieferten Geräte müssen frei von Gefahrstoen (Säuren,

Laugen, Lösungen, etc.) sein.

44 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 45

9. Rücksendung und Entsorgung / 10. Zubehör

Zur Rücksendung des Stromschleifenkalibrator die Originalverpackung oder eine geeignete Transportverpackung verwenden.

Um Schäden zu vermeiden:

1. Das Gerät in eine antistatische Plastikfolie einhüllen.

2. Das Gerät mit dem Dämmmaterial in der Verpackung platzieren.

Zu allen Seiten der Transportverpackung gleichmäßig dämmen.

3. Wenn möglich einen Beutel mit Trocknungsmittel der Verpackung beifügen.

4. Sendung als Transport eines hochempndlichen Messgerätes kennzeichnen.

Dem Gerät das Rücksendeformular ausgefüllt beifügen.

Das Rücksendeformular steht im Internet zur Verfügung:

www.wika.de / Service / Rücksendung

9.2 Entsorgung

Durch falsche Entsorgung können Gefahren für die Umwelt entstehen.

Gerätekomponenten und Verpackungsmaterialien entsprechend den landesspezischen Abfallbehandlungs- und Entsorgungsvorschriften umweltgerecht entsorgen.

Bei Geräten mit dieser Kennzeichnung wird darauf hingewiesen, dass

diese nicht in den Hausmüll entsorgt werden dürfen. Die Entsorgung

erfolgt durch Rücknahme bzw. durch entsprechende kommunale

Stellen. Siehe EU Verordnung 2002/96/EC.

D

10. Zubehör

Zubehör wie 9 V Ni-Cd Batterie (auadbar), AC Netzteil/Ladegerät für Europa, Japan,

UK oder USA, etc., nden Sie in der aktuellen WIKA-Preisliste: Prüf- und Kalibriertech-

nik.

11570351.02 10/2010 GB/D/F/E/I

45WIKA Betriebsanleitung, Typ CEP1000

Page 46

D

46 WIKA Betriebsanleitung, Typ CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 47

Sommaire

Sommaire

1. Généralités 48

2. Sécurité 49

2.1 Utilisation conforme à l'usage prévu 50

2.2 Qualication du personnel 50

2.3 Dangers particuliers 51

3. Caractéristiques techniques 52

4. Conception et fonction 53

4.1 Brève description / Description 53

4.2 Volume de livraison 54

4.3 Marquages de façade du CEP1000 54

4.4 Choix de la pile 55

4.5 Protection entrée 55

5. Transport, emballage et stockage 55

5.1 Transport 55

5.2 Emballage 55

5.3 Stockage 55

6. Mise en service, exploitation 56

6.1 Premières étapes 57

6.1.1 Fonction d’économie de la pile 57

6.1.2 Conguration de la résistance HART™ 58

6.2 Principaux modes de fonctionnement 59

6.2.1 Source en milliampères 59

6.2.2 Simulation en milliampères 60

6.2.3 Mesure en milliampères 61

6.2.4 Mesure en milliampères avec alimentation en tension 24 V 61

6.2.5 Mesure de la tension 62

6.3 Autres modes de fonctionnement 63

6.3.1 Fonction paliers automatique / Mode rampe linéaire 63

6.3.2 Fonction pourcentage d’erreur 63

6.3.3 Acquisition de données pour minimum et maximum 64

7. Entretien, nettoyage et service (ré-étalonnage) 65

7.1 Entretien 65

7.2 Nettoyage 65

7.3 Nouvel étalonnage 65

8. Dysfonctionnements 66

9. Retour et mise au rebut 66

9.2 Retour 66

9.3 Mise au rebut 67

10. Accessoires 67

F

11570351.02 10/2010 GB/D/F/E/I

47WIKA mode d’emploi, type CEP1000

Page 48

1. Généralités

1. Généralités

■

Le calibrateur de boucle décrit dans le présent mode d'emploi est fabriqué selon les

dernières technologies en vigueur. Tous les composants sont soumis à des critères

de qualité et d'environnement stricts durant la fabrication. Nos systèmes de gestion

sont certiés selon ISO 9001 et ISO 14001.

■

Ce mode d'emploi donne des indications importantes concernant l'utilisation de

F

l'appareil. Il est possible de travailler en toute sécurité avec ce produit en respectant

toutes les consignes de sécurité et d'utilisation.

■

Respecter les prescriptions locales de prévention contre les accidents et les

prescriptions générales de sécurité en vigueur pour le domaine d'application de

l'appareil.

■

Le mode d'emploi fait partie de l'appareil et doit être conservé à proximité immédiate

de l'appareil et accessible à tout moment pour le personnel qualié.

■

Le personnel qualié doit, avant de commencer toute opération, avoir lu soigneuse-

ment et compris le mode d'emploi.

■

La responsabilité du fabricant n'est pas engagée en cas de dommages provoqués par une utilisation non conforme à l'usage prévu, de non respect de ce mode

d'emploi, d'utilisation de personnel peu qualié de même qu'en cas de modications

de l'appareil eectuées par l'utilisateur.

■

Les conditions générales de vente mentionnées dans les documents de vente

s'appliquent.

■

Sous réserve de modications techniques.

■

Les étalonnages d'usine et les étalonnages DKD/DAkkS (Service allemand d'étalon-

nage) sont eectués conformément aux normes internationales.

■

Pour obtenir d'autres informations:

- Consulter notre site internet : www.wika.de / www.wika.com

- Fiche technique correspondante : CT 81.01

- Conseiller applications :

Tel. : (+49) 9372/132-9986

Fax : (+49) 9372/132-217

E-Mail : testequip@wika.de

48 WIKA mode d’emploi, type CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 49

1. Généralités / 2. Sécurité

Explication des symboles

AVERTISSEMENT !

… indique une situation présentant des risques susceptibles de provoquer la mort ou des blessures graves si elle n'est pas évitée.

2. Sécurité

ATTENTION !

… indique une situation potentiellement dangereuse et susceptible de

provoquer de légères blessures ou des dommages matériels et pour

l'environnement si elle n'est pas évitée.

Information

… met en exergue les conseils et recommandations utiles de même

que les informations permettant d'assurer un fonctionnement ecace

et normal.

DANGER !

… indique les dangers liés au courant électrique. Danger de blessures

graves ou mortelles en cas de non respect des consignes de sécurité.

AVERTISSEMENT !

Avant le montage, la mise en service et le fonctionnement, s'assurer

que le calibrateur de boucle a été choisi de façon adéquate, en ce qui

concerne la plage de mesure, la version et les conditions de mesure

spéciques, a été sélectionné. Un non respect de cette consigne peut

entraîner des blessures corporelles graves et/ou des dégâts matériels.

F

Vous trouverez d'autres consignes de sécurité dans les sections individuelles du présent mode d'emploi.

11570351.02 10/2010 GB/D/F/E/I

49WIKA mode d’emploi, type CEP1000

Page 50

2. Sécurité

2.1 Utilisation conforme à l'usage prévu

Ce calibrateur de boucle de précision CEP1000 est utilisé pour la mesure de précision

et la simulation de courant et de tension.

L'appareil est conçu et construit exclusivement pour une utilisation conforme à l'usage

prévu décrit ici et ne doit être utilisé qu'en conséquence.

Les spécications techniques mentionnées dans ce mode d'emploi doivent être respec-

F

tées. En cas d'utilisation inadéquate ou de fonctionnement de l'appareil en dehors des

spécications techniques, un arrêt et contrôle doivent être immédiatement eectués par

un collaborateur autorisé du service de WIKA.

Traiter l'appareil de mesure et de précision électronique avec le soin requis (protéger l'appareil contre l'humidité, les chocs, les forts champs magnétiques, l'électricité

statique et les températures extrêmes, n'introduire aucun objet dans l'appareil ou les

ouvertures). Il est impératif de protéger les connecteurs et les prises contre les salissures.

Si l'appareil est transporté d'un environnement froid dans un environnement chaud,

la formation de condensation peut provoquer un dysfonctionnement fonctionnel de

l'appareil. Il est nécessaire d'attendre que la température de l'appareil se soit adaptée à

la température ambiante avant une nouvelle mise en service.

Aucune réclamation ne peut être recevable en cas d'utilisation non conforme à l'usage

prévu.

2.2 Qualication du personnel

AVERTISSEMENT !

Danger de blessure en cas de qualication insusante !

Une utilisation non conforme peut entraîner d'importants dommages

corporels et matériels.

■

Les opérations décrites dans ce mode d'emploi ne doivent être

eectuées que par un personnel ayant la qualication décrite

ci-après.

■

Tenir le personnel non qualié à l'écart des zones dangereuses.

Personnel qualié

Le personnel qualié est, en raison de sa formation spécialisée, de ses connaissances

dans le domaine de la technique de mesure et de régulation et de ses expériences de

même que de sa connaissance des prescriptions nationales, des normes et directives

en vigueur, en mesure d'eectuer les travaux décrits et de reconnaître automatiquement

les dangers potentiels.

50 WIKA mode d’emploi, type CEP1000

11570351.02 10/2010 GB/D/F/E/I

Page 51

2. Sécurité

Les conditions d'utilisation spéciales exigent également une connaissance adéquate

par exemple des liquides agressifs.

2.3 Dangers particuliers

AVERTISSEMENT !

Dans le cas de uides de mesure dangereux comme notamment

l'oxygène, l'acétylène, des substances combustibles ou toxiques, ainsi

que dans le cas d'installations de réfrigération, de compresseurs etc.,

les directives appropriées existantes doivent être observées en plus de

l'ensemble des règles générales.

AVERTISSEMENT !

Protection nécessaire contre les décharges électrostatiques (DES) !

L'utilisation conforme des surfaces de travail mises à la terre et des

bracelets personnels est nécessaire lors des opérations eectuées

avec des circuits ouverts (circuits imprimés) an d'éviter une détério-

ration des composants électroniques sensibles due à une décharge

électrostatique.

An de travailler en toute sécurité sur l'appareil, l'utilisateur doit s'assurer qu'il reçoit à intervalles réguliers des instructions relatives à toutes

les questions pertinentes concernant la sécurité du travail, les premiers

secours et la protection de l'environnement et qu'il connaît le mode

d'emploi et particulièrement les consignes de sécurité contenues dans

celui-ci.

F

DANGER !

Danger de mort lié au courant électrique

Danger de mort en cas de contact avec les pièces sous tension.

En cas d'utilisation avec un appareil d'alimentation défectueux (p. ex.

court-circuit entre la tension du secteur et la tension de sortie), des

tensions présentant un danger de mort peuvent apparaître sur l'appareil!

11570351.02 10/2010 GB/D/F/E/I

51WIKA mode d’emploi, type CEP1000

Page 52

3. Caractéristiques techniques

3. Caractéristiques techniques

Caractéristiques techniques

Entrée

Plage de courant 0,000 … 24,000 mA

Plage de tension DC 0,000 … 28,000 V

F

Protection entrée Sans fusible jusqu'à AC 250 V

Sortie

Plage de courant 0,000 … 24,000 mA

Imprécision de mesure ± 0,015 % de la valeur de mesure ± 2 µA

Résolution 1 µA, 1 mV

Charge maximale

■

Sans résistance HART™ 1200 Ω

■

Avec résistance HART™ 950 Ω

Tension d‘alimentation de la boucle DC 24 V

Sélection de la plage Chires des dizaines ; pas à pas en incréments de

Particularités Fonction palier/rampe linéaire, fonction "erreur %"

Valeurs admissibles :

■

Température de service -10 … +55 °C

■

Température de stockage -20 … +70 °C